Page 1

Building Technologies

FDOOT271

Radio fire detector

Technica l Manual

A6V10227635_g_en_-2015-03-11 Control Products and Systems

Page 2

Legal notice

Legal notice

Technical specifications and availability subject to change without notice.

© Siemens Switzerland Lt d, 2011

Transmitt al, reproduction, dissemination and/or editing of this doc ument as well as

utilization of its contents and communication thereof to others without expr ess

authorization are prohibited. Offenders will be held liable for payment of damages.

All rights creat ed by patent grant or registration of a utility model or design patent

are reserved.

Issued by:

Siemens Switzerland Ltd.

Building Technologies Div ision

International Headquarters

Gubelstrasse 22

CH-6301 Zug

Tel. +41 41 724-2424

www.siemens.com/buildingtechnologies

Edition: 2015-03-11

Document ID: A6V10227635_g_en_--

2

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Page 3

Table of contents

1 About this document ......................................................................................5

1.1 Applica ble docu ments .......................................................................................7

1.2 Download center...............................................................................................7

1.3 Technica l terms ................................................................................................7

1.4 Revision his tory ................................................................................................8

2 Safety ..............................................................................................................9

2.1 Safety instru ct ions ............................................................................................9

2.2 Safety regu lat ions for the meth od of operat ion ................................................ 11

2.3 Standa rds an d directives co mp lied with .......................................................... 13

2.4 Releas e Notes ................................................................................................ 13

3 Structur e and function ................................................................................. 14

3.1 Overview ........................................................................................................ 14

3.1.1 Details for ordering ........................................................................... 15

3.1.2 Product version ES .......................................................................... 15

3.1.3 Feature s of fire detection function s ................................................... 16

3.1.4 Sensory ........................................................................................... 17

3.2 Power supply .................................................................................................. 18

3.3 Function ......................................................................................................... 19

3.3.1 Parame ter sets ................................................................................ 19

3.3.2 Danger levels ................................................................................... 19

3.3.3 Diagnosis levels ............................................................................... 20

3.3.4 Interna l alarm indicator ..................................................................... 20

3.3.5 Renovation mode ............................................................................. 22

3.3.6 Test mode ....................................................................................... 23

3.3.7 Degra ded mode in the FDnet/C-NE T................................................ 23

3.3.8 Interface to ser vice devices .............................................................. 23

3.4 Mechanical setup ............................................................................................ 24

3.5 Accessories .................................................................................................... 25

3.5.1 Detecto r base FDB271..................................................................... 25

3.5.2 Battery pack BAT3 .6-10 ................................................................... 25

3.5.3 Detecto r locking device FDBZ293 .................................................... 25

3.5.4 Design ation plate FDBZ29 1 ............................................................. 26

3.5.5 Detecto r dust cap FDZ291 ............................................................... 26

3.5.6 Detecto r base seal RS720 ............................................................... 26

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

3

Page 4

4 Planning ........................................................................................................ 27

4.1 Compatibility FDnet/C-NET ............................................................................. 27

4.2 Ambient features ............................................................................................ 2 8

4.3 Parame ter sets for FDOOT2 71 ....................................................................... 29

4.3.1 Sens or mode 0 'Neura l fire detec to r' ................................................ 29

4.3.1.1 Descr iption ...................................................................................... 29

4.3.1.2 Use .................................................................................................. 30

4.3.1.3 Specification .................................................................................... 30

4.3.2 Sens or mode 1 'Heat detec tor' ......................................................... 31

4.3.2.1 Descr iption ...................................................................................... 31

4.3.2.2 Specification .................................................................................... 31

4.3.3 Sens or mode 2 'Smoke detecto r' ...................................................... 32

4.3.3.1 Descr iption ...................................................................................... 32

4.3.3.2 Use .................................................................................................. 32

4.3.3.3 Specification .................................................................................... 32

4.4 Application examples ...................................................................................... 33

5 Mount ing / Installatio n .................................................................................. 34

5.1 Required space .............................................................................................. 3 4

5.2 Detecto r bas e FDB27 1 ................................................................................... 35

5.3 Installing the rad io fire detecto r FDOOT2 71 .................................................... 36

5.4 Detecto r locking device FDBZ293 ................................................................... 38

5.5 Design ation plate FDBZ291 ............................................................................ 39

5.6 Detecto r dust cap FDZ29 1 .............................................................................. 40

5.7 Detecto r base seal RS720 .............................................................................. 41

6 Commissioning............................................................................................. 42

7 Mainte nance / Repair .................................................................................... 4 3

7.1 Status query ................................................................................................... 43

7.2 Performance check ......................................................................................... 43

7.3 Testing detecto rs ............................................................................................ 44

7.4 Confir ming the detector pos ition ...................................................................... 44

7.5 Estab lishing factory settings ............................................................................ 45

7.6 Basic princip les for replacing the battery pack ................................................. 46

7.7 Replacing the batte ry pack ............................................................................. 47

8 Specifications ............................................................................................... 49

8.1 Technica l data ................................................................................................ 5 0

8.2 Dimens ions .................................................................................................... 5 1

8.3 Environ mental compatib ility and dispo sal ........................................................ 51

Glossa ry ...................................................................................................................... 5 2

Index ....................................................................................................................... 53

4

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Page 5

Applicable documents

1 About this document

Goal and purpose

This document contains all information on the radio fire detector FDOOT271.

Following the instruc tions consistently will ensure that the product can be used

safely and without any problems.

Intended use

The radio fire detector FDOOT271 may only be used in a detector base FDB271

and together with a radio gateway FDCW241 in a fire detection system

FS20/FS720.

Target groups

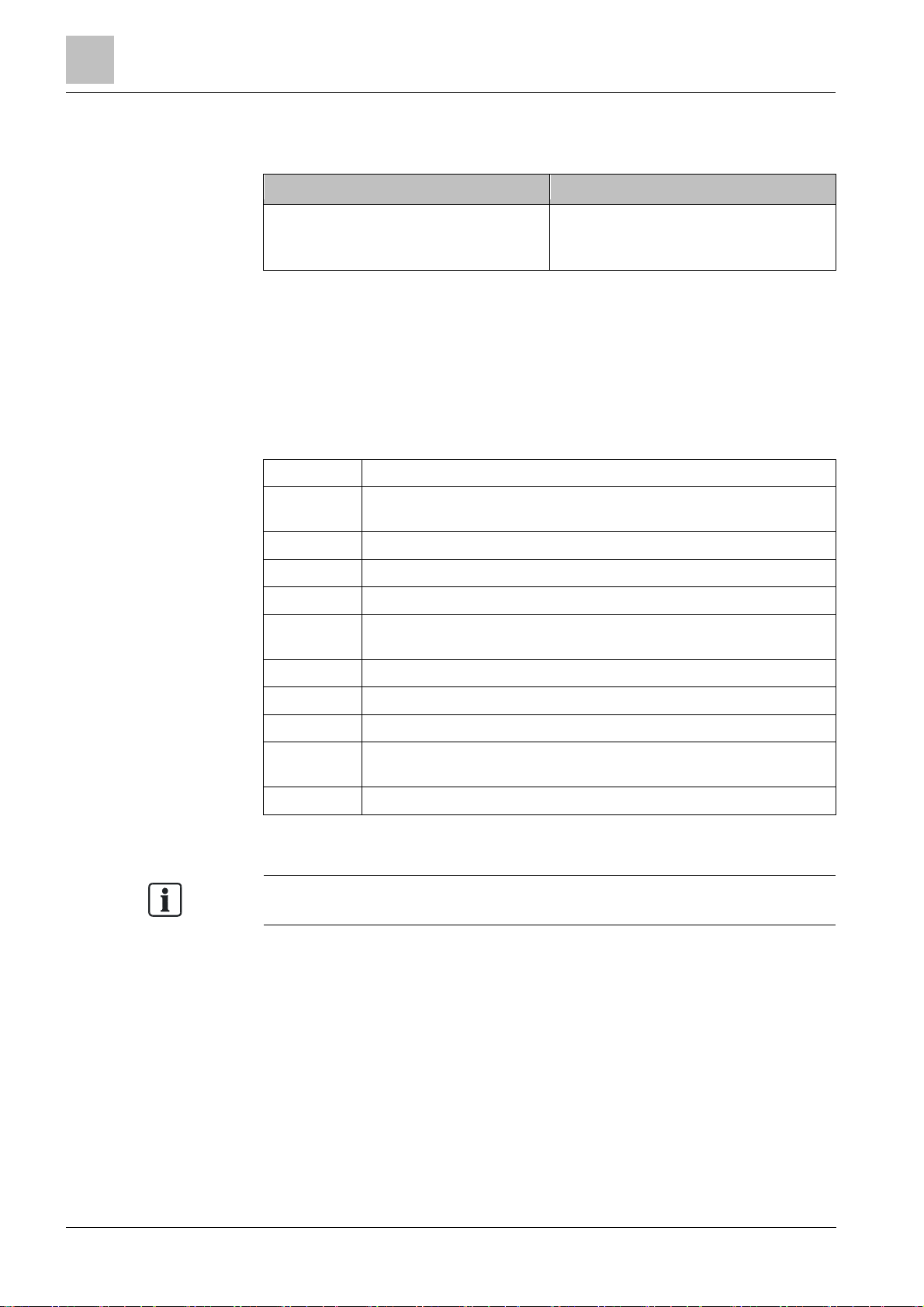

The information in this document is intended f or the following target groups:

Target group Activity Qualificat ion

About this document

1

Product Manager

Project Manager

Project engineer

Installation personnel

Maintenance personnel l Carries out all maintenance work.

l Is responsible for information passing

between the manufacturer and regional

company.

l Coordinates the flow of information

between the individual groups of people

involved in a project.

l Coordinates the deployment of all

persons and resources involved in the

project according to schedule .

l Provides the information required to run

the project.

l Sets parameters for product depending

on specific national and/or customer

requirements.

l Checks operability and approves the

product for commissioning at the place

of installation.

l Is responsible for trouble-shooting.

l Assembles and installs the product

components at the place of installation.

l Carries out a performance check

following installation.

l Checks that the products are in perfect

working order.

l Searches for and corrects malfunctions.

l Has obtained suitable specialist training

for the function and for the products.

l Has attended the tr aining courses for

Product Managers.

l Has obtained suitable specialist training

for the function and for the products.

l Has attended the tr aining courses for

Project Managers.

l Has obtained suitable specialist training

for the function and for the products.

l Has attended the tr aining courses for

Product Engineer.

l Has received specialist tr aining in the

area of building installation technology

or electrical installations.

l Has obtained suitable specialist training

for the function and for the products.

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

Source language and reference document

l The source/original language of this document is German (de).

l T he reference version of this document is the international version in English.

The international ver sion is not localized.

5

Page 6

About this document

Applicable documents

The 'i' symbol identif ies supplementary information and tips for an easier way of

1

Document identification

The document ID is structured as follows:

ID code Examples

ID_ModificationIndex_Language_COUNTRY

-- = multilingual or international

A6V10215123_a_de_DE

A6V10215123_a_en_-A6V10315123_a_--_--

Date format

The date format in the document corresponds to the recomm endation of

international standard ISO 8601 (format YYYY-MM-DD).

Conventions for text marking

Markups

Special markups are shown in this document as follows:

⊳ Requirement for a behavior instruction

1.

2.

– Version, option, or detailed information for a behavior instruction

⇨ Intermediate result of a behavior instruction

⇨ End result of a behavior instruction

l

Behavior instruction with at least two operation sequences

Numbered lists and behavior instructions with an operation

sequence

[➙ X] Reference to a page number

'Text' Quotation, reproduced identically

<Key> Identificat ion of keys

>

In addition to relation symbols and for identif ication between steps

in a sequence, e.g., 'Menu bar' > 'Help' > 'Help topics'

↑ Te xt Identif ication of a glossary entry

Supplementary information and tips

working.

6

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Page 7

Applicable documents

1.1 Applicable documents

You will also find inform ation about search variants and links to mobile

Document ID Title

About this document

1

001508

008331 List of compatibility (for 'Sinteso™' product line)

009409

010030 Application guideline Sinteso Fire detectors

A6V10208552 Installation Detector locking device FDBZ293

A6V10227631 Planning Radio fire detection system SWING

A6V10227637

A6V10227639 Technical manual Radio gateway FDCW241

A6V10227643 User Guide SWING-Tool FXS2061

A6V10229261 List of compatibility (for 'Cerberus™ PRO' product line)

A6V10254740 Operating instructions Solo461 heat detector tester kit RE7T

A6V10271323

A6V10367669 Open-Source Software (OSS) Licenses SWING

Guidelines Connection factors, line resistances and

capacitances for fire detection systems collective, AnalogPLUS,

interactive, FDnet

Data sheet Colored detectors, bases and base attachment

FDO.., FDOOT…, FDT…, FDB…

Installation Radio fire detector FDOOT271, Detector base

FDB271

Data sheet SWING Neural radio fire detector FDOOT271,

FDCW241

1.2 Download center

You can download various types of documents, such as data sheets, installation

instructions, and license texts v ia the following Internet address:

http://siemens.com/bt/download

l Ent er the document ID in the 'Find by keyword' input box.

applications (apps) for various systems on the home page.

1.3 Technical terms

Term Explanation

AI Alarm indicator

Battery empty Fault message in the event of a battery failing completely

Battery low Fault message in the event that the spare battery is activated

FDnet/C-NET Addressed detector line

LED Light-emitting diode

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

7

Page 8

About this document

Revision history

The first edition of a language version or a country variant may, for example, be

The language versions and country variants pr oduced by a local comp

any have

1

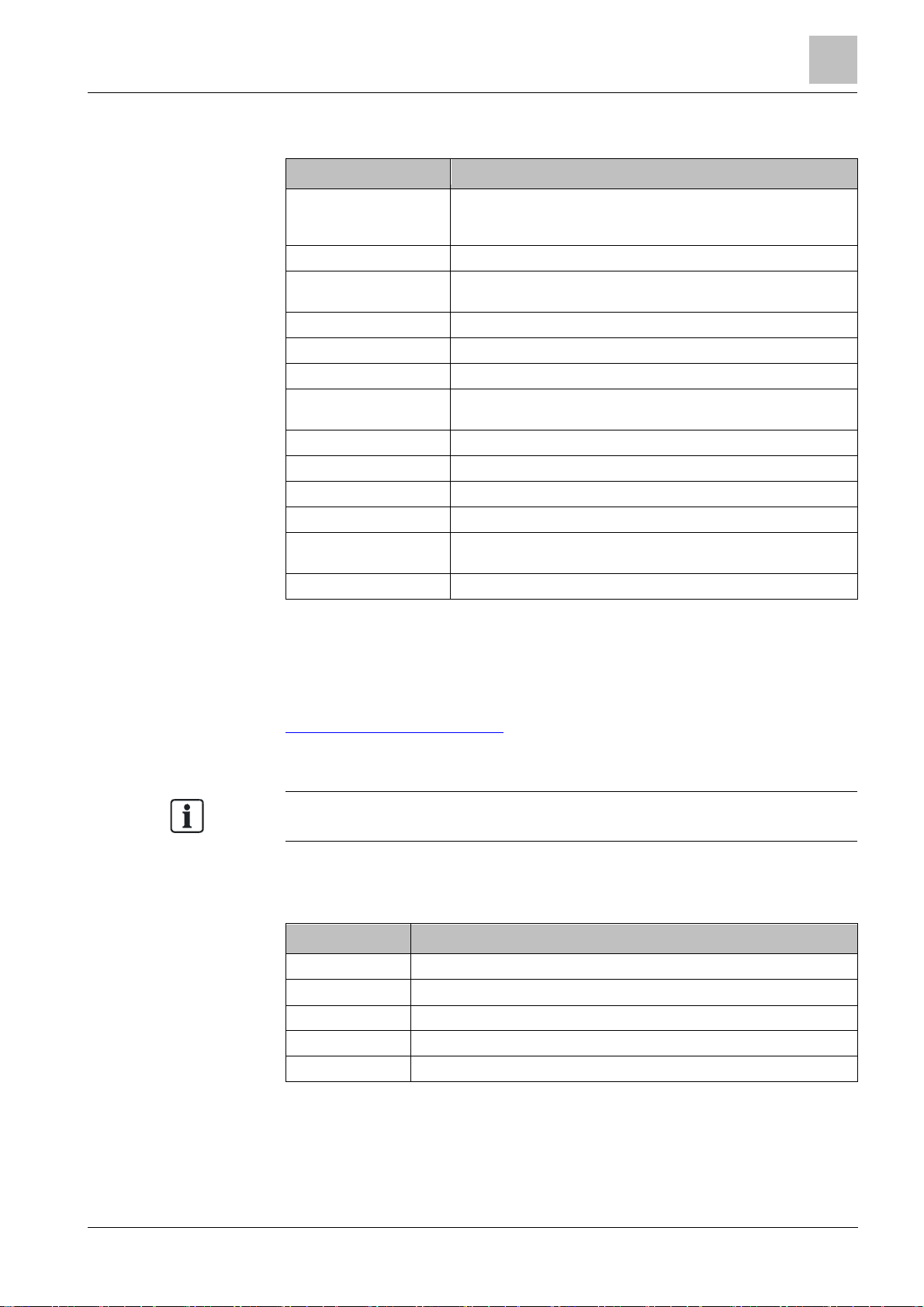

1.4 Revision history

The reference docum ent's version applies to all languages into which the reference

document is trans lated.

version 'd' inst ead of 'a' if the reference document is already this version.

The table below shows this document's revision history:

Modification index Edition date Brief description

g 2015-03-11

f 2014-01-31

e 2013-09-01 Changes in chapter: Planning, Technical data

d 2012-11-02 Parameter sets extended

c 2012-10-19 Value for permissible wind speed changed

b 2012-05-01 Editing

a 2011-11-01 First edition

l Detector base seal RS720 added; mounting marking in 'Mechanical

setup' chapter removed

l Flashing behavior table added

l Editorial changes

Changes in chapter: Parameter sets for FDOOT271; data sheet in

'Applicable documents' chapter added; reference to approvals added;

information on flashing pattern and sensory added; chapter with reference

to download center added; neural fire detector function added; value for

response sensitivity change d

Note on service devices added

the same modification index as the corresponding reference document. They are

not however included in the t able below.

The table below shows the published language versions and count ry variants with

the corresponding modif ication index:

Modification index en_-- de_-- fr_-- it_-- es_--

g X X X X X

f – X – – –

e X X X X X

d – X – – –

c X X X X X

b X X X X X

a – X – – –

X = published

– = no publication with this modification index

8

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Page 9

Safety instructions

2 Safety

2.1 Safety instructions

The safety notices mus t be observed in order to protect people and property.

The safety notices in this document contain the following elements:

l Symbol for danger

l Signal word

l Nature and origin of the danger

l Consequences if the danger occurs

l Measures or prohibitions for danger avoidance

Symbol for danger

This is the symbol for danger. It warns of risks of injury.

Follow all measures ident ified by this symbol to avoid injury or deat h.

Additional dan ger symbols

These symbols indic ate general dangers, the type of danger or poss ible

consequences, measures and prohibitions, examples of which are shown in the

following table:

Safety

2

General danger Explosive atmosphere

Voltage/electric shock Laser light

Battery Heat

Signal word

The signal word classifies the danger as defined in the following table:

Signal word Danger level

DANGER

WARNING

CAUTION

NOTICE

DANGER identifies a dangerous situation, which will result directly in deat h or

serious injury if you do not avoid this situation.

WARNING identifies a dangerous situation, which may result in death or serious

injury if you do not avoid this situation.

CAUTION identif ies a dangerous situation, which could result in slight to

moderately serious injury if you do not avoid this situation.

NOTICE

observance.

identifies possible damage to property that may result from non-

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

9

Page 10

2

Safety instructions

Nature and origin of the danger

Nature and origin of the danger

●

Measures / prohibit ions for danger av

oidance

Safety

How risk of injury is presented

Information about the risk of injury is shown as follows:

WARNING

Consequences if the danger oc curs

● Meas ures / prohibitions for danger avoidance

How possible damage to property is presented

Information about possible damage to property is s hown as follows:

NOTICE

Consequences if the danger oc curs

10

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Page 11

Safety

Safety regulations for the method of operation

Electrical volt age

regulations.

2.2 Safety regulations for the method of operation

National standards, regulations and legislation

Siemens products ar e developed and produced in compliance with the relevant

European and international safety standards . Should additional national or local

safety standards or legislation concerning the planning, mounting, inst allation,

operation or disposal of the product apply at the place of operation, then these

must also be taken into account together with the safety regulations in the product

documentation.

Electrical installations

WARNING

Electric shock

● Work on electrical installations may only be carried out by qualified

electricians or by instructed persons work ing under the guidance and

supervision of a qualified electrician, in accordanc e with the electrotechnical

2

l W herever possible disconnect products from the power supply when carrying

out commissioning, maintenance or repair work on them.

l Lock volt-free areas to prevent them being switched back on again by mistake.

l Label the connection terminals with external external voltage using a

'DANGER External voltage' sign.

l Rout e mains connections to products separately and fuse them with their own,

clearly marked fuse.

l F it an easily accessible disconnecting device in accordance with IEC 60950-1

outside the installation.

l Produce earthing as stated in local safety regulations.

Mounting, installation, commissioning and maintenance

l If you require tools such as a ladder, these must be safe and must be intended

for the work in hand.

l W hen starting the fire control panel ensure that unstable conditions cannot

arise.

l Ensure that all points listed in the 'Testing the product operability' section below

are observed.

l You may only set controls to normal function when the product operability has

been completely tested and the system has been handed over to the customer.

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

11

Page 12

2

Safety regulations for the method of operation

Safety

Testing the product operability

l Prevent the remot e transmis sion from t riggering erroneously.

l I f testing building installations or activating devices from third-party companies,

you must collaborate with the people appointed.

l T he activation of fire control installations for test purposes must not cause

injury to anyone or damage to the building installations. The following

instructions m ust be observed:

– Use the correct potential for activation; this is generally the potential of the

building installation.

– Only check controls up to the interface (relay with blocking option).

– Make sure that only the controls to be tested are activated.

l I nform people before testing the alarm devices and allow for possible panic

responses.

l I nform people about any noise or mist which may be produced.

l Bef ore testing the remote transmission, inform the corresponding alarm and

fault signal receiving stations.

Modifications to the system design and the products

Modifications to the system and to individual products m ay lead to faults,

malfunctioning and safety risks. Written confirmation must be obtained from

Siemens and the corresponding safety bodies for m odifications or additions.

Modules and spare parts

l Components and spare parts must comply with the technical specifications

defined by Siemens. Only use products specified or recommended by

Siemens.

l Only use fuses with the specified fuse charact eristics.

l Wrong battery types and improper battery changing lead to a risk of explosion.

Only use the same battery type or an equivalent battery t ype recommended by

Siemens.

l Bat teries must be disposed of in an environmentally friendly manner. Observe

national guidelines and regulations.

Disregard of the safety regulations

Before they ar e delivered, Siemens products ar e tested to ensure they function

correctly when used properly. Siemens disclaims all liability for damage or injuries

caused by the incorrec t application of the instructions or the disregard of danger

warnings contained in the documentation. This applies in particular to the following

damage:

l Per sonal injuries or damage to property caused by improper use and incorrect

application

l Per sonal injuries or damage to property caused by disregarding safety

instructions in the documentation or on the product

l Personal injury or damage to property caused by poor maintenance or lack of

maintenance

12

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Page 13

Standards and directives complied with

2.3 Standards and directives complied with

Limited or non

-

existent fire detection

detection installation.

Incorrect planning and/or configurat ion

A list of the standards and directives complied wit h is available from your Siemens

contact.

2.4 Release Notes

Limitations t o the configuration or use of devices in a fire detection installation with

a particular firmware version are possible.

WARNING

Personal injury and damage to property in the event of a fire.

● Read the 'Release Notes' before you plan and/or configure a fire detection

installation.

● Read the 'Release Notes' before you carry out a firmware update to a fire

Safety

2

NOTICE

Important st andards and specifications are not satisfied.

Fire detection installation is not accepted f or commissioning.

Additional expense result ing from necessary new planning and/ or configuration.

● Read the 'Release Notes' before you plan and/or configure a fire detection

installation.

● Read the 'Release Notes' before you carry out a firmware update to a fire

detection installation.

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

13

Page 14

Structure and function

Overview

3

3 Structure and functio n

In this document, the term 'detector' refers to an automatic fire detector that

communicates with a radio gateway and other radio devices in a radio cell using

radio signals. The detector is connected to a cont rol panel FC20xx or FC72x via

the radio gateway and the detector line.

3.1 Overview

Properties

l Radio communication with:

– Radio gateway

– Other radio devices

l Signal processing with ASAtechnology and opt ional detection behavior

(application-specific ASA parameter sets)

l Software can be used to set as:

– Neural fire detector

– Heat detector

– Wide-spectrum smoke detector

l Int ernal alarm indicator with status display (red and green):

– identifies alarm

– confirms positioning on detector base

– confirms contact with the radio network

l Easy installation on t he detector base

14

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Page 15

Overview

3.1.1 Details f or orderi ng

The battery pack and det ector base are not included in the scope of deliver y. A

ES

Depending on the product and various approvals, the product labels may differ in

Type Order no. Designation

FDOOT271 S54313-F1-A1 Radio fire detector

FDOOT271

battery pack and detector base are required for commissioning and operation.

3.1.2 Product version ES

The product version ES provides the technical stat us of a device in t erms of

software and hardware. The product version is provided as a two-digit number.

You will find the det ails of your device's product ver sion:

l On the packaging label

l On the product label or the type plate

S54313-F1-A2 +

RAL no.

Structure and function

Radio fire detector (colored)

3

Product version on the packaging label

Details of the product version can be found directly on the pac kaging label in the

barcode:

Example of a packaging label with details of the product version

Product version on the product label and t he type plate

Details of the product version can be found after the device order number:

04

ES

Example of a product label with details of the product version

terms of the informat ion type and layout.

Look for your device' s order number on the product label.

You will find the produc t version after the order number.

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

15

Page 16

Structure and function

Overview

3

3.1.3 Features of fire detection functions

The FDOOT271 has the following features in terms of its fire detection functions:

l Dynamic influence on t he parameter sets

l Pattern recognition

l Real time interpretation of t he situat ion

l Process- and time-controlled switchover of the parameter sets

Signal processing is based on ASAtechnology (ASA = Advanced Signal Analysis).

ASAtechnology can als o be characterized as second generation algorithms. Signal

processing with ASAtechnology allows for opt imum adaptation of detector behavior

to the corresponding ambient conditions.

The detectors are char acterized by their unique detect ion reliabil ity and high

immunity to deceptive phenomena.

Operating mode: Signal processing with ASAtechnology

The figure below shows signal processing in the form of a diagram.

Environment

Evaluation of the

situation

C

Signal analysisSensory

Signal processing with ASAtechnology

Algorithms

Dynamic influence

of parameter

Danger

level

Result

16

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Page 17

Overview

Sensory

2

3

4

The signals captured by the sensory are transmitted to the algorithm. The

algorithms are set by selec t ing the parameter set.

Algorithms

In comparison t o the det ection algorithms, the individual parameters of the selected

parameter set can be adapted with ASAtechnology. A real time interpretation of the

situation leads t o a dynamic influence on the algorithm. This results in a

broadening of the application range of the parameter set and thus of the detector.

The detector reacts more sensitively in the event of fire, and more robustly in the

event of deceptive phenomena.

Switching over the parameter set

In addition to selec ting the parameter set, the detectors enable time- or processcontrolled switching over of the parameter sets (M anned/Unmanned s witchover).

Thanks to this function, the detector can be us ed in places where the situation

changes significant ly on a regular basis (e.g., kitchen, production hall).

3.1.4 Sens ory

The radio fire detector has optical and thermal sensors. T he radio fire detector can

be parameterized as a smoke detector or a heat detector.

Structure and function

3

1

Fire detector structure

1 Heat sensors 3 Forward scatterer

2

Backward scatterer 4 Labyrinth

The radio fire det ector has a sophisticated opto-electronic measuring chamber wit h

two optical transmitters, an optical rec eiver, and two thermal sensors.

The transmitt ers illuminate the smoke par ticles from different angles. One sensor

acts as forward scatterer, the other as backward scatterer. The scattered light then

hits the receiver (photodiode) and generates a measurable elect ric signal.

The combination of a forward and backward scatt erer facilitates an optimum

detection and the dif ferentiation of light and dark par ticles, which leads to a

homogenous response behavior and optimizes the differentiation of wanted signals

and deceptive phenomena.

17

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

Page 18

Structure and function

Power supply

3

4

3

The combination of optical and thermal sensor signals optim izes detection

reliability. This has the following advantages:

l Early detection of all types of fire, whether they generate light or dark smoke, or

no smoke at all.

l The neural fire detector can be operated at a lower sensitivity level and thus

achieves a higher immunit y against false alarms which may otherwise be

caused by cold aerosols (e.g. by smoking, electric al welding, etc.). In the cas e

of an open fire, the smoke sensitivity is heightened by the t emperature

increase, which means that a detection reliability level that is comparable to

that of the wide-spectrum smoke detector can be achieved.

In addition, the heat sensors make it possible to detect fires without smoke

generation.

The radio fire detector can be used purely as an optical smoke det ector or purely

as a heat detector. This is determined by selecting one of the following sensor

modes (using the cont rol panel):

l Sensor mode 0: Application as neural fire detector

l Sensor mode 1: Application as heat detector

l Sensor mode 2: Application as smoke detector

3.2 Power supply

The battery pack BAT3.6-10 supplies the radio devices with power. The batt ery

pack consists of lithium batteries plus a battery cable and a battery connector.

1

2

Battery pack BAT3.6-10

1 Battery pack consisting of:

l 4 lithium batteries for normal operation

l 1 lithium battery as a spare in the case of 'Battery low' operation

2 Label with area for filling in the commissioning date

3 Battery cable

4 Battery connector with protection against polarity reversal

18

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Properties

l In normal operation: Can be used for the service life stated

l In 'Battery low' operation: subject to reduced operating life

l Connect ions cannot be reversed thanks to battery connector with protection

against polarity reversal

Page 19

Function

3.3 Function

3.3.1 Parameter sets

The detection behavior of the detectors is influenced by the parameter sets, so that

it can be specifically adjusted to the fire phenomena and environment al conditions

to be expected in the envir onment to be monitored.

The parameter s ets for smoke and heat detection are programmed in the

detectors. During commissioning, the optimum parameter set must be selected for

the conditions at the place of installation. This is carried out using the control panel.

3.3.2 Danger levels

The detector' s signal processing efficiently distinguishes between fire ev ents and

deceptive phenomena. The basis for reaching a danger level is not only given by

measured values exceeding a 'response threshold'; moreover, the smoke density

progression is observ ed over a longer period of time and asses sed by the

algorithms.

Fire detectors can transmit the following danger levels to the control panel:

Structure and function

3

Danger level Meaning Comment

0 No danger Normal condition

1 Check the situation.

2 War ning Possible danger

3 Alarm Fire

The evaluation of the danger level and the decisions to be taken (e.g. activation of

remote transmission) are configured in the cont rol panel.

A different parameter set should

potentially be selected (inappropriate

application)

19

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

Page 20

Structure and function

Function

1

1

Internal alarm indicator

Several flashing pat terns are available for normal operation. The flashing patt ern

3

3.3.3 Diagnosis levels

The detector monitors its operation largely aut onomously. The signals of all

sensors are permanently monitored. In particular, the temperature sensors, light

emitters, and light receivers are monitored to ensure that they ar e functioning

correctly. Signal processing takes account of the monitoring results and adapts its

behavior accordingly.

The following diagnosis levels are derived from the different control measurements:

l Normal

l Observe information

l Replacement recommended

l Replacement necessary

l Fault

When an error occur s which impairs the correct functionality of the detector, a fault

message is reported to the control panel. To correct the cause of the fault,

additional information is available in the detector. The diagnosis levels can be read

out using the FXS2061 SWING tool. You will find more informat ion in

document A6V10227643.

See also

2 Applicable documents [➙ 7]

3.3.4 Internal alarm indicator

The internal alarm indicator's LED has two colors and shows the operating

condition of the radio fire detector.

The table below describes the flashing behavior of the internal alarm indicator in

the radio fire detector FDOOT271:

is selected using the software 'FXS2002'.

20

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Page 21

Function

Operating condition Flashing mode Graphic

t

2345678

9

[s]

t

2345678

9

[s]

t

2345678

9

[s]

t

2345678

9

[s]

t

2345678

9

[s]

t

2345678

9

[s]

3456789

[s]

t

2345678

9

[s]

t

2345678

9

[s]

t

2345678

9

[s]

t

2345678

9

[s]

Structure and function

3

Alarm

Alarm in test mode

Fault There is an error.

CommissioningThe radio fire detector

has not yet been

logged on to a radio

gateway.

And

The radio fire detector

is not installed on a

detector base.

And

There is no contact

with the radio network .

The radio fire detector

has already been

logged on to a radio

gateway.

And

The radio fire detector

is not installed on a

detector base.

And

There is no contact

with the radio network .

IAI flashes red

once a second

IAI flashes green

twice every

four seconds and

red every second

in-between

IAI flashes red

four times every

second

IAI flashes red

once every two

seconds

IAI flashes green

once every two

seconds

0 1

0 1

0 1

0 1

0 1

10 1211

10 1211

10 1211

10 1211

10 1211

The radio fire detector

is installed on the

base but has not yet

IAI flashes green

twice every two

seconds

0 1

10 1211

been logged on to the

radio network.

Normal Configuration 1

IAI flashes green

once every 30

0 1 2

t

3130

seconds

Configuration 2 IAI off

Test

IAI flashes green

twice every four

0 1

0 1

10 1211

10 1211

seconds

New battery

IAI lights up once

for five seconds

0 1

x1

10 1211

Battery is flat IAI off

0 1

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

10 1211

21

Page 22

Structure and function

Function

Several operating conditions may be indicated at the same time. This may lead to

Not all fire control panels support the flashing patterns described.

3

the flashing patterns overlapping one another. The red LED indicator has prior ity

over the green LED indicat or.

Flashing patterns with a higher frequency will overlap those with a lower

frequency, which means that the latter may no longer be discernible.

Please also observe the documentation for your fire detection system.

3.3.5 Renovation mode

Renovation mode is set using the control panel.

Renovation mode can be used under t he following conditions:

l If there is a large amount of dust in the air around the radio fire detector

temporarily

l If there are aerosols in the air around the radio fire detector temporarily

The radio fire detector does not issue alarms in renovation mode unt il a

temperature of 80 °C has been exceeded f or 20 seconds.

You will find more detailed information in the fire detection system documentation.

22

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Page 23

Function

3.3.6 Test mode

The detector exchanger and tester FDUD292 and the intelligent detector tester

In test mode the radio fire detectors react faster and with a higher sensitivity level.

For testing purposes, the radio fire detectors can be set to test mode using the

control panel or the FXS2061 S WING tool.

The following tests can be performed:

l Test of optical detector function using test gas

l Test of heat detector function using hot air

You will find more detailed information in the fire detection system documentation.

3.3.7 Degraded mode in the FDnet/C-NET

When the main processor of the fire control panel fails, the control panel is in

degraded mode operation. Depending on the control panel type, the fire control

panel can continue to perform the most important alarming and signaling functions

in degraded mode operation.

l There are no restrictions on the function of the detector when it is in degraded

mode operation.

l Degraded mode operation does not affect radio cell communication.

l A fault message is transmitted to the fire control panel via the radio gateway.

The fire control panels support degraded mode operation in different ways.

During planning, t herefore, you must observe t he information in the 'List of

compatibility' document and the fire control panel documentation. See the

'Applicable documents [➙ 7]' chapter.

You will find more detailed information in the fire detection system documentation.

Structure and function

3

3.3.8 Interface to service devices

The fire control panel or the software FXS2061 SWING tool is used to read out and

set the parameter sets.

FDUD293 cannot be us ed to read out or set the parameter sets.

See also

2 Applicable documents [➙ 7]

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

23

Page 24

Structure and function

Mechanical setup

456

7

3

3.4 Mechanical setup

An installed detector base FDB271 is required to install the detector.

Once the detector is ready for use, twist it onto the detector base either manually or

using the detector exchanger.

2 3

1

new

8

Mechanical setup

1 Battery connector 5 Fixing screws

2 Battery pack 6 Detector

3 Switch 7 Internal alarm indicator

4 Detector base 8 'new' button

See also

2 Accessories [➙ 25]

24

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Page 25

Accessor

ies

3.5 Accessories

3.5.1 Detector base FDB271

See also

2 Det ector base FDB271 [➙ 35]

Structure and function

l For installing radio fire detectors

l Directly attached to the mounting surface

l Fastened with two screws

l Compatible with:

– Radio fire detector FDOOT271

– Wireless alarm sounder FDS271

l Order no. FDB271-W: S54319-F12-A1

l Order no. FDB271-R: S54xxx-Fx-Ax

3

3.5.2 Battery pack BAT3.6-10

l For supplying radio devices and the radio gateway

with power

l Lithium batteries

– BAT3.6-10 LI-SOCl2 battery pack 3.6 V, 10 Ah

l Batteries with battery cable

l Connector system with protection against polarity

reversal

l Inscription field for commissioning date

l Compatible with:

– Radio gateway FDCW241

– Radio manual call point FDM273

– Radio fire detector FDOOT271

l Order no.: S54370-Z11-A1

3.5.3 Detector locking device FDBZ293

l For protection against theft

l Compatible with:

– Point detectors from the 'Sinteso' product line

– Alarm sounder FDS221

– Alarm sounder with supplementary optical

indication FDS229

– Interbase FDSB22x

l Order no.: A5Q00005035

See also

2 Detector locking device FDBZ293 [➙ 38]

25

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

Page 26

Structure and function

Accessories

3

3.5.4 Desig nation plate FDBZ291

l To identify the location

l Compatible with:

– Detector base FDB2xx/-AA

– Detector base FDB271

– Sounder base FDSB29x

– Base attachment FDB291

– Interbase FDSB22x

l Order no.: A5Q00002621

See also

2 Designat ion plate FDBZ291 [➙ 39]

3.5.5 Detector dust cap FDZ291

l To protect the point detector from dust

l Compatible with:

– Point detectors from the 'Sinteso' product line

l Order no.: A5Q00004814

See also

2 Detector dust cap FDZ291 [➙ 40]

3.5.6 Detector base seal RS720

l For mounting in wet rooms

l Protection category IP42

l Compatible with:

l Not compatible with:

l Order no.: S54319-F8-A1

– Detector base (collective) DB110

– Detector base (collective) DB110x

– Detector base (collective) DB110xx

– Detector base FDB271

– Detector base FDB271-R

– Designation plate FDBZ291

26

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Page 27

Compatibility FDnet/C

-

NET

4 Planning

The radio connection means that there is no need to wire the radio devices,

such as the radio fire detector, radio manual call point, etc., in the usual way.

Together with the radio gateway, the radio devices form a r adio cell. The control

panel treats t his radio cell as a loop or a stub. It is used for the 'Sinteso' and

'Cerberus PRO' pr oduct lines.

In the 'Planning' document (A6V10227631), you will find detailed information about

the components of the radio fire detection system as well as the necessar y devices

and device combinations.

You will find more inf ormation in the 'List of compatibility'.

See also

2 Applicable documents [➙ 7]

2 Applicable documents [➙ 7]

4.1 Compatibility FDnet/C-NET

Compatible with control panels that support the FDnet/C-NET detector line.

Planning

4

Detector line Control panel

FC20xx FC72x SIGMASYS AlgoRex

FDnet X

From MP5

C-NET – X

X = compatible

– = not compatible

You will find detailed information in the 'List of compatibility'.

– – –

– –

From IP5

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

27

Page 28

4

Ambient features

Planning

4.2 Am bient features

In selecting the optimum parameter set, the following factors must be taken into

account:

l Risk of damage to persons

l Value concentration

l Room geometry

l Deceptive phenomena

l Risk of fire

l Critical fire size

Risk of injury to persons

People's lives are severely at risk in venues such as concert halls, nursing homes,

and hospitals. The risk of damage to persons is therefore very high in such places.

In canteen kit chens the situation is different. Few people work in such facilities and

are able to save themselves in the event of timely alarms. The risk of damage to

persons is thus rather low in this case.

Value concentration

Irreplaceable cultural assets are often on display in m useums. Computer centers

house servers wit h large data volumes. The concentration of valuable items is

rather high. I n a normal hotel room the concentration of valuable items must be

classified as low.

Room geometry

High ceilings, complex r oom shapes or well-ventilated rooms have a c omplex room

geometry. This aggravates early fire detection, as it is difficult for the fire

phenomenon to reach t he fire detector. An office room with normal ceiling height

has a simple room geometry.

Deceptive phenomena

Deceptive phenomena can deceive a fire detector and bring about a false alarm.

The deceptive phenomena differ depending on the fire detector. Examples of

deceptive phenomena include steam, cigarette smoke, dust, dry ice in

discotheques, exhaus t fumes, aerosols occurring during welding, and heat sources

such as radiant heaters or hot engines.

In a small hotel room with a rather low ceiling where vapor from the bathroom may

penetrate the room, or in operating facilities where a lot of dust is generated, many

deceptive phenomena must be taken into consideration. In a clean room where

electronic modules are fabricated the ris k of decept ive phenomena is rather low.

Risk of fire

In production facilities where highly combust ible materials such as flammable

liquids, cotton, paper, etc., are processed and where electrical machines are

operated, the risk of fire is very high. Minor overheating or sparks may cause a fire.

In a storehouse where steel is stored and where no electrical inst allation is

provided with the exception of lighting, the fire risk is very low.

Critical fire size

When a waste paper basket in a met al-processing facility catches fire, the

consequential damage is usually rather low. Here we are talking about a critical,

medium fire size that can still be tolerated. The situation is completely different in

pharmaceutical production facilities where even the lowest smoke concentration

may impair the process and where combustible materials are proc essed. Even the

smallest fire must be detected immediately. Therefore, we need to define what is

termed a small admissible critical fire size.

28

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Page 29

Parameter sets for FDOOT271

4.3 Parameter sets for FDOOT271

4.3.1 Sensor mode 0 'Neural fire detector'

4.3.1.1 Description

(Parameter set numbers in brackets)

Robust (0)/(2):

The priority of the 'Robust' parameter set is to a robust response. The sensitivity is

the same as with the 'Suppression' parameter set; however, deceptive phenomena

are not explicitly analyzed and suppressed. It is thus particularly suited t o

application in rooms where deceptive phenomena such as cigarette smoke or dust

can be expected. The 'Robust (2)' parameter set is suitable for higher rooms in

comparison to the 'Suppression (5)' parameter s et.

Balanced (4):

The 'Balanced' parameter set reveals a balanced response behavior regarding

reaction to fires and robustness to deceptive phenomena. It reacts faster wit h open

fires. It reacts slower with vapor, cigarette smoke or smoldering fires.

Planning

4

Suppression (5):

Thanks to its very robust behavior , the 'Suppression' parameter set is particularly

suitable for rooms where deceptive phenomena such as cigarette smoke or

exhaust fumes can be ex pected. It reacts in a very robust way to the deceptive

phenomenon vapor.

Fast Response (6):

This parameter set reacts in a fast and highly sensitive manner. It is thus especially

suited for rooms without deceptive phenomena, where the priority is on detecting

the fire as early as possible.

High Sensitive Fast (9):

This parameter set is suited for applications requiring very high sensitivity levels. It

reveals a significant ly higher optical and thermal sens itivity than 'Fast Response'.

This parameter set is also suited for applications that can otherwise only be

covered with special detectors.

Download 1 (14) / download 2 (15):

Application-specific parameter set s that can be loaded on site (depending on the

control panel).

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

29

Page 30

4

Parameter sets for FDOOT271

The 'High Sensitive Fast' parameter set is only suitable for special applications.

All parameter sets except for 14 and 15 comply with standards EN

54-7 and

Planning

4.3.1.2 Use

No. Name

0 Robust

2 Robust

4 Balanced

5 Suppression

6 Fast Response

9

High Sensitive

Fast

Risk of damage

to persons

small…

large

Concentration

of valuable

items

low…

high

Room

geometry

simple…

complex

Deceptive

phenomena

few…

many

Risk of fire Critical fire size

small…

large

small…

medium

4.3.1.3 Specification

The following table displays the properties and fields of application of the

parameter sets of radio fire detector FDOOT271 in sensor mode 0.

No. Name Optical Thermal

Typ. Response

time

from - typ. - to

[s] [%/m] [%/m] [°C] ∆T [K] [°C]

0 Robust 80 3.2 11.4 80 29 30

2 Robust 80 3.2 11.4 80 29 30

4 Balanced 40 - 64 - 300 2.3 8 80 25 30

5 Suppression 90 -160 - 760 3.2 11.4 80 29 30

6 Fast Response 20 - 30 1.6 5.6 80 22 3

9 High Sensitive Fast 20 - 30 0.8 2.8 60 16 3

14 Application-specific parameter sets

15

1

Applicable with fast temperature increases >10 K/ min.

Sensitivity,

open fir e

Sensitivity,

smold ering fire

Static

activation

temperature

Differential activation

temperature

1

Differential

activation

possible from:

CEA 4021.

30

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Page 31

Parameter sets for FDOOT271

4.3.2 Sensor mode 1 'Hea t detector'

This parameter set meets the criteria of standard EN

54-5.

4.3.2.1 Description

This sensor mode is espec ially suited for applications where the detector should

only react therm ally.

The heat detector FDOOT271 has the following parameter sets:

l A1R (1)

l A1S (3)

Notes on A1 designations

l A1 parameter sets should be operated at a room temperature of around 25 °C.

However, they can be applied at temperatures up to 50 °C. T he static response

temperature is 60 °C.

Notes on the designations R and S

Compared with S parameter sets, R parameter sets also trigger an alarm when the

temperature inc reases (e.g. from 20 °C to 50 °C wit hin a few minutes).

Planning

4

No. Name

1 A1R

60 °C rate of

rise

3 A1S

60 °C

maximum

4.3.2.2 Specification

Operating

temperature

typ. / max.

[°C] [°C] ∆T [K] [°C]

25 / 50 60 25 3

25 / 50 60 – –

1

Applicable with slow temperature increases <1 K/min.

2

Applicable with fast temperature increases of >10 K/min. When there is a slow

temperature inc rease of < 10 K/min, this value rises by a few degrees.

Static activation

temperature

1

Different ial activation

temperature

2

Different ial activation

possible from:

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

31

Page 32

4

Parameter sets for FDOOT271

All parameter set s meet the criteria of standard E

N54-

7.

Planning

4.3.3 Sensor mode 2 'Smoke detector'

4.3.3.1 Description

This sensor mode s hould be selected if fast temperature changes that are not

caused by fire may occur (e.g. in the case of radiant heaters, hot engines). In this

sensor mode the det ector only reacts optically; this is comparable with a widespectrum smoke detector. Having to a second optical sensor, however, it reveals a

balanced response behavi or in relation to the dif ferent types of fire.

Universal (1):

With 'Univers al' the sensitivity and response time to aerosols are between 'Robust'

and 'Sensitive'.

Robust (2):

This parameter set responds to aerosols in a similar way as the neural fire detector

FDOOT271 in sensor mode 0 with the 'Robust' parameter set, without taking into

account the temperat ure.

Sensitive (3):

With regard to aerosols, this parameter set reacts in a way that is comparable to

'Fast Respons e' in sensor mode 0 without temperat ure influence.

No. Name

1 Universal

2 Robust

3 Sensitive

4.3.3.2 Use

Risk of damage

to persons

small…

large

Concentration

of valuable

items

low…

high

4.3.3.3 Specification

No. Name Response tim e [s] Sensitivity

1 Universal 50 2.3 / 8

2 Robust 80 2.3 / 8

3 Sensitive 30 1.6 / 5.6

Room

geometry

simple…

complex

Deceptive

phenomena

few…

many

Risk of fire Critical f ire s ize

small…

large

open fire/smoldering fire

small…

medium

[%/m]

32

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Page 33

Application examples

4.4 Application examples

Please refer to document 010030 for application recommendations , such as

choosing the detector type and its sett ings for various applications.

See also

2 Applicable documents [➙ 7]

Planning

4

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

33

Page 34

Mounting / Installation

Required space

c

m

5

5 Mounting / Installation

5.1 Required space

l Upon insertion of the detector, the detector base is stressed by compression,

tension and torsion. The fixing must thus be designed accordingly.

l Detect or bases must be placed flat on the ceiling.

l Avoid mounting on steps, concrete ribs, etc.

l W hen selecting the installation position, take into account any structures that

may impair radio reception.

l There must be at least 50 cm of free space below and at least 2 cm to the

sides of the detector, so that the detector can be removed with the detector

exchanger.

l Cont orted detector bases complicate or even impede the insertion of the

detectors with the detector exchanger.

* = min. 2 cm

min. 50

Minimum spacing when installing detector bases

34

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Page 35

Detector base FDB271

5.2 Detector base FDB271

2

423

46 mm

90 mm

The detector base must be securely connected to the substruc ture.

Screw the detector bas e securely onto the substructure using two screws.

2

2

1

1

Mounting / Installation

5

Installing the detector base

1 Detector base

Screws with max. Ø of 4 mm

2

3

Holder for detect or locking device

Switching cam

4

See also

2 Det ector base FDB271 [➙ 25]

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

35

Page 36

Mounting / Installation

Installing the radio fire detector FDOOT271

The action of inserting the radio fire detector int o the detect or ba

se activates it;

The flashing behavior of the internal alarm indic ator is described in the technical

5

5.3 Installing the radio fire detector FDOOT271

the detector then logs on to other radio devices immediately. Therefore, start from

the radio gateway and work outwards to install the individual radio fire detectors.

1

2

3

4

5

Installing the radio fire detector

1 Battery pack BAT3.6-10

2 Inserting the battery pack 5 Battery connector

3 Holder

1

not included in the scope of delivery

1

4 Battery cable

manual A6V10227635 provid ed by the manufacturer in the 'Internal alarm

indicator [➙ 20]' chapter.

w The radio gateway has been activated and switched to maintenance mode.

w The radio fire detector is set to the factory settings.

w You have the battery pack and the required accessories to hand.

w The detector base FDB271 is installed [➙ 35].

36

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Page 37

Mounting / Installation

Installing the radio fire detector FDOOT271

1. Install the accessories you require.

2. Label the new battery pack (1) with the current date.

3. Connect t he battery connector (5) of the new battery pack.

4. Insert the new battery pack (1), paying attention to the position of the battery

cable (arrows at 4).

5. Make sure t hat the holder (3) latches into place corr ectly.

a When the battery connector is connected, the internal alarm indicator lights

up red for 5 seconds.

a After a further 10 seconds, the radio fire detector signals that it is not

installed on the det ector base and the internal alarm indicator flashes. If it

flashes red, this indicates the factory settings. If it flashes green, this

indicates that the radio fire detector has already been logged on to a radio

gateway.

a If this does not happen, this means the battery pack is defective and must

not be used.

6. Insert the radio fire detector into the detector base.

a The internal alarm indicator flashes green and the radio fire detector is

logged on to the radio gateway.

a If the process of logging on to the radio gateway is successful, the internal

alarm indicator st ops flashing.

5

a The radio fire detector is now installed and is ready for commissioning.

See also

2 Det ector base FDB271 [➙ 35]

2 Establishing factory settings [➙ 45]

2 Internal alarm indicator [➙ 20]

2 Establishing factory settings [➙ 45]

2 Internal alarm indicator [➙ 20]

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

37

Page 38

Mounting / Installation

Detector locking device FDBZ293

5

5.4 Detector locking device FDBZ293

The detector can be protected against theft wit h the detect or locking device

FDBZ293.

Mounting of detector locking device FDBZ293

1 Detector bas e 4 Detector

2

Set screw with a hexagon socket 5 Allen key

3 Hole

1. Place the 's et screw with a hexagon socket' (2) in the hole (3) on the

detector (4).

2. Insert the detector (4) into the detector base (1).

3. Using the Allen key provided (5), inser t the 'set screw with a hexagon

socket' (2) through the hole in the detector base (1) and tight en.

a The detector can no longer be removed from the base without tools.

See also

2 Detector locking device FDBZ293 [➙ 25]

38

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Page 39

Designation plate FDBZ

291

5.5 Designation plate FDBZ291

E

FDBZ291

FDB271

2

1

Designation plate

2

Detector base

Designation plate FDBZ291 is used to assign a location address to the detector.

1. Label the designation plate.

2. Slide the designation plate into the det ector base from the side.

1

4

3

1

B

A

Mounting / Installation

5

Installing the designation plate

See also

2 Designat ion plate FDBZ291 [➙ 26]

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

39

Page 40

Mounting / Installation

Detector dust cap FDZ291

3

The detector dust cap can be put on or removed either manually or using

the

5

5.6 Detector dust cap FDZ291

During the construction phase the detector may be c overed with a detector dust

cap FDZ291 to protect it from dust and dirt.

1

FDZ291

2

Mounting / removal of detector dust cap FDZ291

1 Detector

2 Detector dust cap

3 Rem oving detector dust cap by tu rning it to the right

detector exchanger , e.g., FDUD291.

See also

2 Detector dust cap FDZ291 [➙ 26]

40

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Page 41

Detector base seal RS720

5.7 Detector base seal RS720

l Use the detector base seal RS720 to install point detectors in wet rooms.

Protection category: IP42.

l Not compatible with designat ion plate FDBZ291.

Installing the detector base seal

1. NO TICE! Excessively large holes in the detector base seal will impair the

potential I P prot ection category. Do not cut or drill holes in the detector base

seal.

2. Fit the det ector base seal RS720 between the ceiling and the detector base or

the sounder base.

Mounting / Installation

5

Installing the detector base seal RS720

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

41

Page 42

6

Insert the battery packs into the devices at the location where they are going to be

Commissioning

6 Commissioning

When the battery c onnector is connected, the radio f ire detector FDOOT271 is

activated. Once inserted into the detector base, the radio fire detector automatically

looks for radio devices within range in the vicinity and automatically integrates itself

into the radio network .

You will find the procedure for logging on and creating a radio cell in document

A6V10227639.

You must fully commission a radio cell before establishing the connection to the

FDnet/C-NET.

used just before commissioning the fire detect ion installation.

The device is commissioned via the control panel. The exact procedure is

described in the control panel documentation.

Conduct a performance check once commissioning is complete.

See also the following documents for more information:

l Document A6V10227639

l Document A6V10227631

See also

2 Applicable documents [➙ 7]

42

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Page 43

Status query

7 Maintenance / Repair

Check the detect or on a regular basis, but at least once a year.

To do this, look for/check the following and resolve any pr oblems you identify:

l Mechanical damage

l Soiling

l Correct fastening

l Detector function by means of t est activat ion

7.1 Status query

The query is issued from the control panel, via the radio gateway.

The following queries may be issued:

l Danger level

l Detector fault

l Radio status

Depending on the authorization level of the user and t he control panel type, the

following actions can be performed:

l Device test (Go/No Go or detailed by status polling)

l Activation of a test alarm

l Reading out the identificat ion number, customer text and measure text

l Localizing and set ting the parameters of t he detector

l Switching off the detector

Maintenance / Repair

7

See also

2 Diagnosis levels [➙ 20]

2 Internal alarm indicator [➙ 20]

7.2 Performance check

The selftest automatically subjects t he detectors to an extensive electrical

performance check. Regular performance checks of the detectors are required

nonetheless. These can be performed using test gas or hot air.

Recommendation:

l Per form a visual inspection on all detectors every year. Detectors that are

heavily soiled or mechanically damaged must be replaced.

l All detectors should be replaced after 6 to 8 years of service, depending on the

ambient conditions.

43

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

Page 44

Maintenance / Repair

Testing detectors

To trigger a detector using test gas, normally 2… 4

gas discharges at intervals of

7

7.3 Tes ting detectors

Depending on the sensor mode, testing may be performed with one or more of the

following tools:

l Test gas

– Detector tester RE6 for smoke detectors

– Test gas REF8-S (recommended)

– Test gas REF8

l Hot air

– Solo461 heat detector tester kit RE7T

The following table shows which mode may be tested with which test aid.

Mode Test gas Hot air SWING tool

Sensor mode 1 – X Communication

Sensor mode 2 X – Communication

The fire detectors are highly resistant to decept ive phenomena. This means that

optical fire detectors, for example, will recognize the immediate occurrence of

smoke (such as that which occurs during testing with test gas) as a decept ive

phenomenon and will not trigger an alarm. This is des irable in normal operation;

however, it does make testing with test gas problematical.

To enable detector testing with test gas or hot air, the detect or must be switched to

test mode. Testing with test gas or hot air is perf ormed differently on addressed

detector lines and collective detector lines.

Proceed as follows:

1. First switch the zone to 'Test' on the control panel.

2. Then perf orm the test using test gas.

approx. 2 seconds ar e required. When the detector is in test mode, activation

takes place aft er approximately 10 seconds.

7.4 Confirming the detector position

The procedures in 'Testing detectors [➙ 44] ' may also be used to confirm the

position of the det ector.

l T he corresponding status display on the radio gateway is cleared.

l The 'Device localization error' display on the control panel disappears.

See also

2 Testing detectors [➙ 44]

44

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Page 45

Establishing factory settings

7.5 Establishing factory settings

2

All existing settings are deleted and reset to the factory settings.

1

new

Establishing factory settings

1 Internal alarm indicator

2

'new' opening with button

Maintenance / Repair

7

To create the factory settings on the radio fire detector, proceed as follows:

w The radio fire detector is being supplied with power.

w You have a slim pen or pencil to hand.

1. Remove the radio fire detector from the det ector base.

2. Wait until the internal alarm indicator (1) flashes green (2-second interval).

a The detector is 'out of base'.

3. Press the pen or pencil into the 'new' opening (2) for 5 seconds.

a The internal alarm indicator flashes red (2-second interval).

a The radio fire detector is set to the factory settings.

See also

2 Internal alarm indicator [➙ 20]

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

45

Page 46

Maintenance / Repair

Basic principles for replacing the battery pack

Risk of explosion due to fire or short

-

circuit, even if the battery pack is empty

●

Do not heat the battery pack to more than 100

°C.

Disposing of damaged or leaky battery packs

●

Do not breathe in vapors. Ens ure that there is sufficient vent ilation.

7

7.6 Basic principles for replacing the battery pack

CAUTION

Injuries caused by f lying parts

● To prevent t he connection wires short-circuiting, insulate the connections and

stick the battery cable to the battery pack.

● Do not allow the battery pack to come into cont act with water.

● Do not extinguish a burning battery pack with water.

● Do not recharge the battery pack.

● Do not damage or dism antle the bat tery pack.

CAUTION

Lithium can burn the sk in and produce toxic vapors.

● Avoid direct contact with the body. Wear appropriate protective clothing

(safety gloves, safety goggles, etc.). Use appropriate means of transportation

to move damaged batt eries around.

Always observe the following information:

l W hen the control panel issues the message 'Battery low', replace the battery

pack.

l Use the control panel to identify the location of the radio device.

l Only use battery pack BAT3.6-10.

l The battery pack must be new and free from damage. The battery cable is

attached to the bat tery pack with an adhesive label.

l Store, transport, and dispose of the battery pack in accordance with local

regulations, guideli nes, and laws.

l Label the battery pack with the commissioning date.

See also

2 Environmental compatibility and disposal [➙ 51]

46

Building Technologies A6V10227635_g_en_--

Fire Safety 2015-03-11

Page 47

Replacing the battery pack

7.7 Replacing the battery pack

Each radio device st ores its contact data in the event of an interruption

in the

power supply lasting two minutes. The stored contact data enables t he radio

device to reintegrate itself into the radio network without delay and without any

problems. If the power supply for a radio device is interrupted for more than two

minutes, t he contact data will be lost and this radio device will not be detected. If

this happens to multiple radio devices at the same time, this means there is a

fault in the radio cell.

l Do not interrupt the power supply for longer than 2 minutes.

l Do not interrupt the power supply to mult iple radio devices simultaneously.

Replace the battery pack for one radio device as described below before

replacing the battery pack for the next radio device. This will prevent mix-ups

and will ensure the devices c an be reintegrated into the radio cell without any

problems.

Maintenance / Repair

7

1

1

2

2

3

3

4

4

5

5

Replacing the detector battery pack

1 Battery pack BAT3.6-10 4 Holder

2 Removing the battery pack 5 Battery cable

3 Inserting the battery pack 6 Battery connector

w You have a new, undamaged battery pack to hand.

w You have tools for removing the detector to hand.

Building Technologies A6V10227635_g_en_-Fire Safety 2015-03-11

47

Page 48

Maintenance / Repair

Replacing the battery pack

7

1. Remove the det ector from the detector base.

2. Wait until the internal alarm indicator flashes green (interval: 2 seconds).

a The detector is 'out of base'.

3. Push the holder (4) to the side and remove the battery pack (1).

4. Release the battery connector (6).

5. Dispose of t he old battery pack.

6. Label the new battery pack with the current date.

7. Connect t he battery connector (6) of the new battery pack.

8. Insert the new b attery pack, paying attent ion to the position of the battery cable

(arrows at 5).

9. Make sure t hat the holder (4) latches into place corr ectly.

a When the battery connector is connected, the internal alarm indicator lights

up red for 5 seconds (f lashing pattern number 1 Internal alarm indicator

[➙ 20]).

a Af ter a further 10 seconds, the detector signals that it is not installed on the

detector base and the internal alarm indicat or flashes green (flashing

pattern number 3).

a I f this does not happen, this means the battery pack is defective and must

not be used.

10. Insert the detector into the detector base.

a The internal alarm indicator flashes green (flashing pattern number 4) and

the detector is logged on to the radio gateway.

a If the process of logging on to the radio gateway is successful, the internal

alarm indicator st ops flashing.

11. Following the successful logon, replace the batter y pack of the next radio

device.

12. Check the status display on t he radio gat eway or the 'Device localization error'

display on the control panel.

– If there is a 'Device localization error' message on the radio gateway or the

control panel, the detector will need to be assigned again. As sign the

detector by following the information in Confirming the detector position

[➙ 44].

a The battery pack has now been replaced.

See also

2 Internal alarm indicator [➙ 20]

2 Bat tery pack BAT3.6-10 [ ➙ 25]

2 Applicable documents [➙ 7]