Page 1

FLUOROSPOT H/HK

Installation Instructions

AX

Non-SIEMENS Laser Camera

Digitally Connected

Valid for FL-H/HK

© Siemens AG 1995

The reproduction, transmission or

use of this document or its contents

is not permitted without express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

Register 3 English

Print No.: RX41-020.031.01.10.02 Doc. Gen. Date: 12.96

Replaces: RX41-020.031.01.09.02

Page 2

0 - 2Revision

Chapter Page Revision

0all09

1all09

2all09

3all06

4all01

0all10

1all10

2all10

3all07

4all02

5all01

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 2 of 4 Siemens AG

Rev. 10 12.96 TD AX 5 Medical Engineering

Page 3

Contents 0 - 3

Page

1 _______Prerequisites __________________________________________________ 1 -1

Required Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -1

Required Test Equipment and Devices . . . . . . . . . . . . . . . . . . . . . . . . . 1 -1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -1

Parts of optical Camera Link (OCL) for La ser Cam e ras. . . . . . . . . . . . . . . . . 1 -2

Survey of OCL Connection (Block Diagram) . . . . . . . . . . . . . . . . . . . . . . 1 -2

Units without OCL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -3

Check of the Opto Modules OZDV 241/246* (Hirschmann). . . . . . . . . . . . . . . 1 -4

FLUOROSPOT H/HK System Configuration . . . . . . . . . . . . . . . . . . . . . . 1 -4

2 _______Connection of the Camera _______________________________________ 2 -1

3M PLUS (M952 with HCI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -1

Hardware Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -1

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -1

Jumper Setting HCI-BOX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -2

Hardware Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -3

3M (M959 XL with HCI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -4

Jumper Setting HCI-BOX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -5

3M HQ (M969 with SHPT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -6

AGFA MCL with AGFA-MIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -8

Hardware Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -8

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -8

AGF A MG 3000 + LR 3300.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -10

KODAK XLP / 1120 / 2180 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -12

DU PONT LINX-NET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -14

Hardware Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -14

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -14

KONICA LI10A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -16

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -17

FUJI FL-IM 3543 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -18

Hardware Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -18

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -18

3 _______Service _______________________________________________________ 3 -1

Hardcopy Driver Modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -1

Service Tools for Tracing the SPCI/SPDI Interface . . . . . . . . . . . . . . . . . . . 3 -2

1. Tester for the Control Interface . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -2

2. Linktest Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -3

Check of the OCL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -6

Camera Interface Test System . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -6

Hardcopy Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -8

4 _______Abbreviations__________________________________________________ 4 -1

5 _______Changes to Previous Version_____________________________________ 5 -1

Siemens AG Register 3 RX41-020.031.01 Page 3 of 4 FLUOROSPOT H/HK

Medical Engineering Rev. 10 12.96 TD AX 5

Page 4

0 - 4 Contents

Page

This page intentionally left blank.

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 4 of 4 Siemens AG

Rev. 10 12.96 TD AX 5 Medical Engineering

Page 5

Prerequisites 1

Required Documents 1

• Service Manual FLUOROSPOT H 89999-0031

Required Test Equipment and Devices 1

• Service PC according specificat ions in the ARTD part 1 3.1.0

• SST 320 terminal emulation, 97 04 586 Y4364

General Remarks 1

The startup of the camera is performed by the technical service of the respective camera

manufacturer.

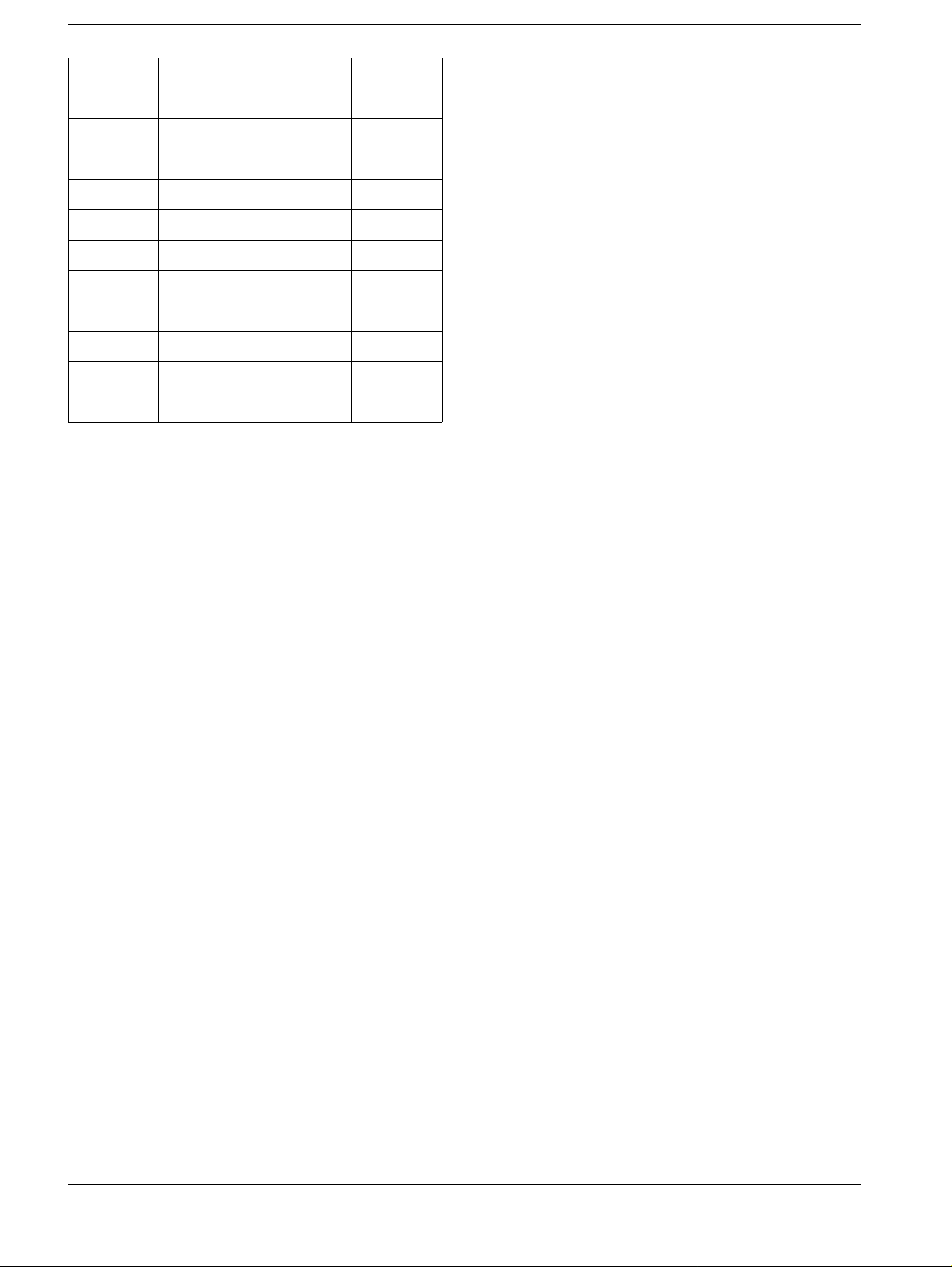

Survey when an OCL is necessary

1 - 1

Camera Distance between

FL-H and HCC

3M XL(959)

3M HQ(969)

AGFA MCL /

MIN / MG 3000

with MFRI Board

Rev. A-D

AGFA MCL /

MIN / MG 3000

with MFRI Board

Rev. E and >

All other cameras,

Multiple Modality

All other cameras,

Single Modality

___________ ___________

< = 30m

< = 30 m

> 30 m

> 30 m

< = 60m

< = 60 m

> 60 m

> 60 m

< = 60m

< = 60 m

> 60 m

> 60 m

< = 60m

< = 60 m

> 60 m

> 60 m

FL-H / HK and

HCC at the same

power distribution

YES

NO

YES

NO

YES

NO

YES

NO

n.a.

n.a

n.a

n.a

YES

NO

YES

NO

OCL

necessary

NO

NO

YES

YES

YES

NO

NO

YES

YES

YES

YES

YES

YES

NO

YES

YES

YES

Siemens AG Register 3 RX41-020.031.01 Page 1 of 6 FLUOROSPOT H/HK

Medical Engineering Rev. 10 12.96 TD AX 5

Page 6

1 - 2Prerequisites

Parts of optical camera link (OCL) for laser cameras 1

Kit for the optical camera link, Part No:11 76 671 X2176

Includes:

Transmitter (Host Module) No: 46 83 629 B4001

Date cable to FL-H No: 46 84 270 B5620

Control cable to FL-H No: 46 83 561 B1940

Mains cable No: 11 69 197 X2115

Receiver (Camera Module) No: 46 83 637 B4002

Data cable to laser camera No: 46 83 579 B1940

Control cable to laser camera No: 46 83 561 B1940

Power cable (3 m) No: 46 83 595 B1948

Order separately: :

Duplex optical fiber (30 m) No: 46 89 469 B4003 or

Duplex optical fiber (100 m No: 46 90 756 B4003

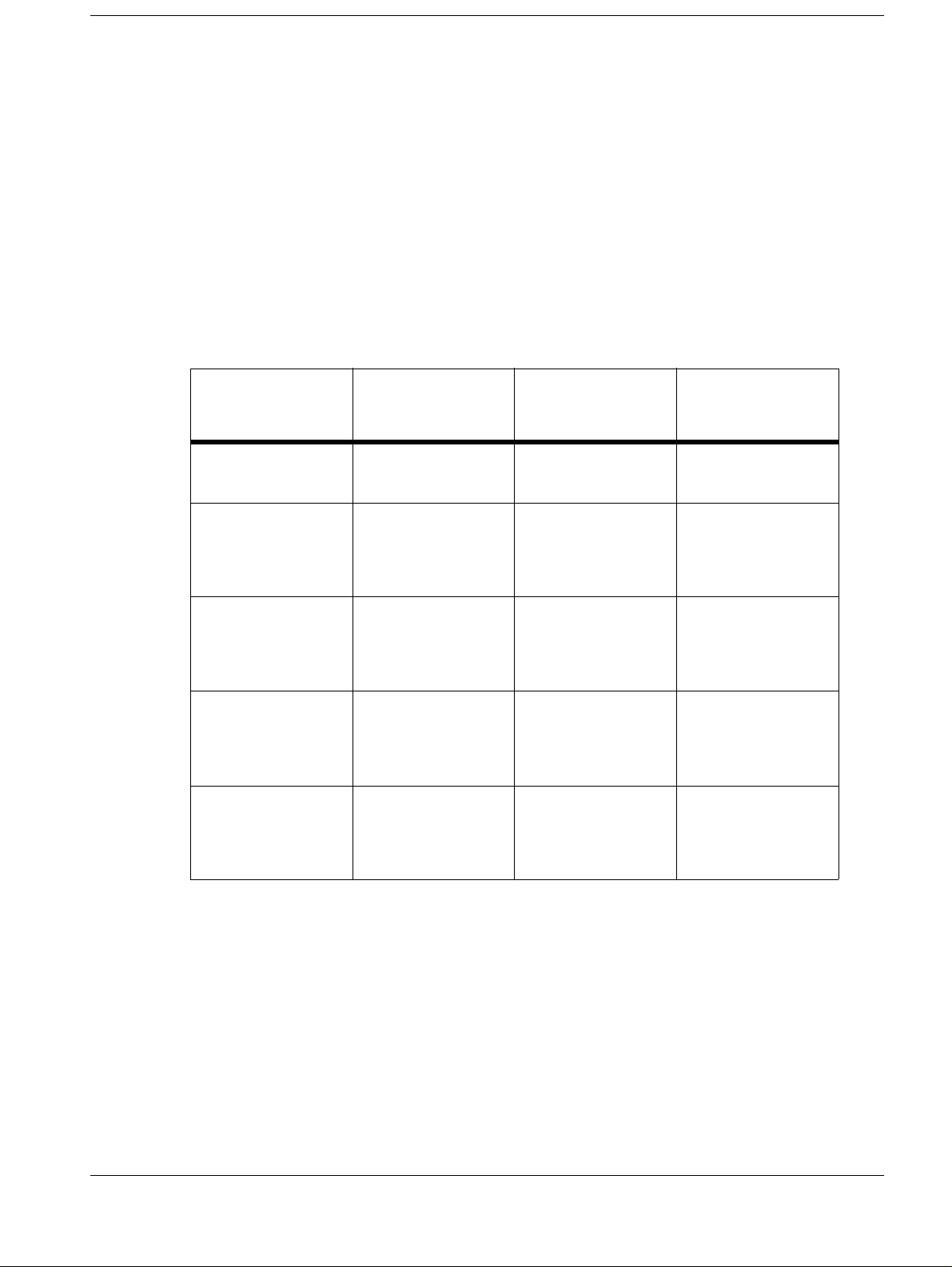

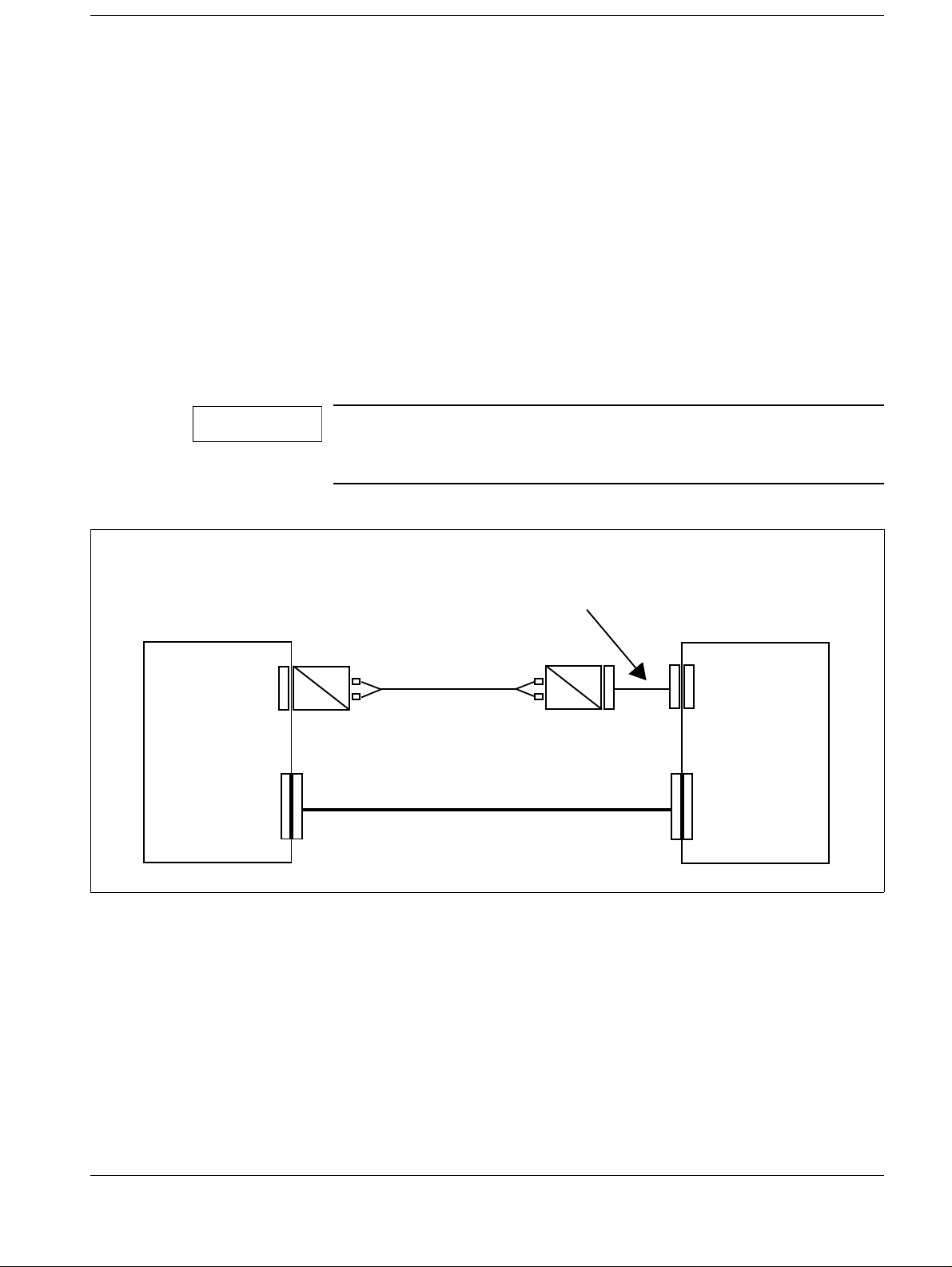

Survey of OCL connection (Block Diagram) 1

Transmitter

FL-H

J26

J29

46 84 270

B5620

46 83 561

11 69 197 X2115

46 83 629B4001

Host module

Camera Request

Host Clock

Leds

green:Power supply ok

red blinking:

Power supply failure

Fig. 1

Duplex optical fiber

46 90 756 B4003 (100 m)

OPT FIBER

230 VAC power

46 89 469 B4003 (30 m)

Receiver

46 83 637 B4002

Camera module

Camera Request

Host Clock

green:Power supply ok

red blinking: Power supply failure

230 VAC power

46 83 595 B1948 (3 m)

Leds

Digital laser camera

46 83 579 B1940

Data cable

Control cable

46 83 561 B1940

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 2 of 6 Siemens AG

Rev. 10 12.96 TD AX 5 Medical Engineering

Page 7

Prerequisites 1 - 3

NOTICE

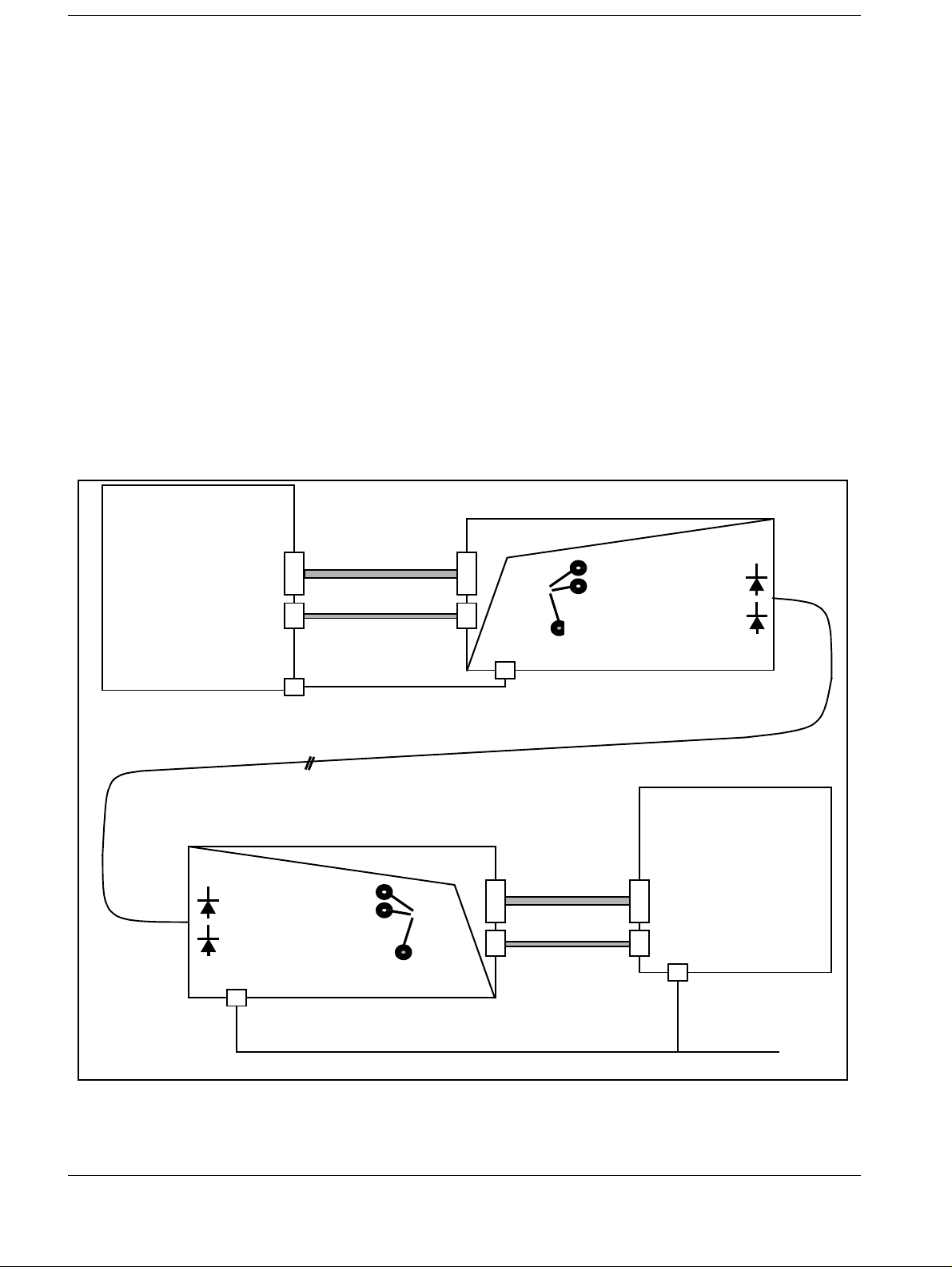

Units without OCL 1

Cable set, 26 m 26 m No: 44 90 421 RH041

Includes:

Data cable 26 m No: 11 63 307 X1755

Fiber optic cable (FOC) 30 m No: 77 60 598 B4003

2 Opto modules for 30 m FOC) 2 x No: 77 60 606 B4002

Cable set, 60m 60 m No: 44 90 439 RH041

Includes:

Data cable 60 m No: 16 00 100 X1755

Fiber optic cable (FOC) 60 m No: 46 95 821 B 4003

2 Opto modules for 60 m FOC 2 x No: 46 71 228 B4002

Adapter cable for 60 m FOC No: 11 76 978 X2115

Note: When opto module for 60 m FOC is used, there is a danger

of kinking the FOC. To avoid kinking, use an adapter cable

between J 29 (FLUOROSPOT) and the opto module.

Fig. 2

Connection HCC

Adapter cable only used

by opto decoupler for 60m foc

*

O

E

Fiber Optical Cable 30/60 m

Image Data Cable 26/60 m

O

FLUOROSPOT H /HK

Transition Panel

*

E

HCC Control

J29

HCC IMAGE

J26

Siemens AG Register 3 RX41-020.031.01 Page 3 of 6 FLUOROSPOT H/HK

Medical Engineering Rev. 10 12.96 TD AX 5

Page 8

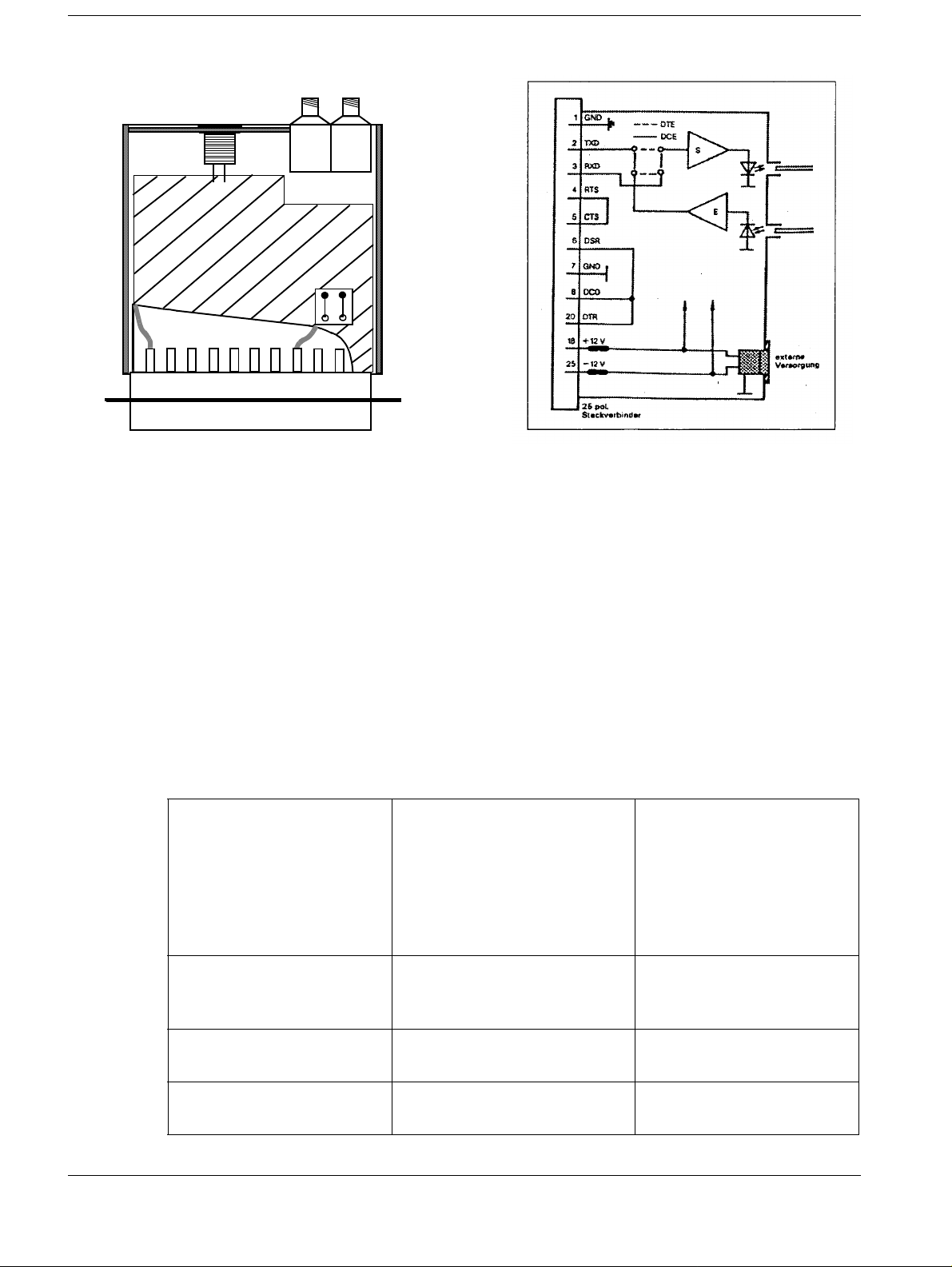

1 - 4Prerequisites

Pin 25 Pin 18

Fig. 3 Fig. 4

Check of the OZDV 241/246* Opto Modules (Hirschmann) 1

• Open both Opto Modules and check whether the jumpers for TxD and RxD are in th e

correct position (see Fig. 1).

• Check whether the solder connections for the internal voltage supply (ñ12 V) have been

made (see Fig. 2) and close the Opto Modules.

Safety note

Observe the safety notes in Reg. 2 of the FLUOROSPOT H service manual.

FLUOROSPOT H/HK System Configuration 1

(see also Service Manual FLUOROSPOT H VC21 / VD10 or VC22 / VD11 Chapter 3

”Software Configuration”).

HCC type DIGICAM/LINXNET2; 3M

959/969-SHPT-2;AGFA-MCL3; AGFA-MCL-4 ;KODAK-XLP4; KODAK-2180/1120-2;KONICA-LI10A-2; FUJI-3543P2Further camera driver see

2-26

e. g. DIGICAM /LINXNET 2

Default HCC multiple format 1:1; 2:1; 4:1; 6:1; 8:1; 9:1;

12:1; 15:1; 16:1; 20:1; and

mixed formats *

Default HCC multiple film

size

Default HCC single format same selection as multiple for-

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 4 of 6 Siemens AG

Rev. 10 12.96 TD AX 5 Medical Engineering

14 x 17; 1 1 x 14; 8 x 10; 14 x

14 *

mat possible

e.g. 4:1

e.g. 14 x 17

e.g. 2 + 8:1

Page 9

Prerequisites 1 - 5

Default HCC single film size same selection as multiple

size possible

HCC interpolation mode

(multiple)

HCC interpolation mode

(single)

HCC film density (optical

density x100)

HCC LUTs 1

HCC black level used for analog cameras only 0

HCC white to black level

(mV)

*depending on camera used

Configuration of format default settings

It is possible to configure one of the camera supported formats as default in both menu

points HCC multiple format and HCC single format.

used for analog cameras only 700

e.g. 11 x 14

SMOOTH

SMOOTH

300

Hardcopy Camera HCC Firmware

(minimum version)

3M PLUS (M952)

via HCI

3M XL (M959)

via HCI,

3M HQ (M969)

via SHPTV1.2

AGFA MCL

MIN

Mixed formats

AGFA MG 3000 + LR 3300 MeGa1P10

Version 2.3

Version 3.2 (HCI

Special LUT firmware: 321A

Version 2.0

Version 3.2 (HCI)

Special LUT firmware:322AO

SMCL 01416

SUM 02017

AGFA Camera patch required

OEMMG 010

FL-H Camera Driver

3M 952-HCI-2

3M 959/969-HCI-2

3M 959/969-SHPT-2

AGFA-MCL-3

AGFA-MCL-4

AGFA-MCL-3 /

AGFA-MCL-4

Siemens AG Register 3 RX41-020.031.01 Page 5 of 6 FLUOROSPOT H/HK

Medical Engineering Rev. 10 12.96 TD AX 5

Page 10

1 - 6Prerequisites

Hardcopy Camera HCC Firmware

(minimum version)

KODAK XLP CPDI 2.2 KODAK-XLP-3

KODAK 1120 CPDI 2.2 KODAK-XLP-3

KODAK XLP CPDI 2.3 KODAK-XLP-4

KODAK 1120 CPDI 2.3

CPDI > 2.3 (planned for future)

KODAK 2180 CPDI 2.3

CPDI > 2.3 (planned for future)

DIGICAM

Du Pont LINXNET,

LP400 with LINXNET only

KONICA LI10A Version 2.0 FLH Protocol KONICA-LI10-A-2

FUJI FL-IM 3543 (portrait)

884 x 884 Matrix

1024 x 1024 Matrix

Version 22

Rev. 2.0

14Y5749001D05, AE01PR 003

14Y5749001D05, AE01PR 002

FL-H Camera Driver

KODAK 2180/1120-2

KODAK 2180/1120-3

KODAK 2180/1120-2

KODAK 2180/1120-3

DIGICAM/LINXNET2

FUJI-3543-P2

FUJI FL-IM 3543 (landscape)

884 x 884 Matrix

1024 x 1024 Matrix

Other cameras Generic Digital 2

14Y5749001D05, AE01PR 003

14Y5749001D05, AE01PR 002

FUJI-3543-L2

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 6 of 6 Siemens AG

Rev. 10 12.96 TD AX 5 Medical Engineering

Page 11

Connection of the camera 2

3M PLUS (M952 with HCI) 2

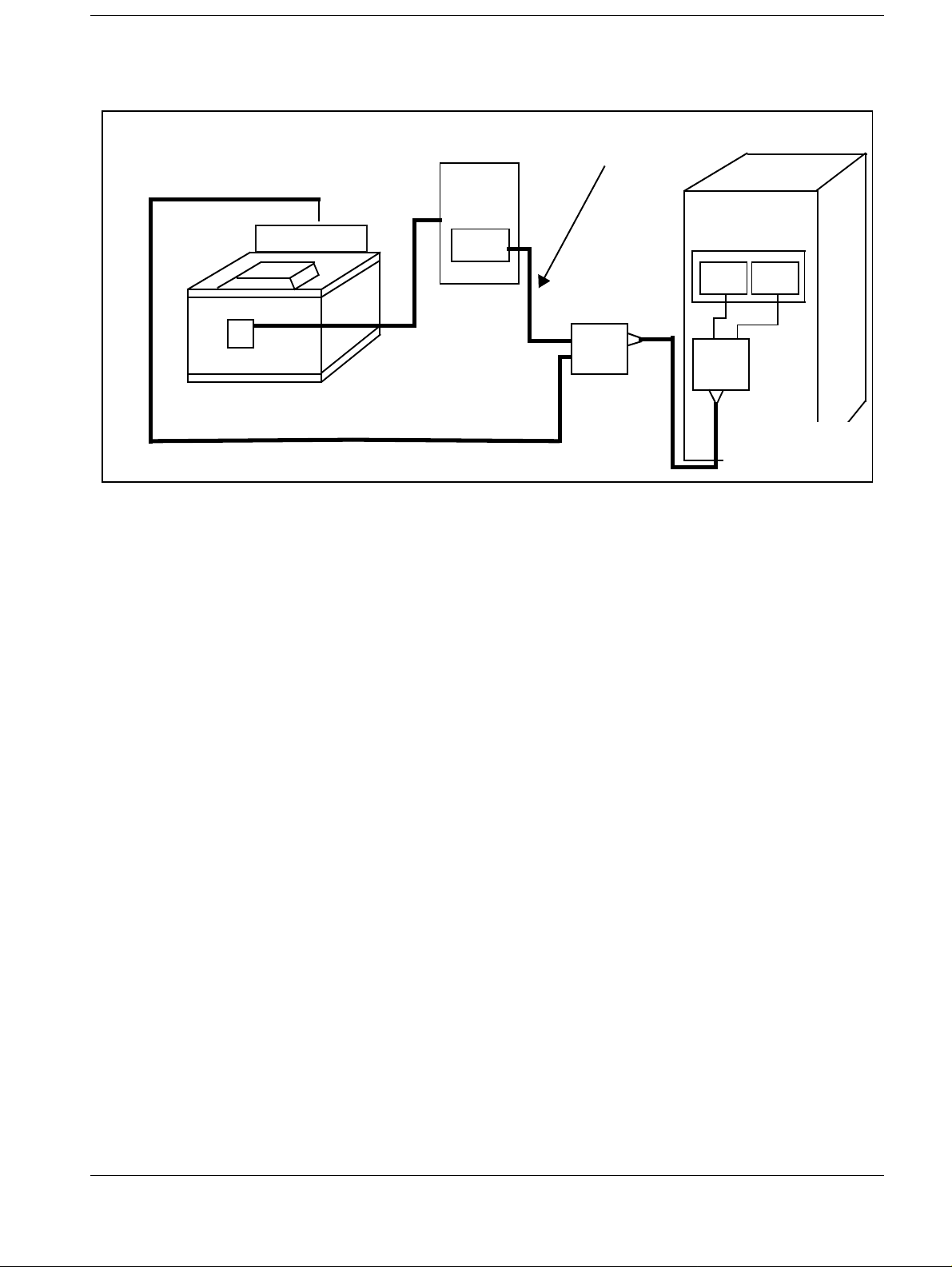

Example with OCL

FLUOROSPOT H/HK

HOST- CONTR.

3-M laser camera

DIGITAL

HCI

Box

OEM

HC

TRANSITION

PANEL

2 - 1

J26

*

Duplex Optical

Fiber Cable *

*

*

IMAGE- DATA *

Fig. 1

*Parts of the Optical Camera Link

*

CAM.

MOD.

J29

*

Host

MOD.

Hardware requirements 2

• HCC digital board or VIDEO OUT III board in the FLUOROSPOT is neces sary

• Whether an OCL is necessary see page 1-1

Configuration 2

In the FLUOROSPOT SYSTEM CONFIGURATION (see page 1-4), set the menu point

”HCC type” to ”3M 952-HCI-2”.

Supported formats see page 2-20

The selectable formats are also depending from the memory-expansion of the 3M-PLUS

camera

Siemens AG Register 3 RX41-020.031.01 Page 1 of 22 FLUOROSPOT H/HK

Medical Engineering Rev. 10 12.96 TD AX 5

Page 12

2 - 2 Connection of the camera

FLUOROSPOT H/HK TRANSITION PANEL..

HCC IMAGE

Fig. 2

.

J26

J26

J25

SK 111

J32

AUX 2

J22 J23 J24

AC DIST KEYBOARD REMOTE

J27 J28

SERVICE

AUX 1

J29

HCC CTL

Fig. 3

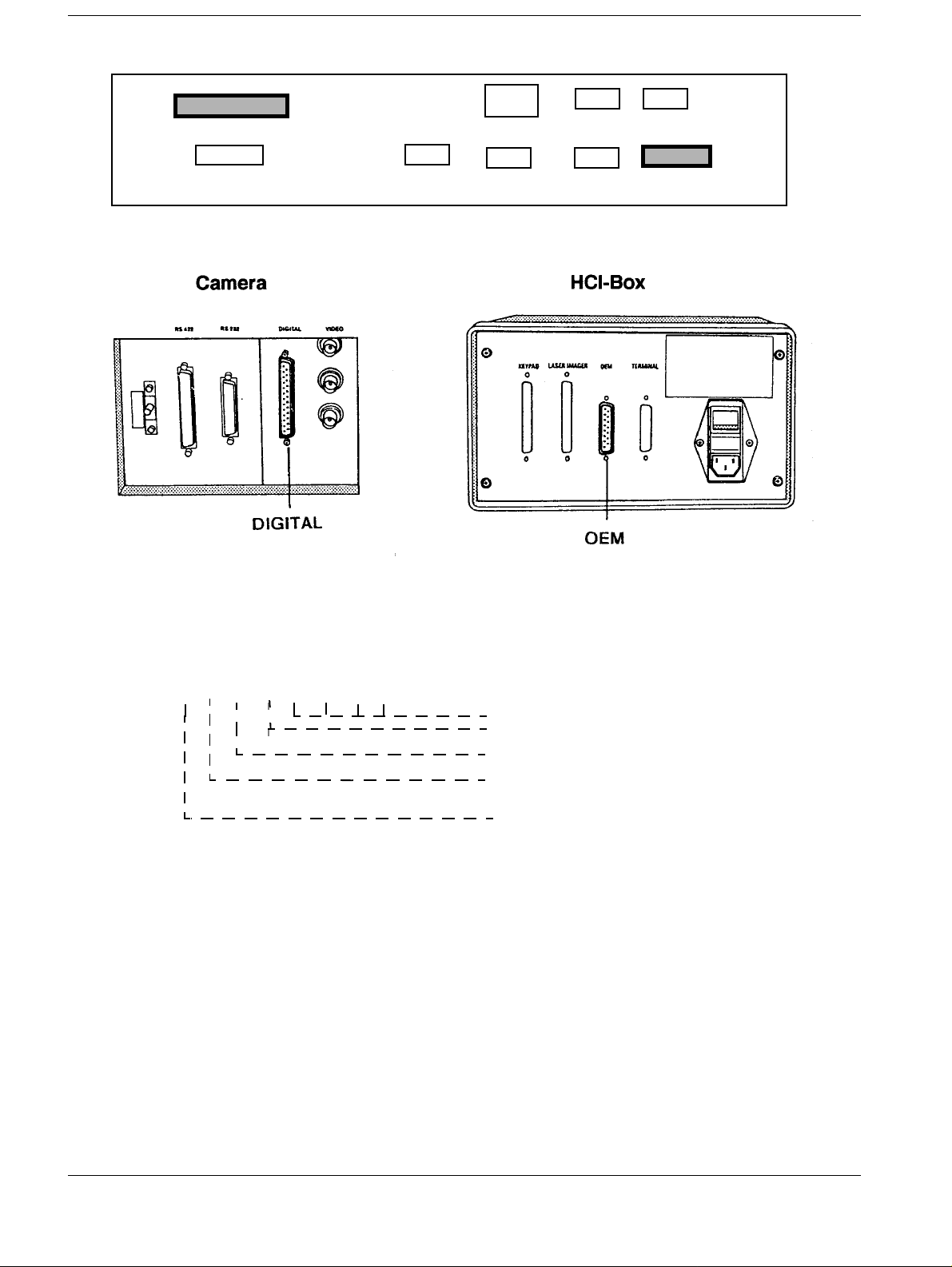

Jumper Setting HCI-BOX 2

The DIP switch on the CPU-Board (HCI-Box) has to be set to the proper position

DIP switch on HCI-CPU Board

1 2 3 4 5 6 7 8

not used

OFF

ON: FLUOROSPOT selected

OFF: others

ON: LASER IMAGER (M959)

OFF: LASER IMAGER (M952)

ON: MMU Operation

OFF:stand-alone

Fig. 4

If the CPU is correctly set, the HCI must display ”SET UP FOR FLUOROSPOT H” for

some seconds after power up.

Other notes

If contrast curve 12 is selected in the 3M-PLUS camera, the monitor image impression

largely coincides with the film.

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 2 of 22 Siemens AG

Rev. 10 12.96 TD AX 5 Medical Engineering

Page 13

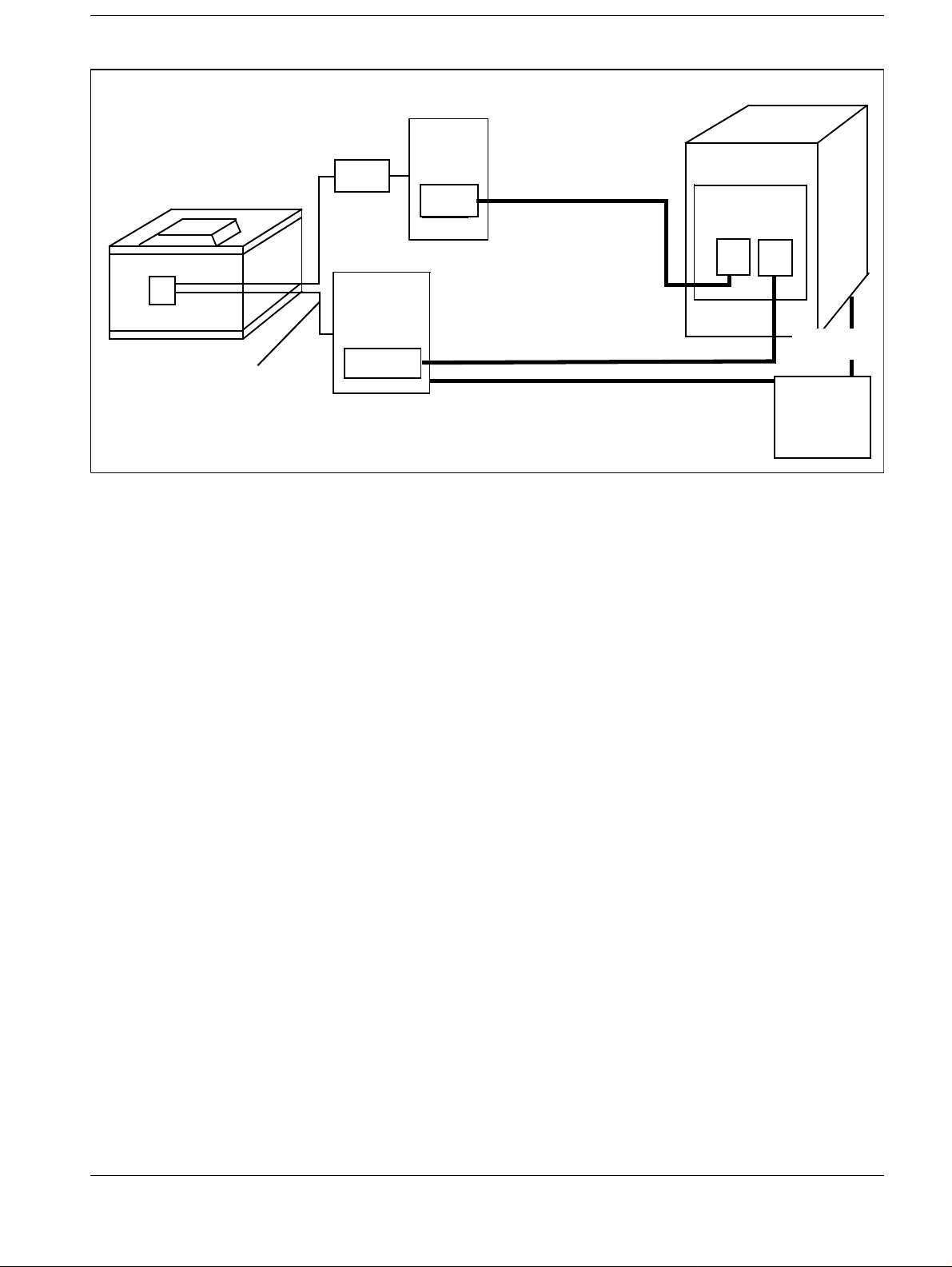

Connection of the camera 2 - 3

FLUOROSPOT H/HK

3-M laser camera

3M fiber optic cable

Fig. 5

*) connect to the same power distribution panel

KEIB = KEYPAD-EXTERNAL-INTERFACE-BOX

HCI = HOST-CONTROL-INTERFACE

DEIB = DATA-EXTERNAL-INTERFACE-BOX

KEIB

DEIB

PORT 0

HCI

Box

OEM

HC

HOST-CONTR.

fiber-optic cable

IMAGE-DATA CABLE

power (DEIB)

TRANSITIONPANEL

*)

J29

J26

power*)

power

distrib.

Hardware requirements 2

• HCC digital board or VIDEO OUT III Board in the FLUOROSPOT is necessary

• OCL (Optical Camera Link) is not necessa ry.

• Cable sets 30/60m: see page 1-2

Siemens AG Register 3 RX41-020.031.01 Page 3 of 22 FLUOROSPOT H/HK

Medical Engineering Rev. 10 12.96 TD AX 5

Page 14

2 - 4 Connection of the camera

3M (M959 XL with HCI) 2

Configuration

In the FLUOROSPOT H SYSTEM CONFIGURATION (see page 1- 4), set the menu point

”HCC type” to ”3M-959/969-HCI-2”.

Supported formats see page 2-20

The selectable formats are also depending from the memory-expansi on of the 3M

camera.

FLUOROSPOT H/HK TRANSITION PANEL.

HCC IMAGE

Fig. 6

J26

J26

J25

SK 111

J32

AUX 2

J22 J23 J24

AC DIST KEYBOARD REMOTE

J27 J28

SERVICE

AUX 1

J29

HCC CTL

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 4 of 22 Siemens AG

Rev. 10 12.96 TD AX 5 Medical Engineering

Page 15

Connection of the camera 2 - 5

.

Fig. 7

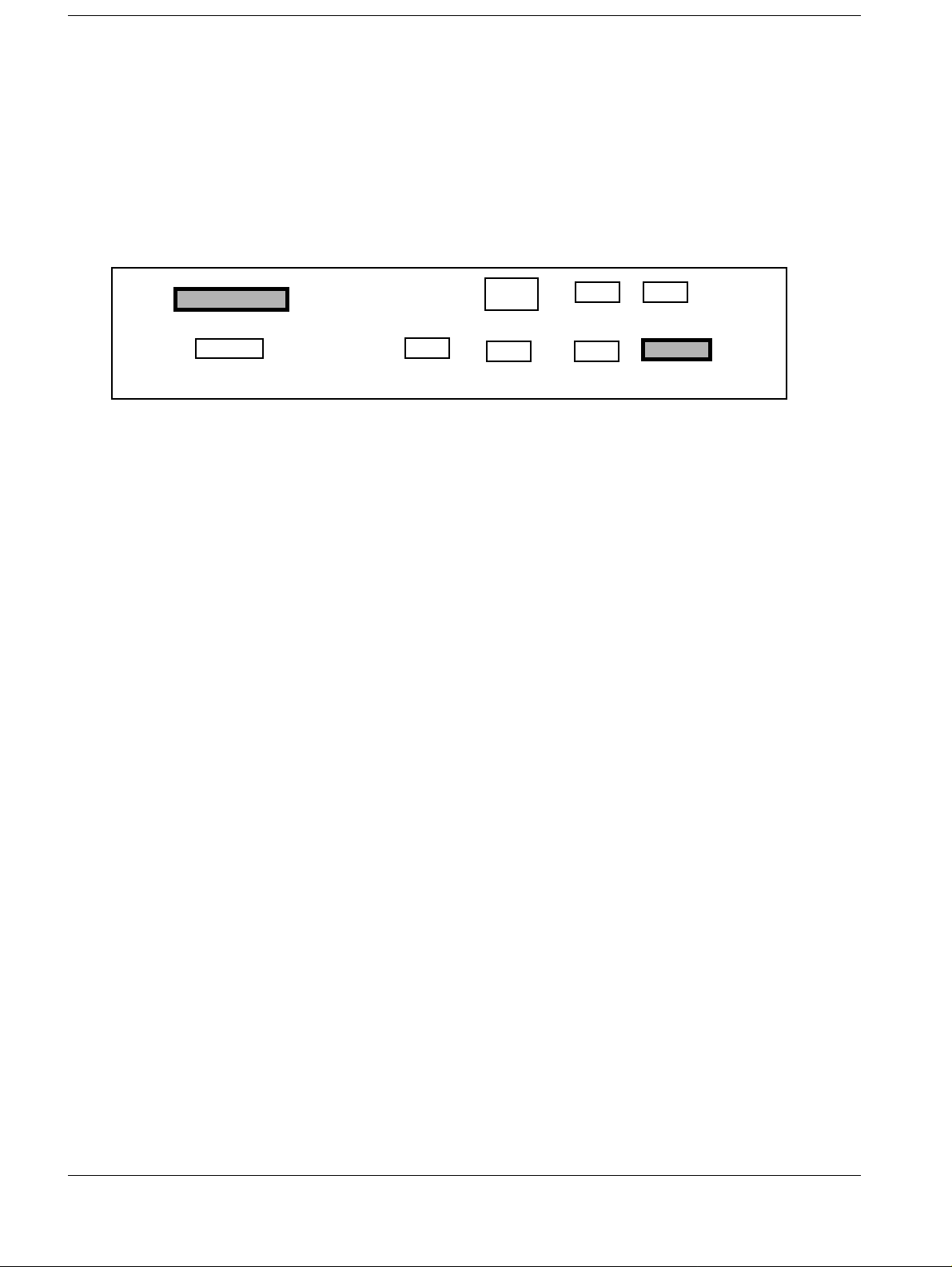

Jumper Setting HCI-BOX 2

The DIP switch on the CPU-Board (HCI-Box) has to be set to the proper position

DIP switch on HCI-CPU Board

1 2 3 4 5 6 7 8

not used

OFF

ON: FLUOROSPOT selected

OFF: others

ON: LASER IMAGER (M959)

OFF: LASER IMAGER (M952)

ON: MMU Operation

OFF:standalone

Fig. 8

If the CPU is correctly set , the HCI must display ”SET UP FOR FLUOROSPOT H” for

some seconds after power up

..

Fig. 9

Other notes

If contrast curve 9 is selected i n the 3M-XL camera, t he monitor image impressi on largel y

coincides w ith th e film

Siemens AG Register 3 RX41-020.031.01 Page 5 of 22 FLUOROSPOT H/HK

Medical Engineering Rev. 10 12.96 TD AX 5

Page 16

2 - 6 Connection of the camera

NOTICE

3M HQ (M969 with SHPT). 2

FLUOROSPOT H/HK

Translator

Keypad

TRANSITION

3-M 969/ 959 laser camera

Fiber Optical Cables

KEY

PAD

UKEIB

HOS

DEIB

PORTO

HOST-CONTROL

Fiber Optical cable

IMAGE-DATA-CABLE

PANEL

J 26J 29

Power connection (DEIB*)

POWER

DISTRIB.

*Connected to the same power distribution

UKEIB = Universal Keypad External Interface Box

DEIB = Data External Interface Box

Hardware requirements

Power

connect.

FL-H/HK*

• HCC digital board or VIDEO OUT III board in the FLUOROSPOT is necessary

• OCL (Optical Camera Link) is not necessary

• Cable sets 30/60m: see page 1-2

For the connection of the fiber optical control cable use the opto

decouplers (OZDV) on the TRANSITION Panel and on the UKEIB.

Configuration

In the FLUOROSPOT SYSTEM CONFIGURATION (see page 1-4), set the menu point

”HCC Type” for the 3M 969”3M 959/969-SHPT-2”.

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 6 of 22 Siemens AG

Rev. 10 12.96 TD AX 5 Medical Engineering

Page 17

Connection of the camera 2 - 7

Supported formats see page 2-26

The selectable formats are also depending from the memory-expansion of3M HQ

(3M969)

If contrast curve 9 is selected in the 3M XL (3M 959) camera, th e monitor image impression rather coincides with the film.

FLUOROSPOT H/HK TRANSITION PANEL

HCC IMAGE

Fig. 10

J26

J26

J25

SK 111

J32

AUX 2

J22 J23 J24

AC DIST KEYBOARD REMOTE

J27 J28

SERVICE

AUX 1

J29

HCC CTL

Opto Decoupler

RS232 Host Adapter cable

UKEIB

FIBEROPTIC

XMT

FTSW

A-CH B-CH

RCV

Keypad Cable

HOST

KEYPAD

IMAGER

Translator

Keypad

Fig. 11 Fig. 12

Siemens AG Register 3 RX41-020.031.01 Page 7 of 22 FLUOROSPOT H/HK

Medical Engineering Rev. 10 12.96 TD AX 5

Page 18

2 - 8 Connection of the camera

AGFA MCL with AGFA-MIN 2

.Example with OCL

FLUOROSPOT H/HK

AGFA MCL

AGFA MIN

MFRI

*Parts of the Optical Camera Link

Camera

CTR

*

*

CAM.

MOD.

*

TRANSITION

PANEL

J 29

*

Host

*

MOD

Duplex Optical

Fiber Cable*

J 26

*

Hardware requirements 2

• HCC digital board or VIDEO OUT III board in the FLUOROSPOT is necessary

• Whether an OCL is necessary see page 1-1

Configuration 2

For FLUOROSPOT SYSTEM CONFIGURATION (see page 1-4).

For mixed formats ask AGFA Service for camera patch. With patch, load hardcopy driver

”AGFA-MCL- 4”. Respectively without patch load driver

”AGFA-MCL- 3”.

To test the function of the patch start a mixed format hardcopy

Supported formats see page 2-20

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 8 of 22 Siemens AG

Rev. 10 12.96 TD AX 5 Medical Engineering

Page 19

Connection of the camera 2 - 9

FLUOROSPOT H/HK TRANSITION PANEL

HCC IMAGE

Fig. 13

.

J26

J26

J25

SK 111

J32

AUX 2

J22 J23 J24

AC DIST KEYBOARD REMOTE

J27 J28

SERVICE

AUX 1

J29

HCC CTL

Other notes

If the ”KANAMORI” curve is selected in the AGFA MCL camera, the monitor image

impression largely coincides with the film.

The AGFA MCL with AGFA MIN is expandable to support up to four image systems.

It is necessary to set the”Autoeject” flag to? Active Auto print function” at the AGFA Cam-

era (performed by the AGFA technical service).

Siemens AG Register 3 RX41-020.031.01 Page 9 of 22 FLUOROSPOT H/HK

Medical Engineering Rev. 10 12.96 TD AX 5

Page 20

2 - 10 Connection of the camera

AGFA MG 3000 + LR 3300. 2

LR 3300

FLUOROSPOT H/HK

AGFA MCL

(alternative

to LR 3300)

AGFA MG 3000

MFRI

Host - Control

Fiber Optical Cable

Image Data Cable

MFRI= Multi Format Receiving Interface

Hardware requirements

TRANSITION

PANEL

J 29

J 26

• HCC DIGITAL BOARD or VIDEO OUT III board in the FLUOROSPOT is necessary

• Whether an OCL is necessary see page 1-1

Configuration

In the FLUOROSPOT SYSTEM CONFIGURATION (see page 1-4) set the menu point

”HCC type” to ”AGFA-MCL-4 or AGFA-MCL-3”.

Supported formats see page 2-20

If the FLUOROSPOT H/HK dedicated LUT (OEM 101 L UT) in t he MG 3 000 is c onfigur ed

the monitor image impression rather coincides with the film.

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 10 of 22 Siemens AG

Rev. 10 12.96 TD AX 5 Medical Engineering

Page 21

Connection of the camera 2 - 11

FLUOROSPOT H/HK TRANSITION PANEL

HCC IMAGE

Fig. 14

.

J26

J26

J25

SK 111

J32

AUX 2

J22 J23 J24

AC DIST KEYBOARD REMOTE

J27 J28

SERVICE

AUX 1

J29

HCC CTL

Siemens AG Register 3 RX41-020.031.01 Page 11 of 22 FLUOROSPOT H/HK

Medical Engineering Rev. 10 12.96 TD AX 5

Page 22

2 - 12 Connection of the camera

KODAK XLP / 1120 / 2180 2

Example with OCL.

FLUOROSPOT H/HK

KODAK XLP / 1120 2180

TRANSITION

PANEL

DATA PORT 1

COMMAND PORT 2

*Parts of the Optical Camera Link

Hardware requirements

*

*

Duplex Optical

Fiber Cable *

CAM.

MOD.

*

J

*

Host

MOD.

J

*

*

• HCC digital board or VIDEO OUT III board in the FLUOROSPOT is necessary

• Whether an OCL is necessary see page 1-1

Configuration

In the FLUOROSPOT SYSTEM CONFIGURATION (see page 1-4) select a KODAK hardcopy driver depending on the firmware of the KODAK hardcopy camera. (see page 1-5)

Supported formats see page 2-21

The selectable formats are also depending from the memory-expansion of KODAK camera.

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 12 of 22 Siemens AG

Rev. 10 12.96 TD AX 5 Medical Engineering

Page 23

Connection of the camera 2 - 13

NOTICE

FLUOROSPOT H/HK TRANSITION PANEL

HCC IMAGE

Fig. 15

J26

J26

J25

SK 111

J32

AUX 2

J22 J23 J24

AC DIST KEYBOARD REMOTE

J27 J28

SERVICE

AUX 1

J29

HCC CTL

Fig. 16 Fig. 17

If ”CURVE SHAPE 4” is selected in the KODAK XLP or 1120 or

2180 camera, the monitor image impression largely coincides

with the film.

Siemens AG Register 3 RX41-020.031.01 Page 13 of 22 FLUOROSPOT H/HK

Medical Engineering Rev. 10 12.96 TD AX 5

Page 24

2 - 14 Connection of the camera

DU PONT LINX-NET 2

Example with OCL.

LINX-NET

SID-BOX

HCC

connection

adapter

*Parts of the Optical Camera Link

**Parts of the LINX-Net

Hardware requirements 2

not used

**

HOST- CONTR.

*

*

CAM.

MOD.

Duplex Optical

Fiber Cable *

*

FLUOROSPOT H/

TRANSITIO

N

J

*

Host.

MOD.

J

*

*

• HCC digital board or VIDEO OUT III board in the FLUOROSPOT is necessary

• Whether an OCL is necessary see page 1-1

Configuration 2

In the FLUOROSPOT SYSTEM CONFIGURATION (see page 1-4), set the menu point

”HCC type” to ”DIGICAM / LINX NET 2”.

Supported formats see page 2-21

The selectable formats are also depen ding from the memory-expansi on of DIGICAM / DU

PONT cameras.

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 14 of 22 Siemens AG

Rev. 10 12.96 TD AX 5 Medical Engineering

Page 25

Connection of the camera 2 - 15

FLUOROSPOT H/HK TRANSITION PANEL

HCC IMAGE

Fig. 18

.

J26

J26

J25

SK 111

J32

AUX 2

J22 J23 J24

AC DIST KEYBOARD REMOTE

J27 J28

SERVICE

AUX 1

J29

HCC CTL

Other notes

The DU PONT laser camera and DIGICAM are identical in design.

KONICA LI10A

Siemens AG Register 3 RX41-020.031.01 Page 15 of 22 FLUOROSPOT H/HK

Medical Engineering Rev. 10 12.96 TD AX 5

Page 26

2 - 16 Connection of the camera

KONICA LI10A 2

Example with OCL

FLUOROSPOT H/HK

TRANSITION

KONICA LASER

IMAGER LI 10A

KEY

PAD

*

CAM

MOD

*

*

J 29

*

HOST

MOD.

PANEL

J 26

*

*

* Parts of the Optical Camera Link (OCL)

Example without OCL

**

KONICA LASER

IMAGER LI 10A

KEY

PAD

MSP 12**

J1HSTCNT

Fiber Optical Cable

J3Host

Duplex Optical

Fiber Cable*

FLUOROSPOT H/HK

TRANSITION

PANEL

J 29

J 26

DataCable

** Parts of Konica installation kit

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 16 of 22 Siemens AG

Rev. 10 12.96 TD AX 5 Medical Engineering

Page 27

Connection of the camera 2 - 17

FLUOROSPOT H/HK TRANSITION PANELL

J26

J26

HCC IMAGE

J25

SK 111

Fig. 19

KEYPAD FLUOROSPOT

J1 HSTCNT

J3 HOST

MSP 12

J32

AUX 2

LINE

J22 J23 J24

AC DIST KEYBOARD REMOTE

J27 J28

SERVICE

AUX 1

J29

HCC CTL

Connection Panel Konica Laser

VIDEO2

VIDEO1

CONT2

CONT1

VIDEO4

VIDEO3

CONT4

CONT3

Q7

J1 J2

J3

J4

Command port Data port

Hardware requirements

• HCC digital board or VIDEO OUT III board in the FLUOROSPOT is neces sary

• Whether an OCL is necessary see page 1-1

Configuration 2

In the FLUOROSPOT SYSTEM CONFIGURATION (see page 1-4), set the menu point

”HCC type” to ”KONICA-LI10A-2””.

Supported formats see page 2-22

The configuration of the LI 10A includes a special FL-H LUT.

With this LUT the monitor image impression rat her coincides with the film.

Siemens AG Register 3 RX41-020.031.01 Page 17 of 22 FLUOROSPOT H/HK

Medical Engineering Rev. 10 12.96 TD AX 5

Page 28

2 - 18 Connection of the camera

FUJI FL-IM 3543 2

Example with OCL.

FLUOROSPOT H/HK

FUJI FL-IM 3543

**

*

*Parts of the Optical Camera Link (OCL)

**Part of the Fuji Multi Formatter

FUJI MULTI

FORMATTER

**

*

CAMERA

MODULE

J29

*

HOST

MOD.

*

Duplex Optica

Fiber Cable*

J26

*

*

Hardware requirements 2

• HCC DIGITAL BOARD or VIDEO OUT III board in the FLUOROSPOT is necessary

• Whether an OCL is necessary see page 1-1

Configuration 2

In the FLUOROSPOT SYSTEM CONFIGURATION (see page 1-4), set the menu point

”HCC type” to ”FUJI-3543-P2” for portrait or ”FUJI -3543-L2” for landscape.

Supported formats see page 2-21

The configuration of the Fuji FL-IM 3543 includes a special FL-H LUT.

With this LUT the monitor image impression rather coincides with the film.

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 18 of 22 Siemens AG

Rev. 10 12.96 TD AX 5 Medical Engineering

Page 29

Connection of the camera 2 - 19

FLUOROSPOT H/HK TRANSITION PANELL

HCC IMAGE

Fig. 20

J26

J26

J25

SK 111

J32

AUX 2

FUJI Multiformatter

J22 J23 J24

AC DIST KEYBOARD REMOTE

J27 J28

SERVICE

AUX 1

J29

HCC CTL

Data cable

from OCL

Siemens AG Register 3 RX41-020.031.01 Page 19 of 22 FLUOROSPOT H/HK

Medical Engineering Rev. 10 12.96 TD AX 5

Page 30

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 20 of 22 Siemens AG

Rev. 10 12.96 TD AX 5 Medical Engineering

2 - 20 Connection of the camera

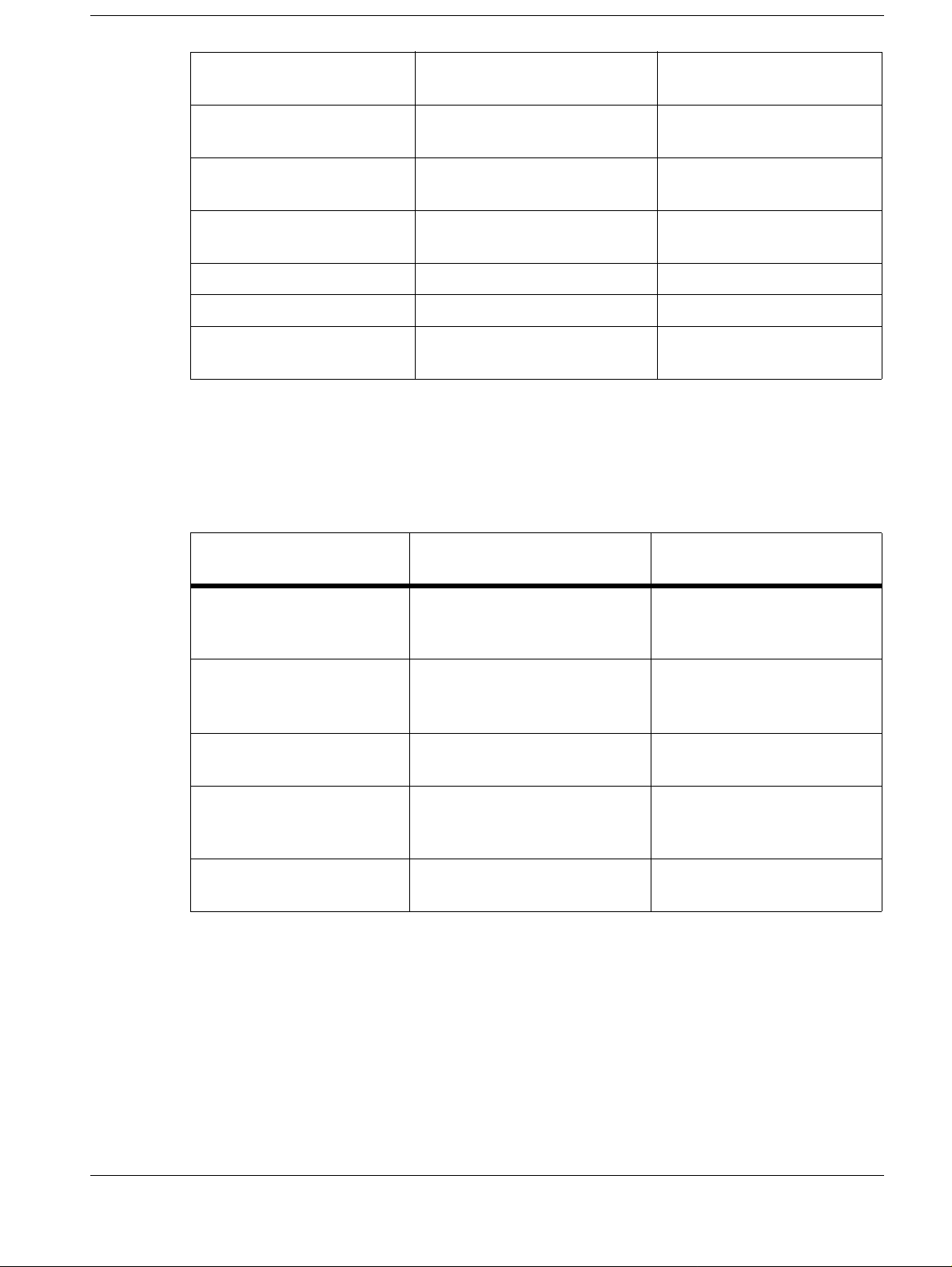

Sizes and Formats for FLUOROSPOT H formats (images/filmsh e et )

driver name camera size

"3M952-HCI-2" 3M952 (Plus) 14x17

14x17c

3M959/969-HCI-2 3M959 (XL) 14x17

3M969 (HQ) 14x17c

3M959/969-SHPT-2 3M959 (XL) 14x17

3M969 (HQ) 14x17c

AGFA-MCL-3 MCL(solo, MIN, 14x17

+ Spoler) 14x17c

1 2 4 6 8 9 12 15 16 20

1246

24812

1246

24812

1246-9 12 15 16 20 2 + 6 6 + 2 2 + 12 12 + 2 20s

24812-18 24

1246-912-16 20

24812-18 24

--12---

--24--12 15

--

--24---

20

-

---

---

4 + 12 12 + 4

mixed formats

--

Camera driver and supported formats

40s

MG3000+LR3300

AGFA-MCL-4 MCL(solo, MIN, 14x17

+ Spoler) 14x17c

MG3000+LR3300 14x11

14x11c

8x10

8x10c

KODAC-XLP-3 Kodak XLP, 14x17

Kodak 1120 14x17c

1246-912-16 20 2 + 8 8 + 2 3 + 4 4 + 2

24812-18 24

1246-91215-20 3 + 2 2 + 4

24812-18 24

1246-9

24812-18

1246-912151620

24812-18 24

---

--16 20 4 + 4

--

----

---

4 + 16 16 + 4 6 + 8 8 + 4

6 + 4 4 + 8

8 + 8

-

(CPDI 2.2)

KODAK-XLP-4 KODAK-XLP 14x17

(CPDI 2.3) 14x17c

11x14

11x14

14x14

14x14c

1 2 4 6 8 9 12 15 16 20

2 4 8 12161824- - 12468 9 12- - 2 4 8 12161824- - 12468 9 12- 162 4 4 12161824- - -

Page 31

Siemens AG Register 3 RX41-020.031.01 Page 21 of 22 FLUOROSPOT H/HK

Medical Engineering Rev. 10 12.96 TD AX 5

Connection of the camera 2 - 21

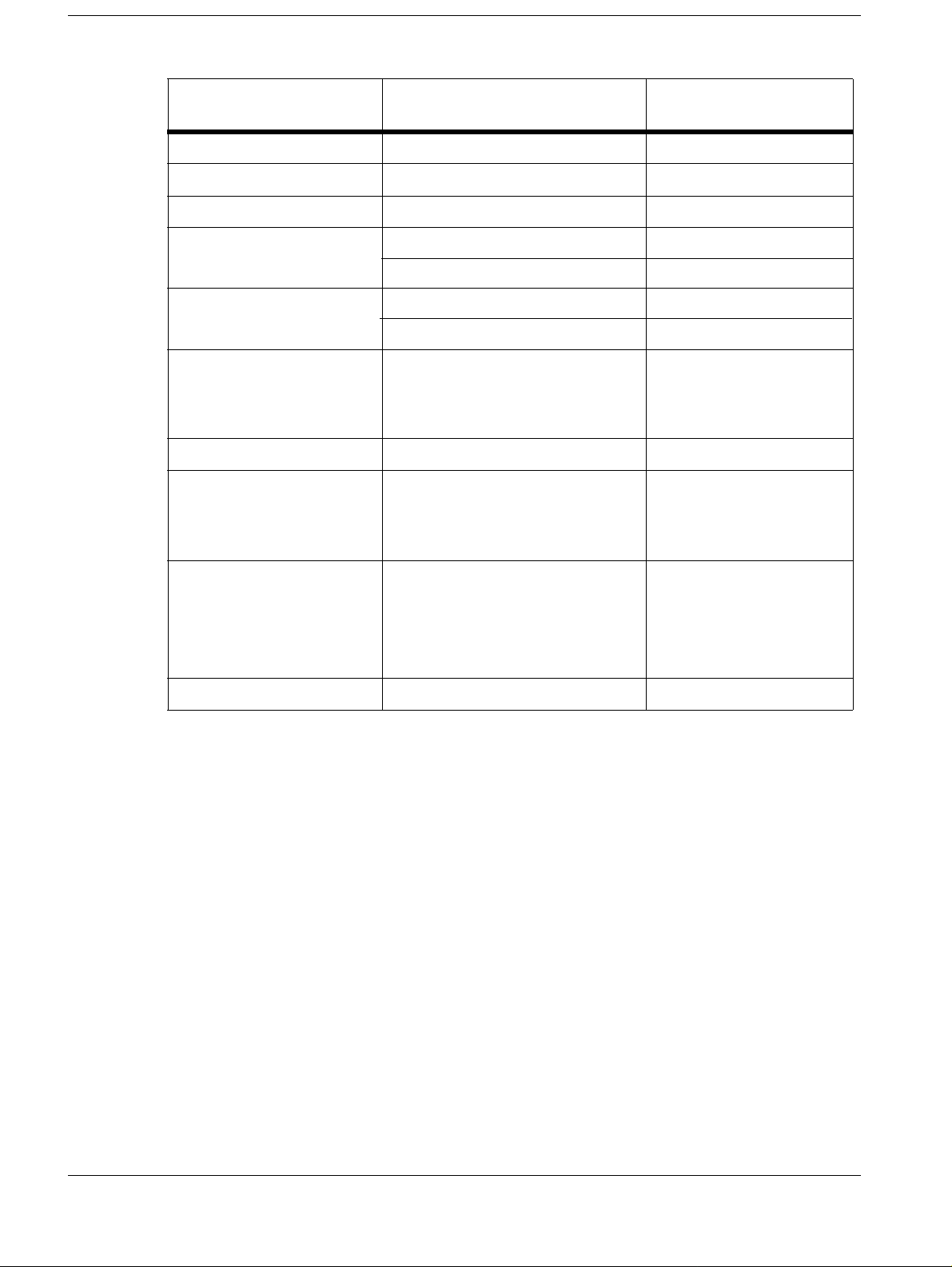

formats (images/filmsheet)

KODAK-2180/1120-2 KODAK 2180. 14x17

1 2 8 6 8 9 12 15 16 20

KODAK 1120 14x17c 24812161824 - - -

(CPDI 2.3) 11x14 124 6 8 912 - - -

11x14c 24812161624 - - -

8x10 124 6 - - - - - -

8x10c 24812 - - - - - -

14x14 124 6 8 912 -16 -

14x14c 24812161824 - - -

DIGICAM/LINXNET 2 DIGICAM 14x17 1 2 4 6 8 9 12 15 16 20 1 + 8 2 + 12 6 + 1 9 + 2 12 + 2

LINXNET 14x17c 2 4 8 12 16 18 24 - - - 2 + 16 - 12 + 2 18 + 4

LP400

FUJI-3543-P2 Fuji FL-IM3543 14x17

14x17c

FUJI-3543-L2 Fuji FL-IM3543 14x17

14x17c

1246

24812

1249

24818

12 15

--

--24---

----16-

------

20 1 + 2 1 + 6 6 + 12 9 + 8

2 + 4 2 + 12

2 + 3 3 + 2 2 + 8 8 + 2

4 + 6 6 + 4

-

4 + 16

16 + 4

KonikaLI10A-2 Konika LI10A 14x17 1 2 4 6 8 9 12 15 16 20 2 + 3 3 + 2 2 + 6 6 + 2 2 + 9 9 + 2 12s

14x17c 2 4 8 12 16 18 - - - - 4 + 6 6 + 4 4 + 12 12 + 4 - - 24s

11x14 1 2 4 6 8 9 12 15 16 20 2 + 3 3 + 2 2 + 6 6 + 2 2 + 4 4 + 2 -

11x14c 2 4 8 12 16 18 - - - - 4 + 6 6 + 4 4 + 12 4 + 12 4 + 8 8 + 4 -

14x14 1 2 4 6 - 9 12 15 16 20 - - - - - - 12s

14x14c 2 4 8 12 - 18 - - - - - - - - - - 24s

Page 32

2 - 22 Connection of the camera

This page intentionally left blank.

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 22 of 22 Siemens AG

Rev. 10 12.96 TD AX 5 Medical Engineering

Page 33

Service 3

Hardcopy Driver Modification 3

The following problem can be avoided by applying the 3rd disk of the VD12 Software:

Some types of Laser Cameras will l ock, wh en the modality selects a film si ze, which is not

available in the camera. The customer can make a mistake when selecting a film size at

the Fluorospot, which is not supported by the camera.

The following procedure is also described in the file readme.bat on the 3rd disk:

1. Put DISK 3 of the FLH Installation floppy set into your Service PC.

2. Select drive a:.

3. Run the executable file CUSTOM.EXE...

4. Select the original HCC driver. Look at the ta ble below!

5. Answer the questions about the supported fil m size(s) with yes and the

unsupported film size(s) wi th no [n].

6. If you gave a wrong answer, run CUSTOM.EXE once more.

7. Then boot the FLUOROSPOT with your Service PC (ST320) connected.

3 - 1

8. At the Service PC, enter the password to get to th e MAIN Menu. Proceed to the S/

W Installation Menu, then to the RESTORE Menu.

9. Remove the floppy from the Service PC and place it in the FLH floppy drive.

10. Use the RESTORE HCC CONFIGURATION FILES function to copy the new

HCC driver to the FLH. Go back to the S/W Installati on Menu, and select

SYSTEM CONFIGURATION.

11. From the SYSTEM CONFIGURATION Menu, select CHANGE

CONFIGURATION.

12. Choose the HCC driver "CUSTOM" in the FLUOROSPOT configuration menu.

13. Save the new configuration.

14. Switch the FLUOROSPOT off and on again for the new driver to take eff ect.

Tab. 1 Correlation between HCC driver in FLH configuration<>name.def on disk 3

HCC Config Name Disk 3 Driver Name

3M952-HCI-2 3M952B.DEF

3M959/969-HCI-2 3M959B.DEF

3M952-SHPT2 952SHPTB.DEF

3M959/969-SHPT2 959SHPTB.DEF

AGFA-MCL-3 AGFMCL1B.DEF

AGFA-MCL-4 AGFMCL2B.DEF

DIGICAM/LINXNET DIGILNXB.DEF

FUJI-3543-L2 FU3543LB.DEF

Siemens AG Register 3 RX41-020.031.01 Page 1 of 12 FLUOROSPOT H/HK

Medical Engineering Rev. 07 12.96 TD AX 5

Page 34

3 - 2 Service

FUJI-3543-P2 FU3543PB.DEF

KODAK-XLP-3 KODXLP1B.DEF

KODAK-XLP-4 KODXLP2B.DEF

KODAK2180/1120-2 KOD2180B.DEF

KODAK2180/1120-3 K OD2180C. D EF

KONICA-LI10A-2 KOLI10AA.DEF

GENERIC-DIGITAL-2 GENERICB.DEF

ANALOG CAMERAS

AGFA- CR2050-1 AGF2050.DEF

Analog-2 ANALOGB.DEF

MI-11-2 MI11B.DEF

Service Tools for Tracing the SPCI/SPDI Interface 3

There are two tools for troubleshoot ing the Command and DAT A tra nsmission t o and from

the camera.

The first tool is a cheap tool to check the drivers of the Optical Camera Link (OCL) modules, the fiber optic cables, and the hardware signals on the DATA and CONTROL path.

The tool is called Linktest and can be ordered as a spare part with the part number

46 92 177. It consists of two ma in p ar ts :

1. Tester for the Control Interface 3

RS 232 Check Tester

Note: ( only pin 2 and pin 3 are used )

female male

TXD and RXD are monitored via Leds

pin2

pin3

RS232 Check Tester

TD

RD

8-pin modular socket:

1 NC

2 NC

3 NC

4 GND

5 NC

6 RXD

7 TXD

8 +5V

The Control Interface of the Fluorospot can be tested with the help of the Loop Back

Connector, which is part of the CTX accessories. The Loop Back makes a connection

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 2 of 12 Siemens AG

Rev. 07 12.96 TD AX 5 Medical Engineering

Page 35

Service 3 - 3

between pin 2 and 3, so that one can test the control interface of the FLH by starting the

Loop Back Test in the service menu Interface Tests.

The Check Tester can be used to display the RXD and TXD signals.

The Loop Back Connector can be plugged into transition panel of the FLH or into the

SPCI output of the OCL on camera side. The loop back can not be used to check the

Hirschmann modules, because they need the power supply from the camera.

2. Linktest Board 3

The link test board consists of three independent functional units:

a) 13 LED pairs to display the s tatus of the 13 RS485 lines of the par allel camera in terface

SPDI:

DATA0 to DATA7, PAR, CLOCK, MODSEL and DAREQ, REP.

This display functions even without power supply via the OCL fibre optic link.

b) 2 LED pairs to monitor the RS232 lines of the SPCI interface:

RXD and TXD.

Functions only if used with the OCL fibre optic link.

c) Test signal generator: In connection with a short-circuit cable, it actively tests the function of the OCL fibre optic link FOC path in both directions (fla shing red and green SPCI

TEST LED); for this purpose, press the TEST-ON key. No host and camera connection is

necessary for the test.

For functional testing of the SPDI drivers, press the DAREQ-ON key (functions only if

used with the OCL fibre optic link). The link test board is fully transparent for the dat a of

the SPCI and SPDI interface if neither the TEST-ON key nor the DAREQ-ON key has

been pressed! Therefore, it may remain inserted in the cable during normal operation of

the camera interface.

LED circuits:

SPCI: SPDI:

+/- 8 to 13 VDC

470 Ohm

RXD

DATA0

470 Ohm

red

Siemens AG Register 3 RX41-020.031.01 Page 3 of 12 FLUOROSPOT H/HK

Medical Engineering Rev. 07 12.96 TD AX 5

green

GND

red

green

DATA0

Page 36

3 - 4 Service

LED schematics and pin allocation table:

WP Linktest

Data 0

Data 1

Data 2

Data 3

Data 4

Data 5

Data 6

Data 7

PAR

CLOCK

MODSEL

DAREQ

REP

male

female

SPCI

TEST

ON

SPCI

TEST

RXD

TXD

DAREQ

ON

used for :

SPCI SPDI

Pin allocation table of the link test board:

Female connector Sub-D Male connector Sub-D

1 Shield / GND Shield / GND

2NC NC

3REP REP

4 DAREQ DAREQ

5 MODSEL MODSEL

6 CLOCK CLOCK

7PAR PAR

8DATA7 DATA7

9DATA6 DATA6

10 DATA5 DATA5

11 DATA4 DATA4

12 DATA3 DATA3

13 DATA2 DATA2

14 DATA1 DATA1

15 DATA0 DATA0

16 NC NC

17 NC NC

18 TXD NC/TXD as from update level (Äst) 03 of OPSP

19 RXD NC/RXD as from update level (Äst) 03 of OPSP

20 +5V GND

21 NC NC

22 REP* REP*

23 DAREQ* DAREQ*

24 MODSEL* MODSEL*

25 CLOCK* CLOCK*

26 PAR* PAR*

27 DATA7* DATA7*

28 DATA6* DATA6*

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 4 of 12 Siemens AG

Rev. 07 12.96 TD AX 5 Medical Engineering

Page 37

Service 3 - 5

29 DATA5* DATA5*

30 DATA4* DATA4*

31 DATA3* DATA3*

32 DATA2* DATA2*

33 DATA1* DATA1*

34 DATA0* DATA0*

35 NC NC

36 NC NC

37 GND +5V

• Start of image transfer

The image transfer is initiate d by marking images in postprocessing mode and sendi ng

them from the FLH memory via the hardcopy interfa ce (HCC or Vid Out3 board) with the

button HARDCOPY SINGLE or HARDCOPY MULTI to the laser camera.

• SPCI error

After the job has been started, the FLH communic ates with the laser camera. Film size,

format and other parameters are sent t o the camera, if the camera is re ady. If not, the

FLH displays the message ’camera does not seem to be connected’.

• SPDI error

When there is no problem in communication via SPCI i nterface and the camera is ready

for data transmission - the camera rece ived the necessary parameters from the FLH- ,

the FLH waits for the signal DATA REQUEST on the SPDI from the camera. I f the

camera does not request any data within a ce rtain time (less than 1 minute) or i f there is

a timing error, the FLH display s the message ’error in data transmission’. The FL H

tries to resend the HCC background job after a certain timeout.

• Image transmission

The data transfer begins, when the communicati on via SPCI works and when the

parameters for the camera has been transmi tted from the FLH. After this handshake, the

image is sent via SPDI to the Laser Camera, when the following timing is ok:

SPDI Diagram

Siemens AG Register 3 RX41-020.031.01 Page 5 of 12 FLUOROSPOT H/HK

Medical Engineering Rev. 07 12.96 TD AX 5

Page 38

3 - 6 Service

The signals can be measured with 5V level on the Vid Out 3 board as follows:

Camera signal DATA REQUEST U1200.3

FLH CLOCK U1211.9

FLH MOD SELECT U1211.7

FLH PARITY EVEN U1211.1

Check of the OCL 3

Status LED green: Hardware is ok

Status LED red blinking:

Cause:

- fibre optic cable may be defective

- the OCL box on the other side may be

defective or without mains

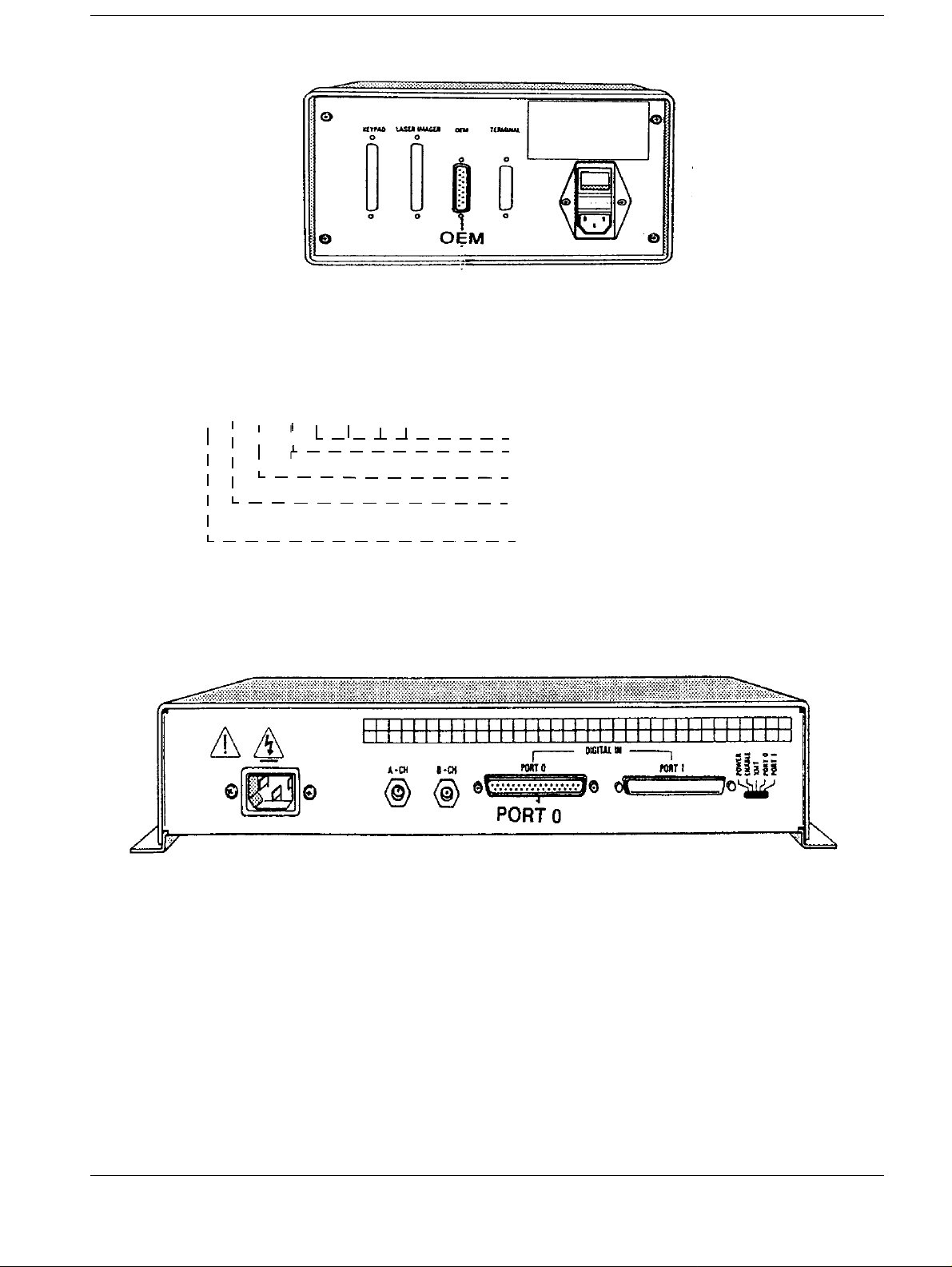

Camera Interface Test System 3

• Purpose

The CITS (Camera Interface Test System) enab les the user to record communications

between Laser Cameras and Imaging Systems and to look into the SPCI and SPDI

communication.

It records the transmissio n of image information and contro ls information. It monitors the

conformity in respect to the i nterface protocols and detects errors within the syntax of

the control commands.

Digital Laser Cameras are simulated by ut ilizing their own control commands (Camera

Mode).

Previously recorded information can again be analyzed by means of the “Postanalys is

Mode“.

Status LED

Function

Opto

• Elements

The tool consists of a box with several connectors and some LEDs. Cables are included

to connect this box to:

- Line Voltage, Service PC, SPCI In terface, SPDI Interface

• Application

The CITS box is controlled by the CAMWIN software, which runs on a Service PC,

connected to the control input of the box. The software is a Windows applicati on.

• Result

The result of listening the SPCI and SPDI int erface is stored in a *.ctl fi le. This file looks

like the following.

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 6 of 12 Siemens AG

Rev. 07 12.96 TD AX 5 Medical Engineering

Page 39

Service 3 - 7

******* CITS USP/SPCI/SPDI-PROTOCOL-A NALYSER VERSION 0.4 *******

PARAMETERS OF RECORDING:

CAMERA-TYPE: 3M M9 59 XL

MODALITY-TYPE:Fluorospot H

DATE OF RECORDING:05/20/1994

TIME OF RECORDING:15:47:58

PARAMETERS OF ANALYSIS :

MODE: POST-ANALYSIS OF LISTENER

RECORDING:ALL

DATE OF ANALYSIS:05/24/1994

TIME OF ANALYSIS:10:32:00

************************ START OF ANALYSIS ************************

15:48:11,426 Mod: 2h; STXStart of TeXt

15:48:11,430 Mod: xa1; Select serial control port 1

15:48:11,444 Mod: 3h; ETXEnd of TeXt

15:48:11,451 Cam: 13h; RNR0Receiver Not Ready 0

15:48:11,456 Cam: 11h; RR0Receiver Ready 0

15:48:11,491 Cam: 2h; STXStart of TeXt

15:48:11,495 Cam: xa1; Serial control port 1 selected

15:48:11,509 Cam: 3h; ETXEnd of TeXt

15:48:11,515 Mod: 13h; RNR0Receiver Not Ready 0

15:48:11,519 Mod: 11h; RR0Receiver Ready 0

15:48:11,555 Mod: 2h; STXStart of TeXt

15:48:11,559 Mod: ?\; Query camera status

15:48:11,569 Mod: 3h; ETXEnd of TeXt

15:48:11,575 Cam: 14h; RNR1Receiver Not Ready 1

15:48:11,580 Cam: 12h; RR1Receiver Ready 1

15:48:11,612 Cam: 2h; STXStart of TeXt

15:48:11,617 Cam: \>51-0010210; Camera status

15:48:11,671 Cam: 3h; ETXEnd of TeXt

15:48:11,676 Mod: 14h; RNR1Receiver Not Ready 1

15:48:11,681 Mod: 12h; RR1Receiver Ready 1

15:48:11,695 Mod: 2h; STXStart of TeXt

15:48:11,700 Mod: ?/; Query exposure status

15:48:11,708 Mod: 3h; ETXEnd of TeXt

15:48:11,716 Cam: 13h; RNR0Receiver Not Ready 0

15:48:11,719 Cam: 11h; RR0Receiver Ready 0

.

*********************** ANALYSIS-STATISTICS ***********************

CLOSEDATE OF RECORDING:05/24/1994

CLOSETIME OF RECORDING:10:40:25

COUNT OF DETECTED

RTC-INTERRUPTS:1290

COUNT OF SUPERNUMERARY

RTC-INTERRUPTS:265

************************* END OF ANALYSIS *************************

• Order information

The CITS (without PC) can be ordered with Siemens part number 99 00 531. CAMWIN

software is included.

Siemens AG Register 3 RX41-020.031.01 Page 7 of 12 FLUOROSPOT H/HK

Medical Engineering Rev. 07 12.96 TD AX 5

Page 40

3 - 8 Service

Hardcopy Error Messages 3

The hardcopy errors, displayed on the Fl uorospot H monitor, are initiated by the hardcopy

cameras. The error codes are only converted in the Fluorospot to the error codes, which

originally were specified for the DIGICAM Laser camera.

For error interpretation, detailed information can be obtained by means of the camera

error code contained in the camera documentation of the manufactur er.

FL-H/HK display 3M laser

713

811

10 12

11 10

13 20, 21

14 22-28

17 29-31, 37

17 40-42, 79-85

19 14-16

24 54

31 39, 56-59

35 6

41 96

42 38, 47-53

42 72, 76-78

43 92-95, 98

50 18

52 17

53 33

57 1, 2, 5, 7, 9, 19, 43-46

57 60-71

57 87- 91, 97

69 55, 73-75

69 86

70 99

80 3

82 4

86 0,8

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 8 of 12 Siemens AG

Rev. 07 12.96 TD AX 5 Medical Engineering

Page 41

Service 3 - 9

KODAK XLP AGFA MCL-LASER

FL-H/HK KODAK XLP FL-H/HK MCL

00 05, 29, 35, 39, 54 10 30

00 59, 65, 73, 74 11 33

07 02 18 20, 41, 47, 49

08 04 35 05, 06, 17, 18

10 01 50 32

11 03 52 31,44

11 09 57 45

34 25 70 07

35 81 83 1, 08, 42, 43

50 06 84 02, 03, 04, 40, 46

57 62, 64 86 19

80 55

83 31-34, 40, 53

Siemens AG Register 3 RX41-020.031.01 Page 9 of 12 FLUOROSPOT H/HK

Medical Engineering Rev. 07 12.96 TD AX 5

Page 42

3 - 10 Service

KONICA LI-10A

FL-H / HK KONICA Laser

7 301B

301C

8 3065

10 3019

301A

11 301E

18 300A

300B

21 4180

34

35 510E

5125

35

44 4181

4190

50 3032

69

73 301F

3020

3021

3023

3024

3028

300C

300D

3014

3015

3016

3018

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 10 of 12 Siemens AG

Rev. 07 12.96 TD AX 5 Medical Engineering

Page 43

Service 3 - 11

FL-H / HK KONICA Laser

75

78 3035

3036

3037

3038

80

83

85 2903

88

92 303C

93 303D

96

99

FUJI FL-IM 3543

FLUOROSPOT H/HK FUJI-Laser

06 01, 02, 23, 24, 52, 53

10 13

11 12

18 06, 15-21, 51, 54-61

31 11

52 51, 61

57 22,25

80 05

83 07

97 10, 14

Siemens AG Register 3 RX41-020.031.01 Page 11 of 12 FLUOROSPOT H/HK

Medical Engineering Rev. 07 12.96 TD AX 5

Page 44

3 - 12 Service

This page intentionally left blank.

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 12 of 12 Siemens AG

Rev. 07 12.96 TD AX 5 Medical Engineering

Page 45

Abbreviations 4

CPU Central Processing Unit

CTR Control

DEIB Data External Interface Box

FOC Fiber Opti cal Cable

HCC Hardcopy Camera

HCI Host Control Interface

KEIB Keypad External Interface Box

LUT Lookup Table

MCL Matrix Laser Camera

MFRI Multi Format Receiving Interface

MG Medical Gateway

MIN Matrix Image Network

OCL Optical Camera Link

OEM Original Equipment Manufacturer

PC Personal Computer

SHPT Siemens Host Protocol Translator

SID-BOX Scanner interface Device Box

UKEIB Universal External Interface Box

4 - 1

Siemens AG Register 3 RX41-020.031.01 Page 1 of 2 FLUOROSPOT H/HK

Medical Engineering Rev. 02 12.96 TD AX 5

Page 46

4 - 2 Abbreviations

This page intentionally left blank.

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 2 of 2 Siemens AG

Rev. 02 12.96 TD AX 5 Medical Engineering

Page 47

Changes to Previous Version 5

All pages: New layout.

5 - 1

Chap.0 Page 1:

Page 2,3,4:

Chap.1 Page 2: Chap "Units without OCL" expanded.

Chap.2 Page 20/21:

Page22,23,24

Chap.3 New.

Chap.5 Page 1: Updated.

Date, Revision level changed.

Revision level table, table of contents updated.

Tables expanded.

New.

TD AX 5 / Blum

TD AX 1 / Biedermann

Siemens AG Register 3 RX41-020.031.01 Page 1 of 2 FLUOROSPOT H/HK

Medical Engineering Rev. 01 12.96 TD AX 5

Page 48

5 - 2 Changes to Previous Version

This page intentionally left blank.

FLUOROSPOT H/HK Register 3 RX41-020.031.01 Page 2 of 2 Siemens AG

Rev. 01 12.96 TD AX 5 Medical Engineering

Loading...

Loading...