Shibaura N843L, N843, N844L-T, N844L, E673L User Manual

...

Shibaura Diesel Engine

Operation Manuals

E673L

S773L

N843

N843L

N844L

N844L-T

Supported by

Hustler Turf Equipment Company

and

Excel Industries, Inc.

109821_0508 1

2 109821_0508

FOREWORD

The IHI Shibaura Machinery Corporation (ISM) industrial diesel engines are a product of ISM's long years of experience,

advanced technology. Shibaura takes great pride in the superior durability and operating economy of these engines.

In order to get the fullest use and benefit from your industrial engine, it is important that you operate and maintain it correctly.

This Manual is designed to help you do this.

Please read this Manual carefully and follow its operating and maintenance recommendations. This will ensure many years of

trouble-free and economical engine operation.

Should your engine require servicing, please contact your nearest Authorized Hustler Turf Dealer. He knows your engine best

and is ready to meet your needs.

All information, illustrations, and specifications contained in this Manual are based on the latest product information available

at the time of publication.

Shibaura reserves the right to make changes in this Manual at any time without prior notice.

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other

reproductive harm.

Battery posts, terminals and related accessories contain lead and lead compounds, chemicals known to the State of California

to cause cancer and birth defects or other reproductive harm. Wash hands after handling.

109821_0508 3

FEDERAL and CALIFORNIA EMISSIONS WARRANTY

WARRANTY STATEMENT

IHI Shibaura Machinery Corporation (ISM) warrants that your 2004 and later non -road diesel engine was designed, built and

equipped to conform to applicable U.S. Environmental Prot ection Agency (EPA) and California Air Resources Board (CARB)

regulations and is free from defects in materials and workmanship which cause it to fail to conform with such regulations, for the

following period of operation:

● For a period of two (2) years or 1,500 hours of operation, whichever occurs first, after the date of delivery to the initial

retail owner of any variable speed non-road diesel engine rated at less than 19kW (25hp) and any constant-speed non-

-1

road diesel engine rated at less than 37 kW (50hp) with rated speed greater than or equal to 3,000 min

● For a period of five (5) years or 3,000 hours of operation, whichever occurs first, after the date of delivery to the initial

owner for all other non-road diesel engines.

.

WARRANTY INFORMATION

The model year, class of diesel engine, and emission application for your engine are iden tified on th e emission control information label affixed to the right hand side of your engine's timing gear case.

Any emission control system parts that are proven defective during normal use will be repaired or replaced during the warranty period.

The warranty repair or replacement will be performed by any Authorized Hustler Turf Dealer or the distributor of the original

equipment manufacturer, with no charge for parts or labor (including diagnosis).

As the engine owner, you are responsible to perform all the required maintenance listed in your owner's manual.

ISM will not deny an emission warranty claim solely because you have no record of maintenance; however, a claim may be

denied if your failure to perform maintenance resulted in the failure of a warranted part. Receipts covering regular maintenance

should be retained in the event of questions and these receipts should be passed on to each subsequent owner of the engine.

It is recommended that replacement parts used for maintenance or repairs be ISM Service Parts to maintain the quality originally designed into your emission certified engine. The use of non-ISM parts does not invalidate t he warranty on other components unless the use of such parts causes damage to warranted parts.

ISM wishes to assure that the emission control systems warranty is being properly administered. If you believe you have not

received the service to which you are entitled to under this warranty, you should contact your Authorized Hustler Turf Distributor.

EXCEPTIONS

Please note that Emission Warranty does not cover the following:

1. Diagnosis or inspection expenses that do not result in eligible claim.

2. Consequential damage such as loss of time, inconvenience, loss of use of the engine or equipment.

3. Replacement parts used for required maintenance.

4. Conditions resulting from tampering, misuse, abuse, improper adjustment, engine alteration, use of add-on or modified

parts, use of replacement parts that are not the same in performance and durability as the approved parts, accident, failure to

use recommended fuel or oil, use of unapproved fuel or oil additives, or not performing required maintenance.

5. Damages or repair costs caused by the Owner's unreasonable delay in making the engine available for inspection and repair.

6. Replacement parts used for required or scheduled maintenance.

PARTS COVERED

This emission control system warranty applies to the following emission control parts.

• Fuel Injection Pump

• Fuel Injectors

• Intake Manifold

• Exhaust Manifold Turbocharger (if equipped)

• Positive Crankcase Ventil at ion system parts (including PCV Valve and Oil Filler Cap)

4 109821_0508

TABLE OF CONTENTS

Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Engine external views

Engine main parts nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

General information

3.1 Engine data and specifications. . . . . . . . . . . . . . . . . . . . . . . . .7

ISM engine after service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Fuel, lubricant and coolant

5.1 Fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

5.2 Lubricant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

5.3 Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Engine operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

6.1 Check before operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

6.2 Engine starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

6.3 Check and operation after the engine start-up. . . . . . . . . . . .13

6.4 Precautions during engine operation . . . . . . . . . . . . . . . . . . .13

6.5 Engine stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6.6 Run-in (break-in) for new engine . . . . . . . . . . . . . . . . . . . . . .15

6.7 Engine care for over cooling. . . . . . . . . . . . . . . . . . . . . . . . . .15

6.8 Starting the engine after being left

unused for a long period of time. . . . . . . . . . . . . . . . . . . . . . .15

Periodic inspection and maintenance

7.1 Lubricating system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

7.2 Cooling system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

7.3 Fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

7.4 Air intake system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

7.5 Engine electricals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

7.6 Engine assembly and others . . . . . . . . . . . . . . . . . . . . . . . . .20

Engine care in cold season . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

8.1 Fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

8.2 Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

8.3 Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

8-4 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

8-5 Engine starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Engine maintenance schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Simple engine troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

109821_0508 5

1. Safety

Introduction

This Operation Manual contains the information you will

need to operate the engine correctly. Check that you have the

correct Operation Manual for your engine.

Read the book carefully before operating or servicing

the engine. Incorrect operation or servicing of the engine

could result in personal injury or material dam age as well as

damaging the engine itself. If you do not understand or are

uncertain on any operation in this book, contact your

dealer who can explain or demonstrate the procedure for

you.

Warning and Caution

In this manual and on the engine you will find the following special warning symbols.

Safety Warnings

WARNING: This means there is something that could

hurt you or other people.

In the warning area, we tell you what the hazard is. Then

we tell you what to do to help avoid or reduce the hazard.

Please read these warnings. If you don't, you or others could

be hurt.

Engine or Equipment Damage Warnings

In the caution area, we tell you about something that can

damage your engine or equipment. Many times, this damage

would not be covered by your warranty, and it could be costly.

But the caution will tell you what to do to help avoid the damage.

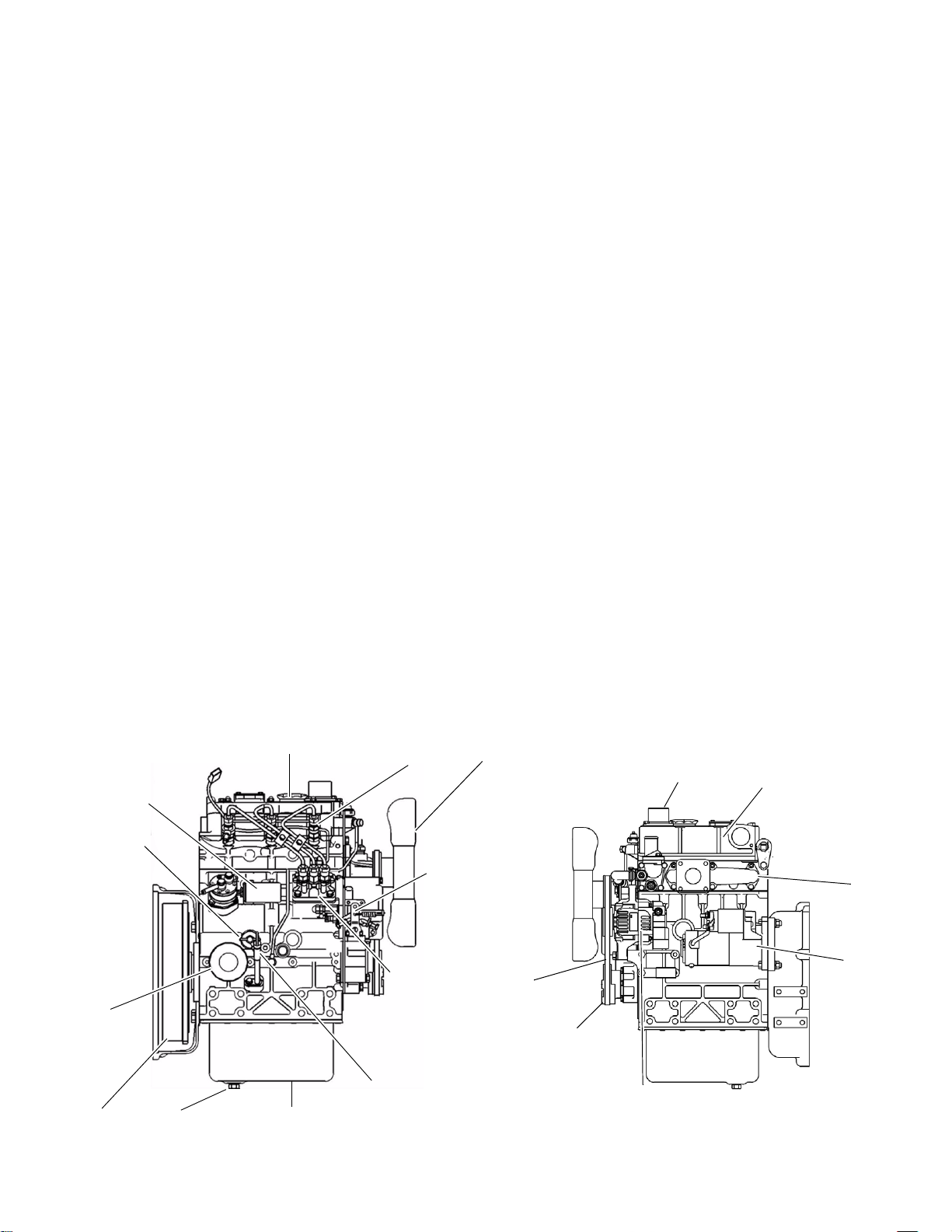

2. Engine external views

Engine main parts nomenclatures

1. Stop solenoid

2. Oil filler cap

3. Nozzle and holder

4. Fan

5. Engine control lever

6. Oil dipstick

7. Oil sump

8. Injection pump

9. Oil drain plug

10. Flywheel

11. Oil filter

12. Water drain cock

13. Air intake

14. Head cover

15. Exhaust manifold

16. Starting motor

17. Alternator

18. Crankshft pulley

19. Belt

CAUTION: This means there is something that could

damage your engine or equipment.

1121

12

8

11

3

5

4

13

19

18

14

15

16

10

6

9

7

6 109821_0508

17

3. General Information

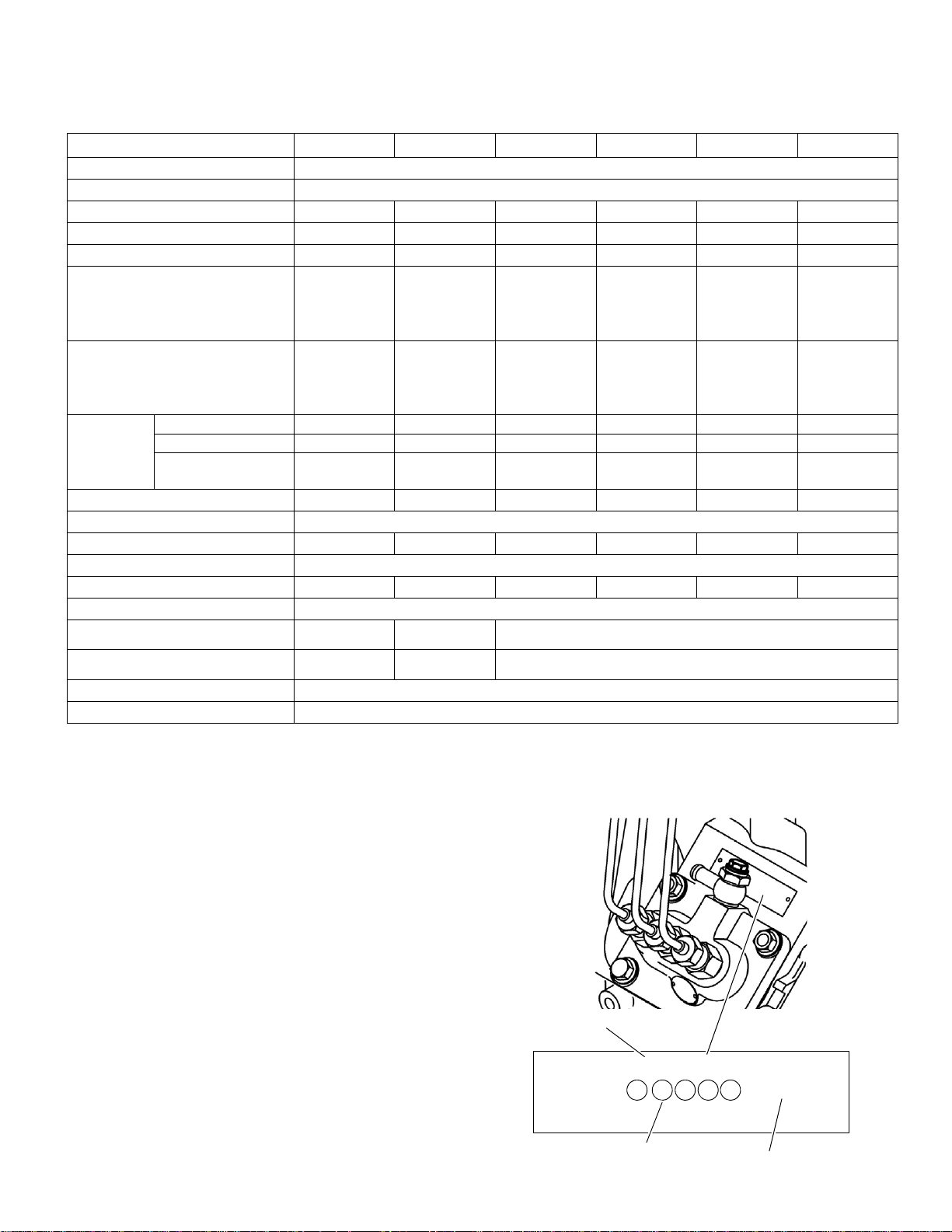

3.1.Engine data and specifications

Model Name E673L S773L N843 N843L N844L N844L-T

Engine Type Four cycle, water-cooled, in-line overhead valve type

Combustion type Swirl chamber

No.of cylinder-bore×stroke (mm) 3 - 67×72 3 - 77×81 3 - 84×90 3 - 84×100 4 - 84×100 4 - 84×100

Engine displacement (L) 0.761 1.131 1.496 1.662 2.216 2.216

Compression ratio 23.5 23.5 22.5 22.5 22.5 22.5

16.5hp/3000

* Max output

* Rated output

Overall length (in) (mm) 17.4 (443) 17.8 (453) 21.0 (534) 21.0 (534) 25.1 (637) 25.3 (642)

* Engine

dimension

* Engine dry weight (lbs.) (kg) 165.3 (75) 191.8 (87) 330.7 (150) 352.7 (160) 429.9 (195) 447.5 (203)

Direction of rotation Counter clockwise (Look at Flywheel side)

Coolant volume (Engine only) (qt) (L) 1.37 (1.3) 2.00 (1.9) 2.85 (2.7) 2.96 (2.8) 3.80 (3.6) 3.80 (3.6)

Lubrication method Pressurized circulation by trochoid pump

Lub. Oil volume (qt) (L) 3.28 (3.1) 5.18 (4.9) 2.85 (2.7) 6.34 (6.0) 8.66 (8.2) 8.66 (8.2)

Specified engine oil (API grade) Quality better than CD class(API)

* Alternator (V-A) 12-14 12-15 12-40

* Starting Motor (V-kW) 12-0.8

Specified fuel SAE NO. 2-D, DIN 51601, BS Class A-1

Governor Centrifugal all-speed control

Overall width (in) (mm) 15.2 (385) 15.1 (384) 18.1 (459) 18.1 (459) 17.8 (453) 20.3 (516)

Overall height (in) (mm)

(12.3kW/3000)

18.5hp/3600

(13.8kW/3600)

13.8hp/3000

(10.3kW/3000)

15.4hp/3600

(11.5kW/3600)

21.5 (546) 23.6 (600) 25.9 (657) 27.1 (689) 28.1 (713) 27.5 (698)

24.7hp/3000

(18.4kW/3000)

29.1hp/3600

(21.7kW/3600)

23.3hp/3000

(17.4kW/3000)

24.8hp/3600

(18.5kW/3600)

12-1.7

29.4hp/2600

(21.9kW/2600)

30.8hp/3600

(23.0kW/3000)

16.6hp/1500

(12.4kW/1500)

19.7hp/1800

(14.7kW/1800)

32.6hp/2600

(24.3kW/2600)

34.2hp/3600

(25.5kW/3000)

N/A

N/A

N/A

N/A

44.9hp/2600

(33.5kW/2600)

46.3hp/3600

(35.0kW/3000)

25.3hp/1500

(18.9kW/1500)

29.6hp/1800

(22.1kW/1800)

12-2.0

54.7hp/2600

(40.8kW/2600)

56.8hp/3600

42.4kW/3000

31.1hp/1500

(23.2kW/1500)

37.8hp/1800

(28.2kW/1800)

NOTE:

1. The specifications above are subject to partial changes without notice.

2. Asterisked (*) items may vary depending on the type of equipment in which the engine is installed.

4. Shibaura Engine Service

(1) Shibaura Engine After Service

Please feel free to contact your Hustler Turf Equipment

Dealer which is authorized by Shibaura for periodic inspection and maintenance.

When ordering service or spare parts always quote the

engine model name and serial number.

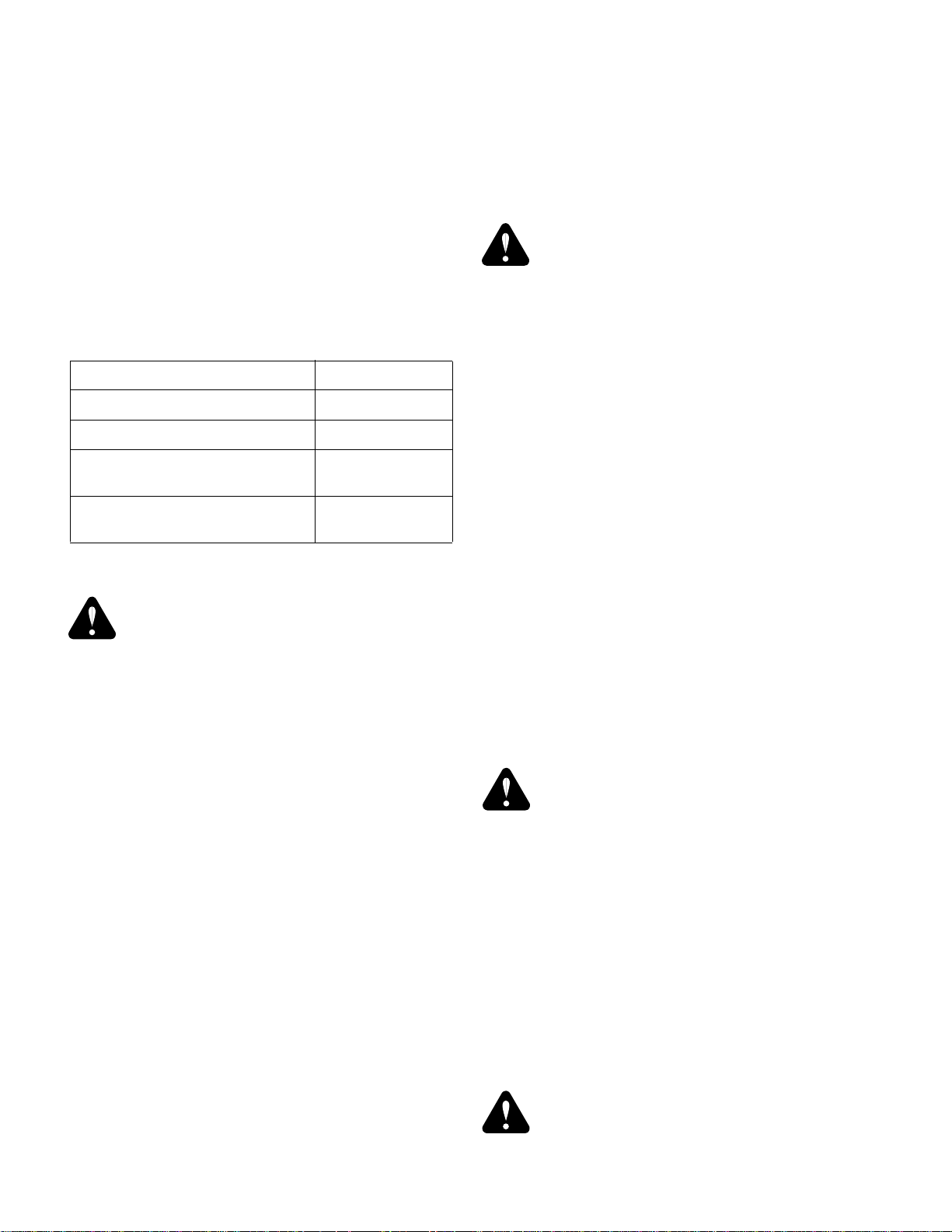

(2) Engine Identification

The engine serial number and engine model are stamped

on the front upper right side of the cylinder body.

109821_0508 7

Model Name

serial no.

IHI Shibaura Machinery Corporation

Serial Number

XXXXXXXXXXX

Assembled Months / Years

3/04

5. Fuel, Lubricant & Coolant

5.1 Fuel

(1) Fuel Selection

The following specific characteristics are required for the

diesel fuel.

1. Must be free from minute dust particles.

2. Must have adequate viscosity.

3. Must have high cetane value.

4. Must have high fluidity at low temperature.

5. Must have low sulfur content.

6. Must have little residual carbon.

Diesel fuels

Applicable Standard Recommendation

JIS (Japanese Industrial Standard NO. 2

DIN (Deutsche Industrie Normen) Din 51601

SAE (Society of Automotive Engi-

neers) Based on SAE-J-313C

BS (British Standard)

Based on BS/2869-1970 Class A-1

NO. 2-D

Number 1-D and Number 2-D). This blended fuel is usually

called Number 2-D also, but can be used in colder temperatures than Number 2-D fuel which has not been "winterized".

Check with the service station operator to be sure you get the

properly blended fuel.

Note that diesel fuel may foam during a fill-up. This can

cause the automatic pump nozzle to shut off even though your

tank is not full.

CAUTION: Do not use home heating oil or gasoline in your diesel engine; either may cause engine

damage.

(3) Handling of the Fuel

Fuel containing dust particles or water will cause engine

failure. Therefore, the following notice must be observed.

1. Prevent dust particles or water from entering when filling

the fuel tank.

When fueling is done from an oil drum directly, keep the

drum stationary for a period of time to allow the sediment

to go to the bottom of the drum.

2. Always fully fill the fuel tank. Drain the sedimented particles in the fuel tank frequently by opening the tank

drain and draining the fuel into approved fuel containers.

(2) Fuel Requirements

CAUTION: The fuel injection pump, injector or

other parts of the fuel system and the engine can

be damaged if you use any fuel or fuel additive

other than those specifically recommended by

Shibaura. Such damage is not Shibaura's responsibility, and is not covered by the Warranty. To help

avoid fuel system or engine damage, please be

aware of the following:

Some service stations mix used engine oil with

diesel fuel. Some manufacturers of large diesel

engines allow this; however, for your diesel

engine, do not use diesel fuel which has been contaminated with engine oil. Besides causing engine

damage, such fuel can also affect emission control.

Before using any diesel fuel, check with the service station operator to see if the fuel has been

mixed with engine oil.

Do not use any fuel additive (other than as recommended under "Biocide" in this section). At the

time this manual was printed, no other fuel additive was recommended. (See your authorized

dealer to find out if this has changed.)

(4) Water in Fuel

During refueling, it is possible for water (and other contaminants) to be pumped into your fuel tank along with the

diesel fuel. This can happen if a service station does not regularly inspect and clean its fuel tanks, or if a service station

receives contaminated fuel from its supplier(s).

To protect your engine from contaminated fuel, there is a

fuel filter system on the engine or equipment which allows

you to drain excess water.

WARNING: The water/diesel fuel mixture is

flammable, and could be hot. To help avoid personal injury and/or property damage, do not touch

the fuel coming from the drain valve, and do not

expose the fuel to open flames or sparks.

Be sure you do not overfill the container. Heat

(such as from the engine) can cause the fuel to

expand. If the container is too full, fuel could be

forced out of the container. This could lead to a

fire and the risk of personal injury and/or vehicle

or equipment damage.

(5) Biocides

Your engine is designed to use either Number 1-D or

Number 2-D diesel fuel. However, for better fuel economy,

use Number 2-D diesel fuel whenever possible. At temperatures less than -7°C, (20°F), Number 2-D fuel may pose operating problems (see "Cold Weather Operation" which

follows). At colder temperatures, use Number 1-D fuel (if

available) or use a "winterized" Number 2-D (a blend of

In warm or humid weather, fungus and/or bacteria may

form in diesel fuel if there is water in the fuel.

CAUTION: Fungus or bacteria can cause fuel system damage by plugging the fuel lines, fuel filters

or injector. They can also cause fuel system corrosion.

8 109821_0508

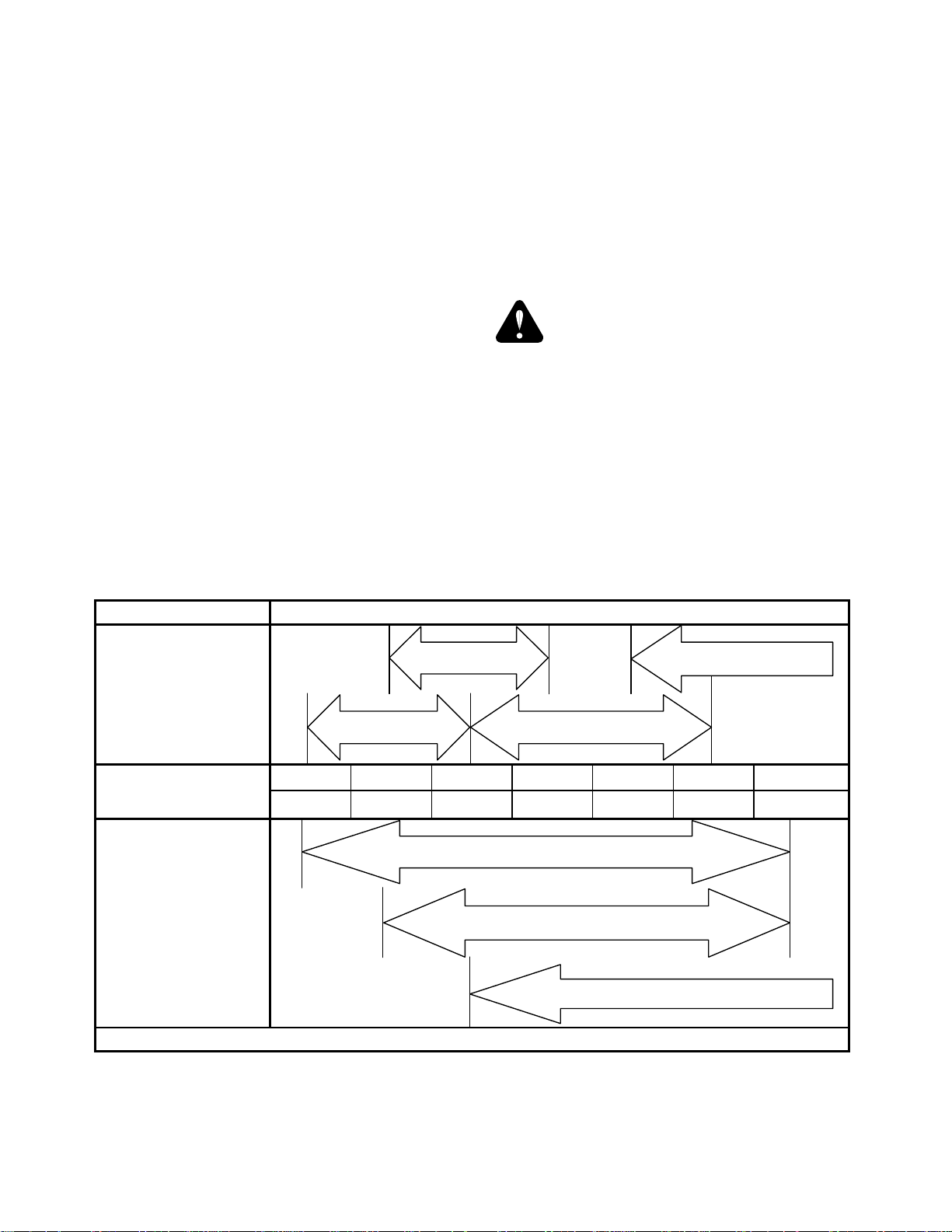

᧩᧯᧬ഒ ᧩᧮᧬ഒ ᧩᧭᧱ഒ ᧬ഒ ᧭᧱ഒ ᧮᧱ഒ ᧯᧬ഒ

᧩᧮᧮ᨂ (-4F) ᧤᧱ᨂ᧥ ᧤᧯᧮ᨂ᧥᧤᧱᧵ᨂ᧥᧤᧳᧳ᨂ᧥ ᧤᧴᧲ᨂ᧥

FIG-1

MULTI GRADE

AMBIENT

TEMPERATURE

ENGINE OIL VISCOSITY GRADE AMBIENT TEMPERATURE

SINGLE GRADE

6$(:

6$(: 6$(

6$(

6$(:

6$(:

6$(:

If fungus or bacteria has caused fuel system problems, you

should have your authorized dealer correct these problems.

Then, use a diesel fuel biocide to sterilize the fuel system (follow the biocide manufacturer's instructions). Biocides are

available from your dealer, service stations, parts stores and

other automotive places. See your authorized dealer for

advice on using biocides in your area and for recommendations on which biocides you should use.

(6) Smoke Suppressants

Because of extensive testing of treated fuel versus

untreated fuel, the use of a smoke suppressant additive is not

recommended because of the greater possibility of stuck rings

and valve failure, resulting from excessive ash deposits.

5.2 Lubricant

The quality of engine oil may largely affect engine performance, startability and engine life.

Use of unsuitable engine oil will result in piston ring, piston and cylinder seizure and accelerate the sliding surface

wear causing increased oil consumption, lowered output and,

finally engine failure. To avoid this, use the specified engine

oil.

(1) Engine Oil Selection

Quality better than CD grade by API classification engine

oil must be used for the Shibaura engines.

(2) Oil Viscosity

Engine oil viscosity largely affect engine startability, performance, oil consumption, speed of wear and occurrence of

seizure, etc.

Using lubricants with viscosity rated according to the

atmospheric temperature is important.

CAUTION:

1. Using a mixture of different brand or quality oils

will adversely affect the original oil quality; therefore, never mix different brands or different types

of oils.

2. Don't use API, CA, CB grade and reconstituted

engine oil.

3. Engine damage due to improper maintenance, or

using oil of the improper quality and/or viscosity,

is not covered by the warranty.

109821_0508 9

Loading...

Loading...