Page 1

XV-Z9000U/E

SERVICE MANUAL

SERVICE-ANLEITUNG

S81Y7XVZ9000U

DLP PROJECTOR

DLP PROJEKTOR

MODELS

MODELLE XV-Z9000U/E

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

Im lnteresse der Benutzersicherheit (erforderliche Sicherheitsregeln in einigen Ländern) muß das Gerät in seinen

Originalzustand gebracht werden. Außerdem dürfen für die spezifizierten Bauteile nur identische Teile verwendet

werden.

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

1

Page 2

XV-Z9000U/E

• SPECIFICATIONS ............................................. 3

• INPOTANT SERVICE SAFETY NOTES ............ 4

• OPERATION MANUAL ...................................... 8

• REMOVING OF MAJOR PARTS ..................... 14

• RESETTING THE TOT AL LAMP TIMER ......... 20

• THE OPTICAL UNIT OUTLINE........................ 21

• ELECTRICAL ADJUSTMENT.......................... 24

• TROUBLE SHOOTING TABLE........................ 32

• CHASSIS LAYOUT .......................................... 92

• BLOCK DIAGRAM ........................................... 94

• OVERALL WIRING DIAGRAM ........................ 96

• DESCRIPTION OF SCHEMATIC DIAGRAM... 98

• WAVEFORMS.................................................. 99

CONTENTS

Page Page

• SCHEMATIC DIAGRAM ................................ 100

• PRINTED WIRING BOARD ASSEMBLIES ... 133

• P ARTS LIST

Ë

ELECTRICAL PARTS............................... 140

Ë

CABINET AND MECHANICAL PARTS .... 154

Ë

ACCESSORIES PARTS........................... 158

Ë

P ACKING PARTS ..................................... 158

• PACKING OF THE SET ................................. 159

Seite Seite

• TECHNISCHE DATEN..................................... 49

• HINWEISE FÜR DAS

WARTUNGSPERSONAL................................. 50

• BEDIENUNGSANLEITUNG............................. 51

• ENTFERNEN DER HAUPTTEILE ................... 57

• RÜCKSTELLEN DES

LAMPENBETRIEBSZEIT-TIMERS.................. 63

• BESCHREIBUNG DER OPTIK-EINHEIT ........ 64

• ELEKTRISCHE EINSTELLUNG ...................... 67

• FEHLERSUCHTABELLE ................................. 75

• CHASSIS-ANORDNUNG ................................ 92

• BLOCKSCHALTBILD ....................................... 94

• GESAMTSCHALTPLAN................................... 96

INHALT

• BESCHREIBUNG DES SCHEMATISCHEN

• WELLENFORMEN........................................... 99

• SCHEMATISCHER SCHALTPLAN................ 100

• LEITERPLATTENEINHEITEN ....................... 133

• ERSATZTEILLISTE

• VERPACKEN DES GERÄTS ......................... 159

SCHALTPLANS ............................................... 98

Ë

ELEKTRISCHE BAUTEILE ...................... 140

Ë

CEHÄUSE UND MECHANISCHE

BAUTEILE ................................................ 154

Ë

ZUBEHÖRTEILE...................................... 158

Ë

VERPACKUNGSTEILE ............................ 158

2

Page 3

Specifications

Product type DLP Projector

Video system

Computer VGA/SVGA/XGA/SXGA

Display method Single panel Digital Micromirror Device™(DMD™) by Texas Instraments

DMD panel Panel size:0.8" (20.3mm)

Projection lamp 250 W NSH lamp

Contrast ratio 1000:1

Video input signal RCA Connector:VIDEO,composite video,1.0 Vp-p,sync negative,75 Ω terminated (INPUT 4)

S-video input signal 4-pin Mini DIN connector (INPUT 3)

Component input signal RCA connector (INPUT 1 and 2 terminals)

Horizontal resolution 720 TV lines (DTV 720P input)

DC output 12V. MAX CURRENT 200mA CENTER + TYPE

Computer RGB input signal 15-PIN MINI D-SUB CONNECTOR (INPUT 5 port):

Wired Remote Control 3.5 ø Mini jack

Pixel clock 12 – 120MHz

Vertical frequency 43 – 100Hz

Horizontal frequency 15 – 80 kHz

Computer control signal 9-pin D-Sub male connector (RS-232C port)

Rated voltage AC 100 – 240 V

Input current 3.6 A

Rated frequency 50/60 Hz

Power consumption 345 W (Selecting "BRIGHT" in the "Theater Mode".)

Operating temperature+ 5 °C to + 35 °C (41 °F to + 95 °F )

Storage temperature− 20 °C to + 60 °C (− 4 °F to + 140 °F)

Cabinet Plastic

I/R carrier frequency 38 kHz

Dimensions (approx.) 18 11⁄16" (W) X 7" (H) X 15 15⁄50" (D)(475 X 178 X 406mm)(main body only)

Weight (approx.) 20.9 lbs.(9.5 kg)

Supplied accessories Remote control, Two AA size batteries, Power cord (1 1' 10" ,3.6 m(XV-Z9000U), 1.8m(XV -Z9000E)),

Replacement parts Lamp unit (Lamp/cage module) (BQC-XVZ9000/1), Remote control (RRMCG1657CESA), AA size

XV-Z9000U/E

Model XV-Z9000U/E

PAL/PAL 60/PAL- M/PAL- N/SECAM/NTSC 3.58/NTSC 4.43/DTV 480I/DTV 480P/DTV 720P/DTV 1080I

No.of dots:921,600 dots (1280 [H ] X 720 [V ])

Lens 1 – 1.35X zoom lens, F3, f = 32.5 – 44.0 mm

Y (luminance signal):1.0 Vp-p,sync negative,75 Ω terminated

C (chrominance signal):Burst 0.286 Vp-p,75 Ω terminated

Y:1Vp-p, sync negative, 75 Ω terminated

PB/PR:0.7Vp-p, 75 Ω terminated (XV-Z9000U)

CB/CR:0.7Vp-p, 75 Ω terminated (XV-Z9000E)

RGB separate/composite sync/sync on green type analog input:0 – 0.7 Vp-p,positive,

75 Ω terminated

HORIZONTAL SYNC.SIGNAL:TTL level (positive/negative)or composite sync (Apple only)

VERTICAL SYNC.SIGNAL:Same as above

18 11⁄16" (W) X 8" (H) X 19 1⁄2" (D)(475 X 203 X 496 mm)(including terminal cover and

adjustment feet)

Lens cap (attached), DLP projector operation manual, CD-ROM, CD-ROM operation manual,

Terminal cover, Video cable(XV-Z9000E), VGA cable(XV-Z9000E), 21pin-RCA adaptor(XVZ9000E), Guarrantee card for U.S., Guarrantee card for CANADA.

batteries, Power cord (CACCU5013DE01 (XV-Z9000U), QACCV4002CEZZ (XV-Z9000E),

QACCB5024CENA (XV -Z9000E)), Lens cap (PCAPH1056CESA),DLP projector operation manual

(TINS-7415CEZZ (XV-Z9000U), TINS-7521CEZZ (XV-Z9000E)), CD-ROM(UDSKA0047CEN1),

CD-ROM operation manual (TINS-7418CEZZ (XV-Z9000U), TINS-7523CEZZ (XV-Z9000E)), V ideo

cable(QCNWGA001WJZZ(XV-Z9000E)), VGA cable(QCNW-5050CEZZ(XV -Z9000E)), 21pin-RCA

adaptor(QSOCZ0361CEZZ(XV-Z9000E)), Guarrantee card for U.S.(TGAN-1670CEZZ),

Guarrantee card for CANADA (TGAN-1671CEZZ).

This SHARP projector uses a DMD panels.This very sophisticated

panels contain 921,600 pixels. As with any high technology electronic equipment such as large screen TVs,video systems and video

cameras, there are certain acceptable tolerances that the equipment must conform to.

Specifications are subject to change without notice.

This unit has some inactive pixels within acceptable tolerances which

may result in inactive dots on the picture screen.This will not affect

the picture quality or the life expectancy of the unit.

If you have any questions about this matter,please call toll free 1888-GO-SHARP (1-800-237-4277). U.S.A.ONLY

3

Page 4

XV-Z9000U/E

2

2

IMPORTANT SERVICE SAFETY NOTES (for USA)

Ë Service work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and servicing guidelines as follows:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE PROJECTOR:

(Fire & Shock Hazard)

Before returning the projector to the user, perform

the following safety checks:

1. Inspect lead wires are not pinched between the

chassis and other metal parts of the projector.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

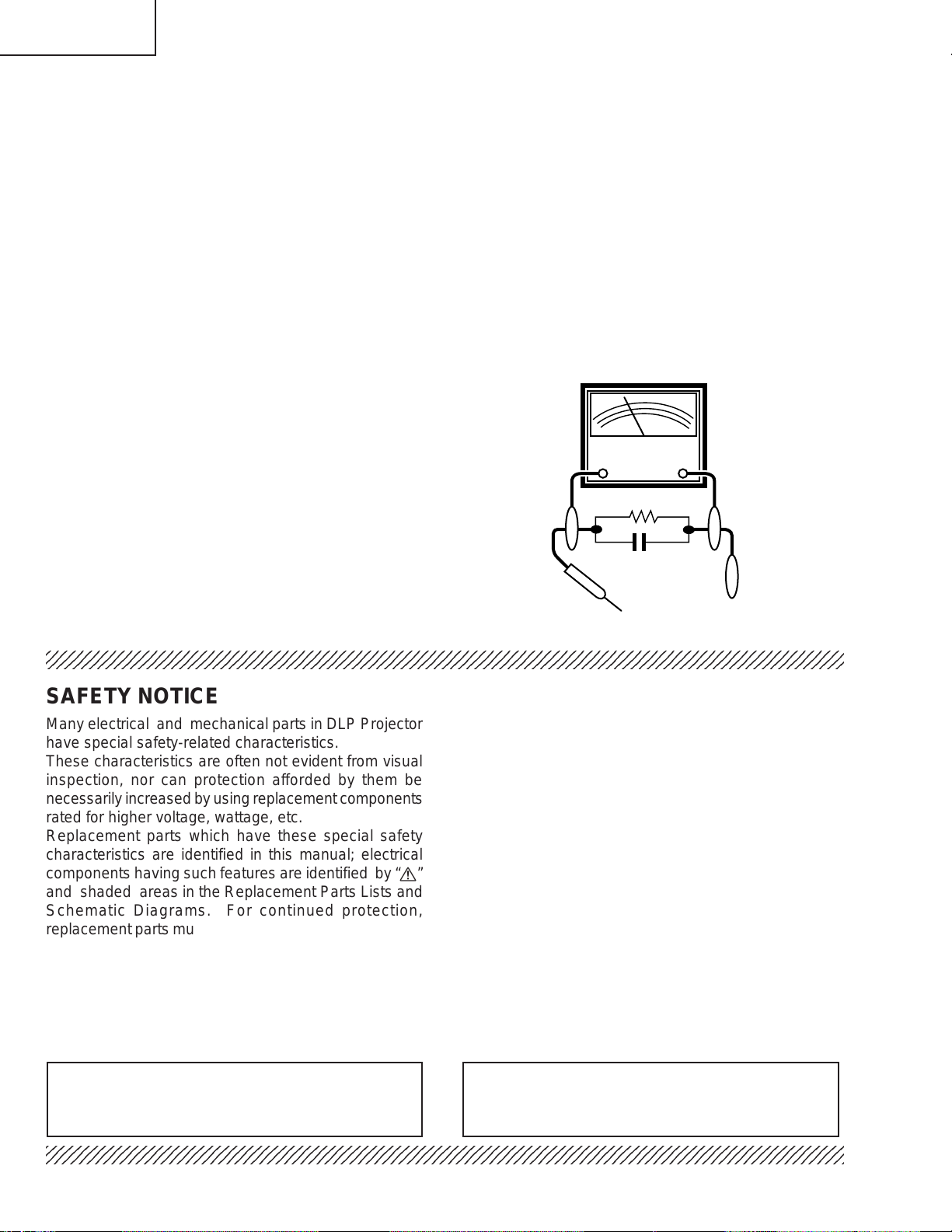

3. To be sure that no shock hazard exists, check for

current leakage in the following manner:

» Plug the AC cord directly into a 120-volt AC outlet,

(Do not use an isolation transformer for this test).

» Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in parallel

between all exposed metal cabinet parts and earth

ground.

» Use an AC voltmeter with sensitivity of 5000 ohm per

volt., or higher, sensitivity to measure the AC voltage

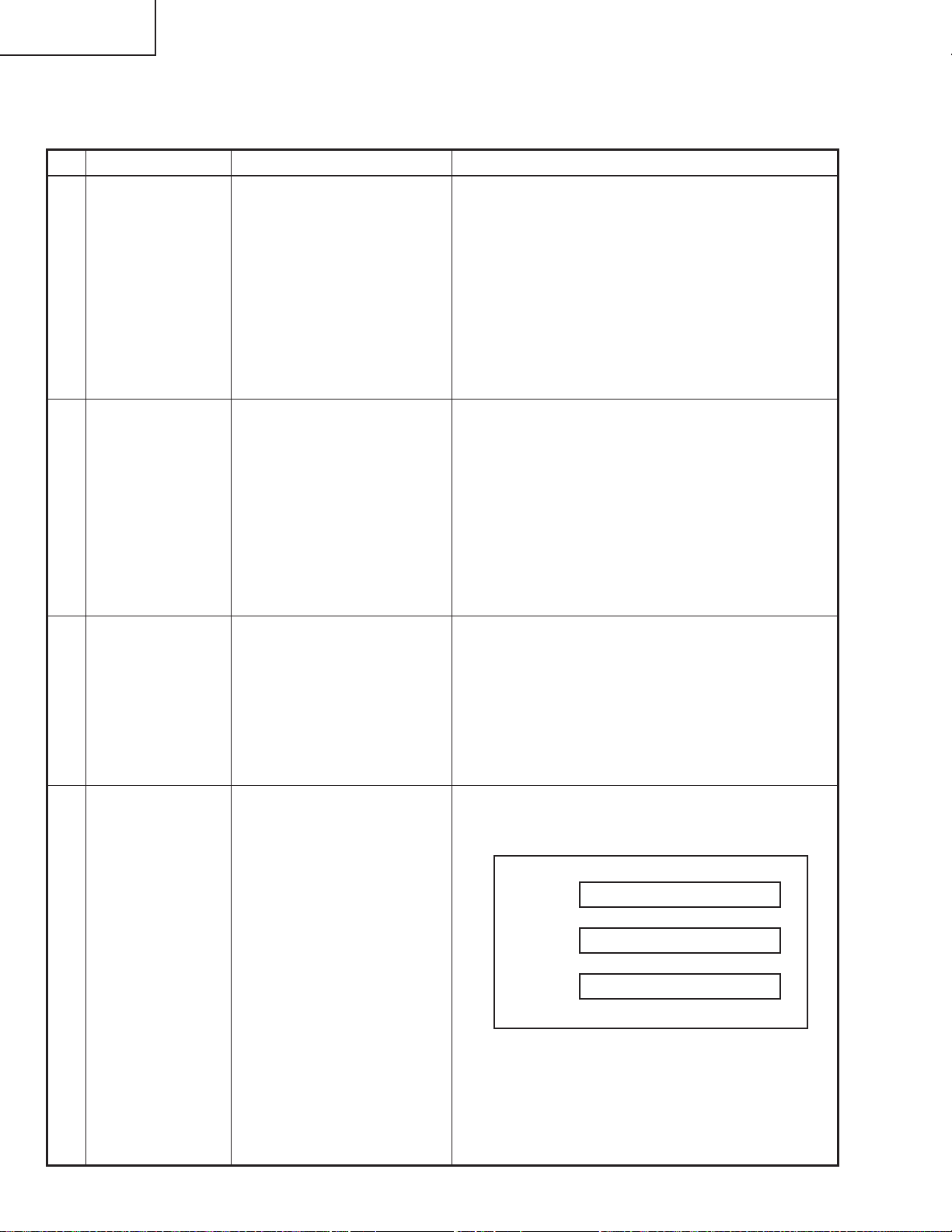

drop across the resistor (See Diagram).

» All checks must be repeated with the AC plug

connection reversed. (If necessary , a non-polarized

adapter plug must be used only for the purpose of

completing these checks.)

Any reading of 0.3 volts RMS (this corresponds to

0.2 milliamp. AC.) or more is excessive and indicates

a potential shock hazard which must be corrected

before returning the unit to the owner.

AC

VOLTMETER

1.5k ohm (10W)

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO KNOWN

EARTH GROUND

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

SAFETY NOTICE

Many electrical and mechanical parts in DLP Projector

have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by “å”

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams. For continued protection,

replacement parts must be identical to those used in the

original circuit. The use of a substitute replacement parts

which do not have the same safety characteristics as

the factory recommended replacement parts shown in

this service manual, may create shock, fire or other

hazards.

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les projecteur à DLP présentent des caractéristiques

spéciales relatives à la sécurité, qui ne sont souvent

pas évidentes à vue.

Le degré de protection ne peut pas être nécessairement

augmentée en utilisant des pièces de remplacement

étalonnées pour haute tension, puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel;

les pièces électriques qui présentent ces particularités

sont identifiées par la marque “å” et hachurées dans la

liste des pièces de remplacement et les diagrammes

schématiques. Pour assurer la protection, ces pièces

doivent être identiques à celles utilisées dans le circuit

d’origine. L’utilisation de pièces qui n’ont pas les mêmes

caractéristiques que les pièces recommandées par

l’usine, indiquées dans ce manuel, peut provoquer des

électrocutions, incendies ou autres accidents.

WARNING: The bimetallic component has the primary

conductive side exposed. Be very careful in

handling this component when the power is on.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

AVERTISSEMENT: La composante bimétallique dispose du

conducteur primaire dénudé. Faire

attention lors de la manipulation de cette

composante sous tension.

4

Page 5

XV-Z9000U/E

5

5

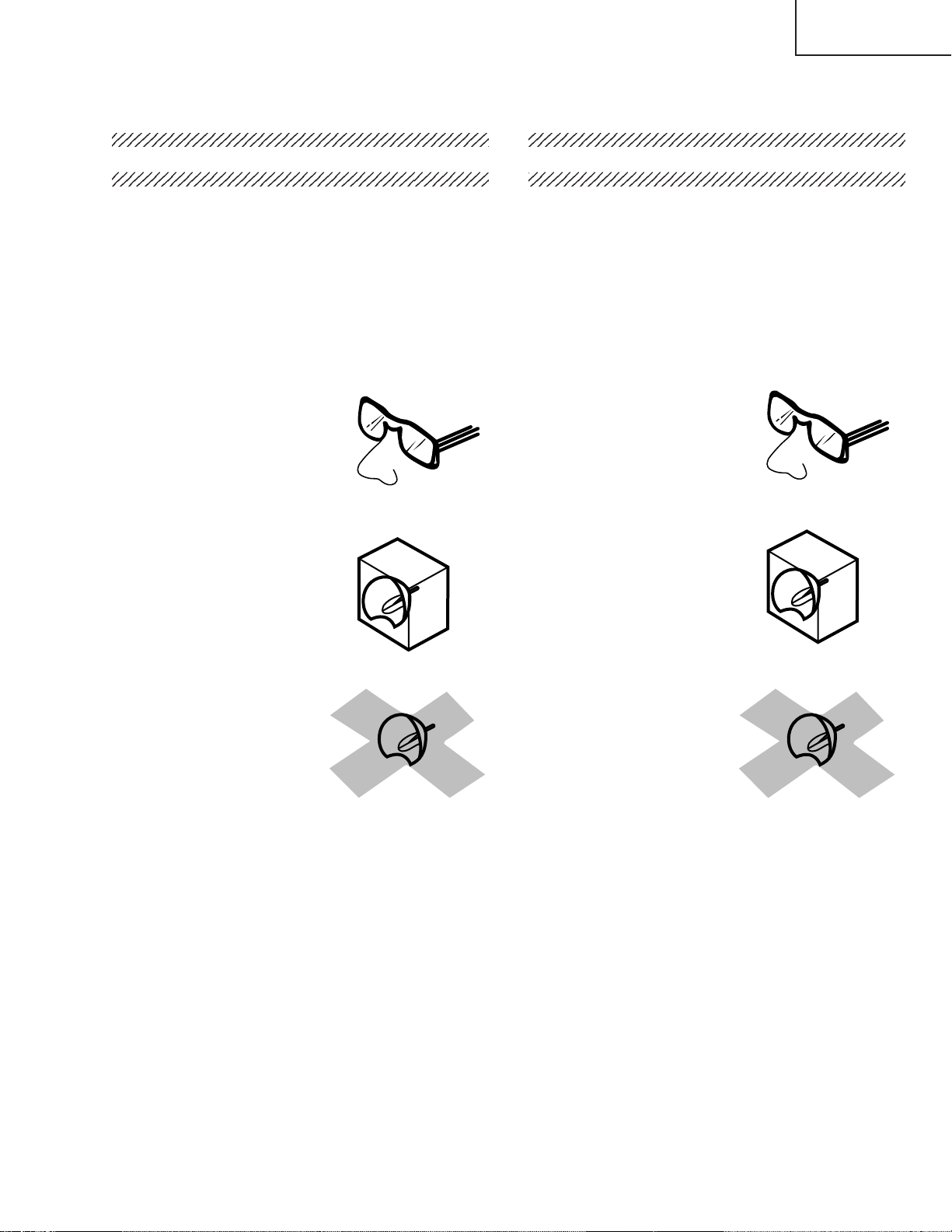

NOTE TO SERVICE

PERSONNEL

UV-RADIATION PRECAUTION

234567890123456789012345678901212345678901234

The light source, lamp, in the projector emits small

amounts of UV-Radiation.

A VOID DIRECT EYE AND SKIN EXPOSURE.

To ensure safety please adhere to the following:

1. Be sure to wear sun-glasses when servicing the

projector with the lamp

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

NOTE POUR LE PERSONNEL

D’ENTRETIEN

PRECAUTION POUR LES RADIATIONS UV

234567890123456789012345678901212345678901234

La source de lumière, la lampe , dans le projecteur

émet de petites quantités de radiation UV.

EVITEZ TOUTE EXPOSITION DIRECTE

DES YEUX ET DE LA PEAU.

Pour votre sécurité, nous vous prions de respecter

les points suivants:

1. Toujours porter des lunettes de soleil lors d’un

entretien du projecteur

avec la lampe allumée

et le haut du coffret retiré.

2. Ne pas faire fonctionner la lampe à l’extérieur du

boîtier de lampe.

3. Do not operate for more than 2 hours with the

enclosure removed.

UV-Radiation and Medium Pressure

Lamp Precautions

1. Be sure to disconnect the AC plug when replacing

the lamp.

2. Allow one hour for the unit to cool down before

servicing.

3. Replace only with same type lamp. Type BQCXVZ9000/1 rated 355V/250W.

4. The lamp emits small amounts of UV-Radiation, avoid

direct-eye contact.

5. The medium pressure lamp involves a risk of

explosion. Be sure to follow installation instructions

described below and handle the lamp with care.

3. Ne pas faire fonctionner plus de 2 heures avec le

coffret retiré.

Précautions pour les radiations UV

et la lampe moyenne pression

1. Toujours débrancher la fiche AC lors du

remplacement de la lampe.

2. Laisser l’unité refroidir pendant une heure avant de

procéder à l’entretien.

3. Ne remplacer qu’avec une lampe du même type.

Type BQC-XVZ9000/1, caractéristique 355V/250W.

4. La lampe émet de petites quantités de radiation UVéviter tout contact direct avec les yeux.

5. La lampe moyenne pression implique un risque

d’explosion. Toujours suivre les instructions

d’installation décrites ci-dessous et manipuler la

lampe avec soin.

5

Page 6

XV-Z9000U/E

5

4

5

5

234567890123456789012345678901212345678901234

UV-RADIATION PRECAUTION (Continued)

23456789012345678901234567890121234567890123

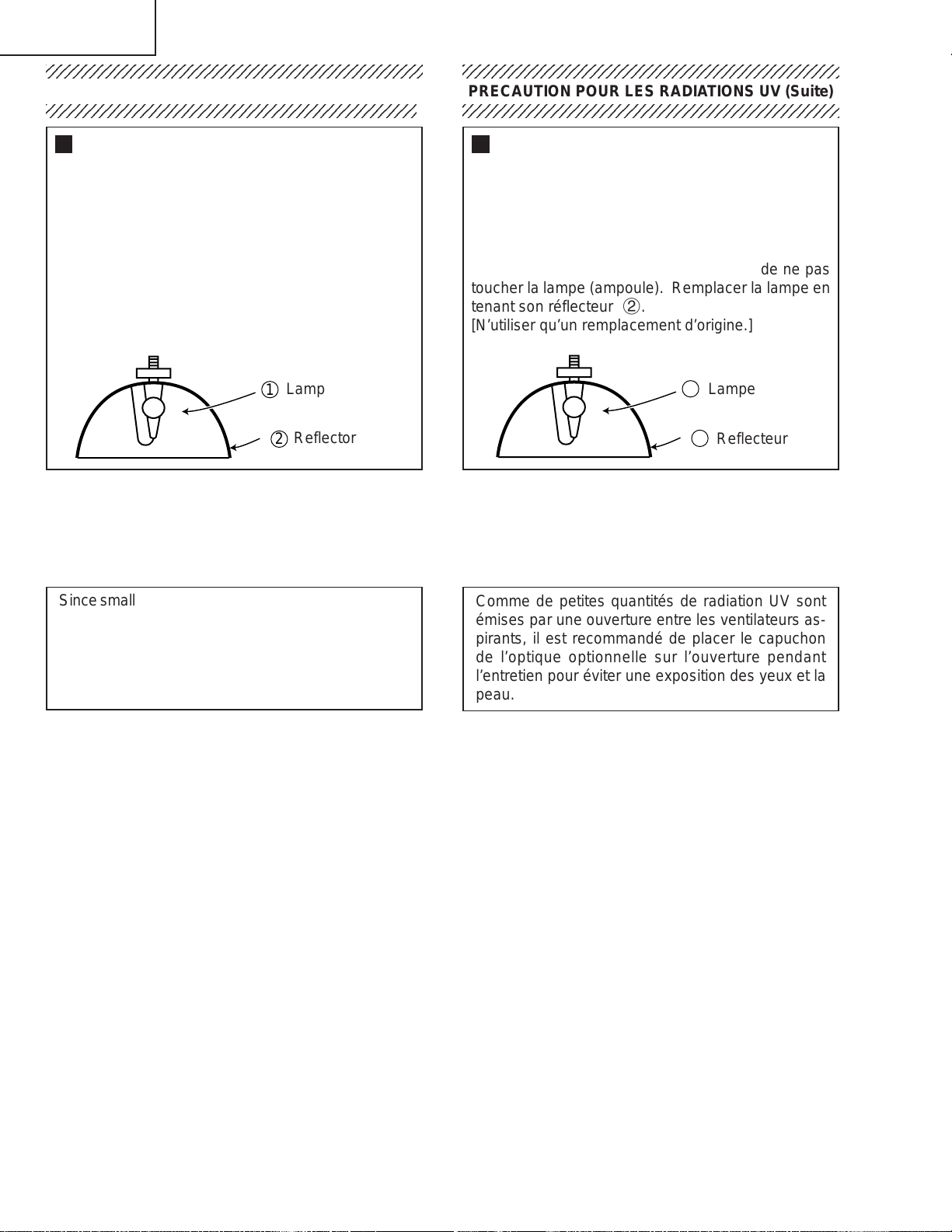

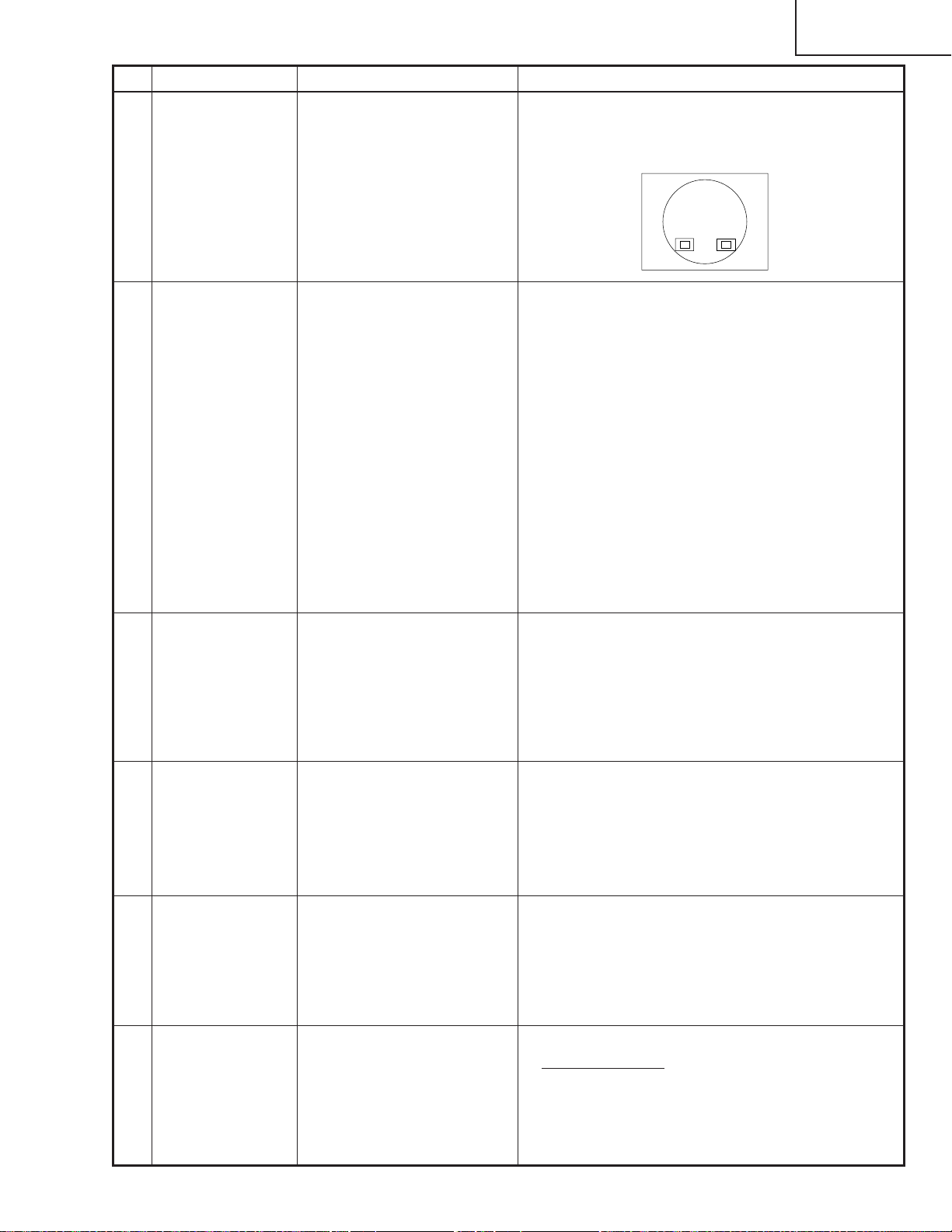

Lamp Replacement

Note:

Since the lamp reaches a very high temperature

during units operation replacement of the lamp

should be done at least one hour after the power

has been turned off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

2.

[Use original replacement only.]

Lamp

1

Reflector

2

DANGER ! –– Never turn the power on without the

lamp to avoid electric-shock or damage of the

devices since the stabilizer generates high voltages

at its start.

234567890123456789012345678901212345678901234

PRECAUTION POUR LES RADIATIONS UV (Suite)

234567890123456789012345678901212345678901234

Remplacement de la lampe

Remarque:

Comme la lampe devient très chaude pendant le

fonctionnement de l’unité, son remplacement ne doit

être effectué au moins une heure après avoir coupé

l’alimentation (pour permettre à la lampe de refroidir).

En installant la nouvelle lampe, s’assurer de ne pas

toucher la lampe (ampoule). Remplacer la lampe en

tenant son réflecteur 2.

[N’utiliser qu’un remplacement d’origine.]

1

Lampe

2

Reflecteur

DANGER ! –– Ne jamais mettre sous tension sans

la lampe pour éviter un choc électrique ou des

dommages des appareils car le stabilisateur génère

de hautes tensions à sa mise en route.

Since small amounts of UV-radiation are emitted from

an opening between the exhaust fans, it is recommended to place the cap of the optional lens on the

opening during servicing to avoid eye and skin exposure.

Comme de petites quantités de radiation UV sont

émises par une ouverture entre les ventilateurs aspirants, il est recommandé de placer le capuchon

de l’optique optionnelle sur l’ouverture pendant

l’entretien pour éviter une exposition des yeux et la

peau.

6

Page 7

XV-Z9000U/E

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

WARNING: High brightness light source, do not stare into the beam of light, or view directly . Be especially

careful that children do not stare directly in to the beam of light.

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS UNIT TO

MOISTURE OR WET LOCATIONS.

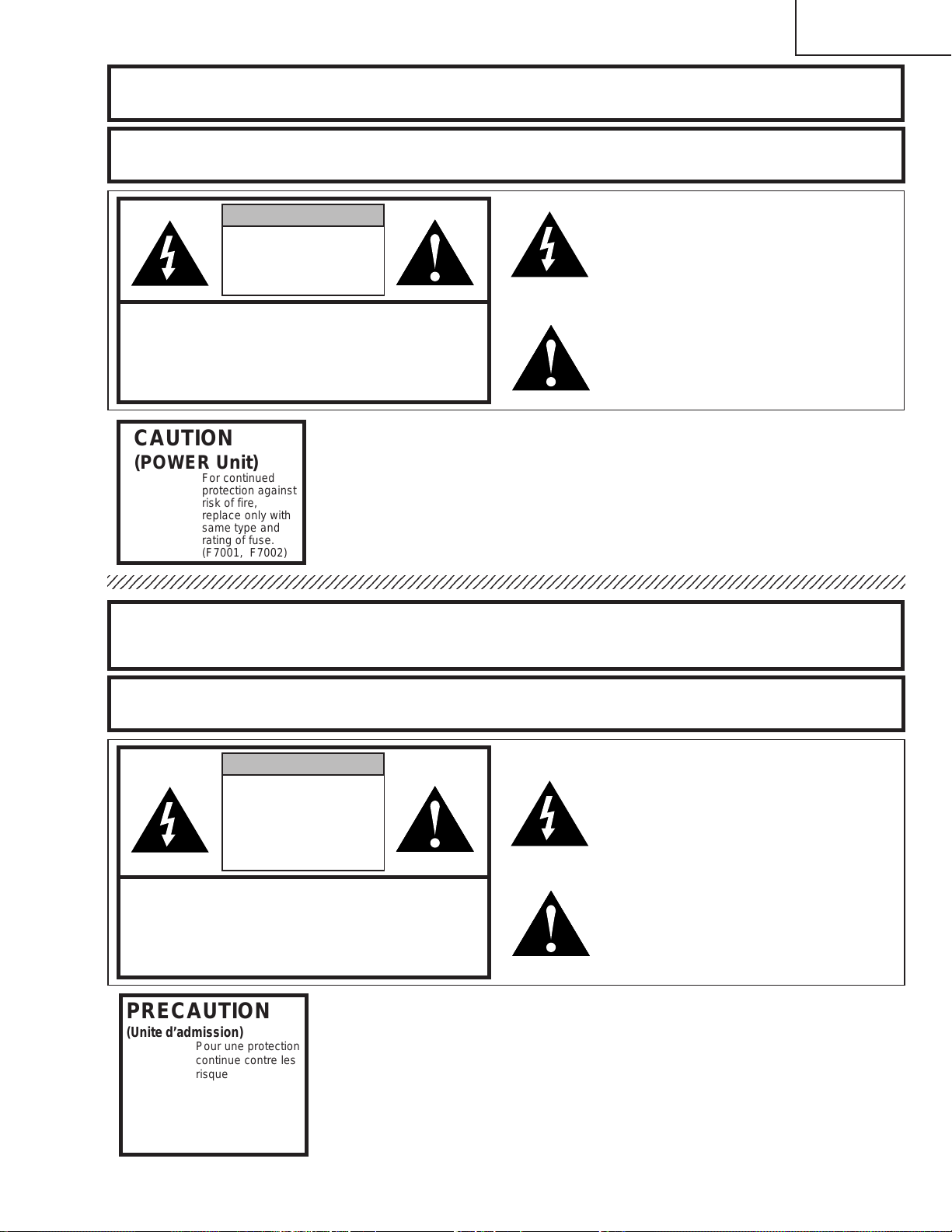

CAUTION

RISK OF ELECTRIC SHOCK.

DO NOT REMOVE SCREWS

EXCEPT SPECIFIED USER

SERVICE SCREW

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE CABINET.

NO USER-SERVICEABLE P ARTS EXCEPT LAMP UNIT.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

The lighting flash with arrowhead within a

triangle is intended to tell the user that

parts inside the product are risk of electric

shock to persons.

The exclamation point within a triangle is

intended to tell the user that important

operating and servicing instructions are in

the manual with the projector.

CAUTION

(POWER Unit)

A VERTISSEMENT : Source lumineuse de grande intensité. Ne pas fixer le faisceau lumineux ou le regarder

For continued

protection against

risk of fire,

replace only with

same type and

rating of fuse.

(F7001, F7002)

directement. Veiller particulièrement à éviter que les enfants ne fixent directement le

faisceau lumineux.

A VERTISSEMENT : AFIN D’EVITER TOUT RISQUE D’INCENDIE OU D’ELECTROCUTION, NE P AS PLACER

CET APPAREIL DANS UN ENDROIT HUMIDE OU MOUILLE.

ATTENTION

RISQUE

D’ELECTROCUTION NE

PASRETIRER LES VIS, A

L’EXCEPTION DES VIS DE

REPARATION UTILISATEUR

SPECIFIEES

L’éclair terminé d’une flèche à l’intérieur

d’un triangle indique à l’utilisateur que les

pi‘eces se trouvant dans l’appareil sont

susceptibles de provoquer une décharge

électrique.

Le point d’exclamation à l’intérieur d’un

ATTENTION: POUR EVITER TOUT RISQUE

D’ELECTROCUTION, NE PAS RETIRER LE CAPOT.

AUCUNE DES PIECES INTERIEURES N’EST REP ARABLE

PAR L’UTILISA TEUR, A L’EXCEPTION DE L’UNITE DE

LAMPE. POUR TOUTE REP ARATION, S’ADRESSER A UN

TECHNICIEN D’ENTRETIEN QUALIFIE.

triangle indique à l’utilisateur que les

instructions de fonctionnement et

d’entretien sont détaillées dans les

documents fournis avec le projecteur.

PRECAUTION

(Unite d’admission)

Pour une protection

continue contre les

risques d’incendie,

ne remplacer

qu’avec un fusible

du même type.

(F7001, F7002)

7

Page 8

XV-Z9000U/E

r

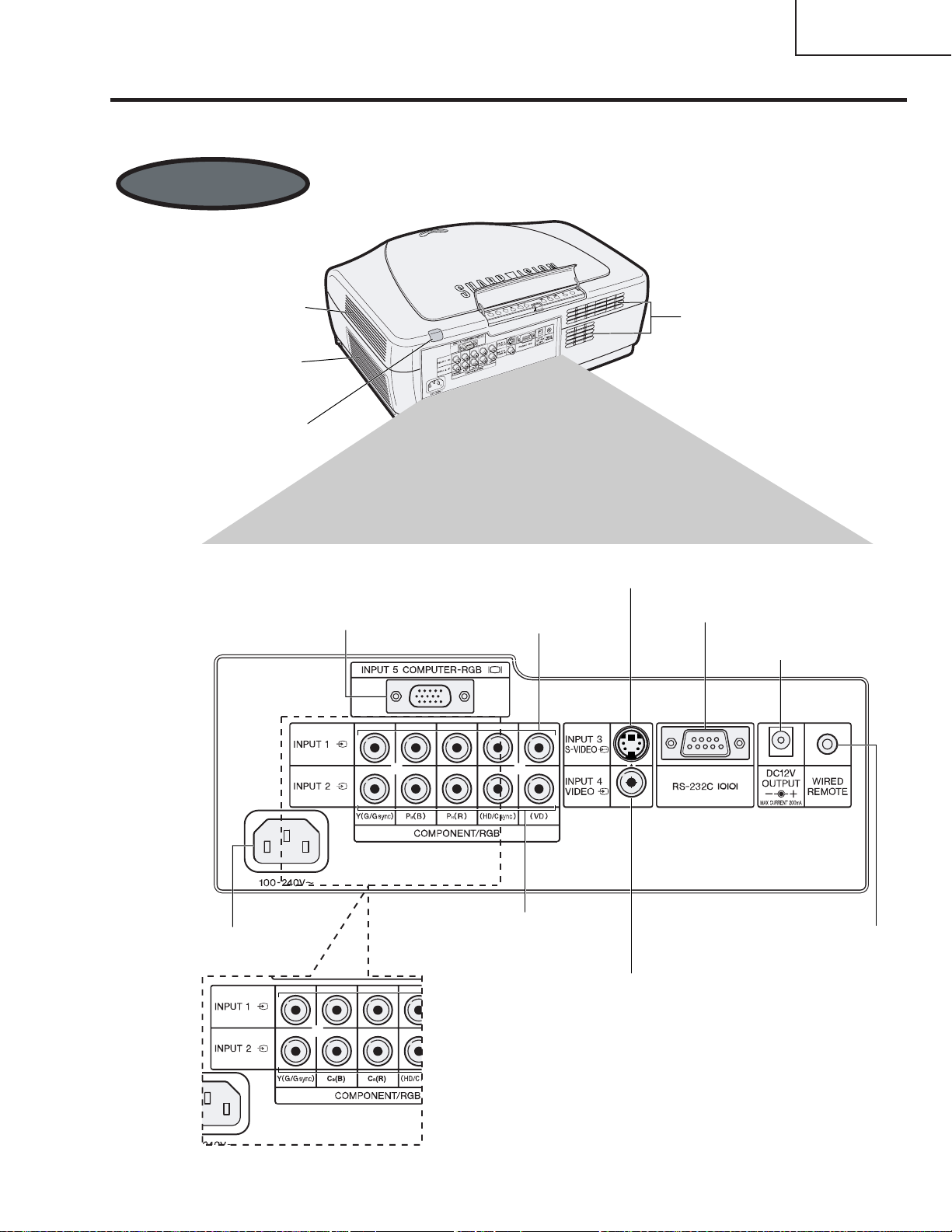

Location of Controls

Projector

Front and Top View

Lens shift dial

Remote control sensor

Zoom knob

Focus ring

Adjuster

ENTER button

UNDO button

Lens cap

ADJUSTMENT buttons

('/"/\/|)

Remote control sensor

MENU button

RESIZE button

TEMPERATURE WARNING indicato

LAMP REPLACEMENT indicator

POWER indicator

Intake ventilative hole

Adjuster

INPUT button

POWER buttons

(ON/OFF)

Side and Rear View

8

Page 9

Projector

Side and Rear Vie

w

AC socket

Intake ventilative hole 4

DC 12 V OUTPUT terminal

(200 mA MAX.)

INPUT 5 COMPUTER-RGB port

RGB terminals (RCA)

INPUT 2 COMPONENT/

RGB terminals (RCA)

Wired remote

control jack

VIDEO INPUT 4 terminal (RCA)

S-VIDEO INPUT 3 terminal

(4-pin Mini DIN)

RS-232C port

(9-pin D-sub)

Intake ventilative hole

Exhaust ventilative hole

Remote control sensor

INPUT 1 COMPONENT/

(15-pin Mini D-sub)

XV-Z9000U

XV-Z9000E

XV-Z9000U/E

9

Page 10

XV-Z9000U/E

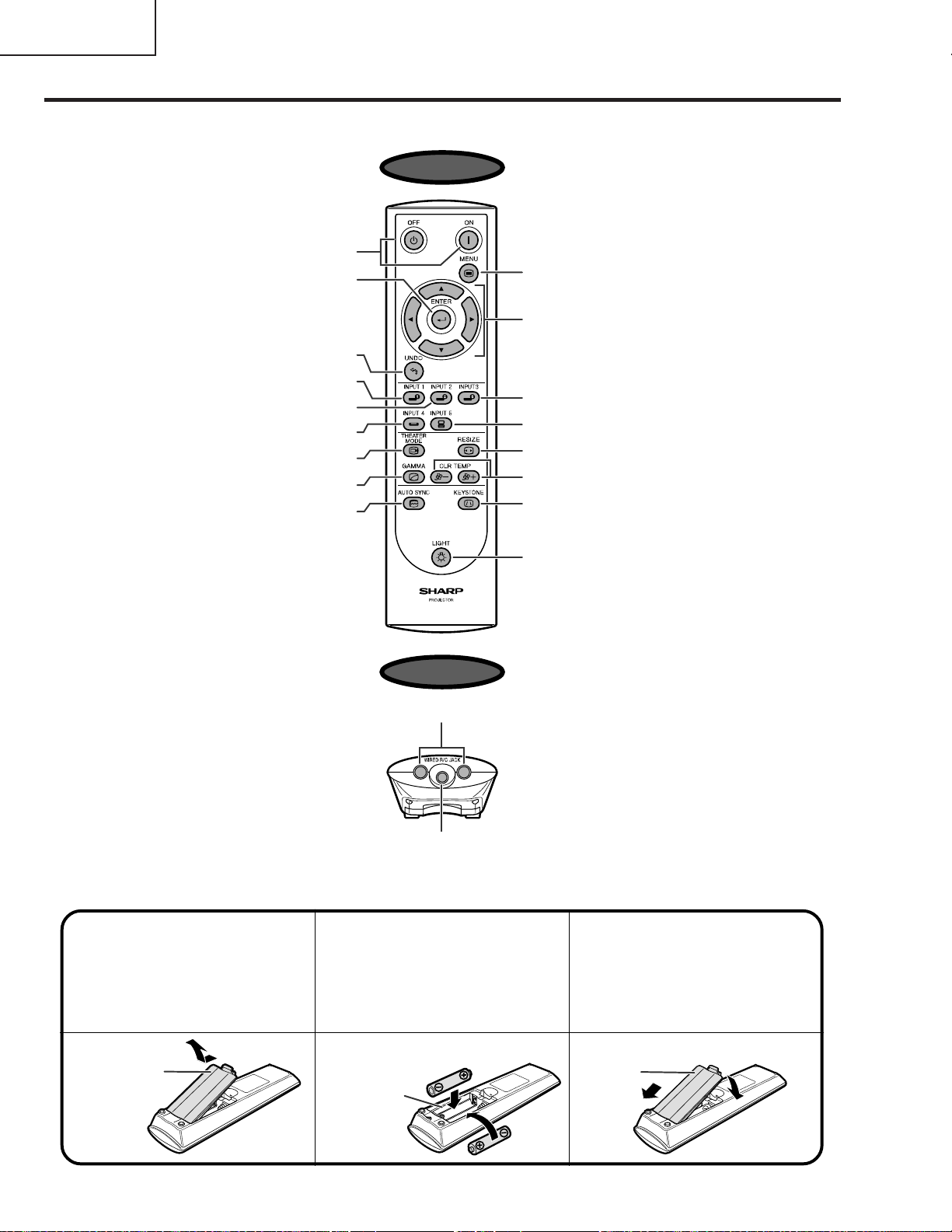

Remote Control

POWER buttons (ON/OFF)

ENTER button

UNDO button

INPUT 1 button

INPUT 2 button

INPUT 4 button

THEATER MODE button

GAMMA button

AUTO SYNC button

Front View

MENU button

ADJUSTMENT buttons

(\/|/'/")

INPUT 3 button

INPUT 5 button

RESIZE button

CLR TEMP buttons

KEYSTONE button

Inserting the batteries

Pull down the tab on the

1

battery cover and

remove the cover

towards the direction of

the arr o w.

T op View

Remote control signal transmitter

Wired remote control jack

Insert tw o AA size

2

batteries, making sure

the polarities match the

+ and – marks inside

the battery compartment.

BACKLIGHT button

Insert the lower tab of

3

the battery cover into

the opening, and press

the cover until it clicks

in place.

Battery cover

Battery

Battery

compartment

10

Page 11

a

Remote Control

d

l

e

XV-Z9000U/E

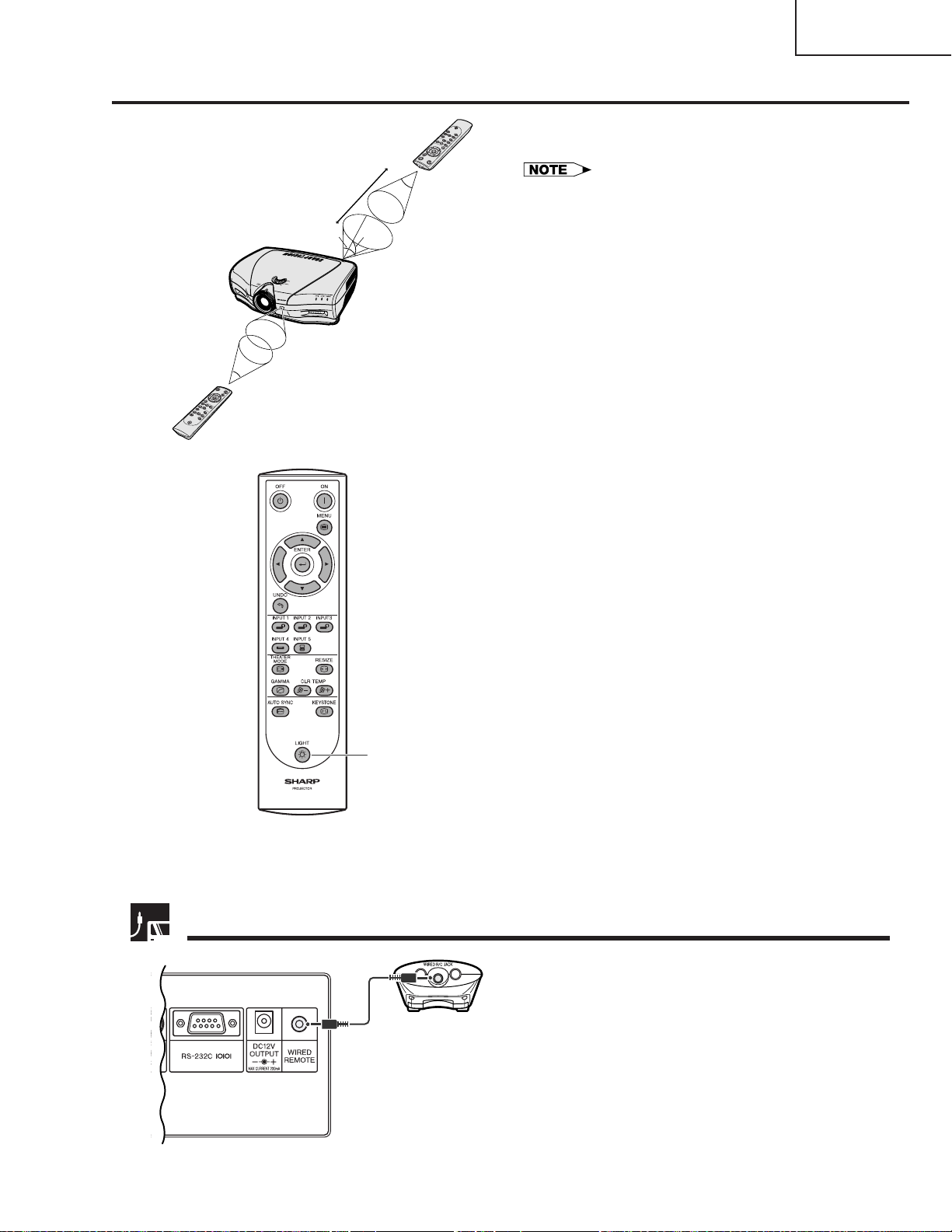

The remote control can be used to control the projector within the range shown on the left.

45˚

30˚

Remote Control

23 (7 m)

45˚

30˚

30˚

• The signal from the remote control can be r eflected of f

screen for easy operation. However, the effective distance

of the signal may differ due to the scr een material.

Using the remote control in a dark

room

The backlights of the operation buttons can be tur ne

on for five seconds and off by pressing BACKLIGHT.

If you want to turn off the backlights while they ar

press BACKLIGHT again.

BACKLIGHT button

Using as a Wired Remote Control

When the remote control cannot be used due to the

range or positioning of the projector (r ear projection,

etc.), connect a 3.5 mm stereo minijack cable

(commercially available) from the wired remote contro

3.5 mm stereo minijack cable

(commercially available)

jack on the top of the remote control to the Wired remot

control jack on the back of the projector.

11

Page 12

XV-Z9000U/E

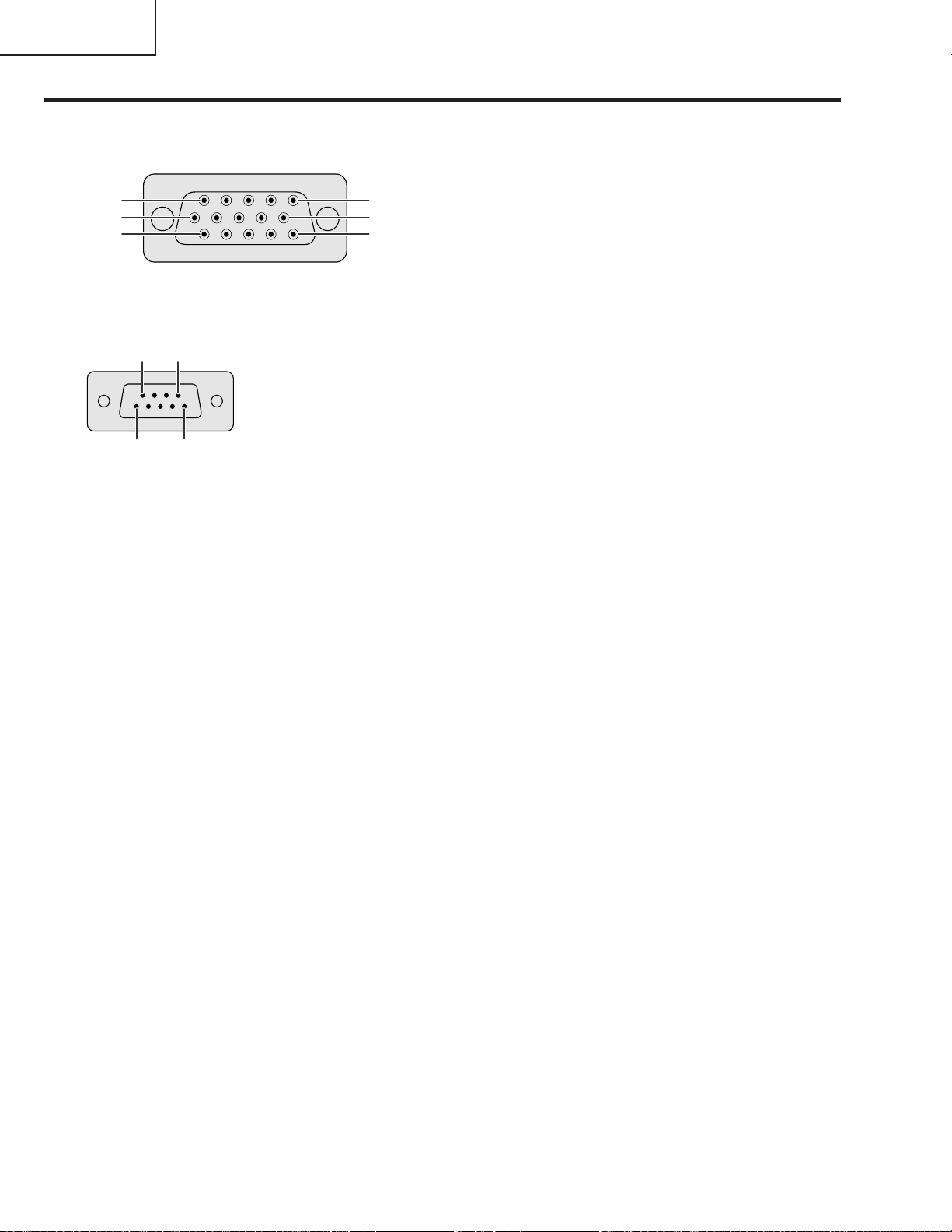

Connection Pin Assignments

INPUT 5 RGB Signal Input Port: 15-pin Mini D-sub female connector

RGB Input

Analog

1. Video input (red)

11

6

1

15

10

5

RS-232C Port: 9-pin D-sub male connector of the DIN-D-sub RS-232C cable

356

1

Pin No. Signal Name I/O Reference

1 Not connected

2 RD Receive Data Input Connected to internal circuit

3 SD Send Data Output Connected to internal circuit

4 Reserved Connected to internal circuit

5 SG Signal Ground Connected to internal circuit

6 Reserved Connected to internal circuit

7 Reserved Connected to internal circuit

8 Reserved Connected to internal circuit

9 Not connected

2. Video input

(green/sync on green)

3. Video input (blue)

4. Not connected

5. Composite sync

6. Earth (red)

7. Earth (green/sync on green)

8. Earth (blue)

9. Not connected

10. GND

11. GND

12. Bi-directional data

13. Horizontal sync signal

14. Vertical sync signal

15. Data clock

12

Page 13

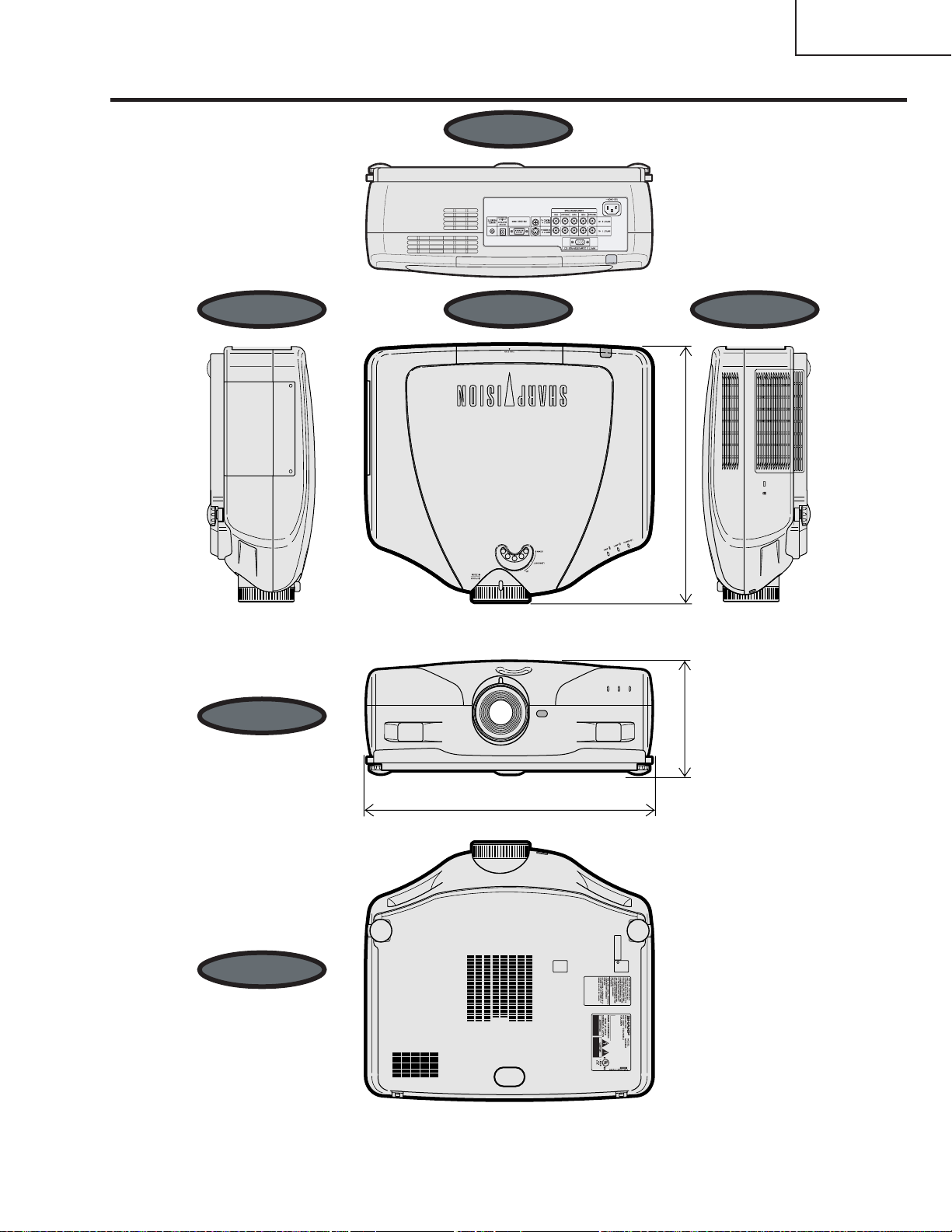

Dimensions

Side View Top View Side View

Rear View

(406)

50

/

49

15

XV-Z9000U/E

Front View

Bottom View

18

11

/16 (475)

7 (178)

Unit: inches (mm)

13

Page 14

XV-Z9000U/E

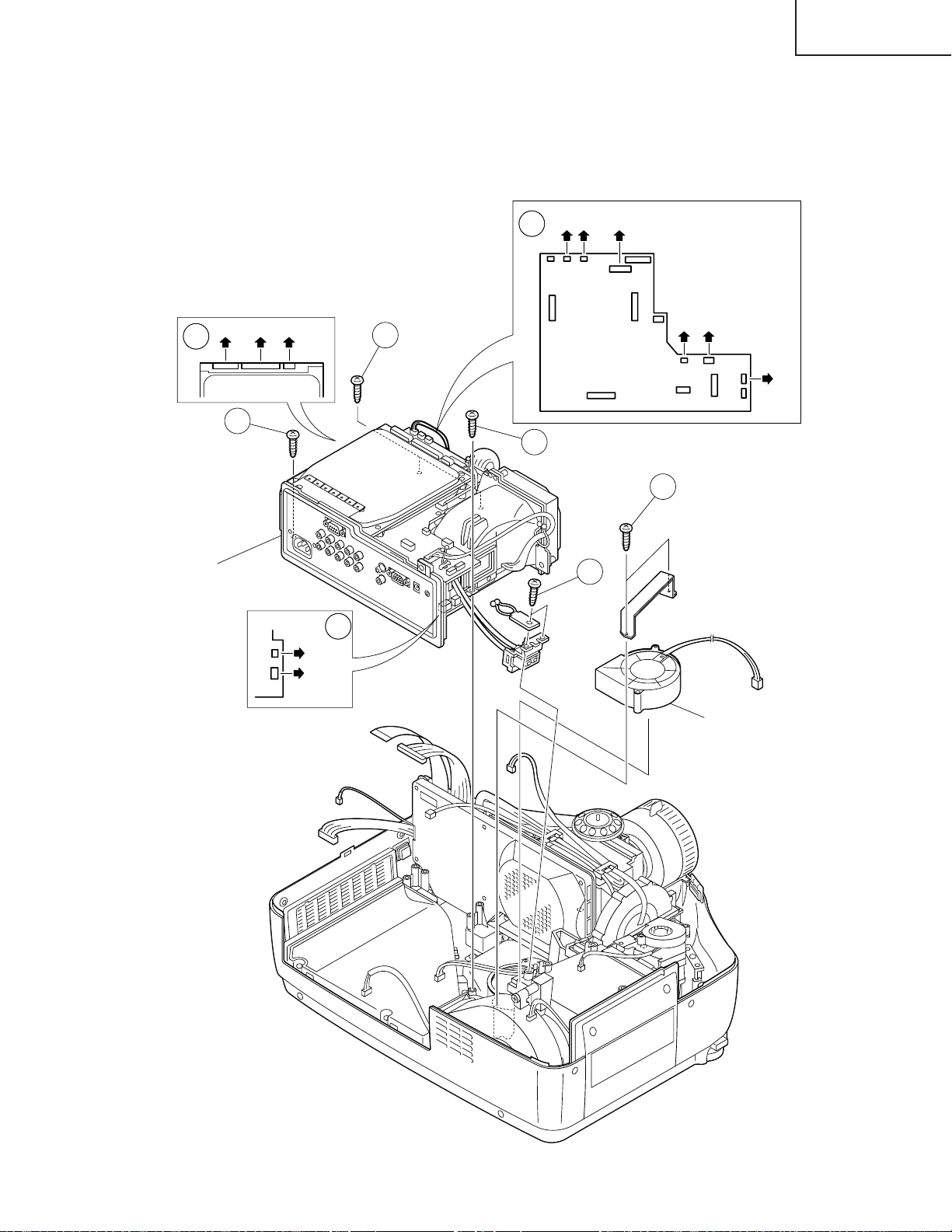

REMOVING OF MAJOR PARTS

1.Removing the top panels

1-1. Remove the six lock screw.

1-2. Press on side Arrow A of the bottom body

and Lift the rear body.

1-3. Disconnect the connector.

1-4. Press on front Arrow B of the bottom

body and unhook the claws, and detach

the top body.

2-1. Remove the two screws and detach the LED PWB.

2-2. Remove the one screw and detach the R/C PWB.

2-3. Remove the three screws and detach the operation PWB.

2-1

2-2

LED PWB

R/C PWB

2-3

Operation PWB

Top body

1-1

1-4

1-4

1-1

1-3

1-1

1-4

B

1-4

B

1-2

A

A

1-1

14

Page 15

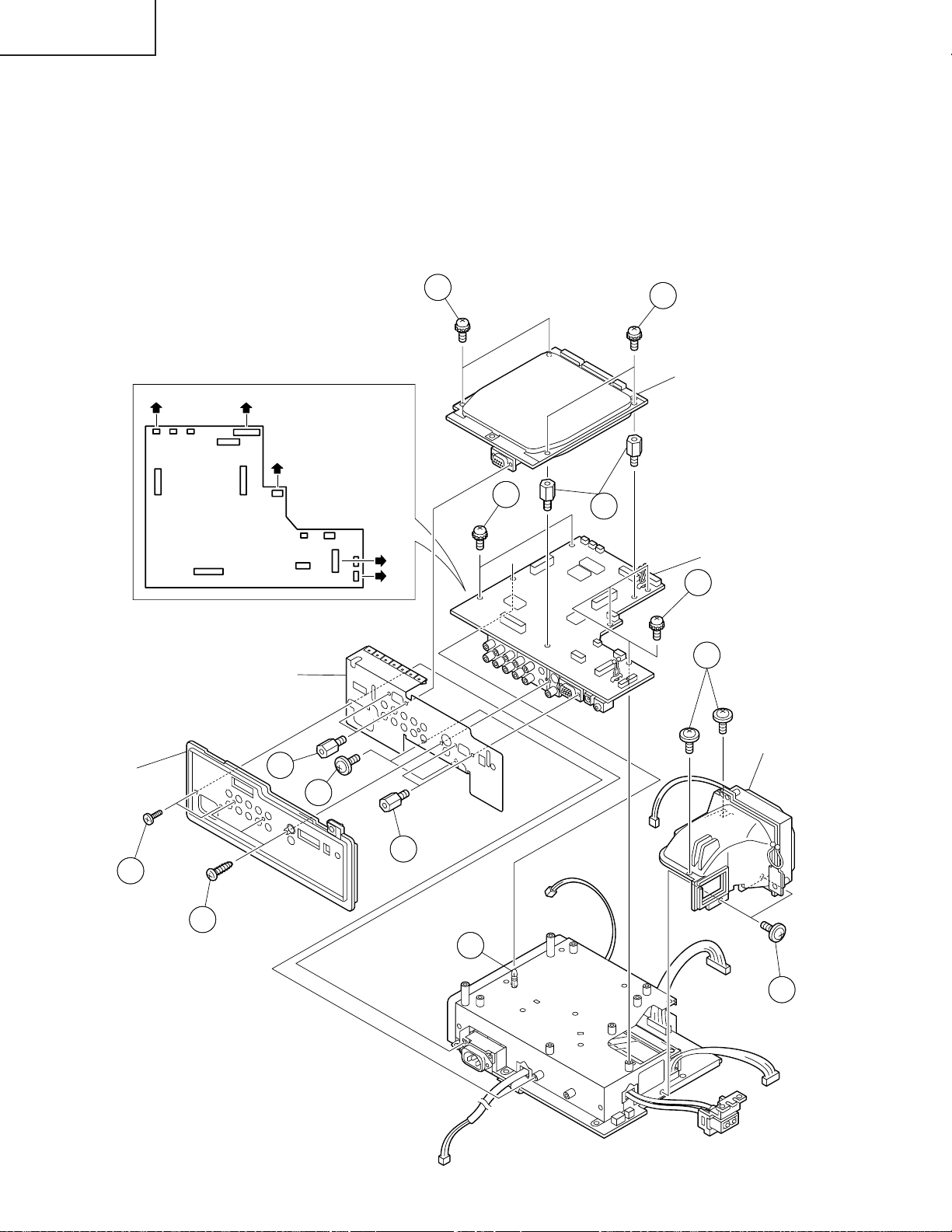

2.Removing the cooling fan and PWB unit assembly.

3-1. Disconnect the eleven connectors.

3-2. Remove the two screws and detach the lamp socket.

3-3. Remove the two screws and detach the cooling fan.

3-4. Remove the four screws and detach the PWB unit assembly.

(RC)(TA) (J2)

3-1

XV-Z9000U/E

(J5) (J3) (DB1)

3-1

3-4

PWB unit assembly

LAMP

3-1

Door SW

Bi-Metal

3-4

(FD) (FB)

(FA)

3-4

3-3

3-2

Cooling Fan

15

Page 16

XV-Z9000U/E

3.Removing the rear panel, PC unit, cooling duct and main PWB unit.

4-1. Remove the two screws.

4-2. Remove the three screws and detach the rear panel.

5-1. Remove the two screws.

5-2. Remove the four hexagonal supports and detach the shield plate.

6-1. Remove the four screws and detach the PC I/F unit.

7-1. Remove the four screws and detach the cooling duct.

8-1. Remove the two hexagonal supports.

8-2. Remove the five screws and detach the main PWB unit.

8-3. Remove the lock of the holder.

(TB) (EA)

Shield plate

(FC)

(EB)

(CA)

6-1

8-2

6-1

PC I/F unit

8-1

Main PWB unit

8-2

7-1

Rear panel

4-1

Cooling duct

5-2

5-1

5-2

4-2

8-3

7-1

16

Page 17

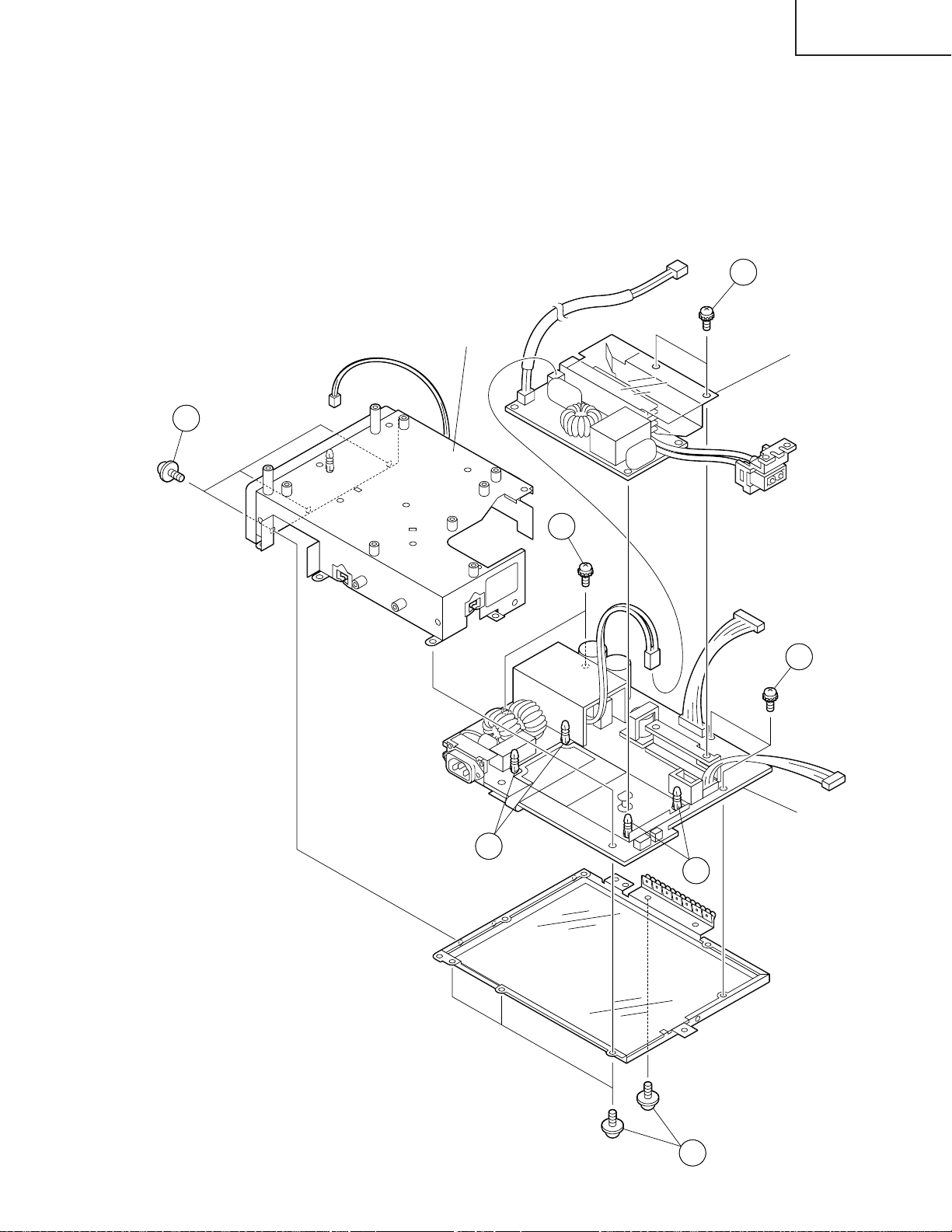

4.Removing the power unit shield , power/ballast unit and power unit.

9. Remove the seven screws and detach the power unit shield.

10-1. Remove the two screws.

10-2. Remove the four white supports and detach the power unit.

11. Remove the four screws and detach the power unit.

10-1

XV-Z9000U/E

Power unit shield

9

11

Ballast unit

11

10-2

Power unit

10-2

9

17

Page 18

XV-Z9000U/E

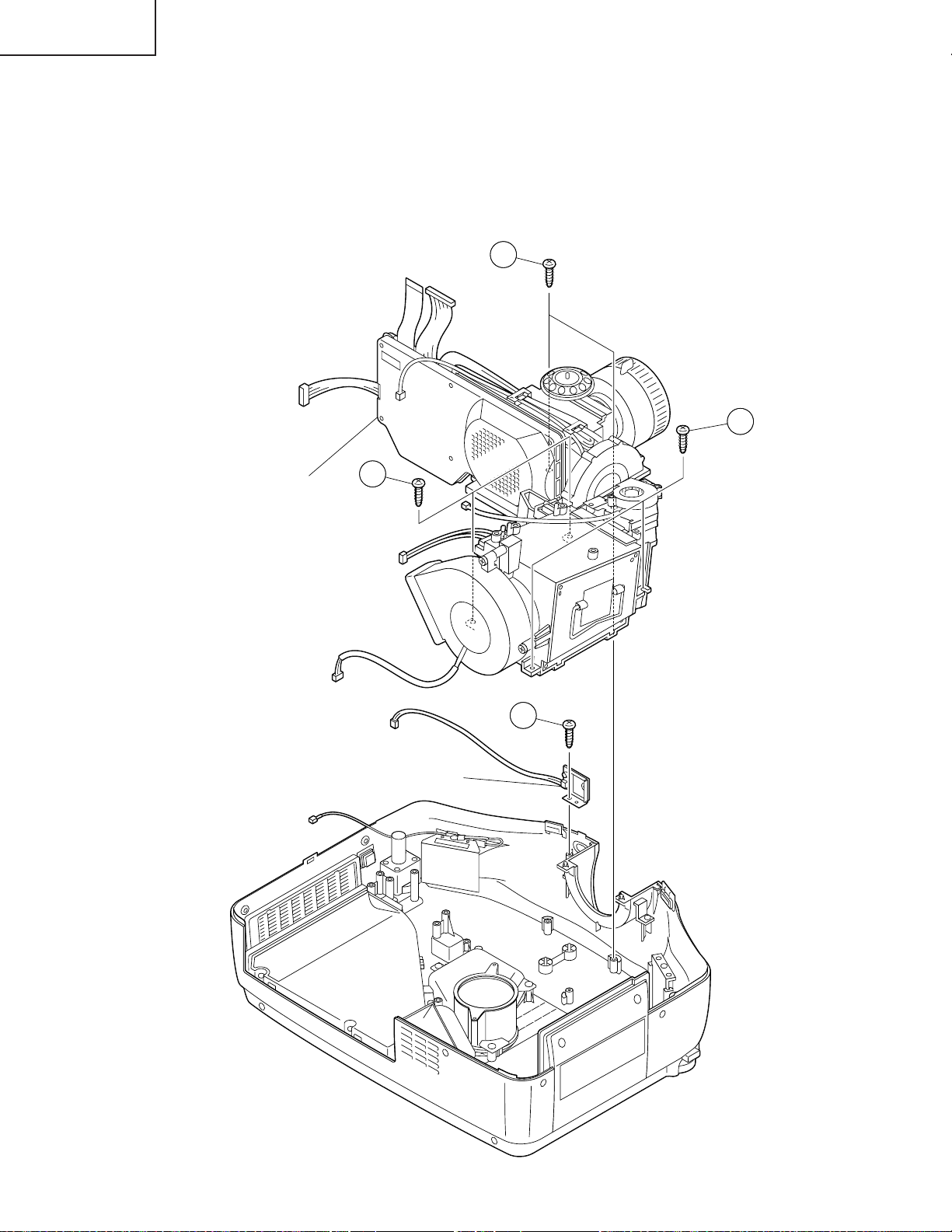

5.Removing the optical mechanism unit and R/C PWB unit.

12. Remove the six screws and detach the optical mechanism unit.

13. Remove the one screw and detach the R/C PWB unit.

12

12

Optical mechanism unit

12

13

R/C PWB unit

18

Page 19

XV-Z9000U/E

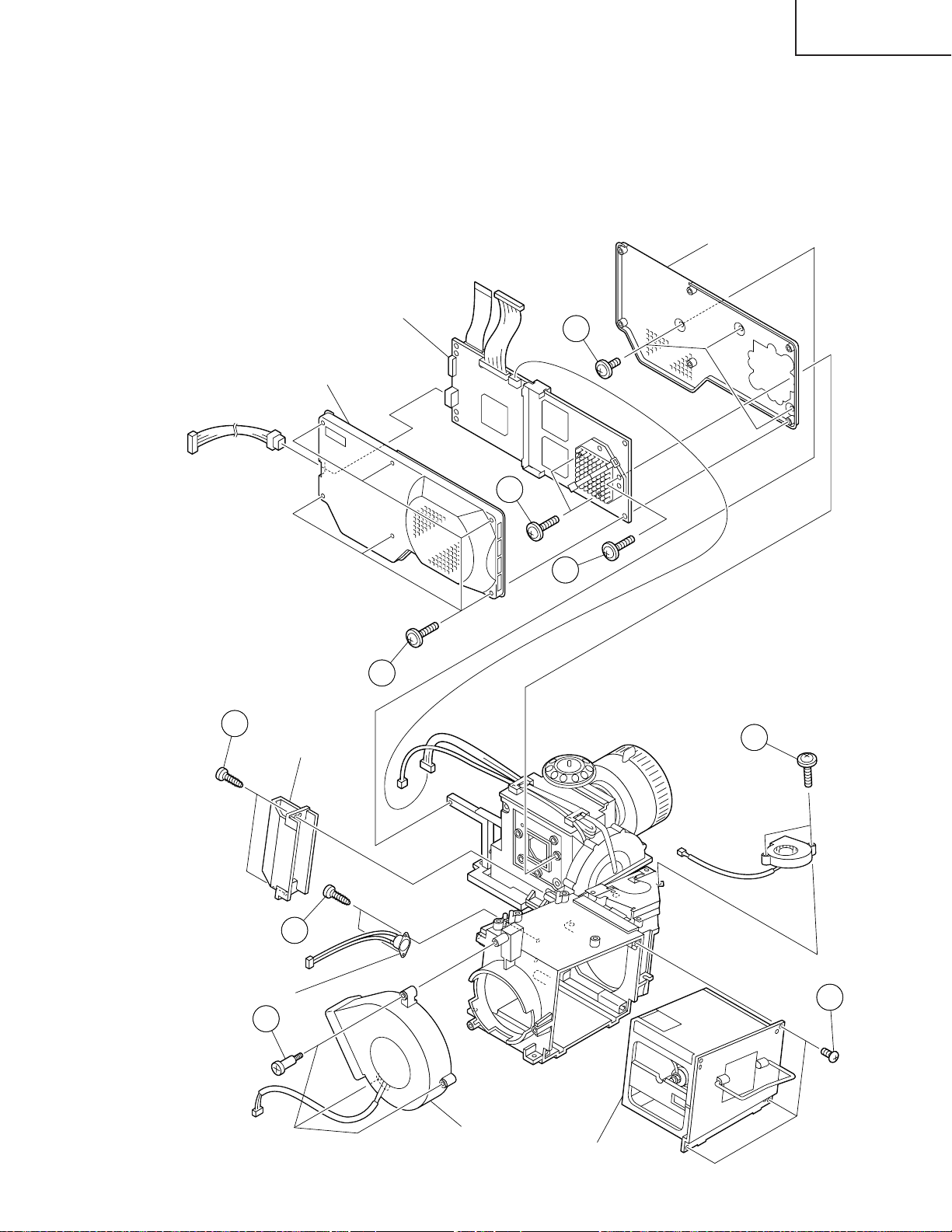

6.Removing the lamp unit, CW fan, outlet fan, bimetal, wind way duct, shield

plate and formater PWB.

14. Remove the three screws and detach the lamp unit.

15. Remove the two screws and detach the CW fan.

16. Remove the three screws and detach the outlet fan.

17-1. Remove the two screws and detach the bimetal.

17-2. Remove the two screws and detach wind way duct.

18-1. Remove the six screws and detach the shield plate(B).

18-2. Remove the three screws and detach the formater PWB.

18-3. Remove the three screws and detach the shield plate(A).

Formater PWB

18-3

Shield Plate(B)

Shield Plate(A)

17-2

Wind way Duct

18-2

18-2

18-1

15

17-1

Bimetal

16

14

Outlet Fan

Lamp unit

19

Page 20

XV-Z9000U/E

Resetting the TOTAL LAMP TIMER

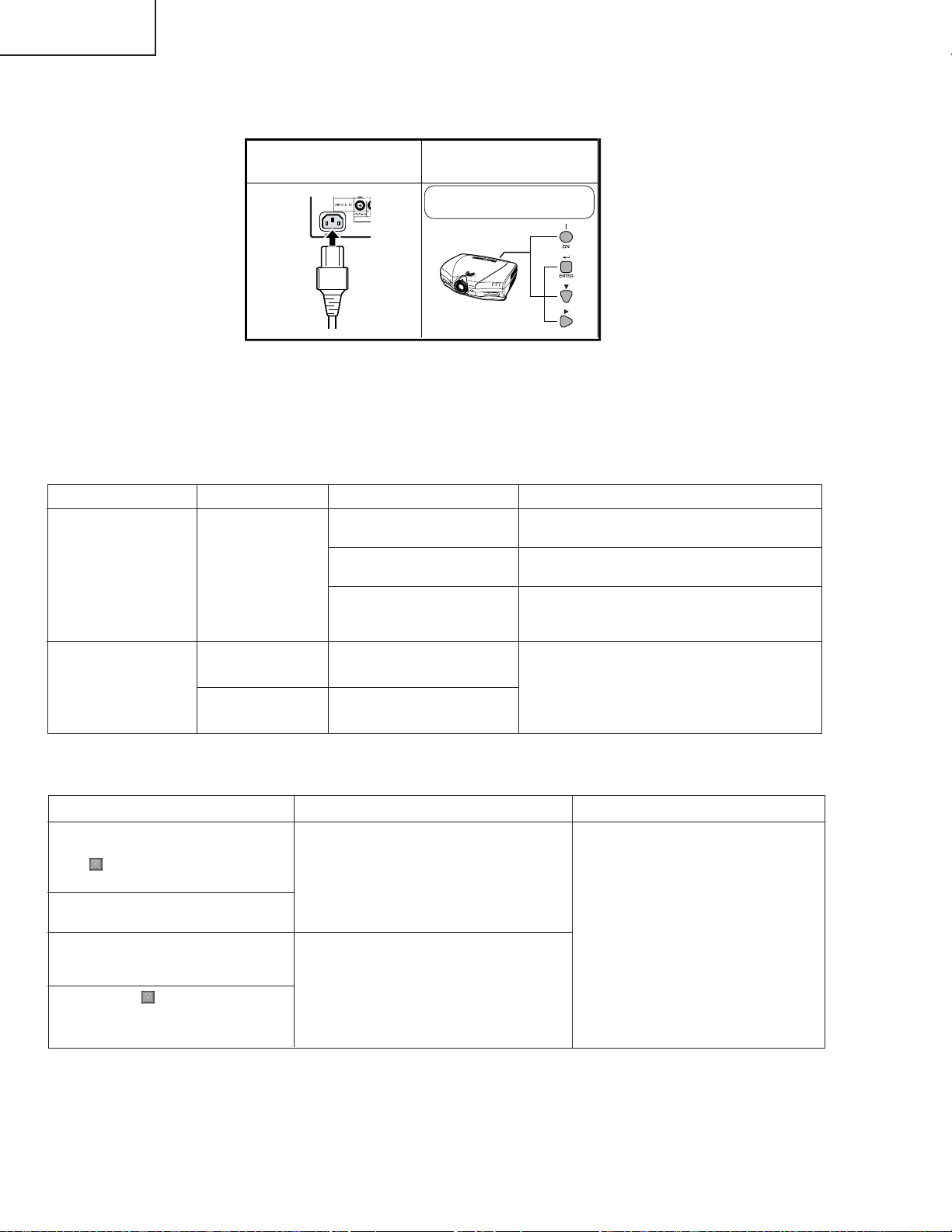

● Resetting the total lamp timer

When replacing the lamp, reset the total lamp timer in the procedure below.

Plug in the power cord.

1

● Light source (lamp)

The lamp in this projector operates for approximately 2,000 cumulative hours, depending on the usage environment. (As the usage environment can vary significantly, the projector lamp may not operate for 2,000 hours.) It is

recommended that the lamp be replaced after approximately 1,900 cumulative hours of use or when you notice a

significant deterioration of the picture and color quality. The lamp usage time can be checked with the On-screen

Display.

Press POWER ON on

2

projector to reset lamp

timer.

While holding down ENTER, [

and >, press POWER ON.

Maintenance Indicator

TEMPERATURE

WARNING indicator

LAMP REPLACEMENT indicator

Condition

The LAMP REPLACEMENT

indicator lights up red, and “LAMP”

and “

” will flash in yellow in the

lower-left corner of the picture.

A significant deterioration of the

picture and color quality occurs.

The power will automatically turn

off and the projector will enter

stand-by mode.

“LAMP” and “

the lower-left corner of the picture,

and the power will turn off.

” will flash in red in

Condition Possible Solution

The internal

temperature is

abnormally high.

The lamp does not

light up.

The lamp requires

replacement.

Problem

• Blocked air intake.

• Clogged air filter.

• Cooling fan breakdown.

• Internal circuit failure.

• Burnt-out lamp.

• Lamp circuit failure.

• Lamp has been used for

over 1,900 hours.

Problem

• Lamp has been used for over 1,900

hours.

• Lamp has been used for over 2,000

hours.

• Relocate the projector to an area with

proper ventilation.

• Clean the filters.

• Take the projector to your nearest

Authorized SharpVision or Service Center

or Dealer for repair.

• Carefully replace the lamp.

• Take the projector to your nearest

Authorized Sharp Vision Service Center or

Dealer for repair.

Possible Solution

• Purchase a replacement lamp unit

(lamp/cage module) of the current

type BQC-XVZ9000/1 from your

nearest Authorized SharpVision

Service Center or Dealer.

• Replace the lamp. If you wish, you

may have the lamp replaced at your

nearest Authorized SharpVision

Service Center or Dealer.

20

Page 21

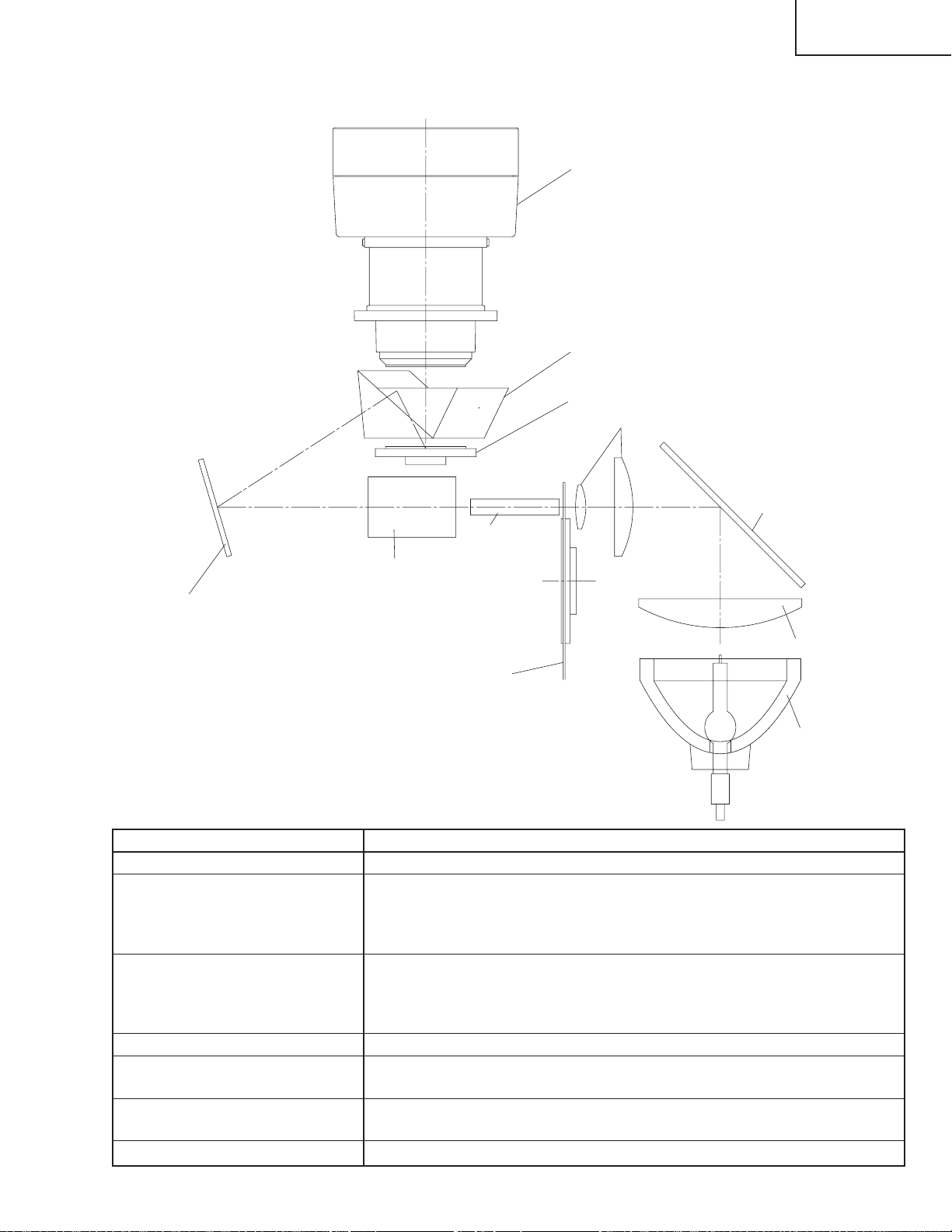

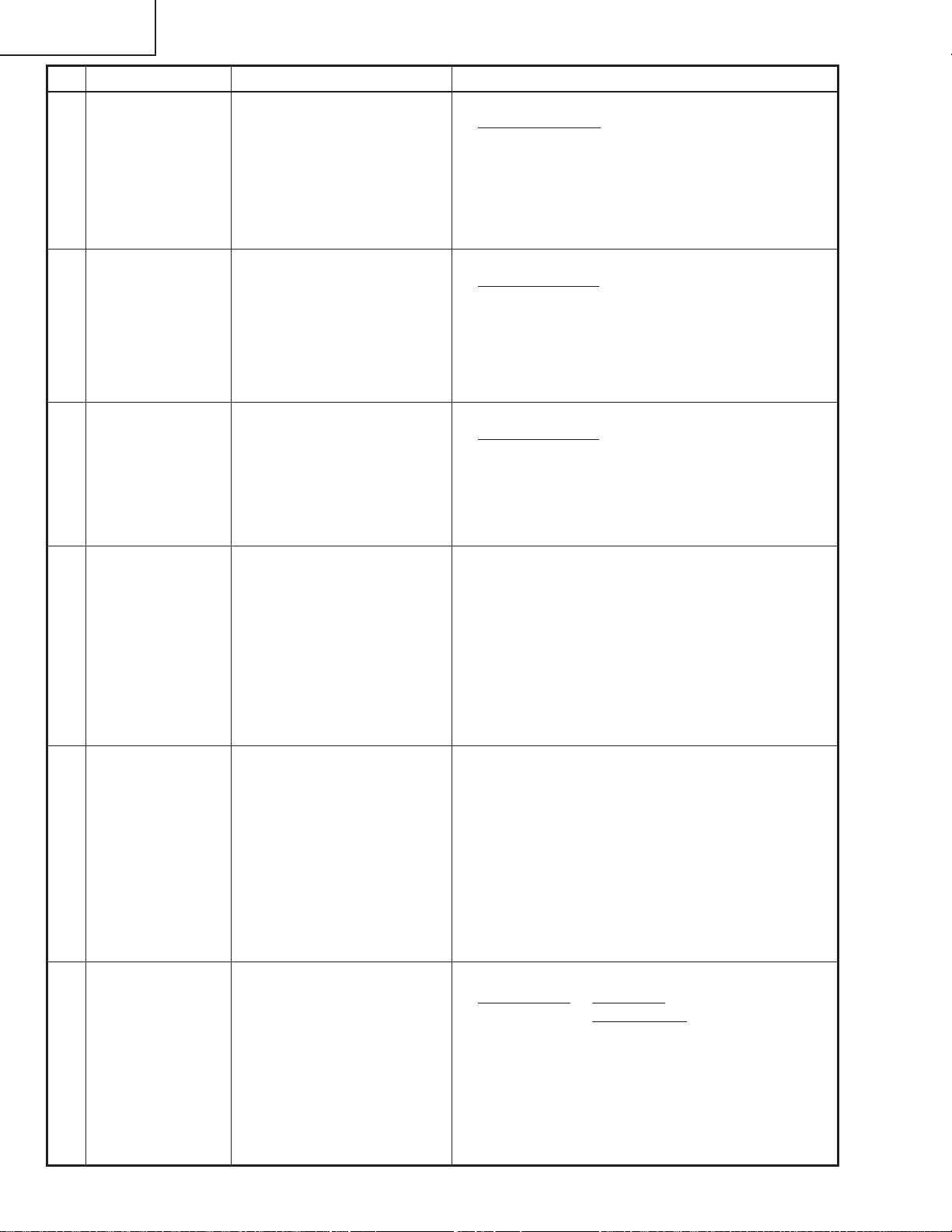

THE OPTICAL UNIT OUTLINE

Layout for proper setup of the optical components and parts (top view)

Projection lens

Prism

DMD Chips

Condensor lens

XV-Z9000U/E

Fold mirror

Item

1 Lamp

2 Condebsor lens, IR-cut mirror

and light- tunnel

3 Color filter

4 Relay lens and fold mirror

5 Prism

6 DMD chip

7 Projection lens

IR-cut mirror

Light tunnel

Relay lens

Condensor lens

Color filter

Lamp

Descriptions

The DC Light source lamp with parabola reflector.

The condensor lens leads the light generated from the lamp to the end sur-

face of the light-tunnel through the IR-cut mirror.

The IR-cut mirror is set in this unit to eliminate the excessive heat by the lamp

energy .

This color filter separates the white light into the 3 colors R,G and B.

A photo-sensor should be set in this unit to detect the transition timing pproperly

between color filters.

The maximum rrotating speed is 9000rpm.

This unit leads the illumination spot to effective area on DMD.

This prism also leads the illumination spot to effective area on DMD and at the

same time leads the reflection lights on the DMD to the projection lens.

This chip turns on and off in projection to each color component per dot de-

pending on the input source.

This lens enlarges and projects the incidend light coming from the DMD.

21

Page 22

XV-Z9000U/E

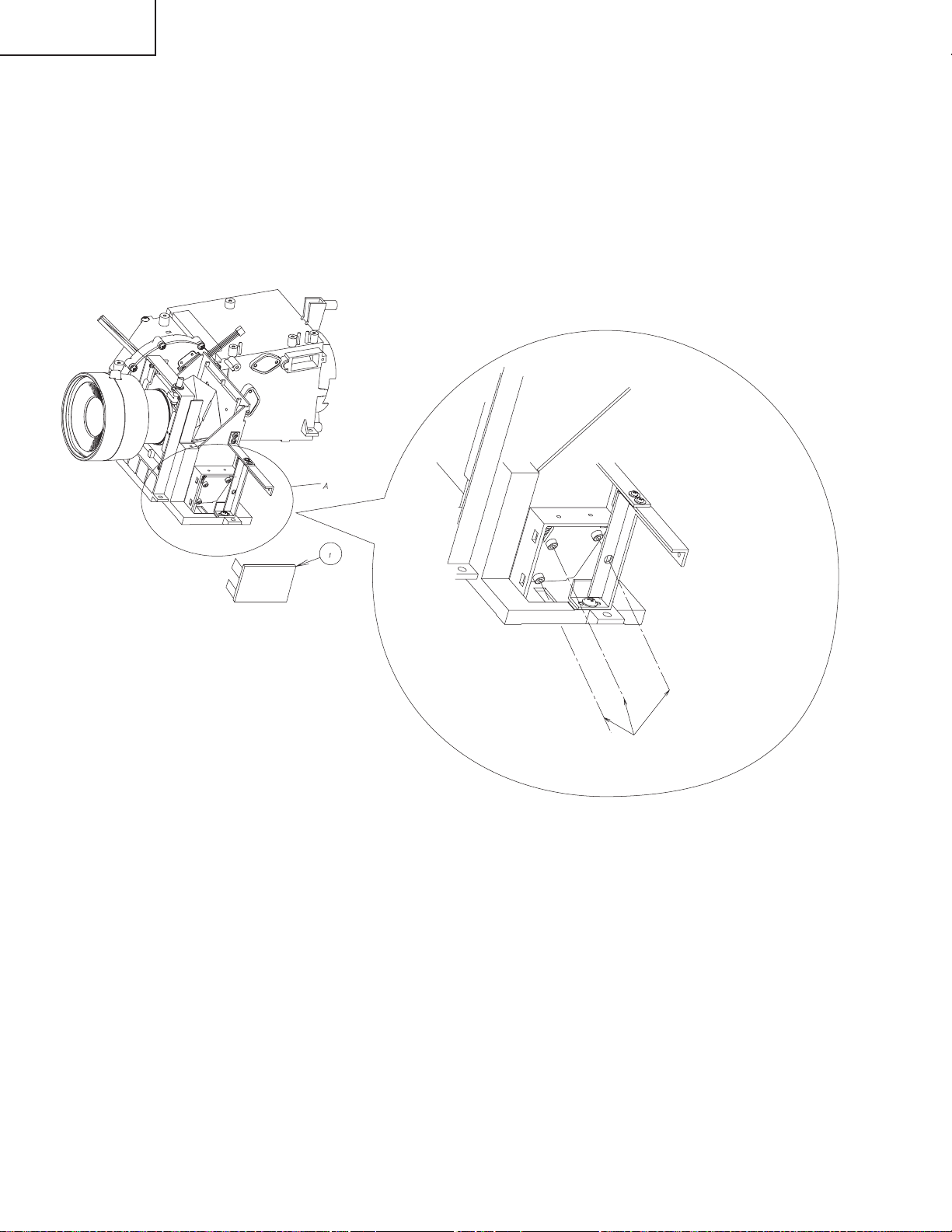

Adjusting the mirrors

Make adjustment by the indication territory on the screen to prevent the circumference of the screen from getting

dark because a lighting range deviated.

1. Remove the top body so that the optical unit may be seen. Display white only screen on the screen.

2. Detach the mirror adjustment part cover 1 on the bottom right of the projection lens.

3. T urn three screws with special hexagon wrench (9HPH10XL120) and adjust so that a part of the screen may not get

dark because a lighting range deviated.

4. Mount the adjustment part cover 1.

5. Mount the top panel.

Insert hexagon wrench

in this direction.

Expansion figure of part A

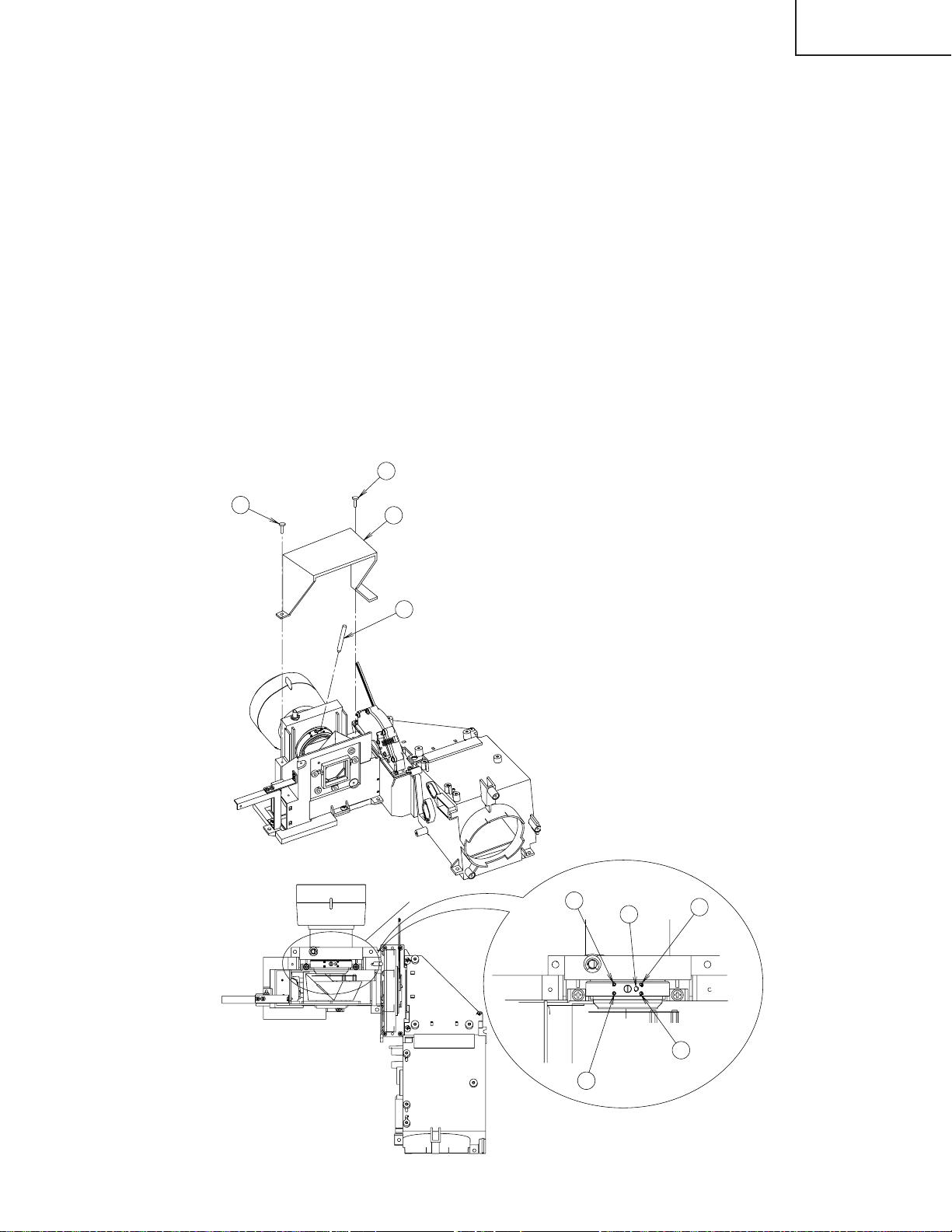

Adjusting the back focal distance after replacing the projection lens

Note: A piece of temporary tape is attached on the focus ring that comes with the replacement projection lens. Keep

this tape in place until the finish of the adjustment.

(1)Provide a distance of 2.4 m between the set and the screen and adjust the zoom knob to “wide end”.

(2)Adjust the lens shift until the projection lens comes to the same level as the center of the screen.

(3)Detach the optical unit top cover A from behind the projection lens.

(4)Loosen the four hex screws B in the back of the projection lens.

(5)Insert the adjustment screwdriver C (9EVDRIVERZ9000) in the hole D at the back of the lens. Put the center of the

screen in the best focus. (Preferably feed the SXGA signal for 1-dot white crosshatch pattern or 1-dot white dot

pattern on black background.)

(6)Tighten the four hex screws B to the torque of 0.3 Nm (3.06 kgfcm), and apply screw loctite to them.

(7)Peel the temporary tape off the focus ring of the projection lens.

(8)Attach the optical unit top cover A back into position. Finally fix the two screws E and apply screw loctite to them.

22

Page 23

XV-Z9000U/E

When the DMD unit has been replaced

Note: DMD chip and Formatter PWB are supplied at the same time, and an exchange only with DMD isn't done.Refer

to "REMOVING OF MAJOR PARTS" when exchanging Formatter PWB.

There is no need to readjust the back focal distance of the projection lens. If focusing is noticeably poor, however,

make this readjustment.

(1) Provide a distance of 2.4 m between the set and the screen.

(2) Adjust the lens shift until the projection lens comes to the same level as the center of the screen.

(3) Detach the optical unit top cover A from behind the projection lens.

(4) Loosen the four hex screws B in the back of the projection lens.

(5) Adjust the zoom knob at the front of the projection lens to “tele end” and ensure good focusing.

(6) Then adjust the zoom knob at the front of the projection lens to “wide end”.

(7) Insert the adjustment screwdriver C (9EVDRIVERZ9000) in the hole D at the back of the lens. Put the center of

the screen in the best focus. (Preferably feed the SXGA signal for 1-dot white crosshatch pattern or 1-dot white

dot pattern on black background.)

(8) Move the zoom knob from “wide end” back to “tele end” and see if focusing is ensured. If not, repeat the above

steps (5), (6) and (7) until the best focus is achieved.

(9) Tighten the four hex screws B to the torque of 0.3 Nm (3.06 kgfcm), and apply screw loctite to them.

(10) Attach the optical unit top cover A back into position. Finally fix the two screws E and apply screw loctite to them.

E

E

A

C

X

B

D

B

B

Expansion figure of part X

23

B

Page 24

XV-Z9000U/E

ELECTRICAL ADJUSTMENT

Hook up a signal generator, or a DOSV or Mac personal computer to the projector in order to feed the

signals specified in the Adjusting conditions.

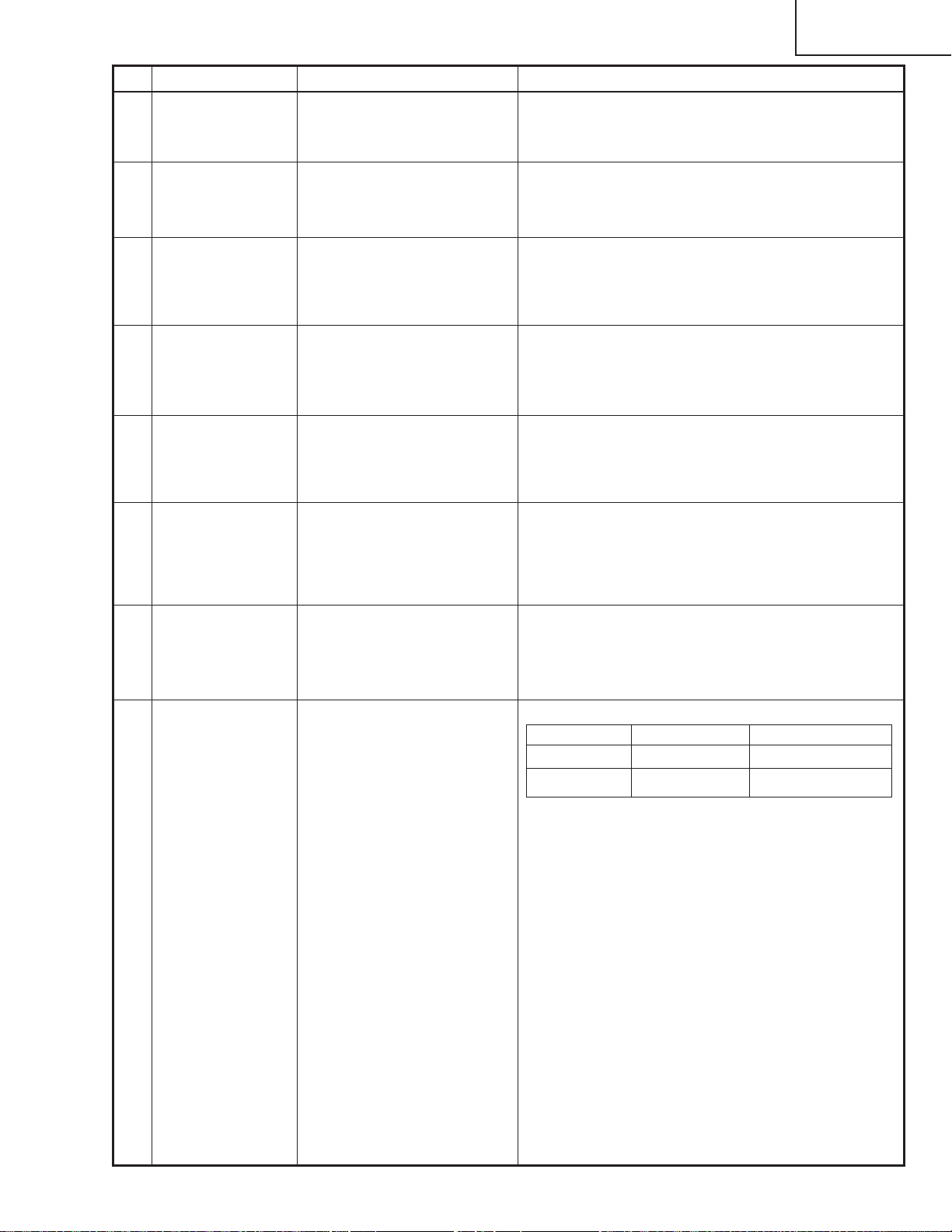

No. Adjusting point Adjusting conditions Adjusting procedure

1 EEPROM

initialization

2 RGB drive

adjustment (on

the PC board)

3 DLP voltage

adjustment

(reference)

1. Turn on the power (with the

lamp on) and warm up the

set for 15 minutes.

1. Feed the 100% and 0% signals for each of the red,

green and blue colors.

INPUT5

2. Select the following group

and subject.

Group: A/D

Subject: R-D (R)

G-D (G)

B-D (B)

1. Keep out any signal input.

2. Select the following group

and subject.

Group: DLP

Subject: VOLTAGE

1. Make the following settings.

Press SW2002 to enter the process mode. Execute

the S2 and S4 commands on the SSS menu. With

the S2 command, all the circuit boards than the PC

board will be initialized. Do not activate the S1 command because otherwise the PC board itself will be

initialized.

(The delivered PC board has been factory-adjusted.)

If by any chance the PC board must be readjusted,

follow the instructions in "Adjusting the PC Board"

on page 28.

1. Using the control switches on the set or the buttons

on the remote control, adjust the setting until bit dropouts start at the white level.

1. Select the setting of the rank marked on the formatter

PWB, referring to the menu.

2. Make this adjustment when the DLP chip has been

replaced or when the combination of DLP chip and

formatter PWB has been changed.

3. Rank B C D E

Setting 1 2 3 4

4 Color wheel

index adjustment

1. Feed the color wheel index

adjustment pattern signal.

INPUT5

2. Select the following group

and subject.

Group: DLP

Subject: CW INDEX

1. Adjust the setting so that the R, G and B lamp tone

pattern should be smooth without noises.

R

G

B

24

Page 25

No. Adjusting point Adjusting conditions Adjusting procedure

XV-Z9000U/E

5 RGB tone

reproduction

adjustment

6 Adjusting the

Background

Color

1. Feed the SMPTE pattern

signal.

INPUT5

2. Select the following group

and subject.

Group: DLP

Subject: R-BRIGHT

G-BRIGHT

B-BRIGHT

1. Select the following group

and subject.

Group: DLP

Subject: R-GAIN

G-GAIN

B-GAIN

2. Feed the Component

video, 75% white signal.

3. Signal level: 0.7±0.05 Vp-p

(sync section not included)

4. R-GAIN, G-GAIN and BGAIN initial settings: 95

5. Target chromaticity:

x = 0.272 ± 0.005

y = 0.310 ± 0.005

(color temperature 9500K+15 µV)

1. Make sure the 100% and 95% white and the 0%

and 5% black tones are visible.

2. If the black tone appears otherwise, finely adjust the

R-BRIGHT, G-BRIGHT and B-BRIGHT settings.

1. Project an image over a 40-inch screen and

measure the chromaticity at the center using a

chromaticity meter.

2. Keep the G-GAIN setting fixed at 95.

3. Adjust the B-GAIN setting to get the y value to its

target chromaticity.

4. Adjust the R-GAIN setting to get the x value to its

target chromaticity.

7 Video horizontal

center adjustment

8 Video BRIGHT-

NESS adjustment

9 Video picture

adjustment

10 Video tint

adjustment

1. Feed the NTSC monoscope pattern signal.

INPUT4

2. Select the following group

and subject.

Group: VIDEO 1

Subject: NTSC-H

1. Feed the NTSC 10-step

gray-scale signal.

2. Select the following group

and subject.

Group: VIDEO1

Subject: BRIGHT

1. Feed the NTSC 10-step

gray-scale signal.

2. Select the following group

and subject.

Group: VIDEO1

Subject: PICTURE

1. Feed the internal 8CH (split

color bar) signal.

INPUT4

2. Select the following group

and subject.

Group: VIDEO1

Subject: TINT

1. Using the control switches on the set or the buttons

on the remote control, adjust the setting until the

overscan should be equal at right and left.

1. Using the control switches on the set or the buttons

on the remote control, adjust the setting until more

bit dropouts start at the 0% black level.

1. Using the control switches on the set or the buttons

on the remote control, adjust the setting until bit dropouts start at the 100% white level.

1. Check the fixed setting.

Fixed setting: 128

25

Page 26

XV-Z9000U/E

No. Adjusting point Adjusting conditions Adjusting procedure

11 NTSC color

saturation

adjustment

1. Feed the internal 8CH (split

color bar) signal.

INPUT4

2. Select the following group

and subject.

Group: VIDEO1

Subject: N-COLOR

1. Check the fixed setting.

Fixed setting: 105

12 PAL color

saturation

adjustment

13 SECAM color

saturation

adjustment

14 DTV BRIGHT-

NESS adjustment

(Take this

procedure for

Model XVZ9000U only.)

1. Feed the P AL color bar signal.

INPUT4

2. Select the following group

and subject.

Group: VIDEO1

Subject: P-COLOR

1. Feed the SECAM color bar

signal.

INPUT4

2. Select the following group

and subject.

Group: VIDEO1

Subject: S-COLOR

1. Feed the 100% color bar

signal (component signal)

or the 10-step gray scale

signal to the input terminal

480I.

INPUT2

2. Select the following group

and subject.

Group: DVD

Subject: BRIGHT

1. Check the fixed setting.

Fixed setting: 110

1. Check the fixed setting.

Fixed setting: 110

1. Using the control switches on the set or the buttons

on the remote control, adjust the setting until more

bit dropouts start at the 0% black level.

15 DTV CONTRAST

adjustment

(Take this

procedure for

Model XVZ9000U only.)

16 DVD color

saturation

adjustment

DVD tint adjustment

1. Feed the 100% color bar

signal (component signal)

or the 10-step gray scale

signal to the input terminal

480I.

INPUT2

2. Select the following group

and subject.

Group: DVD

Subject: CONTRAST

1. Feed the 100% color bar

signal (480I component

signal) to the Y, Pb and Pr

input terminals.

INPUT2

2. Select the following group

and subject.

Group: DVD

Subject: COLOR

TINT

1. Using the control switches on the set or the buttons

on the remote control, adjust the setting until bit dropouts start at the 100% white level.

1. Check the fixed settings.

Fixed setting: TINT at 32

COLOR at 36

26

Page 27

No. Adjusting point Adjusting conditions Adjusting procedure

XV-Z9000U/E

17 White balance

checking and

readjustment

18 Color-related

performance

checking

19 Video-related

performance

checking

20 RGB-related

performance

checking

21 Off-timer per-

formance

performance

checking

1. Take the adjustment conditions discussed for Item

Make sure there is no white balance difference between the set and the standard monitor.

11 .

1. Feed the color bar signal. 1. Select L1 from the process mode LINE.

Check the Color and Tint performance.

1. Feed the monoscope pattern signal.

1. Select L2 from the process mode LINE.

Check the Picture, Brightness and Sharpness performance.

1. Feed the RGB signal. 1. Select L4 from the process mode LINE.

Check the Picture, Brightness, Red, Blue, Clock,

Phase, H-Position and V-Position performance.

1. Select OFF from the process mode LINE.

Make sure the off-timer starts with 5 minutes

onscreen and the set turns itself off in 5 minutes.

1. Heat the thermistor with a

1. Make sure that the temperature is indicated.22 Thermistor

hair dryer.

23 Auto sync

performance

checking

24 Delivery set-

tings

1. Feed the phase check pattern signal.

1. In the VGA, SVG Aand XGAmodes, make sure the

Clock, Phase, H-Pos and V-Pos settings can be automatically adjusted.

1. Make the following settings.

Destination Adjustment process Remote control setting

XV-Z9000U S4 Factory setting 4

XV-Z9000E S3 Factory setting 3

27

Page 28

XV-Z9000U/E

Adjusting the PC Board

1. Initializing the EEPROM

1) Press SW2002 to enter the process mode.

2) Execute the S1 command on the SSS menu. (The S1 command initializes the PC board alone. Do not

execute the S2 command because otherwise the adjustment data other than the PC board will be initialized.)

3) Make sure that the program version VER.XXX on the SPECIAL menu is the latest one.

2. Adjusting the levels

2.1 Setting the oscilloscope

Set the oscilloscope range to DC 1V/div. and 5 µsec/div.

2.2 Connecting the PC interface

1) Connect the specified cable between the analog output jack (signal generator) and the DUSB connector

(INPUT5 of the projector). Set the projector’s input selector to INPUT5.

2) Set the signal generator to the XGA mode (1024x768, 60 Hz, 32 tones). Adjust the output amplitude to 700

mVp-p between the black and white levels (terminated with a 75-ohm impedance).

3) Turn on the power.

2.3 Adjusting and checking the levels

1) Press SW2002 to enter the process mode.

2) Adjust the R-BRIGHT setting of Group A/D until bit dropouts start at the black level of the red signal.

3) Adjust the B-BRIGHT setting of Group A/D until bit dropouts start at the black level of the blue signal.

4) Adjust the G-BRIGHT setting of Group A/D until bit dropouts start at the black level of the green signal.

2.4 Adjusting the DTV

1) Feed the signal to the INPUT2’s RCA input terminal.

2) Set the signal generator to the 1080i 60-Hz mode with white signal. Adjust the output amplitude to 700 mVp-

p between the black and white levels.

3) Connect the specified cable between the analog output (signal generator) and the RCA connector (INPUT2

of the projector).

4) Make the G-BRIGHT setting the same as the G-BRIGHT setting of Group A/D.

5) Adjust the CB-OFFSET setting of Group DTV to 20.

6) Adjust the CR-OFFSET setting of Group DTV to 20.

7) When the CB-OFFSET and CR-OFFSET settings have been made, add 5 points to the G-BRIGHT setting for

Model XV-Z9000U and 4 points for Model XV-Z9000E.

8) Finally press SW2002 to exit from the process mode.

28

Page 29

Process menu 1

Group Sub Group Subject

Adjust PC Image A/D R-BRIGHT

G-BRIGHT

B-BRIGHT

R-D

B-D

G-D

Adjust HDDE formatter DLP VOLTAGE

CW-INDEX

R-BRIGHT

G-BRIGHT

B-BRIGHT

R-GAIN

G-GAIN

B-GAIN

XV-Z9000U/E

Adjust Component DTV G-BRIGHT

(High Definition) CB-OFFSET

CR-OFFSET

Adjust VIDEO Image VIDEO1 NTSC-H

PICTURE

BRIGHT

TINT

N-COLOR

P-COLOR

S-COLOR

SET UP

SET UP B

SET UP C

VIDEO2 PEAK FIL

PEAK GAIN

PEAK COR

N358 DLY

N433 DLY

PAL DLY

SECAM DLY

Adjust Component DVD CONTRAST

(480i) BRIGHT

TINT

COLOR

29

Page 30

XV-Z9000U/E

Process menu 2

Group Sub Group Subject

Process mode LINE L1

INITIAL SETTING SSS TIME

L2

L3

L4

OFF

TEMP OFF

SENSOR CHECK

S1

S2

S3

S4

S5

LAMP

Sample Pattern PATTERN RGB

RGB(50)

CROSS

STEP

COLOR

CHR

Adjust CVIC CVIC MODDE

-PROGRESSIVE IP

FILM

PTG

MSW

LSW

C-LEVEL

C-LIMIT

C-LPF

C-THRESH

C-MISSTH

C-MOVIEA

C-MOVIEB

C-MOVIEC

30

Page 31

Process menu 3

Group Sub Group Subject

Adjust CVIC CVIC BBN-TBL0

-ENHANCE-VIDEO BBN-TBL1

DFC-TBL0

DFC-DIR0

DFC-EDG0

DFCTBL1

DFC-DIR1

DFC-EDG1

CVIC BBN-TBL0

-ENHANCE-HDTV BBN-TBL1

DFC-TBL

DFC-DIR

DFC-EDG

CVIC BBN-GAIN0

XV-Z9000U/E

-ENHANCE-RGB BBN-GAIN1

BBN-GAIN2

BBN-TBL

DFC-TBL

DFC-DIR

DFC-EDG

CVIC CUBIC-RGB

-SCREEN CUBIC-VIDEO

CVIC XEGTH

-IDC XLTH1-H

XLTH1-L

XLTH2-H

XLTH2-L

VEGTH

VLTH1-H

VLTH1-L

VLTH2-H

VLTH2-L

Version Check etc. Special IPL

(High Definition) E2PROM

ADR RD/RW

31

Page 32

XV-Z9000U/E

TROUBLE SHOOTING TABLE

Checking the basic

performance

Is the POWER LED on or

flickering in red or blue?

YES

Is the set turned on by the

set's or remote controller's

power key?

YES

Is the cooling fan

running? Is the lamp on?

YES

Is the user menu

displayed?

YES

Is the video input as

specified?

YES

Is the component input as

specified?

YES

If the RGB input as

specified?

YES

NO

NO

NO

NO

NO

NO

NO

Go to "Checking the

power unit"

Go to "Checking the

microcomputer

peripherals" and

"Checking the PC PWB".

Go to "Checking the lamp

light-up".

Check the formatter

circuit’s peripheral circuits.

Are there output signals at

pins (32), (34) and (37) of

P3580?

Are there output signals at

every other pin from pins

(41) to (60) of P3580?

Check the PC board

circuit’s peripheral circuits.

NO

NO

Check the IC2505 circuit

and its peripheral circuits.

Check the IC2505 circuit

and its peripheral circuits.

Does the RS-232C

interface function?

YES

Recommended

communication software:

“TERA TERM”

Make the following settings:

baud rate at 9600 bps, bit

length at 8 bits, stop bit at 1

bit and no parity. Press the

RETURN key on the

keyboard. Does “ERR”

show up again?

YES

END

NO

NO

Are there output signals at

every other pin from pins

(41) to (60) of P3580?

Are there output signals

at pins (32), (34) and (37)

of P3580?

32

NO

NO

Check the IC2505 circuit

and its peripheral circuits.

Check the IC2005 circuit

and its peripheral circuits.

Page 33

Checking the power unit

XV-Z9000U/E

Are all the connectors

inside the power unit tightly

connected?

YES

Is the lamp cover closed

completely?

YES

Is the bimetal switch off?

YES

Is AC voltage applied

across the RL7001 relay?

YES

Is AC voltage applied

across L7005?

YES

NO

Insert the connectors

CN7105, 7103, 7101AND

7102 tightly.

NO

Tighten up the lamp door

closed with the screws.

NO

Replace the bimetal switch

or press the red button to

reset.

NO

Replace F7001.

NO

Replace F7002.

Is there DC voltage of

about 6 V across C7151?

YES

Is there DC voltage of

about 340 V across

CN7003?

YES

Are there the specified

voltages at the output

terminals of CN7101 and

CN7102?

YES

Check the output PWB

circuits.

NO

Check the peripheral

circuits of Q7101~Q7107.

Replace any of them as

required.

NO

Check the circuits leading

to the primary side of

T7002 for damage.

Replace any of them as

required.

NO

Check the circuits leading

to the secondary side of

T7002 for damage.

Replace any of them as

required.

33

Page 34

XV-Z9000U/E

Checking the PC PWB

0

Is the user menu properly

displayed?

NO

Check the on-screen

display.

Check the DTV RGB

input.

Check the DTV

component input.

Check the VIDEO input.

YES

Check the basic signal flow. The signal flow from

CVIC_IC to the panel output is the same for the

component and video signals. Therefore the lines

after CVIC are not checked. (The 480i and 580i

component signals are not included.)

The signal flows through the same circuits as the

DTV RGB signal does. Check the SOG (Sync On

Green) circuit and the color adjustment circuit. (The

480i and 580i component signals are not included.)

The video signal flows through a different route from

the RGB input signal, and goes into CVIC_IC.

Therefore check the video signal ICs.

Check the D-SUB input.

Check the D-SUB input.

End

34

Page 35

XV-Z9000U/E

YES

YES

NO

YES

Checking the RGB input

Feed the sync-separated DTV

RGB signal to INPUT1 or

INPUT2. (The 480i and 580i

component signals are not

included.)

Check to see if the video input is

as specified.

Is the contour as specified?

Using the front-panel key or

the remote control, select

INPUT1 or INPUT2.

NO

NO

Is the image disturbed?

Go to "Checking the sync signal".

Do R, G and B colors appear?

Go to "Checking the RGB signal".

NO

IC8004 or its peripheral circuit

defective.

End

YES

Does the image appear?

1

2

3

35

Page 36

XV-Z9000U/E

Checking the video input

Make sure the input signal

setting is as specified.

YES

Is there the video signal at

the land of C8077?

YES

Check the sync signal.

YES

IC8025 or IC8004

defective.

Checking the input signal

setting

Is the input signal setting

as specified?

YES

NO

Input PWB defective.

NO

Select the specified signal.

Is the connector properly

connected?

YES

End

2

NO

Reconnect the connector.

1

36

Page 37

Checking the sync signal

XV-Z9000U/E

Is there vertical sync signal

at TL8134?

YES

Is there horizontal sync

signal at TL8133?

YES

Is there vertical sync signal

at TL8131?

YES

Is there horizontal sync

signal at TL8130?

YES

NO

NO

Check the input signal

setting.

Input PWB defective.

NO

NO

IC8302, IC8325, IC8299 or

their peripheral circuits

defective.

Are both the vertical and

horizontal sync signals

timely?

YES

Is the signal generator

(input source) as

specified?

YES

Input PWB defective.

NO

There is no problem with

the sync signal.

End.

NO

Make the specified signal

source settings.

2

37

Page 38

XV-Z9000U/E

Checking the RGB signal

Is the type of signal set at

RGB?

NO

Call the process mode.

Select R, G and B

separately on the pattern

menu.

Go to “Checking the GA4

peripheral circuits”.

Set the signal generator to

the gradation signal mode

in order to check the input

signal.

Measure the gradation

signals at TL8073, T8074,

T8075 and T8080.

YES

Set to the RGB signal.

Are there specified signals

at TL8073, TL8074,

TL8075 and TL8080?

YES

IC8025 or its peripheral

circuit defective.

NO

Are there input signals at

C8069 and C8061?

YES

IC8004 or its peripheral

circuit defective.

NO

Input PWB defective.

38

Page 39

Checking the GA4

peripheral circuits

Call the process mode, and

select R, G and B

separately on the pattern

menu.

XV-Z9000U/E

Are there specified R, G

and B video output signals?

NO

Are the measured signals

the same as the signals

selected on the pattern

menu?

NO

Is there clock signal at

R974?

YES

Are there sync signals at

TL8026, TL8027 and

TL8028?

YES

Using the oscilloscope,

measure the signals at

TL8141 thru TL8148.

YES

YES

NO

NO

End of checking the GA4

peripheral circuits.

Output PWB defective.

Is there clock signal

(37.125 MHz) at TL8114?

NO

Is there clock signal

(37.125 MHz) at FL8110?

YES

IC8025 defective.

Are there sync signals at

TL8112 and TL8133?

YES

IC8029 defective.

YES

IC8029 defective.

NO

X8005 defective.

NO

IC8025 defective.

Are the measured signals

the same as the signals

selected on the pattern

menu?

YES

Using the oscilloscope,

measure the signals at

TL8106 thru TL8111.

Are the measured signals

the same as the signals

selected on the pattern

menu?

YES

IC8029 defective.

NO

Digital panel PWB

defective.

NO

IC8025 defective.

39

Page 40

XV-Z9000U/E

Checking the

component inputs

(Except for 480I)

Feed the component signal

to INPUT1 or INPUT2.

Using the front panel key

or the remote control,

select INPUT1 or INPUT2.

Does an image appear on the

screen?

4

Are the colors as

specified?

Is the type of signal set at

COMPONENT?

Carry out the process

adjustment.

YES

NO

NO

NO

4

NO

Go to "Checking the

SOG circuit".

YES

YES

Set the type of signal to

COMPONENT.

Is the image contour as

specified?

NO

End of checking the

component input.

YES

IC8004 or IC8025

defective.

40

Page 41

Checking the SOG circuit

Measure the signal at

TL8136 on the

oscilloscope.

XV-Z9000U/E

Is the composite sync

signal played back timely?

NO

Measure the land of C8069

on the oscilloscope.

Is there the Y signal

including the sync signal?

YES

SOG sync separation

circuit defective.

Checking the on-screen

display.

Is the on-screen display

color as specified?

YES

There is no problem with

the SOG circuit. End.

NO

Go to “Checking the input

signal settings”.

Input PWB defective.

YES

NO

Carry out the output line

adjustment in the

adjustment process.

0

Go to “Checking the GA4

peripheral circuits”.

Get the flash ROM

reprogrammed.

41

Page 42

XV-Z9000U/E

5

Checking the video input

Feed the composite video

signal to INPUT4.

Using the front panel key

or the remote control,

select INPUT4.

Select VIDEO as the type

of signal on the user menu.

Does the image appear?

YES

Is the image disturbed?

NO

Is the contour as specified?

YES

There is no problem with

the video input. End.

Is there the video signal at

pin (72) of IC8338?

NO

YES

NO

NO

Go to "Checking the video

sync signal".

Go to "Checking the video

sync signal".

Carry out the process

adjustment.

5

Is the video signal as

specified?

NO

6

YES

IC8338 defective.

42

Page 43

6

Measure the VPC (IC8338)

clock signal at TL8004.

XV-Z9000U/E

Is the clock signal as

specified?

YES

Go to “Checking the video

sync signal”.

IC8025 or its peripheral

circuit defective.

Checking the video sync

signal

Using the oscilloscope,

measure the signal at

TL8140. (Check the

vertical sync signal.)

NO

IC8338 defective.

Is the vertical sync signal

as specified?

YES

Using the oscilloscope,

measure the signal at

TL8142. (Check the

horizontal sync signal.)

Is the horizontal sync

signal as specified?

YES

7

NO

NO

Go to "Checking the input

signal setting".

Input PWB defective.

43

Page 44

XV-Z9000U/E

Checking the DSUB input.

Feed the PC-RGB signal to INPUT5.

Select INPUT5 as the input.

Does the image appear?

YES

Check to see if there are the R, G

NO

and B signals at pins (126), (136)

and (146) of IC8004.

Is there any distortion with the image?

NO

3

Check the vertical and horizontal sync

signals at pin (6) of IC8364 and pin (6)

of IC8385.

Are the sync signals as specified?

YES

Are there the horizontal and vertical sync

signals at TL8130 and TL8131?

YES

YES

NO

NO

Are there the R, G and B signals?

YES

Sync separation circuit, IC8354m

IC8365 or their peripheral circuit

defective.

IC8302 or its peripheral circuit

defective.

NO

DSUB connector

or its peripheral

part defective.

IC8025, IC8004 or their peripheral

circuit defective.

44

Page 45

Checking the lamp

light-up

The lamp fails to light up.

XV-Z9000U/E

Is discharge sound heard

when turning on the power

switch?

NO

Are the cooling fans

running well?

YES

Is a voltage of about DC

340 V applied across the

ballast power circuit

CP1001?

YES

Is a voltage of over 3.5 V

applied at pin (1) of the

ballast power circuit

CP1501?

YES

Check the

microprocessor circuit.

Replace the ballast power

PWB.

YES

NO

NO

NO

Is the lamp or CW line

socket out of position?

YES

Replace the lamp or the

CW.

Check the power circuit

or the fan circuit on the

main circuit.

Check the power circuit.

Replace the ballast power

PWB. Check the

microprocessor circuit.

NO

Reconnect the sockets

tightly.

45

Page 46

XV-Z9000U/E

No horizontal

synchronization

Is the terminal input

connection as specified? Is

the cable tightly

connected?

NO

YES

Use the specified cable.

Reconnect it tight enough.

Is there the horizontal sync

pulse at pin (14) of

IC2506?

YES

Is there the horizontal

sync pulse at pin (11) of

IC2509?

YES

Go to "PC Board

Troubleshooting".

No vertical

synchronization

Is the terminal input

connection as specified? Is

the cable tightly

connected?

NO

NO

Check the line between

IC2506 and the input

terminal.

NO

Check the line between

IC2506 and IC2509.

YES

Use the specified cable.

Reconnect it tight enough.

Is there the vertical sync

pulse at pin (14) of

IC2501?

YES

Is there the vertical sync

pulse at pin (8) of

IC2509?

YES

Go to "PC Board

Troubleshooting".

NO

Check the line between

IC2501 and the input

terminal.

NO

Check the line between

IC2506 and IC2509.

46

Page 47

Checking IC3504 (3D

Noise Reduction) and its

Peripheral Circuits

XV-Z9000U/E

Are there the input signals

at pins (88) (Y signal) and

(96) (C signal) of IC3504?

YES

Are there the output

signals at pins (84) (Y

signal) and (83) (C signal)

of IC3504?

YES

Check the line up to the

PC board connector or

the circuits that follow the

PC board.

NO

Check the signal input

circuit or IC2505 and its

peripheral circuits.

NO

Check IC3504 and its

peripheral circuits.

47

Page 48

XV-Z9000U/E

Checking the

Component and RGB

Inputs

Are there signals at pins

(34), (36) and (38) of

IC2505?

YES

Are there signals at pins

(3), (5) and (6) of IC2507?

YES

Are there signals at pins

(56/26), (58/28) and

(60/30) on the board-toboard section of P3580?

YES

NO

NO

NO

Check the signal input

circuit or IC2505 and its

peripheral circuits.

Check the line between

Q2509 and Q2517 and its

peripheral circuits, or

IC2507.

Check the line between

Q2518 and Q2520 and its

peripheral circuits.

NO

There are no RGB colors.

YES

Check the circuit of the

color that fails to appear.

NO

There are no RGB colors.

YES

Check the circuit of the

color that fails to appear.

Are there signals at pins

(49/19), (51/21) and

(53/23) on the board-toboard section of P3580?

YES

Check the board-to-board

connections or the

circuits that follow the PC

board.

NO

Check the line from

Q2525 through Q2523 to

Q2524 and its peripheral

circuits.

48

Page 49

Technische Daten

XV-Z9000U/E

Produkttyp

Modell

Videosystem

Display-Verfahren

DMD-Feld

Linse

Projektionslampe

Videoeingangssignal

S-Videoeingangssignal

Komponenten-

Eingangssignal

Horizontal-Auflösung

RGB-Eingangssignal

Punkatetakt

Vertikale Frequenz

Horizontale Frequenz

Computersteuerungs-Signal

Nennspannung

Eingangsspannung

Nennfrequenz

Stromaufnahme

Stromverlust

Betriebstemperatur

Lagertemperatur

Gehäuse

I/R-Trägerfrequenz

Abmessungen (ca.)

Gewicht (ca.)

Mitgeliefertes Zubehör

Ersatzteile

Projector

XV-Z9000E

PAL/PAL 60/PAL-M/PAL-N/SECAM/NTSC 3.58/NTSC 4.43

DTV 480i/480P/720P/1080i

Single Panel Digital Micromirror Device (DMD™) von Texas Instruments, RGB optisches

Verschlussverfahren

Feldformat: 0,8"

Antriebsverfahren: Digital Light Processing (DLP™) von Texas Instruments

Anzahl der Punkte: 921.600 Punkte (1.280 [H] × 720 [V])

1 –1,35 Zoom-Linse, F3,0,f=32,5 –44,0 mm

250 W NSH-Lampe

RCA-Stecker: VIDEO (INPUT 4), Gemischtes Video, 1,0 Vp-p, negatives Sync.-Signal, 75

Ω terminiert

4-Pin Mini DIN-Stecker (INPUT 3)

Y (Luminanz-Signal): 1,0 Vp-p, negatives Sync.-Signal, 75Ω terminiert

C (Chrominanz-Signal): Stoß 0,286 Vp-p, 75Ω terminiert

RCA-Stecker (INPUT 1, 2)

Y: 1,0 Vp-p, negatives Sync.-Signal, 75Ω terminiert

CB: 0,7 Vp-p, 75Ω terminiert

CR: 0,7 Vp-p, 75Ω terminiert

520 TV-Zeilen (NTSC 3,58 Eingang), 750 TV-Zeilen (DTV 720P Eingang)

15-PIN MINI D-SUB STECKANSCHLUSS (INPUT 5):

RGB getrennt/gemischte Sync./Sync. auf Grün-Typ analoger Eingang: 0–0,7 Vp-p,

positiv, 75Ω terminiert

HORIZONTALES SYNC.-SIGNAL: TTL-Pegelsignal (positiv/negativ) oder gemischtes Sync.-Signal

(nur Macintosh)

VERTIKALES SYNC.-SIGNAL: Wie oben

12–120 MHz

43–100 Hz

15–81 kHz

9-Pin D-Sub-Steckanschluß (RS-232C-Eingangs-Port)

100–240 V Wechselstromspannung

3,6 A

50/60 Hz

345 W (Wenn in “Kinofilm-Modus” “HELLIGK.” angewählt ist)

310 W (Wenn in “Kinofilm-Modus” “NORMAL” angewählt ist)

1.400 BTU/Stunde

+5°C bis +35°C

-20°C bis +60°C

Kunststoff

38 kHz

475 × 178 × 406 mm (B × H × T) (nur Hauptgerät)

475 × 178 × 496 mm (B × H × T) (einschließlich Buchsenabdeckung)

9,5 kg (nur Hauptgerät)

Fernbedienung, Zwei AA-Batterien, Netzkabel (1,8 m), 21-Pin RCA-Konversionsadapter,

Video-Kabel, RGB-Kabel, Buchsenabdeckung, Linsenkappe (aufgesetzt), CD-ROM, Zwei

Projektor-Bedienungsanleitungen, SharpVision Manager-Bedienungshandbuch

Lampeneinheit (Lampe/Gehäusemodul) (BQC-XVZ9000/1), Fernbedienung

(RRMCG1657CESA), AA-Batterien, Netzkabel (QACCV4002CEZZ, QACCB5024CENA),

21-Pin RCA-Konversionsadapter (QSOCZ0361CEZZ), Video-Kabel (QCNWGA001WJZZ),

COMPUTER-RGB-Kabel (QCNW-5050CEZZ), Buchsenabdeckung (GCOVA1985CEKA),

Linsenkappe (PCAPH1056CESA), CD-ROM (UDSKA0047CEN1), Zwei ProjektorBedienungsanleitungen(TINS-7521CEZZ, TINS-7522CEZZ), SharpVision ManagerBedienungshandbuch(TINS-7523CEZZ)

Dieser SHARP-Projektor verwendet einen DMD-Chip. Dieser

hochentwickelte Chip beinhaltet 921.600 Pixel. Wie bei allen

hochtechnologischen Elektronikgeräten wie großen

Fernsehbildschirmen, Videosystemen und Videokameras, gibt es

auch hier bestimmte akzeptable Toleranzen, denen das Gerät

entsprechen muß.

Änderungen der technischen Daten ohne vorherige Ankündigung vorbehalten.

Dieses Gerät hat einige inaktive Pixel innerhalb akzeptabler

Toleranzen, die in inaktiven Punkten auf dem Bildschirm resultieren.

Dies hat keinen Einfluß auf die Bildqualität oder die Lebensdauerdes

Gerätes.

49

Page 50

XV-Z9000U/E

5

5

HINWEIS FÜR DAS

WARTUNGSPERSONAL

234567890123456789012345678901212345678901234

ACHTUNG: UV-STRAHLUNG

234567890123456789012345678901212345678901234

Die Beleuchtungsquelle des LCD-Projektors, eine

UHP-Lampe, emittiert eine geringe Menge

UV-Strahlung.

DIREKTE BESTRAHLUNG AUF AUGEN

UND HAUT MUSS VERMIEDEN WERDEN.

Zur Gewährleistung der Sicherheit muß folgendes

beachtet werden:

1. Bei Arbeiten am Projektor bei eingeschalteter

Lampe und abgenommenem oberen Gehäuse muß

unbedingt eine Sonnenbrille getragen werden.

Auswechseln der Lampe

Hinweis:

Da die Lampe während des Betriebs sehr heiß wird,

sollte die Lampe erst ausgewechselt werden, nachdem

das Gerät mindestens eine Stunde ausgeschaltet war ,

damit die Lampe ausreichend abkühlen kann.

Beim Installieren der neuen Lampe muß darauf

geachtet werden, die Lampe selbst (Glaskolben)

nicht zu berühren. Vielmehr muß die Lampe am

Reflektor 2 gehalten werden.

[Es darf nur ein Original-Ersatzteil verwendet

werden.]

Lampe

1

Reflektor

2

2. Die Lampe darf nicht außerhalb des

Lampengehäuses eingeschaltet werden.

3. Betrieb für länger als 2 Stunden bei

abgenommenem Gehäuse ist nicht zulässig.

Zur Beachtung bei UV-Strahlung

und Mitteldruck-Lampen

1. Vor dem Auswechseln der Lampe muß der

Netzstecker gezogen werden.

2. Vor Durchführung von Wartungsarbeiten muß das

Gerät eine Stunde abkühlen.

3. Die Lampe darf nur gegen eine der gleichen Art

ausgewechselt werden. T yp BQC-XVZ9000/1,

bemessen für 355 V/250 W.

4. Die Lampe gibt eine geringe UV-Strahlung ab,

daher muß direkter Augenkontakt vermieden

werden.

5. Die Mitteldruck-Lampe weist ein Explosionsrisiko

auf. Daher müssen die nachstehenden

Installationsanweisungen beachtet werden, und die

Lampe muß vorsichtig behandelt werden.

GEFAHR! — Niemals die Spannungsversorgung

einschalten, ohne daß eine Lampe vorhanden ist,

um elektrische Schläge und Schäden am Gerät zu

vermeiden, da der Stabilisator anfangs hohe

Spannungen erzeugt.

Da eine geringe Menge UV-Strahlung an der Öf fnung

zwischen den Lüftern austritt, wird empfohlen,

während der Wartungsarbeiten die Abdeckkappe des

Zusatzobjektivs an dieser Öffnung anzubringen, um

Augen und Haut vor den UV-Strahlen zu schützen.

50

Page 51

Lage der Bedienelemente

Linsenversteller

Zoom-Knopf

Fokusring

Einsteller

Temperaturwarnanzeige

(TEMPERATURE WARNING)

Lampenaustausch-Anzeige

(LAMP REPLACEMENT)

Netzanzeige (POWER)

Einlass-Lüftungsöffnung

Einsteller

Fernbedienungssensor

Linsenkappe

Einstelltasten (ADJUSTMENT)

('/"/\/|)

Eingabetaste

(ENTER)

Rückgängig-Taste

(UNDO)

Menü-Taste (MENU)

Skalierungstaste (RESIZE)

Eingangstaste (INPUT)

Netztasten (POWER)

Ein/Aus (ON/OFF)

Seiten- und

Rückansicht

Ansicht von vorne

und oben

Projektor

XV-Z9000U/E

51

Page 52

XV-Z9000U/E

Projektor

Seiten- und

Rückansicht

Einlass-Lüftungsöffnung

Auslass-Lüftungsöffnung

Fernbedienungssensor

Eingang 5 Computer-RGB-Port

(INPUT 5 COMPUTER-RGB)

(15poliger Mini-D-Sub)

S-Video-Eingang 3-Buchse

(S-VIDEO INPUT 3) (4poliger Mini DIN)

Eingang 1 Komponente / RGB-Buchsen

(INPUT 1 COMPONENT / RGB) (RCA)

Einlass-Lüftungsöffnung

RS-232C-Port(9poliger D-Sub)

12 V Gleichstrom-Ausgang

(DC 12V OUTPUT)

Wechselstrom-Buchse

Eingang 2 Komponenten / RGB-Buchsen

(INPUT 2 COMPONENT / RGB) (RCA)

Video-Eingang 4-Buchsen

(VIDEO INPUT) (RCA)

52

Eingangsbuchse für

Drahtfernbedienung

12 V Gleichstrom 200 mAAusgangsbuchse (OUTPUT)

Page 53

Fernbedienung

Netztasten (POWER)

Ein/Aus (ON/OFF)

Eingabetaste (ENTER)

Rückgängig-Taste (UNDO)

Eingang 1-Taste (INPUT 1)

Eingang 2-Taste (INPUT 2)

Eingang 4-Taste (INPUT 4)

Kinofilm-Modus-Taste

(THEATER MODE)

GAMMA-Taste

Taste für automatische

Synchronisation

(AUTO SYNC)

XV-Z9000U/E

Vorderansicht

Menü-Taste (MENU)

Einstelltasten (ADJUSTMENT)

(\/|/'")

Eingang 3-Taste (INPUT 3)

Eingang 5-Taste (INPUT 5)

GRÖSSE ÄNDERN-T aste (RESIZE)

Farbtemperatur-Tasten (CLR TEMP)

Trapeztaste (KEYSTONE)

Hintergrundbeleuchtungs-Taste

(BACKLIGHT)

Ansicht von oben

Fernbedienungssignal-Sender

Einlegen der Batterien

Ziehen Sie die Lasche

1

auf der

Batterieabdeckung nach

unten und nehmen Sie

die Abdeckung in

Pfeilrichtung ab.

BatterieAbdeckung

Eingangsbuchse für

Drahtfernbedienung

Legen Sie zwei AA-

2

Batterien unter

Anpassung der im

Batteriefach

aufgezeigten (+)- und (–)Markierungen ein.

Batteriefach

Setzen Sie die untere

3

Lasche

der

Batterieabdeckung in die

Öffnung ein und drücken

Sie die Abdeckung

herunter, bis sie einrastet.

BatterieAbdeckung

53

Page 54

XV-Z9000U/E

s

Fernbedienung

Mit der Fernbedienung kann der Projektor innerhalb de

links aufgeführten Bereiches gesteuert werden.

45˚

30˚

Fernbedienung

7 m

45˚

30˚

30˚

• Für einfachen Betrieb kann das Signal von der

Fernbedienung von einem Bildschirmreflektiertwerden.

Dennoch variiert die effektive Signalentfernung

entsprechend des Bildschirmmaterials.

Benutzung der Fernbedienung in

einem dunklen Raum

Die Hintergrundbeleuchtung der Betriebstasten kann

durch Betätigung von BACKLIGHT für 5Sekunden

ein- und ausgeschaltet werden. Wenn Sie die

eingeschalteten Hintergrundbeleuchtungen

ausschalten möchten, drücken Sie noch einmal

BACKLIGHT.

Hintergrundbeleuchtungs-Taste

(BACKLIGHT)

Benutzung einer Drahtfernbedienung

Wenn die Fernbedienung aufgrund des Bereiches

oder der Positionierung des Projektors

(Rückprojektion usw.) nicht verwendet werden kann,

schließen Sie ein 3,5 mm Stereo-Minibuchsenkabel

3,5 mm StereoMinibuchsenkabel

(im Handel erhältich)

(im Handel erhältlich) von der DrahtfernbedienungsEingangsbuchse oben auf der Fernbedienung an die

sich auf der Rückseite des Projektors befindliche

Drahtfernbedienungs-Eingangsbuchse an.

54

Page 55

Pin-Belegung

INPUT 5 RGB-Signaleingangs-Port: 15-Pin Mini-D-Sub-Buchse

RGB-Eingang

Analog

1. Videoeingang (rot)

11

6

1

15

10

5

RS-232C-Anschlußstelle: 9-Pin D-Sub-Stecker des DIN-D-Sub RS-232C-Kabels

9 6

5

1