Sheffer HH User Manual

HH SERIES

Heavy-Duty Hydraulic Cylinders

Pressure Rating 3,000 PSI

Piston rods through 4" diameter have a

minimum expected yield of 100,000 psi.

They are case hardened to 50 Rockwell C

to a depth of .030" for damage resistance.

They are then hard chrome plated for wear

and corrosion resistance. Larger diameter

rods have an expected minimum yield

of 50,000 to 60,000 psi depending on

diameter and are hard chrome plated.

Offers much longer fatigue life through

elimination of thread relief stress concentration point. Standard as Style 2 rod end on

all rod sizes through 2

1

/2" diameter. Studs

are pretorqued and locked in to prevent

loosening. They are machined from high

tensile steel and the threads rolled.

The steel tube is honed to an 8 to 16

microinch finish for low friction and long

seal and piston bearing life. Tube ends

are machined on the O. D. concentric with

the I. D. They are confined by the close

tolerance machining of the head and cap

which provides greater hoop strength.

Maximum strength is obtained through a

prestressed tie rod assembly.

Four wrench flats are provided as standard

for easy attachment. Spanner holes, in lieu

of flats, are standard on large diameter rods.

All pistons are machined from a fine grain

alloy cast iron. They are threaded directly

onto the piston rod, torqued, sealed and

locked in place with one or more set

screws.

The special piston seal is an endless

glass filled Teflon material with an O-ring

expander. One or more (depending on

bore size) bronze filled Teflon bearing

strips are also employed on this type piston

to eliminate metal-to-metal contact. This

type piston offers long life, low friction,

near zero leakage, and great tolerance for

side loading. It can be used successfully

on virtually any application.

Pressure activated O-ring seals are used

at rod gland and tube ends. Located to

eliminate extrusion and to provide positive

leak tight seal.

High load bearing bronze piloted into the

head. Located inboard of the seals to insure

a well lubricated bearing for the fastest

cycling applications. It need not be

removed for rod seal replacement.

The polyurethane wiper is designed to

wipe off abrasive dust and contaminants

on the retract stroke to insure long life for

packings, rod bearing, and piston rod.

Where the rod will be exposed to gummy

materials such as road tar, a metallic rod

scraper is available.

The polyurethane rod seal has a unique

design which incorporates the optimum

sealing properties of a U configuration with

the elastomeric properties of a compressiontype seal. The polyurethane material was

selected for toughness, abrasion resistance,

and the ability to resist extrusion under

rough service conditions.

Cushion pistons (29) are tapered to provide

gradual deceleration and eliminate shock

upon entrance. The Adjusting Screw

with fine threads (30) provides a wide range

of adjustment.

When required, air bleeds are located

where they can be employed most

successfully – at the tube and head juncture.

The straight thread plugs are equipped

with metallic O-rings so they can be used

repeatedly with a good seal every time.

Easily removable for replacement of rod

seal and wiper. In most cases it is not

necessary to demount or disassemble the

cylinder. Easier to service since on removal

of the ductile iron gland, the piston rod

remains supported by the separate rod

bearing.

DIMENSIONALLY INTERCHANGEABLE TO MEET ANSI SPECIFICATIONS

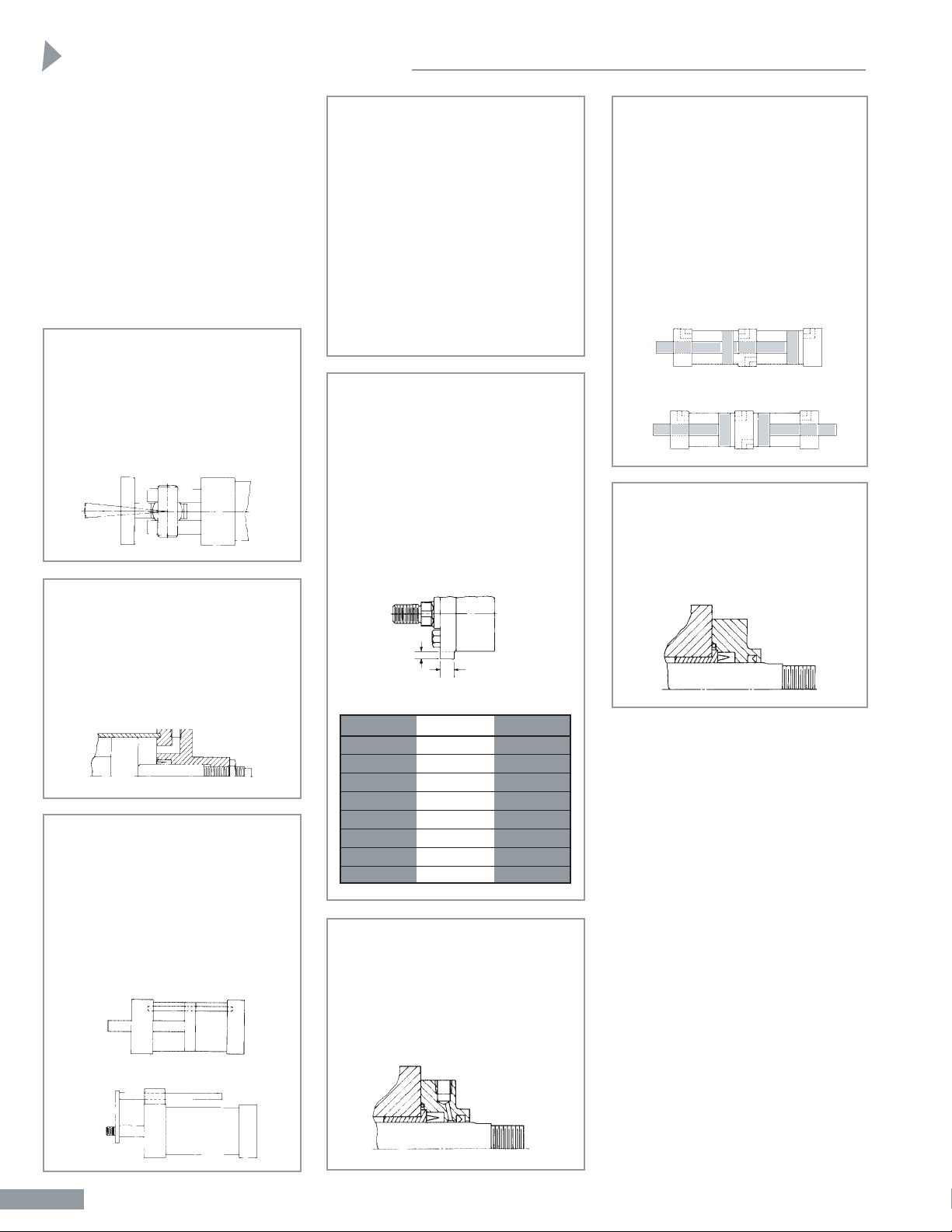

Construction

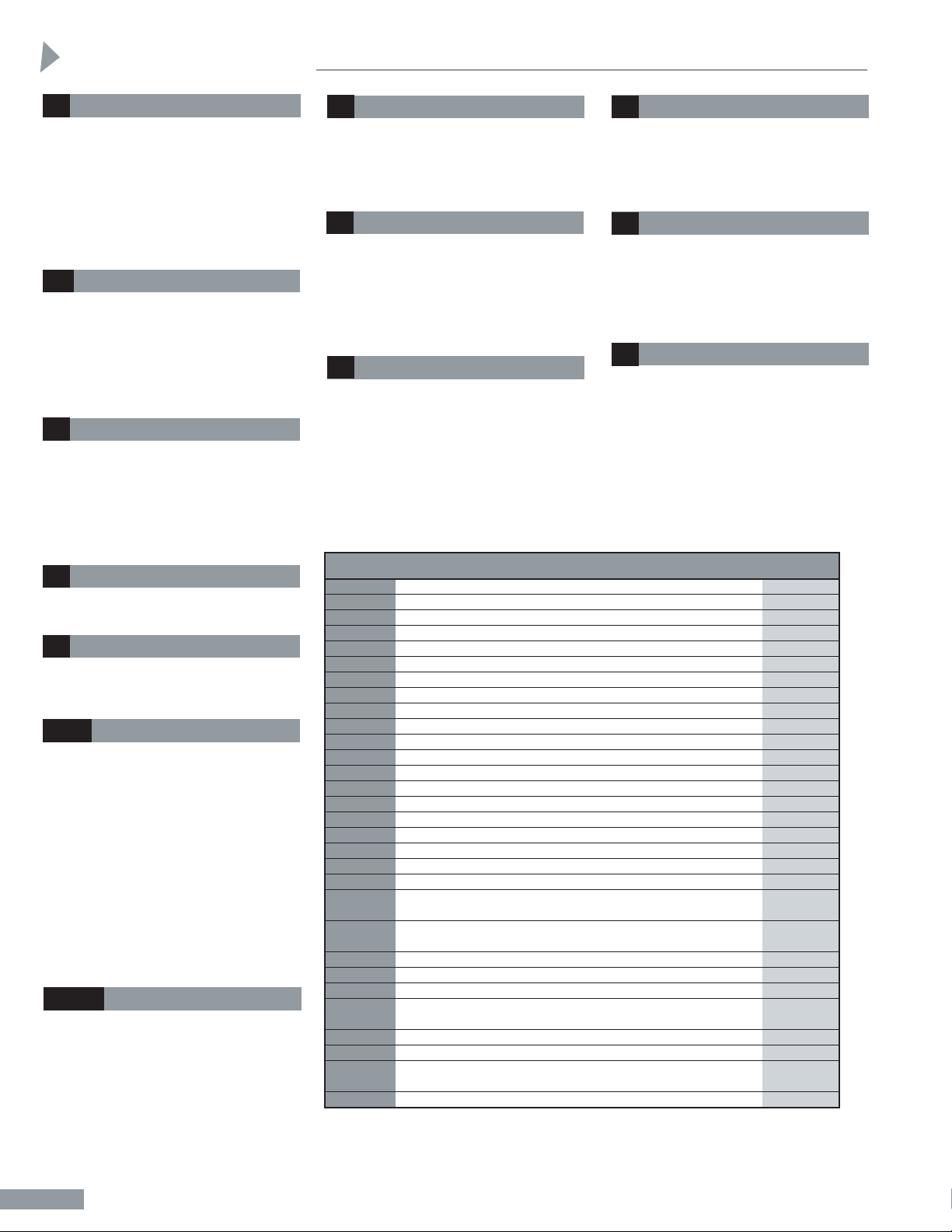

ITEM QUANTITY

NUMBER

DESCRIPTION

REQUIRED

1 HEAD 1

2 CAP 1

3 PISTON ROD 1

3A “STUD – STYLE II THREAD THRU 2

1

/2" ROD DIA.” 1

4 TUBE 1

5 TIE ROD 4

6 ROD GLAND RETAINER 1

6A ROD GLAND & RETAINER – SINGLE PIECE 1

9 PISTON – SLIPPER SEAL TYPE 1

10 RETAINER SCREW 1

11 SEAL - PISTON I.D. ‡

13 TIE ROD NUT 4

16 † TUBE SEAL 2

18 † PISTON SEAL – SLIPPER SEAL TYPE 1

18 A† EXPANDER – FOR SLIPPER SEAL 1

21 † ROD BEARING 1

22 † ROD GLAND SEAL 1

24 † ROD WIPER 1

25 † ROD SEAL 1

29 CUSHION PISTON – FRONT **

30 CUSHION ADJ. SCREW – FRONT OR REAR

(CROSS SLOT) **

31 “SEAL – CUSHION ADJUSTING AND CUSHION

CHECK – FRONT OR REAR” **

36 CUSHION CHECK BALL – FRONT OR REAR **

38 CUSHION CHECK PLUG – FRONT OR REAR **

40 CUSHION ADJ. CAPTIVATOR – FRONT OR REAR **

41 SEAL - CUSHION ADJ. CAPTIVATOR –

FRONT OR REAR **

57 PISTON BEARING STRIP *

58 AIR BLEED PLUG **

66 A “BACK-UP WASHER – CUSHION ADJUST AND

CUSHION CHECK – FRONT OR REAR” **

70 ROD GLAND 1

3

Piston Rod

4

Tube

5

Tie Rod Construction

7

Wrench Flats

9&18

Pistons & Piston Seals

21

Rod Bearing

24

Rod Wiper

25

Rod Seal

58

Air Bleeds (Optional)

70

Rod Gland

3A

Studded Rod End

Parts List

16, 22

Static Seals

29

Cushions

1

HH-1

‡Retainer Screws required varies by bore and mount

†Recommended Spare Parts

*One required thru 4" bore, 2 required 5" thru 8" bores, 3 required on 10" and 12" bores,

4 required on 14" bore.

**As required; specify if cushioned front, cushioned rear or cushioned both ends.

Round, single piece rod gland

and retainer used on all but some

of the smaller bore sizes. Consult

pages on specific mounts.

1 1/8" THRU 24" BORE SIZES

Parts List

6A

Ordering Information:

Also see separate ordering information. When ordering parts, the

Model No. and Serial No. must be

specified. Give item no., name and

quantity of part desired. The Model

No. and Serial No. will be found on

a metal plate that has been drivescrewed to either the head or the

cartridge retainer.

Please Note:

Complete replacement packing kits

are available. For purposes of economy

and less down-time, it is recommended

that replacement packing kits be

stocked. They are described and priced

in the current Sheffer Replacement

Parts Price List and on CD Rom.

Contact your distributor or the factory

for these lists.

HH-2

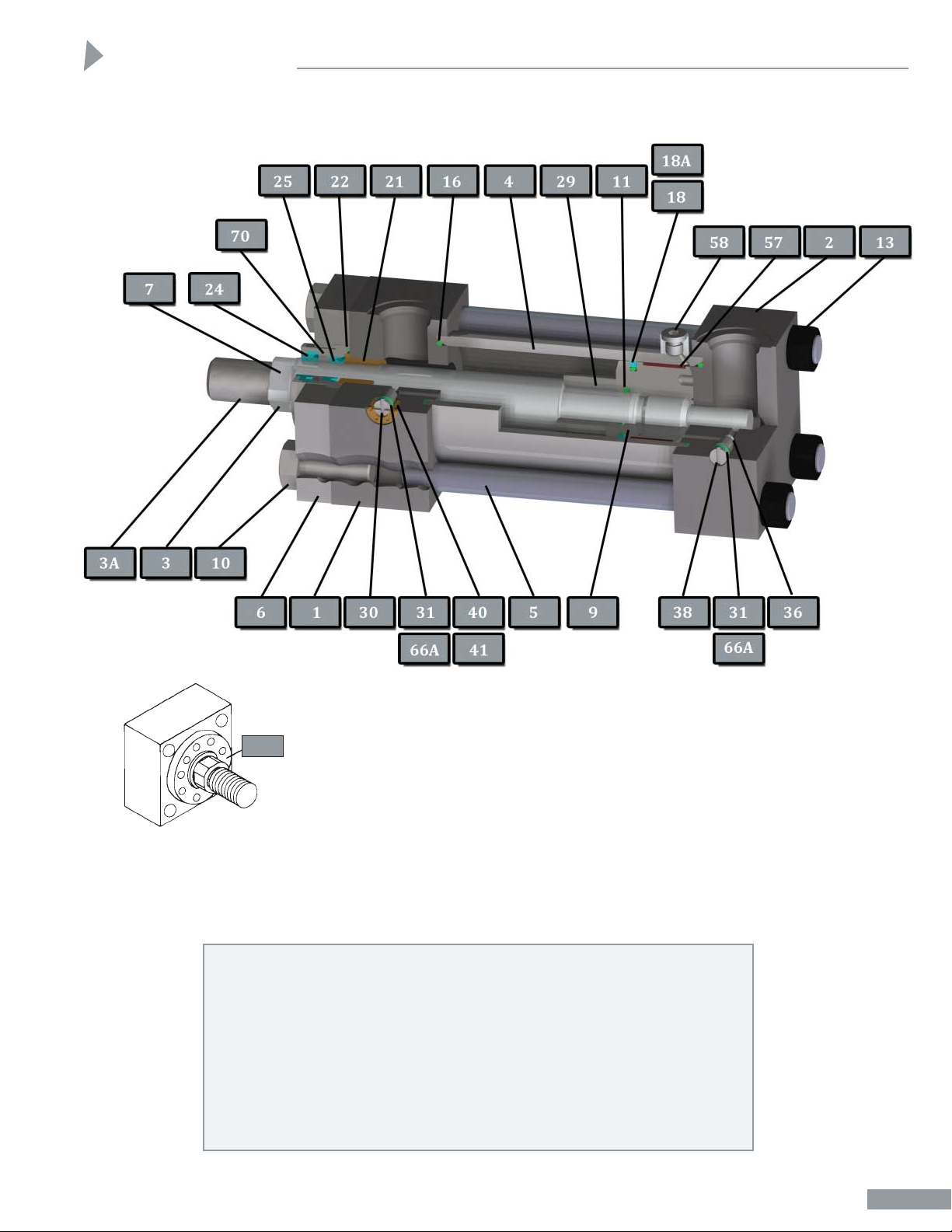

ITEM QTY.

NUMBER DESCRIPTION REQ'D

100 FRONT FLANGE 1

102 FRONT FLANGE EXTRA 1

103 REAR FLANGE 1

104 REAR FLANGE EXTRA 1

105 * FOOT BRACKET – FRONT 1

106 * FOOT BRACKET – SCREW 2

107 * FOOT BRACKET – REAR 1

112 CLEVIS PIN 1

117 INTERMEDIATE TRUNNION 1

108 * END LUG – FRONT 2

110 * END LUG – REAR 2

*Not available on 10", and larger bore cylinders.

FRONT FLANGE

MOUNT

STYLE FF

REAR FLANGE MOUNT

EXTRA SIZE

STYLE RFX

FRONT FLANGE MOUNT

EXTRA SIZE

STYLE FFX

FOOT BRACKET MOUNT

STYLE FB

INTERMEDIATE TRUNNION MOUNT

STYLE T

REAR FLANGE MOUNT

STYLE RF

CLEVIS MOUNT

STYLE C

END LUG MOUNT

STYLE

EL

100

107

102

112

103

104

110

108

106

105

117

Parts List

L

Scribe on Line Head

1

2

3

4

5

6

7

8

9

10

11

Screw Torque in Foot Pounds

BORE PISTON ROD HEX HEAD SOCKET HEAD

SIZE DIAMETER CAP SCREW CAP SCREW

11/8

5

/8 8

11/2 ALL 13.6

2 ALL 5

21/2 1, 13/8 5

21/2 1

3

/4

33

31/4 ALL 5

4 ALL 5

5 2, 21/2 5

5 3, 31/2 10

6 21/2 5

6 3, 31/2, 4 10

7 ALL 10

8 ALL 10

10 41/2, 5, 51/2 10

10 740

12 51/2 10

12 740

12 870

14 740

14 10 95

COLUMN 1 FULL 2 FULL 3 FULL

1 TURN TURNS TURNS

TURN (T) L PLUS T PLUS T PLUS T

IN 12THS LENGTH L LENGTH L LENGTH L LENGTH

1 23/4 361/2 70 1035/8

2 55/8 391/4 723/4 1061/2

3 81/2 42 755/8 1091/4

4 111/4 443/4 781/2 112

5 14 475/8 811/4 1143/4

6 163/4 501/2 84 1175/8

7 195/8 531/4 863/4 1201/2

8 221/2 56 895/8 1231/4

9 251/4 583/4 921/2 126

10 28 615/8 951/4 1283/4

11 303/4 641/2 98 1315/8

12 335/8 671/4 1003/4 1341/2

For 7" bore cylinders and larger, the tie

rods are given an initial torque, the tie

rods are heated, and then the tie rod

nuts are turned a calculated amount.

First torque all 4 tie rod nuts to 200-250

foot pounds. Measure the cylinder to

obtain length L, consult the chart for the

proper number of turns or fractions (in

12ths). The figures in Column 1 shown

in 12ths corresponds to the points and

flats of the hex nut (see illustration).

The piston rod of the cylinder should be

either fully retracted or fully extended

prior to heating. Place an asbestos sheet

between the tube and tie rod and heat to

800°F for as long a length as possible.

When the distance between the cylinder

heads is 18" or less, do not heat closer

than 3" of either head. Tie rods should

be heated and tightened in cross corner

rotation and in steps up to full tension.

Allow the tie rods to cool before testing

or installation.

Parts List

Tie Rod Torque for

1 1/8" through 6" Bores

TORQUE IN TORQUE IN

BORE FOOT POUNDS BORE FOOT POUNDS

11/8 8 31/4 110

11/2 30 4 130

2 50 5 325

21/2 50 6 480

Tie Rod Torque for

7" Bore and Larger

1

HH-3

Cushions

Sheffer pioneered tapered cushions,

designed to provide gradual deceleration and eliminate shock upon entrance

of the cushion pistons, have now been

considerably improved. The tapered

cushion has been married with a fine

thread, wide range, adjusting screw.

This new combination offers a positive,

low-shock deceleration and a method to

adjust the cushioning effect for speeds

and loads.

The adjusting screw is identified by a

tag affixed to the head (or cap) and can

be further distinguished by the fact that

it is captivated with the Sheffer

exclusive captivator This allows full

open to close adjustment without

concern for damaging seals.

The cushion check, which does not

require adjustment, has a single slot in

its head. It does not project beyond the

surface of the head (or cap). The

cushion check plus the tapered cushion

piston provides rapid acceleration out

of cushioning. There is no spring in the

cushion check to fatigue, hence, no

worry of mechanical failure.

Cushioning is designed to properly

cushion the cylinder and is not

intended to cushion large inertia loads.

Cushions do not substitute for speed

controls or deceleration valves on most

installations.

As indicated on page HH-6, the

standard positions for ports are 1 and 5.

Where possible, the standard positions

for cushion adjusting screws will be 2

and 6 and the standard positions for

cushion checks will be 4 and 8. With

some mounting styles, it is not possible

to so locate the adjusting screws and

checks. For example, a Trunnion Front

Mount has the trunnion pins located in

positions 2 and 4 on the head. With the

port in position 1, the only side

available for both adjusting screw and

check is position 3. Since both will then

be located on the same side, they will be

located off-center. This example would

hold true with the TR, CL, FHF and

RHF mounts. See Chart A for standard

positions that will be supplied unless

otherwise specified. When requested,

other positions can be supplied so long

as there is no interference with

mounting.

Where access to an adjusting screw or

check could be made difficult because

of proximity to a mount, the locations

of the screws will be slightly off-center.

An example of this would be a small

bore cylinder with a side lug mount.

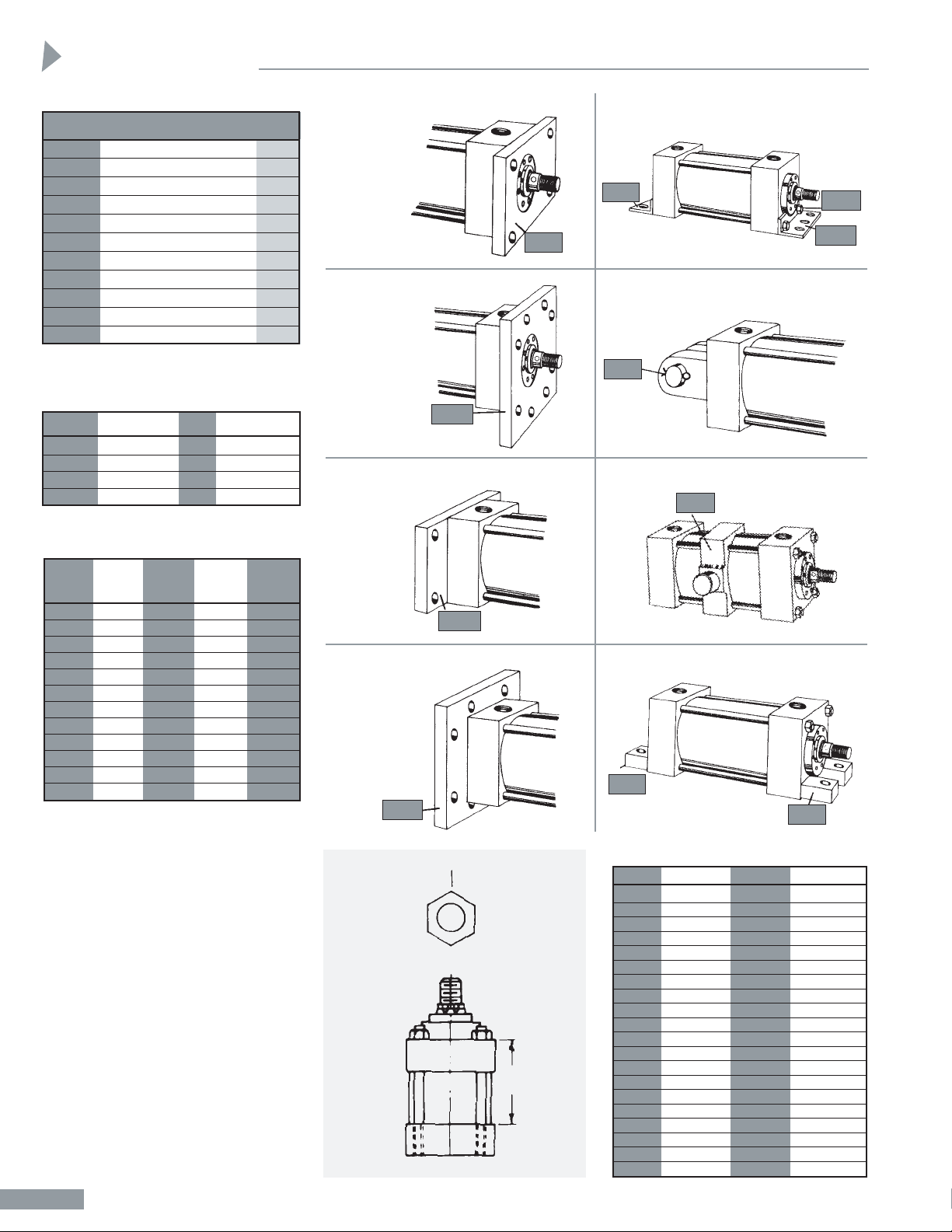

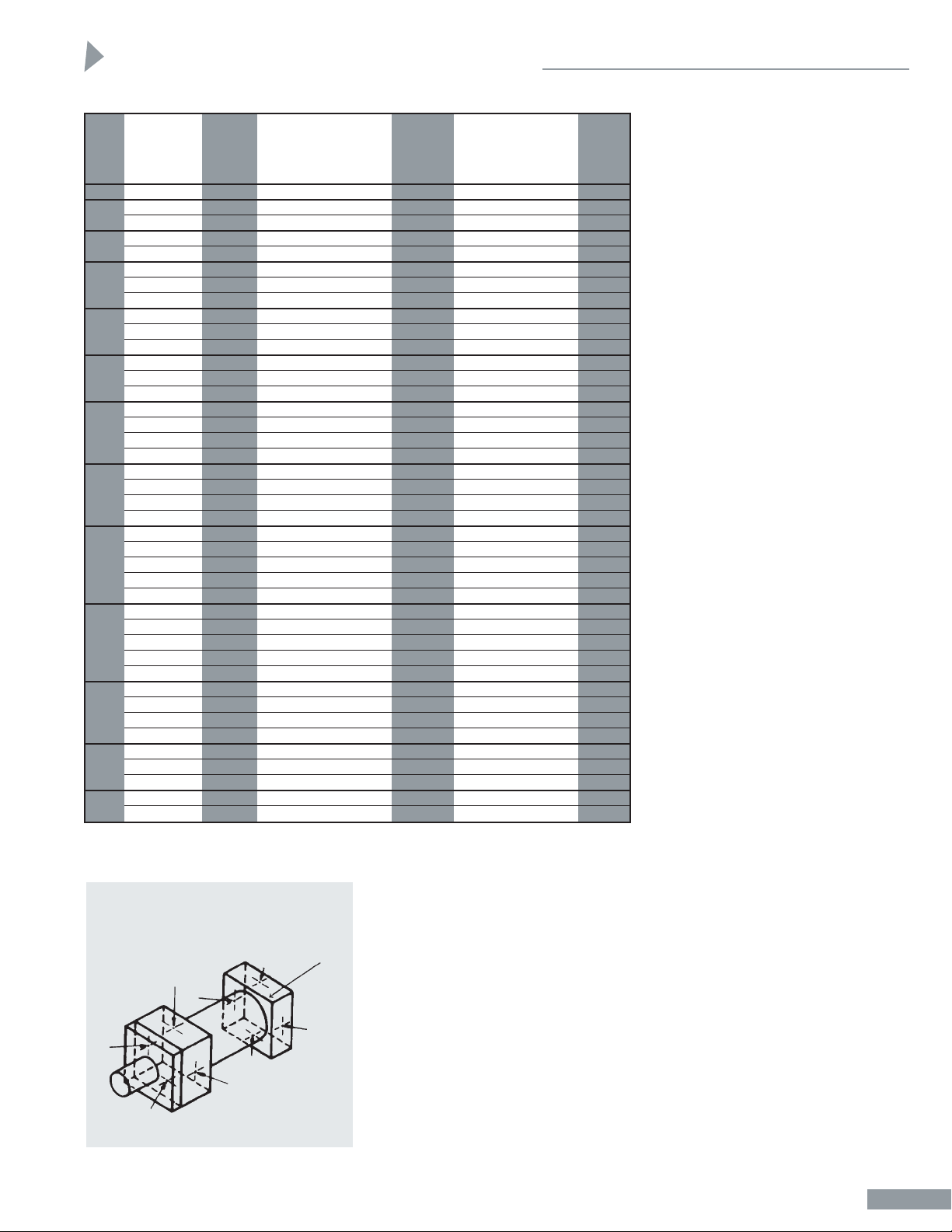

BORE 11/8 11/2 2 21/2 31/4 4 5 6 7 8 10 12 14

ZERO STROKE 3 8 14 19 37 50 90 140 210 290 650 975 1600

ADD PER INCH

OF STROKE

Note: The above weights are based on an average value for cushioning, rod size, and the various types of

mountings for uncrated cylinders to establish approximate shipping weights. Add 10% of cylinder weight

to determine estimate weight of crated cylinder.

Position Diagram for Ports,

Air Bleeds, Cushion Adjusting

Screws and Cushion Checks

1

2

3

4

5

6

7

8

9

Pressure and Shock

HH SERIES Cylinders are suitable for

working pressures to 3,000 psi and

maximum pressure including any shock

to 5,000 psi. Refer to

Chart B for the

maximum operating pressure that can

be used with a 3:1 safety factor based on

yield. It is felt that this is an adequate

safety factor for any well designed

hydraulic system where shock

conditions have been considered and

reduced to an acceptable level. Not all

mounting styles will take the thrust

generated at these pressures. See

separate Accessories Brochure.

The following factors in shock loading

should be considered:

n Relief valves in the circuit do not

protect the components from shock

because of the time lag.

n Gauges do not necessarily register

shock conditions, either because of

their position in the circuit, or the

short duration of shock.

n The two general types of shock

loading to be considered are pressure

rise caused by quick stop of the flow

in the circuit and quick pressure drop.

Decompression shock is particularly

important in large bore cylinders and

can be as destructive as compression

shock.

n The magnitude of the pressure

difference and the duration that the

maximum pressure exists are the

factors that determine the damage

from shock.

3:1

HEAVY MAX. SAFETY

DUTY SHOCK FACTOR

BORE SERVICE SERVICE (YIELD)

SIZE PSI PSI PSI

11/8 3,000 5,000 3,612

11/2 3,000 5,000 3,085

2 3,000 5,000 3,412

21/2 3,000 5,000 2,783

31/4 3,000 5,000 2,842

4 3,000 5,000 2,667

5 3,000 5,000 2,778

6 3,000 5,000 2,760

7 3,000 5,000 2,558

8 3,000 5,000 2,391

10 3,000 5,000 2,936

12 3,000 5,000 2,549

14 3,000 5,000 2,443

All above figures are based on the cylinder as a

pressure vessel. Some styles of mountings will not

withstand the thrust generated at these pressures.

See information on specific mounts.

.25 .5 .8 1.3 1.8 2.5 4 5.8 6.5 9 16 25 35

Cushions and Pressure

HH SERIES Cylinder Weight Chart

CUSHION

ADJUSTING CUSHION

MOUNT SCREW CHECK

TF AND FHF 3 and 6 3 and 8

CL 3 and 7 3 and 7

TR AND RHF 2 and 7 4 and 7

ALL OTHER

MOUNTS 2 and 6 4 and 8

Standard positions for cushion adjusting screws

and cushion checks in relation to port positions

by style of mounting.

Chart A

Note: Because of space limitations,

neither cushion adjusting screws

nor cushion ball checks can be put

into 11/2" and 2" bore sizes for

cushioned front when they are

specified with 2:1 rod diameters.

Chart B

Maximum Pressure Ratings

HH- 4

1

HH-5

Tandem Cylinders and

Multi-stage Cylinders

The tandem cylinder (Figure A)

has two pistons connected to a

common rod, resulting in twice

the force output of a single

cylinder. Multi-stage cylinders

(Figure B) offer multiple, positive

strokes by pressurizing one

cylinder, the other, or both.

Contact the factory for other

variations.

Rod Gland Drain Back

When not even a drop of external

leakage can be tolerated, the rod

gland drain back provides a signal

that the rod seal set has worn to the

point of replacement – without the

danger of contamination from

leakage.

External Rod Seal

When a cylinder is to be operated

under water, provision is made to

prevent the water from being drawn

into the cylinder at the time of

valve shift or pressure differential.

Stainless Steel Piston Rods

Many applications, especially those

subjected to water spray, require

the use of stainless steel piston

rods. We stock AISI Type 304 hard

chrome plated, stainless steel and

will furnish that type unless

otherwise specified. Type 304 is

considered a good, corrosion

resistant type of stainless steel, but

the minimum expected yield is

approximately 35,000 psi and that

factor must be considered with

respect to operating pressure,

column loading, etc.

FIGURE B

FIGURE A

Adjustable Stroke

Shown is an integral stroke

adjustment (externally adjusted)

that is accomplished by the use

of a bump rod threaded into the

cylinder cap. Seals are incorporated

to prevent external leakage and a

lock nut is included.

Thrust Key

All side mounted cylinders (SF, FB,

EL and SL mounts) can be supplied

with thrust keys. Thrust keys are

available in bore sizes 1

1

/8" thru 6".

Extending the rod gland retainer,

as shown, provides a key which fits

into a milled slot in the mounting

surface of the machine member.

Combined with the mount this key

assures that cylinder will not shift

in severe service.

Spherical Bearings

Pivot mounting brackets and rod

eyes can be provided with spherical

bearings to compensate for misalignment on both ends of cylinders.

Consider also the use of the Sheffer

Uni-Lign described in separate

Accessories Brochure.

Non-Rotating Piston Rod

Two methods of providing nonrotating piston rods are employed.

The internal rod type

(Figure A)

is generally used since it requires

less space and is neater. The type

shown in Figure B must be used

on small bore cylinders where

internal space is limited.

FIGURE A

FIGURE B

The Sheffer Corporation manufactures

many cylinders with variations to meet

special customer needs. In addition to

those illustrated below, some of the

more popular variations are:

• Cylinders with Boots

• Combination Mount Cylinders

• Cylinders with Built-In Limit

Switch Actuators

• Locking Cylinders

• Precision Stroke Cylinders

• Precision Mount Cylinders

• Electrically Insulated Cylinders

FK

FA ± .0005

Special Variations

BORE FA FK

11/8 .3120

3

/16

11/2 .3120

3

/16

2 .5620

5

/16

21/2 .5620

5

/16

31/4 .6870

3

/8

4 .8120

7

/16

5 .8120

7

/16

6 .9370

1

/2

Thrust Key Bore Sizes

Porting

S.A.E. Ports, located in positions 1 and

5 (See Position Diagram for Ports) are

standard and will be furnished unless

otherwise specified. Other types and

sizes of ports are available on request,

at slight additional cost.

Port Positions - Where mounting

clearances permit, the ports can be in

any of four positions in the head and

in the cap at no extra cost. Indicate

both port positions desired by position

number. If no preference is stated, ports

will be furnished in positions 1 and 5.

NOTE: The head and cap can be rotated

in relation to each other as long as

mounting and porting are convenient

for installation.

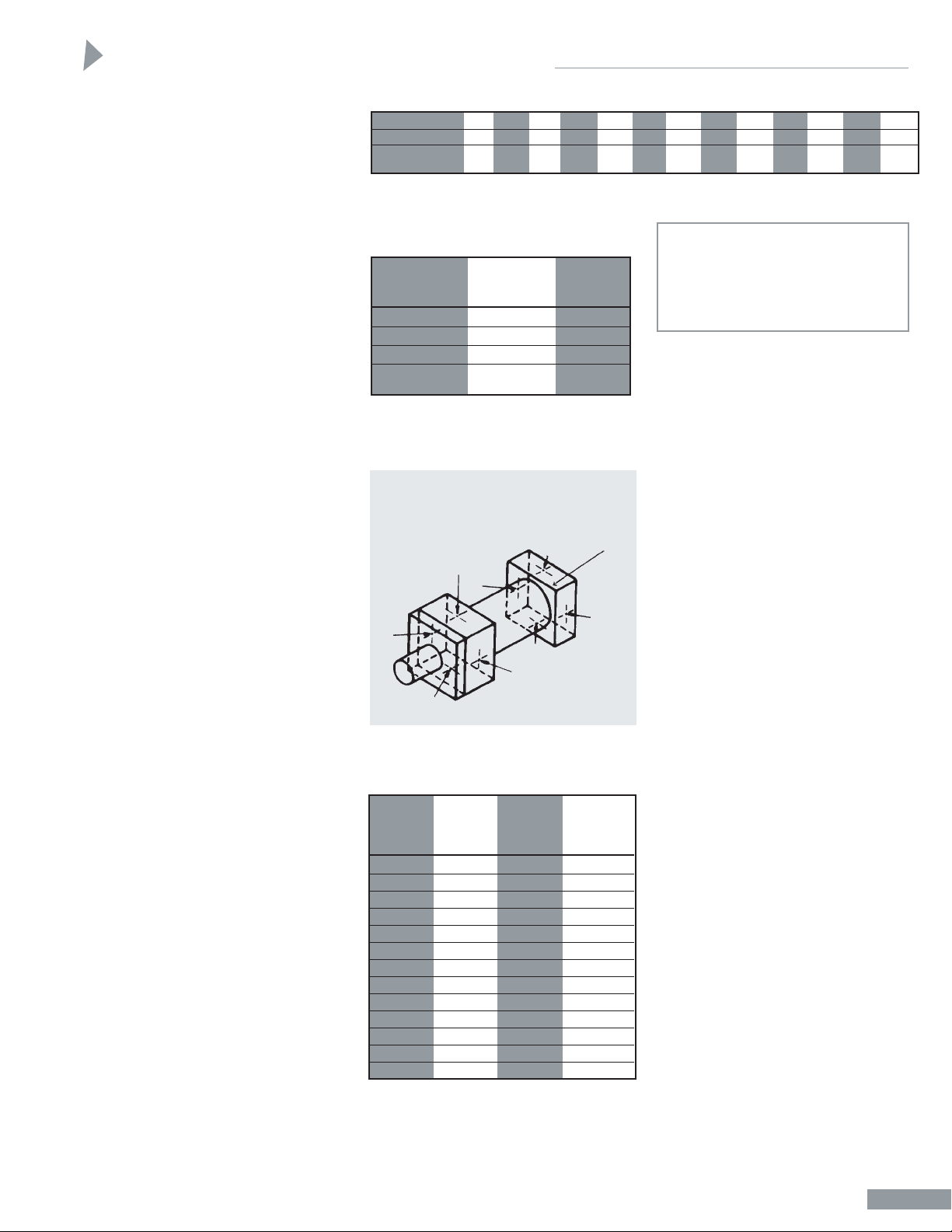

1 2 3 4 5 6 7

STD. MAX.

S.A.E. S.A.E. MAX.

MM STD. MAX. ST. THRD. S.A.E.

ROD NPT. NPT.PORT THRD. PORT FLG.

BORE DIA. PORT HEAD CAP PORT HEAD CAP PORT

11/8

5

/8 STD.

1

/4

3

/8*

3

/8* -6 -6 -6 —

5

/8 STD.

1

/2

3

/4

3

/4 -10 -10 -10 —

1 2:1

1

/2

3

/4

3

/4 -10 -10 -10 —

1 STD.

1

/2

3

/4*

3

/4* -10 -12* -12* —

13/8 2:1

1

/2

3

/4*

3

/4* -10 -12* -12* —

1 STD.

1

/2

3

/4*

3

/4* -10 -12 -12 3050

13/8

1

/2

3

/4*

3

/4* -10 -12* -12* 3050

13/4 2:1

1

/2

3

/4*

3

/4* -10 -12* -12* 3050

13/8 STD.

3

/4

3

/4 1* -12 -12 -16* 3075

13/4

3

/4

3

/4 1* -12 -12 -16* 3075

2 2:1

3

/4 1* 1* -12 -16* -16* 3075

13/4 STD.

3

/4

3

/4 1* -12 -14 -16* 3075

2

3

/4

3

/4 1* -12 -14 -16* 3075

21/2 2:1

3

/4 1* 1* -12 -14 -16* 3075

2 STD.

3

/4

3

/4 1* -12 -16* -16* 3075

21/2

3

/4 1* 1* -12 -16* -16* 3075

3

3

/4 1* 1* -12 -16* -16* 3075

31/2 2:1

3

/4 1* 1* -12 -16* -16* —

21/2 STD. 1 11/4*1

1

/4* -16 -20* -20* 3125*

3 1 11/4*1

1

/4* -16 -20* -20* 3125*

31/2 1 11/4*1

1

/4* -16 -20* -20* 3125*

4 2:1 1 11/4*1

1

/4* -16 -20* -20* —

3 STD. 11/4 11/2 11/2 -20 -24 -24 3150

31/2 11/4 11/2 11/2 -20 -24 -24 3150

4 11/4 11/2 11/2 -20 -24 -24 3150

41/2 11/4 11/2 11/2 -20 -24 -24 3150

5 2:1 11/4 11/2 11/2 -20 -24 -24 3150

31/2 STD 11/2 22-24 -32* -32* 3200

4 11/2 22-24 -32* -32* 3200

41/2 11/2 22-24 -32* -32* 3200

5 11/2 22-24 -32* -32* 3200

51/2 2:1 11/2 22-24 -32* -32* 3200

41/2 STD. 2 21/2 21/2 -32 -32 -32 3250

5 2 21/2 21/2 -32 -32 -32 3250

51/2 2 21/2 21/2 -32 -32 -32 3250

7 2:1 2 21/2 21/2 -32 -32 -32 3250

51/2 STD. 21/2 33-32 -32 -32 3300

7 21/2 33-32 -32 -32 3300

8 2:1 21/2 33-32 -32 -32 3300

7 STD. 21/2 33-32 -32 -32 3300

10 2:1 21/2 33-32 -32 -32 3300

*Y and P dimensions as shown on mounting dimensions pages must change to

accommodate these port sizes.

Position Diagram for Ports,

Air Bleeds, Cushion Adjusting

Screws and Cushion Checks

1

2

3

4

5

6

7

8

9

1 1/8" THRU 14" BORES

Porting and Air Bleeds

Port Sizes - Standard ports are S.A.E.

and sizes as shown in Column 5 on the

adjacent chart. Unless otherwise

specified, those sizes are what will be

furnished. Smaller than standard

ports can be supplied at no extra

cost. It is recommended that cylinders

be ordered with ports no larger than

needed so that the trouble and expense

of obtaining and installing reducing

fittings can be avoided. At a modest

cost, larger than standard ports, as

shown in COLUMN 6, can be

furnished. While these larger ports

can be put in a standard cylinder, it is

necessary in some cases to slightly alter

the Y and the P dimensions shown

on our mounting dimension pages.

Contact the factory for those

dimensional changes.

S.A.E. Straight Thread Ports - This

type of port offers positive seal with full

thread engagement. It also eliminates

the problem of faulty

pipe threads since sealing takes

place independently of the thread. No

messy pipe dope to bother with or to

contaminate the hydraulic system. No

wedging, distortion, or breakage due

to over-tightening. Alignment and full

sealing are both assured since the

fittings can be tightened after lining up.

Straight thread fittings may be reused,

indefinitely. COLUMN 6 shows the

maximum size of S.A.E. port that can be

furnished in a standard cylinder. Larger

sizes accommodated with special heads

and caps.

S.A.E. Flanged Ports - At a slight

additional cost, flanged ports can be

provided. COLUMN 7 shows the

maximum standard S.A.E. flange sizes

available.

Air Bleeds

An air bleed may be ordered at either

or both ends of the cylinder as an

option. To provide for maximum

bleeding of air from the cylinder,

Sheffer places its air bleeds in the tube

to bleed air from the tube/head or

tube/cap juncture. The air is bled from

the cylinder by backing out the straight

thread metallic seal plug to allow air to

pass by the threads. When air bubbles

stop and oil starts to flow, retighten

plug. It is recommended that bleeding

be done with pressure on the opposite

end of the cylinder so that the bleed

plug is not subjected to pump pressure

when being backed out. Air bleeds

should always be positioned at the

highest point of the cylinder tube.

Please specify positions of air bleeds by

position number from the chart.

NOTE: Since Sheffer puts air bleeds

in the cylinder tube, position can be

changed by loosening the tie rods and

rotating the tube. Photos and Line

Drawings show ports in positions 1

and 5.

11/2

2

2

1

/2

31/4

4

5

6

7

8

10

12

14

Porting Dimensions

HH- 6

UF

E

E

TF

R

FB

BOLT

SIZE

FB

BOLT

SIZE

G

WF

Y

J

K

WG

VB

MM

ROD

DIA.

EE

P + STROKE

ZB + STROKE

FA

RD - .001

- .003

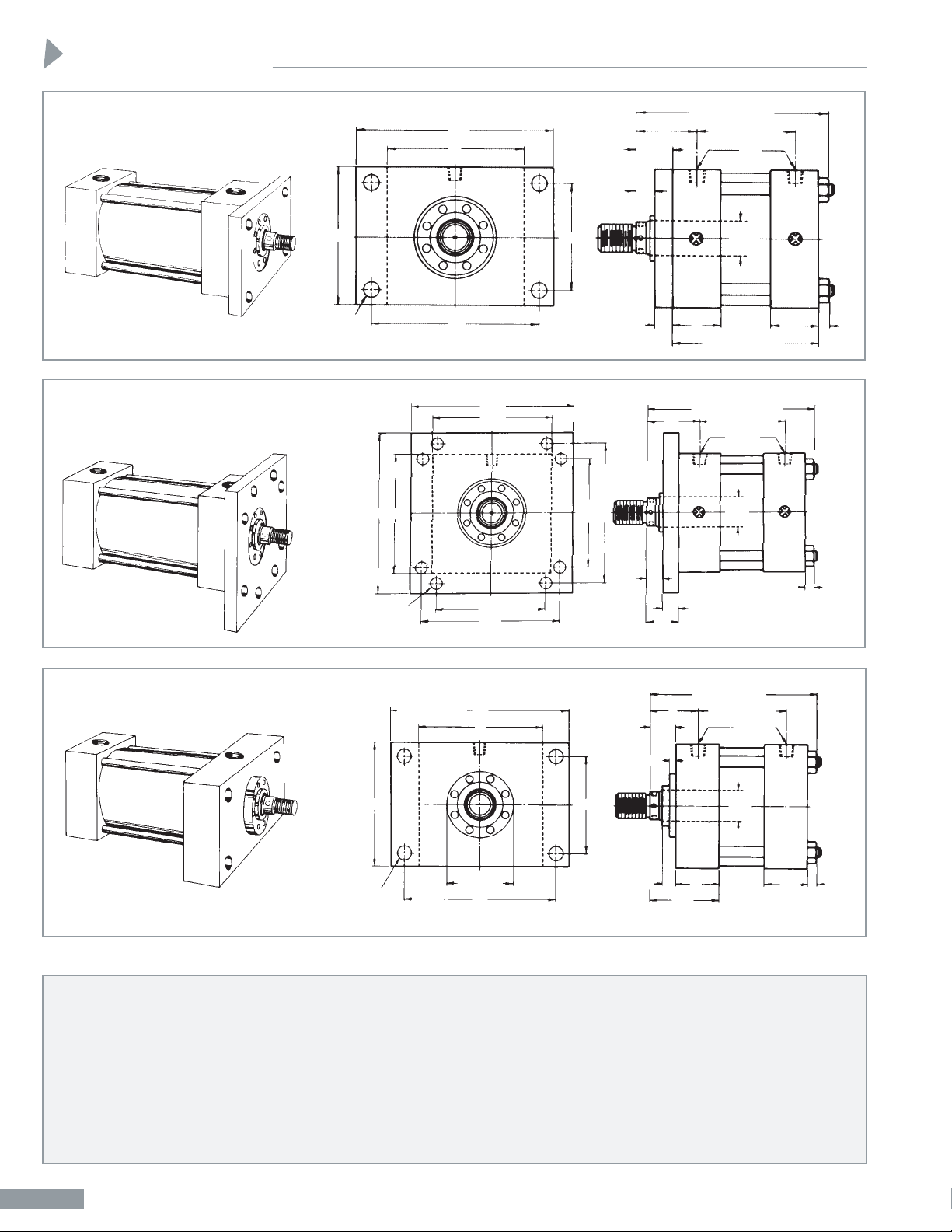

FRONT FLANGE MOUNT

STYLE FF (MF1)*

FRONT FLANGE MOUNT

EXTRA SIZE

STYLE FFX (MF5)*

FRONT HEAD FLANGE MOUNT

STYLE FHF (ME5)*

*ANSI/B93.1-1964 Mounting Style

Designation.

UF

E

E

FB

BOLT

SIZE

TF

R

LB + STROKE

J

G

W

WF

ZB + STROKE

Y

P + STROKE

EE

FF

K

MM

ROD

DIA.

IIMMPPOORRTTAANNTT NNOOTTIICCEE

There is a construction variance in the 11/8", 11/2", 2"

bores, the 21/2" bore with a 13/8" or a 13/4" rod, and in the

31/4" bore with a 2" diameter rod. On the Front Flange

(FF) and Front Flange Extra (FFX) Mounts, in these

sizes, the round retainer shown above is not used. The

tie rods thread into the flange, and the flange serves as

the rod gland retainer. Hence, in these sizes, the gland

cannot be removed without loosening the tie rods. The

basic cylinder dimensions shown above do not change.

On the Front Head Flange Mount (FHF), in the 1

1

/8",

11/2", the 21/2" bore with a 13/4" rod, and the 31/4" bore

with a 2" rod, the retainer is the same rectangular size

as the head. Tie rods thread into the retainer and the

retainer holds in the packing gland. Hence, in these sizes

the gland cannot be removed without loosening the tie

rods. Dimensions for these sizes of the FHF mount

cylinders can be obtained from the Front Flange Mount

(FF) charting. Mounting bolts will clear through both the

flange (FF dimension) and the head (G dimension).

UF

UF E

E

R

R

ZB + STROKE

P + STROKE

EE

MM

ROD

DIA.

Y

W

W

F

FF

K

TF

TF

For assistance in establishing your mounting requirements, also see the s eparate Accessories Brochure.

1000 PSI Rated

FRONT FLANGE MOUNTINGS

Mountings

1

HH-7

Good – Front Flange Mount

While this style of mount is a widely

used one, its use should be restricted

to pressures under 1000 psi, short

strokes (under 36") and standard rod

diameters. Note that the Front Head

Flange mount has the same mounting

hole pattern.

Better – Front Flange

Extra Mount

Satisfactory for maximum operating

pressure and long strokes if properly

applied. See separate Accessories

Brochure for detailed mounting data

and separate Engineering Brochure for

long stroke information.

Best – Front Head Flange

Mount

Highly recommended. This is the best

style of flange mounting. With this

style, the cylinder can be mounted on

the back face of the Head Flange if

desired. This mounting style is used

extensively on high tonnage presses

and other heavy duty applications. To

dimensionally interchange with the FF

mount, see separate Accessories Brochure

for Front Head Flange Spacer Bars.

We highly recommend that consideration be given to the use of a Style 6 rod

end (see pages HH-21 and HH-22)

and S.A.F.E. Coupling (see separate

Accessories Brochure) to achieve good

radial alignment.

Selection of piston rod diameter can be

determined by consulting the separate

Engineering Brochure.

CAUTION

See separate Accessories Brochure

for information concerning the

application of Flange Mount Cylinders.

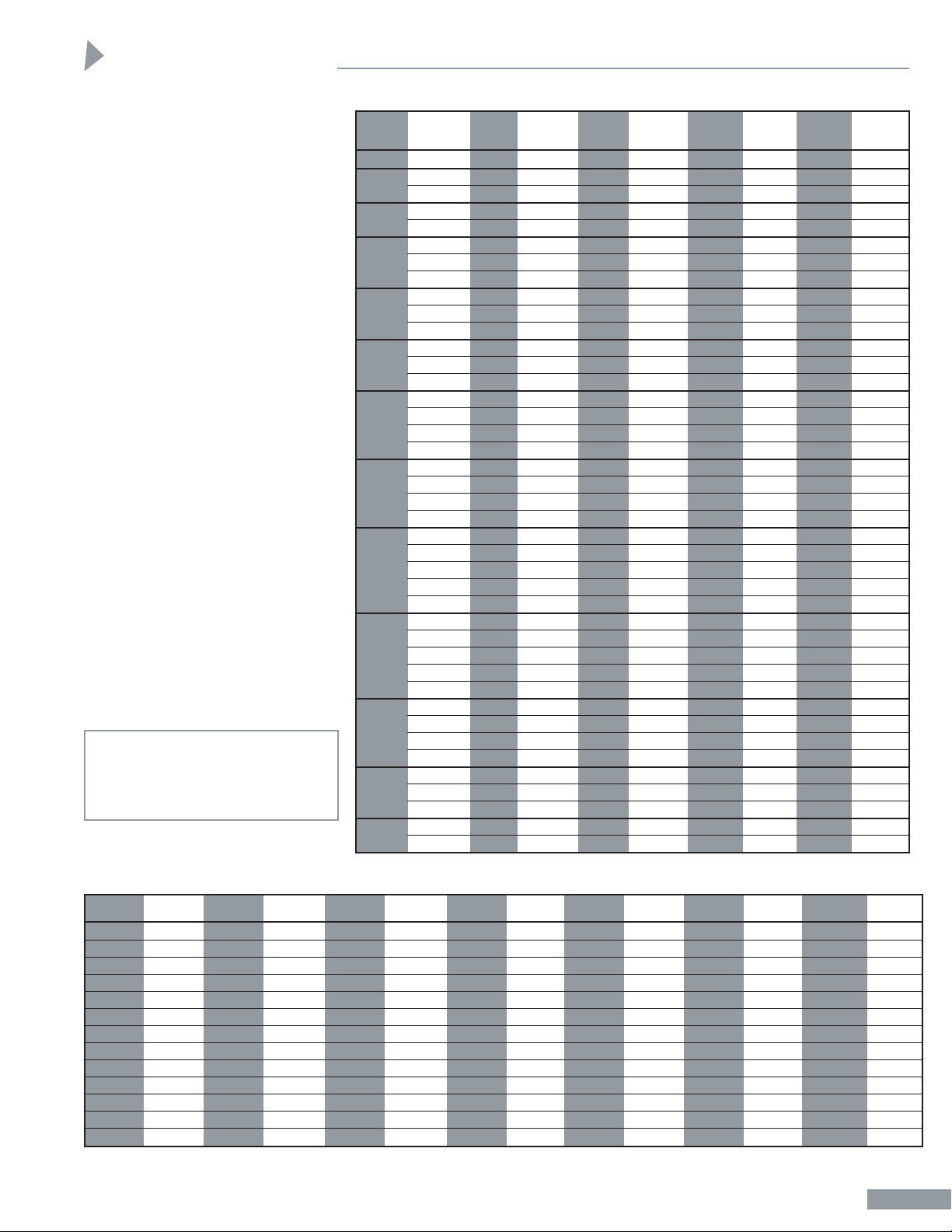

MM

ROD

BORE DIA. FA RD VB W WF WG Y ZB*

11/85/8 STD. — — —

5

/8 11/8 21/4 123/32 45/8*

5

/8 STD. — — —

5

/8 1 23/4 2 515/16*

1 2:1 — — — 1 13/8 31/8 23/8 65/16*

1 STD.

11

/32 2.375

7

/8

3

/4 13/8 31/8 23/8 67/16*

13/8 2:119/32 2.875 1 1 15/8 33/8 25/8 611/16*

1 STD.

11

/32 2.375

7

/8

3

/4 13/8 31/8 23/8 69/16*

13/8

19

/32 2.875 1 1 15/8 33/8 25/8 613/16*

13/4 2:1 — — — 11/4 17/8 35/8 27/8 71/16*

13/8 STD.19/32 2.875 1

7

/8 15/8 35/8 23/4 711/16*

13/4

19

/32 3.250 11/8 11/8 17/8 37/8 3 715/16*

2 2:1 — — — 11/4 2 4 31/8 81/16*

13/4 STD.19/32 3.250 11/8 1 17/8 37/8 3 83/16*

2

19

/32 3.562 11/8 11/8 2 4 31/8 85/16*

21/2 2:119/32 4.000 11/4 13/8 21/4 41/4 33/8 89/16*

2 STD.

19

/32 3.562 11/8 11/8 2 4 31/8 9*

21/2

19

/32 4.000 11/4 13/8 21/4 41/4 33/8 91/4*

3

19

/32 4.750 11/4 13/8 21/4 41/4 33/8 91/4*

31/2 2:123/32 5.187 11/4 13/8 21/4 41/4 33/8 91/4*

21/2 STD.19/32 4.000 11/4 11/4 21/4 45/8 31/2 101/2*

3

19

/32 4.750 11/4 11/4 21/4 45/8 31/2 101/2*

31/2

23

/32 5.187 11/4 11/4 21/4 45/8 31/2 101/2*

4 2:1

23

/32 5.750 11/4 11/4 21/4 45/8 31/2 101/2*

3 STD.

19

/32 4.750 11/4 11/4 21/4 51/8 313/16 1115/16*

31/2

23

/32 5.187 11/4 11/4 21/4 51/8 313/16 1115/16*

4

23

/32 5.750 11/4 11/4 21/4 51/8 313/16 1115/16*

41/2

3

/4 6.250 11/4 11/4 21/4 51/8 313/16 1115/16*

5 2:1

3

/4 6.750 11/4 11/4 21/4 51/8 313/16 1115/16*

31/2 STD.23/32 5.187 11/4 11/4 21/4 51/2 315/16 13*

4

23

/32 5.750 11/4 11/4 21/4 51/2 315/16 13*

41/2

3

/4 6.250 11/4 11/4 21/4 51/2 315/16 13*

5

3

/4 6.750 11/4 11/4 21/4 51/2 315/16 13*

51/2 2:13/4 7.250 11/4 11/4 21/4 51/2 315/16 13*

41/2 STD. 15/8 6.250 115/16 11/4 215/16 613/16 5 163/4*

5 15/8 6.750 23/16 11/2 33/16 71/16 51/4 17*

51/2 15/8 7.250 23/16 11/2 33/16 71/16 51/4 17*

7 2:1 15/8 9.750 23/16 2 311/16 79/16 53/4 171/2*

51/2 STD. 15/8 7.250 23/16 11/4 33/16 81/16 53/4 195/8*

7 15/8 9.75 23/16 17/8 313/16 811/16 63/8 201/4*

8 2:1 17/8 10.875 27/16 27/16 43/8 91/4 615/16 2013/16*

7 STD. 23/8 9.75 213/16 17/8 45/16 911/16 77/16 2315/32*

10 2:1 23/8 13.73 215/16 21/2 415/16 105/16 81/16 243/32*

*Be sure to add stroke to this dimension.

EE EE

BORE E NPT† SAE FB** FF G J K LB* P* R TF UF

11/8 13/4

1

/4 -6

1

/4

1

/2 11/8 1

1

/4 31/4* 23/16* 1.19 23/8 3

11/2 21/2

1

/2 -10

3

/8

3

/8 13/4 11/2

5

/16 45/8* 27/8* 1.63 37/16 41/4

2 3

1

/2 -10

1

/2

5

/8 13/4 11/2

7

/16 45/8* 27/8* 2.05 41/8 51/8

21/2 31/2

1

/2 -10

1

/2

5

/8 13/4 11/2

7

/16 43/4* 3* 2.55 45/8 55/8

31/4 41/2

3

/4 -12

5

/8

3

/4 2 13/4

9

/16 51/2* 31/2* 3.25 57/8 71/8

4 5

3

/4 -12

5

/8

7

/8 2 13/4

9

/16 53/4* 33/4* 3.82 63/8 75/8

5 61/2

3

/4 -12

7

/8

7

/8 2 13/4

3

/4 61/4* 41/4* 4.95 83/16 93/4

6 71/2 1 -16 1 1 23/8 23/8

7

/8 73/8* 47/8* 5.73 97/16 111/4

7 81/2 11/4 -20 11/8 1 27/8 27/8 13/16 81/2* 53/8* 6.58 105/8 125/8

8 91/2 11/2 -24 11/4 1 31/4 31/4 11/4 91/2* 61/8* 7.50 1113/16 14

10 125/8 2 -32 13/4 111/16 37/8 37/8 111/16 121/8* 8* 9.62 157/8 19

12 147/8 21/2 -32 2 115/16 47/8 47/8 115/16 141/2* 93/8* 11.45 181/2 22

14 171/4 21/2 -32 21/4 27/16 53/8 53/8 25/32 17* 103/4* 13.34 211/8 251/4

*Be sure to add stroke to this dimension.

**Clearance holes for indicated bolt size.

†Alternate port at no extra charge. SAE port is standard.

14

12

10

8

7

6

5

4

3

1

/4

21/2

2

1

1

/2

1 1/8" THRU 14" BORES

Dimensions

Front Flange Dimensions

Front Flange Dimensions

HH- 8

Loading...

Loading...