Page 1

Arnold

ARCADIS Avantic

Startup

System

SP

Start-up Instructions

1004768010048590

Print No.:

Replaces: SPR2-330.815.01.02.02

SPR2-330.815.01.03.02

© Siemens AG

The reproduction, transmission or use

of this document or its contents is not

permitted without express written

authority. Offenders will be liable for

damages. All rights, including rights

created by patent grant or registration

of a utility model or design, are

reserved.

English

Doc. Gen. Date: 12.06

2006

Page 2

2 Revision / Disclaimer

1Revision / Disclaimer

Document revision level

The document corresponds to the version/revision level effective at the time of system

delivery. Revisions to hardcopy documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified

personnel who are employed by Siemens or one of its affiliates or who are otherwise

authorized by Siemens or one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated

with or authorized by Siemens or one of its affiliates are directed to contact one of the

local offices of Siemens or one of its affiliates before attempting installation or service procedures.

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 2 of 66

Medical Solutions

Page 3

Table of Contents 3

0Table of Contents

1 _______ General Information______________________________________________ 5

Notes and symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Additionally Required Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General safety information (in existing documents) . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General electrical safety information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Radiation safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Systems equipped with an I.I. laser light localizer or a single tank laser light localizer.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Systems equipped with an integrated I.I. laser light localizer . . . . . . . . . . . . . . . . . . 10

Information on the protective conductor resistance test . . . . . . . . . . . . . . . . . . . . . . 11

System leakage current measurement information . . . . . . . . . . . . . . . . . . . . . . . . . 13

Tools, aids (partially for IQ test) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Note on the log book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Notes on adapting the power plug to local conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Note on the power connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2 _______ General Startup ________________________________________________ 23

Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Measuring the local line voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Adapting the programmed system line voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Function check of the EMERGENCY STOP switches . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Functional checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Functional test of C-arm lift movement and parking brakes . . . . . . . . . . . . . . . . . . . . . . 27

3 _______ Specific System Settings ________________________________________ 28

System configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Note regarding Hibernation Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Customer and country-specific configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Service login: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Customer address configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Main system configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Fluoroscopy footswitch configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Country-specific adaptation of the maximum tube current . . . . . . . . . . . . . . . . . . . . 37

Configuring the network (optional) and remote service . . . . . . . . . . . . . . . . . . . . . . 40

Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4 _______ Final Work Steps _______________________________________________ 45

Paper printer (optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Codonics printer 1660L. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Sony printer UP-D72 X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Sony Printer UP-970 and UP-990. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Final Work Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

IQ test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Completing protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 3 of 66

Page 4

4 Table of Contents

Protective conductor resistance test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Leakage current measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Completing the "ARCADIS Avantic Installation" protocol. . . . . . . . . . . . . . . . . . . . . . 51

5 _______ Protocols______________________________________________________ 52

Protective Conductor Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Measuring circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Remarks: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

System leakage current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Measuring circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Remarks: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

C-arm movement and emergency stop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Network checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6 _______ Changes to Previous Version _____________________________________ 65

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 4 of 66

Medical Solutions

Page 5

General Information 5

Notes and symbols 0

1- 1General Information

Emphasized text in this technical documentation has the following meanings:

Tab. 1 GEFAHR / DANGER

Bei einer unmittelbar drohenden Gefahr, die bei Nichtvermeidung

zum Tod oder zu einer schweren Körperverletzung führt.

Indicates when there is an immediate danger that leads to death

or serious physical injury.

Tab. 2 WARNUNG / WARNING

Bei einer Gefahr, die bei Nichtvermeidung zum Tod oder zu einer

schweren Körperverletzung führen kann.

Indicates a risk of danger that may lead to death or serious physical injury.

Tab. 3 VORSICHT / CAUTION

Tab. 4 ACHTUNG / NOTICE

Bei einer Gefahr, die bei Nichtvermeidung zu einer leichten oder

mittleren Körperverletzung und/ oder zu einer Sachbeschädigung führt oder führen kann.

Indicates a risk of danger that leads to slight or moderate physical injury and/or damage to property.

Bei einer Gefahr, die bei Nichtvermeidung zu einem unerwünschten Ergebnis oder Zustand führt oder führen kann (nicht Tod ,

Körperverletzung oder Sachbeschädigung).

Indicates a risk of danger that if disregarded leads or may lead to

a potential situation which may result in an undesirable result or

state (not death, physical injury or property damage).

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 5 of 66

Page 6

6 General Information

Tab. 5 HINWEIS / NOTE

Ist als Tipp zu verstehen. Der Anwender muss diese Anweisung

nicht unbedingt beachten. Er erfährt jedoch Vorteile, wenn er

dies tut.

Should be understood as a tip. The user does not absolutely

have to observe these instructions. However, there will be advantages if he does.

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 6 of 66

Medical Solutions

Page 7

General Information 7

Additionally Required Documents 1.1

• ARCADIS Avantic Operator Manual

• ARCADIS Avantic Wiring Diagram

• IQ test (quality assurance)

• Local printer (optional) assembly and setting instructions

• Image intensifier laser light localizer (optional) assembly and setting instructions

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 7 of 66

Page 8

8 General Information

Safety information 1.2

General safety information (in existing documents) 0

WARNING

Danger of injuries, death or material damage.

Non-compliance can lead to death, injury or material damage.

Please note:

¹ The product-specific safety information in these instruc-

tions,

¹ The general safety information in TD00-000.860.01... and

¹ The safety information in accordance with ARTD Part 2.

General electrical safety information 0

WARNING

Electrical safety!

Non-compliance can lead to severe injury or even death, as well

as material damage.

¹ Parts under electrical voltage are accessible when the

covers are open. To avoid danger, disconnect the system

from the power supply before opening the covers. Disconnect the power plug.

¹ If an uninterruptible power supply (UPS) is installed in

the system, the voltage output of the UPS must also be

deenergized or the voltage output plug must be disconnected.

¹ If work steps must be performed using electrical power,

the general safety information according to

TD00-000.860.01... must be observed.

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 8 of 66

Medical Solutions

Page 9

General Information 9

Avantic basic unit

WARNING

Danger, high voltage!

Disregarding safety precautions can result in death or serious

bodily injury.

¹ Even after the system has been switched off - and for an

extended period afterward, voltage is still present in the

electrolyte condenser battery and the generator boards

(D20, D21 and D30).

¹ Before work is started on the electrolyte condenser bat-

tery, it must must be discharged.

¹ To do this, switch D21.S2 must be set to the UZ_OFF

position; LEDs D21.X22 and D21.X23 must not continue

to glow.

¹ Then the voltage between points X109.UZ_IST(ACT) and

X109.ANA_GND is measured. The voltage must be ≤ 0.2V

(corresponding to Uz < 20V

).

-

Radiation safety information 0

WARNING

X-ray radiation!

Non-compliance can lead to illness, irreversible damage to body

cells and the genotype, severe injury and even death.

During work on the system in which radiation must be released,

the radiation protection directives and the rules for radiation protection according to ARTD-002.731.02.. must be complied with.

Please note:

¹ Use available radiation protection devices.

¹ Wear radiation protection clothing (lead apron).

¹ Stay as far away as possible from the radiation source.

¹ Release radiation only if necessary.

¹ Set the radiation activity as low as possible. (low kV and

mA values, short radiation time)

¹ Release radiation for as short a time as possible.

X ¹ Checks requiring the release of radiation are identified by

the radiation warning symbol shown on the left.

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 9 of 66

Page 10

10 General Information

Systems equipped with an I.I. laser light localizer or a single tank laser light localizer

0

CAUTION

Laser emissions!

This product contains class 2 lasers. (USA: Laser class 2)

Disregarding safety precautions can lead to bodily injury, especially to the retina of the eye, resulting in irreversible damage to

vision.

¹ Observe the safety information in ARTD-002.731.03...

When working with the laser light localizer, do not look

directly into the laser beam.

NOTE

Laser emissions!

There is no direct hazard to the eye (blinking reflex). Nevertheless

do not look directly into the laser beam.

Systems equipped with an integrated I.I. laser light localizer 0

CAUTION

Laser emissions!

This product contains lasers of the class 1M.

Disregarding safety precautions can lead to bodily injury, especially to the retina of the eye, resulting in irreversible damage to

vision.

¹ Observe the safety information in ARTD-002.731.03...

When working with the laser light localizer, do not view

the laser beams directly with optical instruments.

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 10 of 66

Medical Solutions

Page 11

General Information 11

Information on the protective conductor resistance test 0

Observe the instructions in the "Safety Rules for Installation and Repair"

(ARTD-002.731.17 ...).

The protective conductor resistance of 0.2 ohms must not be exceeded.

First measured value

In the case of systems thoroughly tested at the factory prior to delivery, the protective conductor resistance test was already performed and the measured values were recorded in

the system test protocol.

The measurements were performed using the measuring procedures and equipment

recorded in the system test protocol.

The test protocol is included with the accompanying documentation.

If no covers were opened while installing the system and no additional components (e.g.

options) were installed or modified, the values recorded in the test protocol including the

measuring point (e.g. cover of the basic unit or cover of the image intensifier) can be

transferred in the protective conductor resistance protocol as the first measured values.

If the power plug was changed during system installation, covers were removed, or additional components were installed or modified, the values provided in the test protocol are

invalid.

The values must be labeled invalid. Cross out the values, enter the comment "invalid

value" and confirm this with name, date, and signature.

The protective conductor test must be performed again after all work has been completed.

In the case of systems with no measured values for the protective conductor test recorded

in the system test protocol, the protective conductor test must be performed after all work

has been completed.

Measurement

The measurement must be performed in accordance with DIN VDE 0751, Part 1 (refer to

ARTD Part 2). The protective conductor resistance for all touchable conductive parts must

be measured during the normal operating state of the system.

Make sure that control cables or data cables between the components of the system are

not mistaken for protective conductor connections.

During the measurement, the power cable and additional connection cable with the integrated protective conductor (e.g., monitor cable between the basic unit and monitor trolley) must be moved section by section to detect cable breaks.

The protective conductor resistance must not exceed 0.2 ohms.

The values, including the measuring points, must be recorded as first measured values in

the protective conductor resistance protocol.

The measuring procedure and the measuring device used (designation and serial number) must also be documented.

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 11 of 66

Page 12

12 General Information

Separate the page with the protocol from these instructions and file it in the "Protocols"

register in the system binder or log book.

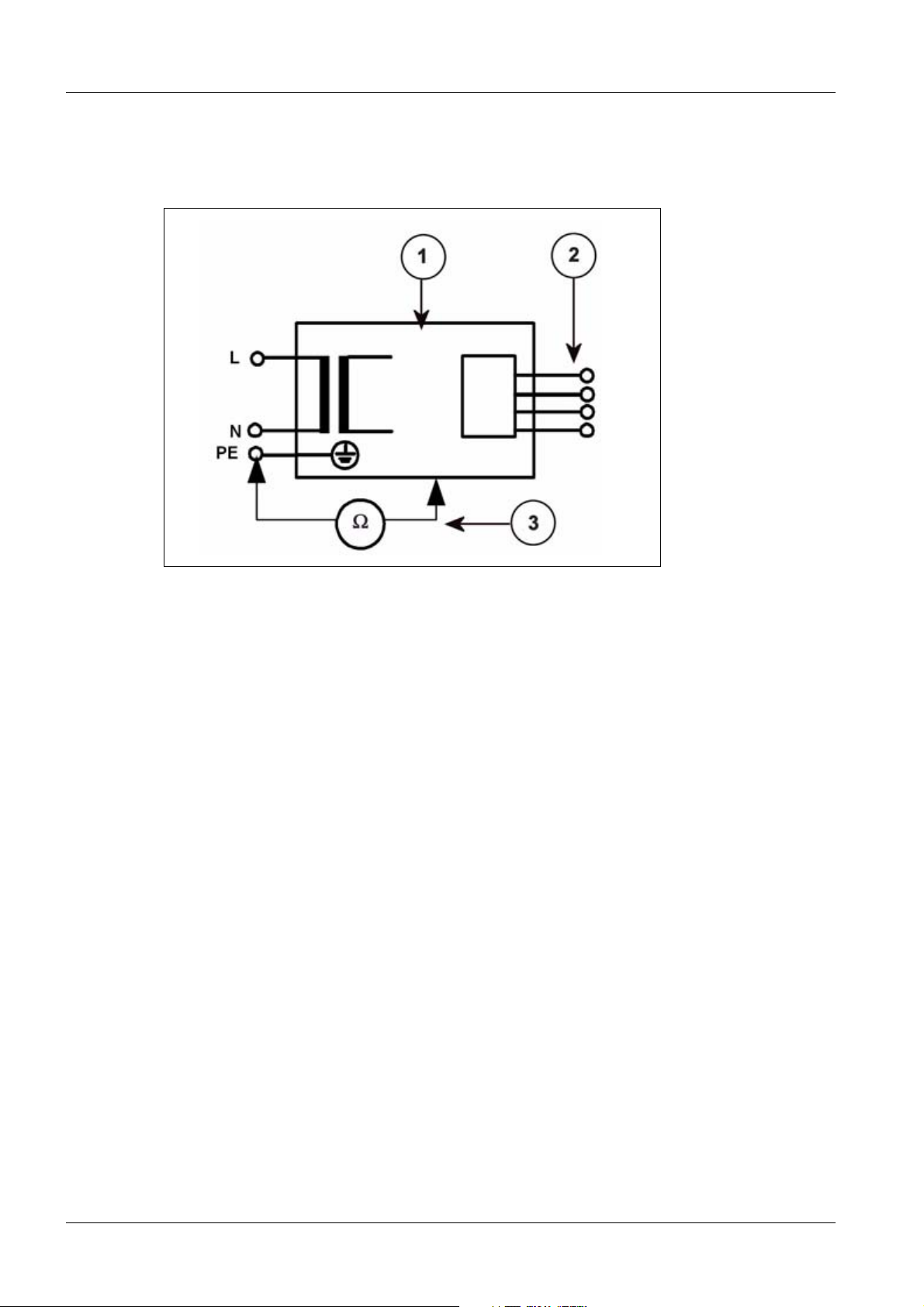

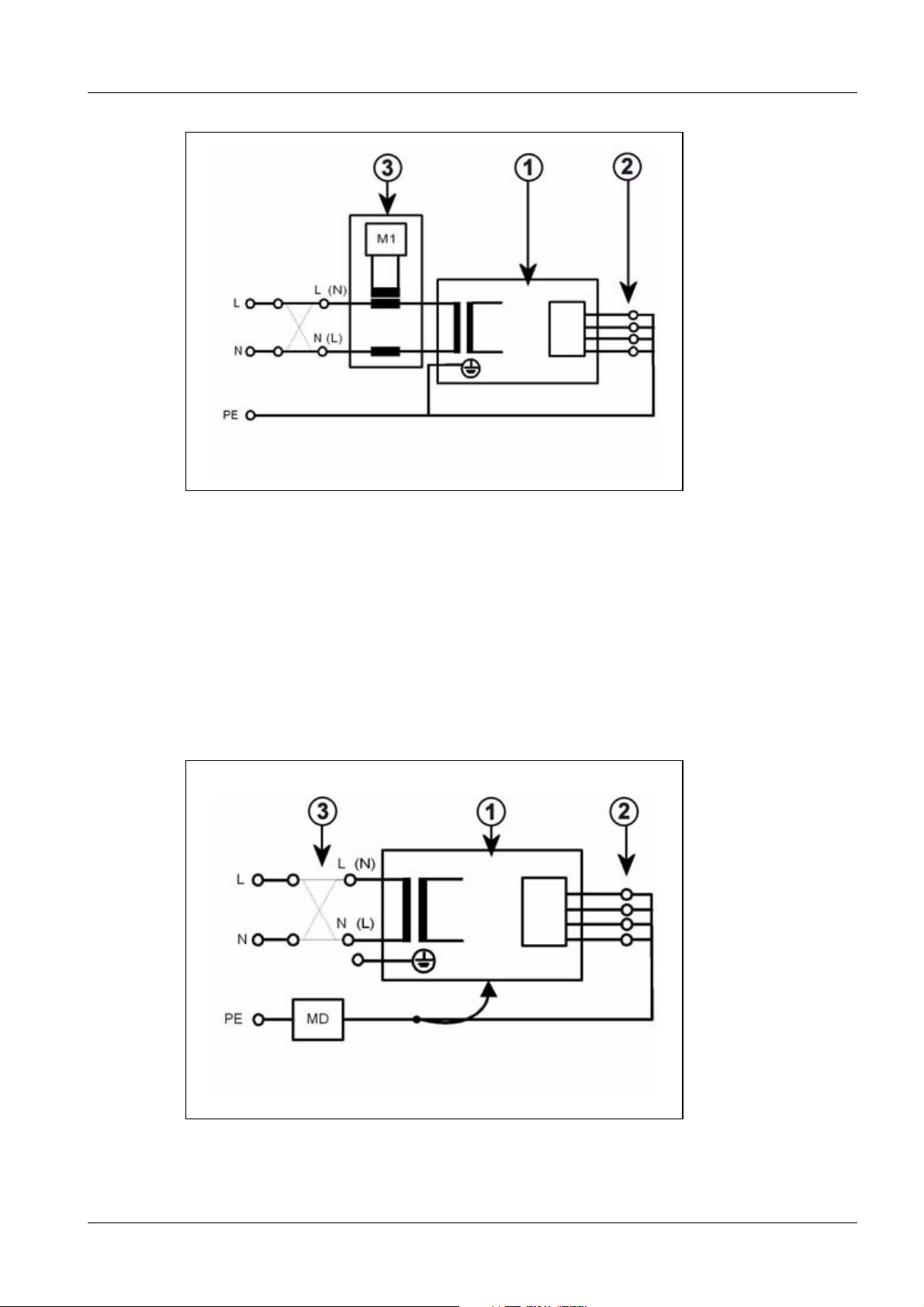

Fig. 1: Measuring circuit for measuring the protective conductor resistance for units that are

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 12 of 66

Medical Solutions

Page 13

General Information 13

disconnected from power, in compliance with DIN VDE 0751-1/2001-10, Fig. C2.

Pos. 1 = Syste m

Pos. 2 = Application part type B (if available)

Pos. 3 = Measurement setup (integrated into measuring device)

Repeat measurement

In the case of maintenance or repairs, perform the protective conductor resistance measurement again.

Document and evaluate the values determined in the repeat measurement.

The measurement must be performed in accordance with DIN VDE 0751, Part 1 (refer to

ARTD Part 2). The protective conductor resistance for all touchable conductive parts must

be measured during the normal operating state of the system.

Make sure that control cables or data cables between the components of the system are

not mistaken for protective conductor connections.

During the measurement, the power cable and additional connection cables with the integrated protective conductor (e.g. monitor cable between the basic unit and monitor trolley)

must be moved section by section to detect cable breaks.

The protective conductor resistance must not exceed 0.2 ohms.

The values determined in the repeat measurement, including the measuring points, must

be recorded and evaluated in the protective conductor resistance protocol.

The measuring procedure and the measuring device used (designation and serial number) must also be documented.

NOTE

For evaluation purposes, the first measured value and the values

documented during previous maintenance or safety checks must

be compared to the measured values. A sudden or unexpected

increase in the measured values may indicate a defect in the protective conductor connections (protective conductor or contacts)

- even if the limit value of 0.2 ohms is not exceeded.

System leakage current measurement information 0

Observe the instructions in the "Safety Rules for Installation and Repair"

(ARTD-002.731.17 ...).

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 13 of 66

Page 14

14 General Information

WARNING

Electrical voltage!

Non-compliance can lead to severe injury and even death.

¹ The system leakage current measurement may be per-

formed on systems of protection class I only after the

protective conductor test has been passed.

First measured value

In the case of systems thoroughly tested at the factory prior to delivery, the system leakage current measurement was already performed at the factory and the measured value

was recorded in the system test protocol.

The measurement was performed using the line voltage and line frequency, the measuring procedure, and the measuring equipment recorded in the system test protocol.

The test protocol is included with the accompanying documentation.

When the line voltage and line frequency match, the value recorded in the test protocol

must be used as the first measured value in the leakage current protocol.

If the local line voltage or line frequency differs from the delivery state of the system or if

no measurement was performed and recorded at the factory, the system leakage current

must be measured.

If the local line voltage or line frequency differs from the delivery state of the system, the

values listed in the test protocol are invalid.

The values must be labeled invalid. The reason for newly determining the first measured

value must be documented and confirmed with date, name, and signature.

Adjust/program the system to the local line voltage/line frequency before the measurement.

In the case of systems without a system leakage current measurement value recorded in

the system test protocol, the system leakage current measurement must be performed

after all work has been completed.

Measurement

Perform the measurement according to DIN VDE 0751, Part 1 (see ARTD-002.731.17....),

and record the determined value as the first measured value.

Measurement of the system leakage current according to the differential current method

(measurement setup according to (Fig.2/p.15)) must be given preference, since this

method is not dangerous to the person performing the measurement and other persons.

However, please note the minimum resolution of the system leakage current measuring

device and any additional manufacturer information restricting the use of the measuring

device.

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 14 of 66

Medical Solutions

Page 15

General Information 15

Fig. 2: Measuring circuit for measuring the system leakage current according to the differential

current method in compliance with DIN VDE 0751-1/2001-10, Fig. C6 for protection

class I.

Pos. 1 = Syste m

Pos. 2 = Application part type B (if available)

Pos. 3 = Measurement setup (integrated into measuring device)

If the direct measurement of the leakage current is used (measurement setup according

to (Fig.3/p.15)), the system must be insulated during the measurement and must not be

touched.

Fig. 3: Measuring circuit for direct measurement of the system leakage current in compliance

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 15 of 66

Page 16

16 General Information

with DIN VDE 0751-1/2001-10, Fig. C5 for protection class I.

Pos. 1 = Syste m

Pos. 2 = Application part type B (if available)

Pos. 3 = Measurement setup (integrated into measuring device)

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 16 of 66

Medical Solutions

Page 17

General Information 17

WARNING

Electrical voltage!

Non-compliance can lead to severe injury and even death.

¹ No housing parts of the system may be touched during

direct measurement of the leakage current (measurement setup according to (Fig.3/p.15)).

¹ Third-person access to the system must be prevented.

The system must be switched on during measurement. Measuring devices with automated measuring sequences must therefore be set to manual measurement.

Enter the highest value as the first measured value in the system leakage current protocol.

This value must not exceed the permissible leakage current values according to DIN VDE

0751-1/2001-10, Table F.1, row "system leakage current for units according to remarks 1

and 3" of

2.5 mA.

Measure and record the current line voltage. If the measured line voltage deviates from

the nominal voltage, correct the measured value to the value corresponding to a measurement at the nominal value of the line voltage. This must also be documented.

Document the measuring procedure (differential measurement or direct measurement)

and the measuring device used (designation and serial number).

Separate the protocol sheet from these instructions and attach it to the protocols already

in the system binder or log book.

Repeat measurement

When maintenance or repair work is performed on the primary power supply circuit (e.g.

repairs to the power-on circuit or replacement of the line filter), the system leakage current

measurement must be repeated.

The same measuring conditions as in the first measurement apply.

Record and evaluate the highest value determined in the repeat measurement in the

existing leakage current protocol.

This value must not exceed the permissible leakage current values according to DIN VDE

0751-1/2001-10, Table F.1, row "system leakage current for units according to remarks 1

and 3" of

2.5 mA.

Measure and record the current line voltage. If the measured line voltage deviates from

the nominal voltage, correct the measured value to the value corresponding to a measurement at the nominal value of the line voltage. This must also be documented.

Document the measuring procedure (differential measurement or direct measurement)

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 17 of 66

Page 18

18 General Information

and the measuring device used (designation and serial number).

NOTE

For evaluation purposes, the first measured value and the values

documented during previous maintenance or safety checks must

be compared to the measured values. A sudden or unexpected

increase in the measured values may indicate that a fault has

occurred in the primary power supply circuit (insulation damage,

damage from moisture, defective interference suppressor, etc.) even if the limit value of 2.5 mA is not exceeded.

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 18 of 66

Medical Solutions

Page 19

General Information 19

Tools, aids (partially for IQ test) 1.3

• Tool kit 97 02 457 Y1971

• Dynamic test kit 37 90 156 X1963

• Copper filter set 44 06 120 RV090

• Densitometer 97 02 416 Y1996

• Radiation filter set (incl. 25 mm Al) 97 98 596 G5321

• Resolution test 28 71 820 RE999

• Safety tester (leakage current and ground wire testing device)

e.g., Unimed 1100

51 38 727 Y0766

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 19 of 66

Page 20

20 General Information

Note on the log book 1.4

The log book is located in the monitor cart behind the keyboard. It is accessible if the

cover on the back of the monitor cart is removed.

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 20 of 66

Medical Solutions

Page 21

General Information 21

Notes on adapting the power plug to local conditions. 1.5

The customer can have the power plug on the supplied power cable replaced with an

appropriate local plug by an electrician, provided that:

• The power plug used can conduct the power required for the operation of the ARCADIS

Avantic (refer to current and voltage values stated on the line voltage label, back of

monitor cart).

• The required line internal resistance is reached (refer to ARCADIS Avantic Planning

Guide).

• The selectivity of the fuse protection is assured - according to the relevant national

standards.

It must also be ensured by the customer that connection to an unsuitable power supply is

prevented (e.g., by identification or design measures).

As concluding measures, perform and document protective conductor measurements (in

Germany, e.g., in the medical device book).

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 21 of 66

Page 22

22 General Information

Note on the power connection 1.6

The system delivery state is provided by the power connection values on the the line voltage label (back of the monitor cart).

Necessary adjustments to local conditions are to be performed as required according to

the adjustment instructions of the ARCADIS Avantic system.

The system leakage current measurement guidelines must be observed.

WARNING

Electrical voltage!

Non-compliance can lead to severe bodily injury and even death.

¹ The internal uninterruptible power supply of the system

(UPS) provides several components with line voltage even when the system is switched off or the system

power plug is disconnected.

¹ Before the system is programmed to the local line volt-

age/line frequency, it must be disconnected from the

power supply (the power plug must be disconnected)

and the voltage output plug of the UPS must be disconnected as well.

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 22 of 66

Medical Solutions

Page 23

General Startup 23

Power Connection 0

2- 2General Startup

Measuring the local line voltage 0

• Measure the voltage and frequency at the intended outlet for the ARCADIS Avantic sys-

tem.

• Compare the measured line voltage with the line voltage label on the back of the moni-

tor cart.

¹ The measured voltage (+/- tolerance) has to correspond to the voltage read from

the label.

Adapting the programmed system line voltage 0

NOTE

NOTE

Perform this procedure only if the on-site line voltage does not

correspond to the programmed line voltage of the system delivered.

After the line voltage is adapted, the leakage current values

recorded in the system test protocol are no longer valid.

After closing all covers and successfully performing a protective

conductor test, repeat and document the device leakage current

measurement.

Observe the leakage current measurement instructions in the

"General Information" chapter of these instructions.

WARNING

Danger high voltage!

Disregarding safety precautions can result in death or serious

bodily injury.

¹ Before the line voltage is adapted, the power plug on the

UPS in the monitor cart must be pulled out, since the

monitor cart is not free of voltage after the power plug is

pulled out.

• Remove the back and bottom covers (Fig.4/p.24) from the monitor cart.

• Pull the power plug out of the UPS in the monitor cart.

• Adapt the voltage by changing the connections to transformers T1 and T2. Refer to the

ARCADIS Avantic wiring diagram.

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 23 of 66

Page 24

24 General Startup

Fig. 4: Monitor cart line voltage

Pos. 1 Power plug

Pos. 2 T1 and T2

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 24 of 66

Medical Solutions

Page 25

General Startup 25

Function check of the EMERGENCY STOP switches 2.1

• Connect the system to the voltage and boot it.

• Click "Emergency" for the patient registration.

• Activate the EMERGENCY STOP switch on the C-arm.

• The safety switch moves audibly and the following message appears on the lower left

monitor edge: "The emergency stop has been pressed"

• Disengage the EMERGENCY STOP switch.

• The safety switch moves audibly and the following message appears on the lower left

monitor edge: "The emergency stop switch has been released."

• Document the function of the EMERGENCY STOP switch in the "Test protocol, C-arm

movement and emergency stop" (C-arm movement and emergency stop / p. 60).

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 25 of 66

Page 26

26 General Startup

Functional checks 2.2

Operating the ARCADIS Avantic, refer to the Operator Manual

• Stand and C-arm system movements

X

X

• Semi-transparent slot and iris diaphragm in fluoroscopy procedure.

• Collimation of the semi-transparent slot and iris diaphragm using fluoroscopy proce-

dure.

• Mechanical functions of the monitor cart

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 26 of 66

Medical Solutions

Page 27

General Startup 27

Functional test of C-arm lift movement and parking brakes 2.3

Fig. 5: Function test

• Switch on the main system (C-arm).

• To move the C-arm downward, press the downward button.

• The lifting column moves to position 1 (1/Fig.5/p.27) and remains there automati-

cally. A stop signal (3 beeps) sounds simultaneously.

• To lower the lifting column further, press the downward button once again.

• The lifting column can then be moved by a further 7cm to the lowest point, position 2

(2/Fig.5/p.27). In this area a signal (3 beeps) sounds for safety reasons each time the

downward button is pressed.

• To move the C-arm upward, press the upward button. No signal sounds in this case.

• When both switches are pressed, the lifting motor moves in the initially selected direc-

tion.

• Loosen the different parking brakes and apply them again. Secure blocking of the rele-

vant movement must be assured.

• Document the function of the C-arm movements, brakes and warning signals in the test

protocol, "C-arm movement and emergency stop" .

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 27 of 66

Page 28

28 Specific System Settings

System configuration 0

3- 3Specific System Settings

Note regarding Hibernation Mode 0

NOTE

Customer and country-specific configurations 0

Hibernation Mode

With the introduction of the Hibernation Mode, system configuration changes are not applied if the system is switched off and

then switched on again using the power buttons on the monitor

cart.

To correctly apply the modified data, perform a system shutdown.

Open the <Options> - <End Session> menu and click the “Shutdown system” button. Immediately thereafter, press the Power off

button on the monitor cart.

The system shuts down and switches off automatically.

• Please clarify in advance with the customer whether the following system configura-

tions are required.

Service login: 0

Fig. 6: Service login

• Select <Options> <Customer service> <Local service>.

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 28 of 66

Medical Solutions

Page 29

Specific System Settings 29

Fig. 7: Authentication_

• Enter the 6-character password and click OK (see system folder for password).

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 29 of 66

Page 30

30 Specific System Settings

Customer address configuration 0

Fig. 8: Configuration_

• Select <Configuration>.

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 30 of 66

Medical Solutions

Page 31

Specific System Settings 31

Fig. 9: Configuration

• Click <Next>.

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 31 of 66

Page 32

32 Specific System Settings

Fig. 10: Local Host

• Click <Site Info>.

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 32 of 66

Medical Solutions

Page 33

Specific System Settings 33

Fig. 11: Site info

• The marked customer-specific data may be adapted. Do not change "Serial No.".

• Click <Save>.

• Click <Home>.

Main system configuration 0

• In the service software, select "Main System".

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 33 of 66

Page 34

34 Specific System Settings

Fig. 12: Main_system

• Click <Main system>.

Fig. 13: Mainsys start

• Select ARCADIS Avantic - I.I. type and click <Next>.

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 34 of 66

Medical Solutions

Page 35

Specific System Settings 35

Fig. 14: Buzzer setting

• Under Configuration click <Buzzer>.

Make changes according to the following description:

• Block time settings

- Warning time limit: The buzzer sound starts when the entered radiation time has

elapsed.

- Block time limit: After the entered radiation time has elapsed - without reset of the

"warning time limit" - the radiation is blocked the next time it is selected. Every reset

of "Warning Time Limit" also resets the "Block Time Limit" to "0".

• Buzzer mode (indirect, I.I.)

- Buzzer off: Buzzer sound off. Exceptions: Push mode and "Warning Time Limit" has

ended.

- Buzzer on: Buzzer sound always during radiation.

The country-specific regulations must be observed for the max. fluoroscopy time and radiation blockage.

Factory setting:

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 35 of 66

Page 36

36 Specific System Settings

"Warning time limit" "Blocking time limit"

USA

Service mask

input in 1/10 min.

Europe

Service mask

input in 1/10 min.

5 min.

50

5 min.

50

• Make country-specific changes and click <Save>.

• Click <Home>.

• Perform a system shutdown.

• Switch on the system and wait for the system to boot.

NOTE

With the introduction of the Hibernation Mode, system configuration changes are not applied if the system is switched off and then

switched on again using the power buttons on the monitor cart.

To correctly apply the modified data, perform a system shutdown.

Open the <Options> - <End Session> menu and click the “Shutdown system” button. Immediately thereafter, press the Power off

button on the monitor cart.

0 min.

0

10 min. (5 min. + 5 min.)

50

The system shuts down and switches off automatically.

• If a change is made to the fluoro time, check this function.

Fluoroscopy footswitch configuration. 0

NOTE

Program the footswitch as follows.

• Start service program and log in as described under "Service Login".

Select Main System / Configuration / Main System / Footswitch CFC / right.

• Save the changes with <Save>.

• Click on <Home> button.

• Perform a system shutdown.

The footswitch is set at the factory so that fluoroscopy is performed with the left pedal and the freely-selectable operating

modes such as digital radiography, SUB, etc., are performed with

the right pedal. The setting can be changed to meet customer

requirements.

• Switch on the system and wait for the system to boot.

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 36 of 66

Medical Solutions

Page 37

Specific System Settings 37

NOTE

With the introduction of the Hibernation Mode, system configuration changes are not applied if the system is switched off and then

switched on again using the power buttons on the monitor cart.

To correctly apply the modified data, perform a system shutdown.

Open the <Options> - <End Session> menu and click the “Shutdown system” button. Immediately thereafter, press the Power off

button on the monitor cart.

The system shuts down and switches off automatically.

NOTE

Once the configuration has been changed, the label affixed to the

footswitch has to be removed and replaced by the new label

included in the delivery volume. In the case of an "enhanced" footswitch, there are two labels on the pedals that have to be replaced.

• Remove the label affixed to the footswitch. In the case of an "enhanced" footswitch,

remove both labels from the pedals.

• If necessary, remove any remaining adhesive where the labels were removed.

• Affix the new label to the footswitch. In the case of an "enhanced" footswitch, affix both

labels to the pedals.

• If the footswitch configuration was changed, check the footswitch pedal function.

¹ The footswitch pedal functions have to correspond to the functions indicated on

the newly affixed label(s).

Country-specific adaptation of the maximum tube current 0

NOTE

• Start service program and log in as described under "Service Login".

A maximum tube current limit is required - as far as known - only

in Denmark.

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 37 of 66

Page 38

38 Specific System Settings

Fig. 15: Main_system

• Click <Main system>.

Fig. 16: Mainsys start

• Select ARCADIS Avantic - I.I. type and click <Next>.

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 38 of 66

Medical Solutions

Page 39

Specific System Settings 39

Fig. 17: Current limitation

• Click <Current limitation>.

• Make country-specific changes (only Denmark) and click <Save>.

• Click <Home>.

• Perform a system shutdown.

• Switch on the system and wait for the system to boot.

NOTE

With the introduction of the Hibernation Mode, system configuration changes are not applied if the system is switched off and then

switched on again using the power buttons on the monitor cart.

To correctly apply the modified data, perform a system shutdown.

Open the <Options> - <End Session> menu and click the “Shutdown system” button. Immediately thereafter, press the Power off

button on the monitor cart.

The system shuts down and switches off automatically.

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 39 of 66

Page 40

40 Specific System Settings

Configuring the network (optional) and remote service 0

• Configure the network according to the Configuration Guide,

SPR2-310.843.01.01.xx.xx and the remote connection according to Installation, Siemens Remote Service, SP00-000.816.02.01.xx.xx.

NOTE

With the introduction of the Hibernation Mode, system configuration changes are not applied if the system is switched off and

then switched on again using the power buttons on the monitor

cart.

To correctly apply the modified data, perform a system shutdown.

Open the <Options> - <End Session> menu and click the “Shutdown system” button. Immediately thereafter, press the Power off

button on the monitor cart.

The system shuts down and switches off automatically.

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 40 of 66

Medical Solutions

Page 41

Specific System Settings 41

Backup 3.1

NOTE

NOTE

A backup must be created following software installation, every

software update, and every system adjustment.

After a backup group has been successfully burned to CD, the following message is displayed: "Please insert medium in CD-RW in

order to continue."

Confirm this message with "OK".

This does not require a new CD.

• Select "Backup & Restore" in the Service Software Home Menu.

• Place the backup CD (located in the monitor cart service compartment) in the CD-ROM

drive.

Fig. 18: Backup & Restore_Command

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 41 of 66

Page 42

42 Specific System Settings

• Select the <Backup> command.

Fig. 19: Backup & Restore_Command_Backup

• Select the respective drive under Drives.

- Save to CD-ROM (standard save).

Fig. 20: Backup

SW - Settings02

• Select "SW-Settings02" under Packages.

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 42 of 66

Medical Solutions

Page 43

Specific System Settings 43

• Click <Go> and wait until the message “Ready” appears in the footer.

Fig. 21: Backup & Restore_Command_Backup_SW-Settings02

ASPIA settings

• Select "ASPIA settings" under Packages.

• Click <Go>

- Wait until "Ready” is displayed in the footer.

Exam set

• Select "ExamSet" under Packages.

• Click <Go>

- Wait until "Ready” is displayed in the footer.

Security settings

For systems with HIPAA configuration

• Select "Security-Settings" under Packages.

• Click <Go>

- Wait until "Ready” is displayed in the footer.

Main system

• Select "MainSystem" under Packages.

- Wait until "Ready” is displayed in the footer.

Exiting backup

• Close the window via <Home>.

• Remove the backup CD-ROM from the CD-ROM drive.

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 43 of 66

Page 44

44 Specific System Settings

• Store the CD-ROM with the other system documentation.

NOTE

It is not possible to perform a backup of the database (patient

images)!

Store the patient images in an archive.

Saving to CD-ROM as a long-term archive is prohibited.

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 44 of 66

Medical Solutions

Page 45

Final Work Steps 45

Paper printer (optional) 0

4- 4Final Work Steps

NOTE

Codonics printer 1660L 0

Perform the following steps according to the "User Manual" of the printer:

• Transport instructions (see preface).

Note: Unpack the printer and remove the two transport pins. Place the printer in the

cart, connect the power cable and the 25-pin plug to the printer (cables are ready for

use in the printer slot of the cart), and set the power switch to "1".

• Install the print media>(SPR2-310.815.01 / General Start-up)

If a paper printer was ordered with the system, all mechanical

work and programming was performed at the factory.

In the case of paper printers delivered after the system, they have

to be installed and started up in accordance with the Installation

and Setting instructions SPR2-310.814.03...

NOTE

Keep the transport safety materials. They are required when

replacing or shipping the printer.

Sony printer UP-D72 X 0

Perform the following steps according to the user manual for the printer (CD-ROM):

• Unpack the printer.

• Fill the paper tray with paper (follow instructions on paper package).

• Plug in the USB cable.

• Print a test page after the automatic test.

• Follow the instructions on the CD-ROM from the manufacturer in the event of problems.

Sony Printer UP-970 and UP-990 0

Perform the following steps according to the user manual for the printer (CD-ROM):

• Unpack the printer.

• Fill the paper tray with paper (follow instructions on paper package).

• Plug in the USB cable.

• Print a test page after the automatic test.

• Follow the instructions on the CD-ROM from the manufacturer in the event of problems.

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 45 of 66

Page 46

46 Final Work Steps

Final Work Steps 4.1

IQ test 0

Perform IQ test according to instructions SPR2-330.820.01.xx.xx.

¹ Remove the supplied IQ test protocols from the monitor cart service compart-

ment.

Completing protocols 0

After completing all adjustment work steps and check measurements, the responsible

technician must sign and date the test protocols and country-specific protocols to confirm

that all values have been correctly determined and recorded.

Protective conductor resistance test 0

Transferring the values from the test protocol to the "protective conductor" protocol

NOTE

If no covers were opened while installing the system and no additional components (e.g. options) were installed or modified, the

values recorded in the test protocol 1 can be transferred as the

first measured value.

The protective conductor test need not be performed.

Perform the protective conductor resistance test if the conditions

specified above do not apply.

Refer to the section "Protective conductor resistance test during

start-up (if necessary)".

• Complete the "Protective Conductor Resistance" protocol found in the "Protocol" sec-

tion of this manual.

• If the system test protocol only contains the confirmation of the protective conductor

resistance threshold, enter this value in the "Protective conductor resistance" table, row

"Measurement point 1", column "First measured value" (< 0.18 Ohm). Enter "n.a." in

rows "measurement point 2" through "measurement point 22" of column "First measured value."

• If the system test protocol specifies the measured protective conductor resistance val-

ues and their measurement points, transfer the values to rows "Measurement point 1"

through "Measurement point 22" of column "First measured value". Mark empty fields

with "n.a." as "not applicable".

• In row "(1) Meas. circuit", column "First measured value", enter the text "VDE0751-1

Image C2".

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 46 of 66

Medical Solutions

Page 47

Final Work Steps 47

• If specified in the system test protocol, read off the measuring equipment used at the

factory for the protective conductor test.

¹ Enter this measuring equipment in the "Protective conductor resistance" proto-

col, in the "Measuring device, type:" row.

• If specified in the system test protocol, read off the identification of the measuring

equipment specified in the test protocol.

¹ Enter the ID of the measuring equipment in the "Protective conductor resistance"

protocol, in the "Measuring device, Ser. No.:" row.

• Mark the following rows in the "Protective conductor resistance" protocol with "n.a." as

"not applicable":

¹ Row "Meas. inst. calibrated up to:"

¹ Row "Evaluation:"

• Complete the following rows in the "Protective conductor resistance" protocol:

¹ In the row "Date:" enter the current date.

¹ In the "Name" row, enter your name in block letters.

¹ Sign the protocol in the "Signature" row.

• If you want to complete the protocol with additional remarks, enter them in the

"Remarks" table in the protocol addendum.

Protective conductor resistance test during start-up (if necessary)

NOTE

If covers were opened while installing the system and/or additional components (e.g. options) were installed or modified, the

protective conductor resistance value recorded in system test

protocol 1 is invalid.

The protective conductor resistance test has to be performed

after closing all covers.

NOTE

Observe the instructions for the protective conductor resistance

test in the "General Information" chapter of these instructions.

• Perform the protective conductor resistance test.

¹ The protective conductor resistance must not exceed 0.2 ohms at any measure-

ment point.

• Complete the "First measured value" column of the "Protective conductor resistance"

protocol.

• If you want to complete the protocol with additional remarks, enter them in the

"Remarks" table in the protocol addendum.

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 47 of 66

Page 48

48 Final Work Steps

Tab. 6 Measurement points for the protective conductor resistance measurement

Measurement points

Measurement from the protective conductor connection of the power plug to the:

Base unit, handle attachment screw for I.I. cover

Base unit, one attachment screw at I.I. grid

Base unit, one attachment screw at I.I. flange

Base unit, one attachment screw at I.I. cap

Base unit, one attachment screw at POWERPHOS

Base unit, one screw at cover of horizontal carriage

Base unit, one lateral screw at brake pedal (left or right)

Base unit, back cover (electronics box)

Base unit, equipotential bonding connection

Base unit, near footswitch cable outlet (electronics box)

Base unit, one lifting column screw at the base plate of the electronics box

Base unit, base plate of electronics box (at unpainted location)

Base unit, one screw at the back of each monitor

Monitor cart, one screw at monitor support

Monitor cart, one screw at the small, top back cover

Monitor cart, one screw at the large, lower back cover

Monitor cart, one screw at back cover of switch-on assembly

Monitor cart, one screw at the front cover

Monitor cart, one screw at the right side cover

Monitor cart, one screw at the left side cover

Monitor cart, one screw at the right handle

Monitor cart, one screw at the left handle

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 48 of 66

Medical Solutions

Page 49

Final Work Steps 49

Leakage current measurement 0

Transferring the values from the test protocol to the "device leakage current" protocol

NOTE

If the programmed line voltage has not been changed from its status at delivery, and there have been no changes of parts in the

system's primary circuit, the device leakage current value specified in the test protocol delivered with the system is valid.

The device leakage current test need not be performed.

The value recorded in the test protocol must be used as the "first

measured value" in the "Device Leakage Current" protocol.

Perform the device leakage current measurement if the conditions

specified above do not apply.

Refer to the section "Device leakage current measurement during

start-up (if necessary)".

• Complete the "Device leakage current" protocol found in the "Protocol" section of this

manual.

• Enter the system serial number on the "Serial Number" row of the "Device leakage cur-

rent" protocol.

• If applicable, enter the customer-specific system ID number in the "Customer-specific

ID Number" row of the "Device leakage current" protocol.

• In test protocol 1, table "Alternative leakage current measurement (DIN VDE 0751)" or

"Device leakage current measurement (DIN VDE 0751-1), read off the higher recorded

value between rows "Leakage current under normal operation and with nominal voltage" and "Leakage current with power reversion of polarity and nominal voltage."

¹ Enter the higher value from test protocol 1 in the "Device leakage current" proto-

col, row "Device leakage current (highest measured value) [mA]" and in row

"Device leakage current corrected value [mA]", column "First measured value".

• Read off the line voltage in test protocol 1 under "Revision Level".

¹ Enter the value from test protocol 1 in the "Device leakage current" protocol, row

"Line voltage during measurement [V~]", column "First measured value".

• Read off the production resources entered in test protocol 1, table "Production

resources used".

¹ Enter the production resources from test protocol 1 in the "Device leakage cur-

rent" protocol, row "Measuring device: type", column "First measured value".

• Read off the measuring device ID entered in test protocol 1, table "Production

resources used".

¹ Enter the measuring device ID from test protocol 1 in the "Device leakage cur-

rent" protocol, row "Measuring device, ser. no.", column "First measured value".

• In "Device leakage current" protocol, row "(1) Meas. circuit", column "First measured

value", enter the text "VDE0751-1 Image C5".

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 49 of 66

Page 50

50 Final Work Steps

• Mark the following rows in the "Device leakage current" protocol, column "First mea-

sured value", with "n.a." as "not applicable":

¹ Row "Meas. inst. calibrated up to:"

¹ Row "Evaluation:"

• Complete the following rows in the "Device leakage current" protocol, column "First

measured value":

¹ In the row "Date:" enter the current date.

¹ In the "Name" row, enter your name in block letters.

¹ Sign the protocol in the "Signature" row.

• If you want to complete the protocol with additional remarks, enter them in the

"Remarks" table in the protocol addendum.

Device leakage current measurement during start-up (if necessary)

NOTE

If the programmed line voltage has been changed from its status

at delivery, and/or there have been changes of parts in the system's primary circuit, the device leakage current value specified

in test protocol 1 delivered with the system is no longer valid.

The device leakage current measurement has to be performed.

NOTE

WARNING

Observe the leakage current measurement instructions in the

"General Information" chapter of these instructions.

Electrical voltage!

Non-compliance can lead to severe injury and even death.

¹ The system leakage current measurement may be per-

formed on systems of protection class I only after the

protective conductor test has been passed.

• Perform the device leakage current measurement after successfully completing the

protective conductor test.

• Complete the "First measured value" column of the "Device leakage current" protocol.

• If you want to complete the protocol with additional remarks, enter them in the

"Remarks" table in the protocol addendum.

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 50 of 66

Medical Solutions

Page 51

Final Work Steps 51

Completing the "ARCADIS Avantic Installation" protocol. 0

The manufacturer of this product requires information and the legislator demands proofs

that a product delivered free of defects from the factory continues to possess the required

and certified quality properties on installation and start-up.

It is therefore absolutely necessary that the installation report with the installation and

start-up data is sent without delay after completion of the work to the address stated on

the installation report.

You will find the report in the system folder.

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 51 of 66

Page 52

52 Protocols

Protective Conductor Resistance 0

5- 5Protocols

System: ARCADIS Avantic

Material no.: 10048590

Serial number: .........................................................................

Customer-specific ID number .........................................................................

Ta b . 7

Protective Conductor Resistance

First measured value Repeat measurement values

Meas. point 1:

.....................................

Meas. point 2:

.....................................

Meas. point 3:

.....................................

Meas. point 4:

.....................................

Meas. point 5:

.....................................

Meas. point 6:

.....................................

Meas. point 7:

.....................................

Meas. point 8:

.....................................

Meas. point 9:

.....................................

Meas. point 10:

.....................................

Meas. point 11:

.....................................

Meas. point 12:

.....................................

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 52 of 66

Medical Solutions

Page 53

Protocols 53

Protective Conductor Resistance

First measured value Repeat measurement values

Meas. point 13:

.....................................

Meas. point 14:

.....................................

Meas. point 15:

.....................................

Meas. point 16:

.....................................

Meas. point 17:

.....................................

Meas. point 18:

.....................................

Meas. point 19:

.....................................

Meas. point 20:

.....................................

Meas. point 21:

.....................................

Meas. point 22:

.....................................

(*1) Meas. circuit:

Measuring device, type:

Meas. device ser. no.:

Meas. inst. calibrated up to:

Evaluation: n.a.

Date:

Name:

Signature

(*1) Meas. circuit. See (Fig. 22 / p. 54)

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 53 of 66

Page 54

54 Protocols

Measuring circuit 0

Fig. 22: Measuring circuit for measuring the protective conductor resistance for units that are

Pos. 1 Measurement setup (measuring device)

Pos. 2 System

Pos. 3 Application part (if applicable)

disconnected from power, in compliance with DIN VDE 0751-1/2001-10, Fig. C2.

Remarks: 0

Ta b . 8

Date Comments Name Signature

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 54 of 66

Medical Solutions

Page 55

Protocols 55

Date Comments Name Signature

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 55 of 66

Page 56

56 Protocols

System leakage current 5.1

System: ARCADIS Avantic

Material no.: 10048590

Serial number: .........................................................................

Customer-specific ID number .........................................................................

Ta b . 9

System leakage current

First measured value Repeat measurement values

System leakage current

(Highest measured value)

[mA]

Line voltage during the measurement

[ V~]

System leakage current

Corrected value [ mA]

(*1) Meas. circuit:

Measuring device, type:

Meas. device ser. no.:

Measuring device,

calibrated to:

Evaluation:

Date:

Name:

Signature:

(*1) Meas. circuit: See (Fig. 23 / p. 57) through (Fig. 26 / p. 58),

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 56 of 66

Medical Solutions

Page 57

Protocols 57

Measuring circuit 0

Direct measurement

Fig. 23: Measuring circuit for direct measurement of the system leakage current in compliance

with DIN VDE 0751-1/2001-10, Fig. C5 for protection class I.

Pos. 1 = Syste m

Pos. 2 = Application part type B (if available)

Pos. 3 = Measurement setup (integrated into measuring device)

Fig. 24: Measuring circuit for direct measurement of the system leakage current in compliance

with DIN VDE 0751-1/2001-10, Fig. C5 for protection class II.

Pos. 1 = Syste m

Pos. 2 = Application part (if applicable)

Pos. 3 = Measurement setup (integrated into measuring device)

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 57 of 66

Page 58

58 Protocols

Differential measurement

Fig. 25: Measuring circuit for measuring the system leakage current according to the differential

current method in compliance with DIN VDE 0751-1/2001-10, Fig. C6 for protection

class I.

Pos. 1 = Syste m

Pos. 2 = Application part type B (if available)

Pos. 3 = Measurement setup (integrated into measuring device)

Fig. 26: Measuring circuit for measuring the system leakage current according to the differential

current method in compliance with DIN VDE 0751-1/2001-10, Fig. C6 for protection

class II.

Pos. 1 = Syste m

Pos. 2 = Application part (if applicable)

Pos. 3 = Measurement setup (integrated into measuring device)

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 58 of 66

Medical Solutions

Page 59

Protocols 59

Remarks: 0

Tab. 1 0

Date Comments Name Signature

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 59 of 66

Page 60

60 Protocols

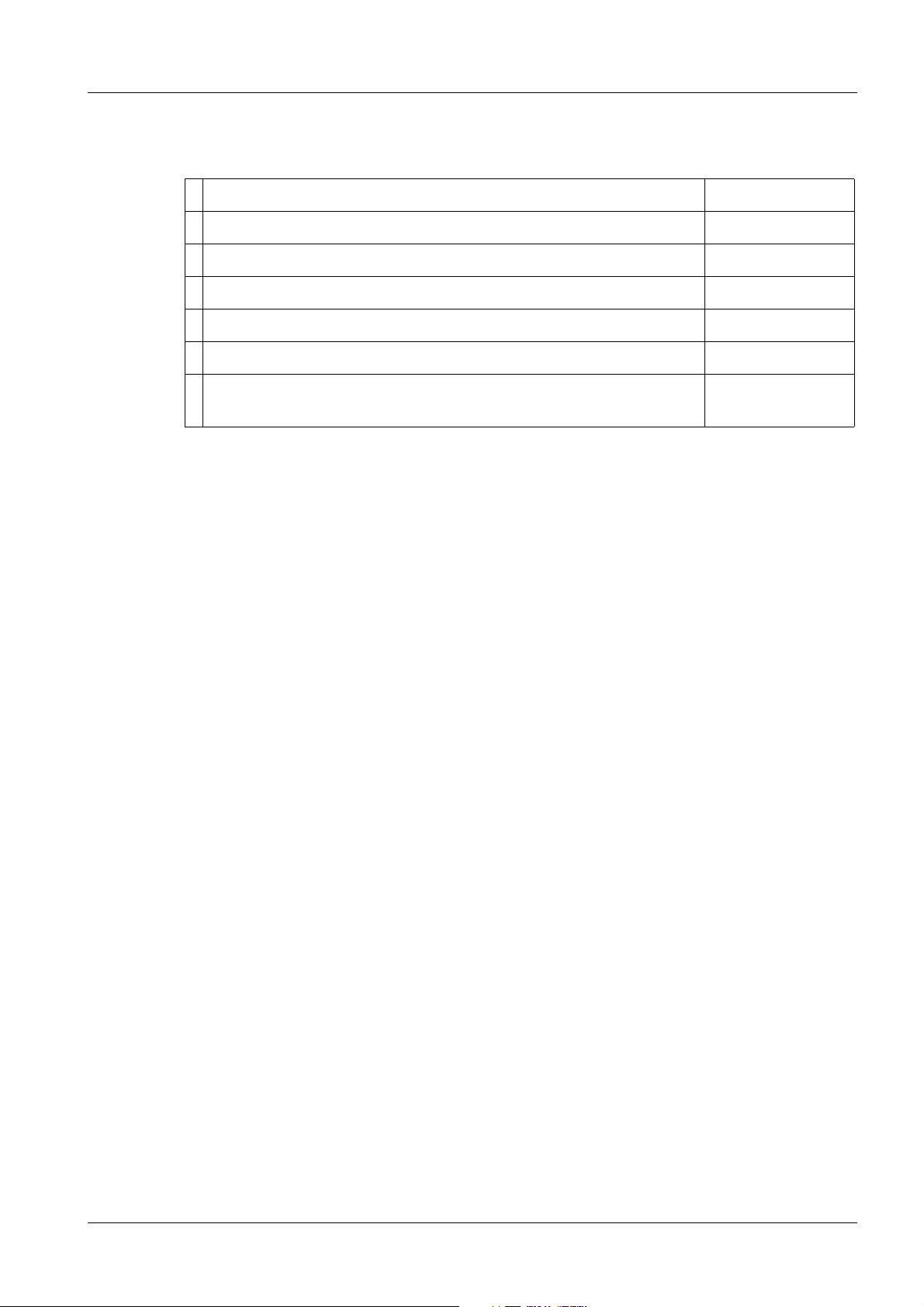

C-arm movement and emergency stop 5.2

System: ARCADIS Avantic

Material no.: 10048590

Serial number: .........................................................................

Customer-specific ID number .........................................................................

Tab. 11 C-arm movement and emergency stop protocol

Movement OK

Yes/No

Releasing/locking the brakes

Downward movement, position

1

Downward movement, position

2

The warning signals sound as

described.

Function,

EMERGENCY_STOP_button

Name Date Initials

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 60 of 66

Medical Solutions

Page 61

Protocols 61

Network checklist 5.3

System: ARCADIS Avantic

Material no.: 10048590

Serial number: .........................................................................

Customer-specific ID number .........................................................................

Network checklist (1+) For SAP order no.:_______________________

Will the system have a network connection (HIS/RIS, Camera,

PAC S)?

Mandatory for image system with network connection!

To ensure that the system is preconfigured at the factory and thus optimize installation at the customer site, we

request that you complete and return this list if a network connection is available (and used).

Person responsible for network configuration at customer site

Name:

Phone/fax:

E-mail:

System network data

Tab. 12 System network data

Not networked

Identification:

Computer name *

Yes No

Configuration/Local Host/TCP IP address

IP address:

TCP/IP address

* Configuration/local host/TCP IP address

Subnet mask * Configuration/local host/TCP IP address

Gateways * Configuration/local host/TCP IP address

General: Local AE title for:

HIS/RIS *

Configuration/DICOM/General

Study transfer * Configuration/DICOM/general

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 61 of 66

Page 62

62 Protocols

Print * Configuration/DICOM/general

Comments

Network data for HIS/RIS network partner (only with HIS/RIS option)

Tab. 13 Network data for HIS/RIS

Not available

Device: Version: Manufacturer:

Host properties:

Host name

TCP/IP address * Configuration/DICOM/HIS RIS nodes

General Node Properties

Logical name

Application entity

AE title

Por t number * Configuration/DICOM/HIS RIS nodes

Comment:

Network checklist (2+)

Network data for diagnostic console/archive system (only with DICOM Basic

option) (1)

Tab. 14 Network data for reporting console/archiving system

Information on each: Reporting console/

Archive system

* Configuration/DICOM/HIS RIS nodes

* Configuration/DICOM/HIS RIS nodes

* Configuration/DICOM/HIS RIS nodes

Not available

Product: Version: Manufacturer:

Host properties:

Host name

* Configuration/DICOM/network nodes

TCP/IP address * Configuration/DICOM/network nodes

General node properties:

Logical name

* Configuration/DICOM/network nodes

Application entity:

AE title

* Configuration/DICOM/network nodes

Port number * Configuration/DICOM/network nodes

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 62 of 66

Medical Solutions

Page 63

Protocols 63

Supported Dicom Services

Storage yes no

* Configuration/DICOM/network nodes

Storage commitment yes no * Configuration/DICOM/network nodes

Node name: * Configuration/DICOM/network nodes

Query yes no * Configuration/DICOM/network nodes

Retrieve yes no * Configuration/DICOM/network nodes

Comment:

Network data for diagnostic console/archive system (only with DICOM Basic

option) (2)

Tab. 15 Network data for reporting console/archiving system

Information on each: Reporting console/

Not available

Archive system

Product: Version: Manufacturer:

Host properties:

Host name

* Configuration/DICOM/network nodes

TCP/IP address * Configuration/DICOM/network nodes

General node properties:

Logical name

Application entity:

Port number * Configuration/DICOM/network nodes

Supported Dicom Services

Storage commitment yes no * Configuration/DICOM/network nodes

Comment:

Network checklist (3-)

Network data for a DICOM camera in the network (only with the DICOM Print option)

(1)

* Configuration/DICOM/network nodes

AE title

Storage yes no

* Configuration/DICOM/network nodes

* Configuration/DICOM/network nodes

Node name: * Configuration/DICOM/network nodes

Query yes no * Configuration/DICOM/network nodes

Retrieve yes no * Configuration/DICOM/network nodes

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 63 of 66

Page 64

64 Protocols

Tab. 16 Network data for DICOM camera in the network

Information for Any camera No camera available

Device: Version: Manufacturer:

Default camera yes no

Host properties:

Host name

* Configuration/DICOM/Print devices

TCP/IP address * Configuration/DICOM/Print devices

General node properties:

Logical name

* Configuration/DICOM/Print devices

Application entity:

AE title

* Configuration/DICOM/Print devices

Port number * Configuration/DICOM/Print devices

Comment:

Network data for a DICOM camera in the network (only with the DICOM Print option)

(2)

Tab. 17 Network data for DICOM camera in the network

Information for Any camera No camera available

Device: Version: Manufacturer:

Default camera yes no

Host properties:

TCP/IP address * Configuration/DICOM/Print devices

General node properties:

Logical name

Application entity:

Comment:

Host name

AE title

* Configuration/DICOM/Print devices

* Configuration/DICOM/Print devices

* Configuration/DICOM/Print devices

Port number * Configuration/DICOM/Print devices

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 64 of 66

Medical Solutions

Page 65

Changes to Previous Version 65

6- 6Changes to Previous Version

Section Changes

Specific system settings The specification for the buzzer setting for the USA was

changed as follows:

Warning time limit: changed from "45" to "50"

Blocking time limit: changed from "5" to "0"

Siemens AG SPR2-330.815.01.03.02 ARCADIS Avantic

Medical Solutions

12.06 CS PS SP

Page 65 of 66

Page 66

66 Changes to Previous Version

ARCADIS Avantic SPR2-330.815.01.03.02 Siemens AG

12.06 CS PS SP

Page 66 of 66

Medical Solutions

Loading...

Loading...