Page 1

®

REGULATORS

(SRB3300)

(SRB3400)

(SRB3500)

®

®

®

Assembly & Maintenance Guide

Includes

(SRB3200)

®

Page 2

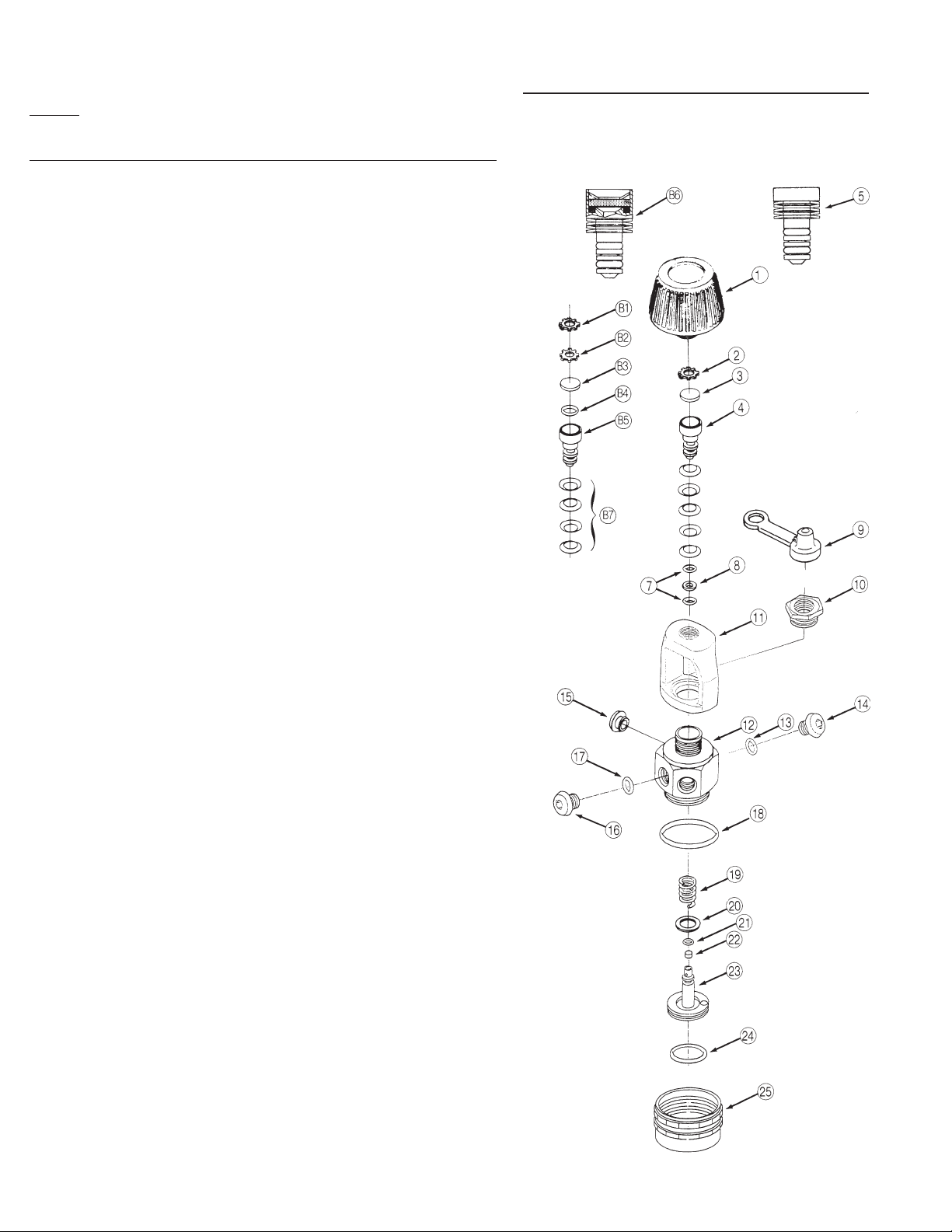

FIRST STAGE - MAGNUM®II SRB3300, BLIZZARD® SRB3200, OASIS® SRB3400

NOTE: The Oasis®+ SRB3500 uses the SRB3601 externally adjustable first stage. The parts

breakdown and servicing of the SRB3601 is covered in the Oasis2/Blizzar

d Assembly & Maintenance

Guide. Oasis®+ regulators manufactured in 1990 have the SRB3801 first stage with the DSS feature.

The servicing of the SRB3801 first stage is covered in the

Ultima SRB3800 Assembly & Maintenance Guide

. To

determine the first stage of a particular regulator, compare

the regulator with the pictures and diagrams in this guide as

well as the other guides referenced above. For further

information, contact your authorized Sherwood Distributor.

ITEM # CATALOG # DESCRIPTION

SRB3305 ........First Stage Complete

1 ....................3701-70 ......Handwheel

2......................3504-6 ........Star Washer Retainer

3......................1390-7 ........Filter

4.................29-3106-13A ....Moving Orifice

(bare, no o-rings etc.)

5 ....................3601-20 ......Moving Orifice Assembly

(with o-rings & washers)

6.................19-8010-8 ........Belleville Spring Washers (5 needed)

7 ....................G007A ..........O-ring (2 needed)

8 .............MS28774-007 ....White Backup Washer

9..................... 5705-20 ......Dust Cap

10.................. 1-1665-17 ......Yoke Nut

11 ................. 2-3801-4..........Yoke

12 .................2-3305-1 ........Body

13 ................... G904A ........O-ring (for H. P. port plug)

14 .................1-3405-4 ........H. P. Port Plug

15 ....................3106-6 ........One Way Bleed Valve

16...................1-3105-6 ........L. P. Port Plug

17 ....................G011B ........O-ring (for L. P. port plugs)

18 ....................G122A ........O-ring (seals cap to main body)

19 .....................3801-12B ....Main Spring

20..................19-6526 ..........Shim (to raise hose pressure)

21 ....................G007A ........O-ring (for small end of piston)

22 ....................3801-5 ........Piston Seat

23 ....................3107-10 ......Piston Assembly

(includes seat & O-rings)

24 ....................G022A ........O-ring (for large end of piston)

25.................. 2-3305-2 ........Cap

ORIFICE ASSEMBLY PARTS FOR BLIZZARD FIRST STAGE SRB3205

The following parts are the only parts that differentiate

the Blizzard SRB3205 first stage from the standard

Magnum II type SRB3305 first stage:

ITEM # CATALOG # DESCRIPTION

B1......................3504-6 ........Larger Star Washer (holds orifice in body)

B2 ...............J26005-43B ......Smaller Star Washer (holds filter in orifice)

B3 ..................18-3106-14 ....Filter

B4 ....................G011B ........O-ring (seals filter to orifice)

B5 ...............29-3106-13 ......Moving Orifice (bare, no O-rings etc.)

B6 ....................3106-9 ........Moving Orifice Assembly (with O-rings & washers)

B7 ..............64-8010-8 ........Belleville Spring Washers (4 needed)

Page 3

TABLE OF CONTENTS

Page

1.0 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2.0 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.1 SRB3300 (Magnum II, SRB3400 (Oasis)

and SRB3500 (Oasis+) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

3.0 O-ring Reference Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

4.0 First Stage Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4.1 Tools Required for First Stage Servicing . . . . . . . . . . . . . . . .5

4.2 Disassembly of First Stage . . . . . . . . . . . . . . . . . . . . . . . . . .5

4.3 Assembly of First Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.4 Testing of First Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

5.0 Second Stage Procedures . . . . . . . . . . . . . . . . . . . . . . . . .12

5.1 Tools Required for Second Stage Servicing . . . . . . . . . . . . . .12

5.2 Disassembly of Second Stage . . . . . . . . . . . . . . . . . . . . . . . .12

5.3 Assembly of Second Stage . . . . . . . . . . . . . . . . . . . . . . . . . .14

5.4 Set-Up of Second Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

5.5 Testing of Second Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

6.0 Helpful Hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

6.1 Troubleshooting Regulators . . . . . . . . . . . . . . . . . . . . . . . . . .19

6.2 Parts Cleaning Recommendations . . . . . . . . . . . . . . . . . . . . .21

6.3 Commonly Used Cleaning Solutions . . . . . . . . . . . . . . . . . . .21

6.4 Handling Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

7.0 Two Year Warranty and Maintenance Information . . . . . . .23

7.1 Proper Procedure for Warranty Paperwork . . . . . . . . . . . . . .23

7.2 Scheduled Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

BEFORE YOU BEGIN.....

READ THESE INSTRUCTIONS COMPLETELY BEFORE YOU BEGIN SERVICING THE

REGULATOR.

THESE INSTRUCTIONS ARE INTENDED FOR PEOPLE WHO HAVE BEEN AUTHORIZED BY

SHERWOOD TO REPAIR SHERWOOD SCUBA EQUIPMENT. IF YOU ARE NOT SO

AUTHORIZED - STOP.

Page 4

1

1.0 INTRODUCTION

1. The procedures in this manual apply to the Sherwood Scuba MAGNUM II (SRB3300),

OASIS (SRB3400), and OASIS+ (SRB3500).

The most current part numbers can be obtained by calling your Sherwood Sales

Representative or Sherwood Scuba Customer Service.

All current Sherwood Scuba Regulators have service kits available which contain the parts

which

must be changed at every annual service no matter what their condition. The standard

annual service kit for the Oasis, Oasis+, and Magnum is 4000-15. All other parts not contained

in this kit must be inspected by the technician and changed under warranty

only if they have

failed due to problems with material or workmanship.

2. This manual gives breakdowns of regulator parts, equipment specifications, servicing

instructions, troubleshooting recommendations, and guidelines for proper care of these

regulators. This manual is intended for use

only by persons specially trained and authorized to

service Sherwood Scuba equipment.

3. Anyone attempting to service or repair Sherwood Scuba regulators

must have a thorough

understanding of the principles of operation of scuba regulators and valves, as well as the

appropriate mechanical ability. The technician

must be properly trained in the safe use of

compressed air and the various tools and cleaning solutions involved in the procedures

outlined in this manual.

4. The best source for current part numbers for any of the parts listed in this manual is your

current parts and price list from Sherwood.

5. Because of the many unique features found in Sherwood regulators, Sherwood conducts

seminars on a regular basis throughout North America to train technicians in proper service and

repair procedures for all current Sherwood regulators. In addition, all Sherwood dealers and

their staff members are encouraged to attend the seminars to gain an in-depth understanding

of the construction, special features and operation of Sherwood regulators. For information on

the dates and locations of upcoming Sherwood service seminars near you, contact your

Sherwood Sales Representative.

NOTE

: You must be authorized by Sherwood to work on Sherwood Scuba equipment. You can obtain

proper authorization by attending all appropriate seminars given in your area. This is the only way you can

become an authorized Sherwood technician.

NOTE

: Oxygen Enriched Air conversion kits are available for all current Sherwood regulators and valves.

The part number for the models covered in this manual is 4000-15N. These kits are to be installed into

properly cleaned and prepared regulators only by technicians trained by one of the major oxygen enriched

air training agencies.

WARNING

NEVER tighten the hose fitting to the first stage with more than 40 in. lbs. (4.5 Joules)

of torque. The inlet hose fitting can be weakened by overtightening.

Page 5

6. Companion instructional VHS videotapes to this and other Sherwood Scuba repair manuals are

available from Sherwood Scuba at a nominal cost. Ask your Sherwood Scuba Sales

Representative for details.

7. If you have any questions, or need more information, contact your Sherwood Scuba Sales

Representative or Sherwood Distributor.

2

Page 6

2.0 SPECIFICATIONS

2.1 SPECIFICATIONS FOR THE SRB3300 MAGNUM® II, SRB3400 & SRB3500 OASIS®

REGULATOR MODELS: Sherwood Magnum II SRB3300,

Oasis SRB3400 & SRB3500

AIR FLOW: 28-29 cu. ft. (793-821liters)/min. @ 1 atmosphere

INHALATION RESISTANCE: 1.1” (2.8 cm) w.c. @ 1 atmosphere

EXHALATION RESISTANCE: 0.8” (2 cm) w.c. max. @ 1 atm.

RECOMMENDED LUBRICANT: LTI Christo-Lube

®

A. First Stage Regulator:

TYPE: Flow-by piston with Moving Orifice Balancing and

Dry Air Bleed - U.S. Pat. # 4,226,257

WEIGHT: 1 lb. 3 oz. (.54kg)

INTERSTAGE PRESSURE: 135 -150 psi (9-10 bar)

MAXIMUM INLET PRESSURE: 232 Bar for SRB3300CE, SRB3900CE,

SRB3400CE & SRB3500CE Models

POSITIVE AIR PURGE

FLOW RATE: 13-27 cc/minute

# LOW PRESSURE PORTS: 4 (3/8”-24 UNF)

# HIGH PRESSURE PORTS: 2 (7/16”-20 UN)

MATERIALS: Body - CDA-360 Brass

O-rings - Buna-N

Bleed Valve - Ethylene Propylene

Piston Seat - Teflon

®

B. Second Stage Regulator:

TYPE: Downstream valve, diaphragm, Variable Fulcrum

- U.S. Pat. #3,991,785

WEIGHT: 7.6 oz. (.22 kg) ( w/o hose)

HOSE LENGTH: 31 in. (.79 m)

MATERIALS: Cover - Thermoplastic Vinyl

Case - Thermoplastic Triax

®

Poppet Seat - Buna-N

Poppet Seat - Buna-N

O-Rings - Buna-N

Diaphragm - Tufel®(black)

Exhaust Valve - Thermoplastic Elastomer (blue)

Mouthpiece - Liquid Silicone Rubber

Maximum certified depth is 50m

3

Page 7

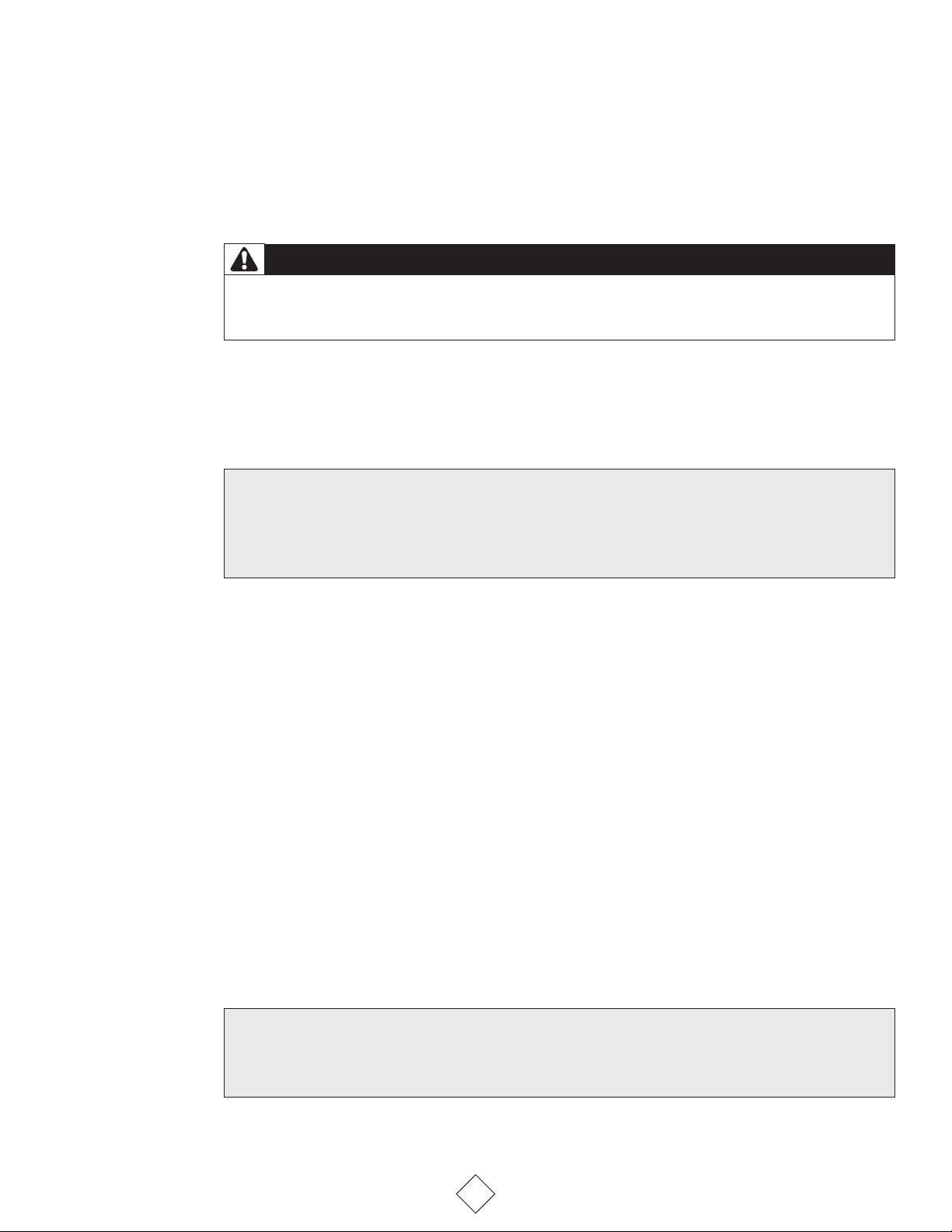

3.0 O-RINGS REFERENCE CHART

1. Before you begin disassembly of the regulator, test the first and second stages for output

pressures and leakage. Pre-testing in this way will help the technician to pinpoint any specific

problems requiring repair.

2. The work area must be clean and well lighted, with clean compressed air available to blow

sand and dirt from parts.

4

G907A

Seals second stage

orifice

to case

G022A

Large End of

piston

G122A

Seals cap to body

G007A

Moving orifice, small

end of piston

G0101A

Outlet end of hose

G011B

L.P. port plug, inlet end

of hose

G904A

Under filter in first stage

H.P. port plug

Page 8

4.0 FIRST STAGE PROCEDURES

4.1 TOOLS REQUIRED FOR FIRST STAGE SERVICING

– Bench vise

– 3/32" Allen wrench

– 5/32" Allen wrench

– 6" or 8" adjustable wrenches

– 15" adjustable wrench

– Phillips screwdriver

– #10 Torx screwdriver

– Sherwood 50 cc Graduated Cylinder (p/n TL110)

– Sherwood Piston Seat Removal Tool (p/n TL112)

– Sherwood Plastic Probe (p/n TL111) to push out orifice

– Sherwood Regulator Support Handle (p/n TL113)

– Sherwood Intermediate Pressure Gauge (p/n TL119)

– Sherwood Inlet Filter Installation Tool (p/n TL115)

– Sherwood O-ring Installation Cones:

Brass-colored - p/n TL106 ( for installing small O-ring on piston tip )

Green-colored - p/n 38-TL107 ( for installing 1st O-ring onto moving orifice )

Black-colored - p/n 29-TL108 ( for installing 2nd O-ring onto moving orifice )

– Sherwood Oxygen Compatable Lubricant (Crystolube LTI) p/n SW-MS150

4.2 DISASSEMBLY OF FIRST STAGE

To view all the parts used in the first stage, fold out the front cover of this manual. The

circled numbers below refer to the corresponding numbers on the drawing.

1. Use 6” or 8” adjustable wrenches to disconnect all hoses from the first stage. Pull back the

hose protector from the inlet end of the hose. Inspect the hoses for wear. Pay particular

attention to the area where the metal ferrules meet the rubber hose material. Replace hoses if

necessary.

2. Unscrew and remove the handwheel .

3. Remove the dust cap .

5

NOTE

: For more information on Sherwood tools and their uses, see Sherwood’s Tools, Repair Kits and

Accessories - Assembly & Maintenance Guide, available from Sherwood.

1

9

Page 9

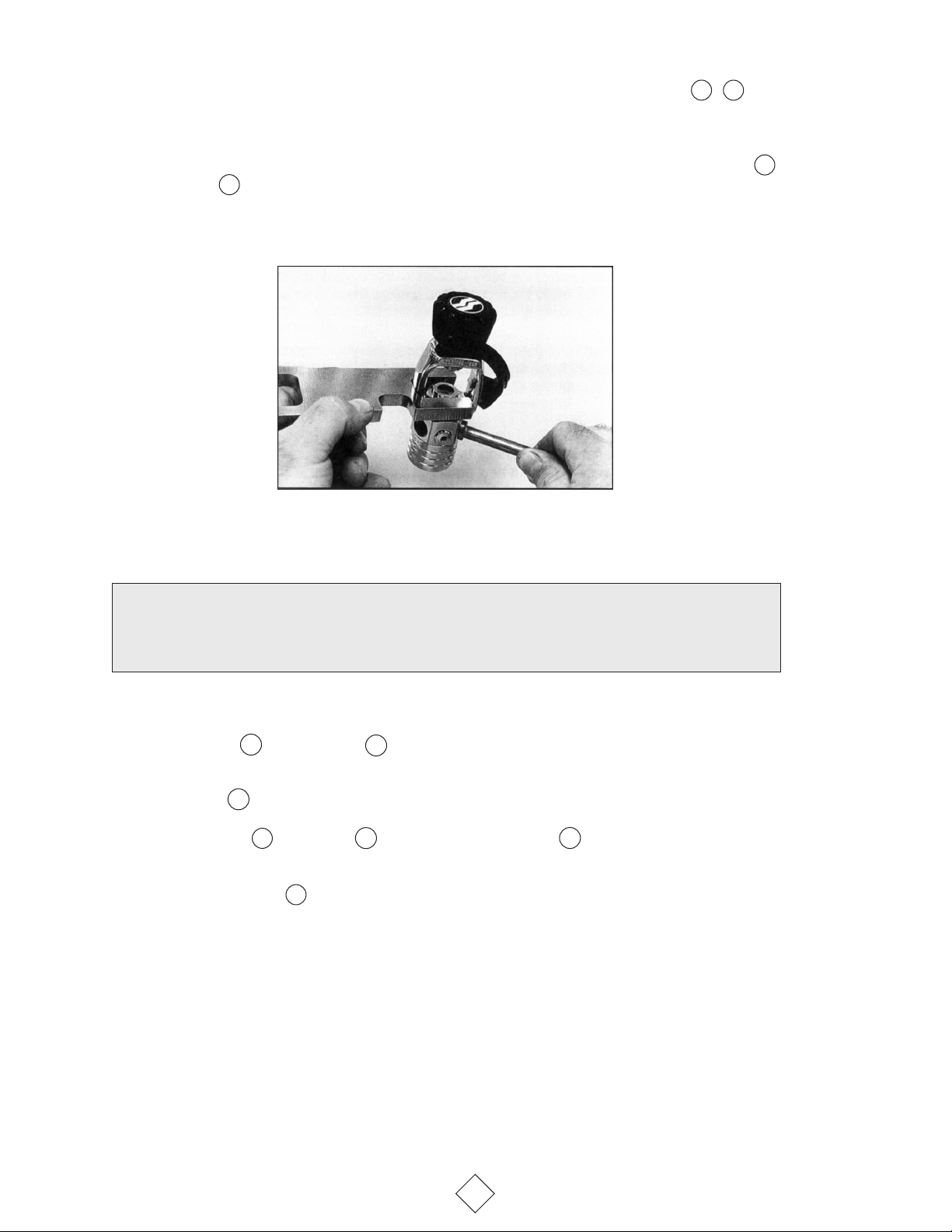

4. Use a 5/32” Allen wrench, and a small adjustable wrench to remove all port plugs and

hoses from the body.

5. Install a Sherwood regulator support handle (p/n TL113) into one of the low-pressure ports.

Use the support handle and a 15” adjustable wrench or bench vise to loosen the yoke nut

from the body . See Photo #1.

6. Remove the yoke and yoke nut from the body.

7. Use the Sherwood regulator support handle and a 15” adjustable wrench or a bench vise to

remove the cap from the main body.

8. Remove the spring any shims and the piston assembly from the cap. Remove both

piston O-rings and discard them.

9. Remove the piston seat by pushing through the stem with the Sherwood piston seat

removal tool (p/n TL112) from the large end. The seat will then pop out. Discard the old seat.

6

Photo #1

10

16

12

10

25

20

11

23

22

19

14

NOTE

: If a Sherwood DIN adapter (p/n SAA5200, or SAA5300) is installed in place of the more common yoke

assembly, remove it at this time. See Sherwood Technical Bulletin #104 for servicing procedures for the DIN

adapter.

Page 10

a. Keep greasy fingertips away from the flow element during servicing.

b. Use a clean, dry cloth to wipe the piston surface if it needs cleaning.

c. Do not put the piston in a cleaning solution or ultrasonic cleaner. If there is any oil on the

surface, it will coat the piston.

d. A coating of grease or oil will interfere with the air flow through the flow control element in

the face of the piston (see Photo #2). It may also cause the Dry Air Bleed System to cease

working. Although this is not dangerous to the diver, it may increase the difficulty of

breathing though the regulator upon descent.

e. If no air is bubbling from the one-way bleed valve, this is a good indication that the positive

air purge system is not working.

10. Use a pocket screwdriver to remove the star washer that holds the inlet filter in place.

Most units used a star washer (a flat disc washer with six outwards facing legs) Units made in

1997 use a wire retaining ring with inward hook. The only first stage bodies that can use this reusable ring have a groove machined into the area above the filter for the ring to fit snugly into.

Always discard the used inlet filter. Old style star washers are discarded, newer style retaining

rings are saved for reuse.

11. Remove the moving orifice assembly from the body by pushing it with the Sherwood

plastic probe (p/n TL111) from the large threaded end of the body. Catch the orifice assembly

in your hand as it comes out the yoke nut thread end of the body. Carefully inspect the disc

springs for any cracks. Replace all five disc springs if any cracks are found.

12. Remove the one way bleed valve from the body with your fingers or a soft plastic probe.

DO NOT use a metal screwdriver or blade since this will scratch the sealing surface against

which the bleed valve seals. A scratch may allow water to enter the first stage spring chamber

during use.

7

2

3

4

6

Photo #2

15

CAUTION

If any grease or oil gets on the piston flow control element, the air flow through the Dry

Air Bleed System will be impeded.

Page 11

The sealing surface on the body where the one-way valve seals must be totally clean of

deposits. If any deposits remain on the sealing surface after initial cleaning, take a

fine abrasive

polishing stick or a pencil with a new eraser and polish the surface to remove deposits (see

Photo #3).

13. Blow all residue from the body after polishing.

14. Remove the large O-ring from the body. This O-ring can usually be reused.

15. If necessary, clean all metal parts of the first stage

except piston in an ultrasonic cleaner or

cleaning solution. Remove the O-rings before cleaning any metal parts; most cleaning

solutions can damage the O-ring material. See Section 6.3 for recommendations on cleaning

solutions. If major visible corrosion or deposits exist on parts, use a bristle brush, wooden, or

plastic stick to rub the deposits off. Allowing acidic cleaning solutions to do all of the work if

deposits are severe, will result in damage to internal chrome plating which will make parts even

more susceptible to future corrosion.

16. Remove the regulator parts from the cleaning solution. Blow all internal passageways dry with

clean, dry compressed air.

17. Inspect the bores in which the piston and orifice O-rings move for corrosion or wear. If the

bores are leaking air because of wear, replace the parts. If some corrosion deposits persist,

carefully wipe them away with a plastic scrubbing cloth. Blow any resulting dust out of the

regulator parts.

18. Remove and discard the two black O-rings from the moving orifice . Save the white

backup washer; it can be reused. Inspect the moving orifice’s sealing surface (located at the

top edge of the orifice cone). Any nicks, scratches, or corrosion at the top of the cone can

allow air to pass, which will result in creeping hose pressures. Polish out the defects using a

fine abrasive polishing stick or pencil eraser. When polishing, apply a light pressure to prevent

excessive wear on the cone. Use compressed air to blow away any dust created by the

polishing process. You do not have to polish or smooth the relatively rough lower/outer edge of

the orifice cone. This is not a sealing surface.

8

Photo #3

18

4

7

Page 12

4.3 ASSEMBLY OF FIRST STAGE

1. The part number for each regulator kit can be found in Sherwood’s Tools, Repair Kit and

Accessories - Assembly & Maintenance Guide. The kits contain the minimumparts that must

be replaced at every annual service interval. The technician will also evaluate the condition of

all other parts to determine replacement needs. The kit number for the regulators covered in

this manual is 4000-15. The Nitrox kit for these models is p/n 4000-15N

2. Before installing new O-rings on the piston and moving orifice, lubricate the O-rings with LTI

Crystolube (Sherwood p/n SW-MS150). Installation of the small O-ring on the piston is

made much easier by using the brass-colored Sherwood O-ring installation cone (p/n TL106).

Place the cone over the tip of the piston. Slide the lubricated O-ring over the cone until it slips

into the piston groove.

3. Place the new piston seat on a clean piece of paper on a hard flat surface. Press the piston tip

firmly over the seat until it is fully installed. The piston is now rebuilt and ready for installation.

4. Use the Sherwood installation cones to prevent damage to the new O-rings during installation

onto the moving orifice. Use the black O-ring installation cone (p/n 29-TL108) to install first the

new O-ring and then the used backup washer onto the wider groove on the moving

orifice. Postion them so that the black O-ring is closest to the wide end of the moving orifice.

Use the green O-ring installation cone (p/n 38-TL107) to install the O-ring into the groove

closest to the pointed tip of the orifice.

5. Using a greased soft probe,

lightly lubricate the first 1/8” of the small bore in the body

where the small piston and moving orifice O-rings seal.

6. With your finger, push the moving orifice assembly, pointed orifice end first, into the yoke end

of the main body as far as possible. Place the inlet filter , rough side up, on top of the

moving orifice. Place the retaining ring or star washer on top of the filter. Push the retaining

ring or star washer firmly into place with a dowel or screwdriver.

7. Replace the cleaned and lightly lubricated O-ring on the body .

8. Install the piston assembly squarely into the cap . If any shims were found when the

regulator was disassembled, place them over the piston stem. Then place the main spring

over the piston stem.

9. Install the cap assembly onto the body. Hand-tighten the assembly as tightly as possible, then

install the Sherwood regulator support handle into one of the low pressure ports. Using a 15”

adjustable wrench or a bench vice to hold the cap, tighten the cap onto the body until it

bottoms on the thread.

Do not tighten further.

10. Using your index finger, install the clean and dry one-way bleed valve into the body.

11. Lightly lubricate the body yoke nut threads with grease, and install the yoke and the yoke

nut onto the body.

12. Using the regulator support handle (p/n TL113) in one of the L. P. pressure ports of the body

and a 15” adjustable wrench, tighten the yoke nut snugly (see Photo #1).

9

21

7

13

2

18

3

25

23

12

10

11

19

15

8

NOTE

: If you use the bleed valve with the Sherwood logo molded into it P/N 3106-06 you will notice a

“dot” molded near the right side of the logo. Install the bleed valve with the “dot” oriented closest to the

inlet of the regulator (toward the yoke).

Page 13

13. Install the handwheel and the dust cap onto the yoke.

14. If the first stage has a SAA-5300 DIN adapter installed instead of a standard yoke, see the

installation instructions given in Sherwood Technical Bulletin #104 for overhaul and installation

instructions of the DIN adapter.

4.4 TESTING OF FIRST STAGE

A. Before You Begin Testing

1. Install an intermediate pressure test gauge (p/n TL119) into one of the low pressure ports of the

first stage. Plug any open outlet ports with suitable port plugs.

2. Install the first stage onto a tank valve, and introduce 2700 - 3500 psig (186-240 bar) to the

inlet of the regulator. Flow air through the regulator by pushing the purge button on the second

stage several times to get all parts properly seated.

B. Dry Air Bleed Flow Test

1. Submerge the first stage under several inches of water.

2. A small stream of bubbles should be escaping from the one-way bleed valve on the first stage

and nowhere else on the body (see Fig. 1). The number and size of the bubbles may vary from

regulator to regulator, but the volume of air should be 13 - 27 cc per minute. To check this, use

the following steps:

a. Invert a small (50 cc capacity) graduated cylinder (p/n TL110) filled with water over the

underwater flow of bubbles (see Fig. 1). The air entering the cylinder will gradually empty

some of the water out of the cylinder.

b. After one minute, remove the graduated cylinder from the air flow and raise the cylinder to

the surface so that the air/water dividing line inside the cylinder matches the water level

outside the cylinder. The measurement at this point should be between 13 and 27 cc.

c. If the reading is significantly higher than 27 cc, check the O-rings and sealing surfaces

mated to the piston. If the reading is below 13 cc, check the flow control element in the

piston (see photo 2) to determine if it has been clogged by grease or other foreign matter.

If it is clogged, the piston must be replaced.

10

NOTE

: For safety, always test the first stage regulator with at least one second stage installed.The

demand valve on the second stage acts as a relief valve in the event of a malfunction.

Figure #1

1

9

Page 14

C. Intermediate Pressure Test

1. Attach any Sherwood second stage to one of the low pressure ports, and the Sherwood

intermediate pressure gauge (p/n TL119) to another low pressure port. Plug all other ports with

appropriate port plugs.

2. Attach the regulator to a tank valve giving a source pressure of between 2700 and 3500 psig

(186-240 Bar).

3. Turn the supply air on

slowly while listening for any unusual air leaks. If any are heard, turn the

air off immediately and determine the source of the leak. If no leaks are found, watch the

pressure gauge reading rise as you continue turning the air on

slowly. It should stop around

145 psig ( 10 bar).

4. If the pressure gauge continues to rise above 155 psig (10.4 bar), turn the air supply off

immediately and inspect the regulator to determine the cause.

5. Once the air pressure stops rising, the internal parts should be worked into place by allowing

air to escape from the second stage several times by pushing the purge button.

6. If you have depressed the purge button several times and the pressure is below 135 psig

(9.3 bar), you can add shims to increase the pressure.

Do not use more than three shims.

7. If the pressure is too high, above 150 psig ( 10.3 bar), remove the necessary shims.

8. After the correct pressure has been reached, let the regulator sit for several minutes and then

depress the purge button again to check that the regulator returns to the proper pressure.

Never set the output pressure of the first stage above 150 psig (10.3 bar).

11

20

NOTE

: This test determines the regulator’s lock-up pressure (the pressure put out by the first stage during

a no-flow condition).

Page 15

5.0 SECOND STAGE PROCEDURES

5.1 TOOLS REQUIRED FOR SECOND STAGE SERVICING

– Two good quality 6" or 8" (15 or 20 cm) adjustable wrenches

– #10 Torx screwdriver

– Small Phillips ACR Screwdriver

– Size 0 Square Drive (Robertson Head) screwdriver

– Side cutting pliers

– Sherwood In-line Adjusting Tool ( p/n TL102 )

– Sherwood Plastic Probe (p/n TL111) to push out orifice

– Sherwood Lever Height Adjusting Tool (p/n TL123)

5.2 DISASSEMBLY OF SECOND STAGE

To view the complete parts list of the second stage, fold out the back cover of this manual.

1. Pull back the hose protector from the inlet end ferrule. Remove the hose assembly

from the orifice housing . Inspect the hose assembly for any cuts or cracks, especially on

the hose at the metal ferrules. Replace the hose assembly if any cuts or cracks are found.

2. Remove the mouthpiece by cutting the mouthpiece tie with side cutting pliers. Discard

the old mouthpiece tie. Examine the condition of the mouthpiece. Pay particular attention to

the area on top just behind where the old tie tightened. This is a prime area for small holes to

develop. If the mouthpiece is in good condition, it can be reused.

3. Remove the exhaust tee retaining screw with a Phillips or Square Drive screwdriver.

4. Remove the exhaust tee from the case by pulling it back and off the top edge.

5. Remove the front cover from the case by turning the bezel ring by hand. Some older units

(manufactured before 1986) have a metal bezel ring with a small metal locking tab in the

mouthpiece area. Remove this ring with a small slotted screwdriver.

A. Purge Button Change:

12

5

27

14

19

18

15

26

22

WARNING

NEVER tighten the hose fitting to the first stage with more than 40 in. lbs. (4.5 joules) of

torque. The inlet hose fitting can be weakened by overtightening.

NOTE

: At this point, the purge button can be removed from the cover. This will be necessary

oonnllyy

if the

button travel is impeded by silt deposits, or if the logo is to be changed to a different color. If it is

necessary to remove the purge button, follow the next sub-steps A to E. Otherwise, go on to Step 6.

1

Page 16

13

a. Place the cover assembly with the purge button logo face down on a clean flat surface.

b. From the inside of the cover assembly, push the four barbed tabs holding the purge button

assembly in place in towards each other. This will release the purge button

assembly from the cover.

c. If only the label insert was purchased for installation, carefully remove the old label

insert from the purge button with a thin flat-blade screwdriver, and install the new

colored label insert in its place.

d. Reverse the disassembly procedure to reassemble the case assembly with the new color

logo installed.

6. Gently remove the diaphragm from the case. Hold the diaphragm up to a light source.

Gently stretch the diaphragm and look for tears or pinholes. If any are found, replace the

diaphragm. Otherwise, the diaphragm can be reused. If you are repeatedly tearing diaphragms

during this visual inspection, you are using too much force. You cannot return diaphragms torn

in this way for warranty credit.

7. Clamp the Sherwood modified 3/4” deep socket (p/n TL118) in a bench vise. Lower the lever

into the socket until the 3/4” hex of the lever support is engaged in the socket. Use a

13/16” wrench to loosen and remove the orifice housing .

8. Use the Sherwood in-line adjusting tool (p/n TL102) to back the adjusting orifice out of the

orifice housing until the threads disengage. Remove the in-line adjusting tool, and push the

adjusting orifice the rest of the way out of the orifice housing with the Sherwood Plastic Probe

(p/n TL111).

9. Remove the O-ring from the adjustable orifice.

10. Before removing the exhaust valve from the case, bend it over as far as it will go from the

top, bottom, left, and right sides. If it fails to snap back quickly, and does not lie perfectly flat

against the case, the valve should be replaced. If it does snap back satisfactorily, remove it and

inspect the sealing edges. If they appear smooth, and the locking tab on the nipple is good,

the valve can be reused.

11. Remove the spacing washer , and the O-ring from the threads of the lever support .

Remove the lever support from the inside of the case .

12. Normally, you will simply need to change the poppet stem seat insert to restore the second

stage to maximum performance. To change the stem seat insert , leave the lever assembly

together. With a penknife or similar object, carefully remove the old seat insert. Put the new

seat insert on a clean flat surface and lower the poppet cavity (from which the old seat insert

was removed) over the new seat insert. The new style black molded seat ( p/n 978-9BN)

should be installed with the identifying Sherwood symbol facing outward.

2

9

10

22

1

10

13

13

23

17

20

16

21

6

NOTE

: The purge button spring is located behind the purge button, with the wide end of the coil toward

the cover. Be sure to replace the spring with the wide end facing the cover.

NOTE

: Some regulators (Oasis, Blizzard, Classic) will have heat transfer fins (10B) attached to the lever

support. The modified 3/4” socket will still fit onto the lever support with the fins attached. You can leave

the fins attached throughout your servicing. If the fins are damaged and need to be replaced, use the

Sherwood 5/32” drive socket to remove and replace the two 5/32” hex head screws (10A).

Page 17

13. If parts of the lever assembly (stem, spring, lever, etc.) need to be replaced, take apart the

assembly with the Sherwood stem socket tool (p/n TL124) Clamp the stem socket tool in a

bench vice. Insert the square head of the poppet stem into the tool. With a Phillips screwdriver,

or preferably a size 0 Square Drive (Robertson Head) screwdriver, loosen the screw that

holds the assembly together.

14. Rinse all plastic and silicone parts in clean fresh water, and then blow the parts dry with

compressed air to remove any sand and dust particles.

15.

If necessary, clean all metal parts of the second stage in an ultrasonic cleaner or cleaning

solution. Remove the O-rings before cleaning any metal parts; most cleaning solutions are

damaging to the O-ring material. See Section 6.3 for recommendations on cleaning solutions.

16. Inspect the case for any cracks. Look particularly closely at the area where the orifice

housing and the lever support clamp down. Replace the case if any cracks are found.

17. Inspect the orifice sealing cone (where the poppet insert seals) for any nicks, scratches, or

corrosion. Corrosion or minor scratches can be polished out using a fine-grit rubberized

polishing stick or a clean new pencil eraser. Do not apply heavy pressure when rotating the

polishing stick. Stop polishing immediately after the corrosion or scratch disappears. An orifice

will not be accepted for warranty replacement simply because it is dirty or corroded. The

technician must clean the orifice sealing surface at every service interval.

18. Blow all dust and debris out of the orifice housing with clean compressed air.

5.3 ASSEMBLY OF SECOND STAGE

1. Re-install the cleaned and lubricated O-ring onto the adjustable orifice . Install the

adjustable orifice back into the orifice housing. Push it in with your finger as far as it will go.

2. Install the exhaust valve into the case by inserting the nipple into the small hole from the

outside of the case. Reach inside the case and pull the nipple firmly with the fingers until you

hear or feel it “click” into place. Inspect the exhaust valve to see that it is properly seated.

3. Install the lever assembly into the case.

4. Install the O-ring on the threads of the orifice housing. Install the spacing washer

around the outside of the O-ring.

14

NOTE

: Prior to this point, you should have cleaned and inspected all parts, following proper servicing

procedures. Do not continue until this has been done.

NOTE

: The spacing washer must be installed with the outer lip facing upward toward the orifice housing.

NOTE

:If only the lever is to be replaced, do not totally remove the screw. You can remove the lever

from under the washer by pushing the poppet into the lever support when the screw is almost all the

way out.

NOTE

: If you use an ultrasonic cleaner to clean the second stage adjustable orifice , use a plastic

container to prevent the orifice from vibrating against other metal parts which could damage the orifice seal.

7

17

23

24

20

21

9

22

8

16

Page 18

5. Screw the orifice housing onto the threads of the lever assembly. With a 13/16” wrench on

the orifice housing and a Sherwood modified 3/4” deep socket (clamped in a vise) on the hex

of the lever support inside the case, tighten the orifice housing and the lever assembly

together snugly (70 in. lbs. / 8 Nm).

6. Install the diaphragm into the case so that it sits evenly on the ledge.

7. Install the cover onto the case by sliding it carefully and firmly into place. Keep the cover

straight so that the cover vent holes and the purge button emblem are properly aligned. Install

the bezel ring over the cover and tighten it firmly by hand onto the case.

8. Install the exhaust tee onto the case flange by sliding it up from the bottom.

9. Install the retaining screw through the screw hole in the exhaust tee and into the hole in the

case using a # 1 Phillips, or Size 0 Square Drive screwdriver.

DDOO NNOOTT OOVVEERR--TTIIGGHHTTEENN

. This screw is threading into plastic, which will hold well in service but is

easily stripped if over-tightened.

10. Install a new mouthpiece and mouthpiece tie .

11. Install one end of the hose into a serviced first stage, tighten snugly.

5.4 SET- UP OF SECOND STAGE

For the following adjustments, remove the cover and diaphragm.

1. Install Sherwood’s in-line adjusting tool (p/n TL102) between the orifice housing and the

hose assembly . Use the tool to screw the adjustable orifice clockwise. Watch the end

of the lever as you do this. As soon as the tip of the lever begins to drop, stop turning the

tool. The slight amount of friction this operation produces between the orifice and the stem

seat will not harm the stem seat.

2. Attach the in-line tool and the second stage to its accompanying overhauled and properly

adjusted first stage, and mount on an air tank filled to between 2700 and 3500 psig (186 and

240 bar).

3.

Slowly turn on the tank valve. If you hear any leaks, determine the location of the leak, shut the

air off, and repair the leak as necessary.

15

22

10

5

4

14

15

18

19

22

6

26

9

24

NOTE

: Do not allow lubrication (grease on fingers, or silicone over-spray) to get on the case , the

diaphragm , or the exhaust valve . This may cause slippage or deterioration of these parts.

17

16

6

NOTE

: THE FOLLOWING STEPS (6 - 10) ARE INCLUDED HERE FOR CONTINUITY. THEY MUST BE

PERFORMED AF

TER THE REGULATOR SECOND STAGE IS ADJUSTED (see 5.4 Setup of Second Stage).

WARNING

NEVER tighten the hose with more than 40 in. lbs. (4.5 joules) of torque. The inlet hose

fitting can be weakened by overtightening.

Page 19

4. Turn on the air. Use the in-line adjusting tool to turn the adjusting orifice counter-clockwise

until you hear a slight hissing. Then turn the adjusting orifice clockwise just enough to stop the

hissing. HINT: A slight clockwise turn past the point where the hissing just stops will reduce

wear and tear on regulators used heavily in rental or training situations.

5. Depress the lever assembly in the second stage five or six times to get the internal parts

seated in their proper positions. Listen for any hissing. Adjust if necessary.

6. After setting the adjusting orifice, check the relationship between the diaphragm wear plate and

the tip of the lever assembly. To do this, use the Sherwood lever height gauge and adjusting

tool (p/n TL123). Use the tool as a gauge by laying it across the top of the case as shown in

Photo #4.

7. Look across the case and gauge tool. The tip of the lever should be even with the bottom

surface of the gauge. If you are re-using the same major parts of the regulator, this

measurement will most likely be correct, and no adjustment will be needed. In fact bending the

lever should be avoided unless necessary to get the tip of the lever in the proper position.

8. If you have installed a new lever, and the lever tip is noticeably high, bend it lower by installing

the lever in the slot of the tool as shown in Photo #5.

9. Holding the tool in one hand, with the tip of the lever toward the fingers, bend the lever

carefully. Do not hold on to the case when making this adjustment, as this can result in the

lever bending at the wrong area (near the lever support instead of at the mid-point of the lever).

If necessary, bend the lever upward using the same holding method.

10. After the regulator is assembled, turn on the air. If the regulator hisses slightly, but stops

hissing when the diaphragm is removed, the lever is too high. Use the lever bending tool to

bend the lever slightly downward.

16

Photo #5

Photo #4

24

Page 20

11. Replace the diaphragm. Continue to test the gap between the lever and the diaphragm after

each bending until the lever is in the correct position.

12. Return to Section 5.3.4 of this manual to complete assembly of the regulator.

5.5 TESTING OF SECOND STAGE

A. Inhalation Effort

Check the inhalation effort of the second stage with a pan of water about five inches deep.

1. Slowly immerse the second stage with the front cover down and level. The regulator should

flow as soon as the diaphragm is a little deeper than level with surface of the water.

2. If you use a water column or water manometer to check inhalation effort, it should not exceed

1” w.c. (2.5 cm) at cracking. It should drop to about 3/4” w.c. (1.9 cm) at one atmosphere and a

moderate flow rate. You can alter the inhalation effort within a certain range.

3. You can increase the inhalation effort by turning the adjusting orifice clockwise.

However, discontinue clockwise adjusting when the lever becomes loose against the lever

support .

4. You can decrease the inhalation effort by turning the adjusting orifice counter-clockwise.

Discontinue counter-clockwise adjusting when air begins to hiss past the second stage orifice.

5. Install the second stage on the end of the hose. Use two wrenches to tighten the hose fitting

with 40 in. lbs. (4.5 Joules) of torque

B. Exhalation Effort

1. If you do not use instruments to check the exhalation effort, the flow should feel smooth and

unrestricted.

2. If you use a water column, it should not exceed 1/2” w.c.(.02 bar) at one atmosphere.

3. Brand new exhaust valves will sometimes adhere slightly to the case, causing a slight increase

in inhalation effort. This condition will disappear with use.

C. Leak Test

1. Disconnect the air supply. Purge the regulator of all positive air pressure.

2. Slowly immerse the second stage in a pan of water with the mouthpiece pointing straight up.

3. Immerse the regulator until the water is 1/4” to 1/8”( .64 to .32 cm ) from the lip of the

mouthpiece.

4. Hold the regulator in this position for one minute and then slowly raise it out of the water.

5. Tip the regulator mouthpiece downward and watch the inside of the mouthpiece tube. If any

water escapes from the mouthpiece tube, check for source of leakage.

17

6

7

22

Page 21

D. External Air Leaks

1 Attach the regulator first stage to a tank short enough to totally submerge the first and second

stage in your filling station cooling water.

2. With the tank valve still turned off, flood the second stage completely with water, and then

position it mouthpiece up.

3. Turn the tank air valve on

slowly and then watch for any leaks in the first or second stage

(except for the normal flow of air from the one-way bleed valve on the first stage).

4. Repair any leaks.

5. Check for the correct positive air purge flow rate.

See Section 4.4 “Testing of First Stage,” for

the proper method.

18

Page 22

6.0 HELPFUL HINTS

6.1 TROUBLESHOOTING REGULATORS

POSSIBLE CAUSE RECOMMENDED ACTION

A. High Inhalation Effort at Depth:

1. Inlet filter clogged. Replace the filter.

2. No air flowing through the dry air bleed system. Check the flow rate coming out of the

one-way bleed valve . If no or low

air flow is detected, clean the flow

element in the piston, or replace the

piston.

3. High pressure air supply insufficient. Verify the supply air pressure. Make

sure the customer had the tank valve

turned

all the way on.

4. Second stage improperly adjusted. Repeat Steps 1 through 6 in Section

5.4, “Set-Up of Second Stage.”

B. Free Flowing:

1. Intermediate pressure too high. Adjust the first stage’s outlet pressure

to below 150 psig. Removing some 1st

stage shims .

2. Damaged or worn H.P. piston seat. Replace 1st stage seat (p/n 3801-5).

This also gives high intermediate

pressure..

3. Damaged or worn L.P. poppet stem seat. Replace 2nd stage seat (p/n 978-9BN).

4. Nicked or corroded orifice sealing. Dress the orifices in the first and

second stages with a polishing stick, or

replace the orifices.

5. Demand lever in second stage bent too high. Adjust or replace the lever.

6. Weak spring in second stage. Replace the spring.

7. Second stage improperly adjusted. Repeat Steps 1 through 6 in

Section

5.4, “Set-Up of Second Stage

.”

8. Parts in the second stage have been severely Allow the second stage to warm back

chilled due to repeated purging and have shrunk, up to room temperature. If the

allowing air to flow. regulator is to be used for Ice diving,

set the second stage up after cooling it

in Ice water. This will help prevent this

type of leakage from occuring due to

cold water conditions.

19

15

20

Page 23

C. Wet Breathing:

1. Improper clearing, or diver diving in total Instruct the diver on proper clearing

head-down position. technique.

2. Diaphragm improperly installed. Check position of diaphragm visually.

3. Hole in the mouthpiece at tie area. Replace the mouthpiece.

4. Hole in the diaphragm. Replace the diaphragm.

5. Damaged exhaust valve, or edges of Replace exhaust valve.

the exhaust valve not firmly seated on

the case.

6. Crack in case. Replace case.

D. Humming or Buzzing During Inhalation:

1. Harmonic resonance between the springs Disassemble the first stage and flip the

and the mass of the piston. main spring over. Change the position

of the piston in its bore. If

resonance is still present, install a new

piston and spring.

1. Harmonic resonance between the 2nd stage This “honking” effect in the second

lever assembly springs, and the mass of the stage can be lessened by installing one

diaphragm. of Sherwoods new denser black

diaphragms shipped under the same

4006-13A part number as the older

blue diaphragm (available since 1997).

20

Page 24

6.2 PARTS CLEANING RECOMMENDATIONS

Regulators which see heavy use, particularly those used in salt water, often require extra effort

to remove dirt and corrosion from the parts of the regulator. Some suggested cleaning solutions

are listed at the end of this section, and there are probably many others being used

successfully. Here are a few general suggestions we can make:

1. Don’t expect your cleaning solution to do all the work in a matter of seconds. If the solution

cleans extremely rapidly, it is probably too strong and is etching the finish on the parts. Use

a wooden or plastic stick or a

soft bristle brush to help get rid of the thickest deposits. Take

special care not to damage orifice sealing areas. Dress the orifice sealing areas with a fine

grit polishing stick or pencil eraser after drying the parts.

2. Immerse only those parts which really need cleaning. With Sherwood’s Dry Air Bleed

System, the interior of the first stage is always clean and dry, so the piston and spring

should never need cleaning. Immersing the clean Sherwood piston in contaminated cleaning

solution can plug the flow control element in the face of the piston, which could slow or stop

the flow through the positive air purge system.

3. Many of the solutions used for cleaning metal parts can damage the nitrile compounds

found in O-rings. For this reason, remove all O-rings before placing parts in a cleaning bath.

6.3 COMMONLY USED CLEANING SOLUTIONS

SOLUTION COMMENTS

Cleaning solutions recommended The preferred choice. Check with the

by ultrasonic cleaner manufacturers manufacturer for strengths and

recommended uses for their cleaners.

Soapy water Good for plastic and silicone parts.

Vinegar and water (equal part solution) Ingredients easily available. Approx. 15

minutes cleaning time. May damage

chrome finish.

1000 cc water Fast-acting solution that must be made

60 gr. sulfuric acid and used with care. Use gloves and

60 gr. potassium dichromate safety glasses. Can damage chrome

finish.

21

Page 25

6.4 HANDLING TIPS

How your customers treat their regulators will directly influence the unit’s function and

durability. Following are a few tips that you can pass on to your customers to help assure the

durability of their Sherwood Scuba regulator.

A. Pre-Dive Checks

1. Check the hoses and hose connections for cuts, abrasions or other signs of damage before

mounting the regulator on the tank valve. Slide the hose protectors back to inspect the areas of

the hose normally covered. Be sure all hose connections are tight.

2. Too prevent a common source of internal corrosion and contamination of the Dry Air Bleed

System, AL

WAYS turn the tank air valve on briefly before mounting the regulator. Many valve

contain contaminated water in the outlet because of rain or splashing.

3. After mounting the regulator first stage, but before turning on the tank air valve, check to make

sure that the yoke nut or DIN connection is tight and the regulator body is aligned properly, with

no kinks in the hoses.

4. Turn the tank valve on

slowly and listen for leaks. If any leaks are found, replace or repair parts

as recommended.

5.

Never lift the tank/BCD assembly by the regulator or hoses.

6. Surface-test the regulator by breathing lightly through the mouthpiece. Depressing the purge

button above the water’s surface is not meaningful an appropriate method for testing the func-

tion of the regulator.

B. Post-Dive Care

1. After the dive, blow all water out of the dust cap with clean dry air and place the cap securely

on the regulator inlet. On multiple tank dives, use great care to keep salt water out of the

regulator inlet when tanks are changed. Briefly release air from the valve before mounting the

regulator on the valve. Neglecting thesesimple procedures is the greatest cause of corrosion

and wear in scuba regulators. When used properly, Sherwood’s exclusive Dry Air Bleed System

keeps all other water-borne contamination out of the first stage body.

2. With the dust cap securely in place, rinse the first and second stages in

clean fresh water.

DO NOT depress the purge button before or during rinsing since this may introduce water into

the second stage and the low pressure hose. Shake or blow all excess water from the second

stage and allow the entire regulator to air-dry before storing.

3. Store the regulator in a clean bag or storage box, away from sunlight, excessive heat and

humidity.

22

NOTE

: A tiny stream of air bubbles escaping from a small black valve on the first stage indicates that the

Dry Air Bleed System is working. The amount of air used is negligible (13 - 27 cc/min.). Check the system

periodically (see Section 4.3B in this manual), particularly after servicing, to ensure that there is some air

escaping from the black one-way bleed valve. If no air is escaping from the valve when air pressure is applied

to the first stage, have the regulator inspected.

Page 26

7.0 TWO YEAR WARRANTY AND MAINTENANCE

INFORMATION

7.1 PROPER PROCEDURE FOR WARRANTY PAPERWORK

1. For detailed information on the operation of Sherwood Scuba Two Year Limited Warranty,

please refer to Sherwood Scuba Technical Bulletin # 112. You can also contact your Sherwood

Distributor if you still have questions about the warranty.

2. In most situation no paperwork will be necessary. The customer will bring his or her regulator in

for one of its two annual servicings under the warranty. No parts other than those contained in

the standard annual service kits will be needed. Discard all old parts replaced by new kit parts.

Please do not return these used parts to Sherwood Scuba!

3. Remove one of the colored annual service rings from the main hose protector. When you have

collected several of these rings (25-50), contact your Sherwood Distributor for a Return Goods

Authorization Number. The color of the ring will determine the credit of type of service kit you

will receive.

4. If you replace parts other than those contained in the standard annual servicing kit, you

will

have to submit paperwork. If the regulator meets the conditions of the two-year warranty, and

the warranty is still active fill out the Sherwood Warranty Replacement Parts Form. You

must

describe the problem with the part you are returning in Part Five of the form. If this area is

blank, you will not receive credit for that part.

5. In Sherwood Scuba regulators

manufactured before Jan. 1, 1993 which still have a valid

Lifetime Limited Warranty you, the dealer, must send the white Warranty Service Form to

Sherwood. The information will be recorded by Sherwood to determine whether or not the

warranty on that particular regulator is still in effect.

7.2 SCHEDULED MAINTENANCE

1. To keep the owner warranty in effect, your customers must have their regulators inspected and

serviced annually (within six weeks before or after the anniversary of the date of purchase) by

an authorized Sherwood Dealer.

Failure to do so invalidates the warranty.

2. Even with infrequent use, the regulator should be serviced annually to ensure proper

performance and satisfy warranty requirements.

3. In Sherwood regulators

manufactured before Jan. 1, 1993 which still have a valid Lifetime

Limited Warranty, you, the dealer, must send in the white Warranty Service Form in to

Sherwood. The information will be recorded by Sherwood to determine whether or not the

warranty on that particular regulator is still in effect.

23

Page 27

ITEM # CATALOG # DESCRIPTION

1 ...................................3207-2 ..........................Label

2 ...............................3004-1 ............................Purge Button (no label insert)

3 ..........................19-4006-12 ..........................Purge Button Spring

4 ...............................3302-7 ............................Bezel Ring

5 ................................3302-6BK ........................Cover

6 ...............................4006-13A ........................Diaphragm (black Tufel

®

)

7..........................J12C04045B..........................Screw (combination Phillips/square drive)

8 ..........................19-4006-17 ..........................Washer

9 ..........................46-3302-20 ..........................Lever (for Blizzard)(black Teflon®-coated)

9 ................................3302-20 ..........................Lever (for Mag II, Oasis, Oasis+, Classic)

10...........................1-3004-8RH........................Lever Support (for Magnum II, no screw holes)

10 .........................1- 3106-17R ........................Lever Support (for Blizz.,Oasis,Oasis+,Classic)

10A ....................J113481874BARC ..................Screws (2 needed)(for Blizz.,Oasis,Oasis+,Classic)

10B ......................25-3106-16 ..........................Fins (2 needed)(for Blizz.,Oasis,Oasis+,Classic)

11 .........................19-978-10 ..........................Spring

12 ..........................9-4006-18 ..........................Stem (no seat insert installed)

13 ............................978-9BN ............................Seat Insert (for Stem)

14 .............................3302-2 ............................Exhaust Tee

15........................J12C04045B..........................Screw (combination Phillips/square drive)

16 .............................4006-15 ..........................Exhaust Valve

17 ............................3302R-1 ............................Case

18 ..............................3208-9S ..........................Mouthpiece

19 .............................3786-9W ........................Mouthpiece Tie

20 ............................G907A ..............................O-ring

21 ..........................1-3004-12 ..........................Spacing Washer

22 ..........................1-3004-4A ..........................Orifice Housing

23 ............................G010A ..............................O-ring (for adjustable orifice)

24 ........................43-4006-20 ..........................Adjustable Orifice (no O-ring)

25 ............................G010A ..............................O-ring (for hose outlet end)

26 .........................5016-20-31 ..........................Hose Assembly (31”)(includes hose protector)

27 .............................5100-27 ..........................Hose Protector

28 ............................G011B ..............................O-ring (hose inlet end)

SECOND STAGE REGULATOR - MAGNUM® II SRB3300, BLIZZARD® SRB3200, OASIS® SRB3400, OASIS® (SRB3500)

NOTE: Labels (Item 1 below) are also available in different colors.

Page 28

Printed in the U.S.A on recycled paper

Sherwood Scuba, the SS symbol, Oasis, Blizzard, Magnum, Brut and Wisdom

are trademarks of Sherwood, Harsco Corporation Gas and Fluid Control Group.

All other names are trademarks of their respective owners.

ALL PRODUCTS SUBJECT TO CHANGE WITHOUT NOTICE.

6204 Goodrich Road

Clarence Ctr, New York 14032

www.sherwoodscuba.com

© 2001 The Liberty Group

Part Number S-MAN2003

Loading...

Loading...