Shimano ALFINE SL-S500 - TECHNICAL, Alfine SL-S500, Alfine CJ-8S20 Service Instructions Manual

Page 1

CJ-8S20

JAPAN

LOCK

CJ-8S20

JAPAN

LOCK

CJ-8S20

JAPAN

LOCK

SI-6M20A

SL-S500

CJ-8S20

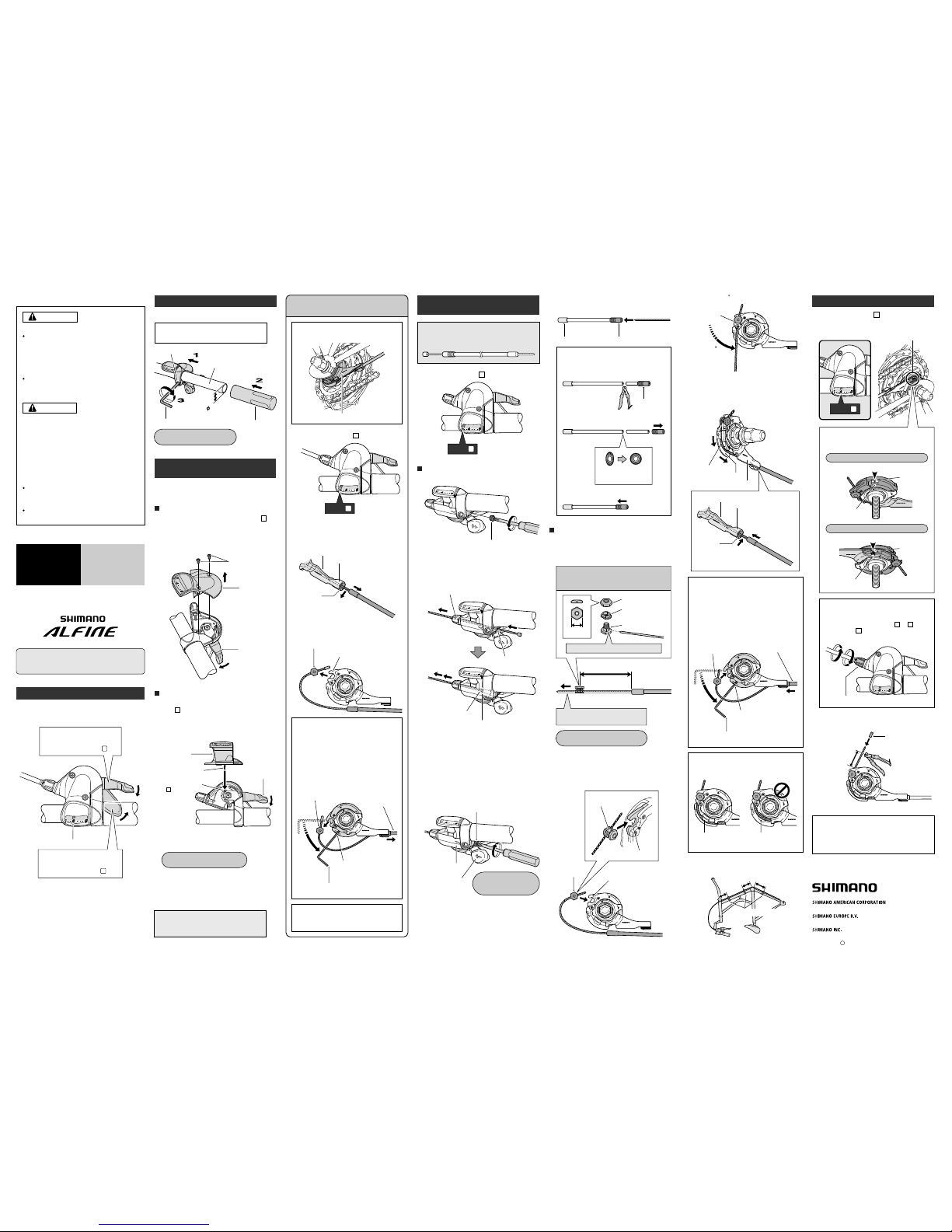

Shifting Lever

Cassette Joint

CJ-8S20

JAPAN

LOCK

2 mm Allen key

or #14 spoke

Pulley hole

Turn the

pulley

Pull out from

the outer

casing holder

CJ-8S20

JAPAN

LOCK

3

1

Remove the inner

cable fixing bolt unit

2

CJ-8S20

JAPAN

LOCK

CJ-8S20

JAPAN

LOCK

CJ-8S20

JAPAN

CJ-8S20

JAPAN

LOCK

CJ-8S20

JAPAN

LOCK

2

1

1

2

3

CJ-8S20

JAPAN

LOCK

CJ-8S20

JAPAN

LOCK

CJ-8S20

JAPAN

LOCK

CJ-8S20

JAPAN

LOCK

Be sure to shift the lever one gear at a time, and

reduce the force being applied to the pedals

during shifting. If you try to force operation of the

shifting lever while the pedals are being turned

strongly, your feet may come off the pedals and

the bicycle may topple over, which could result

in serious injury.

Indicator

General Safety Information

CAUTION

WARNING

– To avoid serious injuries:

– To avoid serious injuries:

NOTE:

For maximum performance we highly

recommend Shimano lubricants and

maintenance products.

Parts are not guaranteed against natural wear

or deterioration resulting from normal use.

Obtain and read the service instructions

carefully prior to installing the parts. Loose,

worn, or damaged parts may cause serious

injury to the rider.

We strongly recommend only using genuine

Shimano replacement parts.

Read these Technical Service Instructions

carefully, and keep them in a safe place for

later reference.

Technical Service Instructions

Be sure to read these service instructions in

conjunction with the service instructions for

the SG-S500 hub or Inter-8 hub before use.

Shifting lever operation

After you release your finger from lever A /lever B once

shifting is complete, the lever will always return to its

original position.

Tighten

Handlebar

Grip

5 mm Allen key

Clamp bolt

22.2 mm

Tightening torque:

5 – 7 N·m {50 – 70 kgf·cm}

Tightening torque:

0.3 – 0.5 N·m {3 – 5 kgf·cm}

Tightening torque:

3.5 – 5.5 N·m {35 – 55 kgf·cm}

Installation of the shifting lever

Install the shifting lever as shown in the illustration.

Use a handlebar grip with a maximum outer

diameter of 32 mm.

Cover fixing screws

Indicator unit

Lever B

Pin of change plate

Lever B

Indicator unit

Hole in winder unit

( position)

Note:

If reusing the cable, refer to steps 7 to 9 in

"Installation of the shifting cable".

Do not disassemble the indicator unit or the

shifting lever unit. Disassembling them may

result in malfunctions.

1

Set the shifting lever to .

Pull the outer casing out from the outer

casing holder of the cassette joint, and then

remove the inner cable from the slit in the

bracket.

Remove the inner cable fixing bolt unit from

the cassette joint pulley.

Disconnecting the shifting cable when

removing the rear wheel from the frame

Cassette joint

Inner cable fixing bolt unit

Cassette joint pulley

Remove from

the slit

Pull out from outer

casing holder

Bracket

Wire end hooking cap

Hole in cable adjustment bolt

Groove in winder unit

Hole in winder unit

Inner cable drum

Wire end hooking cap

unit cover

Lever A

Slit

If it is difficult to pull the outer casing out

from the outer casing holder of the cassette

joint, insert a 2 mm Allen key or a #14

spoke into the hole in the cassette joint

pulley, and then turn the pulley to loosen

the inner cable. Then remove the inner

cable fixing bolt unit from the pulley first,

and after this remove the outer casing from

the outer casing holder.

Outer casing holder

CJ-8S20

JAPAN

2

1

Installation of the shifting

cable

Use a shifting cable with one inner cable drum.

Cable with one inner cable drum:

SIS-SP41/SP40 (4 mm dia.)

Replacement and assembly

of the indicator unit

Shifting lever side

Operate lever B 7 times or more to set it to .

Removal

101 mm

Gap in pulley

Bring the cable around to the cassette joint pulley,

hold so that the inner cable fixing nut is facing to

the outside (toward the fork end), and then slide

the flats part of the inner cable fixing washer into

the gap in the pulley.

Flats part of inner

cable fixing washer

Inner cable

fixing nut

Pulley

After checking that the end of the outer casing is

sitting securely in the cable adjustment bolt of the

shifting lever, attach the inner cable fixing bolt unit

to the inner cable.

Cassette joint side

Inner cable fixing bolt unit

Note: Do not use this inner cable fixing bolt

unit with the CJ-4S30 cassette joint.

Inner cable fixing nut

Inner cable fixing

washer

Inner cable fixing bolt

Pass the inner cable through the hole.

Pull the inner cable while attaching

the inner cable fixing bolt unit.

Pulley

Bracket

Guide

OK Not OK

Secure the cable to the frame with the outer

casing bands.

10 cm

10 cm

15 cm

Turn the

cable 60

Hook

Turn the cable 60 counterclockwise and attach it

to the hook.

Attach the inner cable to the pulley as shown in

the illustration, pass the inner cable through the

slit in the cassette joint bracket, and then insert

the end of the outer casing securely into the outer

casing holder.

Inner cable

Slit

Outer casing holder

Pass through

the slit.

Note:

Check that the inner cable is correctly seated

inside the pulley guide.

If first inserting the outer casing into the

outer casing holder is easier, then first insert

the outer casing into the outer casing holder,

and then insert a 2 mm Allen key or a #14

spoke into the hole in the cassette joint

pulley, and then turn the pulley so that the

inner cable fixing bolt unit fits into the gap in

the pulley.

Hole in pulley

Insert into the

outer casing

holder

Insert the inner cable

fixing bolt unit

Guide

Outer casing bands

Bracket

Insert into the

outer casing

holder.

2 mm Allen key

or #14 spoke

Turn the

pulley

These service instructions explain how to use and

maintain the Shimano bicycle parts which have been

used on your new bicycle. For any questions regarding

your bicycle or other matters which are not related to

Shimano parts‚ please contact the place of purchase or

the bicycle manufacturer.

Adjusting the cassette joint

Set the shifting lever to .

Check to be sure that the yellow setting lines on

the cassette joint bracket and pulley are aligned at

this time.

After adjusting the cassette joint, cut off the

excess length of inner cable and then install the

inner end cap.

4

Cable adjustment bolt

Cassette joint

pulley

Cassette joint

pulley

Yellow setting lines

15 – 20 mm

Should be straight

Should be straight

When bicycle is upside down

When bicycle is standing up

If the yellow setting lines are not aligned, turn

the cable adjustment bolt of the shifting lever

to align the setting lines. After this, move the

shifting lever once more from to and

then back to , and then re-check to be

sure that the yellow setting lines are aligned.

These service instructions are printed on recycled paper.

Please note: Specifications are subject to change for improvement

without notice. (English)

The yellow setting lines on the cassette joint

are located in two places. Use the one that

is easiest to see.

Cassette joint bracket

Cassette joint bracket

Pass the inner cable through the SIS-SP41/ SP40

outer casing through the end with the plastic cap.

If cutting the outer casing, cut it near the end

with the plastic cap while the cap is still

attached. Then make the cut end perfectly

round and attach the plastic cap.

(Lever side)

Remove the plastic cap.

Make the cut end

perfectly round.

Attach the plastic cap.

Aluminum cap

Plastic cap

Plastic cap

Disassembly and assembly should only be carried

out when removing and replacing the indicator unit.

1

Set the shifting lever to .

4

1 4

1

Pedaling becomes lighter.

Lever B:

(Indicator moves toward )

8

Pedaling becomes heavier.

Lever A:

(Indicator moves toward )

Set to

1

Set to

1

May 2006 by Shimano Inc. PIT. SZK. Printed in Japan

C

1.

1.

1.

Loosen and remove the wire end hooking cap.

2.

Insert the inner cable into the groove in the winder

unit, and then pass it through the hole in the cable

adjustment bolt. Next, pull the inner cable so that

the inner cable drum fits into the hole in the

winder unit.

3.

Screw in the wire end hooking cap as shown in

the illustration until it stops. If it is turned any

further, it will damage the screw thread in the

cover.

In addition, the unit cover may become bent,

which may cause an obstruction between the unit

cover and lever A, and lever A may not operate

correctly. If lever A does not return properly,

loosen the wire end hooking cap slightly to make

a gap between lever A and the unit cover, and

check that this improves the returning of lever A.

4.

5. 8.

1.

2.

9.

10.

6.

7.

2.

3.

Check that the needle of the indicator is on the left

side ( position), and then install the indicator

unit so that it is facing straight upward. Insert the

pin of the change plate that is protruding from the

bottom of the indicator unit into the hole in the

winder unit at this time.

Installation

4.

Loosen and remove the two cover fixing screws

which are securing the indicator unit.

2.

Remove the indicator unit as shown in the

illustration.

3.

Secure the indicator unit with the two cover fixing

screws.

5.

Operate lever A and lever B, and check their

operation. If they do not operate correctly, reinstall

the indicator unit while taking particular note of

step 4. above.

6.

1

1

1

Disconnect the cable from the cassette joint

when removing the rear wheel from the

frame.

Tightening torque:

0.3 – 0.5 N·m

{3 – 5 kgf·cm}

10 mm

Inner end cap

One Holland, Irvine, California 92618, U.S.A. Phone: +1-949-951-5003

Industrieweg 24, 8071 CT Nunspeet, The Netherlands Phone: +31-341-272222

3-77 Oimatsu-cho, Sakai-ku, Sakai, Osaka 590-8577, Japan

Set to

4

Loading...

Loading...