Siemens HUB-4 Installation Instructions Manual

Installation Instructions

Model HUB-4

Communication Card for NCC WAN/PMI-2 Concentrator

INTRODUCTION The Model HUB-4 Communication Card from Siemens Industry, Inc., mounts in the

CC-5 Card Cage and provides up to four independent data channels, which can be

wired as either Style 4 or Style 7 for communication to the remote XLS, MXL, XL3 or

other UL864 listed local fire alarm panel providing dry relay contacts that can be used

for event monitoring.

The HUB-4 consists of a single Main-2 board on which two COM-2 boards are

installed. In turn, up to two modem or RS-485 Interface blocks can be installed on

each COM-2 board. Each modem block installed provides a single FSK data channel.

Each RS-485 Interface block installed provides a proprietary RS-485 interface channel.

Either a RS-485 Interface or a Modem Block module can be used, dependent on

application. Table 1 describes the connections that can be made.

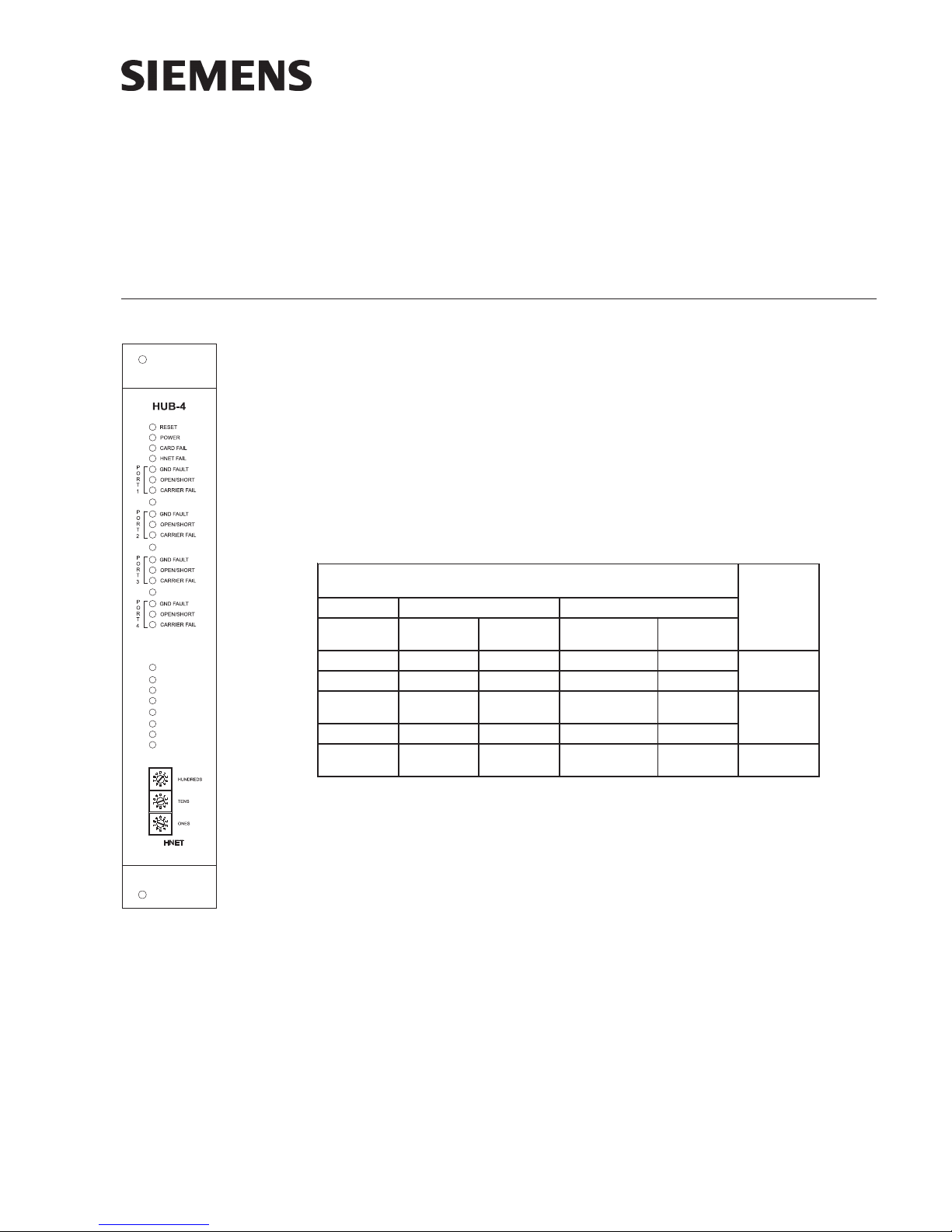

Figure 1

HUB-4 Communication

Card

1ELBAT

LENAP584-SRMEDOM

BssalC

)4elytS(

3LX A/NA/NXMMXMMNAWCCN

LXM A/NA/N003-IMC003-IMC

LXM-ISF W1-MINA/NdnaM1/W1-MIN

SLX-ISF MPR/BUHBUHBUHA/N

rehtO sOIAW

)61-1(

Each of the four data channels is controlled by a separate micro-controller which

provides all background supervision of the data lines (to the remote panel) as well as

sending and receiving Fire Panel information to the primary micro-controller. The

information from these four channels is concentrated into a single data stream and

sent to the NCC WAN via the NIC-C or the PMI-2 Concentrator via HNET. On NCC

WAN, the HUB-4 communicates on each of four ports with either the MMX (XL3

Modem), the CMI-300 (MXL modem), NIM-1 FSI (MXL FSI modem), NIM-1W (MXL

RS-485), RPM (XLS RS-485), HUB-4 (XLS RS-485), HUB-4 (XLS modem) or up to 16

WAIO (Wide Area Input Output) boards. On the PMI-2 Concentrator, the HUB-4

communicates on each of the four ports with either the NIM-1W/NIM-1M (MXL

Modem), NIM-1W (MXL RS-485), RPM (XLS RS-485), HUB-4 (XLS RS-485), or HUB-4

(XLS modem).

AssalC

)7elytS(

sOIAW

)61-1(

A/NA/NNAWCCN

SEPYTNOITCENNOCDNASLENAPERIFDNA4-BUH

BssalC

)4elytS(

kcolBmedoM

alC

Ass

)7elytS(

A/NroNAWCCN

ylno

MP

2-I

rotartnecnoC

ylno

Using the Modem Block module, communication distance is 8 miles (CMI-300/MMX-1)

or 10 miles (HUB-4 to HUB-4) over 18 gauge twisted pair lines depending on the quality

of the communication wires (attenuation cannot exceed -23 dBm [CMI-300/MMX-1] or

P/N 315-099458-9

Building Building

Building

Building Building

Siemens Siemens

Siemens

Siemens Siemens

TT

ecec

hnologies Dihnologies Di

T

ec

hnologies Di

TT

ecec

hnologies Dihnologies Di

IndustryIndustry

Industry

IndustryIndustry

visionvision

vision

visionvision

,,

Inc. Inc.

,

Inc.

,,

Inc. Inc.

-38dBm [HUB-4 to HUB-4] @ 2.5KHz), however, using conditioned data grade leased

lines from the phone company, the distance is unlimited.

Using the RS-485 Interface module, the communication distance is 12,000 feet using

18 gauge twisted pair lines.

OPERATION On NCC WAN, the HUB-4 can communicate using either the CMI-300, MMX, NIM-1W/

NIM-1M or HUB-4 slave Modem supervising the data circuit as well as the connected

MXL or XL3 Control Panel. Each of the four independent HUB-4 channels provides the

means to transmit data to and from the XLS, MXL or XL3 and the NCC WAN Head-End

System. The HUB-4 can also communicate with up to 16 WAIO cards, supervising the

data circuit for them as well as their inputs. Each of the four independent HUB-4

channels provides the means to transmit data to and from the WAIOs and the NCC

WAN head end system. In addition, the HUB-4 can support FSI protocol to communicate to an MXL using a NIM-1W or to an XLS using a HUB-4 slave so that an NCC or a

Desigo CC via the PMI-2 Concentrator will act as the remote management system.

Similarly, the HUB-4 can support FSI protocol to an RPM in an XLS fire system.

The HUB-4 Card is divided into five main sections: four external link sections and a

control section. The control section provides supervision of the HNET data channel

(Connection to the NCC WAN/PMI-2 Concentrator) and receives data from each of the

external links for transmission to the NCC WAN/PMI-2 Concentrator. The control

section also provides on board processor and integrity supervision. When installed in

the XLS system, the HUB-4 operates in slave mode.

Controls and Indicators The front panel of the HUB-4 contains one reset switch, 15 LEDs and three HNET

address switches as shown in Figure 1.

A reset switch is located on the top of the front panel. Pushing the reset switch reinitializes the HUB-4 operation.

The LEDs follow the reset switch and their functions are defined as follows:

POWER (Green) Normally ON. When illuminated, indicates that power

for the HUB-4 is applied to the card.

CARD FAIL (Yellow) Normally OFF. When illuminated, indicates that the

card microprocessor has failed. May illuminate for 2-4

seconds when initially powered.

HNET FAIL (Yellow) When consistantly illuminated, the HUB-4 has de-

tected an HNET loss of supervision of the NCC. When

the HUB-4 detects an HNET failure, it will cause all

configured ports to shut down communication to

remote units. The muted ports will be indicated by a

flashing OPEN/SHORT LED. When flashing rapidly, the

HUB-4 has been addressed via the front panel HNET

address select switches with an inappropriate address,

i.e., address zero, or addressed above 252 decimal.

PORTS 1 – 4 The LEDs for each independent modem block module

Siemens Industry, Inc.

Building Technologies Division

or RS-485 Interface module are referred to as ports.

When all three LEDs are flashing for a specific port,

P/N 315-099458-92

that port is considered to be an unspecified,

unconfigured port that has detected a modem

originate signal or RS-485 data from a remote unit.

GND FAULT (Yellow) Normally OFF. When illuminated, indicates that the

HUB-4 has detected either a negative or positive

ground fault on its field wiring.

OPEN/SHORT (Yellow) Normally OFF. When consistently illuminated, the HUB-

4 has detected an OPEN/SHORT in either the primary or

secondary wired communications line. When flashing,

there is a loss of communications between the HUB-4

main module, and the specific HUB-4 communication

port. If the HNET FAIL LED is also illuminated, this port

has been muted.

CARRIER FAIL (Yellow) Normally OFF. When consistently illuminated, the

HUB-4 has detected CARRIER FAIL with a modem

block or a polling supervision fail with a RS-485

Interface card between the HUB-4 and the remote

device. When flashing, there is a loss of communications between the modem or RS-485 Interface card

and the communications controller of the HUB-4 or

loss of communications between the HUB-4 and the

remote fire system.

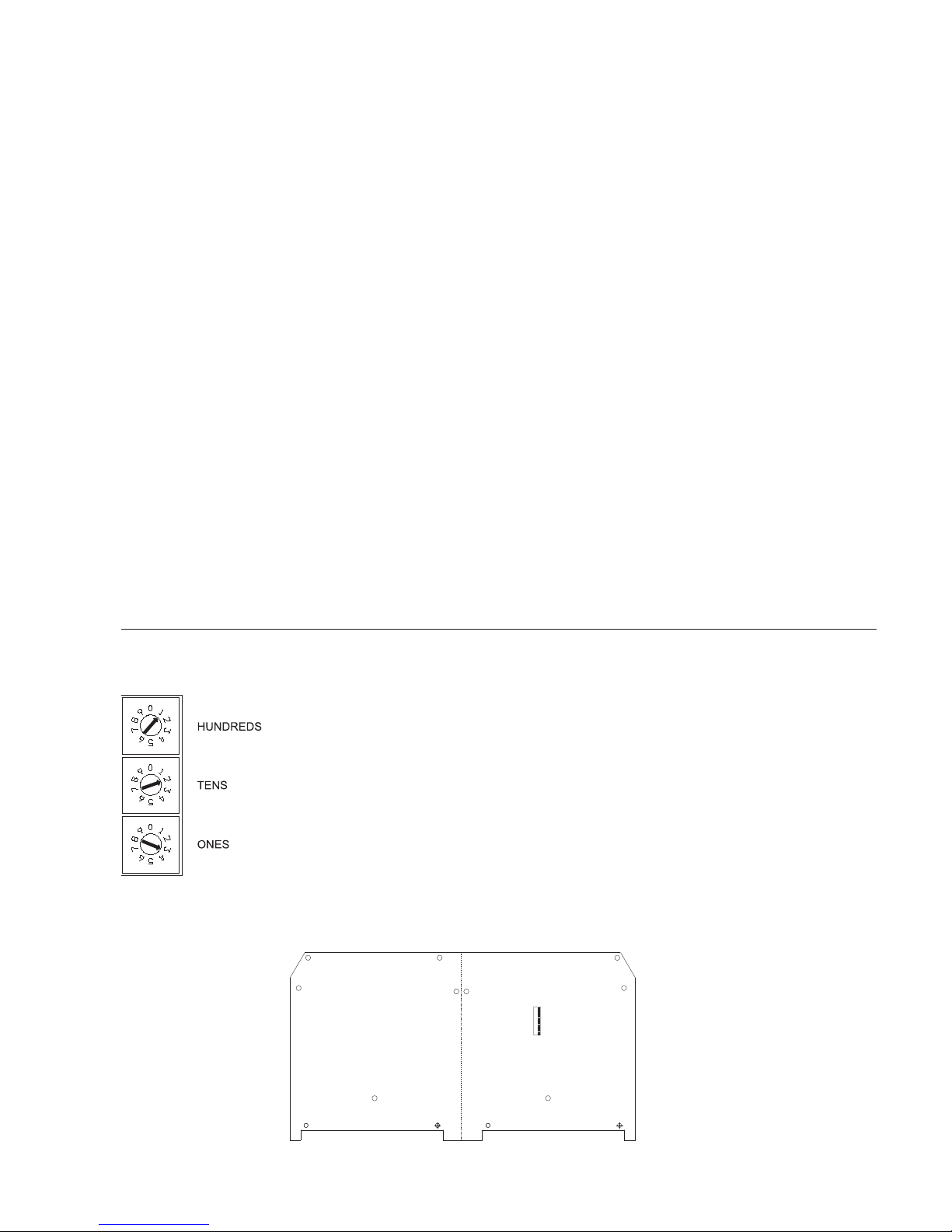

Three rotary dial switches at the bottom of the front panel are used to set the HNET

network address of the HUB-4.

PRE-INSTALLATION Switch and Jumper Settings are required only on HUB-4, Main-2 and HUB-4, COM-2

boards that are not factory preassembled.

1. Network Address Switches: Set the three-digit HNET network address for

the HUB-4 using the three rotary dial switches located near the bottom of

the front panel. (Refer to Figure 1 for the location of the switches.) The

address for the HUB-4 must be the same as the address selected for it in

the NCC WAN/PMI-2 Concentrator. To set the address, turn the pointers on

each of the three dials to the numbers for the selected address. For example, if the address is 123, set the pointer for the HUNDREDS dial to “1”,

set the pointer for the TENS dial to “2”, and set the pointer for the ONES dial

to “3”. The range of allowable addresses is from 001 to 251 (leading zeros

HNET

must be used).

2. HUB-4, Main-2 Board (Switch S2): Currently Not Used. All switches must

be set to the ON position.

HUB-4 MAIN-2

(Bottom side of board)

OFF

ON

12345678

Siemens Industry, Inc.

Building Technologies Division

S2

Figure 2

Location of S2 On HUB-4 Main-2

P/N 315-099458-93

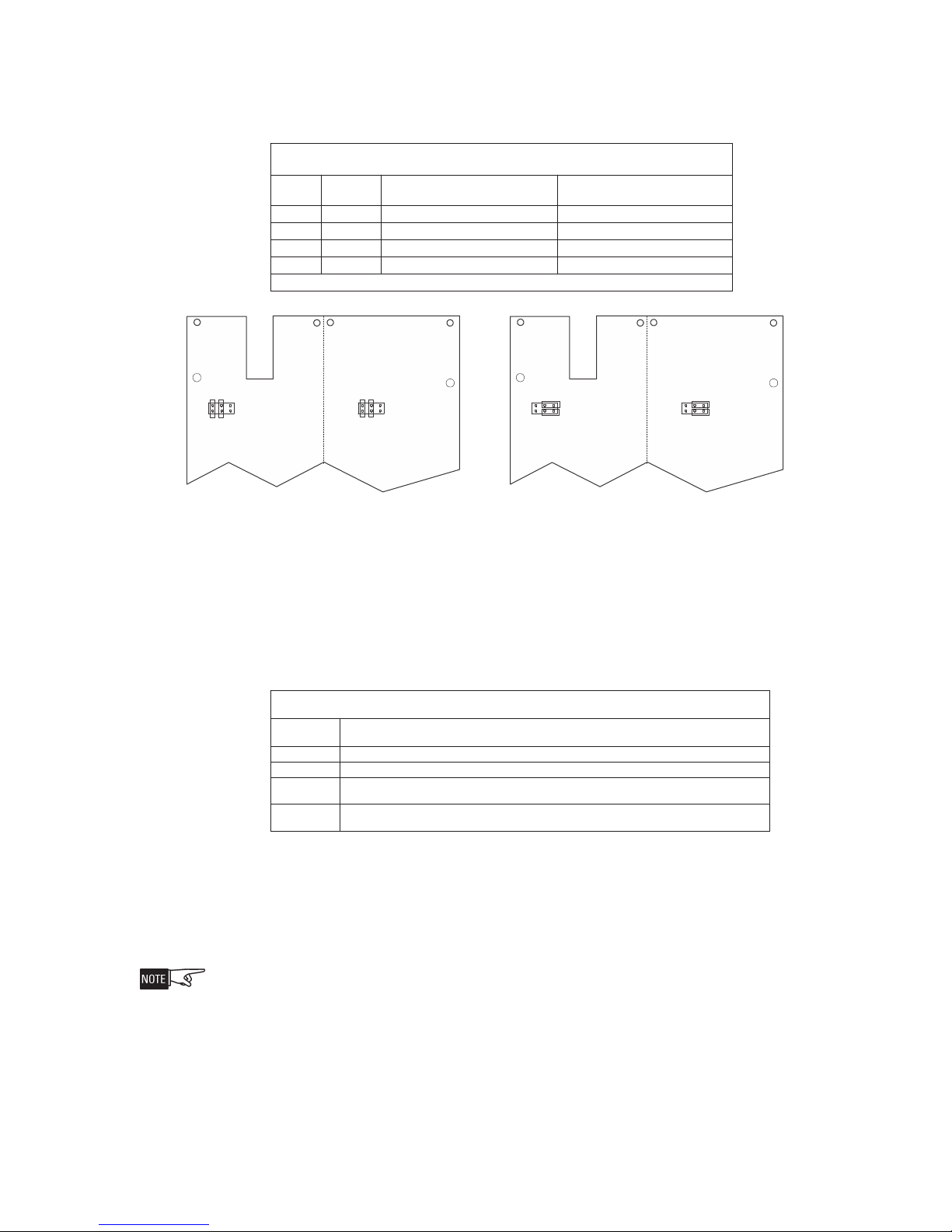

3. HUB-4, COM-2 Board: Make sure that the jumper settings are correct for the

desired application (either Modem Block or RS-485 Interface Module). Refer

to Table 2 and Figure 3 for the correct placement of jumpers on P5 and P6.

2ELBAT

SGNITTESREPMUJ2MOC

*troPrepmuJnoitacilppAeludoMkcolBmedoM

1troP5P

2troP6P

3troP5P

4troP6P4-3,2-16-4,5-3

tacolehtrof4erugiFotrefeR*

,2-16-4,5-3

4-3

4-3,2-16-4,5-3

4-3,2-16-4,5-3

HUB-4,

COM-2

.draob2niaM,4-BUHehtno4-1stroPfonoi

eludoMecafretnI584-SR

noitacilppA

HUB-4,

COM-2

256

1

P5

JUMPER SETTINGS FOR MODEM MODULE JUMPER SETTINGS FOR RS-485 INTERFACE MODULE

256

1

P6

256

1

P5

256

1

P6

Figure 3

Jumper Settings of P5 and P6 on HUB-4, COM-2

HUB-4 Configuration The HUB-4 can be configured to support from one to four independent communica-

tion channels (Modem Block or RS-485 Interface modules). Refer to Table 3 to

determine the required modules for the desired configuration. Modem Block and RS485 Interface modules can not be mixed on a single COM-2 card.

3ELBAT

NOITARUGIFNOC4-BUH

forebmuN

slennahCseludoMderiuqeR

1 eludoMecafretnI584-SR1rokcolBmedoM1,2-MOC4-BUH

2 seludoMecafretnI584-SR2roskcolBmedoM2,2-MOC4-BUH1,2-niaM4-BUH1

3

4

1,2-niaM4-BUH1

lBmedoM2roskcolBmedoM3,2-MOC4-BUH2,2-niaM4-BUH1

tnI584-SR4roseludoM

.seludoMecafre

ecafretnI584-SR1dnaskco

seludoMecafetnI584-SR3roseludoMecafretnI584-SR2dnakcolBmedoM1roseludoM

ecafretnI584-SR2dnaskcolBmedoM2roskcolBmedoM4,2-MOC4-BUH2,2-niaM4-BUH1

HUB-4 Assembly The HUB-4 Assembly consists of the HUB-4 Main-2, two COM-2 boards, and from

one to four Modem Block or RS-485 Interface modules, depending on your desired

configuration. If your HUB-4 is preassembled, complete Steps 1 and 2 below and then

go to Step 9. Refer to Table 4 for correct placement of modem block or RS-485 Interface modules on the HUB-4 Main -2.

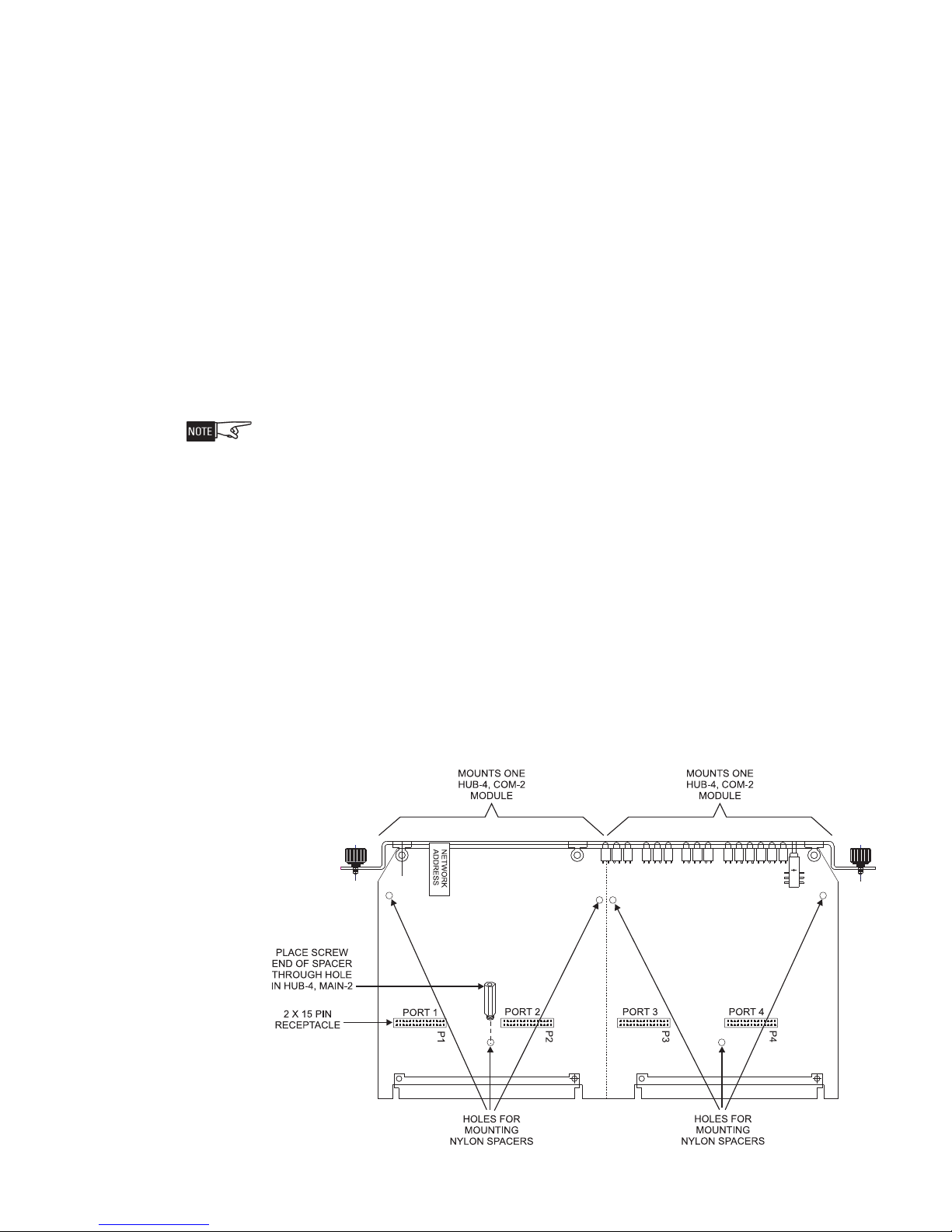

When assembling the HUB-4, note that P1, the 2 X 15 receptacle on the HUB-4, Main-2, connects

to Port 1, P2 connects to Port 2, P3 connects to Port 3, and P4 connects to Port 4.

1. Begin connecting the components by following the instructions for the

2. Determine the number of channels (from one to four) that your system will

Siemens Industry, Inc.

Building Technologies Division

Modem Block module, P/N 315-099356, or the RS-485 Interface module, P/

N 315-049930.

require. Install the HUB-4 COM-2 and Modem Block or RS-485 Interface

modules on the HUB-4 Main-2 according to Table 4, page 6.

P/N 315-099458-94

3. Using the three nylon spacers provided with each HUB-4, COM-2, place the

screw end of the spacers through the holes in the top of the HUB-4, Main-2

board. (Refer to Figure 4, page 5.)

4. Secure the spacers in place on the underside of the HUB-4, Main-2 board

with the nylon nuts provided.

5. Connect the HUB-4, COM-2 to the HUB-4, Main-2 by lining up the 2x15

connectors on the HUB-4 COM-2 to the 2x15 receptacles on the HUB-4,

Main-2. Keep in mind that Port 1 is the P1 receptacle, etc. Gently insert the

connectors into the receptacles being careful not to bend the connectors.

6. Note that the spacer holes on the HUB-4, COM-2 board line up with the

spacers on the HUB-4 Main-2 board. (Refer to Figure 5, page 6.)

7. Insert the 3 nylon screws (packaged with the HUB-4, COM-2) through the

holes in the HUB-4, COM-2 into the spacers in the HUB-4, Main-2 and

secure them in place. (Refer to Figure 5, page 6.)

8. If a second HUB-4, COM-2 is required, install it now by following the

previous steps.

When installing Modem Block or RS-485 Interface modules, refer to Table 4 for correct placement

on HUB-4 Main-2.

9. Connect the Modem Block or RS-485 Interface module to the HUB-4, COM2 by lining up the 2x10 connector on the Modem Block or RS-485 Interface

module to the 2x10 receptacle on the HUB-4, COM-2. Gently insert the

connector into the receptacle being careful not to bend the connector.

10. Note that the spacer holes on the Modem Block or RS-485 Interface module

line up with the spacers on the HUB-4 COM-2. (Refer to Figure 5, page 6.)

11. Insert the 3 nylon screws (packaged with the Modem Block or RS-485

Interface module) through the holes in the Modem Block module or RS-485

Interface module into the spacers in the HUB-4, COM-2 and secure them in

place. (Refer to Figure 5, page 6.)

12. If additional Modem Block or RS-485 Interface modules are required, install

them now by following steps 9-11 above.

Figure 4

Spacer Placement on HUB-4, Main-2

Siemens Industry, Inc.

Building Technologies Division

P/N 315-099458-95

Loading...

Loading...