Page 1

222

HARTREY AVE EVANSTON.

AREA CODE 3t2/328-~000

ILL.

(60204) U.S.A.

CABLE SHUREMICRO

DATA

I

SHEET

MODELS M5D AND M6S

PROFESSIONAL DYNETIC

CARTRIDGE

(Stylus

Models

N5D

and

N6S)

I

Specifications

MODEL

NO.

M5D

M6S

33% - 45 R.P.M.

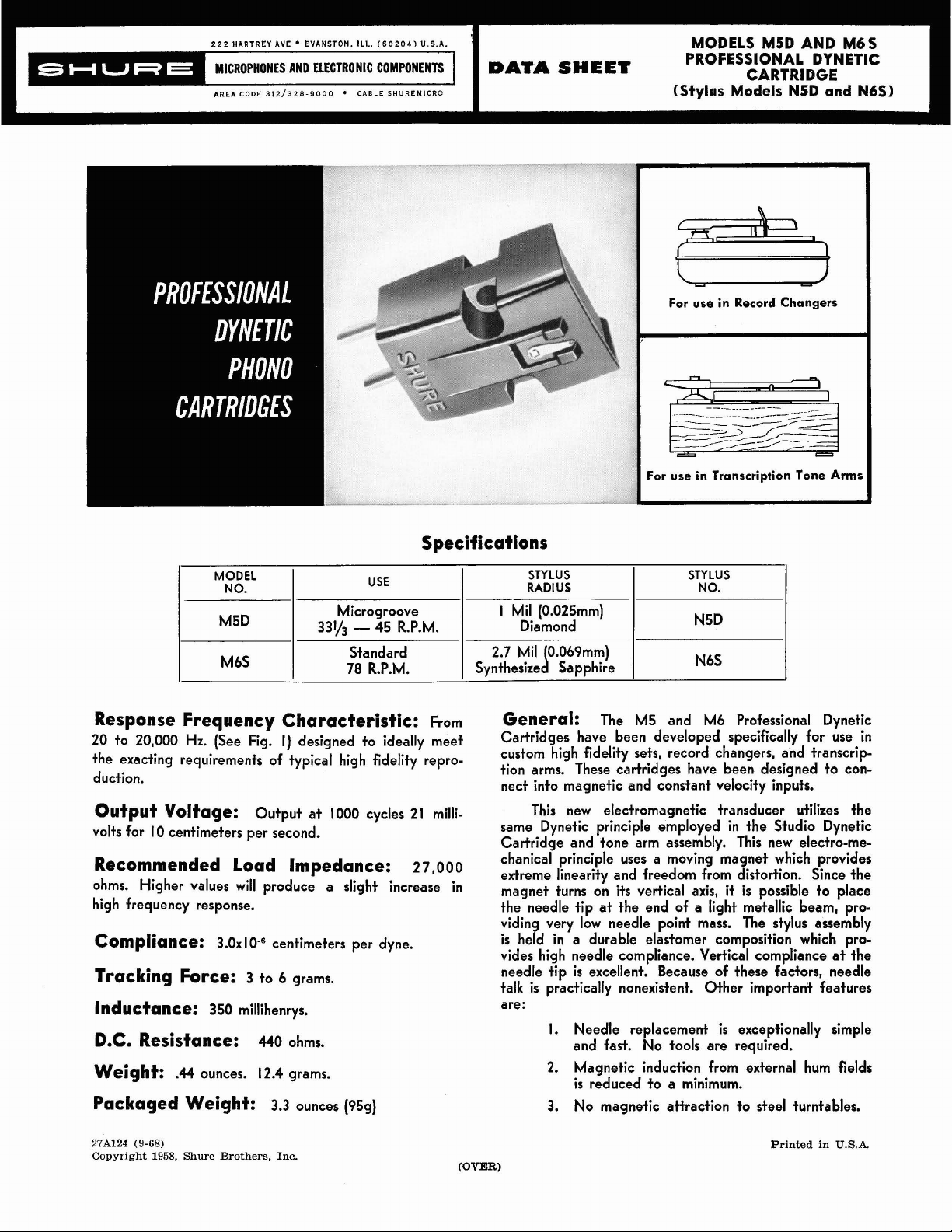

Response Frequency Characteristic:

20 to 20,000

the exacting requirements of typical high fidelity repro-

duction.

Output Voltage:

volts for

ohms. Higher values will produce a slight increase in

high frequency response.

Compliance:

Tracking Force:

Inductance:

D.C. Resistance:

Weight:

Packaged Weight:

Hz.

(See Fig.

I0 centimeters per second.

Load

3.0~

350 millihenrys. are:

.44 ounces. 12.4 grams.

I)

designed to ideally meet

Output at 1000 cycles 21 milli-

Impedance:

1

O-S

centimeters per dyne.

3 to 6 grams.

440 ohms.

3.3 ounces (95g)

USE

Microgroove

Standard

78

R.P.M.

From

27t000

STYLUS

RADIUS

I

Mil

(0.025mm)

Diamond

Mil

2.7

synthesize6 Sapphire

Cartridges have been developed specifically for use in

custom high fidelity sets, record changers, and transcription arms. These cartridges have been designed to connect into magnetic and constant velocity inputs.

same

Cartridae and tone arm assemblv. This new electro-mechanical principle uses a moving magnet which provides

extreme linearity and freedom from distortion. Since the

magnet

the needle

viding very

is

vides high needle compliance. Vertical compliance at the

needle

talk is practically nonexistent. Other

0.069mm)

General:

This new electromagnetic transducer utilizes the

Dynetic principle employed in the Studio Dynetic

The M5 and M6 Professional Dynetic

-

turns

on

its

vertical

tip

at the end of a liqht metallic beam, pro-

lbw needle point mass. The stylus assembly

held in a durable elastomer composition which pro-

tip

is

excellent. Because of these factors, needle

Needle replacement

I.

and fast. No tools are required.

2.

Magnetic induction from external hum fields

is

reduced to a minimum.

3. No magnetic attraction to steel turntables.

STYLUS

NO.

N5D

N6S

axis,

it

is

possible

importan* features

is

exceptionally simple

to

place

278124

(9-68)

Copyright

1958,

Shure Brothers,

Inc.

(OVER)

Printed

in

U.S.A.

Page 2

Mounting:

the standard

#3-48x5/16" long machine screws are supplied with

these cartridges for mounting purposes.

The recommended needle point force is 3 to 6

grams. When replacing magnetic cartridges, adjustment

is

generally unnecessary. Should

ment may usually be made by adjusting the counter balance or spring at the rear of the arm.

Connections:

specifically intended to be connected to preamplifiers

having magnetic or constant velocity inputs. The recommended input resistance

provide increased high frequency response. The gold

colored terminal of the cartridge must be connected to

the "hot" lead of the tone arm. The "hot" lead can be

verified

screwdriver or similar tool and the connection that produces a loud hum from the speaker is the "hot" terminal.

The silver colored terminal must be connected to the

"ground" lead of the arm.

by touching the bare lead or pin jack with a

Guarantee:

Cartridges are guaranteed to be free from electrical and

mechanical defects for one year from the date of shipment from the factory, provided all instructions are com-

plied with fully. The guarantee does not cover needle

wear nor does

from abuse or mishandling.

The M5 and M6 series cartridges have

1/2"

(12.7mm) mounting centers. Two

it

be necessary, adiust-

The M5 and M6 series cartridges are

is

27,000

The M5 and M6 Professional Dynetic

it

cover damage to the needle assembly

ohms. Higher values

Caution

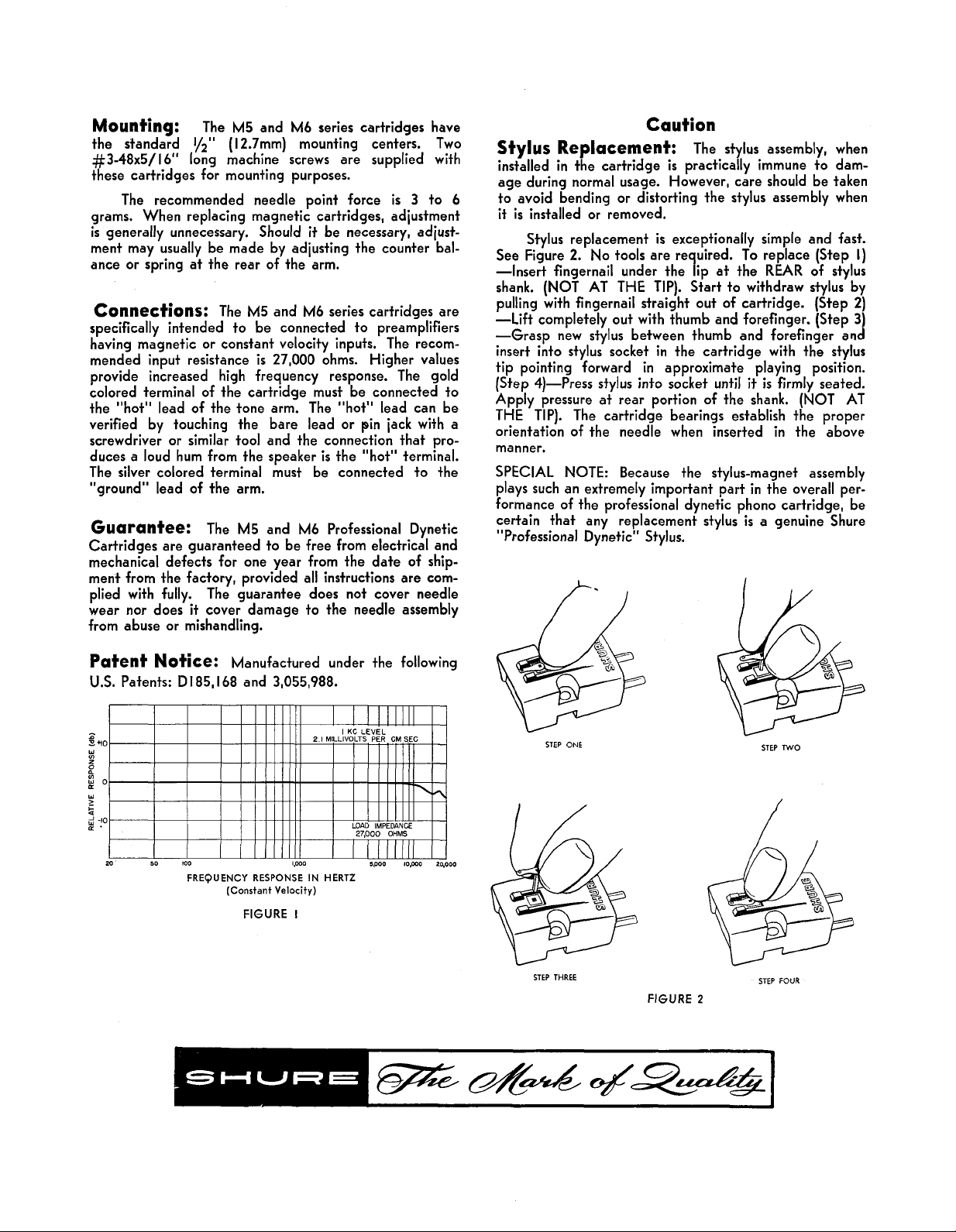

Stylus Replacement:

installed in the cartridge is practically immune to damage during normal usage. However, care should be taken

to avoid bending or distorting the stylus assembly when

it

is

installed or removed.

Stylus replacement

See Figure 2. No tools are re uired. To replace (Step

-Insert fingernail under the

shank. (NOT AT THE TIP). Start to withdraw stylus by

pulling with fingernail straight out of cartridge. (Step 2)

-Lift completely out with thumb and forefinger. (Step 3

-Grasp new stylus between thumb and forefinger

insert into stylus socket in the cartridge with the stylus

tip pointing forward in approximate playing position.

(Step 4)-Press

Apply pressure at rear portion of the shank. (NOT AT

THE TIP). The cartridge bearings establish the proper

orientation of the needle when inserted in the above

manner.

SPECIAL NOTE: Because the stylus-magnet assembly

plays such an extremely important part in the overall per-

formance of the professional

certain that any replacement stylus

"Professional

stylus into socket until

Dynetic" Stylus.

The stylus assembly, when

is

exceptionally simple and fast.

I

ip

at the REAR of stylus

it

is firmly seated.

dynetic phono cartridge, be

is

a genuine Shure

an

I)

d

Patent Notice:

U.S. Patents:

D

185,168 and 3,055,988.

FREQUENCY RESPONSE IN HERTZ

Manufactured under the following

(Constant

Velocity)

FIGURE

I

u

STEP THREE

STEP

ONE

FIGURE

STEP

TWO

STEP

FOUR

2

Loading...

Loading...