Page 1

Flow Energy Calculator

FEC920

User Guide

A5E45696052A Rev-AA

September 2018

Page 2

© 2018

All rights are strictly reserved. No part of this document may be reproduced, modified, or transmitted in any

form by any means, nor may it be stored in a retrieval system other than for the purpose to act as an aid in

operating the equipment to which the document relates, without prior written permission of the

manufacturer.

The manufacturer pursues a policy of continuous development and product improvement. The

specifications in this document may therefore be changed without notice. The information in this document

is given in good faith, but is intended for guidance only. The manufacturer will not accept responsibility for

any losses arising from errors in this document.

Page 3

FEC920: USER GUIDE

Page i

A

September 18

FEC920 Flow Energy Calculator

User Guide

List of sections

Section Page

1 Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Cybersecurity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6 Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7 Modbus TCP slave comms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

8 BACnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

9 iTools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

10 User Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

11 USB Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

A Technical specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

B Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

C Web Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Associated documents

HA028838 Printable version of iTools Help

HA025464 EMC installation guidelines

HA027962 Printable version of ‘Review’ Help

Software effectivity

This manual refers to instruments fitted with software version 8.0x.

Software versions 2.20 onwards are ‘backwards compatible’ so that it can be used on

all hardware versions of the unit.

Previous software versions are not compatible with instruments with hardware status

greater than 2.

The status level may be found on the instrument label and consists of a letter indicating

software status followed by a numeral indicating the hardware status (e.g. ‘B2’)

A5E45696052A Rev-AA

Page 4

FEC920: USER GUIDE

September 18

Page ii

1 SAFETY NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 USB DEVICE PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 32-BIT RESOLUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 SYMBOLS USED ON THE RECORDER LABELLING . . . . . . . . . . . . . . . . . . . 3

2 CYBERSECURITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 WHAT’S IN THIS CHAPTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 SECURE NETWORK TOPOLOGIES AND GOOD PRACTICES . . . . . . . . . . . 4

2.4 SECURITY FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4.1 Principle of Secure by Default . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4.2 HMI Access Level / Comms Config Mode . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4.3 HMI Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4.4 Ethernet security features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4.5 Configuration backup and recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5 MEMORY INTEGRITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.6 FIRMWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.7 SUPPORTED PROTOCOLS AND THREAT MITIGATIONS . . . . . . . . . . . . . . 6

2.7.1 FTP Client . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.7.2 FTP Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.7.3 ICMP (ping) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.7.4 DHCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.7.5 SNTP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.7.6 ModBus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.7.7 HTTP (Web Server) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.7.8 UHH Navigator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.7.9 Ethernet IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.7.10 BACnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.8 DECOMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 UNPACKING THE INSTRUMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 MECHANICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1.1 Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1.2 Demounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1.3 Removing the Instrument from its Sleeve . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2 ELECTRICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.1 Termination details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.2 Low Voltage Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2.3 Dual Input Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2.4 Modbus Master communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2.5 EtherNet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.1 Display Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.2 Navigation Pushbuttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.3 On Screen Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2 PROCESS VARIABLE DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2.1 Alarm Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2.2 Status Bar Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2.3 Breaks in recording . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

FEC920 - Flow Energy Calculator

User Guide

Contents List

Section

A5E45696052A Rev-AA

Page 5

FEC920: USER GUIDE

Page iii

A

September 18

5.3 TOP LEVEL MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3.1 Home . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3.2 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3.3 Go to View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.3.4 History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.3.5 Faceplate Cycling on/off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.3.6 Operator Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.3.7 Demand Archiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.3.8 Login . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.4 DISPLAY MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.4.1 Vertical Trend Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.4.2 Horizontal Trend Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.4.3 Vertical Bargraph Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.4.4 Horizontal Bargraph Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.4.5 Numeric Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.4.6 Alarm Panel Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.4.7 Modbus Master display mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.4.8 EtherNet/IP display mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.5 TREND HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.5.1 Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.5.2 History Options Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.6 TEXT ENTRY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.6.1 Numeric keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.6.2 USB keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6 CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.1 INSTRUMENT MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.1.1 Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.1.2 Locale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.1.3 Display configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.1.4 Info menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.1.5 Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.1.6 Security menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.1.7 I/O fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.1.8 Save/Restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.1.9 Input adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.1.10 Output adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.1.11 User Accounts (Auditor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.2 NETWORK MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.2.1 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6.2.2 Archiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.2.3 FTP Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.2.4 Modbus TCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.2.5 BACnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.3 GROUP CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.3.1 Group Trend configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.3.2 Group Recording configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.4 INPUT CHANNEL CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.4.1 Channel Main . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.4.2 Channel Trend configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6.4.3 Alarm 1 menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.4.4 Alarm 2 menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.4.5 Alarm types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.5 VIRTUAL CHANNEL CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.5.1 Maths channel configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.5.2 Totalizer configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.5.3 Wiring Example using a counter in combination with a totalizer . . . . . . . . 87

6.5.4 Counter configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.6 MODBUS MASTER CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

6.6.1 Slave Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

6.6.2 Slave Diagnostics menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

6.6.3 Modbus master data configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6.7 ETHERNET/IP CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

List of Contents (Cont.)

Section Page

A5E45696052A Rev-AA

Page 6

FEC920: USER GUIDE

September 18

Page iv

6.7.1 Ethernet/IP Configuration Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

6.7.2 Implicit inputs/outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

6.7.3 Explicit inputs/outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

6.8 WEB SERVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6.8.1 Configuration Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6.9 DIGITAL I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6.9.1 Digital input/output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6.9.2 Relay outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

6.9.3 Digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6.9.4 Digital outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6.10 DC OUTPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

6.10.1 Configuration display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6.11 USER LIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6.11.1 User linearization table rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

6.12 LOGIC (2 INPUT) BLOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6.12.1 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6.13 LOGIC (8 INPUT) BLOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6.13.1 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6.13.2 Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6.13.3 Invert input decoding table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

6.14 Multiplexer block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6.14.1 Configuration parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6.15 MATH (2 INPUT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

6.15.1 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

6.15.2 Sample and Hold details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

6.16 TIMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

6.16.1 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

6.16.2 Timer modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

6.17 USER VALUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

6.17.1 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

6.18 ALARM SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

6.19 REAL TIME EVENT CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

7 MODBUS TCP SLAVE COMMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

7.1 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

7.2 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

7.2.1 Function Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

7.2.2 Data types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

7.2.3 Invalid multiple register writes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

7.2.4 Master communications timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

7.2.5 Non-volatile parameters in EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

7.3 PARAMETER LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

8 BACnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

8.1 BACnet Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

8.2 BACnet Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .180

8.3 BACnet Object Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

8.3.1 Mapping to I/O and Loop Data Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

8.3.2 Mapping to Virtual Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

8.3.3 Read/Write Access to Internal Modbus Registers . . . . . . . . . . . . . . . . . .182

8.3.4 Optional parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

8.3.5 BACnet Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

8.3.6 Foreign Device Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

8.3.7 BACnet Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

9 iTOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

9.1 iTOOLS CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

9.1.1 Ethernet (Modbus TCP) communications . . . . . . . . . . . . . . . . . . . . . . . . .184

9.1.2 Direct Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

9.2 SCANNING FOR INSTRUMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

List of Contents (Cont.)

Section Page

A5E45696052A Rev-AA

Page 7

FEC920: USER GUIDE

Page v

5

September 18

9.3 GRAPHICAL WIRING EDITOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

9.3.1 Tool bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

9.3.2 Wiring Editor Operating Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

9.4 PARAMETER EXPLORER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .198

9.4.1 Parameter explorer detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .199

9.4.2 Explorer tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200

9.4.3 Context Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200

10 USER WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

10.1 DRIVE RELAY EXAMPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

10.1.1 Wire removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

10.2 COUNTER EXAMPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

11 USB DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

11.1 MEMORY STICK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

11.2 BARCODE READER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

11.3 USB KEYBOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

Appendix A: TECHNICAL SPECIFICATION . . . . . . . . . . . . . . . . . . . . 208

A1 INSTALLATION CATEGORY AND POLLUTION DEGREE . . . . . . . . . . . . . . .208

A2 RECORDER SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

A3 ANALOG INPUT SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

A4 RELAY AND LOGIC I/O SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . .212

A5 DIGITAL INPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

A6 DC OUTPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

A7 BLOCKS SUPPORTED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .212

A7.1 ‘Toolkit’ Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Appendix B: REFERENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

B1 BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .213

B2 SETTING UP AN FTP SERVER USING FILEZILLA . . . . . . . . . . . . . . . . . . . . .214

B2.1 Downloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

B2.2 Server Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .216

B2.3 PC Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

B2.4 Recorder/Controller Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

B2.5 Archive Activity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

B3 FUNCTION BLOCK DETAILS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .219

B3.1 Eight Input OR Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

B4 TCP PORT NUMBERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

B5 ISOLATION DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .220

Appendix C: WEB SERVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

C1 BROWSERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

C1.1 Connecting to the Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .221

C1.2 Denied Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .221

C1.3 Error Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

C1.4 Home Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

C1.5 About Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .222

C1.6 Contact Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .223

C1.7 Bar Graph Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

C1.8 Line Graph Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

C1.9 Numeric Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .226

C1.10 Alarm Summary Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

C1.11 Message Summary Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

C1.12 Historical Line Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

C1.13 Status Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .228

List of Contents (Cont.)

Section Page

A5E45696052A Rev-AA

Page 8

FEC920: USER GUIDE

September 18

Page vi

C1.14 DHCP Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .228

C1.15 Network Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

C1.16 Languages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .228

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

List of Contents (Cont.)

Section Page

A5E45696052A Rev-AA

Page 9

FEC920: USER GUIDE

Page 1

A

September 18

1 SAFETY NOTES

Warning: Any interruption of the protective conductor inside or outside the apparatus, or

disconnection of the protective earth terminal is likely to make the apparatus

dangerous under some fault conditions. Intentional interruption is prohibited.

Warning: Live sensors: The unit is designed to operate if the temperature sensor is connected

directly to an electrical heating element. It must be ensured that service personnel do

not touch connections to such inputs whilst the inputs are live. With live sensors, all

cables, connections and switches for connecting the sensor must be mains rated for

use in 240V Cat II.

Warning: Grounding the temperature sensor shield: Where it is common practice to replace

the temperature sensor whilst the instrument is live, it is recommended that the

shield of the temperature sensor be grounded to safety earth, as an additional

protection against electric shock.

Warning: The instrument must not be wired to a three-phase supply with an unearthed star

connection, because, under fault conditions, such a supply could rise above 240V

RMS with respect to ground, thus rendering the instrument unsafe.

Note: Safety requirements for permanently connected equipment state:

a. A switch or circuit breaker shall be included in the building installation.

b. It shall be in close proximity to the equipment and within easy reach of the operator.

c. It shall be marked as the disconnecting device for the equipment.

Note: Recommended external fuse ratings are: 2A Type T 250V.

A5E45696052A Rev-AA

Page 10

FEC920: USER GUIDE

Page 2

September 18

1. This instrument is intended for industrial temperature and process control applications within the

requirements of the European directives on safety and EMC.

2. Installation may be carried out only by qualified personnel.

3. To prevent hands or metal tools coming into contact with parts that are electrically live the instrument

must be installed in an enclosure.

4. Where conductive pollution (e.g. condensation, carbon dust) is likely, adequate air conditioning/filtering/

sealing etc. must be installed in the enclosure.

5. The mains supply fuse within the power supply is not replaceable. If it is suspected that the fuse is faulty,

the manufacturer’s local service centre should be contacted for advice.

6. Whenever it is likely that protection has been impaired, the unit shall be made inoperative, and secured

against accidental operation. The manufacturer’s nearest service centre should be contacted for advice.

7. If the equipment is used in a manner not specified by the manufacturer, the protection provided by the

equipment might be impaired.

8. The unit must be wired according to the instructions in this manual.

9. Before any other connection is made, the protective earth terminal shall be connected to a protective

conductor. The mains (supply voltage) wiring must be terminated in such a way that, should it slip, the

Earth wire would be the last wire to become disconnected. The protective earth terminal must remain

connected (even if the equipment is isolated from the mains supply), if any of the I/O circuits are

connected to hazardous voltages*.

The protective earth connection must always be the first to be connected and the last to be disconnected.

Wiring must comply with all local wiring regulations, e.g. in the UK, the latest IEEE wiring regulations

(BS7671) and in the USA, NEC class 1 wiring methods.

10. Signal and supply voltage wiring should be kept separate from one another. Where this is impractical,

shielded cables should be used for the signal wiring.

11.

The maximum continuous voltage applied between any of the following terminals must not exceed 240Vac.

1. Relay output to logic, dc or sensor input connections.

2. Any connection to ground.

The ac supply must not be connected to sensor input or low-level inputs or outputs.

12. Over temperature protection: A separate over-temperature protection unit (with an independent

temperature sensor) should be fitted to isolate the process heating circuit should a fault condition arise.

Alarm relays within the recorder/controller do not give protection under all fault conditions.

13. In order to allow the power supply capacitors to discharge to a safe voltage, the supply must be

disconnected at least two minutes before the instrument is removed from its sleeve. The touching of the

exposed electronics of an instrument which has been removed from its sleeve should be avoided.

14. Instrument labels may be cleaned using iso-propyl alcohol, or water or water-based products. A mild soap

solution may be used to clean other exterior surfaces.

* A full definition of ‘Hazardous’ voltages appears under ‘Hazardous live’ in BS EN61010. Briefly, under normal

operating conditions, hazardous voltages are defined as being > 30V RMS (42.2V peak) or > 60Vdc.

A5E45696052A Rev-AA

Page 11

FEC920: USER GUIDE

Page 3

A

September 18

1.1 USB DEVICE PRECAUTIONS

1. Precautions against electrostatic discharge should be taken when the instrument terminals are being

accessed. The USB and Ethernet connections are particularly vulnerable.

2. Ideally, the USB device should be plugged directly into the instrument, as the use of extension leads may

compromise the instrument’s ESD compliance. Where the instrument is being used in an electrically

‘noisy’ environment however, it is recommended that the user brings the USB socket to the front of the

panel using a short extension lead. This is because the USB may ‘lock up’ or reset in noisy environments

and the only means of recovery is to remove the device, then re-insert it. For memory sticks, EMC-related

failure during a write operation might cause corruption of the data held on the stick. For this reason, the

data on the memory stick should be backed up before insertion and checked after removal.

3. When using a USB extension cable, a high quality screened cable must be used. The total length of USB

cable between the device and the USB port must not exceed 3m (10ft).

4. Most barcode readers and keyboards are not designed for use in industrial EMC environments, and their

operation in such environments may result in impaired performance of the recorder/controller.

1.2 32-BIT RESOLUTION

Floating point values are stored in IEEE 32-bit single precision format. Values which require greater resolution

than is available in this format are rounded up or down.

1.3 SYMBOLS USED ON THE RECORDER LABELLING

One or more of the symbols below may appear as a part of the recorder labelling.

Note: The use of U3 USB Flash drives is not recommended.

Refer to manual for instructions

This unit is CE approved

C-Tick mark for Australia (ACA)

and New Zealand (RSM)

Underwriters laboratories listed mark for

Canada and the U.S.A.

For environmental reasons, this unit must be

recycled before its age exceeds the number of

years shown in the circle.

Risk of electric shock

Precautions against static electrical discharge

must be taken when handling this unit

Ethernet connector

USB connector

Protective conductive terminal

(Safety Earth)

A5E45696052A Rev-AA

Page 12

FEC920: USER GUIDE

Page 4

September 18

2 CYBERSECURITY

2.1 WHAT’S IN THIS CHAPTER

This chapter outlines some good practice approaches to cybersecurity as they relate to use of the FEC920

instrument, and draws attention to several FEC920 features that could assist in implementing robust

cybersecurity.

2.2 INTRODUCTION

When utilising the FEC920 in an industrial environment, it is important to take ‘cybersecurity’ into consideration:

in other words, the installation’s design should aim to prevent unauthorized and malicious access. This includes

both physical access (for instance via the front panel or HMI screens), and electronic access (via network

connections and digital communications).

2.3 SECURE NETWORK TOPOLOGIES AND GOOD PRACTICES

Overall design of a site network is outside the scope of this manual. The Cybersecurity Good Practices Guide,

Part Number HA032968 provides an overview of principles to consider. This is available from

www.eurotherm.co.uk.

Typically, an industrial controller such as the FEC920 together with any associated HMI screens and controlled

devices should not be placed on a network with direct access to the public Internet. Rather, good practice

involves locating the devices on a fire-walled network segment, separated from the public Internet by a so-called

‘demilitarized zone’ (DMZ).

2.4 SECURITY FEATURES

The sections below draw attention to some of the cybersecurity features of the FEC920.

2.4.1 Principle of Secure by Default

Some of the digital communication features on the FEC920 can provide greater convenience and ease-of-use

(particularly in regards to initial configuration), but also can potentially make the controller more vulnerable. For

this reason, some of these features are turned off by default. In particular, ID061 (the BACnet port is closed

unless the BACnet option is enabled).

2.4.2 HMI Access Level / Comms Config Mode

As described in Section 5.3.8, the FEC920 device features tiered, password-restricted operator levels, so that

available functions and parameters can be restricted to appropriate personnel.

2.4.2.1 Logged Out Access Level

Logged out mode allows the user to select viewing mode, to view history, to view alarms, to toggle faceplate

cycling on and off, to send notes, to suspend/resume USB archiving and to access the login process.

2.4.2.2 Operator Access Level

In addition to the logged out features, Operator access level allows the user to acknowledge alarms, to edit

notes and to perform demand archive operations. By default, no password is required in order to enter Operator

level, but a password can be set either at Supervisor level or at Engineer level.

If the Auditor feature is enabled, the Operator user is disabled and instead replaced by the 25 User accounts.

2.4.2.3 Supervisor Access Level

In addition to the logged out features, this access level allows the user to view the recorder’s configuration, and

to edit some values (such as alarm thresholds).

2.4.2.4 Engineer Access Level

This allows full access to all areas of the recorder configuration.

A5E45696052A Rev-AA

Page 13

FEC920: USER GUIDE

Page 5

A

September 18

2.4.3 HMI Passwords

When entering passwords via the HMI, the following features help protect against unauthorized access:

• Each digit is obscured (replaced with an asterisk character) after entry, to help protect against an

unauthorized person seeing the password as it is typed in.

• Password entry is locked after a configurable number of invalid attempts (if Auditor option is enabled). If

this number of attempts is exceeded, the User account is disabled. This helps protect against “brute

force” attempts to guess the password.

• The controller records the number of successful and unsuccessful login attempts for each level of

password. This is recorded in the History. Regular auditing of this History is recommended, as a means

to help detect unauthorized access to the controller.

2.4.4 Ethernet security features

Ethernet connectivity is available on the FEC920. The following security features are specific to Ethernet:

2.4.4.1 Ethernet rate protection

One form of cyberattack is to try to make a controller process so much Ethernet traffic that this drains systems

resources and useful control is compromised. For this reason, the FEC920 device includes an Ethernet rate

protection algorithm, which will detect excessive network activity and help to ensure the controller’s resources

are prioritized on the control strategy rather than the Ethernet. If this algorithm is activated, a message will be

entered into the History.

2.4.4.2 Broadcast Storm protection

A ‘broadcast storm’ is a condition which may be created by cyberattack: spurious network messages are sent

to devices which cause them to respond with further network messages, in a chain reaction that escalates until

the network is unable to transport normal traffic. The FEC920 device includes a broadcast storm protection

algorithm, which will automatically detect this condition, stopping the controller from responding to the spurious

traffic. If this algorithm is activated, a message will be entered into the History.

2.4.5 Configuration backup and recovery

Using the iTools software, you can ‘clone’ a FEC920 device, saving all its configuration and parameter settings

to a file. This can then be copied onto another controller, or used to restore the original controller’s settings.

Clone files are digitally signed using an SHA-256 cryptographic algorithm, meaning that if the file contents is

tampered with, it will not load back into a controller.

2.5 MEMORY INTEGRITY

When a FEC920 device powers up, it automatically performs an integrity check on the contents of its internal

non-volatile memory devices. Additional periodic integrity checks are performed during normal runtime and

when non-volatile data is being written. If any integrity check detects a difference from what is expected, the

controller enters Standby mode and a message is displayed on then screen.

A5E45696052A Rev-AA

Page 14

FEC920: USER GUIDE

Page 6

September 18

2.6 FIRMWARE

From time to time, to provide new functionality or address known issues, Siemens may make new versions of the

FEC920 firmware available.

This firmware may be downloaded from the Siemens website, and transferred to a FEC920 instrument in the field,

via a USB memory stick (or FTP server).

2.7 SUPPORTED PROTOCOLS AND THREAT MITIGATIONS

The FEC920 supports the following protocols on Ethernet. For each protocol, a list of mitigations are provided.

As a general comment, the firewall is configured to block all ports except those required for installed/enabled

options.

2.7.1 FTP Client

An external FTP client can access the FTP server on the instrument. This FTP server has default remote

username & password for each of the default users, passwords can be modified. Additional users can be added

with configurable remote username and passwords.

To mitigate threats:

1. Physically protect access to subnet(s) in use.

2. Firewall to block TCP port 21.

3. It is recommended that user’s should change their passwords regularly, this could be done manually or by

using the password expiry feature.

2.7.2 FTP Server

Up to two external FTP servers can be configured. The FEC920 will then connect to these servers as an FTP

client and push archive files to the servers.

Threat mitigation as for FTP Client.

2.7.3 ICMP (ping)

The FEC920 will respond to a ping to aid network diagnostics.

To mitigate threats:

1. Physically protect access to subnet(s) in use.

2. Use a firewall to block ICMP / ping.

2.7.4 DHCP

The FEC920 can allocate its IP address using DHCP; however this is typically set to fixed IP address allocation

by configuration. The DHCP server could be spoofed allocating an invalid IP address to the instrument.

To mitigate threats:

1. Use fixed IP address allocation.

2. Physically protect access to subnet(s) in use.

Caution: Non-Schneider Electric firmware

There is a potential risk that an attacker could upgrade a FEC920 with nongenuine firmware that contains malicious code. To mitigate this potential risk,

genuine FEC920 firmware upgrade utility executables are always supplied digitally

signed with the publisher as Schneider Electric. Do not use a firmware upgrade

utility if it has not been signed by Schneider Electric.

Failure to follow these instructions can result in injury or equipment damage.

A5E45696052A Rev-AA

Page 15

FEC920: USER GUIDE

Page 7

A

September 18

2.7.5 SNTP

The FEC920 can support SNTP for network time synchronisation.

To mitigate threats:

1. Physically protect access to subnet(s) in use.

2. Firewall to block UDP port 123.

2.7.6 ModBus

The FEC920 supports ModBus, which can be configured to act as Master via TCP and Slave via serial or TCP.

To mitigate threats:

1. Physically protect access to subnet (or serial cabling) in use.

2. Firewall to block TCP port 502 (or alternate non-standard port if so configured).

2.7.7 HTTP (Web Server)

To mitigate threats:

1. Physically protect access to subnet(s) in use.

2. Firewall to block TCP port 80.

2.7.8 UHH Navigator

To mitigate threats:

1. Physically protect access to subnet(s) in use.

2. Firewall to block TCP port 50010.

2.7.9 Ethernet IP

To mitigate threats:

1. Physically protect access to subnet in use.

2. Firewall to block TCP port 2222. This port is opened when Ethernet IP option is enabled.

2.7.10 BACnet

To mitigate threats:

1. Physically protect access to subnet in use.

2. Firewall to block UDP port 47808. This port is opened when BACnet option is enabled.

2.8 DECOMMISSIONING

When a FEC920 instrument is at the end of its life and being decommissioned, Siemens advises reverting all

parameters to their default settings using the Engineer Password ‘reset’ or via iTools (see Section 6.1.6 and

Section 9 for instructions). This can help to protect against subsequent data and intellectual property theft if the

controller is then acquired by another party.

A5E45696052A Rev-AA

Page 16

FEC920: USER GUIDE

Page 8

A

September 18

3 INTRODUCTION

This document describes the installation, operation and configuration of a paperless graphic recorder/

controller. The instrument comes, as standard, with four input channels and is equipped for secure archiving

via FTP transfer and/or to USB memory stick.

3.1 UNPACKING THE INSTRUMENT

The instrument is despatched in a special pack, designed to give adequate protection during transit. Should

the outer box show signs of damage, it should be opened immediately, and the contents examined. If there is

evidence of damage, the instrument should not be operated and the local representative contacted for

instructions. After the instrument has been removed from its packing, the packing should be examined to

ensure that all accessories and documentation have been removed. The packing should then be stored

against future transport requirements.

A5E45696052A Rev-AA

Page 17

FEC920: USER GUIDE

Page 9

A

September 18

4 INSTALLATION

4.1 MECHANICAL INSTALLATION

Figure 1 gives installation details.

4.1.1 Installation Procedure

1. If it is not already in place, fit the IP65 sealing gasket behind the front bezel of the instrument.

2. Insert the instrument through the panel cutout, from the front of the panel.

3. Spring the retaining clips into place, and secure the instrument by holding it firmly in place whilst pushing

both clips towards the rear face of the panel.

4. The protective membrane can now be removed from the display.

Figure 1 Securing the Instrument

4.1.2 Demounting

1. Isolate the mains supply and secure it against accidental operation. Remove all wiring and the USB

device and Ethernet cable (if any).

2. Remove the retaining springs by unhooking them from the sides using a small flat-blade screwdriver.

3. Pull the instrument forwards out of the panel.

Caution: Before installation, ensure that the specified instrument supply voltage matches the

facility supply.

Warning: Before removing the supply voltage wiring, isolate the supply voltage and secure it

against unintended operation.

For the sake of clarity, the

panel is shown as though

transparent

Retaining spring (two places)

Push springs towards panel

Push springs towards panel

A5E45696052A Rev-AA

Page 18

FEC920: USER GUIDE

Page 10

A

September 18

4.1.3 Removing the Instrument from its Sleeve

The instrument is designed to be removed from its sleeve from the front panel. However, if a USB memory stick

or the Ethernet cable is fitted then this must be removed first.

When the instrument is shipped from the factory it is fitted with two small red clips, one in the top side of the

sleeve and the other below. These are intended as a safeguard against removal of the instrument from its

sleeve when an Ethernet cable is fitted. These clips must also be removed, using a small screwdriver, before

the instrument can be taken out of its sleeve.

Ease the latching ears (Figure 2) outwards and pull the controller forward.

When plugging back in ensure that the latching ears click into place to maintain the panel sealing.

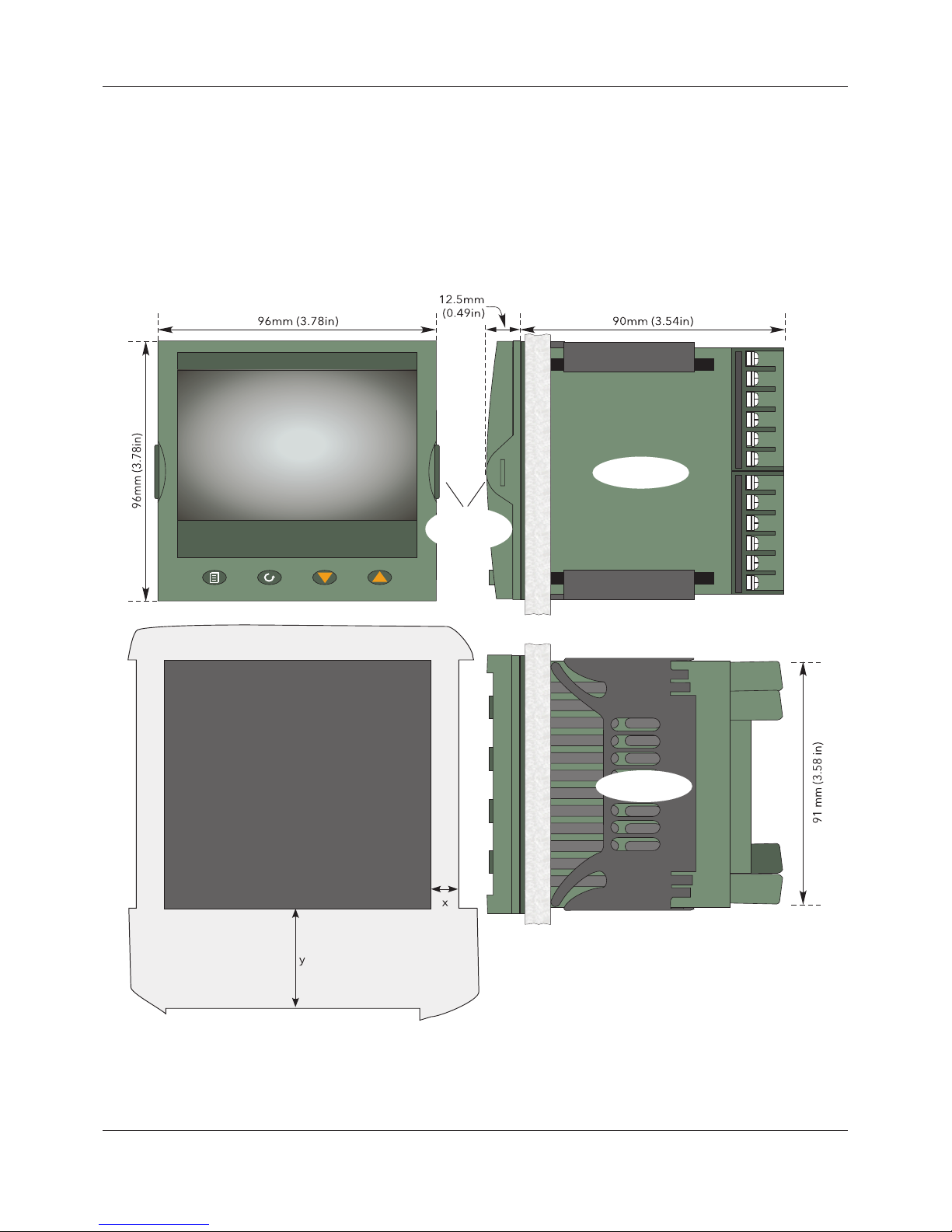

Figure 2 Mechanical installation details (standard case)

Panel cutout:

92mm x 92mm (both -0 + 0.8mm)

3.62in x 3.62in (both -0.00 + 0.03in)

Minimum inter-unit spacing:

Horizontal (‘x’) = 10mm (0.4in)

Vertical (‘y’) = 38mm (1.5in)

Side View

Top View

Latching

ears

A5E45696052A Rev-AA

Page 19

FEC920: USER GUIDE

Page 11

A

September 18

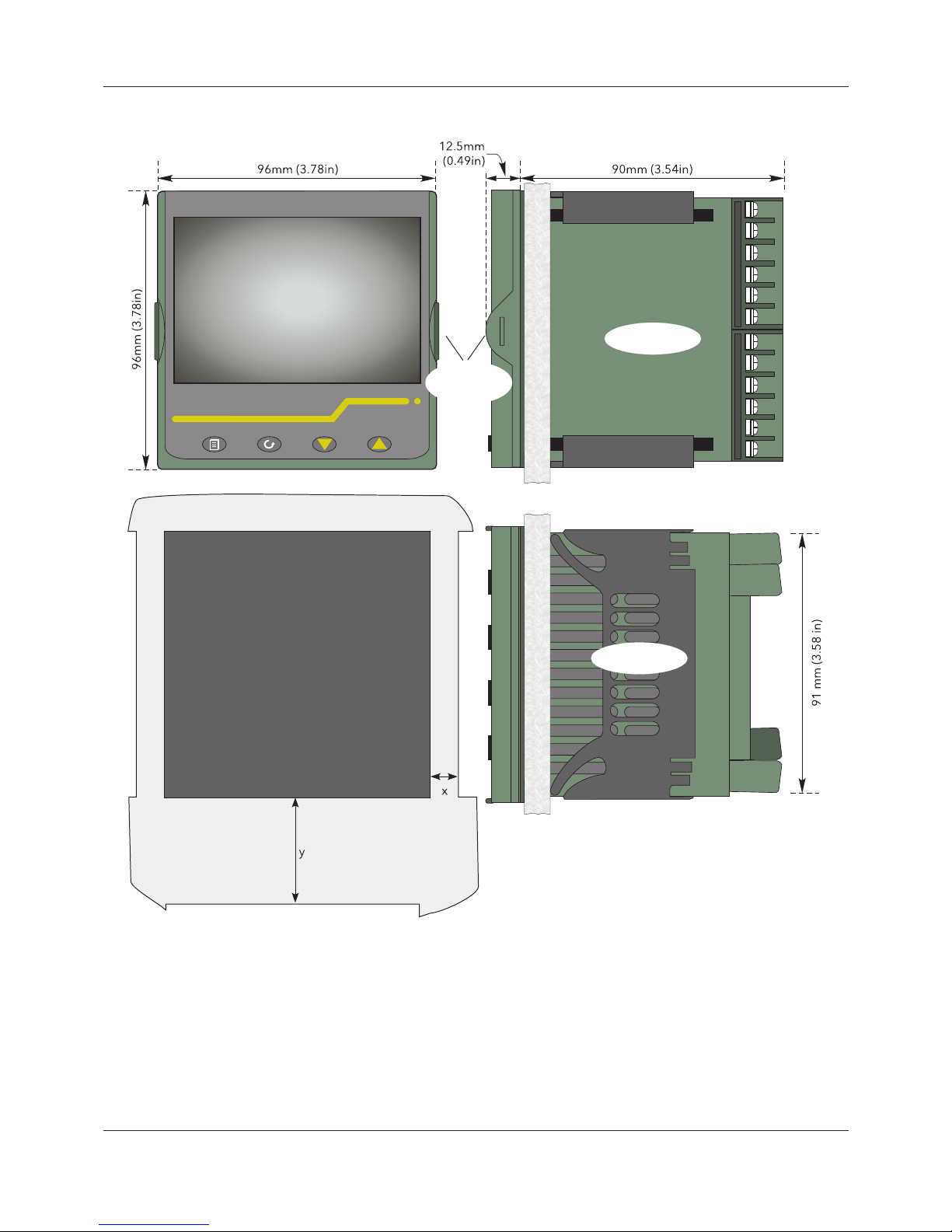

Figure 3 Mechanical installation details (wash down case option)

Panel cutout:

92mm x 92mm (both -0 + 0.8mm)

3.62in x 3.62in (both -0.00 + 0.03in)

Minimum inter-unit spacing:

Horizontal (‘x’) = 10mm (0.4in)

Vertical (‘y’) = 38mm (1.5in)

Side View

Top View

Latching

ears

A5E45696052A Rev-AA

Page 20

FEC920: USER GUIDE

Page 12

A

September 18

4.2 ELECTRICAL INSTALLATION

Figure 4 shows the locations of the various user terminations along with signal and supply wiring pinouts.

4.2.1 Termination details

The screw terminals accept single wires in the range 0.21 to 2.08mm2 (24 to 14 AWG) inclusive, or two wires

each in the range 0.21 to 1.31mm2 (24 to 16 AWG) inclusive.

Screw terminals should be tightened to a torque not exceeding 0.4Nm (3.54lb in).

A5E45696052A Rev-AA

Page 21

FEC920: USER GUIDE

Page 13

A

September 18

Figure 4 Connector locations and pinouts (rear panel)

8

1

mV

0 to 1V

0 to 10V

T/C

1R0≤R≤1k0

Supply

Voltage

Safety Earth

Brown

Blue

Each wire connected to

LA, LB and LC must be

less than 30m (98.43ft).

I/O1

Contact closure

O/P2

O/P3

Dig InA

Dig InB O/P4; O/P5

Relay output

Contact closure Relay outputContact closure

An In1; An In2; An In3; An In4

T/C, Volts, millivolts

RTD (two wire)

RTD (three wire)

Milliamps Digital

R<200R = active

R>350R = inactive

100 to 230Vac±15%;

48/62 Hz

24Vac; -15%, +10%

48 to 62 Hz or

24Vdc; -15%, +20%

(polarity irrelevant)

Isolated DC o/p (mA)

Ohms inputs

R>500R = inactive

R<150R = active

Relay output

Logic o/p (active high)

Isolated DC o/p (mA/V)

Internal Link (0V)

R>600R = inactive

R<300R = active

Relay output

Logic o/p (active high)

Isolated DC o/p (mA)

An In1; An In2; An In3; An In4

Dual mV/TC

Dual mA

Dual input option (Section 4.2.3, below)

(Primary and secondary inputs are not electrically isolated from one another.)

For maximum accuracy, it is recommended that separate returns are made to

the negative terminal.

Mains (Line) supply voltage

Low voltage option wiring

A5E45696052A Rev-AA

Page 22

FEC920: USER GUIDE

Page 14

A

September 18

4.2.2 Low Voltage Option

This option allows the use of a low voltage ac or dc 24V supply. The specification in Appendix A gives full details.

The polarity of the dc supply connection is not important - it may be connected either way round.

4.2.3 Dual Input Option

This is a cost option, enabled on a channel-by-channel basis by means of entering the relevant password in the

‘Feature3 Pass’ field in Instrument.Security menu described in Section 6.1.6.

For each enabled channel, a pair of thermocouple, mV or mA inputs can be connected to the instrument. These

inputs are called ‘primary’ and ‘secondary’, and are terminated at the analog input terminals (An In1 to An In 4)

as shown in Figure 4, above. The primary inputs 1 to 4 are assigned to channels 1 to 4, as normal. Each

secondary input must be soft wired to a maths channel configured as Operation = ‘Copy’ if it is to be recorded/

displayed/alarmed etc.

Soft wiring is described in Section 9.

Maths channels are described in Section 6.5.1.

Channel configuration is described in Section 6.4.1.

Input adjust is carried out as described in Section 6.1.9.

4.2.3.1 Sample Rate

For dual input channels, both primary and secondary sample rate is reduced to 4Hz (250ms) from the normal

8Hz (125ms).

4.2.3.2 Sensor Break Detection

Input sensor break detection is not supported for secondary inputs. The internal circuit acts as a ‘pull up’ on the

secondary input which therefore saturates high in the event of a sensor break.

4.2.3.3 Dual Milliamp Offset Correction

If ‘Dual mA’ is selected as input type, then an automatic offset correction will be made, according to the shunt

value entered in channel configuration. Refer to Section 6.4.1 for further information.

4.2.3.4 Input Range Limitation

There is no 10V range associated with the secondary input. Any input greater than +2V or less than -2V is

deemed to be ‘bad range’.

4.2.4 Modbus Master communications

The master instrument can be connected directly to up to two slaves using standard Ethernet network cable

either directly (single slave only) or via a hub or switch (one or two slaves). In either case, ‘straight through’ or

‘crossover’ cable may be used. The cable is terminated at the RJ45 socket at the rear of the unit.

4.2.5 EtherNet/IP

The Client and Server are connected in the same way as described above for Modbus Master communications,

except that there can be only one client and one server.

Note: Due to the nature of the input circuit, a large offset may appear for secondary thermocouple

inputs. This offset can be removed only by using the input adjust feature described in Section

6.1.9. Because of this offset, the dual thermocouple input option is not suitable for AMS2750D

applications.

A5E45696052A Rev-AA

Page 23

FEC920: USER GUIDE

Page 15

A

September 18

5 OPERATION

On power up a default or custom splash screen appears and remains visible whilst the unit is

initialising. If during this process a network broadcast storm is detected, the unit stops, displaying a

network failure icon until the broadcast storm has cleared, after which the initialisation process

resumes.

5.1 INTRODUCTION

The operator interface consists of a display screen and four push buttons.

5.1.1 Display Screen

The display screen is used both to display channel information (in one of a number of display modes), and to

display the various configuration screens which allow the user to setup the recorder to display the required

channels, to set up alarms and so on. Display modes are described in Section 5.4 below; configuration is

described in Section 6.

In display mode, the screen is split horizontally into three areas (Figure 5):

1. a faceplate giving channel details.

2. the main display screen showing channel traces etc.

3. the status area, displaying instrument name, the current time and date and any system icons.

Figure 5 Display mode screen (vertical trend)

In configuration mode, the entire display screen is devoted to the selected configuration menu.

5.1.2 Navigation Pushbuttons

Figure 6 Top level menu (Engineer level access)

There are four navigation buttons, called ‘Page’, ‘Scroll’, ‘Lower’ and ‘Raise’ located below the screen. The

general properties of these buttons are described in the remainder of this section, but some have additional,

context sensitive functions, which, for the sake of clarity are not described here but in the relevant sections (e.g.

‘Message summary’) of the manual.

12:01:08

Channel 1 6.23V

Instrument name

Faceplate

Main display screen

Status area

Home

Configuration

Go to View

Faceplate cycling (On)

Operator Notes

Demand Archiving

Log out

History

A5E45696052A Rev-AA

Page 24

FEC920: USER GUIDE

Page 16

A

September 18

PAGE BUTTON

From any non-configuration page, pressing this push button causes the top level menu (Figure 6) to appear.

The figure shows the menu for a user logged in with ‘Engineer’ level access. Other access levels may have

fewer menu items.

Within configuration pages, the Scroll button can be used as an enter key to select lower menu levels. In such

cases the page button is used to reverse this action, moving the user up one menu level per operation.

SCROLL BUTTON

From trending pages, operation of the scroll push-button scrolls through the channels enabled in the group. The

Faceplate cycling ‘Off’ selection can be used to keep a particular channel permanently displayed, and the scroll

pushbuttons can then be used to select channels manually.

In configuration pages, the scroll key operates as an ‘enter’ key to enter the next menu level associated with

the highlighted item. Once the lowest menu level is reached, operation of the scroll key allows the value of the

selected item to be edited by the relevant means (for example, the raise/lower keys, or a keyboard entry).

The ‘Page’ key is used to move the user back up the menu structure, until the top level menu is reached, when

the scroll key can be used again to return to the Home page.

The scroll button is also used to initiate user wiring as described in Section 9.

RAISE/LOWER BUTTONS

Within trending displays, the Raise and Lower keys can be used to scroll through the enabled display modes in

the sequence: vertical trend, horizontal trend, vertical bargraph, horizontal bargraph, numeric, vertical trend,

and so on.

Within configuration pages, these pushbuttons act as cursor keys, allowing, for example, the user to highlight

menu items for selection using the scroll button, and in many cases allowing the user to select one from a number of alternative values within menu items. These keys are also used to navigate through the virtual keyboards

(Section 5.6) and number pads used to enter text or numeric strings.

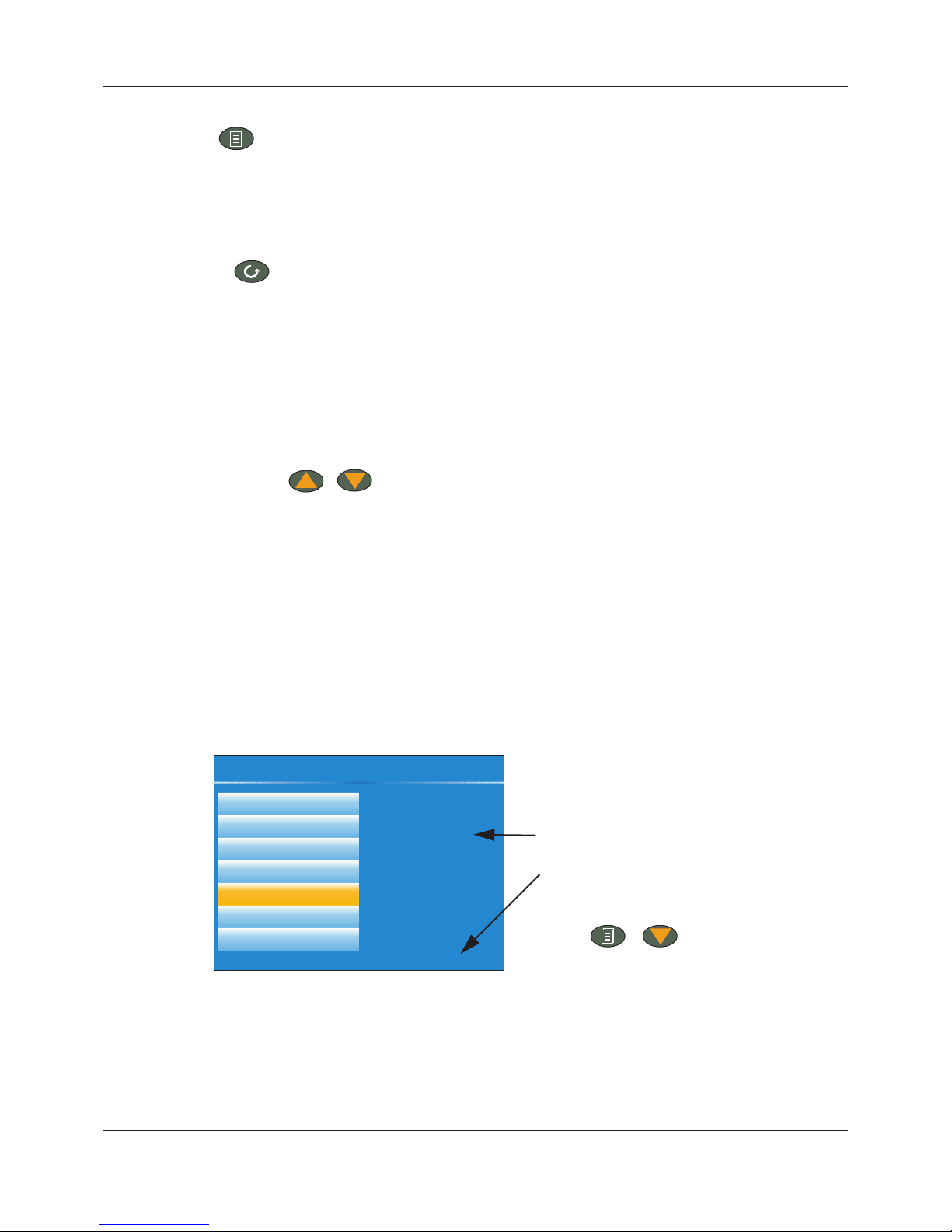

5.1.3 On Screen Help

The top level configuration menu includes contextual help text on the right-hand half of the screen. Mostly this

text fits within on screen height. Where this is not the case, the text can be moved up or down the screen by

holding the Page button operated whilst using the up and down arrows to move the text.

The down arrow moves the text upwards on the screen; the up arrow moves it downwards.

Figure 7 On-screen help (typical)

Select configuration menu

Logic (2 Input)

Logic (8 input)

Multiplexer

Math (2 input)

Timer

User values

Alarm Summary

The timer function block

offers a universal timer

which may be

re-configured between

single pulse outputs

and re-triggering

outputs. Timer types

are:

On pulse on-timer

On-screen help.

(Use the Page button with the

down arrow to access hidden

text at the bottom of the screen)

+

A5E45696052A Rev-AA

Page 25

FEC920: USER GUIDE

Page 17

A

September 18

5.2 PROCESS VARIABLE DISPLAY

As discussed above, the operator interface consists of a display screen and associated push buttons. The

display screen shows process variables in one of a number of formats, or operational details (notes or alarm

history for example), or configuration details for use in setting up the recorder to produce the required displays

and history formats. The remainder of this section discusses the process variable displays, alarm displays and

so on; configuration details are to be found in Section 6.

Figure 8 depicts a typical trend display and gives details of the various areas of the display page.

Figure 8 Typical display screen (Vertical trend)

Figure 8 shows a vertical trend page. Operating the Raise/Lower push-buttons allows the user to scroll through

the other display modes: Horizontal trend, Vertical bargraph, horizontal bargraph, numeric, vertical trend, and

so on. All these display modes are described in Section 5.4, below.

A display mode can also be selected from the Top level menu ‘Go To View’ item which appears when the ‘Page’

key is operated.

The scroll button can be used to scroll through the points in the group, overriding the ‘Faceplate Cycling’ on or

off selection

5.2.1 Alarm Icons

The alarm icons shown below appear in some display modes. The icons on a channel faceplate show the status

of that channel’s alarm(s), as follows:

Icon is flashing alarm is active but unacknowledged or it is an Auto alarm which is no longer active

but which has not been acknowledged.

Icon steadily illuminated the alarm is active and has been acknowledged.

Alarm thresholds and deviation alarm bars appear for horizontal and vertical trend modes. For deviation bars,

the bar stretches from (Reference - Deviation) to (Reference + Deviation). Vertical and Horizontal bargraph

modes display only absolute alarm symbols.

Note: Some of the items below can be selected for use only by users with a suitable permission

level as set up in the ‘Instrument’ ‘Security’ menu described in Section 6.1.6.

Note 1: A full discussion of alarms is given in the Channel Configuration section of this manual,

Section 6.4.3.

Note 2: Trigger alarms do not display threshold marks or bars, or faceplate symbols.

12:01:08

Channel 1 6.23V

Inst name

Current time/date

Current point value and units

Current point ‘pen’

Current point scale

Time/date stamps

Current point name

Recording status

Instrument name

A5E45696052A Rev-AA

Page 26

FEC920: USER GUIDE

Page 18

A

September 18

Figure 9 Alarm icons

5.2.2 Status Bar Icons

The following items can appear in a dedicated window immediately to the left of the time and date, at the bottom

right-hand corner of the display. The width of this window expands as the number of icons increases, and the

instrument name is truncated, as necessary, to make room.

SYSTEM ALARMS

This indicator appears, flashing, if any one or more of the alarms listed below is active. The System Alarms

summary page (accessed from ‘Go to View in the top level menu) allows the user to view such system alarms

as are active. It is not possible to ‘acknowledge’ system alarms.

Archive Disabled An unattended archiving strategy has temporarily been disabled.

Archiving Failed An unattended archiving strategy has failed to complete.

Archiving Timeout A configured archiving strategy has timed out.

Battery failure Indicates that the battery is approaching the end of its useful life, or that

it is missing or is completely exhausted. Immediate battery replacement

is recommended (Appendix B, Section B1).

Broadcast Storm detected Networking is limited until the storm has passed.

Clock failure The internal clock was found to be corrupt at power up, or that the time

has never been set. Time is forced to 00:00 1/1/1900. Can be caused

by battery failure, in which case a battery failure message appears. The

error is cleared by setting the time and date.

Channel error Indicates a hardware failure in the channel circuit or in the internal cold

junction temperature measurement.

Database failure Corrupted EEPROM or flash memory.

DHCP Server failure For units with ‘IP Type’ set to ‘DHCP’ (Network.Interface configuration)

this alarm occurs if the instrument is unable to obtain an IP address from

the server.

FTP Archiving file lost A file has been deleted that had not yet been archived. Possible causes:

Communications with the server could not be established,; archive is

disabled; archive rate too slow.

FTP Archiving too slow The archive rate is too slow to prevent the internal memory from

overflowing. The recorder effectively switches to ‘Automatic’

(Section

6.2.2) to ensure that data is not lost.

Absolute High

Absolute Low

Deviation High

Deviation Low

Deviation Band

Rising Rate of change

Falling Rate of change

Digital High

Digital Low

A5E45696052A Rev-AA

Page 27

FEC920: USER GUIDE

Page 19

A

September 18

FTP Primary Server Failure This error occurs if the recorder fails to establish connection with the

primary server, after two attempts. After the second attempt fails, the

recorder attempts to establish connection with the secondary server

instead. Primary and secondary server details are entered in the

Network. Archiving area of configuration (Section 6.2.2).

FTP Secondary Server Failure This error occurs if the recorder fails to establish connection with the

secondary server, after two attempts. Primary and secondary server

details are entered in the Network.Archiving area of configuration

(Section 6.2.2).

Maths channel failure Appears if, for example, the divisor of a divide function is zero.

Media archiving file lost A file has been deleted that had not yet been archived. Possible causes:

memory stick missing, full or write protected; archiving has been

disabled; archiving rate too slow.

Media archiving too slow The archive rate is too slow to prevent the internal memory from

overflowing. The recorder effectively switches to ‘Automatic’ (Section

6.2.2) to ensure that data is not lost.

Media full Archive storage device is full. The alarm becomes active only when an

archive is in progress.

Media missing No archive storage device present when archive attempted.

Non-volatile memory failure RAM copy of non-volatile parameters is corrupted.

Non-volatile Write Frequency warning

One or more parameters are being written frequently to non-volatile

memory. If this continues, it may lead to ‘memory depletion’ (i.e. the

memory will no longer be able to store values correctly). A common

cause of this problem is frequent writes over Modbus comms.

Recording failure (message) Message explains reason for failure.

SNTP failure Invalid data received from SNTP server, for example, the year received

from the server is <2001 or >2035, or the server cannot be accessed.

Time synchronization failure Instrument time has failed to synchronize with SNTP server.

If more than 5 ‘Time change events’ occur within 24 hours a ‘Time

synchronization failure’ alarm is set. The alarm occurs 24 hours after

the first event. Once synchronization is re-established, the alarm self-

clears within 24 hours. A ‘Time change event’ occurs whenever the

recorder time is found to be more than two seconds different from the

server time. If the instrument time differs from the SNTP time by less

than two seconds, the instrument time is updated gradually (1ms, eight

times a second) to prevent time changes being recorded.

SNTP time is based on elapsed seconds since 00:00 hours on 1st

January 1900. The time is not affected by time zones or daylight saving

adjustments.

USB overcurrent USB power fault - too much current (i.e. >100mA) is being drawn by a

USB device.

Wiring failure The user wiring has failed to verify, i.e. one or more wires has been

detected that does not have both a source and a destination defined.

This may be the result, for example, of power loss during a download

from iTools.

A5E45696052A Rev-AA

Page 28

FEC920: USER GUIDE

Page 20

A

September 18

CHANNEL ALARM

This indicator appears if any channel (including channels not in the display group) is in an alarm state. The

symbol is illuminated continuously if all alarms are acknowledged or flashes if any one or more alarms is

unacknowledged. Alarms are acknowledged from the Root menu ‘Alarm summary’ item as described in Section

5.3.3 or in the Channel configuration area (Section 6.4.3) if the user’s access permission is appropriate.

USB

This icon appears whenever a memory stick (max. capacity 8GB) or other supported USB device (Section 11)

is plugged into the USB port at the rear of the recorder.

When data transfer is in progress between the instrument and the memory stick, the icon changes to a ‘busy’

version.

FTP ICON

The FTP icon appears whenever transfer activity is taking place.

RECORD ICON

One of four icons appears at the bottom left corner of the display to indicate recording status.

Record

This indicates that the recorder is recording the items selected in the Group Recording area of configuration

(Section 6.3).

Stopped

This means that ‘Enable’ has been set to ‘no’ in the Group Recording area of configuration (Section 6.3).

Trending is not affected.

Paused (Suspended)

This means that recording has been paused by a wire to the Suspend parameter (Group Recording area of

configuration

(Section 6.3) going true (high). Trending is not affected.

In Configuration

The recorder has been placed in configuration mode either at the user interface, or via iTools. Recording is

stopped until the recorder is no longer in configuration mode. For each non-recording state (Stopped, Paused

or In Configuration). A new history file is created when the unit comes out of configuration mode.

MESSAGE ICON

This ‘envelope’ icon appears when a message is generated and it remains on display until the Message

Summary (see Message Summary on page 24) is accessed, when it is removed from the display until the next

new message is generated.

AUTOTUNE ICON

For instruments fitted with the Loop option, this symbol appears during the Autotune process.

Caution: The Memory stick must not be removed while archiving

(demand or automatic) is in progress, as to do so may

irreparably damage the file system of the memory stick,

rendering it unusable. It is recommended that all archiving is

suspended before the memory stick is removed.

Note: For recording to be enabled, configuration status must be ‘logged out’ both at the instrument

and at iTools.

Memory

stick fitted

Transfer in

progress

A5E45696052A Rev-AA

Page 29

FEC920: USER GUIDE

Page 21

A

September 18

5.2.3 Breaks in recording

Breaks in recording can be caused by the unit being powered down, by the user entering configuration mode

or when the recorder time is changed manually. In vertical and horizontal trend modes, a line is drawn across

the width/height of the chart to indicate that recording has been interrupted.

On power up, a red line is drawn across the chart. In ‘History’, if messages are enabled the message:

Date Time System power up

is printed on the chart, together with the configuration and security revisions.

On exiting configuration mode, a blue line is drawn on the chart and in ‘History’, if messages are enabled, the

messages:

Date Time Logged out.

Date Time Config Revision: N was N-1 (assuming a configuration change was made)

Date Time Logged in as: Engineer

appear on the chart.

When the instrument time is changed (manually - not through daylight saving action) a green line is drawn on

the chart and in ‘History’, if messages are enabled, the message:

Date Time Time/Date changed

appears on the chart.

5.3 TOP LEVEL MENU

This menu appears when the page key is operated from any non-configuration page. The menu items displayed

depend on the access permission of the user. One of the menu items is highlighted, and if the scroll key is

operated, then it is the highlighted item that is ‘entered’.

Figure 10 shows the top level menu for Engineer level access.

Figure 10 Top level menu

5.3.1 Home

Operating the scroll key whilst ‘Home’ is highlighted causes a return to the ‘Home’ page. By default, this is the

vertical trend mode, but the mode can be changed in ‘Instrument.Display’ configuration (Section 6.1.3).

5.3.2 Configuration

Operating the down arrow key highlights the ‘Configuration’ item. Operating the Scroll key enters the

configuration submenu described in Section 6.

Note 1: ‘Configuration’ appears only if the user has an appropriate access level.

Note 2: If the Auditor feature is enabled, additional user accounts are available. If one of these

users are logged in, the ‘Configuration’ menu option is replaced by the ‘User’ menu option

instead (see Section 5.3.2.1).

Section 5.3.1

Section 5.3.2

Section 5.3.3

Section 5.3.4

Section 5.3.5

Section 5.3.6

Section 5.3.7

Section 5.3.8

Home

Configuration/User

Go to View

History

Faceplate cycling (On)

Operator Notes

Demand Archiving

Log out

Page key

Scroll key

A5E45696052A Rev-AA

Page 30

FEC920: USER GUIDE

Page 22

A

September 18

5.3.2.1 User menu

If the Auditor feature is enabled, up to 25 additional user accounts are available with configurable access

permissions and passwords. If one of these users are logged in, the ‘Configuration’ menu option is replaced by

a ‘User’ menu option which provides the ability for the user to change their password and set the Archive Interval

(if the user has appropriate permissions).

Operating the scroll key whilst the ‘User’ item is highlighted, displays the individual user account menu, as

shown in the following figure. The menu title matches that of the username used to log in.

Figure 11 User menu

Password Allows the user to change their password (up to a maximum of 20 characters). The

minimum password length can be configured using the Min Password Len parameter in

the Security menu (see Section 6.1.6).

Archive Rate Allows the user to specify the frequency at which the contents of the flash memory are

archived to the USB port, or via FTP to a PC. Scrollable settings are:

None: Automatic archiving is disabled. Any archiving must be initiated by the user

using Demand Archiving.

Minute: Archive is initiated on the minute, every minute.

Hourly: Archive is initiated at 00:00 each day.

Weekly: Archive is initiated at midnight every Sunday.

Monthly: Archive is initiated at 00:00 on the 1st of every month.