Page 1

SIMODRIVE 611 analog

Start–Up Guide 10.2000 Edition

Transistor PWM Inverters for

AC Feed Drives and

AC Main Spindle Drives

Manufacturer/Service Documentation

Page 2

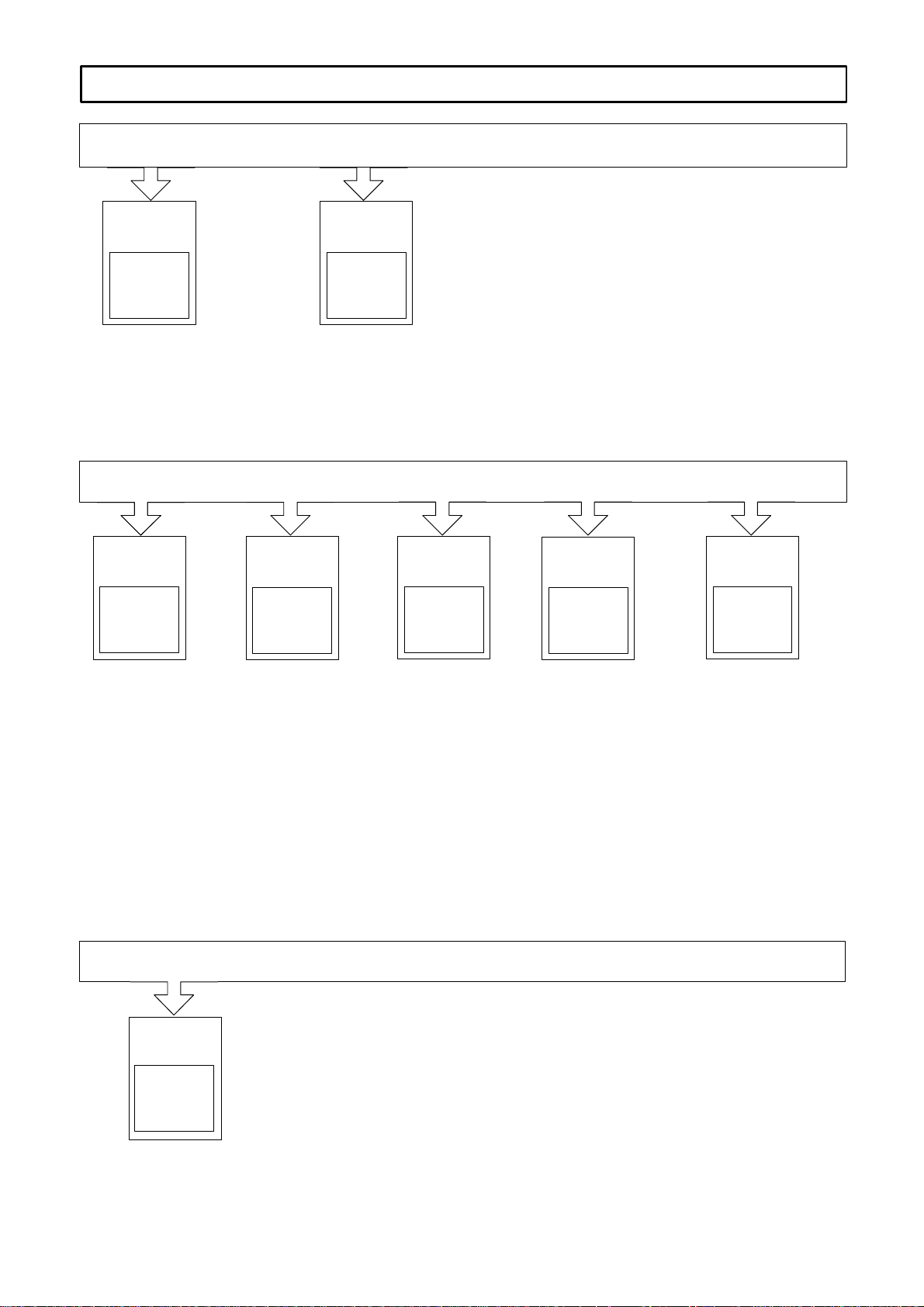

Overview of Documentation for SIMODRIVE 61 1 analog

General Documentation

SINUMERIK

SIMODRIVE

Catalog

Order Document NC 60

SINUMERIK

SIROTEC

SIMODRIVE

Accessories

Catalog

Accessories and

Equipment for Special–

Purpose Machines

Order Document NC Z

Manufacturer/Service Documentation

SIMODRIVE

SIMODRIVE

611

SINUMERIK

SIROTEC

SIMODRIVE

611–A

SIMODRIVE

611–A

Planning Guide

Motors

AC Motors for

Feed and Main

Spindle Drives

Planning Guide

Transistor PWM

Inverters for AC Feed

Drives and AC Main

Spindle Drives

Electronic Documentation

SINUMERIK

SIMODRIVE

840D/810D/

FM–NC/611/

Motors

DOC ON CD

The SINUMERIK System

EMC Guidelines

for SINUMERIK

and SIROTEC

Controls

Description

SIMODRIVE 611 analog

Start–up Software for

Main Spindle and

Induction Motor Modules

Start–up Guide

SIMODRIVE 611 analog

Transistor PWM

Inverters for AC Feed

Drives and AC Main

Spindle Drives

Page 3

Foreword

SIMODRIVE 611 analog

Transistor PWM Inverters

for AC Feed Drives

and AC Main Spindle

Drives

Start–Up Guide

General Information

Supply Infeed NE

Feed Modules VS

Feed Modules,

Resolver Control VR

Main Spindle Modules HS

Induction Motor Modules AM

Spare Parts ES

Attachment A

Short reference NE/VS

AL

Valid for

Equipment series 6SN11–

Short reference VR

Short reference HS

Short reference AM

Overall Index

10.00 Edition

Page 4

3

SIMODRIVEdocumentation

Edition coding

Brief details of the Edition and previous editions are listed below.

IThe status of each Edition is shown by the code in the “Remarks” column.

Status code in the “Remarks” column”:

A New documentation.. . . . .

B Unrevised reprint with new Order No.. . . . .

C Revised edition with new status.. . . . .

If factual changes have been made on the page since the last edition,

this is indicated by a new Edition coding in the header on that page.

Edition Order No. Remarks

07.94 6SN1197–0AA60–0BP0 A

10.94 6SN1197–0AA60–0BP1 C

12.94 6SN1197–0AA60–0BP2 C

03.96 6SN1197–0AA60–0BP3 C

04.97 6SN1197–0AA60–0BP4 C

10.00 6SN1197–0AA60–0BP5 C

This Manual is also included in the documentation on CD–ROM (DOCONCD)

Edition Order No. Remarks

10.00 6FC5298–6CA00–0BG0 C

Trademarks

SIMATIC, SIMATIC HMI, SIMATIC NET, SIROTEC, SINUMERIK and SIMODRIVE are registered

trademarks of Siemens. Other names in this publication might be trademarks whose use by a third party for

his own purposes may violate the rights of the registered holder.

You will find additional information in the Internet under:

http://www.ad.siemens.de/simodrive

This document was generated with Interleaf V 7

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created by patent grant or registration of a utility model or design,

are reserved.

Siemens AG 2000. All rights reserved.

Functions may be executable in the control but are not described in

this documentation. No claims can be made on these functions if

included with a new shipment or when involved with service.

We have checked the contents of this document to ensure that they

coincide with the described hardware and software. The information

in this document is regularly checked and necessary corrections are

included in reprints.

We are thankful for any recommendations for improvement.

Subject to change without prior notice.

Printed in the Federal Republic of Germany

Siemens–AktiengesellschaftOrder No. 6SN1197–0AA60–0BP5

Page 5

Foreword

This document is part of the documentation developed for SIMODRIVE. All documents are available individually.

The documentation list, which includes all advertising Brochures, Catalogs,

Overviews, Short Descriptions, User Manuals and Technical Descriptions can

be obtained from your local Siemens office with Order No., location and price.

This Manual does not purport to cover all details or variations in equipment, nor

to provide for every possible contingency to be met in connection with installation, operation or maintenance.

Should further information be desired or should particular problems arise, which

are not covered sufficiently for the purchaser’s purposes, the matter should be

referred to the local Siemens sales office.

The contents of this Guide shall not become part of nor modify any prior or existing agreement, commitment or relationship.

The sales contract contains the entire obligation of Siemens. Any statements

contained herein neither create new warranties nor modify the existing warranty.

Siemens AG 2000 All rights reserved

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

i

Page 6

1.2 bbbbbbbbbb

Definitions

!

10.00

07.94

Qualified personnel

For the purpose of this documentation and product labels, a “qualified person” is

someone who is familiar with the installation, mounting, start–up and operation

of the equipment and the hazards involved. He or she must have the following

qualifications:

Trained and authorized to energize, de–energize, clear , ground and tag cir-

cuits and equipment in accordance with established safety procedures.

Trained in the proper care and use of protective equipment in accordance

with established safety procedures.

Trained in rendering first aid

Danger

This symbol indicates that death, severe personal injury or substantial property

damage will result if proper precautions are not taken.

Warning

!

!

This symbol indicates that death, severe personal injury or property damage

can result if proper precautions are not taken.

Caution

This warning (with warning triangle) indicates that minor personal injury can

result if proper precautions are not taken.

Caution

This warning (without warning triangle) indicates that material damage can

result if proper precautions are not taken.

Notice

This warning indicates that an undesirable situation or condition can occur if

the appropriate instructions/information are not observed.

ii

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

Siemens AG 2000 All rights reserved

Page 7

10.00

07.94

Important

!

!

This symbol appears in the documentation if a particular issue is significant.

Note

For the purpose of this documentation, “Note” indicates information about the

product or the respective part of the document which is essential to highlight.

Warning

Operational electrical equipment has parts and components which are at hazardous voltage levels.

Incorrect handling of these units, i.e. not observing the warning information, can

therefore lead to death, severe bodily injury or significant material damage.

Only appropriately qualified personnel may commission/start–up this equipment.

This personnel must have in–depth knowledge regarding all of the warning

information and service measures according to this Guide.

Perfect, safe and reliable operation of this equipment assumes that it has been

professionally transported, stored, mounted and installed as well as careful

operator control and service.

Hazardous axis motion can occur when working with the equipment.

Note

When handling cables, observe the following

they must not be damaged,

they must not be strained and

they must not come into contact with rotating components.

Siemens AG 2000 All rights reserved

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

iii

Page 8

10.00

07.94

Note

It is not permissible to connect SIMODRIVE equipment to a supply system with

ELCBs (this restriction is permitted acc. to DIN VDE 0160 / 05.88, Section 6.5).

When operational, protection against direct contact is provided in a form to allow the unit to be used in enclosed electrical equipment rooms

(DIN VDE 0558 Part 1 / 07.87, Section 5.4.3.2.4)

In compliance with DIN VDE 0160 / 05.88, all SIMODRIVE units are subject to

a high–voltage test at the time of routine testing. If the electrical equipment of

industrial tools is subject to a high–voltage test, all connections must be

disconnected so that sensitive electronic components in the SIMODRIVE

converter are not damaged (permissible acc. to DIN VDE 0113 / 06.93, Part 1,

Section 20.4).

Warning

!

Start–up/commissioning is absolutely prohibited until it has been ensured that

the machine in which the components described here are to be installed, fulfills

the regulations/specifications of the Directive 89/392/EWG.

Warning

!

The information and instructions in all of the documentation supplied and any

other instructions must always be observed to eliminate hazardous situations

and damage.

For special versions of the machines and equipment, the information in the

associated catalogs and quotations applies.

Further , all of the relevant national, local and plant/system–specific regula-

tions and specifications must be taken into account.

All work should be undertaken with the system in a no–voltage condition!

Warning

!

Before commissioning SIMODRIVE 611 analog it should be checked that the

encoder cable does not have a ground fault.

If ground faults occur for loads which extert a force on the drive (e.g. hanging,

vertical axes), uncontrolled movement could occurr.

This no longer occurs for 6SN1118–0D2–0AA0, Version B.

iv

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

Siemens AG 2000 All rights reserved

Page 9

10.00

07.94

ESDS information

Electro–static discharge sensitive devices

Components which can be destroyed by electrostatic discharge are individual

components, integrated circuits, or boards, which when handled, tested or

transported, could be destroyed by electrostatic fields or electrostatic

discharge. These components are designated as ESDS (ElectroStatic

Discharge Sensitive Devices).

Handling ESDS boards:

The human body, working area and packing should be well grounded when

handling ESDS components!

Electronic boards should only be touched when absolutely necessary.

Components may only be touched, if

– you are continuously grounded through an ESDS bracelet,

– you are wearing ESDS shoes or ESDS shoe grounding strips in

conjunction with an ESDS floor surface.

Boards may only be placed on conductive surfaces (desk with ESDS

surface, conductive ESDS foam rubber, ESDS packing bag, ESDS

transport containers).

Boards may not be brought close to data terminals, monitors or television

sets (a minimum of 10 cm should be kept between the board and the

screen).

Boards may not be brought into contact with materials which can be

charged–up and which are highly insulating, e.g. plastic foils, insulating

desktops, articles of clothing manufactured from man–made fibers.

Measuring work may only be carried out on the boards, if

– the measuring equipment is grounded (e.g. via the protective conductor)

or

– for floating measuring equipment, the probe is briefly discharged before

making measurements (e.g. a bare control housing is touched).

Only touch the control boards at the front panel

Note

Start–up software is available for starting–up/commissioning the main spindle

and induction motor modules.

Start–up software Order No.: 6SN1153–2AX10–AB

Documentation Order No.: 6SN1197–0AA30–0P

Siemens AG 2000 All rights reserved

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

v

Page 10

SINUMERIK and SIMODRIVE

Enhanced productivity as a result of fast, reliable commissioing

10.00

07.94

Handling

Check list

Sophisticated industrial electronics, as are involved here, have to be handled

especially carefully. We regularly evaluate and investigate equipment which is

returned, and in so doing, we have identified some of the main fault causes,

which in some cases results from incorrect handling during commissioning and

troubleshooting.

The following check list should help you to simply commission the components

we have supplied and guarantee a high availability when used in conjunction

with your product or equipment.

Observe all of the ESD measures when handling components.

Tighten–up all bolts and screws to the specified torque. Pay special

attention to the DC link bolt connections (1.8 Nm tightening torque).

Correctly insert all connectors and lock/screw into place.

Screw the control components into the power module.

Observe the power–on sequence in the Planning Guide.

If the unit is frequently powered–down and up, the DC link charge circuit is

locked–out. The DC link can only be charged again after it has cooled down

for several minutes with the supply off.

Are there line supply/motor contactors connected to the drive converter?

These are only switched in a no–current condition.

Ground all components and connect all of the shields. Connection X131 is

grounded.

Observe the load capability of the central power supply.

Only discharge the unit at the DC link buses through a minimum of 10 Ω.

In operation, units with hard disks may only be stressed with a max. of 1 g

read/write error; defective).

Are OEM components (ISA–/PCMCIA card) used? Their current drain must

lie within the specified values.

CRT monitors may not be subject to magnetic fields (e.g. power supply unit

coils).

When commissioning and fault finding, always proceed in a modular step–

by–step fashion. This means: First commission the central controller and

line supply module, then connect–up and commission the components one

after another.

vi

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

Siemens AG 2000 All rights reserved

Page 11

10.00

07.94

The units are designed for the specified mechanical, climatic and electrical

ambient conditions. None of the limit values may be exceeded, neither in

operation nor during transport. Please pay specific attention to the following:

– line supply conditions

– pollutants

– damaging gases

– climatic ambient conditions

– storage/transport

– shock stressing

– vibration stressing

– ambient temperature

Further

information

Further detailed information is provided in the Planning Guides and Installation

Start–up Guides associated with our products.

Siemens AG 2000 All rights reserved

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

vii

Page 12

Space for notes

10.00

10.00

07.94

viii

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

Siemens AG 2000 All rights reserved

Page 13

General Information (AL)

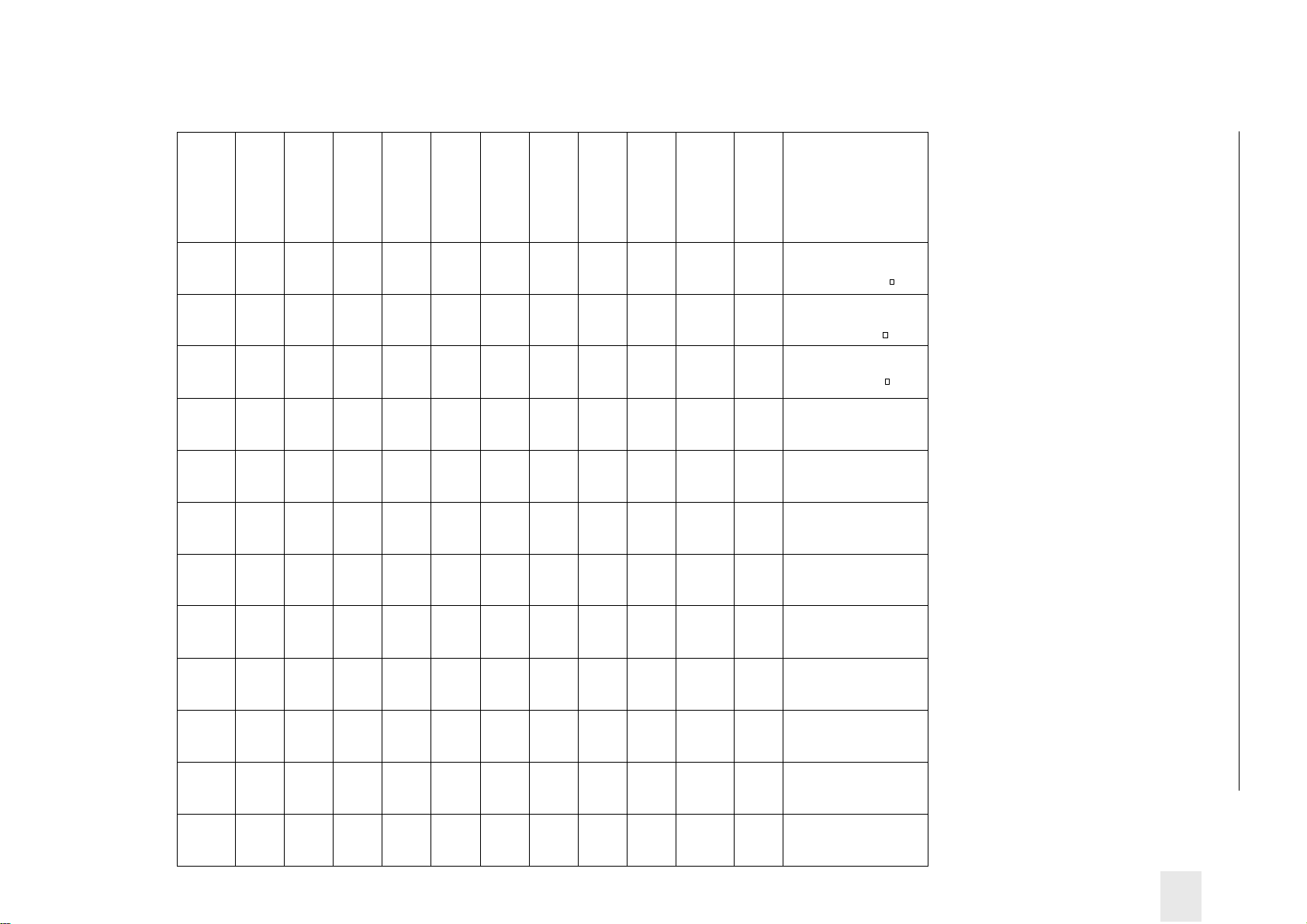

1 Permissible Combination of Power Modules and Control Boards AL/1-3. . . . . . .

AL

Siemens AG 2000 All rights reserved

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

AL–i

Page 14

AL

Space for notes

10.00

07.94

AL–ii

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

Siemens AG 2000 All rights reserved

Page 15

Siemens AG 2000 All rights reserved

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

Power module, 200A

pipe connection

6SN112–1AA0–0FA

FD:

100/200A

FD:

100/200A

_____ _____ _____ MSD:

85/110/12

7A

MSD:

85/110/12

7A

MSD:

85/110/12

7A

IM:

85/110/12

7A

IM:

85/110/12

7A

AL/1-3

IM:

85/110/12

7A

Power module, 200A

6SN112–1AA0–0FA

FD:

100/200A

FD:

100/200A

_____ _____ _____ MSD:

85/110/

127A

MSD:

85/110/

127A

MSD:

85/110/

127A

IM:

85/110/

127A

IM:

85/110/

127A

MSD:

85/110/

127A

Power module, 160A

6SN112–1AA0–0EA

FD:

80/160A

FD:

80/160A

_____ _____ _____ MSD:

60/80/

102A

MSD:

60/80/

102A

MSD:

60/80/

102A

IM:

60/80/

102A

IM:

60/80/

102A

MSD:

60/80/

102A

Power module, 108A

6SN112–1AA0–0LA

_____ _____ _____ _____ _____ MSD:

45/60/76A

MSD:

45/60/76A

MSD:

45/60/76A

IM:

45/60/76A

IM:

45/60/76A

MSD:

45/60/76A

Power module, 120A

6SN112–1AA0–0GA

_____ _____ _____ _____ _____ MSD:

45/60/76A

MSD:

45/60/76A

MSD:

45/60/76A

IM:

45/60/76A

IM:

45/60/76A

MSD:

45/60/76A

Power module, 80A

6SN112–1AA0–0DA

FD:

40/80A

FD:

40/80A

_____ FD–R:

28/56A

_____ MSD:

30/40/51A

MSD:

30/40/51A

MSD:

30/40/51A

IM:

30/40/51A

IM:

30/40/51A

MSD:

30/40/51A

Power module, 50A

6SN112–1AA0–0CA

FD:

25/50A

FD:

25/50A

_____ FD–R:

18/36A

_____ MSD:

24/32/32A

MSD:

24/32/32A

MSD:

24/32/32A

IM:

24/32/32A

IM:

24/32/32A

MSD:

24/32/32A

Power module, 25A

6SN112–1AA0–0BA

FD:

12.5/25A

FD:

12.5/25A

_____ FD–R:

9/18A

_____ _____ _____ _____ IM:

8/10/16A

IM:

8/10/16A

_____ IM:

Power module, 15A

6SN112–1AA0–0AA

FD:

7.5/15A

FD:

7.5/15A

_____ FD–R:

5/10A

_____ _____ _____ _____ IM:

5/5/8 A

IM:

5/5/8 A

_____ IM:

Power module, 8A

6SN112–1AA0–0HA

FD:

4/8A

FD:

4/8A

_____ FD–R:

3/6A

_____ _____ _____ _____ IM:

3/3/3 A

IM:

3/3/3 A

_____ IM:

HS option FD analog

user–friendly

6SN1114–0AA02–0AA

Possible _____ _____ _____ _____ _____ _____ _____ _____ _____ _____ _____

Parameter board

FD analog user–friendly

6SN1114–0AA01–0AA0

Required _____ _____ _____ _____ _____ _____ _____ _____ _____ _____ _____

FD control, analog

1–axis, user–friendly interface

6SN1118–0AA11–0AA

FD control, analog

1–axis, standard interface

6SN1118–0AD11–0AA

FD control, analog

2–axis, standard interface

6SN1118–0AE11–0AA

FD resolver control, analog

1–axis, standard interface

6SN1118–0BJ11–0AA0

FD resolver control, analog

2–axis, standard interface

6SN1118–0BK11–0AA0

MSD control, analog

No direct measuring system

6SN1121–0BA11–0AA0

MSD control, analog

Dir. meas. system, TTL signal

6SN1121–0BA12–0AA0

MSD control, analog

Ext. position output

6SN1121–0BA13–0AA0

IM control, analog

Fixed setpoints, motorized pot

6SN1122–0BA11–0AA0

IM control, analog

Anal. speed f. setp. mot. pot.

6SN1122–0BA12–0AA0

MSD control, analog

Permissible Combination of Power

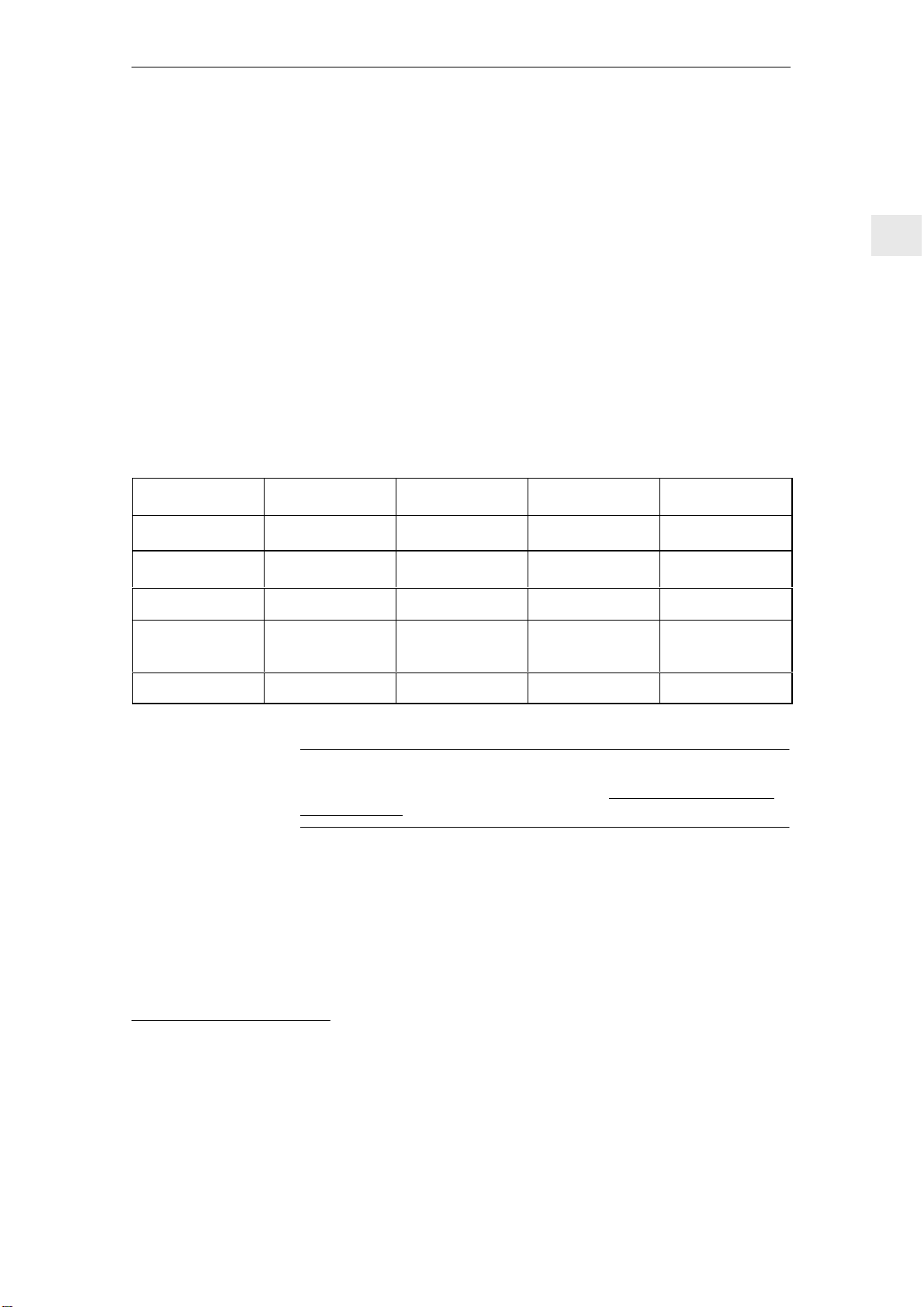

Table 1-1 Selection list to set the current controller referred to the resulting power module currents

SIMODRIVE 611

components

Modules and Control Boards

10.00

07.94

1 Permissible Combination of Power Modules and Control Boards

General Information (AL)

1

8/10/16A

IM:

24/32/32A

IM:

30/40/51A

IM:

45/60/76A

IM:

45/60/76A

IM:

60/80/

102A

IM:

85/110/

127A

IM:

85/110/12

7A

5/5/8 A

3/3/3 A

IM control, analog

6SN1122–0BA11–0AA1

AL

6SN1121–0BA11–0AA1

Page 16

AL/1-4

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

Siemens AG 2000 All rights reserved

6SN1130–1AE11–0A0 FD module, 2–axis, standard interface

6SN1135–1BA1–0A0 MSD module

6SN1140–1BA1–0A0 IM module

This Start–Up Guide appropriately applies to the following drive modules:

6SN1130–1AA11–0A0 FD module, 1–axis, user–friendly interface

6SN1130–1AA12–0A0 FD module, 1–axis, user–friendly with

6SN1130–1AD11–0A0 FD module, 1–axis, standard interface

MSD option

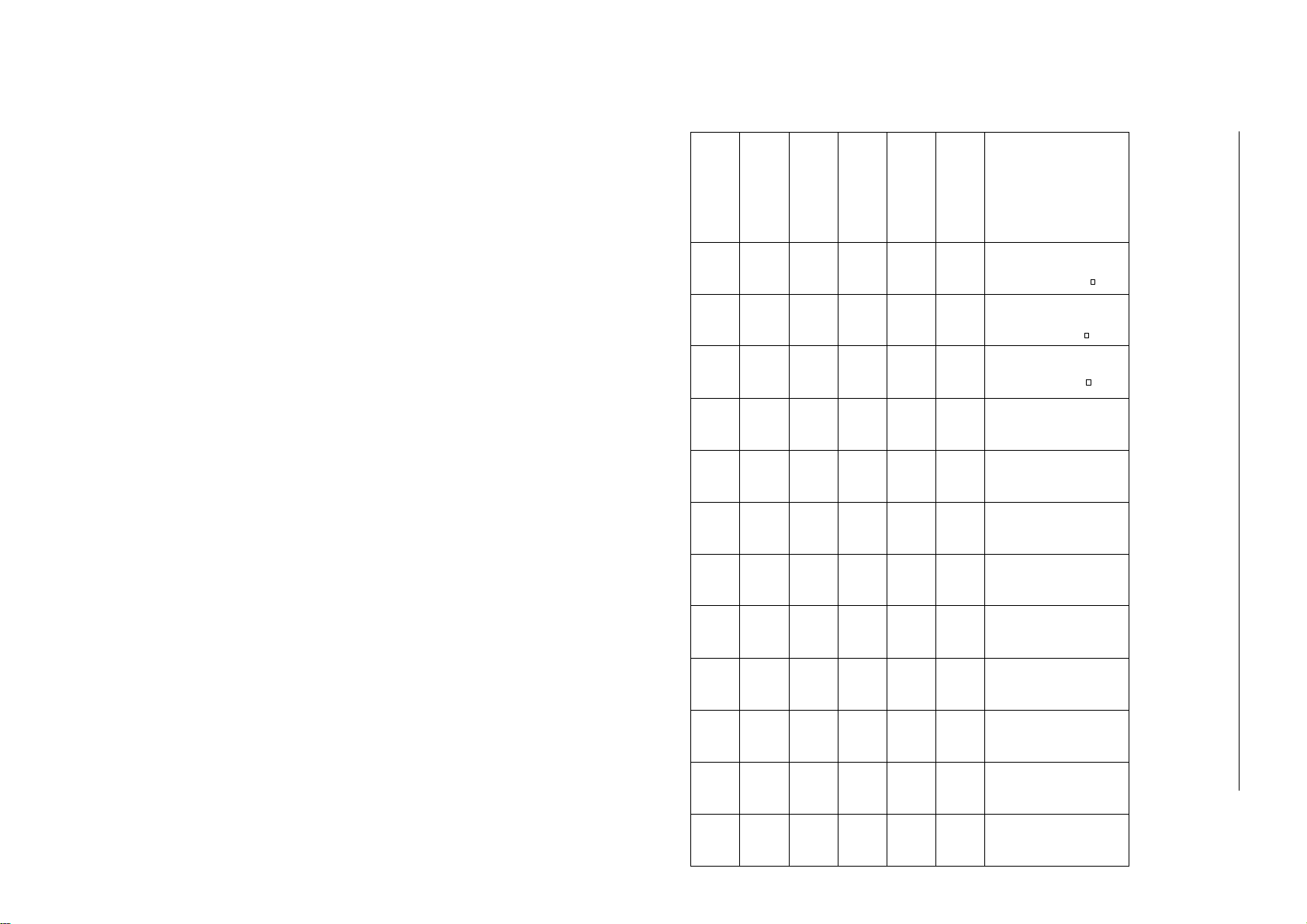

Power module, 2x50A

6SN112–1AB0–0CA

_____ _____ FD:

2x25/50A

_____ FD–R:

2x18/36A

_____ _____ _____ _____ _____ _____ _____

Power module, 2x25A

6SN112–1AB0–0BA

_____ _____ FD:

2x12.5/

25A

_____ FD–R:

2x9/18A

_____ _____ _____ _____ _____ _____ _____

Power module, 2x15A

6SN112–1AB0–0AA0

_____ _____ FD:

2x7.5/15A

_____ FD–R:

2x5/10A

_____ _____ _____ _____ _____ _____ _____

Power module, 2x8A

6SN112–1AB0–0HA0

_____ _____ FD:

2x4/8A

_____ FD–R:

2x3/6A

_____ _____ _____ _____ _____ _____ _____

Power module, 400A

6SN112–1AA0–0KA0

_____ _____ _____ _____ _____ MSD:

200/250/

257A

MSD:

200/250/

257A

MSD:

200/250/

257A

IM:

200/250/

257A

IM:

200/250/

257A

IM:

200/250/

257A

Power module, 300A

6SN112–1AA0–0JA

_____ _____ _____ _____ _____ MSD:

120/150/

193A

MSD:

120/150/

193A

MSD:

120/150/

193A

IM:

120/150/

193A

IM:

120/150/

193A

IM:

120/150/

193A

components

FD control, analog

1–axis, user–friendly interface

6SN1118–0AA11–0AA

FD control, analog

1–axis, standard interface

6SN1118–0AD11–0AA

FD control, analog

2–axis, standard interface

6SN1118–0AE11–0AA

FD resolver control, analog

1–axis, standard interface

6SN1118–0BJ11–0AA0

FD resolver control, analog

2–axis, standard interface

6SN1118–0BK11–0AA0

MSD control, analog

No direct measuring system

6SN1121–0BA11–0AA0

MSD control, analog

Dir. meas. system, TTL signals

6SN1121–0BA12–0AA0

MSD control, analog

Ext. position output

6SN1121–0BA13–0AA0

IM control, analog

Fixed setpoints, motorized pot.

6SN1122–0BA11–0AA0

IM control, analog

Anal. speed f. setp. mot. pot.

6SN1122–0BA12–0AA0

MSD control, analog

AL

General Information (AL)

Table 1-1 Selection list to set the current controller referred to the resulting power module currents

SIMODRIVE 611

1 Permissible Combination of Power Modules and Control Boards

07.94

200/250/

257A

6SN1121–0BA11–0AA1

IM:

IM control, analog

IM:

120/150/

193A

6SN1122–0BA11–0AA1

Page 17

07.94

General Information (AL)

1 Permissible Combination of Power Modules and Control Boards

AL

Note

This document describes the steps which are necessary to start–up

(commission) an installed SIMODRIVE drive group. Please refer to the

associated Planning Guides for additional technical information, e.g. regarding

ambient conditions

recommended circuits

connection diagrams

dimension sheets/dimension drawings

SIMODRIVE 611

Transistor PWM Inverters for AC Feed Drives and AC Main Spindle Drives

Order No.: 6SN1197–0AA00–0P

SIMODRIVE

AC Motors for Feed and Main Spindle Drives

Order No.: 6SN1197–0AA20–0P

Siemens AG 2000 All rights reserved

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

AL/1-5

Page 18

AL

General Information (AL)

1 Permissible Combination of Power Modules and Control Boards

Space for notes

10.00

07.94

AL/1-6

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

Siemens AG 2000 All rights reserved

Page 19

Supply Infeed (NE)

1 Standard Settings, NE Modules (UE and I/R Modules), Monitoring and Pulsed

Resistor Modules NE/1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Service and Diagnostics NE/2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Terminals and relay functions NE/2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Attachment NE/3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Terminals, NE, monitoring and pulsed resistor modules NE/3-14. . . . . . . . . . .

3.2 Terminals, UE module 5/10 kW NE/3-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NE

Siemens AG 2000 All rights reserved

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

NE–i

Page 20

NE

Space for notes

10.00

07.94

NE–ii

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

Siemens AG 2000 All rights reserved

Page 21

10.00

07.94

Supply Infeed (NE)

1 Standard Settings NE Modules, Monitoring and Pulsed Resistor Modules

Standard Settings, NE Modules (UE and

I/R Modules), Monitoring and Pulsed

Resistor Modules

Important

!

Observe the information/instructions regarding closed–loop sinusoidal current

control for I/R modules!

If you do not observe the difference between sinusoidal/squarewave current

control, the equipment could be destroyed!

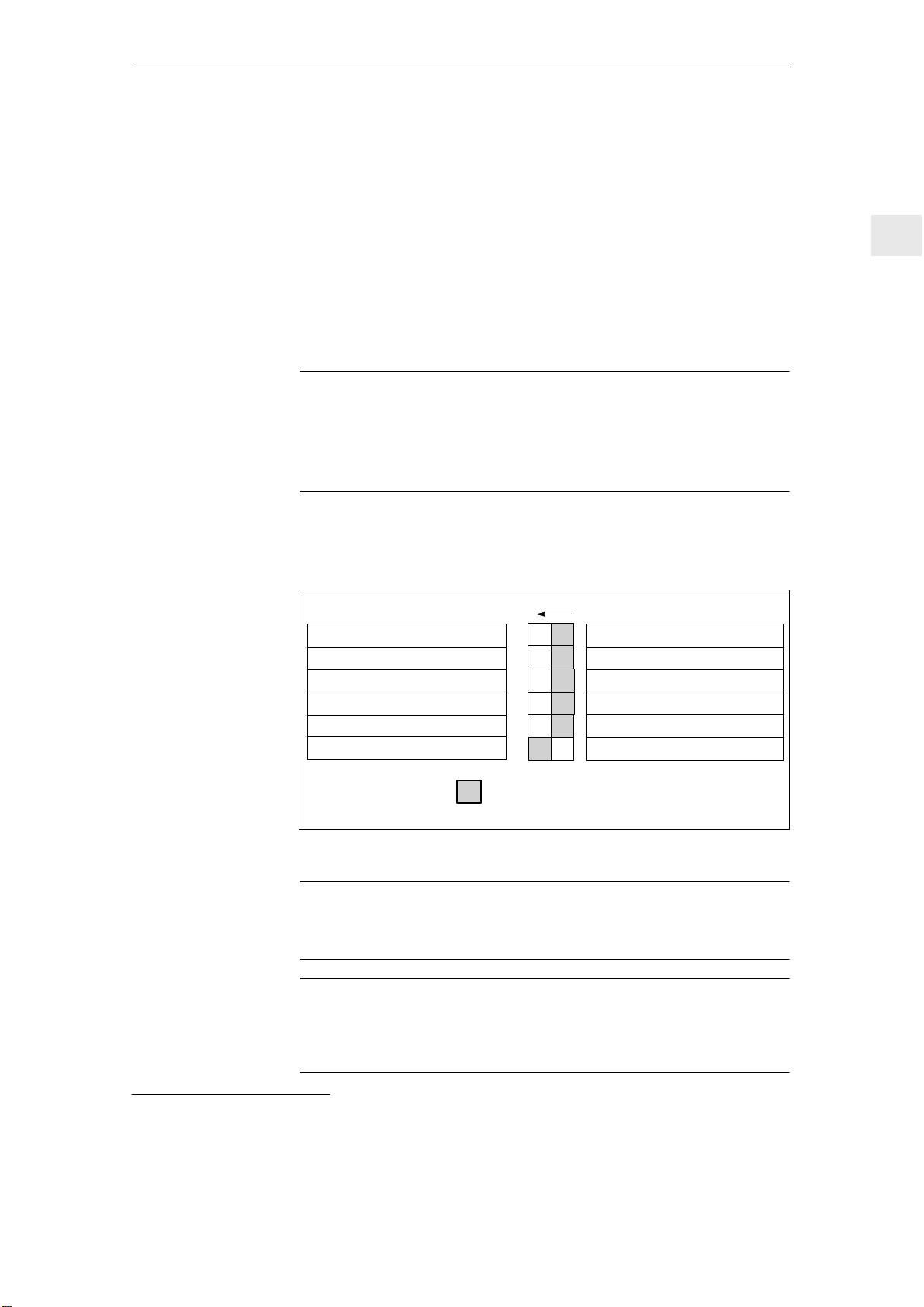

There is a switch S1 on the upper side of the NE and monitoring module which

is used to select the following functions:

ON: OFF:

=415V

10%

V

+6%–10%

= 625 V

DC link

1)

; S1.1 inactive

V

supply

Fault signal

Regenerative feedback off

V

=480V

supply

Controlled infeed off

Sinusoidal current control

S1

1)

1

2

3

4

5

6

V

=400V

supply

Ready signal

Regenerative feedback on

S1.1 active

Controlled infeed

Squarewave current control

NE

1

10%

V

DC link

= 600 V

1)

Standard setting

Fig. 1-1 DIL switch S1

Important

!

!

1) only possible for I/R module, monitoring thresholds are increased for all NE modules

For I/R modules. Order No. 6SN114–10–01 the basic setting is

closed–loop sinusoidal control . Observe the information on NE/1–5!

Important

Before the system is powered–up/down using the main switch or a line

contactor, terminal 63 (pulse enable) and/or terminal 48 (start terminal,

contactor control), must be de–energized or disconnected!

Siemens AG 2000 All rights reserved

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

NE/1-3

Page 22

Supply Infeed (NE)

1 Standard Settings NE Modules, Monitoring and Pulsed Resistor Modules

07.94

NE

Switch S 1.1 :

Switch S 1.2 :

Switch S 1.3 :

OFF: I/R moduleV

V

=600V (DC link voltage)

DC link

UE module V

=400V10%;

supply

=400V10%; V

supply

DC link

=1.35*V

Monitoring thresholds: (I/R, UE, monitoring modules)

Pulsed resistor on =644V (pulsed res. switch–on threshold);

Pulsed resistor off =618V (pulsed res. switch–off threshold)

V

>> =710V (DC link overvoltage threshold);

DC link

ON: I/R module V

UE module V

=415V10%; V

supply

=415V10%; V

supply

DC link

DC link

=625V

=1.35*V

Monitoring thresholds: (I/R, UE, monitoring modules)

Pulsed resistor on =670V; Pulsed resistor off =640V

V

>> =740V;

DC link

Comment: Only active, if S1.4 OFF

OFF: Ready signal (X111: Ready relay)

ON: Fault signal (X111: Ready relay )

refer to NE/Section 2.1

OFF: Standard setting, regenerative feedback active

I/R modules are capable of regenerating into the line supply

UE module: The pulsed resistor in the module is effective

ON: Regenerative feedback is disabled

I/R module: Regenerative feedback operation is inhibited

UE module: The pulsed resistor in the module is not effective

supply

supply

Switch S 1.4 :

Comment: The function is only effective for UE 10kW from

Order No.[MLFB]: 6SN1146–1AC00–0AA1 onwards

(not for UE 28kW)

OFF: S1.1 active

ON: V

= 480V+6%–10%; V

supply

DC link

=1.35*V

supply

in the

regenerative feedback direction

Monitoring thresholds: (I/R, UE, monitoring modules)

Pulsed resistor on = 744V; Pulsed resistor off =718V

V

>> = 795V

DC link

Comment: Uncontrolled operation in the regenerative feedback direction.

(valid for Order No. [MLFB] 6SN114–10–01)

Note

Only in conjunction with power modules, Order No. [MLFB]

(6SN114–10–01).

For motors with shaft heights < 100 mm: Utilized up to max. the 60 K values.

Please observe the Planning Guide, Motors.

S1.4 ON overwrites the functions of S1.5 and S1.1.

NE/1-4

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

Siemens AG 2000 All rights reserved

Page 23

07.94

Supply Infeed (NE)

1 Standard Settings NE Modules, Monitoring and Pulsed Resistor Modules

Switch S 1.5 :

Switch S 1.6 :

I/R

16 kW

6SN114–

1B01–0BA1

HF reactor

16 kW

6SN1111–

0AA00–0BA0

Line filter

sinusoidal current

16 kW

6SN1111–

0AA01–2BA0

This function is only available in conjunction with I/R modules

Order No.: 6SN114–10–01

OFF: Standard setting, controlled infeed active.

ON: Uncontrolled operation in the regenerative feedback direction

=1.35*V

V

DC link

Regenerative feedback starts at V

supply .

=600 or 625V,

DC link

depending on the setting of S1.1.

OFF: Closed–loop squarewave current control (current square

waveform is drawn from the line supply)

ON: (Standard) This function is only available in conjunction with

I/R modules 6SN114–10–01

closed–loop sinusoidal current control (sinusoidal current is

drawn from the line supply)

Sinusoidal current is only permissible if the following secondary

conditions are fulfilled:

I/R

36 kW

6SN114–

1B02–0CA1

HF reactor 36 kW HF reactor 55 kW HF reactor 80kW HF reactor 120kW

6SN1111–

0AA00–0CA0

1)

Line filter for

sinusoidal current

36 kW

6SN1111–

0AA01–2CA0

1)

I/R

55 kW

6SN114–

1B0–0DA1

6SN1111–

0AA00–0DA0

Line filter for

sinusoidal current

55 kW

6SN1111–

0AA01–2DA0

1BB00–0EA1

0AA00–1EA0

1)

Line filter for

sinusoidal current

0AA01–2EA0

I/R

80 kW

6SN114–

6SN1111–

80 kW

6SN1111–

1)

sinusoidal current

I/R

120 kW

6SN114–

1BB01–0FA1

6SN1111–

0AA00–1FA0

Line filter for

120 kW

6SN1111–

0AA01–2FA0

NE

1)

Important

!

For all combinations which are not listed, only closed–loop squarewave

current control is permissible .

1) In the sinusoidal line filters, contrary to the squarewave current filter modules, there are no HF commutating reactors.

The HF commutating reactor must be separately mounted.

The specified line filter types are also suitable for the squarewave current mode.

Siemens AG 2000 All rights reserved

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

NE/1-5

Page 24

NE

Supply Infeed (NE)

1 Standard Settings NE Modules, Monitoring and Pulsed Resistor Modules

Space for notes

10.00

07.94

NE/1-6

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

Siemens AG 2000 All rights reserved

Page 25

10.00

07.94

Supply Infeed (NE)

2 Service and Diagnostics

Service and Diagnostics

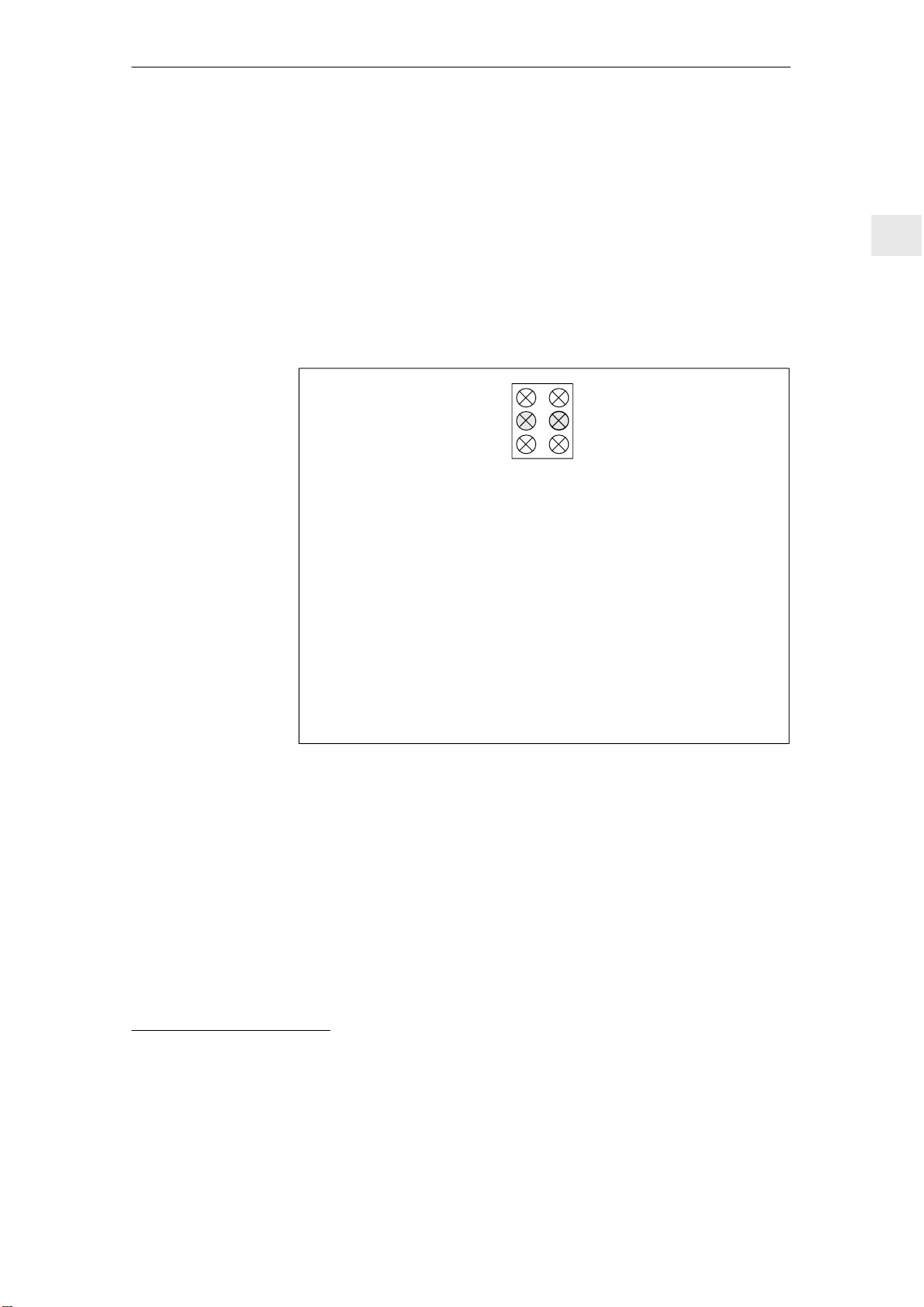

Display elements on the monitoring and NE modules

1 LED red – Electronics power supply 15 V faulted

2 LED red – 5 V voltage level faulted

3 LED green –Ext. enable signal not available (terminal 63 and/or 64 missing)

4 LED yellow – DC link charged

5 LED red – Line supply fault (single or multi–phase line supply failure at

terminals U1, V1, W1)

– No commutating reactor, incorrectly installed

or incorrectly selected

– Fault level of the line supply or transformer too low

6 LED red – DC link overvoltage

Possible causes: Regenerative feedback off, setting–up operation,

line supply fault, for UE, pulsed resistor not operational or too small,

line supply voltage too high, dynamic overload, line supply filter

installed between the I/R and commutating reactor

12

34

56

1)

2

NE

Effects:

1 LED red bright: Pulses are deleted for the complete drive group

2 LED red bright: Pulses are deleted for the complete drive group

4 LED yellow dark: Pulses are deleted for the complete drive group

5 LED red bright: Only the I/O module pulses are deleted (regenerative feed

back no longer possible. Axes initially continue to run,

ready relay drops–out)

6 LED red bright: Pulses are deleted for the complete drive group

1) Line supply fault recognition time, approx. 30 ms

Line supply fault is recognized when the three–phase voltage is < 280 V.

For a single–phase power failure, the drive axis pulses are deleted after approx. 1 min

(saved signal) valid for Order No. [MLFB] 6SN1114–10–01

Siemens AG 2000 All rights reserved

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

NE/2-7

Page 26

Supply Infeed (NE)

2.1 Terminals and relay functions

2.1 Terminals and relay functions

X111 Ready relay

10.00

07.94

NE

– terminals 72 – 73.1 NO contacts closed for “ready”

– terminals 73.2 – 74 NC contacts open for “ready”

Switch S1.2 OFF, the relay pulls–in, if:

– internal main contactor CLOSED (terminals NS1 – NS2 connected, terminal 48

energized)

– terminal 63, 64 = ON

– it is not permissible that a fault is present

(this is also true for FD 611A Standard, 611D drives or MCU)

– FD with standard interface or resolver for the “ready” setting must be enabled

(terminals 663, 65)

– NCU must have run–up (SINUMERIK 840D, SINUMERIK 810D)

– the MCU must have run–up

Switch S1.2 ON, relay pulls–in, if:

– internal main contactor CLOSED (terminal NS1 – NS2 connected, terminal 48

energized)

– it is not permissible that a fault is present

(this is also true for FD 611A Standard, or 611D drives or MCU)

– FD with standard interface or resolver for the “ready” setting must be enabled

(terminals 663, 65)

– NCU must have run–up (SINUMERIK 840D, SINUMERIK 810D)

– the MCU must have run–up

X121 I

Terminals 5.1 – 5.2 NO contacts open for “no fault”

Terminals 5.1 – 5.3 NC contacts closed for “no fault“

2

t pre–alarm and motor overtemperture

This relay switches, if:

– at the I/R ––> the heatsink temperature monitoring responds

– at FD 611D ––> the motor temperature monitoring responds

––> heatsink temperature monitoring responds

– at FD 611A user–friendly

––> motor–temperature monitoring responds

(for resolvers: this is not saved, no shutdown!!)

––> heatsink temperature monitoring responds

2

––> I

t pre–alarm responds (this is not saved)

– at FD611A Standard

––> motor–temperature monitoring responds

––> heatsink temperature monitoring responds

2

––> I

t temperature monitoring responds

X171 terminals NS1 – NS2

(coil circuit of the internal line supply and pre–charging contactor)

– is used to provide electrical isolation from the line supply

(signaling contact, terminals 11 1 – 213 must be interrogated)

– may only be switched when terminal 48 is open–circuit

(without any restrictions from

Order No. [MLFB] 6SN1145–101–0 for 10, 16 and 55 kW

Order No. [MLFB] 6SN1145–102–0 for 36 kW , all 80 and 120 kW)

NE/2-8

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

Siemens AG 2000 All rights reserved

Page 27

10.00

07.94

2.1 Terminals and relay functions

Terminal 48 Start

– has the highest priority

– sequence:

pre–charging ON – interrogate V

– 50 V.

If yes, then

500 ms pre–charging contactor OPEN, interrogate whether actually

OPEN, main contactor CLOSE

1 s internal enable signal (for I/R and module group)

– is saved during pre–charging

Terminal 63 Pulse enable

– has the highest priority for enabling the pulses for all of the modules

– acts instantaneously

Terminal 64 Drive enable

– acts instantaneously on all modules

– when the signal is withdrawn, n

– For MSD / IM 611A, after a selectable speed has fallen below,

the pulses are cancelled. The drive is braked along a ramp.

– For VSA 611A, all of the controllers and pulses are inhibited after

a selected time has expired (setting when supplied: 240 ms).

The drive is braked along the current limit.

– For 611D drives, the pulses are deleted after a selectable speed has

been fallen below or after a selectable time has expired. The drive is

braked at the selected limit! (for spindles, the ramp can only be

achieved along the regenerative limit [kW]!)

Terminal 112 open–circuit Setting–up operation

300V and V

DC link

is set to 0 for all drives, and

set

DC link

√2 V

Supply Infeed (NE)

supply

NE

– The V

– Regenerative feedback is not possible,

i.e. when braking, V

– This function can be interrogated using the start inhibit signal,

terminals AS1 – AS2.

!

Terminals AS1 – AS2 Start inhibit signal

– Terminals AS1 – AS2 closed means “start inhibit is effective”

(i.e. terminal 48 = open–circuit, setting–up operation)

Terminals 111, 113, 213 Signaling contacts, internal line contactor

– Terminals 111 – 113 NO contacts

– Terminals 111 – 213 NC contacts (for I/R 16 kW and UE 10 kW,

control is inhibited

DC link

can be > 600 V !

DC link

Caution

Induction motors can reach high speeds even at low V

only from

Order No.[MLFB] 6SN1145–101–0)

DC link

!

Siemens AG 2000 All rights reserved

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

NE/2-9

Page 28

NE

Supply Infeed (NE)

2.1 Terminals and relay functions

Terminal 19 FR–

– Reference ground, enable voltage

– Floating (connected with the general reference ground terminal 15 via10 kΩ)

– Terminal 19 may not be connected to terminal 15

(connect to PE rail, or to X131 )

Terminal 9 FR+

– Enable voltage : +24 V

– Maximum load capacity of the power supply (power supply): 500 mA

(corr. to 8 EP;1 optocoupler input required 12 mA, for UE = 5 kW ––> 1A)

X 141 Electronic voltages

– Term. 7 P24 +20.4 to 28.8 V / 50 mA

– Term. 45 P15 +15 V / 10 mA

– Term. 44 N15 –15 V / 10 mA

– Term. 10 N24 –20.4 to –28.8 V / 50 mA

– Term. 15 M 0 V

– Terminal 15 may not be connected to PE (ground loop)

– Terminal 15 may not be connected to terminal 19

(short–circuit via reactor, which internally connects terminal 15 to X131)

Terminals L1 – L2 for 80 kW and 120 kW I/R

10.00

07.94

– Is used to supply the coil circuit of the internal line contactor

– directly supplied with 2–ph. 400 V AC at the line supply

(not between I/R and reactor)

– Fuse: I

Fan connection for 80 and 120 kW I/R

– 3–ph. 360 to 510 V AC, 45 – 65 Hz directly from the line supply

(not between I/R and reactor)

– Observe the direction of rotation!

– Fuse: I

6–wire connection

with additional power supply connection at the DC link:

– For this mode, terminals 2U1, 2V1 and 2W1 of the power supply

must be supplied with the line supply voltage between the series reactor and

I/R, as otherwise the power supply will be destroyed. The also applies to the

montioring modules!

Note

This is guaranteed by the jumpers inserted in the factory at connector X181.

Monitoring mod u l e w i t h c o n n e c t i o n t o t h e l i n e supply and additional power

supply connection at the DC link :

4 A, version gL

N

1.5 A (motor protection circuit–breaker)

N

NE/2-10

– For this mode, terminals 2U1, 2V1 and 2W1 of the power supply

must be supplied with the line supply voltage between the series reactor and

I/R, as otherwise, the power supply will be destroyed!

– Terminal 63 may only be energized (enabled) after the NE module has run–up

(ready). (Interrogation “ready” or terminal 111 – 113 – 213).

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

Siemens AG 2000 All rights reserved

Page 29

10.00

07.94

Supply Infeed (NE)

2.1 Terminals and relay functions

Diagnostics

The overvoltage limiting module must be checked if a line supply fault is

displayed or the yellow LED is dark.

Procedure:

1. Power–down the unit so that it is in a no–voltage condition

2. Remove the overvoltage limiting module and insert connector X181 on the

NE module. If the NE module functions, then the overvoltage limiting module

is defective and must be replaced. Otherwise, check the line supply and if

necessary check the NE module/group.

Note

In this way, continued operation is possible, without overvoltage protection.

3. Insert the overvoltage limiting module 566018.9415.00 up to its end stop,

and insert connector X181 on the overvoltage limiting module.

Note

Operation without overvoltage limiting module is not in conformance with UL!

NE

Siemens AG 2000 All rights reserved

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

NE/2-11

Page 30

NE

Supply Infeed (NE)

2.1 Terminals and relay functions

Space for notes

10.00

07.94

NE/2-12

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

Siemens AG 2000 All rights reserved

Page 31

07.94

Supply Infeed (NE)

3.1 Terminals, NE, monitoring and pulsed resistor modules

Attachment

3

Note

When using non PEL V circuits at terminals AS1, AS2, terminal 111, terminal

1 13 and terminal 213, connector coding must be used to prevent connectors

being interchanged.

––> refer to EN 60204–1, Section 6.4.

Order No. for the coding connector ––> refer to Catalog NC 60.1.

Only PELV circuits may be connected to terminal 19.

NE

Siemens AG 2000 All rights reserved

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

NE/3-13

Page 32

NE

Supply Infeed (NE)

10.00

07.94

3.1 Terminals, NE, monitoring and pulsed resistor modules

3.1 Terminals, NE, monitoring and pulsed resistor modules

Table 3-1 Terminal functions

Term.

No.

U1

V1

W1

PE

P600

M600

Desig. Function

Line supply I 3–ph. 400 V/480 V AC Refer to the

L1

L2

Line supply

for contactor

Protective conductor

DC link

DC link

Grounding bar

5)

Type

1)

Typ. voltage/limit values

Max.

cross–section

available in

Planning Guide I/R, UE

Bolt

2 4)

I/R 80/104 kW,

2 4)

I/R, UE, MM, PR

II2–ph. 400 V AC, directly at

the line supply

I

0 V

I/O

+300 V

I/O

–300 V

16mm2/10mm

16mm2/10mm

Busbar

Busbar

I/O –300 V Busbar I/R, UE

Terminals

120/156 kW

3)

P600

M600

1R,

2R,

DC link

DC link

Connection, internal/

external resistor

II+300 V

–300 V

16mm2/10mm

16mm2/10mm

I/O 300 V 16mm2/10mm

2 4)

2 4)

2 4)

3R

X131 Electronics M I/O 0 V 16mm2/10mm

2 4)

X351 Equipment bus I/O Various Ribbon cable I/R, UE, MM, PR

M500

P500

1U1

2U1

1V1

2V1

1W1

2W1

45

44

10

15

5.3

5.2

5.1

63

64

19

X181

X181

X181

X181

X181

X181

X181

X181

7

X141

X141

X141

X141

X141

R

X141

X121

X121

X121

X121

9

X121

9

X121

X121

DC link power supply

DC link power supply

Output L1

Input L1

Output L2

Input L2

Output L3

Input L3

P24

P15

N15

N24

M

6)

RESET

Relay contact

Group signal

I2t/motor temp.

Pulse enable

Enable voltage

Enable voltage

Drive enable

2)

2)8)

2)8)

2)

Enable voltage, ref.

I

600 V/680 V DC

I

600 V/680 V DC

O

3–ph. 400 V/480 V AC

I

3–ph. 400 V/480 V AC

O

3–ph. 400 V/480 V AC

I

3–ph. 400 V/480 V AC

O

3–ph. 400 V/480 V AC

I

3–ph. 400 V/480 V AC

O

+20.4...28.8 V/50 mA

O

+15 V/10 mA

O

–15 V/10 mA

O

–20.4...28.8 V/50 mA

O

0 V

I

Term.15/R

NC

50 V DC/0.5 A/12 VA max

NO

5 V DC/3 mA min

E

I

I

+13 V ...30 V/RE = 1.5 kΩ

O

+24 V

O

+24 V

I

+13 V ...30 V/RE = 1.5 kΩ

0 V

= 10 kΩ

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

potential

74

nc

73.2

73.1

nc

72

X111

X111

X111

X111

X111

X111

Relay contact

Ready signal

NC

I

1–ph. 250V AC/50V DC/2A

I

max

5V DC/3mA min

NO

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

2

2

2

2

2

2

MM

PR

I/R, UE, MM

I/R, UE, MM

I/R, UE, MM

I/R, UE, MM

I/R, UE, MM

NE/3-14

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

Siemens AG 2000 All rights reserved

Page 33

10.00

07.94

Table 3-1 Terminal functions

Supply Infeed (NE)

3.1 Terminals, NE, monitoring and pulsed resistor modules

Term.

No.

112

111

213

113

48

9

X161

X161

X161

X161X

161

X161

FunctionDesig.

Enable voltage

Setting–up operation/

Normal operation

Contactor control

2)8)

2)

2)

Signaling contact

Line contactor

Type

Typ. voltage/limit values

1)

OI+24 V

+21 V ...30 V/RE = 1.5 kΩ

I

+13 V ...30 V/RE = 1.5 kΩ

I

NC

+30 V/1 A (111–113)

1–ph. 250 V AC/50 V DC/

7)

2 A max

17 V DC/3 mA min

Max.

cross–section

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

Terminals

available in

I/R, UE, MM

I/R, UE

NO

AS1

AS2

NS1

NS2

X172

X172

X171

X171

Signaling contact

Start inhibit (term.112)INC

Coil contact for line

OI+24 V 1.5 mm

supply, pre–charging

250V AC/1A/50V DC/2A max

5 V DC/10 mA min

1.5 mm

1.5 mm

1.5 mm

2

2

2

2

I/R

I/R, UE

contactor

1950X221

X221

Enable voltage ref. potential

Control contact for fast

OI0 V

0 V

1.5 mm

1.5 mm

2

2

PR

discharge

Notes:

1) I = Input, O = Output, NC = NC contact, NO = NO contact (for signal: closed = high, open = low)

2) T erminal19 is the reference ground (this is connected inside the module to general reference ground X131/terminal 15

with 10 k). Terminal 15 may not be connected to PE or to terminal 19. Do not connect external voltage sources to

terminal 15! Terminal 19 can be connected to X131 .

3) I/R = Infeed/regenerative feedback module;

UE = Uncontrolled infeed;

MM= Monitoring module;

PR = Pulsed resistor module

4)The 1st data is valid with cable lug. The 2nd data is valid for finely–stranded conductor without end sleeve.

5)The grounding bar is used to ground the DC link M bus via 100 kΩ (this should be preferably inserted, for non–grounded

line supplies, always insert).

6)RESET = Reset the fault memory, edge–triggered for the complete drive group (terminal R→ terminal15 = RESET)

7) Terminals 111–213, positive opening NC contact (for I/R 16 kW and UE 10kW only from Order No.[MLFB]

6SN114–101–0).

Terminals 111–113, NC contact, not positively driven

8)Max. current load, terminal 9 – terminal 19: 0.5 A

3)

NE

Siemens AG 2000 All rights reserved

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

NE/3-15

Page 34

Supply Infeed (NE)

3.2 Terminals, UE module 5/10 kW

3.2 Terminals, UE module 5/10 kW

Table 3-2 Terminal functions

10.00

07.94

NE

Term.

Desig–

No.

nation

U1

X1 Line supply I 3–ph. 400 V AC/480 V 4 mm

Function

Type

1)

Typ. voltage limiting values Max. cross–section

V1

W1

PE1

–

Protective conductor

I

0 V

2

finely stranded

without end sleeve

2

6 mm

with cable lug

Thread M5

PE2

P600

M600

M500

P500

1U1

2U1

1V1

2V1

1W1

2W1

5.3

5.2

5.1

nc

74

73.2

73.1

72

63

64

19

9

9

R

X131

X351

X181

X181

X181

X181

X181

X181

X181

X181

X121A

X121A

X121A

X121A

X121B

X121B

X121B

X121B

X141A

X141A

X141A

X141A

X141A

X141A

Electronics M

Equipment bus

Grounding bar

3)

DC link

DC link

DC link power supply

DC link power supply

Output L1

Input L1

Output L2

Input L2

Output L3

Input L3

Relay contact

Group signal

I2t/motor temp.

Relay signal

Ready/

Fault

Pulse enable

FR+

FR+

Drive enable

RESET

2)

2)4)

2)4)

2)

2)

FR–, reference ground, enable si-

I

0 V

I/O

Various

I/O

–300 V

I/O

+300 V

I/O

–300 V

I

–300 V

I

+300 V

O

3–ph. 400 V AC/480 V

I

3–ph. 400 V AC/480 V

O

3–ph. 400 V AC/480 V

I

3–ph. 400 V AC/480 V

O

3–ph. 400 V AC/480 V

I

3–ph. 400 V AC/480 V

NC

1–ph. 50 V DC/0.5 A/12 VA

NO

max

I

1–ph. 5 V DC/3 mA min

NC

1–ph. 250 V AC/50 V DC/2 A

I

max

I

NO

1–ph. 5 V DC/3 mA min

I

+13 V ...30 V/R

O

+24 V

O

+24 V

I

+13 V ...30 V/R

I

0/+24 V

O

0 V

= 1.5 kΩ

E

= 1.5 kΩ

E

Thread M4

34 core ribbon cable

Busbar

Busbar

Busbar

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

gnal voltage

111

213

112

48

NS1

NS2

15

9

X161

X161

X141B

X141B

X141B

X141B

X141B

X141B

Signaling contact

Line contactor

FR+ 2)4)

Setting–up/standard operation

Contactor control

2)

Coil contact for line,

pre–charging contactor

M

INC1–ph. 250 V AC/50 V DC/2 A

1–ph. 17 V DC/3 mA min

O

2)

+24 V

I

+13 V ...30 V/R

I

+13 V ...30 V/R

O

+24 V

I

0/+24 V

O

0 V

= 1.5 kΩ

E

= 1.5 kΩ

E

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

1.5 mm

2

2

2

2

2

2

2

2

Notes:

1)I = Input, O = Output, NC = NC contact, NO = NO contact (for signal: closed = high, open= low)

2)T erminal 19 is the reference terminal (this is connected inside the module to general reference ground X131 with 10 k) .

3)The grounding bar is used to ground the DC link M busbar through 100 kΩ (this should be preferably inserted; always

insert for non–grounded line supplies).

4)Max. current load, terminal 9 – terminal 19: 1 A

NE/3-16

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

Siemens AG 2000 All rights reserved

Page 35

Feed Modules(VS)

1 Short Commissioning, Standard Settings VS/1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Tachometer adaptation for motors with tachometer voltages 3 16.5 V

at rated speed VS/1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Current controller settings VS/1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Speed Controller Optimization VS/2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Tachometer calibration VS/2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Setting the proportional gain Kp without adaptation VS/2-19. . . . . . . . . . . . . . .

2.3 Setting the integral action time TN without adaptation VS/2-20. . . . . . . . . . . . .

2.4 Integral action time with adaptation (if required) VS/2-21. . . . . . . . . . . . . . . . . .

2.5 P gain with adaptation (only user–friendly interface) VS/2-22. . . . . . . . . . . . . .

2.6 Setting the adaptation range (generally not required) VS/2-23. . . . . . . . . . . . .

2.7 I–component speed controller limiting VS/2-23. . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 Drift compensation (offset) VS/2-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VS

3 Supplementary Commissioning Functions VS/3-25. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Setting elements with the standard interface VS/3-25. . . . . . . . . . . . . . . . . . . . .

3.1.1 Dimensioning the setting elements (Standard interface) VS/3-27. . . . . . . . . . .

3.2 Setting elements with user–friendly interface VS/3-29. . . . . . . . . . . . . . . . . . . .

4 Setpoint Interfaces VS/4-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Commissioning with the MSD Option VS/5-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Pre–settings VS/5-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 Settings with the control board withdrawn VS/5-35. . . . . . . . . . . . . . . . . . . . . . .

5.1.2 Settings in operation VS/5-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Analog outputs VS/5-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Free for Expansions VS/6-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Powering–Up VS/7-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Service and Diagnostics VS/8-47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Test sockets and display elements of the feed modules VS/8-47. . . . . . . . . . .

8.1.1 User–friendly interface VS/8-47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.2 Standard interface VS/8-49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Troubleshooting VS/8-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siemens AG 2000 All rights reserved

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

VS–i

Page 36

VS

9 Attachments VS/9-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Terminals VS/9-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Layout diagram MSD option board VS/9-53. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Layout diagram, parameter board VS/9-54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 Layout diagram, standard interface VS/9-55. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5 Layout diagram, speed control loop (user–friendly interface) VS/9-56. . . . . . .

9.6 Motor encoder, assignment of X311/X313 (1st/2nd axis) VS/9-57. . . . . . . . . .

10.00

07.94

VS–ii

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

Siemens AG 2000 All rights reserved

Page 37

10.00

07.94

Feed Modules (VS)

1 Short Commissioning, Standard Settings

Short Commissioning, Standard Settings

The setting elements for the user–friendly interface are provided on the

parameter board, and for the standard interface on the control (refer to

Section 9 Attachment). For a standard commissioning procedure, the

tachometer adaptation, current normalization and current controller gain

parameters should be set.

Commissioning

stages of the FD

modules with the

user–friendly and

standard interface

Commissioning is sub–divided into various stages; after the standard settings

have been made, an additional commissioning stage can follow, or the unit can

be powered–up.

Short commissioning,

standard settings

Speed controller

optimization

Sec. 1

Sec. 2

1

VS

Supplementary

functions

Setpoint interfaces

Service and diagnostics

Attachment

Commissioning with

MSD option

Sec. 3

Sec. 4

Sec. 5

Powering–up, Sec. 7

Sec. 8

Sec. 9

Siemens AG 2000 All rights reserved

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

VS/1-3

Page 38

Feed Modules (VS)

1.2 Current controller settings

1.1 Tachometer adaptation for motors with tachometer

voltages ≤ 16.5 V at rated speed

Only involves motors 1FT503–AF71 and 1FT504–AF71

10.00

07.94

VS

User–friendly and

standard interface

All three contacts of switch S1 (S4 for a 2nd axis standard interface) = ON

In addition, discrete resistors can be used for calibration, refer to Sections

3.1 - 3.2.

1.2 Current controller settings

The settings for the current limit and current controller gain Kp(I) can be taken

from the adaptation tables, Table 1-3 up to Table1-9. The values can be determined according to the formulas if the required feed module/motor combination

cannot be found.

User–friendly

interface

Standard interface

Parameter board, switch S2

Control board, switch S2 (S5 for a 2nd axis)

Note

The following setting values apply for both control versions unless specific

differences are referred to in individual cases.

Actual value

normalization

Table 1-1 Current limit

S2.x

or

S5.x

to ON

(%) 100 85 68 61 50 46 41 39 36 34 30 29 26 25 24 23

– 2 3 234 2

Current limit =

The current limit must be at least reduced to the peak value permitted for the

particular motor. This may have to be further reduced depending on the

mechanical system.

I

(set maximum current)

max

I

(peak power module current)

limit

2

434

5 25352

3

4

4

2

3

5

5

3

4

4

5

5

[%] 100

2

3

4

5

VS/1-4

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

Siemens AG 2000 All rights reserved

Page 39

10.00

07.94

Current controller

gain Kp(I)

Table 1-2 Current controller gain

Kp(I) <

I

max

L

D

Feed Modules (VS)

1.2 Current controller settings

I

L

max

A

40

= selected max. current of the axis in A

= rotating field inductance of the motor in mH

(refer to the Planning Guide, AC Motors for Feed and Main Spindle

Drives)

S2.x

or

S5.x

to ON

Kp(I) 0.5 1 2 2.5 4 4.5 5.5 6 6.5 7.5 8 9.5 11 11.5

User–friendly

interface

– 6 7 6

The current controller gain setting range can be additionally increased using

R15 on the parameter board.

8 6

7

7

8

9 6

8

7

6

8

9

9

7

9

7

9

8

9

The following formula is valid for S2.6 to S2.9 closed (ON):

Kp(I) 11.5

1230

R15

Adaptation tables

Table 1-3 Adaptation table for 6SN112–1A00–0HA1 4/8 A power module

Servomotor Current limit

1FT... M

5034–AK71 0.5 0.93 6000 x o x o 3.68 o x o o 2.0

5036–AK71 0.75 1.4 6000 o x o o 5.44 o x o o 2.0

5042–AF71

5042–AK71

5044–AF71

5044–AK71

5046–AF71 2.6 3.0 3000 o o o o 8.0 o x o o 2.0

5062–AC71

5062–AF71

5062–AG71

5062–AK71

5064–AC71 4.5 2.7 2000 o o o o 8.0 o x o x 7.5

5066–AC71 6.5 3.9 2000 o o o o 8.0 x o x o 4.5

5070–AC71

5070–AF71

5070–AG71

5071–AC71 4.5 2.9 2000 o o o o 8.0 x x o x 8.0

[Nm] I

o

0.66

0.66

1.3

1.3

2.2

2.2

2.2

2.2

3.0

3.0

3.0

[A] n

o

0.75

1.2

1.5

2.3

1.3

2.0

2.7

3.9

1.8

2.6

3.6

rated

[RPM]

3000

6000

3000

6000

2000

3000

4000

6000

2000

3000

4000

Contacts

2 3 4 5

xxoxoox

ooxoooo

o

x

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

1)

I

[A]

max

2.72

o

4.88xxxxoooo

5.44

o

8.0

o

5.44

o

8.0

o

8.0

o

8.0

o

8.0

o

8.0

o

8.0

Current controller gain

Contacts

6 7 8 9

xxxooooo2.5

x

x

o

o

x

x

o

x

x

x

o

o

x

o

o

x

x

x

o

o

x

Kp(I)

x

x

o

o

x

x

o

6

7

8

9

2.5

2.5

1.0

11.5

7.5

4.0

1.0

11.5

7.5

4.5

VS

Definition: o = Contact in the basic OFF setting

x = Contact in the ON setting

1) The specified value is the maximum permissible current of the particular power module/motor combination. It may be

necessary to reduce the specified value depending on the driven mechanical systems.

Siemens AG 2000 All rights reserved

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

VS/1-5

Page 40

VS

Feed Modules (VS)

10.00

1.2 Current controller settings

Table 1-4 Adaptation table for 6SN112–1A00–0AA1 7.5/15 A power modules

Servomotor Current limit

1FT... M

5034–AK71 0.5 0.93 6000 o x x x 3.68 o x o o 2.0

5036–AK71 0.75 1.4 6000 o o o x 5.44 o x o o 2.0

5042–AF71

5042–AK71

5044–AF71

5044–AK71

5046–AF71

5046–AK71

5062–AC71

5062–AF71

5062–AG71

5062–AK71

5064–AC71

5064–AF71

5064–AG71

5066–AC71

5066–AF71

5070–AC71

5070–AF71

5070–AG71

5070–AK71

5071–AC71

5071–AF71

5071–AG71

5072–AC71 10.0 6.1 2000 o o o o 15.0 x x o x 8.0

5073–AC71

5073–AF71

5100–AC71 10.0 6.2 2000 o o o o 15.0 o x x o 5.5

[Nm] I

o

0.66

0.66

1.3

1.3

2.6

2.6

2.2

2.2

2.2

2.2

4.5

4.5

4.5

6.5

6.5

3.0

3.0

3.0

3.0

4.5

4.5

4.5

7.0

7.0

[A] n

o

0.75

1.2

1.5

2.3

3.0

4.7

1.3

2.0

2.7

3.9

2.7

4.1

5.5

3.9

6.0

1.8

2.6

3.6

5.3

2.9

4.3

5.2

4.3

6.4

rated

[RPM]

3000

6000

3000

6000

3000

6000

2000

3000

4000

6000

2000

3000

4000

2000

3000

2000

3000

4000

6000

2000

3000

4000

2000

3000

Contacts

2 3 4 5

xxxxxox

xxxxxoo

xoooooo

x

o

o

o

o

o

o

o

ooooooo

o

o

o

o

x

o

o

ooooooo

o

o

x

x

o

o

o

x

o

o

o

o

o

o

x

x

o

o

o

o

o

o

o

o

o

o

o

1)

I

[A]

max

3.45

x

4.5

5.85

o

9.15oooxxooo

12.7

o

15.0oxooxooo

x

5.1

o

7.5

o

10.2

o

15.0

o

10.2

o

15.0

o

15.0

15.0

o

15.0ooooxxxo

o

7.5

o

10.2

o

15.0

o

15.0

o

12.7

o

15.0

o

15.0

15.0

o

15.0ooooxxxo

Current controller gain

Contacts

6 7 8 9

oooxxooo4.0

o

x

x

x

o

o

x

x

x

o

o

x

o

x

x

x

x

o

o

x

x

o

o

x

x

x

o

x

o

x

o

x

x

o

o

o

x

x

o

x

o

o

x

x

x

x

o

x

x

o

x

x

o

x

x

o

07.94

Kp(I)

2.0

4.0

2.0

4.0

1.0

11.0

6.5

5.5

2.5

9.5

6.5

2.5

9.5

4.0

11.5

9.5

8.0

4.0

11.5

6.5

4.5

9.5

4.0

Definition: o = Contact in the basic OFF setting

x = Contact in the ON setting

1) The specified value is the maximum permissible current of the particular power module/motor combination. It may be

necessary to reduce the specified value depending on the driven mechanical systems.

VS/1-6

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

Siemens AG 2000 All rights reserved

Page 41

10.00

07.94

Feed Modules (VS)

1.2 Current controller settings

Table 1-5 Adaptation table for 6SN112–1A00–0BA1 12.5/25 A power modules

Servomotor Current limit

1FT... M

5036–AK71 0.75 1.4 6000 x x x x 5.75 o x o o 2.0

5044–AF71

5044–AK71

5046–AF71

5046–AK71

5062–AC71

5062–AF71

5062–AG71

5062–AK71

5064–AC71

5064–AF71

5064–AG71

5064–AK71

5066–AC71

5066–AF71

5066–AG71

5066–AK71

5070–AC71

5070–AF71

5070–AG71

5070–AK71

5071–AC71

5071–AF71

5071–AG71

5071–AK71

5072–AC71

5072–AF71

5072–AG71

5073–AC71

5073–AF71

5073–AG71

5073–AK71

5074–AC71 14.0 8.5 2000 o o o o 25.0 x x o x 8.0

5076–AC71 18.0 11.5 2000 o o o o 25.0 o x x o 5.5

5100–AC71

5100–AF71

5100–AG71

5101–AC71 15.0 9.4 2000 o o o o 25.0 o x x o 5.5

5102–AA71 27.0 9.9 1200 o o o o 25.0 x x o x 8.0

5103–AC71 19.0 12.0 2000 o o o o 25.0 o o x o 4.0

[Nm] I

o

1.3

1.3

2.6

2.6

2.2

2.2

2.2

2.2

4.5

4.5

4.5

4.5

6.5

6.5

6.5

6.5

3.0

3.0

3.0

3.0

4.5

4.5

4.5

4.5

10.0

10.0

10.0

7.0

7.0

7.0

7.0

10.0

10.0

10.0

[A] n

o

1.5

2.3

3.0

4.7

1.3

2.0

2.7

3.9

2.7

4.1

5.5

8.0

3.9

6.0

7.9

11.6

1.8

2.6

3.6

5.3

2.9

4.3

5.2

7.9

6.1

9.1

12.0

4.3

6.4

8.1

12.5

6.2

9.2

12.5

rated

[RPM]

3000

6000

3000

6000

2000

3000

4000

6000

2000

3000

4000

6000

2000

3000

4000

6000

2000

3000

4000

6000

2000

3000

4000

6000

2000

3000

4000

2000

3000

4000

6000

2000

3000

4000

Contacts

2 3 4 5

ooxoxox

oooxxoo

x

x

x

x

x

x

o

o

o

o

o

o

o

o

x

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

x

o

o

o

x

x

o

o

x

x

o

o

o

o

o

x

o

o

o

o

o

o

o

x

o

o

x

x

o

o

o

o

x

x

o

o

o

o

o

o

o

o

o

o

o

x

o

o

o

o

o

o

o

o

o

o

o

o

o

1)

I

[A]

max

6.0

x

9.0

12.5

o

17.0oooxxooo

x

5.75

x

8.5

o

10.25

o

15.75

o

10.25

o

17.0

o

25.0

o

25.0

o

17.0

o

25.0

o

25.0

o

25.0

x

7.5

o

11.5

o

17.0

o

25.0

o

12.5

o

17.0

o

25.0

o

25.0

o

25.0

o

25.0

o

25.0

o

17.0

o

25.0

o

25.0

o

25.0

o

25.0

o

25.0

o

25.0

Current controller gain

Contacts

6 7 8 9

oooxxooo4.0

x

x

x

o

x

x

x

o

x

o

x

x

o

x

o

o

x

x

x

x

x

x

o

x

o

x

x

x

o

o

x

x

x

o

x

x

x

o

x

x

o

o

x

x

x

o

o

x

o

o

x

o

x

o

x

x

x

x

o

x

o

o

x

x

x

o

x

o

x

o

x

x

o

o

x

o

o

x

o

o

o

x

o

o

o

x

o

x

x

o

Kp(I)

x

x

o

o

x

x

o

o

x

x

o

o

x

x

x

x

x

x

x

o

x

x

o

x

x

o

o

x

o

o

2.0

4.0

2.0

11.5

8.0

5.5

2.5

11.5

6.5

5.5

2.5

9.5

6.5

2.5

2.0

11.5

11.0

9.5

6.5

11.5

8.0

8.0

2.5

11.5

6.0

2.5

9.5

6.5

4.5

1.0

9.5

4.0

2.5

VS

Definition: o = Contact in the basic OFF setting

x = Contact in the ON setting

1) The specified value is the maximum permissible current of the particular power module/motor combination. It may be

necessary to reduce the specified value depending on the driven mechanical systems.

Siemens AG 2000 All rights reserved

SIMODRIVE 611 analog Start–Up Guide (IAA) – 10.00 Edition

VS/1-7

Page 42

VS

Feed Modules (VS)

10.00

1.2 Current controller settings

Table 1-6 Adaptation table for 6SN112–1A00–0CA1 25/50 A power modules

Servomotor Current limit

1FT... M

5044–AK71 1.3 2.3 6000 o o x x 13.0 x x o o 2.5

5046–AF71

5046–AK71

5062–AG71

5062–AK71

5064–AC71

5064–AF71

5064–AG71

5064–AK71

5066–AC71

5066–AF71

5066–AG71

5066–AK71

5070–AF71

5070–AG71

5070–AK71

5071–AC71

5071–AF71

5071–AG71

5071–AK71

5072–AC71

5072–AF71