Siemens SINAMICS G120D, CU250D-2 DP-F, CU250D-2 PN-F, CU250D-2 PN-F PP, CU250D-2 PN-F FO Original Instructions Manual

Page 1

Page 2

Page 3

Converter with control units CU250D-2

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SINAMICS

SINAMICS G120D

Converter with control units

CU250D-2

Operating Instructions

Edition 04/2014, Firmware V4.7

Original instructions

04/2014, FW V4.7

A5E34261542B AA

Changes in this manual

Fundamental safety

instructions

1

Introduction

2

Description

3

Installation

4

Commissioning

5

Adapt inputs and outputs

6

Configuring the fieldbus

7

Setting functions

8

Backing up data and series

commissioning

9

Corrective maintenance

10

Alarms, faults and system

messages

11

Technical data

12

Appendix

A

Page 4

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E34261542B AA

Ⓟ

Copyright © Siemens AG 2012 - 2014.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

for the specific

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

07/2014 Subject to change

Page 5

Changes in this manual

Important changes with respect to the Manual, 01/2013 Edition

New hardware

in Chapter

Connections and cables (Page 36)

New Firmware Functions for V4.7

In Chapter

limit in the case of high-inertia starting.

(Page 209)

(I&M1 … 4)

(I&M) (Page 310)

Revised descriptions

In Chapter

(Page 237)

Corrections

in Chapter

±15 %, but rather -15 % / +20 %.

(Page 325)

New CU250D-2 PN-F FO Control Units with fieldbus via

fiber-optic cable

Reducing the pulse frequency and increasing the current

Supporting the identification & maintenance data

An overview of all the new and changed functions in the V4.7 firmware can be found in

Section New and extended functions (Page 337).

STO safety function Safe Torque Off (STO) safety function

The tolerance of the 24 V power supply of the inverter is not

The current carrying capacity of connector X01 is not 7 A,

but rather 8 A.

SINAMICS G120D CU250D-2 Inverter

(Page 23)

Inverter temperature monitoring

Identification & maintenance data

Performance ratings Control Unit

Cascading of the 24 V supply

(Page 51)

Converter with control units CU250D-2

Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

5

Page 6

Changes in this manual

Converter with control units CU250D-2

6 Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

Page 7

Table of contents

Changes in this manual ........................................................................................................................... 5

1 Fundamental safety instructions ............................................................................................................ 13

2 Introduction ........................................................................................................................................... 21

3 Description ............................................................................................................................................ 23

4 Installation ............................................................................................................................................ 29

5 Commissioning ..................................................................................................................................... 55

1.1 General safety instructions .......................................................................................................... 13

1.2 Safety instructions for electromagnetic fields (EMF) ................................................................... 17

1.3 Handling electrostatic sensitive devices (ESD) ........................................................................... 17

1.4 Industrial security ......................................................................................................................... 18

1.5 Residual risks of power drive systems ......................................................................................... 19

2.1 About this manual ........................................................................................................................ 21

2.2 Guide through this manual ........................................................................................................... 22

3.1 SINAMICS G120D CU250D-2 Inverter ........................................................................................ 23

3.2 Commissioning tools .................................................................................................................... 25

3.3 Supported motor series ................................................................................................................ 27

4.1 Mechanical Installation ................................................................................................................. 29

4.1.1 Drill pattern SINAMICS G120D .................................................................................................... 30

4.2 Electrical Installation .................................................................................................................... 32

4.2.1 Permissible line supplies .............................................................................................................. 32

4.2.2 Electrical data ............................................................................................................................... 33

4.2.3 Basic EMC Rules ......................................................................................................................... 34

4.2.4 Overview of the interfaces ........................................................................................................... 35

4.2.5 Connections and cables ............................................................................................................... 36

4.2.6 Connecting the motor holding brake ............................................................................................ 44

4.2.7 Factory settings of the inputs and outputs ................................................................................... 45

4.2.8 Default settings of inputs and outputs .......................................................................................... 46

4.2.9 Connecting the PROFINET interface ........................................................................................... 46

4.2.10 Encoders examples ..................................................................................................................... 47

4.2.11 Grounding converter and motor ................................................................................................... 47

4.2.12 Cable protection and cascading of the 400 V supply................................................................... 49

4.2.13 Cascading of the 24 V supply ...................................................................................................... 51

4.2.14 Connections and interference suppression ................................................................................. 51

4.2.15 Equipotential bonding .................................................................................................................. 52

5.1 Commissioning guidelines ........................................................................................................... 55

5.2 Preparing for commissioning ....................................................................................................... 57

5.2.1 Which motor fits the converter? ................................................................................................... 58

Converter with control units CU250D-2

Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

7

Page 8

Table of contents

6 Adapt inputs and outputs ...................................................................................................................... 79

7 Configuring the fieldbus ........................................................................................................................ 85

5.2.2 Introduction, V/f control, vector control ....................................................................................... 58

5.2.3 Defining additional requirements for the application ................................................................... 60

5.2.4 Encoder assignment ................................................................................................................... 60

5.3 Restoring the factory setting ....................................................................................................... 62

5.4 Basic commissioning with IOP .................................................................................................... 64

5.5 Basic commissioning with STARTER ......................................................................................... 68

5.5.1 Generating a STARTER project .................................................................................................. 69

5.5.2 Transfer inverters connected via USB into the project ............................................................... 69

5.5.3 Configuring a drive ...................................................................................................................... 71

5.5.4 Carry-out basic commissioning ................................................................................................... 72

5.5.5 Adapting the encoder data .......................................................................................................... 75

5.5.6 Loading the configured data into the drive .................................................................................. 76

5.5.7 Identifying motor data .................................................................................................................. 76

6.1 Digital inputs ................................................................................................................................ 80

6.2 Fail-safe digital input ................................................................................................................... 81

6.3 Digital outputs ............................................................................................................................. 83

7.1 Fieldbus versions of the Control Unit .......................................................................................... 85

7.2 Communication via PROFINET .................................................................................................. 86

7.2.1 What do you need for communication via PROFINET? ............................................................. 87

7.2.2 Integrating converters into PROFINET ....................................................................................... 88

7.2.3 Configuring communication to the control ................................................................................... 88

7.2.4 Select telegram ........................................................................................................................... 89

7.2.5 Activating diagnostics via the control .......................................................................................... 90

7.3 Communication via PROFIBUS .................................................................................................. 91

7.3.1 What do you need for communication via PROFIBUS? ............................................................. 91

7.3.2 Integrating the inverter in PROFIBUS ......................................................................................... 91

7.3.3 Configuring the communication using SIMATIC S7 control ........................................................ 92

7.3.4 Setting the address ..................................................................................................................... 92

7.3.5 Select telegram ........................................................................................................................... 93

7.4 PROFIdrive profile for PROFIBUS and PROFINET ................................................................... 94

7.4.1 Cyclic communication ................................................................................................................. 94

7.4.1.1 Positioner: Cyclic communication ............................................................................................... 94

7.4.1.2 Control and status word 1 ........................................................................................................... 97

7.4.1.3 Control and status word 2 ........................................................................................................... 99

7.4.1.4 Control and status word for the positioner ................................................................................ 100

7.4.1.5 Control and status word 1 for the positioner ............................................................................. 102

7.4.1.6 Control and status word 2 for the positioner ............................................................................. 104

7.4.1.7 Control word block selection ..................................................................................................... 106

7.4.1.8 Control word MDI mode ............................................................................................................ 107

7.4.1.9 Status word messages .............................................................................................................. 108

7.4.1.10 Function block FB283 ............................................................................................................... 109

7.4.1.11 Extend telegrams and change signal interconnection .............................................................. 109

7.4.1.12 Slave-to-slave communication .................................................................................................. 110

7.4.2 Acyclic communication .............................................................................................................. 110

Converter with control units CU250D-2

8 Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

Page 9

Table of contents

8 Setting functions ................................................................................................................................. 111

8.1 Overview of the converter functions........................................................................................... 111

8.2 Inverter control ........................................................................................................................... 113

8.2.1 Switching the motor on and off .................................................................................................. 113

8.2.2 Running the motor in jog mode (JOG function) ......................................................................... 115

8.2.3 Switching over the inverter control (command data set)............................................................ 117

8.3 Setpoints .................................................................................................................................... 119

8.3.1 Overview .................................................................................................................................... 119

8.3.2 Specifying the setpoint via the fieldbus ...................................................................................... 120

8.3.3 Motorized potentiometer as setpoint source .............................................................................. 120

8.3.4 Fixed speed as setpoint source ................................................................................................. 123

8.4 Setpoint calculation .................................................................................................................... 126

8.4.1 Overview of setpoint preparation ............................................................................................... 126

8.4.2 Invert setpoint ............................................................................................................................. 127

8.4.3 Inhibit direction of rotation .......................................................................................................... 128

8.4.4 Skip frequency bands and minimum speed ............................................................................... 129

8.4.5 Speed limitation.......................................................................................................................... 130

8.4.6 Ramp-function generator ........................................................................................................... 131

8.5 Motor control .............................................................................................................................. 136

8.5.1 V/f control ................................................................................................................................... 136

8.5.1.1 Characteristics of U/f control ...................................................................................................... 137

8.5.1.2 Selecting the U/f characteristic .................................................................................................. 138

8.5.1.3 Optimizing with a high break loose torque and brief overload ................................................... 138

8.5.2 Vector control ............................................................................................................................. 140

8.5.2.1 Checking the encoder signal ...................................................................................................... 141

8.5.2.2 Select motor control ................................................................................................................... 141

8.5.2.3 Optimizing the speed controller ................................................................................................. 142

8.5.2.4 Advanced settings ...................................................................................................................... 144

8.5.3 Operating the converter without position controller ................................................................... 145

8.6 Basic positioner and position control ......................................................................................... 147

8.6.1 Basic positioner and position control ......................................................................................... 147

8.6.2 Commissioning sequence .......................................................................................................... 148

8.6.3 Normalizing the encoder signal.................................................................................................. 149

8.6.3.1 Define the resolution .................................................................................................................. 149

8.6.3.2 Modulo range setting ................................................................................................................. 151

8.6.3.3 Checking the actual position value ............................................................................................ 153

8.6.3.4 Setting the backlash ................................................................................................................... 154

8.6.4 Limiting the positioning range .................................................................................................... 156

8.6.5 Setting the position controller ..................................................................................................... 158

8.6.5.1 Precontrol and gain .................................................................................................................... 158

8.6.5.2 Optimizing the position controller ............................................................................................... 159

8.6.5.3 Limiting the traversing profile ..................................................................................................... 162

8.6.6 Setting the monitoring functions................................................................................................. 164

8.6.6.1 Standstill and positioning monitoring ......................................................................................... 164

8.6.6.2 Following error monitoring ......................................................................................................... 166

8.6.6.3 Cam sequencer .......................................................................................................................... 168

8.6.7 Referencing ................................................................................................................................ 169

8.6.7.1 Referencing methods ................................................................................................................. 169

8.6.7.2 Setting the reference point approach ......................................................................................... 170

Converter with control units CU250D-2

Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

9

Page 10

Table of contents

9 Backing up data and series commissioning .......................................................................................... 257

8.6.7.3 Setting the flying referencing..................................................................................................... 176

8.6.7.4 Set reference point .................................................................................................................... 181

8.6.7.5 Absolute encoder adjustment ................................................................................................... 183

8.6.8 Jogging ...................................................................................................................................... 185

8.6.8.1 Jog velocity................................................................................................................................ 185

8.6.8.2 Incremental jogging ................................................................................................................... 186

8.6.8.3 Setting jogging .......................................................................................................................... 186

8.6.9 Traversing blocks ...................................................................................................................... 188

8.6.9.1 Travel to fixed stop .................................................................................................................... 196

8.6.9.2 Examples................................................................................................................................... 201

8.6.10 Direct setpoint input (MDI) ........................................................................................................ 203

8.7 Protection and monitoring functions .......................................................................................... 209

8.7.1 Inverter temperature monitoring ................................................................................................ 209

8.7.2 Motor temperature monitoring using a temperature sensor ...................................................... 212

8.7.3 Protecting the motor by calculating the motor temperature ...................................................... 215

8.7.4 Overcurrent protection .............................................................................................................. 217

8.8 Application-specific functions .................................................................................................... 218

8.8.1 Functions that match the application ........................................................................................ 218

8.8.2 Unit changeover ........................................................................................................................ 219

8.8.2.1 Changing over the motor standard ........................................................................................... 220

8.8.2.2 Changing over the unit system ................................................................................................. 221

8.8.2.3 Switching units with STARTER ................................................................................................. 222

8.8.3 Electrically braking the motor .................................................................................................... 224

8.8.3.1 DC braking ................................................................................................................................ 224

8.8.3.2 Braking with regenerative feedback to the line ......................................................................... 227

8.8.4 Motor holding brake .................................................................................................................. 228

8.8.5 Monitoring the load torque (system protection)......................................................................... 232

8.8.6 Load failure monitoring .............................................................................................................. 234

8.8.7 Speed deviation monitoring....................................................................................................... 235

8.9 Safe Torque Off (STO) safety function ..................................................................................... 237

8.9.1 Function description .................................................................................................................. 237

8.9.2 Prerequisite for STO use ........................................................................................................... 239

8.9.3 Commissioning STO ................................................................................................................. 239

8.9.3.1 Commissioning tools ................................................................................................................. 239

8.9.3.2 Protection of the settings from unauthorized changes .............................................................. 240

8.9.3.3 Resetting the safety function parameters to the factory setting ................................................ 240

8.9.3.4 Changing settings ..................................................................................................................... 241

8.9.3.5 Interconnecting the "STO active" signal .................................................................................... 242

8.9.3.6 Setting the filter for safety-related inputs .................................................................................. 243

8.9.3.7 Setting the forced checking procedure (test stop) .................................................................... 246

8.9.3.8 Activate settings ........................................................................................................................ 247

8.9.3.9 Checking the assignment of the digital inputs........................................................................... 248

8.9.3.10 Acceptance - completion of commissioning .............................................................................. 250

8.10 Switchover between different settings ...................................................................................... 254

9.1 Saving settings on a memory card ............................................................................................ 258

9.1.1 Saving settings to the memory card .......................................................................................... 259

9.1.2 Transferring the settings from the memory card ....................................................................... 260

9.1.3 Safely remove the memory card ............................................................................................... 261

Converter with control units CU250D-2

10 Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

Page 11

Table of contents

10 Corrective maintenance ...................................................................................................................... 275

11 Alarms, faults and system messages .................................................................................................. 299

12 Technical data .................................................................................................................................... 325

9.2 Backing up and transferring settings using STARTER .............................................................. 263

9.3 Saving settings and transferring them using an operator panel ................................................ 265

9.4 Other ways to back up settings .................................................................................................. 266

9.5 Write and know-how protection .................................................................................................. 267

9.5.1 Write protection .......................................................................................................................... 267

9.5.2 Know-how protection ................................................................................................................. 269

9.5.2.1 Settings for the know-how protection ......................................................................................... 271

9.5.2.2 Creating an exception list for the know-how protection ............................................................. 273

10.1 Spare parts - external fan .......................................................................................................... 275

10.2 Overview of replacing converter components ............................................................................ 276

10.3 Replacing a Control Unit with enabled safety function .............................................................. 278

10.4 Replacing the Control Unit without the safety functions enabled .............................................. 282

10.5 Replacing the Control Unit without data backup ........................................................................ 284

10.6 Replacing a Control Unit with active know-how protection ........................................................ 285

10.7 Replacing a Power Module with enabled safety function .......................................................... 287

10.8 Replacing a Power Module without the safety function being enabled ..................................... 288

10.9 Upgrading firmware .................................................................................................................... 289

10.10 Firmware downgrade ................................................................................................................. 292

10.11 Correcting a failed firmware upgrade or downgrade.................................................................. 295

10.12 Reduced acceptance test after component replacement .......................................................... 296

10.13 If the converter no longer responds ........................................................................................... 297

11.1 Alarms ........................................................................................................................................ 299

11.2 Faults ......................................................................................................................................... 303

11.3 Status LED overview .................................................................................................................. 308

11.4 Identification & maintenance data (I&M) .................................................................................... 310

11.5 System runtime .......................................................................................................................... 311

11.6 List of alarms and faults ............................................................................................................. 312

12.1 Performance ratings Control Unit ............................................................................................... 325

12.2 Performance ratings Power Module........................................................................................... 327

12.3 SINAMICS G120D specifications ............................................................................................... 328

12.4 Ambient operating conditions ..................................................................................................... 329

12.5 Current and voltage derating dependent on the installation altitude ......................................... 330

12.6 Pulse frequency and current reduction ...................................................................................... 331

Converter with control units CU250D-2

Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

11

Page 12

Table of contents

A Appendix ............................................................................................................................................. 337

Index ................................................................................................................................................... 375

12.7 Standards (PM250D) ................................................................................................................ 332

12.8 Electromagnetic Compatibility ................................................................................................... 333

A.1 New and extended functions ..................................................................................................... 337

A.2 Star-delta motor connection and application examples ............................................................ 340

A.3 Parameter.................................................................................................................................. 341

A.4 Handling STARTER .................................................................................................................. 344

A.4.1 Change settings ........................................................................................................................ 344

A.4.2 Optimize the drive using the trace function ............................................................................... 346

A.5 Interconnecting signals in the inverter ...................................................................................... 349

A.5.1 Fundamentals ........................................................................................................................... 349

A.5.2 Example .................................................................................................................................... 351

A.6 Application Examples ................................................................................................................ 353

A.6.1 Setting an absolute encoder ..................................................................................................... 353

A.6.2 Go online with STARTER via PROFINET ................................................................................. 357

A.6.2.1 Adapting the PROFINET interface ............................................................................................ 357

A.6.2.2 Create a reference for STARTERS ........................................................................................... 358

A.6.2.3 Call the STARTER and go online ............................................................................................. 359

A.6.3 Connecting the safety-related input .......................................................................................... 359

A.6.4 Connecting fail-safe digital inputs ............................................................................................. 360

A.7 Setting a non standard HTL encoder ........................................................................................ 361

A.8 Setting a non standard SSI encoder ......................................................................................... 362

A.9 Acceptance tests for the safety functions ................................................................................. 365

A.9.1 Recommended acceptance test ............................................................................................... 365

A.9.2 Machine documentation ............................................................................................................ 368

A.9.3 Log the settings for the basic functions, firmware V4.4 ... V4.7 ................................................ 370

A.10 Manuals and technical support ................................................................................................. 371

A.10.1 Manuals for your inverter .......................................................................................................... 371

A.10.2 Configuring support ................................................................................................................... 372

A.10.3 Product Support ........................................................................................................................ 372

A.11 Mistakes and improvements ..................................................................................................... 373

Converter with control units CU250D-2

12 Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

Page 13

1

1.1

General safety instructions

DANGER

Danger to life due to live parts and other energy sources

WARNING

Danger to life through a hazardous voltage when connecting an unsuitable power supply

Death or serious injury can result when live parts are touched.

• Only work on electrical devices when you are qualified for this job.

• Always observe the country-specific safety rules.

Generally, six steps apply when establishing safety:

1. Prepare for shutdown and notify all those who will be affected by the procedure.

2. Disconnect the machine from the supply.

– Switch off the machine.

– Wait until the discharge time specified on the warning labels has elapsed.

– Check that it really is in a no-voltage condition, from phase conductor to phase

conductor and phase conductor to protective conductor.

– Check whether the existing auxiliary supply circuits are de-energized.

– Ensure that the motors cannot move.

3. Identify all other dangerous energy sources, e.g. compressed air, hydraulic systems, or

water.

4. Isolate or neutralize all hazardous energy sources by closing switches, grounding or

short-circuiting or closing valves, for example.

5. Secure the energy sources against switching on again.

6. Ensure that the correct machine is completely interlocked.

After you have completed the work, restore the operational readiness in the inverse

Converter with control units CU250D-2

Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

sequence.

Touching live components can result in death or severe injury.

• Only use power supplies that provide SELV (Safety Extra Low Voltage) or PELV-

(Protective Extra Low Voltage) output voltages for all connections and terminals of the

electronics modules.

13

Page 14

Fundamental safety instructions

WARNING

Danger to life when live parts are touched on damaged devices

WARNING

Danger to life through electric shock due to unconnected cable shields

WARNING

Danger to life due to electric shock when not grounded

WARNING

Danger to life due to electric shock when opening plug connections in operation

WARNING

Danger to life due to fire spreading if housing is inadequate

1.1 General safety instructions

Improper handling of devices can cause damage.

For damaged devices, hazardous voltages can be present at the enclosure or at exposed

components; if touched, this can result in death or severe injury.

• Ensure compliance with the limit values specified in the technical data during transport,

storage and operation.

• Do not use any damaged devices.

Hazardous touch voltages can occur through capacitive cross-coupling due to unconnected

cable shields.

• As a minimum, connect cable shields and the conductors of power cables that are not

used (e.g. brake cores) at one end at the grounded housing potential.

For missing or incorrectly implemented protective conductor connection for devices with

protection class I, high voltages can be present at open, exposed parts, which when

touched, can result in death or severe injury.

• Ground the device in compliance with the applicable regulations.

When opening plug connections in operation, arcs can result in severe injury or death.

• Only open plug connections when the equipment is in a no-voltage state, unless it has

been explicitly stated that they can be opened in operation.

Fire and smoke development can cause severe personal injury or material damage.

• Install devices without a protective housing in a metal control cabinet (or protect the

device by another equivalent measure) in such a way that contact with fire is prevented.

• Ensure that smoke can only escape via controlled and monitored paths.

Converter with control units CU250D-2

14 Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

Page 15

Fundamental safety instructions

WARNING

Danger to life through unexpected movement of machines when using mobile wireless

devices or mobile phones

WARNING

Danger to life due to the motor catching fire in the event of insulation overload

WARNING

Danger to life due to fire if overheating occurs because of insufficient ventilation clearances

WARNING

Danger of an accident occurring due to missing or illegible warning labels

1.1 General safety instructions

Using mobile wireless devices or mobile phones with a transmit power > 1 W closer than

approx. 2 m to the components may cause the devices to malfunction, influence the

functional safety of machines therefore putting people at risk or causing material damage.

• Switch the wireless devices or mobile phones off in the immediate vicinity of the

components.

There is higher stress on the motor insulation through a ground fault in an IT system. If the

insulation fails, it is possible that death or severe injury can occur as a result of smoke and

fire.

• Use a monitoring device that signals an insulation fault.

• Correct the fault as quickly as possible so the motor insulation is not overloaded.

Inadequate ventilation clearances can cause overheating of components with subsequent

fire and smoke. This can cause severe injury or even death. This can also result in

increased downtime and reduced service lives for devices/systems.

• Ensure compliance with the specified minimum clearance as ventilation clearance for

the respective component.

Missing or illegible warning labels can result in accidents involving death or serious injury.

• Check that the warning labels are complete based on the documentation.

• Attach any missing warning labels to the components, in the national language if

necessary.

• Replace illegible warning labels.

Converter with control units CU250D-2

Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

15

Page 16

Fundamental safety instructions

NOTICE

Device damage caused by incorrect voltage/insulation tests

WARNING

Danger to life when safety functions are inactive

Note

Important safety notices for Safety Integrated functions

If you want to use Safety In

Safety Integrated manuals.

WARNING

Danger to life or malfunctions of the machine as a result of incorrect or changed

parameterization

1.1 General safety instructions

Incorrect voltage/insulation tests can damage the device.

• Before carrying out a voltage/insulation check of the system/machine, disconnect the

devices as all converters and motors have been subject to a high voltage test by the

manufacturer, and therefore it is not necessary to perform an additional test within the

system/machine.

Safety functions that are inactive or that have not been adjusted accordingly can cause

operational faults on machines that could lead to serious injury or death.

• Observe the information in the appropriate product documentation before

commissioning.

• Carry out a safety inspection for functions relevant to safety on the entire system,

including all safety-related components.

• Ensure that the safety functions used in your drives and automation tasks are adjusted

and activated through appropriate parameterizing.

• Perform a function test.

• Only put your plant into live operation once you have guaranteed that the functions

relevant to safety are running correctly.

tegrated functions, you must observe the safety notices in the

As a result of incorrect or changed parameterization, machines can malfunction, which in

turn can lead to injuries or death.

• Protect the parameterization (parameter assignments) against unauthorized access.

• Respond to possible malfunctions by applying suitable measures (e.g. EMERGENCY

STOP or EMERGENCY OFF).

Converter with control units CU250D-2

16 Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

Page 17

Fundamental safety instructions

1.2

Safety instructions for electromagnetic fields (EMF)

WARNING

Danger to life from electromagnetic fields

1.3

Handling electrostatic sensitive devices (ESD)

NOTICE

Damage through electric fields or electrostatic discharge

1.2 Safety instructions for electromagnetic fields (EMF)

Electromagnetic fields (EMF) are generated by the operation of electrical power equipment

such as transformers, converters or motors.

People with pacemakers or implants are at a special risk in the immediate vicinity of these

devices/systems.

• Ensure that the persons involved are the necessary distance away (minimum 2 m).

Electrostatic sensitive devices (ESD) are individual components, integrated circuits, modules

or devices that may be damaged by either electric fields or electrostatic discharge.

Electric fields or electrostatic discharge can cause malfunctions through damaged

individual components, integrated circuits, modules or devices.

• Only pack, store, transport and send electronic components, modules or devices in their

original packaging or in other suitable materials, e.g conductive foam rubber of

aluminum foil.

• Only touch components, modules and devices when you are grounded by one of the

following methods:

– Wearing an ESD wrist strap

– Wearing ESD shoes or ESD grounding straps in ESD areas with conductive flooring

• Only place electronic components, modules or devices on conductive surfaces (table

with ESD surface, conductive ESD foam, ESD packaging, ESD transport container).

Converter with control units CU250D-2

Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

17

Page 18

Fundamental safety instructions

1.4

Industrial security

Note

Industrial security

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, solutions, machines, equipment and/or networks. They are

important components in a holistic industrial secur

products and solutions undergo continuous development. Siemens recommends strongly

that you regularly check for product updates.

For the secure operation of Siemens products and solutions, it is necessary to take su

preventive action (e.g. cell protection concept) and integrate each component into a holistic,

state

also be considered. For more information about industrial sec

(

To stay informed about product updates as they occur, sign up for a product

newsletter. For more information, visi

(

WARNING

Danger as a result of unsafe operating states resulting from software manipulation

1.4 Industrial security

ity concept. With this in mind, Siemens’

itable

-of-the-art industrial security concept. Third-party products that may be in use should

urity, visit Hotspot-Text

http://www.siemens.com/industrialsecurity).

-specific

t Hotspot-Text

http://support.automation.siemens.com).

Software manipulation (e.g. by viruses, Trojan horses, malware, worms) can cause unsafe

operating states to develop in your installation which can result in death, severe injuries

and/or material damage.

• Keep the software up to date.

You will find relevant information and newsletters at this address

(http://support.automation.siemens.com).

• Incorporate the automation and drive components into a holistic, state-of-the-art

industrial security concept for the installation or machine.

You will find further information at this address

(http://www.siemens.com/industrialsecurity).

• Make sure that you include all installed products into the holistic industrial security

concept.

Converter with control units CU250D-2

18 Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

Page 19

Fundamental safety instructions

1.5

Residual risks of power drive systems

1.5 Residual risks of power drive systems

The control and drive components of a drive system are approved for industrial and

commercial use in industrial line supplies. Their use in public line supplies requires a

different configuration and/or additional measures.

These components may only be operated in closed housings or in higher-level control

cabinets with protective covers that are closed, and when all of the protective devices are

used.

These components may only be handled by qualified and trained technical personnel who

are knowledgeable and observe all of the safety instructions on the components and in the

associated technical user documentation.

When assessing the machine's risk in accordance with the respective local regulations (e.g.,

EC Machinery Directive), the machine manufacturer must take into account the following

residual risks emanating from the control and drive components of a drive system:

1. Unintentional movements of driven machine components during commissioning,

operation, maintenance, and repairs caused by, for example,

– Hardware and/or software errors in the sensors, control system, actuators, and cables

and connections

– Response times of the control system and of the drive

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– Parameterization, programming, cabling, and installation errors

– Use of wireless devices/mobile phones in the immediate vicinity of the control system

– External influences/damage

2. In the event of a fault, exceptionally high temperatures, including an open fire, as well as

emissions of light, noise, particles, gases, etc. can occur inside and outside the inverter,

e.g.:

– Component failure

– Software errors

– Operation and/or environmental conditions outside the specification

– External influences/damage

Inverters of the Open Type/IP20 degree of protection must be installed in a metal control

cabinet (or protected by another equivalent measure) such that contact with fire inside

and outside the inverter is not possible.

Converter with control units CU250D-2

Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

19

Page 20

Fundamental safety instructions

Note

The components must be protected against conductive contamination (e.g. by installing them

in a control cabinet with degree of protection IP54 according to IEC 60529 or NEMA 12).

Assuming that conductive contamination at the installation site can definitely be excluded, a

lower degree of cabinet protection may be permitted.

1.5 Residual risks of power drive systems

3. Hazardous shock voltages caused by, for example,

– Component failure

– Influence during electrostatic charging

– Induction of voltages in moving motors

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– External influences/damage

4. Electrical, magnetic and electromagnetic fields generated in operation that can pose a

risk to people with a pacemaker, implants or metal replacement joints, etc., if they are too

close

5. Release of environmental pollutants or emissions as a result of improper operation of the

system and/or failure to dispose of components safely and correctly

For more information about residual risks of the components in a drive system, see the

relevant sections in the technical user documentation.

Converter with control units CU250D-2

20 Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

Page 21

2

2.1

About this manual

Who requires the operating instructions and what for?

What is described in the operating instructions?

What is the meaning of the symbols in the manual?

An operating instruction starts here.

This concludes the operating instru

The subsequent text is applicable for an operator panel.

Th

Exampl

The description of the corresponding inverter function starts with one

of these symbols.

See also:

These operating instructions primarily address fitters, commissioning engineers and machine

operators. The operating instructions describe the devices and device components and

enable the target groups being addressed to install, connect-up, set, and commission the

converters safely and in the correct manner.

These operating instructions provide a summary of all of the information required to operate

the converter under normal, safe conditions.

The information provided in the operating instructions has been compiled in such a way that

it is sufficient for all standard applications and enables drives to be commissioned as

efficiently as possible. Where it appears useful, additional information for entry level

personnel has been added.

The operating instructions also contain information about special applications. Since it is

assumed that readers already have a sound technical knowledge of how to configure and

parameterize these applications, the relevant information is summarized accordingly. This

relates, e.g. to operation with fieldbus systems and safety-related applications.

e following text applies if you are using a PC with STARTER.

es of the inverter-function symbols

Overview of the converter functions (Page 111).

ction.

Converter with control units CU250D-2

Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

21

Page 22

Introduction

2.2

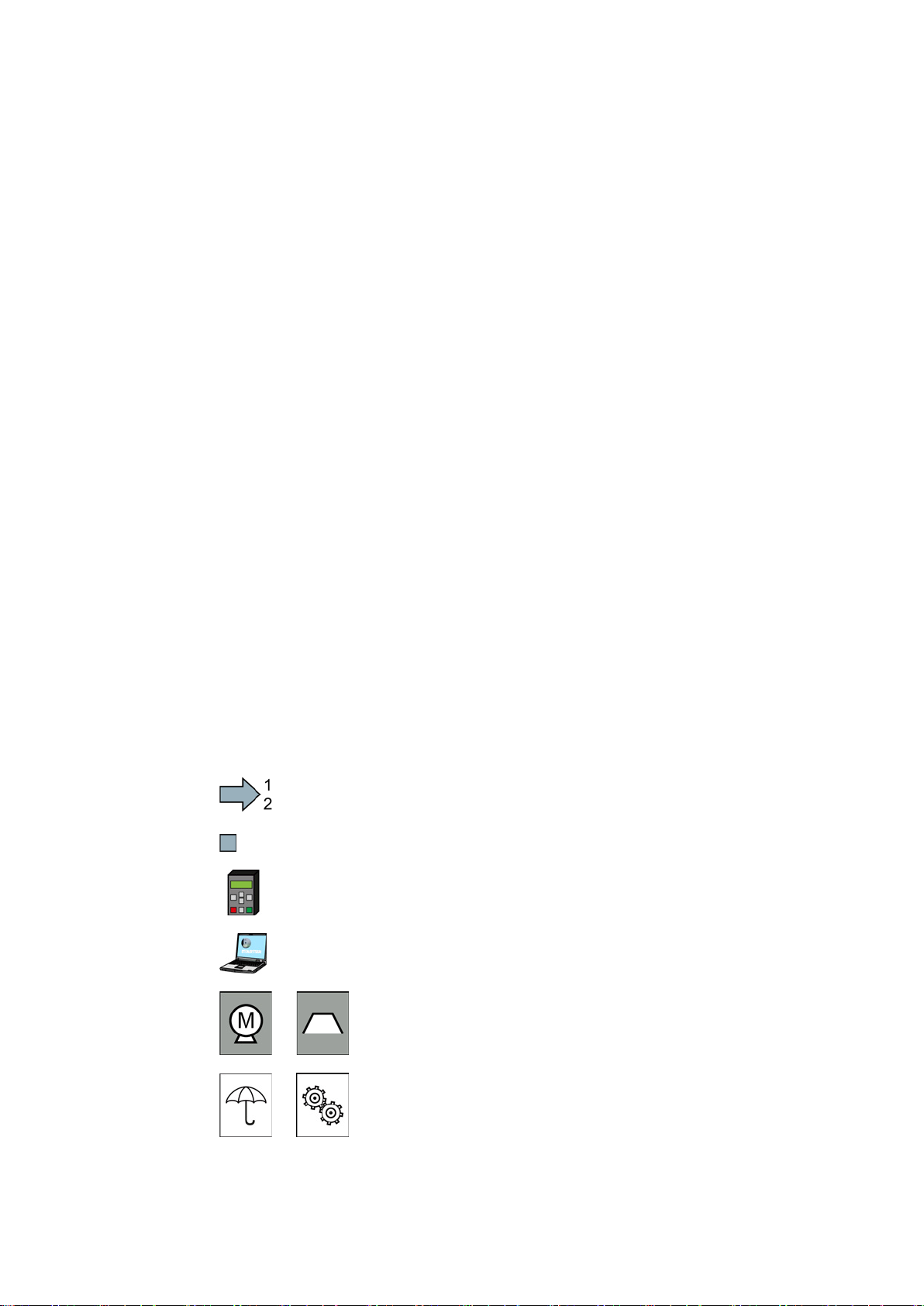

Guide through this manual

①

Inverter components and accessories.

Permissible motors.

Tools for commissioning.

②

Install and wire the inverter and its components.

Install the inverter in accordance with EMC.

③

Prepare for commissioning.

Restore the inverter to factory settings.

Define the inverter’s basic settings.

④

Adjust the function of the inputs and outputs.

⑤

Configure communication via PROFIBUS or PROFINET.

Communicati

"Fieldbus" function manual; see also:

support (Page 371).

⑥

Set up the funct

and protection functions.

⑦

Backup the inverter’s settings to an external data storage

medium, e.g. a memory card or an operator panel.

⑧

Replace the inverter and its components.

Firmware update.

⑨

Meaning of the LEDs on the front of the inverter.

System runtime.

Faults and warnings.

⑩

The most important technical data of the inverter.

⑪

Setting up the new inverter functions.

Application examples.

2.2 Guide through this manual

on using other fieldbuses can be found in the

ions, e.g. setpoint processing, motor control

Manuals and technical

Converter with control units CU250D-2

22 Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

Page 23

3

Use for the intended purpose

3.1

SINAMICS G120D CU250D-2 Inverter

Overview

Designation

Interface

Encoder type

Order number

SSI Absolute Encoder

Push-Pull connections

The inverter described in this manual is a device for controlling an induction motor. The

inverter is designed for installation in electrical installations or machines.

It has been approved for industrial and commercial use on industrial networks. Additional

measures have to be taken when connected to public grids.

The technical specifications and information about connection conditions are indicated on

the rating plate and in the operating instructions.

The SINAMICS G120D is a converter for controlling the position of a drive. The converter

consists of two parts, the Control Unit (CU) and the Power Module (PM).

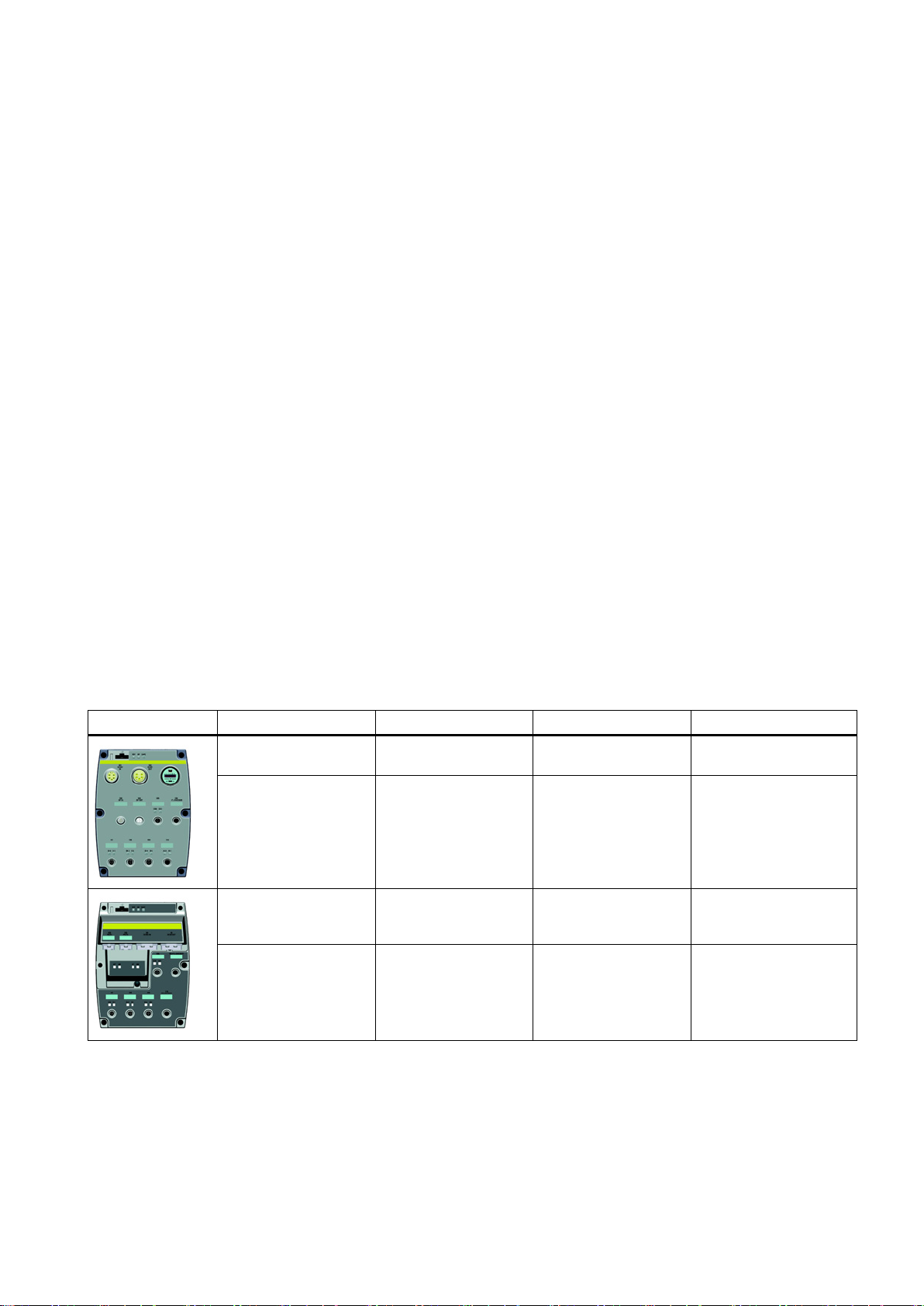

Table 3- 1 CU250D-2 Control Units

CU250D-2 DP-F PROFIBUS HTL Encoder

CU250D-2 PN-F PROFINET,

CU250D-2 PN-F PP PROFINET,

CU250D-2 PN-F FO PROFINET,

EtherNet/IP

EtherNet/IP

EtherNet/IP

Fibre optic connections

HTL Encoder

SSI Absolute Encoder

HTL Encoder

SSI Absolute Encoder

HTL Encoder

SSI Absolute Encoder

6SL3546-0FB21-1PA0

6SL3546-0FB21-1FA0

6SL3546-0FB21-1FB0

6SL3546-0FB21-1FC0

Converter with control units CU250D-2

Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

23

Page 24

Description

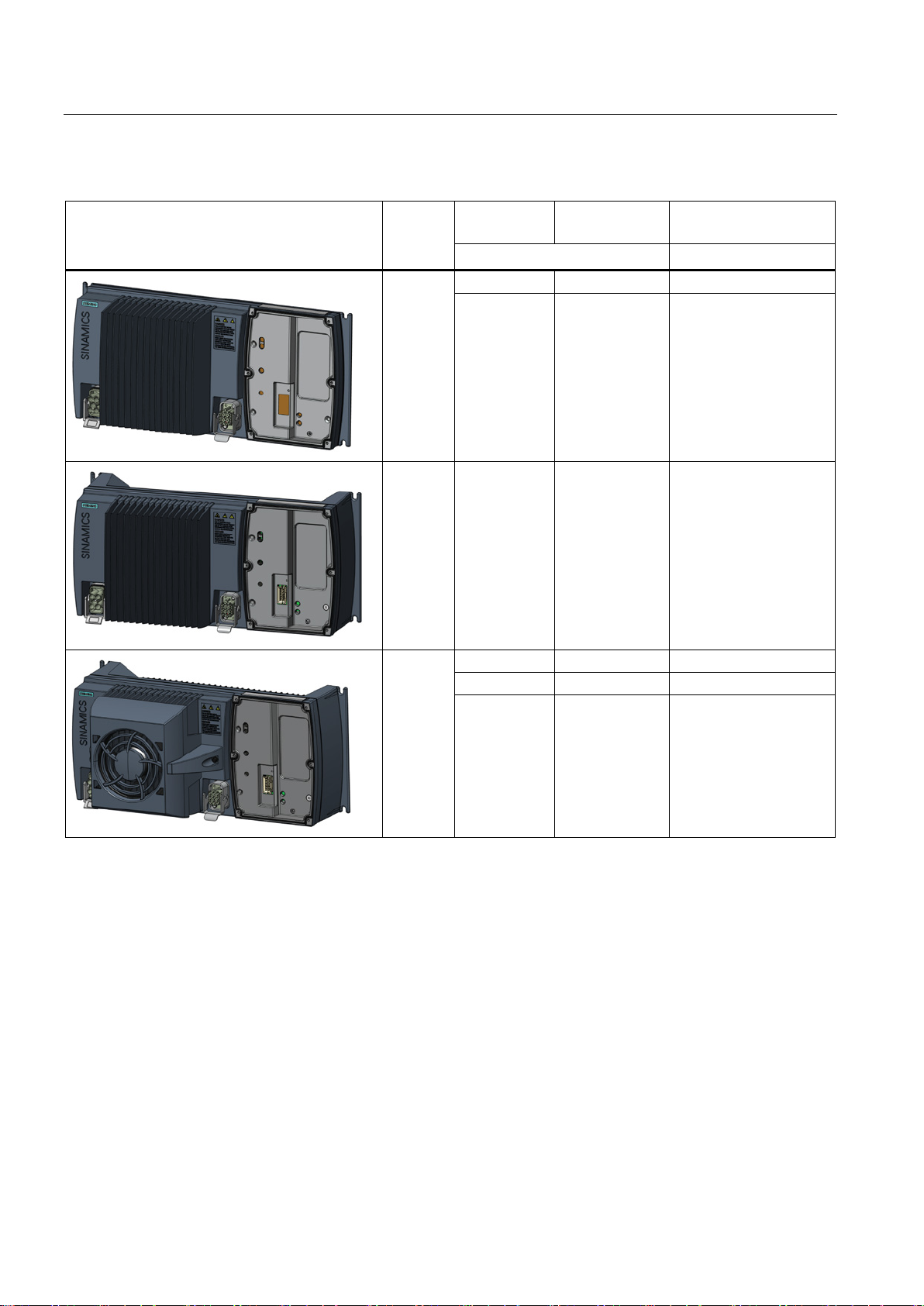

Frame

size

Rated output

power

Rated output

current

Order number

based on High Overload (HO)

0.75 kW

2.2 A

6SL3525-0PE17-5AA1

4.0 kW

10.2 A

6SL3525-0PE24-0AA1

5.5 kW

13.2 A

6SL3525-0PE25-5AA1

3.1 SINAMICS G120D CU250D-2 Inverter

Table 3- 2 PM250D Power Modules

FSA

1.5 kW 4.1 A 6SL3525-0PE21-5AA1

FSB 3.0 kW 7.7 A 6SL3525-0PE23-0AA1

FSC

7.5 kW 19.0 A 6SL3525-0PE27-5AA1

Converter with control units CU250D-2

24 Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

Page 25

Description

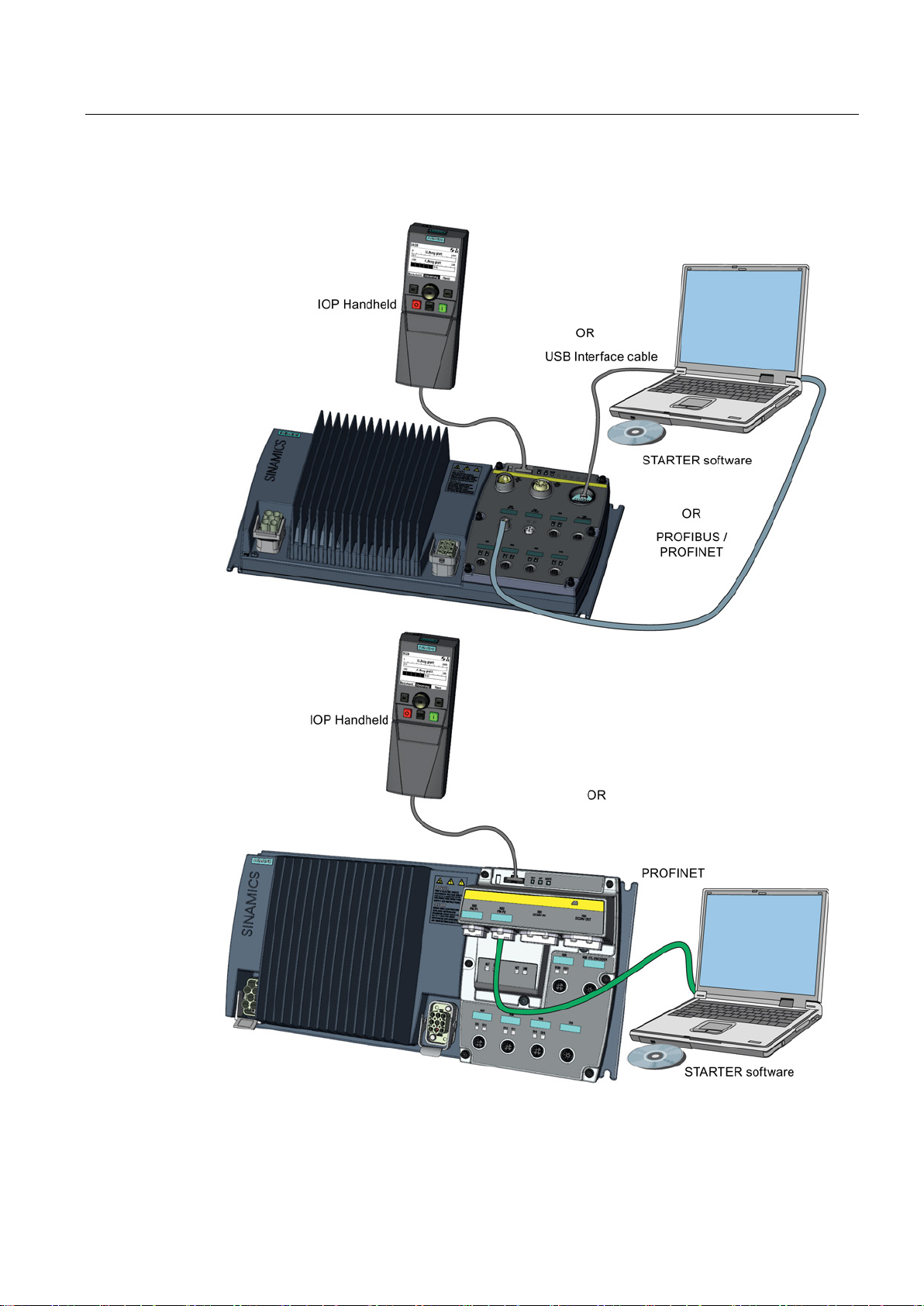

3.2

Commissioning tools

3.2 Commissioning tools

Figure 3-1 Commissioning tools - PC or IOP Handheld Kit

Converter with control units CU250D-2

Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

25

Page 26

Description

Component or tool

Order number

Operator Panel

IOP Handheld

6SL3255-0AA00-4HA0

ns.com/WW/view/en/26233208)

PC Connection Kit

Comprising USB cable (3 m).

6SL3255-0AA00-2CA0

Memory cards

3.2 Commissioning tools

Table 3- 3 Components and tools for commissioning

STARTER Commissioning tool (PC

software)

You obtain STARTER on a DVD

(Order number: 6SL30720AA00-0AG0)

and it can be downloaded:

Download STARTER

(http://support.automation.sieme

The following memory cards are available as medium to back up converter settings:

● Card without firmware: Order No. 6SL3054-4AG00-2AA0.

● Card with firmware: Order No. 6SL3054-7Ex00-2BA0.

The digit at position x designates the firmware version:

4.6 ≙ EG, 4.7 ≙ EH

Converter with control units CU250D-2

26 Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

Page 27

Description

3.3

Supported motor series

SIMOTICS GP, SIMOTICS SD IEC motors

SIMOTICS M main motors

en/84049346).

On request: Encoderless permanently excited

synchronous motors SIMOTICS S

Motors from other manufacturers

3.3 Supported motor series

The inverter is designed for the following motor series:

1LG6, 1LA7, 1LA9 and 1LE1 standard induction

motors

Multi-motor drive is permissible, i.e. multiple

motors operated on one inverter. See also: Multimotor drive

(http://support.automation.siemens.com/WW/view/

1FK7 synchronous motors

1PH8 induction motors

Standard induction motors

Converter with control units CU250D-2

Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

27

Page 28

Description

3.3 Supported motor series

Converter with control units CU250D-2

28 Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

Page 29

4

4.1

Mechanical Installation

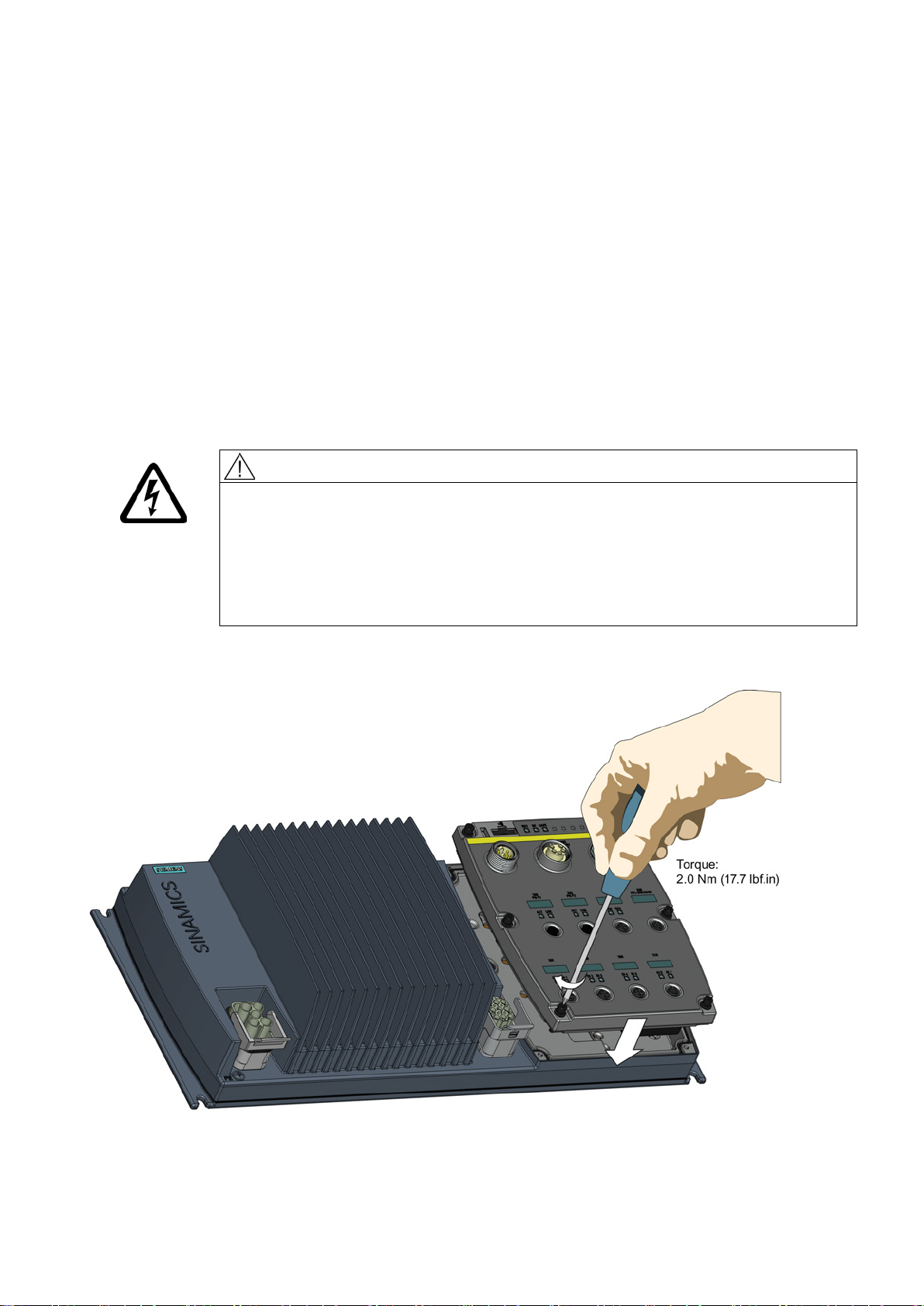

Fitting the Control Unit to the Power Module

CAUTION

Seals fitted correctly

TN and TT mains supplies

The inverter is delivered as two separate components - the Power Module (PM) and the

Control Unit (CU). The CU must be fitted to the PM prior to any further commissioning taking

place.

It is important that when assembling the Power Module and the Control Unit that all the

seals are fitted correctly to ensure IP65 rating.

The SINAMICS PM250D Power Module with the Class A integrated mains filter is only

suitable for operation on TN and TT mains supplies.

The CU is fitted to the PM as shown in the diagram below.

Figure 4-1 Fitting the Control Unit to the Power Module

Converter with control units CU250D-2

Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

29

Page 30

Installation

4.1.1

Drill pattern SINAMICS G120D

Drill pattern and dimensions

4.1 Mechanical Installation

The inverter has an identical drill pattern for all frame sizes. The drill pattern, depth and

tightening torques are shown in the diagram below.

Figure 4-2 SINAMICS G120D drill pattern

Converter with control units CU250D-2

30 Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

Page 31

Installation

Mounting orientation

Restrictions due to vertical mounting

4.1 Mechanical Installation

Mount the converter on a table or on a wall. The minimum clearance distances are as

follows:

● Side-by-side - no clearance distance is required

● Above and below the inverter 150 mm (5.9 inches).

Figure 4-3 Mounting orientation: correct (✓), impermissible (X), permissible with restrictions (!)

If the converter is mounted in the vertical position, the maximum ambient temperature is

40°C.

Additionally you have to reduce the converter output current to 80 % of rated converter

current.

If the output current derating adversely affects the application, you have to use an converter

of the next highest power rating.

Converter with control units CU250D-2

Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

31

Page 32

Installation

4.2

Electrical Installation

NOTICE

Material damage from inappropriate supply system Vt > 1%

4.2.1

Permissible line supplies

Operation on an IT line system is not permitted.

Operation on TN and TT line systems

TN line system

TT system

Prohibited operation

4.2 Electrical Installation

Operating the converter on an inappropriate supply system can cause damage to the

converter and other loads.

• Only operate the converter on supply systems with V

≤ 1%.

t

In an IT line system, all of the conductors are insulated with respect to the PE protective

conductor – or connected to the PE protective conductor through an impedance.

Operation on IT line systems is not permitted.

The TN line system in accordance with IEC 60364-1 (2005) transmits the PE conductor to

the installation via a conductor.

Generally, in a TN line system the neutral point is grounded. There are versions of a TN line

supply with a grounded line the conductor, e.g. with grounded L1.

A TN line system can transfer the neutral conductor N and the PE protective conductor either

separately or combined.

In a TT line system, the transformer grounding and the installation grounding are

independent of one another.

There are TT line supplies where the neutral conductor N is either transferred – or not.

Operation of the inverter on the TN and TT line system

The inverter is designed for TN and TT line systems with a grounded neutral point

Above an installation altitude of 2000 m, the permissible line supplies are restricted. See

also: Current and voltage derating dependent on the installation altitude (Page 330).

● Operation on TN line systems with grounded external conductors is prohibited.

● Operation on TT line systems without grounded neutral points is prohibited.

Converter with control units CU250D-2

32 Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

Page 33

Installation

4.2.2

Electrical data

Power Module specifications - 3AC 380 V ... 500 V ± 10 %

Product

Frame size

Rated output

HO

Fuse

Rated output

current

Rated input

current

3NA3…

6SL3525-…

kW A A A Type

0PE17-5AA1

A

0.75

2.2

2.1

10

803-

0PE21-5AA1

A

1.5

4.1

3.8

10

803-

0PE23-0AA1

B 3 7.7

7.2

16

805-

0PE24-0AA1

C 4 10.2

9.5

20

807-

0PE25-5AA1

C

5.5

13.2

12.2

20

807-

0PE27-5AA1

C

7.5

19

17.7

32

812-

Standby current

Converter

Standby current (A)

50 Hz

60 Hz

380 V

400 V

415 V

380 V

440 V

480 V

0.75 - 1.5 kW

0.6

0.63

0.66

0.7

0.8

0.91

3.0 - 4.0 kW

2.2

2.32

2.40

2.7

3.2

3.33

5.5 - 7.5 kW

2.9

3.05

3.15

3.5

4.0

4.40

Brake voltage

4.2 Electrical Installation

Table 4- 1 Rated Output, Input and Fuses

If the converter is powered-up, but the motor is still switched off, the converter requires a

standby current.

You have to consider the standby current when calculating the size of the conductors and

selecting the correct protective devices on the line supply.

Table 4- 2 Standby currents of the converter

For more comprehensive information on the standby current, please read the following FAQ:

Standby currents for PM250D

(http://support.automation.siemens.com/WW/view/en/31764702)

The brake voltage of 180 V DC is suitable for brakes which require 400 V AC with rectifier.

Remove the rectifier module and connect the brake output of the converter directly to the

brake coil.

The UL approved current rating for the brake output is 600 mA.

Converter with control units CU250D-2

Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

33

Page 34

Installation

4.2.3

Basic EMC Rules

Measures to limit Electromagnetic Interference (EMI)

Cables

Cable shields

4.2 Electrical Installation

Listed below are the necessary measures that must be taken to ensure the correct

installation of the Inverter within a system, which will minimize the effect of EMI.

● Keep all cable lengths to the minimum possible length; avoid excessive cable lengths.

● Route always signal and data cables, as well as their associated equipotential bonding

cables, in parallel and with as short a distance as possible.

● Don't route signal and data cables and line supply cables in parallel to motor cables.

● Signal and data cables and line supply cables should not cross motor cables; if crossing

is necessary, they should cross at an angle of 90 °.

● Shield signal and data cables.

● Route particularly sensitive signal cables, such as setpoint and actual value cables, with

optimum shield bonding at both ends and without any interruptions of the shield.

● Ground spare wires for signal and data cables at both ends.

● Route all power cables (line supply cables, as well as motor cables) separately from

signal and data cables. The minimum distance should be approximately 25 cm.

Exception: hybrid motor cables with integrated shielded temperature sensor and brake

control wires are allowed.

● Shield the power cable between inverter and motor. We recommend shielded cables with

symmetrical three-phase conductors (L1, L2, and L3) and an integrated, 3-wire, and

symmetrically arranged PE conductor.

● Use shielded cables with finely stranded braided shields. Foil shields are not suitable

since they are much less effective.

● Connect shields to the grounded housings at both ends with excellent electrical

conductivity and a large contact area.

● Bond the cable shields to the plug connectors of the inverter.

● Don't interrupt cable shields by intermediate terminals.

● In the case of both, the power cables and the signal and data cables, the cable shields

should be connected by means of suitable EMC shield clips or via electrically conductive

PG glands. These must connect the shields to the shield bonding options for cables and

the unit housing respectively with excellent electrical conductivity and a large contact

area.

● Use only metallic or metallized connector housings for shielded data cables (e. g.

PROFIBUS cables).

Converter with control units CU250D-2

34 Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

Page 35

Installation

4.2.4

Overview of the interfaces

Interfaces of the converter

①

Digital inputs 0 … 5 with status LED

⑧

HTL Encoder connection

②

PROFIBUS)

⑨

③

⑩

Unit

④

handheld

⑪

⑤

Converter status LED

⑫

PE grounding terminal

⑥

termination switch for PROFIBUS

⑬

⑦

⑭

connections

4.2 Electrical Installation

Fieldbus IN and OUT (PROFINET or

24 V DC supply IN and OUT

Optical interface for operator panel IOP

USB PC connection, address and bus

Digital outputs 0 and 1 with status LED

Figure 4-4 Interfaces on the converter variants

Converter with control units CU250D-2

Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

SSI Encoder connection

Slot for a memory card at rear of the Control

PROFINET status LED

Mains supply connection

Motor, brake and temperature sensor

35

Page 36

Installation

4.2.5

Connections and cables

DANGER

Danger of electrical shock by touching the pins in the motor terminal box

NOTICE

Damage of the converter by disconnecting the motor during operation

Connectors

"Switched" and "unswitched" 24 V power supply

4.2 Electrical Installation

The temperature sensor and motor holding brake connections are at DC link negative

potential. Touching the pins in the motor terminal box can lead to death due electrical

shock.

• Keep the motor terminal box closed whenever the mains is applied to the converter.

• Insulate the cables that are not used.

• Use appropriate insulation on the cables.

The disconnection of the motor cable by a switch or contactor during operation may

damage the converter.

• Disconnect converter and motor during operation only if it is necessary in terms of

personal security or machine protection.

The unswitched 24 V power supply (1L+) is required for the device to function.

The switched 24 V (2L+) supplies the two digital outputs. Switching brings all of the actuators

connected to the digital outputs into the no-voltage state.

If you don't need the switching of 2L+ power supply, then both the switched as well as the

non-switched 24 V may come from the same supply.

Converter with control units CU250D-2

36 Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

Page 37

Installation

4.2 Electrical Installation

Figure 4-5 G120D CU250D-2 PROFIBUS connectors

Converter with control units CU250D-2

Operating Instructions, 04/2014, FW V4.7, A5E34261542B AA

37

Page 38

Installation

4.2 Electrical Installation

Figure 4-6 G120D CU250D-2 PROFINET connectors

Converter with control units CU250D-2