Page 1

s

FM 458-1 DP

Function Blocks

Contents, Foreword

Input/output blocks

Communication blocks

Logic blocks

Manual

Edition 12.2004

Service-/diagnostic blocks

SIMOLINK blocks

Closed-loop control blocks

Index

Page 2

Safety guidelines

DANGER

!

WARNING

!

CAUTION

!

CAUTION

This Manual contains notices which you should observe to ensure your own personal

safety, as well as to protect the product and connected equipment. These notices are

highlighted in the Manual by a warning triangle and are marked as follows according to

the level of danger:

indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

used with the safety alert symbol indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

used without safety alert symbol indicates a potentially hazardous situation which, if not

avoided, may result in property damage.

NOTICE

Correct usage

Trademarks

used without the safety alert symbol indicates a potential situation which, if not avoided,

may result in an undesireable result or state.

Note the following:

This device and its components may only be used for the applications described in the

catalog or the technical description, and only in connection with devices or components

from other manufacturers which have been approved or recommended by Siemens.

SIMATIC and SIMADYN D are registered trademarks of Siemens AG.

Third parties using for their own purposes any other names in this document which refer

to trademarks might infringe upon the rights of the trademark owners.

Copyright SIEMENS AG 2004 All rights reserved

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created by patent grant or registration of a utility model or design,

are reserved.

Siemens AG

A&D

Frauenauracher Straße 80

91056 Erlangen

Disclaimer of liability

We have checked the contents of this manual for agreement with

the hardware and software described. Since deviations cannot be

precluded entirely, we cannot guarantee full agreement.

However, the data in this manual are reviewed regularly and any

necessary corrections included in subsequent editions.

Suggestions for improvement are welcomed.

Siemens AG 2004

Technical data subject to change.

Siemens Aktiengesellschaft

Page 3

Editions

FM 458-1 DP

Manual

Function Blocks

Edition 12.2004

NOTE

Overview

(chapter editions)

Please note that the current edition of this documentation contains

different editions of the individual chapters. The following overview tells

you when a chapter was revised the last time.

Chapter Edition

Foreword Edition 12.2004

1 Input/output blocks Edition 12.2004

2 Communication blocks Edition 12.2004

3 Logic blocks Edition 03.2003

4 Service-/diagnostic blocks Edition 03.2003

5 SIMOLINK drive coupling Edition 12.2004

6 Closed-loop control blocks Edition 12.2003

Function Blocks - FM 458-1 DP ii

Edition 12.2004

Page 4

Foreword

Purpose of this

Manual

Basic knowledge

required

Validity of the

Manual

Additional support

Training Center

This Manual explains the principle use and functions of the STEP 7

automation software with the main focus on the appropriate technological

and drive control components T400, FM 458-1 DP, SIMADYN D,

SIMATIC TDC or D7-SYS.

TDC: Technology and Drives Control

This Manual addresses programmers and commissioning engineers.

General knowhow regarding automation technology is required in order to

understand the contents of the Manual

This Manual is valid for SIMATIC D7-SYS Version 6.2.

If you have questions relating to the use of the products described in the

Manual, which cannot be answered here, then please contact your local

Siemens office. You can also call the Hotline:

• Tel.: +49 (180) 5050-222

• Fax: +49 (180) 5050-223

• e-mail: adsupport@siemens.com

Appropriate training courses are available in order to make it easier to get

to know the SIMADYN D automation system. Please contact the central

Training Center in D-Erlangen (I&S IS INA TC):

• Tel.: +49 (9131) 7-27689, -27972

• Fax: +49 (9131) 7-28172

• Internet: www.siemens.de/sibrain

• Intranet: http://info-tc.erlm.siemens.de/

NOTE

This user part of the Manual does not include any detailed

information/instructions with individual descriptions, but is only intended

to provide a basic procedure. More detailed information on the dialog

boxes in the software and how they are handled is provided in the

appropriate online help.

Function Blocks - FM 458-1 DP iii

Edition 12.2004

Page 5

Foreword

Information

overview

This manual is part of the overall documentation for the technological and

drive control components T400, FM 458, SIMADYN D, SIMATIC TDC

and SIMATIC D7-SYS:

Title Content

System and

communications

configuring D7-SYS

STEP 7 option packages

for D7-SYS

Hardware The complete hardware spectrum is described as reference in this Manuals.

Function blocks

The first project in a few steps

This Section provides an extremely simple entry into the methodology when

assembling and programming the SIMATIC TDC/SIMADYN D control

system. It is especially conceived for first-time users of a control system.

System software

This Section provides basic know-how about the structure of the operating

system and an application program of a CPU. It should be used to obtain an

overview of the programming methodology, and basis for configuring user

programs.

Communications configuring

This section provides you with basic know-how about the communication

possibilities and how you configure links to the communication partners.

Changeover from STRUC V4.x to D7-SYS

Essential features are included in this section, which have changed over

STRUC V4.x with the introduction of SIMATIC D7-SYS.

Basis software

This section explains the essential use and the functions of the STEP 7

automation software. For first users, it provides an overview on configuring,

programming and commissioning a station.

When working with the basis software, you can access the online help which

provides you with support when it comes to detailed questions on using the

software.

CFC

The CFC language (Continuous Function Chart) allows you to graphically

interconnect blocks.

When working with the particular software, you can also use the online help

which can answer detailed questions regarding the use of the

editors/compiler.

SFC

Configuring sequence controls using SFC (Sequential Function Chart) of

SIMATIC S7.

In the SFC editor, you generate a sequence chart using graphic resources.

The SFC elements of the chart are then positioned according to specific

rules.

These Reference Manuals provide you with an overview of selected function

blocks for the associated technological and drive control components T400,

FM 458-1 DP, SIMADYN D and SIMATIC TDC.

iv Function Blocks - FM 458-1 DP

Edition 12.2004

Page 6

Foreword

Guide

A&D Technical

Support

As first time user, we recommend that this Manual is used as follows:

• Please read the first section on using the software in order to get to

know some of the terminology and basic procedure.

• Then use the particular sections of the Manual if you wish to carry-out

certain processing steps (e.g. loading programs).

If you have already executed a small project, and have gained some

experience, then you can read individual sections of the Manual in order

to get up to speed about a specific subject.

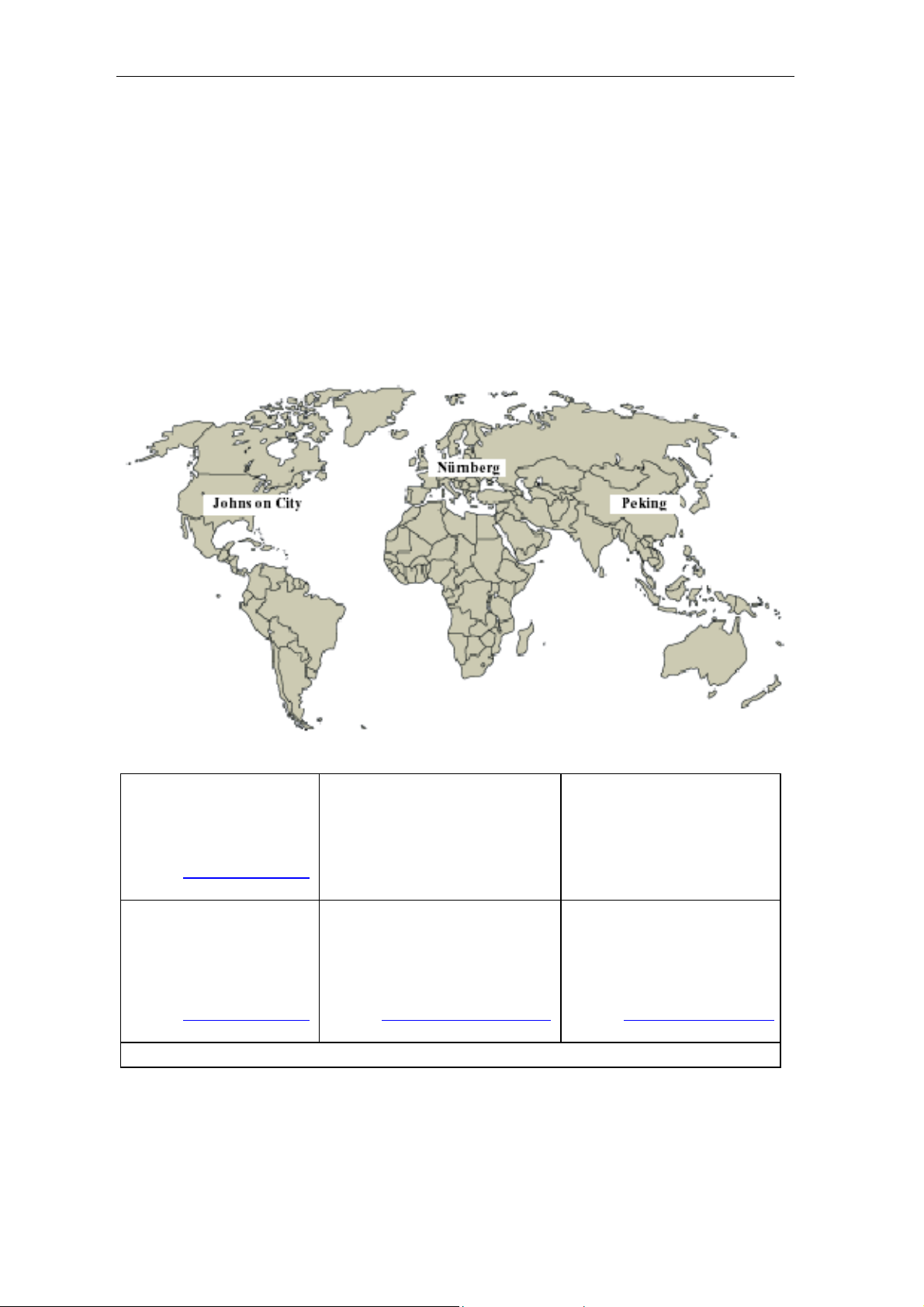

Can be accessed globally at any time of the day:

World-wide

(Nürnberg)

Technical Support

Local time: 0:00 to 24:00 / 365 days

Phone: +49 (180) 5050-222

Fax: +49 (180) 5050-223

E-Mail: adsupport@siemens.com

GMT: +1:00

Europe / Africa

(Nürnberg)

Authorization

Local time: Mo.-Fr. 8:00 to 17:00

Phone: +49 (180) 5050-222

Fax: +49 (180) 5050-223

E-Mail: adsupport@siemens.com

GMT: +1:00

Technical Support and Authorization speak generally German and English.

United States

(Johnson City)

Technical Support and

Authorization

Local time: Mo.-Fr. 8:00 to 17:00

Phone: +1 (423) 262 2522

Fax: +1 (423) 262 2289

E-Mail:

GMT: -5:00

simatic.hotline@sea.siemens.com

Asia / Australia

(Peking)

Technical Support and

Authorization

Local time: Mo.-Fr. 8:00 to 17:00

Phone: +86 10 64 75 75 75

Fax: +86 10 64 74 74 74

E-Mail: adsupport.asia@siemens.com

GMT: +8:00

Function Blocks - FM 458-1 DP v

Edition 12.2004

Page 7

Contents

Foreword ........................................................................................................................................ iii

1 Input/output blocks ................................................................................................................ 1-1

1.1 SBM Rotary encoder block....................................................................................... 1-2

2 Communication blocks.......................................................................................................... 2-1

2.1 Central coupling blocks............................................................................................. 2-1

2.1.1 @CSL2F PROFIBUS FMS coupling central block ................................................... 2-1

2.1.2 @CSL2L PROFIBUS FDL central block................................................................... 2-1

2.1.3 @CSPRO Central block PROFIBUS DP coupling ................................................... 2-1

2.1.4 @PRODP Central block PROFIBUS DP coupling ...................................................2-2

2.2 Kopplung PROFIBUS DP .........................................................................................2-3

2.2.1 DPDIAG Diagnostics overview, PROFIBUS DP....................................................... 2-3

2.2.2 DPSLDG Slave diagnostics, PROFIBUS DP ........................................................... 2-6

2.2.3 DPEVT Alarm information, PROFIBUS DP .............................................................. 2-9

2.2.4 DPPEVT Process alarm information, PROFIBUS DP Symbol............................... 2-12

2.3 FM 458-specific coupling........................................................................................ 2-15

2.3.1 @CPB P-bus, central coupling block...................................................................... 2-15

2.3.2 S7RD_P Reading data from a SIMATIC-CPU (P Bus) .......................................... 2-16

2.3.3 S7WR_P Sending data to a SIMATIC-CPU (P Bus) .............................................. 2-18

2.3.4 BRCV Block-oriented data reception via an S7 coupling ....................................... 2-20

2.3.5 S7STAT S7 CPU operating state ........................................................................... 2-23

2.3.6 S7RD, S7RD_B, S7RD_I, S7RD_D Read from the peripheral area of the S7-

CPU......................................................................................................................... 2-25

2.3.7 S7WR, S7WR_B, S7WR_I, S7WR_D Write into the peripheral area of the S7-

CPU......................................................................................................................... 2-27

2.4 Parameterizing SIMADYN D................................................................................... 2-29

2.4.1 @FMPAR Parameter processing on FM 458-1 DP modules................................. 2-29

2.4.2 CBCONF COMBOARD configuration..................................................................... 2-32

2.4.3 CBRFAW Receiving warnings from a COMBOARD ..............................................2-36

2.4.4 PNAME Parameter names ..................................................................................... 2-38

2.4.5 PSTAT Change enable for parameters ..................................................................2-40

3 Logic blocks ........................................................................................................................... 3-1

3.1 SAV_TR Save FB for NOV_RAM............................................................................. 3-1

3.2 PAS7 Initiate process interrupt at the S7-CPU......................................................... 3-3

Function Blocks - FM 458-1 DP vii

Edition 12.2004

Page 8

Contents

4 Service-/diagnostic blocks .................................................................................................... 4-1

4.1 FMLED Control FM 458-1 DP diagnostics LED .......................................................4-1

5 SIMOLINK drive coupling ...................................................................................................... 5-1

5.1 @SL SIMOLINK central block ..................................................................................5-1

5.2 SLAV, SLAVE_R SIMOLINK receive block for one actual value..............................5-9

5.3 SLD SIMOLINK delta evaluation.............................................................................5-11

5.4 SLDIS SIMOLINK dispatcher.................................................................................. 5-12

5.5 SLSV, SLSV_R SIMOLINK send block for one setpoint ........................................5-13

5.6 SLSV2, SLSV2R SIMOLINK send block for 2 setpoints.........................................5-15

5.7 SLSVAV SIMOLINK send and receive block for one slave.................................... 5-17

6 Closed-loop control blocks ................................................................................................... 6-1

6.1.1 INT_M Modulo integrator for axis cycle correct integration ...................................... 6-1

Index ..............................................................................................................................................I-1

viii Function Blocks - FM 458-1 DP

Edition 12.2004

Page 9

1 Input/output blocks

Assignment of the input/output blocks to processor- and peripheral

devices.

Blocks Modules

PM5 PM6 T400 IT41 IT42 EA12 EB11 FM

458

SBM x x

*) with SBM2 Module

EXM

438

EXM

448*)

ITSL*)

Function Blocks - FM 458-1 DP 1-1

Edition 12.2004

Page 10

Input/output blocks

1.1 SBM Rotary encoder block

Symbol

SBM

hardware address ―GV AD YPI DI―position in increments

alarm- or normal FP ―BO DM QF BO―group error message

encoder type ―I TYP RPI DI―max. increments/revolution

baud rate ―I BDR Y R―normalized speed

resolution ―I EXP U I―revolutions

rated speed ―R RS YF DW―error detection

Brief description

The SBM function block is used to realize the following tasks:

• Initialize the rotary encoder, which is connected at the SBM2 module

• Determine the position and speed from the encoder data

• Error handling when communication errors develop between the

encoder and SBM2 module

Mode of operation

During the initialization phase of the system, the initialization I/O are read

and the appropriate mode set at the SBM2 module. The following

settings are made for the EQN1325 encoder:

• The encoder power supply is set to 5 V

• Number of revolutions to 4096

• Signal periods per revolution 8192

After the mode has been set, the zero position is determined, and the

starting values for the position and the speed output at the connections.

In the standard mode, the block can assume four different statuses:

• NRM

The values read-out from the SBM2 module (position and speed) are

displayed at the block connections. If an error is detected, the block

goes into the ERR error condition.

• ERR

The following errors can occur in operation:

• Encoder is defective or is not connected

• Encoder was disconnected

• Data transfer error for serial communications between the encoder

and SBM2 module

• SBM2 module not available

In the first three cases, the block goes into the "INI“ initialization

status and in the latter case into the "OFF" status.

1-2 Function Blocks - FM 458-1 DP

Edition 12.2004

Page 11

Input/output blocks

• INI

as for the "initialization phase“ mode

• OFF

Output QF is set and processing terminated.

I/O

AD

TYP

BDR

EXP

DM

RS

YPI

RPI

Y

Hardware address of the SBM2 (initialization input)

Encoder type

TYP = 0 not available

TYP = 1 EQN1325

TYP > 1 incorrect encoder type

Baud rate

BDR = 0 100 kHz

BDR = 1 500 kHz

BDR = 2 1 MHz

BDR = 3 2 MHz

BDR > 3 incorrect baud rate

Resolution in bits

Value range: 16 ≤ EXP ≤ 32

Configure the block in cyclic tasks or interrupt tasks

DM=0 SBM in interrupt tasks

This mode is only practical in conjunction with the alarmcontrolled SIMOLINK events (sync interrupt from SLB). Using this

sync interrupt, in this mode, the values of the SBM module are

de-latched. The block should then be configured in the alarm task

started by the same event.

DM=1 SBM in cyclic tasks

If the block is computed in cyclic tasks, then the SBM2 module

register is read-out in the system mode. The contents of the register

are then read-out in the normal mode and the values for the output

connections computed.

Rated speed in revolution/min (RS>0) (default: 1.0)

Position in increments (default: 0)

Max. number of increments per revolution

(depending on the input connection EXP)

RPMmin

encoderrotary the speedform Normalized

RS

(initialization input

default: 1)

(initialization input

default: 0)

(default: 23)

(initialization input

default: 0)

(default: 0)

(default: 0.0)

U

QF

YF

Revolutions (default: 0)

Group error message

QF=0 no error, QF=1 for error (if YF≠0)

Error status of the block

YF=0x0000 no error, YF>0x0000 (refer to error statuses)

(default: 0)

(default:

16#0000 0000)

Function Blocks - FM 458-1 DP 1-3

Edition 12.2004

Page 12

Input/output blocks

Error statuses

Value Significance

Nibble 1

0x0001 Initialization mode

0x0002 No SBM2 module available

0x0004 SBM2 module is processed from another SBM

0x0008 Encoder defective/not available

Nibble 2

0x0010 Unknown carrier or illegal module code

0x0020 Incorrect hardware address

0x0040 Encoder fault/error

→ Check the hardware (encoder, cable etc.)

0x0080 No voltage or short-circuit

Nibble 3

0x0100 No data transfer from or to the encoder

→ check the hardware (encoder, cable etc.)

0x0200 Erroneous data transfer from or to the encoder

→ check the hardware (encoder, cable etc.)

0x0400 Invalid mode parameterized

0x0800 Invalid encoder parameterized

Nibble 4

0x1000 Invalid speed normalization parameterized

0x2000 Invalid baud rate parameterized

0x4000 Sampling time too high; speed computation not possible

→Sampling time: ≤ 4.0 ms

0x8000 Error for the request to save

Nibble 5

0x10000 Invalid resolution parameterized

0x20000 Function block is not configured in the alarm task

0x40000

0x80000

Nibble 6-8

Not defined: Reserve → Default: 0

Not defined: Reserve → Default: 0

Not defined: Reserve → Default: 0

Configuringdata

Computation time [µs] FM 458-1 DP 13,2

Can be inserted online No

Can be configured in Interrupt tasks

Cyclic tasks

Executed in Initialization mode

Normal mode

Special features Can only be used with an EQN 1325 encoder

1-4 Function Blocks - FM 458-1 DP

Edition 12.2004

Page 13

2 Communication blocks

2.1 Central coupling blocks

NOTE

Additional information on this group of function blocks, e.g. symbol,

mode of operation, I/O and technical data are provided in the online

help for the particular block.

2.1.1 @CSL2F PROFIBUS FMS coupling central block

Brief description

• the function block initializes and monitors the PROFIBUS FMS

coupling (CS7 and SS5 module).

• the function block may only be configured in the sampling interval

32 ms <= TA <= 256 ms and only in the communications FP

"Transmit". Otherwise, an entry is made in the communications error

field.

2.1.2 @CSL2L PROFIBUS FDL central block

Brief description

• the function block initializes and monitors the PROFIBUS FDL

coupling (CS7 and SS5 module).

• the function block may only be configured in the sampling interval

32 ms <= TA <= 256 ms and only configured in the communications

FP "transmit". Otherwise an entry will be made in the communications

error field.

2.1.3 @CSPRO Central block PROFIBUS DP coupling

Brief description

Function Blocks - FM 458-1 DP 2-1

Edition 12.2004

• the function block initializes and monitors the PROFIBUS DP coupling

(EXM 448/EXM 448-1).

• the function block may only be configured in the sampling interval

32 ms <= TA <= 256 ms . Otherwise an entry is made in the

communications error field.

Page 14

Communication blocks

2.1.4 @PRODP Central block PROFIBUS DP coupling

Brief description

• the function block initializes and monitors the PROFIBUS DP coupling

at connector X03 on FM 458-1 DP.

• the function block may only be configured in the sampling interval

32 ms <= TA <= 256 ms . Otherwise an entry is made in the

communications error field.

2-2 Function Blocks - FM 458-1 DP

Edition 12.2004

Page 15

Communication blocks

―

―

―

―

―

―

―

―

2.2 Kopplung PROFIBUS DP

2.2.1 DPDIAG Diagnostics overview, PROFIBUS DP

Symbol

DP module name.connector ―GV CTS OK BO―Diagnostics valid

Brief description

DPDIAG

Enable ―BO EN DG1

DG2

DG3

DG4

DL1

DL2

DL3

DL4

MST BY―Master status

ID W―Identification number

QTS BO―Block status

YTS W―Status display

Slave diagnostics; bits 0 to 31

DW

Slave diagnostics; bits 32 to 63

DW

Slave diagnostics; bits 64 to 95

DW

Slave diagnostics; bits 96 to 127

DW

Data transfer list; bits 0 to 31

DW

Data transfer list; bits 32 to 63

DW

Data transfer list; bits 64 to 95

DW

Data transfer list; bits 96 to 127

DW

The task of the DPDIAG function block is to provide the following

information and data to the user program (i.e. the configured CFC

software):

• System diagnostics (an overview of which slave had signaled

diagnostics)

Mode of operation

• Data transfer list (overview of with which slave data transfer took

place within the PROFIBUS-DP time frame)

• Master status (master-specification information such as the Stop,

Operate and Clear stati)

The PROFIBUS-DP interface is selected using connection CTS.

The function block only enters a communications error for errors, which

are detected during initialization. A communications error cannot be

acknowledged and this function block is only used for diagnostics. This

means, that in normal operation, a communications error is not entered.

Only the cause of the error is signaled at output YTS.

Function Blocks - FM 458-1 DP 2-3

Edition 12.2004

Page 16

Communication blocks

I/O

CTS

EN

Module name.connector of the Profibus-DP interface

Block enable

(Initialization

connection)

(Default: 1)

The block is not processed if EN=0; output OK=0 and YTS=1;

the last value is kept at the other outputs

OK Diagnostics data valid (Default: 0)

DG1

Overview of which slave signaled diagnostics data. This output is

(Default: 0)

bit-coded. Every bit is assigned to a slave with its Profibus

address.

Bit 3 of the 32 bit is, for example, assigned to the slave with

Profibus address 3.

Comment: The bits 0 up to and including 2 are always 0 as the

associated addresses (0 to 2) should be reserved for the DP

master, for a PG and an OP.

For a more detailed description, refer to the user manual

"FM 458-1 DP", chapter "Configuring", section "PROFIBUS DP

coupling".

DG2

Overview of which slave had signaled diagnostics data. This

(Default: 0)

output

is bit-coded. Every bit is assigned to a slave with its Profibus

address. The bit 0 of the 32-bit word is, for example, assigned to

the slave with Profibus address 32.

For a more detailed description, refer to the user manual

"FM 458-1 DP", chapter "Configuring", section "PROFIBUS DP

coupling".

DG3

Overview of which slave had signaled diagnostics data. This

(Default: 0)

output

is bit-coded. Every bit is assigned to a slave with its Profibus

address. The bit 0 of the 32-bit word is, for example, assigned to

the slave with Profibus address 64.

For a more detailed description, refer to the user manual

"FM 458-1 DP", chapter "Configuring", section "PROFIBUS DP

coupling".

DG4

Overview of which slave had signaled diagnostics data. This

(Default: 0)

output

is bit-coded. Every bit is assigned to a slave with its Profibus

address. The bit 0 of the 32-bit word is, for example, assigned to

the slave with Profibus address 96.

For a more detailed description, refer to the user manual

"FM 458-1 DP", chapter "Configuring", section "PROFIBUS DP

coupling".

DL1

Overview of with which slave data transfer took place. This output

(Default: 0)

is bit-coded. Every bit is assigned to a slave with its Profibus

address. For example, bit 3 of the 32-bit word is assigned to the

slave with Profibus address 3.

For a more detailed description, refer to the user manual

"FM 458-1 DP", chapter "Configuring", section "PROFIBUS DP

coupling".

2-4 Function Blocks - FM 458-1 DP

Edition 12.2004

Page 17

Communication blocks

DL2

Overview of with which slave data transfer took place. This output

is bit-coded. Every bit is assigned to a slave with its Profibus

address. For example, bit 0 of the 32-bit word is assigned to the

slave with Profibus address 32.

For a more detailed description, refer to the user manual

"FM 458-1 DP", chapter "Configuring", section "PROFIBUS DP

coupling".

DL3

Overview of with which slave data transfer took place. This output

is bit-coded. Every bit is assigned to a slave with its Profibus

address. For example, bit 0 of the 32-bit word is assigned to the

slave with Profibus address 64.

For a more detailed description, refer to the user manual

"FM 458-1 DP", chapter "Configuring", section "PROFIBUS DP

coupling".

DL4

Overview of with which slave data transfer took place. This output

is bit-coded. Every bit is assigned to a slave with its Profibus

address. For example, bit 0 of the 32-bit word is assigned to the

slave with Profibus address 96.

For a more detailed description, refer to the user manual

"FM 458-1 DP", chapter "Configuring", section "PROFIBUS DP

coupling".

MST Status of the DP master:

Stop (0x40 ), Clear (0x80) or Operate (0xC0)

ID Master identification number:

(0x8037 for EXM448 as Profibus interface, 0x80EB when

using X3 of the FM458-1)

QTS Block output QTS is used to display whether the block is operating

error-free (QTS = 1) or was de-activated after a communications

error message was entered (QTS = 0).

YTS

Detailed status display:

• YTS=0 Æ o.k.

• YTS=1 Æ Block processing inhibited (EN=0)

For additional values at YTS, refer to: D7-SYS Online Help "Help

events". (Press the F1 button in the CFC and call the topic

"Help on events" under "CFC for D7-SYS".)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

Configuring data

Computation time [µs] FM458-1 DP 42,7

Can be inserted online No

Can be configured in Cyclic tasks

Executed in Initialization mode

Normal mode

Special features This function block may only be configured

once for each PROFIBUS communications

module.

Function Blocks - FM 458-1 DP 2-5

Edition 12.2004

Page 18

Communication blocks

―

―

―

2.2.2 DPSLDG Slave diagnostics, PROFIBUS DP

Symbol

DP module name. connector ―GV CTS OK BO―Diagnostics valid

Number of device-related

Brief description

DPSLDG

Slave address ―I SLA ST1 BY―Status 1, standard diagnostics

I LEN ST2 BY―Status 2, standard diagnostics

diagnostic bytes

Enable ―BO EN ST3 BY―Status 3, standard diagnostics

MPA BY―Master Profibus address

ID W―Slave identification number

D01

D59

QTS BO―Block status

YTS W―Status display

1)

normally invisible

Diagnostic bytes v, w, x u. y 1)

DW

Diagnostic bytes v, w, x u. y 1)

DW

The DPSLDG function block provides diagnostics data from a DP slave

to the user program. This diagnostics data correspond, with the exception

of the maximum possible length, to EN 50170. According to this

Standard, the diagnostics data can be a maximum of 244 bytes long. The

function block supports a maximum of 240 bytes

Note

Mode of operation

On the EXM448, there are restrictions regarding the quantity of

diagnostics data. Only diagnostics data (Standard diagnostics data) is

supplied which the function block DIAPRO supplies.

The consistency of the outputs is not ensured. When new diagnostics

data is received, some of the outputs can have "New" information and

some can still have "old" information.

The PROFIBUS-DP interface is selected using connection CTS.

The function block only enters a communications error for errors, which

are detected during initialization. A communications error cannot be

acknowledged and the function block DPSLDG is only used for

diagnostics. This means, that in normal operation, a communications

error is not entered. Only the cause of the error is signaled at output

YTS.

2-6 Function Blocks - FM 458-1 DP

Edition 12.2004

Page 19

Communication blocks

I/O

CTS DP module name, connector of the Profibus DP interface (Initialization connection)

SLA

Diagnostics data required from the slave with the appropriate

station number (3 to 123)

LEN Number of the device-related diagnostic bytes; this means the

diagnostics bytes which extend beyond the Standard diagnostics.

Here, a maximum value of 234 may be set. Whether device-related

diagnostics data is available and, if yes, which significance they

have, should be taken from the user documentation of the relevant

DP slave.

EN Block enable. If EN=0, the block is not processed;

output OK=0 and YTS=1, the last value remains at the other

outputs.

OK Diagnostics data valid (Default: 0)

ST1 Status 1 of the diagnostics according to the Standard (byte 1).

For a more detailed description, refer to the user manual

"FM 458-1 DP", chapter "Configuring", section "PROFIBUS DP

coupling".

ST2 Status 2 of the diagnostics according to the Standard (byte 2).

For a more detailed description, refer to the user manual

"FM 458-1 DP", chapter "Configuring", section "PROFIBUS DP

coupling".

ST3 Status 3 of the diagnostics according to the Standard (byte 3).

For a more detailed description, refer to the user manual

"FM 458-1 DP", chapter "Configuring", section "PROFIBUS DP

coupling".

MPA Master Profibus address (byte 4 of the diagnostics according to the

Standard)

ID Identification number of the slave

(bytes 5 and 6 of the diagnosics according to the Standard)

D01

to

D59

Device-related diagnostic bytes; 4 bytes are combined in one

32-bit

word. Bytes 7, 8, 9 and 10 of the diagnostics telegram can be

found

(Initialization connection)

(Default: 3)

(Initialization connection)

(Default: 0, i.e. only

Standard diagnostics, not

device-related diagnostic

bytes)

(Default: 1)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

in D01.

For a more detailed description, refer to the user manual

"FM 458-1 DP", chapter "Configuring", section "PROFIBUS

DP

coupling".

When data is entered at LEN, this has an influence on the

update

of the outputs. For LEN=0, these outputs are not updated.

For LEN=234, D01 up to and including D59 are updated.

Comment:

Bytes 1 to 6 of a diagnostics telegram for PROFIBUS DP

corresponds to the Standard Diagnostics; bytes from 7 onwards

depend on the particular slave (referred to the particular device).

QTS Block output QTS is used to display whether the block is operating

error-free (QTS = 1) or was de-activated after a communications

error message was entered (QTS = 0).

Function Blocks - FM 458-1 DP 2-7

Edition 12.2004

(Default: 0)

Page 20

Communication blocks

YTS Detailed status display:

• YTS=0 Æ o.k.

• YTS=1 Æ Block processing inhibited (EN=0)

• YTS=2 Æ An initialization connection (SLA er LEN) was

changed in cyclic opertion; this change only becomes effective

the next time that the FM458-1 starts

• YTS=3 Æ The block has already been configured once for the

slave addressed via SLA

• YTS=4 Æ The slave, with the address specified at SLA, has not

been configured in the PROFIBUS network.

For additional values at YTS, refer to: D7-SYS Online Help "Help

events". (Press the F1 button in the CFC and call the topic

"Help on events" uncer "CFC for D7-SYS".)

Configuring data

Computation time [µs] FM458-1 DP 29

Can be inserted online No

Can be configured in Cyclic tasks

Executed in Initialization mode

Special features The function block may only be configured

(Default: 0)

Normal mode

once for each slave.

2-8 Function Blocks - FM 458-1 DP

Edition 12.2004

Page 21

Communication blocks

―

―

―

―

―

―

―

2.2.3 DPEVT Alarm information, PROFIBUS DP

Symbol

Brief description

DPEVT

Expanded info ―BO EXT OB I―Appropriate S7 alarm OB

STA I―Station

SLO I―Slot

SUB I―Sub-module

SBN I―Sub-network

YO1

YO2

YO3

YO4

YO5

YO6

YO21

QTS BO―Block status

YTS W―Status display

1)

normally invisible

Diagnostic bytes 0, 1, 2 and 3

DW

Diagnostic bytes 4, 5, 6 and 7

DW

Diagnosebytes 8, 9, 10 and 11

DW

Diagnostic bytes 12, 13, 14 and 15

DW

Diagnostic bytes 16, 17, 18 and 19

DW

Diagnostic bytes ...

DW

Diagnostic bytes ...

DW

1)

1)

The DPEVT function block (DP event) provides more detailed information

about a Profibus-DP process or diagnostics alarm. The information/data,

provided at the outputs, correspond to the information/data which a

SIMATIC S7 module also has when processing the appropriate alarm

OBs (e.g. OB40, OB55 etc.).

Mode of operation

When an alarm event is output, all of the values at the outputs are

updated.

When the appropriate alarm occurs, the alarm task configured for this

purpose, is started, Within the alarm task, DPEVT reads-out the alarm

information. A new alarm of the same time is only detected again after

the alarm task has been completed.

When a communications error occurs, the cause is also output at output

YTS and the QTS output is set to "0".

Function Blocks - FM 458-1 DP 2-9

Edition 12.2004

Page 22

Communication blocks

I/O

EXT

For EXT=0, only the data/information at outputs Y01

to Y05 is updated.

For EXT=1, in addition, the information/data at outputs Y06 to

Y21 is updated.

OB The number of the appropriate SIMATIC S7 organizational block

(OB) is displayed at this output. In an error-free state, values 40,

55, 56, 57, 82, 83 and 86 are possible here. The actual value

depends on the process alarm configured in the HWConfig for the

particular alarm task.

STA Station address of the slave which had initiated the alarm. Values

of between 1 and 126 are valid values for this address.

SLO Slot of the module which initiated the alarm. Values of between 1

and 244 are valid values for the slot data.

SUB Sub-module of the module which initiated the alarm. Values of

between 1 and 31 are valid values for the sub-module data.

A value of 0 means no sub-module.

SBN Sub-network to which the module, which initiated the alarm, is

connected. Values of between 1 and 255 are valid values for the

sub-network data. The number for the sub-network can be taken

from the properties dialog box in NetPro or HY-Config.

YO1 The first 4 bytes with information about the last alarm event are

available at this output. The actual significance corresponds to

the first byte of the local data of the appropriate S7-OB.

As a whole, the local data comprise 20 bytes; the structuring of

the local data can be taken from the help for the appropriate OB.

YO2 The second 4 bytes with information about the last alarm event

are available at this output.

YO3 The third 4 bytes with information about the last alarm event are

available at this output.

YO4 The fourth 4 bytes with information about the last alarm event are

available at this output.

YO5 The fifth 4 bytes with information about the last alarm event are

available at this output.

Y06

to

Y21

QTS Block output QTS is used to display whether the block is

YTS Detailed status display for additional values at YTS,

You can obtain additional information/data about the alarm, which

goes beyond the local data of the S7-OBs, at these outputs.

The information/data correspond to that which you would obtain if

you would have called the SFB54 "RALRM" within the appropriate

S7-OBs. The outputs are only updated if EXT=1 is set to 1.

Normally, these outputs are switched so that they are invisible,

and, when required, must be first made visible in the CFC, under

the tab "I/O".

operating error-free (QTS = 1) or was de-activated after a

communications error message was entered (QTS = 0).

refer to: D7-SYS Online Help "Help events".

(Press the F1 button in the CFC and call the topic "Help on

events" uncer "CFC for D7-SYS".)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

2-10 Function Blocks - FM 458-1 DP

Edition 12.2004

Page 23

Communication blocks

Configuring data

Computation time [µs] FM458-1 DP 23,6

Can be inserted online No

Can be configured in Alarm tasks

Executed in Initialization mode

Normal mode

Special features

The DPEVT may only be configured in an

alarm

task for which one of the following alarm

causes

is configured in HW-Config:

• Process alarm 1 (OB40)

• DPV1 status alarm (OB55)

• DPV1 update alarm (OB56)

• DPV1 manufacturer-specific alarm (OB57)

• Diagnostics alarm (OB82)

• Withdraw/insert alarm (OB83)

• Failure, subrack alarm (OB86)

If this is not the case, DPEVT signals an

appropriate communications error and stops

processing.

Function Blocks - FM 458-1 DP 2-11

Edition 12.2004

Page 24

Communication blocks

―

2.2.4 DPPEVT Process alarm information, PROFIBUS DP Symbol

Symbol

Brief description

DPPEVT

STA I―Station

SLOI―Slot

SUB I―Sub-module

SBN I―Sub-network

EVC BY―Event classes and IDs

IOF BY―IO flag

IN BO―Input module

OUT BO―Output module

MDL W―Logical address

PAD

YYR I―Year

YMOI―Month

YDA I―Day

YHR I―Hour

YMII―Minute

YSE I―Seconds

QTS BO―Block state

YTS W―Status display

OB40_POINT_ADDR

DW

The DPPEV (DP process event) provides more detailed information

about the Profibus DP process alarm (OB40 alarm). Contrary to the

DPEVT, only selected information/data is available, but then, in a

conditioned form.

Mode of operation

When an alarm event is output, all of the values at the outputs are

updated.

For a communications error, the cause is additionally output at YTS and

the QTS output is set to "0".

2-12 Function Blocks - FM 458-1 DP

Edition 12.2004

Page 25

Communication blocks

I/O

STA Station address of the slave which had initiated the alarm. Values

of between 1 to 126 are valid values for this address.

SLO Slot of the module which initiated the alarm. Values of between 1

and 244 are valid values for the slot data.

SUB Sub-module of the module which initiated the alarm. Values of

between 1 and 31 are valid values for the sub-module data.

A value of 0 means no sub-module.

SBN Sub-network to which the module, which initiated the alarm, is

connected. Values of between 1 and 255 are valid values for the

sub-network data. The number for the sub-network can be taken

from the properties dialog box in NetPro or HW-Config.

EVC

This output corresponds to the local data variables

OB40_EV_CLASS of the OB40 for a SIMATIC-S7. A value of

B#16#11(11 hexadecimal) means that the alarm is active.

IOF

This output corresponds to the local data variables

OB40_IO_FLAG of the OB40 for a SIMATIC-S7.

The significance is as follows:

B#16#54 (54 hexadecimal) Æ Input module

B#16#55 (55 hexadecimal) Æ Output module

The (present) possible information is available, in a

conditioned form, at outputs IN and OUT.

IN

OUT OUT=1 Æ Output module had initiated an alarm

MDL This value outputs the logical basis address of the module.

PAD This value supplies additional information about the cause of the

YYR Year

YMO Month

YDA Day

YHR Hour

YMI Minute

YSE Second

QTS Block output QTS is used to display whether the block is

IN=1 Æ Input module has initiated an alarm

IN=0 Æ The alarm was not initiated from an input module

OUT=0 Æ The alarm was not initiated from an output module

The value corresponds to the local data variables

OB40_MDL_ADDR of the OB40 for a SIMATIC-S7.

process alarm. The value corresponds to the local data variables

OB40_POINT_ADDR of the OB40 for a SIMATIC-S7. Additional

information about this is provided in the SIMATIC documentation.

(specifies in which year the alarm was initiated)

(specifies in which month the alarm was initiated)

(specifies on which day the alarm was initiated)

(specifies at which hour the alarm was initiated)

(specifies at which minute the alarm was initiated)

(specifies at which second the alarm was initiated)

operating error-free (QTS = 1) or was de-activated after a

communications error message was entered (QTS = 0).

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

(Default: 0)

Function Blocks - FM 458-1 DP 2-13

Edition 12.2004

Page 26

Communication blocks

YTS Detailed status display; for additional values at YTS,

refer to: D7-SYS Online Help "Help events".

(Press the F1 button in the CFC and call the topic

"Help on events" uncer "CFC for D7-SYS".)

Configuring data

Computation time [µs] FM458-1 DP 23,6

Can be inserted online No

Can be configured in Alarm tasks

Executed in Initialization mode

Normal mode

Special features The DPPEV may only be configured in an

alarm task for which the following alarm

cause is configured in HW-Config

• Process alarm 1 (OB40)

If this is not the case, DPPEV signals an

appropriate communications error and stops

processing.

A new alarm of the same time is only again

detected after the alarm task has been

completed.

(Default: 0)

2-14 Function Blocks - FM 458-1 DP

Edition 12.2004

Page 27

Communication blocks

2.3 FM 458-specific coupling

2.3.1 @CPB P-bus, central coupling block

Symbol

CPU-module-name.PBUS ―GV CTS CDM BO―coupling status

@CPB

QTS BO―block status

Brief description

The central block for the P-bus coupling can only run with an FM 458

application module.

• This function block is responsible for initializing and monitoring the P

bus coupling.

• The function block can only be configured once for each application

module FM 458, as there is only one P-bus coupling for each FM 458.

If a function block is configured a multiple number of times, this is

detected when initializing, and results in an entry in the

communications error field.

• The block may only be configured in the sampling interval

32 ms <= TA <= 256 ms. Otherwise, an entry is made in the

communications error field.

Mode of operation

When initializing the function block, general preparations are made to

enable the coupling. The coupling is only enabled after the standard

mode has been run-through (executed) several times.

After the coupling has been enabled, the central block monitors that

senders and receivers are correctly registered. Further, if required, it reorganizes and updates the block output CDM at each processing cycle.

The function block cannot be used to initialize another P-bus coupling or

monitor this. It can only initialize its own P-bus coupling on which CPU is

configured. An entry is made in the communications error field if another

module name is specified at the CTS input (other than its own).

The CDM block output provides information about the coupling status.

The connection is a 1, if the coupling is enabled for general send/receive

operation. The CDM block output is 0, as long as the coupling is still

being initialized, or is being re-initialized (after a temporary fault).

Function Blocks - FM 458-1 DP 2-15

Edition 12.2004

Page 28

Communication blocks

I/O

CTS The configured name of its own CPU is specified

CDM Specifies the coupling status

QTS Operating status of the function block

at this initialization input.

(faulted = 0, not faulted = 1).

There is an irreparable fault for QTS = 0, for QTS

= 1,

the function block operates error-free.

Configuringdata

Computation time [µs] FM 458-1 DP 16,5

Available online no

Can be configured in Cyclic tasks

Executed in Normal mode

Initialization mode

Special features -

2.3.2 S7RD_P Reading data from a SIMATIC-CPU (P Bus)

Symbol

(default: 0)

(default: 0)

Offs in 128By-PBus-Buffer ―I OFF PTR DW―PtrBuffer Transmitdata

Number bytes to be read ―I LEN QF BO―Error-Status Block

Brief description

Mode of operation

S7RD_P

Enable ―BO EN YF W―StatusInfo Block

This block can only be used for the SIMATIC application module FM 4581 DP.

A SIMATIC-CPU can transfer up to 128 bytes to the FM 458-1 DP in its

output area of the P bus. Block S7RD_P reads this data from the P-Bus

and provides it, via its pointer interface, to the read blocks (DRD…,

CPY_Y) for further processing in the CFC configured software.

This block operates similar to the telegram block CRV_P. A maximum of

128 bytes can be accessed via the pointer interface. These bytes are

sent from the SIMATIC-CPU to the FM 458-1 DP via the P bus.

Data can be read using the read blocks (DRD…) or the copy block

(CPY_P).

This block only communicates with a SIMATIC-CPU. This means that the

required byte or word swap operations are automatically made

(depending on the data type of the connected read/write blocks). The

entry, which is normally required at the SW-connection of the read/write

block, is not evaluated and is therefore not required.

2-16 Function Blocks - FM 458-1 DP

Edition 12.2004

Page 29

Communication blocks

The computation time essentially depends on the amount of data

transferred. A base computation time of approx. 10 µs as well as approx.

1 µs/byte can be assumed as nominal value.

Associated blocks

The following blocks can be connected to this block (pointer input):

DRD, DRD_8, DRD_8D, DRD_8I, DRD_BY, DRD_D, DRD_I, CPY_P

I/O

OFF Offs in 128By-PBus-Buffer

Offset of the value to be sent within the 128 byte memory relative to the start of

the buffer; max. offset: Buffer length - length of the data type

LEN

EN

PTR PtrBuffer Transmitdata

QF

YF

Number bytes to be read

Number of bytes which are read by the SIMATIC-CPU via the P bus.

Max. number: 128 bytes

Enable

For EN=1 at each call, the data sent from the SIMATIC-CPU (max. 128 bytes)

is read.

Pointer to the telegram data buffer; to connect with the same connection type

of other pointer-based communication blocks. The CFC connection can be

changed online.

The connection also includes monitoring information to ensure correct

configuring.

Error status block

QF=1: There is an error; for details, refer to YF

StatusInfo Block

§§ as for the DRD block!

Default:

0

0

1

16#00000000

0.0

16#0000

Configuring data

Computation time [µs] FM 458-1 DP 10,0 + 1 for each byte

Can be inserted online Yes

Can be configured in Interrupt tasks

Cyclic tasks

Executed in Initialization mode

Normal mode

Special features

The block must be configured in the same

sampling time

as the blocks, connected via the pointer interface

(CFC connection via connections PTR). This can

only be used for the FM 458-1 DP!

Several S7RD_P blocks can be configured.

Although this is not a typical application, it can

make sense if, for example, the 128 byte area

should be read in several blocks or if data is

required in different sampling times.

Function Blocks - FM 458-1 DP 2-17

Edition 12.2004

Page 30

Communication blocks

2.3.3 S7WR_P Sending data to a SIMATIC-CPU (P Bus)

Symbol

Offs in 128By-PBus-Buffer ―I OFF PTR DW―PtrBuffer Transmitdata

Number bytes to be write ―I LEN QF BO―Error-Status Block

Number bytes to be write ―BO EN YF W―StatusInfo Block

Brief description

Mode of operation

S7WR_P

This block can only be used for the SIMATIC application module FM 4581 DP.

An FM 458-1 DP can send up to 128 bytes to the SIMATIC-CPU via the

P-Bus. The block S7WR_P sends data which were previously loaded

with write blocks via the pointer interface.

This block operates similar to the telegram block CTV_P. A maximum of

128 bytes can be transferred via this pointer interface and via the P bus

to the SIMATIC CPU. This data is previously loaded into the telegram

buffer using write blocks DWR… of the copy block CPY_Y.

This block only communicates with a SIMATIC-CPU. This means that the

required byte or word swap operations are automatically made

(depending on the data type of the connected read/write blocks). The

entry, which is normally required at the SW-connection of the read/write

block, is not evaluated and is therefore not required.

The computation time essentially depends on the amount of data

transferred. A base computation time of approx. 5 µs as well as approx.

0.7 µs/byte can be assumed as nominal value.

Associated blocks

The following blocks can be connected to this block (pointer input):

DWR, DWR_8, DWR_8D, DWR_8I, DWD_BY, DWR_D, DWR_I, CPY_P

I/O

OFF Offs in 128By-PBus-Buffer

Offset of the value to be sent within the 128 byte memory relative

to the start of the buffer;

max. offset: Buffer length - length of the data type

LEN

EN Enable

PTR PtrBuffer Transmitdata

Number of bytes to be written

Number of bytes which are to be sent to the SIMATIC CPU via the P bus.

Max. number: 128 bytes

For EN=1, at each call, the telegram buffer (max. 128 bytes) is sent to

the SIMATIC-CPU.

Pointer to the telegram/data buffer; to connect with the same connection

type of other pointer-based communication blocks.

The CFC connection can be changed online.

The connection also includes monitoring information to ensure correct

configuring.

Default:

0

0

1

16#00000000

2-18 Function Blocks - FM 458-1 DP

Edition 12.2004

Page 31

Communication blocks

QF Error status block

QF=1: There is an error; for details, refer to YF

YF

StatusInfo Block

§§ as for the DRD block!

Configuring data

0.0

16#0000

Computation time [µs] FM 458-1 DP 5,0 + 0.7 for each byte

Can be inserted online Yes

Can be configured in Interrupt tasks

Cyclic tasks

Executed in Initialization mode

Normal mode

Special features

The block must be configured in the same

sampling time

as the blocks, connected via the pointer interface

(CFC connection via connections PTR).

This can only be used for the FM 458-1 DP!

Several S7WR_P blocks can be configured.

Although this is not a typical application, it can

make sense if, for example, the 128 byte area

should be written in several blocks or if data is

required in different sampling times.

Function Blocks - FM 458-1 DP 2-19

Edition 12.2004

Page 32

Communication blocks

V

2.3.4 BRCV Block-oriented data reception via an S7 coupling

Symbol

Establish ready to receive ―BO ENR PTR DW―Receive data is ready

Addressing parameters ID ―W ID NDR BO―Status parameter NDR

Addressing parameters R_ID ―DW RID LEN DI―Length of data received before

Maximum length, receive data ―DI RLN CTR DI―Number of receive operations

BRC

ERR BO―Status parameter ERROR

STA W―Status, fault display

QTS BO―Block status

YTS W―Status display

Brief description

The function block allows block-oriented data reception via a configured

S7 coupling.

Mode of operation

The BRCV block receives data from a "remote" partner. The "remote"

partner is an SFB/FB, type BSEND (SFB/FB 12) on a SIMATIC S7-400

CPU.

After each data segment which has been received, an acknowledgement

is sent to the partner SFB/FB and the LEN parameter is updated.

The block is ready to receive when a "1" is connected to the control input

ENR. A running task can be interrupted with ENR=0.

The maximum length of the receive area is specified by the data at input

RLN. The length of the data block received is displayed at output LEN.

I/O

ENR Control parameter

The block is ready to receive with ENR = 1

ID Addressing parameter

Reference to the local connection description

(this is specified as a result of the STEP7 configured connection)

RID The value at input RID specifies the association with the send SFB/FB.

The value at the input must match the R_ID parameter for SFB/FB on

the

send side. This allows several SFB/FB pairs to communicate via the

same logical coupling. The block pairs of a logical coupling, defined

using

RID or R_ID must be unique for this coupling.

RLN The maximum length of the received data is defined here.

Only values of between 0 and 65535 may be configured.

PTR The receive data, to be evaluated by the blocks for direct

communication,

is made available here (e.g. types DRD, DRD_I, etc.).

Default: 0

Initialization input,

Default: 0

Initialization input,

Default: 0

Initialization input,

Default: 0

Default: 0

2-20 Function Blocks - FM 458-1 DP

Edition 12.2004

Page 33

Communication blocks

NDR Status parameter NDR

0: Task was still not started (ENR input)or is still running

1: Task was successfully completed

LEN Length of the previously received data in bytes Default: 0

CTR This output counts the total number of successfully complete data

receive

cycles since the last change from STOP to RUN.

ERR An error is output at block output ERR. The detailed information about

the

type of the error is available at output STA.

This output corresponds to the ERROR output of an SFB/FB 13

of an S7-CPU.

STA Detailed status display

This output corresponds to the STATUS output of an SFB/FB 13 of an

S7-CPU.

ERR = 0:

• STA=00H

• STA=11H

ERR = 1:

• STA=01H

• STA=04H

• STA=05H

• STA=12H

• STA=14H

QTS Block output QTS indicates whether the block is operating (QTS = 1) or

became inactive after a communications error message was entered

(QTS = 0).

YTS Detailed status display

• YTS=0 Æ O.K. (ready)

• YTS=1

• YTS=2

For other values at YTS, in addition, a communications error is entered

in

the diagnostics buffer and the block is no longer processed (QTS=0)

No alarm, no fault

Non-synchronous data is received, output LEN indicates the number

of pieces of data previously received in bytes.

Communication problems

(e.g. the coupling description to the ID not loaded, coupling has still

not been established from the partner or the coupling was

interrupted)

Error regarding the data length

The data block sent is longer than the receive range set using input

RLN.

Reset request received, incomplete transfer

R_ID already exists in the coupling

too little working memory

The block is in the DISABLED state, i.e. ENR=0

The initialization connection is changed, the change only becomes

effective at the next STOP Æ RUN transition; the FB operates with

the values at ID, RID and RLN set when running-up

Default: 0

Default: 0

Default: 0

Default: 0

Default: 0

Default: 0

Function Blocks - FM 458-1 DP 2-21

Edition 12.2004

Page 34

Communication blocks

Configuring data

Computation time [µs] FM458-1 DP 5,7

Can be inserted online No

Can be configured in Alarm tasks

Cyclic tasks

Executed in Initialization mode

Normal mode

Special features -

2-22 Function Blocks - FM 458-1 DP

Edition 12.2004

Page 35

Communication blocks

2.3.5 S7STAT S7 CPU operating state

Symbol

Brief description

Mode of operation

Output value

to ACT or OLD

0x0010 Stop 0 1 0

0x0020 Cold start 0 0 0

0x0040 New start 0 0 0

0x0080 Re-start 0 0 0

0x0100 RUN 1 0 0

0x0200 RUN-R 1 0 0

0x0400 Hold 0 0 1

S7STAT

RUN BO―S7-CPU in RUN

STP BO―S7-CPU in STOP

HLD BO―S7-CPU in HOLD

ACT W―actual operating state

OLD W―previous operating state

The actual and previous S7-CPU operating states are displayed at the

outputs.

The actual and previous operating state of the S7-CPU is determined and

displayed at connectors ACT for the actual and OLD for the previous

operating state. Output RUN is set to TRUE if the S7-CPU is either in the

RUN or RUN-R state.

Operating state RUN STP HLD

NOTE

All other values are used for extended diagnostics.

I/O

RUN S7-CPU in RUN (Default: 0)

STP S7-CPU in STOP (Default: 0)

HLD S7-CPU in HOLD (Default: 0)

ACT Actual operating state of the S7-CPU (Default: 0x8000)

OLD Previous operating state of the S7-CPU (Default: 0x8000)

Please refer to the help for STEP7 for a more detailed description of the

operating states.

Function Blocks - FM 458-1 DP 2-23

Edition 12.2004

Page 36

Communication blocks

Configuring data

Commutation time [µs] FM458-1 DP

Can be inserted online yes

Can be configured in Alarm tasks

Cyclic tasks

Executed in Normal mode

Special features -

2-24 Function Blocks - FM 458-1 DP

Edition 12.2004

Page 37

Communication blocks

2.3.6 S7RD, S7RD_B, S7RD_I, S7RD_D Read from the peripheral area of the S7-CPU

Symbol

S7RD

Offset ―I OFF Y R―Output

Enable ―BO EN QF BO―error output

Brief description

The function blocks, read from the peripheral area of the S7-CPU, can

only run with an FM 458 application module.

The S7RD, S7RD_B, S7RD_I, S7RD_D blocks only differ by the data

type at the output, which must correspond with the parameters to be

read:

• S7RD: REAL

• S7RD_B: BOOL

• S7RD_I: INT

• S7RD_D: DINT

Mode of operation

With this block, data can be read into the assigned net data area of the

SIMATIC S7-CPU, (periphery output) assigned to the FM 458 application

module. This PE area is 128 bytes.

If the enable signal is set, the appropriate value is read from the PA area

and made available at output Y.

The offset determines at which location in the PA area, the value is

retrieved.

Depending on the block- or data type, the offset is specified as follows:

• for REAL data type in 4-byte steps (data length)

value range of the offset: 0 . . . 31

• for BOOL data type in 1-byte steps (data length).

value range of the offset: 0 . . . 127

• for INT data type in 2-byte steps (data length).

value range of the offset: 0 . . . 63

• for DINT data type in 4-byte steps (data length).

value range of the offset: 0 . . . 31

Output QF has the value 1, if an invalid offset was selected, or the block

is not configured on the FM 458.

Function Blocks - FM 458-1 DP 2-25

Edition 12.2004

Page 38

Communication blocks

I/O

Configuringdata

OFF

EN

Y

QF

Offset (default: 0)

Enable (default: 0)

Output (default: 0.0)

Error output (default: 0)

Computation time [µs] FM 458-1 DP 3,3

Available online yes

Can be configured in Interrupt tasks

Cyclic tasks

Executed in Normal mode

Initialization mode

Special features -

2-26 Function Blocks - FM 458-1 DP

Edition 12.2004

Page 39

Communication blocks

2.3.7 S7WR, S7WR_B, S7WR_I, S7WR_D Write into the peripheral area of the S7-CPU

Symbol

S7WR

Input ―R X QF BO―Error output

Offset ―I OFF

Enable ―BO EN

Brief description

The function blocks, write the peripheral area (I/O) of the S7-CPU can

only run with one FM 458 application module.

The S7WR, S7WR_B, S7WR_I, S7WR_D blocks differ by the data type

at the input, which must correspond with the parameters to be written:

• S7WR: REAL

• S7WR_B: BOOL

• S7WR_I: INT

• S7WR_D: DINT

Mode of operation

Using this block, data can be written into the net (useful) data area of the

SIMATIC S7-CPU, assigned to the FM 458 application module (periphery

input). This PE area is 128 bytes. If the enable signal is set, the input

value is accepted via the input and entered in the PE area.

I/O

The offset determines at which position in the PE area, the input value is

saved. Depending on the block- or data type, the offset is specified as

follows:

• for REAL data type in 4 byte steps (data length).

value range of the offset: 0 . . . 31

• for BOOL data type in 1 byte steps (data length).

value range of the offset: 0 . . . 127

• for INT data type in 2 byte steps (data length).

value range of the offset: 0 . . . 63

• for DINT data type in 4 byte steps (data length).

value range of the offset: 0 . . . 31

Output QF has the value 1, if an invalid offset was selected, or the block

is not configured on the FM 458 application module.

X Input (default: 0.0)

OFF Offset (default: 0)

EN Enable (default: 0)

QF Error output (default: 0)

Function Blocks - FM 458-1 DP 2-27

Edition 12.2004

Page 40

Communication blocks

Configuringdata

Computation time [µs] FM 458-1 DP 3,3

Available online yes

Can be configured in Interrupt tasks

Cyclic tasks

Executed in Normal mode

Initialization mode

Special features -

2-28 Function Blocks - FM 458-1 DP

Edition 12.2004

Page 41

Communication blocks

2.4 Parameterizing SIMADYN D

2.4.1 @FMPAR Parameter processing on FM 458-1 DP modules

Symbol

EXM448 module name. connector ―GV CTS CS BO―COMBOARD status

Parameter language selection ―I PLA QTS BO―Block status

Parameter type float to Comboard ―BO CF YT1 W―Status 1.COMBOARD parameter channel

Parameter change enable ―BO PEN YT2 W―Status 2.COMBOARD parameter channel

BASEBOARD-Function ―BO BBF

@FMPAR

Brief description

The FB @FMPAR can only be configured on a FM 458-1 DP module.

FB @FMPAR monitors the COMBOARD (communications submodule of

the SIMOVERT MASTER DRIVES, e.g. CBP for PROFIBUS DP) and

processes the parameter tasks which are defined for it.

Several @FMPAR central blocks for various COMBOARDs can be

configured on a FM 458-1 DP module.

It should be configured in a slow sampling time (approx. 100 ms). The

maximum permissible sampling time is 200 ms (as a result of the

monitoring using adjacent modules).

The existence and correction functioning of the COMBOARD is

automatically identified and is displayed at output CS.

Mode of operation

Only one COMBOARD may be configured using FB @FMPAR.

Parameter processing:

Parameters are configured in the comment at each I/O. If the comment

starts with "@TP_", then this I/O is designated as parameter. Every

parameter can be allocated a parameter name (FB-PNAME). Further, a

setting parameter can also be allocated a minimum and a maximum (FBPLIM).

The block handles the following tasks:

• Checks the module code of the COMBOARD

• Monitors the COMBOARD (lifebit counter)

• Transfers the configuration data to the COMBOARD

• Processes the parameter channels

• In standard operation, processes the parameter tasks (in the

sampling time cycle).

Function Blocks - FM 458-1 DP 2-29

Edition 12.2004

Page 42

Communication blocks

The name of the COMBOARD which is to be processed, is configured at

input CTS of the FB @FMPAR. If a name has not be configured at input

CTS, then the FB @FMPAR shuts itself down with an error signal at

output YT1/2.

NOTE

Function blocks CRV and CTV may only be configured once. They can

be configured on any and on different processor modules. However,

parameter processing is possible for all processor modules.

Initialization I/O:

CTS Configured name of the EXM448 coupling module and connector X02, separated by ".".

(Default: - )

CF Parameter data type to transfer SIMADYN D data types REAL and

SDTIME via the parameter channel of the COMBOARD:

• CF=1: Parameter data type, float

• CF=0: 32-bit integer "I4"

(Default: 1)

PLA Parameter language selection (parameter language):

The parameter names are activated, which are configured at all PNAME

function blocks, whose PLA input has the same value

(Default: 0)

Inputs:

PEN Enables the parameter change:

• PEN=1: allows the operator control parameters to be changed through all of the

• PEN=0: inhibits operator control parameter changes via all parameter channels

(Default: 1)

BBF BASEBOARD-Function

• BBF=0: SIMATIC FM 458-1 DP operates as TECHBOARD (parameter number from

• BBF=1: SIMATIC FM 458-1 DP operates as BASEBOARD (parameter number from

(Default: 0)

parameter channels

external view 1000..1999, 3000..3999)

external view 0..999, 2000..2999)

Status outputs:

CS COMBOARD status:

• CS=1, COMBOARD is operational.

• CS=0, COMBOARD has failed or is not available.

(Default: 0)

2-30 Function Blocks - FM 458-1 DP

Edition 12.2004

Page 43

Communication blocks

Diagnose outputs:

QTS Block status:

• QTS=1: Block is operational and is operating error-free.

• QTS=0: Block is shutdown due to a fault with an error output at YT1/2

(Default: 0)

YT1

YT2

• YT1=0: OK status

• Initialization mode: status of the block initialization

• Standard mode: Status of the 1

For additional values, refer to: D7-SYS online help "Help on Events". (press

the F1 key in the CFC and call-up the topic "Help on events"

under "CFC for D7-SYS".)

(Default: 0)

• YT2=0: OK status

• Intialization module: Status of the block initialization

• Standard mode: Status of the 2

For additional values, refer to: D7-SYS online help "Help on events". (press key F1 in the

CFC and call-up the topic "Help on events"

under "CFC for D7-SYS".)

(Default: 0)

st

parameter channel from COMBOARD

nd

parameter channel of COMBOARD

Configuringdata

Computation time [µs] FM 458-1 DP 3,3

Can be inserted online --

Can be configured in Cyclic tasks

Executed in Initialization mode

Normal mode

Special features

• 10<=sampling time<=200 ms

• Block may not be switched-in or

switched-out per task group.

Function Blocks - FM 458-1 DP 2-31

Edition 12.2004

Page 44

Communication blocks

2.4.2 CBCONF COMBOARD configuration

Symbol

CBCONF

name of the module to the right ―GV CTR QTS BO―block status

new configuration command ―BO SET YTS W―status display

COMBOARD parameter 01 ―I P01 D02 W―COMBOARD diagnosis 02

COMBOARD parameter 02 ―I P02 D03 W―COMBOARD diagnosis 03

COMBOARD parameter 03 ―I P03 D04 W―COMBOARD diagnosis 04

COMBOARD parameter 04 ―I P04 D05 W―COMBOARD diagnosis 05

COMBOARD parameter 05 ―I P05 D06 W―COMBOARD diagnosis 06

COMBOARD parameter 06 ―I P06 D07 W―COMBOARD diagnosis 07

COMBOARD parameter 07 ―I P07 D08 W―COMBOARD diagnosis 08

COMBOARD parameter 08 ―I P08 D09 W―COMBOARD diagnosis 09

COMBOARD parameter 09 ―I P09 D10 W―COMBOARD diagnosis 10

COMBOARD parameter 10 ―I P10 D11 W―COMBOARD diagnosis 11

COMBOARD parameter 11 ―I P11 D12 W―COMBOARD diagnosis 12

COMBOARD parameter 12 ―I P12 D13 W―COMBOARD diagnosis 13

COMBOARD parameter 13 ―I P13 D14 W―COMBOARD diagnosis 14

COMBOARD parameter 14 ―I P14 D15 W―COMBOARD diagnosis 15

COMBOARD parameter 15 ―I P15 D16 W―COMBOARD diagnosis 16

COMBOARD parameter 16 ―I P16 D17 W―COMBOARD diagnosis 17

COMBOARD parameter 17 ―I P17 D18 W―COMBOARD diagnosis 18

COMBOARD parameter 18 ―I P18 D19 W―COMBOARD diagnosis 19

COMBOARD parameter 19 ―I P19 D20 W―COMBOARD diagnosis 20

COMBOARD parameter 20 ―I P20 D21 W―COMBOARD diagnosis 21

COMBOARD parameter 21 ―I P21 D22 W―COMBOARD diagnosis 22

COMBOARD parameter 22 ―I P22 D23 W―COMBOARD diagnosis 23

COMBOARD parameter 23 ―I P23 D24 W―COMBOARD diagnosis 24

COMBOARD parameter 24 ―I P24 D25 W―COMBOARD diagnosis 25

COMBOARD parameter 25 ―I P25 D26 W―COMBOARD diagnosis 26

COMBOARD parameter 26 ―I P26 D27 W―COMBOARD diagnosis 27

COMBOARD parameter 27 ―I P27 D28 W―COMBOARD diagnosis 28

COMBOARD parameter 28 ―I P28

station address ―I MAA D01 W―COMBOARD diagnosis 01

Brief description

FB CBCONF can be configured on the following modules:

• FM458 modules

• T400 technology module

Configuring on a

FM458 module

The function block CBCONF may only be configured once on a FM458

module per COMBOARD. It is configured on the FM458 module on

which the function block @FMPAR was configured for the appropriate

COMBOARD.

2-32 Function Blocks - FM 458-1 DP

Edition 12.2004

Page 45

Communication blocks

Mode of operation

The block saves the configured configuration data in the admin. area of

the COMBOARD. It executes this once after run-up and user-controlled

in the RUN mode. In the RUN mode, it outputs diagnostics data from the

COMBOARD at its outputs.

New configuration data can be transferred online to COMBOARD with a

positive edge at input SET.

I/O

CTR Configured name of the "righthand" adjacent module (initialization connection). The

following data can be entered:

• CTR = 0 if an adjacent module was not configured

• CTR=<module name> or

• CTR=<module name>.<connector> if an adjacent board is configured.

(default value: - )

SET The configuration data is transferred online to the COMBOARD with a rising

edge at this input.

(Default value: 0)

MAA The station number should be assigned depending on the particular protocol

(e.g. USS: 0..30, PROFIBUS DP: 3..125).

(Default value: 0)

P01...P28 Max. 28 additional COMBOARD-specific configuration parameters.

(Default value: 0)

QTS Block status:

• QTS = 1: Block is operational.

• QTS = 0: The block is disabled with an error output at YTS

(Default value: 0)

YTS Status display, possible values

• - 0: OK status

• - 7CB3: T400 operates as TECHBOARD and a BASEBOARD is available

Additional values, refer to: D7-SYS Online Help "Help on events" (press key F1 in the CFC

and call-up the topic "Help on events" under "CFC for SIMADYN D".)

(Default value: 0)

D01...D28 Max. 28 words of diagnostics data of the COMBOARD

(Default value: 0)

Function Blocks - FM 458-1 DP 2-33

Edition 12.2004

Page 46

Communication blocks

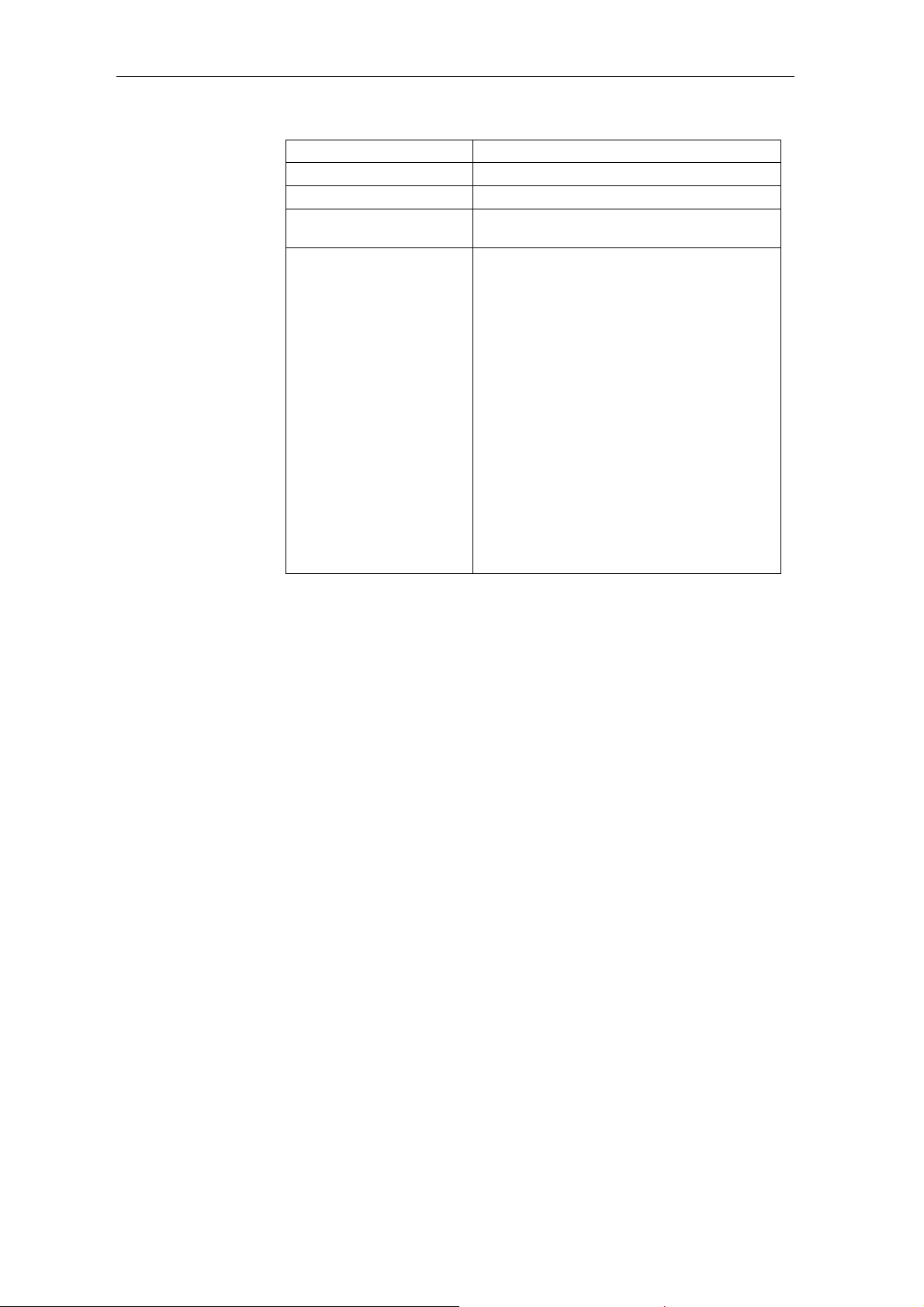

Significance of the

configuring input

for several

COMBOARDs

Input CB-Param

new/old

MAA

P01

P02

P03

P04

P05

P06

P07

P08

P09

P10

P11

P12

P13

P14

...

P28

P918 Bus address Bus address Bus address Bus address Bus address

P711/

P696

P712/

P697

P713/

P698

P714/

P699

P715/

P700

P716/

P701

P717/

P702

P718/

P703

P719/

P704

P720/

P705