Page 1

Operating Instructions Edition 03/2008

Three-phase induction motor

AC COMPACT DRIVES

Type 1PL618.

Page 2

18.03.2008 13:20

Page 3

A

Three-phase induction motor

Safety information

Description

1

2

C COMPACT DRIVES

1PL618

Operating Instructions

Transport, assembly, and

connection

Start-up

Operation

Faults

3

4

5

6

Edition 03/2008

Maintenance

Spare parts

Notes

7

8

9

Page 4

Safety Guidelines

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Prescribed Usage

Note the following:

WARNING

This device may only be used for the applications described in the catalog or the technical description and only

in connection with devices or components from other manufacturers which have been approved or

recommended by Siemens. Correct, reliable operation of the product requires proper transport, storage,

positioning and assembly as well as careful operation and maintenance.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Automation and Drives

Postfach 48 48

90327 NÜRNBERG

GERMANY

A5E00215731A AD

Ⓟ 03/2008

Copyright © Siemens AG 2006,

2007.

Technical data subject to change

Page 5

Table of contents

1 Safety information...................................................................................................................................... 7

1.1 Observing the five safety rules.......................................................................................................7

1.2 Safety and application instructions ................................................................................................7

1.3 Electromagnetic fields....................................................................................................................9

1.4 ESD-sensitive components..........................................................................................................10

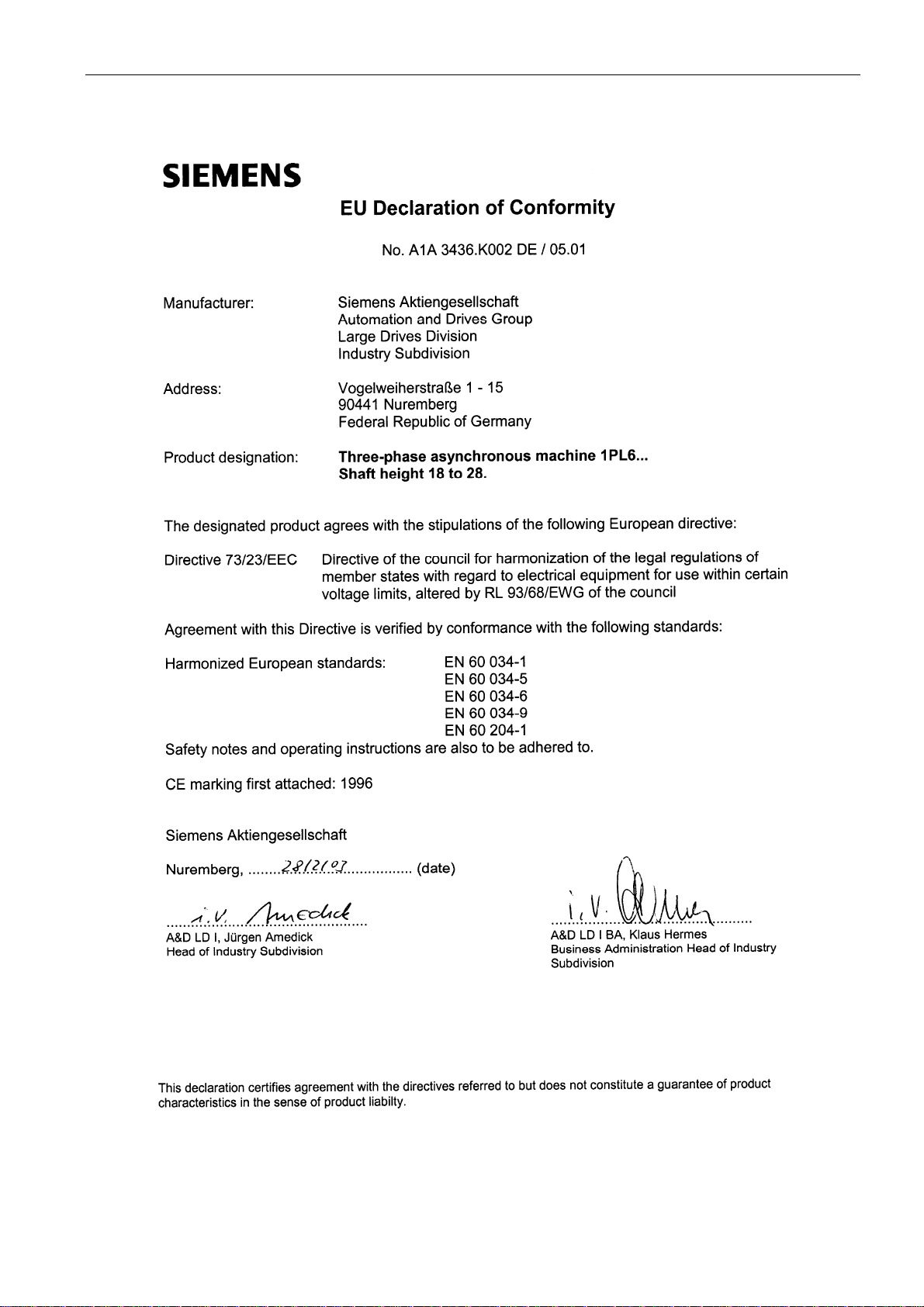

1.5 EC Declaration by the Manufacturer............................................................................................12

1.6 EC Declaration of Conformity ......................................................................................................13

2 Description............................................................................................................................................... 15

2.1 Applications..................................................................................................................................15

2.2 Siemens Service Center ..............................................................................................................15

2.3 Scope of delivery .........................................................................................................................16

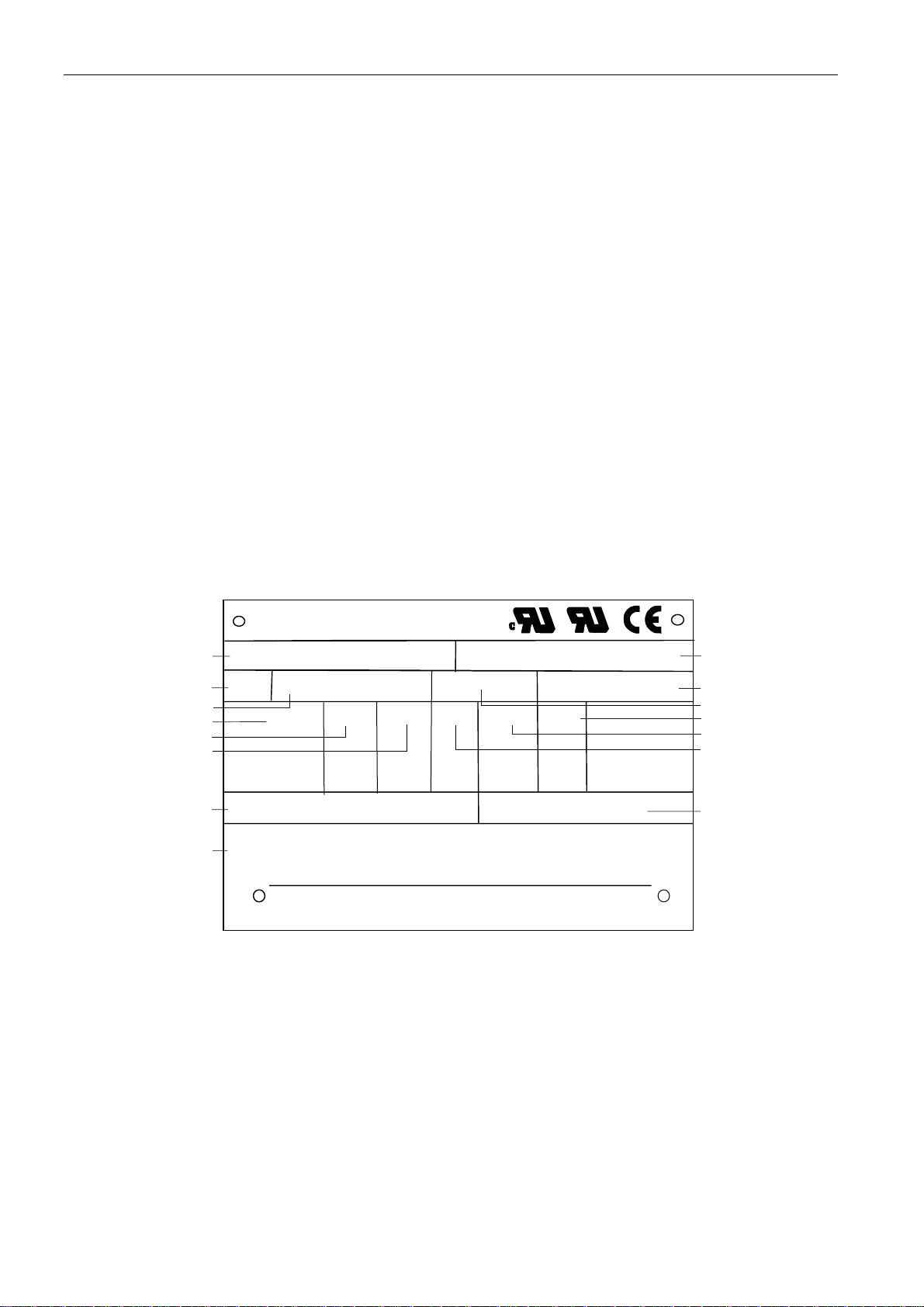

2.4 Rating plate..................................................................................................................................16

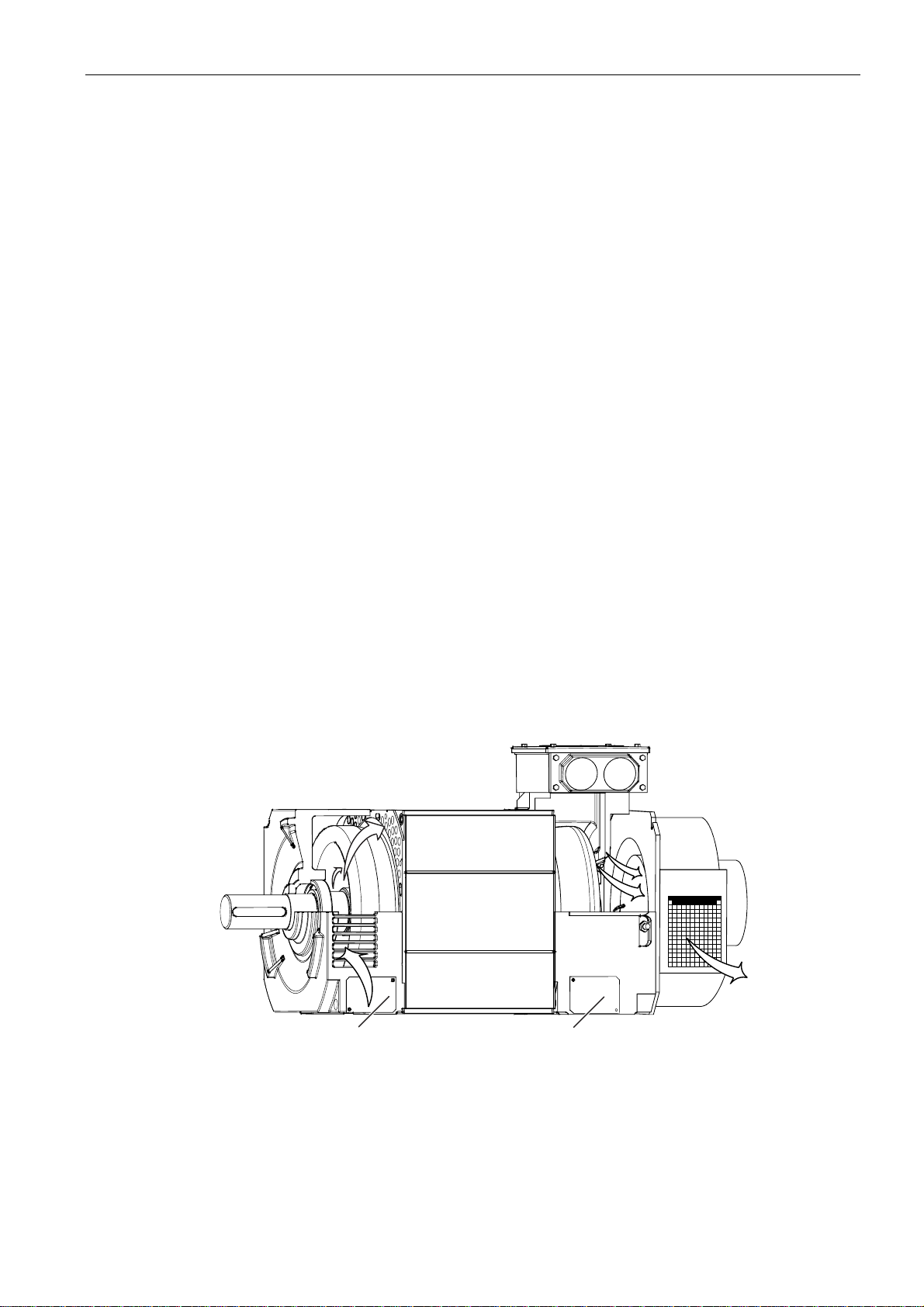

2.5 Layout ..........................................................................................................................................17

2.5.1 Cooling.........................................................................................................................................17

2.5.2 Drive.............................................................................................................................................18

2.5.3 Construction types .......................................................................................................................18

2.5.4 Regulations ..................................................................................................................................19

2.5.5 Degree of protection ....................................................................................................................20

3 Transport, assembly, and connection ...................................................................................................... 21

3.1 Transport, storage, and maintenance..........................................................................................21

3.1.1 Transport, storage........................................................................................................................21

3.1.2 Storage.........................................................................................................................................22

3.1.3 Preservation.................................................................................................................................23

3.2 Assembly......................................................................................................................................24

3.2.1 Installation....................................................................................................................................24

3.2.2 Mounting ......................................................................................................................................26

3.3 Electrical connection ....................................................................................................................27

3.3.1 Safety note for the drive-CLIQ interface ......................................................................................27

3.3.2 Connecting the stator winding............................

3.3.3 Connecting the ground conductor................................................................................................31

3.3.4 Connecting the fan.......................................................................................................................32

3.3.5 Connecting the speed sensor ......................................................................................................34

3.3.6 Connecting the Sensor Module....................................................................................................35

3.3.7 Connecting the temperature sensor ............................................................................................36

..........................................................................27

4 Start-up.................................................................................................................................................... 39

4.1 Preparations.................................................................................................................................39

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

3

Page 6

Table of contents

4.2 Measures to be performed prior to commissioning..................................................................... 41

4.3 Power on ..................................................................................................................................... 42

5 Operation................................................................................................................................................. 43

5.1 Operation..................................................................................................................................... 43

5.2 Stoppages ................................................................................................................................... 44

5.3 Deactivating ................................................................................................................................ 45

6 Faults....................................................................................................................................................... 47

6.1 Fault diagnosis table ................................................................................................................... 47

7 Maintenance ............................................................................................................................................ 49

7.1 Maintenance................................................................................................................................ 49

7.1.1 Maintenance instructions ............................................................................................................ 49

7.1.2 Maintenance intervals ................................................................................................................. 50

7.1.3 Maintenance of the external fan.................................................................................................. 51

7.1.4 Bearings ...................................................................................................................................... 51

7.1.5 Lubrication (optional)................................................................................................................... 52

7.1.6 Cleaning ...................................................................................................................................... 54

7.2 Inspection.................................................................................................................................... 55

7.2.1 General inspection specifications ............................................................................................... 55

7.2.2 Initial inspection........................................................................................................................... 55

7.2.3 Main service ................................................................................................................................ 56

7.3 Corrective Maintenance .............................................................................................................. 57

7.3.1 Instructions for repair .................................................................................................................. 57

7.3.2 Dismantling ................................................................................................................................. 57

7.3.3 Re-assembly ............................................................................................................................... 61

7.3.4 Screw-type connections.............................................................................................................. 62

7.3.5 Replacing the sensor module ..................................................................................................... 63

8 Spare parts.............................................................................................................................................. 65

8.1 Orders for spare parts ................................................................................................................. 65

8.2 Spare parts 1PL6 ........................................................................................................................ 66

9 Notes ....................................................................................................................................................... 69

Index........................................................................................................................................................ 73

Tables

Table 2-1

Table 2-2 Motor rating plate – technical specifications ............................................................................... 16

Table 2-3 Compliance with standards......................................................................................................... 20

Table 3-1 Weights of standard versions (IM B3)......................................................................................... 21

Table 3-2 Pressure drop in motors with pipe connection............................................................................ 25

Table 3-3 Terminal designations (with the 1U1-1 as an example).............................................................. 28

Technical support........................................................................................................................ 15

Table 3-4 Terminal box assignment, max. connectable cross-section per terminal................................... 29

Table 3-5 Tightening torque for the fixing screws on the lid ....................................................................... 31

A5E00215731A AD

4 Siemens AG Operating Instructions 2.02 1PL618

Page 7

Table of contents

Table 4-1 Stator winding insulation resistance at 25 °C ..............................................................................40

Table 6-1 Diagnosis table for mechanical faults ..........................................................................................47

Table 6-2 Diagnosis table for electrical faults ..............................................................................................48

Table 7-1 Operating period intervals............................................................................................................51

Table 7-2 Rolling-contact bearing greases ..................................................................................................52

Table 7-3 Tightening torque for screwed union connections .......................................................................62

Table 8-1 Spare Parts ..................................................................................................................................67

Figures

Figure 1-1

Figure 2-1 Example - 1PL6 motor rating plate ..............................................................................................16

Figure 2-2 Cooling process for ventilating from the drive end to the non-drive end (basic type)..................17

Figure 2-3 View from above onto construction type IM B3 ...........................................................................19

Figure 3-1 (1) Cover sheet (detailed view)....................................................................................................26

Figure 3-2 Connecting direction UVW for connection voltages of 400 V/480 V............................................28

Figure 3-3 Tightening torques for contact nuts and mounting bolts ① contact nut ② mounting bolt...........30

Figure 3-4 Detailed view of fan for operation at 50 Hz..................................................................................33

Figure 3-5 Fan for operation at 60 Hz ...........................................................................................................33

Figure 3-6 Detailed view: Plug-in connection................................................................................................34

Figure 3-7 Electrical connection of the speed sensor ...................................................................................35

Figure 3-8 Sensor Module ① mounted on terminal box ...............................................................................36

Figure 7-1 D-end and N-end end shields with grease nipples ......................................................................53

Figure 7-2 Detailed view of the speed sensor...............................................................................................59

Figure 7-3 Disassembling the speed sensor: forcing off, 1st option .............................................................60

Figure 7-4 Disassembling the speed sensor: forcing off, 2nd option ............................................................61

Figure 8-1 Spare parts 1PL6 .........................................................................................................................66

ESD protective measures ............................................................................................................10

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

5

Page 8

Page 9

Safety information

1.1 Observing the five safety rules

For your personal safety and to prevent material damage when working on the device,

always observe the safety instructions on the product and the following five safety rules: You

must read the information provided in "Safety information".

The five safety rules:

1. isolate,

2. Protect against reconnection,

3. verify that the equipment is not live,

4. Ground and short circuit,

5. Cover or enclose adjacent components that are still live

Qualified personnel

Commissioning and operation of this machine are to be carried out by qualified personnel

only. For the purpose of the safety information in this Instruction Manual, a “qualified person”

is someone who is authorized to energize, ground, and tag equipment, systems, and circuits

in accordance with established safety procedures.

1

1.2 Safety and application instructions

The safe use of electrical machines

WARNING

Rotating or live parts

Rotating or live parts are dangerous.

Fatal or severe injuries and substantial material damage can occur if the required covers

are removed or if the machines are not handled, operated, or maintained properly.

Only remove covers in accordance with regulations and operate machines correctly.

Perform regular maintenance on the machine.

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

7

Page 10

Safety information

1.2 Safety and application instructions

Qualified personnel

These operating instructions only contain the information that is necessary for the machines

to be used by qualified personnel in accordance with their intended purpose.

Those responsible for plant safety must ensure the following:

● The basic planning work for the system and all work relating to transportation, assembly,

installation, commissioning, maintenance and repairs is carried out by qualified personnel

and checked by responsible, suitably skilled personnel.

● The operating instructions and machine documentation are always available.

● The technical data and specifications relating to installation, connection, ambient and

operating conditions are taken into account at all times.

● The system-specific installation and safety regulations are observed.

● Personal protective equipment is used.

● Work on or in the vicinity of these machines by unqualified persons is prohibited.

● If the machines are used outside industrial areas, the installation site must be

safeguarded against unauthorized access by means of suitable protection facilities (e.g.,

safety gates) and appropriate warning signs.

See also

These operating instructions therefore only contain the information which is necessary for

the machines to be used by qualified persons in accordance with their intended purpose.

Note

Siemens Service Center

We recommend engaging the support and services of your local Siemens Service Center for

all planning, installation, commissioning, and maintenance work.

[ID 2.02]

Siemens Service Center (Page 15)

A5E00215731A AD

8 Siemens AG Operating Instructions 2.02 1PL618

Page 11

Safety information

1.3 Electromagnetic fields

1.3 Electromagnetic fields

Safety information

WARNING

Electromagnetic fields "electro smog"

Electromagnetic fields are generated by the operation of electrical power engineering

installations such as transformers, converters or motors.

Electromagnetic fields can interfere with electronic devices, which could cause them to

malfunction. For example, the operation of heart pacemakers can be impaired, potentially

leading to damage to a person's health or even death. It is therefore forbidden for persons

with heart pacemakers to enter these areas.

The plant operator is responsible for taking appropriate measures (labels and hazard

warnings) to adequately protect operating personnel and others against any possible risk.

● Observe the relevant nationally applicable health and safety regulations. In Germany,

"electromagnetic fields" are subject to regulations BGV B11 and BGR B11 stipulated by

the German statutory industrial accident insurance institution.

● Display adequate hazard warning notices.

● Place barriers around hazardous areas.

● Take measures, e.g. using shields, to reduce electromagnetic fields at their source.

● Make sure that personnel are wearing the appropriate protective gear.

[ID5003.011]

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

9

Page 12

Safety information

1.4 ESD-sensitive components

1.4 ESD-sensitive components

ESD guidelines

CAUTION

Electrostatic discharge

Electronic modules contain components that can be destroyed by electrostatic discharge.

These modules can be easily destroyed by improper handling.

To protect your equipment against damage, follow the instructions given below.

● Never touch electronic modules unless absolutely necessary in the course of

maintenance and repair procedures.

● If the modules have to be touched, the body of the person concerned must be

electrostatically discharged immediately beforehand and be grounded.

● Electronic modules should not be brought into contact with electrically insulating materials

such as plastic foil, plastic parts, insulating table supports or clothing made of synthetic

fibers.

● Always place electrostatic endangered assemblies on conductive bases.

● Always store and transport electronic modules or components in conductive packaging

(e.g. metallized plastic or metal containers).

Note

If the modules are to be stored and/or transported in non-conducting packings anyway,

they must be wrapped in conducting materials before doing so. Always use suitable

material for this purpose, for example, conductive foam rubber or household aluminum

foil.

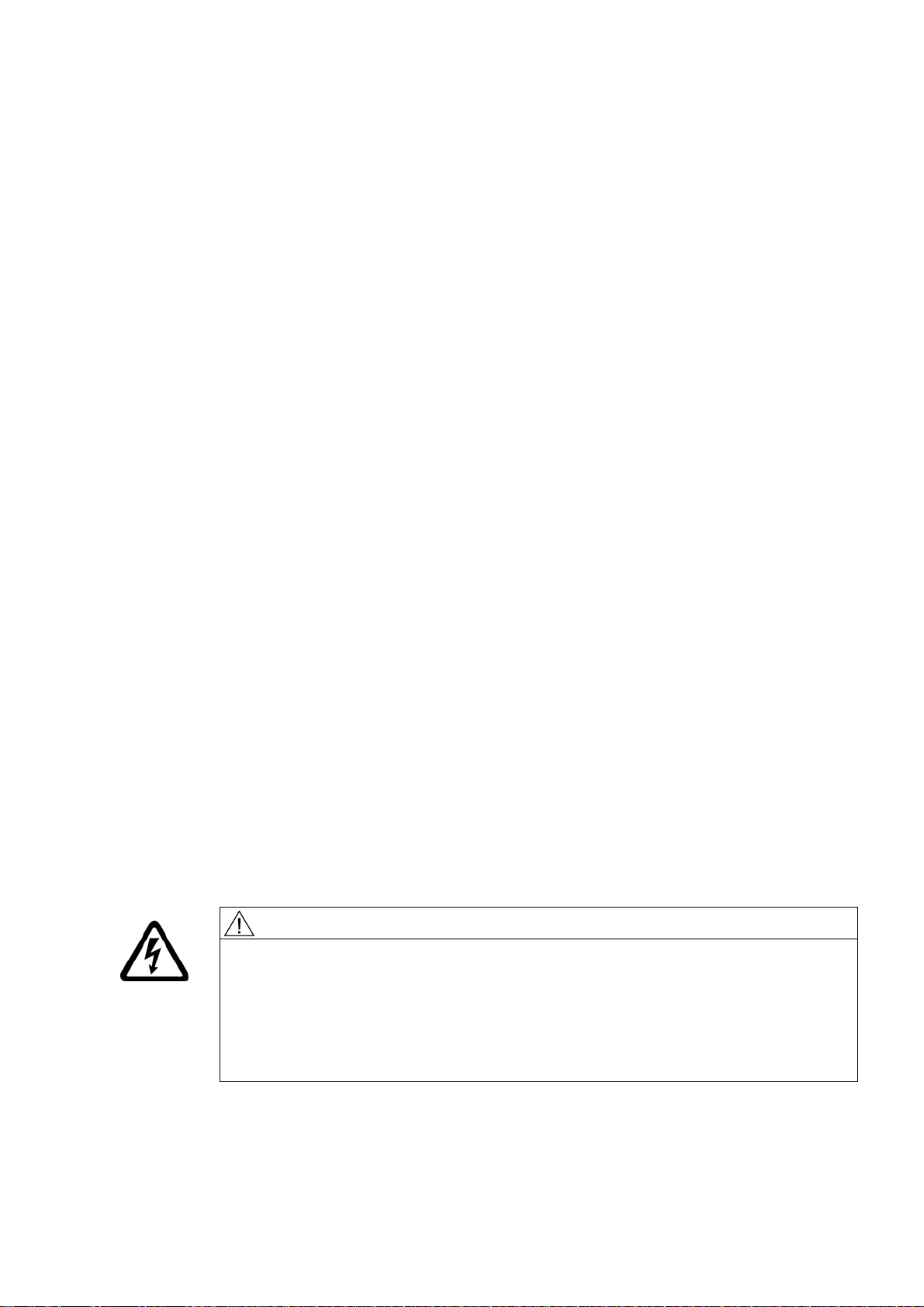

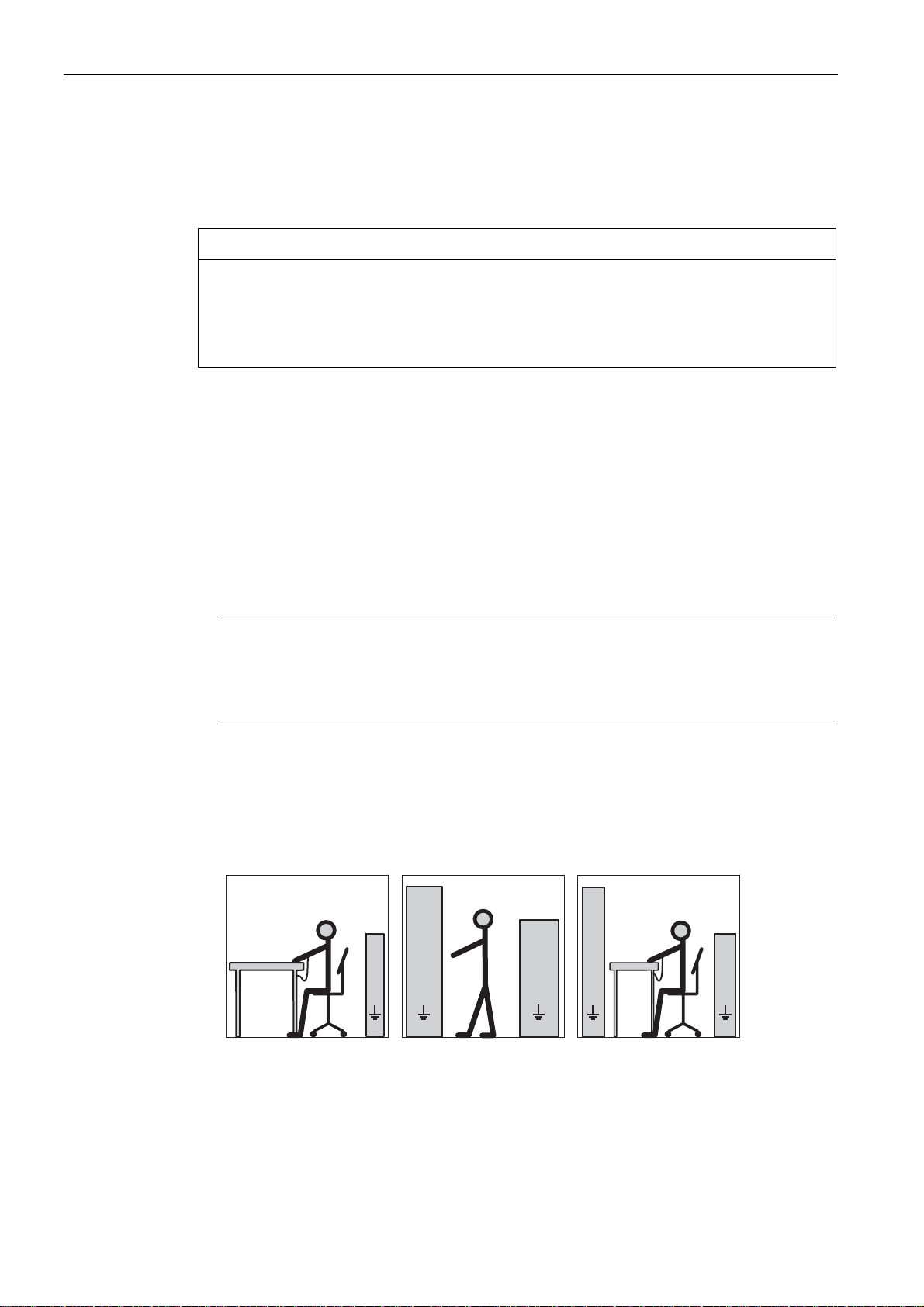

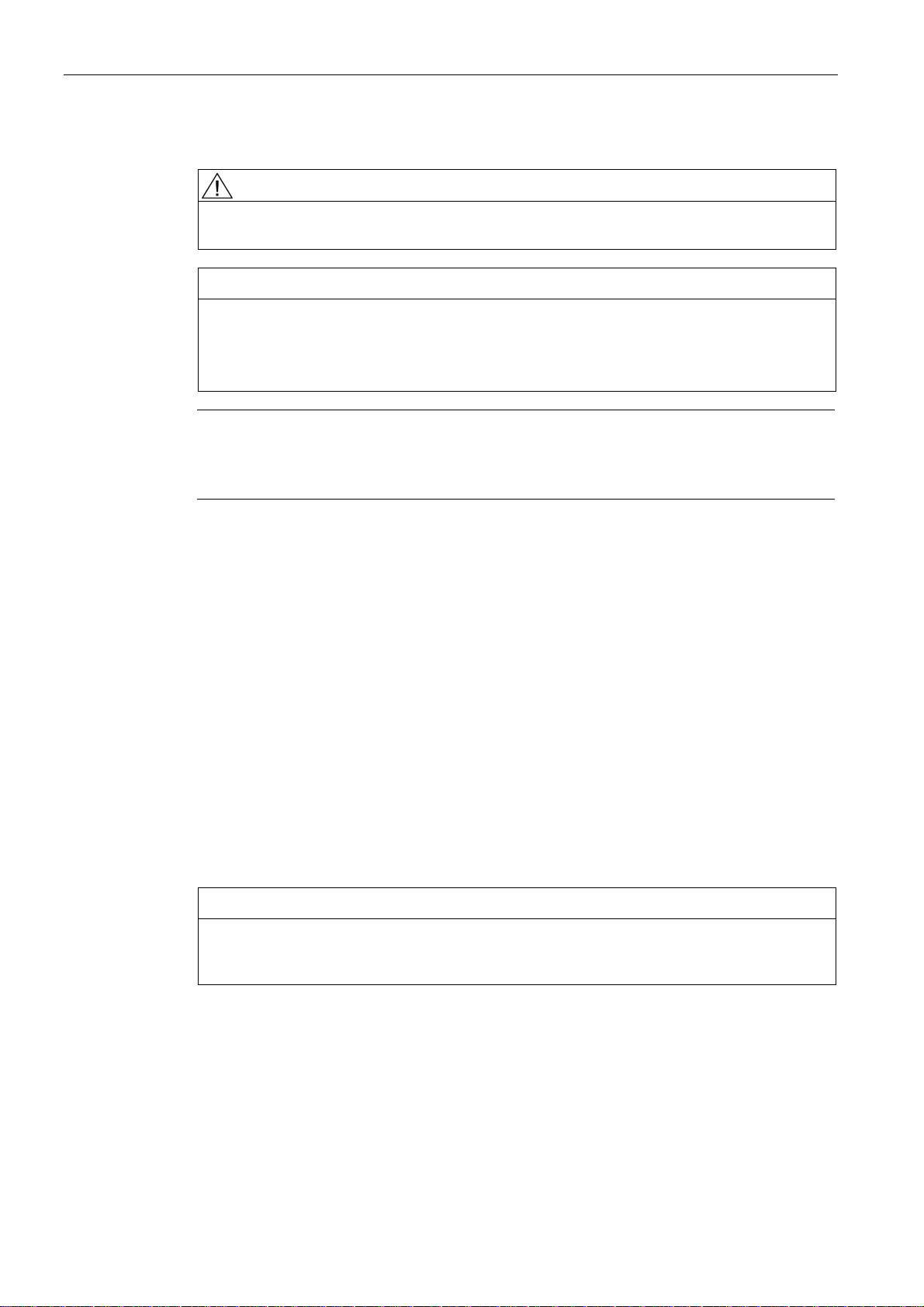

The necessary ESD protective measures for electrostatically sensitive devices are illustrated

once again in the following drawings:

b

cc c

(1) (2) (3)

Figure 1-1 ESD protective measures

A5E00215731A AD

d

ee

ff f f

aaaa

dd

b

e

f

10 Siemens AG Operating Instructions 2.02 1PL618

Page 13

Safety information

1.4 ESD-sensitive components

(1) Sitting

(2) Standing

(3) Standing/sitting

ESD protective measures

a = conductive floor

b = ESD table

c = ESD footwear

d = ESD coat

e = ESD wrist strap

f = cubicle ground connection

[ID 6006.01]

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

11

Page 14

Safety information

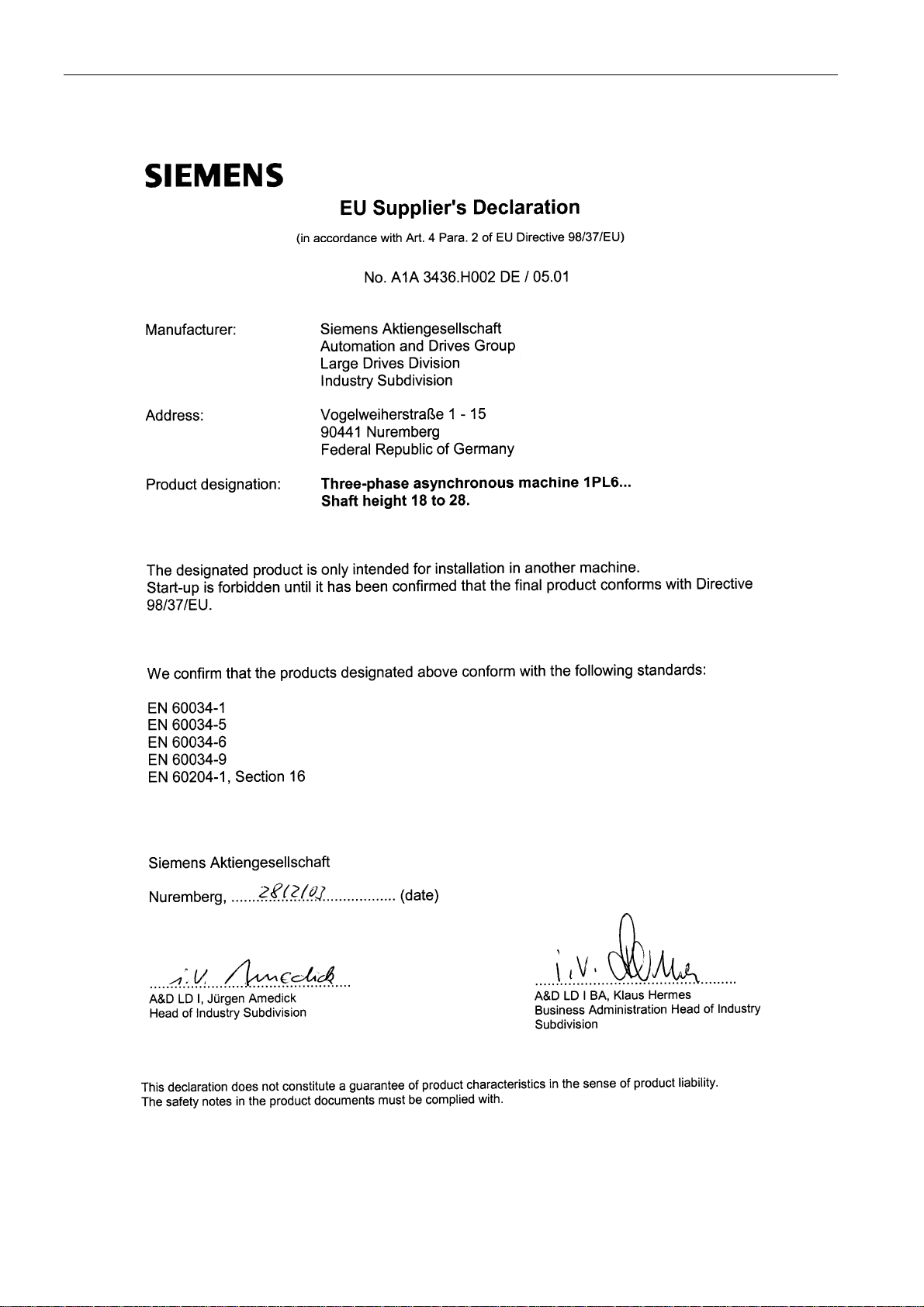

1.5 EC Declaration by the Manufacturer

1.5 EC Declaration by the Manufacturer

A5E00215731A AD

12 Siemens AG Operating Instructions 2.02 1PL618

Page 15

Safety information

1.6 EC Declaration of Conformity

1.6 EC Declaration of Conformity

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

13

Page 16

Page 17

Description

2.1 Applications

Overview

Three-phase motors of the 1PL6 series are used as industrial drives. They have been

designed for a wide range of applications in the fields of drive engineering and power

conversion.

They are characterized by their high power density, ruggedness, long lifetime, and overall

reliability.

[ID: 301]

2.2 Siemens Service Center

Contact for further information

Details regarding the design of this electrical machine and the permissible operating

conditions are described in these operating instructions. If you have any questions or

suggestions, or if you require additional information, please contact the Siemens Service

Center:

2

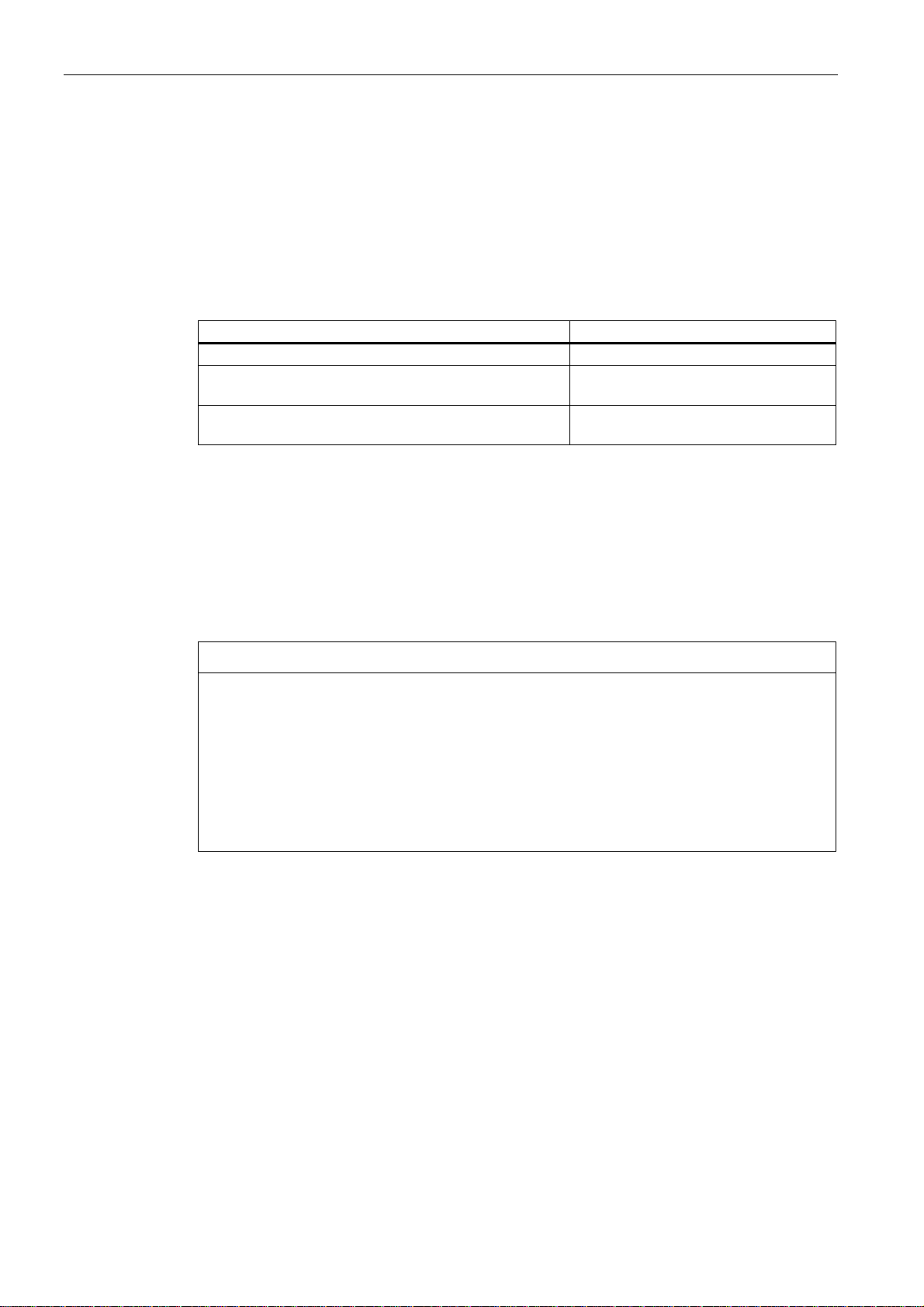

Table 2-1 Technical support

Europe - Germany:

America - USA: Phone: +1 423 262 2522

Asia - China: Phone: +86 1064 719 990

E-Mail: support.automation@siemens.com

Internet English: www.siemens.com/automation/support-request

Internet Deutsch: www.siemens.de/automation/support-request

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

Phone: +49 (0)180 - 50 50 222

Fax +49 (0)180 - 50 50 223

15

Page 18

Description

0$'(,1*(50$1<'1íUQEHUJ

SIEMENS

2.3 Scope of delivery

2.3 Scope of delivery

Checking the scope of delivery for completeness

The drive systems are put together on an individual basis. When you take receipt of the

delivery, please check immediately whether the scope of the delivery matches up with the

accompanying documents. Siemens will not accept any claims relating to items missing from

the delivery and that are submitted at a later date.

● Report any apparent transport damage to the delivery agent immediately.

● Report any apparent defects/missing components to the appropriate SIEMENS office

immediately.

These Operating Instructions are included in the scope of delivery and must be kept in a

location where they can be easily accessed.

The rating plate enclosed as a loose item with the delivery ensures that the motor data can

also be affixed on or near the machine or system.

[ID: 303.02]

2.4 Rating plate

The motor rating plate shows the technical specifications applicable to the supplied motor.

a0RW

ແ

ໂ

%

ໃ

ໄ

ໆ

(1(&

.7<

່

(1&2'(5B+BB65

Figure 2-1 Example - 1PL6 motor rating plate

Table 2-2 Motor rating plate – technical specifications

1 Motor type: Three-phase induction motor

2 Type of construction

3 Degree of protection

4 Rated voltage [V] and winding connection

5 Rated current [A]

3/+'$& 1R17

9

<

<

<

,3,0

$

7K&O

N: FRV

)

+] PLQ

PD[

*HZ:7 NJ

0$'(,1*(50$1<'1íUQEHUJ

PLQ

້

໊

໋

໌

ໍ

໎

'(:

A5E00215731A AD

16 Siemens AG Operating Instructions 2.02 1PL618

Page 19

Description

2.5 Layout

6 Rated output [kW]

7 Standards and regulations

8 Code sensor type, temperature sensor KTY84

9 Serial number

10 Motor weight [kg]

11 Temperature class

12 Rated speed [rpm]

13 Rated frequency [Hz]

14 Power factor [cos φ]

15 Maximum speed [rpm]

[ID: 307.02]

2.5 Layout

2.5.1 Cooling

Description

The three-phase motors of the 1PL6 series are externally and enclosed-ventilated, lowvoltage induction motors with a squirrel-cage rotor and a separately driven fan unit mounted

as standard. The motors have an internal cooling circuit (cooling method IC06 according to

DIN EN IEC 60034-6).

Cooling process (basic type)

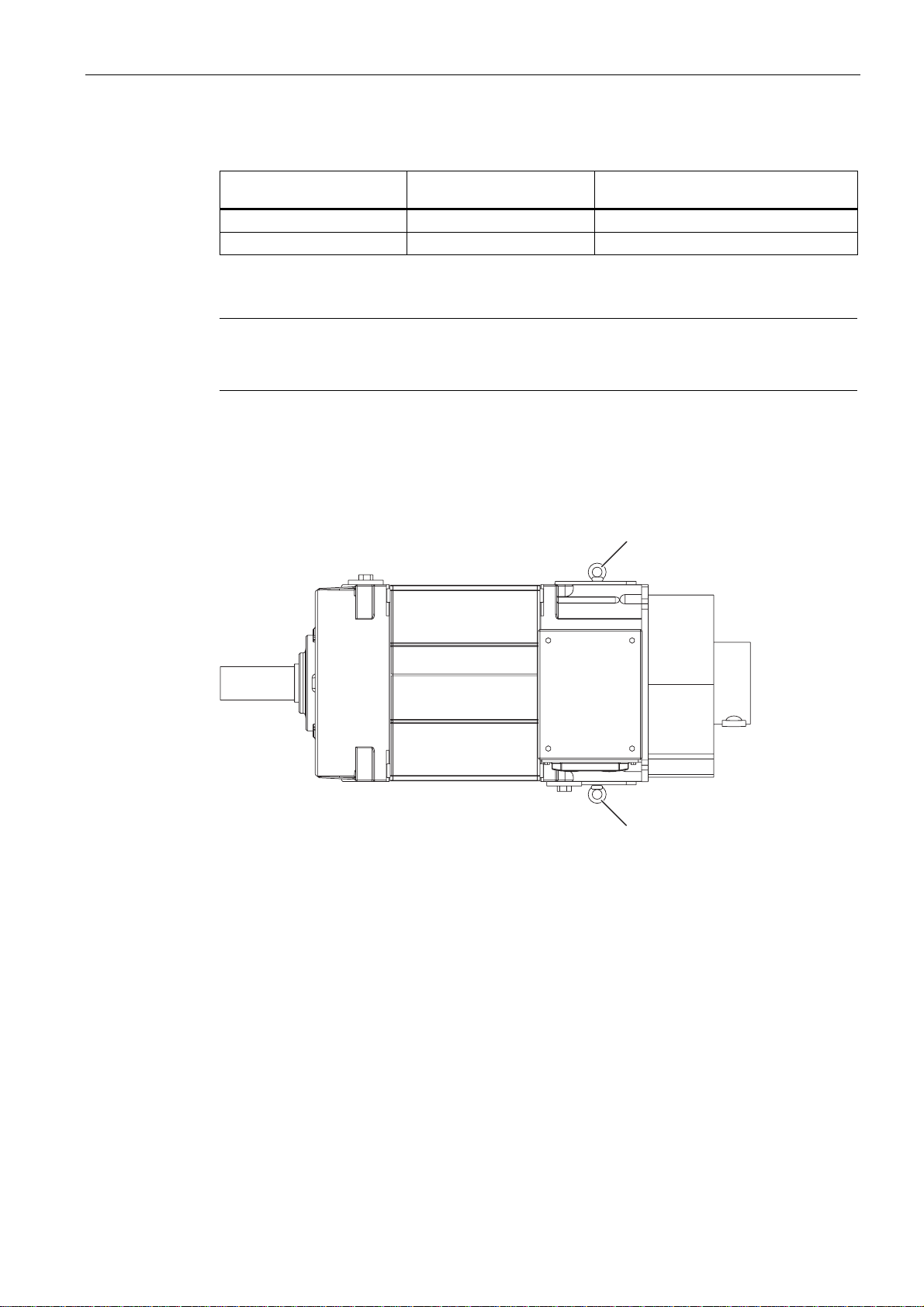

Figure 2-2 Cooling process for ventilating from the drive end to the non-drive end (basic type)

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

ཱ

17

Page 20

Description

2.5 Layout

① Cover sheet

② Cooling flow

A KTY 84 temperature sensor is installed in the stator winding to monitor the winding.

Depending on the order, various additional devices such as sensor systems can be installed

or built on.

NOTICE

A minimum clearance of 100 mm from devices added on by the customer must be

observed at the air intake opening and at the air outlet openings, in order to guarantee the

necessary flow of cooling air.

Securing the cooling capacity

CAUTION

Missing cover sheets can result in considerably reduced cooling capacity and thus cause

an inadmissible temperature rise within the motor.

Please ensure that the cover sheets are always mounted.

[ID: 973.00]

2.5.2 Drive

Description

The variable-speed, three-phase motors of the 1PL6 series are supplied with power by a

frequency converter.

[ID: 313]

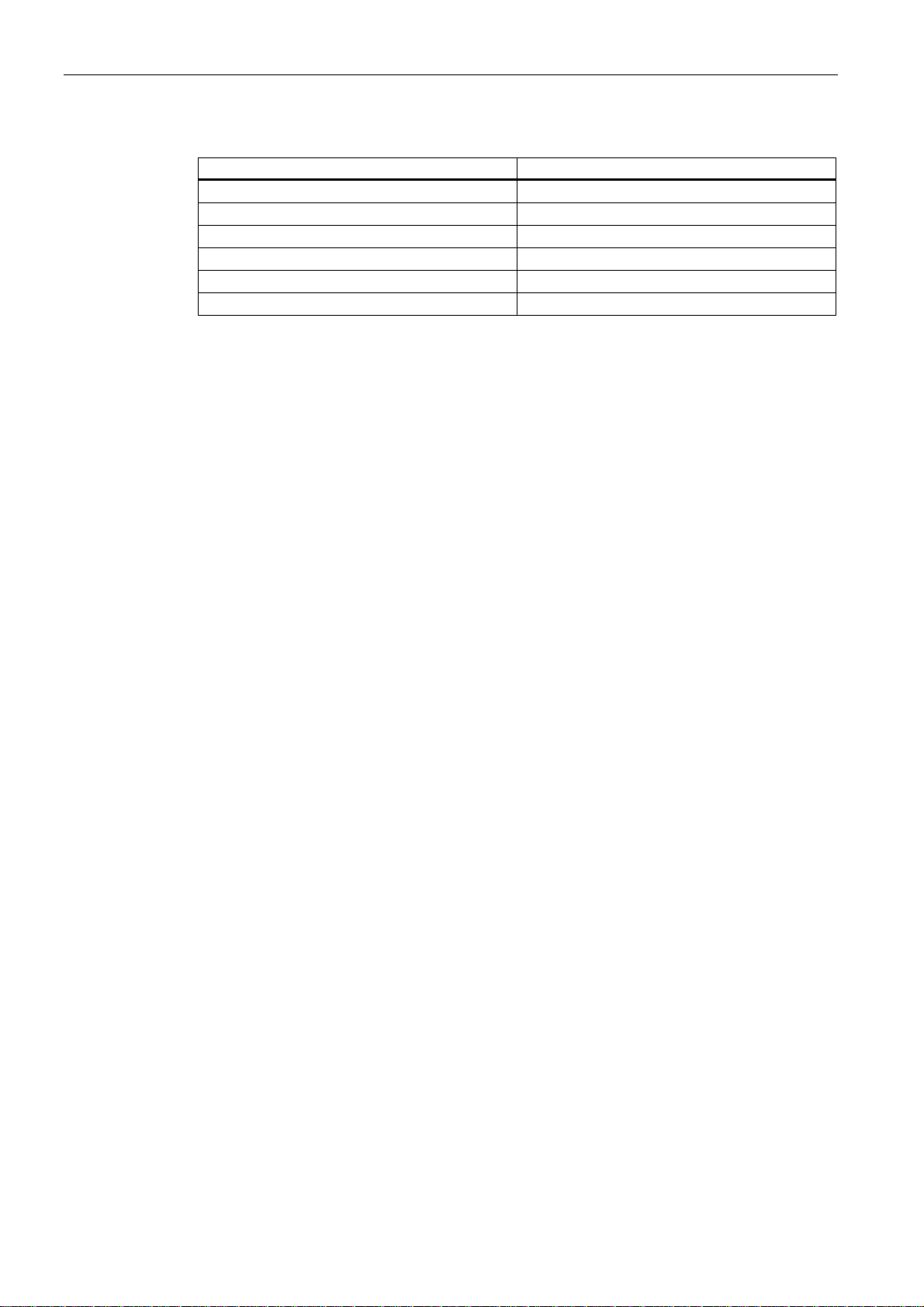

2.5.3 Construction types

Further potential applications

The construction type of the motor is stated on the rating plate.

CAUTION

During transportation, motors must only be hoisted in a position corresponding to their

basic construction type.

A5E00215731A AD

18 Siemens AG Operating Instructions 2.02 1PL618

Page 21

Description

2.5 Layout

Basic construction type acc.

to rating plate

IM B3 1PL6 184…1PL6 186 IM B6, IM B7, IM B8, IM V5, IM V6

IM B35 (1) 1PL6 184…1PL6 186 IM V36, IM V15

The maximum permissible speed for flange-mounted construction types (IM B5, IM V1, IM

V3) is restricted to 3000 rpm (see also "Planning Guide").

Type Other applications in construction type

Note

For additional instructions and restrictions for construction types that do not correspond to

the basic type, please refer to the "Planning Guide".

Additional hoisting points for different construction types (option)

Additional hoisting points are provided for those construction types that differ from the basic

construction types IM B3 and IM B35 (see Fig.).

ແ

Figure 2-3 View from above onto construction type IM B3

① Hoisting points

[ID: 318.01]

2.5.4 Regulations

Overview

The motors comply with the following regulations under IEC EN 60034:

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

ແ

19

Page 22

Description

2.5 Layout

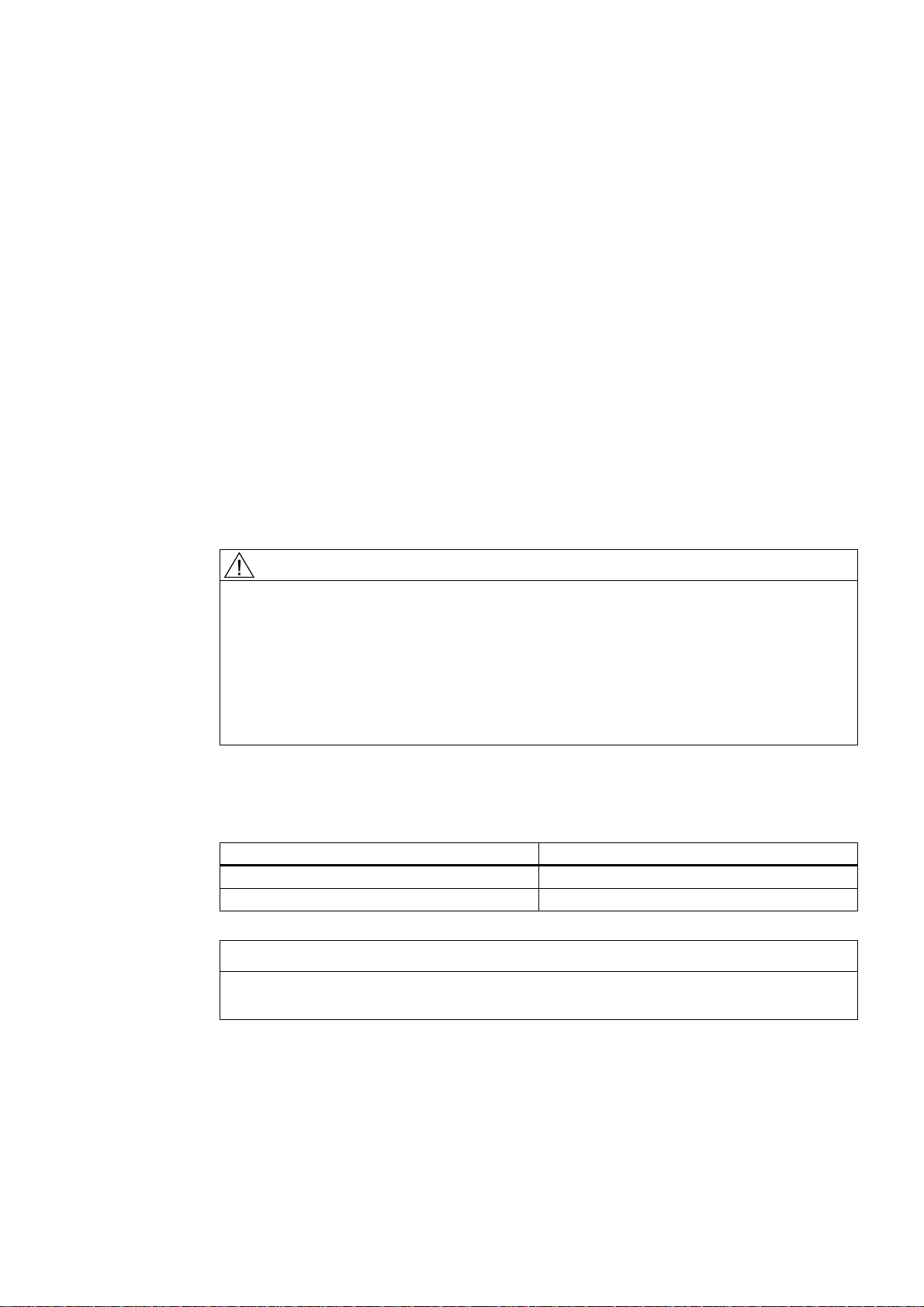

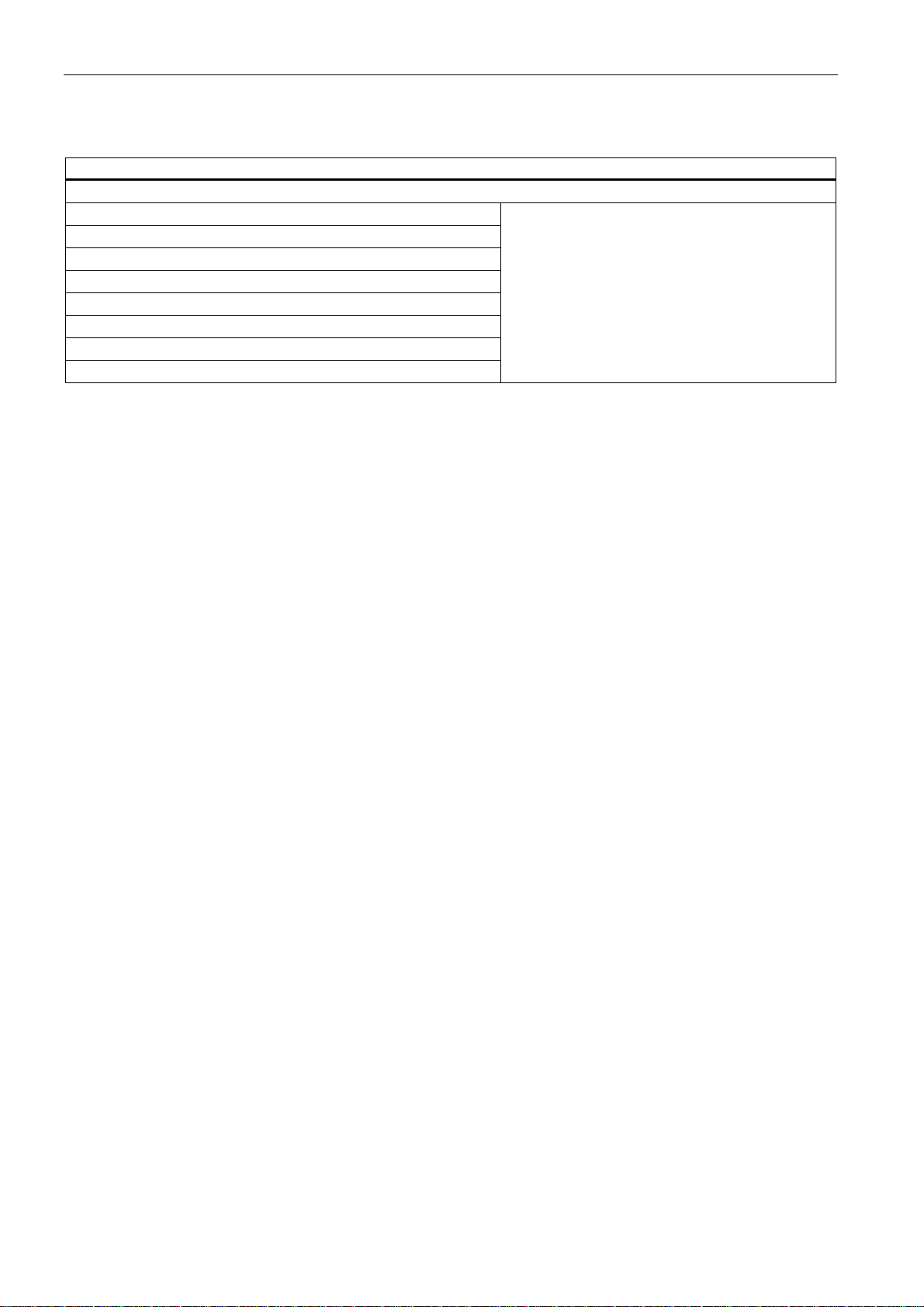

Table 2-3 Compliance with standards

Feature Standard

Dimensions and operating performance IEC/EN 60034-1

Degree of protection (1) IEC/EN 60034-5

Cooling IEC/EN 60034-6

Type of construction IEC/EN 60034-7

Noise emission IEC/EN 60034-9

Vibration severity levels IEC/EN 60034-14

(1) See the rating plate for the degree of machine protection.

[ID: 319.01]

2.5.5 Degree of protection

The three-phase motors of the 1PL6 series are built to degree of protection IP23 in

accordance with IEC EN 60034-5.

The standard version of the motors is not suitable for operation in a salt-laden or corrosive

atmosphere, nor for installation outdoors.

[ID: 391]

A5E00215731A AD

20 Siemens AG Operating Instructions 2.02 1PL618

Page 23

Transport, assembly, and connection

3.1 Transport, storage, and maintenance

3.1.1 Transport, storage

Instructions relevant to safety

Please observe the following instructions on the transportation and storage of motors.

WARNING

Motors may only be attached to and hoisted by the main eyebolts that are located at the

end shields. Auxiliary eyebolts, e.g. on fan cowls and cooler attachments, are suitable only

for hoisting the respective parts.

To hoist the motor, in particular at attachments and built-on assemblies, use suitable cableguidance or spreading equipment.

Observe the lifting capacity of the hoisting gear.

3

(For weight, see rating plate and table "Weights of standard versions")

Table 3-1 Weights of standard versions (IM B3)

Type Weight

1PL6 184 Approx. 370 kg

1PL6 186 Approx. 440 kg

NOTICE

If the motor is not immediately commissioned, then it should be stored in a dry room which

is free from vibration and shock.

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

21

Page 24

Transport, assembly, and connection

3.1 Transport, storage, and maintenance

Transporting motors with a rotor shipping brace

Motors with cylindrical-roller bearings have a rotor shipping brace (shaft block), in order to

prevent the bearings from becoming damaged during transportation/shipping.

● Only remove this brace before fitting the drive element.

[ID: 325.01]

3.1.2 Storage

CAUTION

Seizure damage to friction bearings and rolling-contact bearings

If storage conditions are inappropriate there is a risk of bearing seizure damage. This can

result in brinelling, for example.

Read the following notes on storage.

Storing outdoors

Store the machine in a location that meets the following criteria:

NOTICE

Take other suitable measures to axially fix the rotor if the motor has to be transported

after you have fitted the drive element.

Storing indoors

● Choose a dry storage location with plenty of space, which is safe from flooding and free

from vibrations.

● Repair any damage to the packaging before putting the equipment into storage insofar as

this is necessary to ensure proper storage conditions.

● Position machines, devices, and crates on pallets, wooden beams or foundations that

guarantee protection against ground dampness.

● Prevent the machine sinking into the ground.

● Ensure that the air circulation under the equipment is not impeded.

– Covers or tarpaulins used to protect the equipment against the weather must not

make contact with the surfaces of the equipment.

– Covers or tarpaulins must not trail on the floor around the machine.

– Place wooden spacer blocks between the covers and the machine.

● Store the machine in a room that meets the following criteria:

– Dry, dust-free, frost-free and vibration-free

– Well ventilated

A5E00215731A AD

22 Siemens AG Operating Instructions 2.02 1PL618

Page 25

Transport, assembly, and connection

3.1 Transport, storage, and maintenance

– Offers protection against extreme weather conditions

– The air in the room must not contain any harmful gases.

● Protect the machine from shocks and humidity.

[ID 1079.01xx]

3.1.3 Preservation

Preservation

If you are storing a machine for more than six months, you must check its condition every six

months.

● Check the machine for damage.

● Carry out any necessary maintenance work.

● Document all preservation measures taken so that they can be reversed before the

machines are put back into service.

● Provide a constant source of low heat to the machine windings, along with forced air

Condensation water

Condensation water can collect in the machine as a result of sharp fluctuations in ambient

temperature, exposure to direct sunlight, high levels of humidity in the storage location or

intermittent operation/variations in load during operation.

CAUTION

Damage caused by condensation water

If the stator winding gets damp, its insulation resistance decreases. This results in voltage

flashovers, which can destroy the winding. Condensation can also cause rusting inside the

machine.

ventilation.

CAUTION

Bearing damage caused by vibrations

If storage conditions are inappropriate there is a risk of bearing seizure damage. This

can result in material damage, such as damage to bearings due to vibration.

On machines that have been supplied with a rotor locking device, secure the rotor as

per the notes on transportation. Protect the machine against strong radial vibrations,

since the rotor locking device might not absorb these completely.

Ensure that condensation water is drained off.

In the end shields at the drive end and non-drive end, water drain holes are situated in the

foot area and opposite the regreasing devices. They are sealed with small plastic plugs or

screw plugs. Depending on the type of installation, the water drain holes are located at the

bottom.

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

23

Page 26

Transport, assembly, and connection

3.2 Assembly

1. Remove the screw plugs or plastic plugs regularly to drain off the condensation water.

2. Replace the plugs afterwards.

NOTICE

Degree of protection

Nominally the degree of protection of the machine is reduced to IP44 by removing the

plastic plug or screw plug.

[ID 1079.02]

3.2 Assembly

3.2.1 Installation

Instructions relevant to safety

CAUTION

The enclosure components of electric motors can become very hot (possibly > 100 °C). Do

not touch enclosure components while the motor is running or immediately after it has been

running.

CAUTION

When positioning temperature-sensitive components (wires etc.), make sure that they are

not in contact with the motor enclosure.

NOTICE

Note also the technical specifications on the rating plates on the motor enclosure.

Cooling conditions in general

● In the case of motors that are cooled by the ambient air, the cooling air must be able to

flow unimpeded to and from the motors. Hot discharged air must not be reinducted (see

also "Cooling").

Cooling conditions for motors with pipe connection

Motors that are configured to allow pipes to be connected and/or for operation with a

separately driven fan must have pipes and a fan of suitable type and dimensioning mounted

and connected to them.

A5E00215731A AD

24 Siemens AG Operating Instructions 2.02 1PL618

Page 27

Transport, assembly, and connection

3.2 Assembly

Please refer to the table below for the potential pressure drop inside the motor for motors

with a pipe connection:

Table 3-2 Pressure drop in motors with pipe connection

1PL6 18.

Volumetric flow (V) Pressure drop (Δp)

0.27 m3/s 650 Pa

Balancing quality

NOTICE

Please consider the additional pressure drop that arises in the system when connecting the

pipes.

Also ensure that:

● you comply with the conditions of the IP degree of protection.

Higher IP requirements may necessitate the installation of suitable filters and special

positioning of the intake and outlet openings.

● units and wires are mounted without distortion.

● the shipping covers of the ventilation openings are removed.

The rotors are balanced dynamically. In the case of shaft ends with feather keys, the method

used to balance the rotors can be identified from the following coding to be found on the end

face at the drive end of the shaft end:

● Code "H" means balancing with half a feather key (standard version); this means that in

order to maintain the balancing quality it may be necessary to cut back the part of the

feather key protruding from the drive element and the shaft profile if the motor has a short

output element.

● "F" means balancing with a whole featherkey (optional version).

Make sure that the balancing method of the output element is correct!

CAUTION

A suitable tool must always be used for fitting and pulling off output elements.

The feather keys are only locked against falling out during shipping.

Noise emission

Motors of the 1PL618. series have a measuring surface sound pressure level Lp(A) of

approx. 73 dB(A) + 3 dB (tolerance) in a speed range from 0 through 2000 rpm.

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

25

Page 28

Transport, assembly, and connection

3.2 Assembly

The motors are certified for a wide range of installation and operating conditions. In some

cases, these conditions (e.g. rigid or vibration-isolated foundation design, use of soundabsorbing elements) can have a significant influence on noise emissions.

When evaluating the noise levels at the workplaces of the system operators, consider the

fact that the A-weighted sound pressure level (measured in accordance with DIN EN 21680

Tl.1) of 70 dB(A) is exceeded when the three-phase motors are operated at nominal load.

[ID: 329.01]

3.2.2 Mounting

Requirements

In order to ensure smooth, vibration-free motor operation, a stable foundation design is

required, the motor must be precisely aligned, and the components that are to be mounted

on the shaft end must be correctly balanced.

Removing the cover sheets

Cover sheets are attached by means of the screw positions on the motor feet.

The cover sheets (1) have to be removed before mounting the motor

Figure 3-1 (1) Cover sheet (detailed view)

CAUTION

The cover sheets ensure the cooling of the motor.

Please make sure that the cover sheets are always screwed back onto the motor after

mounting the motor via the motor feet.

ແ

Fixing by means of motor feet

If the motor needs to be aligned, position metal shims underneath the feet in order to prevent

machine deformation.

The number of shims should be kept as low as possible i.e. stack as few as possible.

A5E00215731A AD

26 Siemens AG Operating Instructions 2.02 1PL618

Page 29

Transport, assembly, and connection

3.3 Electrical connection

Fixing bolts

To securely mount the motor and reliably transfer the drive torque, use motor fixing bolts

(M12) with the required strength class (8.8) in accordance with ISO 898-1.

NOTICE

All flange motors must have stable suspension and be supported by means of the endshield feet (foot-flange type of construction). When carrying out commissioning, make sure

that the vibration values permitted in accordance with DIN ISO 10816-3 are maintained.

Motors that are mounted, as a result of their type of construction, to the wall using the

motor feet, must be fixed in place using an adequately dimensioned positive form fit (e.g.

using studs or mounting rails).

[ID: 331.02]

3.3 Electrical connection

3.3.1 Safety note for the drive-CLIQ interface

CAUTION

Electrostatically sensitive devices

The drive-CLIQ interface contains components that are susceptible to electrostatic

charging. DTouching connections on the sensor module with electrostatic charged hands or

tools can cause malfunctions.

Comply with ESD protection measures (Page 10).

[ID 962.01]

3.3.2 Connecting the stator winding

Circuit diagram

Details with respect to wiring and connecting the motor winding are laid down in the circuit

diagram. The circuit diagram is attached to the lid of the terminal box.

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

27

Page 30

Transport, assembly, and connection

$

3.3 Electrical connection

'

:

$':

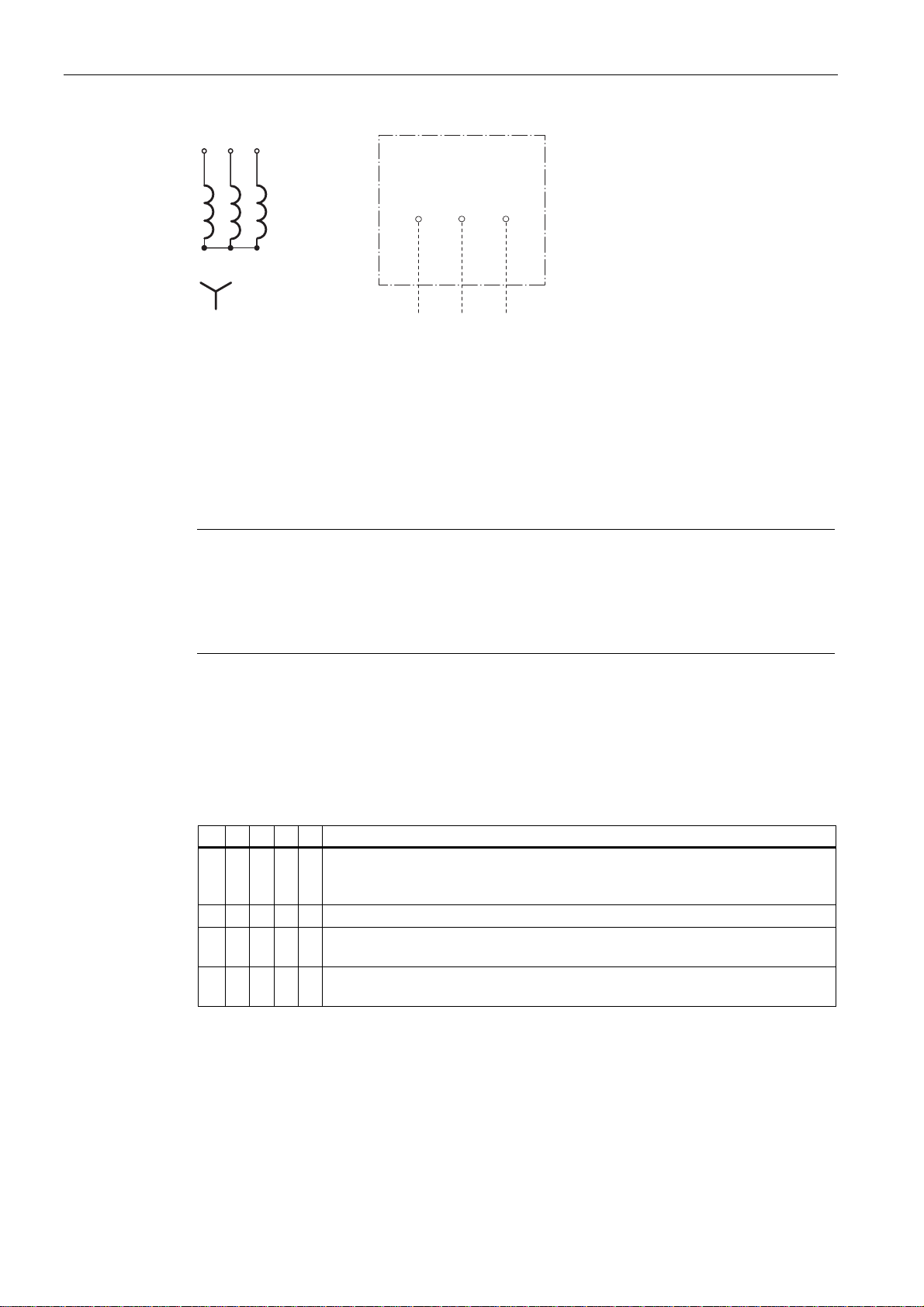

Figure 3-2 Connecting direction UVW for connection voltages of 400 V/480 V

Select the connecting cables taking into account the rated current and the system specific

conditions (e.g. ambient temperature, routing type etc. in accordance with IEC EN 60204-1).

Direction of rotation

Connection of the power cables in the phase sequence L1, L2, L3 to U, V, W results in

clockwise rotation. If two of the connections are swapped then the resulting direction of

rotation is counter-clockwise (e.g. L1, L2, L3 to V, U, W).

Note

These restrictions in terms of the direction of rotation relate to the particular type of motor

design and result, for example, from the use of unidirectional fans. Any restrictions in terms

of the direction of rotation resulting from the installation itself are not shown in the

information on the rating plate and need to be considered separately when making the

connections.

Terminal designations

The following definitions apply in principle to the terminal designations of three-phase motors

in accordance with DIN VDE 0530 Part 8 or IEC 60034-8:

&LUFXLW

Table 3-3 Terminal designations (with the 1U1-1 as an example)

1 U 1 - 1 Identifier

x Index showing the pole assignment for pole-changing motors (where applicable,

a lower number indicates a lower speed) or, in special cases, for a subdivided

winding

x Phase designation (U, V, W)

x Index showing the start (1) / end (2) or tapping point of the winding (if there is

more than one connection per winding)

x Additional index for cases in which it is obligatory to connect parallel power feed

cables to several terminals with otherwise identical designations

Connecting using cable lugs

To connect the cables to the main terminals, select cable lugs that match the necessary

cable cross-section and bolt size M12.

A5E00215731A AD

28 Siemens AG Operating Instructions 2.02 1PL618

Page 31

Transport, assembly, and connection

3.3 Electrical connection

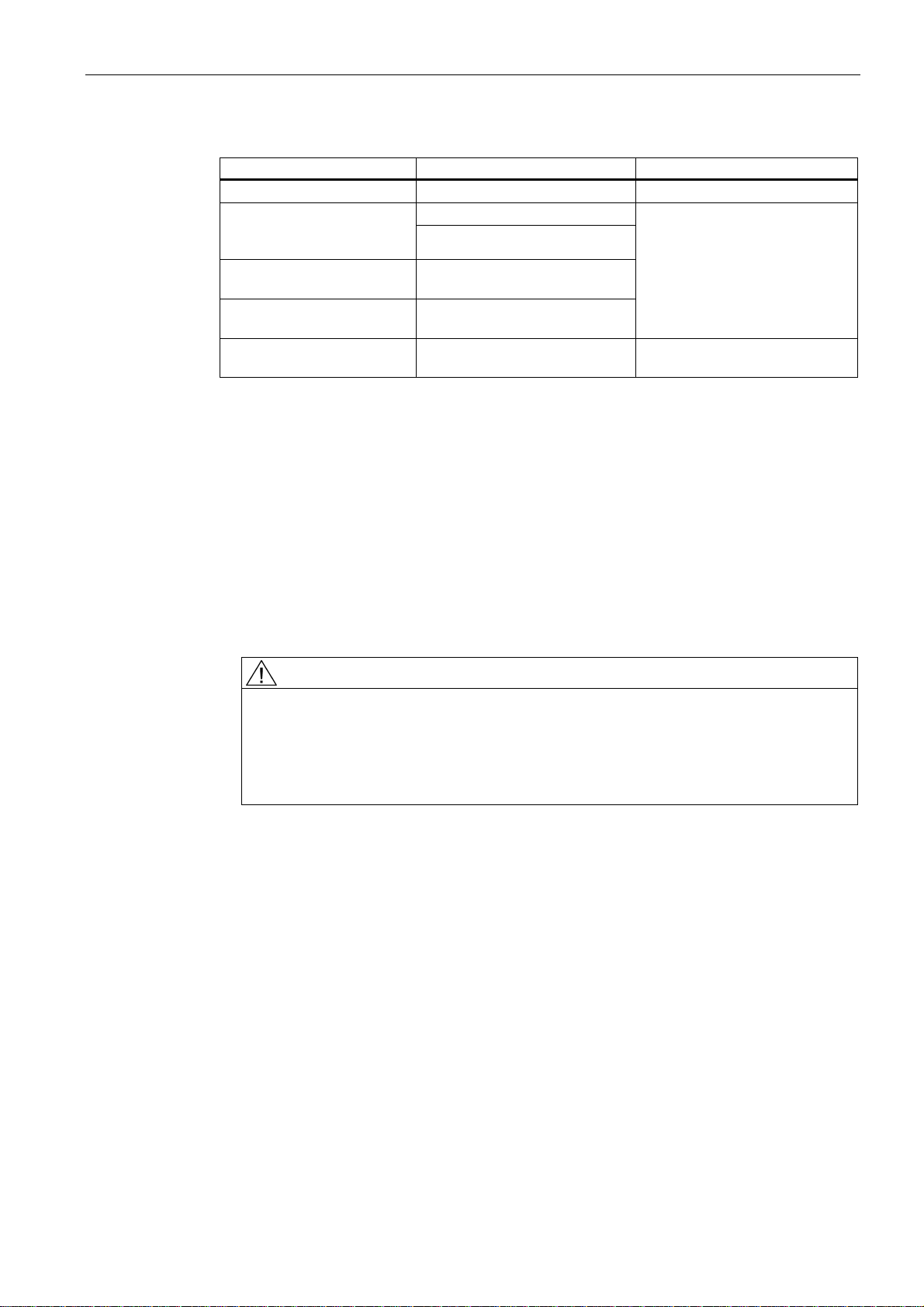

Table 3-4 Terminal box assignment, max. connectable cross-section per terminal

Motor type Terminal

box type

8. th digit of the MLFB = 4, 6

1PL6 184-..B

1PL6184-..D

1PL6184-..F

1PL6184-..L 1XB7 422 2 x M72 x 2 56 3 x M12 2 x 70 242

1PL6186-..B

1PL6186.-..D

1PL6186-..F 1XB7 422 2 x M72 x 2 56 3 x M12 2 x 70 242

1PL6186-..L 1XB7 700 3 x M72 x 2 56 3 x 2 x M12 3 x 150 583

8. th digit of the MLFB = 7, 8

1PL6 184-..B

1PL6184-..D

1PL6184-..F

1PL6184-..L 1XB7 422 2 x M63 x 1.5 53 3 x M12 2 x 70 242

1PL6186-..B

1PL6186-..D

1PL6186-..F 1XB7 422 2 x M63 x 1.5 53 3 x M12 2 x 70 242

1PL6186-..L 1XB7 700 3 x M75 x 1.5 68 3 x 2 x M12 3 x 150 583

1XB7 322 2 x PG 42 40 3 x M12 2 x 50 191

1XB7 322 2 x PG 42 40 3 x M12 2 x 50 191

1XB7 322 2 x M50 x 1.5 38 3 x M12 2 x 50 191

1XB7 322 2 x M50 x 1.5 38 3 x M12 2 x 50 191

Cable entry Max. poss.

outer

diameter of

cable [mm]

No. of main

terminals

Max.

connectable

cross-section

per terminal

2

[mm

]

Max. poss. current per

terminal [A]

(Reduction factor 0.6)

Remove the insulation from the conductor ends so that the remaining insulation is almost

long enough to reach the cable lug.

If necessary, insulate the cable lugs in order to maintain the minimum clearances in air of 10

mm and the 20 mm creepage distance normally present.

The tightening torque for M12 contact nuts and mounting bolts is 40 Nm.

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

29

Page 32

Transport, assembly, and connection

3.3 Electrical connection

1P

Figure 3-3 Tightening torques for contact nuts and mounting bolts

① contact nut

② mounting bolt

Principles of fitting and laying cables

Lead in permanently laid entries using EMC cable glands. Screw the cable glands into the

threaded holes in the entry plate, which can be unscrewed.

Arrange the exposed connecting cables in the terminal box such that the PE conductor has

excess length and the insulation of the cable strands cannot be damaged.

Note

We recommend you use shielded cables whose shields are conductively connected to a

large area of the metal terminal box of the motor (with an EMC cable gland made of metal).

NOTICE

Unused threads must be sealed with a metallic screw plug.

Internal equipotential bonding

The equipotential bonding between the ground terminal in the terminal box housing and the

motor frame is established via the terminal box mounting bolts. The contact points

underneath the bolt heads are bare metal and are protected against corrosion.

The standard terminal box cover mounting screws are adequate as potential bonding

between the terminal box cover and terminal box itself.

Final checks

Before closing the terminal box, please check that:

A5E00215731A AD

30 Siemens AG Operating Instructions 2.02 1PL618

Page 33

Transport, assembly, and connection

3.3 Electrical connection

● the electrical connections in the terminal box are tight and are in full compliance with the

specifications above.

● the required clearances in air of 10 mm are maintained.

● no wire ends are standing proud.

● The inside of the terminal box must be clean and free of any pieces of cable.

● all seals and sealing surfaces are not damaged.

● the connecting cables are laid in an open arrangement and the cable insulation cannot be

damaged.

● cable entries which are not used are sealed and the plugs are tightly screwed in (i.e. so

that they can only be removed using the suitable tools).

● the right cable glands are fitted with respect to the correct degree of protection, method of

laying, permissible cable diameter etc., as stated in the specifications.

Then close the terminal box.

Table 3-5 Tightening torque for the fixing screws on the lid

Bolt Terminal box type Tightening torque

M6 1XB7 322 4.5 Nm

M8 1XB7 422 11 Nm

M10 1XB7 700 22 Nm

[ID: 335.01]

3.3.3 Connecting the ground conductor

General

The cross-section of the ground conductor of the motor must comply with the regulations for

electrical installations, e.g. DIN EN IEC 60204-1.

Wiring

Connect-up the ground-conductor in the motor terminal box. For this purpose, a clamping lug

is provided at the appropriately marked connecting point for the ground conductor This lug

can be used for connecting stranded conductors with cable lugs or ribbon cables with an

appropriately shaped conductor end.

When making connections, ensure that

● The contact surface is clean and protected with a suitable anti-corrosion agent (e.g. acidfree Vaseline).

● the flat and spring washers are located under the bolt head.

● the minimum necessary screw-in depth and the tightening torque for the clamping bolts

must be maintained.

Mandatory tightening torques:

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

31

Page 34

Transport, assembly, and connection

3.3 Electrical connection

Bolt Terminal box type Tightening torque

M5 1XB7 322 2.6 Nm

1XB7 422 11 Nm M8

1XB7 700 11 Nm

[ID: 354]

3.3.4 Connecting the fan

Instructions relevant to safety

Please observe the following safety instructions relating to connecting a fan:

Connection

CAUTION

Provide a protective circuit that prevents the main motor from being switched on when the

fan unit is not in operation.

CAUTION

Please note that the separately driven fan unit is only suitable for the direction of rotation

shown by the direction-of-rotation arrow.

The fan must not be operated with the wrong direction of rotation as this could lead to the

motor being destroyed.

Note

The direction-of-rotation arrow and the direction of movement of the fan impeller are

indicated on the rear side of the blower.

If necessary, switch the direction of rotation by swapping over two phase conductors in the

terminal box.

Connect up the fan in the terminal box of the fan unit.

A5E00215731A AD

32 Siemens AG Operating Instructions 2.02 1PL618

Page 35

Transport, assembly, and connection

3.3 Electrical connection

ུ

ི

ཱ

ཱི

Figure 3-4 Detailed view of fan for operation at 50 Hz

① Fan unit terminal box

② Cable entry

③ Direction of rotation of fan impeller

④ Air outlet grille

⑤ Air outlet throttle sheet fixing points

CAUTION

If the standard fan is operated with ventilation from the DE to the NDE on a 60 Hz system,

you must screw on the air outlet throttle sheet included in the terminal box.

ིུ

ཱ

ཱུ

ཱི

Figure 3-5 Fan for operation at 60 Hz

① Fan unit terminal box

② Cable entry

③ Direction of rotation of fan impeller

④ Air outlet grille

⑤ Air outlet throttle sheet fixing points

⑥ Throttle sheet

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

33

Page 36

Transport, assembly, and connection

3.3 Electrical connection

[ID: 338.01]

3.3.5 Connecting the speed sensor

Connection

Connect the speed sensor to the terminal box by means of a plug-in connection ①. It is

located on top of the box housing.

Figure 3-6 Detailed view: Plug-in connection

Note

The plug-in connection may differ from the standard layout in the case of special orders.

In the version "without sensor", an armored conduit union is located here.

A5E00215731A AD

34 Siemens AG Operating Instructions 2.02 1PL618

Page 37

Transport, assembly, and connection

3.3 Electrical connection

Electrical connection of the speed sensor

ཱ

Figure 3-7 Electrical connection of the speed sensor

ི

① Insert the connector into the socket.

② Press the cable into the holder provided for it.

③ Screw on the sensor cover. Take care that you do not catch the cable as you screw it

in.

[ID: 977.00]

3.3.6 Connecting the Sensor Module

Signal connection

The signal connection between the motor and the converter is via the DRIVE-CLiQ cable

MOTION-CONNECT. Always use prefabricated cables from SIEMENS. Thes cables reduce

the mounting/installation time and costs and increase operational reliability.

Push the connector on the DRIVE-CLiQ cable into the socket until the catch spring latches

into place. Pay attention to the coding of the connector.

Cable outlet directions

The Sensor Module is mounted on the motor terminal box. The Sensor Module can be

rotated through approximately 235°. You can change the cable outlet directions by rotating

the Sensor Module, as shown in the diagram below.

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

35

Page 38

Transport, assembly, and connection

S

3.3 Electrical connection

NOTICE

Do not turn the Sensor Module with a pipe wrench or hammer or any similar tool as this

could damage the Sensor Module.

Turn the Sensor Module by hand.

Typical twisting moment: 4 ... 8 Nm

¡

ແ

Figure 3-8 Sensor Module ① mounted on terminal box

NOTICE

Changing the cable outlet direction by any improper means will cause damage to the

connecting cables.

The permissible rotation range must not be exceeded. A maximum of ten changes to the

rotation angle of the Sensor Module are permissible within the rotation range.

[ID 964]

3.3.7 Connecting the temperature sensor

Connection

Connect the wires of the temperature sensor to the speed sensor connector with the aid of

connecting leads (see section entitled "Connecting the speed sensor").

A5E00215731A AD

36 Siemens AG Operating Instructions 2.02 1PL618

Page 39

Transport, assembly, and connection

3.3 Electrical connection

Note

The plug-in connection may differ from the standard layout in the case of special orders.

In the version "without sensor", an armored conduit union is located here.

[ID: 342]

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

37

Page 40

Page 41

Start-up

4.1 Preparations

Safety note

Checking the insulation resistance

WARNING

Only expert personnel should be entrusted with work on power installations.

Note

There is no need to check the insulation resistance when commissioning. We only

recommend doing so after long storage or shutdown periods.

After long storage or shutdown periods, the insulation resistance of the windings must be

measured to ground with direct voltage.

WARNING

4

Hazardous voltage

During the measurement, and immediately afterwards, hazardous voltage levels are

applied on some of the terminals and they should not be touched. Touching live

components can be result in death or serious injury.

Never touch the terminals when measuring or immediately after the measurement.

Check the supply feeder cables connected in order to ensure that the line supply voltage

cannot be connected.

CAUTION

Before you begin measuring the insulation resistance, please read the manual for the

insulation resistance meter you are going to use.

● Always measure the insulation resistance of the winding to the motor enclosure when the

winding temperature is between 20 and 30°C.

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

39

Page 42

Start-up

4.1 Preparations

● When measuring, wait until the final resistance value is reached; this takes approximately

one minute.

Stator winding insulation resistance limit values

The following table shows the measuring circuit voltage and the limit values for the minimum

insulation resistance and the critical insulation resistance for the stator winding.

Table 4-1 Stator winding insulation resistance at 25 °C

Rated voltage U

Measuring circuit voltage 500 V (min. 100 V)

Minimum insulation resistance with new, cleaned or

repaired windings

Critical specific insulation resistance after a long operating

time

10 MΩ

2.5 MΩ/kV

< 2 kV

N

Note the following:

● Dry, new windings have insulation resistance of between 100 and 2000 MΩ, or possibly

values that are even higher.

If the insulation resistance is close to the minimum value, then the cause could be

humidity and/or fouling.

● Over its operating lifetime, the motor winding insulation resistance can drop due to

ambient and operational influences. The critical insulation resistance at a winding

temperature of 25°C is 2.5 MΩ

NOTICE

Critical insulation resistance is reached or insufficient

If the critical insulation resistance is reached or is insufficient, damage to the insulation and

flashover voltages can result.

Dry the windings or clean and dry them thoroughly, having first removed the rotor.

If the clean windings have not cooled to 25°C, then lower insulation resistance will be

measured. The insulation resistance can only be properly assessed after conversion to the

reference temperature of 25°C. Allow the windings to cool to 25°C or convert the insulation

resistance using 25°C as the reference temperature.

If the measured value is close to the critical value, you must check the insulation resistance

at appropriately frequent intervals subsequently.

[ID: 344.01]

A5E00215731A AD

40 Siemens AG Operating Instructions 2.02 1PL618

Page 43

Start-up

4.2 Measures to be performed prior to commissioning

4.2 Measures to be performed prior to commissioning

Note

This list below does not claim to be complete. It may be necessary to perform additional

checks and tests in accordance with the situation specific to the particular place of

installation.

Inspections after proper installation, prior to commissioning the plant

● All electrical and mechanical connections are securely seated and functioning properly.

● The motor has been assembled and aligned properly.

● The cover sheets have been remounted correctly to ensure that the motor is cooled.

● The operating conditions correspond to the data specified on the rating plate.

● Any supplementary motor monitoring devices and equipment have been correctly

connected and are fully functional.

● Appropriately configured control and speed monitoring functions ensure that the motor

cannot exceed the permissible speeds specified on the rating plate.

● The power output elements have the proper setting conditions according to type, for

example.

– Couplings are aligned and balanced.

– The belt tension is properly adjusted if there is a belt drive.

– Gear tooth flank play and gear tooth tip play as well as radial play are properly

adjusted if there is gearwheel drive.

● The minimum insulation resistance values are maintained.

● The grounding and equipotential bonding connections have been established correctly.

● All fixing screws, connecting elements and electrical connections are firmly tightened.

● The rotor can spin without coming into contact with the stator.

● All touch protection measures for moving and live parts have been taken.

● if the second shaft end has not been used, its feather key has been secured to prevent it

from being thrown out.

● All external fans fitted are ready for operation and have been connected so that they

rotate in the direction specified.

● The flow of cooling air is not impeded.

● All brakes are operating correctly.

NOTICE

Lubricating capacity of lubricating greases

Grease loses its lubricating property over time.

After longer period of storage or standstill (> 2 years) lubricate the bearings or replace

the grease.

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

41

Page 44

Start-up

4.3 Power on

[ID: 399.02]

4.3 Power on

Measures

Before you energize the motor, make sure that the parameters of the frequency converter

have been assigned correctly.

We recommend you use appropriate commissioning tools (e.g. Drive ES or STARTER).

CAUTION

If the motor is not running smoothly or is emitting abnormal noises, de-energize it, and

determine the cause of the fault as the motor runs down.

NOTICE

The critical speed n

periods.

= 5000 rpm is the maximum operating speed permissible over short

max

[ID: 369.01]

A5E00215731A AD

42 Siemens AG Operating Instructions 2.02 1PL618

Page 45

Operation

5.1 Operation

Safety notes

WARNING

Please follow all instructions contained in the "Safety information and application

information (Page 7)" chapter of these operating instructions precisely and ensure that only

persons who have the necessary specialist know-how are entrusted to carry out work on

power installations.

WARNING

Rotating components

Covers prevent contact with live or rotating parts, or are used for proper air routing and thus

effective cooling of the motor.

Removing the covers during operation can result in death, serious injury, and property

damage.

5

Never open covers during operation.

CAUTION

Speed monitoring

The motor is designed for a certain speed range.

If a motor is operated at impermissible speeds damage to the winding, bearings, or

complete destruction of the motor can be the result.

Ensure that the speeds specified on the rating plate are not exceeded by appropriately

configuring controller and speed monitoring components.

Switching on

● See the operating instructions of the frequency converter for switching on.

● After starting the motor, observe it for a while to see if it is running smoothly and check

the monitoring devices.

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

43

Page 46

Operation

5.2 Stoppages

Operation

● Monitor operation and the monitoring devices regularly and record the values you read

off.

[ID: 348]

WARNING

Faults

All deviations from normal operation, such as higher power consumption, higher

temperatures and vibration levels, unusual noises and odors and tripped monitoring

devices, are indications that the motor is no longer functioning correctly.

In this case, the maintenance technician must be notified immediately to prevent

disturbances that could either directly or indirectly lead to severe personal injury or

substantial material damage.

If in doubt, switch off the drive in question immediately.

See also

Rating plate (Page 16)

Power on (Page 42)

5.2 Stoppages

Measures when motors are at standstill and ready for operation

● For longer periods when the motor is not being used, either energize the motor at regular

intervals (roughly once a month), or at least spin the rotor.

● Please refer to the section "Energizing" before restarting the motor.

NOTICE

Damage due to improper storage

The motor can be damaged if it is not stored properly.

If the motor is out of service for extended periods of time, implement suitable anti-

corrosion, preservation, and drying measures.

When restarting the motor after a long shutdown period, carry out the measures

recommended in the section entitled "Commissioning".

[ID: 349.01]

See also

Power on (Page 42)

Measures to be performed prior to commissioning (Page 41)

A5E00215731A AD

44 Siemens AG Operating Instructions 2.02 1PL618

Page 47

Operation

5.3 Deactivating

5.3 Deactivating

Measures

Always refer to the respective manual of the frequency converter when de-energizing.

Note

The fan must be shut down during longer periods in which the motor is not operated.

NOTICE

We strongly recommend that you continue operating the fan for approx. 30 min after

shutting down the motor.

[ID: 351]

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

45

Page 48

Page 49

Faults

6

6.1 Fault diagnosis table

Diagnosis table for mechanical and electrical faults

The tables below list general faults caused by mechanical and electrical influences.

Table 6-1 Diagnosis table for mechanical faults

Overview of mechanical faults

Mechanical fault characteristics

- rubbing/grinding noise

- significant temperature rise

- radial vibration

- axial vibration

Possible causes of faults Remedial measures1)

- Rotating parts rubbing/grinding Determine cause and adjust parts x

- Air supply restricted,

possibly wrong direction of rotation of fan

- Rotor not balanced Rebalance rotor x

- Rotor out of true, shaft bent Consult the manufacturer x

- Poor alignment Align motor unit,

- Coupled motor not balanced Rebalance coupled motor x

- Shocks from coupled motor Check coupled motor x

- Imbalance originating from gearing Adjust/repair gearing x x

- Resonance with the foundation After consultation, reinforce foundations x x

- Changes in foundation Determine cause of changes,

1)

As well as eliminating the cause of the fault (as described under "Remedial measures"), you must also rectify any

damage the motor may have suffered.

2)

Take into account possible changes due to a rise in temperature.

Check air passages,

clean filter, replace fan if necessary

check coupling

eliminate if necessary; realign motor

2)

↴

↴

↴

↴

x

x x

x x

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

47

Page 50

Faults

6.1 Fault diagnosis table

Table 6-2 Diagnosis table for electrical faults

Overview of electrical faults

Electrical fault characteristics

- Motor will not start up

- Motor starts up slowly

- Drumming noise during startup

- Drumming noise during operation

- Drumming noise in time with twice slip frequency

- High temperature rise at no load

- High temperature rise under load

- High temperature rise of individual winding sections

Note:

If electrical faults occur, please refer to the manual

for the frequency converter.

[ID: 353]

A5E00215731A AD

48 Siemens AG Operating Instructions 2.02 1PL618

Page 51

Maintenance

7.1 Maintenance

7.1.1 Maintenance instructions

Safety information

WARNING

Please follow all the instructions contained in the "Safety information" section of these

Operating Instructions precisely and ensure that only persons who have the necessary

specialist know-how are entrusted to carry out work on power installations.

In addition to the main phases, also ensure that supplementary and auxiliary circuits are

also de-energized.

CAUTION

Be careful of those parts of the motor that get hot, and let them cool down before starting

maintenance work.

7

Safety regulations

Always comply with the following safety rules before starting maintenance work:

DANGER

• Disconnect

• Protect against reconnection

• Disconnect from supply

• Fence off or cover up adjacent live parts

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

49

Page 52

Maintenance

7.1 Maintenance

Other safety-related measures

See also

CAUTION

When cleaning using compressed air, make sure you use suitable extraction equipment

and wear protective gear (safety goggles, protective suit, etc.).

CAUTION

If you use chemical cleaning agents, observe the instructions and any warnings given in the

relevant safety data sheet.

Chemical agents must be compatible with the components/parts, especially when they

contain plastics.

Note

If anything is unclear, we urgently recommend that you consult us stating the type and serial

number of the three-phase motor or get one of the SIEMENS Service Centers to carry out

the maintenance work for you.

[ID: 401.01]

Siemens Service Center (Page 15)

7.1.2 Maintenance intervals

General

Careful and regular maintenance, inspections, and overhauls are essential for detecting and

eliminating faults in good time before they can cause any damage.

Operating situations and characteristics can vary widely. For this reason, only general

maintenance intervals can be specified here. Maintenance intervals should therefore be

scheduled to suit the local conditions (dirt, starting frequency, load, etc.).

NOTICE

If faults or exceptional conditions occur that lead to the three-phase motor being overloaded

either electrically or mechanically (e.g. overload, short circuit, etc.), carry out the

inspections immediately.

Measures, intervals

Measures after operating period intervals have elapsed:

A5E00215731A AD

50 Siemens AG Operating Instructions 2.02 1PL618

Page 53

Maintenance

7.1 Maintenance

Table 7-1 Operating period intervals

Measures Operating period intervals Intervals

Initial inspection After 500 operating hours after 6 months at the latest

Belt operation 12 000 h Continuous lubrication

(Machines without regreasing

device )

Machines with regreasing

device (option)

Clean depending on local degree of

General inspection Approximately every 16000

Coupling operation 20 000 h

(see lubrication instruction plate)

pollution

operating hours

After 2 years at the latest

[ID: 356]

7.1.3 Maintenance of the external fan

Procedure

● Check the external fan VDI 2056 annually for mechanical vibrations. The maximum

permissible vibrational severity is 2.8 mm/s measured on the end shield of the impellerside motor bearing.

● Regularly clean and inspect the fan. Impeller and frame are subject to natural wear

depending on the area of application and displacement medium.

● Refer to the maintenance and service information provided by the manufacturer of the

external fan.

7.1.4 Bearings

WARNING

Impeller can crack

Due to deposits and the resulting imbalance there is a hazard of fatigue fracture of the

impeller. The impeller can crack in operation. Death, serious injury, or material damage

can result.

Regularly clean and inspect the fan.

Description

The three-phase motors have grease-lubricated, rolling-contact bearings. A regreasing

device is optional.

A deep-groove ball bearing is installed at the NDE as a locating bearing. Depending on the

type of load, a deep-groove ball bearing or cylindrical-roller bearing is installed at the DE as

a floating bearing.

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

51

Page 54

Maintenance

7.1 Maintenance

For the bearing assignments as well as the associated permissible lateral forces and

minimum loads when cylindrical-roller bearings are installed at the DE, refer to the catalog or

contact us.

The DE bearing contains built-in spring elements that help to rebalance the axial play of the

external bearing rings.

NOTICE

Permanently lubricated bearings should be exchanged approx. every three years,

regardless of the length of use (operating hours)

[ID: 359.01]

7.1.5 Lubrication (optional)

Relubrication intervals

The relubrication intervals are stated on the lubrication instruction plate of the three-phase

motor.

NOTICE

Observe the basic lubrication interval (see section entitled "Measures, intervals").

NOTICE

If there is a long interval between delivery and commissioning of the motor, the bearings

must be relubricated.

The grease change intervals apply for normal loads, operation at speeds corresponding to

those specified on the nameplate, precision-balanced running, almost neutral ambient air

and the use of high-quality rolling-contact bearing greases.

Grease types

The following high-quality rolling-contact bearing greases have been tested and are suitable:

Table 7-2 Rolling-contact bearing greases

K3N greases

ARAL Aralub 4340

ESSO / Unirex N 3

DEA Glissando 30

ESSO Beacon 3

FUCHS Renolit FWA 220

SHELL Alvania RL3

A5E00215731A AD

52 Siemens AG Operating Instructions 2.02 1PL618

Page 55

Maintenance

7.1 Maintenance

K3N greases

WINTERSHALL Wiolub LFK 3

These greases have lithium soap as the thickening agent and mineral oil as the base oil.

They exceed the standard requirements of DIN 51825 in several important respects and are,

therefore, compatible with the specified regreasing intervals.

NOTICE

Never mix greases that have different thickening agents and base oils.

Initial lubrication

ESSO Unirex N grease is used for initial lubrication of the bearings (prior to delivery).

Lubricating using the regreasing device

Figure 7-1 D-end and N-end end shields with grease nipples

① Button head lubricating nipple to DIN 3404, size M10x1, drive end (DE)

② Button head lubricating nipple to DIN 3404, size M10x1, non-drive end (NDE)

1. Clean the grease nipples at the DE and NDE.

2. Press in the type and quantity of grease specified (see lubrication instruction plate).

A5E00215731A AD