CUSTOM

MANUFACTURED

Heavy-Duty Cylinders

At the

Sheffer

Corporation,

we know the

ins-and-outs

of custom

cylinders like

no one else.

Sheffer’s reputation for excellence

in the production of custom

cylinders is derived from a can-do

attitude that dates back to our

earliest days as an engineering

firm. Since 1952, we have enjoyed

the challenge of conceiving new

ways to achieve high-performance

and we have been motivated by

every opportunity to satisfy a

unique requirement.

Whether your custom cylinder

application is industrial or mobile,

you’ll appreciate our desire to

help...because we can!

Space shuttle workover fixture.

This fixture was built for NASA

and is used to rotate the shuttle’s

main engines. It is actuated by

two, three-stage telescopic Sheffer

cylinders which are capable of

lifting a 300,000 pound load. Each

cylinder has a total stroke of 25'

and a main barrel measuring 19"

OD. Sheffer’s Engineering depart-

ment worked closely with NASA

during the design phase and our

Quality Assurance staff helped the

space agency implement a special

QC program.

There’s no

substitute for

experience when

building specialty

cylinders.

Every day, we manufacture special-

ty cylinders that other compa-

nies can’t make, won’t make or

are reluctant to try. All the while,

we meet the demand for high-

quality custom cylinders that are

exposed to the harshest environ-

ments and roughest conditions. Our

experience encompasses virtually

every industry and possibly the

widest range of cylinder media.

There is little we haven’t seen –

even less we couldn’t produce.

CUSTOM

1

A

A

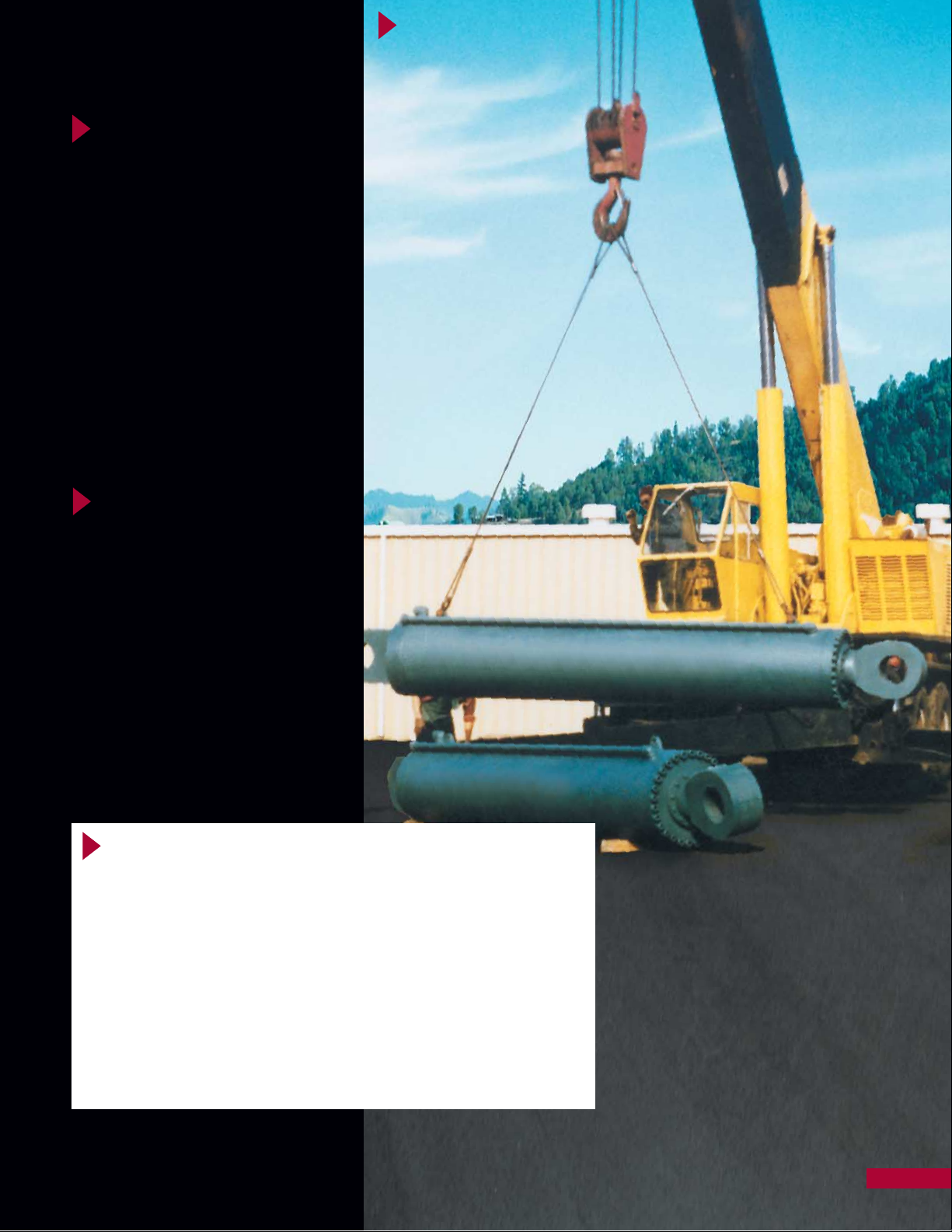

Marine dredge barge cylinders.

These 20,000 pound cylinders

were designed and built to open

and close the split hull of a marine

dredge. Their physical size and

weight required large honing and

machining tools, as well as special

handling equipment. Specific

marine coatings and external seal

arrangements also were necessary.

The cylinders were manufactured

to meet ABS (American Bureau of

Ships) and USCG (United States

Coast Guard) rules of construction.

Cylinders for dumping wood

chips. These three-stage, single

acting, telescopic cylinders were

built for a unique application in

the pulp and paper industry: Lifting

platform and semi-truck trailers to

dump wood chips. The cylinders

required deep hole boring and

honing, and feature a 430" stroke.

Not only did they replace existing

cylinders, but they also dramatically

improved the service life.

2

B

B

C

C

Loading...

Loading...