Page 1

POWERS™ Controls

Technical Instructions

Document No. 155-029P25

AP 331-3

December 3, 2004

No. 6 Pneumatic Damper Actuator

331-2793 Actuator

Description

Features

331-2857 Actuator

with Clevis and Pin

The POWERS Controls No. 6 Pneumatic Damper Actuator is a heavy-duty, rolling

diaphragm, spring return actuator designed to drive large dampers, centrifugal

refrigeration inlet vanes, and other applications requiring a large, effective diaphragm

area and long stroke.

• All metal body construction

• Replaceable ozone-resistant, silicone rubber, rolling diaphragm

• Pivot mounting for extended shaft or frame mounting

• Positioning relay (optional)

• Adjustable forward travel stops (optional)

331-3012 Extended Shaft and Frame

Mounting

Product Numbers

Application

• Three spring ranges for sequencing with other control devices

See Table 1.

The No. 6 Pneumatic Damper Actuator controls outdoor, return air, exhaust, face and

bypass, and fan discharge dampers. It is recommended for heavy-duty applications

using multi-section dampers where either unison or sequence operation is required.

Certain actuators in Table 1 are UL Recognized Components for

fire/smoke applications under category EMKU2. This category covers

pneumatic damper actuators used on fire dampers and leakage rated

dampers.

Siemens Building Technologies, Inc.

Page 2

Technical Instructions POWERS™ Controls No. 6 Pneumatic Damper Actuator

Document No. 155-029P25

December 3, 2004

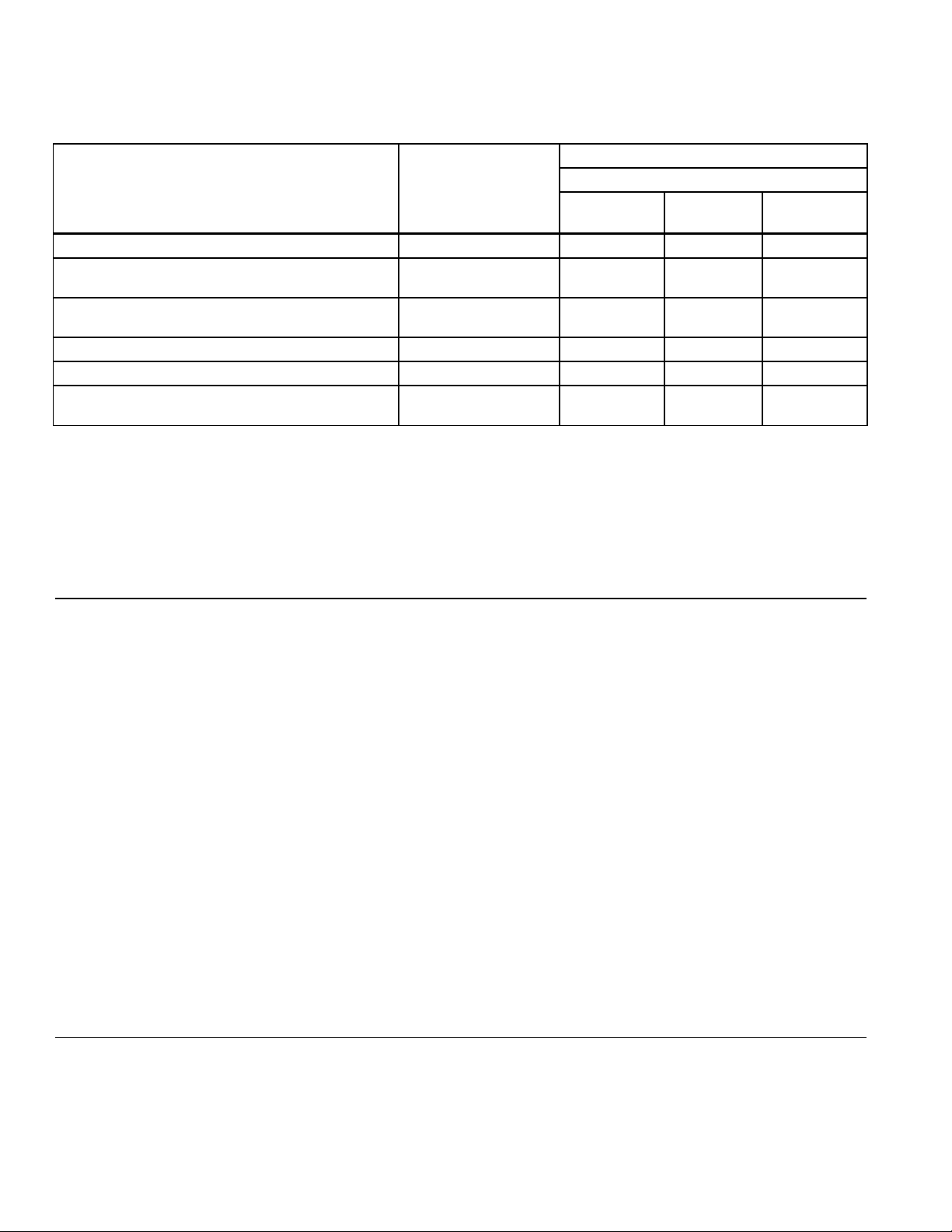

Table 1. Product Numbers for No. 6 Pneumatic Damper Actuators.

Description

Actuator, integral pivot Pivot 331-2793 331-2794

Actuator, integral pivot and forward travel stops (Figure

1)

Actuator with clevis for frame mounting (Figure 2) or

remote extended shaft mounting (Figure 3)

Actuator with clevis and positioning relay (Figure 16)

Actuator, integral pivot with pivot post 3

Actuator, integral pivot with pivot post and positioning

3

relay

(Figure 16)

1

UL Recognized Components for Fire/Smoke Applications.

2

Also order frame mounting kit accessories.

3

Mounted on plate for extended shaft with clevis and crank for 3/8-inch (10-mm), 7/16-inch (11-mm), or 1/2-inch

Mounting Style

Pivot — 331-2796 331-2988

Pivot

Pivot

Extended Shaft 331-3012 331-3013

Extended Shaft with

Positioning Relay

3-8 psi

(21-55 kPa)

2

2

331-2857 331-2858

— — 332-2856

— — 332-3011

Product Numbers

Nominal Spring Range

3-13 psi

(21-90 kPa)

(55-90 kPa)

331-3060

331-28561

331-30111

8-13 psi

1

(13-mm) diameter shaft. Parts for frame mounting (blade drive) included with kit.

NOTE: When the actuator is ordered with universal mounting, the mounting plate, pivot post and hardware, clevis,

damper crank, rocker arm, and all screws/nuts are included. Order other frame mounting accessories as

required, if not supplied by damper manufacturer.

Specifications

Effective diaphragm area 17.9 inches2 (115 cm2)

Stroke 4 inch (102 mm)

Housing Aluminum

Stem Type 416 stainless steel

Diaphragm Ozone-resistant silicone rubber

Spring Steel

Bearing Bronze oilite

Maximum air pressure 30 psig (210 kPa)

Nominal spring ranges 3 to 8 psi (21 to 55 kPa)

3 to 13 psi (21 to 90 kPa)

8 to 13 psi (55 to 90 kPa)

Ambient temperature range

Operation -20°F to 200°F (-29°C to 93°C)

Air connection 1/8-inch NPT

Type of mounting Pivot, universal (extended shaft or

frame mount)

Thrust and torque rating See Table 2

Dimensions See Figure 13 through Figure 16

Shipping Weight 9 lb (4.08 kg)

Agency Approvals Complies with UL555 and UL555S

Page 2 Siemens Building Technologies, Inc.

Page 3

POWERS™ Controls No. 6 Pneumatic Damper Actuator Technical Instructions

Document No. 155-029P25

December 3, 2004

Accessories

Service Kits

Damper shaft extension kits:

1/2-inch (13-mm) diameter, 2-1/4 inch (57-mm) rod 331-631

(See TB-128 POWERS™ Controls Damper Shaft Extension

Technical Bulletin 155-205P25)

1/2-inch (13-mm) diameter, 9-inch (229-mm) long hollow rod 333-184

1/2-inch (13-mm) diameter, 9-inch (229-mm) long rod 333-042

1–inch (25–mm) diameter 11-5/8 inch (295-mm) long (Ruskin) 333–194

Damper shaft extension kit adapter - 3/8 inch (10 mm) diameter 331-632

(for use with Damper Shaft Extension Kit 333-042)

Actuator shaft extensions:

10-1/8 inch (257-mm) long 331-434A

Adapter kit for 1/2-inch NPT pipe 333-030

Cranks - damper shaft:

3/8-inch (10-mm) - 1/2-inch (13-mm) diameter,

Selectable radius 331-941

5/8-inch (16-mm) diameter 333-182

3/4-inch (19-mm) diameter 333-183

1-inch (25-mm) diameter 333-181

Cast iron crank with set screws 333-078

Linkage kit, 4-inch (102-mm) link and crank 331-958

Universal mounting plate

3/4-inch shaft 331-623

1-inch shaft (use with 333-194) 331-623A

Flange bearing (1/2 inch, 13 mm) 331-862

(for 331-623 Universal Mounting Plate)

Right angle mounting plate 333-208

Remote mounting kit (extended shaft), Figure 3 331-618

Positioning relay 147-2000

Positioning relay mounting kit 147-276

Frame mounting kits

One-section damper (Figure 5) 751*

Two-section damper (Figure 6) 752*

* Order frame mounting kits and damper blade clip kit from

Arrow United Industries.

Frame mounting lug 331-569

Mounting lug screws (three required for frame mounting lug) 034-123K

Offset Mounting Bracket (Figure 14) 333-176

Travel Stop Kit (for model 3 and 4 actuators only) 333-197

Damper Blade Rocker Arm 333-034

Screws (two) 030 510J

Nuts (two) 041-230J

Silicone diaphragms (package of five) 333-572

Siemens Building Technologies, Inc. Page 3

Page 4

Technical Instructions POWERS™ Controls No. 6 Pneumatic Damper Actuator

Document No. 155-029P25

December 3, 2004

Actuator Sizing

The quantity of actuators required depends on several torque factors. To determine the

quantity of actuators required for the installation:

1. Obtain damper torque ratings (ft-lb/ft

2. Determine the area of the damper.

3. Calculate the total torque required to move the damper:

Total Torque = Torque Rating x Damper Area

4. Calculate the total quantity of actuators required:

Number of Total Damper Torque Required

Actuators

1

Safety Factor: When calculating the number of actuators required, a safety factor

=

1

× Actuator Torque (see Table 2)

SF

should be included for unaccountable variables such as slight misalignments, aging of

the damper, etc. A suggested safety factor is 0.80 (or 80% of the rated torque).

See AB-300 Damper Actuator Sizing and Selection Application Bulletin in the HVAC

Systems/Controls Reference Data (125-1853) for additional sizing information. See

TB-181 Powers™ Controls Maximum Thrust Ratings of Pneumatic Damper Actuators

Technical Bulletin (155-219P25) for additional torque requirements.

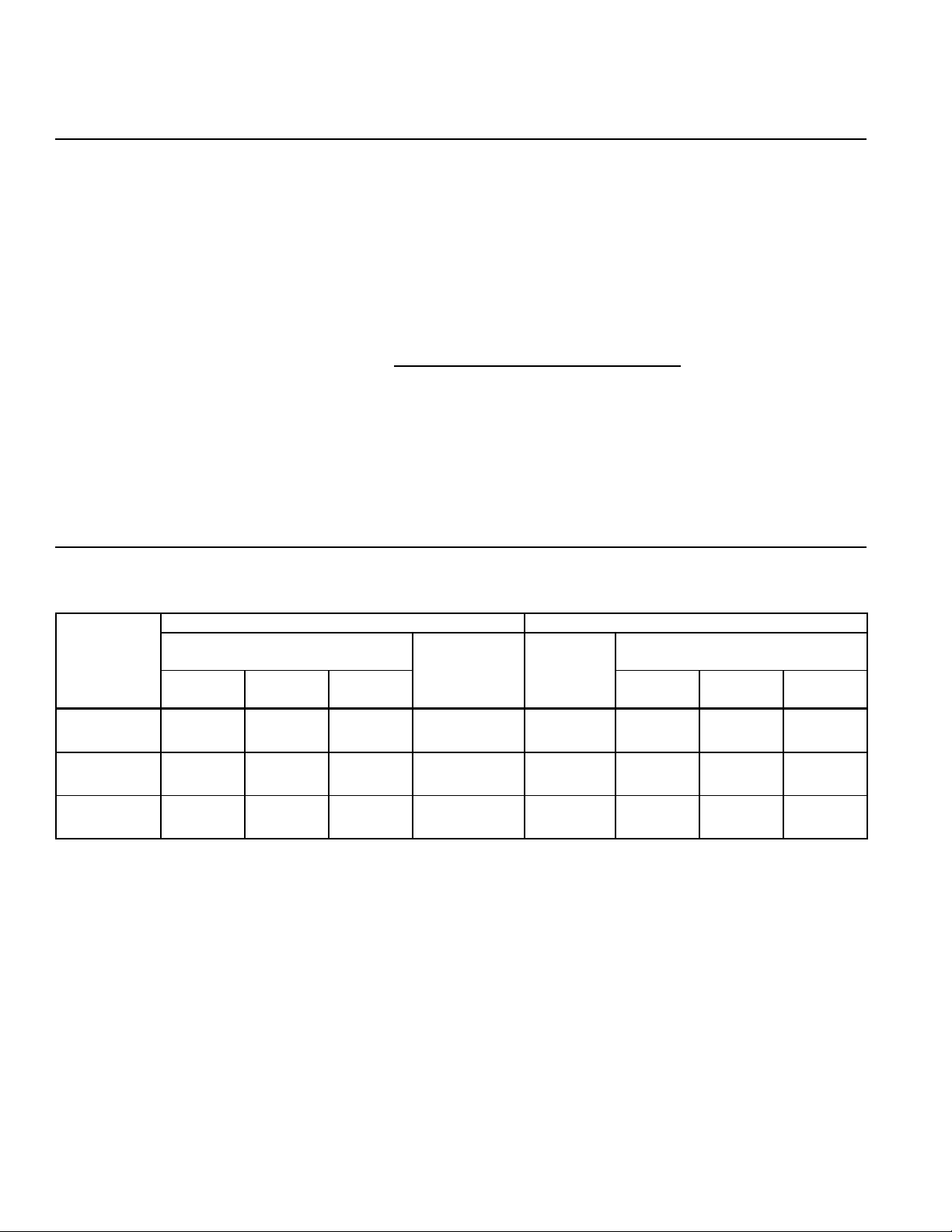

Table 2. Thrust and Torque Rating.

Nominal

Spring

Range

3-8 psi

(21-55 kPa)

3-13 psi

15psi

(103 kPa)

125 (556) 179 (796) 304

36 (160) 89 (396) 214 (952) 54 (240) 50 (5.6) 75 (8.5) 75 (8.5) 75 (8.5)

Maximum Thrust lb. (N) Torque Rating* lb-in (Nm)

Full Stroke Forward 2-Position Operation

Spring

Return

18 psi

(124 kPa)

25 psi

(172 kPa)

(No Stroke)

0 psi (0 kPa)

54 (240) 50 (5.6) 75 (8.5) 75 (8.5) 75 (8.5)

(1352)

(21-90 kPa)

8-13 psi

36 (160) 89 (396) 214 (952) 144 (640) 50 (5.6) 202 (22.8) 202 (22.8) 202 (22.8)

(55-90 kPa)

* With maximum hysteresis of 2.5 psi (17.2 kPa) @ 90° rotation.

2

) from the damper manufacturer.

Gradual

Operation

15 psi

(103 kPa)

or Positioner

18 psi

(124 kPa)

25 psi

(172 kPa)

Page 4 Siemens Building Technologies, Inc.

Page 5

POWERS™ Controls No. 6 Pneumatic Damper Actuator Technical Instructions

Document No. 155-029P25

December 3, 2004

Operation

The air tubing from a controlling instrument is connected to the actuator’s upper housing.

With no control pressure to the actuator, the compression spring forces the spring seat

Standard Actuator

(Figure 1)

and actuator shaft toward the upper housing, but is limited by the E-ring. As the control

pressure increases, the spring compression is overcome and the actuator shaft

gradually moves outward. Conversely, as control pressure decreases, the spring returns

the shaft to the position at which the air pressure on the diaphragm balances the spring

tension. For each value of control pressure there is a corresponding position of the shaft.

Table 3. Standard Actuator Components.

Item Part No. Description Qty. Material

1 047-061J Retaining E-ring 1 Steel

2 333-217 1 × 1-1/4 in. Hex Nut 1 Brass

3 — Spring Retainer 1 —

4 — Stem Guide Assembly 1 —

5 — Lower Housing 1 Aluminum

6 333-572

(pkg. of 5)

7 599-00413 5/16 in.-18 × 1

8 — Upper Housing 1 Aluminum

Figure 1. Standard Actuator.

9 — Helical Compression Spring 1

331-091 3 to 13 psi (21 to 90 kPa) —

331-208 3 to 8 psi (21 to 55 kPa) —

331-094 8 to 13 psi (55 to 90 kPa) —

10 — Piston Plate and Stem

11 — Retaining C-ring 1 Steel

12 333-197 Stop Kit (Optional) — Steel

Diaphragm 1 Silicone

6 Steel

Large Hex Cap Screw

1 Aluminum/

Assembly

rubber

SS

Extended Shaft

Mounting—Pivot

Actuator

1. Order one of the following and see Table 4 for parts lists:

Actuator: 331-3011, 331,-3012, 331-3013, or 332-3011

2. Slip the 3/4-inch (19-mm) diameter hole in the mounting plate over the damper

shaft.

3. Slip the crank over the damper shaft. With the actuator assembly to the left of the

damper shaft, an increase in actuator pressure rotates the damper blade CW

when the crank is above the damper shaft, or CCW when the crank is below the

damper shaft. See Figure 2.

With the actuator assembly to the right of the damper shaft, an increase in

actuator pressure rotates the damper blade CCW when the crank is above the

damper shaft or CW when the crank is below the damper shaft.

4. Position the mounting plate and attach it to the duct with four screws.

5. When the actuator cannot be directly mounted, drive the extended damper shaft

using the Remote Mounting Kit 331-618 and Actuator 331-2856. See Figure 3.

Siemens Building Technologies, Inc. Page 5

Page 6

Technical Instructions POWERS™ Controls No. 6 Pneumatic Damper Actuator

Document No. 155-029P25

December 3, 2004

Table 4. Extended Shaft/Frame Mounting Assemblies Components.

Item Part No. Description Qty. Material

1 041-162J Nut 1 Steel

2 046-020K Lockwasher 1 Steel

3 047-061K Retaining E-ring 2 Steel

4 331-565 Pivot Post 1 Steel

5 041-142 Nut 1 Steel

6 333-207 Clevis 1 Zinc Plated Steel

7 331-293 Clevis Pin 1 Zinc Plated Steel

8 331-807 Hitch Pin 1 Zinc Plated Steel

9 331-941 Crank Assembly 1 —

10 331-623 Actuator Mounting Plate 1 Steel

— 034-283 Mounting Screws 4 Steel

Figure 3. Remote Mounting Kit 331-618 with 331-2856 Actuator Mounted.

Frame Mounting Type A

Figure 2. Extended Shaft/Frame Mounting Actuator Assembly.

Order one each of the following. See Table 4 for parts lists:

Actuator and Clevis: 331-2856, 331-2857, or 331-2858

Frame Mounting Kit: 751 for one-section damper, or 752 for two-section damper

All frame mounting kits must be ordered from Arrow United Industries.

Page 6 Siemens Building Technologies, Inc.

Page 7

POWERS™ Controls No. 6 Pneumatic Damper Actuator Technical Instructions

Document No. 155-029P25

December 3, 2004

One-Section Damper

Kit 751

See Figure 4 and

Figure 5

1. Attach the damper mounting bracket to the lower right-hand corner (or upper

left-hand corner if necessary) of the damper section with the six screws provided.

For Arrow United Industries 1770 dampers, add the shim provided between the

bracket and bottom of the frame. Have the damper manufacturer drill the holes in the

damper frame (Figure 5).

2. Have the damper manufacturer drill the holes in the damper blade for the blade clips

(Figure 4). Use the same clip location for both normally open and normally closed

dampers. Attach the damper blade clip to the damper blade (Figure 4). Put the

damper in its normal position, open or closed. Connect the push rod to the trunnion

in the blade clip and tighten the setscrew. Connect the other end of the push rod to

the crank on the drive shaft and tighten the trunnion setscrew on the push rod.

Position the crank so the push rod is parallel to the bracket, then tighten the crank

setscrews.

3. lnstall the actuator in the actuator support bracket using the pivot shaft and hitch

pins. The pivot shaft should be in the holes about 17-1/2 inch (445 mm) from the

drive shaft. The actuator support bracket can also mount in the vertical position for

installations where space is limited.

Figure 4. Damper Blade Clip.

4. Position the crank driven by the actuator as follows:

a. Normally open damper: the crank is above the drive shaft.

b. Normally closed damper: the crank is below the drive shaft.

5. Connect the actuator clevis to the crank. Put the damper in its normal position, open

or closed. Stroke the actuator 1/4-inch (6 mm) with a hand pump, then tighten the

crank setscrews. This will ensure tight damper closure.

Figure 5. One-section Damper.

Siemens Building Technologies, Inc. Page 7

Page 8

Technical Instructions POWERS™ Controls No. 6 Pneumatic Damper Actuator

Document No. 155-029P25

December 3, 2004

Frame Mounting Type A,

Continued

Two-Section Damper

Kit 752

See Figure 6 and

Figure 7

1. Follow the steps in One-Section Damper.

2. Attach the Damper Blade Clip to the damper blade in the second damper section.

Repeat Step 2 in One-Section Damper. The push rod will connect to the extra crank

on the drive shaft.

Figure 6. Two-section Damper.

Figure 7. Actuator and Clevis Assembly 331-2857 (Typical)

Attached to Frame Mounting Kit 752.

Dimensions in Inches (Millimeters).

Page 8 Siemens Building Technologies, Inc.

Page 9

POWERS™ Controls No. 6 Pneumatic Damper Actuator Technical Instructions

Document No. 155-029P25

December 3, 2004

Frame Mounting Type B

See Figure 8 through

Figure 10

1. Order one each of the following:

Actuator assembly: 331-3011, 331-3012, 331-3013, or 332-3011

Mounting Lug: 331-569

2. Weld the mounting lug parallel and 5/16-inch (8 mm) from the inside edge of the

damper frame and perpendicular to it. See Figure 8. Weld the lug along both sides.

The lug should be as close as possible to the corner of the damper frame to

minimize deflection. The damper manufacturer should weld the lug.

Figure 8. Frame Mounting—Type B.

Dimensions in Inches (Millimeters).

3. If the damper frame is aluminum, light gauge sheet metal, or an unusual shape, bolt

a 3/16-inch (5-mm) thick, flat piece of steel to the frame. Then weld the mounting lug

to it.

4. Attach Rocker 333-034 to blade in proper position for normally open or normally

closed damper using 2 nuts, 041-230K, and 2 screws, 030-510J. See Figure 9 and

Figure 10.

5. Attach the mounting plate to the mounting lug as follows:

a. Normally Open damper: attach the plate to the lug. Place the pivot post in Hole

4. See Figure 9.

b. Normally Closed damper: attach the plate to the lug. Place the pivot post in Hole

3. See Figure 10.

6. Fasten the clevis to the rocker. Discard the crank and other parts not used.

7. The actuator mounting plate has a tendency to pivot at the point where the lug is

welded to the damper frame when the actuator strokes. It is recommended that

some means be devised in the field to prevent this from happening. A threaded rod

attached to the mounting plate and duct wall will normally work.

Siemens Building Technologies, Inc. Page 9

Page 10

Technical Instructions POWERS™ Controls No. 6 Pneumatic Damper Actuator

Document No. 155-029P25

December 3, 2004

Frame Mounting - Type B, Continued

Figure 9. Frame Mounting,

Normally Open Damper.

Actuator Mounting

Figure 11. Actuator Mounting Plate 331-623

Pivot Shaft Locations.

Dimensions in Inches (Millimeters).

Figure 10. Frame Mounting,

Normally Closed Damper.

Table 5. Mounting Plate Hole Identification.

Hole Used For

1 No. 6 Actuator extended shaft

mounting.

2 Not used.

3 No. 4 Actuator extended shaft.

No. 6 Actuator frame mounting NC

4 No. 6 Actuator frame mounting NO

5 No. 4 Actuator frame mounting NC

6 No. 4 Actuator frame mounting NO

Table 6. Pivot Post Hole Identification.

Hole Used For

1 No. 6 Actuator extended shaft mounting

2 Not used

No. 4 Actuator extended shaft 3

Figure 12. Actuator Mounting Plate 331-623A

Pivot Shaft Locations.

No. 6 Actuator frame mounting NC

4 No. 6 Actuator frame mounting NO

5 No. 4 Actuator frame mounting NC

6 No. 4 Actuator frame mounting NO

Page 10 Siemens Building Technologies, Inc.

Page 11

POWERS™ Controls No. 6 Pneumatic Damper Actuator Technical Instructions

Document No. 155-029P25

December 3, 2004

Dimensions

Figure 13. Extended Shaft Remote Mounting with Travel Stops.

Dimensions in Inches (Millimeters).

Offset Mounting

Bracket

This bracket is

designed to offset

Universal Mounting

Plate 331-623 or

331-623A from the

ductwork.

NOTE: Depending on

the application, two

brackets may be

required to support

the actuator and

universal mounting

plate.

Figure 14. Offset Mounting Bracket 333-176.

Dimensions in Inches (Millimeters).

Siemens Building Technologies, Inc. Page 11

Page 12

Technical Instructions POWERS™ Controls No. 6 Pneumatic Damper Actuator

Document No. 155-029P25

December 3, 2004

Dimensions,

Continued

Figure 15. Actuator Mounting Plate 331-623.

Dimensions in Inches (Millimeters).

Figure 16. No. 6 Actuator with the

RL 147 Positioning Relay Mounting.

Dimensions in Inches (Millimeters).

Information in this publication is based on current specifications. The company reserves the right to make changes in specifications and models as

design improvements are introduced. POWERS is a trademark of Siemens Building Technologies, Inc. Other product or company names

mentioned herein may be the trademarks of their respective owners. © 2004 Siemens Building Technologies, Inc.

Siemens Building Technologies, Inc.

1000 Deerfield Parkway

Buffalo Grove, IL 60089-4513

U.S.A.

Your feedback is important to us. If you have

comments about this document, please send

them to technical.editor@siemens.com

Document No. 155-029P25

Country or Origin: US

Page 12

Loading...

Loading...