Page 1

Appendix

REVIEW ENGLISH

27.07.2010

A.4 Application example RFID tag system

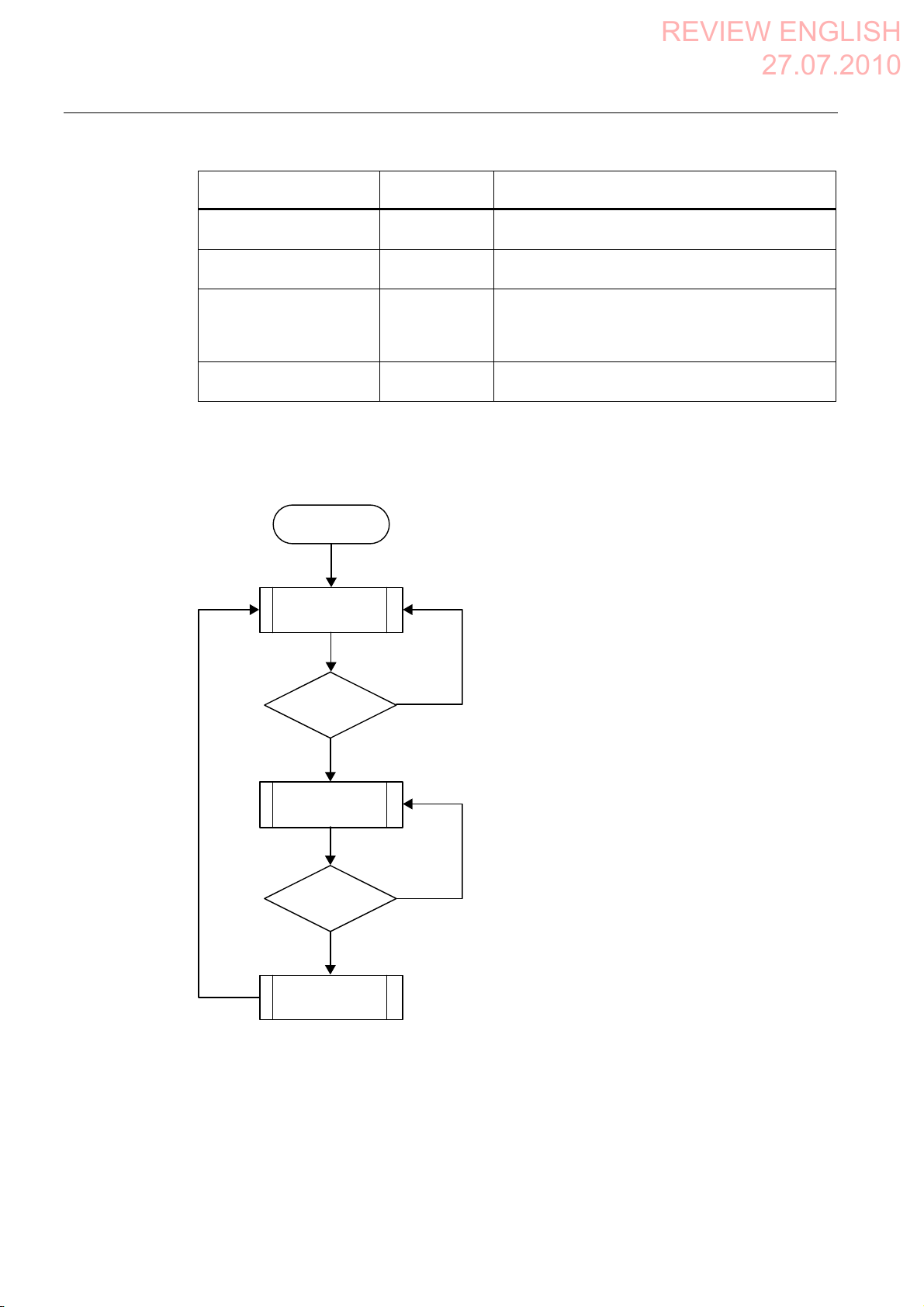

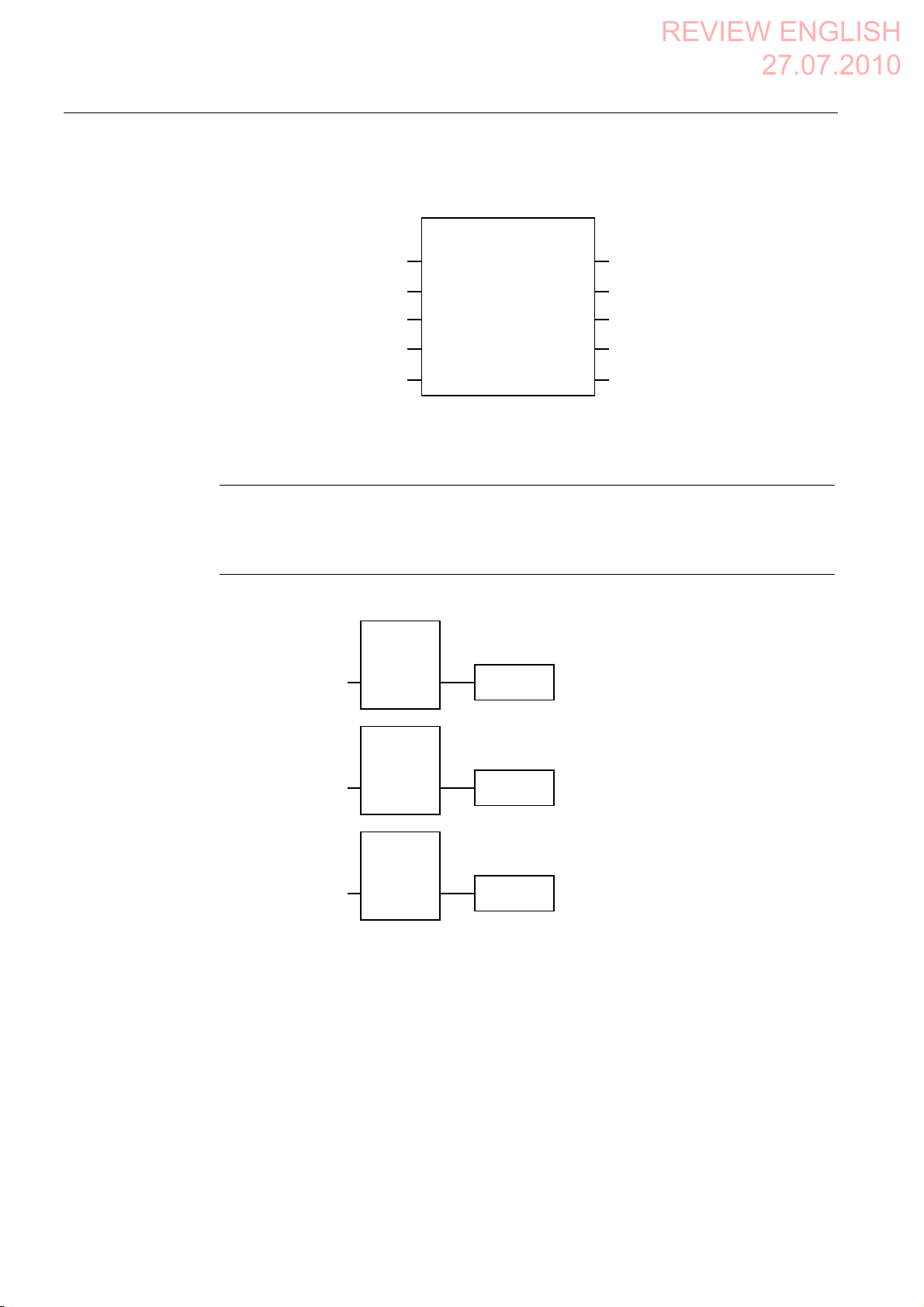

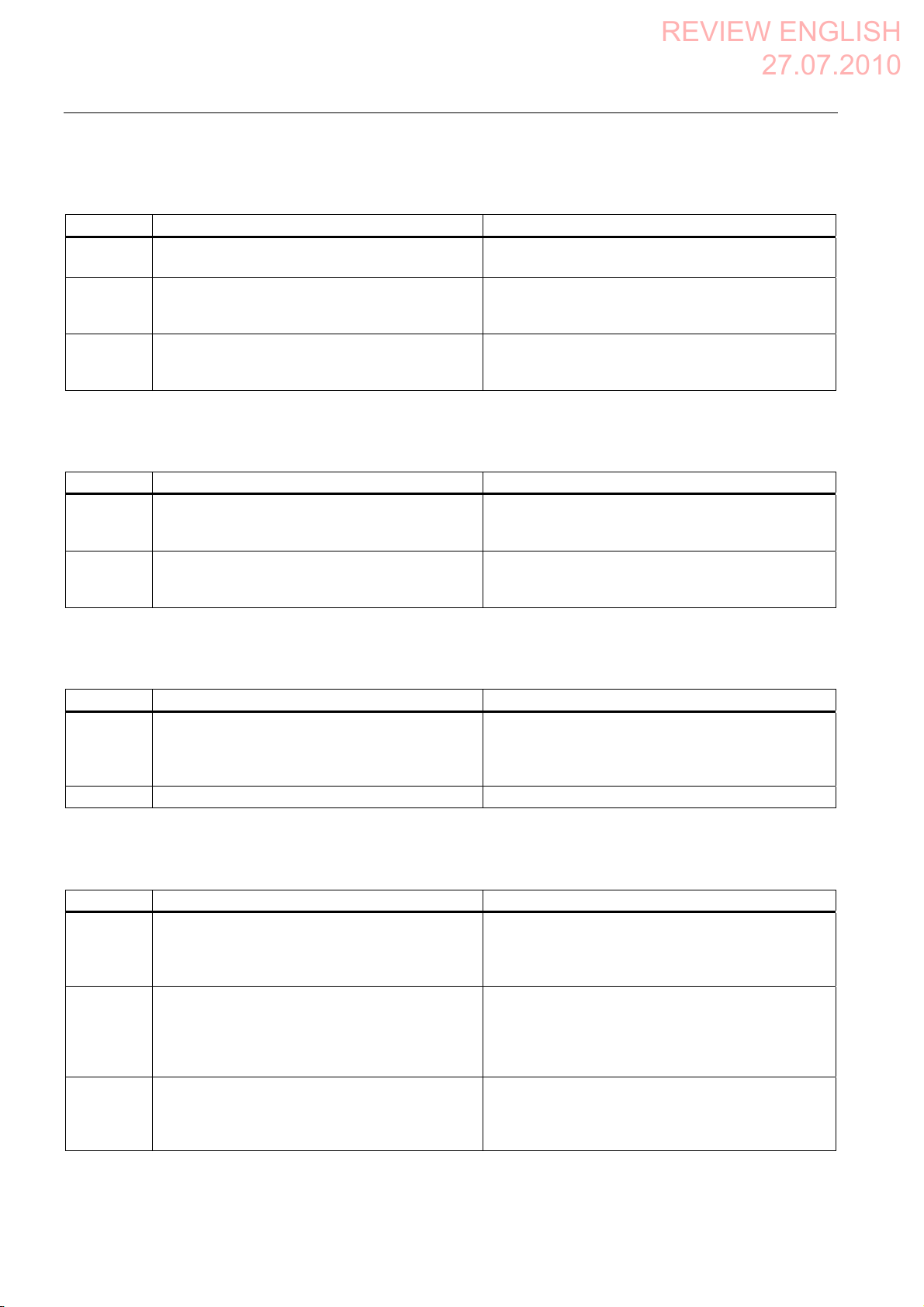

Flowchart

Function

Signal Explanation

Symbolic name

Enabling button ENABLE

(F_FB_RNG_4)

Power ON-OFF robot

O11.0 "0": EMERGENCY STOP triggered.

"E_Stop_Robot"

"0": No enable

"1": Enable

"1": Normal operation of plant.

Actuator to robot O11.1 "0": The robot is not operated with Key1 and the

enabling buttons

"1": The robot is operated with Key1 and the enabling

buttons

Signal lamp O 11.2 "0": Robot is not in use; the signal lamp is off

"1": Robot is in use; the signal lamp is on

The following flowchart shows the operation sequence in the example.

Start

Operation in the

protection zone not

possible

Log on to the

machine?

Yes

Operation in the

protection zone is

possible

Contact with

pressure mat?

Yes

Forced logoff

No

No

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

400 Operating Instructions, 09/2010, A5E02766325-01

Page 2

Appendix

REVIEW ENGLISH

27.07.2010

A.4 Application example RFID tag system

A.4.2 Configuring the controller and HMI device in STEP 7

This section describes the most important parameters you need to set in "HW Config" for the

F-CPU and for the HMI device.

WARNING

Safety category

Any changes to parameters may result in the loss of the safety category.

Set the parameters as described. The parameters will contribute to meeting safety

category 4 PL e/SIL 3.

Requirement

The software for fail-safe operation has been installed, see section "Required software

(Page 25)".

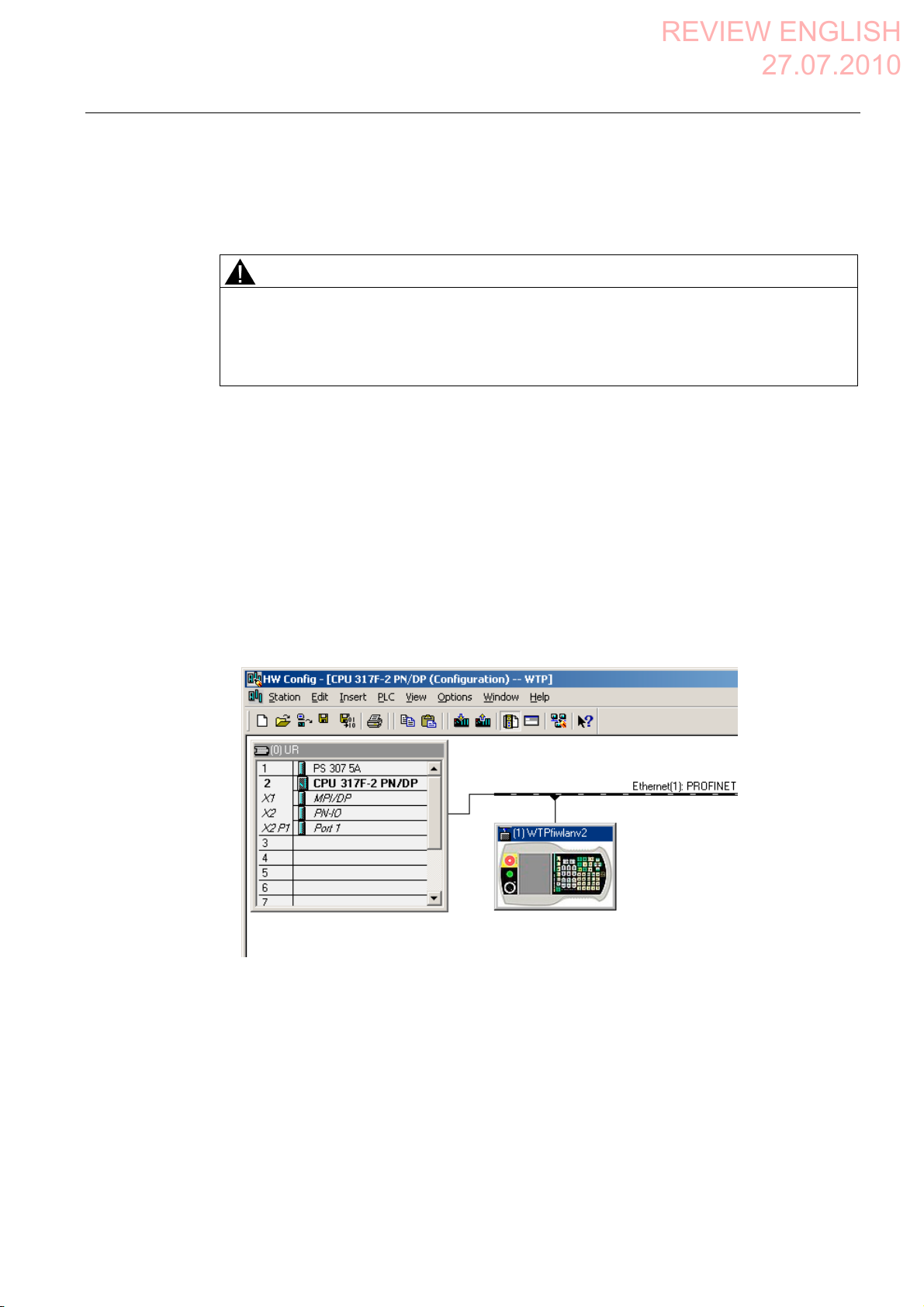

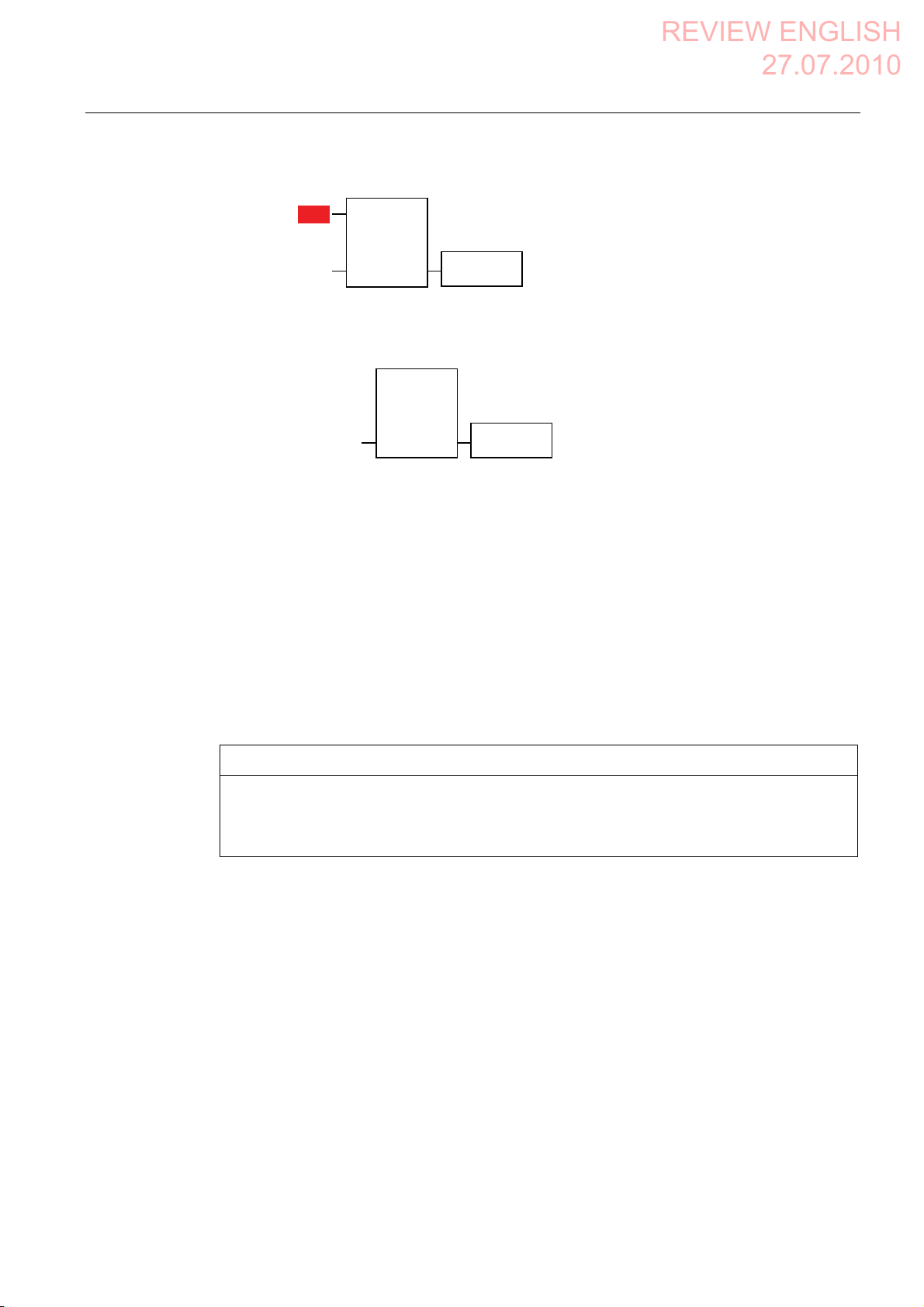

Procedure – Configuring CPU 317F-2 PN/DP

Proceed as follows:

1. Create a STEP 7 project in SIMATIC Manager.

2. Open the "HW Config" hardware configuration and insert the desired F-CPU and a

PROFINET connection, as shown in the following figure:

3. Open the settings by double-clicking the F-CPU in "HW Config".

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

Operating Instructions, 09/2010, A5E02766325-01

401

Page 3

Appendix

REVIEW ENGLISH

27.07.2010

A.4 Application example RFID tag system

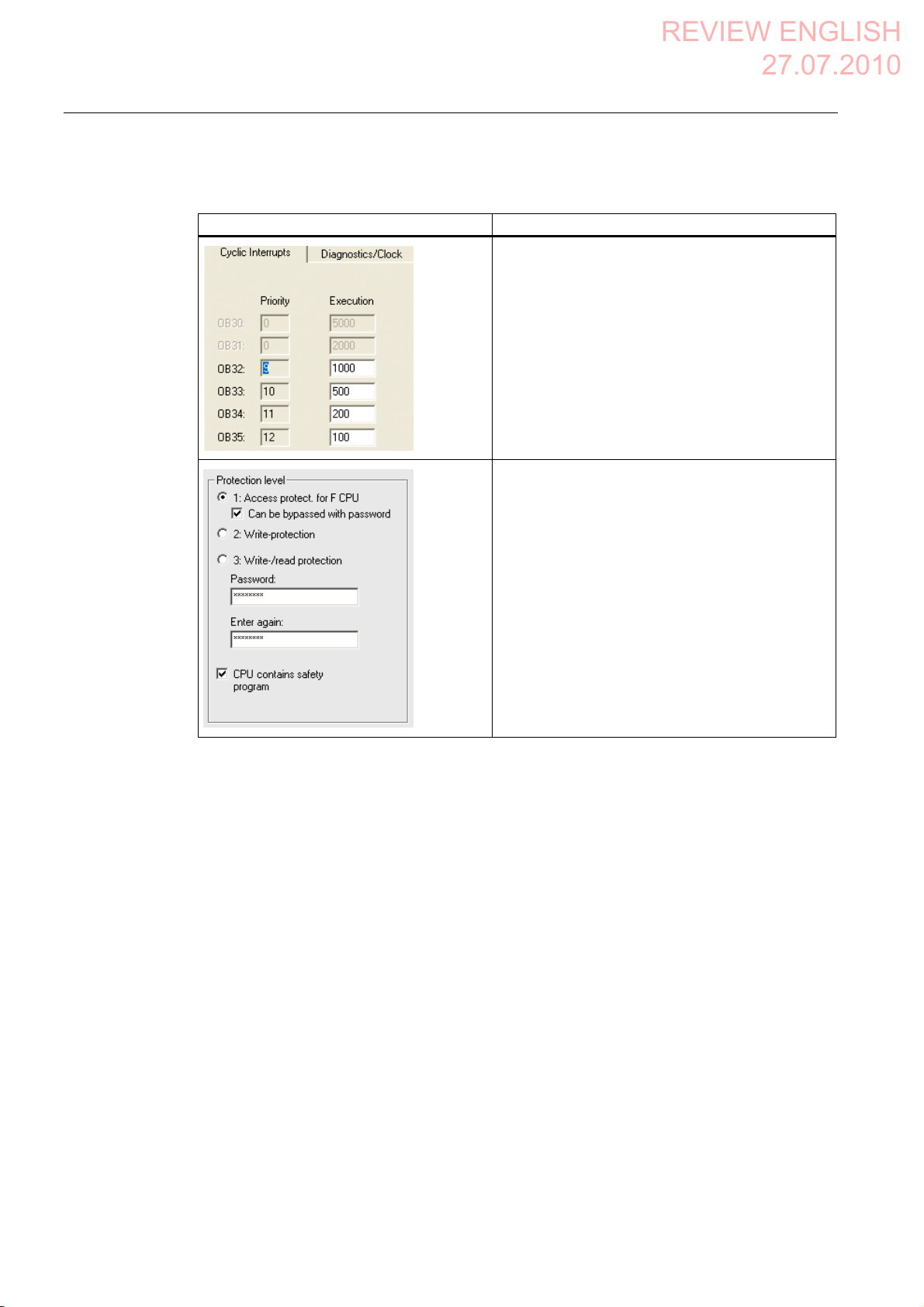

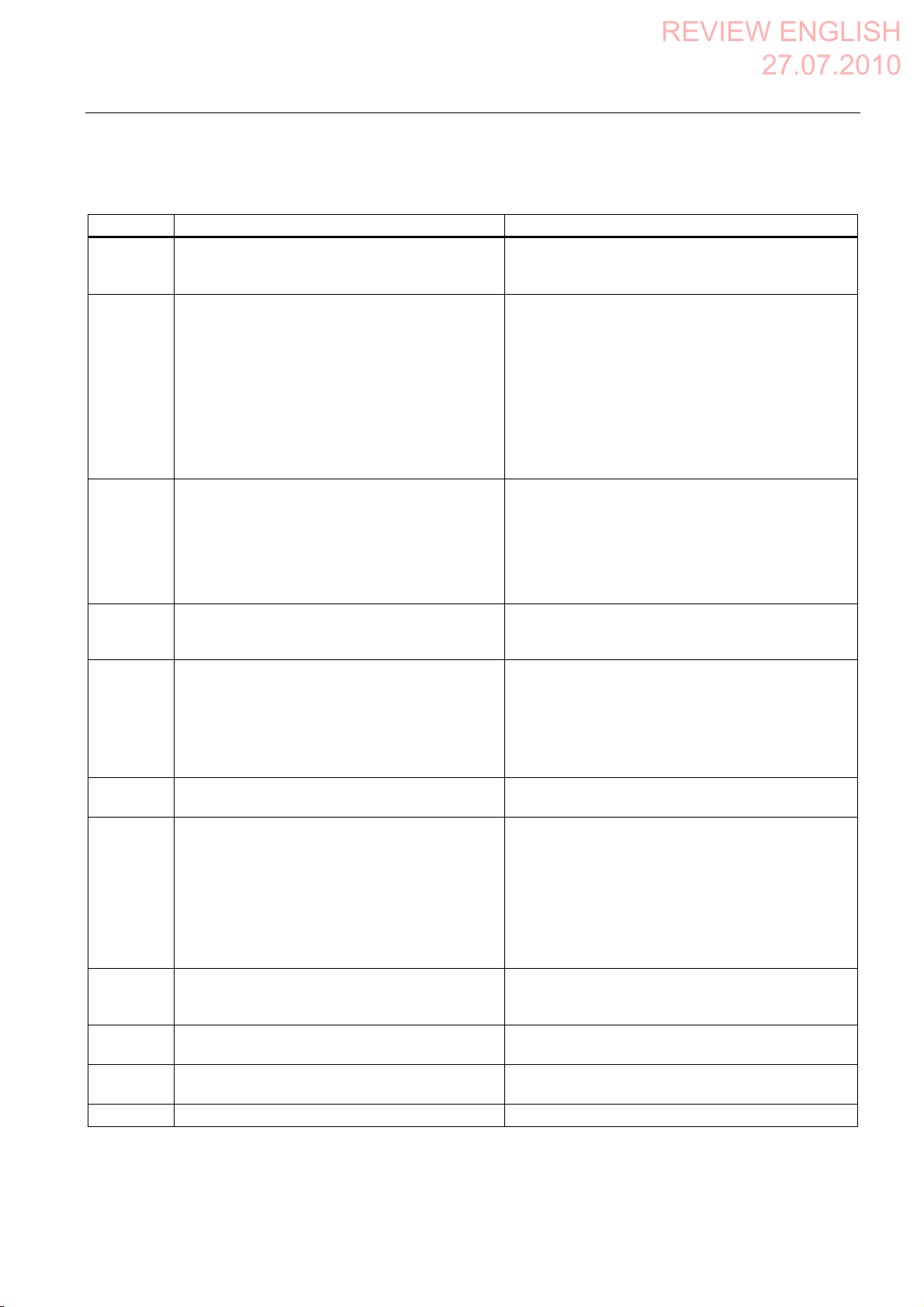

The table below shows the most important settings:

Setting Explanation

This is where you set the cycle time for OB35.

Note

If the cycle time for OB35 is set lower than the PBIO

update time, the message frame may be lost and the

evaluation of the "E-STOP" output of F_FB_RNG_4

or F_FB_RNG_16 may be delayed.

Set the cycle time of OB35 to a value higher than the

PNIO update time.

Assign a password for the safety program.

Set the "CPU contains safety program" check box.

This setting is required to generate all the necessary

F-FBs for safe operation of the fail-safe modules

during compilation of "HW Config" by STEP 7.

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

402 Operating Instructions, 09/2010, A5E02766325-01

Page 4

Appendix

REVIEW ENGLISH

27.07.2010

A.4 Application example RFID tag system

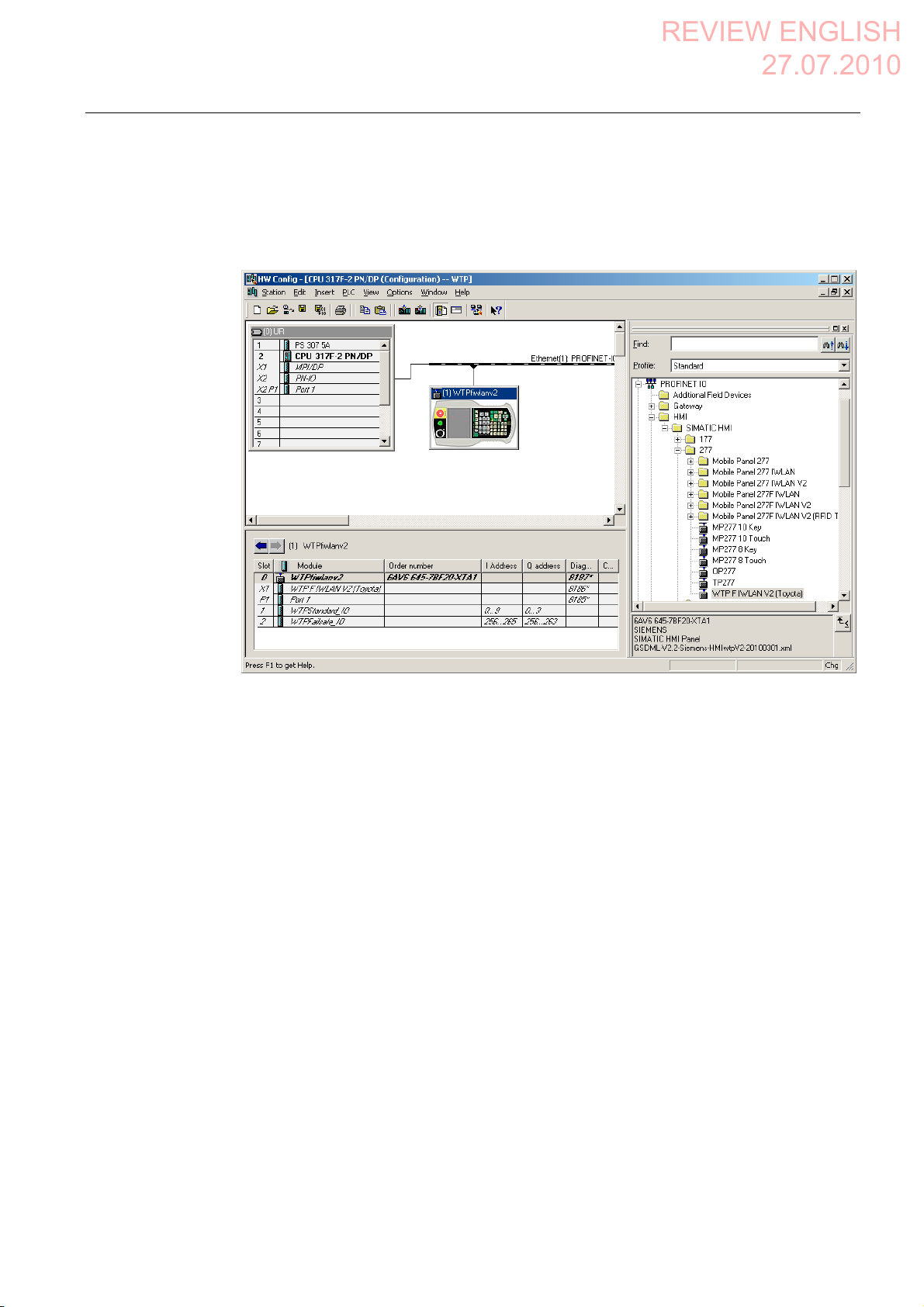

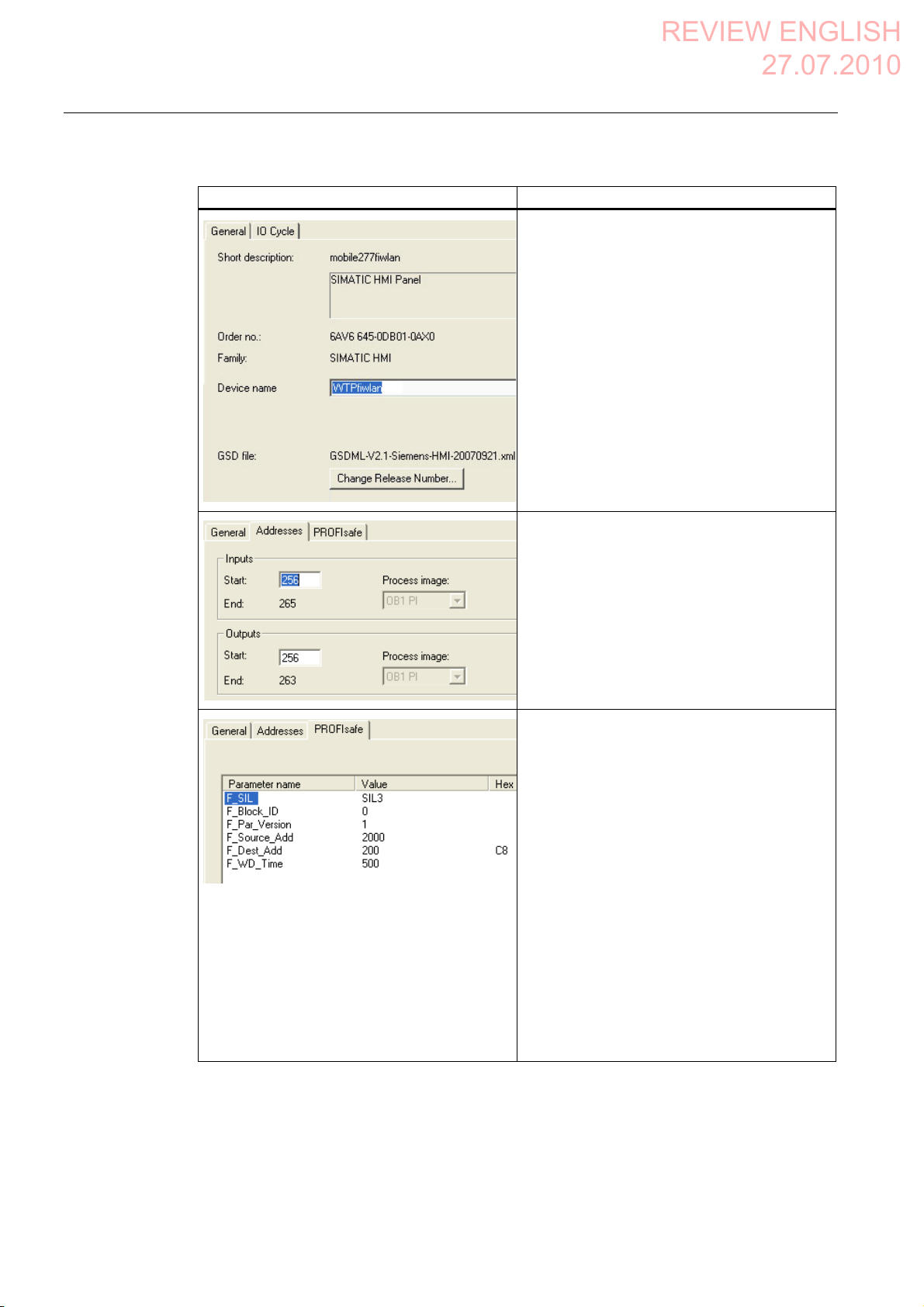

Procedure – Configuring Wireless Teach Pendant F IWLAN

Proceed as follows:

1. Insert the Wireless Teach Pendant F IWLAN in "HW Config" as shown in the following

figure.

2. Open the properties dialog of the HMI device by double-clicking the "WTPfiwlan" icon.

3. Enter the device name of the HMI device in the properties dialog.

4. Open the properties dialog of the "WTPFailsafe_IO" module by double-clicking the

"WTPFailsafe_IO" entry in the detailed view of the HMI device.

5. Change to the "PROFIsafe" tab.

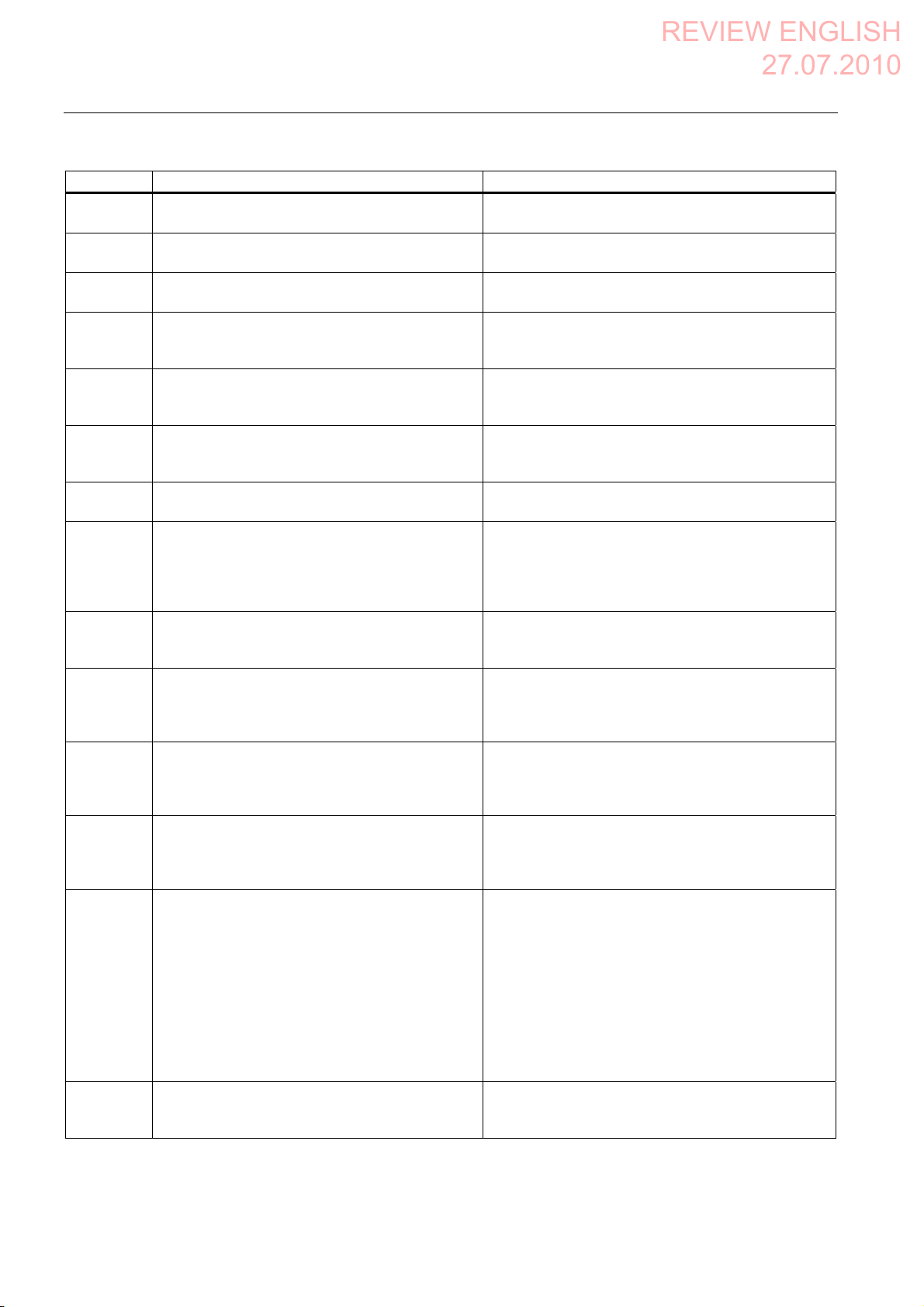

The table below shows the most important settings:

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

Operating Instructions, 09/2010, A5E02766325-01

403

Page 5

Appendix

REVIEW ENGLISH

27.07.2010

A.4 Application example RFID tag system

Setting Explanation

Device name

Here you assign a device name to the HMI

device, which is unique in the local Ethernet

network segment. This name must match the

name defined in the Control Panel of the HMI

device under "PROFINET" in the text box "Device

name:".

Additional information is available in the section:

"Specifying the computer nam

(Page 174)".

Inputs

This is where you specify the start address of the

inputs and the process image associated with this

address area (PII).

Outputs

Here you specify the start address of the outputs

and the process image associated with this

address area (PIQ).

e of the HMI device

F_Dest_Add

PROFIsafe address of the

Wireless Teach Pendant F IWLAN. This address

must match the address on the HMI device.

F_WD_Time

Monitoring time in the fail-safe IO device.

A valid current safety message frame must reach

the F-CPU and be returned to the HMI device

within the monitoring time period. This ensures

that failures and errors are detected and

appropriate responses are triggered to keep the

fail-safe system in a safe state or transfer it to a

safe state.

The monitoring time selected must be long

enough that message frame delays will be

tolerated by the communication system, but also

that the fault reaction function responds quickly

enough in the event of a fault (e.g. interruption in

the communication connection).

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

404 Operating Instructions, 09/2010, A5E02766325-01

Page 6

Appendix

REVIEW ENGLISH

27.07.2010

A.4 Application example RFID tag system

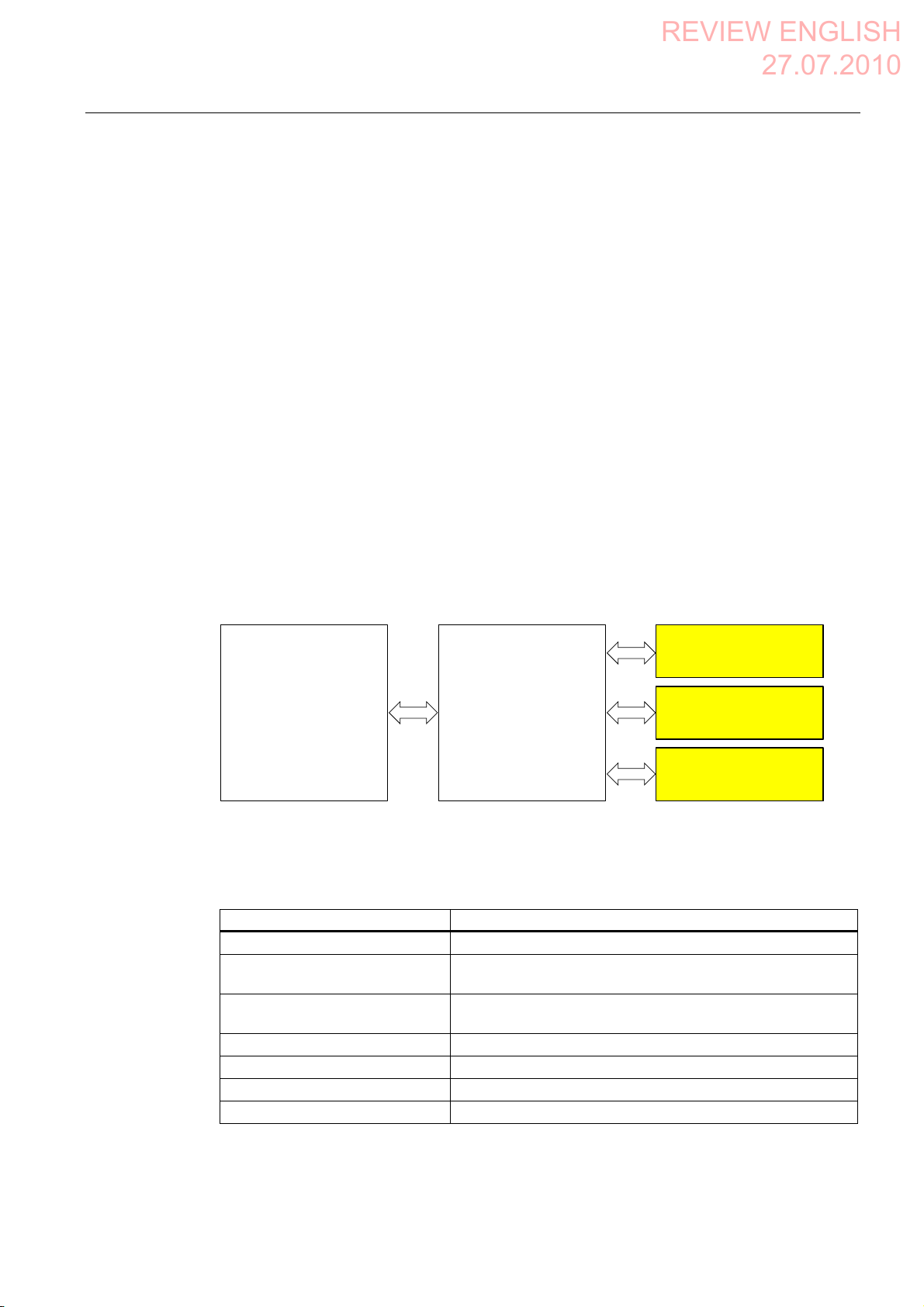

A.4.3 Safety program S7 Distributed Safety

In the safety program of the S7-CPU, the operation sequence of the application example is

implemented by the following programming:

● Once the HMI device is logged on to a machine, the signal lamp and the "Override" mode

are enabled.

● In the protection zone, the operator can operate the robot with the "Key1" button and the

enabling button.

● If the operator leaves the protection zone over the contact pressure mat, the safety

program responds as follows:

– The signal lamp goes out.

– "Override" mode is deactivated.

– The HMI device is logged off the machine.

● After an EMERGENCY STOP, the plant only restarts when the operator performs an

acknowledgment.

● Reactions specific to a plant are initiated when a rampdown or shutdown occurs.

Safety program

Symbolic names

The safety program is structured as follows:

)&DOO

)%

)B)%B03))%

)&

)B)%B51*))%

)B(6723))%

The following symbolic names are used in the networks of the sample programs

Symbolic name Meaning

F00256_WTPFailsafe_IO Fail-safe I/O DB of HMI device

MP1_FB_S7_MP_RE Input which is set when a reset of the HMI device is performed

from the F-CPU.

MP1_FB_S7_ACK_ERR Input which is set when a communication error is acknowledged

from the F-CPU.

MP1_F_DATA_PII Word 1 of the PII of the HMI device

MP1_F_RANGE_PII Word 2 of the PII of the HMI device

MP1_F_DATA_PIQ Word 1 of the PIQ of the HMI device

MP1_F_RANGE_PIQ Word 2 of the PIQ of the HMI device

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

Operating Instructions, 09/2010, A5E02766325-01

405

Page 7

Appendix

REVIEW ENGLISH

27.07.2010

A.4 Application example RFID tag system

Symbolic name Meaning

Interface_DB F-DB for the data transfer of user data

F_DB_States F-DB for the transfer of data between the F_FB_MP of the HMI

device and the F_FB_RNG_n of the effective range

F-CALL (FC 1)

F-CALL (FC1) is the F-run-time group and is called from the cyclic interrupt OB (OB35).

F-CALL (FC1) calls the F-program block (in this case: FB1).

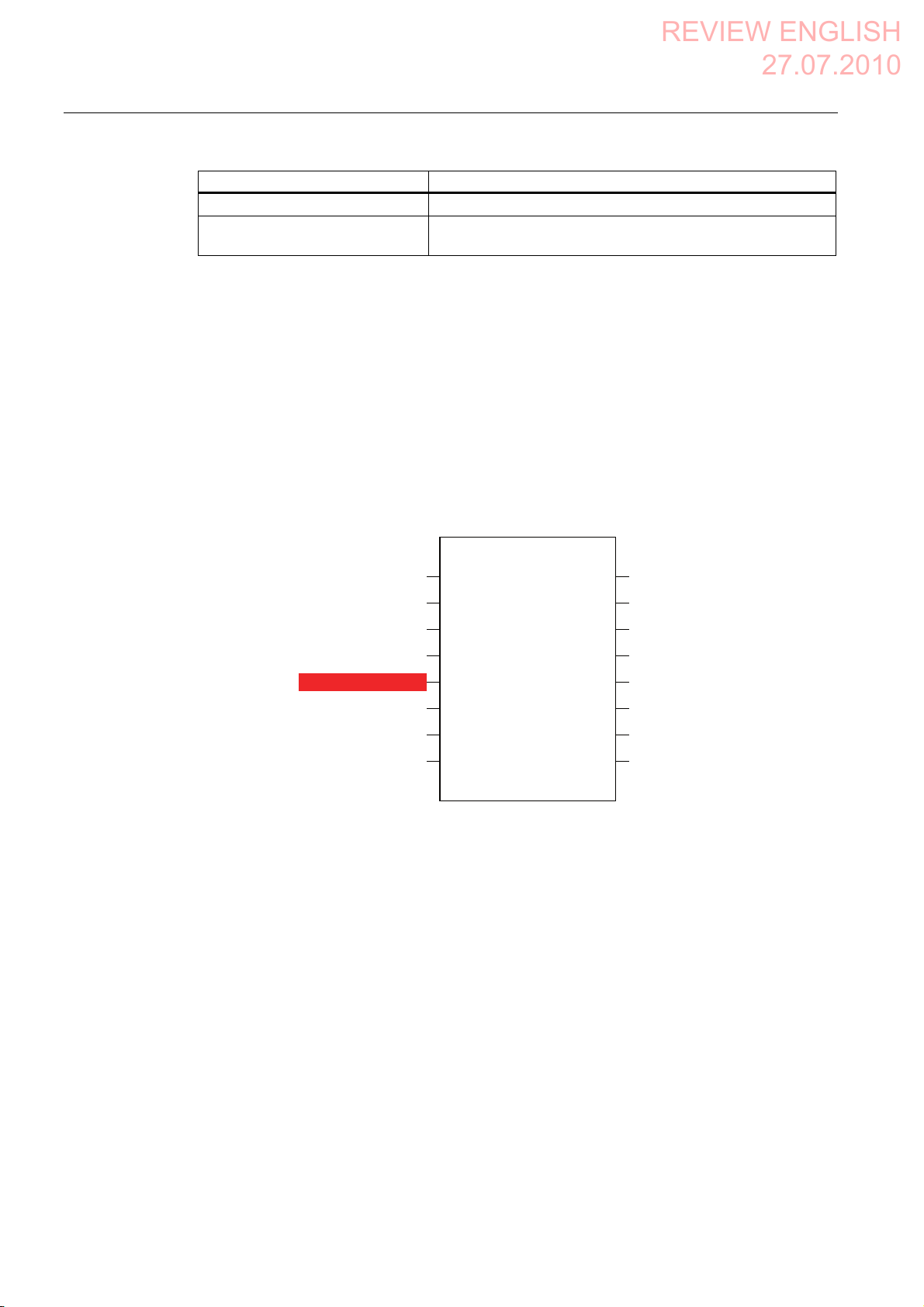

FB1

For reasons of program modularity, all other F-FBs are called from this FB.

In FB 1, you have to call the F-FBs in the following order.

1. Network 1

'%

)B)%B03

)B:73)DLOVDIHB,24%$'

)B:73)DLOVDIH B,2$&. B5(4

03B)%B6B03B5(

03B)%B6B$&.B(55

03B)B'$7$B3,,

03B)B51*B3,,

)B'%B67$7(603BB6WDWXV

(1

4%$'

$&.B 5(4

6B03B5(6

6B$&.B(55

03B'$7$

03B51*

03B67$7

03B'$7$B4

03B51*B4

$&.B 5(,

',$*

(12

)B:73)DLOVDIH B,2ಯ$&. B5(,

03B)B'$7$B3,4ಯ

03B)B51*B3,4

,QWHUIDFHB'%03B)%B',$*

The controller uses this F-FB to monitor the PROFIsafe communication of the HMI

device. The following diagnostics information is indicated at the "DIAG" output:

– Status of the HMI device: integrated or removed

– A communication error has occurred.

– Communication error must be acknowledged

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

406 Operating Instructions, 09/2010, A5E02766325-01

Page 8

Appendix

REVIEW ENGLISH

27.07.2010

A.4 Application example RFID tag system

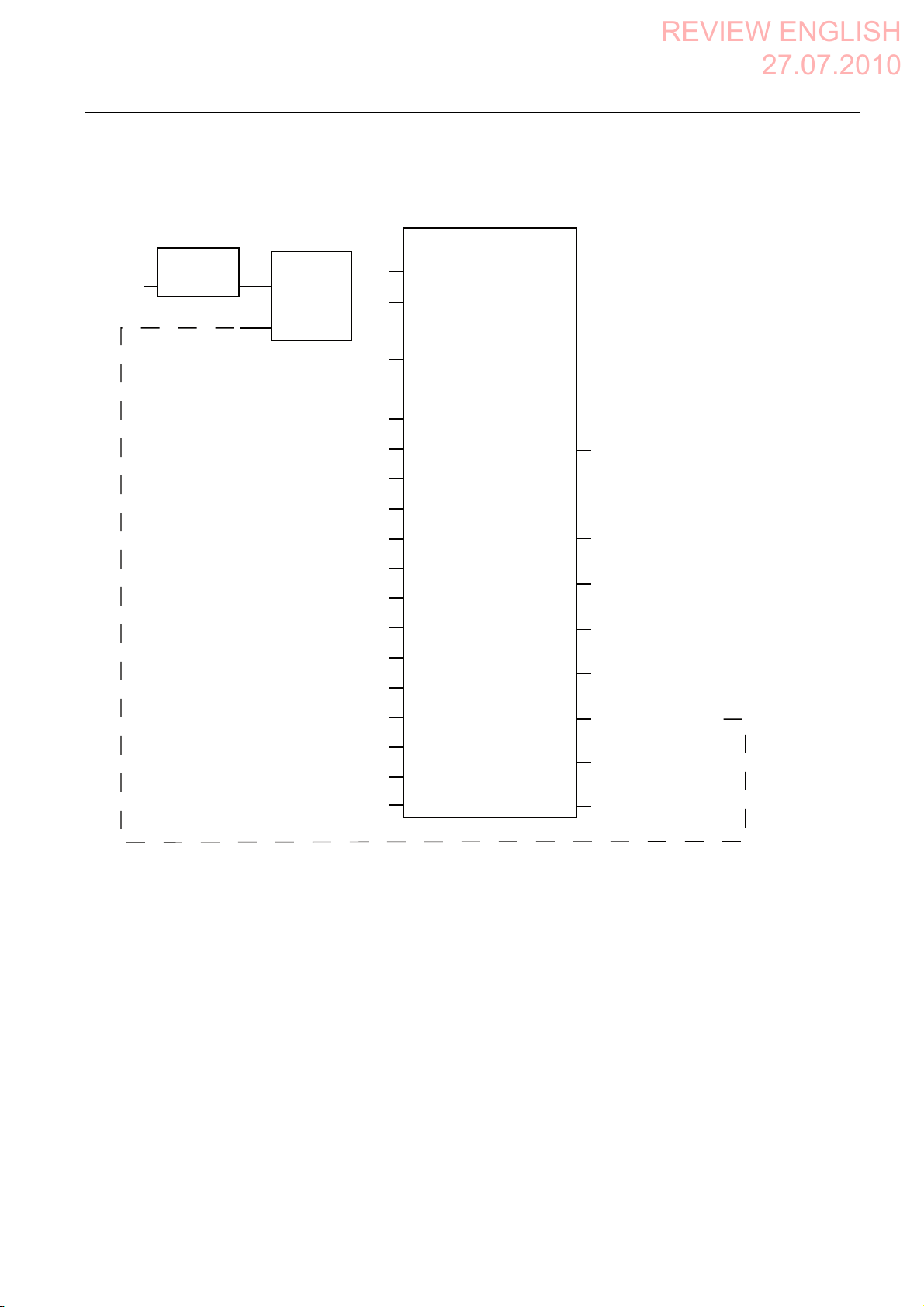

2. Network 2

'%

(GJHB

&RQWDFWB

0DWV

&RQWDFWB0DWV

1(*

0B%,7 4

)B)%B51*B

(1

51*B,'

,QWHUIDFHB'%

(5B51*B%86<

03B)B'$7$B3,,

03B)B51*B3,,

)B'%B67$7(6

03BB6WDWXV

29(55,'(

03B'$7$

03B51*

03B)B.(<

03B'$7$

03B51*

03B)B.(<

03B'$7$

03B51*

03B)B.(<

03B'$7$

03B51*

03B)B.(<

03B67$7

03B67$7

03B67$7

(B6723

*/2%B5'

/2&B5'

6+87'2:1

(1$%/(

)B.(<6

51*B%86<

',$*

,QWHUIDFHB'%

(5B(B6723

,QWHUIDFHB'%

(5B*/2%B5'

,QWHUIDFHB'%

(5B/2&B5'

,QWHUIDFHB'%

(5B6+87'2:1

,QWHUIDFHB'%

(5B(1$%/(

,QWHUIDFHB'%

(5B51*B%86<

,QWHUIDFHB'%

(5B)%B',$*

03B67$7

The activation of the "override" mode is controlled in this network.

"OVERRIDE" is set as soon as the operator has logged the HMI device on to the machine

via the RFID tag. (RNG_BUSY). "OVERRIDE" is reset by a negative edge on the contact

pressure mat, in other words I11.0 = "0". This is the case when the operator leaves the

protection zone.

At the same time, F_FB_RNG monitors the signals "EMERGENCY STOP", "Global

rampdown", "Local rampdown" and "Shutdown". They are scanned in networks 3 to 6.

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

Operating Instructions, 09/2010, A5E02766325-01

(12

407

Page 9

Appendix

REVIEW ENGLISH

27.07.2010

A.4 Application example RFID tag system

3. Network 3

'%

)B(6723

,QWHUIDFHB'%(5B(B6723

(B6723

$&.B1(&

$&.

7,0(B'(/

4B'(/$<

$&.B5(4

',$*

(12

4

(B6WRSB5RERW(1

In network 3, the EMERGENCY STOP signal of the HMI device is monitored via

F_ESTOP1 from the F-library of S7 Distributed Safety. F_ESTOP1 ensures that the plant

is only able to restart following an EMERGENCY STOP after acknowledgment by the

operator via the input "ACK".

Note

Read also the information on FB215 in the online help for F-FBs and in the manual

"SIMATIC S7-Distributed Safety, Configuring and Programming", section "FB215

"F_ESTOP1:" Emergency STOP up to Stop Category 1".

4. Networks 4, 5 and 6

*OREDOB5DPSGRZQ

,QWHUIDFHB'%

(5B*/2%B5'

RF

DOB5DPSGRZQ

/

,QWHUIDFHB'%

(5B/2&B5'

,QWHUIDFHB'%

(5B6+87'2:1

6KXWGRZQ

In network 4, 5 and 6 the signals for a global and a local rampdown and shutdown are

processed further. As the configuration of the monitored plant determines which

responses have to occur following occurrence of a particular safety state, these networks

are not explained in detail in this example.

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

408 Operating Instructions, 09/2010, A5E02766325-01

Page 10

Appendix

REVIEW ENGLISH

27.07.2010

A.5 Safety-related messages

5. Network 7

(

,QWHUIDFHB'%

(5B(QDEOH

If the operator simultaneously presses the Key1 key and the enabling button, the robot is

activated via the output Q11.1.

6. Network 8

,QWHUIDFHB'%

(5B51*B%86<

If the "RNG_BUSY" signal is set in F_FB_RNG, output Q11.2 is used to control the signal

lamp that indicates whether or not the machine is in use.

A.5 Safety-related messages

A.5.1 Transponder system

$

$

The following safety-related messages are displayed in fail-safe mode depending on the

operating situation. In contrast to system alarms, no message window needs to be

configured for safety-related messages.

NOTICE

Function keys inactive for the display length of the alarm

While a safety-related alarm is shown, the function keys of the HMI device are inactive.

Close the window of the safety-related alarm in order to reactivate the function keys.

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

Operating Instructions, 09/2010, A5E02766325-01

409

Page 11

Appendix

REVIEW ENGLISH

27.07.2010

A.5 Safety-related messages

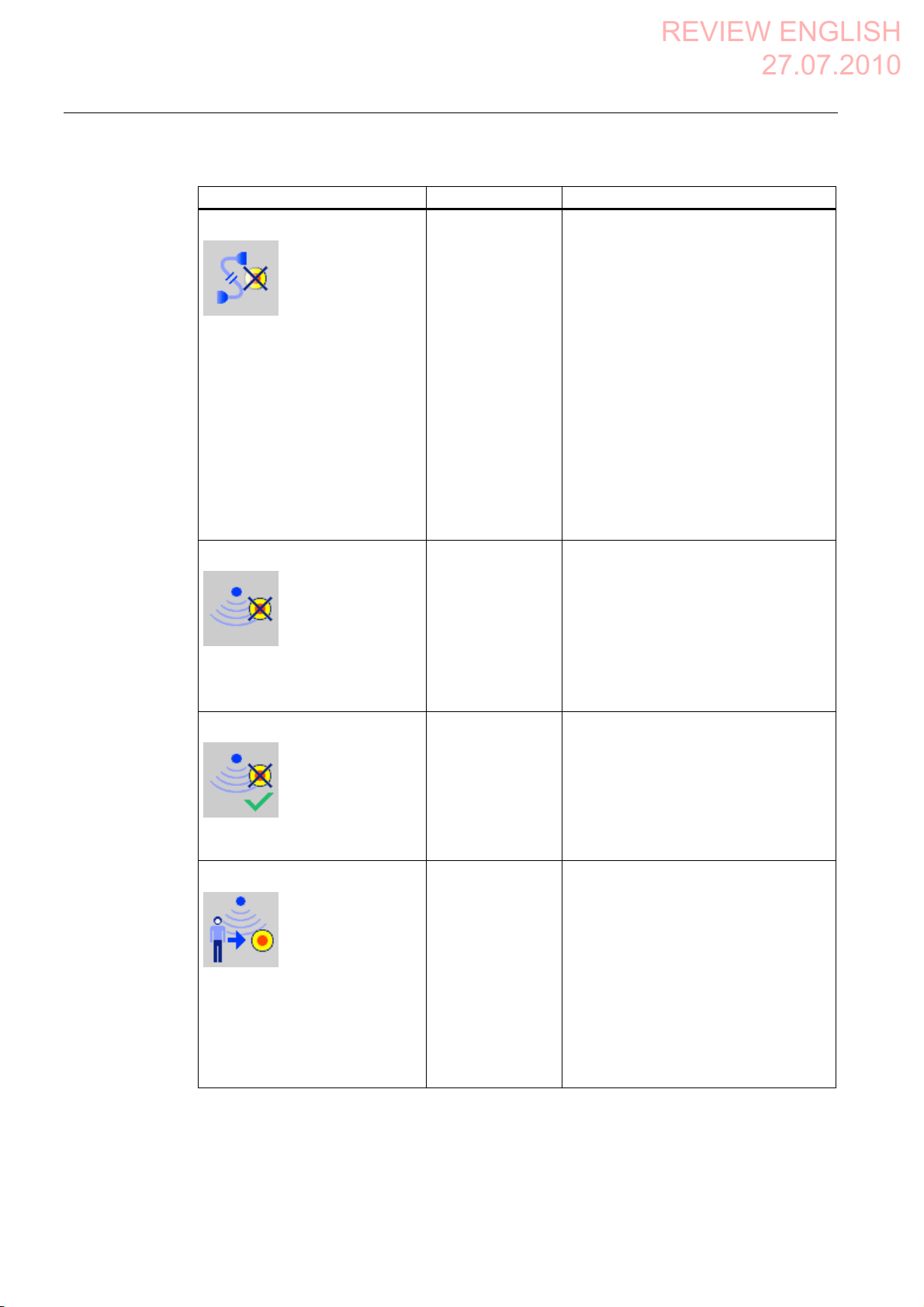

Dialog Reaction Situation

Establishment of safety connection

No safe connection available.

Reason:

Connection not yet completed

PROFIsafe address error

Internal configuration error

Communication error (timeout)

Communication error (CRC)

CPU in STOP

PROFIsafe CRC configuration

error

Should the Panel be switched off?

Start removal

The removal cannot be interrupted

once it has started.

Do you want to start the removal?

Confirm removal

"Yes" button The following is reported in the warning

message depending on the operating

situation:

Connection not yet completed

The safe connection is not yet

established after the project has been

started. Wait until the connection has

been established. The dialog is closed

on completion.

A communication error occurred after

the HMI device was successfully

integrated. Correct the cause of the

error described by "Reason".

"Yes" button

"No" button

Press an enabling

button until the

"Enable" switch

position is reached.

The "Start removal" dialog opens in the

following cases:

The operator has pressed the

"ON/OFF" button for more than

4 seconds.

The operator has pressed the operator

control for closing the project.

The removal starts, in other word, the user

has pressed the "Yes" button in the "Start

removal" dialog.

Please confirm the removal with

the enabling button.

Effective range logon

Do you want to logon to the

following effective range?

Effective range <<EFFECTIVE

RANGE NAME>>

Please enter the effective range

ID:

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

410 Operating Instructions, 09/2010, A5E02766325-01

"Yes" button

"No" button

The HMI device is located within an

effective range but it is not logged on.

The operator has activated the white

"Effective range name" object to log on.

Page 12

Appendix

REVIEW ENGLISH

27.07.2010

A.5 Safety-related messages

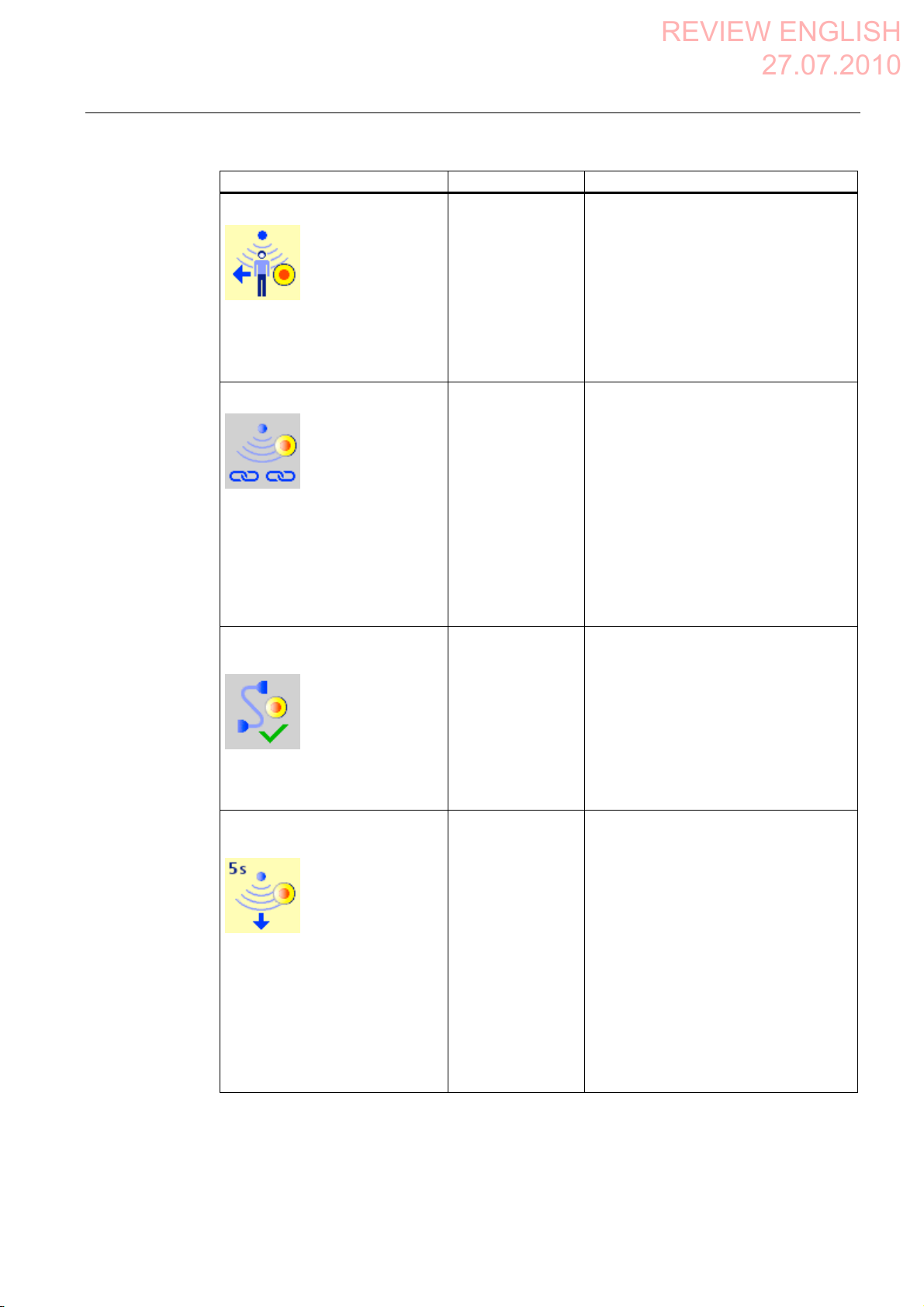

Dialog Reaction Situation

Effective range logoff

"Yes" button

"No" button

The HMI device is logged onto the

effective range. The operator has

activated the "Effective range name"

object to log off.

Do you want to log off from the

following effective range?

Effective range <<EFFECTIVE

RANGE NAME>>

Effective range logoff (shutdown)

The Panel cannot be switched off.

You first have to log off from the

effective range.

Do you want to logoff from the

following effective range?

Effective range <<EFFECTIVE

RANGE NAME>>

Acknowledgment of

communication error

A safe connection is possible

again. Please confirm the

communication error.

Effective range exited without

logoff(5 seconds)

"Yes" button

"No" button

"OK" button Communication was recovered after a

"Yes" button

or

Return to the

effective range

within 25 seconds

The HMI device is logged on to a

machine.

The operator has attempted to:

Shut down the HMI device.

Close the project with the

corresponding operator control.

short communication error. The operator

must confirm this state.

Causes:

The operator has briefly left the WLAN

range and then returned.

PROFIsafe communication was briefly

interrupted.

The operator has left the effective range

with the logged on HMI device for more

than 5 seconds.

WARNING: You have exited the

following effective range without

logging off:

Effective range <<EFFECTIVE

RANGE NAME>>

The enabling button is deactivated.

Do you want to log off from the

effective range?

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

Operating Instructions, 09/2010, A5E02766325-01

411

Page 13

Appendix

REVIEW ENGLISH

27.07.2010

A.5 Safety-related messages

Dialog Reaction Situation

Effective range exited without

logoff(30 seconds)

"OK" button The operator has left the effective range

with the logged on HMI device for more

than 30 seconds.

You have left the effective range

without permission. A local

shutdown was initiated! Please

confirm logging off from the

effective range.

Low battery alarm

Battery charge is less than 20

percent.

Testing transponders

This dialog contains no coherent

text.

Users are informed that they are in

a mode for testing the

transponders. The user muss test

all transponders in all effective

ranges.

Test enabling button

"OK" button The remaining charge of the main

rechargeable battery is less than 20%.

An additional system alarm is output after

the charge of the main rechargeable

battery has dropped to less than 6%.

Diverse A project has been started on the HMI

device that does not contain an up-to-date

CRC checksum for the effective ranges.

The effective ranges and transponders

need to be tested using the dialog.

Press both enabling

buttons until the

"Panic" switch

position is reached.

The operator has started the project.

Perform a function test for the enabling

button.

Both enabling buttons must be

tested to ensure they are

operational. Fully press both

enabling buttons until the panic

position is reached.

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

412 Operating Instructions, 09/2010, A5E02766325-01

Page 14

Appendix

REVIEW ENGLISH

27.07.2010

A.5 Safety-related messages

Dialog Reaction Situation

Error during effective range logon

Error during effective range logon.

The enabling button remains

deactivated.

"OK" button An error occurred during logon of the HMI

device to a machine. The operator cannot

use the enable switches to control the

production process.

Possible causes:

You are already logged on to the

machine with your HMI device or the

logon is currently in progress.

Another HMI device is already logged

on to the machine.

Transponder defective.

Effective range module in the HMI

device is defective.

No ID has been assigned to the

transponder.

The operator has entered an incorrect

effective range ID for the logon.

F_FB_RNG missing in the STEP7

configuration.

F_FB_RNG is wired incorrectly in

STEP7.

Enabling switch discrepancy error

Please release the enabling

button.

A.5.2 RFID tag system

The following safety-related messages are displayed in fail-safe mode depending on the

operating situation. In contrast to system alarms, no message window needs to be

configured for safety-related messages.

NOTICE

Function keys inactive for the display length of the alarm

While a safety-related alarm is shown, the function keys of the HMI device are inactive.

Close the window of the safety-related alarm in order to reactivate the function keys.

Release both

enabling buttons.

The HMI device detects a discrepancy at

one of the two enabling buttons in switch

position "Enable".

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

Operating Instructions, 09/2010, A5E02766325-01

413

Page 15

Appendix

REVIEW ENGLISH

27.07.2010

A.5 Safety-related messages

Dialog Reaction Situation

Establishment of safety connection

No safe connection available.

Reason:

Connection not yet completed

PROFIsafe address error

Internal configuration error

Communication error (timeout)

Communication error (CRC)

CPU in STOP

PROFIsafe CRC configuration

error

Should the Panel be switched off?

Start removal

The removal cannot be interrupted

once it has started.

Do you want to start the removal?

Confirm removal

"Yes" button The following is reported in the warning

message depending on the operating

situation:

Connection not yet completed

The safe connection is not yet

established after the project has been

started. Wait until the connection has

been established. The dialog is closed

on completion.

A communication error occurred after

the HMI device was successfully

integrated. Correct the cause of the

error described by "Reason".

"Yes" button

"No" button

Press an enabling

button until the

"Enable" switch

position is reached.

The "Start removal" dialog opens in the

following cases:

The operator has pressed the

"ON/OFF" button for more than

4 seconds.

The operator has pressed the operator

control for closing the project.

The removal starts, in other word, the user

has pressed the "Yes" button in the "Start

removal" dialog.

Please confirm the removal with

the enabling button.

Effective range logon

Do you want to logon to the

following effective range?

Effective range <<EFFECTIVE

RANGE NAME>>

Please enter the effective range

ID:

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

414 Operating Instructions, 09/2010, A5E02766325-01

"Yes" button

"No" button

The HMI device is located directly in front

of an RFID tag and is not yet logged on to

the corresponding machine.

The operator has activated the "Scan"

object to log on.

6FDQ

Page 16

Appendix

REVIEW ENGLISH

27.07.2010

A.5 Safety-related messages

Dialog Reaction Situation

Effective range logoff

"Yes" button

"No" button

The HMI device is logged on to a

machine.

The operator has activated the "Effective

range name (RFID)" object to log off.

Do you want to log off from the

following effective range?

Effective range <<EFFECTIVE

RANGE NAME>>

Effective range logoff (shutdown)

The Panel cannot be switched off.

You first have to log off from the

effective range.

Do you want to logoff from the

following effective range?

Effective range <<EFFECTIVE

RANGE NAME>>

Acknowledgment of

communication error

A safe connection is possible

again. Please confirm the

communication error.

Forced logoff

"Yes" button

"No" button

"OK" button Communication was recovered after a

"OK" button The operator has left the protection zone

The HMI device is logged on to a

machine.

The operator has attempted to:

Shut down the HMI device.

Close the project with the

corresponding operator control.

short communication error. The operator

must confirm this state.

Causes:

The operator has briefly left the WLAN

range and then returned.

PROFIsafe communication was briefly

interrupted.

with a logged-on HMI device via the safety

system.

You are automatically logged off

from the effective range.

A local rampdown has been

triggered! Confirm the logoff from

the effective range.

Low battery alarm

Battery charge is less than 20

percent.

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

Operating Instructions, 09/2010, A5E02766325-01

"OK" button The remaining charge of the main

rechargeable battery is less than 20%.

An additional system alarm is output after

the charge of the main rechargeable

battery has dropped to less than 6%.

415

Page 17

Appendix

REVIEW ENGLISH

27.07.2010

A.6 System alarms

Dialog Reaction Situation

Test enabling button

Press both enabling

buttons until the

"Panic" switch

position is reached.

The operator has started the project.

Perform a function test for the enabling

button.

Both enabling buttons must be

tested to ensure they are

operational. Fully press both

enabling buttons until the panic

position is reached.

Error during effective range logon

Error during effective range logon.

The enabling button remains

deactivated.

"OK" button An error occurred during logon of the HMI

device to a machine. The operator cannot

use the enable switches to control the

production process.

Possible causes:

You are already logged on to the

machine with your HMI device or the

logon is currently in progress.

Another HMI device is already logged

on to the machine.

RFID tag is defective.

RFID module in the HMI device is

defective.

No ID has been assigned to the RFID

tag.

The operator has entered an incorrect

RFID tag ID for the logon.

F_FB_RNG missing in the STEP7

configuration.

F_FB_RNG is wired incorrectly in

STEP7.

Enabling switch discrepancy error

Release both

enabling buttons.

The HMI device detects a discrepancy at

one of the two enabling buttons in switch

position "Enable".

Please release the enabling

button.

A.6 System alarms

Introduction

System alarms on the HMI device provide information about internal states of the HMI device

and PLC.

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

416 Operating Instructions, 09/2010, A5E02766325-01

Page 18

Appendix

REVIEW ENGLISH

27.07.2010

A.6 System alarms

The following overview shows the causes of system alarms and how to eliminate the cause

of error.

Some of the system alarms described in this section are relevant to individual HMI devices

based on their range of features.

Note

System alarms are only indicated if an alarm window was configured. System alarms are

output in the language currently set on your HMI device.

System alarm parameters

System alarms may contain encrypted parameters which are relevant to troubleshooting

because they provide a reference to the source code of the runtime software. These

parameters are output after the text "Error code:"

Displaying the "System alarms" editor

You can find the text content of the system alarm in WinCC flexible. The "System alarms"

editor is not displayed by default in WinCC flexible.

1. Enable the "System alarms" editor under "Options > Setting... > Workbench > Settings for

Project Window" with "Display all entries".

2. Select the "System alarms" editor under "Alarms" in the project view.

The system alarms are sorted numerically in the "System alarms" editor.

Configuring events for system alarms

You can configure the "Incoming" event for the following system alarm in the "System

alarms" editor.

System alarms

10000

10000 to 10006

150000

150000

150001

230300

230300 to 230308

20000

20000 to 20015

30000

30010 to 20012

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

Operating Instructions, 09/2010, A5E02766325-01

160000

160000

160001

160010 to 160014

170000

170000 to 170004

170007

240000

240000 to 240005

250000

250000 to 250003

417

Page 19

Appendix

REVIEW ENGLISH

27.07.2010

A.6 System alarms

System alarms

40000

40010

40011

180000

180000 to 180002

260000

260000 to 260009

260012 to 260014

260028

260030

260033 to 260045

50000

50000

50001

60000

60010 to 60011

70000

70010 to 70044

80000

80001 to 80035

80044 to 80050

90000

90024 to 90026

90029 to 90033

90040

90041

90044

190000

190000 to 190002

190004 to 190013

190100

190100 to 190102

200000

200000 to 200005

200100

200100 to 200105

210000

210000 to 210006

270000

270000 to 270003

280000

280000 to 280004

290000

290000 to 290008

290010 to 290014

290020 to 290027

290040 to 290042

290044

290050 to 290065

290070 to 290073

290075

300000

300000

300001

310000

310000

310001

110000

110000 to 110006

120000

120000 to 120002

130000

130000 to 130012

140000

140000 to 140020

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

418 Operating Instructions, 09/2010, A5E02766325-01

220000

220000 to 220008

230000

230000

230002

200003

200005

230100

230100

230200

230200 to 230203

600000

600000

620000

620000

Page 20

Appendix

REVIEW ENGLISH

27.07.2010

A.6 System alarms

10000 - Printer alarms

Number Effect/cause Remedy

10000 The print job could not be started or was canceled

due to an unknown error. Faulty printer setup. Or:

No authorization is available for accessing the

network printer.

Power supply failure during data transfer.

10001 No printer is installed or a default printer has not

been set up.

10002 Overflow of the graphics buffer for printing. Up to

two graphics are buffered.

10003 Graphics can now be buffered again. -10004 Overflow of the buffer for printing lines in text mode

(e.g. alarms). Up to 1000 lines are buffered.

10005 Text lines can now be buffered again. -10006 The Windows printing system reports an error.

Refer to the output text and the error ID to

determine the possible causes. Nothing is printed

or the print is faulty.

Check the printer settings, cable connections and the

power supply.

Set up the printer once again. Obtain a network printer

authorization.

If the error persists, contact the Hotline!

Install a printer and/or select it as the default printer.

Allow sufficient intervals between successive print jobs.

Allow sufficient intervals between successive print jobs.

Repeat the action if necessary.

20000 - Global script alarms

Number Effect/causes Remedy

20010 An error has occurred in the specified script line.

Execution of the script was therefore aborted. Note

the system alarm that may have occurred prior to

this.

20011 An error has occurred in a script that was called by

the specified script.

Execution of the script was therefore aborted in the

called script.

Note the system alarm that may have occurred

prior to this.

20012 The configuration data is inconsistent. The script

could therefore not be generated.

20013 The scripting component of WinCC flexible

Runtime is not correctly installed. Therefore, no

scripts can be executed.

20014 The system function returns a value that is not

written in any return tag.

20015 Too many successive scripts have been triggered

in short intervals. When more than 20 scripts are

queued for processing, any subsequent scripts are

rejected. In this case, the script indicated in the

alarm is not executed.

Select the specified script line in the configuration.

Ensure that the tags used are of the allowed types.

Check system functions for the correct number and

types of parameters.

In the configuration, select the script that has been

called directly or indirectly by the specified script.

Ensure that the tags used are of the allowed types.

Check system functions for the correct number and

types of parameters.

Recompile the configuration.

Reinstall WinCC flexible Runtime on your PC.

Rebuild your project with "Project > Compiler >

Generate" and transfer the project to the HMI device.

Select the specified script in the configuration.

Check whether the script name has been assigned a

value.

Find what is triggering the scripts. Extend the times,

e.g. the polling time of the tags which trigger the

scripts.

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

Operating Instructions, 09/2010, A5E02766325-01

419

Page 21

Appendix

REVIEW ENGLISH

27.07.2010

A.6 System alarms

30000 - Alarms for IFwSetValue: SetValue()

Number Effect/causes Remedy

30010 The tag could not accept the function result, e.g.

when it has exceeded the value range.

30011 A system function could not be executed because

the function was assigned an invalid value or type

in the parameter.

30012 A system function could not be executed because

the function was assigned an invalid value or type

in the parameter.

Check the tag type of the system function parameter.

Check the parameter value and tag type of the invalid

parameter. If a tag is used as a parameter, check its

value.

Check the parameter value and tag type of the invalid

parameter. If a tag is used as a parameter, check its

value.

40000 - Linear scaling alarms

Number Effect/causes Remedy

40010 The system function could not be executed since

the parameters could not be converted to a

common tag type.

40011 The system function could not be executed since

the parameters could not be converted to a

common tag type.

Check the parameter types in the configuration.

Check the parameter types in the configuration.

50000 - Data server alarms

Number Effect/causes Remedy

50000 The HMI device is receiving data faster than it is

capable of processing. Therefore, no further data is

accepted until all current data have been

processed. Data exchange then resumes.

50001 Data exchange has been resumed. --

--

60000 - Win32 function alarms

Number Effect/causes Remedy

60000 This alarm is generated by the

“DisplaySystemAlarms” function. The text to be

displayed is transferred to the function as a

parameter.

60010 The file could not be copied in the direction defined

because one of the two files is currently open or the

source/target path is not available.

It is possible that the Windows user has no access

rights to one of the two files.

60011 An attempt was made to copy a file to itself.

It is possible that the Windows user has no access

rights to one of the two files.

--

Restart the system function or check the paths of the

source/target files. Using Windows NT/XP: The user

running WinCC flexible Runtime must be granted

access rights to the files.

Check the path of the source/target file.

Using Windows NT/XP with NTFS: The user running

WinCC flexible Runtime must be granted access rights

to the files.

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

420 Operating Instructions, 09/2010, A5E02766325-01

Page 22

Appendix

REVIEW ENGLISH

27.07.2010

A.6 System alarms

70000 - Win32 function alarms

Number Effect/causes Remedy

70010 The application could not be started because it

could not be found in the path specified or there is

insufficient memory space.

70011 The system time could not be modified.

The error alarm only appears in connection with

area pointer "Date/time PLC". Possible causes:

An invalid time was transferred in the job

mailbox.

The Windows user has no right to modify the

system time.

If the first parameter in the system alarm is

displayed with the value 13, the second parameter

indicates the byte containing the incorrect value.

70012 An error occurred when executing the function

"StopRuntime" with the option "Runtime and

operating system".

Windows and WinCC flexible Runtime are not

closed.

One possible cause is that other programs cannot

be closed.

70013 The system time could not be modified because an

invalid value was entered. Incorrect separators may

have been used.

70014 The system time could not be modified. Possible

causes:

An invalid time was transferred.

The Windows user has no right to modify the

system time.

Windows rejects the setting request.

70015 The system time could not be read because

Windows rejects the reading function.

70016 An attempt was made to select a screen by means

of a system function or job. This is not possible

because the screen number specified does not

exist.

Or: A screen could not be generated due to

insufficient system memory.

Or: The screen is blocked.

Or: Screen call has not been executed correctly.

70017 Date/time is not read from the area pointer because

the address set in the PLC is either not available or

has not been set up.

70018 Acknowledgment that the password list has been

successfully imported.

70019 Acknowledgment that the password list has been

successfully exported.

70020 Acknowledgment for activation of alarm reporting. --

Check whether the application exists in the specified

path or close other applications.

Check the time which is to be set.

Using Windows NT/XP: Users running WinCC flexible

Runtime must be granted the right to modify the

system time of the operating system.

Close all programs currently running.

Then close Windows.

Check the time which is to be set.

Check the time which is to be set.

Using Windows NT/XP: Users running WinCC flexible

Runtime must be granted the right to modify the

system time of the operating system.

--

Check the screen number in the function or job with the

screen numbers configured.

Assign the number to a screen if necessary.

Check the details for the screen call and whether the

screen is blocked for specific users.

Change the address or set up the address in the PLC.

--

--

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

Operating Instructions, 09/2010, A5E02766325-01

421

Page 23

Appendix

REVIEW ENGLISH

27.07.2010

A.6 System alarms

Number Effect/causes Remedy

70021 Acknowledgment for deactivation of alarm

reporting.

70022 Acknowledgment to starting the Import Password

List action.

70023 Acknowledgment to starting the Export Password

List action.

70024 The range of values of the tag was exceeded in the

system function.

No calculation of the system function.

70025 The range of values of the tag was exceeded in the

system function.

No calculation of the system function.

70026 No other screens are stored in the internal screen

memory.

No other screens can be selected.

70027 The backup of the RAM file system has been

started.

70028 The files from the RAM have been copied in the

Flash memory.

The files from the RAM have been copied in the

Flash memory. Following a restart, these saved

files are copied back to the RAM file system.

70029 Backup of the RAM file system has failed.

No backup copy of the RAM file system has been

made.

70030 The parameters configured for the system function

are faulty.

The connection to the new PLC was not

established.

70031 The PLC configured in the system function is not

an S7 PLC.

The connection to the new PLC was not

established.

70032 The object configured with this number in the tab

order is not available in the selected screen.

The screen changes but the focus is set to the first

object.

70033 An e-mail cannot be sent because a TCP/IP

connection to the SMTP server no longer exists.

This system alarm is generated only at the first

attempt. All subsequent unsuccessful attempts to

send an e-mail will no longer generate a system

alarm. The event is regenerated when an e-mail

has been successfully sent in the meantime.

The central e-mail component in WinCC flexible

Runtime attempts, in regular intervals (1 minute), to

establish the connection to the SMTP server and to

send the remaining e-mails.

70034 Following a disruption, the TCP/IP connection to

the SMTP server could be re-established.

The queued e-mails are then sent.

--

--

--

Check and correct the calculation.

Check and correct the calculation.

--

--

--

Check the settings in the "Control Panel > OP" dialog

and save the RAM file system using the "Save Files"

button in the "Persistent Storage" tab.

Compare the parameters configured for the system

function with the parameters configured for the PLCs

and correct them as necessary.

Compare the S7 PLC name parameter configured for

the system function with the parameters configured for

the PLC and correct them as necessary.

Check the number of the tab order and correct it if

necessary.

Check the network connection to the SMTP server and

re-establish it if necessary.

--

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

422 Operating Instructions, 09/2010, A5E02766325-01

Page 24

Appendix

REVIEW ENGLISH

27.07.2010

A.6 System alarms

Number Effect/causes Remedy

70036 No SMTP server for sending e-mails is configured.

An attempt to connect to an SMTP server has

failed and it is not possible to send e-mails.

WinCC flexible Runtime generates the system

alarm after the first attempt to send an e-mail.

70037 An e-mail cannot be sent for unknown reasons.

The contents of the e-mail are lost.

70038 The SMTP server has rejected sending or

forwarding an e-mail because the domain of the

recipient is unknown to the server or because the

SMTP server requires authentication.

The contents of the e-mail are lost.

70039 The syntax of the e-mail address is incorrect or

contains illegal characters.

The contents of the e-mail are discarded.

70040 The syntax of the e-mail address is incorrect or

contains illegal characters.

70041 The import of the user management was aborted

due to an error.

Nothing was imported.

70042 The range of values of the tag was exceeded while

executing the system function.

The system function was not calculated.

70043 The range of values of the tag was exceeded while

executing the system function.

The system function was not calculated.

70044 An error occurred while sending the e-mails. The e-

mails were not sent.

70045 Cannot load a file required for encrypting the e-

mail.

70046 The server does not support encryption. Select an SMTP server that supports encryption.

70047 The SSL versions of the HMI device and SMTP

server may not be compatible.

Configure an SMTP server:

In WinCC flexible Engineering System

using "Device settings > Device settings"

In the Windows CE operating system

using "Control Panel > Internet Settings > E-mail >

SMTP Server"

Check the e-mail parameters (recipient etc.).

Check the domain of the recipient address or disable

the authentication on the SMTP server if possible.

SMTP authentication is currently not used in

WinCC flexible Runtime.

Check the e-mail address of the recipient.

--

Check your user management or transfer it again to

the panel.

Check and correct the calculation.

Check and correct the calculation.

Check the SMTP settings and the error message in the

system alarm.

Update the operating system and Runtime.

Contact your network administrator or the operator of

the SMTP server.

80000 - Log alarms

Number Effect/causes Remedy

80001 The log specified is filled to the size defined (in

percent) and must be stored elsewhere.

80002 A line is missing in the specified log. -80003 The copying process for logging was not

successful.

In this case, it is advisable to check any

subsequent system alarms, too.

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

Operating Instructions, 09/2010, A5E02766325-01

Store the file or table by executing a ‘move’ or ‘copy’

function.

--

423

Page 25

Appendix

REVIEW ENGLISH

27.07.2010

A.6 System alarms

Number Effect/causes Remedy

80006 Since logging is not possible, this causes a

permanent loss of the functionality.

80009 A copying action has been completed successfully. -80010 Since the storage location was incorrectly entered

in WinCC flexible, this causes a permanent loss of

the functionality.

80012 Log entries are stored in a buffer. If the values are

read to the buffer faster than they can be physically

written (using a hard disk, for example),

overloading may occur and recording is then

stopped.

80013 The overload status no longer applies. Archiving

resumes the recording of all values.

80014 The same action was triggered twice in quick

succession. Since the process is already in

operation, the action is only carried out once.

80015 This system alarm is used to report DOS or

database errors to the user.

80016 The logs are separated by the system function

"CloseAllLogs" and the incoming entries exceed

the defined buffer size.

All entries in the buffer are deleted.

80017 The number of incoming events cause a buffer

overflow. This can be caused, for example, by

several copying actions being activated at the

same time.

All copy jobs in the buffer are deleted.

80019 The connection between WinCC flexible and all

logs were closed, for example, after executing the

system function "CloseAllLogs".

Entries are written to the buffer and are then written

to the logs when a connection is re-established.

There is no connection to the storage location and

the storage medium may be replaced, for example.

80020 The maximum number of simultaneously copy

operations has been exceeded. Copying is not

executed.

80021 An attempt was made to delete a log which is still

busy with a copy action. Deletion has not been

executed.

80022 An attempt was made to use the system function

"StartSequenceLog" to start a sequence log for a

log which is not configured as a sequence log. No

sequence log file is created.

In the case of databases, check whether the

corresponding data source exists and start up the

system again.

Configure the storage location for the respective log

again and restart the system when the full functionality

is required.

Archive fewer values.

Or:

Increase the logging cycle.

--

--

--

Reconnect the logs.

Stop the copy action.

--

Wait until the current copying actions have been

completed, then restart the last copy action.

Wait until the current copying actions have been

completed, then restart the last action.

In the project, check

if the "StartSequenceLog" system function was

properly configured.

if the tag parameters are properly provided with

data on the HMI device.

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

424 Operating Instructions, 09/2010, A5E02766325-01

Page 26

Appendix

REVIEW ENGLISH

27.07.2010

A.6 System alarms

Number Effect/causes Remedy

80023 An attempt was made to copy a log to itself.

The log is not copied.

In the project, check

if the "CopyLog" system function was properly

configured.

if the tag parameters are properly provided with

data on the HMI device.

80024 The "CopyLog" system function does not allow

copying when the target log already contains data

("Mode" parameter). The log is not copied.

80025 You have canceled the copy operation.

Data written up to this point are retained. The

destination log file (if configured) is not deleted.

The cancellation is reported by an error entry

$RT_ERR$ at the end of the destination log.

80026 This alarm is output after all logs are initialized.

Values are written to the logs from then on. Prior to

this, no entries are written to the logs, irrespective

whether WinCC flexible Runtime is active or not.

80027 The internal Flash memory has been specified as

the storage location for a log. This is not

permissible.

No values are written to this log and the log file is

not created.

80028 The alarm returns a status report indicating that the

logs are currently being initialized. No values are

logged until the alarm 80026 is output.

80029 The number of logs specified in the alarm could not

be initialized. The logs are initialized.

The faulty log files are not available for logging

jobs.

80030 The structure of the existing log file does not match

the expected structure.

Logging is stopped for this log.

80031 The log in CSV format is corrupted.

The log cannot be used.

80032 Logs can be assigned events. These are triggered

as soon as the log is full. WinCC flexible Runtime is

started and the log is already full, the event is not

triggered.

The log specified no longer logs data because it is

full.

80033 "System Defined" is set in the data log file as the

data source name. This causes an error. No data is

written to the database logs, whereas the logging to

the CSV logs works.

80034 An error has occurred in the initialization of the

logs. An attempt has been made to create the

tables as a backup. This action was successful. A

backup has been made of the tables of the

corrupted log file and the cleared log was restarted.

Edit the "CopyLog" system function in the project if

necessary. Before you initiate the system function,

delete the destination log file.

--

--

Configure "Storage Card" or a network path as the

storage location.

--

Evaluate the additional system alarms related to this

alarm. Check the configuration, the ODBC (Open

Database Connectivity) and the specified drive.

Delete the existing log data manually, in advance.

Delete the faulty file.

Close WinCC flexible Runtime delete the log, then

restart WinCC flexible Runtime.

Or:

Configure a button which contains the same actions as

the event and press it.

Reinstall SQL Sever 2005 Express.

No action is necessary. However, it is recommended to

save the backup files or delete them in order to make

the space available again.

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

Operating Instructions, 09/2010, A5E02766325-01

425

Page 27

Appendix

REVIEW ENGLISH

27.07.2010

A.6 System alarms

Number Effect/causes Remedy

80035 An error has occurred in the initialization of the

logs. An attempt has been made to create backups

of the tables and this has failed. No logging or

backup has been performed.

80044 The export of a log was interrupted because

Runtime was closed or due to a power failure. It

was detected that the export needed to be resume

when Runtime restarted.

80045 The export of a log was interrupted due to an error

in the connection to the server or at the server

itself.

It is recommended to save the backups or to delete

them in order to release memory.

The export resumes automatically.

The export is repeated automatically. Check:

The connection to the server.

If the server is running.

If there is enough free space on the server.

80046 The destination file could not be written while

exporting the log.

80047 The log could not be read while exporting it. Check whether the storage medium is correctly

80049 The log could not be renamed while preparing to

export it.

The job can not be completed."

80050 The log which shall be exported is not closed.

The job can not be completed.

80051 The log to be copied contains an invalid checksum.

The log was not copied.

80052 The log cannot be read. Check the log and the specified path.

80053 The closed log cannot be read. Open the log.

Check whether there is enough space on the server

and it you have permission to create the log file.

inserted.

Check whether the storage medium is correctly

inserted and if there is sufficient space on the medium.

Make sure the "CloseAllLogs" system function is called

before using the "ExportLog" system function. Change

the configuration as required.

Select a log with a valid checksum. The selected log

may have been manipulated.

90000 - FDA alarms

Number Effect/causes Remedy

90024 No operator actions can be logged due to lack of

space on the storage medium for log. The operator

action will therefore not be executed.

90025 No user actions can be logged because of error

state of the archive. Therefore the user action will

not be executed.

90026 No operator actions can be logged because the log

is closed. The operator action will therefore not be

executed.

90028 The password you entered is incorrect. Enter the correct password.

90029 Runtime was closed during ongoing operation

(perhaps due to a power failure) or a storage

medium in use is incompatible with Audit Trail. An

Audit Trail is not suitable if it belongs to another

project or has already been logged.

90030 Runtime was closed during ongoing operation

(perhaps due to a power failure).

Make more space available by inserting an empty

storage medium or swapping out the log files on the

server using "ExportLog".

Check whether the storage medium is correctly

inserted.

Before further operator actions are carried out, the log

must be opened again using the system function

"OpenAllLogs". Change the configuration as required.

Ensure that you are using the correct storage medium.

--

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

426 Operating Instructions, 09/2010, A5E02766325-01

Page 28

Appendix

REVIEW ENGLISH

27.07.2010

A.6 System alarms

Number Effect/causes Remedy

90031 Runtime was closed during ongoing operation

(perhaps due to a power failure).

90032 Running out of space on the storage medium for

log.

90033 No more space on the storage medium for log. As

of now, no more operator actions requiring logging

will be executed.

90039 You do not have the necessary authorization to

perform this action.

90040 Audit Trail is switched off because of a forced user

action.

90041 A user action which has to be logged has been

executed without a logged on user.

90044 A user action which has to be confirmed was

blocked, because there is another user action

pending.

90048 The Audit Trail cannot be printed while data

relevant to the audit is being logged.

90049 Access to required file is not possible. Check the network connection or the storage medium.

90056 The recipe was not imported because the file

contains no checksum.

90057 The recipe was not imported because the file

contains an invalid checksum. The selected file

may have been manipulated.

--

Make more space available by inserting an empty

storage medium or swapping out the log files on the

server using "ExportLog".

Make more space available by inserting an empty

storage medium or swapping out the log files on the

server using "ExportLog".

Adapt or upgrade your authorizations.

Activate the "Audit Trail" again using the system

function "StartLog".

A user action requiring logging should only be possible

with permission. Change the configuration by setting a

required authorization for the input object.

Repeat the user action if necessary.

Stop logging using the system function "StopLogging".

Select a file with a checksum.

As an alternative, disable verification of the checksum

by using the system function "ImportDataRecords".

Select a file with a valid checksum.

110000 - Offline function alarms

Number Effect/causes Remedy

110000 The operating mode was changed. "Offline" mode

is now set.

110001 The operating mode was changed. "Online" mode

is now set.

110002 The operating mode was not changed. Check the connection to the PLCs.

110003 The operating mode of the specified PLC was

changed by the system function

"SetConnectionMode".

The operating mode is now "offline".

110004 The operating mode of the specified PLC has been

changed by the system function

"SetConnectionMode".

The operating mode is now "online".

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

Operating Instructions, 09/2010, A5E02766325-01

--

--

Check whether the address area for the area pointer 88

“Coordination" in the PLC is available.

--

--

427

Page 29

Appendix

REVIEW ENGLISH

27.07.2010

A.6 System alarms

Number Effect/causes Remedy

110005 An attempt was made to use the system function

SetConnectionMode to switch the specified PLC to

"online" mode, although the entire system is in

"offline" mode. This changeover is not allowed.

The PLC remains in "offline" mode.

110006 The content of the "project version" area pointer

does not match the user version configured in

WinCC flexible. WinCC flexible Runtime is

therefore closed.

Switch the complete system to "online" mode, then

execute the system function again.

Check the following:

The project ID entered on the PLC.

The project ID entered in WinCC flexible.

120000 - Trend alarms

Number Effect/causes Remedy

120000 The trend is not displayed because you configured

an incorrect axis to the trend or an incorrect trend.

120001 The trend is not displayed because you configured

an incorrect axis to the trend or an incorrect trend.

120002 The trend is not displayed because the tag

assigned attempts to access an invalid PLC

address.

Change the configuration.

Change the configuration.

Check whether the data area for the tag exists in the

PLC, the configured address is correct and the value

range for the tag is correct.

130000 - System information alarms

Number Effect/causes Remedy

130000 The action was not executed. Close all other programs.

Delete files no longer required from the hard disk.

130001 The action was not executed. Delete files no longer required from the hard disk.

130002 The action was not executed. Close all other programs.

Delete files no longer required from the hard disk.

130003 No data medium found. The operation is canceled. Check, for example, if

The correct data medium is being accessed

The data medium is inserted

130004 The data medium is write-protected. The operation

is canceled.

130005 The file is read only. The operation is canceled. Check whether access has been made to the correct

130006 Access to file failed. The operation is canceled. Check, for example, if

130007 The network connection is interrupted.

Records cannot be saved or read over the network

connection.

Check whether access has been made to the correct

data carrier. Remove the write protection.

file. Edit the file attributes if necessary.

The correct file is being accessed

The file exists

Another action is preventing simultaneous access to

the file.

Check the network connection and eliminate the cause

of error.

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

428 Operating Instructions, 09/2010, A5E02766325-01

Page 30

Appendix

REVIEW ENGLISH

27.07.2010

A.6 System alarms

Number Effect/causes Remedy

130008 The storage card is not available.

The specified data records cannot be saved to /

read from the storage card.

130009 The specified folder does not exist on the storage

card.

Any files saved to this directory are not backed up

when you switch off the HMI device.

130010 The maximum nesting depth can be exhausted

when, for example, a value change in a script

results in the call of another script and the second

script in turn has a value change that results in the

call of yet a further script etc.

The configured functionality is not supported.

130013 The storage card is not available.

The specified data records cannot be saved to /

read from the storage card.

Insert the storage card.

Insert the storage card.

Check the configuration.

Insert the storage card.

140000 - Connection alarms chns7: Connection + device

Number Effect/causes Remedy

140000 An online connection to the PLC is established. -140001 The online connection to the PLC was shut down. -140003 No tag updating or writing is executed. Check the connection and if the PLC is switched on.

Check the parameter definitions in the Control Panel

using "Set PG/PC interface".

Restart the system.

140004 No tag update or write operations are executed

because the access point or the module

configuration is faulty.

140005 No tag updating or writing is executed because the

HMI device address is incorrect (possibly too high).

140006 No tag updating or writing is executed because the

baud rate is incorrect.

Verify the connection and check whether the PLC is

switched on.

Check the access point or the module configuration

(MPI, PPI, PROFIBUS) in the Control Panel with "Set

PG/PC interface".

Restart the system.

Use a different HMI device address.

Verify the connection and check whether the PLC is

switched on.

Check the parameter definitions in the Control Panel

using "Set PG/PC interface".

Restart the system.

Select a different baud rate in WinCC flexible

(according to module, profile, communication peer,

etc.).

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

Operating Instructions, 09/2010, A5E02766325-01

429

Page 31

Appendix

REVIEW ENGLISH

27.07.2010

A.6 System alarms

Number Effect/causes Remedy

140007 Tags are not updated or written because the bus

profile is incorrect (see %1).

The following parameters could not be written to

the registry:

1: Tslot

2: Tqui

3: Tset

4: MinTsdr

5: MaxTsdr

6: Trdy

7: Tid1

8: Tid2

9: Gap Factor

10: Retry Limit

140008 No tag updating or writing is executed because

baud rate is incorrect. The following parameters

could not be written to the registry:

0: General error

1: Wrong version

2: Profile cannot be written to the registry.

3: The subnet type cannot be written to the

registry.

4: The target rotation time cannot be written to the

registry.

5: Faulty highest address (HSA).

140009 Tags are not updated or written because the

module for S7 communication was not found.

140010 No S7 communication partner found because the

PLC is shut down.

DP/T:

The option “PG/PC is the only master” is not set in

the Control Panel under “Set PG/PC interface.”

140011 No tag updating or writing is executed because

communication is down.

140012 There is an initialization problem (e.g. when

WinCC flexible Runtime was closed in Task

Manager).

Or:

Another application (e.g.STEP7) with different bus

parameters is active and the driver cannot be

started with the new bus parameters (transmission

rate, for example).

140013 The MPI cable is disconnected and, thus, there is

no power supply.

140014 The configured bus address is in already in use by

another application.

Check the user-defined bus profile.

Check the connection and if the PLC is switched on.

Check the parameter definitions in the Control Panel

using "Set PG/PC interface".

Restart the system.

Check the connection and if the PLC is switched on.

Check the parameter definitions in the Control Panel

using "Set PG/PC interface".

Restart the system.

Reinstall the module in the Control Panel using "Set

PG/PC interface".

Switch the PLC on.

DP/T:

If only one master is connected to the network, disable

"PG/PC is the only master" in "Set PG/PC interface".

If several masters are connected to the network, enable

these. Do not change any settings, for this will cause

bus errors.

Check the connection and that the communication

partner is switched on.

Restart the HMI device.

Or:

Run WinCC flexible Runtime, then start your other

applications.

Check the connections.

Edit the HMI device address in the PLC configuration.

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

430 Operating Instructions, 09/2010, A5E02766325-01

Page 32

Appendix

REVIEW ENGLISH

27.07.2010

A.6 System alarms

Number Effect/causes Remedy

140015 Wrong transmission rate

Or:

Faulty bus parameters (e.g. HSA)

Or:

OP address > HSA or: Wrong interrupt vector

(interrupt does not arrive at the driver)

140016 The hardware does not support the configured

interrupt.

140017 The set interrupt is in use by another driver. Change the interrupt number.

140018 The consistency check was disabled by

SIMOTION Scout. Only a corresponding note

appears.

140019 SIMOTION Scout is downloading a new project to

the PLC. Connection to the PLC is canceled.

140020 The version in the PLC and that of the project

(FWX file) do not match.

Connection to the PLC is canceled.

Correct the relevant parameters.

Change the interrupt number.

Enable the consistency check with SIMOTION Scout

and once again download the project to the PLC.

Wait until the end of the reconfiguration.

The following remedies are available:

Download the current version to the PLC using

SIMOTION Scout.

Regenerate the project using WinCC flexible ES, close

WinCC flexible Runtime and restart with a new

configuration.

150000 - Connection alarms chnAS511: Connection

Number Effect/causes Remedy

150000 No more data is read or written. Possible causes:

The cable is defective.

The PLC does not respond, is defective, etc.

The wrong port is used for the connection.

System overload

150001 Connection is up because the cause of the

interruption has been eliminated.

Ensure that the cable is plugged in, the PLC is

operational, the correct port is being used.

Restart the system if the system alarm persists.

--

160000 - Connection alarms IVar (WinLC) / OPC: Connection

Number Effect/causes Remedy

160000 No more data is read or written. Possible causes:

The cable is defective.

The PLC does not respond, is defective, etc.

The wrong port is used for the connection.

System overload

160001 Connection is up because the cause of the

interruption has been eliminated.

160010 No connection to the server because the server

identification (CLS-ID) cannot be determined.

Values cannot be read or written.

Ensure that the cable is plugged in, the PLC is

operational, the correct port is being used.

Restart the system if the system alarm persists.

--

Check access rights.

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

Operating Instructions, 09/2010, A5E02766325-01

431

Page 33

Appendix

REVIEW ENGLISH

27.07.2010

A.6 System alarms

Number Effect/causes Remedy

160011 No connection to the server because the server

identification (CLS-ID) cannot be determined.

Values cannot be read or written.

Check, for example, if

The server name is correct.

The computer name is correct.

The server is registered.

160012 No connection to the server because the server

identification (CLS-ID) cannot be determined.

Values cannot be read or written.

160013 The specified server was started as InProc server.

This has not been released and may possibly lead

to incorrect behavior because the server is running

in the same process area as the WinCC flexible

Runtime software.

160014 Only one OPC server project can be started on a

PC/MP. An alarm is output when an attempt is

made to start a second project.

The second project has no OPC server

functionality and cannot be located as an OPC

server by external sources.

Check, for example, if

The server name is correct.

The computer name is correct.

The server is registered.

Note for advanced users:

Interpret the value from HRESULT.

Configure the server as OutProc Server or Local

Server.

Do not start a second project with OPC server

functionality on the computer.

170000 - S7 dialog alarms

Number Effect/causes Remedy

170000 S7 diagnostics events are not indicated because it

is not possible to log on to the S7 diagnostics

functions at this device. The service is not

supported.

170001 The S7 diagnostics buffer cannot be viewed

because communication with the PLC is shut

down.

170002 The S7 diagnostics buffer cannot be viewed

because reading of the diagnostics buffer (SSL)

was canceled with error.

170003 An S7 diagnostics event cannot be visualized. The

system returns internal error %2.

170004 An S7 diagnostics event cannot be visualized. The

system returns an internal error of error class %2,

error number %3.

170007 It is not possible to read the S7 diagnostics buffer

(SSL) because this operation was canceled with an

internal error of class %2 and error code %3.

--

Set the PLC to online mode.

--

--

--

--

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

432 Operating Instructions, 09/2010, A5E02766325-01

Page 34

Appendix

REVIEW ENGLISH

27.07.2010

A.6 System alarms

180000 - Misc/common alarms

Number Effect/causes Remedy

180000 A component/OCX received configuration data with

a version ID which is not supported.

180001 System overload because too many actions

running in parallel. Not all the actions can be

executed, some are rejected.

180002 The screen keyboard could not be activated.

Possible causes:

"TouchInputPC.exe" was not registered due to a

faulty Setup.

Install a newer component.

Several remedies are available:

Generate the alarms at a slower rate (polling).

Initiate scripts and functions at greater intervals.

If the alarm appears more frequently:

Restart the HMI device.

Install WinCC flexible Runtime again.

190000 - Tag alarms

Number Effect/causes Remedy

190000 It is possible that the tag is not updated. -190001 The tag is updated after the cause of the last error

state has been eliminated (return to normal

operation).

190002 The tag is not updated because communication

with the PLC is down.

190004 The tag is not updated because the configured tag

address does not exist.

190005 The tag is not updated because the configured

PLC type does not exist for this tag.

190006 The tag is not updated because it is not possible to

map the PLC type in the data type of the tag.

190007 The tag value is not modified because the

connection to the PLC is interrupted or the tag is

offline.

190008 The threshold values configured for the tag have

been violated, for example, by

A value entered

A system function

A script

--

Select the system function "SetOnline" to go online.

Check the configuration.

Check the configuration.

Check the configuration.

Set online mode or reconnect to the PLC.

Observe the configured or current threshold values of

the tag.

190009 An attempt has been made to assign the tag a

value which is outside the permitted range of

values for this data type.

For example, a value of 260 was entered for a byte

tag or a value of -3 for an unsigned word tag.

Mobile Panel 277F IWLAN V2, Mobile Panel 277F IWLAN (RFID Tag)

Operating Instructions, 09/2010, A5E02766325-01

Observe the range of values for the data type of the

tags.

433

Page 35

Appendix

REVIEW ENGLISH

27.07.2010

A.6 System alarms

Number Effect/causes Remedy

190010 Too many values are written to the tag (for

example, in a loop triggered by a script).

Values are lost because only up to 100 actions are

saved to the buffer.

The following remedies are available:

Increase the time interval between multiple write

actions.

Do not use an array tag longer than 6 words when

you configure an acknowledgment on the HMI

device using "Acknowledgment HMI".

190011 Possible cause 1:

The value entered could not be written to the

configured PLC tag because the high or low limit

was exceeded.

The system discards the entry and restores the

original value.

Possible cause 2:

The connection to the PLC was interrupted.

190012 It is not possible to convert a value from a source

format to a target format, for example:

An attempt is being made to assign a value to a

counter that is outside the valid, PLC-specific value

range.

A tag of the type Integer should be assigned a

value of the type String.