Page 1

FLUOROSPOT H/HK

Maintenance Protocol

AX

Customer:

Department: Room:

Address:

Contact person: Telephone:

Cust. specific no.: Customer no:

The Maintenance Instructions

RX41-020.101.04.01.02

are required for this protocol

Register 9 English

Print Number: RX41-020.105.04.01.02 Doc. Gen.Date: 05.97

Replaces: n. a.

© Siemens AG 1997

The reproduction, transmission or

use of this document or its contents

is not permitted without express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

Page 2

Maintenance Protocol CS No.: . . . . . . . .

SIEMENS office:

Address:

Region: Country:

Contact person: Telephone:

FSE in charge: Telephone:

Information regarding the maintenance protocol

The maintenance protocol serves as a quality record of the maintenance performed

Maintenance must be performed in the prescribed intervals.

The maintenance results must be entered in the maintenance protocol.

The page numbers in the check list at the end of the protocol refer to the corresponding

pages in the associated maintenance instructions (refer to the cover sheet).

The maintenance protocol must be completely filled out by the FSE in charge.

In other words,

• All fields must be completed. If a field does not apply to the system or if there is no

information to be entered, enter ’n.a. ’ in the field.

• The customer number must be entered in the header of every page (CS No.) so that

every page is assigned to a customer.

• In case of complaints, enter the product identification (IVK = WE) for the component as

well as the type of complaint in the ’Open items’ table provided. Record the open items in

the table with the date and signature. Correction of these open points should also be

documented in this table along with the date and signature. If there are no open points,

draw a line through the entire table and enter the date/initials.

• Enter the values measured during the maintenance in the space / table provided.

• After completing the maintenance, fill out page 3 of the protocol and sign it.

Processing and archiving the maintenance protocol:

The maintenance protocol is considered a record and must be archived. It must be filed

after completion of maintenance in the corresponding Register of the Maintenance binder.

If necessary, a copy should be distributed to the customer.

Siemens AG Register 9 RX41-020.105.04 Page 2 of 18 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5 Register 9

Page 3

Maintenance Protocol CS No.: . . . . . . . .

System Status:

System: Ser. No.:

Software Version:

Maintenance contract no.:

Type of contract:

The equipment has no problems

Results of the image quality test

showed no deviations from the

required reference values.

The equipment has minor problems that do not restrict its use.

However they should be corrected as a preventive measure.

Results of the image quality test

showed no deviations from the

required reference values.

The equipment has major problems. For safety reasons, the

equipment may not be used until

the problem has been resolved.

Location

Date

Name of the FSE

Signature

Siemens AG Register 9 RX41-020.105.04 Page 3 of 18 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5 Register 9

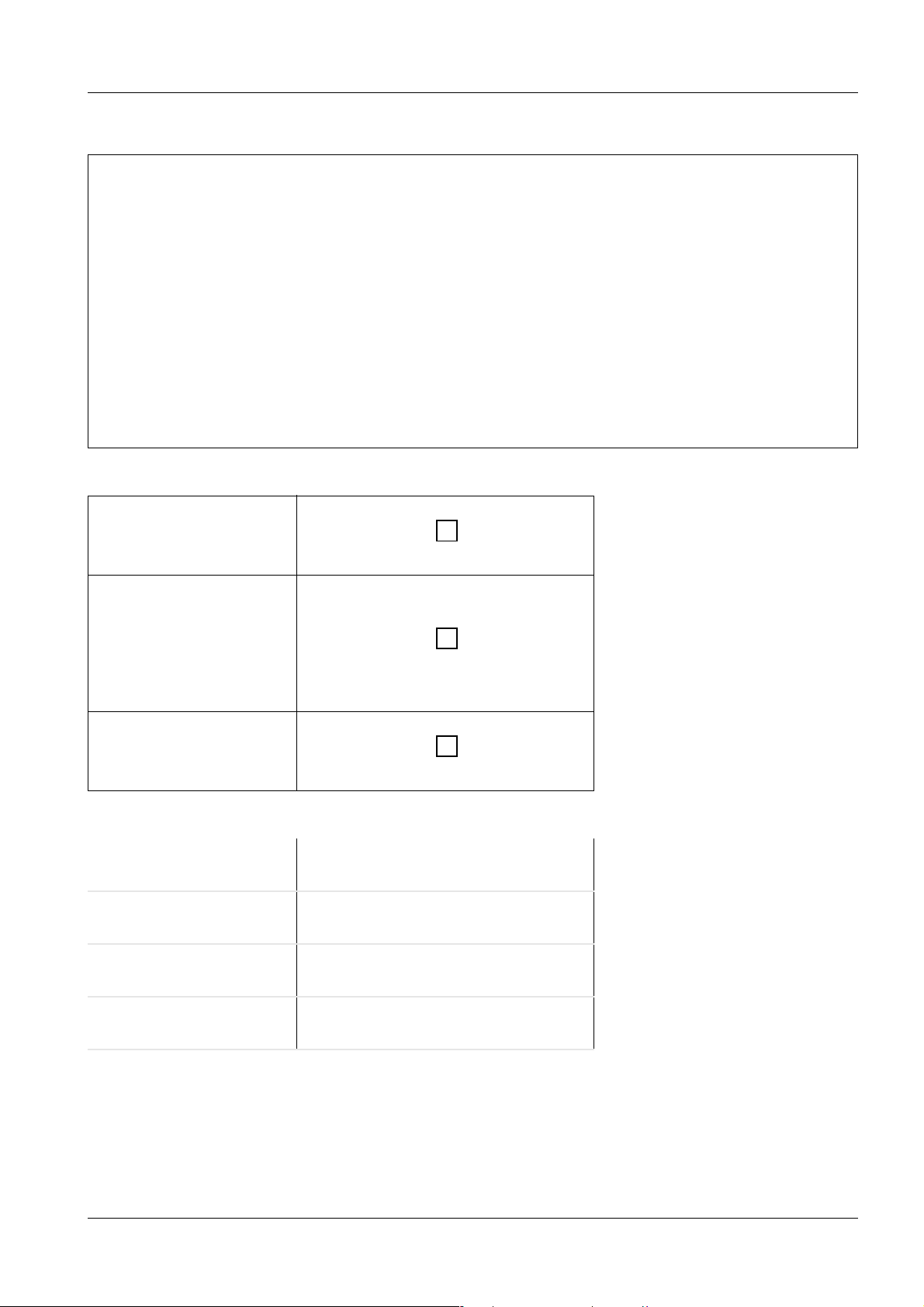

Page 4

Maintenance Protocol CS No.: . . . . . . . .

Performed tasks

Date:

Performed tasks:

OK not OKn.a.

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

❍❍❍

Siemens AG Register 9 RX41-020.105.04 Page 4 of 18 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5 Register 9

Page 5

Maintenance Protocol CS No.: . . . . . . . .

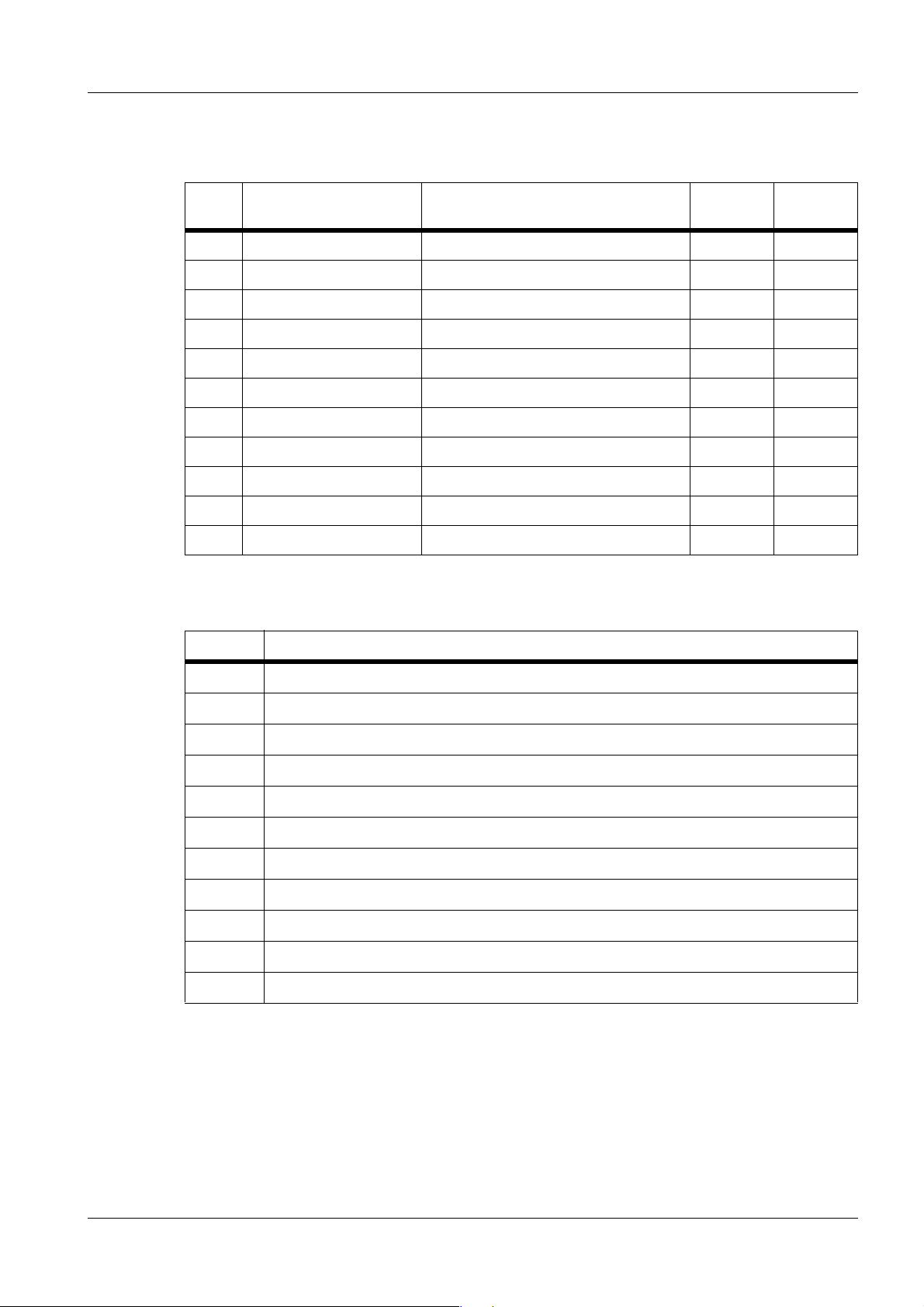

Open points

IVK

(WE)

Component Open points Solved

Explanation of the acronyms:

Abbrev. Explanation

(Date)

FSE

(Date)

SI Safety Inspection

SIE Safety Inspection Electrical Safety

SIM Safety Inspection Mechanical Safety

PM Preventive Maintenance

PMP Preventive Maintenance Preventive Parts Exchange, External Inspection, etc.

PMA Preventive Maintenance Adjustments

PMF Preventive Maintenance Function, Operating-Value Check

Q Quality Check

QIQ Quality Check Image

QSQ Quality Check System

SW Software Maintenance

Siemens AG Register 9 RX41-020.105.04 Page 5 of 18 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5 Register 9

Page 6

Maintenance Protocol CS No.: . . . . . . . .

Measurement devices

Please enter all measuring devices used for maintenance in the table.

Measurement Device Type Serial-No. Date of use Calibrated

until

TV Dynamics Test

Luminous intensity meter

Siemens AG Register 9 RX41-020.105.04 Page 6 of 18 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5 Register 9

Page 7

Maintenance Protocol CS No.: . . . . . . . .

Image Quality Test

Indirect Dose Rate Control (IQ Chap. 4.1.2)

Full format, all control steps

Prefiltering: 2.1 mm precision radiation filter

Operating Conditions Initial Values Mainten.

+-

Control step Fluoro

Progr.

(nGy/s)

Step 1

Fluoro 1

Step 2

Step 1

Fluoro 2

Step 2

Step 1

Fluoro 3

Step 2

Zoom formats, Fluoro 1, Step 1

I.I. Format / I.I. - 1 kV

Zoom 1

Zoom 2

Zoom 3

Curve Zoom - 1 kV

- 10% mA

kV

mA

kV

mA

kV

mA

kV

mA

kV

mA

kV

mA

- 10% mA

kV

mA

kV

mA

kV

mA

+ 1 kV

+ 10% mA

Act.

Initial Values Mainten.

+-

+ 1 kV

Act

+ 10% mA

Remarks: __________________________________________________________

______________________________________________________________________

Siemens AG Register 9 RX41-020.105.04 Page 7 of 18 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5 Register 9

Page 8

Maintenance Protocol CS No.: . . . . . . . .

NOTICE

Indirect Dose Control (IQ Chap. 8.1.) DR

Dose kV F/s Scene Focus

100 70 1 10s

I.I. For-

mat (cm)

Zoom

Dose fac.

Initial Values Qg/n Mainten.

- Act +

- 15% + 15%

DSA

Dose kV F/s Scene Focus

500 70 0.5 10s

I.I. For-

mat (cm)

Remarks: __________________________________________________________

_______________________________________________________________________

Monitor Adjustment (IQ Chap.8.3)

DFR Test Images

Zoom

Dose Fac.

Initial Values Qg/n Mainten.

- Act +

- 15% + 15%

Monitor Initial Values

Luminous intensity

Live

Examination

room

Ref

5% / 95% fields visible?

Live

Control room

Ref

5% / 95% fields visible?

On SIMOMED monitors, switch off the ambient light sensor for

the measurement!

2

(cd/m

-

black 0.7 0.9

white 240 280

black 0.7 0.9

white

240

)

Act +

280

yes

no

black 0.7 0.9

white 240 280

black 0.7 0.9

white 240 280

yes

no

Mainten.

yes

no

yes

no

Remarks: __________________________________________________________

_______________________________________________________________________

Siemens AG Register 9 RX41-020.105.04 Page 8 of 18 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5 Register 9

Page 9

Maintenance Protocol CS No.: . . . . . . . .

Dynamics Test with Fluoroscopy (IQ Chap. 5.8.1) with VIDEOMED SX

B/BA-Signal Amplitudes

Focus-I.I. distance (SID) = _______ cm - with grid

I.I. format 22 cm; 23 cm; 27 cm; 28 cm - Dynamics test (close to I.I.)

- without heart contour collimator

- without capillary test

- B-Signal without bias light

Fluoro curve _______ = _______

B-/BA-Signal (mV) Field No. Initial Values (mV) Mainten.

µGy/s

-

B-Signal

Input

TV CCU

Fluoro dyn.

BA-Signal

Output

TV CCU

Fluoro kV __ __

2L __ __

165 95

5R __ __

2L

1300 400

5R

≥ 1300

__ __

Act

*1 Procedure with SIREGRAPH D2/D3/CF

+

__

Dynamics factor (f) = level/field 2L: level/field 1

Remarks: __________________________________________________________

_______________________________________________________________________

Siemens AG Register 9 RX41-020.105.04 Page 9 of 18 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5 Register 9

Page 10

Maintenance Protocol CS No.: . . . . . . . .

CAUTION

Dynamics Test with DR and DSA (IQ Chap.8.5)

Do not select any additional filtering in the collimator

DR: Dose 100, single image Focus-I.I. distance (SID) = _______ cm

Iris corr. values_______ - I.I. format 22 cm; 23 cm; 27 cm

or 28 cm

- Dynamics test (close to I.I.)

- with heart contour collimator

DSA: Dose 200, F/s = 6, scene 5s - with capillary test

Iris corr. values_______ - with grid

upper window value: W1 = 511

lower window value: W2 = 256

- Measure BA-Signal at DFR output

Amplitudes

Field No. Initial Values (mV) Mainten.

Act

70

70

DR

BA-Signal

(mV)

DSA *

BA-Signal

(mV)

(kV)

U

a

U

(V)

Iris

-

2L 520 620

1200 250

5R __ __

2L

1190 260

5R

DR __

DSA __

DR __ __

DSA __ __

__

__ __

Reference values applicable for 70 kV

* Evaluate Native image (next to last image);

If 2L field would be > 650 mV, field 1 < 190 mV is admissible.

+

< 650

__

__

Remarks: __________________________________________________________

_______________________________________________________________________

Siemens AG Register 9 RX41-020.105.04 Page 10 of 18 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5 Register 9

Page 11

Maintenance Protocol CS No.: . . . . . . . .

Edge Enhancement (IQ Chap.8.5.2)

DR exposure

Function configured

yes

no

Remarks: __________________________________________________________

_______________________________________________________________________

Mean Value Calculation (GGM) (IQ Chap. 8.5.3)

Dig. Fluoro

Function configured

yes

no

Remarks: __________________________________________________________

Maintenance

Maintenance

_______________________________________________________________________

Siemens AG Register 9 RX41-020.105.04 Page 11 of 18 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5 Register 9

Page 12

Maintenance Protocol CS No.: . . . . . . . .

Resolution (IQ Chap. 8.7) and Minimum Contrast (IQ Chap. 8.8)

- 17 µm Cu strips

- With grid,

- Resolution test, Type 41 turned 45°

and collimate to the test size

- Insert 1.2 mm Cu in the collimator

- E (%) = 0; temp. filter = 6%

- Fluoro 1 at fluoro ( 70 kV)

- Dose step 100 with DR ( 70 kV)

- Upper window value: W1 = 511; lower window value: W2 = 256

2

Format

Initial Values (cd/m

(LP/mm)

)

Mainten.

Min. contrast visible?

Full format __

Dig.

Fluoro

1

Min. contrast visible?

Full format __

DR

exposure

Min. contrast visible?

Full format __

Hardcopy

-

__

Zoom 1 __

Zoom 2 __

Zoom 3 __

__

Zoom 1 __

Zoom 2 __

Zoom 3 __

__

Zoom 1 __

Zoom 2 __

Zoom 3 __

Act

yes

yes

yes

+

Remarks: __________________________________________________________

_______________________________________________________________________

Siemens AG Register 9 RX41-020.105.04 Page 12 of 18 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5 Register 9

Page 13

Maintenance Protocol CS No.: . . . . . . . .

Check of the DSA Device (IQ Chap. 8.9)

Focus-I.I. distance (SID)= _______ cm

I.I. format 22 cm; 23 cm; 27 cm; 28 cm

Window values for DSA image: brightness W1 = 80; contrast: W2 = 220

- With grid

- E (%) = 0

- Dynamics test with heart contour collimator and capillary test 37 90 180

- Trigger a DSA scene: 6 F/s, Dose 200, scene 5s, 70 kV

3 mm

2 mm

1 mm

Contrast Sensitivity

16 %

4 %

0.75 %

10 %

3 %

2 %

7.5 %

4 %

2.5 %

Initial Values

Maintenance *1

2L 1 5R 2L 1 5R

Tolerance

n+2

nn - 3

-1

LOG amplifier *2

3 mm 16 %

Subtraction *3

Tol . 0

± 1

*1 mark capillaries not visible

*2 Enter gray step of capillary

*3 Enter basic gray value of test field

Remarks: __________________________________________________________

_______________________________________________________________________

Siemens AG Register 9 RX41-020.105.04 Page 13 of 18 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5 Register 9

Page 14

Maintenance Protocol CS No.: . . . . . . . .

Image Disturbances (Artifacts) (Chap. 8.10)

DR Mode (Chap. 8.10.1)

Images from

MP

8.2

8.5.1 POST PROCESSING

8.5.1 Ghost images

8.2 / 8.5.1 Contouring

*2 Horizontal jitter

8.2 / 8.5.1 Island formation

8.4.3 Vignetting

Other disturbances: ____________________________________

DSA Mode (IQ Chap. 8.10.2)

Images from

MP

8.2

8.5.1 POST PROCESSING

Type of disturbance, Artifact Initial Values

RAM

Pixel errors/

Type of Disturbance, Artifact Initial Values

RAM

Pixel errors/

Mainten. *1

Mainten. *1

8.9 Artifacts caused by exposure

8.9 Logarithming errors

8.9 / *2 Convergence errors

8.9 / *2 Inhomogeneousness (Hum, Line

Errors)

8.9 / *2 Microphony

8.9 / 8.2 Island formation

8.9 Noise patterns

Other disturbances: ____________________________________

*1 Enter No. 1, 2, 3

1 = No disturbances, artifacts

2 = Slight disturbances, artifacts

3 = Intolerable disturbances, artifacts

*2 Soldering wire cross on middle of I.I.; 0.6 mm Cu prefilter

Siemens AG Register 9 RX41-020.105.04 Page 14 of 18 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5 Register 9

Page 15

Maintenance Protocol CS No.: . . . . . . . .

Digital Tomography (IQ Chap. 8.11)

- Tomo test object on tabletop

- Tomo height approx. 11.5 cm

(depending on tomo test object)

- , 0.6 mm Cu

- I.I. format 17 cm (20 cm)

- With grid

- Focus-I.I. distance (SID) = ___________ cm

- Exposure voltage = __________ kV; Dose 100

- Tomo profile

- max. tomo angle: ___________ °

- min. tomo time: ______________ s

Initial Values

Mainten.

* ∆ SHa = SHa - SH (mm)

∆ S

HL

= S

- SH (mm)

HL

Rg (LP/mm)

Shape and

sweep

/ o.k.

/ not o.k.

/ o.k.

Blur

/ not o.k.

*) Explanations

S

S

S

= Displayed tomo height ( ≤ 5 mm)

Ha

= Actual tomo height

H

= Light line height ( ≤ 5 mm)

HL

Rg = Measured resolution ( ≥ 2.0)

Remarks:

_______________________________________________________________________

__________________________________________________________

Siemens AG Register 9 RX41-020.105.04 Page 15 of 18 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5 Register 9

Page 16

Maintenance Protocol CS No.: . . . . . . . .

This page intentionally left blank.

Siemens AG Register 9 RX41-020.105.04 Page 16 of 18 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5 Register 9

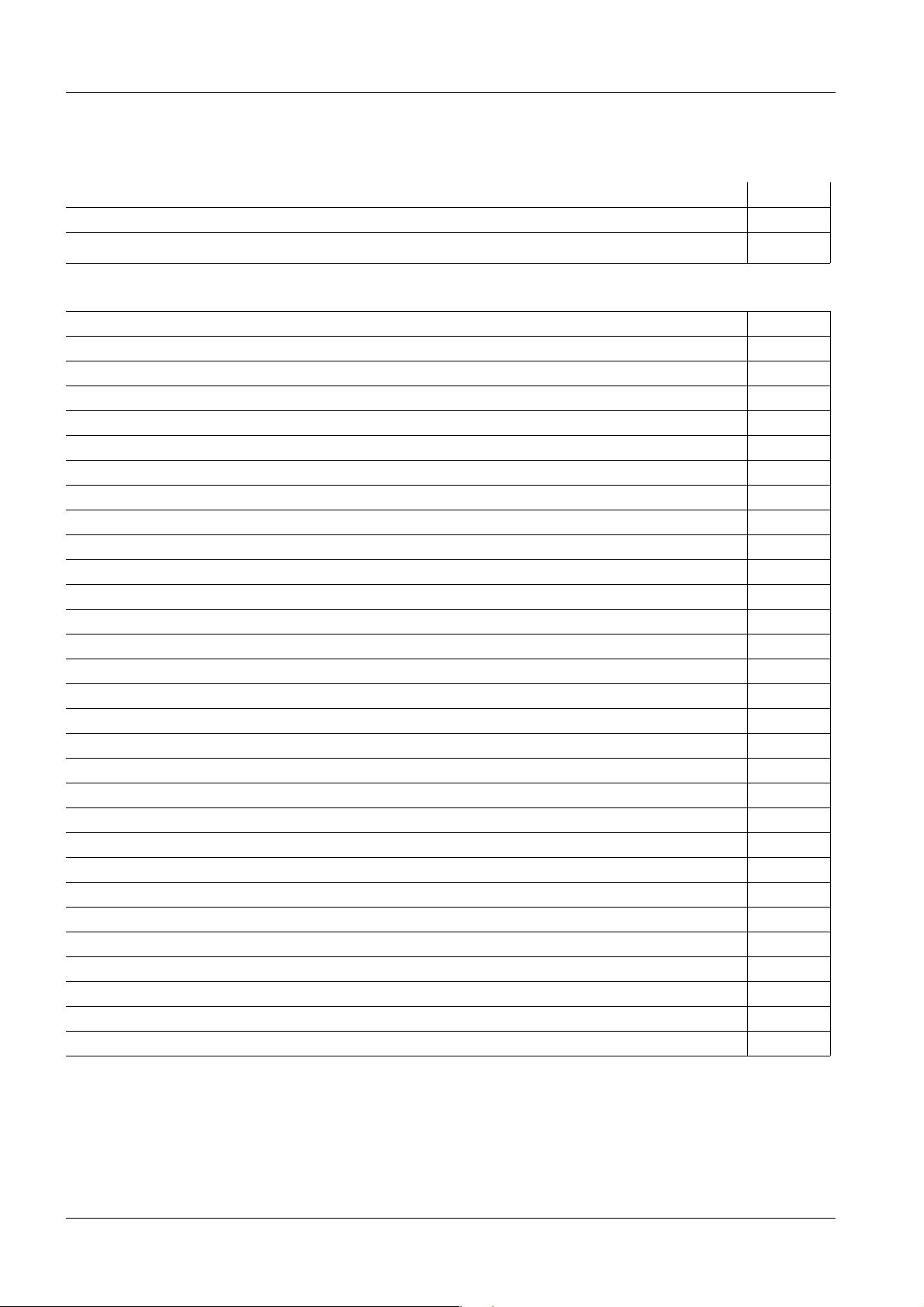

Page 17

Maintenance Protocol CS No.: . . . . . . . .

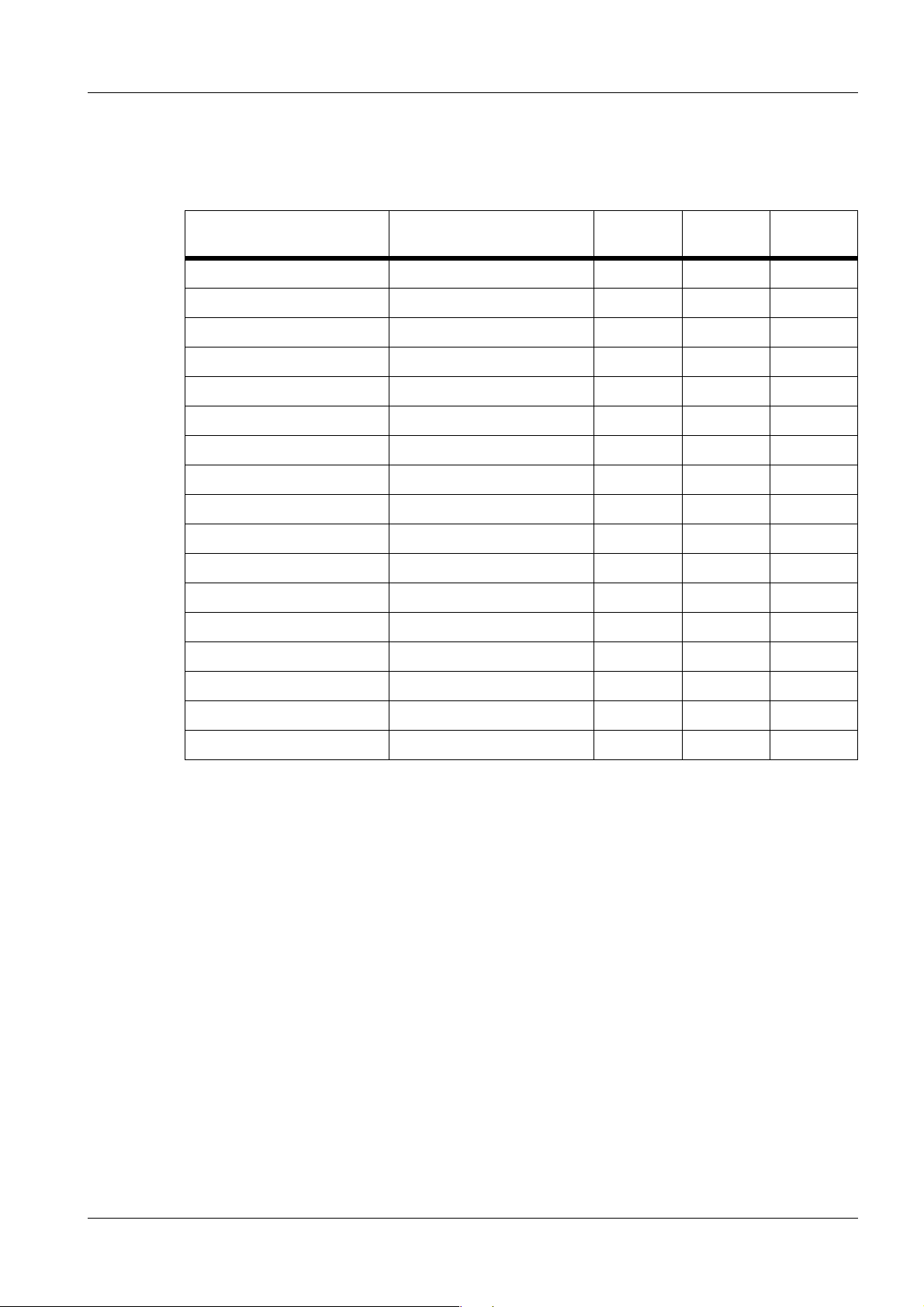

OK notOKn.a.

Page

1 Requirements 1 - 1

1.1. General Remarks 1 - 1

1.2. Required Documents 1 - 1

1.3. Required Test Equipment and Aids 1 - 2

1.4. Explanation of Symbols 1 - 2

2 VIDEOMED SX 2 - 1

2.1. Safety Inspection 2 - 1

SI Checking the Camera Mount. ❍ ❍ ❍ 2 - 1

SI Checking the Camera Housing

SI Checking the Ground Wire

❍ ❍ ❍ 2 - 1

❍ ❍ ❍ 2 - 1

2.2. Maintenance 2 - 1

PM Camera Optics ❍ ❍ ❍ 2 - 1

PM CCU

❍ ❍ ❍ 2 - 1

3 FLUOROSPOT H/HK 3 - 1

3.1. External Visual Inspection 3 - 1

PM Check the Control Console for Damage. ❍ ❍ ❍ 3 - 1

3.2. Maintenance 3 - 1

PM Opening the Unit ❍ ❍ ❍ 3 - 1

PM Remove dust that has collected on the inside of the unit

3.3. Inspection of the internal head vents 3 - 1

PM Check the fan for proper function. ❍ ❍ ❍ 3 - 1

3.4. Monitors 3 - 1

PM Cleaning the Monitor Screens ❍ ❍ ❍ 3 - 1

3.5. Function Inspection 3 - 2

PM Checking / Read Out the Error Log ❍ ❍ ❍ 3 - 2

❍ ❍ ❍ 3 - 1

4 Image Quality Test 4 - 1

4.1. General Remarks 4 - 1

Q Indirect Dose Rate Control (IQ Chap. 4.1.2) ❍ ❍ ❍ 4 - 2

Q Indirect Dose Control (IQ Chap. 8.1.2)

Q Monitor Adjustment (IQ Chap. 8.3)

Q Dynamics Test (Fluoroscopy) (IQ Chap. 5H, 5.8)

Q Dynamics Test (DFR) (IQ Chap. 8.5).

Q Edge Enhancement (IQ Chap. 8.5.2)

Q Mean Value Evaluation (GGM) (IQ Chap. 8.5.3)

Q Resolution (IQ Chap. 8.7) and Minimum Contrast (IQ Chap. 8.8)

Q Checking the DSA Device (IQ Chap. 8.9)

Q Image Disturbances (Artifacts) (Chap. 8.10)

Q Digital Tomo IQ Chap. 8.11)

Q Check of the Tomo Height

Q Checking the Resolution

4.2. Final Work Steps 4 - 24

Siemens AG Register 9 RX41-020.105.04 Page 17 of 18 FLUOROSPOT H/HK

Medical Engineering Rev. 01 05.97 TD AX 5 Register 9

❍ ❍ ❍ 4 - 3

❍ ❍ ❍ 4 - 5

❍ ❍ ❍ 4 - 6

❍ ❍ ❍ 4 - 9

❍ ❍ ❍ 4 - 12

❍ ❍ ❍ 4 - 12

❍ ❍ ❍ 4 - 13

❍ ❍ ❍ 4 - 14

❍ ❍ ❍ 4 - 17

❍ ❍ ❍ 4 - 20

❍ ❍ ❍ 4 - 21

❍ ❍ ❍ 4 - 23

Page 18

CS No.: . . . . . . . . Maintenance Protocol

OK notOKn.a.

4.2.1 Generator Fluoro Curves 4 - 24

4.2.2 SIMOMED H 4 - 24

4.2.3 Function Checks 4 - 24

Page

5 Changes to Previous Version 5 - 1

FLUOROSPOT H/HK Register 9 RX41-020.105.04 Page 18 of 18 Siemens AG

Register 9 Rev. 01 05.97 TD AX 5 Medical Engineering

Loading...

Loading...