AREA

CODE

312/328-9000

*

CABLE

SHUREMICRO

MODEL

M32-3

(see note)

DATA SHEET

MONO

(781

AND

STEREO DYNETICB

PHONOGRAPH CARTRIDGES

SPECIFICA?IONS

M31

AND

M32

CARTRIDGE SERIES

N31

AND

N32

STYLI SERIES

__-

I

I

Model

’

Number1 Replacement

v--

M32E

M32-3

NOTE:

clxtnnels

mono

nect the

Stereo and mono

or

pin

FREQUENCY RESPONSE:

CHANNEL SEPARATION:

RECOMMENDED LOAD IMPEDANCE:

INDUCTANCE:

D.G.

MOUNTING:

WEIGHT:

TERMINALS:

GENERAL:

tridges

plifiei n having rnagnetlc and constant veloclty inputs.

OPERATION

we lisj,ed under “Specifications.” Forces greater than the indi-

rntcd maximum” should

Diamond Stylus

N32E

Elliptical

Side Contact

l?rrdi,,s.

__

__._I.

.0004”

(.010

Frontal Radius:

.0007”

(.018

iN32-3

Radius

,

,0025’’

(.064

Model

M32-3

connected in parallel and

and“stereo systems. Double loop pin jacks are used to con-

R”

to the “L” terminal and the “RG” to the “LG”.

N32E

Stylus. When used with a stereo

jacks should be removcd.

RESISTANCE:

Standard

6

grams

4

The

have been deyeloped for usc with. all high fidelity

:

Recommended needle forces for optimum results

I

Outputvoltage Stylus (Vertical,

1

(1,000

5

.-

mm)

cm/sec) Grip j cm per dyne) (Grams)

.

9.3

millivolts

mm)

5 5

nim)

L.P.

720

terminals

M31

rnilllvolt~

1

for

78

records is supplied with the two output

records. may be played

More than

niilliheiirics per channel

630

ohms per channel

1h’’

(12.7

and

M32

not

Hr.

at

_~_

From

From

From

mm)

Series

be uscd.

I

1

Brown

t

j

I

is

20

20

20

of

1

Cnmnlianr.

__...r

Color

1

Horizontal, I Tracking

Green/

thus suitable for use with

by

system.

to

18.500

to 17,500

to 17,500

20

mounting center

Dynetic phonograph car-

Hz

Hz

Hz

db

at

1,000

47,000

ohms per channel

I

..

__

I

fitting an

the double loop

(M31E)

(M32E)

(M32-3)

Hz

N31E

am-

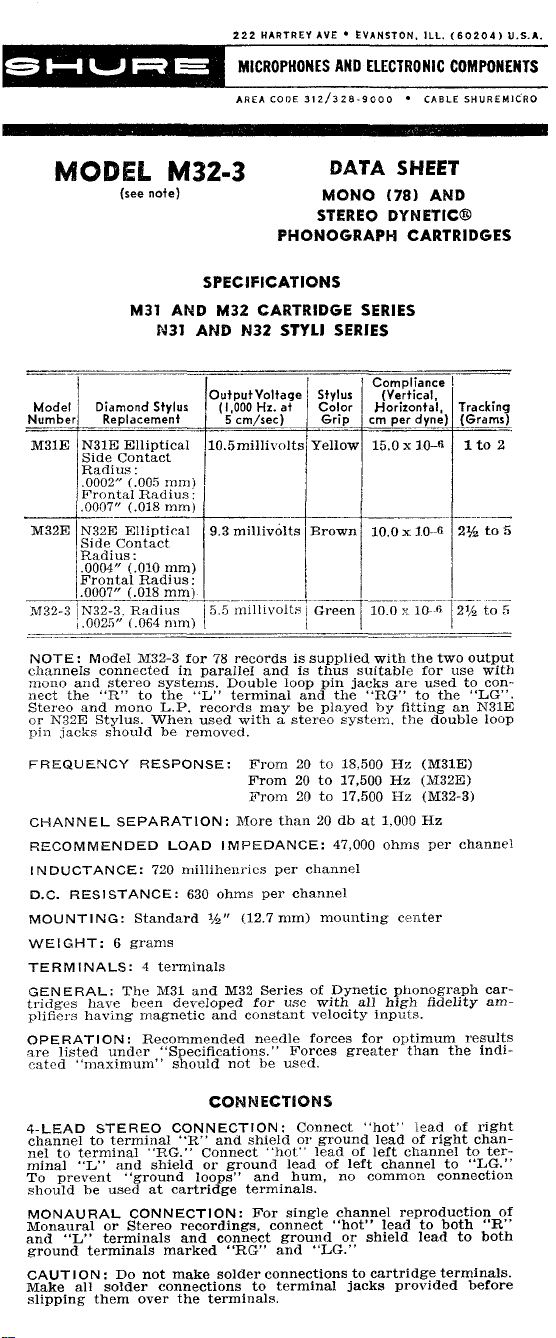

CONNECTlONS

4-LEAD STEREO CONNECTION:

rhnnnpl

ieito-terminal

minal

To

should he used

MONAURAL CONNECTION:

Monaural or Stereo recordings connect “hot” !ead to both

and

ground terminals marked “RG” and

CAUTION

Make all solder connections to termmal jacks provided before

slipping them over the terminals.

to

terminal

“L”

and shield

urevent “mound loops” and hum,

“L”

terminals and conne‘ct ground or shield lead to both

:

Do

“R”

“RG.”

at

not make solder connectionst0 cartridge terminals.

and shield or eround lead of riaht chan-

Connect “hot” 1;ad

or

ground lead

cartridge terminals.

Connect “hot” lead

of

left chann<l to ter-

of

left channel to

no

common connection

For single channel reproduction

“LG.”

of

right

“LG.”

“R”

Of

LEFT RIGHT

CHANNEL CHANNEL

TERMINAL TERMINAL

GROUND TAB

LEFT

CHANNEL

GROUND

TERMINA

TERMINAL DIAGRAM

FIGURE

I

To clean the stylus, use a camel’s%air brush

smaller) dipped lightly in alcohol. The alcohol will remove any

sludge deposits which may have coated the stylus tip. The brush

bristles should be trimmed to a length no longer than

Always brush the stylus with

(terminal end of the cartridge) to, the frqnt. Never brush

the stylus from front to back

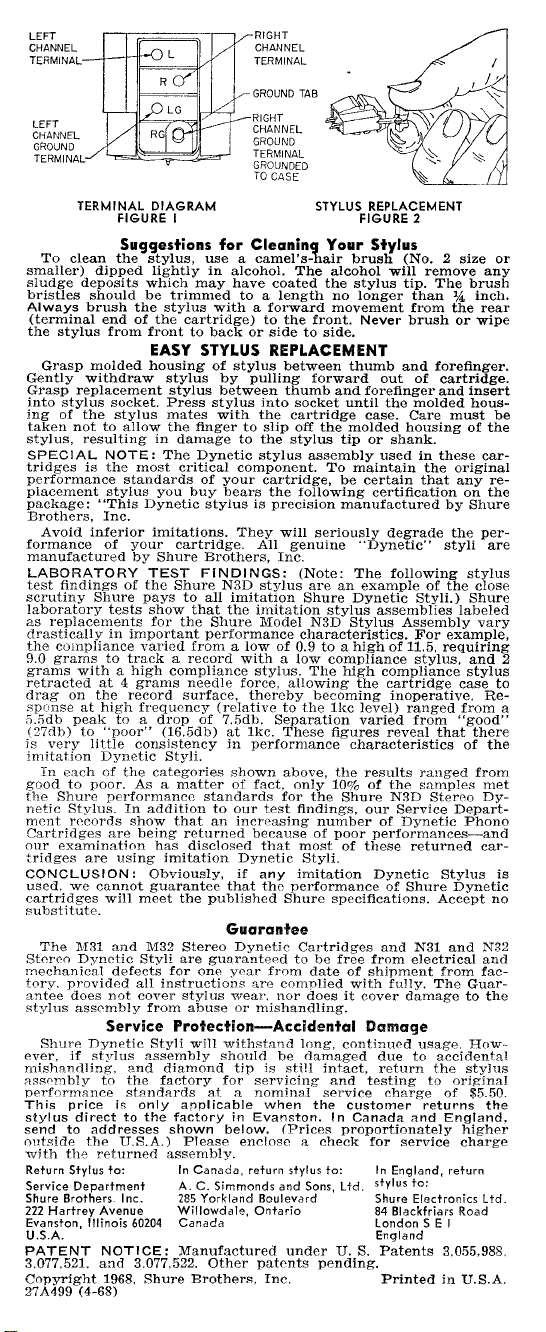

Grasp molded housing of stylus between thumb and forefinger.

Gently withdraw stylus by pulling forward out of cartridge.

Grasp replacement stylus between thumb and forefinger and insert

!nto stylus socket. Press stylus into socket until the molded hous-

ing

of

taken not to allow the finger to slip

stylus, resulting in damage to the stylus tip

SpEClAL NOTE: The Dynetic stylus assembly used in these cartridges is the most critical component. To maintain the original

performance standards of your cartridge, be certain that any

placement stylus you buy bears the tollowing certification on the

package: “This Dynetic stylus is precision manufactured by Shure

Brothers, Inc.

Avoid inferior imitations. They will seriously degrade the per-

formance

manufactured by Shure Brothers, Inc.

LABORATORY TEST FINDINGS: (Note: The following stylus

test findings of the Shure N3D stylus are an example of the close

scrutiny Shure pays to all imitation Shure Dynetic Styli.) Shure

laboratory tests show that the imitation stylus assemblies labeled

as

replacements

drastically in important performance characteristics.

the compliance varied from

9.0

grams to track a record with a low compliance stylus, and 2

grams with a high compliance stylus. The high compliance stylus

retracted

drag on the record surface, thereby becoming inoperative. Resp’uise at high frequency (relative to the ll~ level) ranged from a

5.5db peak to

(3:db)

is

very little consistency in performance characteristics of the

imitation Dvnctic Stvli.

In

good to poor.

the

Shure performance standards for the Shure N3D Stereo Dynetic Stylus. In addition to our test findings, our Service Department records show that

Cartridges are being returned because of poor performances-and

our

examination has disclosed that most of these returned car-

tridges are using imitation Dynetie Styli.

CONCLUSION: Obviously, if any imitation Dynetic Stylus is

used, we cannot guarantee that the performance

cartridges will meet the published Shure specifications. Accept no

substitute.

Suggestions

EASY STYLUS REPLACEMENT

the stylus mates with the cartridge case. Care must be

of

your cartridge. All genuine “Dynetic” styli are

for

the Shure Model N3D Stylus Assembly vary

at

4

grams needle force, allowing the cartridge case to

a

to

each of the categories shown above, t,he results ranged from

drop

“poor” (16.5db) at lkc. These figures reveal that there

As a matter

RIGHT

CHANNEL

GROUND

TERMINAL

GROUNDED

TO

CASE

STYLUS REPLACEMENT

FIGURE

2

for

Cleanin Your Stylus

a

forward movement from the rear

or

side to side.

off

the molded housing of the

a

low of

0.9

to a high of 11.5, requiring

of

7.5db. Separation varied from “good”

of

fact, only 10% of the samples met

an

increasing number of Dynetic Phoiio

(No.

or

shank.

of

Shiire Dynetic

2

For

size

%

inch.

or

wipe

example,

re-

GuaranPee

The

BI31

Stt-rco Dynctic Styli are guaranteed to be free from electrical and

nechanical defects for one ycar from date of shipment from factnry. providcd all instructions are comnlied with fu-lly. The Guarantee does

stylus asscmbly from abuse or mishandling.

and M32 Stereo Dynetic Cartridges and N31 and

nQt

corer stylus wear.. nor does it cover damage to the

N8Z

Service Protection-Accidental Damage

Shure

ever, if stylus assembly should be ilamaged due to accidental

mishandling. and diamond tip is still intact, retiurn the stylus

wsscmbly to the factory

performznce stxndards

This price

stylus

send

ovtside the U.S.A.) Please enclose a check for service charge

with the returned assembly.

Return Stylus to:

Service Department

Shure Brothers Inc.

222

Evanston. Illinois

U.S.A. England

PATENT

3,077,521.

Copyright

27A499

Dynetic Styli will withstand long, continued usage. How-

for

servicing and testing to original

at

n

is

only

direct

to

addresses shown below. (Prices proportionately higher

Hartrey Avenue Willowdale. Ontario

NOTICE:

and

1968,

(4-68)

anwlicable when the customer returns the

to

the factory

In

Canada, return stylus

A.

285

60204

Canada London S E

Manufactured under U.

3,077,522. Other patcnts pending.

Shure Brothers, Inc. Printed in U.S.A.

nominal service charge

in

Evanston.

6.

Simmondr and Sons, Ltd. to:

Yorkland Boulevard Shure Electronics Lid.

In

Canada and England,

to:

In

England, return

84

Blackfriars

S.

Patents 3,055,988,

of

I

$5.50.

Road

or

Loading...

Loading...