Page 1

Siemens

Energy & Automation

USER'S MANUAL ADDENDUM

UMA353-1-6

Rev. 1

April 2001

Model 353 Process Automation Controller

Direct Entry1 Rear Connectors

INVOLVED MANUALS

User’s Manual, Model 353 Process Automation Controller, UM353-1, Rev. 8 and earlier.

DISCUSSION

Direct entry rear connectors will begin shipping in March 2001. Direct entry connectors are described in

this Addendum and all power, ground, station common, and signal terminals are identified.

Consult the nameplate on the case to determine whether direct entry connectors have been installed.

Model 353_2_ _ _ _ _ _ _ _ _ _ Side entry1 connectors are installed

Model 353_4_ _ _ _ _ _ _ _ _ _ Direct entry connectors with Ethernet connector are installed

Section 6 Installation, in UM353-1, describes the black side

entry connectors and the connections to be made to them. In

the following, the direct entry connectors will be described

and illustrated.

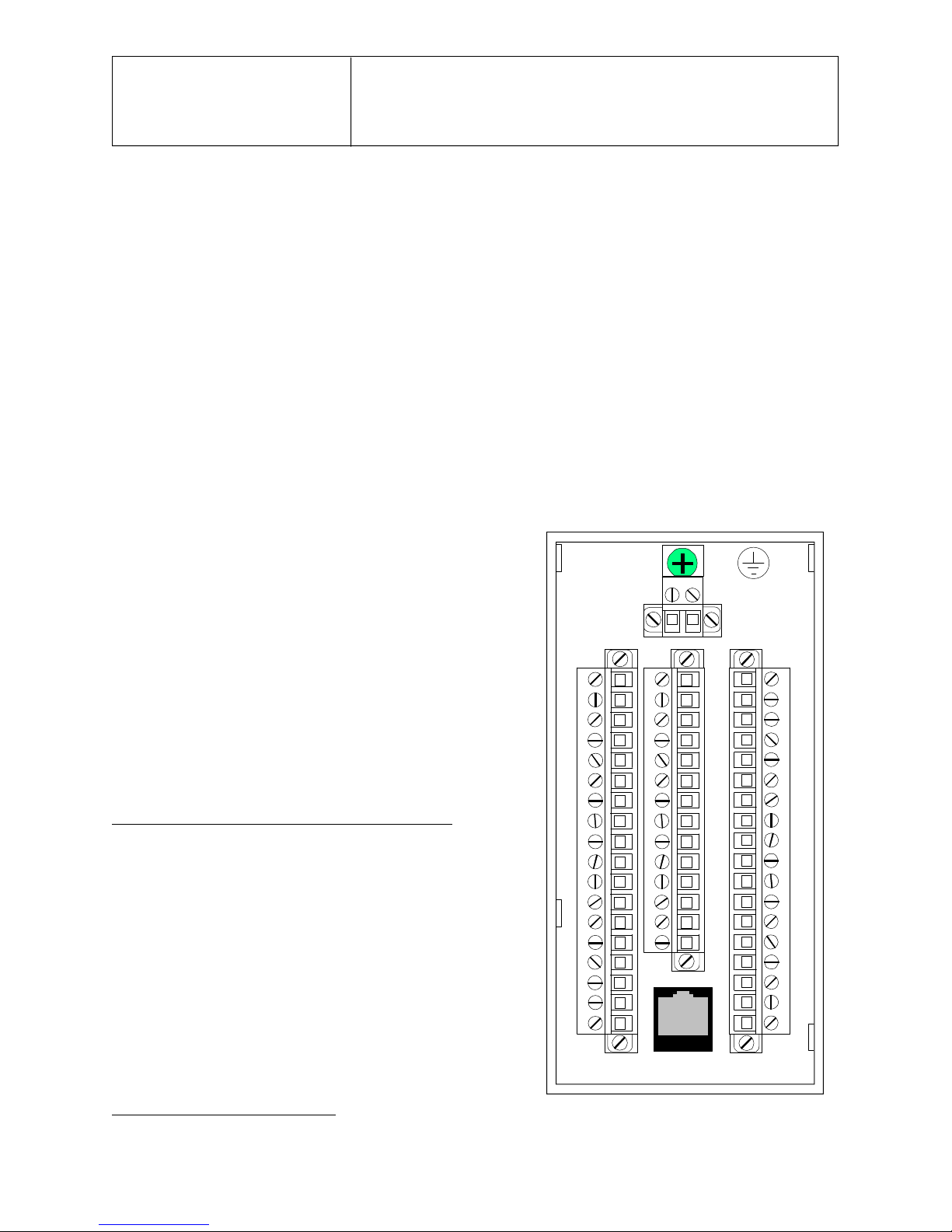

Direct entry connectors are shown in the adjacent figure.

There are four connectors with 52 screw-clamping terminal

connections. Each connector consists of a case mounted

portion and a plug-in portion. The plug-in portion of each

connector is securely fastened to the case mounted portion

by a screw at each end of the plug-in. The plug-in portion

can be completely wired and then plugged into the case

mounted portion.

Terminal functions and numbers have not changed. For

example, Station/Transmitter Common is terminal 6 on the

side entry and direct entry connectors.

A standard 8-wire Ethernet connector is provided near the

bottom of the assembly. A case ground screw is provided

near the top of the assembly, as in the side entry connectors.

The next page contains an illustration that states the

connections to the direct entry connectors.

AG00325a

1

Side entry and direct entry refer to the entry of wires into terminals installed on a rear connector assembly.

Page 2

UMA353-1-6

2

twinaxial cable shields are to be grounded.

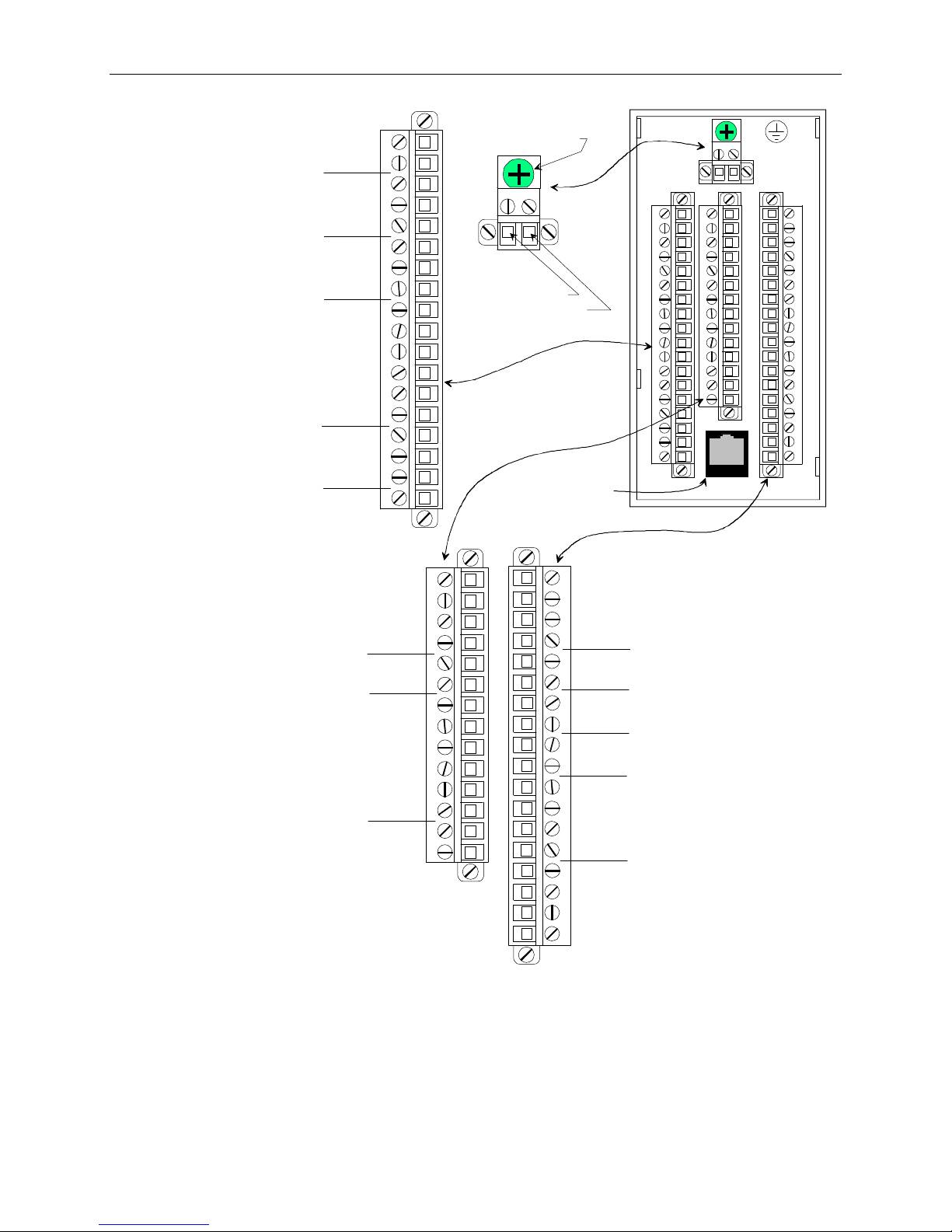

Terminal Function, ID, and Number

Network Communications A, NCA, 3

Network Communications B, NCB, 4

Transmitter Power 26 Vdc+, XMTR+, 5

Transmitter/Station Common, COM, 6

Transmitter Power, 26 Vdc+, XMTR+, 7

Digital Output 1+, DOUT1+, 8

Digital Outputs 1/2 Common, DOUTC, 9

Digital Output 2+, DOUT2+, 10

Digital Input 1+, DIN1+, 11

Digital Input 1-, DIN-, 12

Digital Input 2+, DIN2+, 13

Digital Input 2-, DIN2-, 14

Digital Input 3+, DIN3+, 15

Digital Input 3-, DIN3-, 16

Analog Output 1+, AOUT1+, 17

Analog Output 1/2 Common, AOUTC, 18

Analog Output 2+, AOUT2+, 19

Analog Input 1+, AIN1+, 20

Case/Safety Ground

Power Input

AC Hot or DC+, H

AC Neutral or DC-, N

Ethernet

Connector

Terminal Function, ID, and Number

Analog Input 1/2 Common, AINC, 21

Analog Input 2+, AIN2+, 22

Analog Input 3+, AIN3+, 23

Analog Input 3 Common, AINC, 24

I/O Bus A, IOA, 25

I/O Bus B, IOB, 26

Relay Output 1 Normally Closed, ROUT1nc, 27

Relay Output 1 Common, ROUT1c, 28

Relay Output 1 Normally Open, ROUT1no, 29

Relay Output 2 Normally Closed, ROUT2nc, 30

Relay Output 2 Common, ROUT2c, 31

Relay Output 2 Normally Open, ROUT2no, 32

Analog Output 3+, AOUT3+, 33

Analog Output 3 Common, AOUTC, 34

AG00326a

Notes:

1. Terminal numbers are shown on each connector. The plug-in portions of the connectors are packed with a case.

The connectors are keyed.

2. Case/Safety Ground - Connect to green screw at top center of rear terminal area.

3. NCA and NCB - Connect LIL Twinaxial Cable or twisted pair wiring. Refer to Section 6.5 for additional details.

4. IOA and IOB - LonWorks bus connections. Twisted pair wiring is typical.

5. Ground Bus - An external, user-supplied ground bus can ease connection of multiple grounds, particularly when

Terminal Number, Function, and ID

35, Digital Input Universal 1+, DINU1+

36, Digital Input Universal 1-, DINU137, Digital Input Universal 2+, DINU2+

38, Digital Input Universal 2-, DINU2-

39, Transmitter Power 26 Vdc+, XMTR+

40, Transmitter/Station Common, COM

41, Analog Input 4+, AIN4+

42, Analog Input Common, AINC

43, Digital Input 4+, DIN4+

44, Digital Input 4-, DIN445, Analog Input Universal 1 a, AINU1a

46, Analog Input Universal 1 b, AINU1b

47, Analog Input Universal 1 c, AINU1c

48, Analog Input Universal 1 d, AINU1d

49, Analog Input Universal 2 a, AINU2a

50, Analog Input Universal 2 b, AINU2b

51, Analog Input Universal 2 c, AINU2c

52, Analog Input Universal 2 d, AINU2d

Rear Terminal Layout and Terminal Assignments

Page 3

UMA353-1-6

3

Wiring Guidelines

Wire Size - Each terminal can accept:

• one 12-24 AWG (2.5-0.2 mm2)

• two 16 AWG (1.3 mm2)

• three 18 AWG (0.96 mm2)

Wire stripping length - 1/4" (6 mm) typical, 9/32" (7 mm) maximum.

Terminal and ground screw torque:

• connector terminals - 4.4-5.3 in. lbs (0.5-0.6 N-m)

• green ground screw - 20 in. lbs (2.26 N-m)

Making Connections to the Direct Entry Terminals

The plug-in portions of the connectors are supplied in a kit that accompanies the case. Terminal functions

and numbers have not changed. For example, Station/Transmitter Common is terminal 6 on the side entry

and direct entry connectors.

WARNING

Hazardous voltage can cause death or serious injury.

Remove power from all wires and terminals before

working on this equipment.

For each terminal:

1. Refer to the body of the User’s Manual, particularly Section 6 Installation, for details concerning the

connections to the terminal to be wired.

2. Refer to the figure on the previous page and determine the location of the target terminal.

3. Loosen the captive screw adjacent to the target terminal.

4. Strip the end of a wire 1/4" (6 mm). Component leads should be insulated with sleeving leaving a

bare lead of 1/4" (6 mm).

5. Insert the wire or component lead into the square terminal opening.

6. Tighten the adjacent screw to 4.4-5.3 in. lbs (0.5-0.6 N-m) to clamp the wire or lead. Do not over

tighten.

7. When the connector is completely wired, plug it into the mating connector on the back of the case.

The connectors are keyed. Gently tighten the screw at each end of the connector. Do not over tighten.

8. The Ethernet connector accepts a standard 8-wire Ethernet cable. Insert the cable-mounted connector

until the locking tab engages.

9. When all wiring is complete, check each connection to be sure that the proper wire(s) or component is

connected and that the inserted leads are securely clamped.

Page 4

UMA353-1-6

4

10. Install the supplied cover as described in the illustration below. Use of larger gauge wires or wires

with very thick or very stiff insulation may prevent installation of the cover, or cause the cover to pop

off, unless the cable bundle is securely laced or tie wrapped.

To install or

remove cover:

squeeze

both sides

~1/16"

to clear

alignment

tabs.

AG00327a

To Install Terminal Cover:

1. Orient the cover as shown. Note the four hooked

tabs and Ethernet cable clearance cutout.

2. Squeeze the cover slightly at the two small cutouts

in the cover edges and fully insert the four hooked

cover tabs in the rear panel slots.

3. Allow cover sides to relax. Pull the cover straight

down until it snaps into place. The cutouts in the

cover edges will engage two alignment tabs on

the rear panel.

Where needed, the Ethernet cable should exit

through the large cutout in the cover.

To Remove Cover:

1. Squeeze the cover slightly at the two cutouts

in the cover edges (about 2" down from the

top of the cover) and push cover upward.

2. Pull cover out from rear panel.

Ethernet cable cutout.

Installing the Cover

Servicing Note

A Model 353 case with side entry connectors can be upgraded with direct entry connectors. Order the

Rear Terminal Upgrade Kit below.

Rear Terminal Upgrade Kit - PN16353-230

Includes:

Connector Socket Assembly

Connectors

Cover

n

Siemens Energy & Automation, Inc. assumes no liability for errors or omissions in this document or for the application and use

of information included in this document. The information herein is subject to change without notice.

Procedures in this document have been reviewed for compliance with applicable approval agency requirements and are

considered sound practice. Neither Siemens Energy & Automation, Inc. nor these agencies is responsible for repairs made by

the user.

Loading...

Loading...