Page 1

Operating Instructions Edition 08/2004

FIDAMAT 6

Gas analyzer for the measurement

of total hydrocarbons

7MB2421

gas analysis

Page 2

1

Page 3

s

FIDAMAT 6

Gas analyzer for the measurement of

total hydrocarbons

Operating instructions

A5E00222135-01

Release 08/2004

Page 4

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights created by the

granting of patents or registration of a design are reserved.

Technical data subject to change without notice.

Weitergabe sowie Vervielfältigung dieser Unterlage,

Verwertung und Mitteilung ihres Inhaltes nicht gestattet, soweit

nicht ausdrücklich zugestanden.

Zuwiderhandlungen verpflichten zu Schadenersatz. Alle

Rechte vorbehalten, insbesondere für den Fall der

Patenterteilung oder GM-Eintragung.

Technische Änderungen vorbehalten.

Toute communication ou reproduction de ce document, toute

exploitation ou communication de son contenu sont interdites,

sauf autorisation expresse.

Tout manquement à cette règle est illicite et expose son auteur

au versement de dommages et intérêts. Tours nos droits sont

réservés pour le cas de la délivrance d'un brevet ou celui de

l'enregistrement d'un modèle d'utilité.

Modifications techniques sont réservées.

La divulgación y reproducción de este documento asi como el

aprovechamiento de su contenido, no están autorizados, a no

ser que se obtenga el consentimiento expreso, para ello.

Los infractores quedan obligados a la indemnización por

daños y perjucios. Se reservan todos los derechos, en

particular para el caso de concesion de Patente o de Modelo

de Utilidad.

Salvo modificaciones ténicas.

ULTRAMAT, OXYMAT, CALOMAT, SIPAN

sono marchi registrati di S

IEMENS AG.

Le denominazioni di altri prodotti menzionati in questa

documentazione possono essere marchi il cui uso da parte di

terzi può violare i diritti di proprietà.

Conformemente alla "Legge sulle unità di misura" i dati in

pollici valgono soltanto per l'esportazione.

La trasmissione a terzi e la riproduzione di questa

documentazione, cosiccome lo sfruttamento del suo contenuto

non è permesso, se non autorizzato per iscritto.

Le infrazioni comporteranno una richiesta di danni. Tutti i diritti

sono riservati, in particolare nel caso di brevetti. Modifiche

tecniche possibili.

ULTRAMAT, OXYMAT, CALOMAT, SIPAN

son marcas registradas de S

IEMENS AG.

Las otras designaciones que figuran en este documento

puenden ser marcas cuya utilización por terceros para sus

propios fines puede violar los derechos de los proprietarios de

dichas marcas.

Conforma a la "Ley sobre las unidades de medida", las

dimensiones en pulgadas sólo son válidas para la exportación.

ULTRAMAT, OXYMAT, CALOMAT, SIPAN

sont des marques déposées de S

IEMENS AG.

D'autres dénominations utilisées dans ce document peuvent

également être des marques déposées dont l'utilisation par

des tiers à leurs propres fins peut enfreindre les droits des

propriétaires desdites marques.

ULTRAMAT, OXYMAT, CALOMAT, SIPAN

sind Marken der S

IEMENS AG.

Die übrigen Bezeichnungen in diesem Handbuch können

Marken sein, deren Benutzung durch Dritte für deren Zwecke

die Rechte der Inhaber verletzen können.

Die Angaben in Zoll (inch) gelten gemäß dem Gesetz über

Einheiten im Meßwesen" nur für den Export.

ULTRAMAT, OXYMAT, CALOMAT, SIPAN

are S

IEMENS registered trademarks.

A

ll other product or system names are (registered) trademarks

of their respective owners and must be treated accordingly.

A

ccording to the German law on units in measuring

technology, data in inches only apply to devices for export.

SIEMENS AG

A

utomation and Drives

Process Instrumentation

D-76181 Karlsruhe

Siemens Aktiengesellschaft

© Siemens AG 2004

Subject to modifications without prior notice

Order no. A5E00222135

Printed in Germany

A

G 0804 En 0.05 118 PU

Page 5

Table of contents

1. INFORMATION FOR THE OWNER ..................................................................................................... 1-1

1.1

INFORMATION FOR OUR CUSTOMERS ............................................................................................. 1-2

1.2 GENERAL COMMENTS................................................................................................................... 1-2

1.3 USING THIS MANUAL ..................................................................................................................... 1-3

1.4 HAZARD INFORMATION ................................................................................................................. 1-3

1.5 USE FOR THE PURPOSE INTENDED ................................................................................................ 1-4

1.6 QUALIFIED PERSONNEL ................................................................................................................ 1-5

1.7 WARRANTY INFORMATION............................................................................................................. 1-5

1.8 DELIVERY INFORMATION ............................................................................................................... 1-6

1.9 STANDARDS AND REGULATIONS .................................................................................................... 1-6

1.10 DECLARATION OF CONFORMITY..................................................................................................... 1-7

2. TECHNICAL DESCRIPTION ............................................................................................................. 2-1

2.1

SCOPE OF APPLICATION ............................................................................................................... 2-2

2.2 DESIGN ....................................................................................................................................... 2-4

2.3 MODE OF OPERATION ................................................................................................................... 2-7

2.4 COMMUNICATIONS ..................................................................................................................... 2-10

2.5 TECHNICAL DATA........................................................................................................................ 2-14

3. INSTALLATION INSTRUCTIONS ....................................................................................................... 3-1

3.1

SAFETY INSTRUCTIONS................................................................................................................. 3-2

3.2 GENERAL INSTALLATION REQUIREMENTS ....................................................................................... 3-3

3.3 GAS CONDITIONING ...................................................................................................................... 3-5

3.4 ELECTRICAL CONNECTIONS .......................................................................................................... 3-6

3.4.1 POWER SUPPLY....................................................................................................................... 3-6

3.4.2 CONNECTING THE SIGNAL LINES ............................................................................................... 3-6

3.4.3 CIRCUIT DIAGRAMS (ELECTRICAL CONNECTIONS)....................................................................... 3-8

3.5 DIMENSION DRAWINGS ............................................................................................................... 3-11

4. START-UP.................................................................................................................................... 4-1

4.1

SAFETY INSTRUCTIONS................................................................................................................. 4-2

4.2 START-UP PREPARATIONS ............................................................................................................ 4-3

4.3 START-UP AND OPERATION........................................................................................................... 4-5

4.3.1 MEASURING RANGES ............................................................................................................... 4-5

4.3.2 CALIBRATION........................................................................................................................... 4-7

5. OPERATION ................................................................................................................................. 5-1

5.1

GENERAL COMMENTS................................................................................................................... 5-2

5.2 STATUS DIAGRAM......................................................................................................................... 5-7

5.3 OVERVIEW OF OPERATOR FUNCTIONS ........................................................................................... 5-9

5.3.1 DIAGNOSIS............................................................................................................................ 5-10

5.3.2 CALIBRATION......................................................................................................................... 5-11

5.3.3 MEASURING RANGES ............................................................................................................. 5-17

5.3.4 PARAMETERS ........................................................................................................................ 5-20

5.3.5 CONFIGURATION.................................................................................................................... 5-27

Page 6

6. MAINTENANCE ............................................................................................................................. 6-1

6.1

MAINTENANCE CONCEPT .............................................................................................................. 6-2

6.1.1 PUMP MAINTENANCE................................................................................................................ 6-2

6.1.2 REPLACING THE FILTER PLATE.................................................................................................. 6-2

6.2 REPLACING THE MOTHERBOARD AND OPTION BOARD ..................................................................... 6-3

6.3 CHANGING FUSES ........................................................................................................................ 6-3

6.4 CLEANING THE UNIT ..................................................................................................................... 6-4

6.5 MAINTENANCE REQUEST AND FAULT MESSAGE .............................................................................. 6-4

6.5.1 LIST OF MAINTENANCE REQUESTS ............................................................................................ 6-5

6.5.2 FAULTS................................................................................................................................... 6-7

6.5.3 OTHER FAULTS........................................................................................................................ 6-8

7. LIST OF SPARE PARTS AND RETURNS............................................................................................ 7-1

7.1

INFORMATION ON ORDERING ......................................................................................................... 7-2

7.2 LIST OF SPARE PARTS .................................................................................................................. 7-3

7.3 RETURNS .................................................................................................................................. 7-12

7.4 ABBREVIATIONS ......................................................................................................................... 7-15

7.5 OVERVIEW OF OPERATOR FUNCTIONS ......................................................................................... 7-16

Page 7

1-1

1. Information for the owner

1.1. Information for our customers

1.2. General comments

1.3. Using this manual

1.4. Hazard information

1.5. Use for the purpose intended

1.6. Qualified personnel

1.7. Warranty information

1.8. Delivery information

1.9. Standards and regulations

1.10. Declaration of conformity

Page 8

Information for the owner

FIDAMAT 6 gas analyzer

1-2 Operating manual – A5E00222135-01

1.1 Information for our customers

Please read this manual carefully before beginning operation of the

sensor! It will provide you with important information and data you need to

ensure proper functioning of the sensor and reduce maintenance costs.

Following these instructions will help you to operate the device more

easily and efficiently, allowing you to achieve reliable measuring results.

1.2 General comments

Before product described in this manual left the factory, it was inspected

and found to be in perfect condition as regards safety. To keep it in this

state and to ensure its safe and problem-free operation the product

should only be used in the manner described by the manufacturer. In

addition, proper transportation, storage and installation as well as careful

operation and maintenance of the product are vital for ensuring correct

and safe operation.

This manual provides the information you will need for using the

described product for the purpose for which it is intended.

The manual is intended to be used for technically qualified personnel with

special training or who have relevant knowledge in the field of automation

technology (instrumentation and control technology).

Familiarity with and a technically faultless implementation of the safety

information (including warnings) contained in this manual is essential for

hazard-free installation and commissioning as also for safe operation and

maintenance of the product described. Only qualified personnel possess

the special knowledge required not only for a correct interpretation in the

individual concrete case of the safety information and warnings provided

in this manual for general application but also for putting them into

practice.

This manual is a permanent part of the scope of supply even when

ordering it separately has been permitted for logistical reasons.

Due to the sheer number of technical details it is not possible to cover all

versions of the product described nor every conceivable aspect of

installation, operation, maintenance and use of the product as part of a

system. If you require further information, or should problems be

encountered which are not treated in sufficient depth in this document,

contact your local Siemens representative for the information you require.

Note

Particularly before the device is used for new applications in the area of

research and development, we recommend you contact us to discuss the

application in question.

Page 9

Information for the owner

FIDAMAT 6 gas analyzer

Operating manual – A5E00222135-01 1-3

1.3 Using this manual

This manual provides you with information on using, installing,

operating, and maintaining this device.

Pay particular attention to all warnings and notes. Information of this

type is set apart from the rest of the text and specially identified by

appropriate symbols (see examples on the left). This information

provides you with useful tips on how to avoid operating the analyzer

incorrectly.

1.4 Hazard information

Please observe the following notes not only for your own personal safety

but also to safeguard against damage to the product described as well as

any devices connected to it.

Safety information and warnings are given particular emphasis in this

manual by means of the various "signal” terms defined below. They apply

to both users and maintenance personnel and are intended to help

prevent dangers to life and limb, or to health, and also to prevent damage

to property. These notes are also marked by warning symbols which

reflect the meaning of the accompanying text and may therefore vary

from the examples given below. Within the context of this manual and

information on the product itself, the terms used are defined as follows:

Danger

means that death or severe injury and / or considerable damage

to property will result if the corresponding precautions are not taken.

Warning

means that death or severe injury and / or considerable damage to

property could occur if the corresponding precautions are not taken.

Caution

with a warning triangle means that minor injury may result if the

corresponding precautions are not taken.

Caution

without a warning triangle means that damage to property may result if

the corresponding precautions are not taken.

Page 10

Information for the owner

FIDAMAT 6 gas analyzer

1-4 Operating manual – A5E00222135-01

Attention

means that an undesirable event or condition may result if the note in

question is not observed.

Note

gives important information about the product, about using the

product, or about the corresponding part of the manual to which

special attention is to be drawn.

1.5 Use for the purpose intended

In this manual 'use for the purpose intended' means that this product may

only be used for the application cases described in the catalog and in the

technical description (in this regard see also "Technical description” from

page 2-1 onwards) and only in conjunction with third-party devices and

components recommended or approved by Siemens.

The product described in this manual has been designed, manufactured,

inspected and documented in compliance with the relevant safety

standards. For this reason, provided both the handling requirements

described for planning, installation, operation and maintenance and also

safety instructions are observed, under normal circumstances the unit will

not be a source of danger with respect to personal health and safety nor

with respect to damage to property. The analyzer has been designed in

such a way that a safe separation between primary and secondary

circuits is ensured. Extra-low voltages which are connected must also be

generated by safe separation.

Warning

Once the housing or shock-hazard protection has been removed or the

system cabinet opened, certain parts or components of this unit or

system which could be carrying a hazardous voltage become accessible.

For this reason only appropriately qualified personnel should be

permitted such access to this unit. These persons must have a thorough

knowledge of all sources of danger and of maintenance activities as

described in this operating manual.

Page 11

Information for the owner

FIDAMAT 6 gas analyzer

Operating manual – A5E00222135-01 1-5

1.6 Qualified personnel

Unqualified tampering with the unit or system, or failure to observe the

warnings in the manual or affixed to the unit or system cabinet could

result in severe bodily injury and / or damage to property. Only

appropriately qualified personnel should therefore be permitted such

access to this unit or system.

Within the context of the safety information in this manual or on the

product itself, qualified personnel is defined as persons who:

• as planning and design personnel are familiar with the safety

concepts applicable in automation technology, or

• as operating personnel have been given instruction on working

with automation technology equipment and who are familiar with

the operation-related content of this manual, or

• as commissioning or maintenance personnel possess the

training which enables them to repair automation technology

equipment of this kind or who have been authorized to operate,

ground or label devices, systems and electrical circuits in

accordance with accepted technical safety standards.

1.7 Warranty information

Your attention is expressly directed to the fact that the nature and quality

of the product is described exclusively and conclusively in the contract of

purchase. The contents of this product documentation do not constitute

part of a past or existing agreement, promise, or legal relationship nor are

they intended to modify these. All obligations on the part of Siemens

originate from the purchase contract in question, which also includes the

full and exclusively valid warranty provisions. The contractual provisions

relating to liability for defects are neither extended nor in any way

restricted by the information contained in the present document.

Page 12

Information for the owner

FIDAMAT 6 gas analyzer

1-6 Operating manual – A5E00222135-01

1.8 Delivery information

The scope of supply corresponding to the applicable purchase contract is

shown in the shipping documents enclosed with the consignment.

When opening the packaging, read and comply with the instructions

provided on the packaging material. Make sure the consignment is

complete and undamaged. In particular, you should also, if applicable,

check the order number on the nameplates against the ordering

information.

If possible, you should not discard the packaging material as this could be

needed later should anything need to be returned. A returns form is

provided on page 7-14 of the section entitled "Spare parts and returns.”

1.9 Standards and regulations

As far as possible the specifications and manufacture of this device were

based on the harmonized European standards. Where harmonized

European standards were not applied, the standards and regulations of

the Federal Republic of Germany will apply (see also "Technical data” on

page 2-14).

If this product is used outside the area of validity of these standards and

regulations, the standards and regulations valid in the owner's country

should be observed.

Page 13

Information for the owner

FIDAMAT 6 gas analyzer

Operating manual – A5E00222135-01 1-7

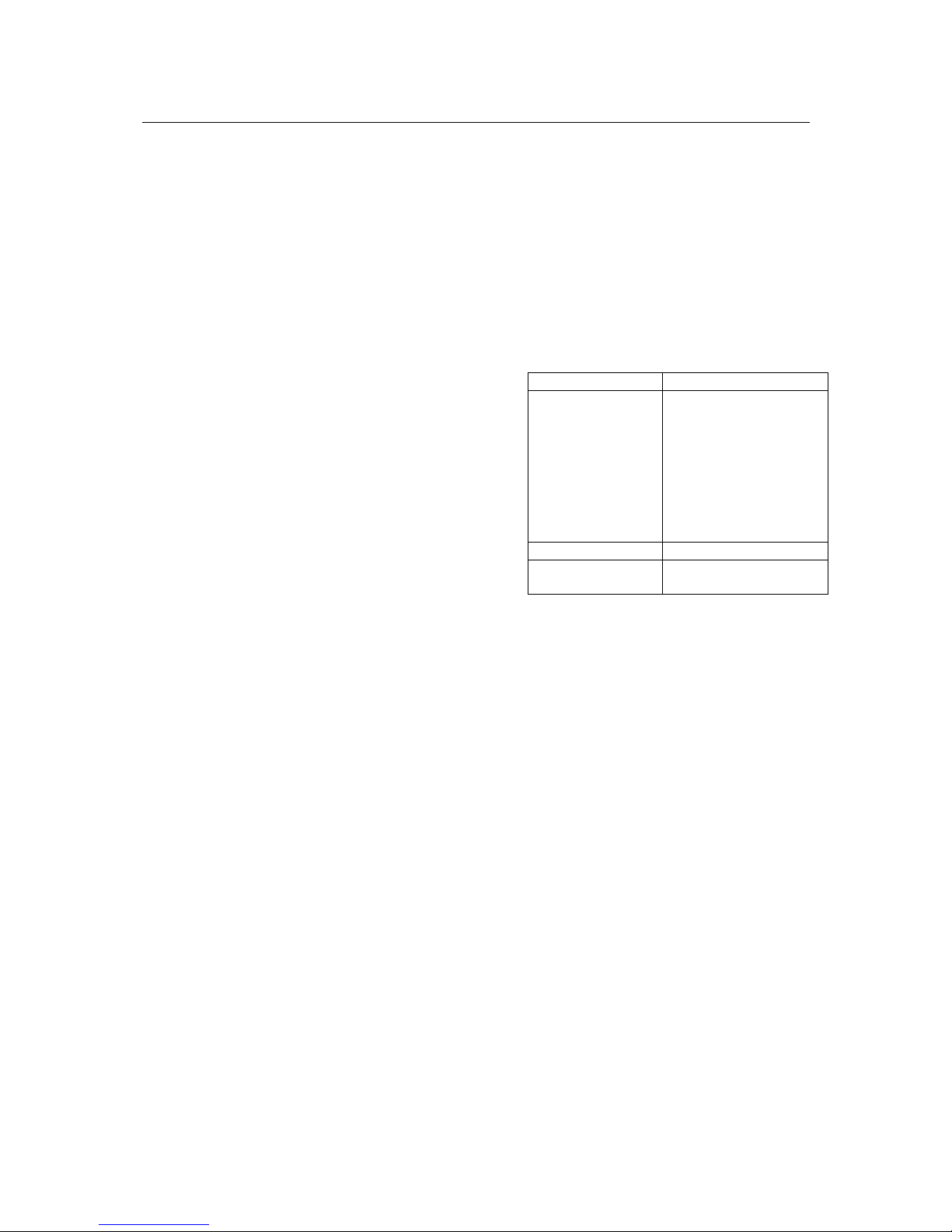

1.10 Declaration of conformity

Product name, model

FIDAMAT 6E

7MB2421-xxxxx-xxxx

7MB2427-xxxxx-xxxx

is in compliance with the following standard(s) or documents:

- Low-Voltage Equipment Directives (73/23/EEC and 93/68/EEC)

- EMC Directives (89/336/EEC, 91/263/EEC, 92/31/EEC, 93/68/EEC and 93/97/EEC)

- Harmonized standards applied to

all devices EN 61326

EN 61010

In accordance with the aforementioned EC directives, the EC

Declarations of Conformity are kept available for the relevant

authorities by

Siemens Aktiengesellschaft

Automation and Drives

A&D PI 2

D-76181 Karlsruhe

If this product is used outside the European Union, the standards and regulations valid in the

owner's country must be observed.

Page 14

Information for the owner

FIDAMAT 6 gas analyzer

1-8 Operating manual – A5E00222135-01

Page 15

2. Technical description

2.1. Scope of application

2.2. Design

2.3. Mode of operation

2.4. Communications

2.5. Technical data

Page 16

Technical description

FIDAMAT 6 gas analyzer

2-2 Operating manual – A5E00222135-01

2.1 Scope of application

The FIDAMAT 6 gas analyzer is used for the

quantitative determination of hydrocarbons. The

analyzer is also suitable for measurements in

corrosive and condensing gas mixtures.

The measuring principle is based on flame

ionization detection (FID) with a minimum

detection level of about 0.1 ppm. During

combustion of hydrocarbons in a hydrogen flame,

ions are produced which are in turn converted into

a current flow by application of an electrical field.

The current intensity arising from this is a

measure of the number of carbon atoms.

Benefits

The FIDAMAT 6 gas analyzer stands out due to

its very wide scope of application.

Accordingly, measurement is possible:

• With H

2

O vapor concentrations up to

100%

• With ultrapure gas applications

• With high-boiling components (up to

200°C)

• When corrosive gases are present

Unlike other comparable devices, the FIDAMAT 6

has:

• A very low transverse gas sensitivity

compared to unwanted gasses

• Low consumption of combustion air

• Low susceptibility to being affected by

oxygen

The device is also equipped with warning and fault

messages, for example:

• Failure of combustion gas supply

• Detector flame extinguished

• Malfunctions of pump and filter

• and so on

Examples of applications

• Environmental protection

• Wastewater (in combination with a

stripping unit, determination of

hydrocarbon content of liquids)

• Measurement in flue gases in accordance

with Emissions Prevention Directives and

Clean Air Guidelines (13. BlmSchV /

17. BlmSchV and TA-Luft) for these types

of fuel: oil, coals, gases and refuse (with

TÜV [Technical Inspectorate] approval)

• Monitoring at workplaces with respect to

maximum allowable concentration of

pollutants

• Quality surveillance

• Process 14

• Ultrapure-gas measurement in media

such as O2, CO2, inert gases and cold

measurement gases

• Measurement of corrosive and

condensing gases

• Process optimization

• Automotive industry (engine

development, vehicle assembly

development and certification)

• Measurement of emissions

(environmental protection)

Locations

• Chemical plants

• Gas manufacturers (quality surveillance

for ultrapure gases)

• Research and development

• Cement industry

• Paint shops and chemical cleaning

facilities

• Refineries (tank farms, wastewater)

• Drying plants

• Solvent recovery facilities

• Pharmaceutical industry

Page 17

Technical description

FIDAMAT 6 gas analyzer

Operating manual –A5E00222135-01 2-3

Main features

• Four measuring ranges freely

parametrizable, also with suppressed

zero point, all ranges linear

• Hydrogen required: H2

• Extremely short measuring spans

• Electrically isolated measured-value

output 0/ 2/ 4 to 20 mA (negated also)

• Automatic or manual range changeover

selectable; remote changeover is also

possible

• Measured values can be retained during

calibration

• Time constants selectable within wide

limits (static / dynamic noise

suppression); in other words, the Unit's

response time can be adjusted to suit the

measurement task on hand

• Simple to use due to menu-controlled

operation

• User operation based on NAMUR

recommendations

• Short response time

• Low long-term drift

• Three operator control levels each with

own authorization code to prevent

inadvertent or unauthorized operator

actions

• External pressure pick-ups can be

connected to correct process gas

pressure fluctuations

• Units easy to swap over since electrical

connections only need to be

disconnected from unit

• Wear-free, corrosion-resistant filter

• No clogging of measuring-gas capillary

since a quartz capillary is used

• Low consumption of combustion air

• Digital display of gas concentration, of

measuring gas, combustion air and

hydrogen pressure

• Response factors meet the minimum

requirements of the Clean Air Guidelines

and of the German Automotive Industry

Working Group

• Simplicity of operation due to a numerical

membrane keyboard and operator

guidance

• Parametrizable automatic measuring

range calibration

• PROFIBUS (DP/ -PA) / AK

• Menu and interface are compatible with

the other Series 6 devices (CALOMAT 6,

OXYMAT 6, ULTRAMAT 6, OXYMAT 61)

• Customer-specific versions of the device,

such as:

- Customer acceptance

- TAG plates

- Drift recording

Page 18

Technical description

FIDAMAT 6 gas analyzer

2-4 Operating manual – A5E00222135-01

2.2 Design

Design of the overall unit

The FIDAMAT 6 consists of two main modules.

a) Analysis module

b) Electronics

a) Analyzer section

This consists of a oven in which the following

components are installed:

- Measuring gas filter (heated)

- Flame ionization detector (FID)

- Various restrictors

- Two pressure regulators

- Two pressure sensors

- Solenoid valves

- Bulkhead connections 6 mm or ¼"?

The unit has been designed in such a way that

interior parts are easily accessible for

maintenance. Access is possible both from the top

(for maintenance of individual parts) and from the

rear (for replacing the measuring-gas filter).

The measuring-gas pump is easily accessible

from above. Both the gas connections and the

electrical connections are located on the rear of

the unit.

b) Electronics module

This consists of:

- Operator control board with display

- Motherboard

- Adapter board

- Option boards: PROFIBUS (DP/ PA), AK,

AUTOCAL

The operator control board is integrated into the

front panel. The adapter board accommodates the

preamplifier for measured data acquisition and for

the control unit.

Design of the FIDAMAT 6 housing

• 19" rack module with 4 HU for installation

in swing frame

• 19" rack module with 4 HU for installation

in cabinets, with telescopic or support

rails

• Front panel for maintenance access,

swings downwards (for example, for

laptop connection, RS 485)

Gas path Material

Piping

Gas entry

Seals

Measuring-gas

restrictor

Reactant-gas

restrictors

Pump diaphragm

Pump head

Stainless steel 1.4571

Stainless steel 1.4571

Graphite

Quartz

Stainless steel 1.4571

PTFE

Stainless steel 1.4571

Detector

Nozzle

FID housing

Quartz

Stainless steel 1.4571

• Gas connections for measuring-gas entry

(sample) and measuring-gas outlet

(exhaust) and also hydrogen and

combustion air; pipe diameter 6 mm or ¼"

(Swagelok)

Page 19

Technical description

FIDAMAT 6 gas analyzer

Operating manual –A5E00222135-01 2-5

Display and control panel

• Large LCD panel for simultaneous display

of:

- Measured value (digital and analog

display)

- Measuring ranges

- Status bar

• LCD panel contrast adjustable via menu

• Permanent LCD backlighting

• Five-digit measured-value display

(decimal point counts as a digit)

• Wipe-clean diaphragm keyboard and front

panel

• Menu-guided operation for

parametrization, test functions and

calibration

• User guidance in plain text

• Graphic display of concentration curve;

time intervals can be parametrized

• User software in two languages in each

case:

German/English;

English/Spanish;

French/English;

Spanish/English;

Italian/English

Inputs and outputs

• Two analog inputs can be configured

• One analog output 0/ 2/ 4 - 20 mA

• Six binary inputs can be configured as

required

for example, for measuring range

changeover, processing of external

signals from sample preparation

• Six relay outputs can be configured as

required for example, for faults,

maintenance request, limit value alarm,

external solenoid valves

• Further eight binary inputs and relay

outputs can be added in each case for

automatic calibration with a maximum of

four calibration gases

Communications

• ELAN (RS 485) contained in base unit

(connection at rear)

Options

• AK interface for the automotive industry

with expanded functions

• Converter to RS 232 (for ELAN)

• Converter to TCP/IP Ethernet (for ELAN)

• Incorporation in networks via

PROFIBUS DP/PA interface

• SIPROM GA software as service and

maintenance utility (for ELAN)

Response factors

Substance Response factors

n-butane 1,00

n-propane 1,00

n-heptane 1,00

Cyclohexane 1,08

Isopropanol 0,81

Toluene 1,06

Acetone 0,92

Ethyl acetate 0,76

Isobutyl acetate 0,83

Methane 1,06

Ethane 0,99

n-hexane 1,01

Isooctane 1,04

Acetylene 0,91

Propene 0,84

Methanol 0,87

Ethanol 0,83

Acetic acid 1,13

Methyl acetate 0,67

Benzole 1,01

Ethyl benzole 0,96

p-xylene 1,03

Dichloromethane 1,13

Trichloroethene 1,01

Tetrachloroethene 1,07

Chloroform 0,72

Chlorobenzene 1,15

Page 20

Technical description

FIDAMAT 6 gas analyzer

2-6 Operating manual –A5E00222135-01

Fig. 2-1: Membrane keyboard and graphics display

Fig. 2-1: Membrane keyboard and graphics display

Page 21

Technical description

FIDAMAT 6 gas analyzer

Operating manual – A5E00222135-01 2-7

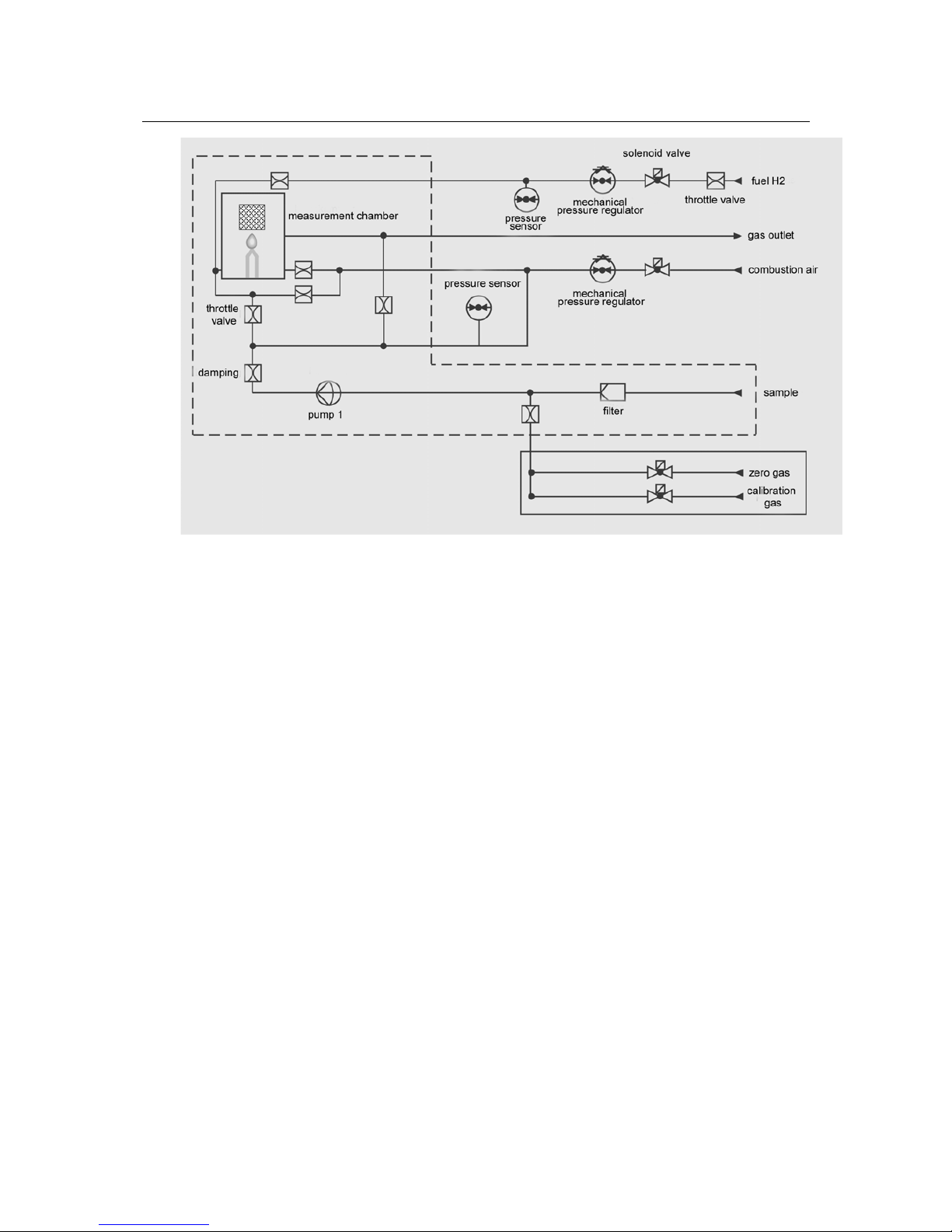

Fig. 2-2: FIDAMAT 6 – Mode of operation

2.3 Mode of operation

The FIDAMAT 6 measures compound-class-specifically not

component-specifically. It measures the total of all organic carbons in

a measuring gas but giving different weighting to the hydrocarbon

molecules.

As a first approximation, the value displayed is proportional to the

number of C atoms in the molecule in question. In practice, however,

there are deviations from this. The reading deviation for the molecule

in question is expressed by the response factor.

The measuring gas is supplied to the FIDAMAT 6 under overpressure

or drawn in by the built-in diaphragm pump (optionally via a heated

line and an additional filter) and then routed to the flame ionization

detector via a non-clogging fused-silica restrictor. Within the detector

the hydrocarbons contained in the measuring gas are combusted in

an oxy-hydrogen flame. During the combustion process the organic

hydrocarbons are ionized.

Page 22

Technical description

The ions which are released are converted into an ion current by the

polarization voltage between two electrodes and then measured using

a highly sensitive amplifier.

The current measured is proportional to the number of organic C

atoms of the hydrocarbons in the measuring gas.

A pressure regulator keeps the pressure of the hydrogen constant. A

mutually adjusted system of pump, capillaries and combustion-air

pressure regulator ensures a constant measuring-gas pressure.

After switching on the analyzer, the flame will be ignited as soon as a

flame temperature of 165°C has been reached. The pump is started

automatically once the flame reaches a temperature of 220°C.

The FIDAMAT 6 sends out various signals in the form of floating

contacts:

• Maintenance request

Measuring-gas flow rate (filter / pump)

Fan failure (advance warning for measurement accuracy)

The unit continues to measure as normal and the measured value is

not affected.

• Fault

Hydrogen, combustion air and measuring gas pressure, temperature,

physical section and pump, fault in the electronics (temperature).

The measured value can be affected; under certain circumstances the

unit will switch into a different state (the combustion-gas valve is

closed). See also "List of maintenance requests” on page 6-5.

Note

Sample gases must be free of dust when they enter the analyzers.

Condensate should be avoided. For this reason, it will in most

application cases be necessary to use a gas conditioning device

suitable for the measurement task in question.

2-8 Operating manual – A5E00222135-01

FIDAMAT 6 gas analyzer

Page 23

Technical description

FIDAMAT 6 gas analyzer

Operating manual – A5E00222135-01 2-9

Fig. 2-3: Gas circuit (unit with pump)

Page 24

Technical description

FIDAMAT 6 gas analyzer

2-10 Operating manual – A5E00222135-01

2.4 Communications

All of the gas analyzers in Series 6, ULTRAMAT

6, OXYMAT 6/ 61, CALOMAT 6, ULTRAMAT 23

and also FIDAMAT 6 provide the following

communication methods:

• ELAN interface (also with SIPROM GA)

• PROFIBUS DP / PA

• AK interface

ELAN interface

ELAN is a serial interface (RS 485) built in as

standard and which allows communication

between several analyzers. A maximum of 12

analyzers with no more than four components

may be networked together. Connection can be

made even without a PC.

The following diagram shows how this works.

Fig. 2-4: Typical arrangement for an ELAN network

(RS 232)

No. Key

1 Computer

2

RS-485 / RS-232 converter with

RS 485 and RS 232 connecting leads

3 RS 485 bus plug with jumper

4 Analyzer

5 RS 485 cable

6 RS 485 bus plugs

7 RS 485 network

8 9-pole SUB D connector

9 Optional: RS-485 repeater

Interface parameters

Level RS 485

Baud rate 9600

Data bit 8

Stop bit 1

Start bit 1

Parity None

No information feedback

Ordering information Order no.

Interface description

C79000-B5200-C176

RS 485-RS 232 converter

C79451-Z1589-U1

SIMATIC cable / bus cable

6XV1 830-OEH10

SIMATIC bus plugs

6ES7 972-OBB11-OXAO

9-pole SUB D connector

6ES7 972-OBB11-OXAO

Repeater

6ES7 972-OAA01-OXAO

For further information, see the ELAN interface

description.

Order number:

C79000-B5200-C176 German

C79000-B5274-C176 English

Page 25

Technical description

FIDAMAT 6 gas analyzer

Operating manual –A5E00222135-01

2-11

SIPROM GA

SIPROM GA is a software utility especially for

service and maintenance tasks. It allows remote

operation and monitoring of all functions of the

analyzers, either as individual units or networked

together.

Functions:

• Display and storage of all device data

• Remote operation of all device functions

• Parameter and configuration settings

• Comprehensive diagnostics information

• Remote calibration

• On-line help

• Cyclic saving of measured values

• Status on hard disk and exportation to

user programs available on the market

• Downloading of new software

Hardware requirements:

• PC or laptop, Pentium 133 MHz,

RAM 32 MB, CD drive

• At least 10 MB free on hard disk

• VGA graphics card supported by

Windows

• Printer supported by Windows

• Unused COM port: RS 232 or for

connection to ELAN network RS 485 /

RS 232

•

For connecting the Ethernet / RS 485

interface converter, a standard 10 Mbit

or 100 Mbit network (RJ 45 connection)

with TCP/ IP is required. With an RS 485

network the distance must not be greater

than 500 m or a repeater will need to be

installed.

Software requirements (optional):

• Windows 95

• Windows 98

• Windows NT 4.0

• Windows 2000

• Windows XP

Ordering information Order no.

SIPROM GA software,

German or English selectable

at time of installation,

consisting of 1 CD with

installation instructions,

software, product certificate

and registration form

S79610-B4014-A1

Firmware retrofit kit for older

analyzers:

FIDAMAT 6

- German

- English

- French

- Spanish

- Italian

A5E00223093

A5E00223146

A5E00223149

A5E00223152

A5E00223155

PROFIBUS DP / PA

PROFIBUS DP / PA is the field-bus market leader.

All Siemens gas analyzers when equipped with an

optional plug-in board (can be retrofitted) have

Profibus capability and meet the mandatory "device

profile for analysis devices” defined by the PNO

(PROFIBUS Nutzer Organisation) (Profibus users

organization). Centralized access to the analyzers

installed in the system is possible using the

SIMATIC PDM operator control utility.

The term "field bus” designates a digital

communication system with which decentrally

installed field devices in a system are networked

together using a single cable and at the same

time connected to automation devices or to a

process control system.

Due to its high transmission speeds coupled with

relatively small data volumes for each device, the

PROFIBUS DP variant is used widely in

production automation, while PROFIBUS PA

takes particular account of properties demanded

in process control, such as large quantities of

data and deployment in explosion-hazard areas.

The benefits to the user lie is considerable

potential for savings in all parts of the system,

from engineering and commissioning, to

operation and maintenance, and later on to

installation expansion.

Page 26

Technical description

FIDAMAT 6 gas analyzer

2-12 Operating manual – A5E00222135-01

The gas analyzers can be operated from a

control system or a separate PC using the

SIMATIC PDM (Process Device Manager)

operator control utility, a program which runs

under Windows XP or Windows 2000 and which

can also be incorporated into the SIMATIC PCS

7 process control system. This means that is

possible to represent in a clear and logical

manner not only the incorporation of the devices

in the system but also the complex parametrical

structure of the analyzers and operating the units

becomes simply a matter of clicking.

The PROFIBUS users organization (PNO) is an

independent international body representing the

interests of a large number of manufacturers and

users. Alongside services such as giving advice,

training and the certification of devices, its

primary duty is the further development,

standardization and promotion of PROFIBUS

technology. Definition of a mandatory

functionality for a class of devices in a profile is a

necessary condition for devices from different

manufactures behaving in a uniform manner –

what is known as "interoperability”. At the end of

1999 a mandatory profile for analysis devices

was established down thereby ensuring that all

devices in a system with PROFIBUS capability

will work together.

This profile defines the functionalities of the analysis

devices in a block model. For example, the device

block (physical block) describes the measurement

procedure, the analyzer and manufacturer names,

serial number and operational state (in operation,

under maintenance). Different functional blocks

contain the execution of specific functions such as

measured-value processing and alarm response. The

transducer blocks describe the functionality of the

measurement procedure itself as well as control of

the procedure – for example, preprocessing of a

measured value, cross-corrections, curves,

measuring ranges and also switching and control

operations. Data transmission between bus users is

defined in protocols.

Here a distinction is drawn between cyclic and

acyclic services. Time-critical data, such as

measured values and states, are transmitted

using cyclic services. Acyclic services, on the

other hand, permit device parameters to be

interrogated or modified during operation.

All of the gas analyzers in Series 6 (ULTRAMAT

6, OXYMAT 6/ 61, CALOMAT 6, ULTRAMAT 6

and FIDAMAT 6 and also ULTRAMAT 23) have

PROFIBUS capability once fitted with an optional

plug-in board (which can also be retrofitted) (see

also the electronics spare parts from page 7-3

onward of the spare parts list).

Fig. 2-5: Typical layout of a PROFIBUS system

Page 27

Technical description

FIDAMAT 6 gas analyzer

Operating manual –A5E00222135-01

2-13

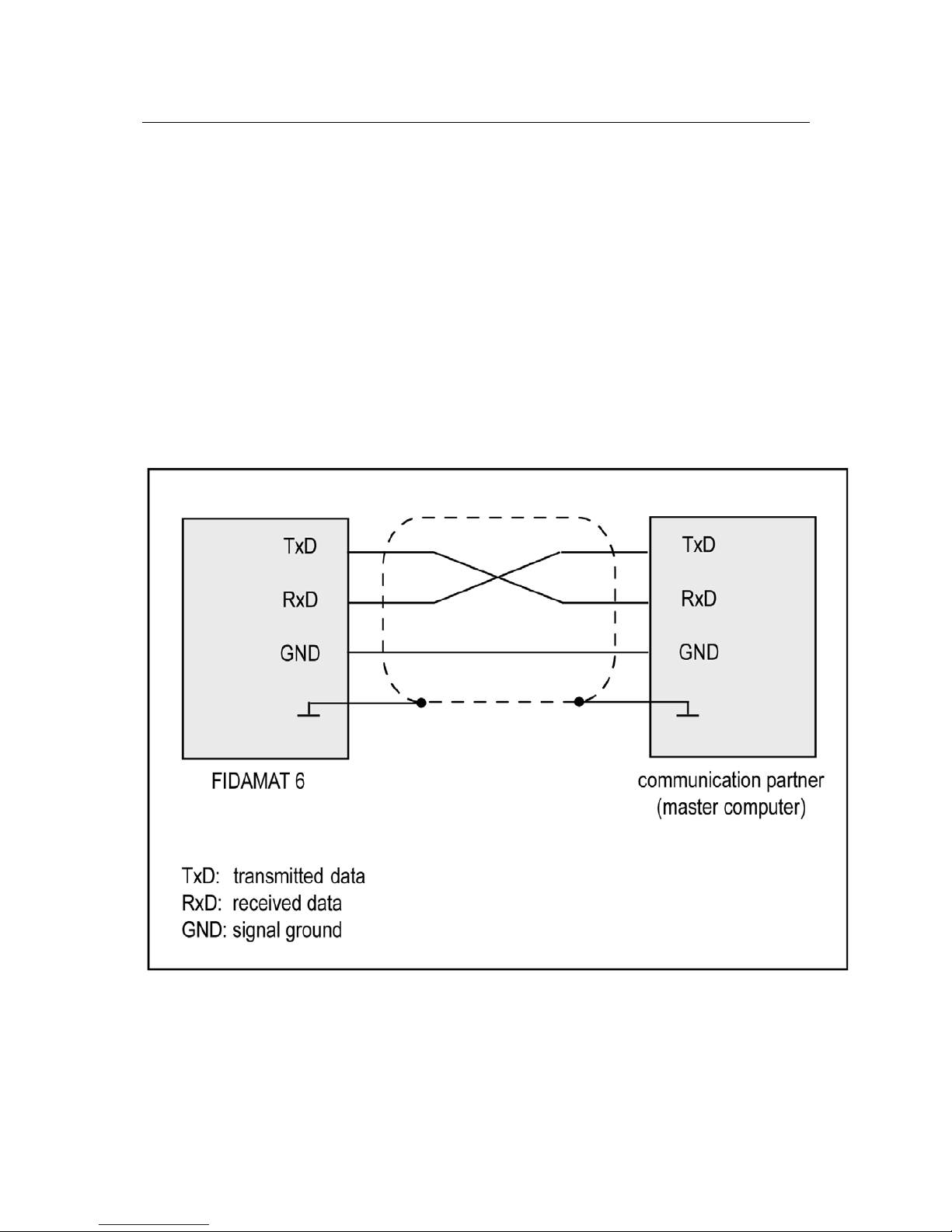

AK interface

AK is an interface which is not a standard

integrated part of Series 6 gas analyzers but

which can only be used when an additional board

is fitted. It can be ordered under this order

number:

C79451-A3474-B61

Unlike PROFIBUS and ELAN, communication

with AK is only possible between a device and a

PC and takes place on the master-slave

principle. The devices transfers data only upon

being so requested by a command telegram, and

here it can only process and reply to one

command at a time.

Fig. 2-6: Basic structure of an AK interface

The AK menu can be accessed via function 88

and the parameters set.

The benefit to the user lies in its numerous

functions which are primarily required in the

automotive industry in order to carry out

relinearization,

The principle behind the connection technology

corresponds to an RS 232 and is shown in the

diagram below.

For further information, see the AK interface

description.

Order number: C79000-B5200-C188 German

C79000-B5276-C188 English

Page 28

Technical description

FIDAMAT 6 gas analyzer

2-14 Operating manual – A5E00222135-01

2.5 Technical data

General comments

Measuring ranges

Autoranging

4, can be switched over internally or

externally;

manual and automatic measuring range

changeover possible

Hysteresis, selectable

Smallest possible

measuring span

0 - 10 ppm

Threshold of detection 0.1 ppm

Largest possible

measuring span

Concentration units

(ppm)

99,999 ppm

C

1

, C3, C6, mg C/m3

Measured-value

display

Digital concentration reading

(5 positions with floating point)

Resolution of the digital

display

Position of normal use

0.1% of the measured value

Front panel vertical

Conformity

Oven temperature

CE symbols to EN 50081-1, EN 50082-2

Adjustable between 100-200 °C

(depending on application)

Design, housing

Degree of protection IP 20 as per EN 60529

Dimensions

See "Dimensional drawings” diagram

Weight

approx. 23 kg

Electrical features

Auxiliary energy

100 - 120 V AC (nominal consumption

range 90 -132 V), 48 - 63 Hz, or

200 - 240 V AC (nominal consumption

range 180 - 264 V), 48 - 63 Hz

Power consumption

approx. 150 VA in operation

approx. 350 VA during warming-up

phase

EMC – resistance to

interference

(electromagnetic

compatibility)

Complies with standard requirements of

NAMUR NE21 (August 1998)

Electrical safety To EN 61010-1,

overvoltage category II

Fuse-protection values 100... 120 V: 4.0 T/ 250

200... 240 V: 2.5 T/ 250

Gas entry conditions

Permitted measuringgas pressure

- With pump

installed

Atmospheric pressure

Measuring-gas flow rate 18 ... 60 l/h (0.3 to 1 l/min)

Measuring-gas

temperature

0 - 200°C

Measuring-gas

humidity

< 90% RH

(RH = relative humidity)

Consumption figures for the gases

Combustion air

approx. 350 ml/min

Hydrogen approx. 20 ml/min

Sample approx. 1 l/min

Neutral gas /

calibration gas

approx. 2 l/min

Time behavior

Warming-up time

At room temperature, approx. 2 - 3 h

Display delay (T90) 2 - 3 s

Attenuation (electrical

time constant)

0 -100 s, parametrizable

Dead time (time for

flushing out gas path

inside unit at 1 l/min)

With filter 2 - 3 s

Time for signal

rocessing within unit

p

< 1 s

Measurement behavior

Output signal fluctuations < 0.75% of smallest measuring

range possible according to

nameplate with electronic

attenuation constant of 1 s (this

corresponds to +/- 0.25% at 2 σ)

Zero-point drift

< 0.5% per month of smallest

measuring range possible according

o nameplate

t

Measured-value drift

< 1% per week of measuring span

concerned

R epeatability < 1% of measuring span concerned

Linearity deviation

< 1% of measuring span concerned

Page 29

Technical description

FIDAMAT 6 gas analyzer

Operating manual –A5E00222135-01

2-15

Influencing variables

Ambient temperature

Ambient pressure

Sample pressure

< 1% / 10 K with respect to the

smallest measuring range possible

according to nameplate

Auxiliary energy

< 1% / 50 hPa

Frequency

< 2% of measuring span /

1% pressure change

Influence due to position < 1% with change of output signal

span of ±10%

< 1%

< 1% with inclination <15°

Electrical inputs and outputs

Analog output 0/ 2/ 4 to 20 mA, floating, output

load max. 750 Ω

Relay outputs 6, with changeover contacts,

parametrizable, for example for

measuring range identification;

output loading capability: AC / DC

24 V / 1 A floating

Analog inputs 2, designed for 0/ 2/ 4 to 20 mA for

external pressure pick-up and

accompanying gas correction

(transverse gas correction)

Binary inputs 6, designed for 24 V , floating, freely

paramerizable, e. g. for

autoranging)

Serial interface ELAN (RS 485)

Options AUTOCAL functions with each

8 additional binary inputs and relay

outputs, also for PROFIBUS PA or

PROFIBUS DP

Climatic conditions

Permitted ambient

temperature

+5 to +45 °C in operation

-30 °C to +70 °C in storage or

during transportation

Permitted humidity <90 RH (RH = relative humidity)

annual mean, during storage and

transportation (no falling below dew

point)

Unit with pump

Gases

Input pressure

hPa (rel.)

Operating pressure

hPa (rel.)

Flow rate

through

FID

ml/ min.

Flow rate

through

bypass

ml/ min.

Without pump

start-up

With pump

start-up

Hydrogen 2.000 – 4.000 1 ± 20 ~ 25 ---

Combustion air 2.000 – 4.000 420 ± 20 500 ~ 320 ~ 500

Sample atmosphere --- 500 ± 2 ~ 3 ~ 1000

Zero gas 2.500 – 3.000 --- 500 ± 2 ~ 3 ~ 1000

Turning gas 2.500 – 3.000 --- 500 ± 2 ~ 3 ~ 1000

Page 30

FIDAMAT 6 gas analyzer

Operating manual – A5E00222135-01

2-16

Page 31

3. Installation instructions

3. Installation instructions

3.1. Safety instructions

3.2. General installation requirements

3.3. Gas conditioning

3.4. Electrical connections

3.4.1. Power supply

3.4.2. Connecting the signal lines

3.4.3. Circuit diagrams (electrical connections)

3.4.3.1. Pin assignments on the motherboard

(default)

3.4.3.2. Pin assignments on the optional plug-in

board and PROFIBUS

3.4.3.3. ELAN interface line

3.5. Dimension drawings

Page 32

Installation instructions

FIDAMAT 6 gas analyzer

3-2 Operating manual –A5E00222135-01

3.1 Safety instructions

Warning

It is essential that you observe the following information and instructions!

Hazardous voltages

Certain parts of this device are carrying hazardous voltages. Before the

unit is switched on, the housing must be closed and grounded.

Failure to comply may result in death, physical injury or damage to

property.

In this regard you should also read and comply with the section entitled

"Electrical connection” on page 3-5.

Poisoning hazard

When toxic or corrosive gases are being analyzed, the exhaust gases

must be taken off in such a way that persons present are not exposed to

any danger. Exhaust gas lines must be made of material which is

resistant to the sample (see also "Design of housing and FID” on page 2-

4).

Failure to comply may result in serious symptoms of poisoning or even

death.

Explosion hazard!

Use of the FIDAMAT 6 gas analyzer for measuring operationally

explosive mixtures is not permitted. If the unit is to be used for measuring

flammable gases which in combination with air or oxygen could form an

explosive mixture, special explosion-protection measures will need to be

taken.

Combustion hazard

During operation the interior of the unit's oven reaches a temperature of

around 200°C. With the aid of function 2 not only the actual temperature

of the oven but also any other temperature setting may be accessed.

Once the unit has been switched off, temperatures fall only at a very slow

rate. This is why the oven is not accessible to operating personnel during

normal operation.

Protective gloves must always be worn during maintenance work. Note

too that hydrogen burns colorlessly. Failure to observe this may result in

serious burns.

Flushing the housing

In accordance with details in the technical data starting on page2-14,

there may be what is to be regarded as a limited escape of flammable

components from leaks in the sample path. With the FIDAMAT 6

there is no need to flush the housing provided it has been ensured

that there is a natural exchange of air from the environment.

Note

However, this does not apply to toxic or corrosive gases! In this regard

the maximum allowable workplace concentration figures must be

observed.

Page 33

Installation instructions

FIDAMAT 6 gas analyzer

Operating manual – A5E00222135-01 3-3

3.2 General installation requirements

Installation conditions A location as free as possible of vibration should be selected for

installation.

Make sure that the permissible ambient temperature of 5°C – 45°C is

observed during operation (see also "Technical data” on page 2-14).

You should also ensure that the unit is not exposed to direct sun light.

If the FIDAMAT 6 is installed in a cabinet or desktop casing, it must be

accommodated on support or telescopic rails. It can also be fitted into a

swing frame. Mounting the unit by its front end is not satisfactory since the

unit's own weight will place too great a load on the chassis.

Due to the unit's great weight the mountings will need to be sized

correctly. Use all four screws to fix the housing in place.

Ventilation

Although the FIDAMAT 6 has an internal fan you still need to ensure

adequate ventilation. If several devices are installed in a single cabinet,

the FIDAMAT 6 should be fitted as the highest-positioned device due to

the great amount of heat it gives off. If this is not possible, a space of

about 4 - 5 cm (1 height unit) must be left above the unit.

Gas connections Bulkhead connectors with an external pipe diameter of 6 mm or ¼"

(Swagelok) are provided as gas connections. Gas connection

assignments are given in both the gas circuit diagrams and the

identification labeling on the rear panel of the unit.

Electrical connections All connecting cables (apart from the mains power line) must be shielded.

The connected cables are shielded via the plug-in connectors.

The core cross-section should be 0.5 mm². Cables of the type

JE- LiYCY...BD are suggested. The line length of the analog outputs

depends on the load.

Caution

When installing the wiring please observe that the device is emitting

heat. Therefore there must be a minimum distance of >2 cm between

wiring and device.

Maintenance In order to ensure that the unit is not only electrically safe but also is

functionally reliable, the FIDAMAT 6 should be given an annual servicing.

In particular, the gas path inside the unit (containment system) must be

checked for leaks. After each servicing of the containment system, a leak

test must be carried out (in this regard see "Checking for leaks” on

page 4-3).

Page 34

Installation instructions

FIDAMAT 6 gas analyzer

3-4 Operating manual –A5E00222135-01

Sample gas line For gas entry and exit there is a directly heated entry (sample) and a

directly heated outlet. Separate heated sample supply lines each require

their own energy supply and temperature regulator.

The hexagon of the bulkhead connectors is seated in an anti-rotation lock.

When tightening up the union nuts on the connectors make absolutely

certain that they are properly locked using a suitable wrench. Failure to do

so will mean the risk of the gas line becoming leaky.

The sample is drawn in by a diaphragm pump (approx. 1 l/min) and if at

all possible should be made available at atmospheric pressure.

Notwithstanding this, the analyzer can also be operated at a constant

over- or underpressure of up to 100 hPa.

Exhaust gas line

The greater part of the sample delivered by the pump is routed via a so-

called bypass to the exhaust gas outlet. If the exhaust gases are

flammable, toxic or otherwise injurious to health, it is essential that they

are taken off using the appropriate measures.

If the exhaust gas is to discharge into a collecting main the following

points should be noted:

•

The flow resistance in the collecting main should be kept low by

means of either the shortest length of pipe possible or a transition to

a larger diameter.

•

The exhaust gas line must not be subject to rapid pressure

fluctuations. If this is not the case, you will need to put in a separate

exhaust gas line or fit a damping vessel with throttle value (>1 l)

between the analyzer and the exhaust gas line (pneumatic low-pass

filter).

•

To prevent blockages of the exhaust gas line (for example, due to

condensed water) and thereby damage to the unit due to water

formation, all parts of the line must have a downward gradient. To

this end, it is advisable to install a siphon as a water trap.

Fig. 3-1: FIDAMAT 6, gas and electrical connections

Page 35

Installation instructions

FIDAMAT 6 gas analyzer

Operating manual – A5E00222135-01 3-5

Sample path within the unit

(containment system)

Sample-wetted materials must be resistant to the sample. Materials used

for the seals are quartz, stainless steel 1.4571, graphite and / or PTFE.

Regular inspections for leaks must be carried out to check the integrity of

the containment system. If the result is negative, the cause of the leaks

must be corrected before you can use the analyzer. A possible remedy in

this case is to fit new seals.

After each servicing of the containment system, a leak test must be

carried out (in this regard see "Checking for leaks” on page 4-3).

Pressure sensors The FIDAMAT 6 has two internal pressure sensors for measuring the

sample pressure (= combustion air pressure) and the hydrogen pressure.

Maintenance Both the electrical safety and the serviceability of all unit components

must be checked regularly. For this reason the FIDAMAT 6 needs an

annual servicing.

The servicing frequency can be reduced in individual cases on the basis

of the owner's judgment if no negative effects on the sample-wetted seals

are to be expected from chemical attack.

The operator panel (viewing window and keyboard) should only be

cleaned by wiping with a damp cloth.

3.3 Gas conditioning

Sample The sample is drawn in through a sample filter heated to 200°C in order to

refilter the sample gases. The filter is made of sintered metal (CrNi steel),

has a pore size of 3 µm and a surface area of 3 cm².

Note

Sample gases must be free of dust when they enter the analyzers.

Condensate should be avoided. For this reason, it will in most

application cases be necessary to use a gas conditioning device

suitable for the measurement task in question.

Supply gas

The supply gases (hydrogen, combustion air) must have a purity level of

5.0 if correct measurement is to be assured. The purity level will need to

be increased in the case of very low concentrations of hydrocarbons

(<1 ppm). The supply gases must be made available with a input pressure

between 2000 and 4000 hPa rel. The pressure of zero gas and test gas is

around 3000 hPa in each case. Higher pressures will result in increased

gas consumption while lower pressure could on the other hand lead to

incorrect calibration (calibration) since sample could also be drawn in as

well.

Page 36

Installation instructions

FIDAMAT 6 gas analyzer

3-6 Operating manual –A5E00222135-01

3.4 Electrical connections

Warning

When carrying out electrical installation, you should observe the

provisions of VDE 0100 or an equivalent international standard relating to

high-voltage systems with nominal voltages below 1000 V.

Failure to comply with these provisions may result in death, physical injury

or damage to property.

3.4.1 Power supply

• An inlet connector for non-heating apparatus is supplied with the unit

and should only be connected to the mains supply line by qualified

personnel (see "Qualified personnel” on page 1-5). The mains supply

line must satisfy the regulations and requirements applicable at the

place of installation and also be provided with a protective conductor

at housing potential. The cross-section of each core must be 1 mm².

The phase-carrying connection cable must be connected at the

marked location in the plug.

• The power cable must be routed separately from the signal lines.

• A power isolator device must be provided in the immediate vicinity of

the unit (load capability shown on nameplate). It must be easily

accessible and have identification labeling.

• A check should be made to ensure that the mains voltage present is

the same as specified on the nameplate.

Caution

Due to the heat radiation a minimum distance of one inch from the

housing must be observed when wiring the device.

3.4.2 Connecting the signal lines

Warning

Signal lines should only be connected to units which are safely electrically

isolated from their auxiliary power.

Page 37

Installation instructions

FIDAMAT 6 gas analyzer

Operating manual – A5E00222135-01 3-7

• With the FIDAMAT 6 the signal lines are connected to the SUB D

connectors at the rear of the unit.

• The connection cables to the relay outputs, the binary inputs and the

analog inputs and outputs must be shielded. They should be

connected to the corresponding trapezoidal plug (SUB-D plug) as

shown in the allocation lists (see "Pin assignments” on page 3-8).

• The reference ground of the analog inputs is the housing potential.

• The analog output is floating.

• The shielding of the interface line must be connected to housing

potential. The cable shielding must have a large-area connection

with the shielding of the SUB D plug. The cross-section of the cores

should be 0.5 mm². The interface line should not exceed 500 m in

length.

All connecting cables (apart from the mains power line) must be

shielded.

The cable shielding of the connected lines must be applied over a

large area and without any gaps at the respective threaded connections.

The core cross-section should be 0.5 mm². Cables of the type

JE- LiYCY...BD are suggested. The line length of the analog outputs

depends on the load.

Page 38

Installation instructions

FIDAMAT 6 gas analyzer

3-8 Operating manual –A5E00222135-01

3.4.3 Circuit diagrams (electrical connections)

3.4.3.1 Pin assignments on the motherboard (default)

Fig. 3-2: FIDAMAT 6, 19" rack module, pin assignments

Page 39

Installation instructions

FIDAMAT 6 gas analyzer

Operating manual – A5E00222135-01 3-9

3.4.3.2 Pin assignments on the optional plug-in board and PROFIBUS

Fig. 3-3: FIDAMAT 6, 19" rack module, pin assignments of AUTOCAL board and PROFIBUS connector

.

Page 40

Installation instructions

FIDAMAT 6 gas analyzer

3-10 Operating manual –A5E00222135-01

3.4.3.3 ELAN interface line

Specifications of the interface cable

Characteristic

impedance

100 to 300 Ω at a measuring frequency of

> 100 kHz

Cable

capacitance

Typically < 60 pF per meter

Core

cross-section

>0.22 mm

2

, corresponds to AWG 23

Cable type twisted pair, 1 x 2 conductors

Signal attenuation max. 9 dB over entire length of line section

Shielding Copper braiding, or braided shield and foil shield

Bus termination

resistors

Before bus termination resistors can be connected, in the first and last

connectors of a bus cable pin 3 has to be jumpered with pin 7, and pin 8

with pin 9 (see Fig. 3-4 "Pin assignments”).

Note

If the bus cable is longer than 500 m or there is a high level of

interference it is advisable to install a repeater. For further information see

function 73 in "ELAN configuration” on page 5-33 or in the description of

the ELAN interface.

Order number: C79000-B5200-C176 German

C79000-B5276-C176 English

Fig. 3-4: Pin assignments

Page 41

Installation instructions

FIDAMAT 6 gas analyzer

Operating manual – A5E00222135-01 3-11

3.5 Dimension drawings

Fig. 3-5: Dimension drawing of the FIDAMAT 6 (dimensions in mm)

Page 42

Installation instructions

FIDAMAT 6 gas analyzer

3-12 Operating manual –A5E00222135-01

Page 43

4. Start-up

4. Start-up

4.1. Safety instructions

4.2. Start-up preparations

4.3. Start-up and operation

4.3.1. Measuring ranges

4.3.2. Calibration

Page 44

Start-up

FIDAMAT 6 gas analyzer

4-2 Operating manual –A5E00222135-01

4.1 Safety instructions

Warning

It is essential that you observe the following information and instructions!

Explosion hazard!

Use of the FIDAMAT 6 gas analyzer for measuring operationally explosive

mixtures is not permitted. If the unit is to be used for measuring flammable

gases which in combination with air or oxygen could form an explosive

mixture, special explosion-protection measures will need to be taken.

Electrical safety

Certain parts of this device are carrying hazardous voltages. Before the

FIDAMAT 6 is switched on, the housing must be closed and grounded.

Failure to comply may result in death, physical injury or damage to

property. For this, please also note "

Electrical connection” on page 3-5.

Flushing the housing

In accordance with details in the technical data, there may be what is to

be regarded as a limited escape of flammable components from leaks in

the sample path. With the FIDAMAT 6 there is no need to flush the

housing provided it has been ensured that there is a natural exchange of

air from the environment. Your attention is particularly drawn to this in the

case where the analyzer is installed in a cabinet.

Warning

However, this does not apply to toxic or corrosive gases! When working

with corrosive or toxic gases the device must be flushed

Page 45

Start-up

FIDAMAT 6 gas analyzer

Operating manual – A5E00222135-01 4-3

4.2 Start-up preparations

Position of unit The FIDAMAT 6 may only be operated in a vertical position.

Gas conditioning Gas preparation takes place via a heated sample gas filter

(approx. 200°C) with a pore size of 3 µm and with a very limited capacity.

For this reason, samples with a high degree of contamination must be

prefiltered before entering the analyzer.

Check for leaks A leakage inspection should be conducted after any maintenance activity

affecting the flame ionization detector (FID) or the gas path. This is done

as follows:

FID

1. Connect

the sample gas outlet (exhaust gas) to a relative

pressure manometer

(0 - 1000 hPa, resolution 0.1 hPa)

2. Apply an overpressure of about 950 hPa at the sample entry and

close off.

3. Wait two minutes or so, until pressure equalization has occurred and

then make a note of the pressure.

4.

Wait another minute and then read off the pressure

The gas path is satisfactory as far as leaks are concerned when

the pressure drop within a minute does not exceed 10 + 2 hPa.

Note

The temperature of the gas path, including the FID, must remain constant

while this measurement is being taken.

Test conditions: The pressures given are relative pressures.

Test medium: Synthetic air (sample path must not become contaminated)

Test pressure: Operating pressure x 1.5 (operating pressure = 500 hPa)

Unit electrically switched off:

Test pressure [hPa]

Permissible pressure drop ∆ p [hPa]

Sample path

750 + 10 (750 + 10 hPa)

∆ p 10+2 (10 + 2 hPa)

Supply gas inlets

3,000 +100 (3,000 + 100 hPa)

∆ p 12+5 (12 + 5 hPa)

Page 46

Start-up

FIDAMAT 6 gas analyzer

4-4 Operating manual –A5E00222135-01

Pressure equalization times: time sequence of test

After application of test pressure, observe start and end of measurement for determination of ∆p.

Measurement starts x min after

application of test pressure

Measurement ends y min after

application of test pressure

Sample path

2 3

Supply gas inlets

1 2

Operation Before connecting up and switching on the unit, the operator must have

familiarized himself with how the unit is operated (see on page 5-2).

Interfaces

Before the unit is used, the interfaces must be correctly assigned and

parametrized (see "Connecting the signal lines” on page 3-6).

Noise damping The output signal fluctuations caused by noise in the measurement signal

can be reduced by means of function 50. Among other things, this

function allows you to parametrize a low-pas filter which can be assigned

a time constant of up to 300 s.

Temperature influence Make sure that the permissible ambient temperature of 5°C – 45°C is

observed during operation (see also "Technical data” on page 2-14).

Pressure influence If measurement is carried out externally, the unit will carry out an

automatic pressure correction. If there are pressure fluctuations within the

unit, pressure compensation will be carried out automatically.

Page 47

Start-up

FIDAMAT 6 gas analyzer

Operating manual – A5E00222135-01 4-5

4.3 Start-up and operation

Check Before switching the unit on, check to see that hydrogen, combustion air, zero

gas and test gas are connected and the required pressures are present.

Switching on

mains power Shortly after switch-on, the measured value display appears on the LCD

screen. Above this, on the top line, is the status display (Section 5.1).

Warming up

With the FIDAMAT 6 it is necessary to wait for about one hour for the

warming-up phase to finish. During this time, the oven heats up to 200°C

(accessible via function 2 "Diagnostics values”). In contrast, the

measuring cell and FID are warmed up with a delay whereby their

temperature derives from the setpoint temperature of the oven. Next, the

unit automatically checks in turn to see whether the corresponding

pressure of the sample and combustion air obtains and whether the

hydrogen supply is adequate. If this is the case, the flame is ignited

automatically. The flame burns when the flame temperature is 20°C

higher than the oven temperature.

Not until the unit has detected that the flame is burning will the pump be

switched on.

So as not to block the automatic heating-up procedure, the unit must be in

its measurement state. Here the current operational status can be read off

from the bottom line.

4.3.1 Measuring ranges

Measuring ranges and

measuring spans

The measuring spans desired (initial value of measuring range and final

value of measuring range) should be defined using function 41. Analog

current values 0/2/4 mA to 20 mA are assigned to the initial and final

values.

If the same values are assigned for a measuring range's initial and

starting values this measuring range will be deemed non-existent.

The smallest measuring span (MS) is to be assigned to measuring range

1, and so on. In general, the following arrangement will apply: MS1 < MS2

< MS3 < MS4

Setpoint value of zero point The setpoint value for the zero point is entered under function 22. It

applies to all measuring ranges.

Calibration of zero point Zero calibration is carried out with the aid of function 20. Here both the

setpoint value and the actual value are displayed.

Page 48

Start-up

FIDAMAT 6 gas analyzer

4-6 Operating manual –A5E00222135-01

Electronically suppressed

zero point If the measuring range initial value (ppm,% vol., etc.) is not at

concentration zero, we speak of measuring ranges with suppressed zero

point (for example, 200 - 300 ppm CO). Here 200 ppm is the initial value,

300 ppm the final value, and 100 ppm the measuring span.

Channels with electronic zero-point suppression are physically identical to

non-suppressed zero points. Where they differ is solely in the parametrization of the measuring ranges and of the setpoint value for the

suppressed zero point (200 ppm CO, for example).

The characteristic

curve

is stored from zero to the characteristic final value (as stated on

the nameplate). Units with non-suppressed zero points can be repara-

metrized subsequently to suppressed zero points by modifying this parameter (functions 22 and 41). It should however be noted that influences

such as noise, temperature and pressure errors are magnified by the

factor

F =

Final value of smallest measuring range

Final value of smallest measuring range – initial value

Here F should not exceed a value of 7. In general it is recommended to

increase the smallest measuring span by about 30%.

Span setpoint value The setpoint value for span should be checked under function 22.

The setpoint value displayed must be the same as the test gas value. If

this is not the case, the values must be made to coincide with the aid of

function 22.

With a total calibration, the leading measuring range should be selected.

The setpoint values must be as far away as possible from the zero point

(at least 60% of the corresponding full-scale value). The corresponding

test gases should be made available for the span calibration. The setpoint

value is input under function 22.

Changing measurement

ranges

For the largest measuring range (according to the nameplate) the

linearized curve is saved in the memory. If the largest measuring range is

changed (function 41) this final value must not be exceeded.

Dropping below the smallest measuring range (according to the