Page 1

Sizing Guide

standby

GENERATORS

Page 2

Generator Sizing Guide

General Information

Important Notice

This booklet is designed to familiarize estimators and installers

with proper sizing guidelines for residential and commercial

generators. The information is not comprehensive, nor does

it replace or supercede any material contained in any of

the written documents shipped with the equipment. This

booklet should only be used in conjunction with the Owner’s

Manual, Installation Manual and other technical documents

shipped with each product. Always read all accompanying

documentation carefully before attempting to install any

generator, transfer switch or related equipment.

How to Use this Booklet

Within this booklet, you will find electrical load information,

plus an outline of generator surge capability, fuel pipe sizing,

liquid propane tank sizing, and UPS / generator compatibility.

The final pages are perforated for easy removal and can be

photocopied to create additional Onsite Estimating Sheets

for use with individual jobs.

Safety Information

Proper sizing of the generator is crucial to the success of

any installation and requires a good working knowledge

of electricity and its characteristics, as well as the varying

requirements of the electrical equipment comprising the load.

When analyzing the electrical load, consult the manufacturer’s

nameplate on each major appliance or piece of equipment

to determine its starting and running requirements in terms

of watts, amps and voltage. When choosing the generator

output for commercial or industrial applications, select a

rating that is approximately 25% higher than the peak load

(for example, if the load is about 40 kilowatts, select a 50 kW

genset). A higher rated generator will operate comfortably

at approximately 80% of its full capacity and will provide a

margin of flexibility if the load increases in the future.

For safety reasons, Siemens recommends that the backup

power system be installed, serviced and repaired by a

Generac Authorized Service Dealer or a competent,

qualified electrician or installation technician who is

familiar with applicable codes, standards and regulations.

It is essential to comply with all regulations established by

the Occupational Safety and Health Administration (OSHA)

and strict adherence to all local, state and national codes

is mandatory. Before selecting a generator, check for

municipal ordinances that may dictate requirements

regarding placement of the unit (setback from building

and/or lot line), electrical wiring, gas piping, fuel storage (for

liquid propane or diesel tanks), sound and exhaust emissions.

If you have a technical question regarding sizing or

installation, contact Siemens Technical Service Center

toll free at

800-844-0029 during normal business hours

(8 a.m. to 5 p.m. CST).

1

Page 3

Generator Sizing Guide

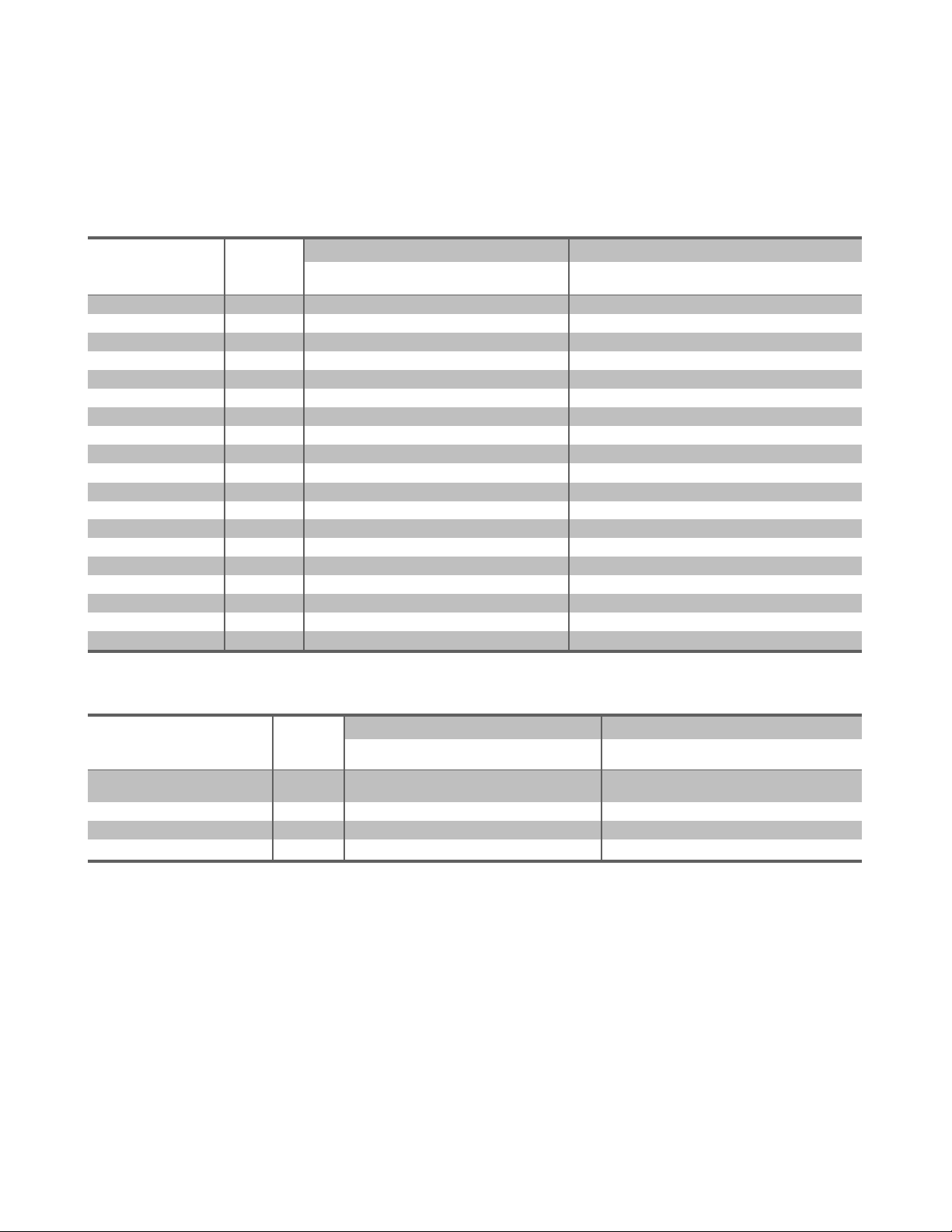

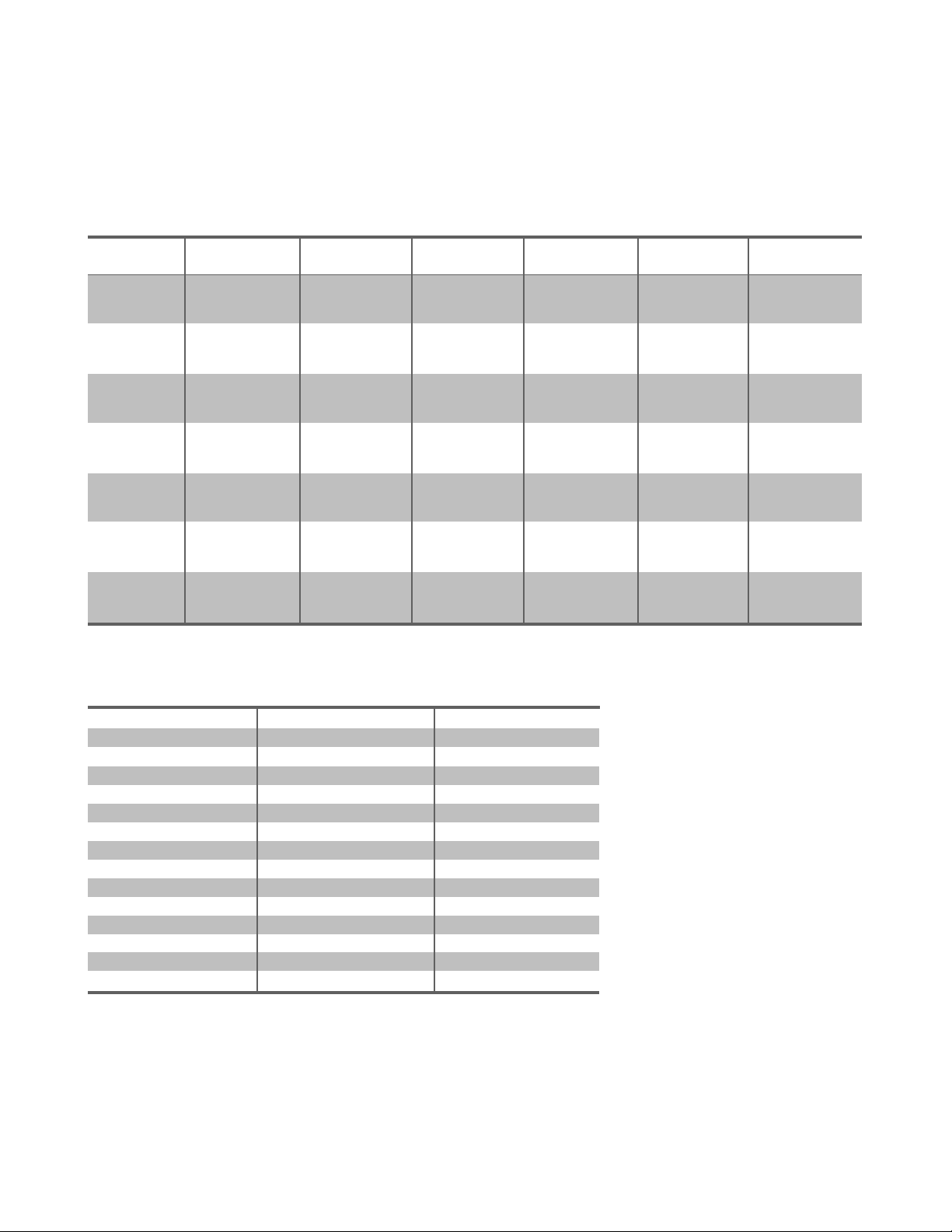

Table 1 – Motor Load Reference

AC and Heat Pumps

Running Load Starting Load

Running Amps at Amps at Amps at Starting LR Amps LR Amps LR Amps

Description Hp kW 240V 1ø 208V 3ø 480V 3ø kW at 240V 1ø at 208V 3ø at 480V 3ø

1 Ton (12,000 BTU) 1 1 5 3 1 3 25 17 7

2 Ton (24,000 BTU) 2 2 10 7 3 6 50 33 14

3 Ton (36,000 BTU) 3 3 15 10 4 9 75 50 22

4 Ton (48,000 BTU) 4 4 20 13 6 12 100 67 29

5 Ton (60,000 BTU) 5 5 25 16 7 15 125 83 36

7.5 Ton (85,000 BTU) 7.5 7.5 37 24 11 17 188 125 54

10 Ton (120,000 BTU) 5 Hp (x2) 10 49 33 14 15 125 83 36

10 Ton (120,000 BTU) 10 Hp 10 49 33 14 20 250 167 72

15 Ton (180,000 BTU) 7.5 Hp (x2) 15 74 49 21 17 188 125 54

15 Ton (180,000 BTU) 15 Hp 15 74 49 21 30 375 250 108

20 Ton (240,000 BTU) 10 Hp (x2) 20 98 65 28 20 250 167 72

20 Ton (240,000 BTU) 20 Hp 20 n/a 65 28 40 500 333 144

25 Ton (300,000 BTU) 25 25 n/a 82 35 50 625 416 180

30 Ton (360,000 BTU) 15 Hp (x2) 30 n/a 98 42 30 375 250 108

30 Ton (360,000 BTU) 30 Hp 30 n/a 98 42 60 750 500 217

40 Ton (480,000 BTU) 20 Hp (x2) 40 n/a 131 57 40 500 333 144

40 Ton (480,000 BTU) 40 Hp 40 n/a 131 57 80 1000 666 289

50 Ton (480,000 BTU) 25 Hp (x2) 50 n/a 163 71 50 625 416 180

50 Ton (480,000 BTU) 50 Hp 50 n/a 163 71 100 1250 833 361

General Residential

Running Load Starting Load

Running Amps at Amps at Starting LR Amps LR Amps

Description Hp kW 120V 1ø 240V 1ø kW 120V 1ø 240V 1ø

Refrigerator, Sump Pump, 0.5 0.5 4.9 2.5 1.5 25 13

Furnace, Garage Opener

Freezer, Washer, Septic Grinder 0.75 0.75 7.4 3.7 2.3 38 19

General 1 Hp 1 1 9.8 4.9 3 50 25

Well and Septic Lift Pump 2 2 19.6 9.8 6 100 50

2

Page 4

Generator Sizing Guide

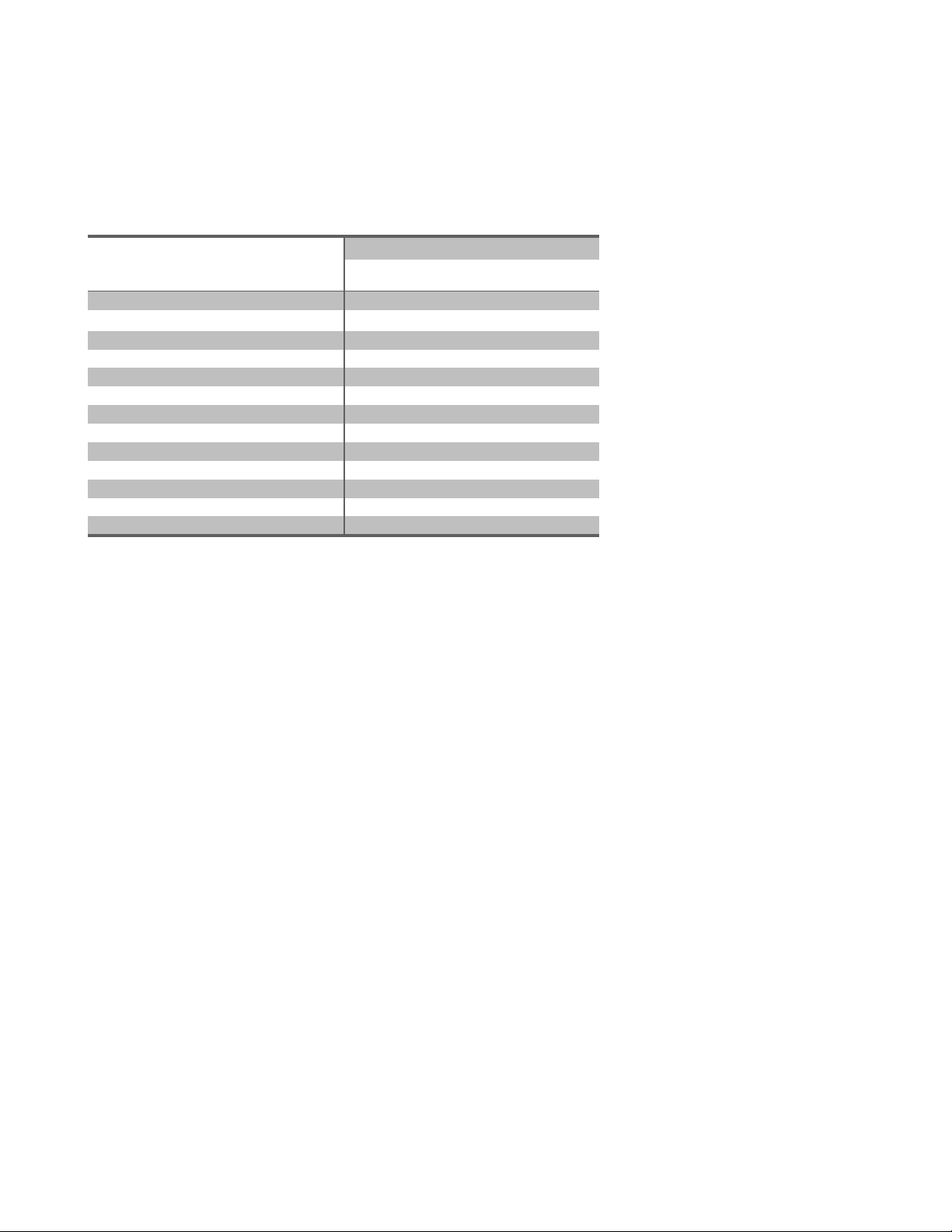

Table 2 – Non-Motor Load Reference

General Residential

Running Load

Amps at Amps at

Description kW 120V 1ø 240V 1ø

Electric heat per 1000 ft.

2

12 n/a 50

Heat pump elements per 1000 ft.

2

7 n/a 29

Dryer 5.5 n/a 23

Hot tub 5 n/a 21

Range oven 5 n/a 21

Hot water 4.5 n/a 19

Stove top per burner 1.5 n/a 6

General receptacles per 1000 ft.

2

1 8.3 n/a

Lighting per 1000 ft.

2

0.75 6.3 n/a

Blow dryer 1.25 10.4 n/a

Dishwasher 1.5 12.5 n/a

Microwave 1 8.3 n/a

Toasters 1 8.3 n/a

3

Page 5

Generator Sizing Guide

Table 3 – Surge Capability

Siemens Liquid Cooled Generators Operating at <3600 RPM

Rated Output Surge Capability Surge Capability

(Running Amps) LR Amps at 15% Voltage Dip LR Amps at 30% Voltage Dip

Size (kW) 240V 1ø 208V 3ø 480V 3ø 240V 1ø 208V 3ø 480V 3ø 240V 1ø 208V 3ø 480V 3ø

25 104 87 38 71 47 26 133 89 52

70 292 243 105 275 183 106 550 366 212

80 333 278 120 275 183 106 550 366 212

100 417 347 150 371 247 142 738 491 284

130 542 451 195 546 364 209 1088 724 419

Siemens Generators Operating at 3600 RPM

Rated Output Surge Capability Surge Capability

(Running Amps) LR Amps at 15% Voltage Dip LR Amps at 30% Voltage Dip

Size (kW) 240V 1ø 208V 3ø 480V 3ø 240V 1ø 208V 3ø 480V 3ø 240V 1ø 208V 3ø 480V 3ø

7 29 24 11 23 n/a n/a 46 n/a n/a

10 42 35 15 31 n/a n/a 63 n/a n/a

13 54 45 20 38 n/a n/a 75 n/a n/a

16 67 56 24 46 n/a n/a 92 n/a n/a

20 83 69 30 63 42 24 121 80 47

25 104 87 38 71 47 26 138 92 53

35 146 121 53 104 69 40 204 136 78

45 188 156 68 146 97 57 292 194 112

60 250 208 90 179 119 69 354 236 136

70 292 243 105 246 164 95 496 330 190

100 417 347 150 333 222 128 663 441 255

150 625 520 226 558 372 215 1121 747 431

4

Note: All kW models listed above are based on nominal LP rating.

Page 6

Generator Sizing Guide

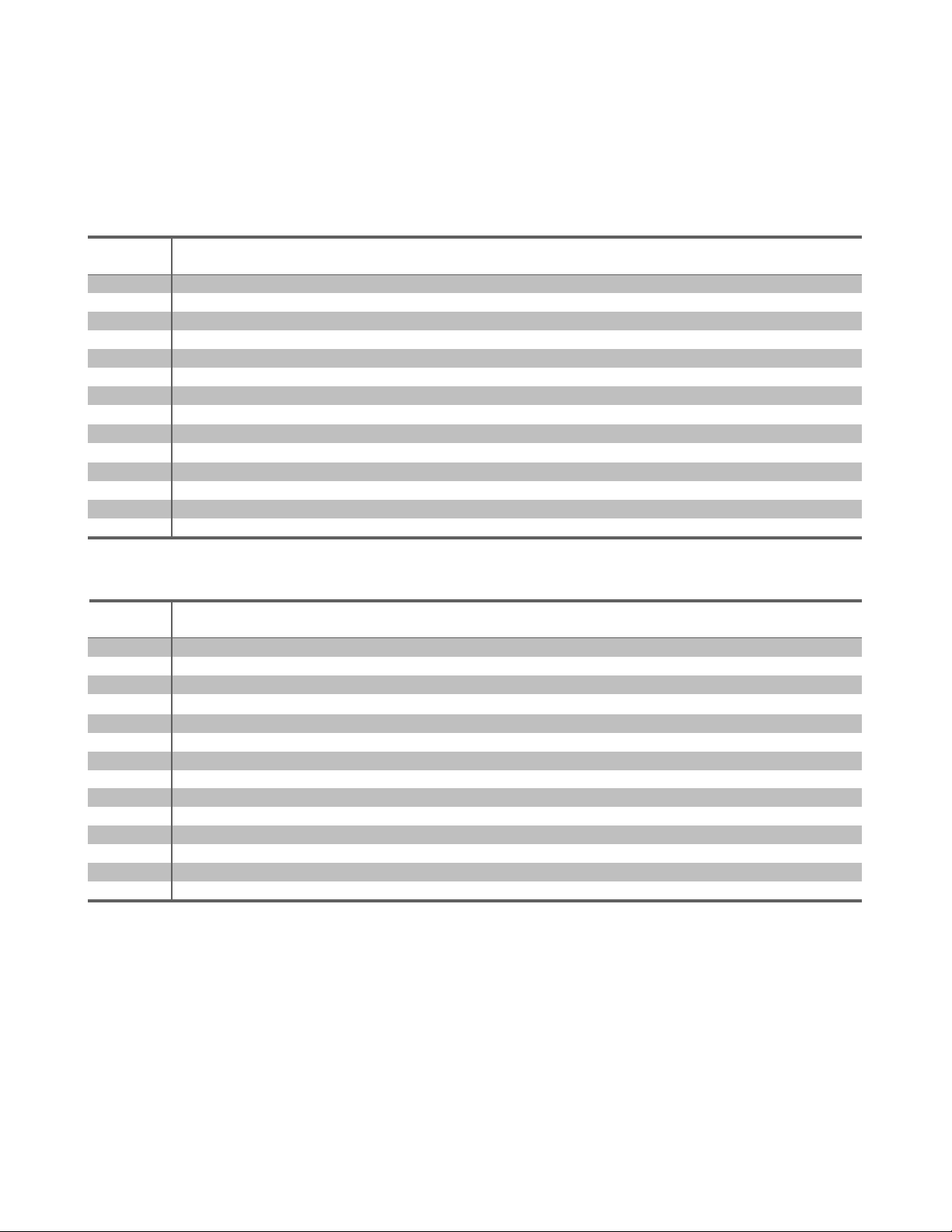

Table 4 – Fuel Pipe Sizing

Natural Gas

Pipe Size (in.)

kW 0.75" 1" 1.25" 1.5" 2" 2.5" 3"

7 55 200 820

10 20 85 370 800

13 10 50 245 545

16 40 190 425

20 20 115 265 950

25 10 75 180 660

35 35 95 370 915

45 15 60 260 650

60 25 145 390 1185

70 5 75 225 710

80 65 195 630

100 40 140 460

130 50 215

150 30 150

LP vapor (LPV)

Pipe Size (in.)

kW 0.75" 1" 1.25" 1.5" 2" 2.5" 3"

7 165 570

10 70 255 1000

13 45 170 690

16 30 130 540

20 15 80 340 745

25 50 235 520

35 20 125 290 1030

45 82 195 725

60 45 115 445 1095

70 20 60 260 660

80 15 50 230 590

100 30 165 430 1305

130 70 205 660

150 45 150 490

Note: – Table values are maximum pipe run in feet.

– Pipe sizing is based on .5" H2O pressure drop.

– Sizing includes a nominal number of elbows and tees.

– Please verify adequate service and meter sizing.

5

Page 7

Generator Sizing Guide

Table 5 – LP Vapor (LPV) Tank Sizing

Vapor Withdrawal

Tank Capacity Tank Capacity Length Diameter Overall Ht. Minimum Temp Tank Capacity

Total (Gal.) Useable (Gal.) (Inches) (Inches) (Inches) (°F) (btu/hr.)

120 72 57 24 33 40 246,240

20 164,160

0 82,080

150 90 68 24 33 40 293,760

20 195,840

0 97,920

250 150 94 30 39 40 507,600

20 338,400

0 169,200

325 195 119 30 39 40 642,600

20 428,400

0 214,200

500 300 119 37 46 40 792,540

20 528,360

0 264,180

850 510 165 41 50 40 1,217,700

20 811,800

0 405,900

1000 600 192 41 50 40 1,416,960

20 944,640

0 472,320

LP Vapor (LPV) Withdrawal Fuel Consumption

Load (kW) BTU / Hr Gal / Hr

7 110,000 1.2

10 190,000 2.1

13 215,000 2.4

16 252,000 2.8

20 340,000 3.8

25 390,000 4.3

35 500,000 5.5

45 620,000 6.8

60 800,000 8.8

70 950,000 10.5

80 1,100,000 12.2

100 1,400,000 15.5

130 1,800,000 19.9

150 2,050,000 22.7

Note: Tank BTU capacity and generator run times based upon maintaining a minimum tank fuel level of 20%.

Note: Fuel consumption based on a generator 80% loaded.

6

Page 8

Generator Sizing Guide

UPS Generator Compatibility

Passive (also referenced as standby or off-line) and

Line-Interactive

These technologies are most common for personal workstations

and point of sale applications. They are typically single phase

equipment with size ranges of 350 VA – 2000 VA for passive

and 500 VA to 5000 VA for line-interactive.

Passive UPS’s are the simplest type. Under normal conditions

AC power passes straight through to the UPS load. When the

input power supply goes outside of specifications, the UPS

transfers the load from input power to the internal DC to AC

power inverter. Passive UPS’s do not correct for voltage or

frequency deviations under “normal” operation.

Line-interactive is similar to the passive technology except

it has circuitry that attempts to correct for standard voltage

deviations. Frequency deviations under “normal” power

operation are not corrected.

Equipment Notes:

These devices tend to be electrically / harmonically very noisy.

A single small UPS is not a significant concern, but applications

with multiple UPS’s can be problematic.

Passive UPS technology typically has normal tolerances of

10 – 25% on voltage and 3 hertz on frequency. If the input

source goes outside of these tolerances, the UPS will switch

onto the UPS battery source. Some line-interactive units may

have frequency tolerances factory set to .5 hertz. These units

will need to have their frequency tolerance increased to a

minimum of 2 hertz.

Generator Sizing Recommendation:

Limit the total UPS loading to 15% – 20% of the generator

capacity.

Double-Conversion

This technology is most common for critical load applications.

Double-conversion UPS’s constantly rectify AC to DC and then

invert the DC back into AC. This configuration results in an

output that corrects for voltage and frequency deviations.

There are single and three phase models covering small

through large applications. Most UPS applications larger than

5000 VA use double conversion technology. This approach is

also the preferred technology for generator applications.

Equipment Notes:

Double-conversion UPS’s that are single phase or unfiltered

three phase models tend to create a significant level of

electrical/ harmonic noise. This is illustrated by harmonic

current distortions that are greater than 35%. When three

phase models are supplied with harmonic filters (current

distortion less than 10%), this concern is no longer an issue.

Generator Sizing Recommendation:

Single phase models: limit the total UPS loading to 25%

of the generator capacity.

Three phase models without filters (current distortion > 30%):

limit the UPS loading to 35% of the generator capacity.

Three phase models with filters (current distortion < 10%):

limit the UPS loading to 80% of the generator capacity.

Supplier(s) Passive (Standby) Line-Interactive Double-Conversion

APC Back-UPS Series Smart-UPS Series Symmetra Series

Liebert PowerSure PST and PSP PowerSure PSA and PSI UPStation and Nfinity Series

Powerware 3000 Series 5000 Series 9000 Series

Note: Ferrups and Delta-Conversion UPS technologies not included in discussion.

7

Page 9

Generator Sizing Guide

Onsite Estimating Sheet

Contractor _____________________________________________

Email _________________________________________________

Phone _________________________ Fax ___________________

Job Name _____________________________________________

Date___________ Location _______________________________

VOLTAGE

120/240 1Ø 120/208 3Ø 277/480 3Ø

TYPE

Natural Gas LP Vapor LPV)

ELEC. SERVICE

100 Amp 200 Amp 400 Amp

600 Amp Other________

Before installation contact local jurisdiction to confirm all

requirements are met. Jurisdictions may vary. Siemens

recommends contacting local authorities prior to installation.

Loads: Look for heavy building loads such as refrigeration,

air conditioning, pumps or UPS systems.

Use the following for sizing and determining generator kW.

QT Upgrade Required

These applications require an upgrade from the QT Series:

NEC 695 Fire Pumps

NEC 700 Emergency Systems

NFPA 20 Fire Pumps

NFPA 99 Healthcare

NFPA 110 Emergency Systems

Reference Codes

Related Codes and Standards:

NEC 225 Branch Circuits and Feeders

NEC 240 Overcurrent Protection

NEC 250 Grounding

NEC 445 Generators

NEC 701 Legally Required Standby

NEC 702 Optional Standby

NFPA 37 Installation and Use of Stationary Engines

NFPA 54 National Fuel Gas Code

NFPA 58 LP Gas Code

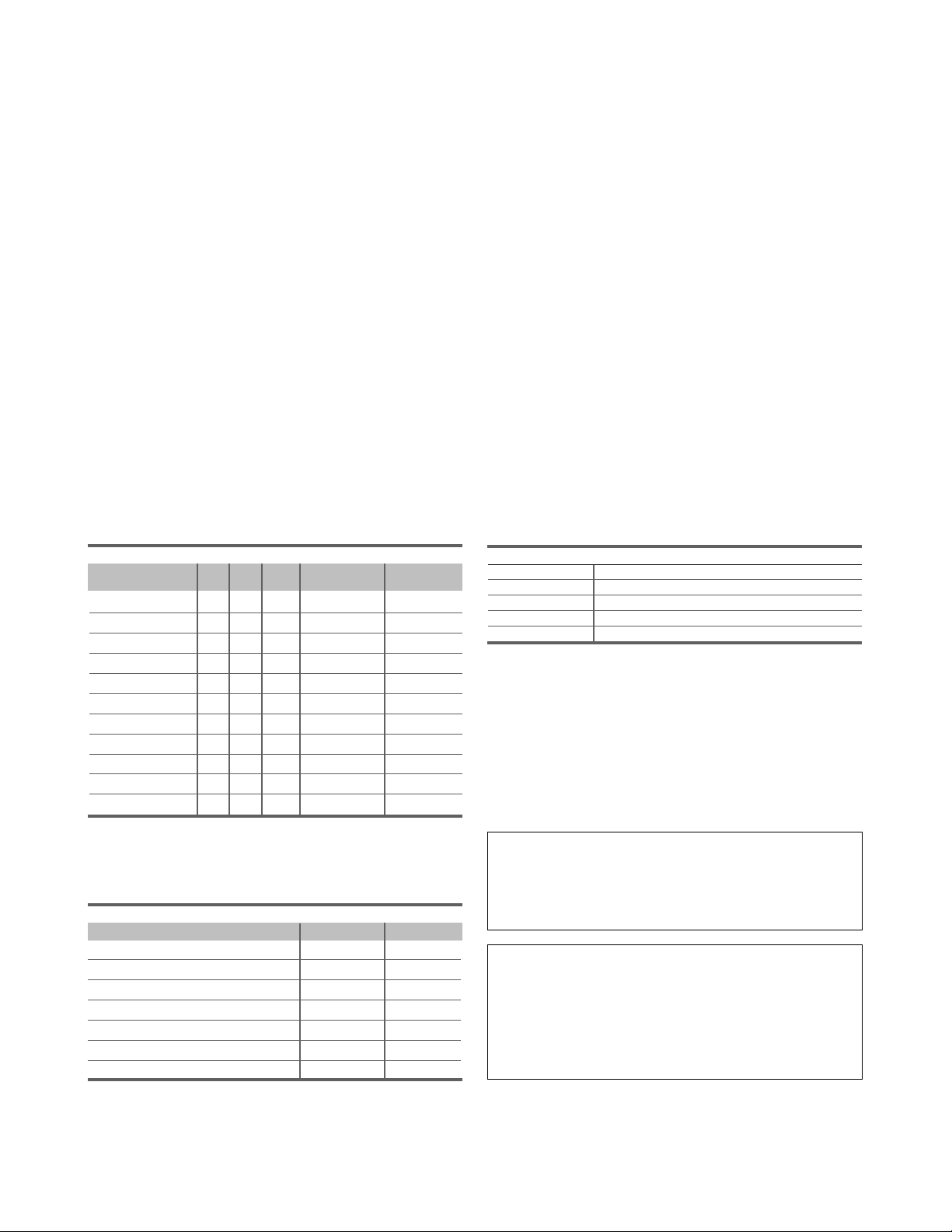

Motor Load Table (refer to Table 1)

Device HP RA LRA kW Running Starting

(= HP) kW

Table 6

Non-Motor Load Table (refer to Table 2)

Device Amps kW

Table 7

Starting kW for HP < 7.5 starting kW = HP x 3

Starting kW for HP > 7.5 starting kW = HP x 2

Starting kW for loading with no listed HP, calculate HP based on running amps

in the chart on the right.

Recommended Generator Size ________ Refer to Generator Sizing Instructions on other side of this sheet.

INSTALL NOTES:

1. Suggested concrete pad minimum thickness of 4" with 12" overhang on all sides. Fiberglass pad included with air-cooled products.

2. Consult manual for installation recommendations.

3. Consult local authority having jurisdiction for local requirements.

To Calculate kW (refer to page 2 for shortcut)

120 V 1Ø Amps x 120/1000 = kW

240 V 1Ø Amps x 240/1000 = kW

208 V 3Ø Amps x 208 x √3 x PF/1000 = kW

240 V 3Ø Amps x 240 x √3 x PF/1000 = kW

480 V 3Ø Amps x 480 x √3 x PF/1000 = kW

PF is application power factor (worst case 1.0)

Typical application power factor is 0.95.

Resources in Sizing Guide

Surge Capability Chart – References running amps of units and LRA

Propane Tank Sizing Chart –

Measures fuel consumption of generator units

Motor Load Reference Guide – Reference guide for basic motor loads

Non-Motor Load Reference Guide – Reference guide for non-motor loads

Fuel Piping Sizing Chart – Assists in calculating adequate pipe size for

natural gas and propane

UPS – Generator Compatibility

UPS Information

1.5 x kVA rating for a filtered system

3 – 5 x kVA rating for an unfiltered system

Siemens recommends you refer to the Siemens UPS Generator

Compatibility sheet and notify the manufacturer of the UPS

system to assist in your installation.

Transfer Switch Availability

SR6ST

– 100 and 200 Amp service entrance rated

RTS – 100, 200, 400 Amp

SR6SI switch only works with R100 controller.

XT 6XR – 100, 150, 200, 300, 400, 600, 800 Amp

HTS switch only works with H100 controller. Avail. in

NEMA 1, NEMA 3R and NEMA 12. Refer to Siemens

product catalog for the appropriate transfer switch.

8

Page 10

Generator Sizing Guide

Onsite Estimating Sheet

Generator Sizing Instructions:

There is not a single correct sizing solution. The instructions

below identify multiple methods that, when mixed with good

judgment, should result in a moderately sized generator.

Remember to consider load growth, seasonality, and effects

of starting motors.

When motors start, they create a current surge that step loads

the generator. As a result of this step loading, the generator

will experience a voltage dip. After selecting a generator,

reference the generator's surge capability using Table 3. Verify

that the generator voltage dip is adequate for the application.

Most commercial applications should be limited to 15%

voltage dip and residential applications should be limited to

30% voltage dip.

Some commercial applications utilize one or multiple

uninterruptible power supplies (UPS) to backup critical loads.

Please read sizing guidelines for this load type.

Measurement Method

Use a clamp-on amp meter or power analyzer to measure facility load levels. The measurement should be made at peak load

levels. Size the generator 25% larger than the peak measured

load. Verify motor and UPS load compatibility.

Measured Amps = _______

Billing History Method

Many commercial customers have a utility rate structure that

has a peak demand charge. Using a year's worth of electric

bills, size the generator 25% larger than the largest peak

demand. Verify motor and UPS load compatibility.

Peak Demand = _______

Load Summation Method

1) Enter all motors loads expected to run during peak load

levels into Table 6. Reference Table 1 for typical motor sizes

and electrical requirements.

2) Enter all non-motor loads expected to run during peak load

levels into Table 7. Reference Table 2 for typical residential

loads and rules of thumb.

3) Sum the running motor load data but do not include

the largest motor that is cycling. Add to this value the

non-motor load data and the starting kW for the largest

cycling motor.

Motor running load total

(minus largest cycling motor): ______ kW (Ref. Table 6)

Motor starting load from

largest cycling motor: + ______ kW (Ref. Table 6)

Non-motor load total: + ______ kW (Ref. Table 7)

Total (above items): = ______ kW

Select generator (Total x 1.25) ______ kW

4) Verify voltage dip compatibility using generator Surge

Capability Table 3. Verify UPS compatibility using sizing

guidelines provided.

Initial Estimate and Cross Check Methods

These methods are for initial estimates and cross checks only.

Size the generator using one of the above methods.

Estimate based on 60% service size:

240 Volts, 1

Ø: ________ amps x .15 = ________ kW

208 Volts, 3

Ø: ________ amps x .22 = ________ kW

480 Volts, 3

Ø: ________ amps x .50 = ________ kW

Estimate Based on Square Footage

Fast food, convenience stores, restaurants, grocery stores

= 50 kW + 10 watts / sq. ft.

Other commercial = 30 kW + 5 watts / sq. ft.

Square footage = ____________

Estimated kW = ____________

LP

LPG: 8.55 ft.3/lb., 4.24 lbs./gal.,

2500 btu/ft.

3

LPG: 36 ft.3= 1 gal.

Natural Gas

1 cubic foot = 1,000 BTUs

1 therm = 100,000 BTUs

Gas consumption = 13,000-16,000 btu

per kW/hr.

Pressure

1 inch mercury = 13.61 inches

Water Column

1 inch Water Column = 0.036 psi

5-14 inches water column = 0.18 psi

to 0.50 psi

Air Conditioning

1 hp per 1 ton

1 ton = 12,000 btu

Rule of Thumb

For 480 volt systems kW x 1.5 = Amps

For 208 volt systems kW x 3.5 = Amps

For 240 volt single phase systems

kW x 4 = Amps

9

Page 11

Generator Sizing Guide

Onsite Estimating Sheet

Contractor _____________________________________________

Email _________________________________________________

Phone _________________________ Fax ___________________

Job Name _____________________________________________

Date___________ Location _______________________________

VOLTAGE

120/240 1Ø 120/208 3Ø 277/480 3Ø

TYPE

Natural Gas LP Vapor LPV)

ELEC. SERVICE

100 Amp 200 Amp 400 Amp

600 Amp Other________

Before installation contact local jurisdiction to confirm all

requirements are met. Jurisdictions may vary. Siemens

recommends contacting local authorities prior to installation.

Loads: Look for heavy building loads such as refrigeration,

air conditioning, pumps or UPS systems.

Use the following for sizing and determining generator kW.

QT Upgrade Required

These applications require an upgrade from the QT Series:

NEC 695 Fire Pumps

NEC 700 Emergency Systems

NFPA 20 Fire Pumps

NFPA 99 Healthcare

NFPA 110 Emergency Systems

Reference Codes

Related Codes and Standards:

NEC 225 Branch Circuits and Feeders

NEC 240 Overcurrent Protection

NEC 250 Grounding

NEC 445 Generators

NEC 701 Legally Required Standby

NEC 702 Optional Standby

NFPA 37 Installation and Use of Stationary Engines

NFPA 54 National Fuel Gas Code

NFPA 58 LP Gas Code

Motor Load Table (refer to Table 1)

Device HP RA LRA kW Running Starting

(= HP) kW

Table 6

Non-Motor Load Table (refer to Table 2)

Device Amps kW

Table 7

Starting kW for HP < 7.5 starting kW = HP x 3

Starting kW for HP > 7.5 starting kW = HP x 2

Starting kW for loading with no listed HP, calculate HP based on running amps

in the chart on the right.

Recommended Generator Size ________ Refer to Generator Sizing Instructions on other side of this sheet.

INSTALL NOTES:

1. Suggested concrete pad minimum thickness of 4" with 12" overhang on all sides. Fiberglass pad included with air-cooled products.

2. Consult manual for installation recommendations.

3. Consult local authority having jurisdiction for local requirements.

To Calculate kW (refer to page 2 for shortcut)

120 V 1Ø Amps x 120/1000 = kW

240 V 1Ø Amps x 240/1000 = kW

208 V 3Ø Amps x 208 x √3 x PF/1000 = kW

240 V 3Ø Amps x 240 x √3 x PF/1000 = kW

480 V 3Ø Amps x 480 x √3 x PF/1000 = kW

PF is application power factor (worst case 1.0)

Typical application power factor is 0.95.

Resources in Sizing Guide

Surge Capability Chart – References running amps of units and LRA

Propane Tank Sizing Chart –

Measures fuel consumption of generator units

Motor Load Reference Guide – Reference guide for basic motor loads

Non-Motor Load Reference Guide – Reference guide for non-motor loads

Fuel Piping Sizing Chart – Assists in calculating adequate pipe size for

natural gas and propane

UPS – Generator Compatibility

UPS Information

1.5 x kVA rating for a filtered system

3 – 5 x kVA rating for an unfiltered system

Siemens recommends you refer to the Siemens UPS Generator

Compatibility sheet and notify the manufacturer of the UPS

system to assist in your installation.

Transfer Switch Availability

SR6ST

– 100 and 200 Amp service entrance rated

RTS – 100, 200, 400 Amp

SR6SI switch only works with R100 controller.

XT 6XR – 100, 150, 200, 300, 400, 600, 800 Amp

HTS switch only works with H100 controller. Avail. in

NEMA 1, NEMA 3R and NEMA 12. Refer to Siemens

product catalog for the appropriate transfer switch.

10

Page 12

Generator Sizing Guide

Onsite Estimating Sheet

Generator Sizing Instructions:

There is not a single correct sizing solution. The instructions

below identify multiple methods that, when mixed with good

judgment, should result in a moderately sized generator.

Remember to consider load growth, seasonality, and effects

of starting motors.

When motors start, they create a current surge that step loads

the generator. As a result of this step loading, the generator

will experience a voltage dip. After selecting a generator,

reference the generator's surge capability using Table 3. Verify

that the generator voltage dip is adequate for the application.

Most commercial applications should be limited to 15%

voltage dip and residential applications should be limited to

30% voltage dip.

Some commercial applications utilize one or multiple

uninterruptible power supplies (UPS) to backup critical loads.

Please read sizing guidelines for this load type.

Measurement Method

Use a clamp-on amp meter or power analyzer to measure facility load levels. The measurement should be made at peak load

levels. Size the generator 25% larger than the peak measured

load. Verify motor and UPS load compatibility.

Measured Amps = _______

Billing History Method

Many commercial customers have a utility rate structure that

has a peak demand charge. Using a year's worth of electric

bills, size the generator 25% larger than the largest peak

demand. Verify motor and UPS load compatibility.

Peak Demand = _______

Load Summation Method

1) Enter all motors loads expected to run during peak load

levels into Table 6. Reference Table 1 for typical motor sizes

and electrical requirements.

2) Enter all non-motor loads expected to run during peak load

levels into Table 7. Reference Table 2 for typical residential

loads and rules of thumb.

3) Sum the running motor load data but do not include

the largest motor that is cycling. Add to this value the

non-motor load data and the starting kW for the largest

cycling motor.

Motor running load total

(minus largest cycling motor): ______ kW (Ref. Table 6)

Motor starting load from

largest cycling motor: + ______ kW (Ref. Table 6)

Non-motor load total: + ______ kW (Ref. Table 7)

Total (above items): = ______ kW

Select generator (Total x 1.25) ______ kW

4) Verify voltage dip compatibility using generator Surge

Capability Table 3. Verify UPS compatibility using sizing

guidelines provided.

Initial Estimate and Cross Check Methods

These methods are for initial estimates and cross checks only.

Size the generator using one of the above methods.

Estimate based on 60% service size:

240 Volts, 1

Ø: ________ amps x .15 = ________ kW

208 Volts, 3

Ø: ________ amps x .22 = ________ kW

480 Volts, 3

Ø: ________ amps x .50 = ________ kW

Estimate Based on Square Footage

Fast food, convenience stores, restaurants, grocery stores

= 50 kW + 10 watts / sq. ft.

Other commercial = 30 kW + 5 watts / sq. ft.

Square footage = ____________

Estimated kW = ____________

LP

LPG: 8.55 ft.3/lb., 4.24 lbs./gal.,

2500 btu/ft.

3

LPG: 36 ft.3= 1 gal.

Natural Gas

1 cubic foot = 1,000 BTUs

1 therm = 100,000 BTUs

Gas consumption = 13,000-16,000 btu

per kW/hr.

Pressure

1 inch mercury = 13.61 inches

Water Column

1 inch Water Column = 0.036 psi

5-14 inches water column = 0.18 psi

to 0.50 psi

Air Conditioning

1 hp per 1 ton

1 ton = 12,000 btu

Rule of Thumb

For 480 volt systems kW x 1.5 = Amps

For 208 volt systems kW x 3.5 = Amps

For 240 volt single phase systems

kW x 4 = Amps

11

Page 13

Generator Sizing Guide

Onsite Estimating Sheet

Contractor _____________________________________________

Email _________________________________________________

Phone _________________________ Fax ___________________

Job Name _____________________________________________

Date___________ Location _______________________________

VOLTAGE

120/240 1Ø 120/208 3Ø 277/480 3Ø

TYPE

Natural Gas LP Vapor LPV)

ELEC. SERVICE

100 Amp 200 Amp 400 Amp

600 Amp Other________

Before installation contact local jurisdiction to confirm all

requirements are met. Jurisdictions may vary. Siemens

recommends contacting local authorities prior to installation.

Loads: Look for heavy building loads such as refrigeration,

air conditioning, pumps or UPS systems.

Use the following for sizing and determining generator kW.

QT Upgrade Required

These applications require an upgrade from the QT Series:

NEC 695 Fire Pumps

NEC 700 Emergency Systems

NFPA 20 Fire Pumps

NFPA 99 Healthcare

NFPA 110 Emergency Systems

Reference Codes

Related Codes and Standards:

NEC 225 Branch Circuits and Feeders

NEC 240 Overcurrent Protection

NEC 250 Grounding

NEC 445 Generators

NEC 701 Legally Required Standby

NEC 702 Optional Standby

NFPA 37 Installation and Use of Stationary Engines

NFPA 54 National Fuel Gas Code

NFPA 58 LP Gas Code

Motor Load Table (refer to Table 1)

Device HP RA LRA kW Running Starting

(= HP) kW

Table 6

Non-Motor Load Table (refer to Table 2)

Device Amps kW

Table 7

Starting kW for HP < 7.5 starting kW = HP x 3

Starting kW for HP > 7.5 starting kW = HP x 2

Starting kW for loading with no listed HP, calculate HP based on running amps

in the chart on the right.

Recommended Generator Size ________ Refer to Generator Sizing Instructions on other side of this sheet.

INSTALL NOTES:

1. Suggested concrete pad minimum thickness of 4" with 12" overhang on all sides. Fiberglass pad included with air-cooled products.

2. Consult manual for installation recommendations.

3. Consult local authority having jurisdiction for local requirements.

To Calculate kW (refer to page 2 for shortcut)

120 V 1Ø Amps x 120/1000 = kW

240 V 1Ø Amps x 240/1000 = kW

208 V 3Ø Amps x 208 x √3 x PF/1000 = kW

240 V 3Ø Amps x 240 x √3 x PF/1000 = kW

480 V 3Ø Amps x 480 x √3 x PF/1000 = kW

PF is application power factor (worst case 1.0)

Typical application power factor is 0.95.

Resources in Sizing Guide

Surge Capability Chart – References running amps of units and LRA

Propane Tank Sizing Chart –

Measures fuel consumption of generator units

Motor Load Reference Guide – Reference guide for basic motor loads

Non-Motor Load Reference Guide – Reference guide for non-motor loads

Fuel Piping Sizing Chart – Assists in calculating adequate pipe size for

natural gas and propane

UPS – Generator Compatibility

UPS Information

1.5 x kVA rating for a filtered system

3 – 5 x kVA rating for an unfiltered system

Siemens recommends you refer to the Siemens UPS Generator

Compatibility sheet and notify the manufacturer of the UPS

system to assist in your installation.

Transfer Switch Availability

SR6ST

– 100 and 200 Amp service entrance rated

RTS – 100, 200, 400 Amp

SR6SI switch only works with R100 controller.

XT 6XR – 100, 150, 200, 300, 400, 600, 800 Amp

HTS switch only works with H100 controller. Avail. in

NEMA 1, NEMA 3R and NEMA 12. Refer to Seimens

product catalog for the appropriate transfer switch.

12

Page 14

Generator Sizing Guide

Onsite Estimating Sheet

Generator Sizing Instructions:

There is not a single correct sizing solution. The instructions

below identify multiple methods that, when mixed with good

judgment, should result in a moderately sized generator.

Remember to consider load growth, seasonality, and effects

of starting motors.

When motors start, they create a current surge that step loads

the generator. As a result of this step loading, the generator

will experience a voltage dip. After selecting a generator,

reference the generator's surge capability using Table 3. Verify

that the generator voltage dip is adequate for the application.

Most commercial applications should be limited to 15%

voltage dip and residential applications should be limited to

30% voltage dip.

Some commercial applications utilize one or multiple

uninterruptible power supplies (UPS) to backup critical loads.

Please read sizing guidelines for this load type.

Measurement Method

Use a clamp-on amp meter or power analyzer to measure facility load levels. The measurement should be made at peak load

levels. Size the generator 25% larger than the peak measured

load. Verify motor and UPS load compatibility.

Measured Amps = _______

Billing History Method

Many commercial customers have a utility rate structure that

has a peak demand charge. Using a year's worth of electric

bills, size the generator 25% larger than the largest peak

demand. Verify motor and UPS load compatibility.

Peak Demand = _______

Load Summation Method

1) Enter all motors loads expected to run during peak load

levels into Table 6. Reference Table 1 for typical motor sizes

and electrical requirements.

2) Enter all non-motor loads expected to run during peak load

levels into Table 7. Reference Table 2 for typical residential

loads and rules of thumb.

3) Sum the running motor load data but do not include

the largest motor that is cycling. Add to this value the

non-motor load data and the starting kW for the largest

cycling motor.

Motor running load total

(minus largest cycling motor): ______ kW (Ref. Table 6)

Motor starting load from

largest cycling motor: + ______ kW (Ref. Table 6)

Non-motor load total: + ______ kW (Ref. Table 7)

Total (above items): = ______ kW

Select generator (Total x 1.25) ______ kW

4) Verify voltage dip compatibility using generator Surge

Capability Table 3. Verify UPS compatibility using sizing

guidelines provided.

Initial Estimate and Cross Check Methods

These methods are for initial estimates and cross checks only.

Size the generator using one of the above methods.

Estimate based on 60% service size:

240 Volts, 1

Ø: ________ amps x .15 = ________ kW

208 Volts, 3

Ø: ________ amps x .22 = ________ kW

480 Volts, 3

Ø: ________ amps x .50 = ________ kW

Estimate Based on Square Footage

Fast food, convenience stores, restaurants, grocery stores

= 50 kW + 10 watts / sq. ft.

Other commercial = 30 kW + 5 watts / sq. ft.

Square footage = ____________

Estimated kW = ____________

LP

LPG: 8.55 ft.3/lb., 4.24 lbs./gal.,

2500 btu/ft.

3

LPG: 36 ft.3= 1 gal.

Natural Gas

1 cubic foot = 1,000 BTUs

1 therm = 100,000 BTUs

Gas consumption = 13,000-16,000 btu

per kW/hr.

Pressure

1 inch mercury = 13.61 inches

Water Column

1 inch Water Column = 0.036 psi

5-14 inches water column = 0.18 psi

to 0.50 psi

Air Conditioning

1 hp per 1 ton

1 ton = 12,000 btu

Rule of Thumb

For 480 volt systems kW x 1.5 = Amps

For 208 volt systems kW x 3.5 = Amps

For 240 volt single phase systems

kW x 4 = Amps

13

Page 15

Notes

Page 16

Siemens Energy & Automation, Inc.

3333 Old Milton Parkway

Alpharetta, GA 30005

1-800-964-4114

infosea@siemens.com

www.sea.siemens.com/generators

RPSA-GENSZ-0506 New 3M0506B&A Printed in USA

©2006 Siemens Energy & Automation, Inc. All Rights Reserved

Siemens is a registered trademark of Siemens AG. Product names mentioned may be trademarks or registered trademarks of their respective

companies. Specifications are subject to change without notice.

Loading...

Loading...