Page 1

FUJI-Reader

Service Manual

SP

Checks, Replacement and Adjustment of Parts

© Siemens AG 2003

The reproduction, transmission or

use of this document or its contents

is not permitted without express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

English

Print No.: SPB7-420.840.53.01.02 Doc. Gen. Date: 01.03

Replaces: n.a.

Page 2

CR-IR347/CR-IR347P

Service Manual

Checks, Replacement and Adjustment

of Parts (MC)

Page 3

Contents Maintenance Checks, Replacement and Adjustment of Parts

0.1

CR-IR347 Service Manual – Contents

Checks, Replacement and Adjustment of Parts (MC)

1. Check/Adjustment Procedures for Each Unit............................................................ MC-2

2. Table of Contents ......................................................................................................... MC-4

3. Removing and Installing the Covers .......................................................................... MC-8

4. Removing and Installing the Cassette Set Unit......................................................... MC-10

4.1 Cassette Set Unit ............................................................................................... MC-10

4.2 Shutter ................................................................................................................ MC-12

4.3 Cassette Ejection Sensor (SK1) ....................................................................... MC-14

4.4 Barcode Reader (BCRK1).................................................................................. MC-16

4.5 Pulling Out the Tray ........................................................................................... MC-20

4.6 Cassette Hold Solenoid (SOLK1) ..................................................................... MC-26

4.7 Cassette Hold Sensor (SK3) ............................................................................. MC-32

4.8 Claw Guide Assembly ....................................................................................... MC-34

4.9 Cassette IN Sensor (SK2) .................................................................................. MC-40

4.10 Rubber Roller ..................................................................................................... MC-50

4.11 Guide Plate ......................................................................................................... MC-52

4.12 Guide Stoppers .................................................................................................. MC-64

4.13 Movable Guides ................................................................................................. MC-66

5. Removing and Installing the IP Removal Unit ........................................................... MC-74

5.1 IP Removal Unit.................................................................................................. MC-74

5.2 IP Leak Valve (SVL1).......................................................................................... MC-78

5.3 Suction Cup HP Sensor (SL1)........................................................................... MC-80

5.4 Timing Belt (for IP Conveyance)....................................................................... MC-86

5.5 Guide Plate A...................................................................................................... MC-90

5.6 Rubber Rollers C and D..................................................................................... MC-92

5.7 Rubber Roller (Large) ........................................................................................ MC-94

5.8 Guide Plate D...................................................................................................... MC-96

5.9 Guide Plates B and C......................................................................................... MC-98

5.10 Supports (for IP Removal Arm) ........................................................................ MC-100

5.11 Suction Cups ......................................................................................................MC-104

5.12 IP Suction Pump (PL1) ...................................................................................... MC-108

5.13 Inch/Metric Sensor (SL4) ...................................................................................MC-110

5.14 Suction Sensor (SL5)......................................................................................... MC-112

5.15 Receiver Rollers .................................................................................................MC-114

5.16 Guide Plates E, F, and G ................................................................................... MC-118

5.17 Suction Cup Driving Motor (ML1) ..................................................................... MC-120

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.1

Page 4

Contents Maintenance Checks, Replacement and Adjustment of Parts

5.18 Timing Belt (for Suction Cup Drive) .................................................................MC-122

5.19 Shaft (for Suction Cup Drive)............................................................................ MC-124

5.20 IP Removal Unit Upper Assembly ....................................................................MC-128

5.21 Rubber Roller A.................................................................................................. MC-130

5.22 IP Transport Motor (ML2) ..................................................................................MC-132

5.23 Shaft (for IP Conveyance) .................................................................................MC-134

5.24 Rubber Roller B.................................................................................................. MC-136

6. Removing and Installing the Erasure Conveyor ....................................................... MC-138

6.1 Erasure Lamp Assembly ...................................................................................MC-138

6.2 Erasure Conveyor ..............................................................................................MC-140

0.2

6.3 Cleaning Roller Assembly................................................................................. MC-144

6.4 Cleaning Rollers................................................................................................. MC-146

6.5 Erasure Lamps (LAMP1-LAMP5) ......................................................................MC-148

6.6 Erasure Thermostatic Switch (TSW2) ..............................................................MC-150

6.7 Erasure Thermostatic Switch (TSW1) ..............................................................MC-152

6.8 Erasure Cooling Fan (FANM1) ..........................................................................MC-154

6.9 Sockets ...............................................................................................................MC-156

6.10 Timing Belts ....................................................................................................... MC-160

6.11 Lamp House Assembly ..................................................................................... MC-164

6.12 Filter ....................................................................................................................MC-166

6.13 Reflection Plate ..................................................................................................MC-168

6.14 IP Transport Motor (MM1) ................................................................................. MC-170

6.15 Rubber Rollers (Upper) ..................................................................................... MC-172

6.16 Light Protect Plates ...........................................................................................MC-174

6.17 Rubber Rollers (Lower) .....................................................................................MC-176

6.18 Guide Plates .......................................................................................................MC-178

7. Pulling Out and Pushing In the Scanner Unit............................................................ MC-182

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.2

Page 5

Contents Maintenance Checks, Replacement and Adjustment of Parts

8. Removing and Installing the Side-Positioning Conveyor......................................... MC-188

8.1 Side-Positioning Conveyor ...............................................................................MC-188

8.2 Grip Release Motor (MN2) .................................................................................MC-192

8.3 Barcode Reader (BCRN1).................................................................................. MC-194

8.4 Side-Positioning Mechanism HP Sensor (SN1) .............................................. MC-196

8.5 Grip Release HP Sensor (SN2) ......................................................................... MC-198

8.6 Cleaning Guide Drive Motor (MN4)................................................................... MC-200

8.7 BCR08A Board ...................................................................................................MC-202

8.8 Side-Positioning IP Sensor (SN3)..................................................................... MC-204

8.9 Cleaning Guide HP Sensor (SN4) .....................................................................MC-206

0.3

8.10 Cleaning Guide Assembly................................................................................. MC-208

8.11 Shaft (for Cleaning Guide Assembly) .............................................................. MC-214

8.12 Guide Plate C...................................................................................................... MC-218

8.13 Timing Belt (for IP Conveyance)....................................................................... MC-220

8.14 Guide Plate G ..................................................................................................... MC-222

8.15 Rubber Rollers (Rear) ........................................................................................MC-226

8.16 Wires (Left Side)................................................................................................. MC-230

8.17 Wires (Right Side) ..............................................................................................MC-234

8.18 Timing Belt (for Side-Positioning Mechanism) ...............................................MC-240

8.19 Shaft (for Grip Release) .....................................................................................MC-246

9. Removing and Installing the Scanning Optics Unit ..................................................MC-250

9.1 Adjusting the Format ......................................................................................... MC-250

9.2 Shading and Sensitivity Corrections ...............................................................MC-254

9.3 Checking for Image Problems ..........................................................................MC-258

9.4 Removing and Installing the Scanning Optics Unit........................................ MC-262

9.5 LD Assembly ......................................................................................................MC-266

9.6 Polygon Assembly ............................................................................................. MC-270

9.7 SYN08A Board.................................................................................................... MC-274

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.3

Page 6

Contents Maintenance Checks, Replacement and Adjustment of Parts

10. Removing and Installing the Subscanning Unit........................................................ MC-278

10.1 Driving-Side Grip Release HP Sensor (SZ2).................................................... MC-278

10.2 Mirror HP Sensor (SZ4) ..................................................................................... MC-280

10.3 Rubber Belt and SUS Belt .................................................................................MC-282

10.4 Kapton® Belt ......................................................................................................MC-284

10.5 Flywheel ..............................................................................................................MC-286

10.6 Subscanning Motor MZ1 (FFM) ........................................................................ MC-288

10.7 PMT08D Board ................................................................................................... MC-292

10.8 PMR08C Board ...................................................................................................MC-296

10.9 Light-Collecting Guide Assembly (for Front Surface) .................................... MC-300

0.4

10.10 Light-Collecting Guide Assembly (for Back Surface) .................................... MC-308

10.11 Light-Collecting Mirror and IP Leading-Edge Sensor (SZ1/SED08D) ........... MC-320

10.12 Glass Guide ........................................................................................................MC-326

10.13 Lower Rubber Rollers........................................................................................ MC-332

10.14 Mirror Driving Motor (MZ4)................................................................................ MC-336

10.15 Driving-Shaft Grip Motor (MZ2) ........................................................................ MC-338

10.16 Driven-Shaft Grip Motor (MZ3).......................................................................... MC-342

10.17 Driven-Side Grip Release HP Sensor (SZ3) .....................................................MC-346

10.18 Subscanning Unit Controller Assembly ..........................................................MC-348

10.19 SCN08D/SCR08D Board ....................................................................................MC-354

10.20 PHV08D Board.................................................................................................... MC-358

11. Removing and Installing the Hard Disk Drive (HDD) ................................................MC-360

11.1 Setting HDD ........................................................................................................MC-361

11.2 Hard Disk Drive (HDD) .......................................................................................MC-362

12. Removing and Installing the Floppy Disk Drive (FDD) ............................................. MC-372

12.1 Setting FDD ........................................................................................................ MC-372

12.2 Floppy Disk Drive (FDD) .................................................................................... MC-372

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.4

Page 7

Contents Maintenance Checks, Replacement and Adjustment of Parts

13. Removing and Installing the Power Supply Unit (JPS-6) .........................................MC-374

13.1 Power Supply Unit (JPS-6) ................................................................................MC-374

13.2 Power Supply Unit Fuses ..................................................................................MC-378

14. Removing and Installing the Monitor ......................................................................... MC-382

14.1 CRT (Monitor) .....................................................................................................MC-382

14.2 Fuse Between Power Supply Unit and CRT ....................................................MC-388

15. Removing and Installing the PC Boards ....................................................................MC-390

15.1 MTH08C Board ...................................................................................................MC-402

15.2 MTH08D Board ...................................................................................................MC-404

15.3 CPU90E Board.................................................................................................... MC-406

0.5

15.4 IMG07B Board ....................................................................................................MC-410

15.5 BSP08A Board.................................................................................................... MC-411

15.6 IMG08M Board ....................................................................................................MC-413

15.7 CPU90F Board (Optional) ..................................................................................MC-414

15.8 LAN90B Board (Optional).................................................................................. MC-416

15.9 HCP08A Board (Optional) ................................................................................. MC-417

15.10 IMG08H Board (Optional) ..................................................................................MC-418

15.11 SNS08C and DRV08A Boards ...........................................................................MC-420

15.12 VOL08A Board.................................................................................................... MC-427

15.13 LED08A Board ....................................................................................................MC-428

15.14 LED08B Board ....................................................................................................MC-428

15.15 BCR08A Board ...................................................................................................MC-429

15.16 SYN08A, PMT08D, PMR08C, SCN08D/SCR08D, and PHV08D boards .......... MC-429

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.5

Page 8

Checks, Replacement and Adjustment of Parts (MC) Control Sheet

Control Sheet

Issue date

10/20/2000 00 New release (FM2732) All pages

05/15/2001 01 Corrections (FM3052) MC - 9, 93, 146, 265, 331

08/30/2001 02 Design changes; measures against noise MC - 25, 91, 93, 95, 130, 131,

08/30/2002 03 Scanning optics unit, HDD, and other MC - 6, 7, 33, 37, 148, 254–261,

Revision number Reason Pages affected

(FM3142) 137, 142-145, 161-162, 173, 177,

information added (FM3476) 261.1–261.4, 262–265,

MC - 1

178, 180, 183, 184, 208-210, 214,

215, 223-225, 227-229, 241, 244,

245, 263, 267, 271, 275, 327,

328, 331, 333, 334, 349-353,

353.1-353.8, 361, 361.1-361.4,

362, 401

265.1–265.8, 275, 293, 297,

356, 357, 359–429

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

MC - 1

Page 9

MC - 2

1. Check/Adjustment Procedures for Each Unit

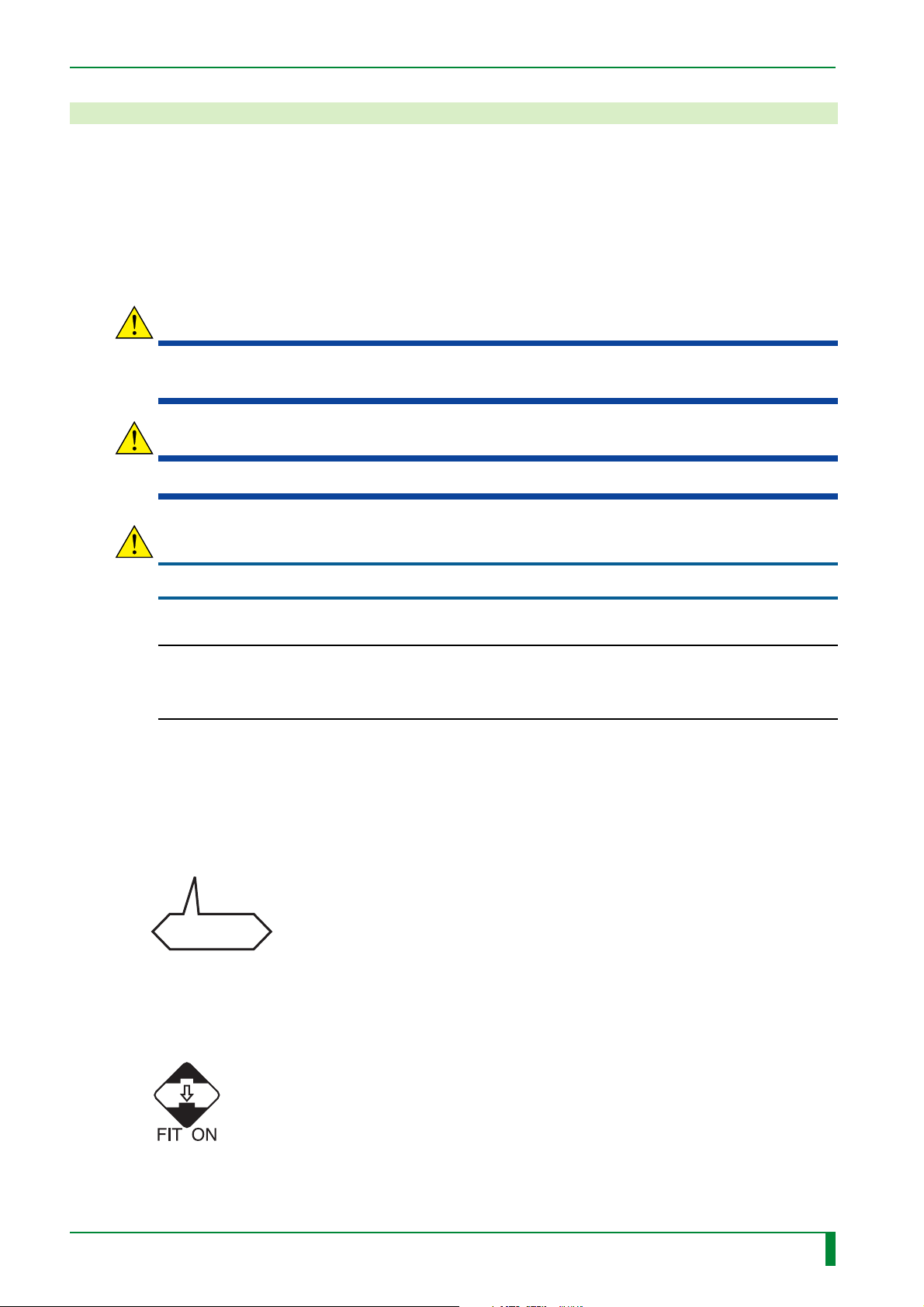

Precautions for Check, Replacement, and Adjustment

In this volume, descriptions are omitted regarding components that do not require special

attention or adjustment during their removal/reinstallation. For removal procedures for such

components, refer to the Parts List Volume.

When performing check/replacement/adjustment procedures on the machine, the following

precautions should be observed.

WARNING

To avoid electric shock hazards, power OFF the machine before performing the

procedures.

WARNING/CAUTION

Observe the warnings and cautions described in the “Safety Precautions.”

CAUTION

Never remove screws to which red paint is applied.

◆

INSTRUCTION

Screws to which yellow paint is applied need to be adjusted at the time of component

installation. When installing a component, follow the specified check/adjustment

procedure.

Some of the illustrations in this volume contain check/adjustment and half-punch indicators

as needed.

For removal and reinstallation, perform the procedures as instructed by such indicators.

• Check/Adjustment indicator: Indicates that it is necessary to check or adjust the

CHECK

◆

installation location when the part or component removed is

to be reinstalled.

This indicator is placed in the illustration that depicts the

procedures for removing the parts and components.

When you see this indicator, refer to its relevant “■ Check/

Adjustment Procedures.”

• Half-punch indicator: Indicates that it is necessary to align the half-punches when

009-058-00

10.20.2000 FM2732 (2)

installing the parts or components.

However, it is not indicated for the half-punches for

improving ease of assembly or preventing erroneous

assembly procedures.

CR-IR347

Service Manual

MC - 2

Page 10

BLANK PAGE

MC - 3

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 3

Page 11

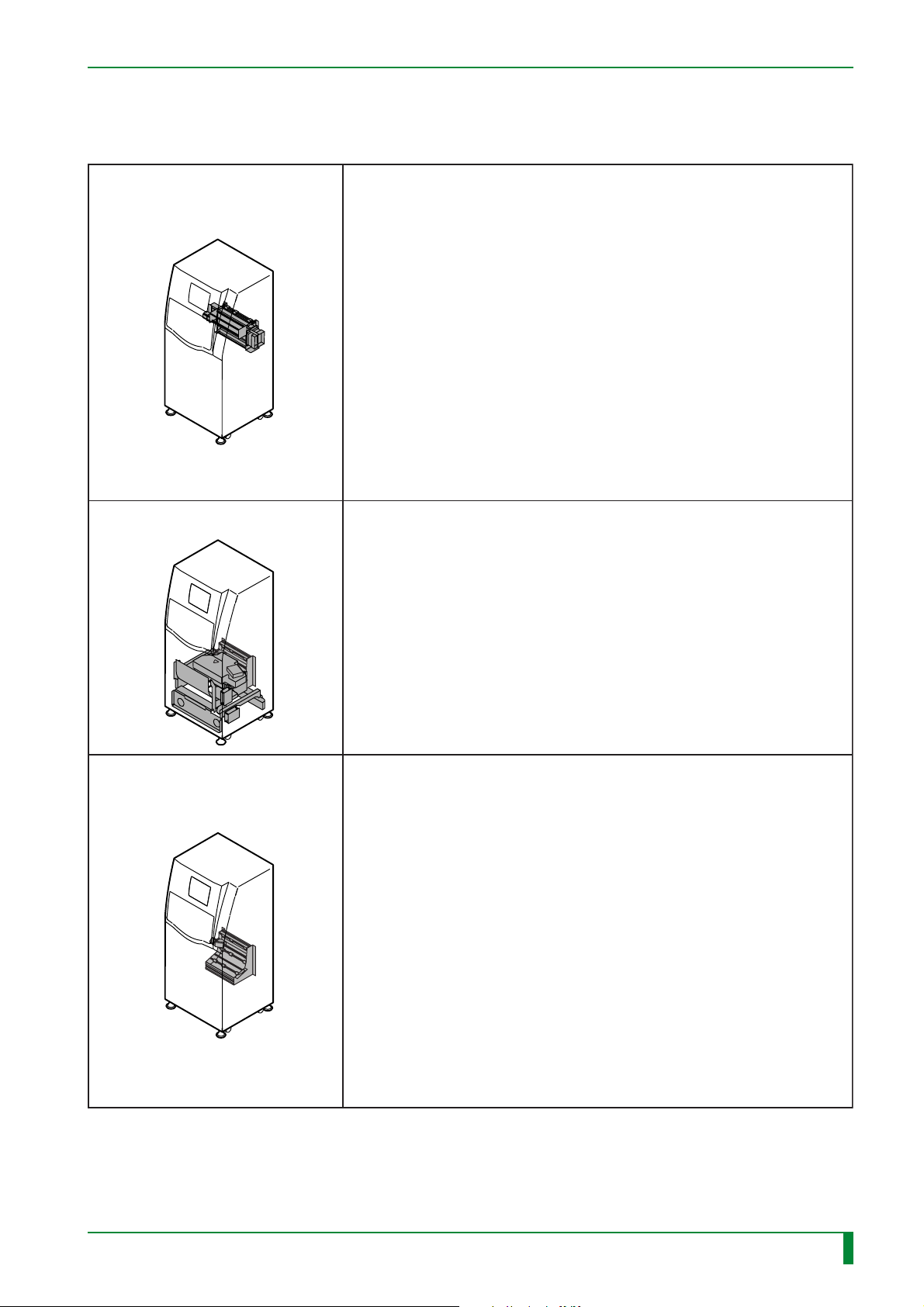

2. Table of Contents

MC - 4

3. Covers

4. Cassette set unit

3. Removing and Installing the Covers MC-8

4. Removing and Installing the Cassette Set Unit MC-10

4.1 Cassette Set Unit MC-10

4.2 Shutter MC-12

4.3 Cassette Ejection Sensor (SK1) MC-14

4.4 Barcode Reader (BCRK1) MC-16

4.5 Pulling Out the Tray MC-20

4.6 Cassette Hold Solenoid (SOLK1) MC-26

4.7 Cassette Hold Sensor (SK3) MC-32

4.8 Claw Guide Assembly MC-34

4.9 Cassette IN Sensor (SK2) MC-40

4.10 Rubber Roller MC-50

4.11 Guide Plate MC-52

4.12 Guide Stoppers MC-64

4.13 Movable Guides MC-66

5. IP Removal Unit

5. Removing and Installing the IP Removal Unit MC-74

5.1 IP Removal Unit MC-74

5.2 IP leak valve (SVL1) MC-78

5.3 Suction Cup HP Sensor (SL1) MC-80

5.4 Timing Belt (for IP Conveyance) MC-86

5.5 Guide Plate A MC-90

5.6 Rubber Rollers C and D MC-92

5.7 Rubber Roller (Large) MC-94

5.8 Guide Plate D MC-96

5.9 Guides Plates B and C MC-98

5.10 Supports (for IP Removal Arm) MC-100

5.11 Suction Cups MC-104

5.12 IP Suction Pump (PL1) MC-108

5.13 Inch/Metric Sensor (SL4) MC-110

5.14 Suction Sensor (SL5) MC-112

5.15 Receiver rollers MC-114

5.16 Guide Plates E, F, and G MC-118

5.17 Suction Cup Driving Motor (ML1) MC-120

5.18 Timing Belt (for Suction Cup Drive) MC-122

5.19 Shaft (for Suction Cup Drive) MC-124

5.20 IP Removal Unit Upper Assembly MC-128

5.21 Rubber Roller A MC-130

5.22 IP Transport Motor (ML2) MC-132

5.23 Shaft (for IP Conveyance) MC-134

5.24 Rubber Roller B MC-136

FR7H30AC.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 4

Page 12

MC - 5

6. Erasure conveyor

7. Scanner unit

6. Removing and Installing the Erasure Conveyor MC-138

6.1 Erasure Lamp Assembly MC-138

6.2 Erasure Conveyor MC-140

6.3 Cleaning Roller Assembly MC-144

6.4 Cleaning Rollers MC-146

6.5 Erasure Lamps (LAMP1-LAMP5) MC-148

6.6 Erasure Thermostatic Switch (TSW2) MC-150

6.7 Erasure Thermostatic Switch (TSW1) MC-152

6.8 Erasure Cooling Fan (FANM1) MC-154

6.9 Sockets MC-156

6.10 Timing Belts MC-160

6.11 Lamp House Assembly MC-164

6.12 Filter MC-166

6.13 Reflection Plate MC-168

6.14 IP Transport Motor (MM1) MC-170

6.15 Rubber Rollers (Upper) MC-172

6.16 Shielding Plates MC-174

6.17 Rubber Rollers (Lower) MC-176

6.18 Guide Plates MC-178

7. Pulling Out and Pushing In the Scanner Unit MC-182

8. Side-positioning conveyor

8. Removing and Installing the Side-Positioning Conveyor MC-188

8.1 Side-Positioning Conveyor MC-188

8.2 Grip Release Motor (MN2) MC-192

8.3 Barcode Reader (BCRN1) MC-194

8.4 Side-Positioning Mechanism HP Sensor (SN1) MC-196

8.5 Grip Release HP Sensor (SN2) MC-198

8.6 Cleaning Guide Drive Motor (MN4) MC-200

8.7 BCR08A Board MC-202

8.8 Side-Positioning IP Sensor (SN3) MC-204

8.9 Cleaning Guide HP Sensor (SN4) MC-206

8.10 Cleaning Guide Assembly MC-208

8.11 Shaft (for Cleaning Guide Assembly) MC-214

8.12 Guide Plate C MC-218

8.13 Timing Belt (for IP Conveyance) MC-220

8.14 Guide Plate G MC-222

8.15 Rubber Rollers (Rear) MC-226

8.16 Wire (Left Side) MC-230

8.17 Wires (Right Side) MC-234

8.18 Timing Belt (for Side-Positioning Mechanism) MC-240

8.19 Shaft (for Grip Release) MC-246

FR7H30AD.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 5

Page 13

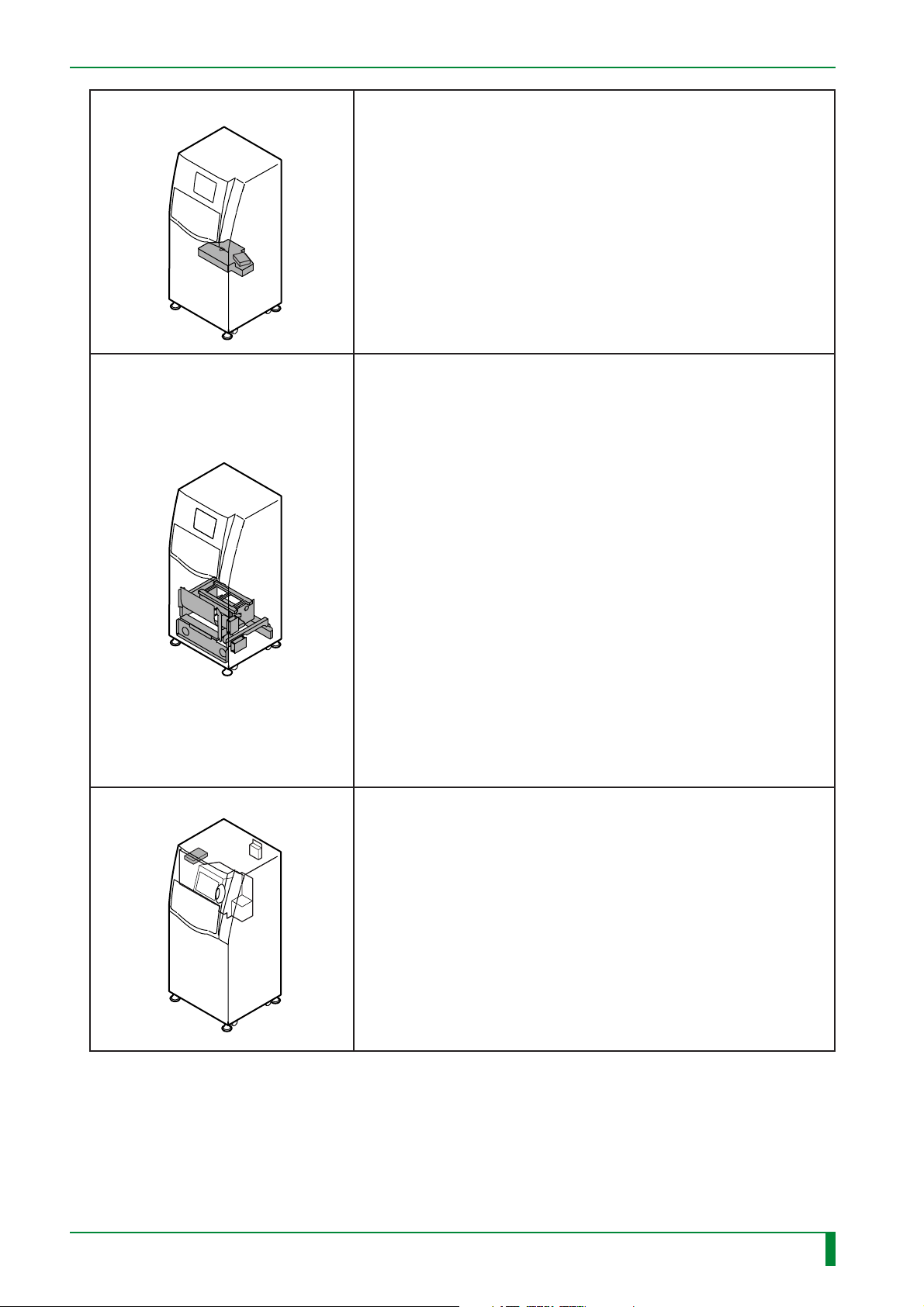

MC - 6

9. Scanning optics unit

10. Subscanning unit

9. Removing and Installing the Scanning Optics Unit MC-250

9.1 Adjusting the Format MC-250

9.2 Shading and Sensitivity Corrections MC-254

9.3 Checking for Image Problems MC-258

9.4 Removing and Installing the Scanning

Optics Unit MC-262

9.5 LD Assembly MC-266

9.6 Polygon Assembly MC-270

9.7 SYN08A Board MC-274

10. Removing and Installing the Subscanning Unit MC-278

10.1 Driving-Side Grip Release HP Sensor (SZ2) MC-278

10.2 Mirror HP Sensor (SZ4) MC-280

10.3 Rubber Belt and SUS Belt MC-282

10.4 Kapton

10.5 Flywheel MC-286

10.6 Subscanning Motor MZ1 (FFM) MC-288

10.7 PMT08D Board MC-292

10.8 PMR08C Board MC-296

10.9 Light-Collecting Guide Assembly

10.10 Light-Collecting Guide Assembly

10.11 Light-Collecting Mirror and IP Leading-Edge

10.12 Glass Guide MC-326

10.13 Lower Rubber Rollers MC-332

10.14 Mirror Driving Motor (MZ4) MC-336

10.15 Driving-Shaft Grip Motor (MZ2) MC-338

10.16 Driven-Shaft Grip Motor (MZ3) MC-342

10.17 Driven-Side Grip Release HP Sensor (SZ3) MC-346

10.18 Subscanning Unit Controller Assembly MC-348

10.19 SCN08D/SCR08D Board MC-354

10.20 PHV08D Board MC-358

®

Belt MC-284

(for Front Surface) MC-300

(for Back Surface) MC-308

Sensor (SZ1/SED08D) MC-320

11. HDD 11. Removing and Installing the Hard Disk Drive

(HDD) MC-360

11.1 Setting HDD MC-361

11.2 Hard Disk Drive (HDD) MC-362

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

FR7H30AE.EPS

MC - 6

Page 14

12. FDD 12. Removing and Installing the Floppy Disk

Drive (FDD) MC-372

12.1 Setting FDD MC-372

12.2 Floppy Disk Drive (FDD) MC-372

13. Power Supply Unit 13. Removing and Installing the Power

Supply Unit (JPS-6) MC-374

13.1 Power Supply Unit (JPS-6) MC-374

13.2 Power Supply Unit Fuses MC-378

MC - 7

14. Monitor 14. Removing and Installing the Monitor MC-382

14.1 CRT (Monitor) MC-382

14.2 Fuse Between Power Supply Unit and CRT MC-388

15. PC Boards 15.

Removing and Installing the PC Boards

15.1 MTH08C MC-402

15.2 MTH08D MC-404

15.3 CPU90E Board MC-406

15.4 IMG07B Board MC-410

15.5 BSP08A Board MC-411

15.6 IMG08M Board MC-413

15.7 CPU90F Board (Optional) MC-414

15.8 LAN90B Board (Optional) MC-416

15.9 HCP08A Board (Optional) MC-417

15.10 IMG08H Board (Optional) MC-418

15.11 SNS08C and DRV08A Boards MC-420

15.12 VOL08A Board MC-427

15.13 LED08A Board MC-428

15.14 LED08B Board MC-428

15.15 BCR08A Board MC-429

15.16 SYN08A, PMT08D, PMR08C, SCN08D/SCR08C,

and PHV08D Boards MC-429

MC-390

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

FR7H30AF.EPS

MC - 7

Page 15

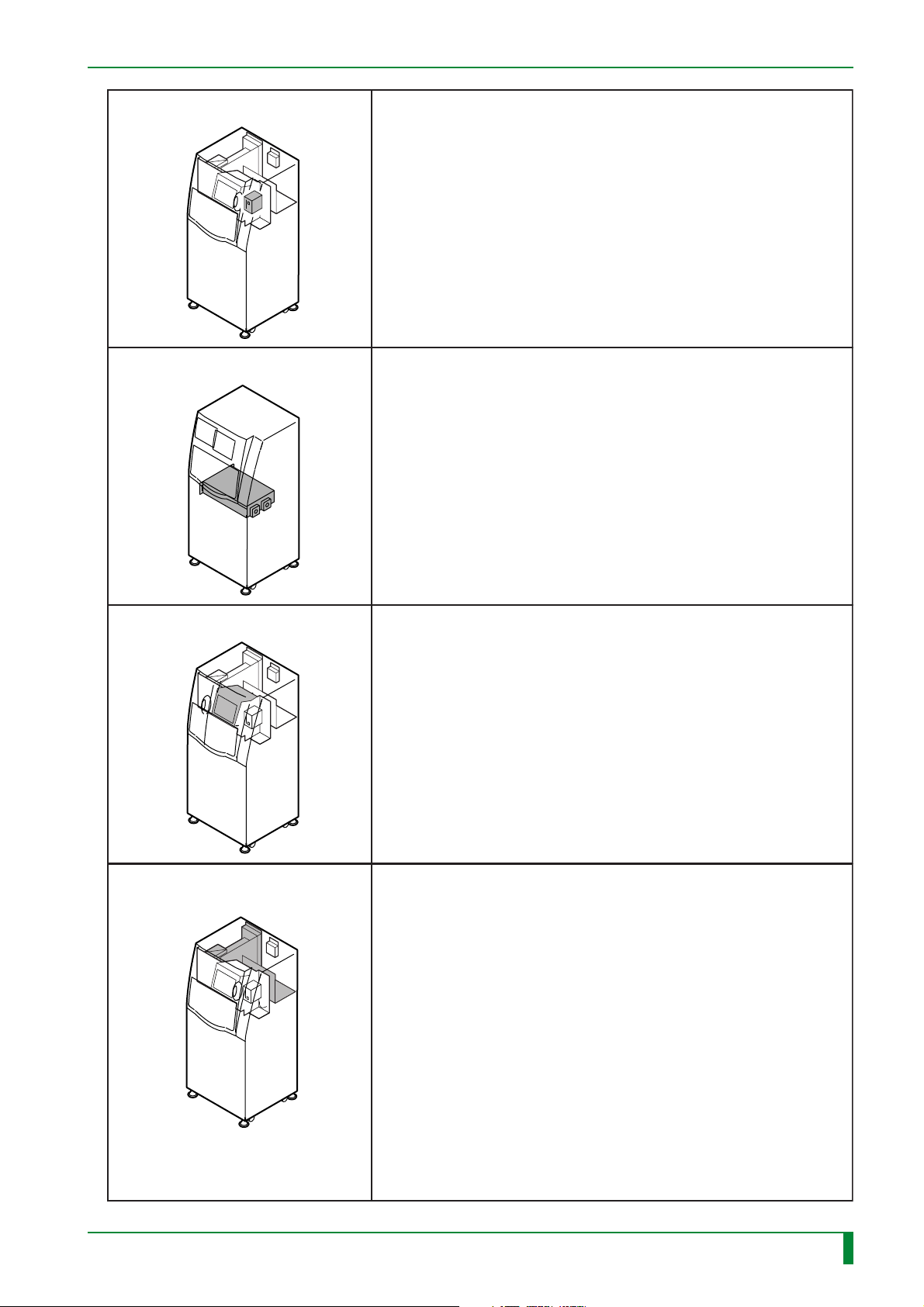

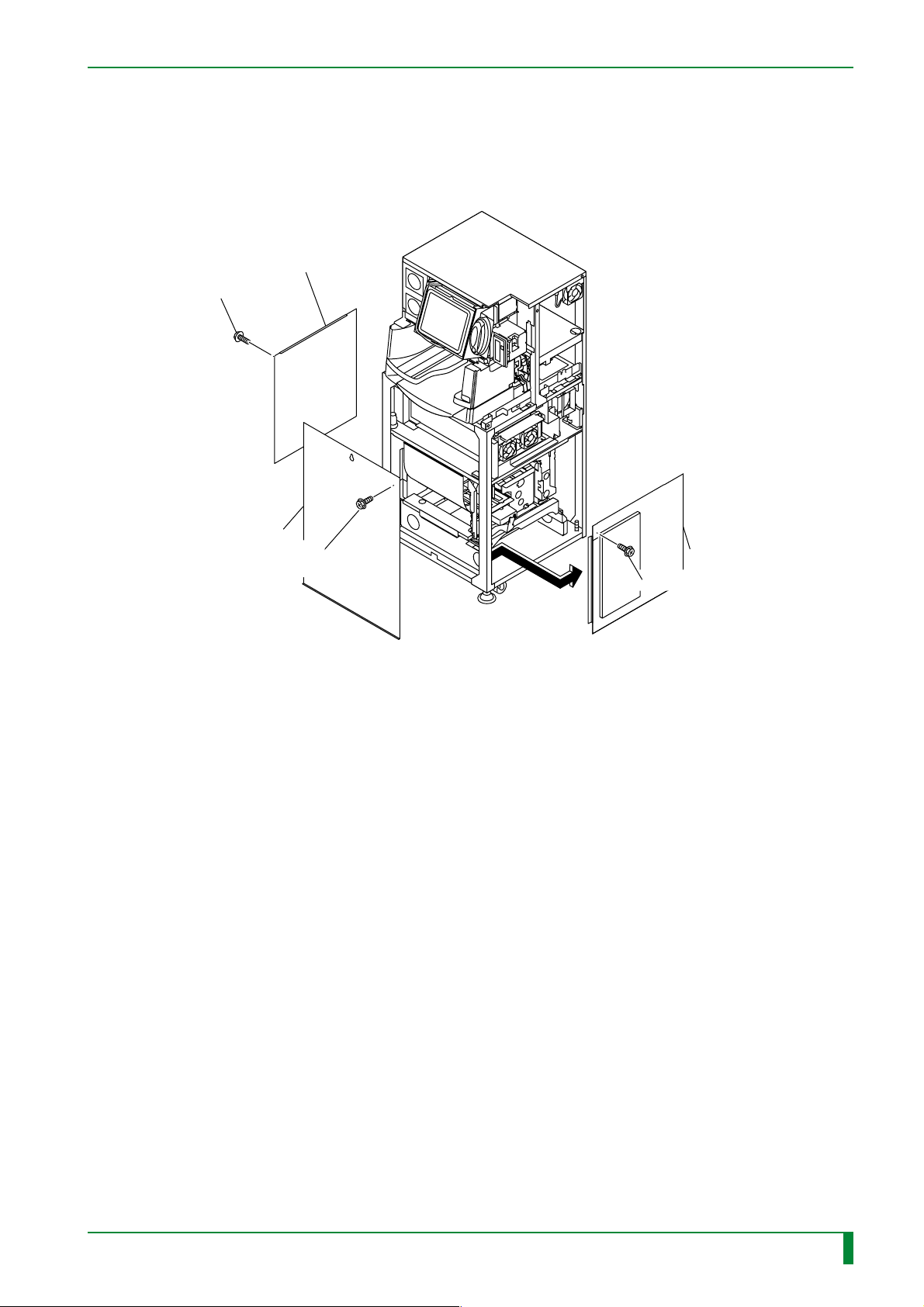

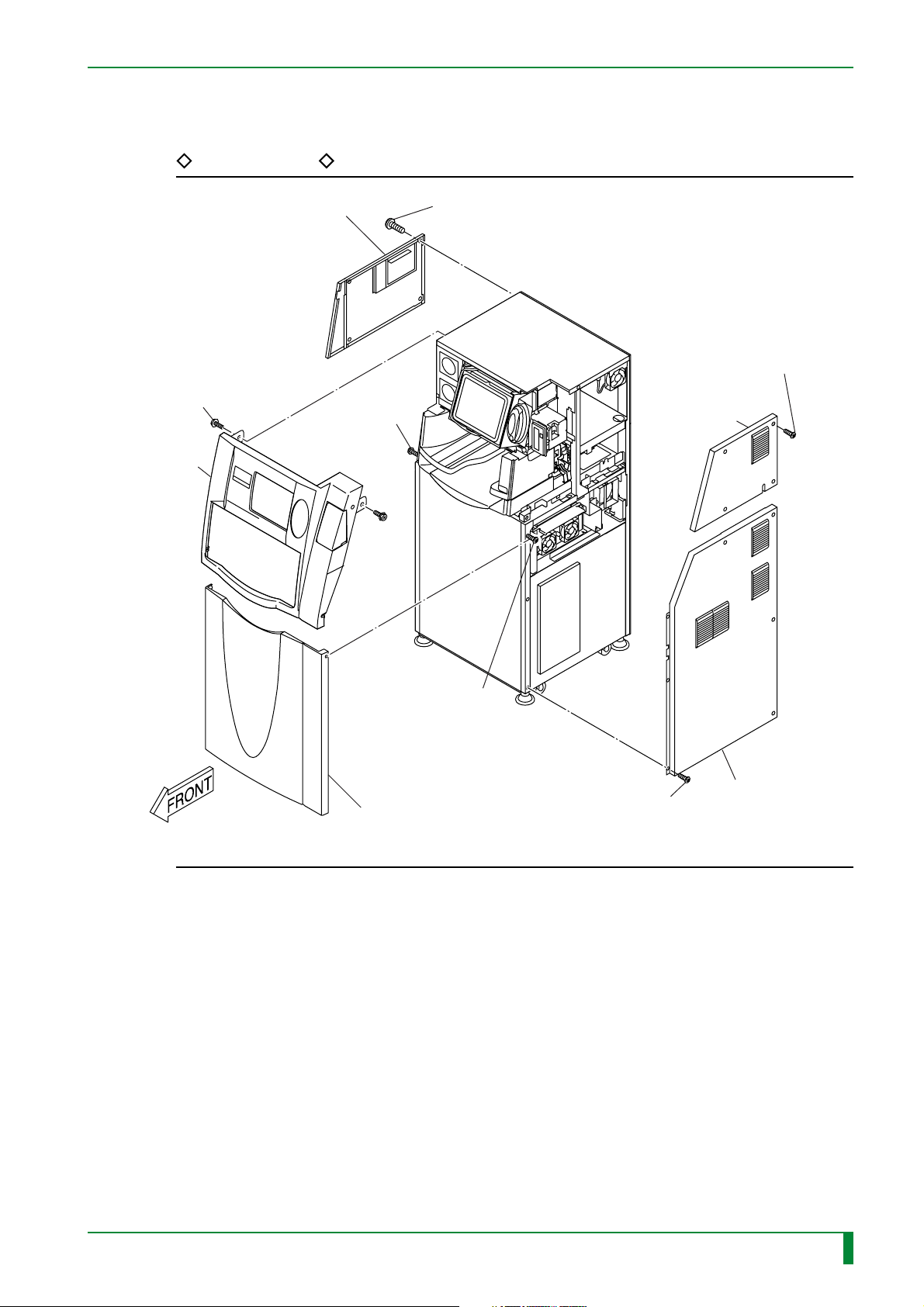

3. Removing and Installing the Covers

FR7H3000.EPS

■ Removal procedure

Upper left-hand side cover

[Remove]

T4x12 (x4)

Upper rear cover

MC - 8

[Remove]

T4x12 (x4)

[Remove]

T4x12 (x6)

T4x6 (x3)

Lower left-hand side cover

Upper front cover

Lower front cover

[Remove]

BR4x8 (x2)

[Loosen] T4x12 (x2)

[Loosen] T4x12 (x2)

[Remove]

T4x12 (x8)

Lower rear cover

[Remove]

T4x6 (x4)

Upper right-hand

side cover

[Remove]

T4x6 (x7)

Lower right-hand side cover

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

FR7H3098.EPS

MC - 8

Page 16

Left-hand inner cover

[Remove]

BR4x8 (x6)

MC - 9

Light protect plate

[Remove]

BR4x8 (x9)

■ Installation procedure

Accomplish installation by reversing the removal procedure.

Right-hand inner cover

[Remove] BR4x8 (x5)

FR7H3099.EPS

009-058-01

009-058-00

05.15.2001 FM3052

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 9

Page 17

MC - 10

4. Removing and Installing the Cassette Set Unit

4.1 Cassette Set Unit

FR7H3001*.EPS

■ Removal procedure

(1) Pull out the tray.

“4.5 Pulling Out the Tray”

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 10

Page 18

MC - 11

E

(2) Remove the cassette set unit.

◆

NOTE

Before removing the cassette set unit, place the removal arm in the following position:

◆

#1

[Rotate] Timing belt

IP removal unit

IP removal arm

#2

[Remove] BR4x8 (x3)

Cassette set unit

Cassette

FR7H3315.

set unit

■ Installation procedure

Accomplish installation by reversing the removal procedure.

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

Positioning screw

FR7H3315.EPS

MC - 11

Page 19

FR7H3301.EPS

Shutter assembly

[Remove] BR4x8 (x2)

Cassette set unit

Shutter

4.2 Shutter

■ Removal procedure

(1) Remove the following covers:

• Upper right-hand side cover

• Upper left-hand side cover

MC - 12

FR7H3002.EPS

• Upper front cover

“3. Removing and Installing the Covers”

(2) Remove the front shelf cover.

“4.5 Pulling Out the Tray”

(3) Remove the shutter assembly.

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 12

Page 20

(4) Remove the shutter.

MC - 13

Bracket

[Remove]

B3x6

Bracket

Torsion

coil spring

Bearing

Shutter

Bracket

Bearing

■ Installation procedure

◆

NOTE

When installing the shutter, ensure that gap A shown above permits the entry of a single

thickness of a 150 mm scale but does not permit the entry of a single thickness of a 300

mm scale.

To accomplish installation, reverse the removal procedure.

◆

Shutter

A

[Remove]

Hook

FR7H3302.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 13

Page 21

4.3 Cassette Ejection Sensor (SK1)

FR7H3003.EPS

■ Removal procedure

(1) Remove the following covers:

• Upper right-hand side cover

• Upper left-hand side cover

MC - 14

• Upper front cover

“3. Removing and Installing the Covers”

(2) Remove the front shelf cover.

“4.5 Pulling Out the Tray”

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 14

Page 22

FR7H3304.EPS

Shutter assembly

(4) #2

[Remove]

Q4x12 (x2)

(Loktite)

(3)

[Remove] BR4x8 (x2)

Cassette set unit

(4) #1

[Disconnect] Connector (SK1)

Bracket

(4) #3

[Remove] SK1

(3) Remove the shutter assembly.

(4) Remove the cassette ejection sensor (SK1).

MC - 15

■ Installation procedure

To accomplish installation, reverse the removal procedure.

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 15

Page 23

4.4 Barcode Reader (BCRK1)

FR7H3004.EPS

■ Removal procedure

(1) Remove the following covers:

• Lower front cover

• Lower right-hand side cover

“3. Removing and Installing the Covers”

MC - 16

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 16

Page 24

(2) Remove the barcode reader (BCRK1).

MC - 17

Cassette set unit

#1

[Disconnect] Connector

BCRK1

Bracket

#2

[Remove]

BR4x8 (x2)

#4

[Remove]

N2x6 (x2)

#3

[Cut] Tie (x2)

FR7H3306.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 17

Page 25

■ Installation procedure

◆

NOTE

When clamping the cable with a tie, ensure that the cable does not come out of the

bracket.

Bracket

◆

MC - 18

Cable

Tie

Cable

OK

To accomplish installation, reverse the removal procedure.

NG

FR7H3307.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 18

Page 26

BLANK PAGE

MC - 19

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 19

Page 27

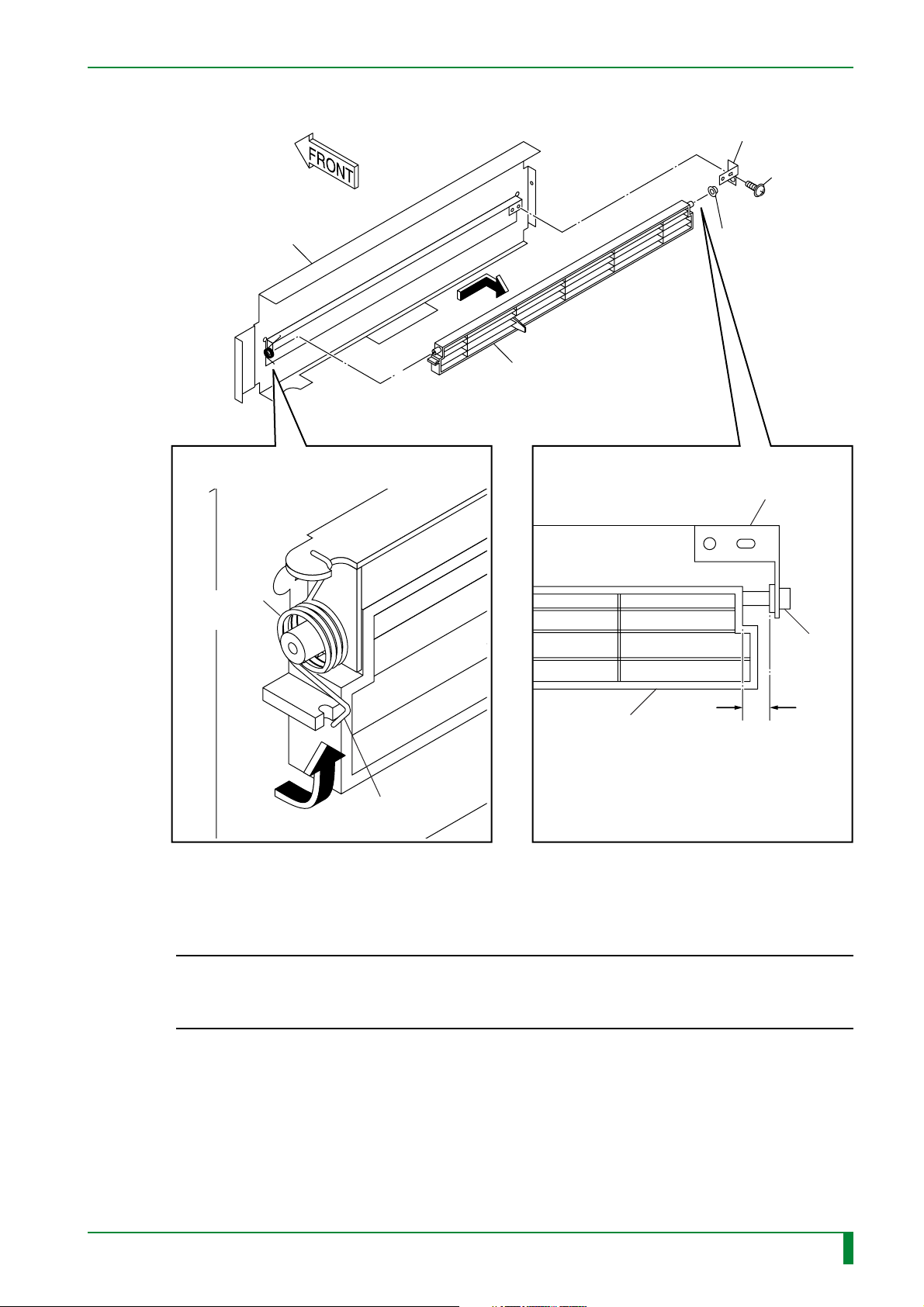

4.5 Pulling Out the Tray

FR7H3005.EPS

■ Pull-out procedure

(1) Remove the following covers:

• Upper left-hand side cover

• Upper right-hand side cover

MC - 20

• Upper front cover

• Lower front cover

• Lower right-hand side cover

“3. Removing and Installing the Covers”

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 20

Page 28

REFERENCE

MC - 21

Upper left-hand side cover

[Remove]

BR4x8 (x2)

Upper front cover

#4

#3

[Loosen]

T4x12 (x2)

#1

[Remove] T4x12 (x4)

#2

[Remove]

T4x6 (x4)

Upper right-

hand side cover

[Loosen]

T4x12 (x2)

Lower front cover

#5

#6

[Remove] T4x6 (x7)

Lower right-hand

side cover

FR7H3308.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 21

Page 29

(2) Disconnect the connectors.

MC - 22

[Disconnect] Connectors

IP removal unit

CNL2

CNL3

CNL1

FRONT

[Disconnect] Connectors

Cassette set unit

CNU1

CNK1

CNK2

CNSOLK1

BCR08A CN1

FR7H3309.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 22

Page 30

(3) Pull out the tray.

#1 [Loosen] BR4x8 (x2)

#2 [Remove] BR4x8 (x2), W6

[Remove] BR4x8 (x2)

MC - 23

Bracket

#3

FRONT

#4

[Pull out] Tray

FR7H3389.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 23

Page 31

(4) Remove the front shelf cover.

#1

[Remove] Screw cover

#2

[Remove] T4x6 (x2)

Stack table

MC - 24

#3

[Remove]

BR4x8 (x2)

Front shelf cover

#4

[Remove] BR4x8 (x4)

FR7H3373.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 24

Page 32

■ Push-in procedure

◆

NOTE

During reinstallation of the front shelf cover, align the cassette insertion face of the front shelf

cover to the guide protrusion of the cassette set unit.

If they are not aligned, a cassette hold failure may result.

◆

MC - 25

Front shelf cover

■ Check

A

CHECK

#1 [Temporarily Tighten]

BR4x8 (x4)

#3 [Temporarily Tighten]

For push-in, reverse the pull-out procedures.

DETAIL A

#2 [Align]

Cassette set unit

Front shelf

cover

Cassette insertion face

Protrusion

Guide

FR7H3391.EPS

Power ON the machine and make sure that a cassette hold failure does not occur when a

cassette is inserted.

009-058-00

009-058-02

10.20.2000 FM2732 (2)

08.30.2001 FM3142

CR-IR347

Service Manual

MC - 25

Page 33

4.6 Cassette Hold Solenoid (SOLK1)

FR7H3006.EPS

■ Removal procedure

(1) Pull out the tray.

“4.5 Pulling Out the Tray”

(2) Remove the shutter assembly.

MC - 26

Shutter

Shutter assembly

Cassette set unit

[Remove] BR4x8 (x2)

FR7H3374.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 26

Page 34

(3) Remove the cassette hold solenoid (SOLK1).

A

#1

[Cut] Tie (x2)

MC - 27

#2

[Disconnect]

Connector

(CN-SOLK1)

DETAIL A

CHECK

Cassette hold

solenoid

Arm

#3

[Remove] B3x6 (x3)

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

FR7H3310.EPS

MC - 27

Page 35

■ Installation procedure

(1) Temporarily retain the cassette hold solenoid.

◆

NOTE

◆

Before temporarily retain the cassette hold solenoid, attach the hold pin to the arm. After

the cassette hold solenoid is temporarily retained, you cannot attach the hold pin to the

arm.

FRONT

#2

[Loosely attach]

B3x6 (x3)

Hold pin

MC - 28

Arm

#1

[Hook]

Cassette hold

solenoid

Cassette hold solenoid

FR7H3312.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 28

Page 36

(2) Set the jig so that its protrusion goes into the hole in the guide plate.

#1

[Lift] Rubber roller

#2

[Set] Jig

Jig

MC - 29

Hold pin

Protrusion

FR7H3375.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 29

Page 37

(3) Adjust the cassette hold solenoid mounting position.

Jig

MC - 30

(4) Remove the jig.

#3

[Loosen] BR3x6 (x3)

#1

[Remove]

Extension spring

#4

[Engage]

#2

[Push up]

Cassette hold solenoid

FR7H3313.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 30

Page 38

■ Check procedure

(1) Check that the cassette hold solenoid is in the following state:

● Normal condition

The hold pin end must be raised above the guide plate by the action of the extension

spring.

● When the lever is lowered

The hold pin end must not be positioned above the guide plate.

MC - 31

Guide plate

[Lower] Lever

Hold pin

Extension spring

Guide plate

Hold pin

Lever loweredNormal

FR7H3314.EPS

◆

If the hold pin is positioned above the guide plate when the lever is lowered, the cassette

is damaged when it is inserted into position.

(2) Complete installation by reversing the removal procedure.

009-058-00

10.20.2000 FM2732 (2)

NOTE

◆

CR-IR347

Service Manual

MC - 31

Page 39

4.7 Cassette Hold Sensor (SK3)

FR7H3007.EPS

■ Removal procedure

(1) Remove the cassette set unit.

“4.1 Cassette Set Unit”

(2) Remove the shutter assembly.

MC - 32

Shutter assembly

Cassette set unit

[Remove] BR4x8 (x2)

FR7H3316.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 32

Page 40

(3) Remove the cassette hold sensor (SK3).

Cassette set unit

T

O

P

#3

SK3

MC - 33

#2

Connector

[Remove] B3x6

■ Installation procedure

◆

NOTE

When mounting the bracket, secure it by aligning it with the dowel and pressing it upward.

◆

Bracket

Bracket

#1

FR7H3317.EPS

009-058-03

08.30.2002 FM3476

Protrusion

FR7H3382.EPS

Accomplish installation by reversing the removal procedure.

CR-IR347

Service Manual

MC - 33

Page 41

4.8 Claw Guide Assembly

FR7H3008.EPS

■ Removal procedure

(1) Remove the cassette set unit.

“4.1 Cassette Set Unit”

(2) Remove the shutter assembly.

MC - 34

Shutter assembly

Cassette set unit

[Remove] BR4x8 (x2)

FR7H3359.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 34

Page 42

MC - 35

◆

NOTE

◆

When you remove the claw guide assembly, hold it down to prevent the compression coil

spring from popping out.

(3) Remove the claw guide assembly.

CHECK

Dowel

Cable

Edge saddle

[Disconnect] Connector (SK3)

Bracket

#1

[Remove]

BR4x8 (x2)

#2

Claw guide assembly

Compression

spring

(L = 31 mm)

Dowel

#4

[Remove] Q4x12 (x2)

(Loktite)

#3

[Remove] BR4x8 (x2)

Cassette set unit

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

FRONT

T

O

P

Service Manual

FR7H3318.EPS

MC - 35

Page 43

■ Installation procedure

◆

NOTE

• When installing the claw guide assembly, adjust the degree of guide plate parallelism

with the mounting screws (BR4x8, x2) loosened.

For parallelism adjustment purposes, apply a 300 mm scale to the guide plate trailing

end (toward the IP removal unit) and measure the gap between the scale and guide

plate.

◆

0.5 mm or greater gap = NG

Gap smaller than 0.5 mm = OK

MC - 36

300 mm scale

Less than 0.5 mm

Guide plate

FRONT

300 mm scale

FR7H3320.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 36

Page 44

MC - 37

◆

NOTES

• When applying Loktite to a guide screw, apply it to the portion of the guide screw on the

bracket side. Do not bring Loktite into contact with the guide.

◆

Shaft

B3x10 (x2)

(Loktite)

SK3

Bearing

A

Guide

Spacer

Bearing

Bracket

B3x6 (x2)

Bracket

DETAIL A

Loktite

Guide

B3x10

Bracket

FR7H3319.EPS

• When installing the SK3 bracket, align it with the dowels and secure it while pressing

the protrusion upward.

Bracket

Protrusion

FR7H3382.EPS

To accomplish installation, reverse the removal procedure.

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

MC - 37

Page 45

■ Check procedure

• Insert a cassette into the cassette set unit to check that the stopper pin opens the

cassette cover. If the cassette cover does not open, adjust the parallelism of the

installed guide plate.

[Insert] Cassette

MC - 38

A

DETAIL A

Stopper

Pin

Cassette

Cover

• Make sure that the coil spring inside the claw guide assembly is engaged with the

009-058-00

10.20.2000 FM2732 (2)

dowels.

CR-IR347

Service Manual

FR7H3390.EPS

MC - 38

Page 46

BLANK PAGE

MC - 39

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 39

Page 47

4.9 Cassette IN Sensor (SK2)

FR7H3009.EPS

■ Removal procedure

(1) Remove the cassette set unit.

“4.1 Cassette Set Unit”

(2) Remove the shutter assembly.

MC - 40

Shutter

Shutter assembly

Cassette set unit

[Remove] BR4x8 (x2)

FR7H3377.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 40

Page 48

(3) Disconnect the connector (SK2).

MC - 41

DETAIL A

O

A

Bracket

#1

[Remove]

BR4x8 (x2)

[Disconnect]

#2

Cable

Edge saddle

T

P

SK2

#3

[Disconnect]

Connector (SK2)

FR7H3323.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 41

Page 49

(4) Remove the cassette IN sensor (SK2).

MC - 42

Cassette set unit

#1

[Remove] BR4x8

#2

[Cut] Tie

CHECK

#3

[Remove]

B2x10 (x2)

SK2

Bracket

FR7H3322.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 42

Page 50

■ Installation/adjustment procedure

◆

INSTRUCTION

The SK2 must be positioned so that the actuator does not interfere with the cut in the

stopper.

◆

MC - 43

DETAIL A

Stopper

Cut

in stopper

Actuator

A

SK2

OK NG

FR7H3324.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 43

Page 51

(1) Mount the SK2 on the bracket.

MC - 44

Actuator

◆

NOTE

#2

[Attach] Tie

SK2

Bracket

◆

#1

[Attach]

B2x10 (x2)

FR7H3325.EPS

When mounting the SK2 assembly, do not allow the actuator to come into contact with

neighboring parts and bend. If the actuator is bent, it does not normally function.

REFERENCE

Ensure that the SK2 connector cable does not come into contact with the IP removal unit.

SK2

009-058-00

10.20.2000 FM2732 (2)

Approx.

10 mm

FR7H3386.EPS

CR-IR347

Service Manual

MC - 44

Page 52

(2) Loosely attach the SK2 assembly.

MC - 45

Stopper

DETAIL A

A

Dowel

SK2

SK2 assembly

[Loosely attach] BR4x8

Actuator

Cassette set unit

SK2

FR7H3326.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 45

Page 53

(3) Connect the SK2 connector.

◆

NOTE

◆

Make sure that the connector cable is not positioned outside the bracket.

DETAIL A

MC - 46

T

O

P

A

Bracket

#3

[Attach] BR4x8 (x2)

#2

[Attach] Cable

Edge saddle

SK2

#1

[Connect]

Connector (for SK2)

(4) To complete installation, reverse the removal procedure.

FR7H3378.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 46

Page 54

■ Check procedure

(1) Turn ON the power.

(2) Start the M-Utility.

(3) Perform SK2 operational checkout.

#1 [Input/ENT]

#2 [Input/ENT]

0. QUIT

1. ERROR LOG UTILITY

2. CONFIGURATION SETTING

3. TEST MODE

4. ELECTRICAL UTILITY

5. SCANNER UTILITY

6. MECHANICAL UTILITY

7. FILE UTILITY

8. BACKUP MEMORY

9. HV OFF

10. MENU SETTING

11.SYSTEM UTILIT

> 6

0. QUIT

1. MOTOR

2. ACTUATOR

3. SENSOR

4. UNIT

MU > 3

Y

MC - 47

0. QUIT

1. NUMBER

2. MONITOR

3. MONITOR ALL

#3 [Input/ENT]

MU : SEN > 3

REFERENCE

For SK2 operational checkout, perform the following steps:

1. Insert a cassette all the way into the cassette set unit.

→

Check that the SK2 closes.

2. Try to pull the cassette while it is locked with the hold pin.

→

Check that the SK2 remains closed.

3. Remove the cassette.

→

Check that the SK2 opens.

FR7H3330.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 47

Page 55

(4) Verify the SK2 assembly mounting position.

MC - 48

150 mm scale

DETAIL B

SK2

A

Actuator

SK2

DETAIL A

[Check]

SK2

SK2

The SK2 should be OFF

when this gap is about 1.0 mm.

B

Guide plate

Scale

Scale

Guide plate

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

SK2

The SK2 should be ON

when this gap is about 1.5 mm.

FR7H3379.EPS

MC - 48

Page 56

MC - 49

(5) Press the actuator with a scale or the like to check that the actuator does not interfere

with the cut in the stopper.

DETAIL A

Stopper

Cut

in stopper

Actuator

A

(6) Exit the M-Utility.

(7) Turn OFF the power.

SK2

GOOD NG

FR7H3328.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 49

Page 57

4.10 Rubber Roller

FR7H3011.EPS

■ Removal procedure

(1) Remove the cassette set unit.

“4.1 Cassette Set Unit”

MC - 50

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 50

Page 58

FR7H3333.EPS

#2

[Remove]

Extension spring

L = 117 mm

Housing

Roller bearing

#1

[Remove]

Extension spring

L = 104 mm

Housing

Roller

bearing

Cassette set unit

Rubber roller

CHECK

(2) Remove the rubber roller.

MC - 51

■ Installation procedure

■ Check procedure

009-058-00

10.20.2000 FM2732 (2)

◆

INSTRUCTION

◆

The extension spring size varies with the mounting location. Pay due attention to the

extension spring mounting location.

To accomplish installation, reverse the removal procedure.

Check that the rubber roller is not installed with right and left reversed.

CR-IR347

Service Manual

MC - 51

Page 59

4.11 Guide Plate

■ Removal procedure

(1) Remove the rubber roller.

“4.10 Rubber Roller”

MC - 52

FR7H3012.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 52

Page 60

(2) Remove the shutter assembly.

(3) Remove the sensor assembly (SK2).

MC - 53

Shutter assembly

Cassette set unit

(2)

[Remove]

BR4x8 (x2)

(3)

[Remove]

BR4x8

SK2

assembly

FR7H3334.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 53

Page 61

(4) Disconnect the SK2 connector.

MC - 54

Bracket

A

T

O

P

#3

[Disconnect] Connector

#1

[Remove]

BR4x8 (x2)

DETAIL A

#2

[Disconnect]

Cable

Edge saddle

SK2

Connector (for SK2)

FR7H3380.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 54

Page 62

MC - 55

FR7H3335.EPS

Guide A

Guide A

#1

[Remove] BR4x8

#2

[Remove] BR4x8

#8

[Remove] BR4x8

#9

[Remove] BQ4x10

Stopper B

#3

[Remove]

BR4x8 (x2)

Guide B

Bracket

Guide B

Stopper B

#7

[Remove]

BQ4x10

Stopper A

Stopper A

Cassette set unit

FRONT

#4

[Remove] BR4x12

#6

[Remove] BR4x8

#5

[Remove] BR4x8

(Guide plate

retaining screw)

(5) Remove the guides and stoppers.

REFERENCE

Stopper A is secured by a dowel on a side plate. To remove stopper A, it is necessary to

remove the guide plate retaining screw.

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 55

Page 63

(6) Remove the guide plate.

Guide plate

FRONT

Hold pin

MC - 56

[Remove]

BR4x8 (x5)

Compression

spring

Guide

plate

FR7H3336.EPS

REFERENCE

Removing the guide plate separates the compression spring from the hold pin.

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 56

Page 64

FR7H3337.EPS

Cassette set unit

Hold pin

■ Installation procedure

◆

INSTRUCTION

When installing the guide plate, mount the hold pin on the arm.

MC - 57

◆

REFERENCE

When installing stoppers A and B, verify their mounting positions. Note that stoppers A

and B differ in shape.

Stopper A Stopper B

FR7H3338.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 57

Page 65

(1) Loosely attach the guide plate.

Guide plate

FRONT

Hold pin

MC - 58

[Loosely attach] BR4x8 (x5)

Guide

plate

FR7H3339.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 58

Page 66

(2) Install the guides and stoppers.

MC - 59

Guide A

Guide A

[Attach]

BR4x8 (x2)

[Remove] BQ4x10

#1

FRONT

#2

Guide B

Guide B

#4

[Attach] BR4x12

Bracket

#3

[Attach]

BR4x8 (x2)

Cassette set unit

Stopper A

#5

[Attach] BR4x8

[Attach] BR4x8

#6

Stopper A

#7

[Attach] BQ4x10

Stopper B

Stopper B

#8

[Attach] BR4x8

#9

[Attach] BQ4x10

FR7H3340.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 59

Page 67

MC - 60

(3) While measuring the levelness of the guide plate with a 300 mm scale or the like,

tighten the remaining four guide plate retaining screws.

300 mm scale

[Tighten] BR4x8 (x4)

FR7H3341.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 60

Page 68

MC - 61

◆

NOTE

For parallelism adjustment purposes, apply a 300 mm scale to the guide plate trailing end

(toward the IP removal unit) and measure the gap between the scale and guide plate.

◆

0.5 mm or greater gap = NG

Gap smaller than 0.5 mm = OK

Guide plate

300 mm scale

300 mm scale

Less than 0.5 mm

FRONT

FR7H3342.EPS

(4) Complete installation by reversing the removal procedure.

◆

NOTE

◆

When installing the SK2 assembly, perform its specified adjustment procedure.

“4.9 Cassette IN Sensor (SK2)”

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 61

Page 69

■ Check procedure

Insert a cassette into the cassette set unit to check that the stopper pin opens the cassette

cover. If the cassette cover does not open, adjust the parallelism of the guide plate.

[Insert] Cassette

DETAIL A

MC - 62

A

Stopper

Pin

Cassette

Cover

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

FR7H3381.EPS

MC - 62

Page 70

BLANK PAGE

MC - 63

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 63

Page 71

4.12 Guide Stoppers

FR7H3013.EPS

■ Removal procedure

(1) Remove the cassette set unit.

“4.1 Cassette Set Unit”

(2) Remove the rubber roller.

“4.10 Rubber Roller”

MC - 64

(3) Remove the guide stoppers.

A

SW3

Guide stopper

#1

[Remove] Q3x12

Guide

#2

[Remove] S3x10

(Loktite)

#3

[Remove] Q3x12

SW3

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

A

FR7H3343.EPS

MC - 64

Page 72

MC - 65

Guide

#8

[Remove] S3x10

(Loktite)

#9

[Remove] Q3x12

Guide stopper

B

Guide

Guide

#4

[Remove] Q3x12

SW3

#5

[Remove] S3x10

(Loktite)

#6

[Remove] Q3x12

SW3

Guide stopper

C

#7

[Remove] Q3x12

SW3

SW3

■ Installation procedure

To accomplish installation, reverse the removal procedure.

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

B

Service Manual

C

FR7H3388.EPS

MC - 65

Page 73

4.13 Movable Guides

FR7H3014.EPS

■ Removal procedure

(1) Remove the guide plate.

“4.11 Guide Plate”

(2) Remove the guide stoppers.

MC - 66

“4.12 Guide Stoppers”

(3) Remove the movable guides.

FRONT

T

O

P

Movable guide (right)

Movable guide (left)

#1

[Remove] Q4x8 (x2)

#2

[Remove] Q4x8 (x2)

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

FR7H3344.EPS

MC - 66

Page 74

Movable guide

MC - 67

Compression spring

(L = 43 mm)

Movable guide

Compression spring

(L = 43 mm)

Bracket

#3

[Remove] BR4x8

FR7H3345.EPS

■ Installation procedure

However, complete the following adjustment procedure immediately before shutter assembly

reinstallation.

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 67

Page 75

■ Adjustment procedure

● Widthwise adjustment

(1) Loosen the movable guide retaining screws.

(2) Tighten the retaining screws so that the bracket pin lodges in the movable guide hole.

MC - 68

Pin

(1)

[Loosen] Q4x8 (x2)

(2)

[Tighten]

Hole

Pin

(1)

[Loosen] Q4x8 (x2)

(2)

[Tighten]

Hole

FR7H3387.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 68

Page 76

● Movable guide rearward adjustment

❍ Metric guide

(1) Loosen the bracket.

(2) Adjust the bracket position to meet the following requirements:

• The up-down movement of the movable guide front end must be smooth.

• The amount of movable guide rear end descent must not exceed 1 mm.

A

B

DETAIL A

MC - 69

DETAIL B

FRONT

Metric guide

Bracket

(1)

[Loosen] BQ4x10

(1)

[Loosen] BQ4x10

Front end check

The movement must be smooth.

(2)

[Adjust] Bracket

F

R

O

N

T

009-058-00

10.20.2000 FM2732 (2)

Rear end check

CR-IR347

Service Manual

1 mm max.

FR7H3347.EPS

MC - 69

Page 77

❍ Inch guide

(1) Loosen the bracket.

(2) Adjust the bracket position to meet the following requirements:

• The up-down movement of the movable guide front end must be smooth.

• The amount of movable guide rear end descent must not exceed 1 mm.

A

B

DETAIL A

Inch guide

MC - 70

DETAIL B

FRONT

(2)

[Adjust] Bracket

(1)

[Loosen] BQ4x10

Front end check

The movement must be smooth.

Rear end check

F

R

O

N

T

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

1 mm max.

FR7H3348.EPS

MC - 70

Page 78

❍ 20 x 30 mammography guide

(1) Loosen the bracket.

(2) Adjust the bracket position to meet the following requirements:

• The up-down movement of the movable guide front end must be smooth.

• The amount of movable guide rear end descent must not exceed 1 mm.

A

B

DETAIL A

24 x 30 mammography guide

MC - 71

(1)

[Loosen] BR4x8

DETAIL B

FRONT

Front end check

The movement must be smooth.

Rear end check

(2)

[Adjust] Bracket

F

R

O

N

T

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

1 mm max.

FR7H3349.EPS

MC - 71

Page 79

■ Check procedure

Insert cassettes of various sizes into the cassette set unit to check that the cassettes open.

If the cassettes do not open, perform the adjustment procedures again.

MC - 72

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 72

Page 80

BLANK PAGE

MC - 73

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 73

Page 81

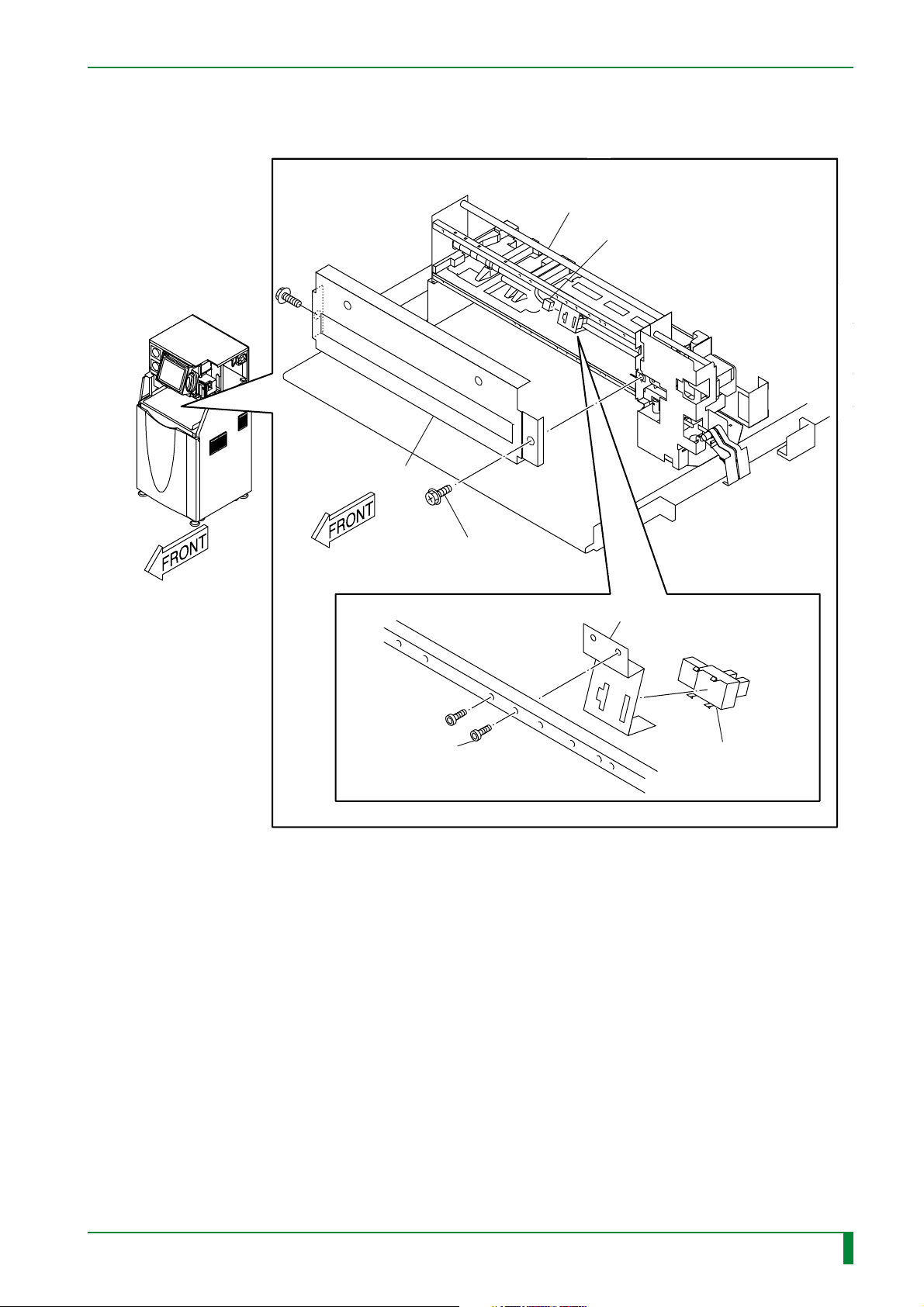

MC - 74

5. Removing and Installing the IP Removal Unit

5.1 IP Removal Unit

FR7H3015.EPS

■ Removal procedure

(1) Remove the cassette set unit.

“4.1 Cassette Set Unit”

(2) Remove the following cover:

• Lower left-hand side cover

“3. Removing and Installing the Covers”

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 74

Page 82

(3) Remove the IP removal unit.

MC - 75

CHECK

IP removal unit

[Remove] BR4x8 (x4)

FR7H3236.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 75

Page 83

■ Installation procedure

To accomplish installation, reverse the removal procedure.

◆

NOTE

When installing the IP removal unit, loosely attach it with the screws, and shift it rearward

and then rightward (toward the reference surface).

◆

MC - 76

IP removal unit

FR7H3237.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 76

Page 84

BLANK PAGE

MC - 77

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 77

Page 85

5.2 IP Leak Valve (SVL1)

FR7H3016.EPS

■ Removal procedure

(1) Remove the following cover:

• Lower rear cover

“3. Removing and Installing the Covers”

MC - 78

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 78

Page 86

(2) Remove the IP leak valve (SVL1)

[Disconnect]

Connector

#5

[Disconnect] Hose

#4

[Cut] Tie

SVL1

MC - 79

#3

#2

[Cut] Tie

Bracket

#1

[Remove] BR4x8 (x4)

#6

[Remove] BR4x8 (x2)

IP removal unit

■ Installation procedure

To accomplish installation, reverse the removal procedure.

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

FR7H3201.EPS

MC - 79

Page 87

5.3 Suction Cup HP Sensor (SL1)

FR7H3017.EPS

■ Removal procedure

(1) Remove the following covers:

• Lower front cover

• Lower right-hand side cover

MC - 80

“3. Removing and Installing the Covers”

(2) Rotate the timing belt to move the actuator away from the SL1.

FRONT

IP removal unit

IP removal arm

Actuator

Timing belt

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

SL1

FR7H3202.EPS

MC - 80

Page 88

(3) Remove the suction cup HP sensor (SL1).

#1

[Disconnect]

Connector

MC - 81

#3

[Remove] SL1

#2

[Remove] B3x6 (x2)

Bracket

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

FR7H3203.EPS

MC - 81

Page 89

■ Installation procedure

(1) Mount the suction cup HP sensor (SL1) on the bracket.

(2) Loosely attach the bracket.

(3) Secure the bracket so that the SL1 end face is flush with the actuator end face when

the distance between the side plate end face and roller bearing end face is 95.0 mm.

MC - 82

Side plate

FRONT

95.0 mm

Roller bearing

End face

Actuator

IP removal unit

Actuator

end face

SL1 end face

SL1 end face

Actuator

end face

Roller bearing

IP removal arm

SL1

Bracket

OK NG

FR7H3204.EPS

(4) Install the IP removal unit and cassette set unit by reversing their removal procedures.

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 82

Page 90

■ Check/adjustment procedure

CAUTION

When turning ON the machine with the laser protective housing (cover installed over the

scanner unit) removed, be sure to turn OFF the high-voltage switch (S1) on the SCN board

(1) Turn ON the power.

(2) Start the M-Utility.

(3) Place the IP removal arm in the HP.

0. QUIT

1. ERROR LOG UTILITY

2. CONFIGURATION SETTING

3. TEST MODE

4. ELECTRICAL UTILITY

5. SCANNER UTILITY

6. MECHANICAL UTILITY

7. FILE UTILITY

8. BACKUP MEMORY

9. HV OFF

10. MENU SETTING

#1 [Input/ENT]

11.SYSTEM UTILIT

> 6

Y

MC - 83

#2 [Input/ENT]

#3 [Input/ENT]

#4 [Input/ENT]

0. QUIT

1. INITIALIZE

2. MOTOR

3. ACTUATOR

4. SENSOR

5. UNIT

MU > 5

0. QUIT

1. IP FEED/LOAD UNIT

2. UP-DOWN UNIT

3. SIDE-POSITIONING GRIP

4. SIDE-POSITIONING UNIT

5. AFTER-READING GRIP

6. DRIVING GRIP

7. DRIVEN GRIP

8. MIRROR UP/DOWN

9. CLEANING GUIDE

MU : UNI > 1

0. QUIT

1. ARM HOME POSITION

2. FEED/LOAD

MU : UNI : IFL > 1

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

FR7H3205.EPS

MC - 83

Page 91

MC - 84

(4) Verify that the distance between the end faces of the IP removal unit side plate and

roller bearing is about 95.0 mm.

Side plate

95.0 mm

FRONT

IP removal unit

Roller bearing

Roller bearing

IP removal arm

FR7H3206.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 84

Page 92

BLANK PAGE

MC - 85

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 85

Page 93

5.4 Timing Belt (for IP Conveyance)

FR7H3019.EPS

■ Removal procedure

(1) Remove the following covers:

• Lower front cover

• Lower right-hand side cover

MC - 86

“3. Removing and Installing the Covers”

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 86

Page 94

(2) Remove the timing belt (for IP conveyance).

[Disconnect] Connector

#2

#1

[Remove] BR4x8 (x2)

MC - 87

Fan

FRONT

FRONT

CHECK

Timing belt

Shaft

Timing belt pulley

Roller bearing

#3

[Remove] BR4x30

Roller bearing

FR7H3207.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 87

Page 95

■ Installation procedure

To accomplish installation, reverse the removal procedure.

■ Check/adjustment procedure

• Verify that the timing belt is properly threaded through its path.

• After the timing belt is replaced with a new one or the tensioner is removed and reinstalled,

remove the IP removal unit and adjust the belt tension with the tensioner screw.

“5.1 IP Removal Unit”

Scales

361 mm

MC - 88

Push-pull gauge

560.5 N

Timing belt

FRONT

FR7H3208.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 88

Page 96

BLANK PAGE

MC - 89

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 89

Page 97

5.5 Guide Plate A

MC - 90

Guide plate A

■ Removal procedure

(1) Remove the following covers:

• Lower front cover

• Lower right-hand side cover

• Lower left-hand side cover

• Lower rear cover

“3. Removing and Installing the Covers”

FR7H3020.EPS

FR7H3209.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 90

Page 98

(2) Remove the fan assembly.

(3) Remove guide plate A.

MC - 91

Fan

#2

[Disconnect] Connector

#1

[Remove] BR4x8 (x2)

Bracket

Anti-static

member

#4

[Remove] B3x6 (x6)

#3

[Remove] BR4x8

#5

[Disconnect]

Connector

A

#6

[Remove]

A3x6 (x2)

CHECK

■ Installation procedure

To accomplish installation, reverse the removal procedure.

■ Check procedure

Make sure that the anti-static member is brought into contact with the roller.

009-058-02

009-058-00

08.30.2001 FM3142

10.20.2000 FM2732 (2)

Guide plate A

CR-IR347

Service Manual

FR7H3210.EPS

MC - 91

Page 99

5.6 Rubber Rollers C and D

IP removal unit

FR7H3021.EPS

■ Removal procedure

(1) Remove the timing belt (for IP conveyance).

“5.4 Timing Belt (for IP Conveyance)”

FRONT

Rubber roller C

MC - 92

Rubber roller D

FR7H3211.EPS

(2) Remove guide plate A.

“5.5 Guide Plate A”

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 92

Page 100

FR7H3212.EPS

FRONT

FRONT

#3

[Remove] E6

Timing belt pulley

Rubber roller D

#4

[Remove]

Extension spring

(L = 92 mm)

Roller bearing

Roller bearing

Housing

Housing

Rubber roller C

#2

[Remove] Extension spring (L = 80 mm)

#1

[Remove] Gear (x2)

Anti-static member

CHECK

(3) Remove rubber rollers C and D.

MC - 93

■ Installation procedure

◆

INSTRUCTION

◆

The extension spring size varies with the mounting location. When installing the

extension springs, pay due attention to their mounting locations.

To accomplish installation, reverse the removal procedure.

■ Check procedure

Make sure that the anti-static member is brought into contact with the roller.

009-058-02

009-058-00

08.30.2001 FM3142

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

MC - 93

Loading...

Loading...