Page 1

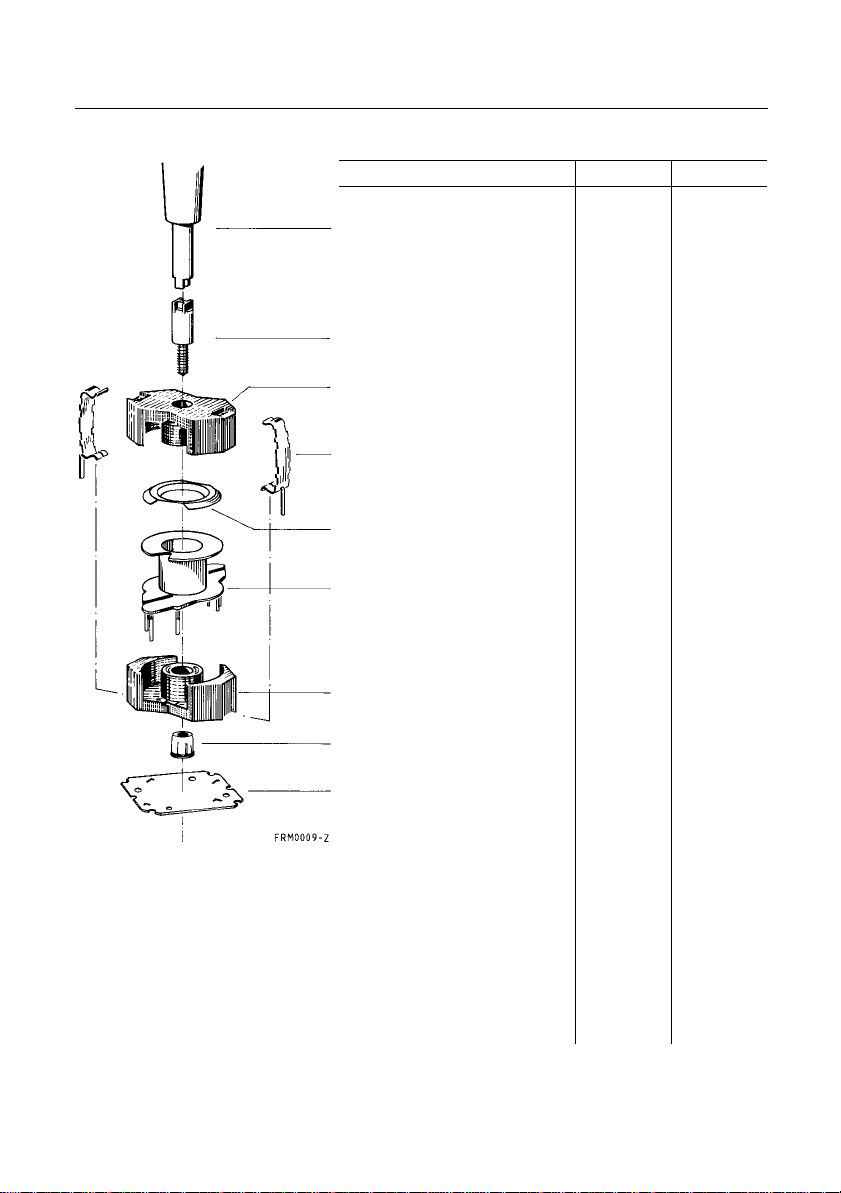

RM 4

Core and Accessories

Individual parts Part no. Page

Adjusting screwdriver

(for assembly only)

Matching handle B63399 189

Adjusting screw B65539 189

Core B65803 185

Clamps B65806 188

Insulating washer 1 B65804 188

Coil former B65804 187

Core B65803 185

Threaded sleeve

(glued-in)

Insulating washer 2 B65804 188

B63399 189

Example of an assembly set

Also available: RM 4 low profile:

Core B65803-P 193

Coil former B65804 194

Clamp B65804 195

Insulating washer 1 + 2 B65804 195

SMD coil former B65804 196

184 Siemens Matsushita Components

Page 2

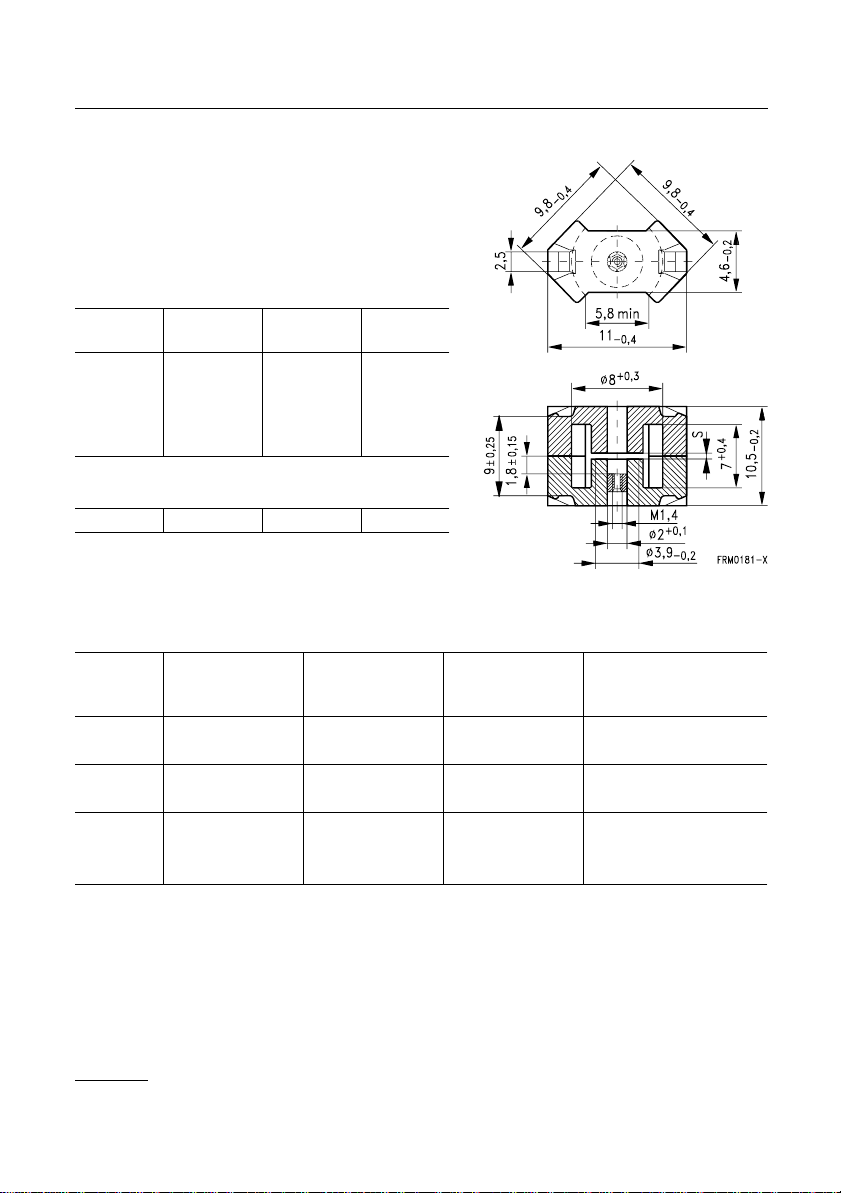

RM 4

Core

● In accordance with IEC 60431

● Core without center hole

for transformer applications

● RM cores are supplied in sets

Magnetic characteristics (per set)

with

center hole

Σ

l/A

l

e

A

e

A

min

V

e

1,9

21

11

232

Approx. weight (per set)

m

1,45 1,65 g

Gapped

Material

A

value

L

nH

K1 16 ± 3 % 1,0 24,2 B65803-+16-A1

25 ± 3 % 0,40 37,8 B65803-+25-A1

M33 40 ± 3 % 0,36 60,4 B65803-+40-A33

63 ± 3 % 0,18 95 B65803-+63-A33

N48 63 ± 3 % 0,16 95 B65803-+63-A48

100 ± 3 % 0,10 151 B65803-+100-A48

160 ± 3 % 0,06 242 B65803-+160-A48

without

center hole

1,7

22

13

11,3

286

s

approx.

mm

mm

mm

mm

mm

mm

–1

2

2

3

µ

e

Ordering code

1)

-A with center hole

-N with threaded sleeve

B65803

1) Replace the + by the code letter “A” or “N” for the required version.

Siemens Matsushita Components 185

Page 3

RM 4

Core B65803

Ungapped

Material

A

value

L

µ

A

L1min

P

V

e

Ordering code

nH

nH

W/set

-J w/o center hole

N30 1900 + 30/– 20 % 2570 B65803-J-R30

T35 2800 + 40/– 30 % 3790 B65803-J-Y35

T38 3700 + 40/– 30 % 5000 B65803-J-Y38

N49 750 + 30/– 20 % 1010 450 0,04

B65803-J-R49

(50 mT, 500 kHz, 100 °C)

N87 1100 + 30/– 20 % 1480 650 0,20

B65803-J-R87

(200 mT, 100 kHz, 100 °C)

186 Siemens Matsushita Components

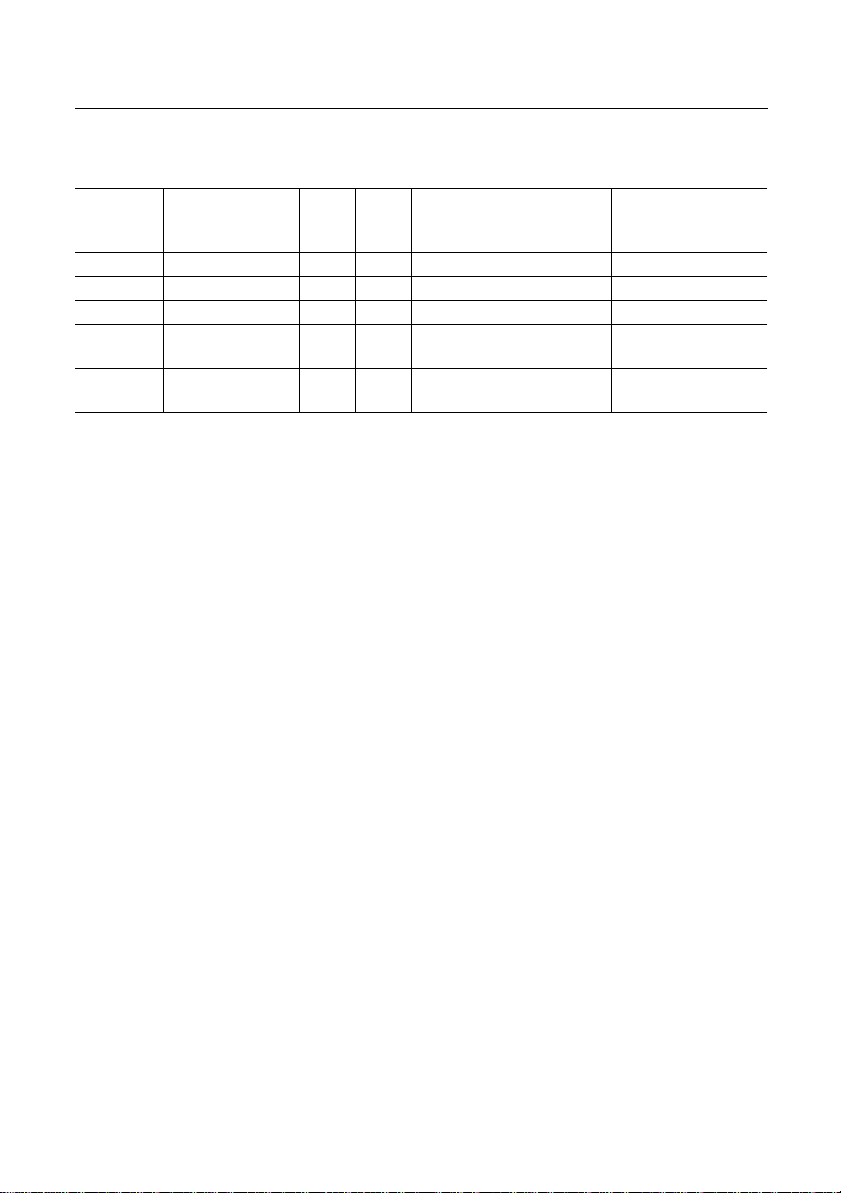

Page 4

RM 4

Accessories

Coil former

Material: GFR thermosetting plastic (UL 94 V-0, insulation class to IEC 60085:

H max. operating temperature 180 °C), color code black

Solderability: to IEC 60068-2-20, test Ta, method 1 (aging 3): 235 °C, 2 s

Resistance to soldering heat: to IEC 60068-2-20, test Tb, method 1B: 350 °C, 3,5 s

Winding: see page 152

Squared pins

For matching clamp and insulating washers see page188

B65804

Sections

A

mm

N

2

l

N

mm

A

valueµΩPins Ordering code

R

1 8,7 20,1 80 5 B65804-N1005-D1

6 B65804-N1006-D1

2 8,1 20,1 85 5 B65804-N1005-D2

6 B65804-N1006-D2

5 pins 6 pins

0,6+0,1

6

4+0,15

5

3

ø4,9 0,1

0,42±0,050,65±0,05

0,17,65

_

_

6,85 0,1

0,45

Hole arrangement

Lochgrupppen

View in mounting direction

Ansicht in Montagerichtung

1

2

4,4±0,3

0,2

6

1

5

4

2

3

__

0,2ø7,9

0,4±0,05

ø1+0,1

2,54

_

10

Erdungspunkte ø1,3+0,1

Ground Ø 1,3+0,1

FRM0264-E

50

Siemens Matsushita Components 187

Page 5

RM 4

Accessories

B65804

B65806

Clamp

● With ground terminal, made of stainless spring steel (tinned), 0,335 mm thick

● Solderability to IEC 60068-2-20, test Ta, method 1 (aging 3): 235 °C, 2 s

● Also available as strip clamp on reels

Insulating washer 1 between core and coil former

● For tolerance compensation and for insulation

● Made of polycarbonate (UL 94 V-0, insulation class to IEC 60085: E 120 °C), 0,06 mm thick

Insulating washer 2 for double-clad PCBs

● Made ofpolycarbonate (UL 94 V-0, insulation class to IEC 60085: E 120 °C), 0,3 mm thick

Ordering code

Clamp (ordering code per piece, 2 are required) B65806-A2203

Insulating washer 1 (reel packing, PU = 1 reel) B65804-A5000

Insulating washer 2 (bulk) B65804-C2005

Clamp Insulating washer 1 Insulating washer 2

Clamping forces for RM 4

F

: Extension of clamp froma to

min

F

: Extension of clamp froma to

max

a

=

X

2

min

a

=

X

1

max

Clamp openinga (mm) 8,3 + 0,15

Core nose

Height of core pairX (mm)

Clamping forceF (N)

Z

(mm) 0,15

max

X

X

F

F

min

max

min

max

8,75

9,25

5

40

188 Siemens Matsushita Components

Page 6

RM 4

Accessories

Adjusting screw

● Tube core with thread and core brake made of GFR polyterephthalate

Plastic adjusting screwdriver (not shown)

Plastic handle for adjusting screwdriver (not shown)

Core RM 4 Adjusting screw Min.

Tube core

Material

K 1 16 1,81 × 2,0 Si 1 black 20 B65539-C1003-X101

M 33 40 1,81 × 2,0 Si 1 black 17 B65539-C1003-X101

N 48 63 1,81 × 2,0 Si 1 black 12 B65539-C1003-X101

Adjusting screwdriver B63399-B4

Handle B63399-B5

A

valuenH∅× lengthmmMaterial Color

L

25 1,81 × 2,0 K 1 yellow 21 B65539-C1003-X1

63 1,81 × 2,0 K 1 yellow 21 B65539-C1003-X1

100 1,81 × 2,0 K 1 yellow 17 B65539-C1003-X1

160 1,81 × 2,7 N 22 red 12 B65539-C1002-X22

code

adjusting

range

%

Ordering code

B65539

B63399

Adjusting screw

Siemens Matsushita Components 189

Page 7

RM 4

Inductance adjustment curves (nominal values)

Relative inductance change ∆

0 at least 1 turn engaged.

L/L

versus turnsNof adjusting screw.

Adjusting screw B65539-C1003-X101

Color code black

Adjusting screw B65539-C1002-X22

Color code red

Adjusting screw B65539-C1003-X1

Color code yellow

190 Siemens Matsushita Components

Page 8

B

B

RM 4

Q factor characteristics (typical values)

Material

K 1 25 nH 5,20

M 33 63 nH 770

A

L

valueLµH

183

Turns Wire; RF litz wire Sec-

14

2,65

1,27

10

7

100

52

54,5

29

45 × 0,04 CuLS

0,5 CuL

0,6 CuL

20 × 0,04 CuL

45 × 0,04 CuL

90 × 0,04 CuL

tions∅*mm

1

1

1

1

1

1

6,6

6,6

6,4

—

—

—

RF litz wire

Enamel copper

wire

K 1

A

= 25 nH

L

Flux density

in the core

< 0,5 mT

M 33

A

= 63 nH

L

Flux density

in the core

< 1 mT

Siemens Matsushita Components 191

Page 9

B

RM 4

Q factor characteristics (typical values)

Flux density in the core < 1 mT

Mate-

rial

A

N 48 —

1,00

3,24

9,60

3,25

= 100 nH

L

L

(mH) for Turns Wire; RF litz wire Sec-

A

= 160 nH

L

0,43

1,60

5,18

15,40

5,35

RF litz wire

Enamel copper

wire

52

100

180

310

183

45 × 0,04 CuLS

20 × 0,04 CuLS

0,18 CuL

0,14 CuL

10 × 0,05 CuL

tions

1

1

1

1

1

N 48

A

= 100 nH

L

N 48

A

= 160 nH

RF litz wire

Enamel coppe

wire

L

192 Siemens Matsushita Components

Page 10

RM 4 »Low Profile«

Core

● For compact transformers with high inductance

● Without center hole

● RM cores are supplied in sets

Magnetic characteristics (per set)

A

–1

2

2

3

value

L

µ

A

e

L1min

Σ

l/A

= 1,2 mm

l

= 17,3 mm

e

A

= 14,5 mm

e

A

= 11,3 mm

min

V

= 251 mm

e

Approx. weight 1,2 g/set

Ungapped

Material

B65803-P

P

V

Ordering code

nH

nH

W/set

T38 5000 + 40/– 30 % 4770 B65803-P-Y38

N49 860 + 30/– 20 % 820 630 0,03

B65803-P-R49

(50 mT, 500 kHz, 100 °C)

N87 1300 + 30/– 20 % 1234 950 0,09

B65803-P-R87

(200 mT, 160 kHz, 100 °C)

Siemens Matsushita Components 193

Page 11

RM 4 »Low Profile«

Accessories B65804

Coil former

Material: GFR thermosetting plastic (UL 94 V-0, insulation class to IEC 60085:

H max. operating temperature 180 °C), color code blue

Solderability: to IEC 60068-2-20, test Ta, method 1 (aging 3): 235 °C, 2 s

Resistance to soldering heat: to IEC 60068-2-20, test Tb, method 1B: 350 °C, 3,5 s

Winding: see page 160 (as SMD coil former)

Pins squared in the start-of-winding area

For matching clamp and insualting washers see page195

Sections

A

mm

N

2

l

N

mm

A

valueµΩPins Ordering code

R

1 4,7 20,1 147 6 B65804-R1006-D1

0,6+0,1

6

4+0,15

5

4

0,14,23

_

ø4,9 0,1

0,45±0,05

_

4,98 0,1

0,65±0,05

ø1+0,1

1

2

3

_

0,2ø7,9

_

ø0,52 max.

4,4±0,3

0,45 max.

2,54

_

Ground Ø 1,3+0,1

Erdungspunkte ø1,3+0,1

FRM0265-M

50

10

Hole arrangement

View in mounting direction

194 Siemens Matsushita Components

Page 12

RM 4 »Low Profile«

Accessories

Clamp

● With and without ground terminal, made of stainless spring steel, 0,3 mm thick, clamp with

ground terminal tinned

● Solderability to IEC 60068-2-20, test Ta, method 1 (aging 3): 235 °C, 2 s

● Clamping force 40 N per pair of clamps (typical value)

● Also available as strip clamp on reels on request

Insulating washer 1 between core and coil former

● For tolerance compensation and for insulation

● Made of polycarbonate (UL 94 V-0, insulation class to IEC 60085: E 120 °C), 0,06 mm thick

Insulating washer 2 for double-clad PCBs

● Made of polycarbonate (UL 94 V-0, insulation class to IEC 60085: E 120 °C), 0,3 mm thick

Ordering code

Clamp with ground terminal (ordering code per piece, 2 are required) B65804-P2203

Clamp without ground terminal (ordering code per piece, 2 are required) B65804-P2204

Insulating washer 1 (reel packing, PU = 1 reel) B65804-A5000

Insulating washer 2 (bulk) B65804-C2005

Clamp with ground terminal Clamp without ground terminal

B65804

Insulating washer 1 Insulating washer 2

Siemens Matsushita Components 195

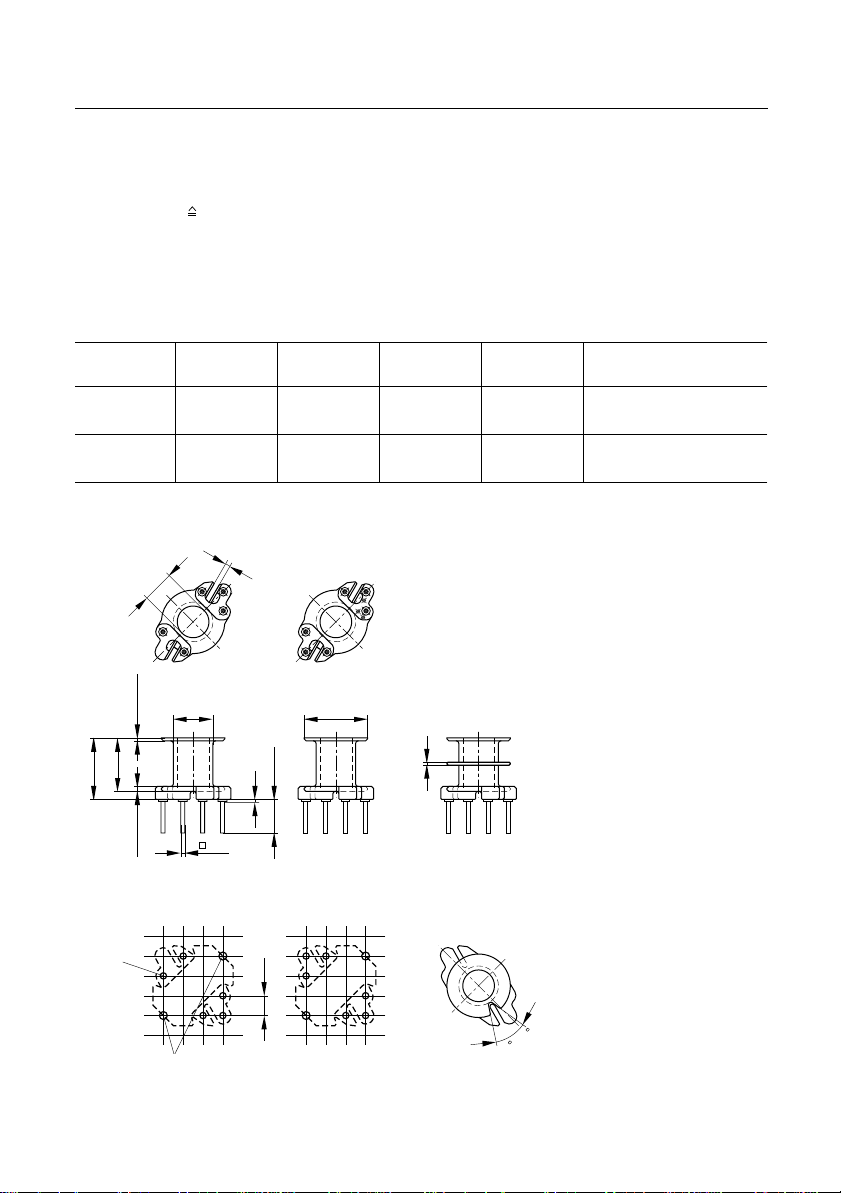

Page 13

RM 4 »Low Profile«

Accessories B65804

SMD coil former with J terminals

Material: GFR liquid crystal polymer (UL 94 V-0, insulation class to IEC 60085:

F max. operating temperature 155 °C), color code black

Solderability: to IEC 60068-2-20, test Ta, method 1 (aging 3): 235 °C, 2 s

Resistance to soldering heat: to IEC 60068-2-20, test Tb, method 1B: 350 °C, 3,5 s

permissible soldering temperaturefor wire-wrapconnection on coil former: 400 °C,1s

Winding: see page 160

Clamp

● Without ground terminal, made of stainless spring steel, 0,3 mm thick

● Also available as strip clamp (each carton containing 2 reels), also on a reel on request

Sections

A

mm

N

2

l

N

mm

A

valueµΩTermi-

R

nals

1)

Ordering code

1 5,0 20,1 138 10 B65804-B6010-T1

2 4,4 20,1 157 10 B65804-B6010-T2

Clamp (ordering code per piece, 2 are required) B65804-P2204

Coil former Clamp

1 section 2 sections

Recommended

PCB layout

1) 6 and 8 terminals on request

196 Siemens Matsushita Components

Loading...

Loading...