Sheffer CL User Manual

CL SERIES

Heavy-Duty Clamp Pneumatic

& Hydraulic Cylinders

Pressure Rating:

CLA-150 PSI Pneumatic

CLH-250 PSI Pneumatic

CLH-1,500 PSI Hydraulic

CLA3/4" AND 11/8" BORES & CLH 11/8" BORE ONLY

Construction

1

CL-1

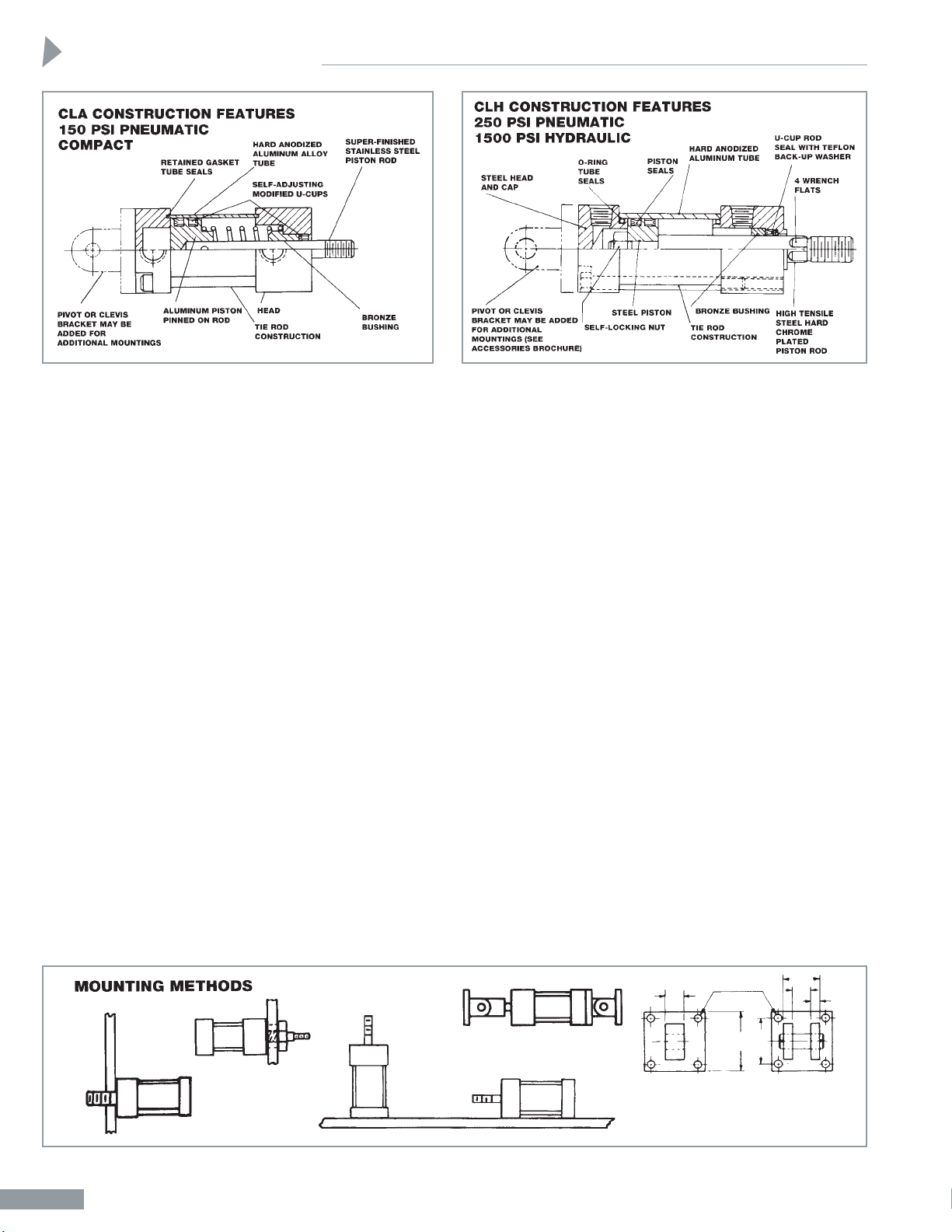

CLA CONSTRUCTION

PISTON RODS are

1

/4" or 5/16" diameter on all CLA cylinders

dependent on bore size. They are super-finished stainless steel

for maximum corrosion resistance.

CYLINDER TUBES are high-tensile aluminum alloy tubing,

hard anodized finish.

PISTONS are aluminum, secured by a roll pin.

HEADS are accurately machined from aluminum bar stock.

SPRINGS employed in the spring return models exert the

following forces to return the piston and rod: The

3

/4" bore

models have a spring which exerts a 4 lbs. force as installed

and a 9.4 lbs. force when compressed by stroke. The 11/8"

bore models rate is 51/2lbs. installed and 9 lbs. compressed.

All spring forces are approximate.

BRONZE BUSHING oil impregnated, for good lubrication

and long life.

CYLINDER ASSEMBLY is held together with high-tensile

steel tie rods. This is recognized by industry to be the best

way to provide pre-stressed construction for rough service.

ROD SEAL is a self-adjusting modified U-cup.

PISTON SEALS are self-adjusting modified U-cups.

TUBE SEALS are flat gaskets, retained type, to prevent any

possible extrusion.

PORTS are

1

/8" N.P.T.

MOUNTING may be accomplished by attaching the head, the

cap, or side mounting by holes provided in the universal

mount. Tie rod holes tapped thru 8-32 or 10-32 for face

mounting. Pivot or clevis mount may be made by attaching

brackets with cap screws provided (See Accessories Brochure).

Stud may be threaded into mounting plate, or secured by use

of jam nut provided.

CLH CONSTRUCTION

PISTON RODS are of adequate size, of approximately

100,000 psi yield steel. They are ground, polished and hard

chrome plated for maximum wear and corrosion resistance.

Wrench flats are standard.

CYLINDER TUBES are high-tensile aluminum alloy with

hard anodized finish.

PISTONS are steel for strength and wear resistance, fastened to

the rod by a self-locking nut.

HEADS are cold rolled steel to provide best strength

characteristics and black oxided for corrosion resistance.

SPRINGS employed in the spring return models exert the

following forces to return the piston and rod: Installed force is

12.8 lbs. Compressed by stroke force is 27.5 lbs. All spring

forces are approximate.

BRONZE BUSHING oil impregnated, for good lubrication

and long life.

CYLINDER ASSEMBLY is held together with high yield

steel tie rods. This is recognized by industry to be the best

way to provide pre-stressed construction for rugged service.

ROD SEAL is a self-adjusting modified U-cup.

PISTON SEALS are self-adjusting modified U-cups.

TUBE SEALS are O-rings located to prevent any possible

extrusion.

PORTS are

1

/4" N.P.T.

MOUNTING may be accomplished by attaching the head, the

cap, or side mounting by holes provided in the universal

mount. Tie rod holes tapped thru for face mounting. Pivot or

Clevis mount may be made by attaching brackets with cap

screws provided (See Accessories Brochure).

PRESSURES of 250 psi pneumatic and up to 1500 psi

hydraulic service.

CLA3/4" AND 11/8" BORES & CLH 11/8" BORE ONLY

Dimensions

1

CL-2

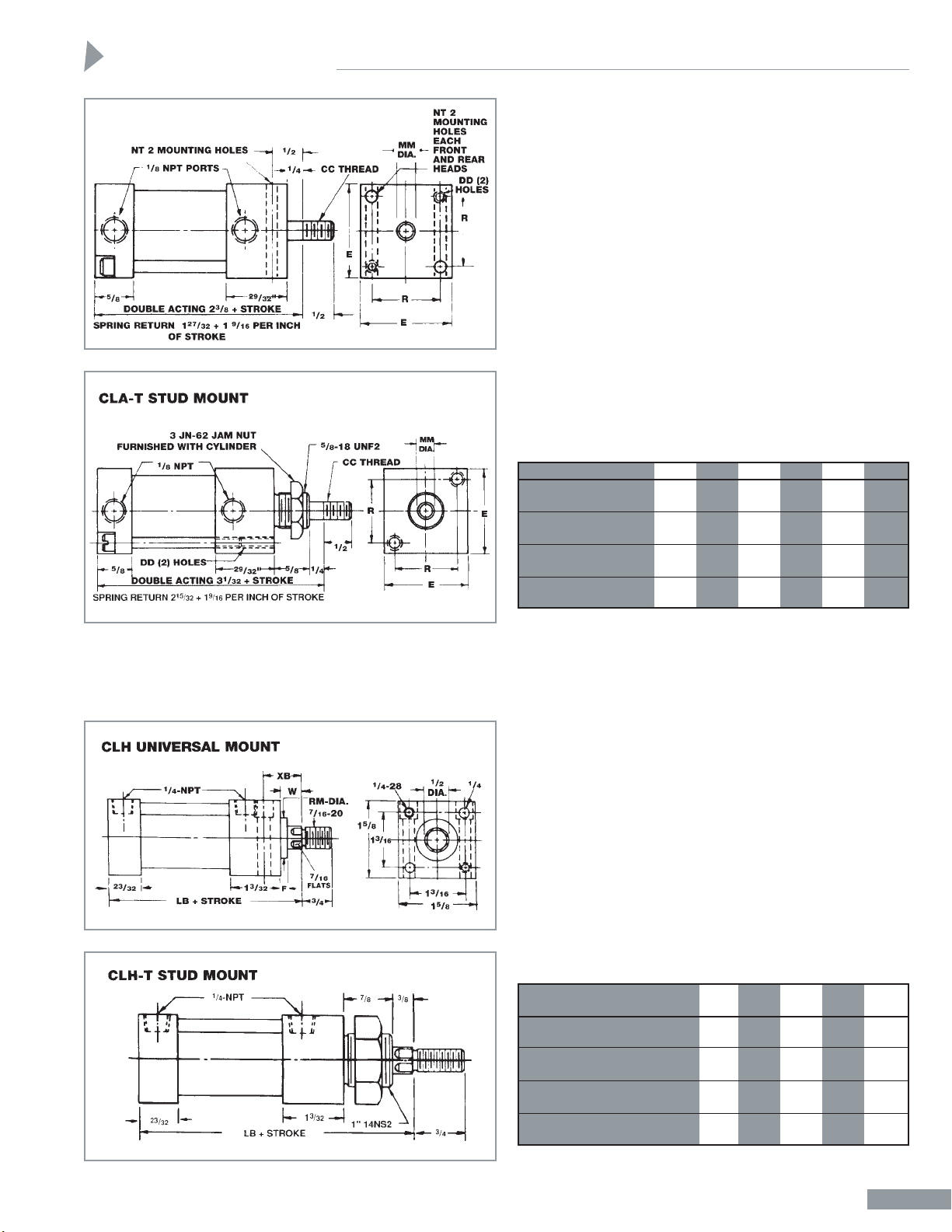

CLA SERIES Dimensions

CLA SERIES cylinders are available in

3

/4" and 11/8" bores,

double acting and spring return, universal and stud mounts,

and in all strokes including fractions of inches. A full line of

accessories is offered. (See Page CL-3)

CLA SERIES cylinders are rated for pneumatic service up to

150 psi. They are pre-lubed and do not require supplemental

lubrication. Like all Sheffer pneumatic cylinders, this offers

the unique advantage of continued operation when the

lubricator is located too distant from the cylinder, when it

has not been refilled, or becomes inoperative. Sheffer prelubed cylinders are also ideal for instrument air systems, food

handling equipment or other applications where it is not

practical or desirable to employ a lubricator or exhaust oil

laden air into the environment.

CLA SERIES cylinders have been specified for years on

automated conveyor systems, automated tool changing

machinery, auto washing equipment, plastic forming presses,

stamping machines, toggle locking mechanisms, and all types

of clamping operations.

CLH SERIES Dimensions

CLH SERIES cylinders are available in a 1

1

/8” bore, doubleacting, spring return, universal mount and stud mount. All

strokes are offered including fractions of an inch.

CLH SERIES cylinders are rated for pneumatic service up

to 250 psi. Used as a pneumatic cylinder, this series is

constructed to satisfy HEAVY DUTY applications. Slightly

higher in cost than the CLA Series, the CLH is an economical

answer to severe operating conditions. See separate

Accessories Brochure.

CLH SERIES cylinders are rated for Hydraulic Service up to

1500 psi providing a low cost solution to small bore, hydraulic

cylinder requirements.

CLA Cylinder Dimensions

DESCRIPTION CC DD E MM NT R

3

/4CLA

UNIVERSAL MOUNT1/4-28 #8-32 11/

8

1

/

4

#8

13

/

16

11/8" - CLA

UNIVERSAL MOUNT 5/16-24 #10-32 11/

2

5

/

16

#10 11/

8

3

/4CLA

STUD MOUNT

1

/4-28 #8-32 11/

8

1

/

4

—

13

/

16

11/8" - CLA

STUD MOUNT

5

/16-24 #10-32 11/

2

5

/

16

— 11/

8

Note: Ports are standard position 1 & 5

CLH Cylinder Dimensions

RM

DESCRIPTION F LB DIA. W XB

11/8" BORE - DOUBLE ACTING1/835/32.9981/

2

7

/

8

UNIVERSAL MOUNT .988

11/8" BORE - SPRING RETURN1/8213/32* .9981/

2

7

/

8

UNIVERSAL MOUNT .988

11/8" BORE - DOUBLE ACTING — 329/32— — —

STUD MOUNT

11/8" BORE - SPRING RETURN — 35/32* — — —

STUD MOUNT

*Spring Return – LB Plus 13/4" per inch of stroke.

Loading...

Loading...