Page 1

Mitsubishi Industrial Robot

BFP-A8741-D

CR800-D series controller

CR750-D/CR751-D series controller

CRnD-700 series controller

PROFIBUS DP-V0 Slave Interface

Instruction Manual

2D-TZ577

Page 2

Page 3

Safety Precautions

Always read the following precautions and the separate "Safety

Manual" before starting use of the robot to learn the required

measures to be taken.

CAUTION All teaching work must be carried out by an operator who has received special

training.

(This also applies to maintenance work with the power source turned ON.)

→Enforcement of safety training

CAUTION For teaching work, prepare a work plan related to the methods and procedures

of operating the robot, and to the measures to be taken when an error occurs

or when restarting. Carry out work following this plan.

(This also applies to maintenance work with the power source turned ON.)

→Preparation of work plan

WARNING Prepare a device that allows operation to be stopped immediately during

teaching work.

(This also applies to maintenance work with the power source turned ON.)

→Setting of emergency stop switch

CAUTION During teaching work, place a sign indicating that teaching work is in progress

on the start switch, etc.

(This also applies to maintenance work with the power source turned ON.)

→Indication of teaching work in progress

DANGER Provide a fence or enclosure during operation to prevent contact of the operator

and robot.

→Installation of safety fence

CAUTION Establish a set signaling method to the related operators for starting work,

and follow this method.

→Signaling of operation start

CAUTION As a principle turn the power OFF during maintenance work. Place a sign

indicating that maintenance work is in progress on the start switch, etc.

→Indication of maintenance work in progress

CAUTION Before starting work, inspect the robot, emergency stop switch and other

related devices, etc., and confirm that there are no errors.

→Inspection before starting work

Page 4

The points of the precautions given in the separate "Safety Manual" are given below.

Refer to the actual "Safety Manual" for details.

DANGER When automatic operation of the robot is performed using multiple control

devices (GOT, programmable controller, push-button switch), the interlocking

of operation rights of the devices, etc. must be designed by the customer.

CAUTION Use the robot within the environment given in the specifications. Failure to do

so could lead to faults or a drop of reliability.

(Temperature, humidity, atmosphere, noise environment, etc.)

CAUTION Transport the robot with the designated transportation posture. Transporting

the robot in a non-designated posture could lead to personal injuries or faults

from dropping.

CAUTION Always use the robot installed on a secure table. Use in an instable posture

could lead to positional deviation and vibration.

CAUTION Wire the cable as far away from noise sources as possible. If placed near a

noise source, positional deviation or malfunction could occur.

CAUTION Do not apply excessive force on the connector or excessively bend the cable.

Failure to observe this could lead to contact defects or wire breakage.

CAUTION Make sure that the workpiece weight, including the hand, does not exceed the

rated load or tolerable torque. Exceeding these values could lead to alarms or

faults.

WARNING Securely install the hand and tool, and securely grasp the workpiece. Failure to

observe this could lead to personal injuries or damage if the object comes off or

flies off during operation.

WARNING Securely ground the robot and controller. Failure to observe this could lead to

malfunctioning by noise or to electric shock accidents.

CAUTION Indicate the operation state during robot operation. Failure to indicate the state

could lead to operators approaching the robot or to incorrect operation.

WARNING When carrying out teaching work in the robot's movement range, always secure

the priority right for the robot control. Failure to observe this could lead to

personal injuries or damage if the robot is started with external commands.

CAUTION Keep the jog speed as low as possible, and always watch the robot. Failure to do

so could lead to interference with the workpiece or peripheral devices.

Page 5

CAUTION After editing the program, always confirm the operation with step operation before

starting automatic operation. Failure to do so could lead to interference with

peripheral devices because of programming mistakes, etc.

CAUTION Make sure that if the safety fence entrance door is opened during automatic

operation, the door is locked or that the robot will automatically stop. Failure to do

so could lead to personal injuries.

CAUTION Never carry out modifications based on personal judgments, non-designated

maintenance parts. Failure to observe this could lead to faults or failures.

WARNING When the robot arm has to be moved by hand from an external area, do not place

hands or fingers in the openings. Failure to observe this could lead to hands or

fingers catching depending on the posture.

CAUTION Do not stop the robot or apply emergency stop by turning the robot controller's

main power OFF. If the robot controller main power is turned OFF during automatic

operation, the robot accuracy could be adversely affected. Also a dropped or

coasted robot arm could collide with peripheral devices.

CAUTION Do not turn OFF the robot controller's main power while rewriting the robot

controller's internal information, such as a program and parameter. Turning OFF

the robot controller's main power during automatic operation or program/parameter

writing could break the internal information of the robot controller.

DANGER Do not connect the Handy GOT when using the GOT direct connection function of

this product. Failure to observe this may result in property damage or bodily injury

because the Handy GOT can automatically operate the robot regardless of whether

the operation rights are enabled or not.

DANGER Do not connect the Handy GOT to a programmable controller when using an iQ

Platform compatible product with the CR750-Q/CR751-Q/CR800-R/CR800-Q controller.

Failure to observe this may result in property damage or bodily injury because the

Handy GOT can automatically operate the robot regardless of whether the operation

rights are enabled or not.

DANGER Do not remove the SSCNET III cable while power is supplied to the multiple CPU

system or the servo amplifier. Do not look directly at light emitted from the tip of

SSCNET III connectors or SSCNET III cables of the Motion CPU or the servo

amplifier. Eye discomfort may be felt if exposed to the light.

(Reference: SSCNET III employs a Class 1 or equivalent light source as

specified in JIS C 6802 and IEC60825-1 (domestic standards in Japan).)

DANGER Do not remove the SSCNET III cable while power is supplied to the controller.

Do not look directly at light emitted from the tip of SSCNET III connectors or

SSCNET III cables. Eye discomfort may be felt if exposed to the light.

(Reference: SSCNET III employs a Class 1 or equivalent light source as

specified in JIS C 6802 and IEC60825-1 (domestic standards in Japan).)

Page 6

DANGER Attach the cap to the SSCNET III connector after disconnecting the SSCNET III cable.

If the cap is not attached, dirt or dust may adhere to the connector pins, resulting in

deterioration connector properties, and leading to malfunction.

CAUTION Make sure there are no mistakes in the wiring. Connecting differently to the way

specified in the manual can result in errors, such as the emergency stop not

being released. In order to prevent errors occurring, please be sure to check

that all functions (such as the teaching box emergency stop, customer

emergency stop, and door switch) are working properly after the wiring setup

is completed.

CAUTION Use the network equipments (personal computer, USB hub, LAN hub, etc)

confirmed by manufacturer. The thing unsuitable for the FA environment

(related with conformity, temperature or noise) exists in the equipments connected

to USB. When using network equipment, measures against the noise, such as

measures against EMI and the addition of the ferrite core, may be necessary.

Please fully confirm the operation by customer. Guarantee and maintenance

of the equipment on the market (usual office automation equipment) cannot

be performed.

CAUTION To maintain the safety of the robot system against unauthorized access from external

devices via the network, take appropriate measures. To maintain the safety against

unauthorized access via the Internet, take measures such as installing a firewall.

Page 7

Revision History

Printing date

Manual No.

Description

2008-03-25

BFP-A8741

Initial edition

2008-04-15

BFP-A8741-A

Error in writing correction.

Hyper link was corrected.

2016-08-08 BFP-A8741-B

・

・The back cover was corrected.

・

・The cover and corporate logo mark of this manual was changed.

2017-05-31 BFP-A8741-C

2018-02-01 BFP-A8741-D

・The CR800-D series controller was added.

・Safety Precautions was revised. (The CR800-Q controller was added.)

Page 8

Introduction

Indicates an immediately hazardous situation which, if not properly dealt

Indicates a hazardous situation which, if not properly dealt with, could result

Indicates a hazardous situation which, if not properly dealt with, could result

This manual or any part thereof may not be reproduced in any form or by any form without permission.

Thank you for purchasing Mitsubishi Electric Industrial Robot.

The PROFIBUS DP-V0 Slave Interface (2D-TZ577) is an optional device which, installed into the

CRnD-700 series, CR750-D/CR751-D series, or CR800-D series Robot Controller, permits you to connect

the Robot Controller to a PROFIBUS DP-V0 network.

Before using the Interface, read this manual and familiarize yourself with all pages to ensure safe operation

and obtain maximum satisfactory service from the PROFIBUS DP-V0 Slave Interface (2D-TZ577).

Note: All descriptions in this manual assume that the user has an adequate understanding about basic

operating procedures and functions which pertain to the Mitsubishi Industrial Robot. For detailed

information about the basic operating procedures, refer to the "Instruction Manual - Detailed Description of

Functions and Operation" which is separately issued.

Safety notation used in this manual:

DANGER

WARNING

CAUTION

·

· All the contents of this manual are subject to change without notice.

· Specification values appearing in this manual are based on the tests conducted in accordance with

Mitsubishi Electric's standard procedures.

· Mitsubishi Electric prepared this manual with close attention to every detail. However, in case that you

find any point in this manual which is not quite clear or any information which is not correctly presented

or missing, your local sales representative or Mitsubishi MELFA Telephone Customer Service Center

should be contacted for advice.

· Trade names or trademarks appearing in this manual are the property of their respective owners.

· The notations "®" and "TM" are omitted in this manual.

Copyright(C) 2009-2018 MITSUBISHI ELECTRIC CORPORATION ALL RIGHTS RESERVED

with, will result in death or serious injury.

in death or serious injury.

in injury, or property damage alone.

Page 9

[Table of Contents]

1. Before Using PROFIBUS DP-V0 Slave Interface .......................................................................................... 1

1.1 About Terms Used in This Manual .......................................................................................................... 1

1.2 How to Use This Manual ......................................................................................................................... 2

2. Workflow ......................................................................................................................................................... 3

2.1 Work Procedure ...................................................................................................................................... 3

3. Features and Specification of 2D-TZ577 Card ............................................................................................... 4

3.1 What is PROFIBUS DP ........................................................................................................................... 4

3.2 Features of 2D-TZ577 Card .................................................................................................................... 5

3.3 Specification of 2D-TZ577 Card .............................................................................................................. 7

3.3.1 General Specification ....................................................................................................................... 7

3.3.2 Transmission Specification .............................................................................................................. 8

3.3.3 Network Configuration ..................................................................................................................... 8

3.3.4 Accommodated Versions ................................................................................................................. 9

3.4 Robot Parameters ................................................................................................................................. 10

3.5 Robot Controller Input/Output Signals .................................................................................................. 12

3.6 About Dedicated Input/Output ............................................................................................................... 13

3.7 Specification Relative to Robot Language ............................................................................................ 13

3.7.1 Robot System State Variables Relative to 2D-TZ577 Card ........................................................... 13

3.8 About Output Signal Reset Patterns ..................................................................................................... 16

3.9 Hardware of 2D-TZ577 Card ................................................................................................................. 17

3.9.1 Overall View ................................................................................................................................... 17

3.9.2 LED ................................................................................................................................................ 17

4. Out of the Package ....................................................................................................................................... 18

4.1 Checking Component Parts .................................................................................................................. 18

4.2 Items To Be Furnished by User ............................................................................................................. 18

5. Hardware Setup............................................................................................................................................ 20

5.1 Hardware Setup for 2D-TZ577 Card ..................................................................................................... 20

6. Connection and Wiring ................................................................................................................................. 21

6.1 Installing A 2D-TZ577 Card into Robot Controller ................................................................................. 21

6.1.1 CR1D Robot Controller .................................................................................................................. 21

6.1.2 CR2D Robot Controller .................................................................................................................. 22

6.1.3 CR3D Robot Controller .................................................................................................................. 23

6.1.4 CR750-D/CR751-D Robot Controller ............................................................................................. 24

6.1.5 CR800-D Robot Controller ............................................................................................................. 25

6.2 Connector Pin Configuration (D-SUB9 Pin) .......................................................................................... 26

6.3 Wiring .................................................................................................................................................... 26

6.4 About Noise Control .............................................................................................................................. 27

Page 10

6.4.1 CR1D Controller ............................................................................................................................. 27

6.4.2 CR2D Controller ............................................................................................................................. 27

6.4.3 CR3D Controller ............................................................................................................................. 28

6.5 Checking Connections .......................................................................................................................... 29

7. Procedure before Startup ............................................................................................................................. 30

7.1 Procedure for Running Self-diagnosis .................................................................................................. 31

7.2 Parameter Settings on the Side of Master Station ................................................................................ 31

7.2.1 Procedure for Establishing Parameters ......................................................................................... 31

7.2.2 Slave Parameters ........................................................................................................................... 32

7.3 Parameter Settings on the Side of Robot Controller ............................................................................. 35

7.4 Have A Try For It .................................................................................................................................... 37

7.4.1 Setting Dedicated Input/Output ...................................................................................................... 37

7.4.2 About General-purpose Input/Output ............................................................................................. 37

7.4.3 Examples of Robot Program (Using General-purpose I/O) ........................................................... 38

7.4.4 A Sample Program for Checking Input/Output ............................................................................... 39

8. Troubleshooting ............................................................................................................................................ 40

8.1 A Listing of Errors .................................................................................................................................. 40

8.2 At the Occurrence of Error 8570 (PROFIBUS Communication Timeout) ............................................. 42

9. Appendix ....................................................................................................................................................... 43

9.1 Displaying Option Card Information ...................................................................................................... 43

Page 11

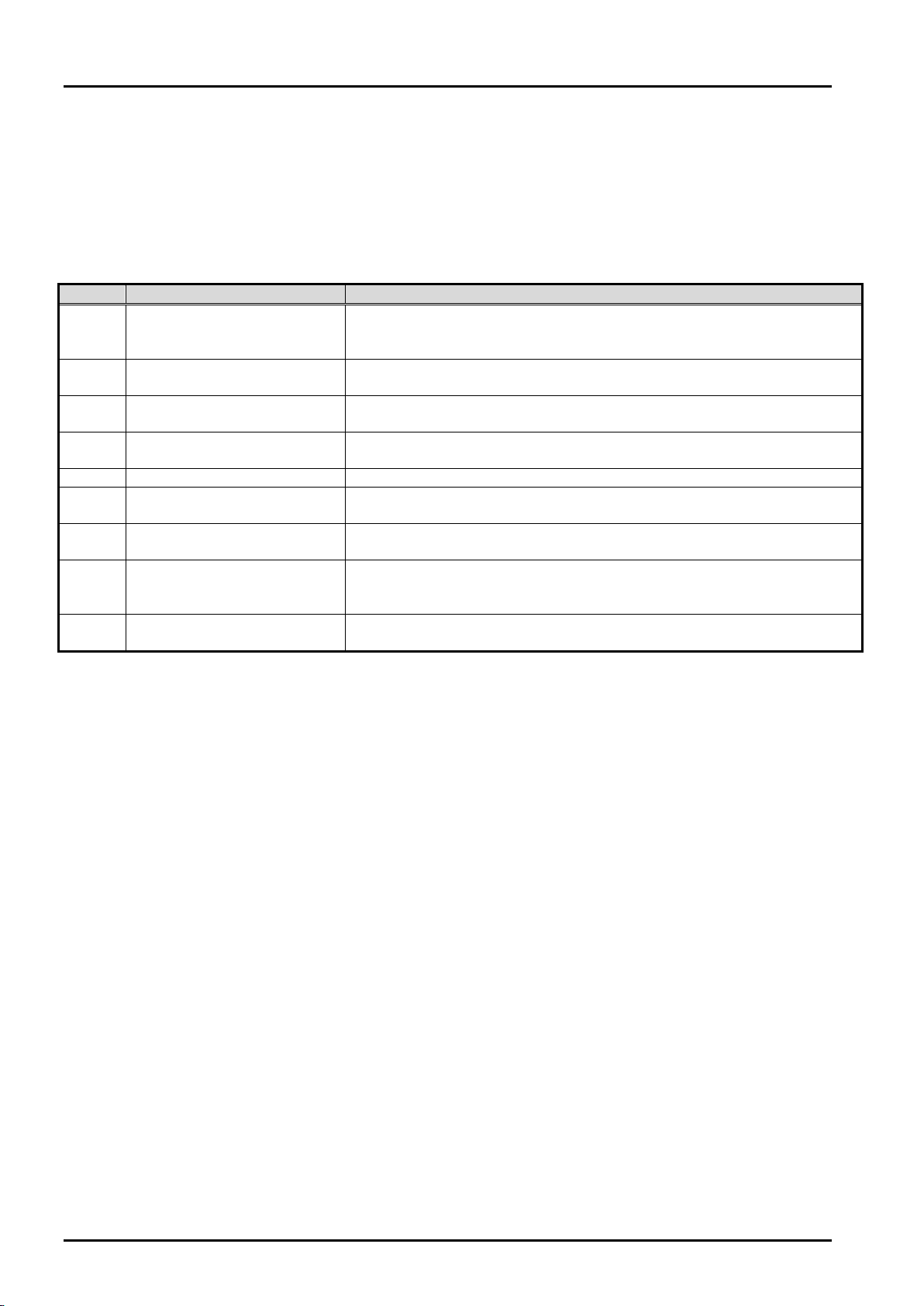

1 Before Using PROFIBUS DP-V0 Slave Interface

Term

Description

PROFIBUS DP-V0

A basic version of PROFIBUS DP which permits the execution of the following

Others

PROFIBUS DP-V1

A version of PROFIBUS DP which permits the execution of the following functions

Others

PROFIBUS DP-V2

A version of PROFIBUS DP which permits the execution of the following functions

Others

2D-TZ577

PROFIBUS DP-V0 Slave Interface (a complete set of products)

2D-TZ577 Card

PROFIBUS DP-V0 Slave Interface Card (TZ577)

Master Station

A station residing in the equipment (typically, PLS or personal computer) which

Class 2.

Class 1 Master Station

Equipment which exchanges input/output data with Slave Stations.

Class 2 Master Station

Equipment which verifies station number settings and operating statuses through

diagnosis.

Slave Station

A lo wer-level station which communicates with Master Station.

Repeater

A device which provides a link between the segments of a PROFIBUS DP network.

Terminator resistor

Resistor connected to the individual segments of a PROFIBUS DP network at each

network are enabled to fulfill intended purposes.

Slave parameter

Slave station parameter established by Master Station. Items of parameter

information are stated on a GSD file.

Station number

A number assigned to Master Station or Slave Station. Numbering is in the range of

0 to 125.

I/O configuration

information (data module)

Information about input/output configuration at Slave Station.

Input data

Data which is sent by 2D-TZ577 Card and received by Master Station.

(Data inputted by Master Station)

Output data

Data which is sent by Master Station and received by 2D-TZ577 Card.

(Data outputted by Master Station)

Global control

A function which allows Class 1 Master Station to send an input/output data

synchronization command to Slave Stations.

Communication WDT

A watchdog timer established in the slave parameter at Master Station.

GSD file

An electronic file stating parameter settings at Slave Station. A data setting

settings.

1. Before Using PROFIBUS DP-V0 Slave Interface

This chapter explains checks or precautions that you should perform or take before using the PROFIBUS DP-V0

Slave Interface (2D-TZ577).

1.1 About Terms Used in This Manual

Table 1-1 Terms Used in This Manual

functions:

· Input/output data communications

·

in additions to those available from PROFIBUS DP-V0:

· A cyclic communications (asynchronous data communications)

· Alarm notification

·

in additions to those available from PROFIBUS DP-V1:

· Time stamping

·

controls a data link system. There must be at least one Master Station in any

system. As described below, Master Station comes in two varieties: Class 1 and

communications with Slave Stations. It serves as a network administration master

station and takes care of such tasks as startup, maintenance service, and

end. Actually, terminator resistors built in the connector used with a PROFIBUS

software compliant with Master Station, which is used to establish slave parameter

About Terms Used in This Manual 1- 1

Page 12

1 Before Using PROFIBUS DP-V0 Slave Interface

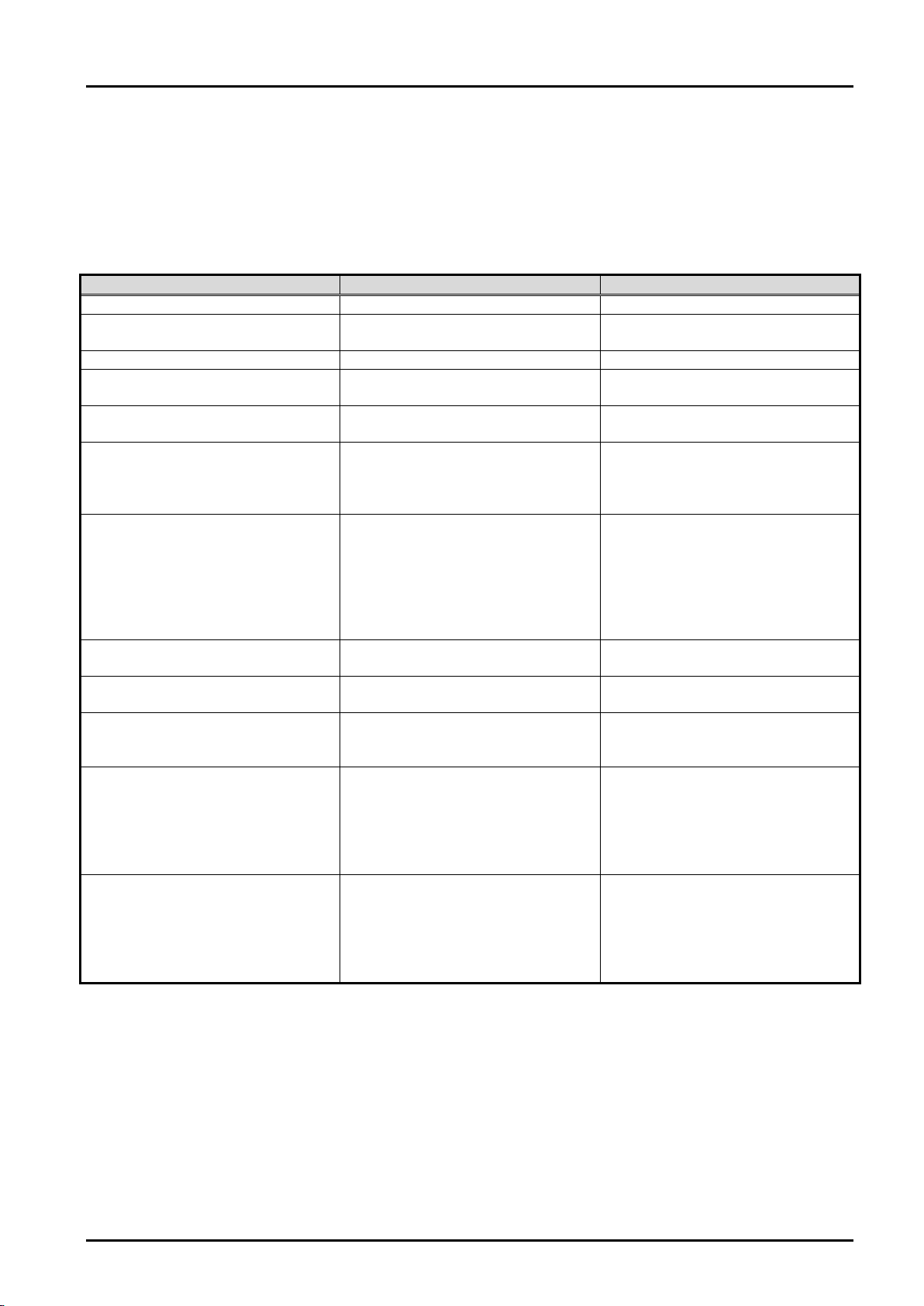

Section

Title

Contents

This section describes how to use this document (PROFIBUS DV-V0

the information contained before attempting to use the 2D-TZ577 Card.

This section describes the work necessary to build a PROFIBUS DP

system. Carry out each work step exactly as indicated.

Features and Specification of

2D-TZ577 Card

This chapter describes the features and specification of the 2D-TZ577

Card.

Upon receipt of the 2D-TZ577 Card, check to see that all items are in the

package and that the version of the Robot Controller is as specified.

5

Hardware Setup

Hardware setup need not be done in regard to the product in question.

This section describes the method used to connect the 2D-TZ577 Card to

the Master Station via cables.

This section describes steps you have to take before placing PROFIBUS

DP system into operation.

This section presents information that helps find solutions when

2D-TZ577 Card. Make reference to this section as occasion arises.

The appendix explains the method for displaying information about the

2D-TZ577 Card by means of RT ToolBox2/RT ToolBox3.

1.2 How to Use This Manual

This manual discusses the functions of the 2D-TZ577 Card with its constituent sections organized as shown in

the table below. For information about the functions available from the standard Robot Controller and the

operating method thereof, refer to the "Instruction Manual" that is supplied with the Controller.

Table 1-2 Organization of This Instruction Manual

Before Using PROFIBUS

1

DP-V0 Slave Interface

2 Workflow

3

4 Out of the Package

6 Connection and Wiring

Slave Interface Instruction Manual). Read and familiarize yourself with

7 Procedure before Startup

8 Troubleshooting

9 Appendix

operational anomalies or errors are encountered during the use of the

How to Use This Manual 1- 2

Page 13

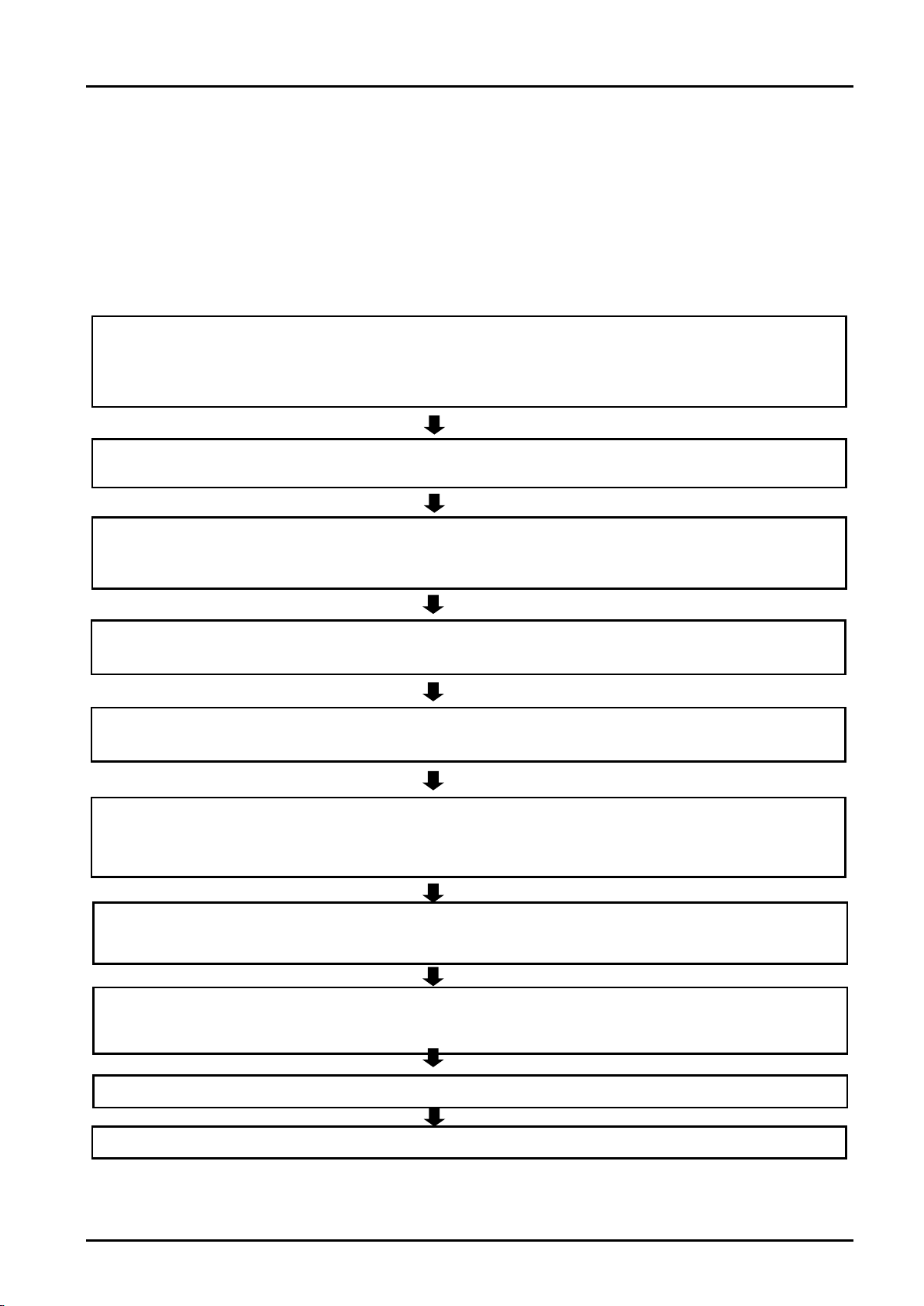

2 Workflow

1 Deciding a specification for PROFIBUS DP network

・・・・・・・・・・

See Section 3.

Make a decision on interface details in regard to system signals utilizing PROFIBUS DP after gaining an

understanding of PR

OFIBUS DP specification.

(Such details include alignment of dedicated input/output signals and arrangement pertaining to general

-purpose

input/output signals.)

2. Unpacking component parts

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

See Section 4.

Unpack cartons containing your purchase and ensure that all the necessary items are ready for installation.

3. Hardware setup and installation to robot controller

・・・・・・・・・・・・

See Section 5 and Section 6.1.

The 2D-TZ577 Card lets you do without hardware setup. Install the Card into the Robot Controller, as it is.

5.

Establishing parameters for Master Station

・・・・・・・・・・・・・・・・・・

See Section 7.2.

Make signal alignment and Slave Station number settings at the Master Station.

6. Establishing parameters for Robot Controller

・・・・・・・・・・・・・・・・・

See Section 7.3.

Make Robot Controller-side station number settings.

Choose a setting to indicate whether the Robot Controller should

run a self-diagnosis at power-on.

Carry out signal alignment for dedicated I/O.

7. Making the connection

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

See Sections 6.2 through 6.5.

Connect the 2D-TZ577 Card installed in the Robot Controller to the Master Station, using the PROFIBUS-specific

cable and connector.

8. Creating a robot program

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

See Section 7.4.

Create a robot program compliant with the specification decided in Step 1 above and activate the robot in auto

operation mode.

9. Actions at the occurrence of a trouble

・・・・・・・

・・・・・・・・・

・・・・・・・

See Chapter 8.

4. Performing self-diagnosis

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

See Section 7.1.

Run a self

-diagnosis and ensure that the 2D

-TZ577 Card has no problems with its hardware.

10. Work complete

2. Workflow

Workflow you should follow to construct a PROFIBUS DP network system is shown below. Carry out each work

step exactly as indicated.

2.1 Work Procedure

Work Procedure 2- 3

Page 14

3 Features and Specification of 2D-TZ577 Card

Robot Controller

CR75n-D

Series

Robot Controller

CR800-D

Series

PROFIBUS DP-VO Slave

Connector with

MELSEC sequencer, etc.

Connector with built

terminator resistors

(to be furnished by the

user)

Equipment from other

Robot Controller

CRnD-700

Series

Master Station unit

Slave Station unit

Personal

computer

QXxxxx

QJ71E71-100QJ71E71-100QJ71E71-100QJ71E71-100

RUN

INIT.

OPEN

SD

RUN

INIT.

OPEN

SD

RUN

INIT.

OPEN

SD

RUN

INIT.

OPEN

SD

ERR.

COM.ERR.

100MRD

ERR.

COM.ERR.

100MRD

ERR.

COM.ERR.

100MRD

ERR.

COM.ERR.

100MRD

QXxxxx

QXxxxx

PULL

MITSUBISHI

MEL S EC

POWER

MP

G

R

I

O

FRONT

M

PG

R

IO

B

AT

BA

T

AC

FA

I

LA

CF

A

IL

FRONT

Q173NCCPU

QJ71E71-100

RUN

INIT.

OPEN

SD

ERR.

COM.ERR.

100MRD

QJ71E71-100

RUN

INIT.

OPEN

SD

ERR.

COM.ERR.

100MRD

QXxxxx

QJ71E71-100QJ71E71-100QJ71E71-100QJ71E71-100

RUN

INIT.

OPEN

SD

RUN

INIT.

OPEN

SD

RUN

INIT.

OPEN

SD

RUN

INIT.

OPEN

SD

ERR.

COM.ERR.

100MRD

ERR.

COM.ERR.

100MRD

ERR.

COM.ERR.

100MRD

ERR.

COM.ERR.

100MRD

QXxxxx

Q

Xxxxx

PULL

MITSUBISHI

MEL S EC

POWER

MPG

RIO

FRONT

MPG

RIO

BATBAT

ACFAILACFAIL

FRONT

Q173NCCPU

Q

J

71

E7

1

-1

0

0

R

UN

INIT.

O

PE

N

S

D

E

RR

.

COM.ERR.

1

00

MR

D

Q

J7

1E

7

1-

1

00

R

UN

INIT.

O

PE

N

S

D

E

RR

.

COM.ERR.

1

00

MR

D

Varied

devices

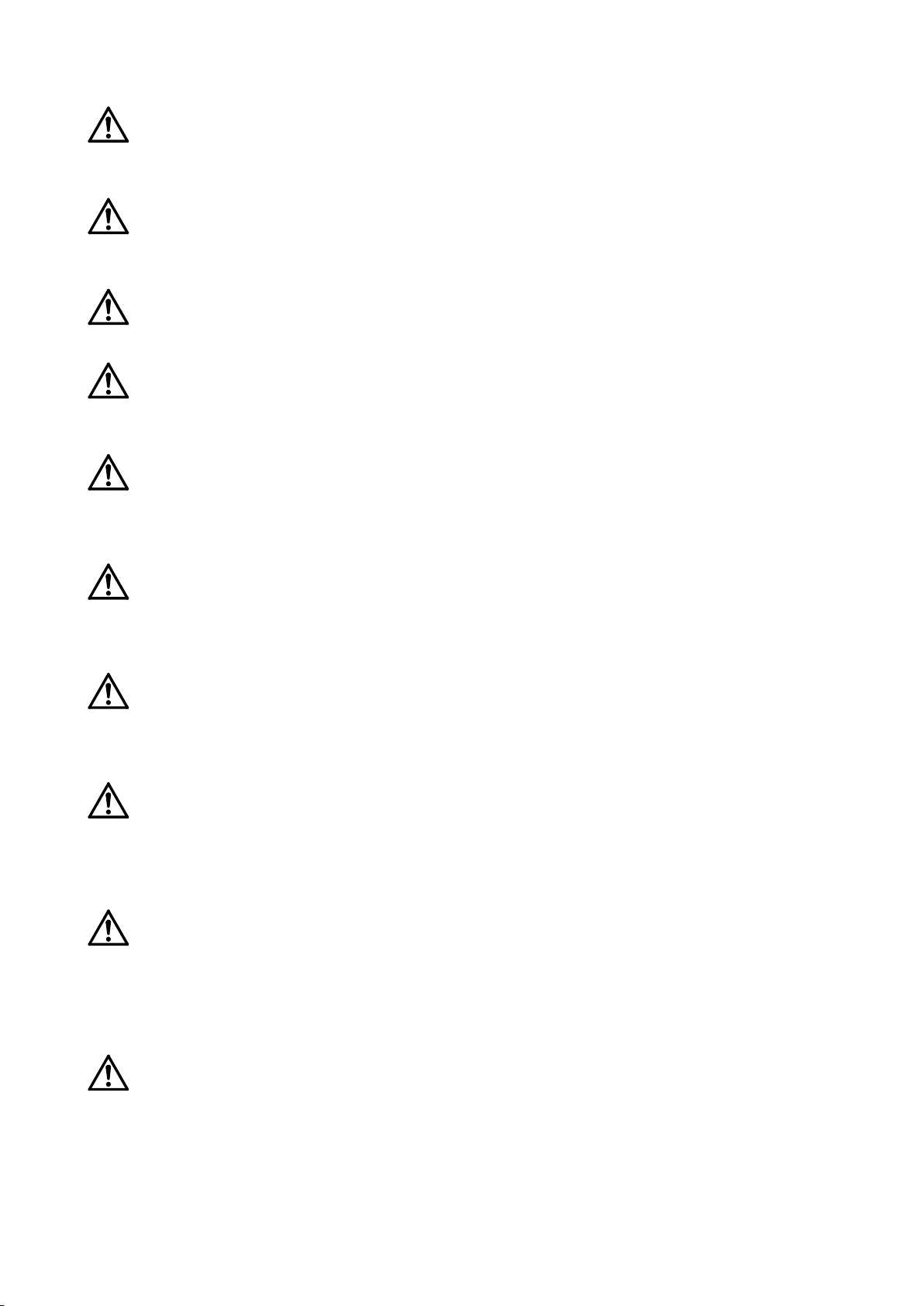

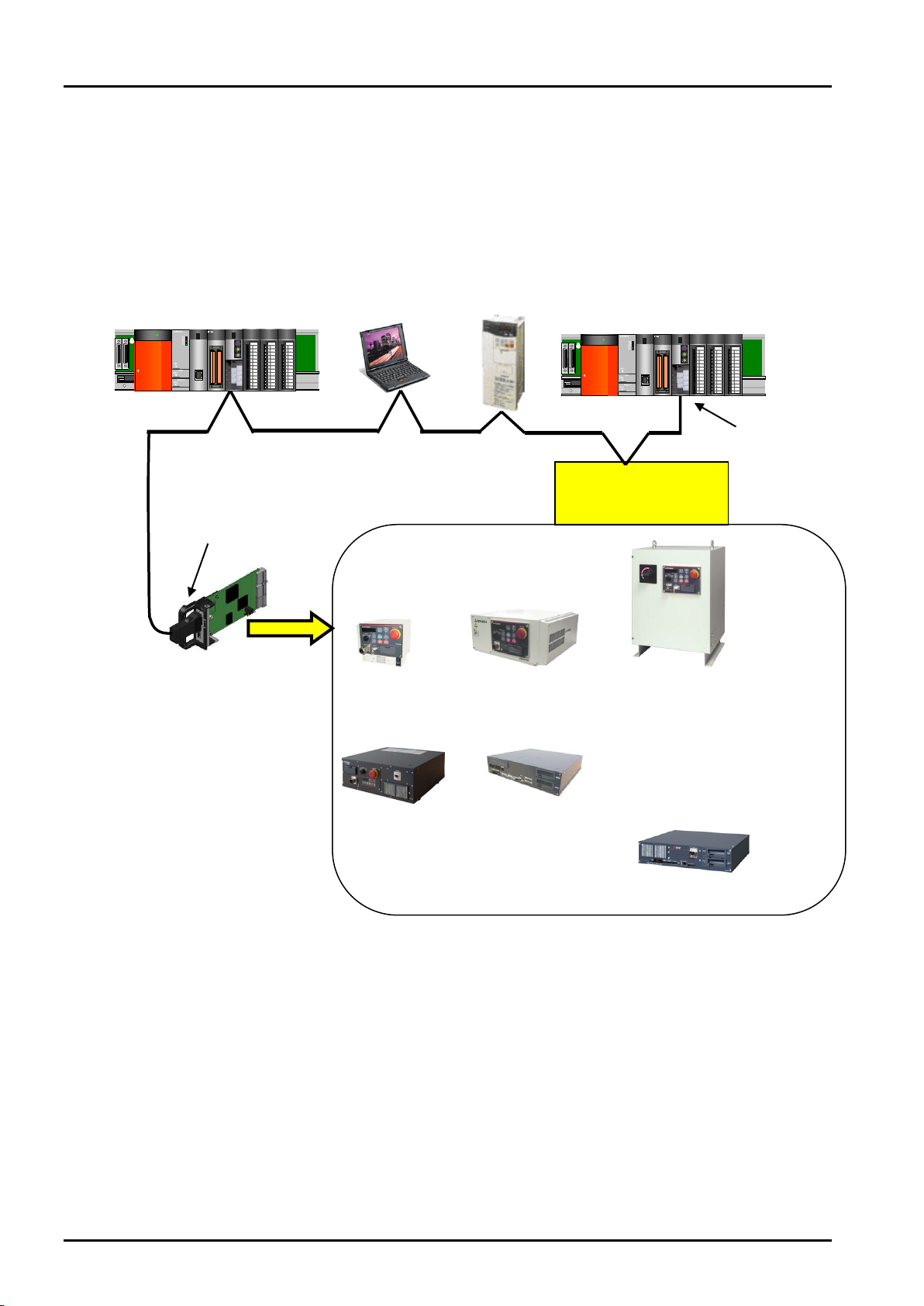

3. Features and Specification of 2D-TZ577 Card

3.1 What is PROFIBUS DP

PROFIBUS-compliant

Interface Card (2D-TZ577)

Only one card can be

installed into an option slot

on the Controller*1.

-in

(to be furnished by the user)

CR1D

CR750-D CR751-D

CR2D

manufacturer or

Mitsubishi associate

CR3D

CR800-D

built-in

terminator

resistors

(to be furnished

by the user)

PROFIBUS is one of the recognized fieldbus standards. PROFIBUS comes in three variations: general-purpose

PROFIBUS FMS, PROFIBUS DP for factory automation application, and PROFIBUS PA for process automation

application.

The 2D-TZ577 Card is intended to serve as a slave station which supports PROFIBUS DP-V0 capabilities.

It does not support PRORIBUS DP-V1 or PROFIBUS DP-V2 which is an extension of PROFIBUS DP-V0.

What is PROFIBUS DP 3- 4

Figure 3-1 An Example of PROFIBUS Network Configuration

Page 15

3 Features and Specification of 2D-TZ577 Card

192 words in combined total

(*1) Number of the option slots varies with the Controller you use.

CR1D: Provided only with Slot 1.

CR2/3D: Provided with Slots 1 thru 3 (only one of the three slots used to install the Card at any one time)

Details about PROFIBUS

To learn more about PROFIBUS, visit a Japan PROFIBUS Association website at http://www.profibus.com/

3.2 Features of 2D-TZ577 Card

The 2D-TZ577 Card has the following features:

(1) Compliance with EN 50170 Vo lume 2 (Part 1, 2, 3, 4, and 8)

Designed to provide compliance with EN 50170 Volume 2 (Part 1, 2, 3, 4, and 8), the 2D-TZ577 Card

serves only as a slave station in a PROFIBUS DP-V0 network.

(2) PROFIBUS DP-V0 Slave Interface Card for D-Type Robot Controller

The 2D-TZ577 Card is an optional card for use with the stand-alone type (D type) Robot Controller, not

usable for iQ Platform compatible type (Q type or R type). To connect iQ Platform compatible type (Q type

or R type) Robot Controller to a PROFIBUS DP network, use a MELSEC-Q Series PROFIBUS DP unit.

To connect R type Robot Controller to a PROFIBUS DP network, use a MELSEC iQ-R Series PROFIBUS

DP unit.

(3) Input/output data communications with Class 1 Master Station

The 2D-TZ577 Card is capable of conducting input/output data communications with PROFIBUS-DP Class

1 Master Station (Master Station which communicates with Slave Stations on a cyclic basis). This card is

intended to serve as a slave station which supports PROFIBUS DP-V0 capabilities. It does not

support PRORIBUS DP-V1 or PROFIBUS DP-V2 which is an extension of PROFIBUS DP-V0.

(a) Communicatable number of pieces of data

A single 2D-TZ577 Card allows communications in the following number:

Input data - 122 words maximum

Output data - 122 words maximum

(4) Communications with Class 2 Mater Station

The 2D-TZ577 Card is capable of conducting communications, as detailed below, with Class 2 Master

Station (Master Station for network administration which takes care of startup, maintenance and diagnosis

services).

• Reading from input send area/output receive area

• Reading I/O configuration information

• Changing station numbers

For instructions on using the each of the listed functions, see instruction manual which is supplied with

Class 2 Master Station being installed.

Features of 2D-TZ577 Card 3- 5

Page 16

3 Features and Specification of 2D-TZ577 Card

(5) Input/output data swapping

The 2D-TZ577 Card permits upper/lower bytes to be swapped at the time when input/output data is sent to

or received from Master Station. In a PROFIBUS DP network, the way the upper/lower bytes of input/output

data is treated differs depending on the type of Master Station, but there is no need for making input/output

data swapping at a program level.

(6) Global control

The 2D-TZ577 Card supports global control capability, enabling Class 1 Master Station to control

input/output data updating on the 2D-TZ577 Card by commands it transmits (SYNC, UNSYNC, FREEZE,

and UNFREEZE). For instructions on using the global control capability, see instruction manual which is

supplied with Class 1 Master Station being installed.

Features of 2D-TZ577 Card 3- 6

Page 17

3 Features and Specification of 2D-TZ577 Card

Item

Specification

Remark

Type name

TZ577

PROFIBUS specification complied

with

EN50170 Volume2(Part1,2,3,4,8)

PROFIBUS DP version supported

DP-V0 only

DP-V1 and DP-V2 not supported

Transmission rate

9.6k/19.2k/45.45k/93.75k/187.5k/5

00k/1.5M/3M/6M/12Mbaud

Set by parameters specified on

Master Station

Station number

0 to 125

Set by parameters specified on

Robot (default setting: 126*1)

Maximum communicatable number

192 words as the combined number

or output data)

Option slot that accepts an

Slot 1/Slop 2/Slot 3

Only one slot is used at any one

and 2 only.)

Number of cards installed

One

Installation of more than one card is

not permitted.

Concurrent use of 2D-TZ577 Card

and other fieldbus option card*2

Not permitted

Robot controller input/output

2000 to 3951

For details about signal alignment,

PROFIBUS Signals."

Terminator resistor

Uninstalled

If the 2D-TZ577 Card is used as a

Be Furnished by User."

Input/output signal access

2D-TZ577 Card send/receive data

signals like parallel I/O signals are.

3.3 Specification of 2D-TZ577 Card

The following table shows the specification of the 2D-TZ577 Card.

3.3.1 General Specification

Table 3-1 General Specification (2D-TZ577 Card)

of pieces of data

interface card

number

of pieces of input/output data (122

words as the total of pieces of input

is assigned to input/output signal

No. 2000 and up. In a

MELFA-BASIC V network, these

signals are treated as input/output

time

(CR1D is provided with Slot 1

only.)

(CR750-D, CR751-D, and

CR800-D are provided with Slot 1

see " Table 3-6 A Listing of

terminal station, terminator resistor

on a dedicated connector should be

enabled. For information about the

connector, see "

Table 4-2 Items To

(*1) Station number 126 causes the interface to be isolated from the PROFIBUS network.

Specify station numbers in the range of 0 to 125 for the purpose of input/output date communications.

(*2) CC-Link Interface Card and Device Net Interface Card (both under development).

Specification of 2D-TZ577 Card 3- 7

Page 18

3 Features and Specification of 2D-TZ577 Card

Item

Specification

Transmission specification

Electrical standard and characteristic

Compliant with EIA-RS485

Medium

Shielded twisted-pair cable (Type A)*1

Network configuration

Bus type (tree type when repeater(s) is (are) used)

Communication method

Polling

Transmission encoding method

NRZ

Maximum transmission range

used [m/network]

9.6kbps

19.2kbps

45.45kbps

93.75kbps

187.5kbps

1000

4000

500kbps

400

1600

1.5Mbps

200

800

3Mbps

6Mbps

12Mbps

Maximum number of intervening repeaters

3*2

Maximum number of units connected

(per segment)

Number of nodes connected/segment

32

3.3.2 Transmission Specification

Table 3-2 Transmission Specification

Transmission rate

Transmission range

[m/segment]

1200 4800

Transmission rate/maximum transmission

*2

range

32 (including repeater(s))

(*1) Specified in EN 50170 standard

(*2) Maximum transmission distance achievable by the use of repeaters:

Maximum transmission distance [m/network] = (number of repeaters + 1) x transmission distance

[m/segment]

3.3.3 Network Configuration

with three repeaters being

100 400

When creating a PROFIBUS DP network, note that the network comes in under the following design limits:

(1) Number of units that can be connected to the entire network (when repeaters are used)

Master + Slave ≤ 126

(2) Number of units which can be connected to a segment

Master + Slave + repeater

*1

≤ 32

(3) Maximum number of intervening repeaters

Up to 3 repeaters are allowed to intervene in the communication path between Master Station and

2D-TZ577 Card

(4) It is necessary to enable terminator resistors on a dedicated connector installed at the terminal station of

each segment.

(5) Maximum number of Slave Stations which can be connected to a Master Station depends on the

specification of the Master Station.

(*1) Repeater is counted in the number of units at each of the segments.

Specification of 2D-TZ577 Card 3- 8

Page 19

Segment

Mater Station

Repeater

…………….

…………….

Slave Station

No. 1

Slave Station

No. 2

Slave Station

No. 030

Slave Station

No. 031

Slave Station

No. 032

Slave Station

No. 060

Figure 3-2 An Example of Basic PROFIBUS DP Network Configuration

Name

Version

Robot Controller

P6k or later

Personal computer support

RT Tool Box 2: Ver.1.0.1 or later

Robot Controller.

3.3.4 Accommodated Versions

3 Features and Specification of 2D-TZ577 Card

software

Table 3-3 Accommodated Versions

* Ver. 1.3 or later is provided with a dialog box which can be used for making

PROFIBUS-related settings.

Even versions preceding 1.3 offer parameter a parameter setting screen that

permits you to make PROFIBUS-related settings.

For more information, see Section7.3

Parameter Settings on the Side of

Specification of 2D-TZ577 Card 3- 9

Page 20

3 Features and Specification of 2D-TZ577 Card

Parameter

name

STOP2

-1, -1

-1 /2000 to 3951

A parameter that specifies a dedicated input signal number to

uses "STOP2" to define an external stop signal.)

ORST2000

ORST3920

00000000,

00000000

0/1/*

A parameter that specifies value of output send data on the

Using PROFIBUS DP-V0 Slave Interface.)

PBMODE

0

0/2

A parameter that switches the operating mode of the 2D-TZ577

normal operation.

PBMC

1

1/2

A parameter that designates Master Station as Class 1 or Class

being used)

PBNUM

126

-1 to 125

A parameter that specifies station number for the 2D-TZ577

= -1."

E8500

0

0/1

A parameter that is used to temporarily reset an error state

power supply resetting is done.

3.4 Robot Parameters

Table 3-4 A Listing of Robot Parameters Used with PROFIBUS

Initial value Setting range Description

stop robot programs.

(Because the parameter "STOP" is fixed at "0", 2D-TZ577 Card

ORST2032

:

00000000,

00000000,

2D-TZ577 Card at the time of signal output reset.

(For details about related settings, see Section 3.8 Before

Card between "normal" and "self-diagnosis."

Normal mode = 0, self-diagnosis mode = 2

· When the self-diagnosis identifies an anomaly, an error

message is displayed.

("H.8504: PROFIBUS self-diagnosis shows occurrence of

an error.")

Return the operating mode to normal to continue with

·

2.

Class 1 Master Station is designated at factory default. To use

"Class 2," choose another parameter setting.

1: Class 1 Master (effected when the station number setting

parameter PBNUM shown below is used)

2: Class 2 Master (effected when changes of station numbers

are made from Class 2 Master Station - with PBNUM not

Card.

0 to 125: Station number setting value (Rewriting of station

number settings takes place within the flash ROM as well.)

-1: Station number clear (Station number settings within the

flash ROM are cleared.)

* After the station numbers are cleared, the value 126 is taken

on.

* If "No_Add_Chg" is specified with "true" when making

station number settings from Class 2 Master Station,

2D-TZ577 Card is disabled for change of station numbers.

To cancel this setting, clear station numbers with "PBNUM

when PROFIBUS-related error (indicated by a number in the

8500s) occurred.

(1: Resettable (But no communications are to be carried out.) /

0: Always error during the occurrence of an anomaly in the link)

* This parameter does not require power supply resetting

on the Robot Controller. The initial value of 0 will return if

Robot Parameters 3- 10

Page 21

3 Features and Specification of 2D-TZ577 Card

Parameter

name

PBCNT

40

0 to 65535

A parameter that specifies an interval at which the 2D-TZ577

TZ577 Card error being detected by the

Controller.

Initial value Setting range Description

Card is checked for error.

Unit interval: msec

In normal condition, use the 2D-TZ577 Card at its factory

default (40).

User may change the setting only when communication errors

are frequently encountered under the undue influence from

noise in his installation environment. Normally, a setting in the

range of 40 to 70msec will do. Increase the setting with great

care as this may result in the inability to generate an error

indication even when one occurs in the 2D-TZ577 Card.

With a value greater than "1" being specified (rounding-up

checked), the Controller generates an error indication only

when it has detected a 2D-TZ577 Card error continuously

during a specified period of time. The Controller does not

generate an error indication unless it has had continuous error

detection.

With "0" being specified, an error indication is generated

immediately upon a 2D-

Robot Parameters 3- 11

Page 22

3 Features and Specification of 2D-TZ577 Card

Input (received from Master Station)

Output (sent to Master Station)

Number

2000 to 3951

2000 to 3951

Number of

words

Usable number

of points

Number of

words

Usable number

of points

Number of

words

Usable number

of points

0 0 - to -

41

656

2000to2655

82

1312

2000to3311

1

16

2000to2015

42

672

2000to2671

83

1328

2000to3327

2

32

2000to2031

43

688

2000to2687

84

1344

2000to3343

3

48

2000to2047

44

704

2000to2703

85

1360

2000to3359

4

64

2000to2063

45

720

2000to2719

86

1376

2000to3375

5

80

2000to2079

46

736

2000to2735

87

1392

2000to3391

6

96

2000to2095

47

752

2000to2751

88

1408

2000to3407

7

112

2000to2111

48

768

2000to2767

89

1424

2000to3423

8

128

2000to2127

49

784

2000to2783

90

1440

2000to3439

9

144

2000to2143

50

800

2000to2799

91

1456

2000to3455

10

160

2000to2159

51

816

2000to2815

92

1472

2000to3471

11

176

2000to2175

52

832

2000to2831

93

1488

2000to3487

12

192

2000to2191

53

848

2000to2847

94

1504

2000to3503

13

208

2000to2207

54

864

2000to2863

95

1520

2000to3519

14

224

2000to2223

55

880

2000to2879

96

1536

2000to3535

15

240

2000to2239

56

896

2000to2895

97

1552

2000to3551

16

256

2000to2255

57

912

2000to2911

98

1568

2000to3567

17

272

2000to2271

58

928

2000to2927

99

1584

2000to3583

18

288

2000to2287

59

944

2000to2943

100

1600

2000to3599

19

304

2000to2303

60

960

2000to2959

101

1616

2000to3615

20

320

2000to2319

61

976

2000to2975

102

1632

2000to3631

21

336

2000to2335

62

992

2000to2991

103

1648

2000to3647

22

352

2000to2351

63

1008

2000to3007

104

1664

2000to3663

23

368

2000to2367

64

1024

2000to3023

105

1680

2000to3679

24

384

2000to2383

65

1040

2000to3039

106

1696

2000to3695

25

400

2000to2399

66

1056

2000to3055

107

1712

2000to3711

26

416

2000to2415

67

1072

2000to3071

108

1728

2000to3727

27

432

2000to2431

68

1088

2000to3087

109

1744

2000to3743

28

448

2000to2447

69

1104

2000to3103

110

1760

2000to3759

29

464

2000to2463

70

1120

2000to3119

111

1776

2000to3775

30

480

2000to2479

71

1136

2000to3135

112

1792

2000to3791

31

496

2000to2495

72

1152

2000to3151

113

1808

2000to3807

32

512

2000to2511

73

1168

2000to3167

114

1824

2000to3823

33

528

2000to2527

74

1184

2000to3183

115

1840

2000to3839

34

544

2000to2543

75

1200

2000to3199

116

1856

2000to3855

35

560

2000to2559

76

1216

2000to3215

117

1872

2000to3871

36

576

2000to2575

77

1232

2000to3231

118

1888

2000to3887

37

592

2000to2591

78

1248

2000to3247

119

1904

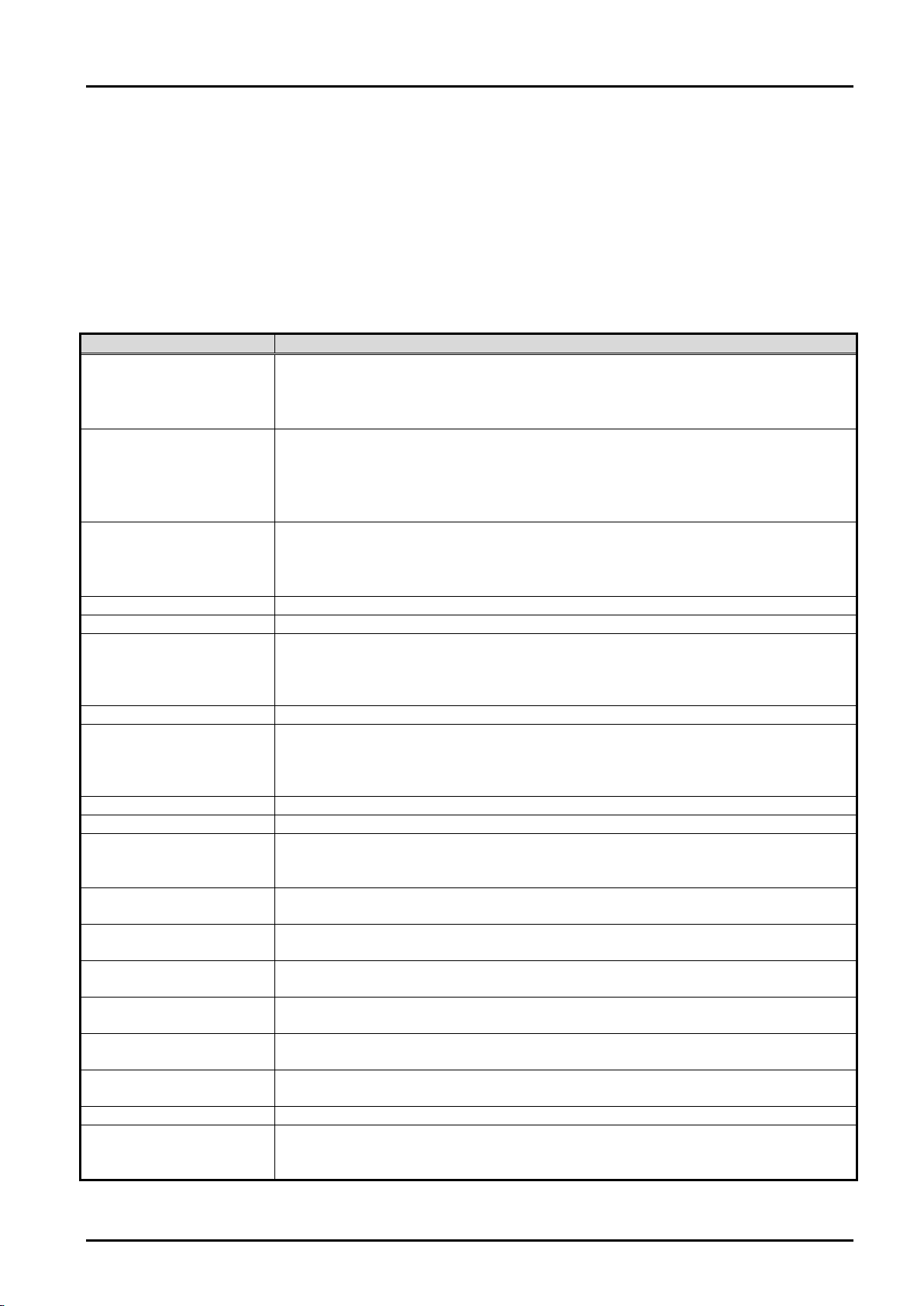

2000to3903

38

608

2000to2607

79

1264

2000to3263

120

1920

2000to3919

39

624

2000to2623

80

1280

2000to3279

121

1936

2000to3935

40

640

2000to2639

81

1296

2000to3295

122

1952

2000to3951

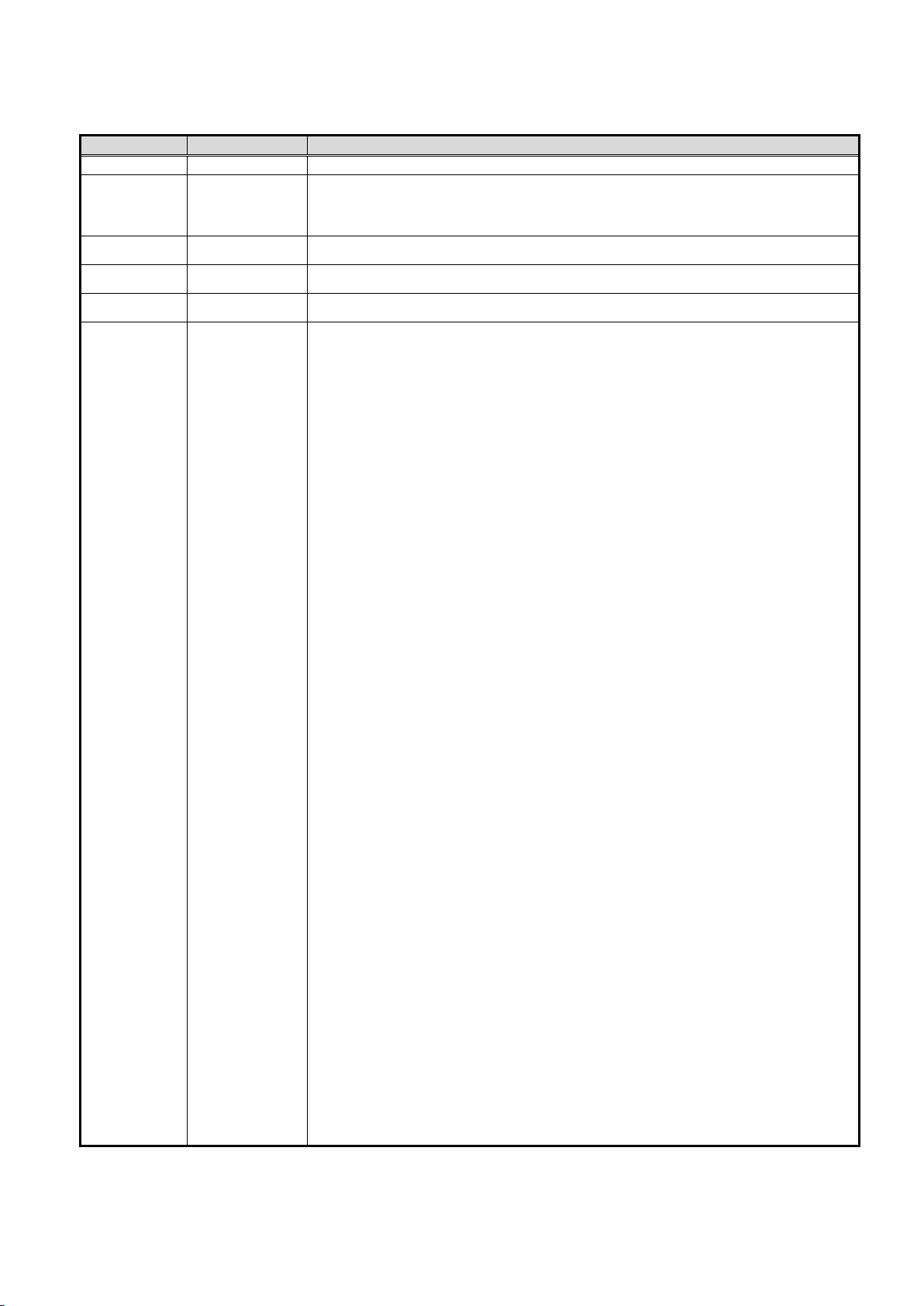

3.5 Robot Controller Input/Output Signals

Input/output signals processed in the Robot Controller are in the range of 2000 to 3951 maximum (equivalent to

192 words), respectively, irrespective of station numbers.

Table 3-5 PROFIBUS Input/Output Signal Numbers

The data sizes of input/output signal are specified by parameter settings on the side of the Master Station. The

combined number of pieces of input/output data is 192 words maximum while the respective number of pieces

of input/output data is 122 words maximum.

Examples: (Input - 122 words) + (output - 70 words) = 192 words in total

(Input - 96 words) + (output - 96 words) = 192 words in total

(Input - 10 words) + (output - 10 words) = 20 words in total

Table 3-6 A Listing of PROFIBUS Signals

Start End

Start End

Start End

Robot Controller Input/Output Signals 3- 12

Page 23

3 Features and Specification of 2D-TZ577 Card

Item

Type

Function

Read/write

M_In

Integer 1

Reads one bit of data from specified input signal.

Read

M_Out

Integer 1

Writes one bit of data into specified output signal.

Write

M_Inb

Integer 1

Reads 8 bits of data from specified input signal.

Read

M_Outb

Integer 1

Writes 8 bits of data into specified output signal.

Write

M_Inw

Integer 1

Read 16 bits of data from specified input signal.

Read

M_Outw

Integer 1

Write 16 bits of data into specified output signal.

Write

3.6 About Dedicated Input/Output

Signal numbers are assigned to 2D-TZ577 Cards. Assignment of these numbers to dedicated input/output

parameters permits them to be used as dedicated input/output. For more information about the dedicated

input/output, see Section 6 "Functions of External Input/Output" of the "Instruction Manual - Detailed Description

of Functions and Operation" which is separately issued.

3.7 Specification Relative to Robot Language

The follow subsection explains robot language (MELFA-BASIC V) which pertains to the 2D-TZ577 Card.

3.7.1 Robot System State Variables Relative to 2D-TZ577 Card

Table 3-7 A Listing of System State Variables Used for Data Input/Output

To avoid "Data separation" a read/write interlock as shown below need be provided in the application concerned

(robot program or PLC ladder).

An example of interlock being used where one-word data is sent from the Master Station to the robot is

illustrated in the form of a flowchart below.

About Dedicated Input/Output 3- 13

Page 24

3 Features and Specification of 2D-TZ577 Card

Meaning

Master Station*1

Robot

Data send/receive region

Data send region

Input: 2000 to 2015

PLC data write completed flag

WRTFLG

Input No. 2016

Robot data write completed flag

RDFLG

Output No. 2020

Start

End

Write one-word data

(data transmitted)

Write W RTFLG = 1

Input No. 2016 = 1?

Read Input Nos. 2000 to

2015 (data received)

Write Output No. 2020 = 1

RDFLG = 1?

Start

End

Master Robot

YES

NO

NO

YES

Write W RTFLG = 0

Input No. 2016 = 0?

Write Output No. 2020 = 0RDFLG = 0?

NO

YES

YES

NO

Table 3-8 An Example of Input/Output Signal Alignment between Master Station and Robot

(*1) For the purpose of explanation, a name is given to the Master Station input/output signal alignment.

Actually, you can make any input/output signal alignment in accordance with a Master Station instruction

manual that governs.

Figure 3-3 An Example of Use of Interlock

Below is an example of robot program which corresponds to the flowchart shown in Fig. 3-3. For information

about the Master Station-side program (ladder, etc.), refer to the instruction manual for the equipment being

used.

*Loop1: If M_In(2016) = 0 Then *Loop1

Mdata = M_InW(2000)

M_Out(2020) = 1

*Loop2: If M_In(2016) = 1 Then *Loop2

M_Out(2016) = 0

Specification Relative to Robot Language 3- 14

Page 25

3 Features and Specification of 2D-TZ577 Card

Variable name

Type

Designation

Function

Read/write

M_PBNUM

Integer 1

Number of station in

action

Number of station which is currently in action

Read

M_PBFNUM

Integer 1

Station number

ROM

Number of station which is stored in flash ROM

Read

M_PBSYNM

Integer 1

SYNC mode signal

(a) Takes on the value "1" when 2D-TZ577

Card goes into SYNC mode in response to

occur (output data is retained).

Read

M_PBFRZM

Integer 1

FREEZE mode

(a) Takes on the value "1" when 2D-TZ577

Card goes into FREEZE mode in response

occur (output data is retained).

Read

Table 3-9 A Listing of System State Variables Used to Verify Configuration

settings in flash

SYNC request from Master Station.

(b) Takes on the value "0" when SYNC mode

terminates due to UNSYNC request from

Master Station/stopping of

communications/reset.

(c) Takes on the value "0" when

communications with Master Station are

stopped with "1" being an existing value

and communication timeout error occurs.

However, if communication WDT setting in

Master Station-side parameter is disabled,

the value "0" is not taken on because

communication timeout error does not

signal

to FREEZE request from Master Station.

(b) Takes on the value "0" when FREEZE

mode terminates due to UNFREEZE

request from Master Station/stopping of

communications/reset.

(d) Takes on the value "0" when

communications with Master Station are

stopped with "1" being an existing value

and communication timeout error occurs.

However, if communication WDT setting in

Master Station-side parameter is disabled,

the value "0" is not taken on because

communication timeout error does not

For information about MELF-BASIC V commands and state variables other than those listed above, refer to the

"Instruction Manual - Detailed Description of Functions and Operation" which is separately issued.

Specification Relative to Robot Language 3- 15

Page 26

3 Features and Specification of 2D-TZ577 Card

Parameter

name

Leading

number

Last

number

Parameter

name

Leading

number

Last

number

ORST2000

2000

2031

ORST3024

3024

3055

ORST2032

2032

2063

ORST3056

3056

3087

ORST2064

2064

2095

ORST3088

3088

3119

ORST2096

2096

2127

ORST3120

3120

3151

ORST2128

2128

2159

ORST3152

3152

3183

ORST2160

2160

2191

ORST3184

3184

3215

ORST2192

2192

2223

ORST3216

3216

3247

ORST2224

2224

2255

ORST3248

3248

3279

ORST2256

2256

2287

ORST3280

3280

3311

ORST2288

2288

2319

ORST3312

3312

3343

ORST2320

2320

2351

ORST3344

3344

3375

ORST2352

2352

2383

ORST3376

3376

3407

ORST2384

2384

2415

ORST3408

3408

3439

ORST2416

2416

2447

ORST3440

3440

3471

ORST2448

2448

2479

ORST3472

3472

3503

ORST2480

2480

2511

ORST3504

3504

3535

ORST2512

2512

2543

ORST3536

3536

3567

ORST2544

2544

2575

ORST3568

3568

3599

ORST2576

2576

2607

ORST3600

3600

3631

ORST2608

2608

2639

ORST3632

3632

3663

ORST2640

2640

2671

ORST3664

3664

3695

ORST2672

2672

2703

ORST3696

3696

3727

ORST2704

2704

2735

ORST3728

3728

3759

ORST2736

2736

2767

ORST3760

3760

3791

ORST2768

2768

2799

ORST3792

3792

3823

ORST2800

2800

2831

ORST3824

3824

3855

ORST2832

2832

2863

ORST3856

3856

3887

ORST2864

2864

2895

ORST3888

3888

3919

ORST2896

2896

2927

ORST3920

3920

3951

ORST2928

2928

2959

ORST3024

3024

3055

ORST2960

2960

2991

ORST3056

3056

3087

ORST2992

2992

3023

ORST3088

3088

3119

3.8 About Output Signal Reset Patterns

Factory default settings are such that startup takes place with all general-purpose output signals being off (0).

You can change the state of general-purpose output signals at power-on by re-specifying the parameters listed

in the table below. Note that these parameters are intended to serve the following purpose as well: performing

general-purpose output signal reset operation (which is carried out with dedicated input signals) and selection of

reset pattern during the execution of Clr command.

Parameter setting options include "off," "on," and "hold." The following table lists parameters which are used on

the 2D-TZ577 Card for general-purpose output resetting.

Table 3-10 A Listing of Output Signal Reset Pattern Parameters

Parameter ORST○○○○ has the default values of "0000000, 00000000, 00000000, and 00000000", and can be

set to specify "off," "on," and "hold" (= "0," "off," and "1") for 32 points. Leading number is assigned from the left

side.

For example, if ORST2000 is set to "*0000001, 00000000, 11110000, and 00000000," the following will result

when power to the Robot Controller is turned back on:

About Output Signal Reset Patterns 3- 16

Output No. 2000: Holds a state in which it was before power to the robot controller has been turned on

Output No. 2007: On

Output Nos. 2016 to 2019: On

Page 27

3 Features and Specification of 2D-TZ577 Card

RUN

ERR

(green)

(red)

LED name

Color

Indications

On: Normal

Off: Watchdog timer error occurred.

On: Parameter setting error or unit error occurred.

Off: Normal

PROFIBUS

cable connector

3.9 Hardware of 2D-TZ577 Card

The following subsections explain the hardware of the 2D-TZ577 Card.

3.9.1 Overall View

Figure 3-4 Overall View of 2D-TZ577 Card

LED

3.9.2 LED

There are two LEDs provided on the 2D-TZ577 Card, each of which indicates the state of the Card by going on

or off.

RUN Green

ERR Red

Figure 3-5 Location of LEDs

Table 3-11 A Listing of LEDs

Hardware of 2D-TZ577 Card 3- 17

Page 28

4 Out of the Package

No.

Item name

Type name

Quantity

[1]

Instruction manual (CD-ROM)

BFP-A8745

1

[2]

PROFIBUS DP-V0 Slave Interface Card

TZ577 1 [3]

Ferrite core

E04SR301334

2

[4]

GSD file (Included on the CD-ROM)

MLFA0BE4.gsd

1

[5]

Icon file for setting software (Included on

the CD-ROM)

2DTZ577ICON.bmp

1

[6]

Cable clamp

AL4 1 [7]

Cable clamp

AL6

1

Item

Requirement

Remark

Master Station*1

Master Station which is compatible with PFOFIBUS DP

Communication

Cable specifically designed for use with PROFIBUS DP

Configuration.

Mitsubishi Electric disclaims all

described here are used.

[2]

[3]

[1] [4] [5]

[6] [7]

4. Out of the Package

4.1 Checking Component Parts

The 2D-TZ577 Card comes standard with the component parts listed in the table below. Check your 2D-TZ577

Card to ensure that it is complete with these parts.

Table 4-1 2D-TZ577 Component Parts

Note: Numbers in the table corresponds to those in the figure below.

Figure 4-1 2D-TZ577 Component Parts (Illustrated)

4.2 Items To Be Furnished by User

The following table shows the items that the user is requested to have ready before using the 2D-TZ577 Card.

Table 4-2 Items To Be Furnished by User

cable*1

Checking Component Parts 4- 18

* There are limits to maximum total cable length and

inter-segment cable length. For details, see

3-2 An Example of Basic PROFIBUS DP Network

Figure

guarantees of PROFIBUS

system performance if any cable

or connector other than those

Page 29

Connector*1

Connector specifically designed for use with PROFIBUS,

having built-in terminator resistors. Recommended type

with the cable run including interference with other

cables or the rear cover (CR2D)

name: 6GK1 500-0FC00 *Siemens.

* Use a connector of straight type (180°cable outlet).

When using a connector of right-angle type (90°

cable outlet), note that it may give rise to problems

(*1) For more details, contact the International PROFIBUS Organization.

4 Out of the Package

Association website at http://www.profibus.com/

Items To Be Furnished by User 4- 19

Page 30

5 Hardware Setup

5. Hardware Setup

5.1 Hardware Setup for 2D-TZ577 Card

Hardware setup need not be done in regard to the 2D-TZ577 Card.

Entire setup activity is performed by using parameter settings on the side of the Master Station and the Robot

Controller.

For details, see Section 7.2 Parameter Settings on the Side of Master Station and Section 7.3 Parameter

Settings on the Side of Robot Controller.

Hardware Setup for 2D-TZ577 Card 5- 20

Page 31

6 Connection and Wiring

Slot 1

Connector

Interface card

Handle

Disconnecting lever

6. Connection and Wiring

6.1 Installing A 2D-TZ577 Card into Robot Controller

*

Note that only one 2D-TZ577 Card should be installed into an option slot

time. If more than one card are installed into the slots, Error H.8502 "More than one PROFIBUS Card is

installed" will be indicated.

(*1) Number of the option slots varies with the Controller being used.

CR1D: Provided only with Option Slot 1

CR2/3D: Provided with Option Slots 1 thru 3

CR750-D/CR751-D: Provided with Option Slots 1 thru 2

CR800-D: Provided with Option Slots 1 thru 2

6.1.1 CR1D Robot Controller

Remove the option slot interface cover on the rear of the Controller and install a 2D-TZ577 Card into the slot.

1

of the Robot Controller at any one

During installation, use the handle fitted to the Card.

Figure 6-1 Installing A 2D-TZ577 Card (in the case of CR1D Controller)

Installing A 2D-TZ577 Card into Robot Controller 6- 21

Page 32

6 Connection and Wiring

Cover-removing lever

Interface cover

Connector

Interface card

Handle

Disconnecting lever

6.1.2 CR2D Robot Controller

Remove any one of the interface covers provided for option slots 1 thru 3 on the rear of the Controller and install

a 2D-TZ577 Card into the slot.

During installation, use the handle fitted to the Card.

Figure 6-2 Installing A 2D-TZ577 Card (in the case of CR2D Controller)

Installing A 2D-TZ577 Card into Robot Controller 6- 22

Page 33

6 Connection and Wiring

6.1.3 CR3D Robot Controller

Open the door of the Robot Controller and you will see R700 CPU unit installed at the right-hand end. Remove

any one of the option slot interface covers provided for option slot 1 thru 3 on the CPU unit and install a

2D-TZ577 Card into the slot.

During installation, use the handle fitted to the Card.

Figure 6-3 Installing A 2D-TZ577 Card (in the case of CR3D Controller)

Installing A 2D-TZ577 Card into Robot Controller 6- 23

Page 34

6 Connection and Wiring

SLOT1

SL

OT2

<CR750 controller (Rear side)>

<CR751 controller (Front side)>

Connector

Handle

Disconnecting lever (Other side)

Interface

cover-removing

lever

Interface cover

Interface card

6.1.4 CR750-D/CR751-D Robot Controller

Remove one interface cover of the option slots 1-2 in the robot controller front or rear, and mount the 2D-TZ577

card there. Please use the handle of the interface card at mounting of the interface card.

Figure 6-4 Installing A 2D-TZ577 Card (in the case of CR750-D/CR751-D Controller)

Installing A 2D-TZ577 Card into Robot Controller 6- 24

Page 35

6 Connection and Wiring

Connector

Handle

Disconnecting lever (Other side)

SLOT1

Interface

cover-removing

lever

SLOT2

Interface cover

Interface card

<CR800 controller (Front side)>

6.1.5 CR800-D Robot Controller

Remove one interface cover of the option slots 1-2 in the robot controller front, and mount the 2D-TZ577 card

there. Please use the handle of the interface card at mounting of the interface card.

Figure 6-5 Installing A 2D-TZ577 Card (in the case of CR800-D Controller)

Installing A 2D-TZ577 Card into Robot Controller 6- 25

Page 36

6 Connection and Wiring

Pin No.

Name

Service

1

Not assigned

-

2

Not assigned

-

3

RxD/TxD-P

Received/transmitted data-P

4

Not assigned

-

5

DGND

(*1)

Data ground earth (0V)

6

VP

(*1)

Voltage + (+5V)

7

Not assigned

-

8

RxD/TxD-N

Received/transmitted data-N

9

Not assigned

-

RxD /TxD-P(3)

DGND(5)

VP(6)

RxD /TxD-

N(8)

Protective

ground earth

Shield

Protective

ground earth

RxD /TxD-P(3)

DGND(5)

VP(6)

RxD /TxD-N(8)

Station 2

Station 1

VP(6)

DGND(5)

RxD /TxD-P(3)

RxD /TxD-N(8)

390Ω

220Ω

390Ω

Data line

Data line

6.2 Connector Pin Configuration (D-SUB9 Pin)

Table 6-1 Connector Pin Configuration

(*1) Signal used when terminator resistors are connected.

6.3 Wiring

The terminal station of each segment on a communication line need be provided with terminator resistors. Use a

connector specifically designed for use with PROFIBUS which has built-in terminator resistors. Note: Terminator

resistors are arranged so as to apply: 220Ω between (+) and (-)、390Ω between 5V and (+), and 390Ω between

0V and (-).

Figure 6-6 Cable Routing

Connector Pin Configuration (D-SUB9 Pin) 6- 26

Figure 6-7 Bus Terminator Resistors

Page 37

6 Connection and Wiring

PROFIBUS cable

Ferrite core

Position where the cable is clamped

Rear Cover

30cm or less

30cm or less

Ferrite core

(attachment)*2

Position where the cable is

clamped for grounding purpose

(earth clamp available as an

attachment to the casing)*1

Rear Cover

PROFIBUS cable

(to be furnish by the

user)

6.4 About Noise Control

To avoid an adverse impact from noise, strip off some sheath of the PROFIBUS cable, and attach the cable's

metal blade portion to the controller casing with an earth clamp and install the accompanying ferrite core within

30cm of where the cable is clamped onto the casing.

Connection method is shown below by controller type.

6.4.1 CR1D Controller

for grounding purpose

(earth clamp available as an

attachment to the casing)*1

(to be furnish by the user)

(attachment)*2

Figure 6-8 Installing PROFIBUS Cable (CR1D Controller)

6.4.2 CR2D Controller

Figure 6-9 Installing PROFIBUS Cable (CR2D Controller)

About Noise Control 6- 27

Page 38

6 Connection and Wiring

30cm or less

Ferrite core

R700 CPU unit

PROFIBUS cable

(to be furnish by the user)

Position where the cable is clamped for

grounding purpose

(earth clamp available as an attachment to

the casing)

keep metal blade portion in contact

Sheath

Sheath

20 to 30mm

Metal blade

portion

AL4: D = 6.4mm (1/4 in.)

AL6: D = 9.5mm (3/8 in.)

6.4.3 CR3D Controller

(attachment)*2

*1

Figure 6-10 Installing PROFIBUS Cable (CR3D Controller)

(*1) Position where the cable is clamped

for grounding purpose

Strip off some sheath of the cable and

with the controller casing.

(*2) When Siemens PROFIBUS FC standard cable (8.0mm O.D.) is used, recommended metal clamps are:

AL4 or AL6 *RICHCO INC

About Noise Control 6- 28

Page 39

6 Connection and Wiring

No.

Item confirmed

Check

1

Is the 2D-TZ577 Card securely installed into the Controller's slot?

Is the RPOFIBUS Cable linking the 2D-TZ577 Card to the user's

external equipment properly connected?

Is the special-purpose connector installed at each end of the

specified?

4

Is the ferrite core is installed in place?

6.5 Checking Connections

Before placing the 2D-TZ577 Card in service, go through the following checklist to avoid oversights.

Table 6-2 Checklist for Proper Connections

2

3

PROFIBUS network configured to apply terminal resistance as

Checking Connections 6- 29

Page 40

7 Procedure before Startup

Run self-diagnosis and c heck to see if the PROFIBUS

Interface Card functions properly as an independent unit.

Establish parameters on the side of the Master Station.

Establish parameters on the side of the Robot Controller.

Link the Master Station to the PROFIBUS Interface with a

cable and enable the terminator resistors in the connector

which is connected to the unit at each end.

Check the Robot Controller to ensure that no PROFIBUS-

associated errors have occurred.

Create a robot program.

Start the sys tem.

Start

End

See Section 7.1

See Section 7.2

See Section 8.

Perform the following steps to turn power on:

[1] Turn on power to the Master Station and other slave s tations.

[2] Turn on power to the Robot Controller.

See Section 7.3

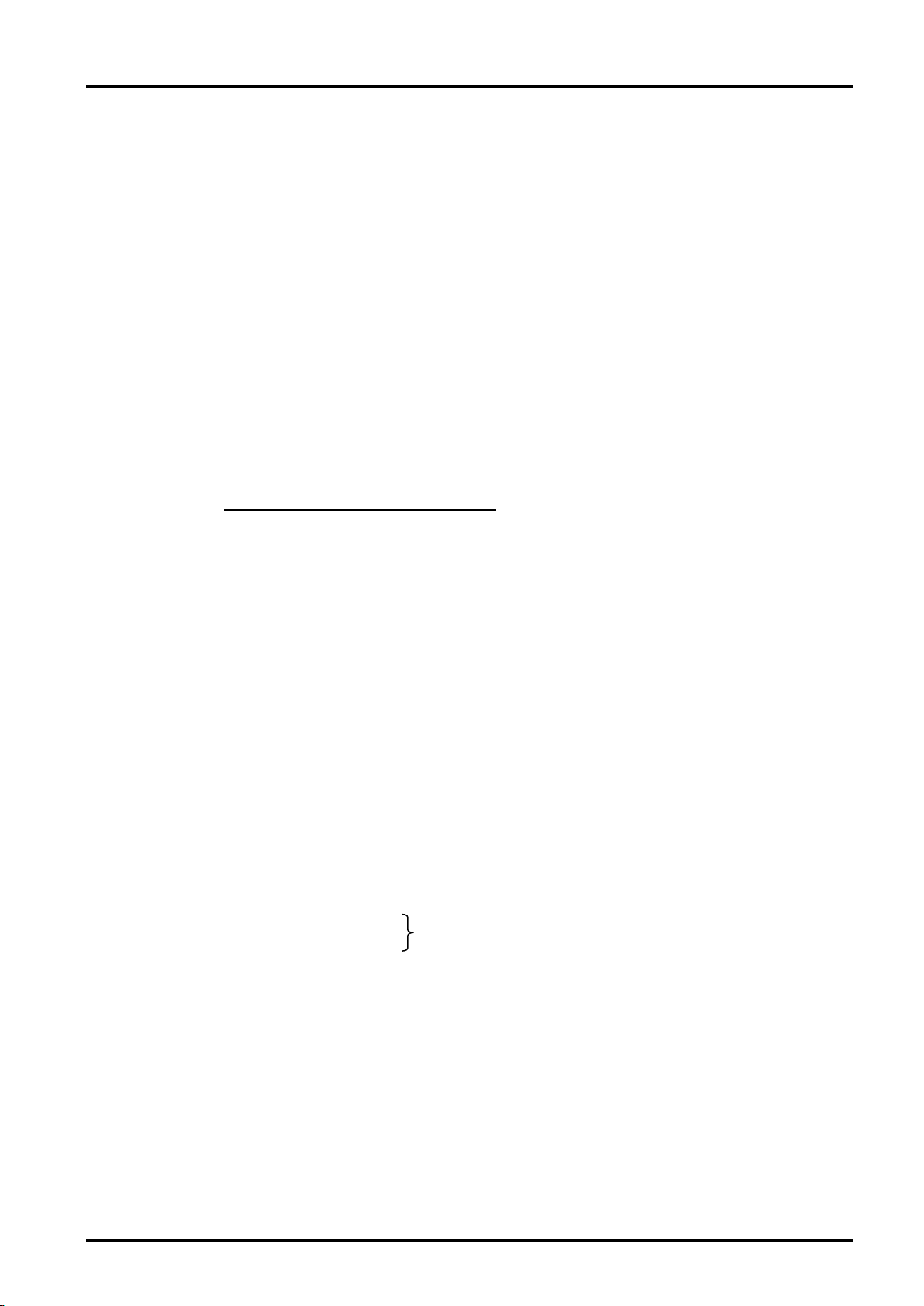

7. Procedure before Startup

The following diagram shows the procedure performed to place the 2D-TZ477 Card in operation.

Figure 7-1 Procedure Before Startup

Checking Connections 7- 30

Page 41

7 Procedure before Startup

Parameters established on the side of Master Station

Reference

Master parameters (parameters for Master Station itself)

-(*1)

Bus parameters (communication parameters for PROFIBUS-DP network)

-(*1)

Slave parameters

Station number (FDL Address)

Communication WDT (Watchdog)

Minimum response time (Min T_sdr)

Group number (group identification number)

Data module setting

Data alignment setting

Swap setting

7.1 Procedure for Running Self-diagnosis

The following subsections explain the procedure used to run self-diagnosis and states which are observed while

the self-diagnosis goes on.

(1) Procedure for running self-diagnosis

[1] Turn on power to the Robot Controller.

[2] Set robot parameter to self-diagnosis mode. (Set robot parameter as "PBMODE = 2." For details,

see “Table 3-4 A Listing of Robot Parameters Used with PROFIBUS”.)

[3] Turn off power to the Robot Controller and turn power back on.

[4] While self-diagnosis goes on, display on the operation panel of the Robot Controller flashes like

>777< ↔ blank.

[5] If the results of self-diagnosis are "normal" ····· The Robot Controller will start normally and the

2D-TZ577 Card will stand by for parameters

from the Master Station.

If the results of self-diagnosis are "abnormal" ·· H.8504 Error (error identified in PROFIBUS

self-diagnosis) will occur.

* Parameter need be set as "PBMODE = 0" if it is not desired to run self-diagnosis at the subsequent

startup.

(2) Corrective actions at the occurrence of error

If the results of self-diagnosis are "error," replace the 2D-TZ577 Card.

When replacing the card, contact its manufacturer for advice.

7.2 Parameter Settings on the Side of Master Station

7.2.1 Procedure for Establishing Parameters

Establish parameters listed below on the side of Master Station.

Table 7-1 Master-side Parameters

(for 2D-TZ577 Card)

(*1) For information about items of setting, see the instruction manual for the Master Station.

For method to specify parameter settings, refer to the instruction manual for the software that is used.

For details, see "Table 7-2 A Listing

of Slave Parameters."

Procedure for Running Self-diagnosis 7- 31

Page 42

7 Procedure before Startup

Setting

software

Master

Station

GSD file for

PROFIBUS

Interface Card

Write

Item

Setting range

Description

Remark

Station number

If connection is made to

"PBNUM" as well.

Communication

Watchdog timer is defined.

Communication WDT setting

(set value x 10msec).

Minimum response

(Min T_sdr)

A mini mum response time lapsed until

to the Master Station is defined.

Group number

Group to which a station belongs is

than one group (Grp 1 thru 8).

Data module settings

I/O configuration information (defined in

Number of settings: 1 - 40

Data alignment

Position of data in the output receive

change is permitted.

<Procedure for establishing 2D-TZ577 Card slave parameters to Master Station>

[1] Read GSD file stored in the CD-ROM supplied with the 2D-TZ577 Card into a setting software

which is compatible with the Master Station.

[2] Establish 2D-TZ577 Card slave parameters, using the setting software.

[3] Write the parameters into the Master Station.

For information about operating the setting software, refer to the instruction manual for the software that is used.

Figure 7-2 Conceptual illustration of GSD file being loaded

7.2.2 Slave Parameters

Parameters other than slave station numbers need be established as slave parameters for use in the Master