Siemens Flowrite 599 Series, SKB62UA Series, SKB62UC Series, SKB62UD Series Technical Instructions

Page 1

Flowrite™ 599 Series

Technical Instructions

Document No. 155-717

September 25, 2018

SKB/C/D 62UA Series

Electronic Valve Actuator 24 Vac

Proportional Control

Advanced Features

SKB/C

SKD

Siemens Industry, Inc.

Description

The Flowrite 599 Series SKB/C/D62UA Electronic Valve Actuator requires a 24 Vac

supply and receives a 0 to 10 Vdc or a 4 to 20 mA control signal to proportionally control

a valve. This actuator is designed to work with valves with a 3/4-inch (20 mm) or 1-1/2inch (40 mm) stroke.

Features

• Direct-coupled installation requires no special tools or adjustments

• Visual and electronic stroke indication

• Die-cast aluminum housing

• Manual override

• Spring return to fail-safe position

• Automatic stroke calibration

• Direct or reverse acting

• Adjustable start and span

• Stroke limit control

• Choice of linear or equal-percentage flow characteristic

• Maintenance-free

Application

These electronic actuators are designed to be used with Flowrite 599 Series valves with

either 3/4-inch (20 mm) stroke (SKB/D) or a 1-1/2 inch (40 mm) stroke (SKC) in liquid

and steam service applications; or other manufacturer's valves with appropriate

Universal Valve Linkage Kits.

Page 2

Technical Instructions Flowrite 599 Series SKB/C/D 62UA Electronic Valve Actuator Advanced Features

Document Number 155-717

September 25, 2018

Page 2 Siemens Industry, Inc.

Product Numbers

Table 1. Product Numbers.

Actuator

Stroke

Order Number

3/4-inch (20 mm)

SKB62UA

SKD62UA

1-1/2 inch (40 mm)

SKC62UA

Warning/Caution Notations

WARNING:

Personal injury or loss of life may occur if you do not

perform a procedure as specified.

CAUTION:

Equipment damage or loss of data may occur if you

do not perform a procedure as specified.

Specifications

Power Supply

Operating voltage (SELV,PELV) 24 Vac ± 20%

Frequency 50 or 60 Hz

Power consumption

SKB62UA 17 VA/12W

SKC62UA 28 VA/20W

SKD62UA 17 VA/12W

Operating

Type of control (proportional) 0 to 10 Vdc; 4 to 20 mA;

or 0 to 1000 ohms

Running time Opening: Closing:

SKB62UA 120 seconds 15 seconds

SKC62UA 120 seconds 20 seconds

SKD62UA 30 seconds 15 seconds

Spring-return time Closing:

SKB62UA 15 seconds

SKC62UA 20 seconds

SKD62UA 15 seconds

Nominal stroke

SKB62UA 3/4-inch (20 mm)

SKC62UA 1-1/2-inch (40 mm)

SKD62UA 3/4-inch (20 mm)

Position force

SKB/C 62UA 2800N

SKD62UA 1000N

Page 3

Flowrite 599 Series SKB/C/D 62UA Electronic Valve Actuator Advanced Features Technical Instructions

Document Number 155-717

September 25, 2018

Siemens Industry, Inc. Page 3

Signal Inputs

Terminal Y

Voltage 0 to 10 Vdc

Input impendence 100K ohm

Current 4 to 20 mA

Input impedance 240 ohm

Signal resolution <1%

Hysteresis <1%

Terminal Z

Resistance 0 to 1000 ohm

Override control functions

Z not connected No function (priority at Terminal Y)

Z connected directly to G Maximum stroke 100%

Z connected directly to G0 Minimum stroke 0%

Z connected to M via 0 to 1000 ohm Linear or equal percentage

Signal Inputs, Continued

Terminal U

Voltage 0 to 9.8 Vdc ± 2%

Load impedance >500 ohm

Current 4 to 19.6 mA ± 2%

Load impedance <500 ohms

Ambient Conditions

Media temperature

SKD 20°F to 300°F (-7°C to 150°C)

SKB/C 20°F to 337°F (-7°C to 170°C)

Operation To IEC 721-3-3

Environmental conditions Class 3K5

Temperature

SKD 5°F to 122°F (-15°C to 50°C)

SKB/C 5°F to 130°F (-15°C to 55°C)

Humidity 5% to 95% rh

Transport To IEC 721-2-1

Environmental conditions Class 3K5

Temperature 22°F to 149°F (-5°C to 65°C)

Humidity <95% rh

Storage To IEC 721-3-1

Environmental conditions Class 1K3

Temperature

SKD 5°F to 122°F (-15°C to 50°C)

SKB/C 5°F to 130°F (-15°C to 55°C)

Humidity 5% to 95% rh

Agency Certification

UL Listed to UL873

C-UL Certified to Canadian standard

C22.2 No. 24-93

Meets CE requirements:

EMC Directive 89/336/EEC

C-tick N474

Protection standard IP54 to EN 60 529

Protection Class III to EN 60 730

Page 4

Technical Instructions Flowrite 599 Series SKB/C/D 62UA Electronic Valve Actuator Advanced Features

Document Number 155-717

September 25, 2018

Page 4 Siemens Industry, Inc.

Miscellaneous

Materials

Actuator housing and bracket Die-cast aluminum

Housing box and manual adjustor Plastic

Conduit opening 1/2-inch NPSM

Dimensions See Figure 23, Figure 24, Figure 25

and Figure 26.

Weight

SKB62UA 18.9 lbs (8,60 kg)

SKC62UA 22.5 lbs (10,00 kg)

SKD62UA 8.5 lbs (3,85 kg)

Housing

NEMA Rating NEMA 1 (Interior only)

See Accessories

Advanced Features

Direction of Operation

Direct acting / reverse acting 0 to 10 Vdc; 10 to 0 Vdc

4 20 mA; 20 to 4 mA

0 to 1000 ohm/1000 to 0 ohm

Stroke Limit Control

Range of lower limit 0% to 45% adjustable

Range of upper limit 100% to 55% adjustable

Sequence Control

Starting Point of Sequence (Start) 0 to 15V adjustable

Operating Range of Sequence (Span) 3 to 15V adjustable

Accessories

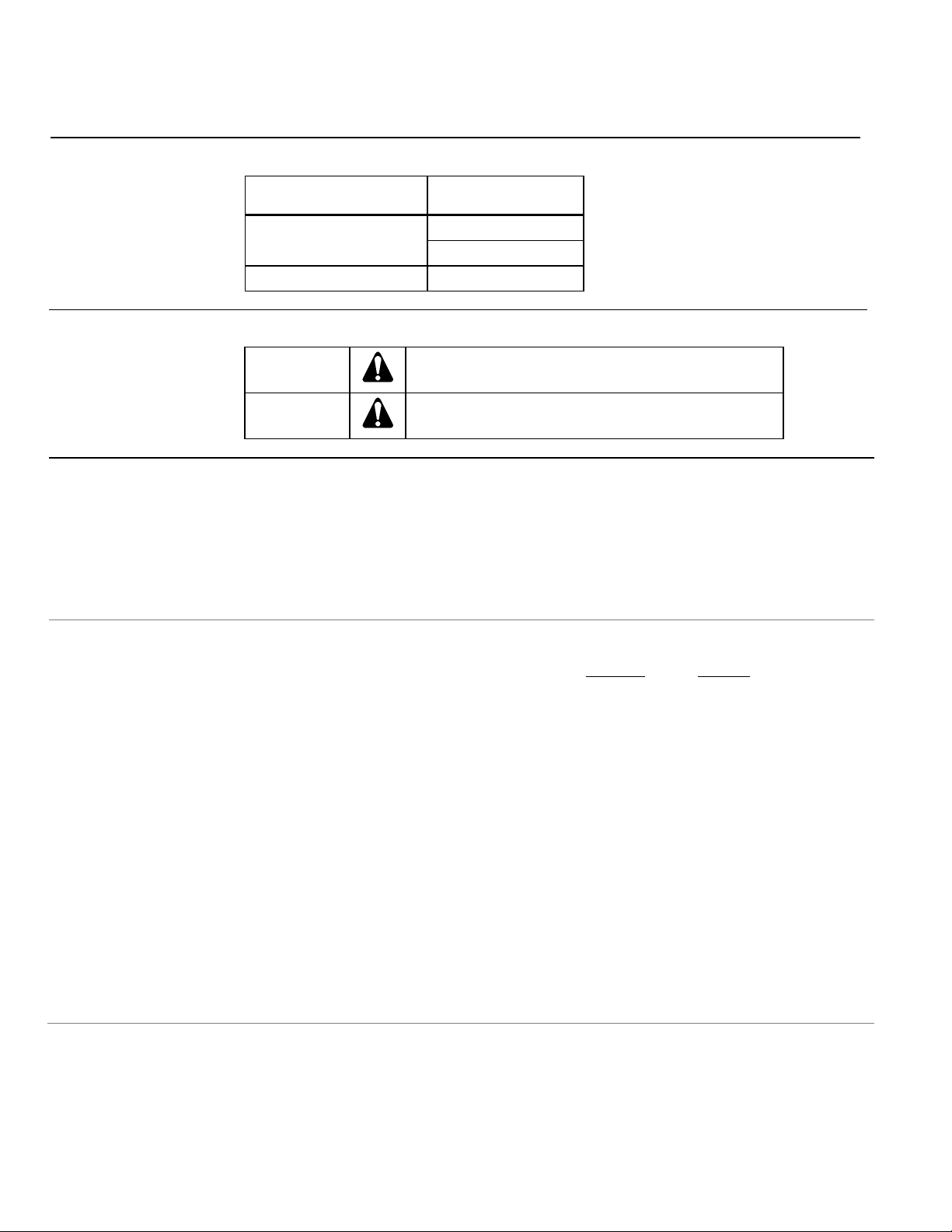

Figure 1. Auxiliary Switch.

ASC1.6 Auxiliary switch

• Sends a signal to indicate that the valve is

in the 0% stroke position.

• The switching point is fixed at the 0%

stroke position.

Switching capacity 24 Vac

4A resistive,

2A inductive

Lowest recommended current 10 mA

Figure 2. Stem Heating Element.

ASZ6.6 The stem heating element prevents

the formation of ice on the stem when the

medium temperature drops below 32°F (0°C).

It is suited for universal use with valves having

a stem or spindle diameter of 10 or 14 mm.

Operating voltage 24 Vac/dc ± 20%

Power consumption ≤ 40 VA/30W

Figure 3. SKB/C Weather Shield.

599-10065 The SKB/C actuator is UL listed to

meet NEMA Type 3R requirements (a degree

of protection against rain, sleet, and damage

from external ice formation) when installed with

this weather shield and outdoor-rated conduit

fittings in the vertical position. See Service Kits

for replacement ultraviolet resistant cable ties.

Page 5

Flowrite 599 Series SKB/C/D 62UA Electronic Valve Actuator Advanced Features Technical Instructions

Document Number 155-717

September 25, 2018

Siemens Industry, Inc. Page 5

Accessories,

Continued

Figure 4. SKD Weather Shield.

599-10071 The SKD actuator is UL listed to

meet NEMA TYPE 3R requirements (a degree

of protection against rain, sleet, and damage

from external ice formation) when installed with

this weather shield and outdoor-rated conduit

fittings in the vertical position. See Service Kits

for replacement ultraviolet resistant cable ties.

Figure 5. Valve Retrofit Kit.

Universal Retrofit Kit

Kit contains the parts needed to adapt a valve

to the following Siemens 599 Series Flowrite

actuators: SKB, SKC, SKD, SQX. Selected

valves from the following manufacturers can

also be accommodated: Honeywell, Johnson

Controls, and Siebe. See your local Siemens

representative for details.

Service Kits

Circuit board replacement 4 668 5751 8

Manual override kit 4268 5510 8

Plastic wiring compartment cover 4 104 5582 8

Stem retainer kit

Contains one stem nut (Figure 7, Item 6) and one stem retainer clip.

2-1/2 and 3-inch valves 599-10048

4, 5, and 6-inch valves 599-10049

Retainer clamp kit 599-10200

Ultraviolet (UV) resistant cable ties (pkg. of 8) 538-994

WARNING:

This product contains a spring under high compression. Do not

attempt to disassemble the actuator.

Valve Details

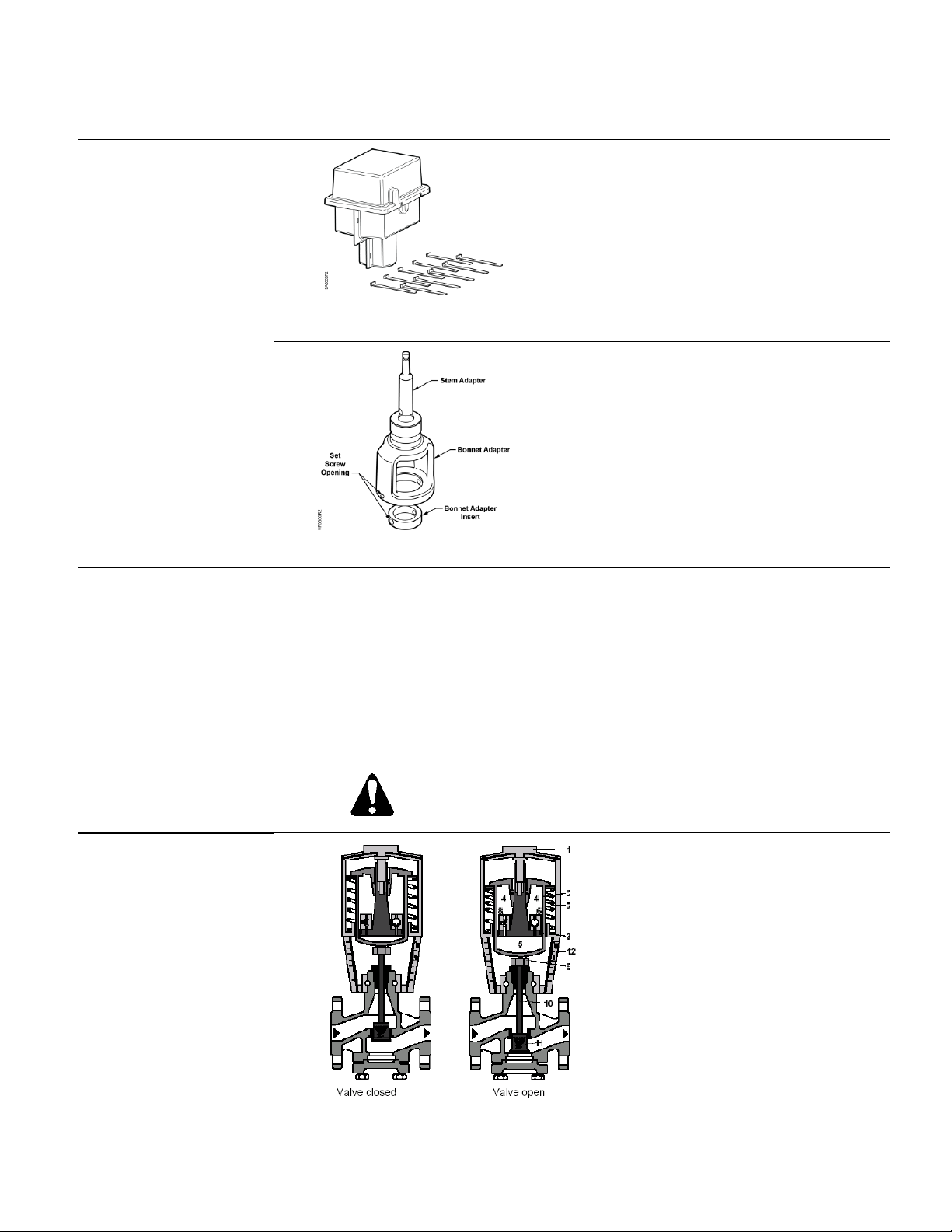

Figure 6. SKB/C Valve Parts.

1. Manual Adjuster

2. Pressure Cylinder

3. Piston

4. Reservoir

5. Pressure Chamber

6. Pump

7. Return Spring

8. Bypass Valve

9. Coupling

10. Valve Stem

11. Inner Valve

12. Position Indicator (0 to 1)

Page 6

Technical Instructions Flowrite 599 Series SKB/C/D 62UA Electronic Valve Actuator Advanced Features

Document Number 155-717

September 25, 2018

Page 6 Siemens Industry, Inc.

Valve Details,

Continued

Figure 7. SKD Valve Parts.

1. Pressure cylinder

2. Piston

3. Oscillating pump

4. Return spring

5. Bypass valve

6. Valve stem retainer

7. Manual override knob

8. Position indicator

Standard Operation

Figure 8. SKB/C Valve Stem Travel Indication.

Figure 9. SKD Valve Stem Travel Indication.

The actuator accepts a 0 to 10 Vdc or a 4 to 20 mA control signal. The actuator

mounted on a valve produces a stroke proportional to the input signal. When power is

turned off or in the event of a power failure, the actuator spring returns the valve to its

normal position.

Direct Acting

Page 7

Flowrite 599 Series SKB/C/D 62UA Electronic Valve Actuator Advanced Features Technical Instructions

Document Number 155-717

September 25, 2018

Siemens Industry, Inc. Page 7

Mounting and

Installation

The vertical position is the recommended position for mounting and the only position for

NEMA Type 3R rating with the Weather Shield. Acceptable mounting positions are shown

in Figure 10.

Figure 10. Acceptable Mounting Positions.

Allow four inches (100 mm) around the sides and back of the actuator and eight inches

(200 mm) above and to the front of the actuator.

See dimensions in Figure 23, Figure 24, Figure 25, and Figure 26.

Detailed installation instructions for field mounting are shipped with the actuator.

CAUTION:

When removing the knockout do not damage the circuit board. Use

the top knockout position, if possible.

Start-up

Check the wiring for proper connections.

NOTE: The valve body assembly determines the complete assembly action.

Spring Return

Function

All SKB/C/D62UA actuators are factory-fitted with a spring-return function. If the control

signal or power supply fails, the actuator will return to the 0% stroke position (stem fully

retracted).

Override Control

The override control input (Z) has three modes of operation:

NOTE: The Z-modes have a "direct acting" factory setting.

Page 8

Technical Instructions Flowrite 599 Series SKB/C/D 62UA Electronic Valve Actuator Advanced Features

Document Number 155-717

September 25, 2018

Page 8 Siemens Industry, Inc.

Stroke Calibration

To determine the stroke positions 0% and 100% in the valve, calibration is required when the

valve/actuator are commissioned for the first time. The actuator must be mechanically

connected to a valve and must have a supply voltage of 24 Vac. The calibration procedure can

be repeated as often as necessary

CAUTION:

Before starting calibration, be sure that the manual adjuster is set to Automatic for

the actual values to register.

There is a slot on the printed circuit boards for the actuators. To

initiate the calibration procedure, the contacts inside this slot must

be short-circuited (possibly with a screwdriver). See Figure 11.

Automatic calibration proceeds as follows (see Figure 12):

• Actuator runs to the 0% stroke position (1), the green LED

flashes.

• Actuator then runs to the 100% stroke position (2), the

green LED flashes.

• Measured values are stored in the EPROM.

• The actuator now moves to the position defined by control

signal Y or Z (3), and the green LED now glows steady

(normal operation).

• Throughout this procedure, output U is inactive, meaning

the values only represent actual positions when the green

LED stops flashing and remains on continuously.

Figure 11.

Figure 12.

Automatic Calibration.

Table 2. LED Status.

LED

Display

Function

Action

Green

ON

Normal Operation

Automatic operation

Flashing

Stroke calibration In

Progress

Wait for calibration to be

completed (LED stops flashing)

Red

ON

Faulty stroke calibration

Internal Error

- Check mounting

- Restart stroke calibration (by

short-circuiting calibration slot)

- Replace electronics

Flashing

Valve plug jammed

Check the valve

OFF

• No power supply

• Faulty electronics

- Check mains

- Replace electronics

Page 9

Flowrite 599 Series SKB/C/D 62UA Electronic Valve Actuator Advanced Features Technical Instructions

Document Number 155-717

September 25, 2018

Siemens Industry, Inc. Page 9

Start-up, Continued

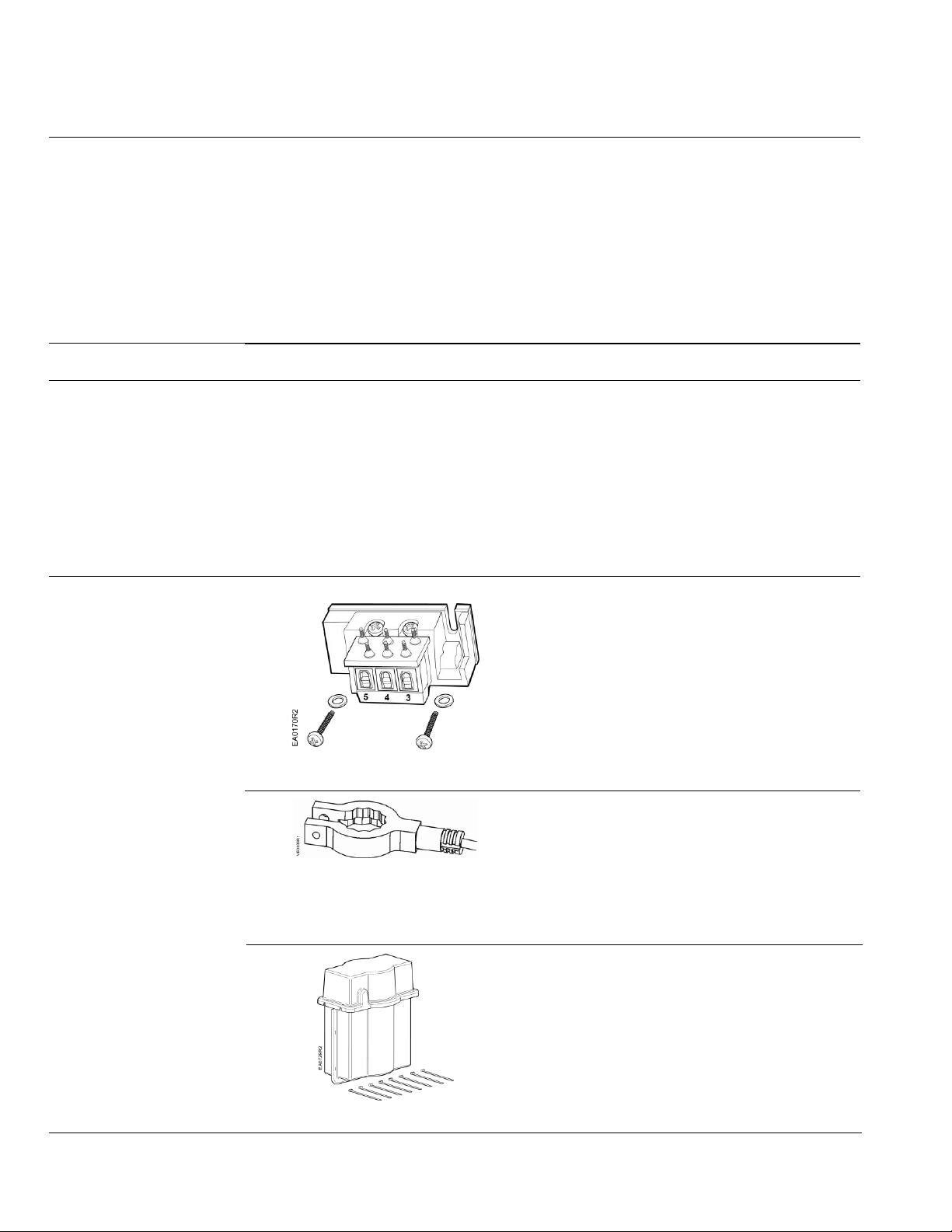

Advanced Features

1 2 3

4

Figure 13. DIP Switches.

DIP Switches

(From Left to Right)

1

Select

Direction of

Operation

2

Sequence Control

or

Stroke Limit Control

3

Selection of

Control

Signal

4

Selection of

Flow

Characteristic

ON

Reverse-acting

Sequence control

4 to 20 mA

Modified*

OFF

(Factory Settings)

Direct-acting

Stroke limit control

0 to 10 Vdc

Default

*Changing the default setting will modify an equal percentage valve to a linear flow characteristic. When

set to default, the flow characteristic is determined by the valve body.

Page 10

Technical Instructions Flowrite 599 Series SKB/C/D 62UA Electronic Valve Actuator Advanced Features

Document Number 155-717

September 25, 2018

Page 10 Siemens Industry, Inc.

Start-Up,

continued

Selecting the

Direction of

Operation

• With normally-closed valves, "direct-acting" means that with a 0 Vdc signal input, the valve

is closed.

• With Normally-open valves, "direct-acting" means that with a 0 Vdc signal input, the valve

is open.

Input:

0 to 10 Vdc

Input

10 to 0 Vdc

0 Vdc

10 Vdc

4 to 20 mA

20 to 4 mA

4 mA

20 mA

0 to 1000 ohm

1000 to 0 ohm

0 ohm

1000 ohm

Figure 14. Direction of Operation.

Sequence Control

or Stroke Limit

Control

Check the wiring for proper connections.

NOTE: The valve body assembly determines the complete assembly action.

Table 3. Table 4.

Setting the Stroke Limit Control

Setting the Sequence Control

The rotary switches LO and UP can be

used to apply an upper and lower limit

to the stroke in increments of 3% up to

a maximum of 45%.

The rotary switches LO and UP can be used

to determine the starting point (Start) or the

operating range of a sequence (Span).

Position

of

LO

Lower

Stroke

Limit

Position

of

UP

Upper

Stroke

Limit

Position

of

LO

Starting

Point for

Sequence

Control

Position

of

UP

Operating

Range of

Sequence

Control

0

0% 0 100% 0

0V 0 10V

1

3% 1 97% 1

1V 1 10V*

2

6% 2 94% 2

2V 2 10V*

3

9% 3 91% 3

3V 3 3V*

4

12% 4 88% 4

4V 4 4V

5

15% 5 85% 5

5V 5 5V

6

18% 6 82% 6

6V 6 6V

7

21% 7 79% 7

7V 7 7V

8

24% 8 76% 8

8V 8 8V

9

27% 9 73% 9

9V 9 9V

A

30% A 70% A

10V A 10V

B

33% B 67% B

11V B 11V

C

36% C 64% C

12V C 12V

D

39% D 61% D

13V D 13V

E

42% E 58% E

14V E 14V

F

45% F 55% F

15V F 15V

*The smallest adjustment is 3 Vdc; Control with 0 to

3 Vdc is possible only via Y.

Page 11

Flowrite 599 Series SKB/C/D 62UA Electronic Valve Actuator Advanced Features Technical Instructions

Document Number 155-717

September 25, 2018

Siemens Industry, Inc. Page 11

Start-up, continued

Normally Closed Valve

When actuator pressure cylinder:

Moves outward (0 to 1): Valve opens.

Moves inward (1 to 0): Valve closes.

Normally Open Valve

When actuator pressure cylinder:

Moves outward (0 to 1): Valve closes.

Moves inward (1 to 0): Valve opens.

Three Way Valve

When actuator pressure cylinder:

Moves outward (0 to 1): Valve opens between port NC and C.

Moves inward (1 to 0): Valve opens between ports NO and C.

The measuring voltage at terminal U provides valve stem position feedback to an

indicating instrument or building automation system.

Manual operation

Figure 15. SKB/C Manual

Operation.

Figure 16. SKD Manual Operation.

Turn the manual setting knob clockwise for

manual operation. As you begin to turn, a red

indicator becomes visible. Each complete

revolution (360°) is equal to 3/32-inch (2.5 mm)

stroke.

NOTE: If a signal is sent to the actuator while it is in manual operation, the actuator

will move, but the control will not be accurate. The valve cannot be

commanded to its 0% position while in manual operation.

Page 12

Technical Instructions Flowrite 599 Series SKB/C/D 62UA Electronic Valve Actuator Advanced Features

Document Number 155-717

September 25, 2018

Page 12 Siemens Industry, Inc.

Start-up, Continued

Automatic Operation

SKB/C

When returning to automatic control, you must turn the crank arm of the manual

setting knob counterclockwise until the red numbers disappear. It is essential that the

window is clear and the crank arm is snapped into position. See Figure 17.

Figure 17. SKB/C Automatic Operation.

SKD

For automatic operation, the manual override knob must be in the fully closed

position. Turn the manual override knob counterclockwise until the red indicator

disappears.

Figure 18.

Fully Retracted Coupling

Fully Extended Coupling

► Stroke = 0%

► Stroke = 100%

CAUTION:

The manual adjuster must be rotated

counterclockwise to the end stop until

the red indicator marked MAN is no

longer visible.

Page 13

Flowrite 599 Series SKB/C/D 62UA Electronic Valve Actuator Advanced Features Technical Instructions

Document Number 155-717

September 25, 2018

Siemens Industry, Inc. Page 13

Wiring

Do not use auto-transformers. Use earth ground isolating step-down Class II power

supplies.

Determine supply transformer rating by summing total VA of all actuators used.

Determine the rating for Class 2 step-down transformer is 100 VA and consider the

following requirements:

SKB62UA = 17 VA SKC62UA = 28 VA SKD62UA = 17 VA;

A maximum of four actuators can be powered by one transformer (80% of transformer

VA). Operating more than four SK series actuators requires additional transformers or

separate 100 VA power supplies.

The position output signal U will switch from 0 to 10 Vdc to 4 to 20 mA when a 4 to

20 mA input signal is selected and used on the Y terminal.

Wiring Diagrams

Figure 19. Terminal Connections.

24 Vac

G

System potential (SP)

G0

System neutral (SN)

Y

Control input signal 0 to 10 (30) Vdc or 4 to 20 mA

M

Measuring neutral

U

Position indication 0 to 10 Vdc or 4 to 20 mA (see Table 1)

Z

Override input.

Figure 20. Auxiliary Switches.

Table 1. Actuator Output Signal U.

Actuator Input Signal

Receiving Impedance

Low

(<500 ohm)

High

(>10K ohm)

0 to 10 Vdc

0 to 20 mA

0 to10 Vdc

4 to 20 mA

4 to 20 mA

2 to 10 Vdc

Page 14

Technical Instructions Flowrite 599 Series SKB/C/D 62UA Electronic Valve Actuator Advanced Features

Document Number 155-717

September 25, 2018

Page 14 Siemens Industry, Inc.

Wiring Diagrams, Continued

System neutral (SN) red

System potential (SP) black

24 Vac/30W

Figure 21.

Auxiliary Switch

ASC1.6.

Figure 22.

Stem Heating Element

ASZ6.6.

Dimensions

Figure 23. Dimensions of 599-10065 SKB\C Weather Shield in Inches (Millimeters).

Page 15

Flowrite 599 Series SKB/C/D 62UA Electronic Valve Actuator Advanced Features Technical Instructions

Document Number 155-717

September 25, 2018

Siemens Industry, Inc. Page 15

Dimensions,

Continued

Figure 24. Dimensions of 599-10071 SKD Weather Shield in Inches (Millimeters).

Figure 25. Dimensions of SKB/C Weather Shield, 599-10071 in Inches (Millimeters).

Page 16

Technical Instructions Flowrite 599 Series SKB/C/D 62UA Electronic Valve Actuator Advanced Features

Document Number 155-717

September 25, 2018

Information in this publication is based on current specifications. The company reserves the right to make changes in specifications and models as

design improvements are introduced. Flowrite is a trademark of Siemens Industry, Inc. Other product or company names mentioned herein may

be the trademarks of their respective owners. © 2018 Siemens Industry, Inc.

Siemens Industry, Inc.

Building Technologies Division

1000 Deerfield Parkway

Buffalo Grove, IL 60089

USA

+ 1 847-215-1000

Your feedback is important to us. If you have comments about this

document, please send them to

sbt_technical.editor.us.sbt@siemens.com

Document No. 155-717

Printed in the USA

Page 16

Dimensions,

Continued

Figure 26. Dimensions of SKD Actuator in Inches (Millimeters).

Loading...

Loading...