Page 1

Sitras ASG25

1- and 2-pole air-insulated switchgear

for AC traction power supply

siemens.com/rail-electrication

The Sitras ASG25® air-insulated switchgear is intended for use in 1- and 2-pole

AC traction power supply systems. It is a type-tested, metal-enclosed switchgear

for indoor installation.

The general concept of the SitrasASG25 is based on a proven technology

offering high reliability and availability. It provides long lifetime, high number of

operating cycles, long lasting insulation properties and low life-cycle costs

Features

• High personnel safety

• High fire safety

• Environment-friendly: minimum use of materials listed in directives

67/548/EEC and 2001/59/EC

• Low life-cycle costs

• High availability

• Fast and easy replacement of the vacuum circuit-breaker by use of

tulip contacts

Page 2

Design

Mechanical design

Frame

• The base frame, door and outer walls are made of screw/

rivet connected steel sheets with 2 mm thickness

• Hinged plates (pressure relief flaps) are installed on top

for pressure relief in case of internal arc faults

• Doors and side walls are painted; galvanized steel sheets

are used for all other parts

Busbars

• Busbars are supported by standard cast-resin post

insulators and bushings

• Busbars can be easily connected by links after cubicle

arrangement on site

• Partitioning of busbar compartment by insulating plate

and bushing

• Busbars can be earthed (see option 9 on page 6)

D

High voltage compartment

• Pressure resistant inspection windows for

− visible position of disconnector and earthing switch

− status indication of vacuum circuit-breaker (ON/OFF,

proven spring charging technology, operation counter)

• Insulating protection plate for safe maintenance while

busbar is energized

Low voltage compartment

Control cables for external connections are led from the

bottom to the low voltage compartment via cable duct or

through flange plate at the top.

All wirings may be provided in non-halogen variants on

request.

Service truck

Thanks to the plug-in / plug-out technology with tulip

contacts, the vacuum circuit-breaker can be fast and conveniently replaced using the easy to handle service truck.

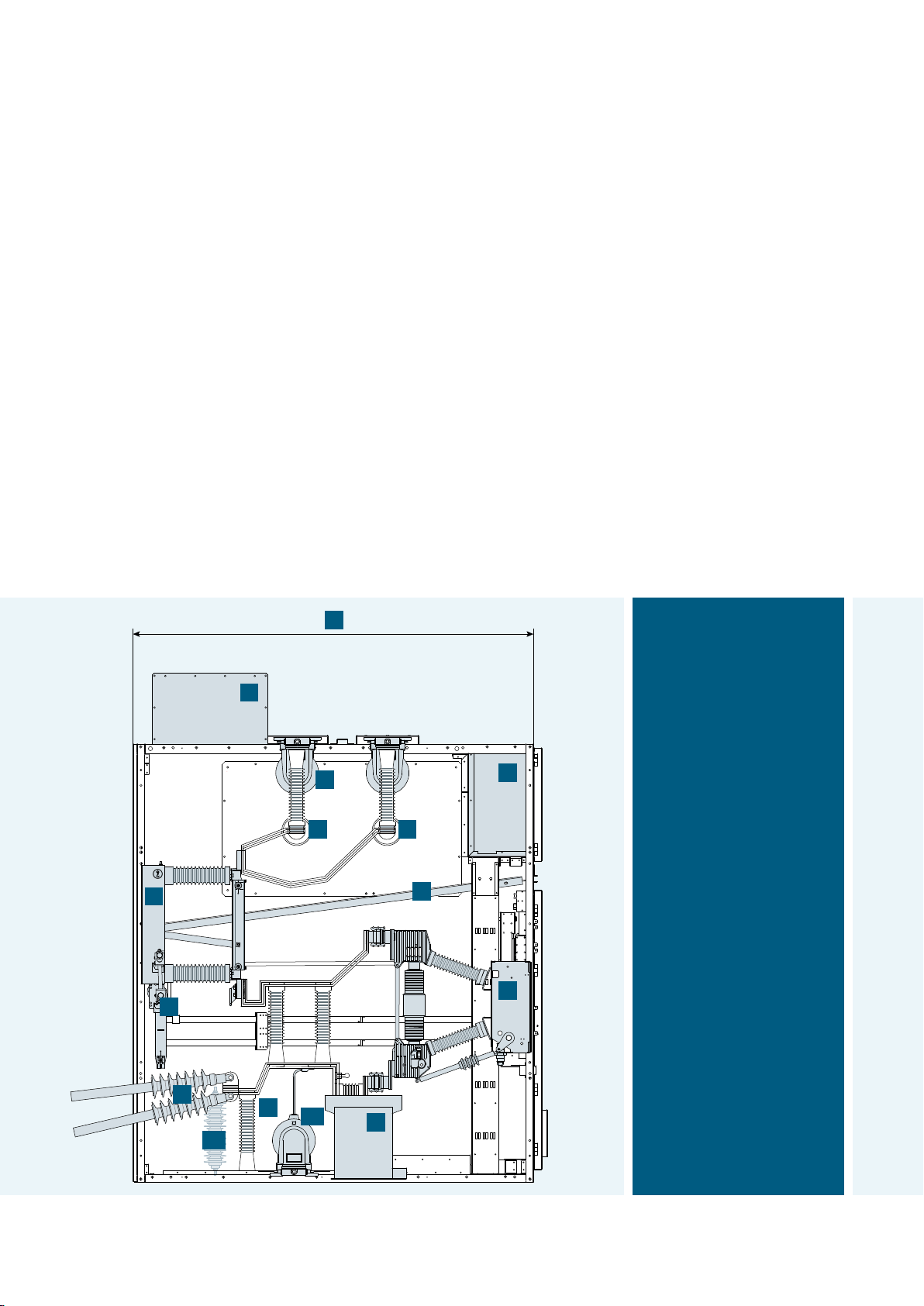

P

9

1 1

2

3

7

12

6

11

B

5

L

1 Busbar

2 Disconnector

3 Earthing switch

4 Vacuum circuit-breaker

5 Current transformer

6 Capacitive voltage detection

system

7 Cable sealing end from rear

(Option)

9 Busbar voltage transformer

(Option)

4

11 Voltage transformer (Option)

12 Surge arrester (Option)

L Low voltage compartment

P Pressure relief channel

B Bearing for insulating

protection plate

D Depth

H1 Height switchgear

H2 Height pressure relief channel

W1 Width 1-pole version

W2 Width 2-pole version

Schematic layout of Sitras ASG25 (shown example: 2-pole version with option cable sealing end from rear)

2

Page 3

Electrical design

Cable connections

• Cable connections from bottom up to 4 x 500 mm² per

feeder

• Cable connections from rear available as an option

• Surge arrester available as an option

High voltage compartment

• Switching devices

− vacuum circuit-breaker, motor operated

− disconnector and earthing switch, manual or motor

operated

− manual emergency operation possible for all switching

devices

• Interlocking between vacuum circuit-breaker,

disconnector and earthing switch

• Measurement transformers for control and protection

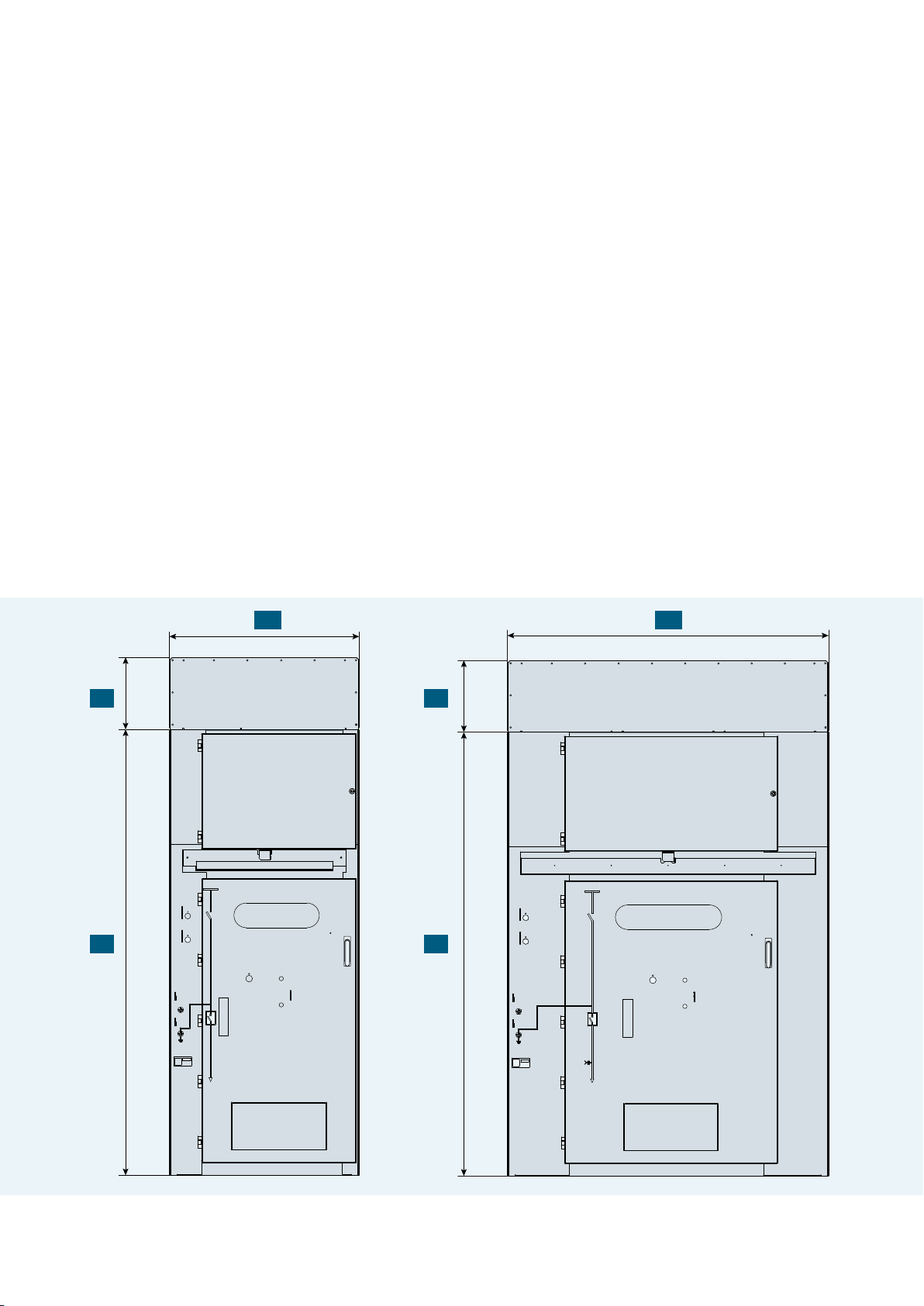

W1

Low voltage compartment

• Protection relay and user interface are installed in the

door of the low voltage compartment

• Miniature circuit-breakers and auxiliary relays are

located inside the low voltage compartment

• Connection between the vacuum circuit-breaker and the

low voltage compartment is made via a 64-pin plug

and-socket arrangement

W2

H2 H2

H1 H1

Front view of Sitras ASG25: 1-pole version (left) and 2-pole version (right)

3

Page 4

Main components

Vacuum circuit-breaker, type 3AH47

Switching capacity

• Switching sequence:

O - 0.3 s - CO - 3 min - CO (other values on request,

multiple auto-reclosing possible)

• Rated short-circuit breaking-current 25 kA with

DC component < 36 %

Operating mechanism

• Service life of 60,000 operating cycles

(maintenance-free up to 10,000 operating cycles, without time limitation under normal operating conditions)

Vacuum interrupter

• Mechanical service life of 30,000 operating cycles (main-

tenance-free)

• Electrical service life dependent on breaking current (see

diagram below)

Disconnector, type 3DA11 / 3DB11

• Service life of 10,000 operating cycles

• Integrated earthing switch, service life of 10,000

operating cycles

• Manual operating mechanism with mechanical interlock

between disconnector and earthing switch and electromagnetic interlock

• Motor-operated mechanism with electrical interlock

(option)

Function

• CLOSED: Main circuit closed between busbar and

circuit-breaker

• OPEN: Main circuit open between busbar and

circuit-breaker

• READY-TO-EARTH: Upper contact of circuit-breaker

earthed; earthing of cable by closing the circuit-breaker

Current and voltage transformer

• Cast resin type for indoor installation

• Service life ≥ 30 years

• Maintenance-free

100000

30000

10000

Permissible operating cycles –>

1000

100

50

30

10

1

1 10 502 5 25 100

Breaking current in kA (r.m.s. value) –>

Electrical service life of vacuum interrupter Sitras ASG25 2-pole version with vacuum circuit-breaker

on a service truck

4

Page 5

Technical data

Electrical data

Variant 1-pole 2-pole

Nominal voltage acc. to IEC 60850, EN 50163 [kV] 25 25

Rated insulation voltage acc. to EN 50124-1 [kV] 27.5 27.5

Rated frequency [Hz] 50 / 60 50 / 60

Rated short duration power frequency withstand voltage

to earth and across open contacts

across isolating distance

Rated lightning impulse withstand voltage

to earth and across open contacts

across isolating distance

Rated short-circuit breaking current [kA] 25 25

Rated short-time withstand current, 1 s [kA] 25 25

Rated short-circuit making current [kA] 63 63

Rated normal current [A] 1,250 / 2,000 1,250 / 2,000

Internal arc classification acc. to IEC 62271-200 IAC A FL I

LSC category / partition class LSC 2A / PI LSC 2A / PI

other values on request

[kV]

[kV]

[kV]

[kV]

25 kA 1 s IAC A FL IAe 25 kA 1 s

Ae

95

110

200

220

95

110

200

220

Mechanical data

Variant 1-pole 2-pole

Dimensions approx.

Height switchgear panel H1

Height pressure relief channel H2

Width W1 / W2

Depth D

Weight per panel [kg] approx. 1,100 approx. 1,600

Degree of protection IP4X IP4X

Permissible ambient temperature [°C] -5…+40 -5…+40

Relative humidity (non condensing) < 85 % < 85 %

General standards IEC 62271-1; IEC 62271-200 IEC 62271-1; IEC 62271-200

Standards for railway applications EN 50124; EN 50152 EN 50124; EN 50152

other values on request

[mm]

[mm]

[mm]

[mm]

2,350

380

1,000

2,150

2,350

1,700

2,150

380

5

Page 6

Application

Application examples for 1-pole version*

Section feeder panel Bus coupler panel

1

2

3

4

5

11 12 14

7

Standard equipment

Standard equipment

1 Busbar

2 Disconnector

3 Earthing switch

4 Vacuum circut-breaker

5 Current transformer

6 Capacitive voltage detection system

7 Cable sealing end

8 Voltage transformer

Optional busbar fittings

9 Busbar voltage transformer

10 Earthing switch

Optional connection fittings

11 Voltage transformer

12 Surge arrester

13 Current transformer

14 Capacitive voltage detection system

15 High-voltage fuse

Options

109

and/or and/or

and/or

1

2

3

4

Standard equipment

Metering panel

1

2

3

8

9

13

and/or

13 14

Options

10

15

* other panel types on request

6

Standard equipment

Options

Page 7

Application examples for 2-pole version*

Incoming & section feeder panel / Autotransformer panel

1

2

3

4

5

6

7

Standard equipment

Options 11, 12 only for incoming and section feeder panel

9 10

11

Options

and/or and/or

12

Section feeder panel

1

2

3

4

5

6

7

Standard equipment

9

11

Options

and/or

12

Bus coupler panel

1

2

3

4

Standard equipment

9

13

and/or

13 14

Options

Metering panel

1

2

3

8

Standard equipment

10

15

Options

7

Page 8

© Siemens Mobility GmbH 2020

All rights reserved

Sitras ASG25 / Product information

No.A6Z08110273695 / Version 2.0.3

Siemens Mobility GmbH

Otto-Hahn-Ring 6

81739 Munich

Germany

For further information please contact:

Siemens Mobility GmbH

Rail Infrastructure

Electrification

Mozartstraße 33b

91052 Erlangen

Germany

electrification.mobility@siemens.com

www.siemens.com/rail-electrification

Subject to changes and errors. The information given in this document only contains general

descriptions and/or performance features which may not always specifically reflect those

described, or which may undergo modification in the course of further development of the

products. The requested performance features are binding only when they are expressly

agreed upon in the concluded contract.

Loading...

Loading...