Sheffer MA User Manual

MA SERIES

Medium-Duty Pneumatic Cylinders

Pressure Rating 200 PSI

High strength aluminum alloy is used for

both head and cap. They are accurately

machined for tube and rod bearing.

Piston rods have a minimum expected

yield of 100,000 psi. They are ground,

polished and hard chrome plated for wear

and corrosion resistance. Four wrench

flats are standard.

The tube is a high tensile, special

aluminum alloy with a hard anodized

finish. The file-hard finish offers long life

and amazing lubrication holding

properties.

Maximum strength is obtained through a

prestressed tie rod assembly.

Pistons are machined from fine grain C.I.

for excellent friction characteristics

against the hard coated tube I.D. Low

friction. The piston is of one-piece design

to provide full thickness bearing and is

threaded onto the piston rod for strength

of assembly.

Static seals at tube ends are confined,

precision cut gaskets.

Modified U-cup seals are Buna-N compound. They are self-adjusting for pressure

and wear and their design permits simple

replacement.

A Buna-N O-Ring provides a positive,

pressure activated, seal for the rod gland.

The quad ring wiper is designed to wipe

off abrasive dust and contamination on

the retract stroke to insure long life for the

seals, bearing and piston rod.

Modified U-cup design offers long life

with minimum friction. It is self-adjusting

to pressure and wear. Seal material is a

standard Buna-N compound.

The rod gland has an extra long bearing

surface and is easily removed. It is made

of a high quality cast iron and Teflon

®

coated. This affords a low friction bearing

which is highly compatible with the hard

chrome plated piston rod.

Seal Rating Temperature: – 40° to

+200°F

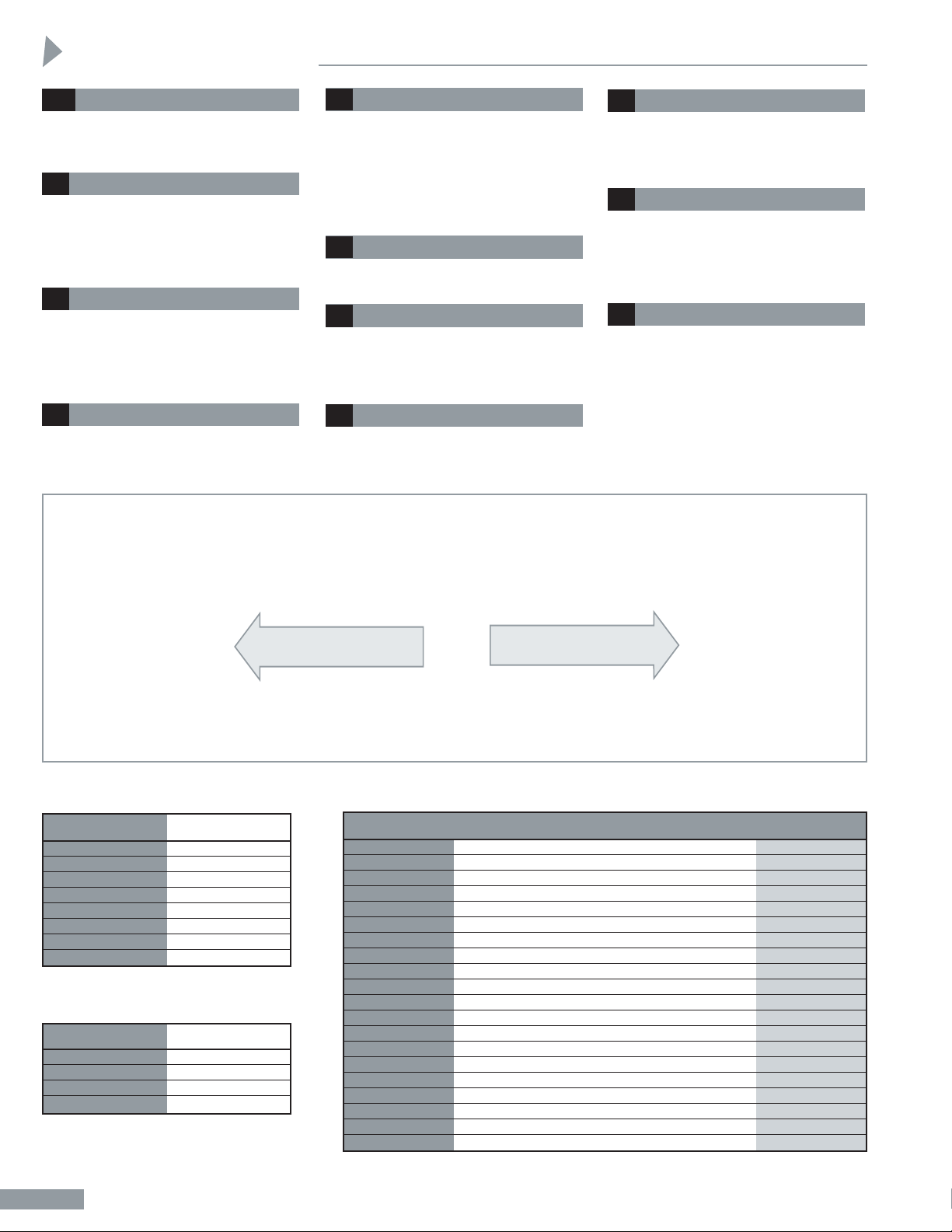

ITEM QUANTITY

NUMBER DESCRIPTION REQUIRED

1 HEAD 1

2 CAP 1

3 PISTON ROD 1

4 TUBE 1

5 TIE ROD 4

6 ROD GLAND RETAINER 1

9 PISTON 1

10 RETAINER SCREW 4

13 TIE ROD NUT 4

16 * TUBE SEAL 2

18 * PISTON SEAL 2

22 * ROD GLAND SEAL 1

24 * ROD WIPER 1

25 * ROD SEAL 1

29 CUSHION PISTON – FRONT **

30 CUSHION ADJUSTING SCREW **

31 CUSHION ADJUSTING SCREW SEAL **

33 * CUSHION SEAL – FRONT **

43 * CUSHION SEAL – REAR **

70 ROD BEARING 1

*Recommended Spare Parts

**As required. Specify if cushioned front, cushioned rear, or cushioned both ends.

TORQUE IN

ROD DIAMETER FOOT POUNDS

5

/8 2.8

1 6

13/8 13

13/4 27

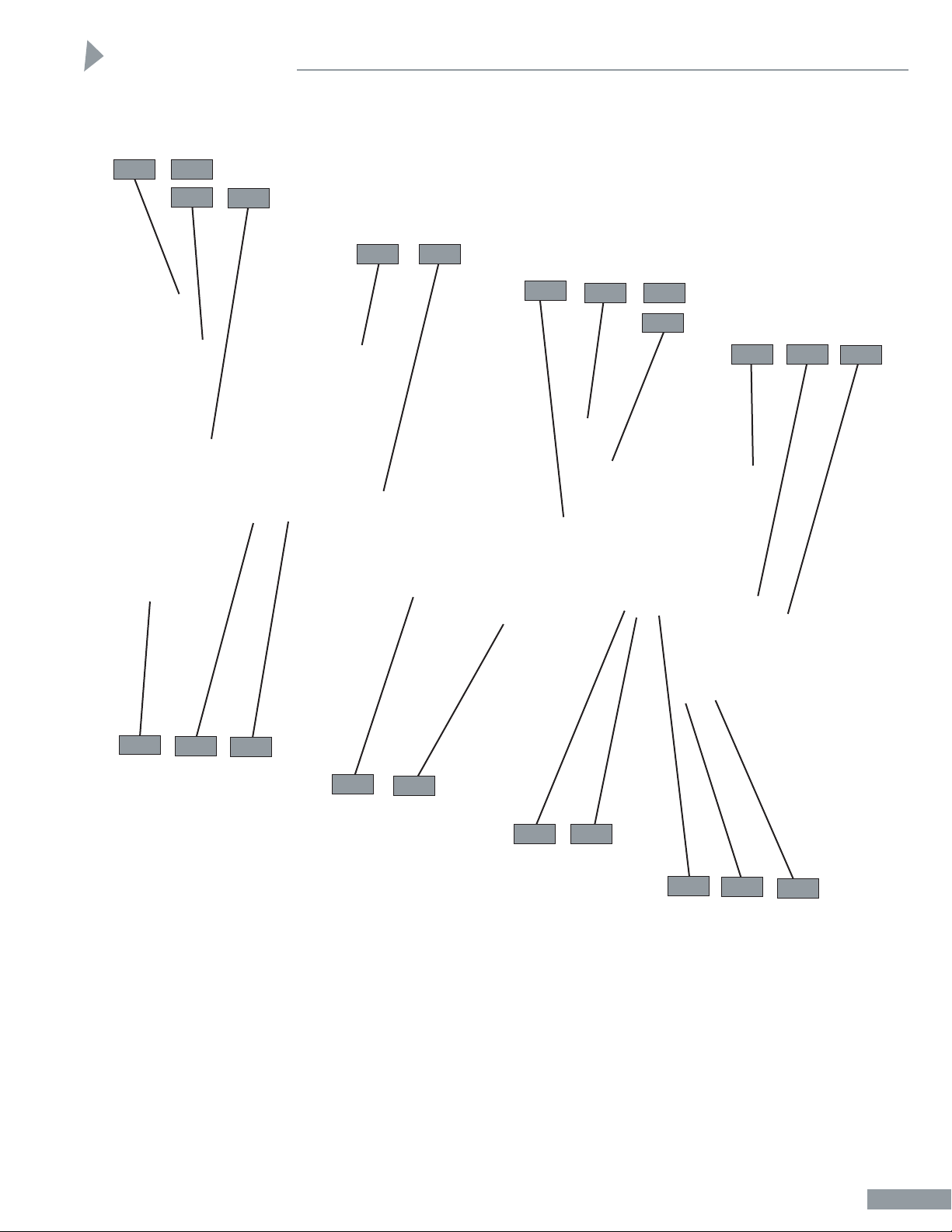

FFIIGGUURREE 11 FFIIGGUURREE 22

Sheffer’s state-of-the-art cushion design

features a unique, one-piece, nitrile

compound seal that is captured within a

precision machined groove. This allows both

linear and radial “float”of the cushion seal

which virtually eliminates problems

associated with misalignment!

Integral flow paths molded in the periphery

of the seal provide exceptionally fast “out

of cushion” stroke reversal without the use

of ball checks.

Figure 1 shown with spear

entering cushion seal.

Figure 2 shown with spear

exiting cushion seal.

DIMENSIONALLY INTERCHANGEABLE TO MEET ANSI SPECIFICATIONS

Construction

1,2

Head & Cap

3

Piston Rod

4

Tube

5

Tie Rod Construction

9

Piston

16

Tube End Seals

18

Piston Seals

24

Rod Wiper

25

Rod Seal

70

Rod Bearing

22

Rod Gland Seal

TORQUE IN

CYLINDER BORE FOOT POUNDS

11/2 6

2 10

21/2 15

31/4 22

4 25

5 40

6 50

8 85

Parts List

Tie Rod Torque Chart

Gland Retainer Torque Chart

1

MA-1

31

30

43

5

29

33

1 31

30

13 24

3

2

9

18

4

16

25

22

70

6

10

Parts List

1

MA-2

13