Sheffer AA User Manual

AA SERIES

Light-Duty Aluminum

Pneumatic Cylinders

Pressure Rating 200 PSI

Accurately machined from aluminum

bar stock and black anodized for

protection and attractive appearance.

Piston rods have a minimum expected

yield of 100,000 psi. They are ground,

polished, and hard chrome plated for

wear and corrosion resistance. Four

wrench flats are standard.

The tube is a high tensile, special

Aluminum alloy with a hard anodized

finish. The file-hard finish offers long

life and amazing lubrication holding

properties.

Maximum strength is obtained through

a prestressed tie rod assembly. The use

of tie rods eliminates axial loading of

the tube.

Pistons are machined from a fine grain

alloy cast iron. They are of one piece

design to give full thickness bearing and

engineered for fast, positive inflation of

seals.

Static seals at tube ends are confined,

precision cut gaskets.

Modified U-cup seals are Buna-N

compound. They are self-adjusting to

pressure and wear and their design

permits simple replacement — no need

to disassemble the piston from the

piston rod.

The replaceable rod bearing is made of

oil impregnated sintered bronze for

lubricated long life.

Synthetic wiper, steel encased, is

designed to wipe off abrasive dust and

contaminates on the retract stroke to

insure long life for seals, rod bearing,

and piston rod. This type of wiper is

efficient, has low friction, and can be

replaced without disassembly of the

cylinder.

Modified U-cup design offers long life

with minimum friction. It is selfadjusting to pressure and wear. Seal

material is a standard Buna-N compound. The rod seal can be replaced

without disassembly of the cylinder.

Adjusting screw is O-Ring sealed and

can be rotated to any position for easy

accessibility. When shipped, cushion

adjusting screws will be in positions 1

and 5 (as shown in illustration).

AA SERIES cylinders can be ordered

with no cushions, cushioned front,

cushioned rear, or cushioned both ends.

A modified U-cup gives positive sealing

during cushioning and free flow of air

for rapid acceleration out of cushion.

No check valve is needed.

Cushion insert sandwiched between the

tube and head (or cap) is sealed with a

pressure-activated

O-RING (16A).

11/2", 2" AND 21/2" BORE SIZE

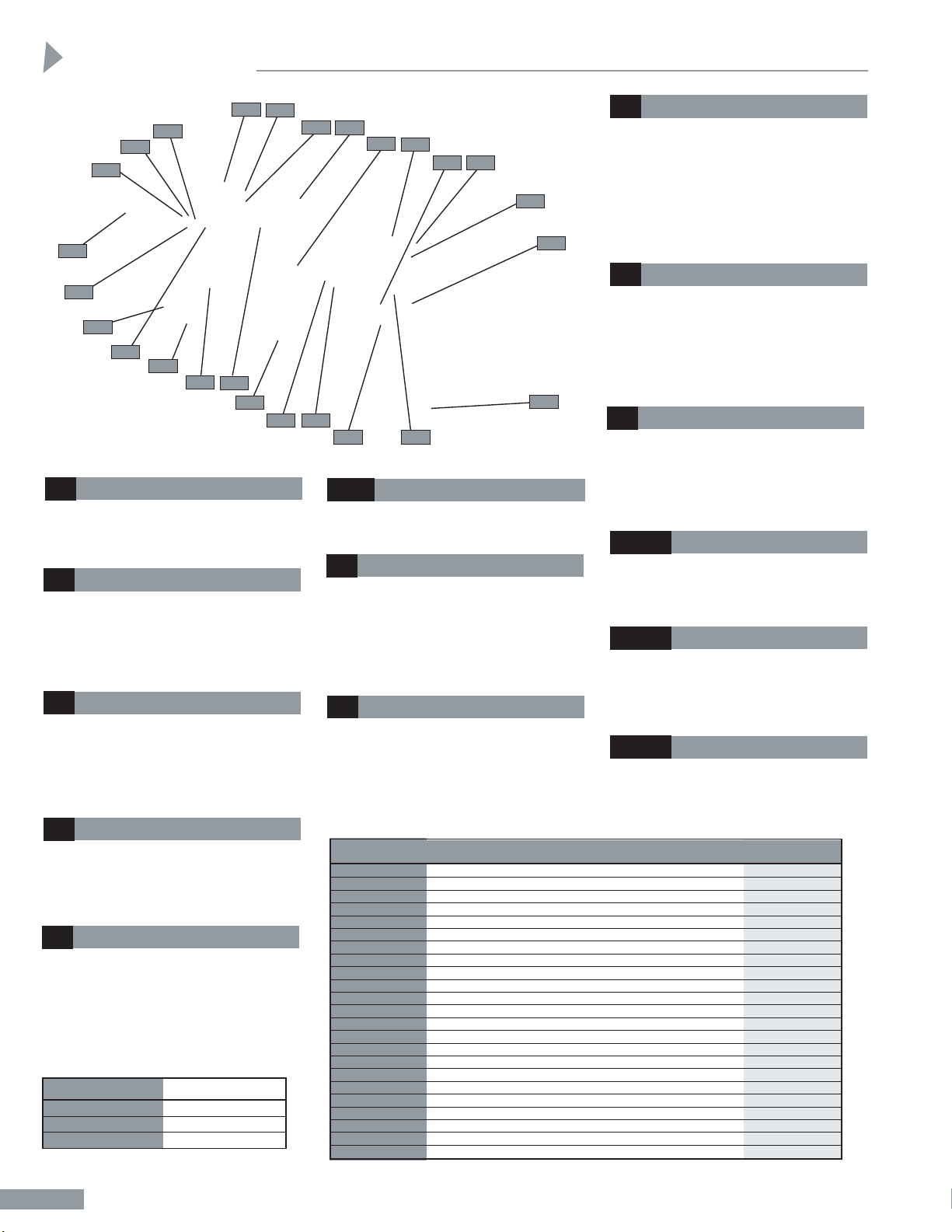

Parts List

24

25

3

27

13

21

1

71

33

5

9 18

72

29

2

16B

30

31

4

29

16A

43 30

31

14

1,2

Head and Cap

3

Piston Rod

4

Tube

5

Tie Rods

9

Piston

16B

Tube End Seals

18

Piston Seals

21

Rod Bearings

24

Rod Wiper

71, 72

Cushion Insert

25

Rod Seal

30

Adjusting Screw

Tie Rod Tourque Chart

CYLINDER TORQUE IN

BORE FOOT LBS.

11/2 6

2 6

2

1

/2 10

33, 43

Cushions

33, 43

Cushion Seal

28

1

AA-1

Parts List

ITEM QUANTITY

NUMBER DESCRIPTION REQUIRED

1 HEAD AND BEARING ASSEMBLY 1

2 CAP 1

3 PISTON ROD 1

4 TUBE 1

5 TIE ROD 4

9 PISTON 1

13 SLEEVE NUT 4

14 PISTON ROD NUT 1

16A† TUBE SEAL—O-RING *

16B† TUBE SEAL—GASKET 2

18† PISTON SEAL 2

21 ROD BEARING 1

24† ROD WIPER 1

25† ROD SEAL 1

27 ROD SEAL SUPPORT WASHER 1

28 ROD SEAL RETAINING RING 1

29 CUSHION PISTON **

30 CUSHION ADJUSTING SCREW *

31† SEAL—CUSHION ADJUSTING *

33† CUSHION SEAL—FRONT *

43† CUSHION SEAL—REAR *

71 CUSHION INSERT—FRONT *

72 CUSHION INSERT—REAR *

†Recommended Spare Parts

*As required: Specify if cushioned front, cushioned rear or cushioned both ends.

**Used on all cushioned front cylinders. Used on cushioned rear cylinders bore sizes 11/2" and 2" only.

31

/32

9

/16

9

/16

1

/4 NPT

1

/2 DIA.

ROD

P + STROKE

ZJ + STROKE

SN +

STROKE

LB +

STROKE

1

1

15

/32

3

/4

7

/16-20

7

/16

WRENCH

FLATS

3

/8-16 1/2" DEEP ON 11/2" BORE, 5/8" DEEP ON

2, 2

1

/2" BORES (3) HOLES EACH HEAD

1

/4-28 5/16" DEEP ON HEAD, 1/2"

DEEP ON CAP (4) HOLES EACH HEAD

E/2

TN

TN

E

E

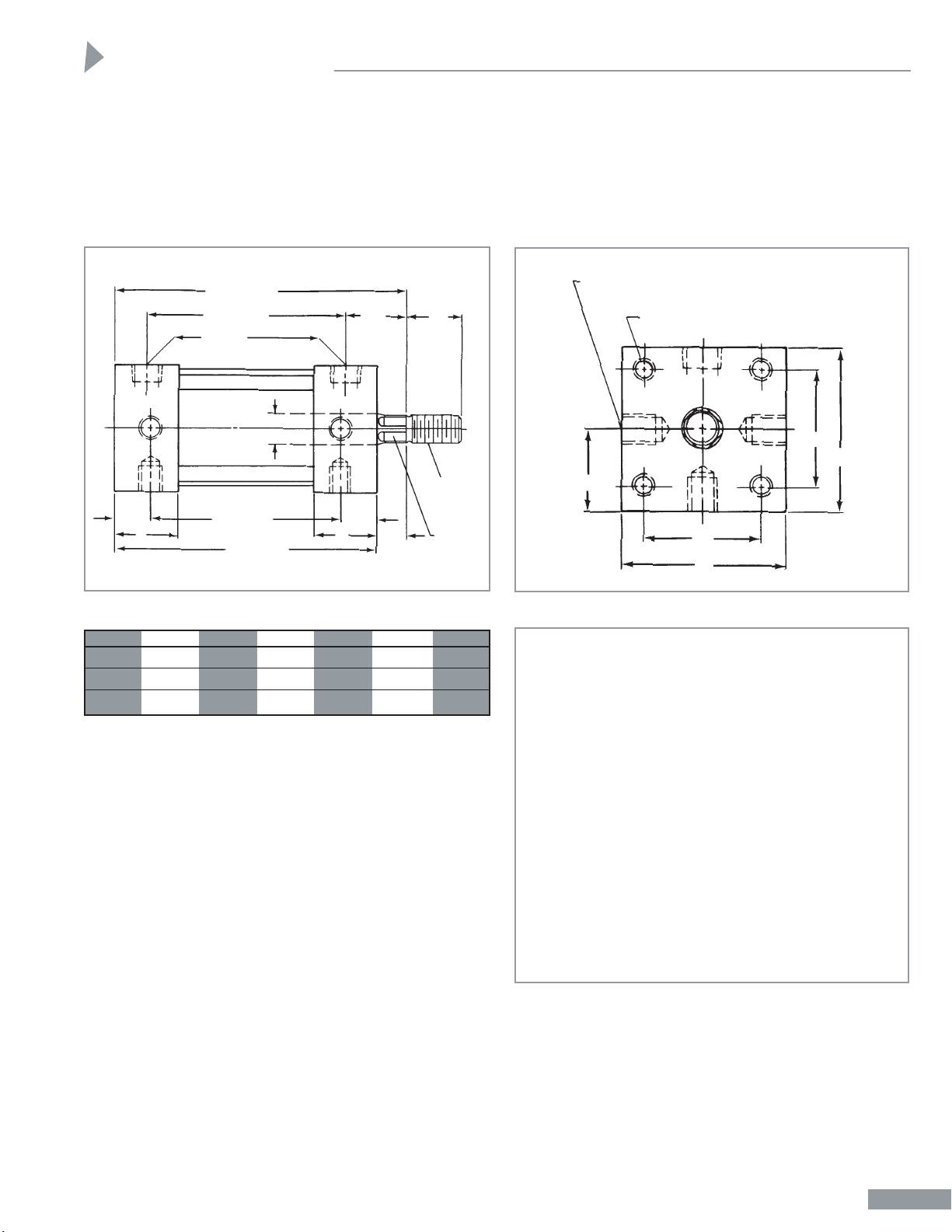

Dimensions for Cusioned Cylinders

Adding a cushion or cushions to a cylinder increases overall

length. A front cushion or rear cushion adds 1 inch to all plus

stroke dimensions. Cushioning a cylinder on both ends adds 2

inches to all plus stroke dimensions.

Double Rod End Cylinders

All dimensions shown below remain unchanged. Second rod

(not shown in dimension drawing) will extend from face of

head the total of the stroke plus 15/32" plus the threaded rod

end dimension.

BORE E LB* P* SN* TN ZJ*

11/2 2 27/8 17/8 13/4 17/16 311/32

2 21/2 27/8 17/8 13/4 127/32 311/32

21/2 3 3 2 17/8 23/16 315/32

*Plus Stroke Dimensions

Universal Mount

The basic cylinder is equipped with Universal Mounting Holes

that permit side flush mount, front head mount and rear head

mount. Using optional mounting kits, shown on Page AA-3,

complete versatility is achieved to satisfy any mounting

requirement and to do so economically.

TP-AA Trunnion Pin Assemblies thread into 3/8–16 holes on

sides of head.

NOTE: For Pivot and Clevis Bracket Mounts, use Mounting

Brackets dimensioned on Page AA-3. Use

1

/4

–28 Cap Screws

supplied to bolt brackets to rear head.

Front Flange, Rear Flange and Foot Bracket Mount use

Universal Mounting Brackets (See Page AA-3).

Affix brackets by using 3/8–16 holes on sides of head and

FMS-AA mounting screws.

Use 1/4–28 cap screws supplied to bolt brackets to each head

as shown.

Dimensions

AA-2

Loading...

Loading...