Page 1

Manual

Industrial Controls

Load Feeders and Motor Starters

SIRIUS 3RM1 Motor Starter

11/2013Edition

Answers for industry.

Page 2

Page 3

SIRIUS 3RM1 motor starter

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

Industrial Controls

Load feeders and motor starters

SIRIUS 3RM1 motor starter

Manual

11/2013

A5E0345285095020A/RS-AB/002

Introduction

1

Product-specific safety

information

2

Description

3

Configuration

4

Mounting

5

Connection

6

Operator control and

monitoring

7

Service and maintenance

8

Technical data

9

Dimension drawings

10

Circuit diagrams

11

Typical circuits

A

Directives

B

Correction sheet

C

Page 4

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

3ZX1012-0RM10-2AC1

Ⓟ 11/2013 Technical data subject to change

Copyright © Siemens AG 2012.

All rights reserved

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury

will

result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury

may

result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by

personnel qualified

for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Page 5

SIRIUS 3RM1 motor starter

Manual, 11/2013, A5E0345285095020A/RS-AB/002

5

Table of contents

1 Introduction................................................................................................................................... 9

1.1 Responsibility of the user for system configuration and functionality .......................................... 9

1.2 Required basic knowledge........................................................................................................ 9

1.3 Scope .................................................................................................................................... 10

1.4 Definition ................................................................................................................................ 10

1.5 Conformity.............................................................................................................................. 10

1.6 Further documentation ........................................................................................................... 11

1.7 Service&Support .................................................................................................................... 11

1.8 DataMatrix code ..................................................................................................................... 14

1.9 Correction sheet ..................................................................................................................... 15

2 Product-specific safety information ................................................................................................ 17

2.1 General safety notes .............................................................................................................. 17

2.2 Safety information for hazardous areas .................................................................................. 17

2.3 Safety instructions for safety-related applications .................................................................... 18

2.4 Intended use .......................................................................................................................... 19

2.5 Current information about operational safety........................................................................... 20

2.6 Declaration of conformity ........................................................................................................ 20

3 Description ................................................................................................................................. 21

3.1 Overview ................................................................................................................................ 21

3.2 Applications............................................................................................................................ 22

3.3 Hybrid technology................................................................................................................... 23

3.4 Device versions ...................................................................................................................... 24

3.5 Functions ............................................................................................................................... 27

3.5.1 Switching the 3RM1 motor starter under normal operating conditions ..................................... 27

3.5.1.1 Direct-on-line starter ............................................................................................................... 27

3.5.1.2 Reversing starter .................................................................................................................... 28

3.5.2 Overload protection ................................................................................................................ 29

3.5.2.1 Protective functions ................................................................................................................ 29

3.5.2.2 Thermal calculation method (motor memory module) .............................................................. 30

3.5.2.3 ATEX-certified motor overload protection in the case of 3RM11/3RM13 Failsafe..................... 32

3.5.3 Shutdown on malfunction ....................................................................................................... 35

3.5.4 Safety-related shutdown with 3RM11/3RM13 Failsafe motor starters ...................................... 36

3.5.5 Carrying out the function test .................................................................................................. 39

3.6 Accessories and order number scheme .................................................................................. 41

3.6.1 Overview of all device components ......................................................................................... 41

Page 6

Table of contents

SIRIUS 3RM1 motor starter

6 Manual, 11/2013, A5E0345285095020A/RS-AB/002

3.6.2 Accessories ............................................................................................................................42

3.6.2.1 Infeed system ..........................................................................................................................42

3.6.2.2 Sealable cover ........................................................................................................................44

3.6.2.3 Wall fixture ..............................................................................................................................44

3.6.2.4 Device connectors ...................................................................................................................45

3.6.2.5 Terminals ................................................................................................................................48

3.6.2.6 Device identification label ........................................................................................................48

3.6.3 Order number scheme for SIRIUS 3RM1 motor starter ............................................................49

4 Configuration .............................................................................................................................. 51

4.1 Rated operational current and derating ....................................................................................51

4.2 Ambient conditions ..................................................................................................................56

4.2.1 Application environment ..........................................................................................................56

4.2.2 Ambient temperature ...............................................................................................................56

4.2.3 Mounting position ....................................................................................................................56

4.2.4 Grounding measures ...............................................................................................................56

4.2.5 Permissible operating voltage ..................................................................................................57

4.2.6 Minimum load current ..............................................................................................................57

4.3 Load feeders - protection against short circuit ..........................................................................58

4.3.1 Protection against short circuit .................................................................................................58

4.3.2 Configuration of load feeders ...................................................................................................58

4.3.3 Configuration of a load feeder with 3RM1 motor starter in compliance with IEC .......................58

4.3.3.1 Fuseless design ......................................................................................................................59

4.3.3.2 Fused design ..........................................................................................................................61

4.3.4 Configuration of a load feeder with 3RM1 motor starter in compliance with UL .........................62

4.3.4.1 Function according to UL 508 ..................................................................................................62

4.3.4.2 SCCR short circuit current ratings............................................................................................62

4.3.4.3 Fuses and circuit breakers ......................................................................................................63

4.4 Infeed for the main circuit ........................................................................................................64

4.4.1 Infeed options .........................................................................................................................64

4.4.2 3RM19 3-phase infeed system ................................................................................................65

4.5 Configuration with device connectors ......................................................................................67

4.5.1 Configuration with device connectors ......................................................................................67

4.6 Examples/applications .............................................................................................................67

4.6.1 Operation with the EMERGENCY-STOP function ....................................................................67

5 Mounting .................................................................................................................................... 71

5.1 Warning notices ......................................................................................................................71

5.2 Mounting the devices on a level surface ..................................................................................72

5.3 Disassembling the devices from a level surface .......................................................................73

5.4 Mounting the devices on a standard mounting rail ...................................................................74

5.5 Disassembling devices from a standard mounting rail ..............................................................75

5.6 Mounting the devices with device connectors on a standard mounting rail ...............................76

5.7 Disassembling the devices with device connectors from a standard mounting rail ....................78

5.8 Mounting the devices with device connectors on a wall ............................................................81

5.9 Disassembling the devices with device connectors from a wall ................................................83

Page 7

Table of contents

SIRIUS 3RM1 motor starter

Manual, 11/2013, A5E0345285095020A/RS-AB/002

7

5.10 Mounting the sealable cover ................................................................................................... 85

6 Connection ................................................................................................................................. 87

6.1 Connecting the screw-type terminals ...................................................................................... 87

6.2 Disconnecting the screw-type terminals .................................................................................. 89

6.3 Connecting the push-in terminals............................................................................................ 90

6.3.1 Wiring rules for spring-loaded terminals (with push-in technology) .......................................... 90

6.3.2 Connecting the push-in terminals............................................................................................ 91

6.4 Disconnecting the push-in terminals ....................................................................................... 93

6.5 Attaching the terminals ........................................................................................................... 94

6.6 Removing the terminals .......................................................................................................... 95

6.7 Connecting the infeed system (option) .................................................................................... 96

7 Operator control and monitoring .................................................................................................... 99

7.1 Operator controls ................................................................................................................... 99

7.1.1 Parameterizing the 3RM1 motor starter ................................................................................ 100

7.1.2 Setting the rated operational current ..................................................................................... 100

7.1.3 Setting the RESET method ................................................................................................... 100

7.2 Displays and location of the connections .............................................................................. 103

7.2.1 Alarms, faults and system events ......................................................................................... 106

7.2.1.1 LEDs .................................................................................................................................... 106

7.2.1.2 Status indicators of the 3RM1 motor starter .......................................................................... 106

7.2.1.3 Signaling faults on external I/O ............................................................................................. 108

7.2.1.4 Fault rectification .................................................................................................................. 108

8 Service and maintenance ........................................................................................................... 111

8.1 Maintenance and service ...................................................................................................... 111

8.2 Device replacement .............................................................................................................. 112

9 Technical data .......................................................................................................................... 113

9.1 Motor starters ....................................................................................................................... 113

9.1.1 General technical specifications ........................................................................................... 113

9.1.2 Electromagnetic compatibility (EMC) .................................................................................... 115

9.1.3 Control circuit ....................................................................................................................... 117

9.1.4 Main circuit ........................................................................................................................... 120

9.1.5 Safety data ........................................................................................................................... 121

9.1.5.1 General safety data .............................................................................................................. 121

9.1.5.2 ATEX-specific safety data..................................................................................................... 122

9.1.6 Connection cross sections .................................................................................................... 123

9.1.7 Number of starting operations............................................................................................... 124

9.1.8 Overload protection/device protection characteristic ............................................................. 125

9.2 Infeed system for 3RM1 motor starter ................................................................................... 128

9.2.1 General technical data.......................................................................................................... 128

10 Dimension drawings .................................................................................................................. 129

10.1 3RM1 dimension drawings ................................................................................................... 129

10.2 Dimension drawings for 3RM1 device connectors ................................................................. 132

Page 8

Table of contents

SIRIUS 3RM1 motor starter

8 Manual, 11/2013, A5E0345285095020A/RS-AB/002

11 Circuit diagrams ......................................................................................................................... 137

11.1 3RM10 circuit diagrams (direct-on-line starter, Standard).......................................................137

11.2 3RM11 circuit diagrams (direct-on-line starter, Failsafe).........................................................139

11.3 3RM12 circuit diagrams (reversing starter, Standard) ............................................................140

11.4 3RM13 circuit diagrams (reversing starter, Failsafe) ..............................................................142

A Typical circuits ........................................................................................................................... 143

A.1 Typical circuits for 3RM1 Standard ........................................................................................143

A.1.1 Direct-on-line starter 24 V DC with switch operation ..............................................................143

A.1.2 Direct-on-line starter 24 V DC with switch operation and 230 V brake ....................................144

A.1.3 Direct-on-line starter 24 V DC with switch operation and 400 V brake ....................................145

A.1.4 Direct-on-line starter 24 V DC with switch operation and single-phase motor .........................146

A.1.5 Direct-on-line starter with group protection, 24 V DC and PLC operation ................................148

A.1.6 Reversing starter 24 V DC with PLC operation ......................................................................149

A.2 Typical circuits for 3RM1 Failsafe ..........................................................................................150

A.2.1 General safety notes .............................................................................................................150

A.2.2 3SK1 safety relay with 3RM13 motor starter via device connector .........................................153

A.2.3 3SK1 safety relay wired with 3RM13 motor starter .................................................................155

A.2.4 3RM13 reversing starter with PLC control, F-DO pp-switching ...............................................157

A.2.5 3RM13 reversing starter with PLC control, F-DO pm-switching ..............................................159

B Directives .................................................................................................................................. 161

B.1 ESD Guidelines .....................................................................................................................161

C Correction sheet ........................................................................................................................ 163

Glossary ................................................................................................................................... 165

Index ........................................................................................................................................ 169

Page 9

SIRIUS 3RM1 motor starter

Manual, 11/2013, A5E0345285095020A/RS-AB/002

9

1

1.1

Responsibility of the user for system configuration and functionality

The SIRIUS 3RM1 motor starters described here have been developed to carry out

switching functions as part of a plant or machine.

The 3RM1 motor starters are available as direct-on-line starters in Standard design without

safety-related shutdown (3RM10) and in Failsafe design with safety-related shutdown

(3RM11 Failsafe), and also as reversing starters without safety-related shutdown (3RM12)

and in Failsafe design with safety-related shutdown (3RM13 Failsafe).

The following must be noted when using 3RM11 Failsafe/3RM13 Failsafe safety-related

motor starters:

A complete safety system consists of sensors, evaluation units, signaling devices and

methods for safety-related shutdown.

The manufacturer is responsible for ensuring safe overall functioning of a plant or machine

with safety-related components.

Siemens AG, its regional offices, and associated companies (hereinafter referred to as

"Siemens") cannot guarantee all the properties of an overall installation or machine that has

not been designed by Siemens.

Nor can Siemens assume liability for recommendations that appear or are implied in the

following description. No new guarantee, warranty, or liability claims beyond the scope of the

Siemens general terms of supply are to be derived or inferred from the following description.

1.2

Required basic knowledge

A general knowledge of the following areas is needed in order to understand this manual:

● Industrial controls

● Digital circuitry

● Automation technology

● Safety engineering

Page 10

Introduction

1.3 Scope

SIRIUS 3RM1 motor starter

10 Manual, 11/2013, A5E0345285095020A/RS-AB/002

1.3

Scope

This manual is valid for SIRIUS 3RM1 motor starters. It contains a description of the motor

starter and its functions. It provides information about configuration, commissioning and

servicing. You will also find information on the infeed system, device connectors and further

accessories in the manual.

To facilitate configuration, the manual contains dimension drawings, circuit diagrams and

technical data of the system components.

SIEMENS reserves the right of including a Product Information for each new component,

and for each component of a later version.

1.4

Definition

In this manual, "3RM1 motor starter" always refers to all variants of the SIRIUS 3RM1 motor

starters.

1.5

Conformity

Standards

All 3RM1 motor starters comply with the following standards:

● IEC 60947-4-2:2011-05

● IEC 60947-4-3:2011-07

The 3RM11 Failsafe and 3RM13 Failsafe motor starters also comply with the following

standards:

● EN 62061: 2005

● EN ISO 13849-1:2008

● IEC 61508-1:2010

● IEC 61508-2:2010

● IEC 61508-3:2010

Approvals, test reports, characteristics

Confirmation of approvals, test certificates and characteristic curves is available via the

Internet (http://www.siemens.com/industrial-controls/approvals).

Page 11

Introduction

1.6 Further documentation

SIRIUS 3RM1 motor starter

Manual, 11/2013, A5E0345285095020A/RS-AB/002

11

Degree of protection

The 3RM1 motor starter's degree of protection is IP20.

The infeed system for the 3RM1 motor starter features IP20 degree of protection.

DANGER

Hazardous Voltage.

Can Cause Death, Serious Injury, or Property Damage.

Hazardous electrical voltage can cause electric shock, burns and damage.

To ensure protection against an electric shock hazard with the hinged cover open at the

signaling contacts 95, 96, 98 at a voltage of ≥ 50 V, screw in all terminal screws that are not

needed to clamp conductors.

1.6

Further documentation

Further documents that might be of interest for your configuration:

Title of the manual

Order number1)

3SK1 safety relays 3ZX1012-0SK11-0AC0

1)

The manuals are available in the Service&Support Portal for downloading free of charge.

1.7

Service&Support

Online Support

The Online Support in the Service&Support portal is an extensive information system for all

questions relating to Siemens products and solutions. This service enables direct and central

access to in-depth information concerning the products, systems and applications for

industry and to a large number of programming, configuration and application examples. Its

content is available via a mobile app.

The Technical Forum of the Online Support provides the opportunity for users to swap

information. Support Request allows contact to be established with Siemens experts in

Technical Support.

Siemens Industry Online Support ensures that users in industry are always kept up-to-date

with news, software updates and announcements by means of newsletters and Twitter.

Links:

Service&Support Portal (http://www.support.automation.siemens.com), Online

Support (http://support.automation.siemens.com/WW/view/en/16605022)

Page 12

Introduction

1.7 Service&Support

SIRIUS 3RM1 motor starter

12 Manual, 11/2013, A5E0345285095020A/RS-AB/002

Product Support

Are you looking for product information such as technical data, updates or FAQs? Here, the

"Product Support" section of the Service & Support Portal offers an extensive collection of all

information about the Siemens Industry Automation and Drive Technologies products and

solutions:

● Answers to frequently asked questions (FAQs)

● Updates/upgrades, service packs and support tools for downloading

● Manuals and operating instructions

● Technical data/CAx data

● Approvals and certificates

● Test certificates and characteristic curves

All Product Support information is at your disposal free of charge and around the clock, and

you always get the current version.

Link:

Product Support (http://support.automation.siemens.com/WW/view/en/4000024)

CAx data

The CAx Download Manager provides you with a simple means of gaining access to up-todate product data for your CAx or CAe system.

You configure your own download package with just a few clicks. You can choose from the

following information for products:

● Product images

● 2D dimensional drawings

● 3D models

● Internal circuit diagrams

● EPLAN macro files

● Manuals

● Characteristics

● Operating instructions

● Certificates

● Product master data

Link:

CAx Download Manager

(http://support.automation.siemens.com/WW/view/en/42455541)

Page 13

Introduction

1.7 Service&Support

SIRIUS 3RM1 motor starter

Manual, 11/2013, A5E0345285095020A/RS-AB/002

13

Applications & Tools

Applications & Tools supports you with various tools and examples when it comes to solving

your automation tasks. Solutions are presented in interaction with several components in the

system, without focusing on individual products.

● Application examples

● Function blocks & tools

● Background and system descriptions

● Performance statements

● Demonstration systems/videos

Link:

Applications & Tools (http://support.automation.siemens.com/WW/view/en/20208582)

My Documentation Manager

My Documentation Manager enables you to compile your own documentation from our

standard documents (manuals), which are located in the Product Support section. Under

mySupport, you have the opportunity to create and manage you own compilations in a

structure of their own.

Link:

MyDocumentationManager (http://support.automation.siemens.com/WW/view/en/38715968)

Reference

You can find further information on structure and navigation in Online Support here

(http://support.automation.siemens.com/WW/view/en/11774658).

Configurator

Various configurators are available on the Internet to assist you with configuration.

The configurator for 3RM1 motor starters and matching accessories is an easy-to-use

selection and configuration tool. You can select the individual components and plan your

system in accordance with your specific requirements. You can save your selection, export it

as a text file or you can order it directly.

The configurator automatically compiles a document list of the information available in

Service&Support for every component. You can use it as the basis for putting together your

system documentation.

Link:

Configurator (http://www.siemens.com/industrial-controls/configurators)

Page 14

Introduction

1.8 DataMatrix code

SIRIUS 3RM1 motor starter

14 Manual, 11/2013, A5E0345285095020A/RS-AB/002

1.8

DataMatrix code

A DataMatrix code is lasered on the lower terminal cover of all 3RM1 motor starters.

DataMatrix codes are standardized in ISO/IEC 16022. The DataMatrix codes on Siemens

devices use ECC200 coding for powerful error correction.

The following device information is encoded in the DataMatrix codes as a bit stream:

● Order number

● Serial number

● MAC address, if applicable

This information is stored in the following format in the DataMatrix code:

1P Order number + S serial number

(+ 23S MAC address)

Data identifier Net content Separator

Note

The information content is displayed without spaces.

This machine-readable information simplifies and accelerates handling of the respective

devices.

As well as fast access to the serial numbers of the respective devices for unique

identification, the DataMatrix codes simplify communication with Siemens Technical Support.

Page 15

Introduction

1.9 Correction sheet

SIRIUS 3RM1 motor starter

Manual, 11/2013, A5E0345285095020A/RS-AB/002

15

SIEMENS Industry Support App

The DataMatrix codes enable in particular extremely fast and convenient access to all the

device-specific information available on an order number in the SIEMENS Service&Support

Portal, such as operating instructions, manuals, data sheets, FAQs, etc.

We offer the SIEMENS Industry Support App free for this purpose. This can be used on

commercially available smartphones and tablet PCs.

The SIEMENS Industry Support App is available for iOS and Android-based terminal devices

and can be accessed via the following links:

Link for Android Link for iOS

1.9

Correction sheet

The appendix to this manual contains a correction sheet for evaluation and feedback. Please

use it to record your suggestions for improvements, additions and corrections, and return the

sheet to us. This will help us to improve the next edition of the manual.

Thank you.

Page 16

Introduction

1.9 Correction sheet

SIRIUS 3RM1 motor starter

16 Manual, 11/2013, A5E0345285095020A/RS-AB/002

Page 17

SIRIUS 3RM1 motor starter

Manual, 11/2013, A5E0345285095020A/RS-AB/002

17

2

2.1

General safety notes

DANGER

Hazardous Voltage.

Can Cause Death, Serious Injury, or Property Damage.

Hazardous electrical voltage can cause electric shock, burns and damage.

To ensure protection against an electric shock hazard with the hinged cover open at the

signaling contacts 95, 96, 98 at a voltage of ≥ 50 V, screw in all terminal screws that are not

needed to clamp conductors.

WARNING

Hazardous Voltage.

Can Cause Death, Serious Injury, or Property Damage.

Turn off and lock out all power supplying this device before working on this device.

CAUTION

Protection against electrostatic charge

When handling and installing the 3RM1 motor starters, ensure that the components are

protected from electrostatic charge. Changes to the system configuration and wiring are

only permissible after disconnection from the power supply.

2.2

Safety information for hazardous areas

WARNING

Hazardous Voltage.

Can Cause Death, Serious Injury, or Property Damage.

Installation of the motor starters in hazardous areas

The components of the 3RM1 motor starters are not suitable for installation in Class I and

Class II Hazardous Locations.

Please contact your ATEX specialist.

You will find additional information in Chapter "ATEX-certified motor overload protection in

the case of 3RM11/3RM13 Failsafe (Page 32)."

Page 18

Product-specific safety information

2.3 Safety instructions for safety-related applications

SIRIUS 3RM1 motor starter

18 Manual, 11/2013, A5E0345285095020A/RS-AB/002

2.3

Safety instructions for safety-related applications

WARNING

Hazardous Voltage.

Can Cause Death, Serious Injury, or Property Damage.

Turn off and lock out all power supplying this device before working on this device.

WARNING

Function test interval for 3RM11/3RM13 Failsafe motor starters

In continuous operation, the key safety values apply in the case of a function test interval

(state change of the outputs) ≤ 1 year.

Annual function test

• Actuate the connected sensors.

• Check their effect on the safety relay and the downstream actuators.

• Activate the safety relay via the connected sensors.

• Check their effect on the safety relay and the downstream actuators.

• Defective devices must be replaced.

WARNING

Bypassing the safety function in the event of a fault in the case of 3RM11/3RM13 Failsafe

motor starters with 110 to 230 V AC/110 V DC control supply voltage

The control signal for the control inputs in the case of 3RM11/3RM13 Failsafe motor

starters with 110 to 230 V AC control supply voltage must come from A1. Otherwise, the

safety function is bypassed in the event of a fault. Thus, only relay outputs are admissible

when using a PLC.

Do not use a separate control voltage. Only use the relay outputs when using a PLC.

WARNING

Bypassing the safety function when using device connectors

When operating with a 3SK1 safety relay and a device connector, the supply voltage for

3RM1 motor starters is established via the device connectors.

In this case, do not connect anything to terminals A1 and A2 of the 3RM1 motor starters, in

order to prevent bypassing of the safety function.

Page 19

Product-specific safety information

2.4 Intended use

SIRIUS 3RM1 motor starter

Manual, 11/2013, A5E0345285095020A/RS-AB/002

19

WARNING

Failure of the safety function during hybrid operation of Failsafe and Standard motor

starters

Hybrid operation of 3RM10/3RM12 Standard motor starters with 3RM11/3RM13 Failsafe

motor starters in safety-related applications is not admissible.

Only ever use safety-related motor starters (3RM11 Failsafe and 3RM13 Failsafe) in safetyrelated applications.

Note

SILCL 3 to EN 62061:2005, PL e/Cat. 4 to EN ISO 13849-1:2008

The 3RM11 Failsafe and 3RM13 Failsafe safety-related motor starters are designed in such

a way as to allow implementation of safety-related applications up to SILCL 3 in accordance

with EN 62061 and PL e/Cat. 4 in accordance with EN ISO 13849-1.

Note

Use of PELV/SELV power supply units

Power to the 3RM11 Failsafe and 3RM13 Failsafe safety-related motor starters must be

supplied from PELV/SELV power supply units.

2.4

Intended use

WARNING

Hazardous Voltage.

Can Cause Death, Serious Injury, or Property Damage.

Proper use of hardware products

This equipment is only allowed to be used for the applications described in the catalog and

in the technical description, and only in conjunction with non-Siemens equipment and

components recommended by Siemens.

Correct transport, storage, installation and assembly, as well as careful operation and

maintenance, are required to ensure that the product operates safely and without faults.

EU note: Commissioning is absolutely prohibited until it has been ensured that the machine

in which the component described here is to be installed complies with the stipulations of

the Directive 2006/42/EC.

Page 20

Product-specific safety information

2.5 Current information about operational safety

SIRIUS 3RM1 motor starter

20 Manual, 11/2013, A5E0345285095020A/RS-AB/002

2.5

Current information about operational safety

Important note for maintaining operational safety of your system

WARNING

Hazardous Voltage.

Can Cause Death, Serious Injury, or Property Damage.

Please take note of our latest information

Systems with safety-related characteristics are subject to special operational safety

requirements on the part of the operator. The supplier is also obliged to comply with special

product monitoring measures. For this reason, we publish a special newsletter containing

information on product developments and features that are (or could be) relevant to

operation of safety-related systems. By subscribing to the appropriate newsletter, you will

ensure that you are always up-to-date and able to make changes to your system, when

necessary:

Siemens newsletter (http://www.industry.siemens.com/newsletter)

Sign on to the following newsletter under "Products & Solutions":

• Control Components and System Engineering News

• Safety Integrated Newsletter

2.6

Declaration of conformity

The manufacturer declares that the safety components of the 3RM1 motor starter series in

the designs marketed by us comply with the applicable basic health and safety requirements

of the EC Directives* stated (including amendments), and that the stated standards* were

applied in their design and construction.

* You can download the complete EC Declaration of Conformity from the Internet

(http://www.siemens.com/industrial-controls/approvals) as a PDF.

Page 21

SIRIUS 3RM1 motor starter

Manual, 11/2013, A5E0345285095020A/RS-AB/002

21

3

3.1

Overview

The 3RM1 motor starter is a compact device with a width of 22.5 mm. The 3RM1 motor

starter comprises combinations of relay contacts, power semiconductors, and a solid-state

overload relay for switching three-phase motors up to 3 kW (at 400 V) and resistive loads up

to 10 A (at AC voltages to 500 V) under normal operating conditions.

Page 22

Description

3.2 Applications

SIRIUS 3RM1 motor starter

22 Manual, 11/2013, A5E0345285095020A/RS-AB/002

3.2

Applications

The 3RM1 motor starters can be used wherever combinations of contactors and overload

relays were previously used.

Thanks to the additional functionality of safety-related shutdown, the 3RM11 Failsafe and

3RM13 Failsafe motor starter variants are ideally suited to safety-related applications up to

SILCL 3 in accordance with EN 62061 and PL e/Cat. 4 in accordance with EN ISO 13849-1.

Short-circuit protection in a load feeder designed in this way must be implemented by

appropriate upstream short-circuit protection devices. These can be, for example, circuit

breakers or appropriate fuses.

You achieve maximum space-savings benefits by means of a group configuration of the

3RM1 motor starters. This enables several 3RM1 motor starters to be protected by one

short-circuit protection device.

The 3RM1 motor starters are used in the following areas, for example:

● Conveyor technology

● Logistics systems

● Production machines

● Machine tools

● Small elevators

Page 23

Description

3.3 Hybrid technology

SIRIUS 3RM1 motor starter

Manual, 11/2013, A5E0345285095020A/RS-AB/002

23

3.3

Hybrid technology

The 3RM1 motor starter combines the benefits of semiconductor technology and relay

technology.

This combination is known as hybrid technology. The hybrid technology in the 3RM1 motor

starter is characterized by the following features:

Switching on

The inrush current in the case of motorized loads is conducted briefly via the

semiconductors.

Advantage: The relay contacts are protected. Longer service life is achieved thanks to

reduced wear and tear.

Current conducting

The continuous current is conducted via relay contacts.

Advantage: Relay contacts cause less thermal losses than semiconductors.

Switching off

Switch-off is implemented again via the semiconductor.

Advantage: The contacts are only slightly burdened by arcs. This results in increased service

life.

Page 24

Description

3.4 Device versions

SIRIUS 3RM1 motor starter

24 Manual, 11/2013, A5E0345285095020A/RS-AB/002

3.4

Device versions

The 3RM1 motor starters are characterized by their compact design and narrow width.

They can be used for easy assembly of fuseless load feeders with SIRIUS motor starter

protectors. Alternatively, combinations with fuses or other short-circuit protection devices are

possible.

This allows implementation of load feeders with coordination type 1 for short-circuit currents

of up to 55 kA at 400 V.

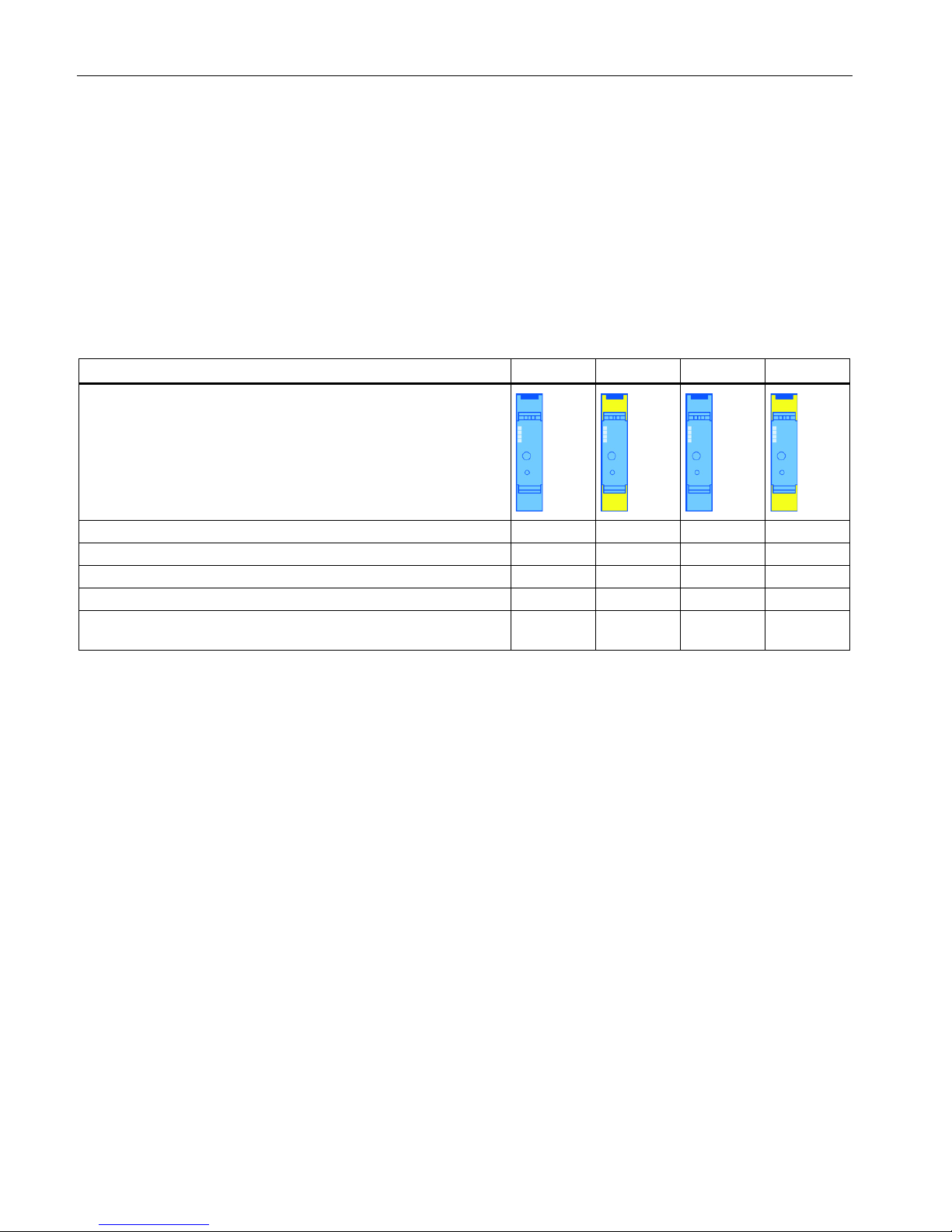

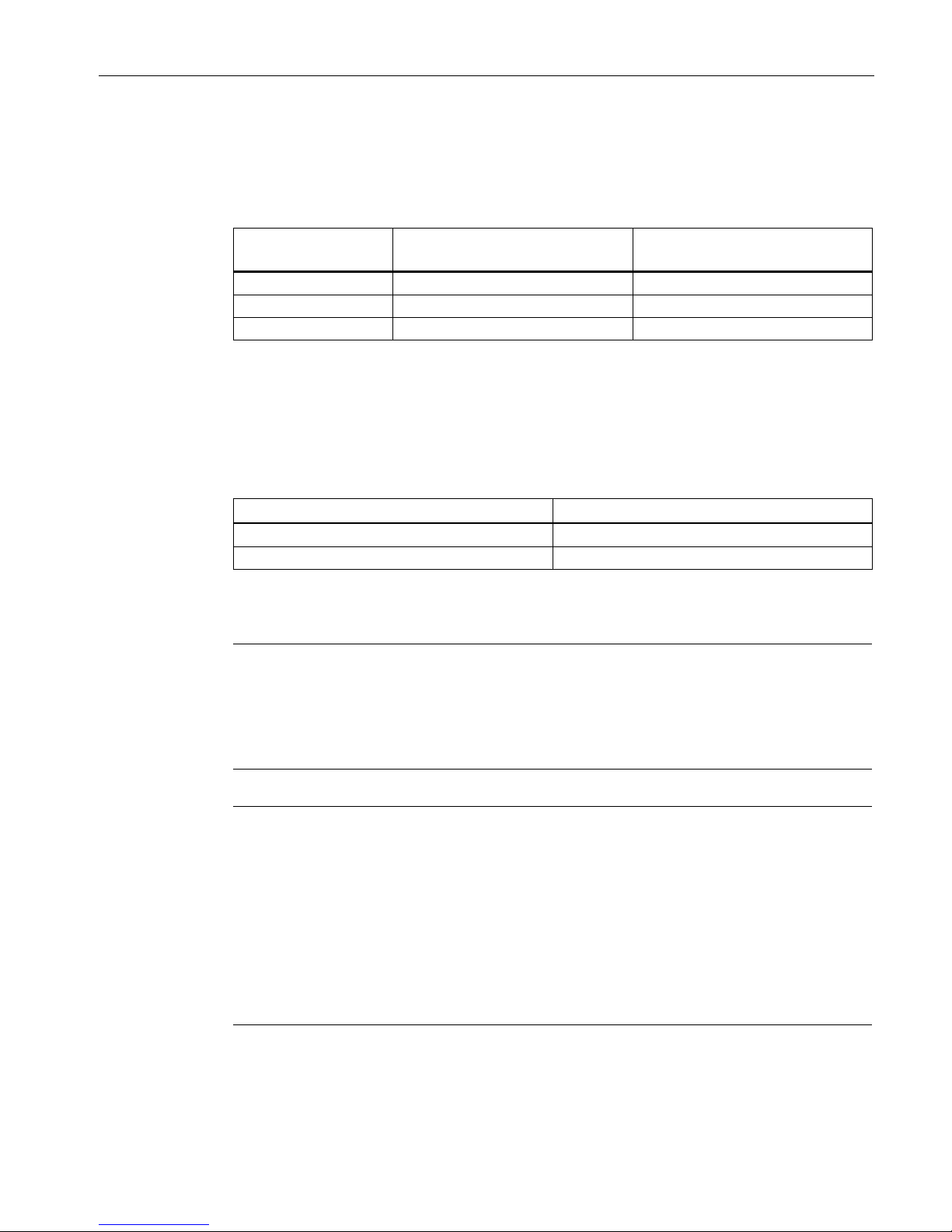

The 3RM1 motor starters are available in four different versions:

Motor starter version

3RM10

3RM11

3RM12

3RM13

Product symbol

Direct-on-line starter ✓ ✓ - Reversing starter - - ✓ ✓

Overload protection with wide setting range ✓ ✓ ✓ ✓

ATEX certification overload protection - ✓ - ✓

Safety-related shutdown up to SILCL 3 to EN 62061, PL e/Cat. 4 to

EN ISO 13849-1

- ✓ - ✓

Connection systems

The 3RM1 motor starters are optionally available with screw connections or push-in

connections.

Push-in connections are a form of spring-loaded terminals allowing fast wiring without tools

for rigid conductors or conductors equipped with end sleeves. For wiring finely-stranded or

stranded conductors without end sleeves on push-in connections, a screwdriver (with

3.0 x 0.5 mm blade) is required. A screwdriver (with 3.0 x 0.5 mm blade) is also required to

disconnect a conductor.

The advantages of the push-in terminals are found, as with all spring-loaded terminals, in

speed of assembly and disassembly and vibration-proof connection. There is no need for the

checking and tightening required with screw connections.

Page 25

Description

3.4 Device versions

SIRIUS 3RM1 motor starter

Manual, 11/2013, A5E0345285095020A/RS-AB/002

25

Current ranges

The 3RM1 motor starters are designed for the following rated operational currents of the

loads:

Versions

Adjustable response value current

[A]

Maximum permissible motor power

at 400 V AC [kW]

3RM1.01-..... 0,1 ... 0,5 0,12

3RM1.02-..... 0,4 ... 2 0,75

3RM1.07-.....* 1,6 ... 7 3

* The versions of the 3RM1.07-..... motor starter are also suitable for operating resistive loads (e.g.

heaters) up to a rated operational current of I

AC51

= 10 A.

Control supply voltages

The 3RM1 motor starters are designed for the following control supply voltages:

Versions

Control supply voltage

3RM1...-.AA0. 24 V DC

3RM1...-.AA1. 110 … 230 V AC 50/60 Hz; 110 V DC

Note the following information for the different device versions:

Note

3RM10/3RM12

Standard motor starters

with 24 V DC control supply voltage

The same voltage source (potential) must be used for the control supply voltage and the

control inputs.

The reference point for the control inputs is terminal A2.

Note

3RM10/3RM12 Standard motor starters with 110 to 230 V AC/110 V DC control supply

voltage

The same voltage source (potential) must be used for the control supply voltage and the

control inputs.

The reference point for the control inputs is terminal A2.

When controlling with a PLC, control must be via relay outputs.

There must be no parallel load (e.g. a lamp) connected at the control inputs in the case of

motor starters with the product version E01.

Page 26

Description

3.4 Device versions

SIRIUS 3RM1 motor starter

26 Manual, 11/2013, A5E0345285095020A/RS-AB/002

Note

3RM11/3RM13 Failsafe motor starters with 24 V DC control supply voltage

The control inputs are electrically isolated from the control supply voltage (A1, A2).

The terminals M1 and M2 are the reference point for the control inputs.

For controlling the control inputs, e.g. via the digital outputs of a PLC, a voltage from an

SELV/PELV Class 2 supply is required.

Note

3RM11/3RM13 Failsafe motor starters with 110 to 230 V AC/110 V DC control supply

voltage

The same voltage source (potential) must be used for the control supply voltage and the

control inputs in safety-related applications.

The reference point for the control inputs is terminal A2.

When controlling with a PLC, control must be via relay outputs.

Page 27

Description

3.5 Functions

SIRIUS 3RM1 motor starter

Manual, 11/2013, A5E0345285095020A/RS-AB/002

27

3.5

Functions

3.5.1

Switching the 3RM1 motor starter under normal operating conditions

A typical application area of the 3RM1 motor starter is the switching and protection of

motors. You can also operate the 3RM1 motor starter on resistive loads such as heaters.

Note

Minimum loads must be observed for the 3RM1 motor starters.

You will find additional information in the chapter "Minimum load current (Page 57)".

NOTICE

Damage from operating capacitive loads

When using capacitive loads, the switching components in the 3RM1 motor starter can be

damaged by excessively high making currents.

Do not operate capacitive loads such as frequency converters on the 3RM1 motor starter.

Operation of single-phase capacitor motors is admissible.

NOTICE

Damage during operation on non-sinusoidal voltages

When operating frequency converters, the switching components in the 3RM1 motor starter

can be damaged by non-sinusoidal voltages.

Do not operate the 3RM1 motor starter on outputs of frequency converters.

3.5.1.1

Direct-on-line starter

Using the 3RM1 motor starter as a direct-on-line starter

All 3RM1 motor starters can be used as direct-on-line starters.

To switch the 3RM1 motor starter on, apply the control voltage at input IN1.

After the motor is switched off, the motor starter accepts a new start after 500 ms.

You can also use the versions of the 3RM1 motor starter with a rated operational current up

to 7 A for switching resistive loads up to I

AC51

= 10 A under normal operating conditions.

Page 28

Description

3.5 Functions

SIRIUS 3RM1 motor starter

28 Manual, 11/2013, A5E0345285095020A/RS-AB/002

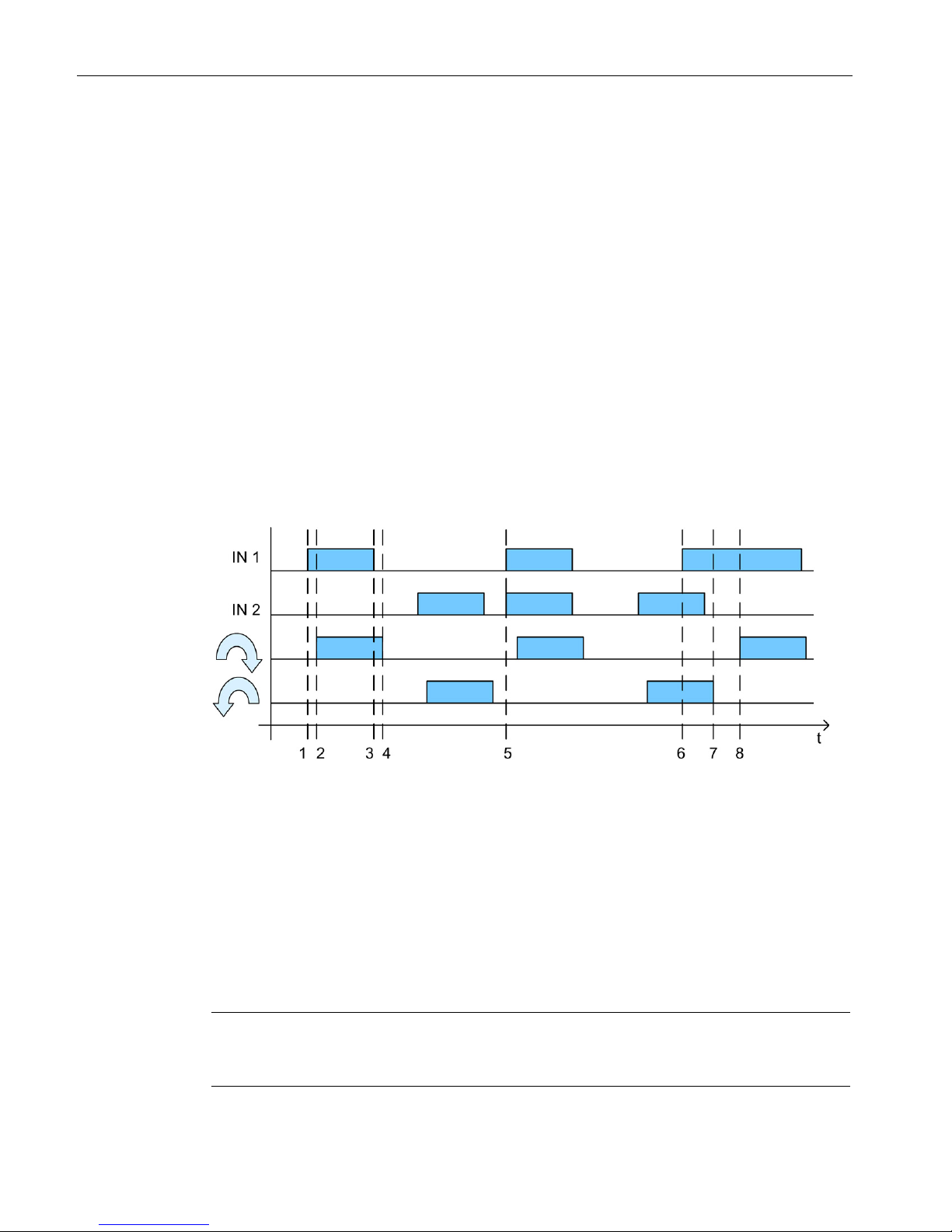

3.5.1.2

Reversing starter

Using the 3RM1 motor starter as a reversing starter

The 3RM12 and 3RM13 motor starters can be used as reversing starters.

The reversing starter starts the motor when the control voltage is applied at input IN1 in

direction of rotation 1 (no phase swapping), when controlling input IN2 in direction of

rotation 2 (phase change from L1 and L3).

Interlocking of the control inputs

After the motor is switched off, the motor starter accepts a new start after 500 ms.

If you apply control inputs IN1 and IN2 simultaneously, control input IN1 has priority. The

motor starts up in this direction of rotation.

When the motor is running, activation of the second input has no effect.

The figure below shows an example of the effects of the signals at the control inputs on the

direction of rotation of the motor:

1 Controller 1 active

2 Motor ON

1-2 Switch-on delay

3 Control input 1 inactive

4 Motor OFF

3-4 Switch-off delay

5 With simultaneous activation of the control inputs, the motor is started in the clockwise

direction.

6 Additional activation of the second control input has no influence.

7-8 After motor OFF, the motor starter accepts a new start (motor ON) after 500 ms.

Note

Please observe the information about the control supply voltage and the control inputs in the

chapter "Device versions (Page 24)".

Page 29

Description

3.5 Functions

SIRIUS 3RM1 motor starter

Manual, 11/2013, A5E0345285095020A/RS-AB/002

29

3.5.2

Overload protection

3.5.2.1

Protective functions

Overload protection

The 3RM1 motor starter protects three-phase motors against overload. If the current

exceeds the set value, the 3RM1 motor starter switches off within the specified tripping time

and signals the fault via the LEDs and the fault signaling output. You will find the tripping

characteristic in the chapter "Overload protection/device protection characteristic

(Page 125)".

Note

ATEX-certified motor overload protection in the case of 3RM11/3RM13 Failsafe

Overload protection of safety-related 3RM11 Failsafe and 3RM13 Failsafe motor starters is

ATEX-certified up to SILCL 2; see Section "ATEX-certified motor overload protection in the

case of 3RM11/3RM13 Failsafe (Page 32)".

Equipment protection

In addition to the motor protection function, the 3RM1 motor starters also protect themselves

against overload. This means that in the case of 3RM1 motor starters with a rated

operational current of 7 A, an overload trip may occur in the upper current range before the

motor protection trips.

If, for example, 8-fold current flows in the case of an unloaded motor memory module and a

set current of 7 A, tripping takes place after approximately one second.

You will find the tripping characteristic in the chapter "Overload protection/device protection

characteristic (Page 125)".

Phase failure protection

The 3RM1 motor starter is provided with phase failure protection to prevent excessive

temperature rise in the load in double phasing if phase failure occurs.

Depending on whether the phase failure already occurs before the ON command or during

the ON state, the devices respond as described in the table and signal a phase failure.

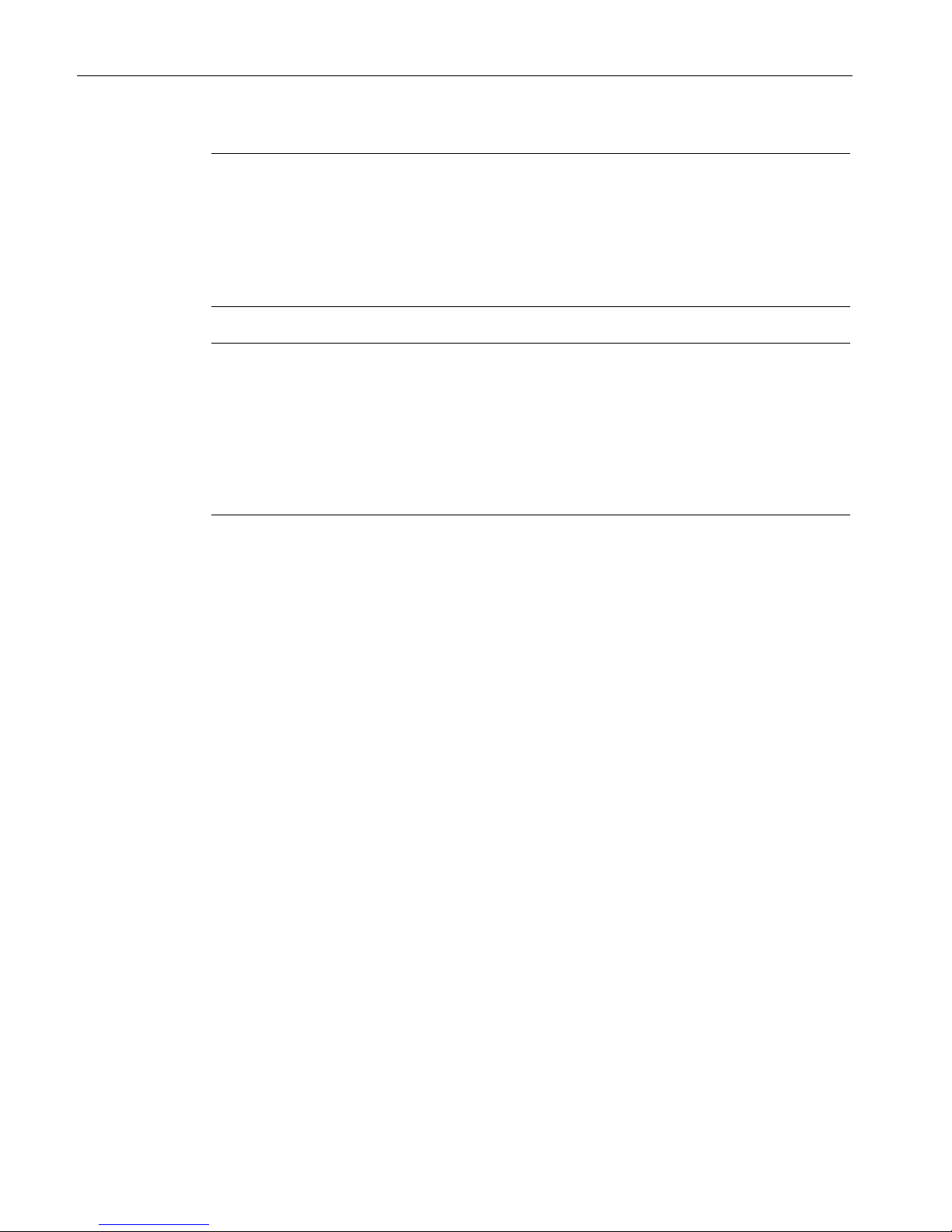

Standard motor starters

3RM10/3RM12

Failsafe motor starters

3RM11/3RM13

Phase failure before the ON

command

The motor starter switches off

after 5 s.

The motor starter does not

switch on.

Phase failure during the ON

state

The motor starter switches off

after 5 s.

The motor starter switches off

after 5 s.

Page 30

Description

3.5 Functions

SIRIUS 3RM1 motor starter

30 Manual, 11/2013, A5E0345285095020A/RS-AB/002

The fault state is indicated by LEDs and the fault signaling output.

NOTICE

Damage due to asymmetrical current consumption by built-in brakes

When connecting and operating motors with built-in brakes, the energy for releasing the

brakes is taken from the motor connection cables. This can result in substantial asymmetry

in power consumption.

Observe the following measures for all 3RM1 motor starters:

• If the current for the braking facility is taken from two phases, connect the motor cables

that are additionally loaded with braking current to terminals T1 and T3. Observe the

additional braking current when setting the motor current.

• Alternatively, the braking facility can be fed externally.

A further braking facility is possible for 3RM10 and 3RM12 Standard motor starters:

• If the current for the braking facility is taken from just one phase and the neutral

conductor, connect the motor cable that is loaded with the braking current to terminal T2

of the motor starter.

Do not use 3RM11 Failsafe and 3RM13 Failsafe motor starters for such braking

facilities.

NOTICE

Damage from incorrect connection

Incorrect connection of the motor can result in damage.

Connect the motor as specified in the typical circuit diagrams.

You can find circuit diagrams for operating motors with brakes in the chapter "Typical circuits

(Page 143)".

3.5.2.2

Thermal calculation method (motor memory module)

Principle of operation

The electronics continuously calculate a model of the thermal load on the motor dependent

on the operating time and the current load. The motor memory module charges when the

motor is switched on. The motor memory module discharges after the motor is switched off.

Following an overload tripping operation, the motor memory module is fully discharged after

approximately three minutes. You must wait for this cooling time to elapse before you can

acknowledge the fault. If the control supply voltage fails, the 3RM1 motor starter stores the

remaining cooling time. When the control supply voltage is restored, the remaining cooling

time elapses before the motor can be switched on again.

If you initiate a restart within a very short time after switching off the motor, it may be that the

motor memory module has not yet fully discharged. This can result in an extremely fast

overload trip after the restart. During continuous operation ("Warm" motor memory module),

tripping times are reduced depending on the prior load.

Page 31

Description

3.5 Functions

SIRIUS 3RM1 motor starter

Manual, 11/2013, A5E0345285095020A/RS-AB/002

31

If voltage is present at terminals A1/A2 and at control inputs IN1/IN2 after resetting the

overload trip, the 3RM1 motor starter restarts.

The rated current of 10 A must not be set for motorized loads but only for resistive loads. In

this setting, the tripping characteristics deviate from Class 10A; see Chapter "Overload

protection/device protection characteristic (Page 125)".

You can find information about typical switching frequencies in Chapter "Number of starting

operations (Page 124)".

WARNING

Hazardous Voltage.

Can Cause Death, Serious Injury, or Property Damage.

Health hazard from automatic hot restart

If the DEVICE LED shows a yellow light and the FAILURE LED a red light, and a manual

RESET or auto RESET takes place following an overload trip, the machine starts up

immediately if there is a control command at IN1/IN2. Personnel in the danger area can be

injured.

Make sure that the danger area of the machine is kept clear of people.

Reset in manual operation

If the RESET method is set to manual RESET, acknowledge an overload trip as follows:

1. Wait for the cooling time to elapse.

2. Press the "TEST/RESET/RESET MODE" button to acknowledge.

As an alternative, in the case of the 3RM10/3RM12 Standard motor starters, you can use

the RESET control input IN3 for acknowledgement.

Note

If you briefly switch the control supply voltage off and on again, there is no automatic

acknowledgment.

Page 32

Description

3.5 Functions

SIRIUS 3RM1 motor starter

32 Manual, 11/2013, A5E0345285095020A/RS-AB/002

3.5.2.3

ATEX-certified motor overload protection in the case of 3RM11/3RM13 Failsafe

Standards

Increased danger in hazardous areas means it is necessary to carefully observe the

following standards:

●

EN 60079-14 / VDE 0165-1

Electrical apparatus for explosive gas atmospheres.

●

EN 60079-17

Inspection and maintenance of electrical installations in hazardous areas.

●

EN 50495

Safety devices required for the safe functioning of equipment with respect to

explosion risks.

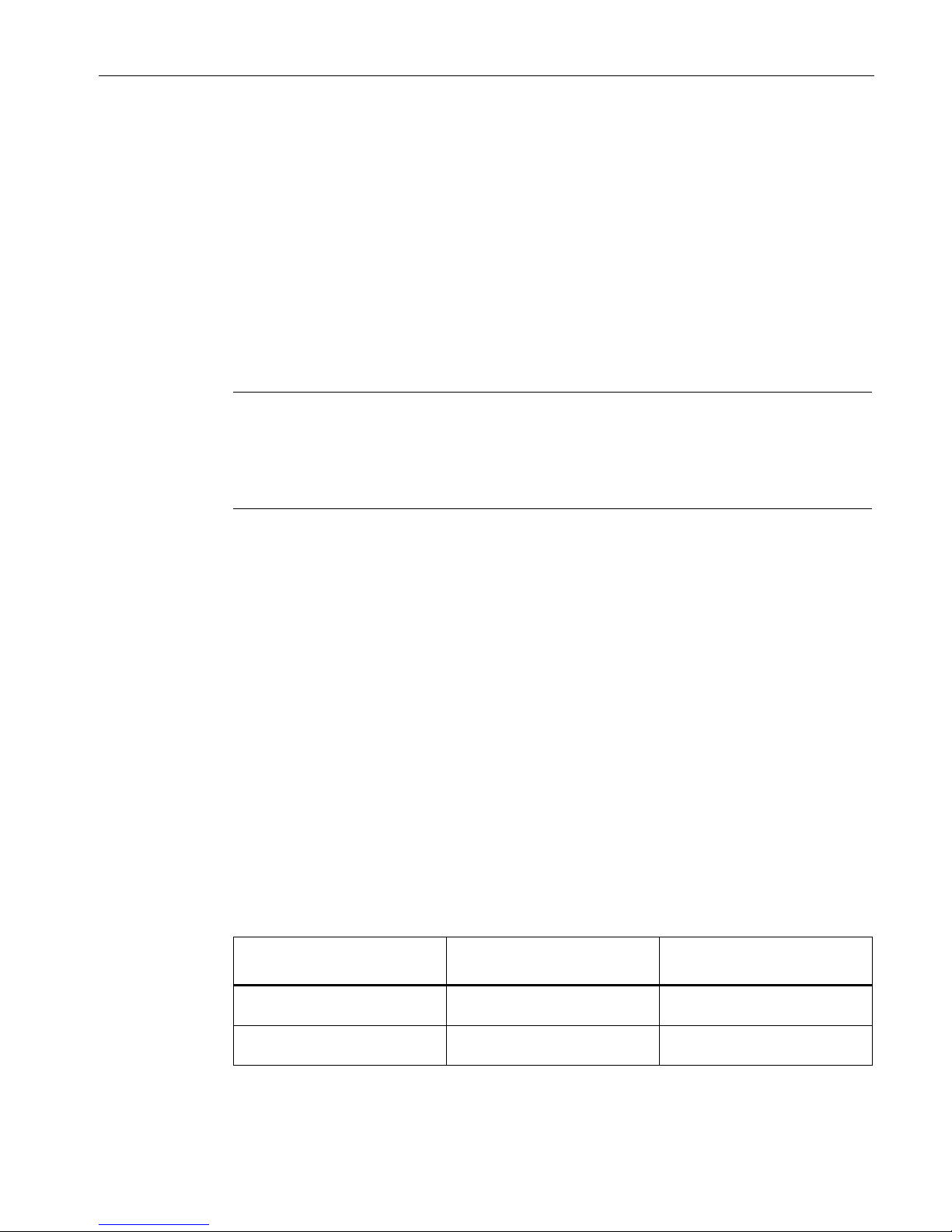

Certification of 3RM11/3RM13 Failsafe motor starters

The 3RM11 Failsafe and 3RM13 Failsafe motor starters are approved under Device

Group II, Category (2) in the area "GD" (areas in which explosive gas, steam, mist, air

mixtures and combustible dust are present):

*) For the px applications, pressure and flow rate monitoring are additionally required for the

overpressure encapsulation systems.

WARNING

Hazardous Voltage.

Can Cause Death, Serious Injury, or Property Damage.

Danger due to incorrect behavior

All work involved in connecting, commissioning and maintenance must be carried out by

qualified personnel.

Page 33

Description

3.5 Functions

SIRIUS 3RM1 motor starter

Manual, 11/2013, A5E0345285095020A/RS-AB/002

33

Control cabinet degree of protection in hazardous areas

WARNING

Hazardous Voltage.

Can Cause Death, Serious Injury, or Property Damage.

The 3RM1 motor starter is not suitable for installation in hazardous areas.

The device must be installed in a control cabinet with the minimum degree of protection of

IP 4x.

Equipment protection

In addition to the motor protection function, the 3RM1 motor starters also protect themselves

against overload. This means that in the case of 3RM1 motor starters with a rated

operational current of 7 A, an overload trip may occur in the upper current range before the

motor protection trips.

If, for example, 8-fold current flows in the case of an unloaded motor memory module and a

set current of 7 A, tripping takes place after approximately one second.

You will find the tripping characteristic in the chapter "Overload protection/device protection

characteristic (Page 125)".

Setting the rated motor operational current

Set the 3RM1 motor starter to the rated motor operational current (according to the type

plate or design test certificate of the motor).

On this topic, refer to the Chapter "Setting the rated operational current (Page 100)".

Note

Observe the trip class or the tripping characteristic of the 3RM1 motor starter in Chapter

"Overload protection/device protection characteristic (Page 125)". The motor and cables

must be designed for the selected trip class.

RESET settings

Note

Restriction in the hazardous area

In applications for the protection of motors in hazardous areas, a 3RM11/3RM13 Failsafe

motor starter may only be operated with the "Manual RESET" setting. The "RESET Mode"

LED must be off.

Page 34

Description

3.5 Functions

SIRIUS 3RM1 motor starter

34 Manual, 11/2013, A5E0345285095020A/RS-AB/002

Short-circuit protection

Short-circuit protection must be handled by separately arranged overcurrent protection

devices.

On this topic, refer to the Chapter "Load feeders - protection against short circuit (Page 58)".

Cable protection

Avoid impermissibly high cable surface temperatures by correctly dimensioning the cross

sections. Select an adequate cable cross-section.

Cyclic test of the protection functions

The tests are run by means of the "TEST/RESET/RESET MODE" button and can take place

when the motor is either on or off. The test consists of three function tests.

Carry out the tests during commissioning

and cyclically every 36 months at the latest.

You will find out how to run the test in Chapter "Carrying out the function test (Page 39)".

Ambient conditions

See the chapter "Ambient conditions (Page 56)".

ATEX-specific safety data

The motor protection function according to ATEX in the case of 3RM11/3RM13 motor

starters has the following safety data:

Safety integrity level (SILCL) 2

Hardware fault tolerance (HFT) 0

Interval for testing the protective functions 3 years

Probability of failure on demand (PFD) 5x10-4

Probability of a dangerous failure per hour (PFH) 5x10-8 1/h

Note

See the data sheet for other specifications. You will find the data sheet in Service&Support

(http://www.siemens.com/industrial-controls/support).

Page 35

Description

3.5 Functions

SIRIUS 3RM1 motor starter

Manual, 11/2013, A5E0345285095020A/RS-AB/002

35

Maintenance and repairs

These devices are maintenance-free.

Note

Repairs to the device may only be carried out by the manufacturer.

Warranty

NOTICE

To meet the conditions of the warranty, you must observe the safety and commissioning

instructions.

Further information

You will find further information on the Internet at

● Internet (http://www.siemens.com/sirius)

● Information and Download Center (http://www.siemens.com/sirius/infomaterial)

● Product and Information System (ProdIS) (http://www.siemens.com/sirius/support)

● Service and Support (http://www.siemens.com/sirius/technical-assistance)

● Certificates (http://www.siemens.com/sirius/approvals)

3.5.3

Shutdown on malfunction

Shutdown via integrated monitoring

The 3RM1 motor starter has integrated monitoring of the main circuit components. During

operation, the 3RM1 motor starter detects when a switching element fails to switch, or when

a phase has failed.

Monitoring before switching on in the case of 3RM11/3RM13 Failsafe motor starters

In the case of the 3RM11 Failsafe and 3RM13 Failsafe motor starters, monitoring prevents

the load from switching on in the case of the following malfunctions:

● Damage to the power semiconductors

● Damage to the relay contacts

● Faults in the control electronics

Page 36

Description

3.5 Functions

SIRIUS 3RM1 motor starter

36 Manual, 11/2013, A5E0345285095020A/RS-AB/002

Acknowledging

A malfunction is acknowledged by switching the control supply voltage back on and then

pressing the "TEST/RESET/RESET MODE" pushbutton.

Note

If a malfunction is repeatedly indicated, the 3RM1 motor starter is defective and must be

replaced.

Safety-related shutdown in the case of 3RM11/3RM13 Failsafe motor starters

Safety-related shutdown is achieved for the 3RM11 Failsafe and 3RM13 Failsafe motor

starters thanks to the special arrangement and checking of the switching elements. Safetyrelated shutdown takes place when the control supply voltage is deactivated or by switching

off the control inputs. Malfunctions result in automatic shutdown. You will find additional

information in Chapter "Safety-related shutdown with 3RM11/3RM13 Failsafe motor starters

(Page 36)."

Display concept

The following events indicate the "Malfunction" status:

● DEVICE LED flashes red

● FAILURE LED shows a red light

● Fault signaling output active

3.5.4

Safety-related shutdown with 3RM11/3RM13 Failsafe motor starters

Safety-related shutdown of 3RM11/3RM13 Failsafe motor starters

In the case of the 3RM11/3RM13 Failsafe motor starters, safety-related shutdown takes

place by removing the control voltage (A1/A2). In the case of units with a 24 V DC supply

voltage, as an alternative safety-related shutdown can take place by removing the ON

command (IN1/IN2).

SILCL 3 to EN 62061, PL e/Cat. 4 to EN ISO 13849-1 can be achieved with both shutdown

methods. To achieve SILCL 3/PL e/Cat. 4 for the safety function, all components of the

safety function (detecting/evaluating/reacting) must be designed accordingly.

Page 37

Description

3.5 Functions

SIRIUS 3RM1 motor starter

Manual, 11/2013, A5E0345285095020A/RS-AB/002

37

In the case of 3RM11/3RM13 Failsafe motor starters, the OFF state is defined as the safe

state. 3RM11/3RM13 Failsafe motor starters are self-monitoring in compliance with SILCL

3/PL e and therefore do not need to be monitored in the feedback circuit of the upstream

evaluation unit/control.

WARNING

Failure of the safety function

Hybrid operation of 3RM10/3RM12 Standard motor starters with 3RM11/3RM13 Failsafe

motor starters in safety-related applications is not admissible.

Only ever use safety-related motor starters (3RM11 Failsafe and 3RM13 Failsafe) in safetyrelated applications.

Possibilities of interfacing to safety relays/fail-safe controllers

In the case of shutdown by removal of the control voltage, interfacing can take place via the

device connector connected to the 3SK1 safety relay or by wiring a 3RM11/3RM13 Failsafe

motor starter to a safety-related output of a fail-safe controller/evaluation unit.

Several 3RM11/3RM13 Failsafe motor starters can also be connected via device connectors

to one another or can be wired as a group of up to five motor starters to one safety-related

output of a failsafe controller/evaluation unit.

Note

The device connector can only be used in combination with motor starters that have a 24

V DC supply voltage.

Configuration with 3SK1 safety relay using device connectors

When interfaced to the 3SK1 safety relay with device connectors, the 3RM11/3RM13

Failsafe motor starters are shut down by removal of the control supply voltage (L+ and M) by

the 3SK1 safety relay. In this case, nothing may be connected to terminals A1 and A2 of the

3RM1 motor starters.

WARNING

Bypassing the safety function when using device connectors

When operating with a 3SK1 safety relay and a device connector, the supply voltage for

3RM1 motor starters is established via the device connectors.

In this case, do not connect anything to terminals A1 and A2 of the 3RM1 motor starters, in

order to prevent bypassing of the safety function.

Page 38

Description

3.5 Functions

SIRIUS 3RM1 motor starter

38 Manual, 11/2013, A5E0345285095020A/RS-AB/002

Configuration with 3SK1 safety relay/fail-safe controller by means of wiring

In a configuration without device connectors, the motor starters are interfaced to the 3SK1

safety relay or to the fail-safe controller and safety-related shutdown by means of wiring. If

steps are taken to ensure that the cables are laid in such a way that they are protected

against a cross-circuit/line-to-line fault, safety-related shutdown of A1 (L+) via a safetyrelated output of the control suffices. If this cannot be ensured, or if a PM-switching output is

used, both A1 (L+) and A2 (M) must be shut down via a safety-related output. In both cases,

safety-related shutdown in compliance with SILCL 3 to EN 62061, PL e/Cat. 4 to EN ISO

13849-1 is achieved.

For units with a 24 V DC supply voltage, safety-related shutdown via the IN1 and IN2 inputs

is alternatively possible. Thus, operational switching takes place via the safety-related output

of the fail-safe controller/evaluation unit.

Depending on peripherals used, shutdown is in one or two channels:

● PM (PPM)-switching: shutdown is in two channels.

● PP-switching: shutdown is in one channel.

Single-channel switching achieves SILCL 3 to EN 62061, PL e/Cat. 4 to EN ISO 13849-1

if steps are taken to ensure that the cables are laid in such a way that they are protected

against a cross-circuit/line-to-line fault.

Typical circuits and further information

WARNING

Function test interval for 3RM11/3RM13 Failsafe motor starters

In continuous operation, the key safety values apply in the case of a function test interval

(state change of the outputs) ≤ 1 year.

Annual function test

• Actuate the connected sensors.

• Check their effect on the safety relay and the downstream actuators.

• Activate the safety relay via the connected sensors.

• Check their effect on the safety relay and the downstream actuators.

• Defective devices must be replaced.

You will find typical circuits for safety-related applications of the 3RM11/3RM13 Failsafe

motor starters in combination with 3SK1 safety relays or with interfacing to a fail-safe

controller/evaluation unit in Chapter "Typical circuits for 3RM1 Failsafe (Page 150)".

You can find the technical data for safety applications in Chapter "General safety data

(Page 121)".

You can find more information on the safety relays in the applicable manuals of the devices

on the Internet; see Chapter "Further documentation (Page 11)".

Page 39

Description

3.5 Functions

SIRIUS 3RM1 motor starter

Manual, 11/2013, A5E0345285095020A/RS-AB/002

39

3.5.5

Carrying out the function test

You can start the different individual tests for the function test with the

"TEST/RESET/RESET MODE" button.

Procedure

Depending on how long the "TEST/RESET/RESET MODE" button is pushed, a specific test

is started:

Actuation time for

starting the test

Explanation

< 2 s

LED-Test

All four LEDs are activated.

1)

2 s ... 5 s

Current measuring test

Current measuring is tested in all 3 phases.

> > 5 s

Motor protection test disconnection

The entire control chain is tested, including the switching elements and the fault signaling output.

If the device responds as standard, an overload trip takes place. This can be reset immediately

without a cooling time by pressing the "TEST/RESET/RESET MODE" pushbutton again.

1)

Exception in the case of 3RM11/3RM13 Failsafe motor starters: in the case of 3RM11/3RM13 Failsafe motor starters,

the LED test is only carried out in the OFF state (without load current). In th

e ON state (with load current), the LEDs stay

unchanged.

Page 40

Description

3.5 Functions

SIRIUS 3RM1 motor starter

40 Manual, 11/2013, A5E0345285095020A/RS-AB/002

Actuation time for

starting the test

Status

OK

Fault

LED test

< 2 s "DEVICE" LED Shows a yellow light1) Off

"FAILURE" LED Shows a red light1) Off

"STATE" LED Shows a green light1) Off

"RESET MODE" button Shows a green light1) Off

Current measuring test

2 s ... 5 s "DEVICE" LED

• Without load current: Flickering red

• With load current: Flashing red

Off

Motor protection trip test

> 5 s "DEVICE" LED Shows a yellow light Flashing red

"FAILURE" LED Shows a red light Shows a red light

Fault signaling output Active Not active

Switching

elements/motor

Deactivated Unchanged

1)

Exception in the case of 3RM11/3RM13 Failsafe motor starters: in the case of 3RM11/3RM13 Failsafe motor starters,

the LED test is only carried out in the OFF state (without load current). In the ON state (with load current), the LEDs stay

unchanged.

Note

If the 3RM1 motor starter does not respond as in the table above during the function test,

check the connections and the supply to the 3RM1 motor starter. If the fault persists after

correct disconnection, the device must be replaced.

Page 41

Description

3.6 Accessories and order number scheme

SIRIUS 3RM1 motor starter

Manual, 11/2013, A5E0345285095020A/RS-AB/002

41

3.6

Accessories and order number scheme

3.6.1

Overview of all device components

①

Basic unit/expansion unit, e.g. 3RM1 motor starter

②

Top cover flap

③

Bottom cover flap

④

Terminals, 3-pole, push-in, 1 x 2.5 mm²

⑤

Terminals, 3-pole, screw-type, 1 x 2.5 mm²

⑥

Terminals, 3-pole, push-in, 1 x 4 mm²

⑦

Terminals, 3-pole, screw-type, 1 x 4 mm²

For connection, there is an infeed system (not shown in the overview diagram) for these

terminals.

⑧

Coding pins

⑨

Push-in lugs for wall mounting

⑩

Cover

⑪

Device connector

⑫

Device connector

⑬

Device termination connector

⑭

Sealable cover

Page 42

Description

3.6 Accessories and order number scheme

SIRIUS 3RM1 motor starter

42 Manual, 11/2013, A5E0345285095020A/RS-AB/002

3.6.2

Accessories

The following accessories are offered for the 3RM1 motor starter:

● Infeed system (Page 42)

● Sealable cover (Page 44)

● Wall fixture (Page 44)

● Device connectors (Page 45)

● Terminals (Page 48)

● Device identification label (Page 48)

3.6.2.1

Infeed system

The infeed system comprises 3-phase busbars, one infeed terminal, and one protective cap