Page 1

FLUOROSPOT H/HK

Maintenance Instructions

AX

FLUOROSPOT H/HK with VID. SX

The Maintenance Protocol

R41-020.105.04.01.02

is required for these Instructions

Register 8 English

Print No.: RX41-020.101.04.01.02 Doc. Gen. Date: 05.97

Replaces: RX41-020.101.02.01.02

© Siemens AG 1997

The reproduction, transmission or

use of this document or its contents

is not permitted without express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

Page 2

0 - 2 Revision

Chapter Page Revision

all all 01

FLUOROSPOT H/HK Register 8 RX41-020.101.04 Page 2 of 4 Siemens AG

Rev. 01 05.97 TD AX 5 Medical Engineering

Page 3

Contents 0 - 3

Page

1 _______Requirements__________________________________________________ 1 - 1

General Remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Required Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Required Test Equipment and Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Explanation of Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

2 _______VIDEOMED SX _________________________________________________2 - 1

Safety Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

3 _______FLUOROSPOT H/HK ____________________________________________ 3 - 1

External Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Inspection of the internal head vents . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Function Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

4 _______Image Quality Test______________________________________________ 4 - 1

General Remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Final Work Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 24

Generator Fluoro Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 24

SIMOMED H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 24

Function Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 24

5 _______Changes to Previous Version_____________________________________ 5 - 1

Siemens AG Register 8 RX41-020.101.04 Page 3 of 4 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5

Page 4

0 - 4 Contents

This page intentionally left blank.

FLUOROSPOT H/HK Register 8 RX41-020.101.04 Page 4 of 4 Siemens AG

Rev. 01 05.97 TD AX 5 Medical Engineering

Page 5

Requirements 1 - 1

1Requirements

1.1 General Remarks

These instructions describe maintenance of the VIDEOMED SX television systems and of

the FLUOROSPOT H/HK with the following image quality test.

1.2 Required Documents

• Completed IQ Test Certificatel RXD0-000.037.01...

• Maintenance Protocol RX41-020.105.04...

• IQ Test Procedure RXD0-000.074.01...

• Speed Info ”FLUOROSPOT H: Passwords” RX22-95

• SIMOMED H Adjustment Instructions RA52-040.071.01

• SIMOMED H Service Note RX52-040.076.17...

• TI 236 VII (Procedures and Checks following Installation,

Repair, Update and Maintenance Work)

• Service Note (Handling of optically active surfaces) RA0-000.076.17

RA0-000.012.20

Siemens AG Register 8 RX41-020.101.04 Page 1 of 2 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5

Page 6

1 - 2 Requirements

1.3 Required Test Equipment and Aids

• Service PC; conforming to specifications of ARTD,

Part 1; 3.0

• ST320 Terminal Emulation program 97 04 586 Y4364

• Service cable, 5m 99 00 440 RE999

• Digital multimeter (e.g. Fluke 8060A) 97 02 101 Y4290

• mAs meter (Siemens) 81 60 400 RE999

• Cu strips, 17µm 11 67 662 G5247

• Resolution test, Type 41 28 71 820 RE999

• 2.1 mm precision radiation filter 99 00 598 XE999

• Copper filter set 44 06 120 RV090

• TV Dynamik Test Kit 37 90 156 X1963

• Mavo monitor 97 02 432 Y0526

• Tomo block with resolution test 44 06 054 RV090

• Oscilloscope

>50 MHz with delayed time base and retriggering of

second time base (e.g. Tektronix 2232)

• Lens brush 47 13 582 GE999

• Lens cleaning cloth 47 03 930 GE999

• Ground wire test instrument 44 15 899 RV090

97 02 234 Y3155

1.4 Explanation of Symbols

- Radiation is switched on. The appropriate protective measures should be taken.

- Enter the measured values in the Maintenance Protocol .

FLUOROSPOT H/HK Register 8 RX41-020.101.04 Page 2 of 2 Siemens AG

Rev. 01 05.97 TD AX 5 Medical Engineering

Page 7

VIDEOMED SX 2 - 1

CAUTION

2 VIDEOMED SX

2.1 Safety Inspection

SI Checking the Camera Mount.

SI Checking the Camera Housing

Check the camera housing for good condition; replace if damaged.

SI Checking the Ground Wire

Carry out the ground wire check of the FLUOROSPOT H / HK per TI 236 VII, but only

after concluding all maintenance work. Ground wire resistance: max. 0.2 Ohm.

2.2 Maintenance

PM Camera Optics

• Loosen the knurled screws on both sides of the camera mount and remove the camera

with the mount (Caution: do not expose the camera optics to bright light).

To clean the light path:

Do not use: Recommended:

• Compressed air • Soft hair brush with protective cap

• Lens leather cloth, window

cleaning cloth

• Paper (also lens paper) • Soft, lint-free cloth (fresh handkerchief which

• Cleaning paste

• Cleaning solvent

Remove dust with the brush; when doing so, do not exert any pressure on the brush.

Carefully wipe away any residue with a suitable cloth.

Breathing on the surface can be helpful; do not get any saliva on optical surfaces.

For further information, see Service Note RA0-000.076.17...

PM CCU

Check all optically active surfaces (I.I. lens, mirror, TV camera

lens and multiplier lens) for dust and dirt and, if needed, clean.

(47 13 582 GE999)

• Lens cleaning cloth (47 03 930 GE999)

has been washed several times)

• Remove any dust that has collected in the CCU.

Siemens AG Register 8 RX41-020.101.04 Page 1 of 2 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5

Page 8

2 - 2 VIDEOMED SX

This page intentionally left blank.

FLUOROSPOT H/HK Register 8 RX41-020.101.04 Page 2 of 2 Siemens AG

Rev. 01 05.97 TD AX 5 Medical Engineering

Page 9

FLUOROSPOT H/HK 3 - 1

3 FLUOROSPOT H/HK

3.1 External Visual Inspection

PM Check the Control Console for Damage.

3.2 Maintenance

PM Opening the Unit

PM Remove dust that has collected on the inside of the unit

3.3 Inspection of the internal head vents

PM Check the fan for proper function.

3.4 Monitors

PM Cleaning the Monitor Screens

- To clean the non-glaring monitor screen, which is recognizable by the mat surface, use

a cloth dampened with plain water .

Clean any stubborn dirt with pure alcohol or a mixture of 1/3 alcohol with 2/3 distilled

water.

- Immediately after cleaning with the items described above, wipe the screen dry with a

soft cotton cloth.

- Soiling, e.g. contrast medium residue, should be removed immediatel.

- Under no circumstances should acidic or caustic agents be used. These can damage

the picture tube.

Siemens AG Register 8 RX41-020.101.04 Page 1 of 2 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5

Page 10

3 - 2 FLUOROSPOT H/HK

3.5 Function Inspection

PM Checking / Read Out the Error Log

• Connect the Service PC to the FLUOROSPOT with the service cable.

• Switch on the FLUOROSPOT.

• Enter the "Service" operating mode.

• The main menu appears after entering the password.

• Use the arrow keys on the keyboard of the Service PC to select ERROR LOG in the

MAIN menu.

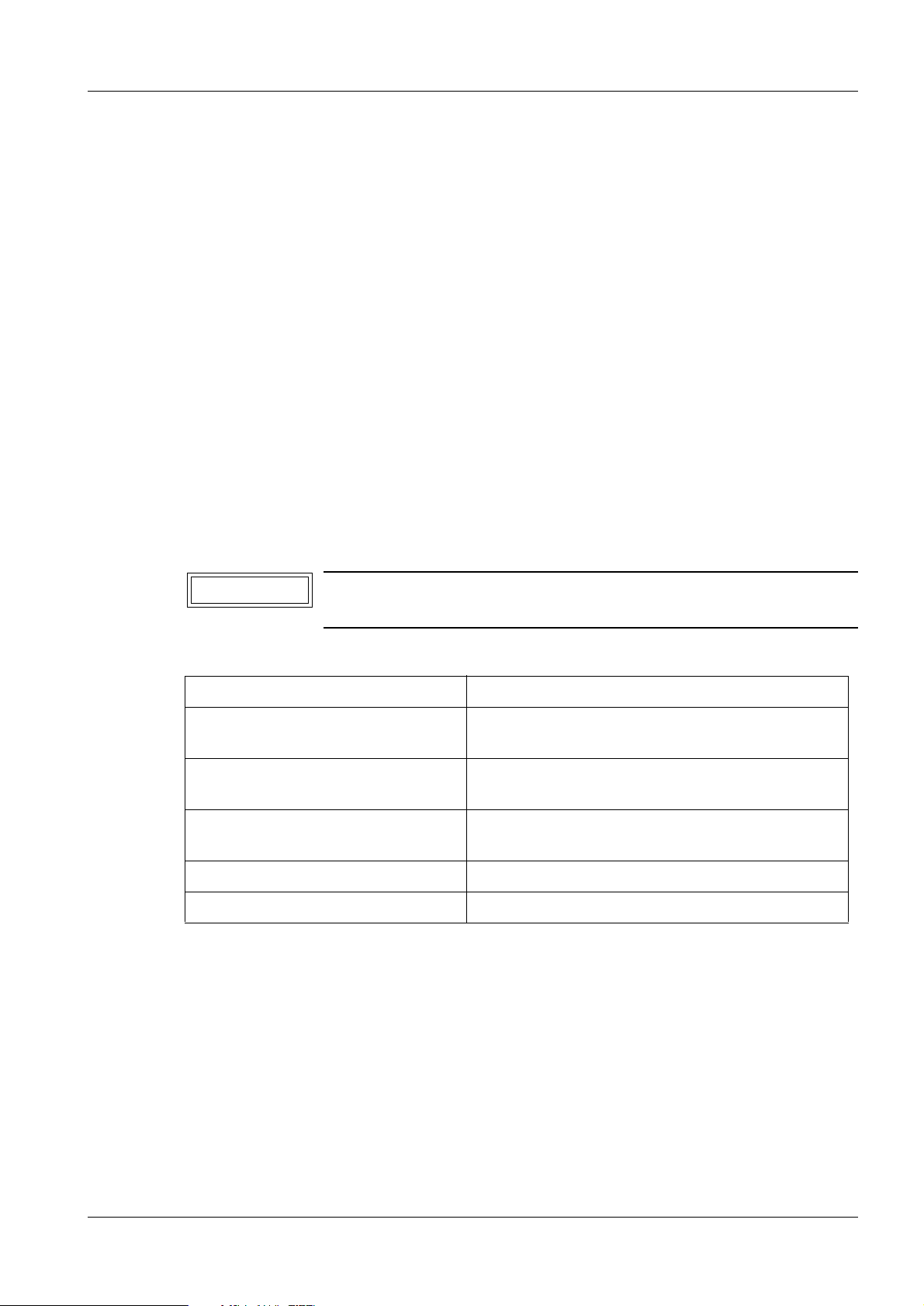

ERROR Logs

ERROR LOG

A LIST FILES

B SELECT FILES

C TYPE FILE

D TRANSFER FILE TO FLOPPY

E

F

G

H

I

J

K

L

M FORMAT 1.44Mb FLOPPY

N

O

- LIST FILES displays a list of the error files in the Service PC.

- A file can be selected for view or transferred to a floppy disk using SELECT FILES.

- TYPE FILE displays the selected error protocol on the Service PC screen.

- TRANSFER FILE TO FLOPPY transfers a selected file to a floppy disk.

- A floppy disk can be formatted from this menu by using FORMAT 1.44Mb FLOPPY.

• Disconnect the Service PC.

FLUOROSPOT H/HK Register 8 RX41-020.101.04 Page 2 of 2 Siemens AG

Rev. 01 05.97 TD AX 5 Medical Engineering

Page 11

Image Quality Test 4 - 1

4 Image Quality Test

4.1 General Remarks

• The image quality test requires that an image quality acceptance test (IQ Test

Certificate) be carried out on the system.

• The test makes it possible to carry out a quick check of the image quality.

• From the complete range of tests in the completed IQ Test Certificate for the system,

only some are required for the "Recurring Tests" (e.g. those required during

maintenance) and those checks are summarized in this image quality test.

• For the 1st test, transcribe the actual values from startup from the IQ Test Certificate to

the Maintenance Protocol, in the column “Initial Values”.

If no upper and lower tolerances are listed, calculate them in accordance with the listed

tolerance and enter them in the columns "+" (upper tolerance) or "-" (lower tolerance).

• A new Maintenance Protocol should be used every time maintenance is carried out.

• The initial values from the 1st maintenance should be used as the reference values for

the 2nd, 3rd and for every other maintenance.

• To make quick comparisons possible, the appropriate chapter in the IQ Test Certificate

or in the IQ Reference Value List is listed in brackets at the back of very chapter in these

instructions.

• Mandatory measurement value entries are labeled with “ ”.

• The measured values must be within the tolerance limits.

• If there are deviations from listed tolerances, an adjustment is required in accordance

withthe corresponding VIDEOMED SX or FLUOROSPOT H / HK Adjustment

Instructions.

• If a new measurement value results following repairs or an adjustment, enter this value

as a new initial value in a new Maintenance Protocol.

• File the Maintenance Protocol in the System Manual, if not available in the

FLUOROSPOT H Manual RX41-020.064.01 or the FLUOROSPOT HK Manual RX41-

025.064.01, in Register 9.

• Order new protocols from Erlangen, TDU 44 by listing the Publication Number,

RX 41-020.105.04....

Siemens AG Register 8 RX41-020.101.04 Page 1 of 24 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5

Page 12

4 - 2 Image Quality Test

CAUTION

NOTICE

Q Indirect Dose Rate Control (IQ Chap. 4.1.2)

No additional filters may be selected in the collimator.

Test Conditions

• Select the operating conditions documented in the IQ Test Certificate:

- Focus-I.I. distance (SID)

OT units = 115 cm

UT units = max. distance (without Distator)

C-Arm units = 100 cm

- Insert the 2.1 mm precision radiation filter into the collimator; with UT units, place it on

the tabletop.

- Open the collimator all the way.

Determining the Initial Values

• With the 1st recurrent test, transcribe the fluoroscopy parameters programmed for the

customer (dose rate values, control curves) for all control steps as well as the

programmed zoom dose factors from the completed IQ Test Certificate to the

Maintenance Protocol.

Transcribe the actual value for kV and mA from the IQ Test Certificate to the

Maintenance Protocol in the column "Initial Values: Ist/Actual".

In addition, calculate the upper and lower tolerance and enter these values in the

columns "-" and "+".

Procedure

• Trigger fluoro : With full format for all automatic steps

With the other I.I. formats only with Fluoro 1 / Step 1

Step 1/Step 2 = 1st/2nd footswitch pressure point for each automatic control step (currently configured only in the POLYSTAR)

• Document the kV and mA values that stabilize (display on the generator console). The

same values as those listed in the column “Initial Values” must result (tolerance:

±10% mA). If there are differences that are outside of the admissible tolerance,

remeasure the dose rates as described under Point 4.1 of the Test Procedure,

RXD0-000.074.01...

If the dose rate values are within tolerance (IQ Reference Value List), determine new

initial values ("-"/"Act"/"+") for indirect dose rate control; this also applies if the dose rate

has been set again.

± 1kV/

FLUOROSPOT H/HK Register 8 RX41-020.101.04 Page 2 of 24 Siemens AG

Rev. 01 05.97 TD AX 5 Medical Engineering

Page 13

Image Quality Test 4 - 3

CAUTION

Q Indirect Dose Control (IQ Chap. 8.1.2)

No additional filter may be selected in the collimator.

- Select the operating conditions doucmented in the IQ Test Certificate.

Test Conditions

- Focus- I.I. distance (SID)

OT units = 115 cm

UT units = max. distance (without Distator)

C-Arm units = 100 cm

- Insert the 2.1 mm precision radiation filter into the collimator; with UT units, place it on

the tabletop.

- Move in the grid.

Determining the Initial Values

• In the 1st recurring test, transcribe the mAs values from the IQ Test Certificate into the

Maintenance Protocol, column "Initial Values, Ist/Actual", and calculate the upper/lower

tolerance limits and enter these values in the columns marked "-" and "+".

Also transcribe the I.I. formats and the Zoom dose factors.

Procedure

• Select the ADC measuring field; with the 40 cm I.I., select the central measuring

field

(POLYSTAR )

• Open the collimator all the way.

• Connect the mAs meter to the generator (high voltage transformer).

• Prior to the DR exposures, briefly trigger fluoro so that the defined exposure data can be

acquired.

• To have the reproducible exposure parameters defined in the DSA scenes acquired,

proceed as follows:

1. Select a scene using the desired organ program.

2. Switch on fluoro for approx. 5 sec. to allow the ADC to stabilize and to allow the

water value calculator to provide the correct exposure data.

3. Trigger an initial brief scene (approx. 5 images) to allow the dose to stabilize in the

constant time mode.

4. Then trigger the actual test scene without first triggering fluoroscopy and evaluate

the scene. Trigger the first brief scene.

Siemens AG Register 8 RX41-020.101.04 Page 3 of 24 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5

Page 14

4 - 4 Image Quality Test

Measurement Sequences to be Carried Out

1. DR mode with dose step 100 for all I.I. formats

Exposure parameters:70 kV; ; 1 F/s; scene time = 10 s

2. DSA mode for one I.I. format (22 cm, 23 cm, 27 cm or 28 cm) with dose

step 500 at 0.5 F/s

Exposure parameters: 70 kV; ; 0.5 F/s; scene time =10 s

• Determine and document the mAs value/pulse = Qg/n for each measurement.

For series, add up the mAs values of all exposures from the mAs meter in the series,

divide this value by the number of exposures and document the result. If there are

differences which are outside of the admissible tolerance, remeasure the dose as

described under Point 8.1 of the Test Procedure, RXD0-000.074.01...

If the dose values are within tolerance (IQ Reference Value List), determine new initial

values ("-"/"Act"/"+") for indirect dose control; this applies also if the dose has been reset.

FLUOROSPOT H/HK Register 8 RX41-020.101.04 Page 4 of 24 Siemens AG

Rev. 01 05.97 TD AX 5 Medical Engineering

Page 15

Image Quality Test 4 - 5

CAUTION

Q Monitor Adjustment (IQ Chap. 8.3)

Switch off the ambient light sensor on SIMOMED monitors for the measurement!

(see SIMOMED H Adjustment Instructions, RA52-040.071.01...)

(see SIMOMED H Service Note, RX52-040.076.01...)

To avoid measurement errors, particularly in the dark step, dim the lights in the room

when measuring!

• Activate the DFR system (no Bypass).

• Connect the SERVICE PC (FLUOROSPOT J27 Transition Panel) and start the ST320

program.

• At the FLUOROSPOT, start Tools <F5>, Service <F8>.

• At the Service PC, select: TEST IMAGES ”Grey Values”.

The gray value fields appear on the monitor.

Determining the Initial Values

• Transcribe the luminous intensity values from the IQ Test Certificate to the Maintenance

Protocol, column "Initial Values, Ist/Actual".

Procedure

• Use the Mavo monitor to check the following luminous intensity values on the monitor:

- In the white field (100%) reference value = 260,

- In the black field (0%) reference value = 0.8, ± 0.1 cd/m

± 20 cd/m

2

2

• If the measurement values differ from the reference values, readjust brightness and

contrast accordingly.

• At the Service PC, select: TEST IMAGES ”SMPTE Test Image”.

The SMPTE test image appears on the monitor.

• In the SMPTE test image, check whether the 5% fields in the white and in the black fields

are still visible; if needed lightly readjust the brightness and contrast so that the 5% fields

are visible.

The 5% fields must always be visible even if the tolerance ranges

are slightly exceeded.

• Set the ambient light sensor back to its original position.

Gray value test image SMPTE test image

Siemens AG Register 8 RX41-020.101.04 Page 5 of 24 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5

Page 16

4 - 6 Image Quality Test

CAUTION

NOTICE

Q Dynamics Test (Fluoroscopy) (IQ Chap. 5H, 5.8)

No additional filter may be selected in the collimator for the

measurements with the Dynamics Test!

Test Conditions and Preparation

• Switch the FLUOROSPOT to Bypass

• Fluoro curve C00

• Grid moved in

• Focus-I.I. distance (SID)

OT units = 115 cm

UT units = max. distance (without Distator)

C-Arm units = 100 cm

• ADC measuring field; with the 40 cm I.I., select the central measuring field

(POLYSTAR

• I.I. format=28 cm, 27 cm, 23 cm or 22 cm

• Move the Dynamics Test close to the I.I.

(without heart contour collimator, without capillary displacement test)

OT units on the tabletop

UT units on the back wall of the spotfilm device

C-Arm units on the grid

• Connect the oscilloscope:

- CH1= TV CCU, inputTP 8 (D8)

- CH2=TV CCU, output TP BAS 1 (D8)

- ext. Trigger = TV CCU, TP V

pulse

(D10)

• Switch on fluoroscopy, center the dynamics test and collimate

The dynamics test must appear on the monitor as shown in Fig.1/Page 4-7).

The reference values for the B/B amplitudes can be reached only

if the AGC measuring field is covered over completely by the 1st

field in the dynamics test. To make the measuring field visible,

jumper between the TP17/KR board and the TP8/VV board.

If the AGC measuring field is larger than the 1st field, move the

dynamics test so that the 2L field is completely outside the AGC

measuring field and only the 5R field projects into the ACG measuring field.

The 5R field adversely affects the measurement much less than

the 2L field

Essentially, the same applies for the rectangular ADC measuring

field for the POLYSTAR

FLUOROSPOT H/HK Register 8 RX41-020.101.04 Page 6 of 24 Siemens AG

Rev. 01 05.97 TD AX 5 Medical Engineering

Page 17

Image Quality Test 4 - 7

AGC measuring field AGC measuring field

Collimation of

collimator

Collimation size Collimation size

Fig. 1

Procedure

• Switch fluoroscopy ON/OFF.

Measure one line in the middle of the screen:

- B-Signal (TP8) in fields 2L / 1/ 5R without bias light

- BA-Signal (TP BAS1) in fields 2L / 1 / 5R

• Read the fluoroscopy kV during fluoro at the generator console and document the value..

B-Signal (TP P8) BA-Signal (TP BAS)

2L

200mV/Div.

1

5R

500mV/Div.

2L

1

5R

Line in middle of screen

Siemens AG Register 8 RX41-020.101.04 Page 7 of 24 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5

Line in middle of screen

Page 18

4 - 8 Image Quality Test

• Calculate the dynamics factor (f) for the B-Signal (TP8).

Field 2L

f =

Field 1

• Compare the calculated dynamics factor with the Fig. on Page 10 (Maintenance

Protocol).

The dynamics factor must be above the illustrated curve, relative to the read-out

fluoroscopy kV.

FLUOROSPOT H/HK Register 8 RX41-020.101.04 Page 8 of 24 Siemens AG

Rev. 01 05.97 TD AX 5 Medical Engineering

Page 19

Image Quality Test 4 - 9

CAUTION

Q Dynamics Test (DFR) (IQ Chap. 8.5).

No additional filter may be selected in the collimator for the measurements with the dynamics test! The reference values are relative to a tube current of 70 kV.

Amplitudes

The BA signal amplitudes of the various attenuation steps (fields 1, 2L, 5R) of the dynamics test are measured at a tube current of 70 kV at the FLUOROSPOT output. The

required BA-levels are reached by correctly adjusting the iris diaphragm.

Test Conditions and Preparations

• Focus-I.I. distance (SID):

OT units = 115 cm

UT units = max. distance (without Distator)

C-Arm units= 100 cm

• Grid moved in.

• ADC measurement field; with the 40 cm I.I., select the central measuring field

(POLYSTAR )

• I.I. format: 22 cm, 23 cm, 27 cm or 28 cm.

• Move the Dynamics test close to the I.I.

(with heart contour collimator and capillary displacement test

OT units on the tabletop

UT units on the back wall of the spotfilm device

C-Arm units on the grid

• Connect the oscilloscope: CH1 to the FLUOROSPOT output (Video output/Live) =

Trans. Panel TP5.

FLUOROSPOT BA -Signal output

2L

100mV/Div.

1

5R

Line in middle of

Siemens AG Register 8 RX41-020.101.04 Page 9 of 24 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5

Page 20

4 - 10 Image Quality Test

NOTICE

CAUTION

Measurement may not be on a line that is covered over by a capillary. To make sure this is not done, use the expanded time base to

move several lines back and forth; when this is done, a change in

amplitude may not take place. One capillary weakens the

BA-Signal.

Determining the Initial Values

• Transcribe the BA-Signal values and U

the in Maintenance Protocol, column "Initial Values, Ist/Actual".

Procedure with DR Exposure

Organ Program for DR Single:

Name: DR Single

kV: manual

kV manual: 70

Dose: 100

Exposure data from fluoroscopy: no

Edge enhancement (%): 0

Filter coefficient: 0

Upper window value: 511

Lower window value: 256

Bone image: black

Image marker: no

Organ curve: manual kV selected

kV for dose reduction: manual kV selected

Max. X-ray pulse length (ms): 3000

Density correction 0.0

Focus: small

for DR/DSA from the IQ Test Certificate into

iris

The iris correction must be =0 at the generator console and in the

organ program.

• Switch on fluoro for approx. 5 sec.

• Trigger a DR exposure and measure and record the BA-Signal amplitudes of fields 2L, 1

and 5R of the dynamics test:

Measure the line in approx. center of screen (approx. line 256) and middle of noise.

Observe the remarks on Page 4-6.

• Record the displayed kV value (Ua) and the programmed iris correction value in the

FLUOROSPOT configuration (see Test Point 8.4).

• Measure the iris voltage value U

PL-SX:N11/D270 and record the result.

FLUOROSPOT H/HK Register 8 RX41-020.101.04 Page 10 of 24 Siemens AG

Rev. 01 05.97 TD AX 5 Medical Engineering

ist

or U

at M98/D2 or N84/D2 or

IRIS

Page 21

Image Quality Test 4 - 11

CAUTIION

Procedure for a DSA Exposure

The DSA test scenes are also used for the test point per IQ Test Certificate 8.9.

Select the following DSA organ program at the FLUOROSPOT:

Organ Program for DSA:

Name: DSA

kV: manual

kV manual: 70

Dose: 200

Exposure data from fluorosocpy: yes

Frames per second: 6

Scene length: 5s

Native image

Edge enhancement (%): 0

Filter coefficient: 0

Upper window value: 511

Lower window value: 256

Bone image: black

Subtraction image

Edge enhancement (%): 0

Filter oefficient: 0

Middle of window(W1): 80

Contrast (W2): 220

Image marker: no

Organ curve: manual kV selected

kV for dose reduction: 109

Density correction: 0.0

Focus: large

Delta kV: Fixed focus selected

Siemens AG Register 8 RX41-020.101.04 Page 11 of 24 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5

The iris correction must be =0 at the generator console and in the

organ program.

• Prior to the DSA scene, “tighten” the displacement test.

• Trigger a DSA scene using the following exposure data and the actuate the

displacement test when approx. half the scene time has elapsed.

- Dose 200; 6 F/s; scene time = 5 sec.

Page 22

4 - 12 Image Quality Test

Proceed as follows to acquire the reproducible exposure parameters that were set for the

DSA test scenes:

1. Select the scene with the desired organ program.

2. Trigger fluoroscopy for approx. 5 sec. to allow the ADC to stabilize and so that the

water value calculator can provide the correct exposure data.

3. Trigger an initial brief scene (5-6 images) to allow the dose to stabilize in the

constant time mode.

4. Then trigger the actual test scene without first triggering fluoroscopy and evaluate

the scene. Delete the first brief scene.

• Evaluate the second to last native image from the scene: measure the BA-Signal

amplitudes of fields 2L, 1 and 5R of the dynamics test and document the results.

Measure the line in the middle of the screen (approx. line 256) and middle of noise.

Position the dynamics test as shown in Page 4-7

• Document the displayed kV value (Ua) and the iris correction value programmed in the

FLUOROSPOT configuration.

• Measure the iris voltage value U

PL-SX: N11/D270 and record the value.

ist

or U

at M98/D2 or N84/D2 or

IRIS

Q Edge Enhancement (IQ Chap. 8.5.2)

•

Use the DR exposure with the dynamics test image on the monitor.

• Change the EDGE ENHANCEMENT from E = 0% to E = 100%, visually check the

function on the monitor and record whether or no the function is okay.

When ”starting up” edge enhancement, gray dropouts get white or black edges:

- A white border is made around black areas (5R field)

• A black border is made around white areas (circles around the field numbers).

Q Mean Value Evaluation (GGM) (IQ Chap. 8.5.3)

• Position the dynamics test in the beam path as described on Page 4-6 under

Preparations.

• At the FLUOROSPOT, select a Fluoro program and set the temporal filtration to 0%.

• Switch on digital fluoroscopy.

• Exactly observe the noise profile of the image and remember what it looks like.

• At the FLUOROSPOT, increase the temporal filtration to 12% in the Fluoro program.

• Again switch on fluoroscopy and evaluate whether the noise in the image has been

reduced.

- The capillaries are more clearly visible, etc.

- When the object is moved, a follow-up effect is visible.

• Document whether or not the function is okay.

• At the FLUOROSPOT, set the temporal filtration back to its original value in the fluoro

program.

FLUOROSPOT H/HK Register 8 RX41-020.101.04 Page 12 of 24 Siemens AG

Rev. 01 05.97 TD AX 5 Medical Engineering

Page 23

Image Quality Test 4 - 13

Q Resolution (IQ Chap. 8.7) and Minimum Contrast (IQ Chap. 8.8)

Test Conditions

• Focus-I.I. distance (SID):

OT units = 115 cm

UT units = max. distance (without Distator)

C-Arm units = 100 cm

• Grid moved in.

• ADC measuring field with the central, round measuring field (40 cm I.I.).

• No edge enhancement (E% = 0)

• Temporal filtration for fluoroscopy 6%

• Windows: W1 = 511; W2 = 256

• Fluoro 1 for fluoroscopy ( ≈ 70 kV)

• Dose step 100 for DR and DSA (70 kV)

• Select .

Test Preparations

• Place the lead strip test, Type 41 in the center of the I.I. and turn it 45° out of the

horizontal position: With OT units, place it on the tabletop, with UT units on the back wall

of the spotfilm device, with C-Arm units on the grid.

• Place the 17 µm Cu strips next to the lead strip test.

• Place 1.2 mmCu prefiltering on the collimator (with UT units on the tabletop).

• Switch on fluoroscopy.

• Collimate the radiation field slightly larger than the lead strip test. Do not undercollimate

the ADC measuring field to avoid over-exposure.

Determining the Initial Values

• Transcribe the resolution values from the IQ Test Certificate into the Maintenance

Protocol, column "Initial Values".

• Transcribe the limit values from the Startup Instruction or from the IQ Reference Value

List into the column "Initial Values".

• After optimizing the system, if these factory-set lower limit values are not reached, the

system can still be operated until the legal limit values are reached.

≥ 1.2 Lp/mm for I.I. nominal formats ≤ 25cm

R

Gr

Determining the Initial Values >25 cm gilt: R

mm]=

Siemens AG Register 8 RX41-020.101.04 Page 13 of 24 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5

Gr

[Lp/

I.I. nom. format [cm]

30

Page 24

4 - 14 Image Quality Test

I.I. nom. format R

40 cm 0.8

33 cm 0.9

28 cm 1.1

27 cm 1.1

25 cm 1.2

Procedure:

Carry out a check in the following modes with each of the I.I. formats.

1

Dig. Fluoro

[Lp/mm]

Gr

Dig.

Exposure

Hardcopy

• At the FLUOROSPOT, select the test programs that are described in the text below while

taking the above-listed test conditions into consideration.

• Determine the maximum visible resolution and document the result (darken the room,

avoid glare).

• Check whether or not the 17 µm Cu strip (minimum contrast) is visible; documentation is

made using either a yes or no answer.

The minimum contrast is more easily detectable at a greater viewing position.

Q Checking the DSA Device (IQ Chap. 8.9)

• Using the test exposures with the dynamics test, check the most important image

properties from the DSA sensitivity – contrast sensitivity, logarithming and subtraction.

For this, evaluate the DSA scenes that were made.

Evaluation Conditions

• For evaluation, it is necessary to set the mask on an image (if needed, using REMASK),

on which it is certain that the stabilization procedure for dose has been completed:

- at 6 F/s on Image 8

• Window values: brightness W1 = 80; contrast W2 = 220

• No edge enhancement; E (%) = 0

• Always evaluate the next to last DSA image in the series.

Determining the Initial Values

• If the contrast sensitivity has already been documented in the IQ Test Certificate using

the new capillary test (Part No. 37 80 180), transcribe the values into the Maintenance

Protocol, column ”Initial Values”.

If the contrast sensitivity has been documented in the IQ Test Certificate using the old

iodone capillary test (Part No. 97 50 019), the initial values for the Maintenance Protocol

must be redetermined using the new capillary test (Part No. 37 80 180) per the IQ Test

Procedure (Chapter 8.9).

FLUOROSPOT H/HK Register 8 RX41-020.101.04 Page 14 of 24 Siemens AG

Rev. 01 05.97 TD AX 5 Medical Engineering

Page 25

Image Quality Test 4 - 15

NOTICE

Contrast Sensitivity

• Determine in the DSA image whether or not all capillaries are visible in the fields 2L, 1

and 5R of the dynamics tests.

• Select DSA scenes at the FLUOROSPOT and evaluate them; postprocessing mode.

• Check off those fields in the Maintenance Protocol in which the particular dark or light

line is no longer visible.

Logarithming (LOG Amplifier)

Logarithming is okay when the capillaries on all Cu steps in the

DSA image have about the same gray value.

The gray value of the capillary (3 mm) that is second from the top

and that is bright is measured in the fields 2L, 1 and 5R using the

DYNAMICS BOX (see Fig.2).

• Connect the Service PC to the FLUOROSPOT and start the ST 320 program.

• Select the DSA mode at the FLUOROSPOT (not native image).

• At the FLUOROSPOT, select PAT-DIR, TOOLS, SERVICE.

Enter the following at the Service PC:

Enter the password

- "IMAGE QUALITY ASSURANCE"

- "SELECT FOLDER FOR ANALYSIS",

Enter the folder name of the DSA scene.

- "SELECT IMAGE FOR ANALYSIS",

The split image is selected. Use the PC arrow keys (left, right) to select an image.

- "SELECT IMAGE FOR ANALYSIS",

The selected image is displayed.

- "DYNAMICS BOX",

The rectangular measuring field appears on the FLUOROSPOT monitor.

- "MOVE BOX"

Use the PC arrow keys to move the rectangle to the middle of the 3 mm capillary.

Make sure that the full width of the capillary is always inside the DYNAMICS BOX

measuring field.

Siemens AG Register 8 RX41-020.101.04 Page 15 of 24 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5

Page 26

4 - 16 Image Quality Test

W

W

Measure the gray step the light capillary displayed at the second from top position in fields

2L, 1 and 5R and document the value (see 1/Fig.2)

Do not evaluate this line, because it is

the outline of the test phantom!

1

6

68 8

2

-1

Fig. 2

Maximum difference between the gray step of the 1st field and the gray step of the 2L field

or of the 5R field = 3 gray steps.

Maximum tolerance to the initial values

Subtraction:

Subtraction is okay when all Cu steps are displayed with the same gray value (2/Fig.2).

• Service PC: use the arrow keys to move the rectangular measuring field between two

capillaries.

0

± 1 gray step.

-1

• Measure the basic gray value of fields 2L, 1 and 5R and document the values. The basic

gray values must be 0,

± 1; in the recurring tests, it must be 0, ± 2.

FLUOROSPOT H/HK Register 8 RX41-020.101.04 Page 16 of 24 Siemens AG

Rev. 01 05.97 TD AX 5 Medical Engineering

Page 27

Image Quality Test 4 - 17

Q Image Disturbances (Artifacts) (Chap. 8.10)

- Enter all image disturbances detected during the maintenance IQ tests in the table in

the Maintenance Protocol with the evaluation numerals 1....3.

- If image disturbances which are not listed in the table are detected, describe them

under ”Other Disturbances”.

- Three evaluation numerals are provided for the particular disturbances; these

numerals indicate the extent of the disturbance.

- Compare the test images made during maintenance with those made during startup.

This way, any deviations and most importantly all newly occurring image disturbances

can be detected and corrected.

Definition of the Evaluation Numerals:

1. Disturbances and artifacts were not detected.

2. Slight disturbances, artifacts occur sporadically. The disturbances scarcely affect

the overall good impression of the image and the ability to diagnose medical

images is in no way adversely affected. The disturbances are thus tolerable.

3. Frequent or more serious disturbances, artifacts occur which disturb the overall

good impression of the image or which adversely affect the ability to make a

medical diagnosis and are thus not tolerable. When this is the case, the system

may not be operated.

Description of Errors:

- Pixel Errors are image pixels which do not contain image information. They are visible

as dark, pixel-size dots in the basic image. In the DSA image, they can occur as black

or white dots, depending on whether they are missing in the mask or in the fill image.

The cause is memory dropouts or addressing errors which occur in the RAM or in the

mass storage device (Post Processing).

Tolerable pixel dropouts are sporadic, do not occur in one location, are always 1 pixel

at one location, maximum of 3 pixels/image and occur at most in every 20th image.

- Ghost Images: are object shapes which are usually offset to one side, and appear

double. They are usually caused by reflections in poorly adapted, long video cables.

Clearly visible ghost images are not tolerable.

- Contouring are horizontal or vertical ”stripes” which mimic linear structures which do

not exist. They can be best detected on an image generated with a sawtooth signal by

continuously changing the windowing. Slight contouring in the above-described test is

tolerable.

- Horizontal Jitter: vertical edges of objects are not displayed on the monitor as “sharp”

borders but as slightly jagged, “frayed” lines. Jitter is caused by slight irregularities in

the horizontal deflection from image line to image line or in image storage and to a

certain extent are unavoidable. In the DSA image it leads to slight, tolerable coverage

errors.

To carry out the check, tape a soldering wire cross on the middle of the I.I., as exactly

vertical and horizontal as possible and make a DR exposure at dose step 100 and as a

single image at the smallest zoom format.

Siemens AG Register 8 RX41-020.101.04 Page 17 of 24 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5

Page 28

4 - 18 Image Quality Test

Image viewing criteria: very narrow windowing with high contrast

(e.g. W1 = 310, W2 = 309).

- Island Formation: We speak of island formation when visibly delineated areas of the

image have an even gray value and generally appear without noise. They often occur

because of insufficient memory, etc. and accordingly contain incorrect image

information. What are called ”burned out” image locations also fall into this category.

They are tolerable only to a very limited extent.

- Vignetting always appears as a decrease in brightness from the center of the image to

the edge of the image; it is caused by the heel effect of X-radiation, by the curve of the

I.I. input screen, by the electron optics in the I.I., by the tandem optics between the I.I.

and the TV camera, by the TV camera tube and by the monitor picture tube. It is

considered to be an image disturbance only if it occurs too strongly asymmetrical (see

also Test Point 5.4 in the IQ Test Certificate), or when greater differences in brightness

appears irregularly distributed over the image area.

If it is below the tolerance limit listed under Point 5.3 or Point 8.4.3 with fluoroscopy, it

should be evaluated as an ”image disturbance” with evaluation numeral 1.

- Artifacts caused by exposure occur only in DSA images and are caused by

fluctuations in exposure from image to image during the DSA scene.

If two completely equal images (mask and fill image) are subtracted from each other,

an evenly bright, completely structureless image results in which only noise is visible. If

the exposure changes between mask and basic image, an apparent image structure

caused by the difference in exposure is created in the DSA image, even when the

object is unchanged. It is acceptable only when it is slightly apparent because a similar

effect caused by patient movement can occur in medical exposures.

- Logarithming Errors: The non-linear attenuation of X-radiation which depends on

object density and object thickness can be largely linearized by logarithming the signal

values of the image.

Incorrect adjustment of a logarithming step results in a jump in brightness in the display

of vessel simulation in the DSA test object. With the DSA standard test object per DIN

6868 Part 8, the transition from the most dense step (1.4 mm Cu) to the lowest step

(0.2 mm Cu) is used for this evaluation. With the dynamics test with the capillary test,

the gray value of capillaries in fields 2L, 1 and 5R must be evaluated (see also the IQ

Test Certificate, Point 8.9). Slight differences in brightness in the vessel simulation is

acceptable over the various Cu step thicknesses.

- Convergence errors occur only in DSA images. If the coordinates of corresponding

projection elements from the image and mask do not match, artifacts form in structured

objects which are referred to as convergence errors. In the tests, only convergence

errors which cannot be attributed to object movement are taken into consideration.

Image structures which occur from a slight change in position of the DSA test object

when moving the vessel simulation can hardly be avoided; however, they are equal in

all DSA images in a series.

The reasons for very bad convergence errors are slight irregularities in the horizontal

and vertical deflection of the TV system or errors in storage of the image pixels.

Slight convergence errors are tolerable because they do not adversely affect the ability

to evaluate medical exposures.

FLUOROSPOT H/HK Register 8 RX41-020.101.04 Page 18 of 24 Siemens AG

Rev. 01 05.97 TD AX 5 Medical Engineering

Page 29

Image Quality Test 4 - 19

To carry out the check, make DSA test scenes at dose step 200; 6 F/s and dose step

500; 1 F/s with the soldering wire cross (see the check for horizontal jitter) and always

evaluate the entire scene. When doing this, place the mask on an image for which the

dose control has been completed with certainty.

- Inhomogeneousness (Hum, Line Errors):

Every image has a certain amount of inhomogeneousness (see also vignetting). Up to

a certain point, it does not influence the ability to evaluate medical exposures.

Inhomogeneousness which is not caused by electromagnetic scatter in the image

generating system is unattractive and bothersome. Depending on the type of

disturbance, it can significantly affect the ability to evaluate images and ideally should

not occur. For this reason, it is tolerable only to a very limited extent. Hum disturbances

(noise) are visible as periodic, horizontal light/dark patterns or as light or dark

horizontal lines in the image; they are temporary and not limited to one location.

Missing or partially missing lines can be recognized as dark horizontal lines in the TV

image.

- Microphony is caused by mechanical vibration (movement of rotating anode, etc.)

which is transferred to the TV camera which affects the deflection fields of the electron

beam and for the most part manifest themselves as very regular disturbance patterns

similar to scattered electromagnetic noise in the TV image. Microphony is scarcely

tolerable.

- Noise Patterns: All noise patterns which were not described above and whose cause

is not known should be entered here.

Disturbances which are caused by dirt on optically active surfaces should be entered

here. They are limited to one location and are not temporary.

As already mentioned, these disturbances are scarcely tolerable.

Siemens AG Register 8 RX41-020.101.04 Page 19 of 24 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5

Page 30

4 - 20 Image Quality Test

Q Digital Tomo IQ Chap. 8.11)

General Remarks: Even mechanical movement of the tomo profile is

checked using the quality of blurring and resolution of

tomo exposures for a tomo test object and the accuracy of the tomo height display is checked. The tomo

profile with the greatest angle and the shortest time is

checked (fastest movement, greatest blurring)

Test Object

The tomo test object is composed of a hard foam block

with 2 slots and 2 lead strip tests.

The holes in the strip tests which are positioned at an

oblique angle of 20

each other. This makes it possible to exactly determine

the tomo height that appears on the exposure.

Line test

° are 2 mm in height apart from

The individual elements of the line test make it possible

to make the following statements about the quality of

the tomo device or about the tomo exposures:

Line groups (LG)

- Visual resolution

- Continuity of blurring

- Selectivity (“tomo thickness” depending on object

size)

- Degree of blur (angle, tomo profile)

Holes, Notch

- Tomo height (tomo plane)

- Tomo profile

- Evenness of the tomo movement

(synchronous movement, smooth movement)

- Dose distribution over the exposure

- Parallelism of focus and film stage

Edge enhancement

- Continuity of blurring

(even or uneven tomo plane)

FLUOROSPOT H/HK Register 8 RX41-020.101.04 Page 20 of 24 Siemens AG

Rev. 01 05.97 TD AX 5 Medical Engineering

Page 31

Image Quality Test 4 - 21

Q Check of the Tomo Height

Test Conditions:

- 115 cm SID (focus-I.I. distance)

- Insert 0.6 mm Cu in the collimator (prefilter)

- Grid in the beam path

- I.I. format 20 cm

- focus

- Exposure voltage 70 kV

- Tomo height approx. 115 mm

- Central ADC measuring field

Procedure:

• Position the tabletop so it is horizontal.

• Center the foam plastic block with the focus test on the tabletop in the beam path. The

focus test must be positioned at the anode side transversely to the table longitudinal

axis.

The notch of the focus test must be in the central beam (see Fig.3).

20°

2mm

approx. 115 mm

SH

Anode side

a

TV Monitor

Fig. 3

• Measure exactly at which height the notch in the focus test is located above the tabletop

(approx. 115 mm, depending on the foam plastic bock size).

Siemens AG Register 8 RX41-020.101.04 Page 21 of 24 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5

Page 32

4 - 22 Image Quality Test

CAUTION

• Select the tomo height so that the numerical tomo height display corresponds exactly to

the measured ”notch height” and document this value as the displayed tomo height.

• Measure at which height above the tabletop the middle of the tomo height light line

appears on the test object and document this value as the line light height.

• Select the “tomo” operating mode .

• Trigger a tomo exposure and evaluation.

Evaluation:

• The hole of the line light test appears sharply focused, it is in the tomo plane.

If the hole next to the notch appears sharply focused, the numerically displayed tomo

height agrees with the actual tomo height, i.e. the deviation = 0.

• If there is a deviation, determine the difference in height in mm between the sharply

focused hole and the notch (there is a difference in height of 2 mm from hole to hole).

• Calculate the actual tomo height and document the value (transverse test):

Actual tomo height = displayed tomo height

When doing this, take into consideration whether the tomo height

is above (+ deviation) or below (– deviation) the selected tomo

height (notch)!

The displayed tomo height or the line light height may not deviate by more than 5 mm

from the actual tomo height..

± difference

FLUOROSPOT H/HK Register 8 RX41-020.101.04 Page 22 of 24 Siemens AG

Rev. 01 05.97 TD AX 5 Medical Engineering

Page 33

Image Quality Test 4 - 23

Q Checking the Resolution

Test Conditions:

Evaluation of the resolution of a tomo exposure is made by comparing it to an exposure

without tomo which has been prepared under comparable conditions. In this way, all factors which influence the resolution of an exposure (focal point size, geometric ratios,

exposure data, ...) are cancelled out and it is possible to make a clear statement about the

quality of the tomo device.

Procedure:

• Position the foam plastic cube with the focus test on the tabletop so it is centered in the

beam path.

• Position the focus test parallel to the table longitudinal axis, see Fig.4.

Fig. 4

Anode side

TV Monitor

• Select the ”DR” opeating mode.

• Trigger an exposure and evaluate it .

• Document the resolution (exposure without tomo).

• Select the ”Tomo” opeating mode.

40

1,2s

• Trigger a tomo exposure and evaluate it.

• Document the resolution (longitudinal test).

• Print out a hardcopy.

Siemens AG Register 8 RX41-020.101.04 Page 23 of 24 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5

Page 34

4 - 24 Image Quality Test

NOTICE

• Compare the maximum visible resolution of the DR exposure and of the tomo exposure.

The resolution of the tomo exposure may not be more than one line group less.

If there are larger differences, check the tomo device for mechanical errors (jamming movement, play, etc.).

Evaluating the Tomo Exposure:

The blur patterns of the holes must be approximately parallel on both the right and left of

the notch.

If the blur patterns of the holes are uneven (jagged, wavy lines), there are unsynchronous

vibrations in the tomo system (jamming locations, ...).

This aslo results in reduced resolution.

The blur pattern of the holes should have an even density along the entire length. If there

is a dotted blur pattern, the tomo movement is uneven. If there is a continuous change in

density of the blur pattern, the speed of movement is uneven or there is a discontinuous

dose rate.

Compare the hardcopy with the hardcopy generated during startup.

4.2 Final Work Steps

4.2.1 Generator Fluoro Curves

• If the fluoro curves were changed, the original customer-specific curves must be

reprogrammed.

4.2.2 SIMOMED H

•

Set the ambient light sensor S476.4 to ON (down).

4.2.3 Function Checks

• Install the cover panels.

• Trigger fluoroscopy.

• Trigger an exposure series.

FLUOROSPOT H/HK Register 8 RX41-020.101.04 Page 24 of 24 Siemens AG

Rev. 01 05.97 TD AX 5 Medical Engineering

Page 35

Changes to Previous Version 5 - 1

5 Changes to Previous Version

None; initial publication.

Siemens AG Register 8 RX41-020.101.04 Page 1 of 2 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5

Page 36

5 - 2 Changes to Previous Version

TD AX 5 / Rödder

TD AX 1 / Biedermann

FLUOROSPOT H/HK Register 8 RX41-020.101.04 Page 2 of 2 Siemens AG

Rev. 01 05.97 TD AX 5 Medical Engineering

Loading...

Loading...