Page 1

Page 2

Page 3

Manual

08/2017

Introduction

1

General information

2

Product information

3

Functions

4

Mounting

5

Connection

6

Operation

7

Commissioning

8

Accessories

9

Service and maintenance

10

Technical specifications

11

Dimension drawings

12

Applications

13

Appendix

A

ESD guidelines

B

List of abbreviations

C

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

L1V30368969104A-02

___________________

Page 4

Legal information

Warning notice system

DANGER

will

WARNING

may

CAUTION

NOTICE

Qualified Personn el

personnel qualified

Proper use of Siemens products

WARNING

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safet y alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

indicates that death or severe personal injury

indicates that death or severe personal injury

indicates that minor personal injury can result if proper precautions are not taken.

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

result if proper precautions are not taken.

result if proper precautions are not taken.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storag e, inst alla ti on, assem b ly, comm is sion ing , oper at ion and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

Siemens AG

Division Energy Management

Postfach 32 20

91050 ERLANGEN

GERMANY

Document order number: 3ZW1012-3KC83-0AC1

Ⓟ 09/2017 Subject to change

Copyright © Siemens AG 2017.

All rights reserved

Page 5

Table of contents

1 Introduction ............................................................................................................................................. 9

2 General informatio n .............................................................................................................................. 11

3 Product information ............................................................................................................................... 13

4 Functions .............................................................................................................................................. 25

5 Mounting ............................................................................................................................................... 27

6 Connection ........................................................................................................................................... 31

2.1 Certification ............................................................................................................................. 11

3.1 Product description ................................................................................................................. 13

3.1.1 Design of the 3KC4 and 3KC8 transfer switching equipment................................................. 14

3.1.2 Current ratings of the 3KC4 and 3KC8 transfer switching equipment .................................... 18

3.2 Product family ......................................................................................................................... 21

3.2.1 The product families 3KC4 and 3KC8 from 250 A to 3200 A ................................................. 21

3.2.2 Use of 3KC4 and 3KC8 transfer switching equipment ........................................................... 22

3.2.3 Properties of the 3KC4 and 3KC8 transfer switching equipment ........................................... 22

3.2.4 Application areas of the 3KC4 and 3KC8 transfer switching equipment ................................ 23

5.1 Mounting position .................................................................................................................... 27

5.2 Installing the 3KC4 and 3KC8 transfer switching equipment.................................................. 27

5.3 Dimensions of the cover frame for door cut-out ..................................................................... 30

6.1 Network types ......................................................................................................................... 31

6.1.1 Three-phase 4-wire network with neutral (3PH + N) .............................................................. 32

6.1.1.1 Circuit diagram for the 3KC4 transfer switching equipment - 4-pole transfer switching

equipment ............................................................................................................................... 32

6.1.1.2 Circuit diagram for the 3KC8 transfer switching equipment - 4-pole transfer switching

equipment ............................................................................................................................... 33

6.1.2 Three-phase 3-wire network without neutral (3PH) ................................................................ 33

6.1.2.1 Circuit diagram for the 3KC4 transfer switching equipment - 3-pole transfer switching

equipment ............................................................................................................................... 34

6.1.2.2 Circuit diagram for the 3KC8 transfer switching equipment - 4-pole transfer switching

equipment ............................................................................................................................... 35

6.1.2.3 Circuit diagram for the 3KC8 transfer switching equipment - 3-pole transfer switching

equipment ............................................................................................................................... 36

6.1.3 Single-phase network with neutral (1PH + N) ......................................................................... 37

6.1.3.1 Circuit diagram for the 3KC4 transfer switching equipment - 3-pole transfer switching

equipment ............................................................................................................................... 37

6.1.3.2 Circuit diagram for the 3KC8 transfer switching equipment - 3-pole transfer switching

equipment ............................................................................................................................... 38

Manual, 08/2017, L1V30368969104A-02

5

Page 6

Table of contents

7 Operation ............................................................................................................................................. 101

6.2 Connecting the main circuit .................................................................................................... 39

6.2.1 Connecting terminals of the transfer switching equipment .................................................... 39

6.2.2 Load connection ..................................................................................................................... 40

6.2.3 Arrangement of the power supply systems ............................................................................ 40

6.2.4 Connection of transfer switching equipment for current ratings 250 A to 1600 A ................. 42

6.2.4.1 Connecting bridging bars on the load side ............................................................................ 42

6.2.4.2 Connecting current ratings 250 A to 1600 A to the main circuit ............................................ 46

6.2.5 Connection of transfer switching equipment for current ratings 2000 A to 3200 A ............... 49

6.2.5.1 Copper bar connection kit ...................................................................................................... 49

6.2.5.2 Connecting current ratings 2000 A to 3200 A to the main circuit (on the line side) ............... 55

6.2.5.3 Connecting current ratings 2000 A to 3200 A to the main circuit (on the load side) ............. 65

6.3 Connecting the control circuit ................................................................................................. 72

6.3.1 Inputs and outputs of the motor operator ............................................................................... 72

6.3.1.1 Overview of motor operator ................................................................................................... 72

6.3.1.2 Connecting the inputs and outputs of the motor operator ..................................................... 73

6.3.2 Power supply of the motor operator (3KC4 only) ................................................................... 75

6.3.2.1 Mounting and connecting the dual power supply (DPS) ........................................................ 77

6.3.2.2 Installing and connecting an autotransformer (400 V / 230 V) .............................................. 79

6.3.3 Auxiliary switch of the transfer switching equipment ............................................................. 81

6.3.3.1 Installing auxiliary switches 250 A to 630 A ........................................................................... 82

6.3.3.2 Installing auxiliary switches of current rating 800 A to 1600 A .............................................. 84

6.3.4 Inputs and outputs of the electronic module (3KC8 only) ...................................................... 88

6.3.5 Connecting the inputs and outputs of the electronic module (3KC8 only) ............................. 89

6.3.5.1 Installing accessories for the electronic module .................................................................... 89

6.3.5.2 Connecting power supply kit 3KC9830-, 3KC9831- (4-pole) .................................................

6

.3.5.3 Connecting the auxiliary conductor terminal 3KC9822-, 3KC9832- for a three-phase

92

3-wire network (3-pole) .......................................................................................................... 95

6.3.5.4 Connecting power supply kit 3KC9833-, 3KC9834- for single-phase network ...................... 98

7.1 Operating modes of the transfer switching equipment ........................................................ 101

7.1.1 Remote mode ....................................................................................................................... 102

7.1.2 Manual operation ................................................................................................................. 103

7.1.3 Padlocking mode.................................................................................................................. 104

7.1.4 Automatic mode (3KC8 only) ............................................................................................... 105

7.2 Functions of the inputs and outputs ..................................................................................... 106

7.2.1 Inputs and outputs of the motor operator ............................................................................. 106

7.2.1.1 Outputs of the motor operator .............................................................................................. 111

7.2.2 Auxiliary switches ................................................................................................................. 114

7.2.3 Inputs and outputs of the electronic module (3KC8 only) .................................................... 115

7.2.3.1 Inputs for voltage measurement and power supply ............................................................. 115

7.2.3.2 Control inputs of the electronic module ............................................................................... 118

7.2.3.3 Functions of the control inputs for network / generator application ..................................... 119

7.2.3.4 Functions of the control inputs for network / network application ........................................ 121

7.2.3.5 Outputs of the electronic module ......................................................................................... 123

7.3 Remote mode ....................................................................................................................... 126

7.3.1 Impulse logic ........................................................................................................................ 126

7.3.2 Continuous operation logic .................................................................................................. 129

6 Manual, 08/2017, L1V30368969104A-02

Page 7

Table of contents

8 Commissioning ................................................................................................................................... 139

9 Accessories ........................................................................................................................................ 145

10 Service and maintenance .................................................................................................................... 177

7.4 Automatic mode - programming of the electronic module (3KC8 only) ................................ 132

7.4.1 Step 1: Preset network conditions ........................................................................................ 132

7.4.2 Step 2: Setting the potentiometer ......................................................................................... 134

7.4.3 Step 3: Automatic configuration of the transfer switching equipment (only with

potentiometer Un = 0) ........................................................................................................... 136

7.4.4 Step 4: Saving the configuration ........................................................................................... 137

7.4.5 Step 5: Switching the 3KC8 transfer switching equipment to automatic mode .................... 137

8.1 Commissioning the 3KC4 transfer switching equipment ...................................................... 139

8.2 Commissioning the 3KC8 transfer switching equipment ...................................................... 141

9.1 Terminal covers .................................................................................................................... 146

9.1.1 Mounting terminal covers ...................................................................................................... 147

9.2 Phase barriers ....................................................................................................................... 148

9.2.1 Mounting phase barriers ....................................................................................................... 149

9.3 Terminal plates ..................................................................................................................... 150

9.3.1 Mounting terminal plates ....................................................................................................... 151

9.4 Mounting spacers .................................................................................................................. 153

9.4.1 Fitting mounting spacers ....................................................................................................... 153

9.5 Bridging bars ......................................................................................................................... 154

9.6 Copper bar connection kit ..................................................................................................... 155

9.7 Autotransformer .................................................................................................................... 157

9.8 Dual power supply (DPS, 3KC4 only) ................................................................................... 158

9.9 Power supply kit 3KC9830-, 3KC9831- (4-po le, 3KC 8 only) ................................................ 159

9.10 Auxiliary conductor terminal 3KC9822-, 3KC 983 2- (3-pole, 3KC8 only) .............................. 160

9.11 Power supply kit 3KC9833-, 3KC9834- (2-po le, 3K C8 only) ................................................ 161

9.12 Cover frame (3KC8 only) ...................................................................................................... 162

9.13 Auxiliary switches .................................................................................................................. 163

9.14 Display (3KC8 only) .............................................................................................................. 164

9.15 Connection cable (3KC8 only) .............................................................................................. 167

9.16 Sealable cover (3KC8 only) .................................................................................................. 168

9.17 Motor operator ...................................................................................................................... 170

9.18 Electronic module (3KC8 only) ............................................................................................. 175

10.1 Fault rectification ................................................................................................................... 177

10.1.1 Fault states and fault detection on the 3KC4 transfer switching equipment ......................... 177

10.1.2 Fault states and fault detection on the 3KC8 transfer switching equipment ......................... 179

10.2 Regular service and maintenance ........................................................................................ 181

Manual, 08/2017, L1V30368969104A-02

7

Page 8

Table of contents

11 Technical specifications ....................................................................................................................... 183

12 Dimension drawings ............................................................................................................................. 191

13 Applications ......................................................................................................................................... 205

A Appendix ............................................................................................................................................. 215

B ESD guidelines .................................................................................................................................... 221

C List of abbreviations ............................................................................................................................. 223

11.1 Technical specifications 3KC4 and 3KC8 from 250 A to 1000 A ......................................... 183

11.2 Technical specifications 3KC4 and 3KC8 from 1250 A to 3200 A ....................................... 186

11.3 Technical specifications of the electronic module ................................................................ 189

12.1 Dimension drawings of the 3KC4 transfer switching equipment ......................................... 192

12.2 Dimension drawings of the 3KC8 transfer switching equipment ......................................... 198

13.1 Transfer between two sources with one outgoing load ....................................................... 206

13.2 Transfer between two sources with two outgoing loads ...................................................... 207

13.3 Transfer between three sources with one outgoing load ..................................................... 209

13.4 Transfer between three sources with two outgoing loads ................................................... 210

13.5 Transfer between two loads with one incoming source (with 3KC4 transfer switching

equipment only).................................................................................................................... 213

A.1 Environmental conditions ..................................................................................................... 215

A.2 Operating conditions ............................................................................................................ 216

A.2.1 Temperature ......................................................................................................................... 216

A.2.2 Humidity ............................................................................................................................... 216

A.2.3 Altitude conditions ................................................................................................................ 216

A.3 Storage conditions ............................................................................................................... 217

A.3.1 Temperature ......................................................................................................................... 217

A.3.2 Storage conditions ............................................................................................................... 217

A.3.3 Storage position ................................................................................................................... 217

B.1 Electrostatic sensitive devices (ESD) .................................................................................. 221

8 Manual, 08/2017, L1V30368969104A-02

Page 9

1

Purpose of this manual

Target groups and required basic knowledge

Technical support

Applicable documents

This manual describes the functions, installation, commissioning, and operation of the

following transfer switching equ ipm ent:

● 3KC4 remotely operated transfer switching equipment (RTSE)

● 3KC8 automatic transfer switching equipment (ATSE)

The following topics are described in the manual:

● Product specifications

● Mounting

● Connection

● Operation

● Commissioning

● Accessories

● Corrective maintenance and fault rectification

● Application examples

This manual is intended for:

● Users

● Qualified electricians

● Switchgear manufacturers

● Maintenance personnel

A general knowledge of low-voltage power distribution is required to understand this manual.

You can find further support on the Internet at:

Technical support (https://www.siemens.com/lowvoltage/technical-support

)

You can find more information on the Internet via the following link:

Manual "3KC Transfer Switching Equipment up to 3200 A"

(https://support.industry.siemens.com/cs/de/en/ps/19749

Manual, 08/2017, L1V30368969104A-02

)

9

Page 10

Introduction

10 Manual, 08/2017, L1V30368969104A-02

Page 11

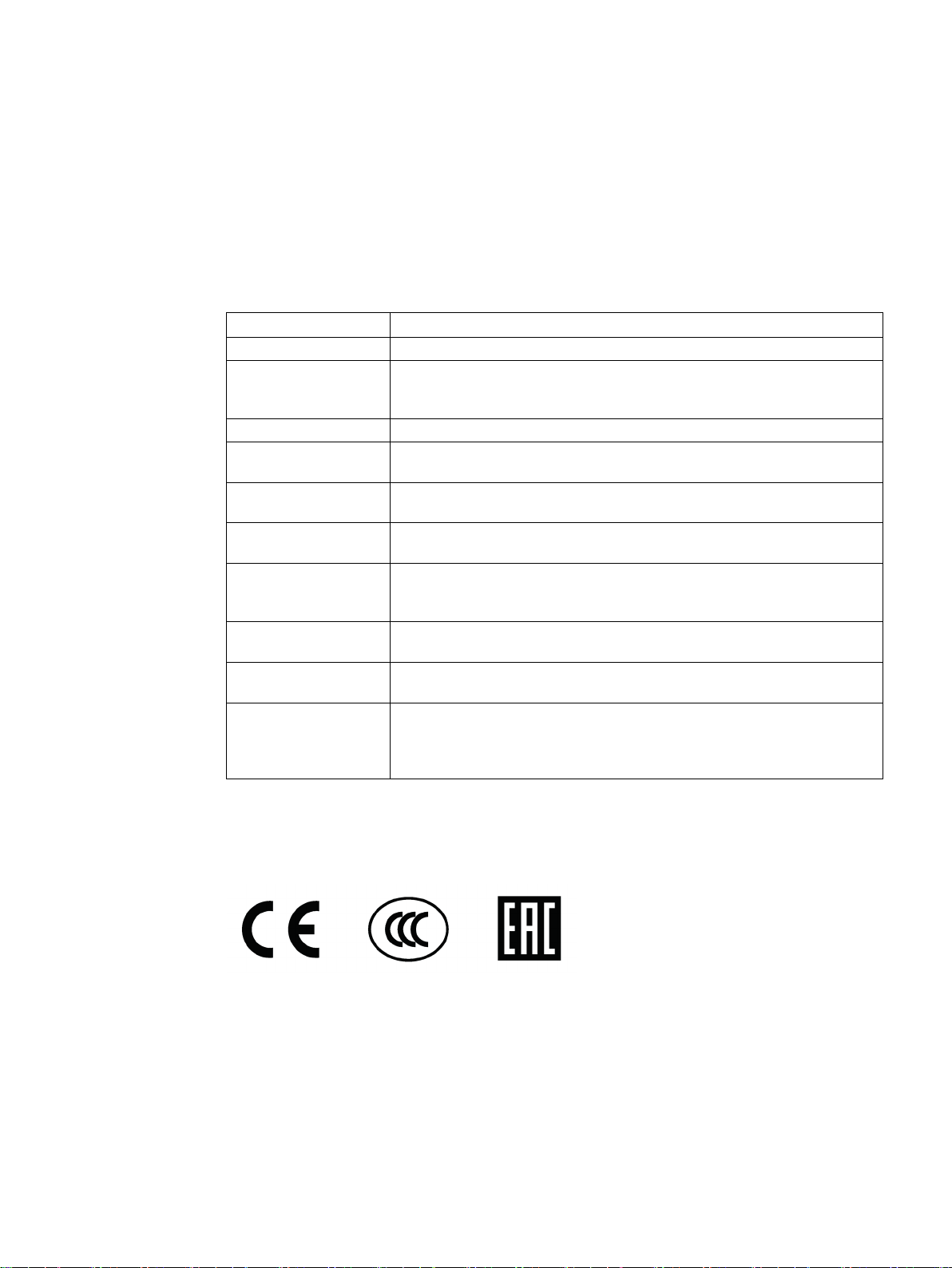

2

Standard

Designation

2.1

Certification

The transfer switching equipment and its accessories comply with the following international

standards:

IEC 60269-1 Low-voltage fuses - Part 1: General requirements

IEC 60269-2 Low-voltage fuses - Part 2: Supplementary requirements for fuses for use

by qualified electrical technicians or electrically trained persons (fuses pre-

dominantly for industrial use)

IEC 60947-1 Low-voltage switchgear and controlgear - Part 1: General requirements

IEC 60947-3 Low-voltage switchgear and control gear - Part 3: Switches, disconnectors,

switch-disconnectors and fuse-combination units

IEC 60947-5-1 Low-voltage switchgear and c ontrolgear - Part 5-1: Control circuit devices

and switching elements - electrom echanic al control circuit devices

IEC 60947-6-1 Low-voltage switchgear and c ontrolgear - Part 6-1: Multiple function equip-

ment - Transfer switching equipm ent

IEC 61010-1 Safety requirements for electrical equipment for measurement, control and

laboratory use - Part 3-1: Conformity verification report for IEC 61010-

1:2001 - General requirements

IEC 61326-1 Electrical equipment for measurement, control and laboratory use - EMC

requirements - Part 1 General requir em ents

EN 61558-1 Safety of transformers, power supplie s, react ors and sim il ar products - Part

1: General requirements and tests

EN 61558-2-13 Safety of transformers, reactors, power supplies and similar products for

supply voltages up to 1100 V - Part 2-13: Particular requ ir em ents and tes ts

for autotransformers and power supply units incorporating autotransform-

ers.

Manual, 08/2017, L1V30368969104A-02

11

Page 12

General information

2.1 Certification

12 Manual, 08/2017, L1V30368969104A-02

Page 13

3

3.1

Product description

The following features of the 3KC4 and 3KC8 transfer switching equipment are described in

this chapter:

● Design

● Current ratings

Manual, 08/2017, L1V30368969104A-02

13

Page 14

Product information

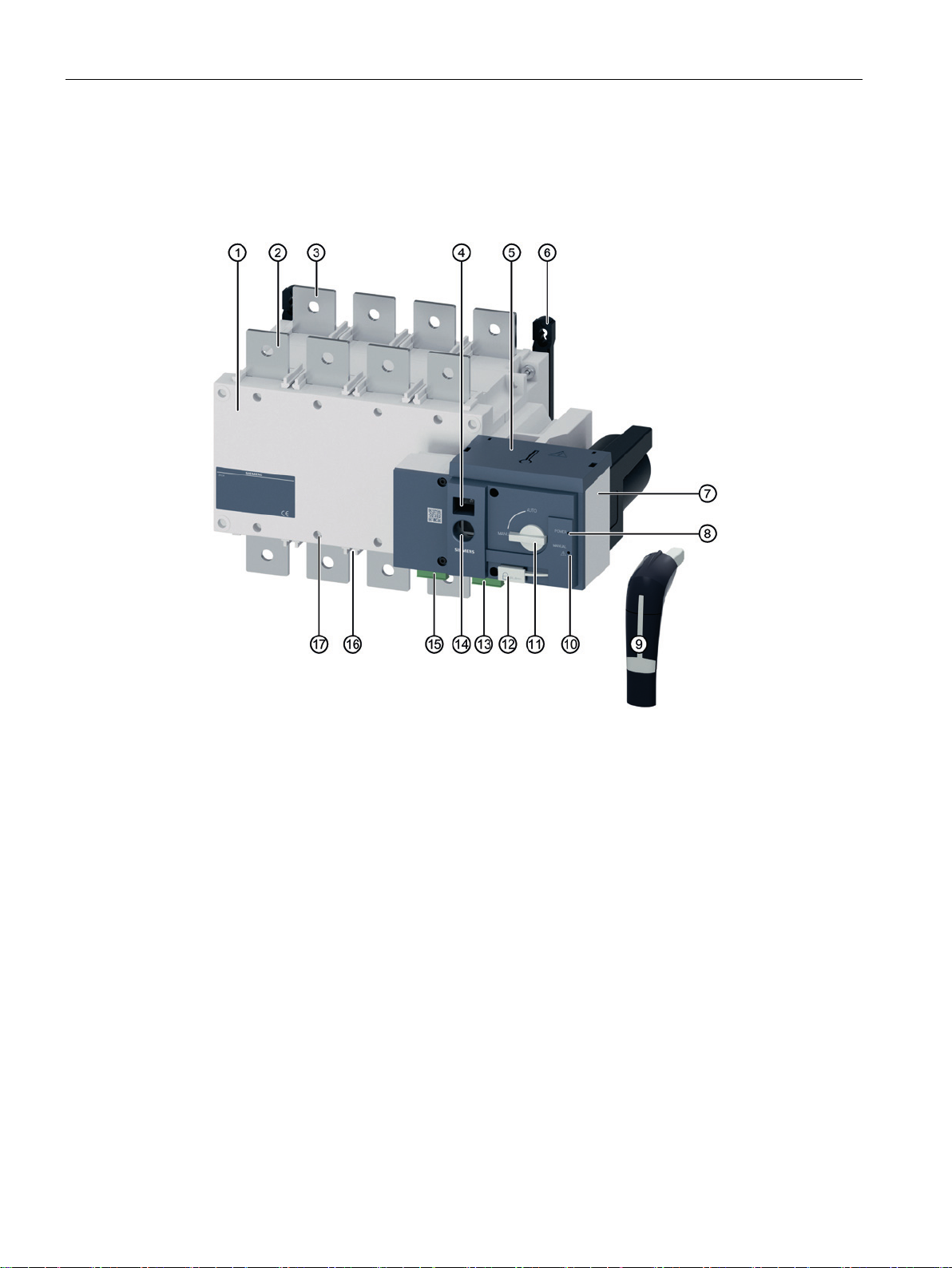

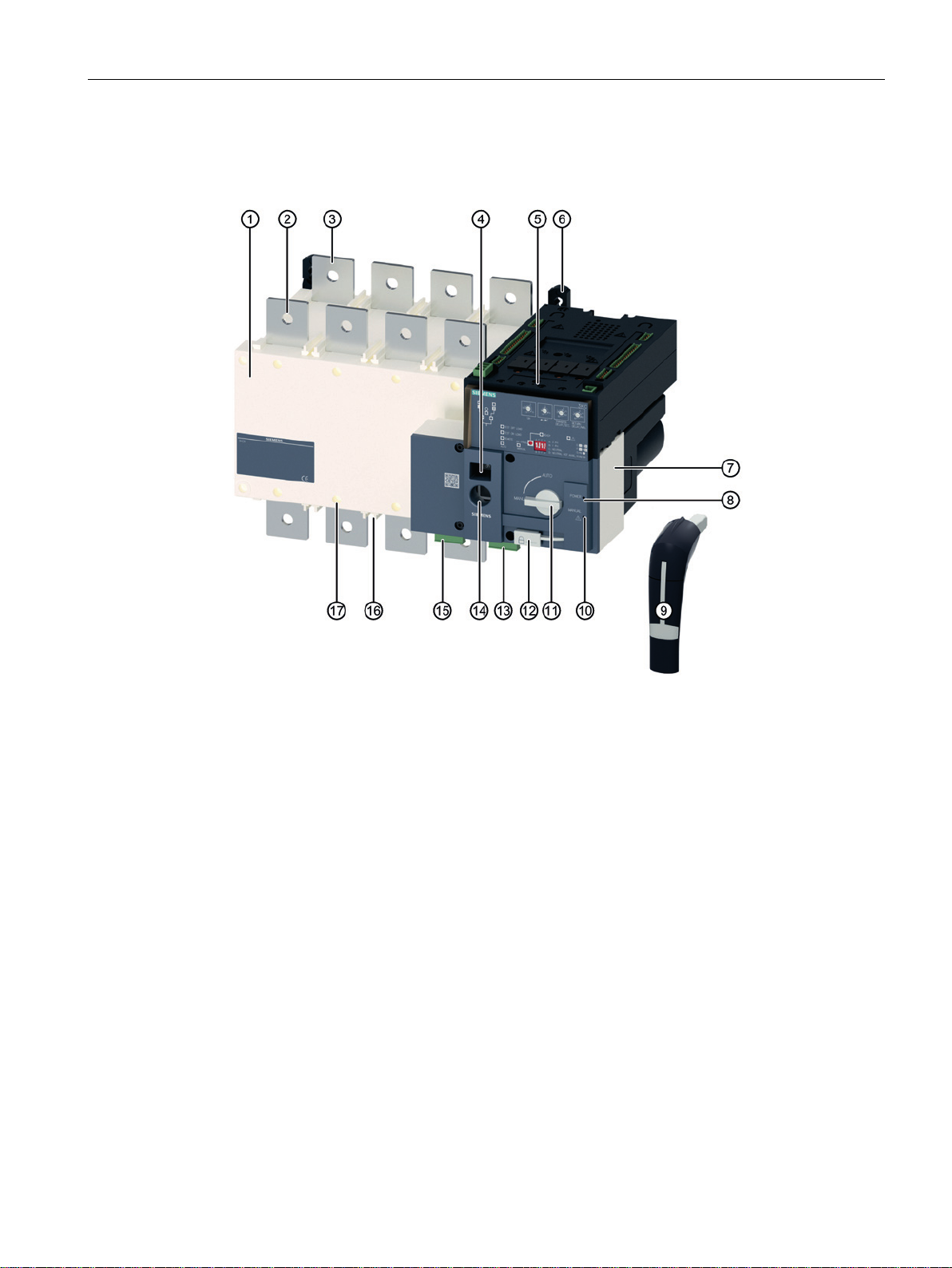

3.1.1

Design of the 3KC4 and 3KC8 transfer switching equipment

3.1 Product description

3KC4 remotely operated transfer switching equipment (RTSE):

14 Manual, 08/2017, L1V30368969104A-02

Page 15

Product information

①

⑪

3.1 Product description

3KC8 automatic transfer switching equipment (ATSE):

Switching unit

②

Connecting terminal of the main source

(source I)

③

Connecting terminal of the alternative source

(source II)

Indication of the selected source: O = Off /

④

I = source I / II = source II

3KC4: Cover of the power supply connection

⑤

3KC8: Electronic module (below this is located the power supply connection)

⑥

Assembly for mounting

⑦

Manual, 08/2017, L1V30368969104A-02

Motor operator

⑧

"Power" LED

⑨

Plug-on handle for manual changeover

⑩

Warning LED

Switch for selecting the mode (Manual /

Automatic)

Padlock assembly

⑫

⑬

4 outputs for

• "Switch position" (I / O / II) indicator

• "Product availability" indicator

⑭

Connection for attachable handle

⑮

5 inputs for

• Positioning commands (I / O / II)

• Activation of remote control

• Priority command for the OFF position

⑯

Mounting channels for terminal protection /

phase barriers

Fixing assembly for terminal plate

⑰

15

Page 16

Product information

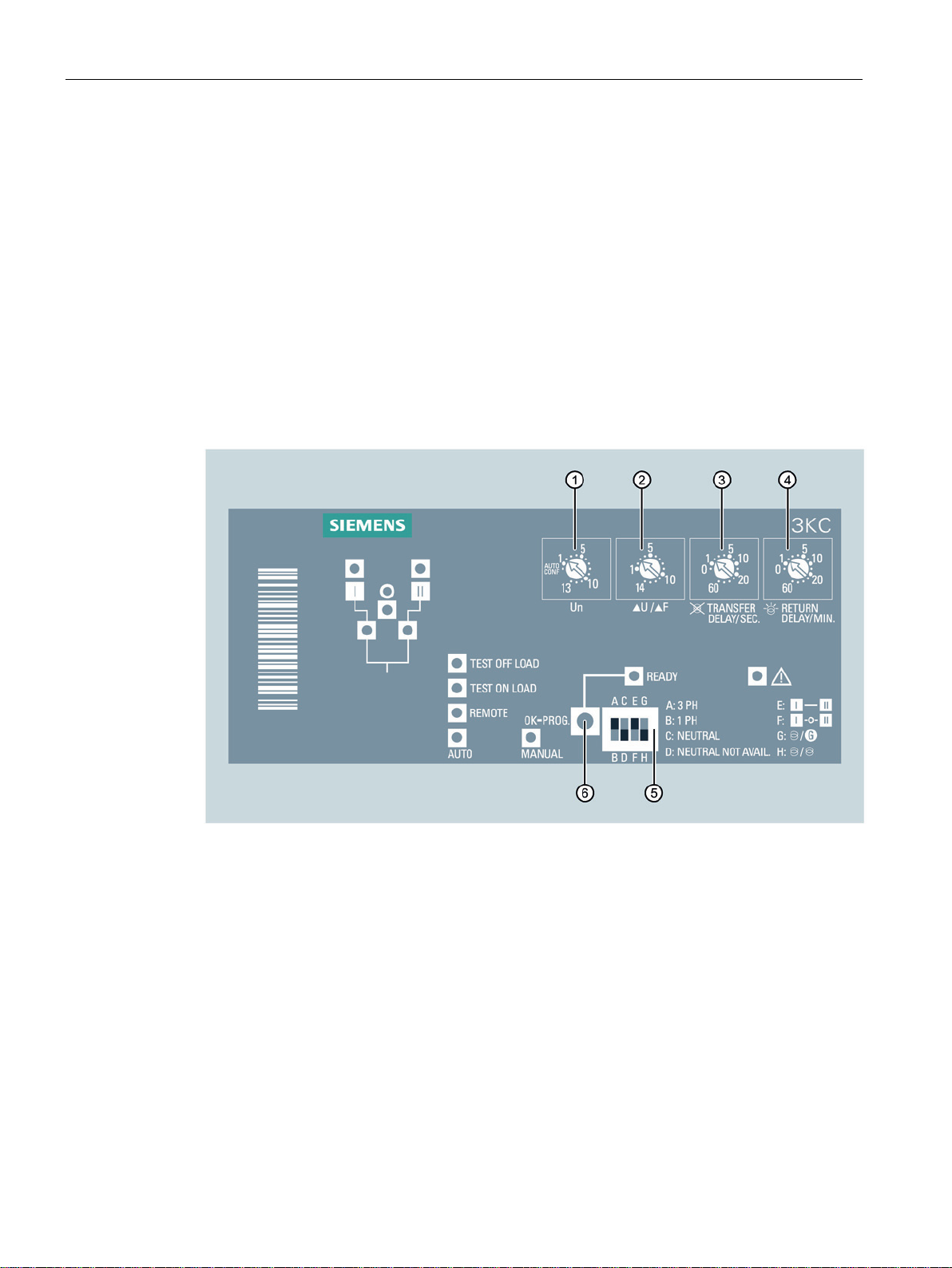

Electronic module

Operator controls

①

②

③

④

⑤

⑥

3.1 Product description

The 3KC8 automatic transfer switching equipment (ATSE) is based on the 3KC4

(RTSE) transfer switching equipment. In contrast to the 3KC4, an electronic module is

additionally integrated into t he 3KC8.

The electronic module enables monitoring of 2 sources as well as automatic transfer

switching. In addition, the electronic module supplies the 3KC8 transfer switching equipment

with power.

The 3KC8 transfer switching equipment is programmed using the electronic module.

You can find more information on programming in the section titled Automatic mode programming of the electronic module (3KC8 only) (Page 132).

Potentiometer 1: Presetting of line voltage/frequency (AutoConf, 1 to 13)

Potentiometer 2: Presetting of voltage/frequency limits (1 to 14)

Potentiometer 3: Presetting of the transfer time delay for source failure (0 to 60 s)

Potentiometer 4: Presetting of the return switching time delay for prioritized source recovered

(0 to 60 min)

DIP switch for configuration

"OK-Prog" pushbutton: Saves the current settings

16 Manual, 08/2017, L1V30368969104A-02

Page 17

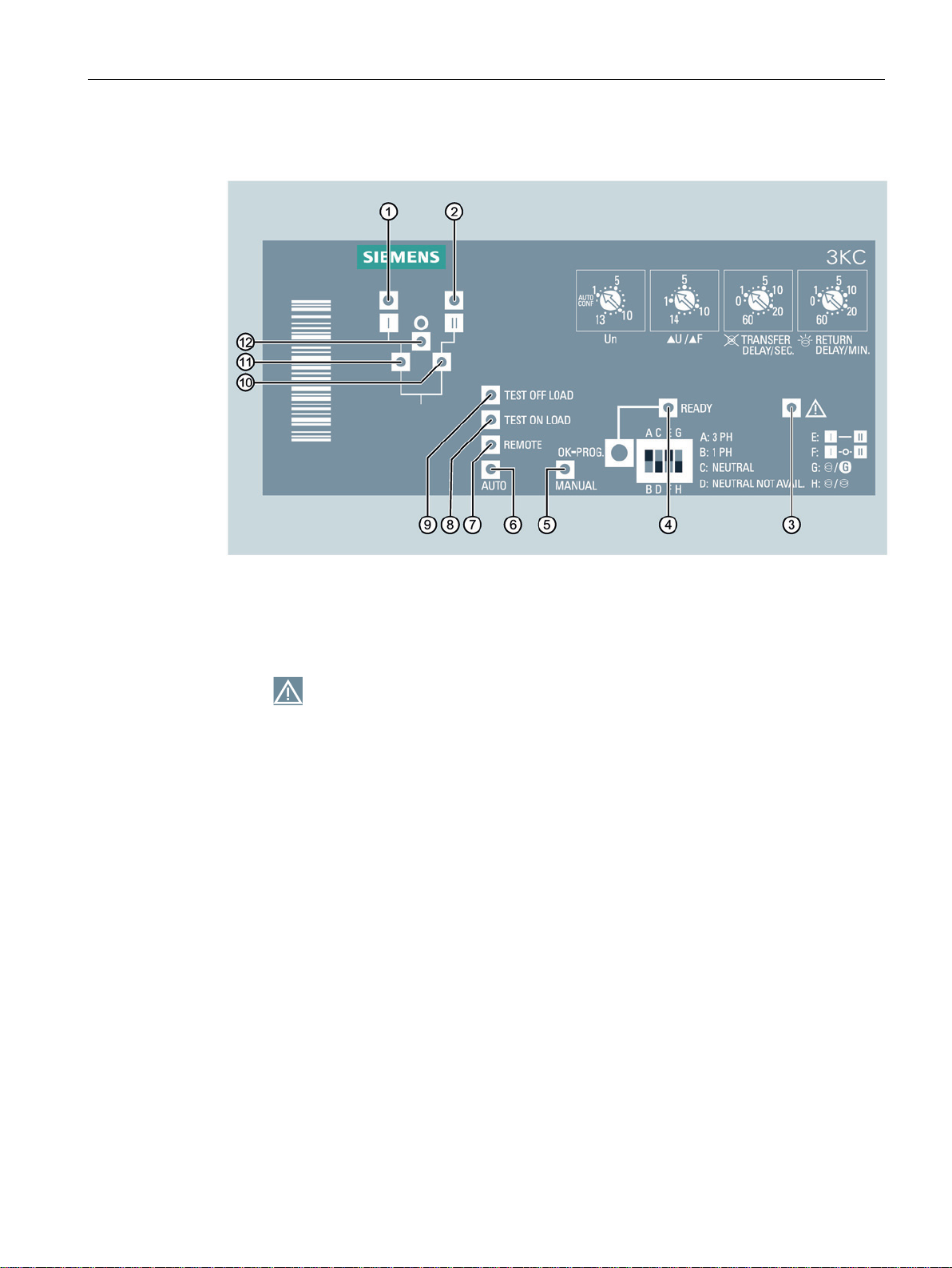

Product information

Indicators (LEDs)

Designation

Function

Meaning

①

②

③

④

⑤

⑥

Flashes green if the transfer switching equipment is in

⑦

⑧

3.1 Product description

I Availability

II Availability

READY "Ready" mode Indicates the status of the transfer switching equipment:

MANUAL "Manual" mode Shows a continuous yellow light if the transfer switching

AUTO "Auto" mode Indicates the activity of "Auto" mode:

REMOTE "Remote" mode Shows a continuous yellow light if the transfer switching

TEST

ON LOAD

source I

source II

Fault indicator

"Test on load"

mode

Shows a continuous green light if source I is available

and is within the accepted tolerance.

Shows a continuous green light if source II is available

and is within the accepted tolerance.

• Flashes red if there is an external fault (e.g. incorrect

• Shows a continuous red light if there is an internal

• Shows a continuous green light if the transfer switch-

• Flashes green if defaults haven not been saved or a

equipment is in "Manual" mode.

• Shows a continuous green light if the transfer switch-

•

equipment is in remote mode (controlled via inputs).

Shows a continuous yellow light if the transfer switching

equipment is in "Test on load" mode.

position of the neutral conductor).

fault of the electronic module.

ing equipment is in "Auto" mode and is ready for

source transfer.

new change has been made.

ing equipment is in "Auto" mode and no timer is active.

"Auto" mode and the timer is active.

Manual, 08/2017, L1V30368969104A-02

17

Page 18

Product information

⑨

⑩

⑪

⑫

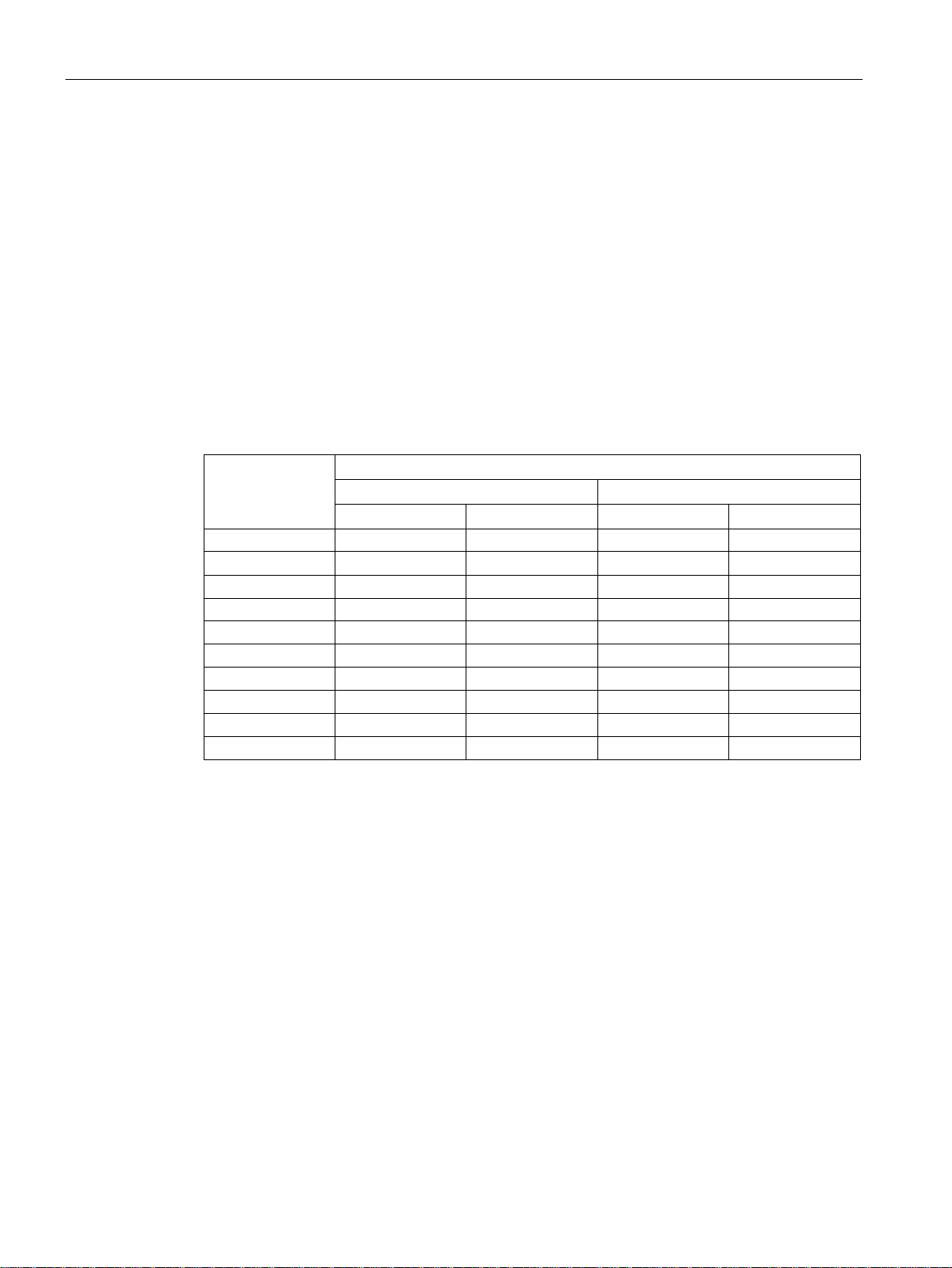

3.1.2

Current ratings of the 3KC4 and 3KC8 transfer switching equipment

Current rating

Device type

3KC4 (RTSE)

3KC8 (ATSE)

3-pole

4-pole

3-pole

4-pole

3.1 Product description

TEST

OFF LOAD

- Position II indication Shows a continuous green light if the switch is in posi-

- Position I indication Shows a continuous green light if the switch is in posi-

O Position "0" indica-

"Test off load"

mode

tion

Shows a continuous yellow light if the transfer switching

equipment is in "Test off load" mode.

tion II.

tion I.

Shows a continuous yellow light if the switch is in posi-

tion "0" (OFF).

The 3KC4 and 3KC8 transfer switching equipment are available in 10 current ratings. The

table shows the types of transfer switching equipment according to the current ratings:

250 A ✓ ✓ ✓ ✓

400 A ✓ ✓ ✓ ✓

630 A ✓ ✓ ✓ ✓

800 A ✓ ✓ ✓ ✓

1000 A ✓ ✓ ✓ ✓

1250 A ✓ ✓ ✓ ✓

1600 A ✓ ✓ ✓ ✓

2000 A ✓ ✓ ✓ ✓

2500 A ✓ ✓ ✓ ✓

3200 A ✓ ✓ ✓ ✓

18 Manual, 08/2017, L1V30368969104A-02

Page 19

Product information

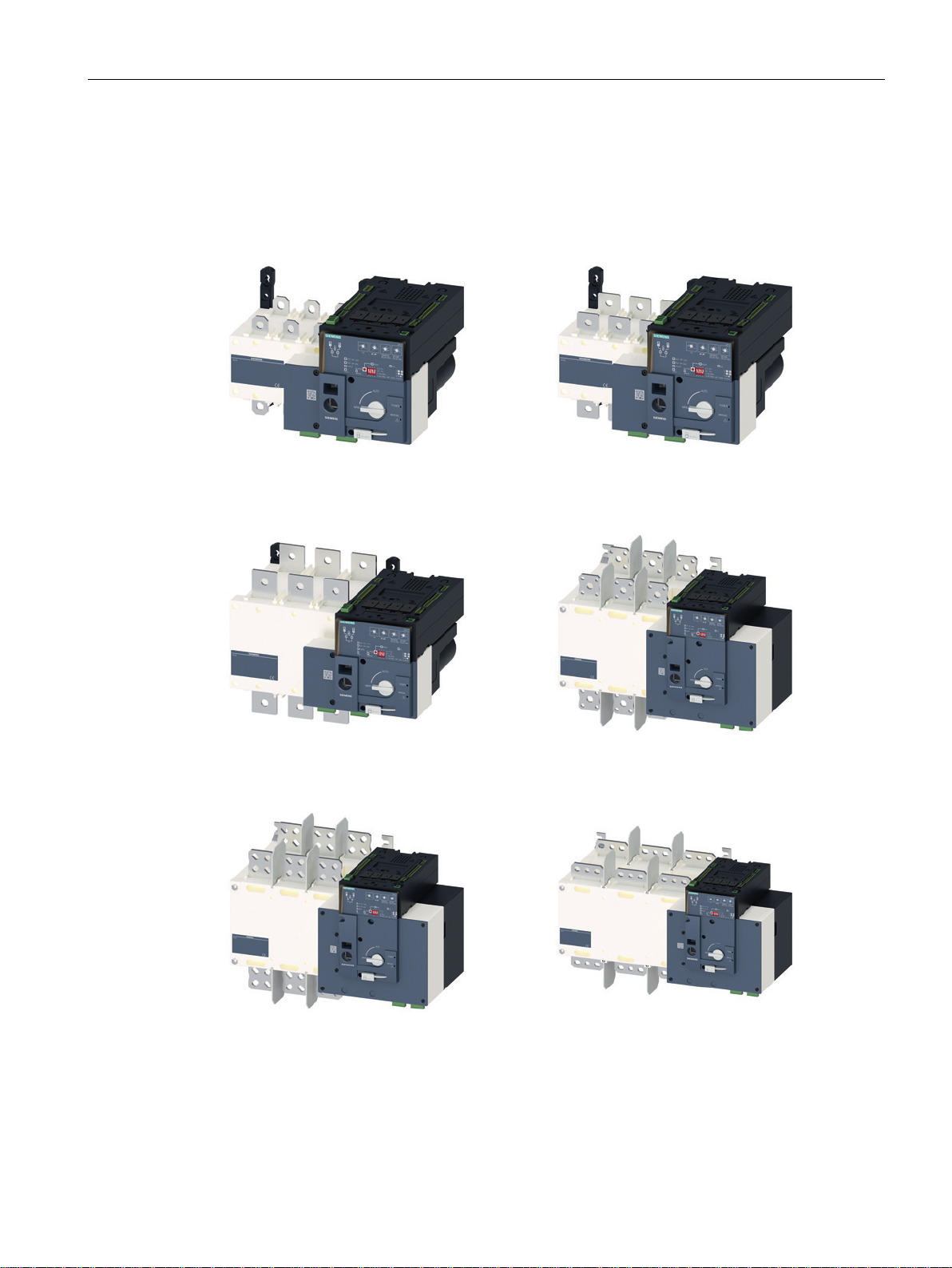

Designs

3KC8 250 A

3KC8 400 A

3KC8 630 A

3KC8 800 A / 1000 A

3KC8 1250 A

3KC8 1600 A

3.1 Product description

The following figures show the different designs of the transfer switching equipment depicted

according to current rating using the example of the 3KC8 transfer switching equipment:

Manual, 08/2017, L1V30368969104A-02

19

Page 20

Product information

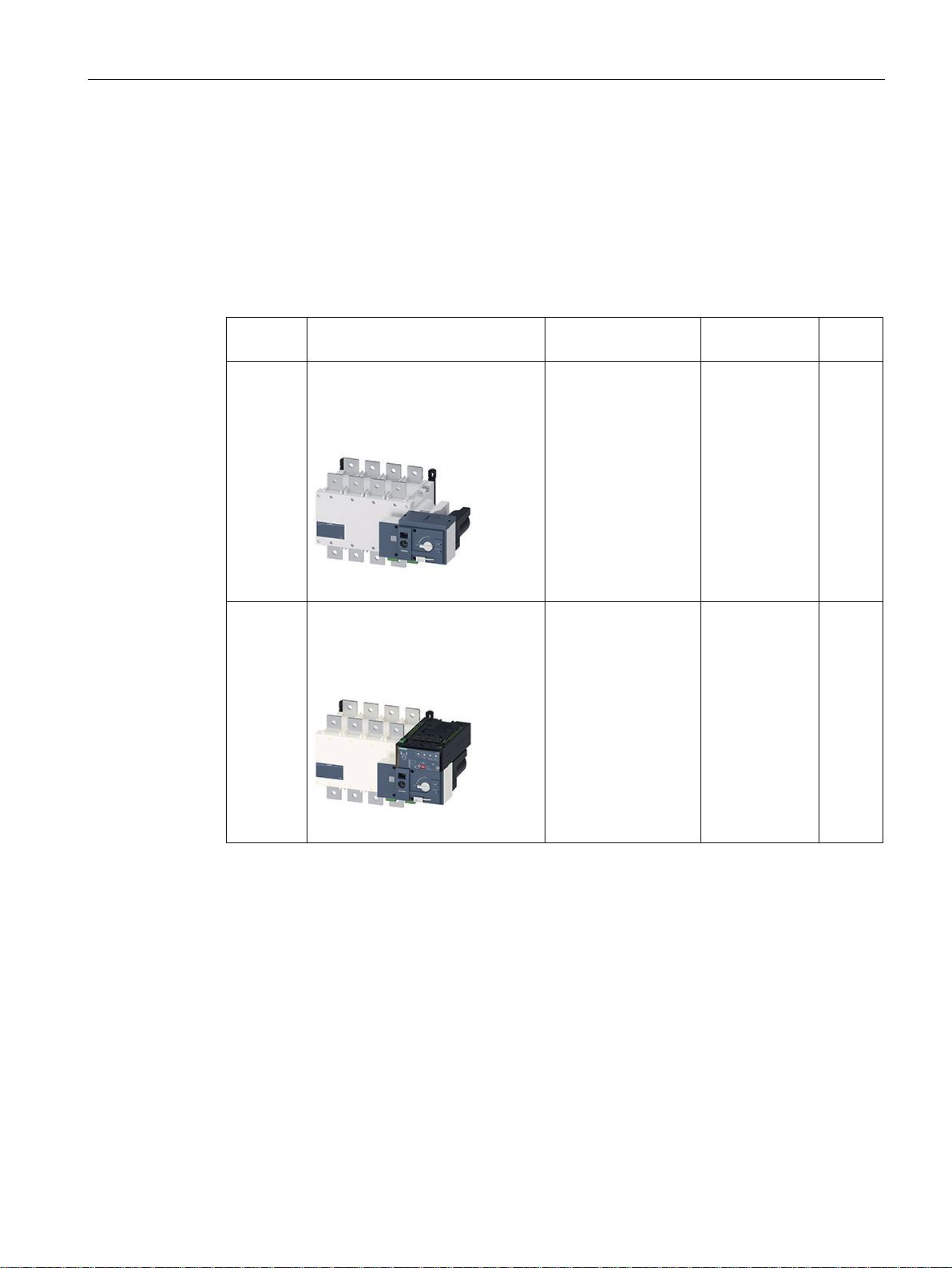

3KC8 2000 A / 2500 A / 3200 A

3.1 Product description

20 Manual, 08/2017, L1V30368969104A-02

Page 21

Product information

3.2

Product family

3.2.1

The product families 3KC4 and 3KC8 from 250 A to 3200 A

Product

family

Type

Designation

Current rating

Number

of poles

O

S

T

E

3.2 Product family

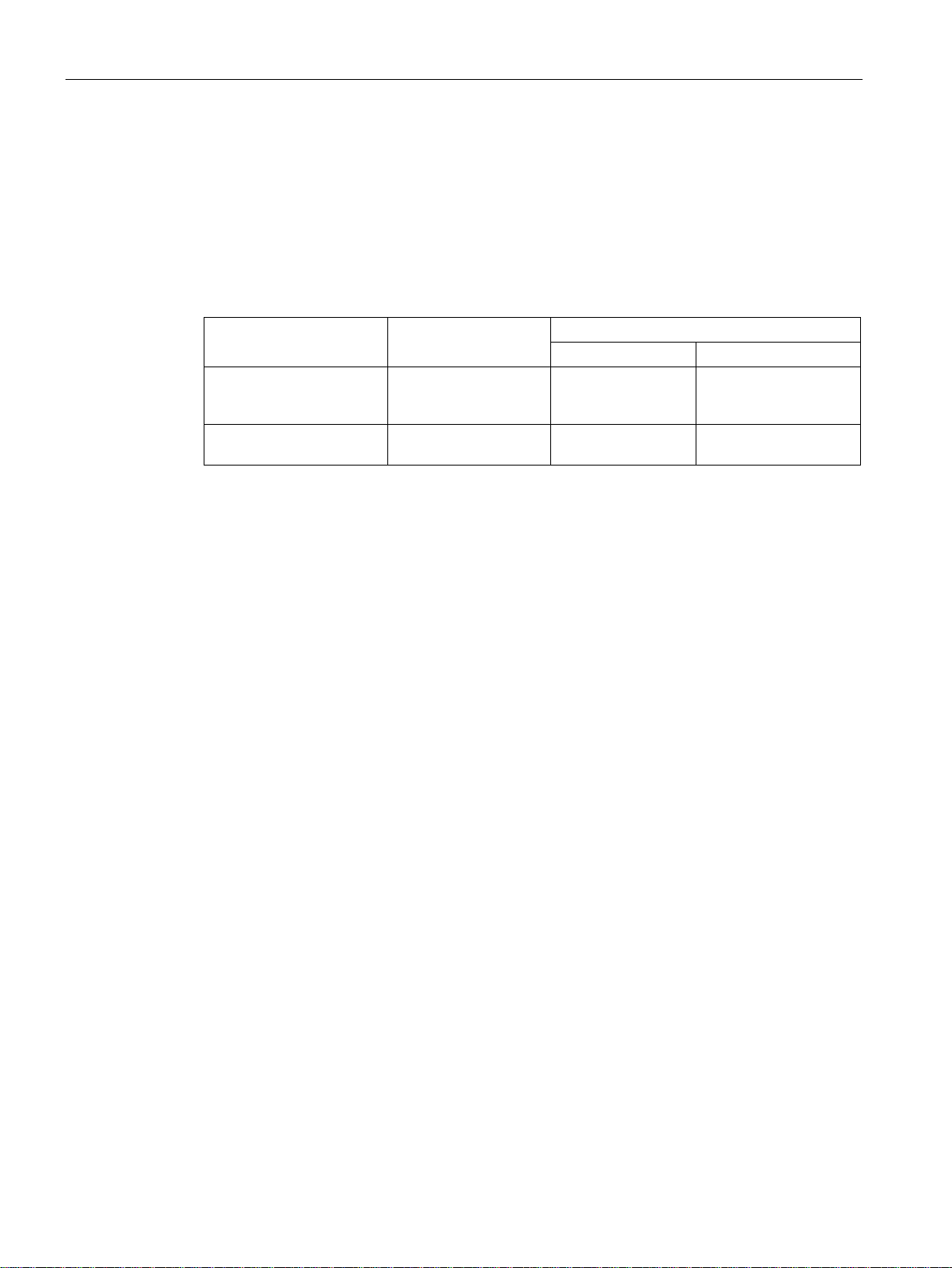

The Siemens product families 3KC4 and 3KC8 from 250 A to 3200 A encompass two types

of transfer switching equipment:

3KC4 Remotely operated transfer switch-

ing equipment

(RTSE)

3KC8 Automatic transfer switching

equipment

(ATSE)

RTSE: Remotely

perated Transfer

witching Equipment

ATSE: Automatic

ransfer Switching

quipment

250 … 3200 A 3; 4

250 … 3200 A 3; 4

Manual, 08/2017, L1V30368969104A-02

21

Page 22

Product information

3.2.2

Use of 3KC4 and 3KC8 transfer switching equipment

Type

Product family

Application areas of transfer switching

Network/network

Network/generator

3.2.3

Properties of the 3KC4 and 3KC8 transfer switching equipment

3.2 Product family

The 3KC4 and 3KC8 transfer switching equipment is used to ensure a continuous supply of

power. The equipment enables reliable transfer between a main source and an alternative

source, thus a power supply is provided by means of an emergency source if the main

source is not available.

The three switch positions of the 3KC4 and 3KC8 series enable maximum stability of the

load power supply, in which case only minimum interruption to the power supply occurs.

Remotely operated transfer switching equipment

(RTSE)

Automatic transfer switching equipment (ATSE)

3KC4 ✓ ✓

3KC8 ✓ ✓

The 3KC4 and 3KC8 transfer switching equipment enables a continuous power supply to be

maintained. The main features are as follows:

● Reliable transfer between two sources with transfer through the OFF position

● Simple installation

● Transfer with open transition

● Minimal interruption in the power supply

● Three- and four-pole designs

● Current ratings from 250 A to 3200 A

● Transfer with the supplied handle

● Extensive accessories and spare parts

● Programming in just 5 steps (3KC8 only)

● Suitability for all load types includi ng ind uc tive loa ds (AC -33)

● Safe maintenance work thanks to locking with padlocks in position 0 (OFF)

● Control signals for starting/stopping the generator, as well as generator and switch device

tests on-load and off-load (3KC8 only)

22 Manual, 08/2017, L1V30368969104A-02

Page 23

Product information

3.2.4

Application areas of the 3KC4 and 3KC8 transfer switching equipment

Service sector

Infrastructure

Industry

3.2 Product family

The 3KC4 and 3KC8 transfer switching equipment can be used in all areas where a

continuous power supply must be ensured.

● Public facilities

● Computing centers (data/server rooms)

● Shopping malls

● Airports

● Subways

● Production lines in continuous operation

● Engine rooms

● Pumps

Manual, 08/2017, L1V30368969104A-02

23

Page 24

Product information

3.2 Product family

24 Manual, 08/2017, L1V30368969104A-02

Page 25

4

Function

3KC4

3KC8

The 3KC4 and 3KC8 transfer switching equipment offers the following functions for

maintaining a power supply:

Remotely operated transfer switch ing (RTSE ) ✓ Automatic transfer switching (ATSE) - ✓

Power supply via 2 inputs (internal dual power supply) - ✓

Remote control (via inputs) ✓ ✓

Network / network applications ✓ ✓

Generator/generator applications ✓

Network / generator applicatio ns ✓

Self-configuration of voltage and frequen cy sett in gs - ✓

Monitoring of voltage and frequency - ✓

Monitoring of the phase sequence - ✓

Configuration using potentiometer and DIP switch - ✓

LED indicator for source availability - ✓

LED indicator for the switch positions - ✓

Test on-load (network/generator application) (via inputs) - ✓

Test off-load (network/generator application) (via inputs) - ✓

Connection for an optional external display - ✓

Setting of the OFF position with priority (via inputs) ✓ ✓

Indication of availability of the motor operator (via output) ✓ ✓

Switch position indication of the transfer switching equipment (via

outputs)

Inhibition of automatic mode (via inputs) - ✓

Inhibition of automatic return transfer to the prioritized sources (via

inputs).

Selection of the prioritized source (network/network application) (via

inputs)

Deactivation of the delay for stabilizing the alternative source (net-

work/generator application)

1)

Possible with the adequate controller

1)

-

1)

✓

✓ ✓

- ✓

- ✓

- ✓

Manual, 08/2017, L1V30368969104A-02

25

Page 26

Functions

26 Manual, 08/2017, L1V30368969104A-02

Page 27

5

5.1

Mounting position

Current rating

Mounting position

Motor operator

right

Motor operator

bottom

Motor operator

left

Motor operator

top

5.2

Installing the 3KC4 and 3KC8 transfer switching equipment

Note

The following content is described in this chapter:

● Mounting positions for the 3KC4 and 3KC8 transfer switching equipment

● Installation of the 3KC4 and 3KC8 transfer switching equipment

250 … 630 A ✓ ✓ ✓ 800 … 3200 A ✓ - ✓ ✓

The 3KC4 transfer switching equipme nt is dep icted in t he foll owi ng inst a llati on ins t ruc tions .

The 3KC8 transfer switching equipment differs from the 3KC4 transfer switching equipment

in its additional electronic module, but it is installed in the same way as the 3KC4 transfer

switching equipment.

Manual, 08/2017, L1V30368969104A-02

27

Page 28

Mounting

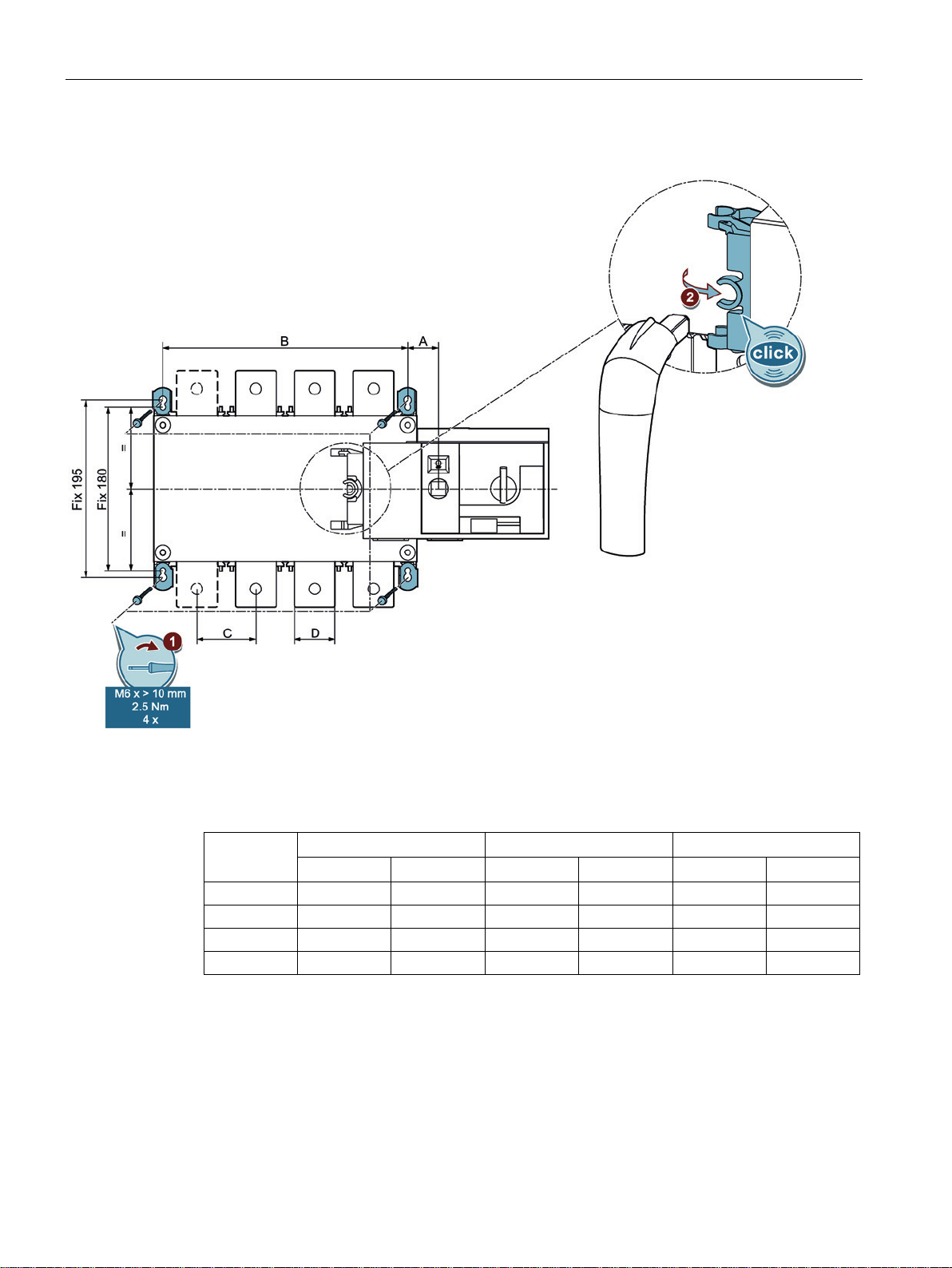

Installing the current ratings 250 A to 630 A

mm

250 A

400 A

630 A

3P

4P

3P

4P

3P

4P

5.2 Installing the 3KC4 and 3KC8 transfer switching equipment

Figure 5-1 Installing the current ratings 250 A to 630 A

The dimensions vary according to the current rating and the number of poles. They can be

found in the table below.

A 35 35 35 35 34 34

B 160 210 160 210 210 270

C 50 50 50 50 65 65

D 25 25 35 35 45 45

Proceed as follows to install the current ratings 250 A to 630 A:

1. Mount the transfer switching equipment with four bolts in the desired position as shown in

the figure (see also the section titled Mounting position (Page 27)).

2. Fasten the holder for the handle on the transfer switching equipment, and insert the

handle into the holder.

The handle and its holder are included in the scope of supply. The bolts are not included with

the 3KC automatic transfer equipment.

28 Manual, 08/2017, L1V30368969104A-02

Page 29

Mounting

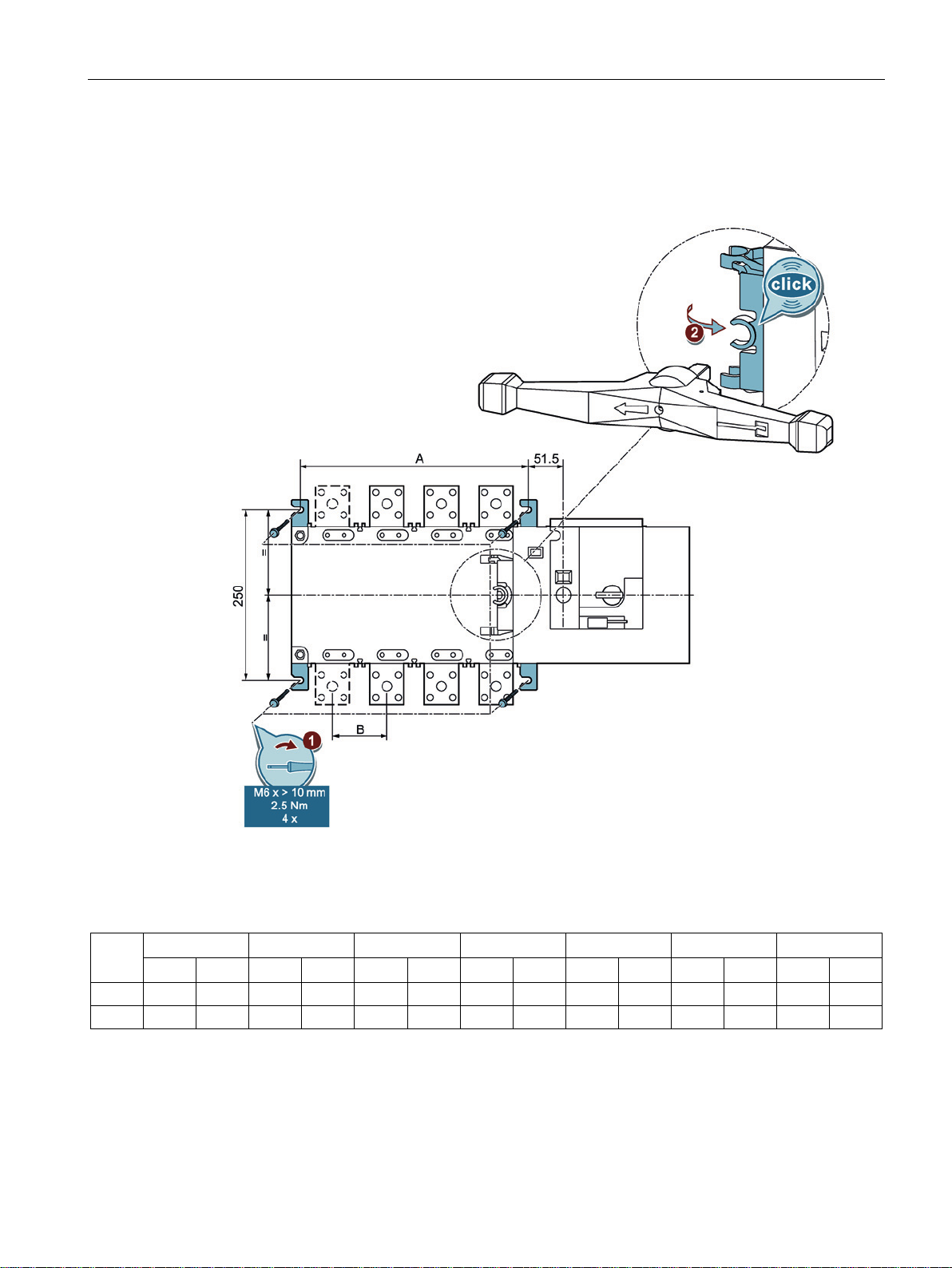

Installing the current ratings 800 A to 3200 A

mm

800 A

1000 A

1250 A

1600 A

2000 A

2500

3200 A

3P

4P

3P

4P

3P

4P

3P

4P

3P

4P

3P

4P

3P

4P

5.2 Installing the 3KC4 and 3KC8 transfer switching equipment

Proceed as follows to install the 3KC4 and 3KC8 transfer switching equipment of current

ratings 800 A to 3200 A:

Figure 5-2 Installing the current ratings 800 A to 3200 A

The dimensions vary according to the current rating and the number of poles. They can be

found in the table below.

A 255 335 255 335 255 335 347 467 347 467 347 467 347 467

B 80 80 80 80 80 80 120 120 120 120 120 120 120 120

The installation steps are identical to those for installing the current ratings 250 A to 630 A,

see above.

Manual, 08/2017, L1V30368969104A-02

29

Page 30

Mounting

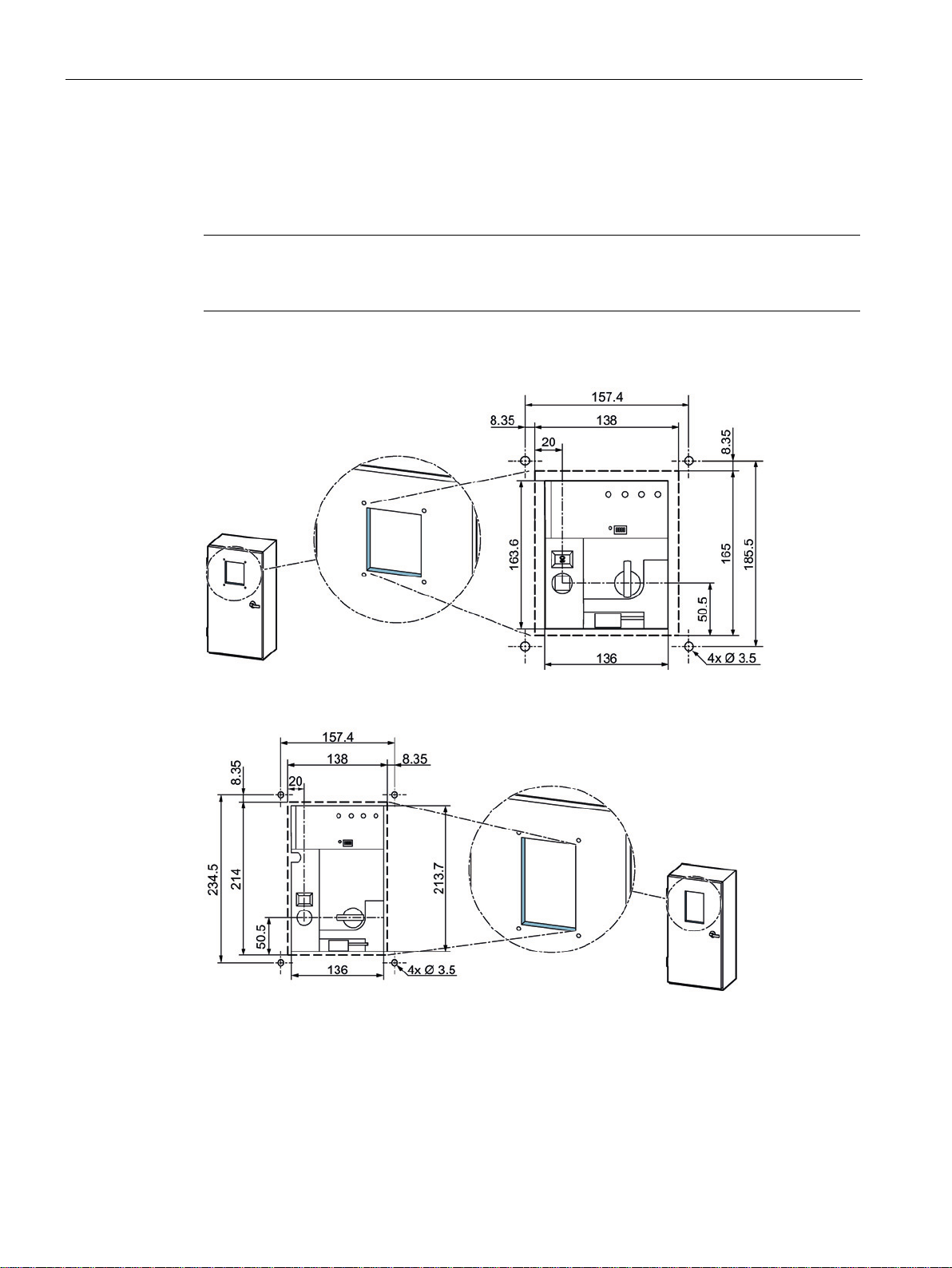

5.3

Dimensions of the cover frame for door cut-out

Note

Current ratings 250 A to 630 A

Current ratings 800 A to 3200 A

5.3 Dimensions of the cover frame for door cut-out

The following figures show the dimensions of the cover frame for door cut-out for the 3KC4

and 3KC8 transfer switching equipment.

On the 3KC8 transfer switching equipment there is an additional electronic module that

enables source monitoring.

Figure 5-3 Dimensions of the cover frame for door cutout 800 A to 3200 A

30 Manual, 08/2017, L1V30368969104A-02

Page 31

6

6.1

Network types

NOTICE

Possible damage to the device

The following content is described in this chapter:

● Network types

● Connection to the source (connecting terminals, connection instructions for each current

rating, required accessories)

● Inputs and outputs of the motor operator and accessories

● Inputs and outputs of the electronic module

● Connection of the transfer switching equipment (motor operator, electronic module,

required accessories)

The 3KC4 and 3KC8 transfer switching equipment can be connected to the following

network types:

● Three-phase 4-wire network with 3 phases with neutral (3PH + N)

● Three-phase 3-wire network with 3 phases without neutral (3PH)

● Single-phase network with 1 phase and neutral (1PH + N)

The product is designed for a rated impulse voltage resistance U

circuit and 4 kV for the electronics and/or motor unit. The dual power supply (DPS)

accessory is designed for a rated impulse voltage resistance U

autotransformer accessory is designed for 2.5 kV.

When using the product in an application in whic h over v oltages of > 4 kV or > 2.5 kV can

occur, suitable measures must additionally be taken to limit these overvoltages to no more

than 4 kV or 2.5 kV, respectively.

of 12 kV for the main

imp

of 4 kV, and the

imp

Manual, 08/2017, L1V30368969104A-02

31

Page 32

Connection

6.1.1

Three-phase 4-wire network with neutral (3PH + N)

6.1.1.1

Circuit diagram for the 3KC4 transfer switching equipment - 4-pole transfer switching equipment

Note

6.1 Network types

The 3KC4 and 3KC8 transfer switching equipment can be used in a network comprising

three phases and a neutral conductor.

Figure 6-1 Three-phase 4-wire network with neutral for the 3KC4 transfer switching equipment

F1 1 x 3NW6004-1

1 x 3NW7013

4 A, gG

For the power supply of the transfer switching equipment, the dual power supply accessory

3KC9625-1 is required. You can find a detailed description in the section titled Mounting and

connecting the dual power supply (DPS) (Page 77).

The F1 fuses must be installed as closely as possible to the tap.

32 Manual, 08/2017, L1V30368969104A-02

Page 33

Connection

6.1.1.2

Circuit diagram for the 3KC8 transfer switching equipment - 4-pole transfer switching equipment

6.1.2

Three-phase 3-wire network without neutral (3PH)

Note

6.1 Network types

Figure 6-2 Three-phase 4-wire network with neutral for the 3KC8 transfer switching equipment

The power supply kit accessories 3KC9830-, 3KC9831- can be used for the power supply of

the transfer switching equipment. You can find a detailed description in the section titled

Connecting power supply kit 3KC9830-, 3KC9831- (4-pole) (Page 92).

The dual power supply (DPS) accessory is not required with the 3KC8 transfer switching

equipment since it is supplied with power via two inputs of the electronic module.

The 3KC4 and 3KC8 transfer switching equipment can be used in a network comprising 3

phases. It can be used both in networks with balanced load, as well as in networks with

unbalanced load.

The fictitiously generated fourth pole is used only for the power supply of the transfer

switching equipment and mus t not be run to the main load.

Manual, 08/2017, L1V30368969104A-02

33

Page 34

Connection

6.1.2.1

Circuit diagram for the 3KC4 transfer switching equipment - 3-pole transfer switching equipment

Note

6.1 Network types

Figure 6-3 Three-phase 3-wire network without neutral for the 3KC4 transfer switching equipment

F1 2 x 3NW6002-1

1 x 3NW7023

F2 1 x 3NW6004-1

1 x 3NW7013

2 A, gG

4 A, gG

With this arrangement there is no neutral conductor available. For this reason, the following

optional accessories can/must be used for establishing this network:

● 2 x autotransformer 3KC9824-1. For information, see the section titled Ins tal ling a nd

connecting an autotransformer (400 V / 230 V) (Page 79).

● 1 x dual power supply 3KC9625-1. For information, see the section titled Mounting and

connecting the dual power supply (DPS) (Page 77).

The F1 fuses must be installed as closely as possible to the tap.

The F2 fuses must be fitted as closely as possible to the output of the autotransformer.

34 Manual, 08/2017, L1V30368969104A-02

Page 35

Connection

6.1.2.2

Circuit diagram for the 3KC8 transfer switching equipment - 4-pole transfer switching equipment

Note

6.1 Network types

Figure 6-4 Three-phase 3-wire network without neutral for the 3KC8 transfer switching equipment

(4-pole)

F1 2 x 3NW6002-1

1 x 3NW7023

F2 1 x 3NW6004-1

1 x 3NW7013

2 A, gG

4 A, gG

With this arrangement there is no neutral conductor available. For this reason, the following

optional accessories can be used for establishing this network:

● 2 x autotransformer 3KC9824-1. For information, see the section titled Ins tal ling a nd

connecting an autotransformer (400 V / 230 V) (Page 79).

● For the power supply: Power supply kit 3KC9830-, 3KC9831-. For information, see the

section titled Connecting power supply kit 3KC9830-, 3KC9 83 1- (4-pole) (Page 92).

The F1 fuses must be installed as closely as possible to the tap.

The F2 fuses must be fitted as closely as possible to the output of the autotransformer.

The dual power supply (DPS) accessory is not required with the 3KC8 transfer switching

equipment since it is supplied with power via two inputs of the electronic module.

Manual, 08/2017, L1V30368969104A-02

35

Page 36

Connection

6.1.2.3

Circuit diagram for the 3KC8 transfer switching equipment - 3-pole transfer switching equipment

6.1 Network types

Figure 6-5 Three-phase 3-wire network without neutral for the 3KC8 transfer switching equipment

(3-pole)

F1 2 x 3NW6002-1

1 x 3NW7023

F2 1 x 3NW6004-1

1 x 3NW7013

2 A, gG

4 A, gG

With this arrangement there is no neutral conductor available. For this reason, the following

optional accessories can/must be used for establishing this network:

● 2 x autotransformer 3KC9824-1. For information, see the section titled Ins tal ling a nd

connecting an autotransformer (400 V / 230 V) (Page 79).

● The auxiliary conductor terminal kit is required in the case of the 3-pole variant for

connecting the electronic module, and it must be mounted before connection to the

source. See the section titled Connecting the auxiliary conductor terminal 3KC9822-,

3KC9832- for a three-phase 3-wire network (3-pole) (Page 95).

The dual power supply (DPS) accessory is not required with the 3KC8 transfer switching

equipment since it is supplied with power via two inputs of the electronic module.

36 Manual, 08/2017, L1V30368969104A-02

Page 37

Connection

6.1.3

Single-phase network with neutral (1PH + N)

6.1.3.1

Circuit diagram for the 3KC4 transfer switching equipment - 3-pole transfer switching equipment

Note

6.1 Network types

The 3KC4 and 3KC8 transfer switching equipment can be used in a single-p has e networ k

comprising one phase and a neutral conductor. Since there is no 2-pole design available for

the transfer switching equipment, the 3KC4 and 3KC8 transfer switching equipment in 3-pole

design is the best choice.

Figure 6-6 Single-phase network without neutra l for 3KC4 transf er switc hing equ ipm ent

F1 1 x 3NW6004-1

For the power supply of the 3KC4 transfer switching equipment, the dual power supply

accessory 3KC9625-1 is required. You can find a detailed description of this in the section

titled Mounting and connecting the dual power supply (DPS) (Page 77).

The F1 fuses must be installed as closely as possible to the tap.

Manual, 08/2017, L1V30368969104A-02

4 A, gG

1 x 3NW7013

37

Page 38

Connection

6.1.3.2

Circuit diagram for the 3KC8 transfer switching equipment - 3-pole transfer switching equipment

Note

6.1 Network types

* No fuse required if the power supply kit accessories 3KC9833-, 3KC9834- are used

Figure 6-7 Single-phase system without 3KC 8 transfer sw itc hin g equipment

F1 1 x 3NW6004-1

1 x 3NW7013

4 A, gG

The dual power supply (DPS) accessory is not required with the 3KC8 transfer switching

equipment since it is supplied with power via two inputs of the electronic module. Before

connecting, the pins 101/102 and 201/202 must be connected to the main circuit. This can

be done most easily with the 3KC9833-, 3KC9834- power supply kit. See the section titled

Connecting power supply kit 3KC9833-, 3KC9834- for single-phase network (Page 98) in this

regard.

The F1 fuses must be installed as closely as possible to the tap.

38 Manual, 08/2017, L1V30368969104A-02

Page 39

Connection

6.2

Connecting the main circuit

6.2.1

Connecting terminals of the transfer switching equipment

Connecting terminals for current ratings 250 A to 630 A

Connecting terminals for current ratings 800 A to 1600 A

Connecting terminals for current ratings 2000 A to 3200 A

2000 A to 3200 A

6.2 Connecting the main circuit

In the following chapter, you will find a description of the connection options for the 3KC4

and 3KC8 transfer switching equipment.

The connecting terminals of the 3KC4 and 3KC8 transfer switching equipment differ

depending on the current rating. The different connecting terminals are shown below.

250 A

800 A – 1000 A

400 A

1250 A

630 A

1600 A

Manual, 08/2017, L1V30368969104A-02

39

Page 40

Connection

6.2.2

Load connection

6.2.3

Arrangement of the power supply systems

Note

NOTICE

Incorrect connection in the case of network/generator applications of the 3KC8 transfer

switching equipme nt

6.2 Connecting the main circuit

The following figure shows the two fundamentally possible arrangements for the connected

load. It can be connected at the top or bottom.

Figure 6-8 Arrangements for load connection

Since both the 3KC4 and the 3KC8 have a flat connector, they can be connected to the

power supply system using cable lugs or busbars.

Transfer switching equipment of 2000 A and higher is connected using the optionally

available copper bar connection kit.

The transfer switching equipment for 2000 A and higher comprises 2 switches (switch 1 and

switch 2) in each case. These must be bridged using the copper bar connection kit.

The main current source must be connected to switch 1. Only then is the transfer switching

equipment functional. Connection of the generator to switch 2 is absolutely necessary for

controlling the generator.

40 Manual, 08/2017, L1V30368969104A-02

Page 41

Connection

Connecting the 3KC8 transfer switching equipment

Note

6.2 Connecting the main circuit

With network/network applications, any arrangement of the connection can be selected.

With the 3KC8 transfer switching equipment, prioritization of the source can be implemented

via the corresponding inputs. For information, see the section titled Functions of the control

inputs for network / generator application (Page 119).

Before you connect the 3KC8 transfer switching equipment to the power supply systems,

you must attach the corresponding accessories to make the electronic module functional.

The required accessories depend on the current rating and the network type. Observe the

information in the section titled Connecting the inputs and outputs of the electronic module

(3KC8 only) (Page 89) before connecting the transfer switching equipment to the power

supply systems.

Figure 6-9 Line-side connection of the main circuit with the 3KC8 transfer switching equipment

Manual, 08/2017, L1V30368969104A-02

41

Page 42

Connection

6.2.4

Connection of transfer switching equipment for current ratings 250 A to 1600 A

6.2.4.1

Connecting bridging bars on the load side

WARNING

Hazardous voltage!

Mounting bridging bars for current ratings 250 A to 630 A

6.2 Connecting the main circuit

The connection of current ratings 250 A to 1600 A to the main circuit is described in the

following section.

To connect the 3KC4 and 3KC8 transfer switching equipment properly, you must first mount

the bridging bar accessories on the load side. The steps listed below describe the mounting

of the bridging bars and connection to the power supply systems.

Ensure there is no live voltage before beginning to mount the bridging bars.

Current ratings 250 A to 1600 A require bridging bars. These serve as a bridge for the loadside connection and they can be mounted either on the top or bottom of the transfer

switching equipment.

The bridging bars are not included with the transfer switch and must be ordered as

accessories.

Figure 6-10 Bridging bar current ratings 250 A to 630 A

42 Manual, 08/2017, L1V30368969104A-02

Figure 6-11 Bridging bar current ratings 800 A to 1600 A

The following steps are necessary for mounting the bridging bars on the transfer switching

equipment. Refer to the table for information about the bolts, tools, and tightening torques.

The bolts are not included with the transfer switch. You can find more detailed information on

the bridging bars in the section titled Bridging bars (Page 154).

Page 43

Connection

Requirements

Procedure

Current rating

Note

completely

6.2 Connecting the main circuit

● Power supply is switched off

● Transfer switching equipment is in the "Manual" position

Figure 6-12 Mounting bridging bars for current ratings 250 A to 630 A

250 A M10 x 20 mm 17 20 ... 26

400 A M10 x 25 mm

630 A M12 x 30 mm 19 40 ... 45

1. Position the bridging bar on the connecting terminal.

2. Fix the first half of the bridging bar to the connecting terminal with the bolt and washer.

3. Fix the second half of the bridging bar to the connecting terminal with the bolt and

washer.

The two halves of the bridging bar must come into contact

before work step 4.

4. Connect the two parts of the bridging bar with 1 bolt, 2 washer s and 1 nut in accordanc e

with the figure.

Manual, 08/2017, L1V30368969104A-02

43

Page 44

Connection

Mounting bridging bars for current ratings 800 A to 1600 A

Requirements

Procedure

6.2 Connecting the main circuit

The following steps are necessary for mounting the bridging bars on the transfer switching

equipment. Refer to the table for information about the bolts, tools, and tightening torques.

The bolts for mounting the bridging bars are included in the scope of supply.

Bolts with washers and nuts are additionally required in the following quantities for fixing the

bridging bars to the connecting terminal:

● 4 x for current ratings 800 A to 1250 A

● 2 x for current rating 1600 A

● Power supply is switched off

● Transfer switching equipment is in the "Manual" position

Figure 6-13 Mounting bridging bars for current ratings 800 A to 1600 A

44 Manual, 08/2017, L1V30368969104A-02

Page 45

Connection

Current rating

Note

completely

6.2 Connecting the main circuit

800 A ... 1000 A M8 x 35 mm 13 8.3 ... 13

1250 A M10 x 40 mm 17 20 ... 26

1600 A M12 x 45 mm 19 40 ... 45

1. Position the bridging bar on the connecting terminal.

2. Fix the first half of the bridging bar to the connecting terminal.

– For current ratings of 800 A to 1250 A with 4 bolts, 8 washers, and 4 nuts.

– For current ratings of 1600 A with 2 bolts, 4 washers, and 2 nuts.

3. Fix the second half of the bridging bar to the connecting terminal.

– For current ratings of 800 A to 1250 A with 4 bolts, 8 washers, and 4 nuts.

– For current ratings of 1600 A with 2 bolts, 4 washers, and 2 nuts.

The two halves of the bridging bar must come into contact

before work step 4.

4. Connect the two parts of the bridging bar with the bolts supplied.

Manual, 08/2017, L1V30368969104A-02

45

Page 46

Connection

6.2.4.2

Connecting current ratings 250 A to 1600 A to the main circuit

WARNING

Hazardous voltage!

NOTICE

System damage

Note

Using bridging bars

before

Note

6.2 Connecting the main circuit

The following steps are necessary for connecting the transfer switching equipment to the

main circuit. Refer to the respective table for information about the permissible copper

connections, required tools, and tightening torques.

Ensure there is no live voltage before connecting the transfer switching equipment to the

main circuit.

Connect the power supply systems with phase equality.

Mount the bridging bars

circuit. For information, see the section titled

connecting the transfer switching equipment to the main

Connecting bridging bars on the load side

(Page 42).

If you are using the 3KC8 transfer switching equipment, mount the corresponding

accessories for the electronic module (see the section titled Connecting the inputs and

outputs of the electronic module (3KC8 only) (Page 89)).

46 Manual, 08/2017, L1V30368969104A-02

Page 47

Connection

Current ratings 250 A to 630 A

Requirements

Procedure

Current

rating

6.2 Connecting the main circuit

● Main circuit is disconnected

● Transfer switching equipment is in the "Manual" position

Figure 6-14 Connecting current ratings 250 A to 630 A

250 A 1 x 30 x 4 ... 1 x 32 x 5 120 ... 150 M10 20 ... 26

400 A 1 x 30 x 8 ... 1 x 32 x 8 240 M10 20 ... 26

630 A 2 x 40 x 5 ... 2 x 50 x 8 2 x 185 ... 2 x 300 M12 40 ... 45

1. Mount the cable lug or the busbar according to the figure.

2. Secure the connection with 1 bolt, 2 washers, and 1 nut on the cable lug or the busbar.

Manual, 08/2017, L1V30368969104A-02

47

Page 48

Connection

Current ratings 800 A to 1600 A

Requirements

Procedure

Current rating

6.2 Connecting the main circuit

● Main circuit is disconnected

● Transfer switching equipment is in the "Manual" position

Figure 6-15 Connecting current ratings 800 A to 1600 A

800 A 2 x 50 x 5 2 x 240 ... 2 x 300 M8 8.3 ... 13

1000 A 2 x 60 x 5 4 x 185 M8 8.3 ... 13

1250 A 2 x 60 x 7 4 x 185 M10 20 ... 26

1600 A 2 x 100 x 5 6 x 185 M12 40 ... 45

1. Mount the cable lug or the busbar according to the figure.

2. Secure the connection with a cable lug or the busbar.

– For current ratings of 800 A to 1250 A with 4 bolts, 8 washers, and 4 nuts in each

case.

– For current ratings of 1600 A with 2 bolts, 4 washers, and 2 nuts.

48 Manual, 08/2017, L1V30368969104A-02

Page 49

Connection

6.2.5

Connection of transfer switching equipment for current ratings 2000 A to 3200 A

6.2.5.1

Copper bar connection kit

Overview of the copper bar connection kit

6.2 Connecting the main circuit

The connection of current ratings 2000 A to 3200 A to the main circuit is described in the

following section.

So that you can connect the 3KC4 and 3KC8 transfer switching equipment to the power

supply systems properly, you must first mount the copper bar connection kit accessory. The

steps listed below describe the mounting of the copper bar connection kit and connection to

the power supply systems.

For current ratings 2000 A to 3200 A, the copper bar connection kit may be mounted on the

line or load side, depending on the connection type. This is not fully included with the

transfer switch and must be ordered separately.

The copper bar connection kit is made up of 5 separately available parts. The different

components of the copper bar connection kit enable a host of connection options.

Figure 6-16 Connection, part A, (3KC9811-0, included in the scope of supply for current rating

3200 A)

Figure 6-17 Bolt set, part B, 45 mm (3KC9811-1)

Figure 6-18 Bolt set, part B, 35 mm short length (3KC9811-2)

Manual, 08/2017, L1V30368969104A-02

49

Page 50

Connection

Note

6.2 Connecting the main circuit

Figure 6-19 T piece, part C (3KC9811-3)

Figure 6-20 Bracket, part D (3KC9811-4)

Figure 6-21 Bridging bar, part E (3KC9811-8)

The required bolts for the T piece (3KC9811-3), the bracket (3KC9811-4), and the bridging

bar (3KC9811-8) are already included with the transfer switch.

The different solutions offered by the copper bar connection kit for current ratings 2000 A to

3200 A are shown below.

With the 3KC4 and 3KC8 transfer switching equipment of current rating 3200 A, the

connection, part A (3KC9811-0) is already included with the transfer switch and must be

mounted on the 3200 A transfer switching equipment on the line and load side.

50 Manual, 08/2017, L1V30368969104A-02

Page 51

Connection

Connection options

Version

Position of the connection

Current rating

Fig.

6.2 Connecting the main circuit

The following connections are possible with the copper bar connection kit:

1 Line side

2 Line side 3200 A

3 Line side 2000 A … 2500 A

2000 A … 2500 A

4 Line side 2000 A … 2500 A

5 Line side 3200 A (2900 A max.)

Manual, 08/2017, L1V30368969104A-02

51

Page 52

Connection

Version

Position of the connection

Current rating

Fig.

6.2 Connecting the main circuit

6 Line side 3200 A

7 Load side 2000 A … 2500 A

8 Load side 3200 A

9 Load side 2000 A … 2500 A

52 Manual, 08/2017, L1V30368969104A-02

Page 53

Connection

Version

Position of the connection

Current rating

Fig.

6.2 Connecting the main circuit

10 Load side 2000 A … 2500 A

11 Load side 3200 A

12 Load side 3200 A

Manual, 08/2017, L1V30368969104A-02

53

Page 54

Connection

Dimensions of the 3KC4 and 3KC8 transfer switching equipment with copper bar connection kit

Dimensions version 1

Dimensions version 2

Dimensions of version 3 to 8

6.2 Connecting the main circuit

Use of the copper bar connection kit changes the dimensions of the 3KC4 and 3KC8 transfer

switching equipment.

Figure 6-22 Dimensions with copper bar connection kit, version 1

Figure 6-23 Dimensions with copper bar connection kit, version 2

Figure 6-24 Dimensions with copper bar connection kit, versions 3 to 8

54 Manual, 08/2017, L1V30368969104A-02

Page 55

Connection

Dimensions of version 9 to 12

6.2.5.2

Connecting current ratings 2000 A to 3200 A to the main circuit (on the line side)

WARNING

Hazardous voltage!

NOTICE

System damage

Note

Busbar requirements

6.2 Connecting the main circuit

Figure 6-25 Dimensions with copper bar connection kit, versions 9 to 12

The connection of current ratings 2000 A to 3200 A on the line side to the main circuit is

described in the following section. Different connection variants are possible here (versions

listed in the form of a table in the section titled Copper bar connection kit (Page 49)).

Ensure there is no live voltage before connecting the transfer switching equipment to the

main circuit.

Connect the power supply systems with phase equality.

If you are using the 3KC8 transfer switching equipment, mount the corresponding

accessories for the electronic module. For information, see the section titled Connecting the

inputs and outputs of the electronic module (3KC8 only) (Page 89).

Manual, 08/2017, L1V30368969104A-02

Busbars with the following minimum dimensions must be used for line-side connection:

● Minimum copper busbar for I

● Minimum copper busbar for I

● Minimum copper busbar for I

2000 A = 3 x 100 x 5 mm

th

2500 A = 4 x 100 x 5 mm

th

3200 A = 3 x 100 x 10 mm

th

55

Page 56

Connection

Mounting and connecting version 1 (2000 A to 2500 A)

Number of poles

Current rating

Bolt set, part B, 35 mm

(3KC9811-2)

1)

Contains only the quantity for line-side connectio n

6.2 Connecting the main circuit

Figure 6-26 Connecting busbar, version 1

The following components of the copper bar connection kit are required in the following

quantities for these versions:

Figure 6-27 Bolt set, part B, 35 mm short length, 3KC9811-2

3-pole 2000 A … 2500 A 6 x

4-pole 2000 A … 2500 A 8 x

1)

This variant is connected directly to the power supply systems via the busbars.

56 Manual, 08/2017, L1V30368969104A-02

Page 57

Connection

Requirements

Procedure

6.2 Connecting the main circuit

● Main circuit is disconnected

● Transfer switching equipment is in the "Manual" position

1. Mount one busbar on each connecting terminal of the 3KC4 or 3KC8 transfer switching

equipment with 6 bolts and 6 washers of the bolt set, part B, 35 mm (3KC9811-2).

Figure 6-28 Connecting busbar, version 1

Manual, 08/2017, L1V30368969104A-02

57

Page 58

Connection

Mounting and connecting version 2 (3200 A)

Number of

poles

Current rating

Bolt set, part B, 35 mm

(3KC9811-2)

1)

Bolt set, part B, 45 mm

(3KC9811-1)

1)

6.2 Connecting the main circuit

Figure 6-29 Connecting busbar, version 2

The following components of the copper bar connection kit are required in the following

quantities for these versions:

Figure 6-30 Bolt set, part B, 35 mm short length, 3KC9811-2

Figure 6-31 Bolt set, part B, 45 mm, 3KC9811-1

3-pole 3200 A 3 x 3 x

4-pole 3200 A 4 x 4 x

1) Contains only the quantity for line-side connec tio n

This variant is connected directly to the power supply systems via the busbars. Part A is

included with the transfer switch and must be secured.

58 Manual, 08/2017, L1V30368969104A-02

Page 59

Connection

Requirements

Procedure

6.2 Connecting the main circuit

● Main circuit is disconnected

● Transfer switching equipment is in the "Manual" position

1. Insert the connection, part A (3KC9811-0, already included with the transfer switch)

between the two connecting terminals.

Figure 6-32 Inserting connection, part A

2. Mount 2 busbars with 3 bolts and 3 washers of the bolt set, part B, 45 mm (3KC9811-1)

on the front connecting terminal.

3. Mount 1 busbar with 3 bolts and 3 washers of the bolt set, part B, 35 mm (3KC9811-2) on

the rear connecting terminal.

Figure 6-33 Connecting busbar, version 2

Manual, 08/2017, L1V30368969104A-02

59

Page 60

Connection

Mounting and connecting version 3 to 6 (2000 A to 3200 A)

6.2 Connecting the main circuit

Version 3: 2000 A to 2500 A

Version 5: 2900 A max.

Version 4: 2000 A to 2500 A

Version 6: 3200 A

60 Manual, 08/2017, L1V30368969104A-02

Page 61

Connection

Number of

poles

Current rating

Connection, part A

(3KC9811-0)

1)

T piece, part C

(3KC9811-3)

1)

Bracket, part D

(3KC9811-4)

1)

6.2 Connecting the main circuit

The following components of the copper bar connection kit are required for these versions:

Figure 6-34 Connection, part A, 3KC9811-0 (already included with the transfer switch for 3200 A)

Figure 6-35 T piece, part C 3KC9811-3

Figure 6-36 Bracket, part D, 3KC9811-4

3-pole 2000 A …

6 x 6 x 6 x

2500 A

3-pole 3200 A Included with the transfer

switch

4-pole 2000 A …

8 x 8 x 8 x

2500 A

4-pole 3200 A Included with the transfer

switch

1) Contains only the quantity for line-side connec tio n

6 x 6 x

8 x 8 x

Manual, 08/2017, L1V30368969104A-02

61

Page 62

Connection

Mounting version 3 to 6 of copper bar connection kit

6.2 Connecting the main circuit

1. Insert the connection, part A (3KC9811-0) between the two connecting terminals.

Figure 6-37 Inserting connection, part A

2. Mount the bracket, part D (3KC9811-4), with the supplied bolts on the outsi de of the

connecting terminals to secure the connection, part A.

Figure 6-38 Mounting bracket, part D

3. Position the T piece, part C (3KC9811-3) with the supplied bolts as shown in the figure on

top of the already mounted parts A and D.

Figure 6-39 Mounting the T piece

62 Manual, 08/2017, L1V30368969104A-02

Page 63

Connection

Connecting versions 3 to 6

Requirements

Procedure

Version

Bolt

Washer

Nut

6.2 Connecting the main circuit

Versions 3 and 5, as well as versions 4 and 6, are connected to the power supply systems in

two different ways:

● Version 3 and 5: Vertically aligned

● Version 4 and 6: Horizontally aligned

● Main circuit is disconnected

● Transfer switching equipment is in the "Manual" position

● Copper bar connection kit is mounted

The bolt set required for mounting is not included with the transfer switch. You can find the

bolt set requirements in the following table:

3 (vertical)

2000 … 2500 A

4 (horizontal)

2000 … 2500 A

5 (vertical)

2900 A

6 (horizontal)

3200 A

3 x H M12-55 6.8 6 x 3 x

5 x H M12-55 6.8 10 x 5 x

3 x H M12-65 6.8 6 x 3 x

5 x H M12-65 6.8 10 x 5 x

Manual, 08/2017, L1V30368969104A-02

63

Page 64

Connection

6.2 Connecting the main circuit

1. Mount the busbar on the transfer switching equipment.

– Version 3 and 5 (vertical alignment) each with 3 bolts, 6 washers and 3 nuts.

– Version 4 and 6 (horizontal alignment) each with 5 bolts, 10 washers and 5 nuts.

Figure 6-40 Connecting versions 3 and 4 (2000 A to 2500 A)

Figure 6-41 Connecting versions 5 and 6 (2900 A or 3200 A)

2. Connect the mounted transfer switching equipment to the power supply systems.

– For the 3-pole type with 6 x the above listed bolt set.

– For the 4-pole type with 8 x the above listed bolt set.

64 Manual, 08/2017, L1V30368969104A-02

Page 65

Connection

6.2.5.3

Connecting current ratings 2000 A to 3200 A to the main circuit (on the load side)

WARNING

Hazardous voltage!

NOTICE

System damage

Note

Busbar requirements

6.2 Connecting the main circuit

The load-side connection of current ratings 2000 A to 3200 A to the main circuit is described

in the following section. Different connection variants are possible here (versions listed in the

form of a table in the section titled Copper bar connection kit (Page 49)).

Ensure there is no live voltage before connecting the transfer switching equipment to the

main circuit.

Connect the power supply systems with phase equality.

If you are using the 3KC8 transfer switching equipment, mount the corresponding

accessories for the electronic module. For information, see the section titled Connecting the

inputs and outputs of the electronic module (3KC8 only) (Page 89).

Busbars with the following minimum dimensions must be used for load-side connection:

● Minimum copper busbar for I

● Minimum copper busbar for I

● Minimum copper busbar for I

2000 A = 3 x 100 x 5 mm

th

2500 A = 4 x 100 x 5 mm

th

3200 A = 3 x 100 x 10 mm

th

Manual, 08/2017, L1V30368969104A-02

65

Page 66

Connection

Mounting and connecting sizes 7 and 8

6.2 Connecting the main circuit

Version 7: 2000 A to 2500 A

Version 8: 3200 A

The same components of the copper bar connection kit are required for versions 7 to 8 as for

versions 3 to 6. Mounting is also identical to mounting of versions 3 to 6. You can find more

detailed information in the section titled Connecting current ratings 250 A to 1600 A to the

main circuit (Page 46).

66 Manual, 08/2017, L1V30368969104A-02

Page 67

Connection

Connecting versions 7 and 8

Requirements

Procedure

Version

Bolt

Washer

Nut

6.2 Connecting the main circuit

● Main circuit is disconnected

● Transfer switching equipment is in the "Manual" position

● Copper bar connection kit is mounted

The bolt set required for mounting is not included with the transfer switch. You can find the

bolt set requirements in the following table:

7 (horizontal)

2000 … 2500 A

8 (horizontal)

3200 A

10 x H M12-55 6.8 20 x 10 x

10 x H M12-65 6.8 20 x 10 x

1. Mount the busbar with 10 bolts, 20 washers and 10 nuts on the transfer switching

equipment.

Figure 6-42 Connecting versions 7 and 8

2. Connect the mounted transfer switching equipment to the power supply systems.

– For the 3-pole type with 3 x the above listed bolt set.

– For the 4-pole type with 4 x the above listed bolt set.

Manual, 08/2017, L1V30368969104A-02

67

Page 68

Connection

Mounting and connecting version 9 to 12

Version 11: 3200 A

Version 12: 3200 A

6.2 Connecting the main circuit

Version 9: 2000 A to 2500 A

Version 10: 2000 A to 2500 A

68 Manual, 08/2017, L1V30368969104A-02

Page 69

Connection

Number of

poles

Current rating

Connection, part A

(3KC9811-0)

Bolt set, part B, 45 mm

(3KC9811-1)

Bridging bar, part E

(3KC9811-8)

6.2 Connecting the main circuit

The following components of the copper bar connection kit are required for these versions:

Figure 6-43 Connection, part A, 3KC9811-0

Figure 6-44 Bolt set, part B, 45 mm, 3KC9811-1

Figure 6-45 Bridging bar, part E, 3KC9811-8

3-pole 2000 A … 2500 A 6 x 6 x 3 x

3-pole 3200 A Included with the transfer

switch

4-pole 2000 A … 2500 A 8 x 8 x 4 x