Page 1

MODEL M1112 12" X 36"

GUNSMITHING LATHE

OWNER'S MANUAL

(FOR MODELS MANUFACTURED SINCE 1/15)

Phone: (360) 734-3482 • Online Technical Support: tech-support@shopfox.biz

COPYRIGHT © NOVEMBER 2007 BY WOODSTOCK INTERNATIONAL, INC., REVISED SEPTEMBER, 2017 (MN)

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

#10091CR

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

Printed in China

Page 2

This manual provides critical safety instructions on the proper setup,

operation, maintenance, and service of this machine/tool. Save this

document, refer to it often, and use it to instruct other operators.

Failure to read, understand and follow the instructions in this manual

may result in fire or serious personal injury—including amputation,

electrocution, or death.

The owner of this machine/tool is solely responsible for its safe use.

This responsibility includes but is not limited to proper installation in

a safe environment, personnel training and usage authorization,

proper inspection and maintenance, manual availability and comprehension, application of safety devices, cutting/sanding/grinding tool

integrity, and the usage of personal protective equipment.

The manufacturer will not be held liable for injury or property

damage from negligence, improper training, machine modifications or

misuse.

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State of

California to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

Work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

Page 3

Table of Contents

INTRODUCTION .....................................2

Woodstock Technical Support .................. 2

Controls and Features ........................... 6

SAFETY ............................................... 7

Standard Safety Instructions ................... 7

Additional Safety Instructions for Lathes .... 9

Avoiding Potential Injuries .................... 10

ELECTRICAL ....................................... 11

Circuit Requirements .......................... 11

Grounding Requirements ...................... 12

Extension Cords ................................ 12

SET UP .............................................. 13

Inventory ........................................ 13

Uncrating and Lifting .......................... 14

Cleaning Machine ............................... 15

Machine Placement ............................ 15

Mounting to Shop Floor ........................ 16

Power Connection .............................. 16

Test Run & Break-In ............................ 17

Tailstock ......................................... 19

OPERATIONS....................................... 21

General .......................................... 21

Spindle Speeds .................................. 21

Mounting Chuck or Faceplate ................ 22

Swapping Jaws .................................. 25

Four-Jaw Chuck ................................ 26

Faceplate ........................................ 27

Centers........................................... 28

Spindle Spider .................................. 28

Steady Rest ...................................... 29

Follow Rest ...................................... 29

Feed Direction Lever .......................... 30

Feed Rod Lever ................................. 30

Gearbox Levers ................................. 31

Feed Rate Chart ................................ 31

Carriage/Cross Feed Lever ................... 32

Half-Nut Lever and Inch Threading.......... 32

Change Gears & Metric Threading ........... 33

Carriage Handwheels .......................... 35

Tool Post & Holder ............................. 35

Tailstock ......................................... 36

Cutting Shallow Tapers with Tailstock ...... 37

Drilling with Tailstock ......................... 37

Gap Piece Removal............................. 38

Model M1112 Lathe Accessories .............. 39

MAINTENANCE .................................... 40

General Maintenance .......................... 40

General Cleaning ............................... 40

General Lubrication ............................ 40

Coolant System ................................. 42

SERVICE ............................................ 43

Troubleshooting ................................. 43

Troubleshooting ................................. 44

Gibs ............................................... 45

Half-Nut Adjustment ........................... 46

Adjusting/Replacing V-Belts .................. 47

Spindle Bearing Preload ....................... 48

M1112 Main Electrical Box Wiring Diagram 51

Headstock Shifters and Change Gears ...... 58

PARTS .............................................. 59

Headstock Gearing and Control Panel ..... 60

Quick Change Gearbox ........................ 62

Apron Assembly ................................. 64

Saddle and Cross Feed ........................ 66

Compound Rest ................................. 68

Tailstock Assembly ............................. 69

Bed and Motor Parts ........................... 70

Cabinet Parts ................................... 71

Spindle Switch Control Rod Assembly ....... 73

Coolant System and Lamp .................... 74

Lathe Accessories .............................. 75

Main Electrical Box ............................ 76

Follow Rest and Steady Rest ................. 77

Label Placement ............................... 78

WARRANTY ........................................ 81

SAFETYINTRODUCTION

SETUPELECTRICAL MAINTENANCE

OPERATIONS

SERVICE PARTS

USE THE QUICK GUIDE PAGE LABELS TO SEARCH OUT INFORMATION FAST!

Page 4

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

INTRODUCTION

INTRODUCTION

Woodstock Technical Support

Your new SHOP FOX® Model M1112 Lathe has been specially designed to provide many years of troublefree service. Close attention to detail, ruggedly built parts and a rigid quality control program assure

safe and reliable operation.

Woodstock International, Inc. is committed to customer satisfaction. Our intent with this manual is to

include the basic information for safety, set up, operation, maintenance, and service of this product.

We stand behind our machines! In the event that questions arise about your machine, please contact

Woodstock International Technical Support at (360) 734-3482 or send e-mail to: tech-support@shopfox.

biz. Our knowledgeable staff will help you troubleshoot problems and process warranty claims.

If you need the latest edition of this manual, you can download it from http://www.shopfox.biz.

If you have comments about this manual, please contact us at:

Woodstock International, Inc.

Attn: Technical Documentation Manager

P.O. Box 2309

Bellingham, WA 98227

Email: manuals@woodstockint.com

-2-

Page 5

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

MODEL M1112

GUNSMITH LATHE WITH STAND

Product Dimensions

Weight........................................................................................................ 1213 lbs.

Width (side‐to‐side) x Depth (front‐to‐back) x Height................................... 61 x 26 x 54‐1/2 in.

Footprint (Length x Width).................................................................... 57‐1/2 x 14‐1/2 in.

Shipping Dimensions

Carton #1

Type................................................................................................ Wood Crate

Content................................................................................................. Machine

Weight................................................................................................. 1050 lbs.

Length x Width x Height..................................................................... 66 x 30 x 29 in.

Carton #2

Type............................................................................................. Cardboard Box

Content.............................................................................................. Left Stand

Weight................................................................................................... 108 lbs.

Length x Width x Height..................................................................... 15 x 15 x 15 in.

Carton #3

Type............................................................................................. Cardboard Box

Content............................................................................................. Right Stand

Weight.................................................................................................... 93 lbs.

Length x Width x Height..................................................................... 15 x 15 x 15 in.

Electrical

Power Requirement.................................................................... 220V, Single‐Phase, 60 Hz

Prewired Voltage................................................................................................. 220V

Full‐Load Current Rating......................................................................................... 12A

Minimum Circuit Size............................................................................................. 15A

Connection Type......................................................................................... Cord & Plug

Power Cord Included............................................................................................... No

Recommended Power Cord............................................... “S”‐Type, 3‐Wire, 14 AWG, 300 VAC

Plug Included........................................................................................................ No

Recommended Plug Type........................................................................................ 6‐15

Switch Type....................................................... Control Panel w/Magnetic Switch Protection

INTRODUCTION

Motors

Main

Horsepower................................................................................................. 2 HP

Phase.............................................................................................. Single‐Phase

Amps.......................................................................................................... 12A

Speed.................................................................................................. 1725 RPM

Type......................................................................... TEFC Capacitor‐Start Induction

Power Transfer ............................................................................ Twin V‐Belt Drive

Bearings............................................................... Shielded & Permanently Lubricated

-3-

Page 6

INTRODUCTION

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

Main Specifications

Operation Info

Swing Over Bed........................................................................................... 12 in.

Distance Between Centers.............................................................................. 36 in.

Swing Over Cross Slide.................................................................................... 7 in.

Swing Over Saddle............................................................................... 11‐11/32 in.

Swing Over Gap........................................................................................... 17 in.

Maximum Tool Bit Size................................................................................. 5/8 in.

Compound Travel..................................................................................... 3‐1/4 in.

Carriage Travel........................................................................................... 24 in.

Cross Slide Travel.................................................................................... 6‐1/4 in.

Headstock Info

Spindle Bore............................................................................................ 1.57 in.

Spindle Taper.............................................................................................. MT#5

Number of Spindle Speeds................................................................................... 9

Spindle Speeds................................................................................. 70 – 1400 RPM

Spindle Type.................................................................................... D1‐5 Camlock

Spindle Bearings............................................................ High‐Precision Tapered Roller

Spindle Length with Faceplate................................................................... 18‐1/2 in.

Tailstock Info

Tailstock Quill Travel..................................................................................... 4 in.

Tailstock Taper........................................................................................... MT#3

Tailstock Barrel Diameter........................................................................... 1.563 in.

Threading Info

Number of Longitudinal Feeds............................................................................. 40

Range of Longitudinal Feeds..................................................... 0.0011 – 0.0310 in./rev.

Number of Cross Feeds...................................................................................... 40

Range of Cross Feeds............................................................... 0.0004 – 0.0105 in./rev

Number of Inch Threads..................................................................................... 40

Range of Inch Threads............................................................................. 4 – 112 TPI

Number of Metric Threads.................................................................................. 29

Range of Metric Threads....................................................................... 0.2 – 4.5 mm

Dimensions

Bed Width............................................................................................. 7‐1/4 in.

Carriage Leadscrew Diameter...................................................................... 0.870 in.

Leadscrew TPI............................................................................................. 8 TPI

Carriage Leadscrew Length............................................................................. 44 in.

Steady Rest Capacity............................................................................. 3/16 – 2 in.

Follow Rest Capacity............................................................................... 1/4 – 1 in.

Faceplate Size............................................................................................ 10 in.

Feed Rod Diameter..................................................................................... 3/4 in.

Floor to Center Height............................................................................. 46‐1/4 in.

Height With Leveling Jacks........................................................................ 48‐1/4 in.

-4-

Page 7

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

Construction

Base.................................................................................................... Cast Iron

Headstock............................................................................................. Cast Iron

End Gears.............................................................................. Flame Hardened Steel

Bed.............................................................. Hardened and Precision‐Ground Cast Iron

Body.................................................................................................... Cast Iron

Stand....................................................................................... Cast Iron and Steel

Paint Type/Finish........................................................................................ Epoxy

Fluid Capacities

Headstock Capacity.................................................................................... 3.5 qt.

Headstock Fluid Type..................................... ISO 32 (eg. Grizzly T23963, Mobil DTE Light)

Gearbox Capacity................................................................................. 1 – 2 Pumps

Gearbox Fluid Type......................................... ISO 68 (eg. Grizzly T23962, Mobil Vactra 2)

Apron Capacity.......................................................................................... 0.5 qt.

Apron Fluid Type...................................... ISO 68 (SB1365, Grizzly T23962, Mobil Vactra 2)

Other

Country of Origin ............................................................................................... China

Warranty ....................................................................................................... 2 Years

Approximate Assembly & Setup Time ..................................................................... 2 Hours

Serial Number Location ................................................................... ID Label on Headstock

ISO 9001 Factory ................................................................................................... No

Certified by a Nationally Recognized Testing Laboratory (NRTL) .......................................... No

INTRODUCTION

Features

Removable Gap Bed Allows Turnings up to 17" in Diameter

Easy to Use Lever Controls

Full Length Splash Guard

On/Off Reverse Switch on Carriage

Halogen Work Light

Ball Bearing Steady/Follow Rests

Outboard End Support Screws

Socket for Tailstock Lock

Steel Stand with Extended Base

Cast Aluminum Gear Cover

Nine Spindle Speeds, Ranging from 70 to 1400 RPM

Accessories

1 MT#3 Live Center

1/2" Chuck with MT#3 Arbor

10" Face Plate

2 MT#3 Dead Centers (1 Carbide Tipped)

6" 3‐Jaw Chuck with 2 Sets of Jaws

8" 4‐Jaw Chuck with Reversible Jaws

Follow Rest with Roller Tips

Quick Change Tool Post with One Tool Holder

Set of Six Change Gears

Steady Rest with Roller Tips

Tool Box

-5-

Page 8

INTRODUCTION

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

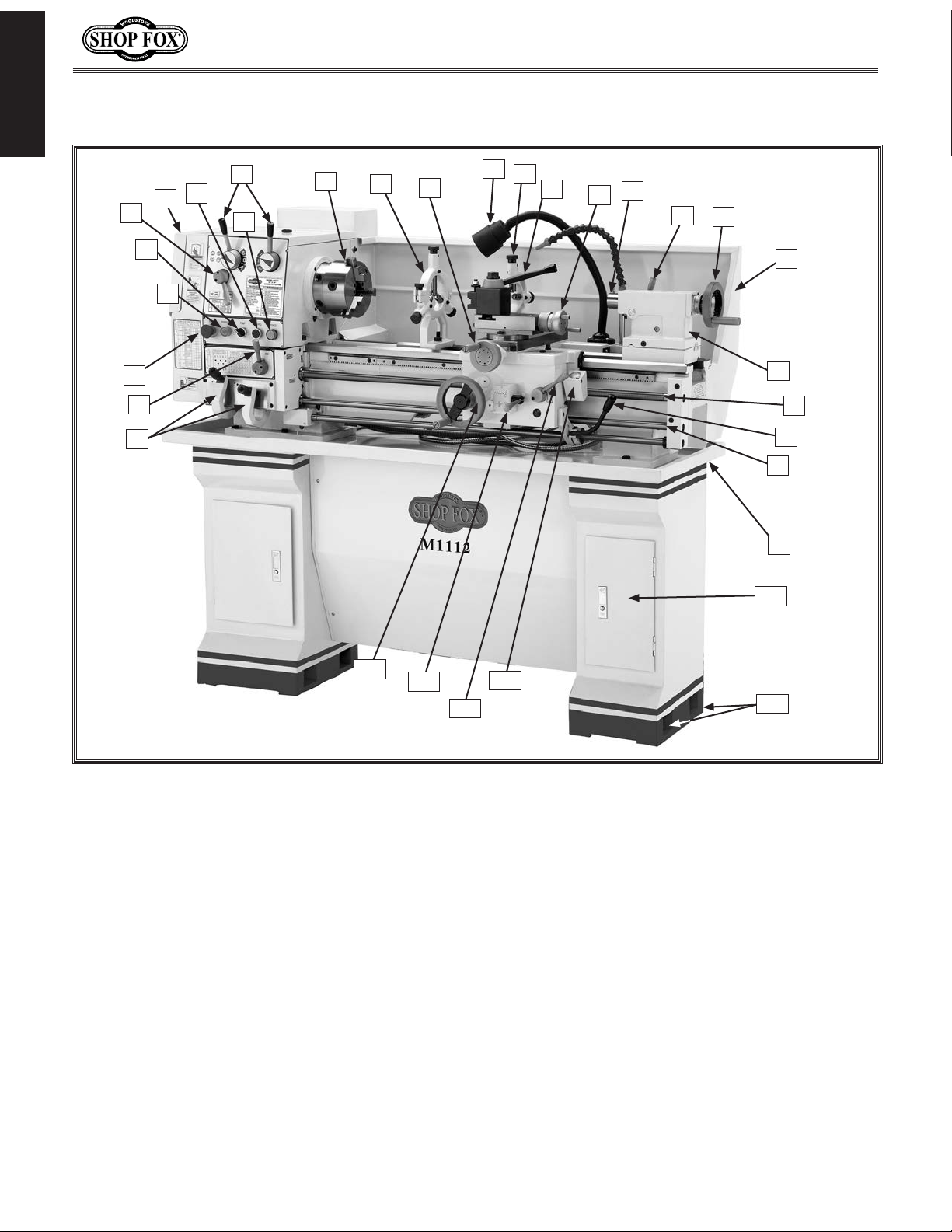

Controls and Features

N

J

H

G

F

I

K

L

M

O

P

R

Q

S

T

E

D

C

B

A

FF

EE

CC

DD

U

V

W

X

Y

Z

AA

BB

A. Quick Change Gearbox Levers

B. Feed Rod Lever

C. Emergency Stop/RESET Button

D. POWER START Button

E. Pump Switch

F. Feed Direction Lever

G. Gear and Belt Cover

H. Inching/Jog Button

I. Power Light

J. Spindle Speed Levers

K. 3-Jaw Chuck

L. Steady Rest

M. Cross Feed Handwheel

N. Halogen Work Light

O. Follow Rest

P. Tool Rest

Model M1112 lathe.

Q. Compound Rest Handwheel

R. Tailstock Spindle and Center

S. Tailstock Spindle Lock Lever

T. Tailstock Spindle Handwheel

U. Back Splash Guard

V. Tailstock

W. Leadscrew

X. Spindle Rotation ON/OFF Lever

Y. Feed Rod

Z. Chip Tray

AA. Storage Cabinet

BB. Stand Mounting Points

CC. Thread Dial

DD. Half-nut Lever

EE. Apron/Cross Feed Lever

FF. Carriage Handwheel

-6-

Page 9

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

SAFETY

READ MANUAL BEFORE OPERATING MACHINE.

FAILURE TO FOLLOW INSTRUCTIONS BELOW WILL

RESULT IN PERSONAL INJURY.

Indicates an imminently hazardous situation which, if not avoided, WILL

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, COULD

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, MAY

result in minor or moderate injury.

This symbol is used to alert the user to useful information about proper

NOTICE

operation of the equipment, and/or a situation that may cause damage

to the machinery.

Standard Safety Instructions

SAFETY

1. Thoroughly read the Instruction Manual before operating your machine. Learn the applications,

limitations and potential hazards of this machine. Keep the manual in a safe and convenient place

for future reference.

2. Keep work area clean and well lighted. Clutter and inadequate lighting invite potential hazards.

3. Ground all tools. If a machine is equipped with a three-prong plug, it must be plugged into a

three-hole grounded electrical receptacle or grounded extension cord. If using an adapter to aid in

accommodating a two-hole receptacle, ground using a screw to a known ground.

4. Wear eye protection at all times. Use safety goggles with side shields or safety goggles that meet

the appropriate standards of the American National Standards Institute (ANSI).

5. Avoid dangerous environments. Do not operate this machine in wet or open flame environments.

Airborne dust particles could cause an explosion and severe fire hazard.

6. Ensure all guards are securely in place and in working condition.

7. Make sure switch is in the OFF position before connecting power to machine.

8. Keep work area clean, free of clutter, grease, etc.

9. Keep children and visitors away. Visitors must be kept at a safe distance while operating unit.

10. Childproof your workshop with padlocks, master switches or by removing starter keys.

11. Stop and disconnect the machine when cleaning, adjusting or servicing.

-7-

Page 10

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

12. Do not force tool. The machine will do a safer and better job at the rate for which it was

designed.

13. Use correct tool. Do not force machine or attachment to do a job for which it was not designed.

14. Wear proper apparel. Do not wear loose clothing, neck ties, gloves, jewelry, and secure long hair

away from moving parts.

15. Remove chuck keys, rags, and tools. Before turning the machine on, make it a habit to check

SAFETY

that all chuck keys and wrenches have been removed.

16. Keep proper footing and balance at all times.

17. Lock the mobile base from moving before feeding the workpiece into the machine.

18. Do not leave machine unattended. Wait until it comes to a complete stop before leaving the

area.

19. Perform machine maintenance and care. Follow lubrication and accessory attachment

instructions in the manual.

20. Keep machine away from open flame. Operating machines near pilot lights or open flames

creates a high risk if dust is dispersed in the area. Dust particles and an ignition source may cause

an explosion. Do not operate the machine in high-risk areas, including but not limited to, those

mentioned above.

21. If at any time you are experiencing difficulties performing the intended operation, stop using the

machine! Then contact our technical support or ask a qualified expert how the operation should be

performed.

22. Be aware that certain materials may cause an allergic reaction in people and animals,

especially when exposed to fine dust. Make sure you know what type of material dust you will be

exposed to and the possibility of an allergic reaction.

23. Habits—good and bad—are hard to break. Develop good habits in your shop and safety will

become second-nature to you.

-8-

Page 11

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

Additional Safety Instructions for Lathes

READ and understand this

entire instruction manual

before using this machine.

Serious personal injury

may occur if safety and

operational information is

not understood and followed. DO NOT risk your

safety by not reading!

1. AVOIDING INJURY: Read and understand this manual before operating this machine.

2. SAFE CLEANING: Do not clear chips by hand. Use a brush to avoid lacerations, and never clear

chips while the lathe is turning, or entanglement may occur.

3. USING CORRECT TOOLING: Always select the right tool bit for the job, and make sure cutting

edges are sharp. Dull or incorrect bits can break and become a projectile causing severe injury.

4. USING CHUCK KEY CORRECTLY: Never walk away from the lathe with the key in the chuck. An

accidental start can throw the chuck key with great velocity causing severe injury.

5. SECURING A WORKPIECE: Make sure workpiece is properly held in chuck before starting lathe. A

workpiece thrown from the chuck will cause severe injury.

USE this and other machinery with caution

and respect. Always consider safety first,

as it applies to your individual working

conditions. No list of safety guidelines can

be complete—every shop environment is

different. Failure to follow guidelines could

result in serious personal injury, damage

to equipment or poor work results.

SAFETY

6. CHUCK SAFETY: Get assistance when installing large chucks. Large lathe chucks are very heavy

and awkward to hold and may cause injury from dropping or lifting incorrectly, so protect your

hands and the precision ground ways. Always use a chuck cradle or piece of plywood over the bed

and ways to prevent accidental damage.

7. WORKPIECE SUPPORT: Support a long workpiece if it extends from the headstock so it will not wobble violently when the lathe is turned on. A workpiece that extends more than 2.5 times its diameter

must be supported by a center or steady rest or it may be thrown from the lathe.

8. AVOIDING STARTUP INJURIES: Make sure workpiece, cutting tool, and tool post have adequate

clearance before starting lathe. Check chuck clearance and saddle clearance before starting the

lathe. Make sure spindle RPM is set correctly for part diameter before starting the lathe. Large

parts can be ejected from the chuck if the chuck speed is set too high.

9. AVOIDING OVERLOADS: Always use the appropriate feed and speed rates. Otherwise you may

break tooling or eject a workpiece causing severe injury.

10. AVOIDING ENTANGLEMENT INJURIES: Never attempt to slow or stop the lathe chuck by hand, and

tie back long hair, ponytails, loose clothing, and sleeves so they do not dangle.

11. MAINTAINING A SAFE WORKPLACE: Never leave lathe unattended while it is running, or coworkers

or passers by may be injured severely.

12. PREVENTING LATHE CRASHES: Disengage the automatic feed levers after completing a job.

-9-

Page 12

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

Avoiding Potential Injuries

SAFETY

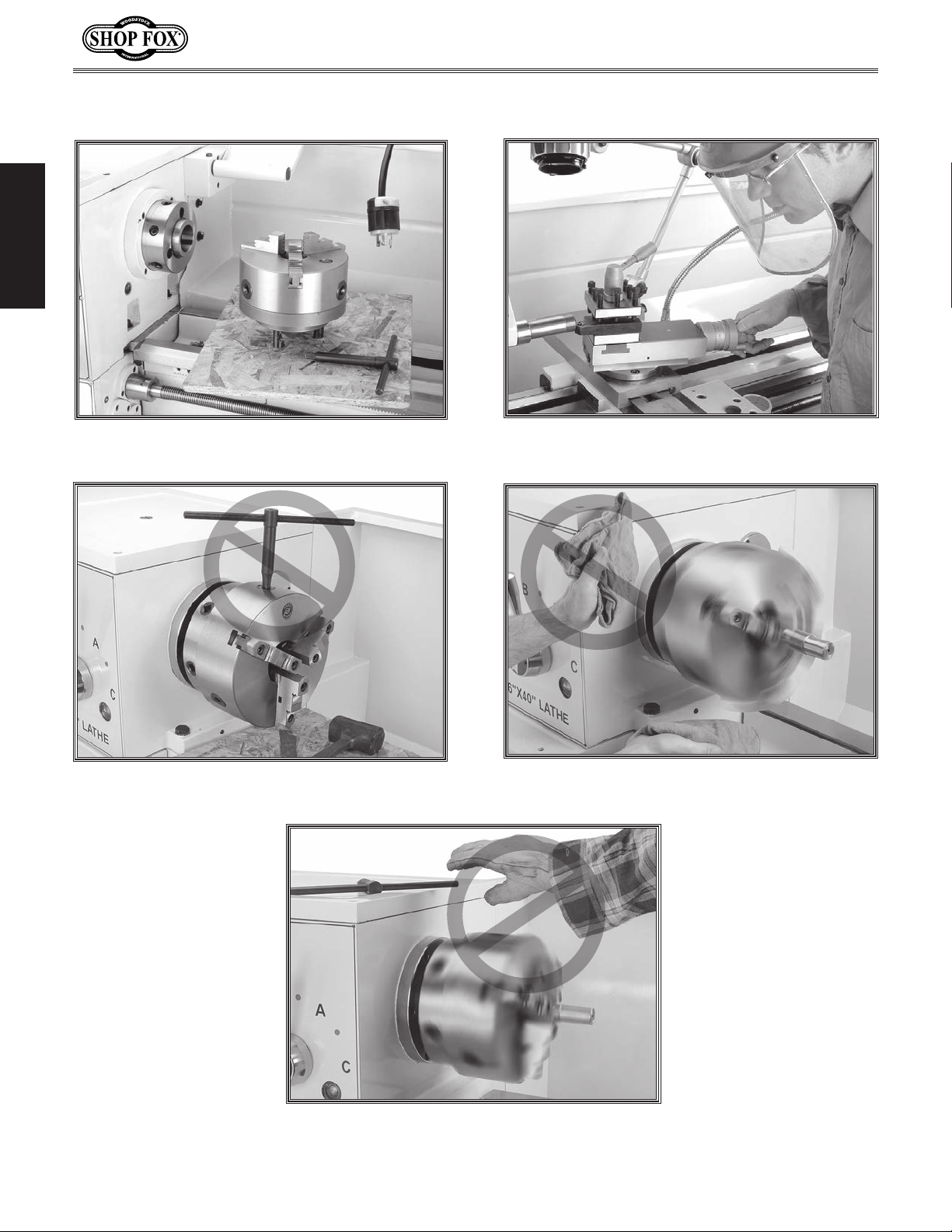

Figure 1. Always protect the bed ways, and

unplug the lathe when retooling the lathe.

Figure 2. Never walk away from the lathe with

the chuck key inserted in the chuck.

Figure 3. Always wear face and eye protection

when using lathes.

Figure 4. Never use hands to stop or slow the

chuck when shutting down the lathe.

Figure 5. Never wear loose clothing or gloves

when working with the lathe.

-10-

Page 13

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

This machine must be connected to the correct size and

type of power supply circuit, or fire or electrical damage

may occur. Read through this section to determine if an

adequate power supply circuit is available. If a correct

circuit is not available, a qualified electrician MUST install

one before you can connect the machine to power.

A power supply circuit includes all electrical equipment

between the breaker box or fuse panel in the building

and the machine. The power supply circuit used for

this machine must be sized to safely handle the fullload current drawn from the machine for an extended

period of time. (If this machine is connected to a circuit

protected by fuses, use a time delay fuse marked D.)

This machine is prewired to operate on a 220V power

supply circuit that has a verified ground and meets the

following requirements:

The full-load current rating is the amperage a machine

draws at 100% of the rated output power. On machines

with multiple motors, this is the amperage drawn by the

largest motor or sum of all motors and electrical devices

that might operate at one time during normal operations.

or machine damage. To reduce this risk,

where only one machine will be running

ELECTRICAL

Circuit Requirements

The machine must be properly set up

before it is safe to operate. DO NOT

connect this machine to the power

source until instructed to do later in

this manual.

ELECTRICAL

Full-Load Current Rating

Full-Load Current Rating at 220V .................. 12 Amps

Circuit Requirements for 220V

Circuit Ty p e ...............220V/240V, 60 Hz, Single-Phase

Circuit Size ............................................. 15 Amps

Plug/Receptacle .................................... NE M A 6 -15

Cord .................“S”-Type, 3-Wire, 14 AWG, 300 VAC

Incorrectly wiring or grounding this

machine can cause electrocution, fire,

only an electrician or qualified service

personnel should do any required

electrical work on this machine.

NOTICE

The circuit requirements listed in this

manual apply to a dedicated circuit—

at a time. If this machine will be

connected to a shared circuit where

multiple machines will be running at

the same time, consult a qualified

electrician to ensure that the circuit is

properly sized for safe operation.

-11-

Page 14

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

This machine MUST be grounded. In the event of certain

types of

a path of least resistance for electric current

order

Improper connection of the equipment-grounding

will

increase

insulation

grounding

cord or plug is necessary, do not connect the equipmentgrounding

Check with a qualified electrician or service personnel

if

or if

properly grounded.

plug is damaged or worn, disconnect it from power, and

immediately replace it with a new one.

We do not recommend using an extension cord with

Any extension cord used with this machine must contain a

plug and receptacle, and

meet the following requirements:

receptacle. Instead, have a qualified

Grounding Requirements

malfunctions or breakdowns, grounding provides

to travel—in

to reduce the risk of electric shock.

wire

the risk of electric shock. The wire with green

(with/without yellow stripes) is the equipment-

wire. If repair or replacement of the power

wire to a live (current carrying) terminal.

you do not understand these grounding requirements,

ELECTRICAL

you are in doubt about whether the tool is

If you ever notice that a cord or

For 220V Connection

The power cord and plug specified under "Circuit

Requirements for 220V" on the previous page has an

equipment-grounding wire and a grounding prong. The

plug must only be inserted into a matching receptacle

(outlet) that is properly installed and grounded in

accordance with all local codes and ordinances (see figure

to the right).

Extension Cords

this machine. Extension cords cause voltage drop, which

may damage electrical components and shorten motor

life. Voltage drop increases with longer extension cords

and smaller gauge sizes (higher gauge numbers indicate

smaller sizes).

ground wire

Minimum Gauge Size at 220V ...................... 14 AWG

Maximum Length (Shorter is Better) ................ 50 ft.

, match the required

-12-

220V

Current Carrying Prongs

6-15 PLUG

Figure 6. NEMA 6-15 plug & receptacle.

DO NOT modify the provided plug or use

an adapter if the plug will not fit your

electrician install the proper receptacle

on a power supply circuit that meets the

requirements for this machine.

GROUNDED

6-15 RECEPTACLE

Grounding Prong

Page 15

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

SET UP

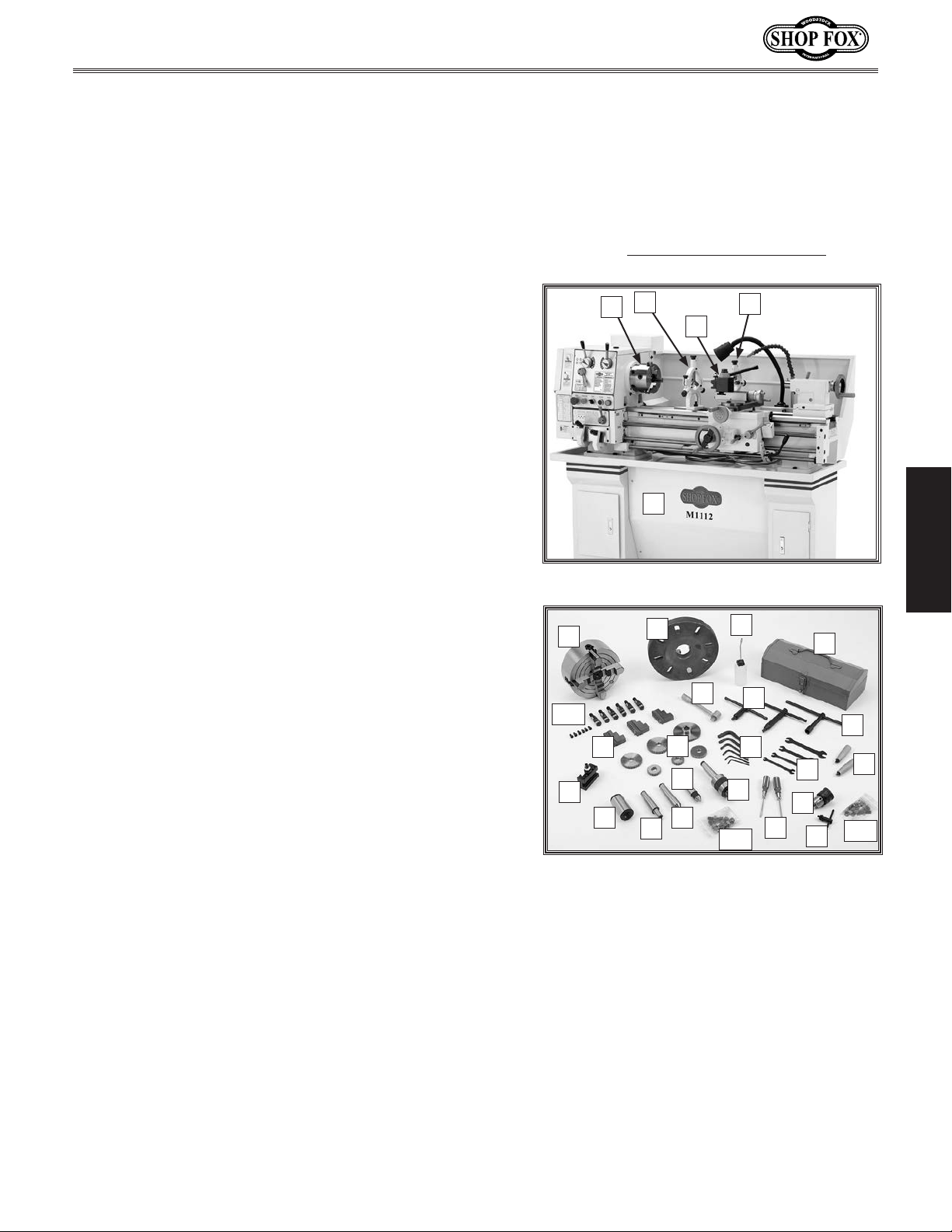

Inventory

Main Components (Figure 7) Qty

A. 6" Three-Jaw Chuck w/Jaws .............................1

B. Steady Rest .................................................1

C. Follow Rest .................................................1

D. Quick Change Tool Post ...................................1

E. Cabinet Base:

—Cabinets (Left & Right) .................................2

—Front Panel ...............................................1

—Front Panel Brackets ....................................2

Accessory Components (Figure 8)

F. 8" Four-Jaw Universal Chuck ............................1

G. 10" Faceplate...............................................1

H. Oil Bottle ...................................................1

I. Tool Box .....................................................1

J. Three-Jaw Chuck Jaws ...................................3

K. Tailstock Wrench ...........................................1

L. 3- and 4-Jaw Chuck Wrenches .......................1 EA

M. Square Socket T-Wrench ..................................1

N. Quick Change Tool Holder ................................1

O. Change Gears ..............................................1

—Gear 27-Tooth ............................................1

—Gear 26-Tooth ............................................1

—Gear 35-Tooth ............................................1

—Gear 40-Tooth (Installed) ..............................2

—Gear 45-Tooth ............................................1

—Gear 50-Tooth ............................................1

—Gear 60-Tooth ............................................1

—Gear 86/91-Tooth (Installed) ..........................1

P. Hex Wrench Set 2, 4, 5, 6, 8, 10 mm ..............1 EA

Q. Wrenches 9/11, 10/12, 12/14, 17/19mm .........1 EA

R. Handwheel Handles .......................................2

S. Dead Center Spindle Sleeve .............................1

T. Arbor B16 to MT#3 ........................................1

U. Standard Dead Center MT#3 .............................1

V. Carbide Tipped Dead Center MT#3 .....................1

W. Live Center MT#3 ................................ ..........1

X. #2 Phillips & Standard Screwdrivers ................1 EA

Y. Drill Chuck B16 1.5-13mm ...............................1

Z. Drill Chuck Key .............................................1

AA. Spider Screws ..............................................4

BB. Camlock Stud Kit ..........................................1

CC. Cabinet Base Fasteners:

—Hex Bolts M12-1.75 x 40 ................................6

—Flat Washers 12mm .....................................6

—Phillips Head Screws M6-1 x 10 ..................... 12

—Hex Nuts M6-1 ............................................4

—Flat Washers 6mm ..................................... 12

If any parts are missing, find the part number in the back of this manual and contact

Woodstock International, Inc. at (360) 7343482 or at tech-support@shopfox.biz

B

A

D

E

Figure 7. Main contents.

F

BB

J

N

S

Figure 8. Packaged components.

G

K

O

U

V

T

W

AA

C

H

I

L

M

P

Q

Y

X

R

CC

Z

SETUP

-13-

Page 16

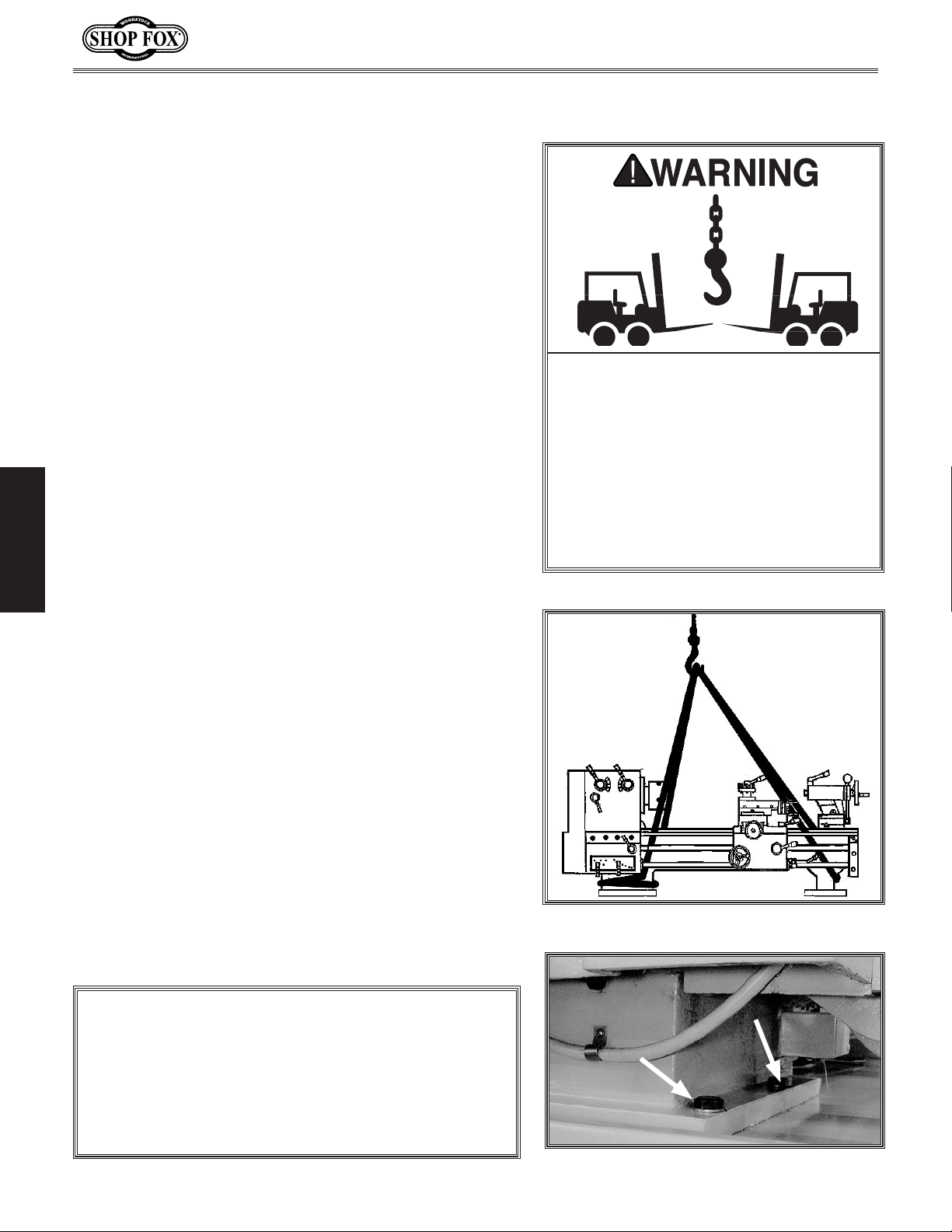

Uncrating and Lifting

The Model M1112 lathe has been carefully crated. If

you notice the lathe has been damaged, contact your

authorized

To lift and move the lathe, do these steps:

1. Wrap two lifting straps around the bedway pedestals

and route them behind the feed rod, control rod, and

the lead screw, as shown in Figure 9.

2. Move the apron toward the right to help balance the

load, as shown in Figure 9.

3. Position the chip pan on top of the base assembly so

that the six lathe mounting holes align with top holes

of the cabinets.

4. Un-bolt the lathe from the pallet.

5. Slowly raise the lathe from the pallet, and move it

over the cabinet base to your prepared location.

SHOP FOX

SETUP

6. Position the lathe so that the six M12-1.75 x 40

hex bolts and flat washers can be inserted through

the chip pan and partially threaded, but not fully

tightened, into the mounting holes of the cabinets

(see Figure 10).

®

dealer immediately.

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

The Model M1112 weighs approximately

1400 lbs. You will need power lifting

equipment and assistance to remove

this machine from the crate and position it. Inspect all lifting equipment

and make sure that all is in perfect

working order and is rated for the load

before attempting to lift and move this

lathe. Ignoring this warning may lead to

serious personal injury or death.

7. Shim between the lathe and cabinet base as required

to make the ways level at all four corner locations as

indicated with a machinist's level.

8. Fully tighten the six hex bolts to secure the lathe to

the cabinet base.

9. For best results, recheck the ways in 24 hours to

make sure the ways are still level and have not

twisted, and re-shim as required.

10. Install the backsplash with four M6-1 x 10 Phillips

head screws and flat washers.

NOTICE

If a lathe is not level, the ways can twist out of

alignment, and cutting operations may be affected.

Make sure that your level is a high-quality machinist's

level, and that all measuring surfaces are perfectly

clean. Recheck the lathe ways in a few weeks to make

sure the floor has not settled. Re-shim as required.

Figure 9. Lifting strap locations.

Figure 10. Lathe mounting hex bolts.

-14-

Page 17

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

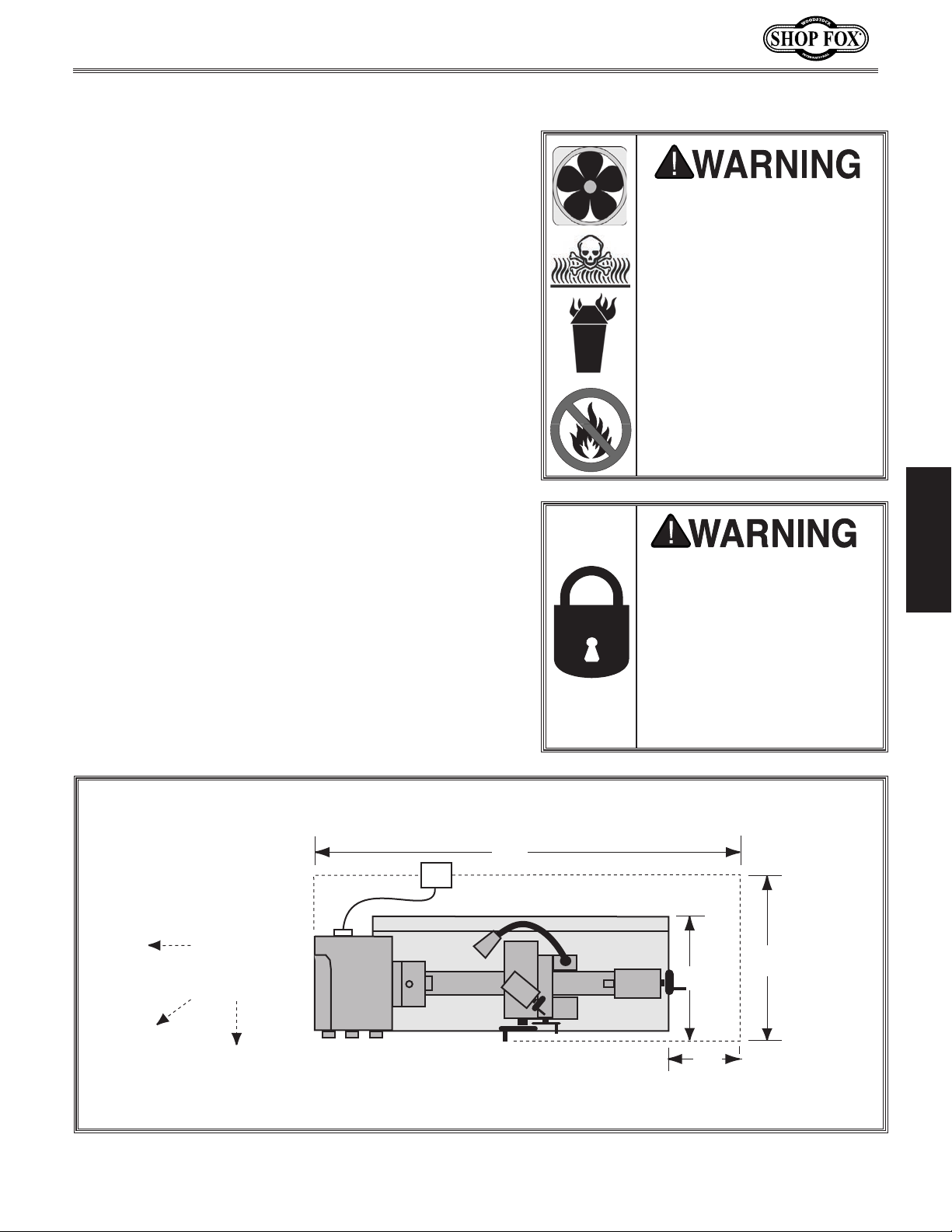

Cleaning Machine

The ways and other unpainted parts of your lathe are

coated with a waxy grease that protects them from

corrosion during shipment. Clean this grease off with a

solvent cleaner or citrus-based degreaser. DO NOT use

chlorine-based solvents such as brake parts cleaner,

lacquer thinner, or acetone—if you happen to splash some

onto a painted surface, you will ruin the finish.

Machine Placement

• Floor Load: Your lathe is a heavy load distributed

in a small footprint, so you must reinforce the floor

if required. The floor MUST be level, or the lathe

frame and ways may twist and distort over time.

• Working Clearances: Consider existing and anticipated needs, service panel access, length of rods

to be loaded into the lathe, and space for auxiliary stands, work tables or other machinery when

establishing a location for your lathe (see Figure 11

for dimensions).

• Lighting: Lighting should be bright enough to eliminate shadow and prevent eye strain.

• Electrical: Outlets must be located near each

machine, so power cords are clear of high-traffic

areas.

ALWAYS work in wellventilated areas far from

possible ignition sources

when using solvents to clean

machinery. Many solvents

are toxic when inhaled or

ingested. Use care when

disposing of waste rags

and towels to be sure

they DO NOT create fire

or environmental hazards.

NEVER use gasoline or

petroleum-based solvents

to clean your lathe.

SETUP

MAKE your shop “child safe.”

Ensure that your workplace

is inaccessible to youngsters

by closing and locking all

entrances when you are

away. NEVER allow untrained

visitors in your shop when

assembling, adjusting or

operating equipment.

Keep

Workpiece

Loading Area

Unobstructed

80"

220V

Supply

Lathe

Figure 11. Minimum wall clearances.

-15-

Chip Tray

60"

36"

24"

Page 18

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

2 T1

6 T3

22NC

4 T2

1 L1

5 L3

21NC

GSC1-1801

KM1

3 L2

A1

A2

26

30313233E

2524232221

20

13NO

JZC3 40d

33NO

43NO

23NO

14NO

34NO

44NO

24NO

2 T1

6 T3

22NC

4 T2

1 L1

5 L3

21NC

GSC1-1801

KM2

KA0

3 L2

Ground

NO

NC

1L1

3L2

5L3

2T1

6T3

4T2

STOP

RESET

95

98

97

JRS4-09/25d

FR1

11

13

A

6

96

TC

20-21 = 110V

20-22 = 220V

20-23 = 230V

20-24 = 240V

20-25 = 380V

20-26 = 400V

A1A1A2

A2

L

L

L

N

N

N

U1

N

N

N

L

L

L

LL0

0

11PE

PE

0

0

0

1

1

2

2

233

55667

7

U2

U2U2Z1

Z1Z1Z2Z2Z2

1066

10

1101326754

PE

PE

Z2Z1U2

U1

PE

L N

8

5

Transformer

Relay

Contactor

Contactor

Contactor

2A

110V

110V

2A

5A

110V

110V

5A

To

Work Light

To

Power Source

To

Motor

To

Control Panel

To

Spindle Switch

8

L

L

11

11

11

11

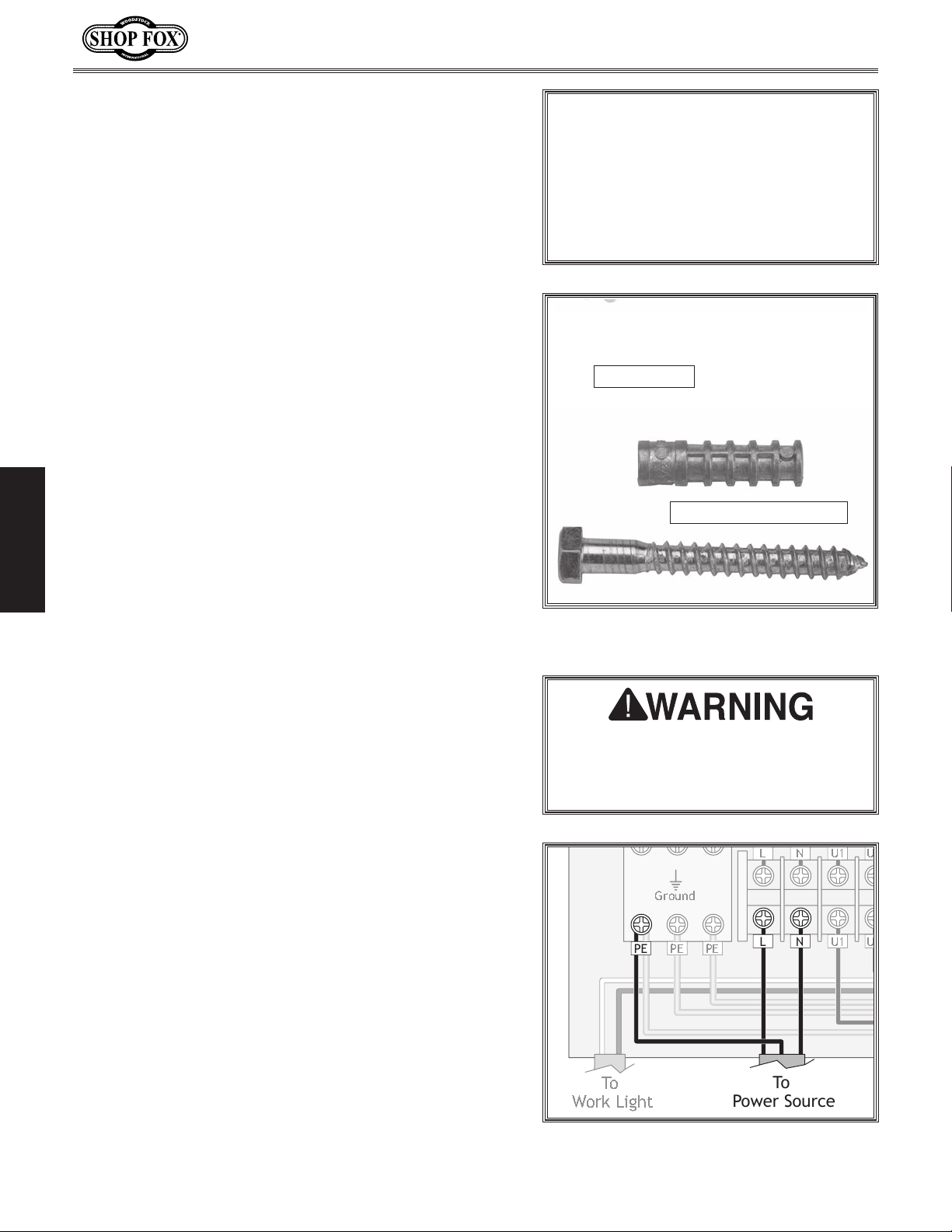

Mounting to Shop Floor

Although not required, we recommend that you mount

your new machine to the floor. Because this is an optional

step and floor materials may vary, floor mounting

hardware is not included. Generally, you can either bolt

your machine to the floor or mount it on machine mounts.

Both options are described below. Whichever option you

choose it will be necessary to use a precision level to

level your machine.

Bolting to Concrete Floors

Anchor studs, lag screw and anchor (Figure 12) are two

popular methods for anchoring an object to a concrete

flo or. We suggest you research the many options and

methods for mounting your machine and choose the one

that best fits your specific application.

Power Connection

Before the machine can be connected to the power

SETUP

source, an electrical circuit, power cord, plug, and

receptacle must be prepared per the ELECTRICAL section

in this manual, and all previous setup instructions in the

manual must be complete to ensure that the machine has

been assembled and installed properly.

NOTICE

Anchor studs are stronger and more

permanent alternatives to lag shield

anchors; however, they will stick out of

the floor, which may cause a tripping

hazard if you decide to move your

machine at a later point.

Anchor Stud

Lag Screw and Anchor

Figure 12. Typical fasteners for mounting

to concrete floors.

To connect the power cord, do these steps:

1. Make sure the power cord is NOT connected to

power.

2. Open the electrical cabinet and identify the L and

N terminals, and the grounding plate (PE) at the

bottom left of the cabinet (see Figure 13).

3. Attach insulated crimp-on wire terminals to the

wires of the power cord.

4. Securely connect the incoming ground to the PE

terminal and the two incoming hot leads to the L

and N terminals.

5. Close and secure the electrical cabinet.

Before connecting the machine to

power, always make sure the reset

button on the control panel is pushed

in to avoid unexpected start-ups.

Figure 13. Locations of power cord

connections inside the electrical cabinet.

-16-

Page 19

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

Test Run & Break-In

The purpose of the test run and break-in is to make sure

the lathe and safety features operate correctly, and

that the lathe can enter service quickly without bearing

damage if heavy work loads are immediately anticipated.

To begin the test run & break-in procedure, do these

steps:

1. Make sure the lathe is lubricated and the headstock

oil level is full. Refer to Lubrication on Page 40.

2. Make sure the chuck is correctly secured to the

spindle. Refer to Mounting Chuck and Faceplate on

Page 22 for details.

3. Disengage the half-nut lever and the feed lever

(Figure 14).

NOTICE

NEVER shift lathe gears when lathe

is operating, and make sure both the

half-nut lever and the feed lever are

disengaged before you start the lathe!

Otherwise the lathe will feed the apron

into the chuck or tailstock causing

severe lathe damage.

Feed Lever is

Horizontal

(Disengaged)

Half-nut Lever

is Pulled Up

(Disengaged)

4. Connect power to the machine.

NOTICE

Make sure all power feed levers and dials are

disengaged before starting the lathe! Thoroughly

familiarize yourself with all the controls and their

functions before using any power feed!

5. Rotate the red stop/RESET button (Figure 15)

clockwise so it pops out.

6. Make sure the spindle rotation ON/OFF lever is in

the central or neutral position (Figure 14).

7. Move the speed levers to B and

rotate at 70 RPM (Figure 15).

I so the spindle will

SETUP

Spindle Rotation

ON/OFF Lever

Figure 14. Apron controls.

Speed Levers

-17-

Figure 15. Headstock controls.

Page 20

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

8. Push the POWER START button, then move

the spindle rotation ON/OFF lever (Figure 14)

down until the chuck turns. The top of the

chuck should turn toward you.

— If you hear squealing or grinding noises,

turn the lathe OFF immediately and correct

any problem before further operation.

— If the problem is not readily apparent, refer

to Troubleshooting on Page 43.

9. Push the emergency stop button.

— If the lathe does not stop, turn the lathe

OFF with the spindle rotation ON/OFF

lever, and disconnect the lathe from power.

Refer to Troubleshooting on Page 43 for

correction.

10. Return the spindle rotation ON/OFF lever

to STOP, reset the emergency stop button,

restart the lathe, and let the lathe run for a

minimum of 10 minutes in both directions.

11. Turn the lathe OFF, and move the speed

levers to C and

200 RPM. Run the lathe in both directions for

10 minutes.

12. Repeat Step 9 for the remaining RPM ranges,

progressively increasing in RPM. When these

steps are complete, the lathe is broken in.

13. Drain and refill the lubricant in the

headstock with Mobil DTE Light or ISO 32 an

equivalent. Refer to Lubrication on Page 40

for steps and apron oil change interval.

I so the spindle will rotate at

SETUP

-18-

Page 21

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

Looking down from above.

Move tailstock toward

back of lathe

1

/2 the

amount of taper.

Tailstock

The tailstock alignment was set at the factory with the

headstock. However, we recommend that you take the

time to ensure that the tailstock is aligned to your own

desired tolerances.

To align the tailstock, do these steps:

1. Center drill a 6'' long piece of bar stock on both

ends. Set it aside for use in Step 4.

2. Make a dead center by turning a shoulder to make

a shank. Flip the piece over in the chuck and turn a

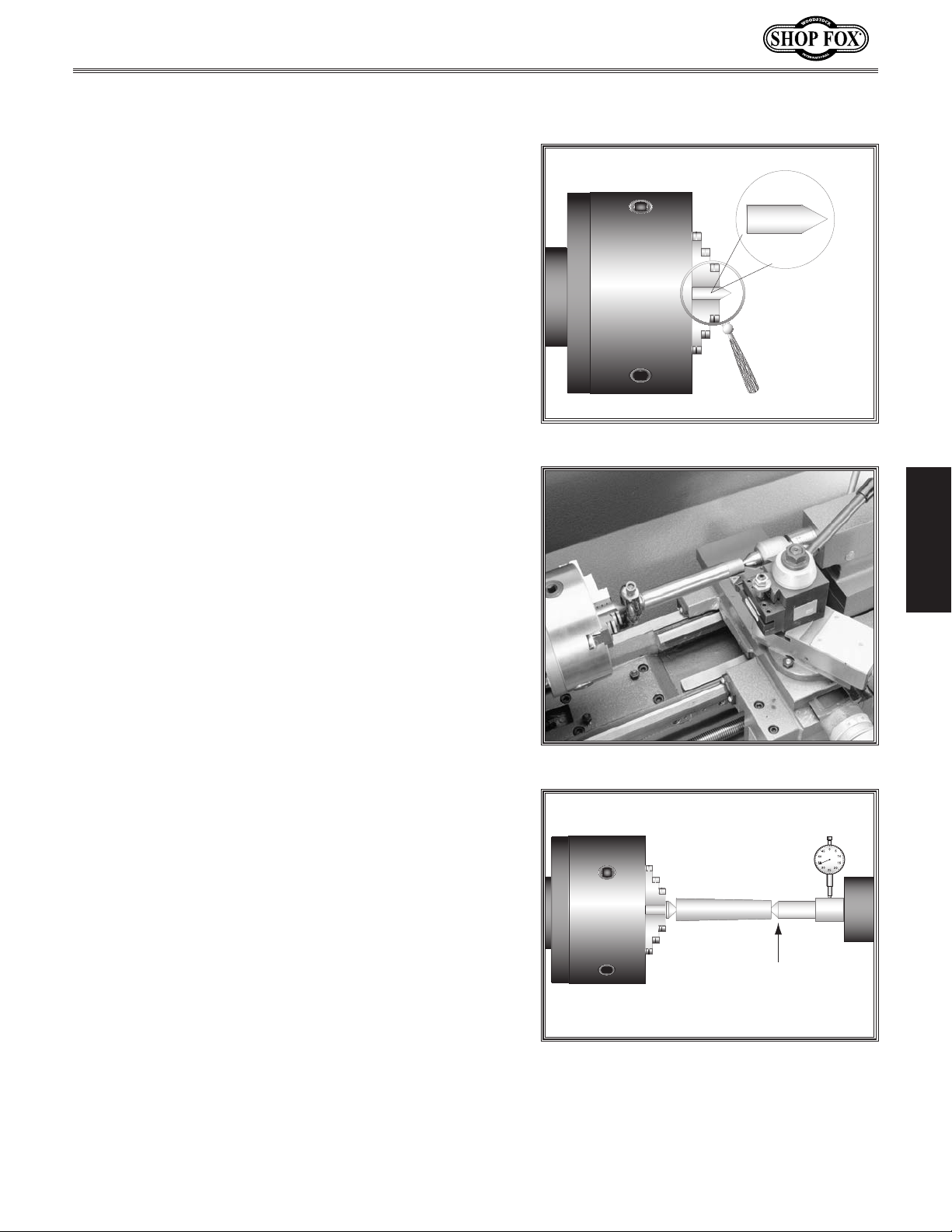

60° point (see Figure 16). As long as it remains in

the chuck, the point of your center will be accurate

to the spindle axis.

Note: Keep in mind that the point will have to be

refinished whenever it is removed and returned to

the chuck.

Figure 16. Finished dead center.

SETUP

3. Place the live center in your tailstock.

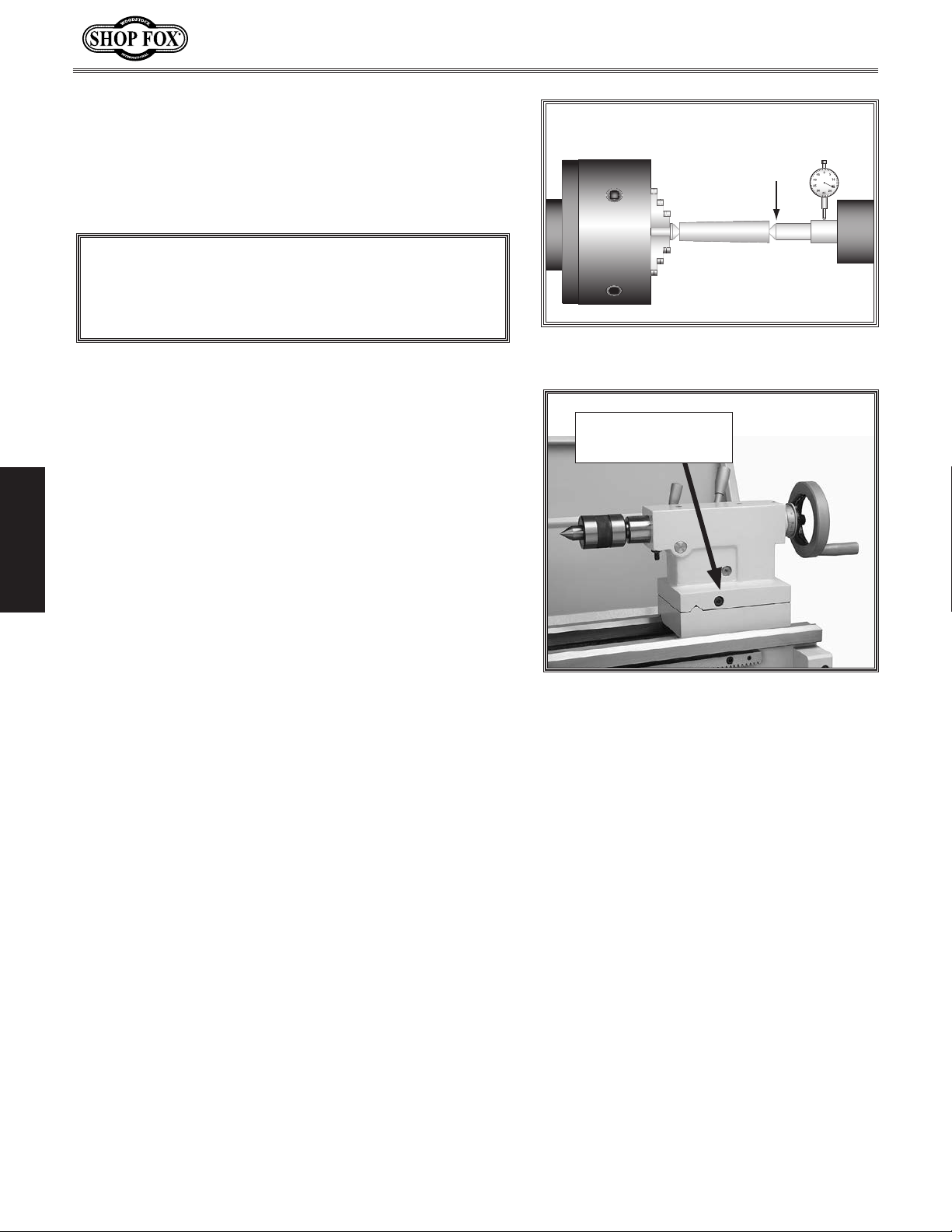

4. Attach a lathe dog to the bar stock from Step 1 and

mount it between the centers (as shown in Figure

17).

5. Turn approximately 0.010" off the diameter.

6. Mount a dial indicator so that the plunger is on the

tailstock barrel (Figure 18).

7. Measure the stock with a micrometer. If the stock is

wider at the tailstock end, the tailstock needs to be

moved toward the cutter the amount of the taper

(Figure 18).

— If the stock is thinner at the tailstock end, the

tailstock needs to be moved away from the

operator by half the amount of the taper (Figure

19).

Figure 17. Bar stock mounted on centers.

Figure 18. Adjusting for headstock end

taper.

-19-

Page 22

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

Move tailstock toward

front of lathe

1

/2 the

amount of taper.

Looking down from above.

8. Loosen the tailstock lock lever and adjust the

tailstock offset by half the taper by turning the

adjustment set screw (Figure 20). Turn another

0.010'' off of the stock and check for taper. Repeat

as necessary until the desired amount of accuracy is

achieved.

NOTICE

DO NOT forget to lock the tailstock to the ways

after each adjustment.

Figure 19. Adjusting for tailstock end

taper.

Adjustment Screw

On Both Sides

SETUP

Figure 20. Tailstock left adjustment

location.

-20-

Page 23

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

I II III

SPINDLE SPEED

OPERATIONS

General

NOTICE

Complete the Test Run and Break-In procedure on

Page 17 before using this lathe for any cutting or

threading operations; otherwise, gear box damage

may o cc ur.

The Model M1112 will perform many types of operations

that are beyond the scope of this manual. Many of these

operations can be dangerous or deadly if performed

incorrectly.

The instructions in this section are written with the

understanding that the operator has the necessary

knowledge and skills to operate this machine. If at any

time you are experiencing difficulties performing any

operation, stop using the machine!

If you are an inexperienced operator, we strongly

recommend that you read books, trade articles, or seek

training from an experienced lathe operator before

performing any unfamiliar operations. Above all, your

safety should come first!

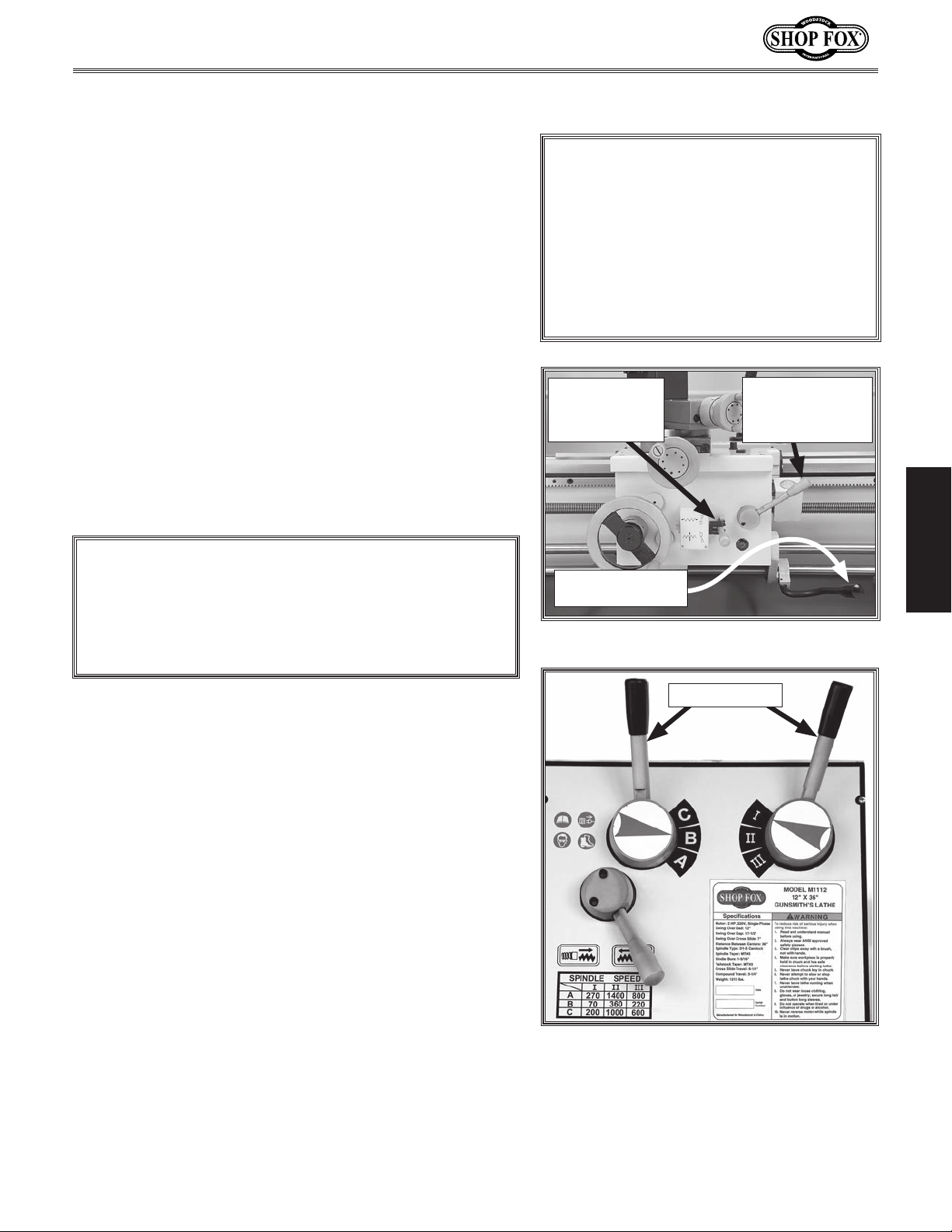

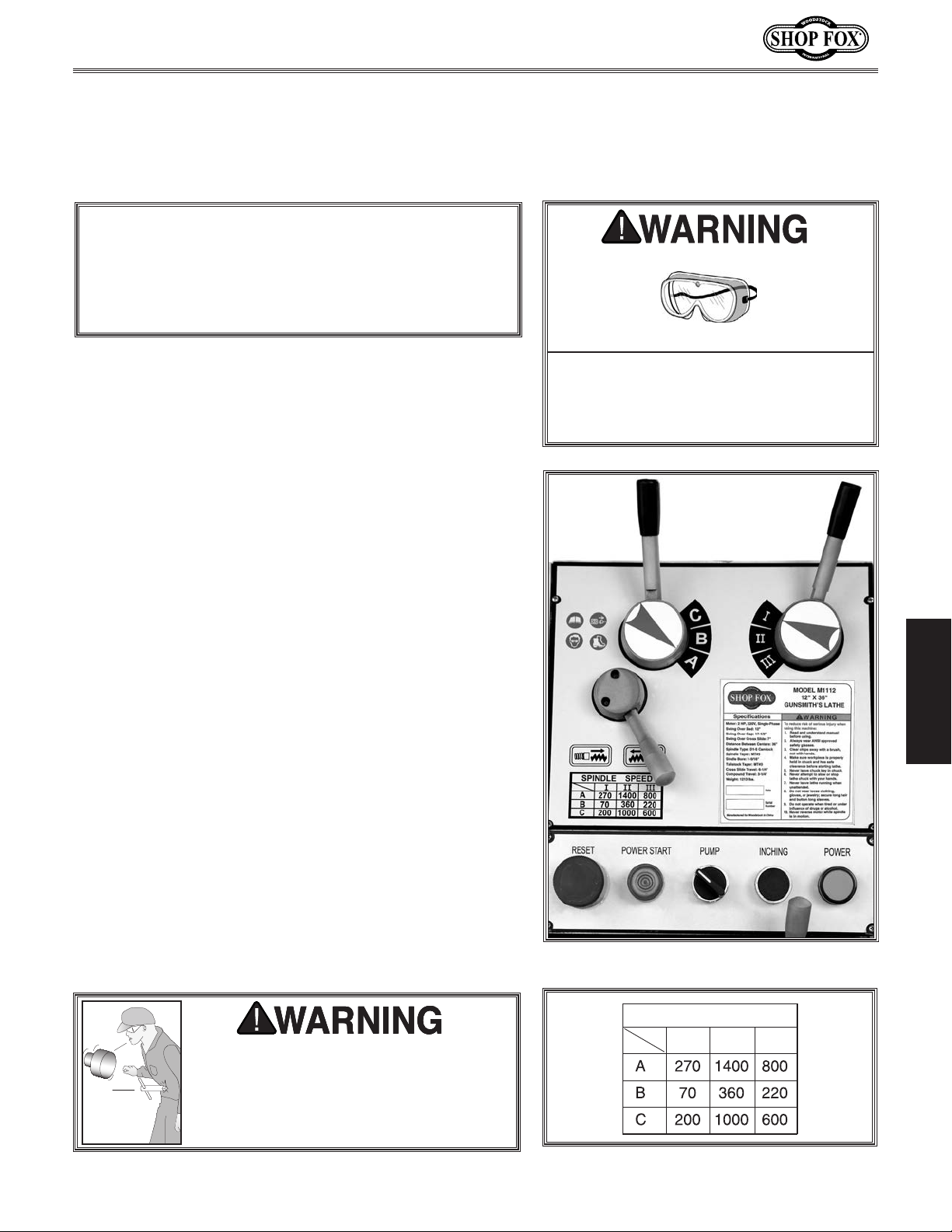

Spindle Speeds

The spindle speed or RPM is controlled by the speed

control levers (Figure 21). Use the chart in Figure 22 to

find the best spindle speed required for your task.

Always wear safety goggles when operating this lathe. Failure to comply may

result in a serious eye injury resulting

in blindness.

OPERATIONS

The chart to the right shows the various combinations of

knob positions for achieving a desired speed.

Example:

To select a spindle speed of 270 RPM, move the alpha

lever until the indicator arrow points to A. Move the

numeric lever so it points to

I (Figure 21).

Securely clamp your workpiece and

remove the chuck key! Thrown objects

from a lathe can cause serious injury or

death to the operator and to bystanders

many feet away.

-21-

Figure 21. Spindle control levers.

Figure 22. Speed chart.

Page 24

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

Mounting Chuck or

Faceplate

The Model M1112 is shipped with the 3-jaw chuck

installed. This is a scroll-type chuck, meaning that all

three jaws move in unison when adjusted.

The 4-jaw chuck, on the other hand, features

independent jaws. This chuck is used for square or

unevenly-shaped stock.

If either chuck cannot hold your workpiece, the castiron faceplate has slots for T-bolts that hold standard or

custom clamping hardware. With the correct clamping

hardware, this faceplate will hold non-cylindrical parts

such as castings.

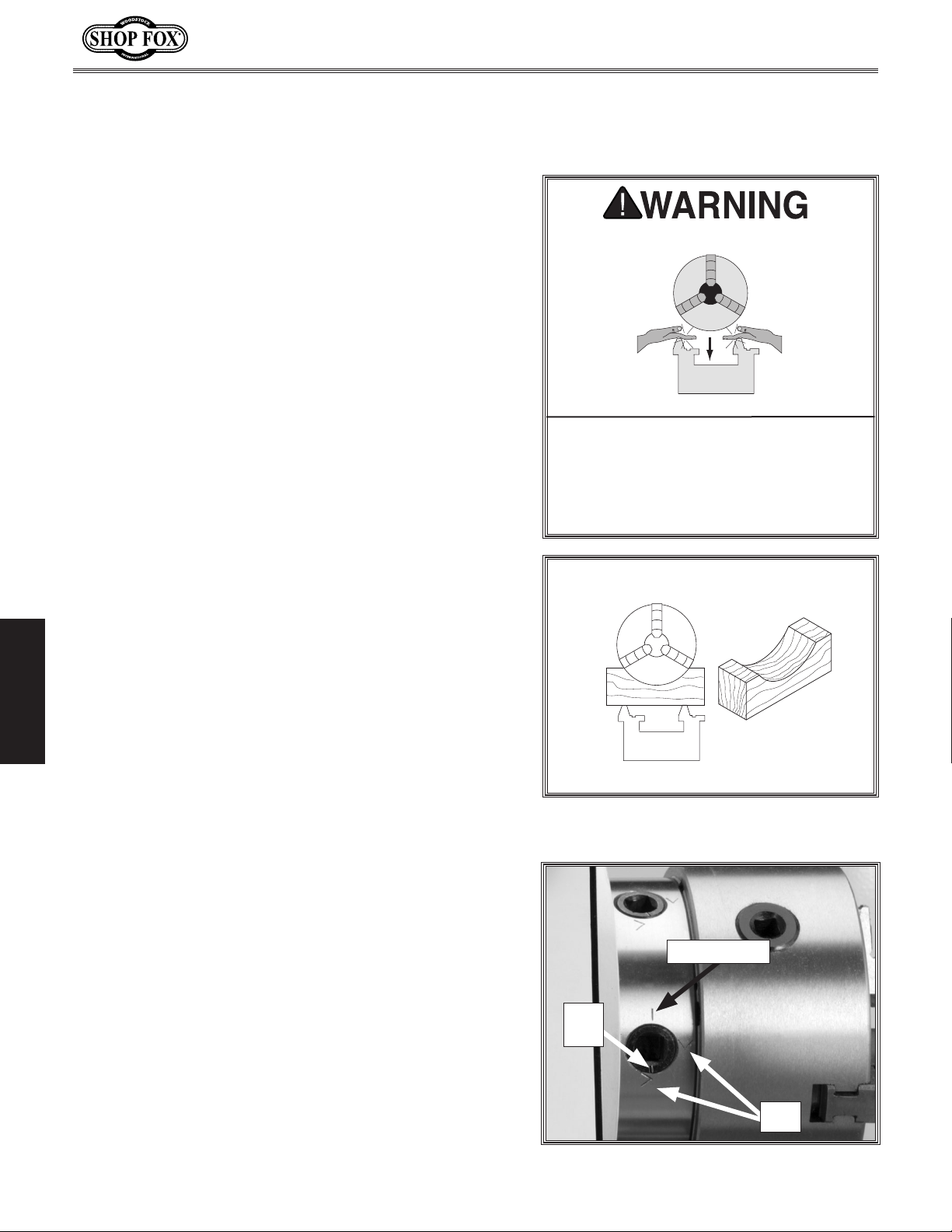

The chucks and faceplate have a D-5 Camlock mount.

Please note that there are lines stamped into the cam

and on the chuck body ( Figure 24). A chuck key is used

to turn the locking cams.

PINCH HAZARD! Protect your hands

and precision ground bedways

with plywood when removing lathe

chuck! The heavy weight of a falling chuck can cause serious injury.

To remove the existing chuck, do these steps:

1. DISCONNECT LATHE FROM POWER!

2. Place a piece of plywood across the lathe ways and

position it just under the chuck. The board should be

at least 8" wide and 10" long.

3. Turn a cam with the chuck key until the cam line

OPERATIONS

aligns with the spindle line mark shown in Figure 24.

4. Turn the other cams in the same way. Make sure to

support the chuck with one hand as you align the last

cam. The chuck may come off at this point, so be

ready to support its weight.

5. Remove the chuck key.

— If the chuck is still tight on the spindle, tap the

back of the chuck with a rubber or wood mallet

while supporting the bottom of the chuck with a

chuck cradle.

— If the chuck does not immediately come off, rotate

the spindle approximately 60˚ and tap again. Make

sure all the marks on the cams and spindle are in

proper alignment.

Figure 23. Simple chuck cradle made of

scrap lumber.

Spindle Line

Cam

Line

V's

-22-

Figure 24. Cam lines aligned to spindle

line.

Page 25

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

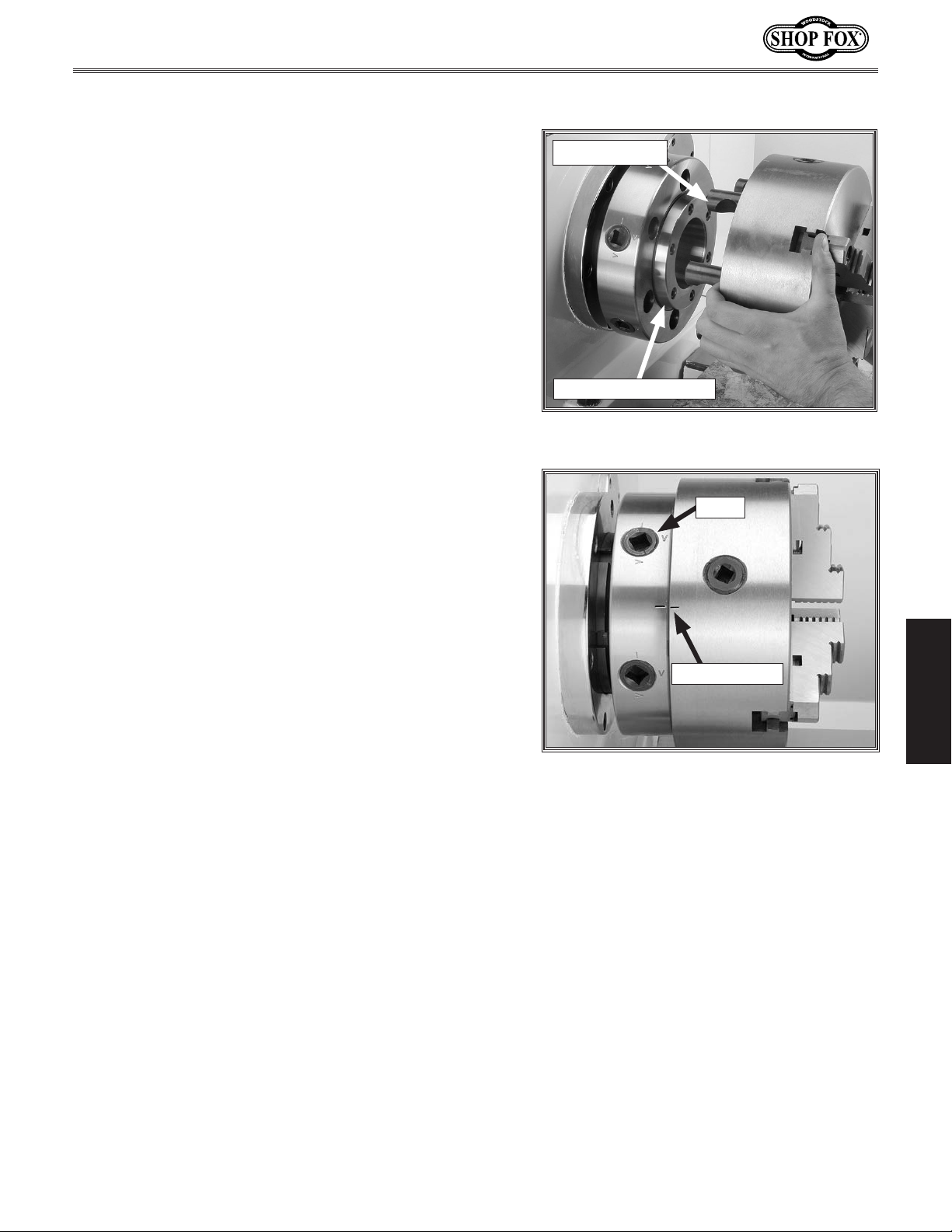

To install a chuck, do these steps:

1. DISCONNECT LATHE FROM POWER!

2. Place a piece of plywood across the lathe bed, wipe

clean the spindle nose taper (Figure 25) and the

mating surface on the chuck with a rag.

3. If stamped with chuck and spindle timing marks

(Figure 26), align the marks and the camlock studs

in the back of the chuck with the holes on the

spindle face, and slide the chuck onto the spindle.

4. While supporting the weight of the chuck, turn

one cam with the chuck key until the cam line is

between the two V's on the spindle. Do not tighten

at this time.

5. Rotate the spindle and repeat Step 4 on the opposite

cam.

Camlock Stud

Spindle Nose Taper

Figure 25. Installing and removing the

chuck.

6. Rotate the spindle and repeat Step 4 on the rest of

the cams in an alternating manner.

7. When all cams are snug, return to the first cam and

tighten the cam completely. Repeat this step with

the rest of the cams.

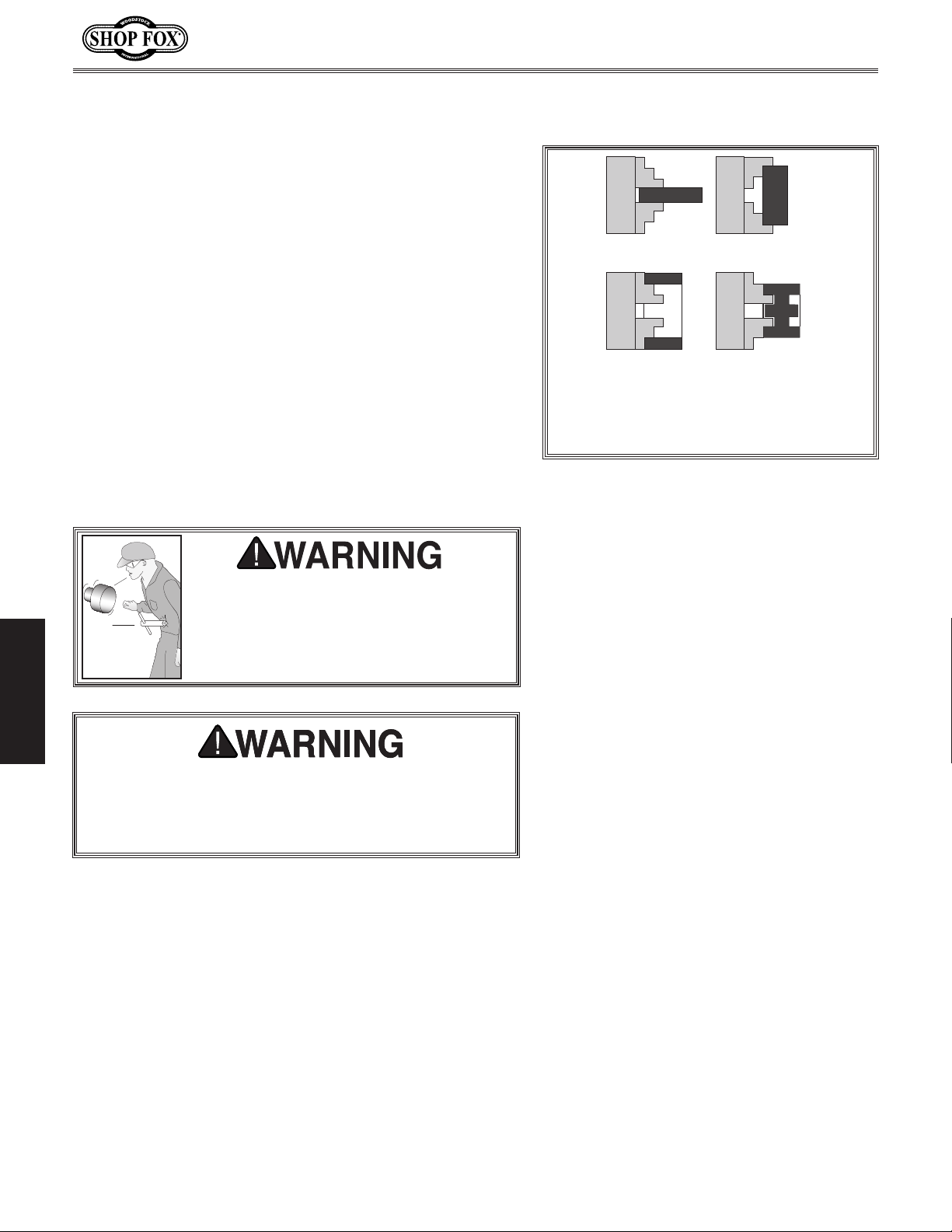

Cam

OPERATIONS

Timing Marks

Figure 26. Tightening the camlocks when

the chuck is in time with the spindle.

-23-

Page 26

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

To load a workpiece, do these steps:

1. With the chuck key, open the jaws so the workpiece

lays flat against the chuck face and jaw step or

fits in the through hole. For jaw and work holding

options, see Figure 27.

2. Slowly turn the workpiece, and turn the chuck

wrench until the jaws make contact with the

workpiece.

3. Turn the chuck by hand to make sure you have even

contact with all three jaws and the workpiece is not

off center.

• If the workpiece is off center, loosen the jaws and

adjust the workpiece.

• If the workpiece is seated correctly, tighten the

jaws.

Securely clamp your workpiece and

remove the chuck key! Thrown objects

from a lathe can cause serious injury or

death to the operator and to bystanders

many feet away.

Clamping on an Outside Diameter

Clamping in an Inside Diameter

Figure 27. Loading a workpiece.

OPERATIONS

If the workpiece protrudes more than 2.5 times its

own diameter, support it with a center, and possibly

a steady rest. Otherwise the workpiece can deflect or

come out of the chuck, causing injury.

-24-

Page 27

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

Swapping Jaws

The three-jaw scroll chuck has removable hardened steel

jaws (Figure 28). The outside of the jaws are used to hold

the workpiece from the outer diameter.

Numbered from 1–3, the jaws must be used in the

matching numbered jaw guides, see (Figure 29).

Note: The chuck need not be removed from the spindle to

swap the jaws.

To swap a set of jaws, do these steps:

1. DISCONNECT LATHE FROM POWER!

2. Place a piece of wood over the ways to protect them

from potential damage.

3. Turn the chuck key counterclockwise and back the

jaws out.

4. Clean the jaw mating surfaces and apply a film of

white lithium grease to the mating surfaces.

5. Set the old jaws aside in a safe place free of

moisture and abrasives.

6. Rotate the chuck key clockwise until you see the tip

of the scroll-gear lead thread just begin to enter jaw

guide #1 (see Figure 30).

7. Insert jaw #1 into jaw guide #1 and hold the jaw

against the scroll gear.

8. Rotate the chuck key clockwise one turn to engage

the tip of the scroll-gear lead thread into the jaw.

Pull on the jaw now and it should be locked into the

jaw guide.

Figure 28. Chuck and jaw selection.

Jaw Guide #1

Figure 29. Jaw guide number.

Jaw Numbers

OPERATIONS

9. Repeat the steps on the remaining jaws.

• If installed correctly, all three jaws will converge

together at the center of the chuck.

• If the jaws do not come together, repeat this pro-

cedure until they do.

-25-

Lead Thread

Figure 30. Lead thread on scroll gear.

Page 28

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

Four-Jaw Chuck

Four-jaw chucks feature hardened steel jaws that are

adjusted independently. Each jaw can be removed

from the chuck body and reversed. Independent jaw

adjustment and re versal allows for a wide range of work

holding versatility.

To install the four-jaw chuck, refer to the Mounting

Chuck or Faceplate procedures on Page 22.

To load a workpiece in the four-jaw chuck, do these

steps:

1. Using the chuck key, open each jaw so the workpiece

will lay flat against the chuck face.

2. Support the workpiece.

3. Position and lock the tailstock, then turn the

tailstock quill so the dead center makes contact or

is close to the center point of your workpiece (see

Figure 32).

4. Turn each jaw until it just makes contact with the

workpiece.

5. In an opposing pattern, tighten each jaw in small

increments. After you have adjusted the first jaw,

continue tightening the opposing jaw. Check the

dead center alignment frequently to make sure

OPERATIONS

you have not wandered off your index point due to

applying too much pressure to a single jaw.

6. After the workpiece is held in place, back the

tailstock away and rotate the chuck by hand. The

center point will move up and down when the chuck

is rotated if the workpiece is out of center.

PINCH HAZARD! Protect your hands

and precision ground bedways

with plywood when removing lathe

chuck! The heavy weight of a falling chuck can cause serious injury.

Figure 31. Simple chuck cradle made of

scrap lumber.

Securely clamp your workpiece and

remove the chuck key! Thrown objects

from a lathe can cause serious injury or

death to the operator and to bystanders

many feet away.

-26-

Figure 32. Clamping workpiece.

Page 29

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

7. Make fine adjustments by slightly loosening one jaw

and tightening the opposing jaw until the workpiece

is precisely aligned.

8. Use a dial indicator to fine-tune your adjustments

(see Figure 33), and use a lower RPM when

machining heavy eccentric workpieces.

PROJECTILE HAZARD! Use a lower RPM when machining

heavy eccentric workpieces. Otherwise, the workpiece

can be ejected by the chuck and cause serious injury.

Faceplate

The faceplate can be used to turn non-cylindrical parts or

for off-center turning by clamping the workpiece to the

faceplate.

Figure 33. Centering workpiece.

To install the faceplate, refer to the Mounting Chuck or

Faceplate procedures on Page 22 to mount the faceplate.

To load a workpiece, do these steps:

1. Support the workpiece on the faceplate with a

minimum of three independent clamping devices

(see Figure 34). Failure to follow this step may lead

to deadly injury to yourself or bystanders. Take into

account rotation and the cutting forces applied to

the workpiece when clamping to the faceplate. Make

sure your clamping application will not fail!

Note: Depending on the workpiece, some additional

support or counter-balance may be needed.

2. Slide the tailstock to the workpiece.

3. Lock the tailstock and then turn the tailstock quill so

the dead center makes contact with the center point

of your workpiece.

4. Lock the tailstock quill when sufficient pressure is

applied to hold the workpiece in place.

OPERATIONS

Figure 34. Faceplate with properly

clamped workpiece in four locations.

Use a minimum of three independent

clamping devices when turning eccentric

workpieces. Failure to provide adequate

clamping will cause workpiece to eject,

which may cause serious injury or death.

Note: Use a lower RPM when machining heavy

eccentric workpieces.

5. Clamp the workpiece securely and counter-balance

as needed.

-27-

Page 30

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

Centers

A tailstock center supports stock that is too long to be

supported by the chuck alone. The tailstock barrel and

live center have an MT#3 taper. Included with this lathe

is an MT#3 to MT#5 spindle sleeve. If you need to install

a center in the spindle when using the faceplate, you can

do so by using this adapter sleeve.

Before installing any center or arbor, make sure that the

mating surfaces are perfectly clean. These parts will last

longer and remain accurate if properly maintained. If oil

is present on the mating surfaces, the tapers will not

interlock.

To install the center, insert the end of the center into

the tailstock bore until it seats. Once the workpiece is

installed, the force of a mounted workpiece will fully seat

the t ape r.

When using a live center, the tailstock barrel should

protrude about

To remove the live center, back the tailstock barrel all

the way into the tailstock casting. The live center will

pop out. Be sure to catch it when it comes out to avoid

damaging the tip.

1

⁄2" and not more than 3" (see Figure 35).

Spindle Spider

OPERATIONS

Remove the spider screws when not in use. Always

disconnect the lathe from power when installing,

removing, or adjusting the spider screws. Ignoring

this warning can lead to personal injury or machine

damage.

Figure 35. Live center installed in

tailstock.

Your lathe is equipped with a set of spindle support bolts

known as the "spider" (Figure 36). Use the spider when

a long workpiece has the potential to wobble or vibrate

when it extends through the outboard side of the lathe.

The tips of the spider screws have brass wear pads that

hold the workpiece without causing indents in the finish.

When installed, make sure to always use the jam nuts to

lock each spider screw in position. Merely tightening the

spider screws against the workpiece and leaving the jam

nuts loose is not safe. The spiders screws may loosen up

during lathe operation and crash into the lathe end cover.

-28-

Figure 36. Spider.

Page 31

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

Steady Rest

The steady rest supports long, small diameter stock that

otherwise could not be turned because of deflection. The

steady rest fingers are fitted with bearings that maintain

consistent non-wearing support throughout the cut. The

steady rest can also be used in place of the tailstock to

allow for cutting tool access at the end of your workpiece.

To use the steady rest, do these steps:

1. Secure the steady rest to the bedway from below

with the locking plate, then snug the mounting bolt

(Figure 37).

2. Adjust the fingers until the bearings make contact

and support the workpiece. Do not over-tighten

the fingers or they will cause deflection in the

workpiece.

Mounting Bolt

Figure 37. Steady rest in place.

3. Oil the finger bearings and the rolling surfaces while

in use to assist in friction-free support.

Follow Rest

The follow rest is normally used with small diameter

stock to prevent the workpiece from “springing” under

pressure from the turning tool. The follow rest fingers are

fitted with bearings that maintain consistent non-wearing

support throughout the cut.

To use the follow rest, do these steps:

1. Secure the follow rest to the saddle with the two

cap screws (Figure 38).

2. Adjust the fingers until the bearings make contact

and support the workpiece. Do not over-tighten the

fingers as to cause deflection in the workpiece.

3. Lubricate the finger bearings and the rolling surfaces

while in use to assist in low friction support.

OPERATIONS

Mounting Cap Screws

Figure 38. Follow rest secured to saddle.

-29-

Page 32

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

Feed Direction Lever

NOTICE

NEVER attempt to shift a lever while the lathe is

running! And when shifting a lever, NEVER force it. If

the lever will not engage, rotate the chuck by hand

while keeping light pressure on the lever. As the

chuck rotates it aligns the gears and the lever will

engage.

Your lathe can cut left or right while feeding or threading,

and it can cut across both ways for facing operations. This

feed direction is controlled by the feed direction lever

shown in Figure 39.

When the selection lever is positioned as depicted in

Figure 39, the carriage will move to the right along

the bed or the cross feed will travel away from the

operator. The cross feed and longitudinal feed selection is

controlled on the apron.

Figure 39. Feed direction lever.

To reverse the direction of the feeding or threading

operation, stop the lathe, move the feed direction lever

completely to the right or left.

When the lever is positioned in the middle, no gear ratio

is selected, and the gear train feeding the apron is in

neutral.

OPERATIONS

Feed Rod Lever

The feed rod can be selected by moving the lever to

the left as in Figure 40. Use this position for all feed

operations.

When the lever is positioned straight up, no drive

mechanism is selected and the gear train feeding the

apron is in neutral.

When the lever is moved to the right, no gear ratio

is selected, and the gear train feeding the apron is in

neutral.

-30-

Figure 40. Feed rod lever.

Page 33

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

Gearbox Levers

NOTICE

NEVER attempt to shift a lever while the lathe is

running! And when shifting a lever, NEVER force it. If

the lever will not engage, rotate the chuck by hand

while keeping light pressure on the lever. As the

chuck rotates it aligns the gears and the lever will

engage.

The two levers (Figure 41) at the bottom of the headstock

change the feed rate or the number of threads cut perinch. The left-hand lever engages in alpha positions A, B,

C, D, and E; and the right-hand lever engages in numeric

positions 1, 2, 3, 4, 5, 6, 7, and 8.

Use the feed rate chart shown in Figure 42 to position

the quick change gearbox levers.

Figure 41. Quick change gearbox.

Feed Rate Chart

The far left column in the feed rate chart (Figure 42)

shows which change gears must be installed so the chart

will be applicable.

For example: Using the metric chart to make a 0.158mm

per revolution longitudinal cut, refer to the row that has

this symbol: .

Then put the left-hand lever in the C position, and the

right-hand lever in the 4 position.

To perform a facing cut, use the chart the same way

but refer to the row that has this symbol: .

Note: When either of the two selector levers are left in

the down position, the drive train is disengaged and is in

neutral.

OPERATIONS

Figure 42. Feed rate chart.

-31-

This symbol indicates longitudinal feed.

This symbol indicates cross feed rates.

Page 34

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

Carriage/Cross Feed

Lever

Longitudinal and cross slide powered motions are

controlled by the carriage/cross feed lever. The lever

pivots through two stops that require moving the lever

left and right as well as up and down. Moving this lever

upward activates the automatic longitudinal feed. Moving

the lever downward activates the cross slide (Figure 43).

Half-Nut Lever and Inch

Threading

The half-nut lever clamps and releases the half-nut, which

clamps around the leadscrew (Figure 44). The lever is

only engaged while cutting threads.

Note: If the apron feed lever is engaged, the half-nut

lever is blocked from use; and if the half-nut lever is

engaged the apron lever is blocked from use. If both

levers are engaged at the same time apron damage will

o c cu r.

After the carriage has been returned, the thread dial tells

you when to re-engage the half-nut and resume threading

(Figure 44).

Figure 43. Carriage/cross feed lever in

neutral position.

Half-nut

Lever

Dial

When the cap screw is loosened, the thread dial housing

pivots so its gear can be engaged or disengaged from the

OPERATIONS

lead screw. When engaged, the dial will turn when the

lead screw and spindle are turning.

When the half-nut lever is engaged, the dial stops turning.

By carefully engaging the half-nut as the appropriate line

or number passes by the indicator mark, a thread can be

re-entered for its next pass of the cutter without wiping

out the previous cut.

The thread dial chart shown in Figure 45 indicates when

to use the thread dial if inch threads are to be cut. If an

inch thread is divisible by 8, then you don't need not use

the thread dial. If cutting metric threads, you cannot use

the thread dial.

Cap Screw

Figure 44. Threading dial and half-nut

lever.

Figure 45. Thread dial chart.

-32-

Page 35

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

While other thread pitches may be achieved, the Model

M1112 is designed so that gear changes are not needed for

cutting inch threads. However, you will have to move the

feed direction lever to the direction of thread you want

to cut, and then move the feed rod lever to the right. To

get the needed threads in inches, you will then use the

standard thread chart (Figure 46) to determine which

positions to move the quick change levers.

Example:

If the desired threads are 11 threads per inch (Figure 46),

move the quick change gearbox levers to positions B and

5. As the thread dial chart shows, engage the half-nut

when the thread dial reads 1 or 3 and begin your first

cut.

When the cut is complete, disengage the half-nut and

manually return the carriage to the beginning of the cut.

Watch the dial. When the 1 or the 3 on the dial comes

around to the indicator mark, engage the half-nut. Begin

your second pass. Repeat this process until the desired

depth of cut is achieved.

Change Gears & Metric

Threading

This lathe can cut 29 different metric threads, but gear

changes are required to cut all of the listed metric

threads. These gear changes take place on the left hand

end of the machine (Figure 47).

Figure 46. Standard thread chart.

F

86-Teeth

91-Teeth

Figure 47. Change gear locations.

G

OPERATIONS

The chart is divided into 3 main columns, starting from

the left: Gear diagram, Combination of Gears and

Pitch.

To use the chart, do these steps:

1.

Find the desired pitch in the chart

m

2. Below the

corresponding number above the desired pitch and

change the right hand quick change lever to that

position.

Note: The holes on the quick change gearbox are

letterd and numbered from left to right.

3. To the left of the desired pitch is a small column

with a letter. This letter indicates placement of the

left hand quick change lever. Move the lever to the

corresponding location.

/m Per Pitch label are numbers. Find the

(Figure 48)

m

/m Per

.

-33-

Figure 48. Metric thread chart.

Page 36

M1112 12" x 36" Gunsmithing Lathe (Mfg. Since 4/08)

5mm

Hex

Socket

17mm

Arm-Support

Hex Nut

3mm

Hex

Socket

17mm

Gear-Support

Hex Nut

4. In the “Combination of Gears” column

(Figure 49)

are 3 small columns. The numbers below F and G

represent the number of gear teeth on a change

gear. Find the required change gears that have the

corresponding number of teeth as stated in the chart

to the left of the desired pitch.

5. Open the gear and belt cover.

6. Loosen the 17mm arm-support hex nut and rotate

the bracket so the middle gear moves away from

gear F (Figure 49).

7. Loosen the 17mm gear-support hex nut and slide the

middle gear away from gear G.

8. Use a 3mm hex wrench and remove the cap screw

and remove change gear F.

9. Use a 5mm hex wrench to loosen the set screw in

the hub of gear G, and pull the gear off of the shaft.

10. Replace change gears F and G with the gears that

will produce your desired metric thread pitch and

tighten the fasteners to hold the gears on the shafts.

OPERATIONS

11. Slide the appropriate middle gear against gear G

until they mesh with (0.002" to 0.004" backlash) and

tighten the cap screw.

12. Rotate the appropriate middle gear against gear F