Page 1

Industry Sector, IA&DT

SCE Training Curriculum

for Integrated Automation Solutions

Totally Integrated Automation (TIA)

Siemens Automation Cooperates with Education

TIA Portal Module 040-020

Startup Programming in High-Level Languages

with S7-SCL and SIMATIC S7-300

SCE Training Curriculum Page 1 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 2

Industry Sector, IA&DT

Suitable SCE trainer packages for these training curriculums

SIMATIC controllers

SIMATIC S7-300 with CPU 314C-2PN/DP

Order no.: 6ES7314-6EH04-4AB3

SIMATIC S7-300 with CPU 314C-2PN/DP (upgrade)

Order no.: 6ES7314-6EH04-4AB4

SIMATIC S7-300 with CPU 315F-2PN/DP

Order no.: ES7315-2FH14-4AB1

SIMATIC ET 200S with CPU IM151-8 F PN/DP

Order no.: 6ES7151-8FB00-4AB1

SIMATIC STEP 7 software for training

SIMATIC STEP 7 Professional V11 - Single license

Order no.: 6ES7822-1CC01-4YA5

SIMATIC STEP 7 Professional V11 - Classroom license (up to 12 users)

Order no.: 6ES7822-1AA01-4YA5

SIMATIC STEP 7 Professional V11 - Upgrade license (up to 12 users)

Order no.: 6ES7822-1AA01-4YE5

SIMATIC STEP 7 Professional V11 - Student license (up to 20 users)

Order no.: 6ES7822-1AC01-4YA5

Please note that these trainer packages may be replaced by successor trainer packages.

An overview of the currently available SCE packages is provided under: HUsiemens.com/sce/tpUH

Advanced training

Please get in touch with your regional SCE contact for information on regional Siemens SCE advanced training

siemens.com/sce/contact

Additional information regarding SCE

siemens.com/sce

Information regarding usage

This SCE training curriculum for the end-to-end automation solution Totally Integrated Automation (TIA) was

prepared for the program "Siemens Automation Cooperates with Education (SCE)" specifically for educational

purposes for public educational institutions and R&D facilities. Siemens AG does not make any guarantee

regarding its contents.

This document may only be used for initial training on Siemens products/systems. That is, it may be copied in

whole or in part and handed out to participants for use within the context of their education. Distribution and

reproduction of this curriculums and disclosure of its contents are permitted within public education and further

education institutions for educational purposes.

Any exceptions require written consent from the Siemens AG contact person: Mr. Roland Scheuerer

roland.scheuerer@siemens.com.

Offenders will be liable for damages. All rights reserved, including those relating to translation and in particular

those rights created as a result of a patent being granted or utility model being registered.

Use for industry customers is expressly prohibited. We do not consent to any commercial use of the training

curriculum.

We would like to thank Michael Dziallas Engineering and all those involved for their support in creating this

training curriculum.

SCE Training Curriculum Page 2 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 3

Industry Sector, IA&DT

PAGE:

1. Preface ....................................................................................................................................................... 4

2. Notes on S7-SCL Programming Language ................................................................................................ 6

3. The S7-SCL Development Environment .................................................................................................... 7

4. Example Task Tank Content ...................................................................................................................... 8

4.1 Description of task ...................................................................................................................................... 8

4.2 Assignment list / tag table ........................................................................................................................... 8

4.3 Program structure ....................................................................................................................................... 9

4.4 Interface of the block calculate_tankcontent [FC140] .............................................................................. 10

4.5 Note on solution ........................................................................................................................................ 11

5. Programming the Tank Content Calculation for SIMATIC S7-300 in S7-SCL .......................................... 12

5.1 Creating a project and configuring hardware ............................................................................................ 12

5.2 Creating a program ................................................................................................................................... 16

5.3 Test program ............................................................................................................................................ 23

5.4 Expanding the program ............................................................................................................................ 26

SCE Training Curriculum Page 3 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 4

Industry Sector, IA&DT

Advanced functions for

PLC programming

Module 30

Basics of PLC

programming

Module 10, Module 20

PROFIBUS PROFINET

Module 60 Module 70

AS interface

Module 50

Safety technology

Module 80

Drive technology

Module 100

Process visualization

(HMI) Module 90

Sensor technology

Module 110

Plant simulation with

SIMIT Module 150

Other programming

languages

Module 40

1. Preface

The content of the SCE_EN_040-020 module is part of the 'Other Programming Languages' training

unit and represents a fast entry point for programming the SIMATIC S7 300 with the S7-SCL

programming language with the TIA Portal.

Learning objective:

This module describes the basic functions of the S7 SCL development environment. Test functions for

eliminating logical programming errors will also be shown.

Requirements:

To successfully work through this module, the following knowledge is required:

Proficiency in working with Windows

Basics of PLC programming with STEP 7 Professional V11 (e.g. modules 020- to 030-)

Basic information on programming in high-level languages, such as Pascal.

SCE Training Curriculum Page 4 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 5

Industry Sector, IA&DT

1 PC

2 STEP 7 Professional

V11 (TIA Portal)

4 S7-300 with

CPU 315F-2 PN/DP

3 Ethernet connection

Required hardware and software

1 PC Pentium 4, 1.7 GHz 1 (XP) – 2 (Vista) GB RAM, approx. 2 GB of free hard disk space

Operating system Windows XP Professional SP3 / Windows 7 Professional / Windows 7

Enterprise / Windows 7 Ultimate / Windows 2003 Server R2 / Windows Server 2008 Premium SP1,

Business SP1, Ultimate SP1

2 Software: STEP 7 Professional V11 SP1 (Totally Integrated Automation (TIA) Portal V11)

3 Ethernet connection between the PC and CPU 315F-2 PN/DP

4 SIMATIC S7-300 PLC, e.g., CPU 315F-2PN/DP with 16DI/16DO signal module. The inputs must be

fed out to a control panel.

SCE Training Curriculum Page 5 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 6

Industry Sector, IA&DT

2. Notes on S7-SCL Programming Language

S7-SCL (Structured Control Language) is a high-level programming language based on PASCAL, which

allows structured programming. The language corresponds to the SFC "Sequential Function Chart"

language specified in the standard DIN EN-61131-3 (IEC 61131-3). In addition to high-level

programming language elements, S7-SCL contains typical elements of the PLC such as inputs, outputs,

timers, bit memories, block calls etc. as language elements. It supports the block concept of STEP 7

and allows data blocks to be programmed according to standard as well as using STL, LAD and FBD. In

other words, S7-SCL supplements and extends the STEP 7 programming software with its LAD, FBD

and STL programming languages.

You do not have to create every function yourself. Instead, you can used already prepared blocks such

as system functions or system function blocks that are present in the operating system of the CPU.

Blocks that are programmed with S7-SCL can be mixed with STL, LAD and FBD. This means that a

block programmed with S7-SCL can call another block programmed in STL, LAD or FBD. In turn,

S7-SCL blocks can also be called in STL, LAD and FBD.

The test functions of S7-SCL allow searching for logical programming errors in an error-free compilation.

SCE Training Curriculum Page 6 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 7

Industry Sector, IA&DT

S7-SCL for S7-300/400

Editor / compiler

Debugger

3. The S7-SCL Development Environment

To use and deploy S7-SCL there is a development environment that is oriented to specific features of

both S7-SCL and STEP 7. This development environment consists of an editor/compiler and a

debugger.

Editor / compiler

The S7-SCL editor is a text editor with which texts can be edited. The central task you use the editor for

is to create and edit blocks for STEP 7 programs. The syntax of the text you input with the editor is

checked thoroughly, making error-free programming simple. Syntax errors are displayed in various

colors.

The editor offers the following options:

- Programming a S7 block in the S7-SCL language.

- Convenient insertion of language elements and block calls using drag-and-drop operation.

- Direct syntax check during programming.

- Adjustment of the editor to your requirements by, for example, syntax-oriented coloring of the

various language elements.

- Checking of the finished blocks by compiling.

- Display of all errors and warnings that occur during compiling.

- Localizing of the faulty position in the block, optionally with description of error and information on

debugging.

Debugger

The S7-SCL debugger provides the option of checking how the program runs in the AS and thus finding

any possible errors.

S7-SCL offers two different test modes for this:

- Step-by-step monitoring

- Continuous monitoring

With "Step-by-step monitoring" the logical execution of the program is completed. You can execute the

program algorithm instruction for instruction and monitor in a result window how the processed tag

contents change during the process.

With "Continuous monitoring" you can test a group of instructions within a block. The values of the tags

and parameters are displayed in chronological order during the test run and - where possible - updated

cyclically.

SCE Training Curriculum Page 7 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 8

Industry Sector, IA&DT

Name

Data type

Address

Comment

FillLevel_tank1

REAL

%MD40

in meters

Diameter_tank1

REAL

%MD44

in meters

Content_tank1

REAL

%MD48

in liters

4. Example Task Tank Content

4.1 Description of task

Our first program is one to program the calculate the content of tank.

The tank has the shape of an upright cylinder. The fill level of the content is measured by an analog

sensor. In the task, the value of the fill level should already existed standardized in the meter unit.

A function FC 140 'calculate_tank content' is to be programmed in the program. The diameter and the fill

level in meter unit are the passed parameters. Result is the tank content in the liter unit.

4.2 Assignment list / tag table

Because modern programming uses tags and not absolute addresses, the global PLC tags must be

defined here.

These global PLC tags are descriptive names with a comment for each input and output used in the

program. The global PLC tags can then be accessed later during programming via their names.

These global tags can be used in all blocks anywhere in the program.

Default tag table

SCE Training Curriculum Page 8 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 9

Main organization

block [OB1]

Block called cyclically

by the operating

system. Here is the

call of the function

calculate_tankcontent

[FC140]

Function:

calculate_tankcontent

[FC140]

The actual program is

contained in this

example.

Is called by Main [OB1].

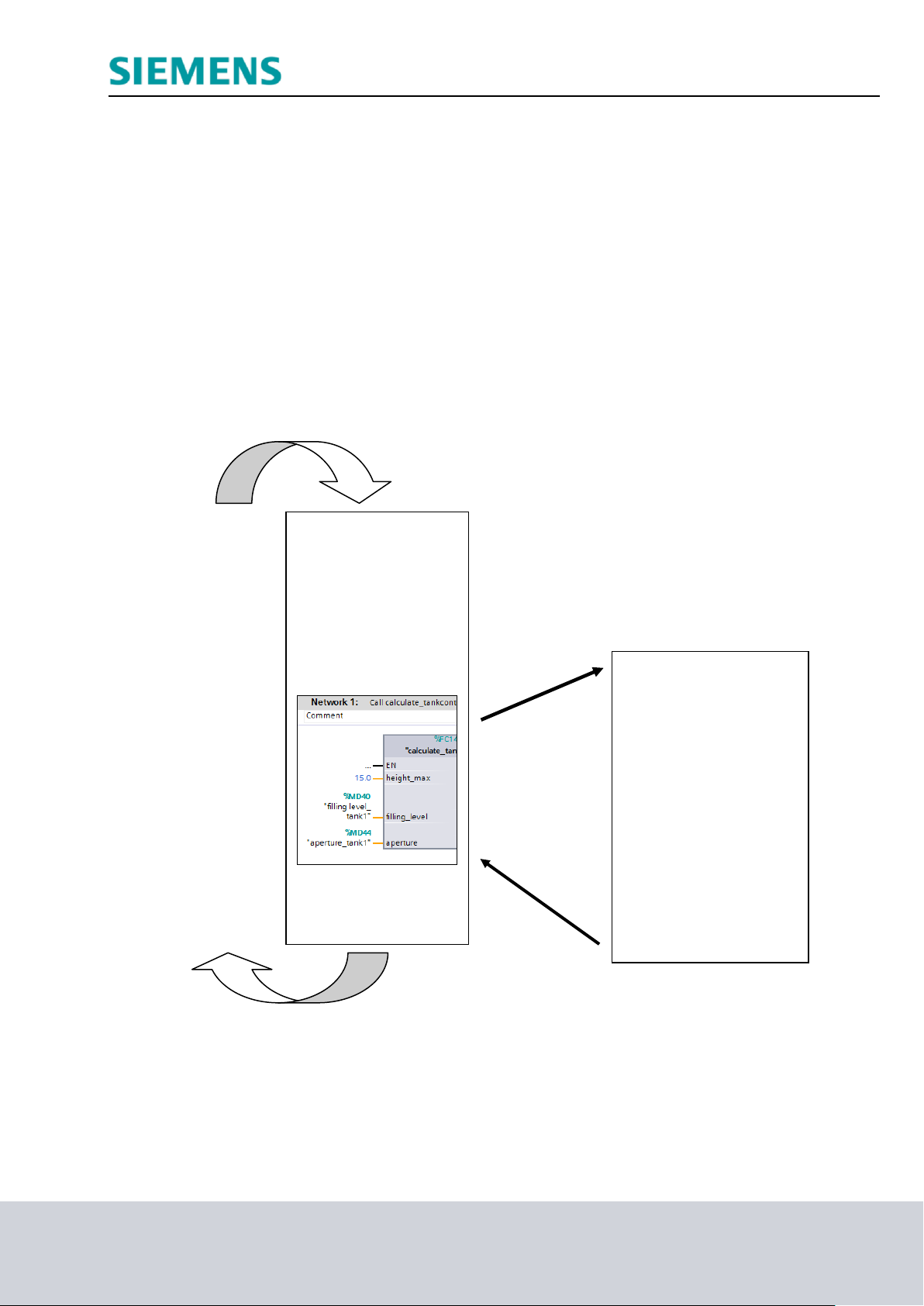

4.3 Program structure

Program execution is written in what are referred to as blocks. The Main [OB1] organization block is

provided as default. This block represents the interface to the CPU operating system and is

automatically called and cyclically processed by this operating system.

From this organization block, additional blocks can be called in turn for structured programming, such as

the function calculate_tankcontent [FC140]

This function is used to break an overall task down into subtasks. These can then be solved more easily

and tested in their functionality.

Structure of the tank content sample task

Industry Sector, IA&DT

SCE Training Curriculum Page 9 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 10

Industry Sector, IA&DT

Type

Designation

Function

Available in

Input parameters

Input

Parameters whose values are

read by the block.

Functions, function blocks, and some

types of organization blocks

Output parameters

Output /

Return

Parameters whose values are

written by the block.

Functions and function blocks

In/out parameters

InOut

A parameter whose value is read

by the block when it is called and

is written back by the block to

the same parameter after it is

processed.

Functions and function blocks

Type

Designation

Function

Available in

Temporary local data

Temp

Tags that are used to store

temporary intermediate results.

Temporary local data is retained

for one cycle only.

Functions, function blocks, and

organization blocks

Static local data

Static

Tags that are used for saving

static intermediate results in the

instance data block. Static data

is retained until it is overwritten,

which may be after several

cycles.

Function blocks

4.4 Interface of the block calculate_tankcontent [FC140]

The interface of the block must be declared before the program can be written. In the interface

declaration, the local tags known only in this block are defined.

The tags or interface parameters are divided into two groups:

Block parameters that form the block interface for the call in the program.

Local data that is used for saving intermediate results.

SCE Training Curriculum Page 10 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 11

Industry Sector, IA&DT

Type

Name

Data type

Comment

IN

Fill level

REAL

in meters

IN

Diameter

REAL

in meters

OUT

Content

REAL

in liters

h*

4

d

V

2

1000f14159.3

4

2

diameter

content levelill

FC140

calculate_tankcontent

Fill level: REAL

Diameter: REAL

REAL :content

The interface parameters for the 'calculate_tankcontent [FC140] block used in our sample program are

as follows.

Interface of the function FC140: calculate_tankcontent

The function call in a block programmed in FBD appears as follows.

Function call: Representation in FBD

4.5 Note on solution

The formula for calculating the volume of an upright cylinder is used to solve the task. The conversion

factor 1000 is used to calculate the result in liters.

SCE Training Curriculum Page 11 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

=>

Page 12

Industry Sector, IA&DT

5. Programming the Tank Content Calculation for SIMATIC S7-300 in S7-SCL

The following steps enable you to create a project for SIMATIC S7-300 and to program the solution for

the task:

5.1 Creating a project and configuring hardware

1. The central tool is the 'Totally Integrated Automation Portal', which is opened here with a

double-click. ( TIA Portal V11)

2. Programs for SIMATIC S7-300 are managed in projects. Such a project is now created in the portal

view. ( Create new project scl_startup Create)

SCE Training Curriculum Page 12 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 13

Industry Sector, IA&DT

3. 'First steps' for configuring are suggested. We want to start with 'Configure a device'.

( First steps Configure a device)

4. The next step is 'Add new device' with the 'Device name Controller 001'. Choose the

'CPU 315F-2 PN/DP' with the appropriate order number from the catalog. ( Add new device

Controller 001 PLC SIMATIC S7-300 CPU CPU 315F-2 PN/DP 6ES7 315-2FH130AB0 V2.6 add)

SCE Training Curriculum Page 13 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 14

Industry Sector, IA&DT

5. The software now switches automatically to the project view containing the opened hardware

configuration in the device view. To ensure that the software will access the correct CPU later, the

'ETHERNET address' of the CPU has to be set.

( Properties General ETHERNET address IP address: 192.168.0.80 Subnet mask:

255.255.255.0)

6. Additional modules can be added for the hardware catalog (on the right). We select the signal

module 'DI16/DO16' with 16 digital inputs and 16 digital outputs and drag this to slot 4.

( Hardware catalog DI/DO DI16/DO16 x 24V / 0.5A 6ES7 323-1BL00-0AA0)

SCE Training Curriculum Page 14 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 15

Industry Sector, IA&DT

7. We also select the 'AI8x12Bit' signal module with 8 analog input and the 'PS307 2A' power supply

module and drag these to the respective slots 5 and 1.

( Hardware catalog

AI AI8 x 12Bit 6ES7 331-7KF02-0AB0

PS PS 307 2A 6ES7 307-1BA00-0AA0)

SCE Training Curriculum Page 15 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 16

Industry Sector, IA&DT

5.2 Creating a program

1. Open the Default tag table' and enter the 'operands' with their name and data type.

( Controller 001[CPU315F-2 PN/DP] PLC-tags Default tag table Enter operands)

SCE Training Curriculum Page 16 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 17

Industry Sector, IA&DT

2. To create the function calculate_tankcontent [FC140], select 'Controller 001 [CPU 315F-2 PN/DP]'

in the project tree and then 'Program blocks'. Then, double-click 'Add new block'. Select

'Function (FC)' and assign the name 'calculate_tankcontent'. Change the programming

language to 'SCL'. You can change the numbering by switching from automatic to manual. Enter

the number 140. Click 'OK' to accept your entries.

( Controller 001 [CPU 315F-2 PN/DP]' Program blocks Add new block Function (FC)

calculate_tankcontent SCL manual 140 OK)

SCE Training Curriculum Page 17 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 18

3. The 'calculate_tankcontent [FC140]' block opens automatically. Enter the 'Input and output

Diagram 0-1

Industry Sector, IA&DT

parameters' of the block as specified. All local tags should also be provided with a 'sufficiently

descriptive comment' for better understanding.

( Enlarge interface of block FC140 Enter interface parameters)

Note:

To avoid confusion with the PLC tags it is helpful to write the local tags with small letters.

SCE Training Curriculum Page 18 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 19

Industry Sector, IA&DT

4. Once the local tags have been declared, you can start to create the program shown here. The

square function 'SQR' is used to square a number for this purpose. The number to be squared is

enclosed in brackets. To insert the function, drag it to the position of use in the program.

( Instructions (menu on the right) Basic instructions Mathematical functions SQR)

5. Supplement the program as specified below.

SCE Training Curriculum Page 19 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 20

Industry Sector, IA&DT

6. The program can now be saved and compiled .

( Save Compile )

7. Syntax errors that occur are recognized during compilation and display in the 'Menu Info/Compile'.

( Info Compile)

SCE Training Curriculum Page 20 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 21

Industry Sector, IA&DT

8. The function can now be called in the 'Main [OB1]'. Before we double-click to open the 'Main

[OB1]' block, we select 'FBP' as its programming language.

( Main [OB1] Switch programming language FBD)

9. The 'calculate_tankcontent [FC140]' function can then be moved into Network 1 of the Main

[OB1] block using a drag-and-drop operation. The interface parameters of the

'calculate_tankcontent [FC140]' function have to be connected to the global PLC tags, as shown

here. Don't forget to document the networks in the Main [OB1] block. ( Main [OB1] Program

blocks calculate_content [FC140])

SCE Training Curriculum Page 21 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 22

Industry Sector, IA&DT

10. The button is used to resave the project.

( )

11. To load the program blocks and the device configuration to the CPU, first select the 'Controller 001

[CPU 315F-2 PN/DP]' folder and then click the Download to device icon . ( Program blocks

)

Note:

During downloading the project is automatically recompiled and checked for errors.

SCE Training Curriculum Page 22 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 23

Industry Sector, IA&DT

12. An overview for checking the steps to be executed is shown before the download process starts.

Click 'Load' to start loading the program. ( Load)

5.3 Test program

1. Clicking the icon (Monitoring on/off) allows you to monitor the state of the simulated input and

output tags on the 'calculate_tankcontent' block. ( )

SCE Training Curriculum Page 23 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 24

Industry Sector, IA&DT

2. Since no analog sensor exists and thus no corresponding process value is available, we have to

specify the values 'Diameter_tank1' and 'Fill-level_tank1' using the watch table. Create a 'new

watch table' and enter the two values. To see the current values, switch 'Monitoring mode on'.

( Controller 001 Watch and force table New watch table Diameter_tank1, Fill-level_tank1

)

3. To specify the values, you have to enter a modify value in the 'Modify value' column. The values

are applied in the CPU by clicking the icon 'Modify all selected values once and now'.

( diameter_tank1 = 10.0 fill level_tank1 = 7.0 )

SCE Training Curriculum Page 24 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 25

Industry Sector, IA&DT

4. The program in OB1 can now be checked. ( )

5. The values of the individual tags can be monitored in the SCL editor. To do this, switch 'Monitoring

mode on'. ( )

Note:

When you click the current values of the tags programmed in this row are displayed.

SCE Training Curriculum Page 25 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 26

Industry Sector, IA&DT

Address

Symbol

Data type

Comment

%Q1.7

Error bit

BOOL

Error, unable to perform calculation

Type

Symbol

Data type

Comment

IN

high_max

REAL

in meters

OUT

er

REAL

er = 1, there is an error, content = -1

FC140

calculate_tankcontent

Fill level: REAL

high_max: REAL

Diameter: REAL

BOOL :er

REAL :content

5.4 Expanding the program

Next, we will check whether faulty information is contained in the input parameters of the

'calculate_tankcontent' block. Another value 'high_max' is also passed to the block. This indicates the

height of the tank.

The block is now to analyze whether the fill-level of the tank is less than zero or greater than the

specified tank height. It is also to be checked whether the diameter was specified as less than zero.

If there is an error, the Boolean output parameter 'er' should return TRUE and the value of the 'Content'

parameter should be -1.

Expanding the assignment list / tag table:

Expansion of the interface of the function FC140: calculate_tankcontent

Function call: Representation in FBD

SCE Training Curriculum Page 26 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 27

Industry Sector, IA&DT

1. Expand the 'Tag table' of the block as specified above.

( Controller 001[CPU 315F-2 PN/DP] PLC- tags Default tag table Enter operands

2. Expand the 'Interface parameters' of the block as specified above.

( Controller 001 [CPU 315F-2 PN/DP] Program blocks calculate_tankcontent) Enter

parameters)

SCE Training Curriculum Page 27 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 28

Industry Sector, IA&DT

3. Next, expand the program as specified below and check it for syntax errors by compiling it. Save

the program and load it to the controller.

(Write program )

SCE Training Curriculum Page 28 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 29

Industry Sector, IA&DT

4. Because the parameters of the block were changed, the call must be updated in OB1. Open OB1

and scroll to the position of the block call. Right-click to open the shortcut menu and then click

'Update'.

( Controller 001 [CPU 315F-2 PN/DP] Program blocks Main [OB1]

Right mouse button Update)

5. The old and the new interface will now be displayed. Click 'OK' to confirm.

( OK)

SCE Training Curriculum Page 29 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Page 30

Industry Sector, IA&DT

6. Complete the values at the input parameter 'high_max' and output parameter 'er' as specified

below. Compile, save and load the program to the controller.

(Add other parameters )

7. Check the changes in the 'Monitoring mode' of the 'calculate_tankcontent' block.

Note:

You can change the display format of the current value by right-clicking the value and opening the

shortcut menu.

SCE Training Curriculum Page 30 of 30 To be used only at Educational and R&D Facilities

TIA Portal Module 040-020, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_040-020_R1209_Startup Programming in High-Level Languages with S7-SCL and SIMATIC S7-300

Loading...

Loading...