Page 1

SHARI=

SERVICE

MANUAL

SYOC7WQT370AG

WQ-T37OA(

In the interests of user-safetythe set should be restored to its original

condition and only parts identical to those specified be used.

/

SPEC,F,CAT,ONS

STR,NG,,+G OF D,AL CORD

NAMES OF PARTS

DISASSEMBLY

REMOVING AND REINSTALLING THE MAIN PARTS

ADJUSTMENT

EXPLODE,, VIEW

BLOCK DIAGRAM

SCHEMATIC DIAGRAM/WIRING SIDE OF P.W.BOARD

REPLACEMENT PARTS LIST.

...............................................................

................................................................

.....................................................................

................................................................

.............................................................

..........................................................

INDEX TO CONTENTS

........................................................

..................................................

.................................

..l. ,*

..........................

..13~2

.2l-25

GY)

Page

...*

.

.

-5

..6.7

.fj-,,-J

0

SHARP CORPORATION

Page 2

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE

REFER TO THE OPERATION MANUAL.

SPECIFICATIONS

7

General

Power source:

AC 230 - 240 V, 50 Hz

DC 12 V [“D” size

IUM/SUM-l,R20

HP-2 ) battery x 8)

Output power:

(Left + Right + Extra bass)

PMPO; 60 W

(15

W + 15 W + 30

(AC operation)

MPO; 27 W (7.5 W + 7.5 W + 12

(AC operation)

RMS;l6W(4W+4W+8W)

(DC operation, 10% T.H.D.)

Speakers:

8 cm (3-l

/8”)

free-edge super woofer

xl

12 cm

(4-3/4”)

free-edge woofer x 2

Tweeter x 2

Input impedance:

Mixing mic; 600 ohms

CD/Line in; 50 k ohms

Load impedance:

Headphones; 16-50 ohms

(recommended 32 ohms)

Dimensions:

Weight:

Width; 560 mm

Height; 210 mm

Depth; 187 mm

5 kg 11 1

122-l/16”)

(8-5/16”)

(7-3/8”)

Ibs.)

without batteries

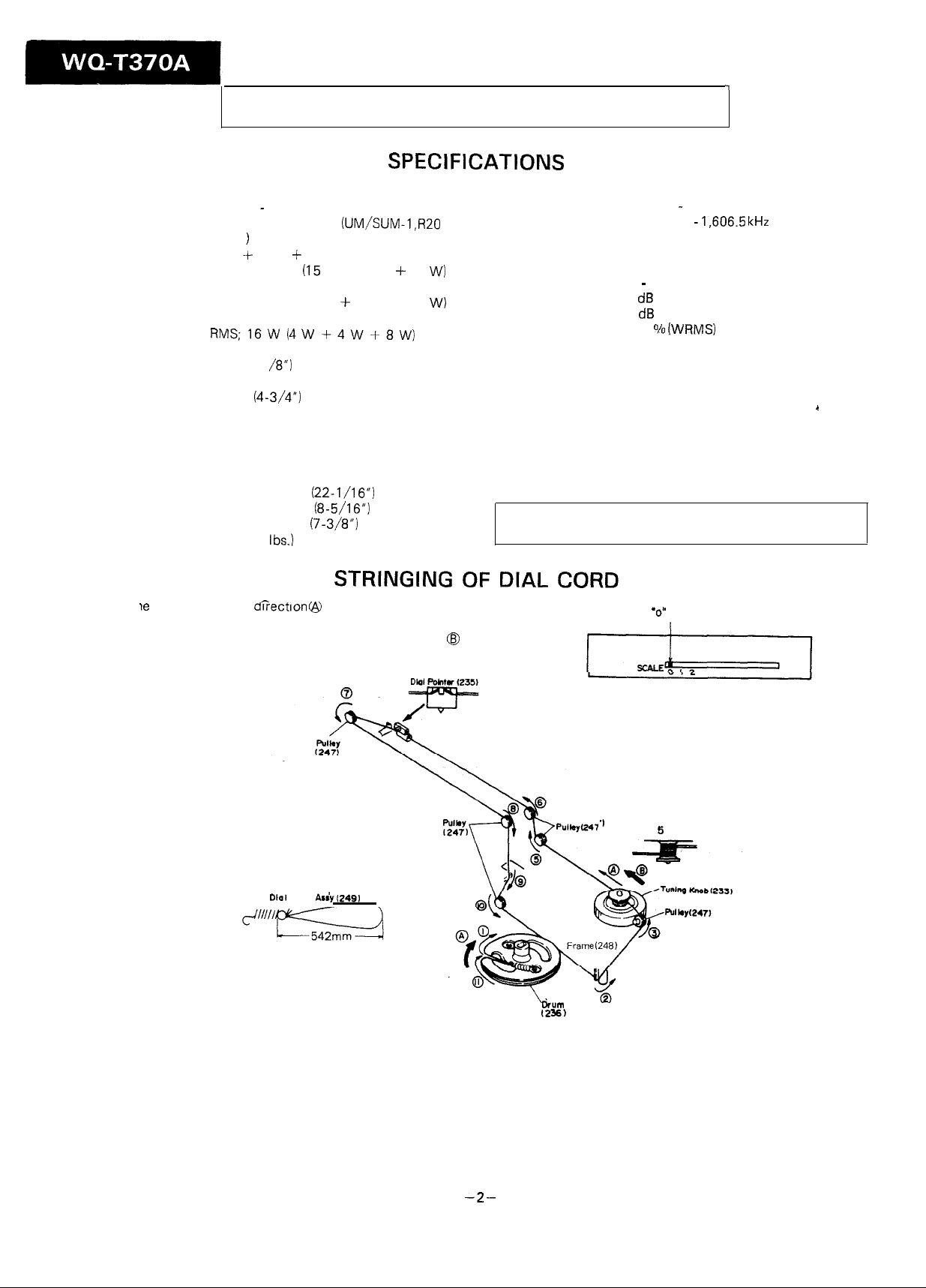

STRINGING

1. Turn tt-le drum fully in the

stretch its cord over the parts in the numerical order.

2. Then turn the tuning control shaft fully in the direction

shown in Fig. 2-2 and fix its pointer as shown in Fig. 2-1.

drrectron (8,

shown in Fig. 2-2 and

Radio

Frequency range:

or

Tape recorder

W)

W)

Tape:

Frequency response: 60 - 12,000 Hz (Normal tape)

Signal/noise ratio:

Wow and flutter:

Specifications for this model are subject to change without

prior notice.

OF DIAL CORD

@

FM; 87.6 - 108 MHz

AM; 526.5 -

I,6065 kHz

Compact cassette tape

55 dB (TAPE 1, playback)

50 dB (TAPE 2, recording/playback)

0.15 oh (WRMS)

4

‘0”

Pdnt

Dial Cord

Asiy(g4g)

Figure 2-1

‘I

.

drum

1236)

5

Turns

Figure 2-2

-2.-

Page 3

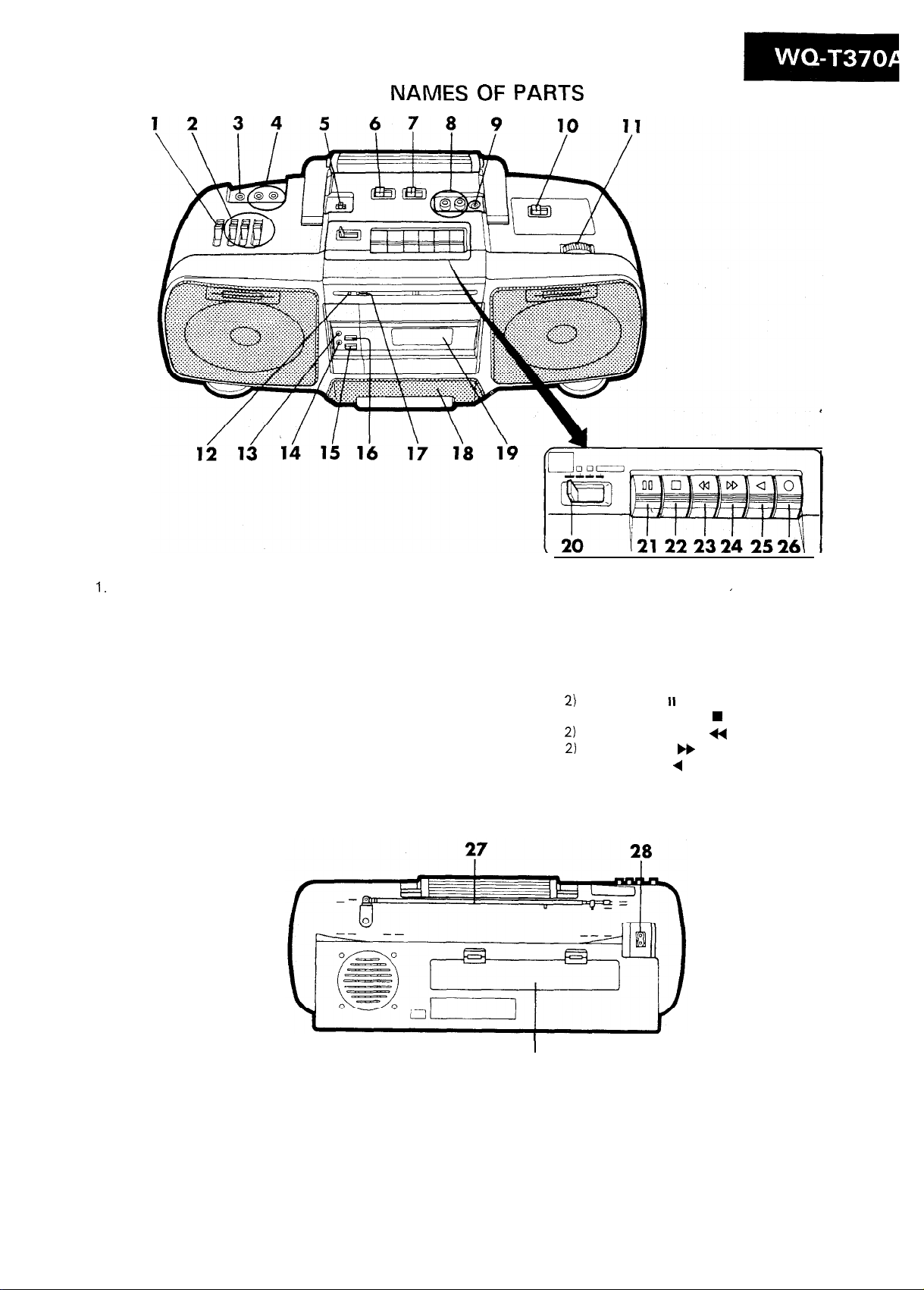

NAMES OF PARTS

1.

Volume Control

2. Graphic Equalizer Controls

3. Headphones Socket

4. Surround Speaker Sockets

5. Beat Cancel Switch

6. Dubbing Speed Switch

7.

Power/Function Switch

8. CD/Line Input Sockets

9. Mixing Microphone Socket

10. Radio Band Selector

11. Tuning Control

12. Power Indicator

13. Surround indicator

14. Extra Bass Indicator: X-BASS

15. Extra Bass Switch: X-BASS

16. Surround Switch

17. FM Stereo Indicator

18. Bass Boost Horn

19. Cassette Compartment

20. Tape Mode Switch

21. TAPE 2) Pause Button: II

22. TAPE 1, 2) Stop/Eject Button: N

23. TAPE 2) Fast Forward Button:

24. TAPE 2) Rewind Button:

25. TAPE 1, 2) Play Button:

26. TAPE 2) Record Button:

),

4

l

3

M

27. FM Telescopic Rod Aerial

28. AC Power Input Socket

I

29

29. Battery Compartment

-3-

Page 4

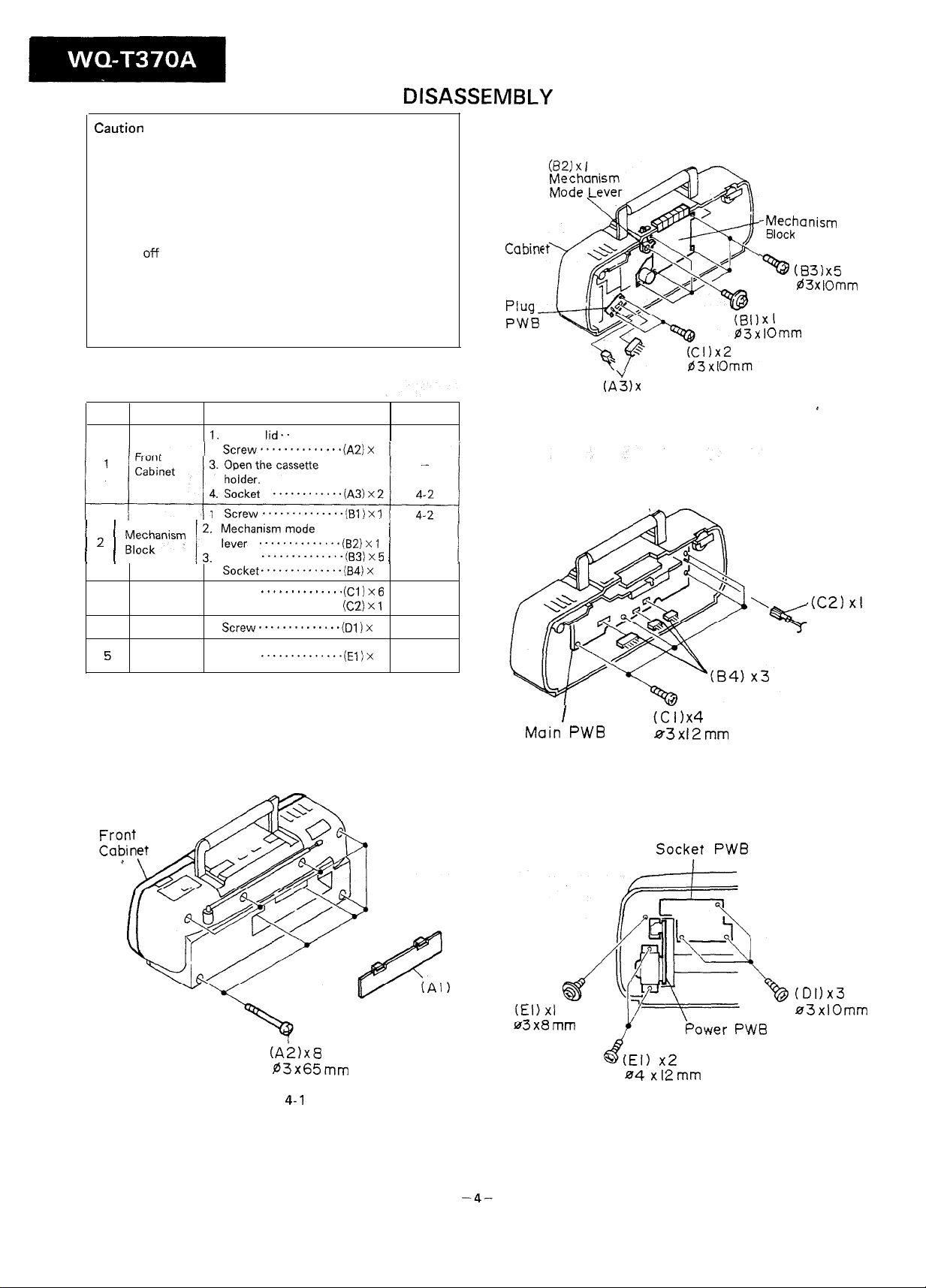

DISASSEMBLY

Caution

Follow

unit and reassembling it, to keep its safety and excellent

performance:

1. Take cassette tape out of the unit.

2. Be sure to remove the power supply plug from the

3. Take

4. Take sufficient care on static electricity of integrated

STEP REMOVAL PROCEDURE

1

2 1

on Disassembly

the below-mentioned notes when disassembling the

wall outlet before starting to disassemble the unit and

remove the batteries from the unit.

off

nylon bands or wire holders where they need be

removed when disassembling the unit. After servicing

the unit, be sure to rearrange the leads where they were

before disassembling.

circuits and other circuits when servicing.

FIGURE

1.

Battery

2.

Screw..............(A2)x

1.

Screw..............(Bl)x

. . . . . . . . . . . . (A,)

lid..

8

I

;;;pnism i2’ ~~ecrharli.“::.mode....iB2)x, 1

Main PWB 1. Screw

3

(with Frame) 2. Tip

4 Socket PWB 1.

Power

5

PWB

3. Screw

4.

1. Screw

....*.........(B3)x!j

Socket..............(B4)x

..............

................

Screw..............(Dl)x

..............(El)x

(Cj)x6

((-2)

x,

3

4-2.3

3 4-4

3

4-1

4-3

4-3

4-4

Rear

Cabins

Plug-

PWB

(Av3)x

2

Figure 4-2

-hJvl;fanism

-?a

(B3lx5

d3xlOmm

Xl

:IOmm

,(C2) xl

Figure

(Ahx8

d3x65mm

4-I

Main

I

PWB

(C 11x4

83xI2mm

Figure 4-3

Socket

Q

* (El) x2

04 x12mm

Figure 4-4

PWB

(DlJx3

03 xl Omm

Power PWB

-4-

Page 5

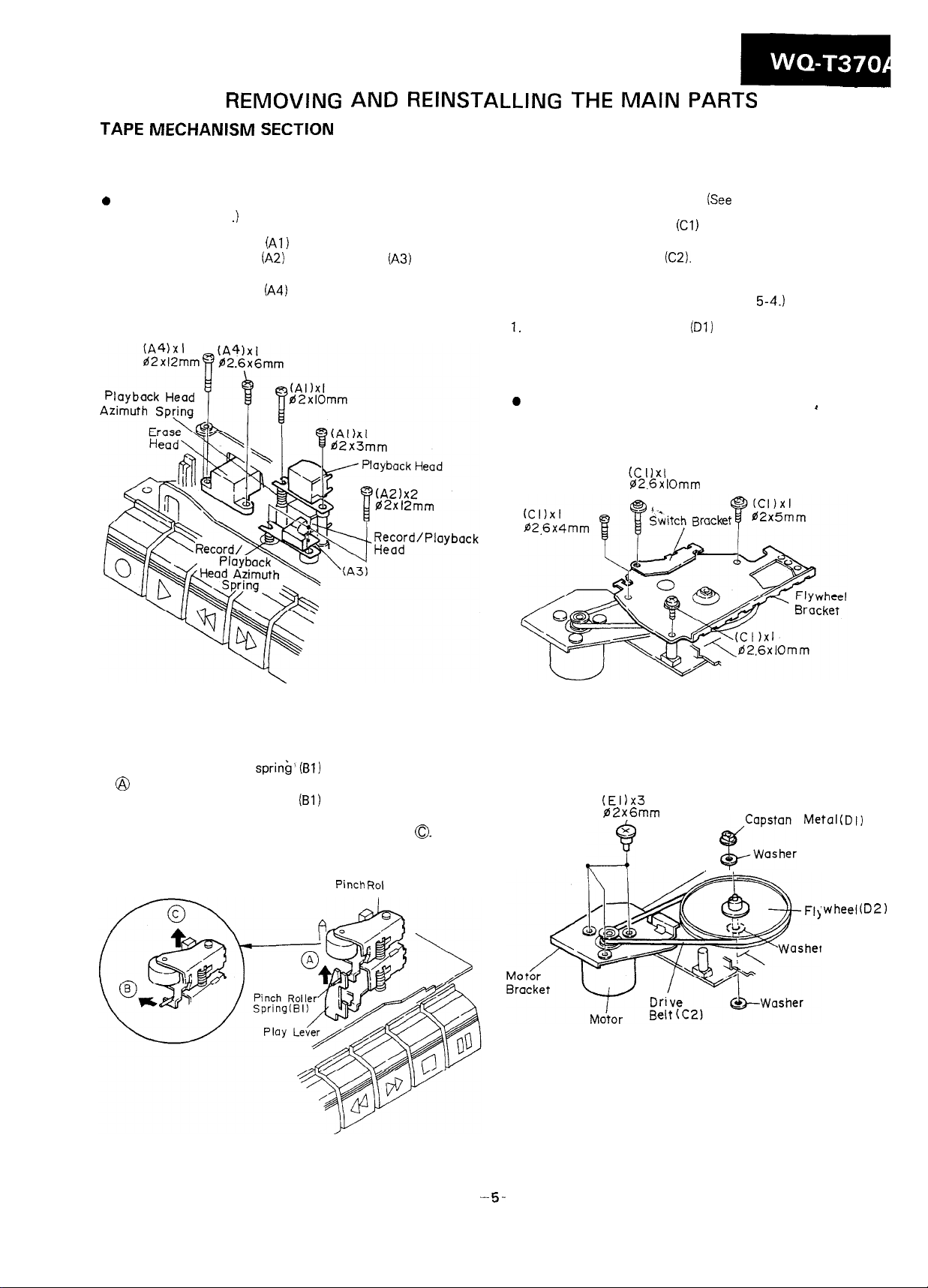

REMOVING

AND

REINSTALLING THE MAIN PARTS

TAPE MECHANISM SECTION

Perform steps 1 and 2 of the disassembly method to remove the

tape mechanism.

0

How to remove the playback, erase and record/playback

heads (See Fig. 5-l

1. Remove the two screws

2. Remove the two screws

the record/playback head.

3. Remove the two screws

Note:

Be careful not to lose the head azimuth springs.

.)

(Al)

to remove the playback head.

(A2)

and shield cover

iA4j

to remove the erase head.

(A3)

to remove

l

How to remove the drive belt

1. Remove the four screws (Cl i to remove the flywheel bracket

and switch bracket.

2. Remove the drive belt iC2).

l

How to remove the flywheel (See Fig.

1.

Remove the capstan metal

Note:

Be careful not to lose the three washers.

(See

Figs. 5-3 and 5-4.)

5-4.)

(Dl)

and pull out the flywheel.

Figure 5-l

l

How to remove the pinch roller (See Fig. 5-2.)

1. Move the pinch roller

@

to remove it from the play lever.

2. Move the pinch roller spring

@to remove it from the pinch roller unit.

3. Remove the pinch roller in the direction of arrow

sprin$‘(Bl)

(Bl)

in the direction of arrow

in the direction of arrow

Metal

~

0

How to remove the motor. (See Fig. 5-4.)

1. Remove the three screws (El) to remove the motor.

cc 11x1

82.6x

IOmm

Figure 5-3Figure 5-3

(El)x3

P2x6mm

0.

Q

,

$@;;;a

Figure 5-2

Pinch Rol

ler

,wheel(D2)

Figure 5-4

-5-

Page 6

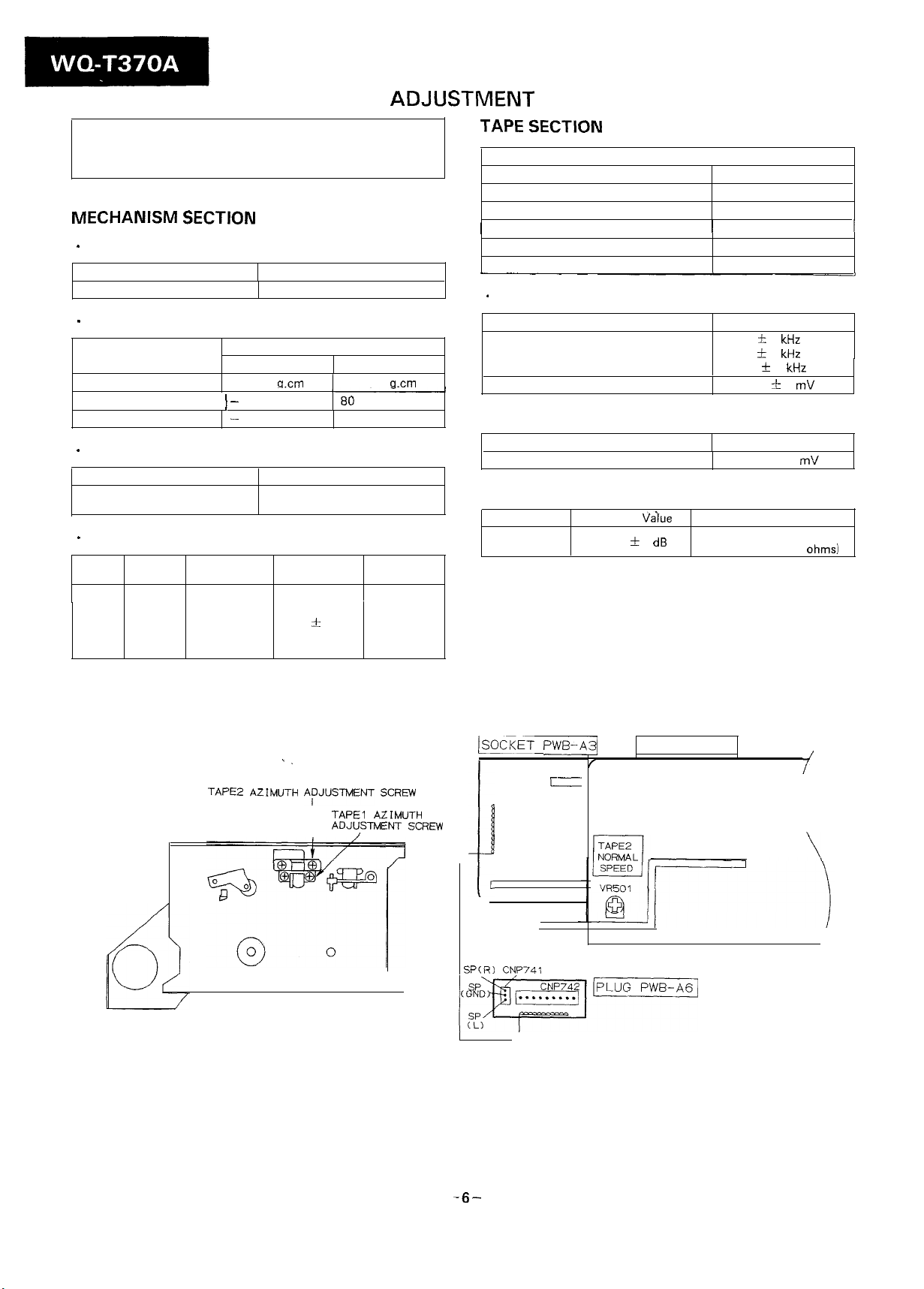

ADJUSTMENT

As for adjusting method refer to the relevant explanation in

Service Manual “ADJUSTMENT PROCEDURES OF AUDIO

PRODUCTS”.

MECHANISM SECTION

-

Driving Force check

Torque Meter

Play: TW-2412

9

Torque Check

Torque Meter

Play: TW-2111

Fast forward: TW-2231 )

Rewind: TW-2231

*

Head Azimuth

Test Tape

MTT-114

*

Tape Speed

Test Tape Adjusting Point Specified Value

Normal

speed

MTT-111 Tape 2: VR501 3,000 + 300 Hz (Load

35 to

-

-

Tape 1

60

Specified Value

Over 140 g

Specified Value

Tape 2

u.cm

Instrument Connection

Speaker terminal

(Load resistance: 4 ohms)

30 to 65

80

80 to 135 g.cm

a.cm

to 135 g.cm

Instrument

C

onnection

Speaker

terminal

resistance:

4 ohms)

TAPE

SECTION

Position of each switch or control

Volume

Beat cancel switch

Graphic equalizer

1

Tape speed

Mechanism mode

Function

*

Bias Oscillation Frequency/Bias Current check

Beat cancel B: -2 t 2 kHz for A

Resistor

measurement:

for

100 ohms

Max

A/STEREO

Center

1

Normal

2

Tape

Specified Value

A: 97 + 4 kHz

-7 f2 kHz for

C:

383~5

. Erase Current check

Specified Value

Resistor for measurement: 1 ohm

65 4 20

. Playback Amplifier Sensitivity check

Test Tape Specified

MTT-118 1.0 V t 3 dB

Vaiue

Instrument Connection

Speaker terminal

(Load resistance: 4 ohms)

-1

B

mV

mV

TAPE2 AZIMUTH AfJJUSTWNT

TAPE1

AZIMUTH

ADJUSTMENT SCREW

/

Figure 6 ADJUSTMENT POINTS

SCREIW

ISOCKET PWB-~31

r

:

SP(R)

CvP74Z

MAIN PWB-Al

/

TAPE2

NORMAL

r---L

/

-6-

Page 7

TUNER SECTION

fL:

Low-range frequency

fH:

High-range frequency

. FM IF/RF

Test Stage

IF

. VCO Frequency

Adjusting Point

VRl

*

AM IF/RF

Test Stage

IF

AM Band

Coverage

AM Tracking

Specified

Tl

Specified Value/

Adjusting Point

T3

fL:

fH:

600

1,400

Value/

Adjusting Point

Specified Value

38 kHz + 100 Hz

L5

TC4

kHz: L3

kHz: TC3

Instrument Connection

Instrument Connection

Pin 6 of IC3

Instrument Connection

Input: Antenna

Output: Pin 9 of IC2

(TPI)

FM

BAND

COVERAGE

Ll

c

1 MAIN PwB-Ai)

Figure 7 ADJUSTMENT POINTS

-7-

SW1

E4

-I-

J

Page 8

TOP

VIEW

I i

510

1

I

2

I

Figure 8 TAPE MECHANISM EXPLODED VIEW

3

I

-a-

4 5

(l/Z)

I

6

I

Page 9

BOTTOM VIEW

A

8-\

512

B

C

D

,E

F

G

H

I6

-

-

1

I

2

I

Figure 9 TAPE MECHANISM EXPLODED VIEW

3

I

-9

4

I

(2/2)

5

I

6

Page 10

C

6Oix4

‘SPl,Z

D

E

F

G

H

L

1

I

2

I

Figure 10 CABINET EXPLODED VIEW

3

I

4

I

5

250

/

I

6

I

-lO-

Page 11

l

Page 12

. NOTES ON

1

SCHEE

I

2

I

3

I

-13-

4

5

I

6

I

Figdk’l~‘!k!ti~k~T~~

I

7

DIAGRAM

(i/2)

9 9

I

-14p

10

I

11

I

12

I

I

Page 13

I ’

-

I

Page 14

i

r

Page 15

NOTES ON SCHEMATIC DIAGRAM

ResIstor:

To differentiate the units of

used: the symbol K means 1000 ohm and the resistor

without

any symbol is ohm-type resistor.

Capacitor:

To indicate the unit of capacitor, a symbol P is used: this

symbol P means

wthout such a symbol is

capacitor, the expression “capacitance/withstand voltage” is

used.

ICH), ITH). IRH), IUJ):

(ML]:

Mylar type

(P.P.1: PolVpropylene

The

indicated

Diaital

with

1. Tuner

( I:

Marking

2.

IClOl

1):

{ I:

Marking except for (

3.

Q-251

Record mode

4.0152

I):

5. M501 (Motor)

I):

Parts marked with

the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance

of the set.

Schematic Diagram and Wiring Side of

model are

voltage !n each

Multimeter between such a section and the chassis

no

slgnal

given.

AM mode

except for ( 1: FM mode

Tape 2 mode

Dubbing mode

Normal/High Speed

High Speed Dubbing mode

sublect

to change for improvement without prior

resrstors,

such symbol as K is

picofarad

and the unit of the capacitor

mlcrofarad.

Temperature compensation

type

sectfon IS

1

II:

Tape 1 mode

Dubbing

“A”

(“I”) are important for maintaining

As to electrolytic

the one measured by

mode

P.W.Board

for this

2Sc1740

SR

2X2001

K

2X2236

1

2

I

I

Figure 19 WIRING SIDE OF

3

-19s

I

4

P.W.9OAP.D

(2/21

6

I

5

I

I

Y

lJ

SLR34VR3

SLR34MG

^

-2o-

Page 16

1 ICl

IC2

lC3

) IClOl

IC401

IC701

IC751

Q101,102

Q151,152

Q251

Q301,302

Q351,352

0451

Q471

Q501,502

Q703

Q771.772

Q781

D3

D4

0101,102

D105

D451

D452

0471

D501

8D601--604

D701-703

D761

D762

CFI

CF2

CF3

Tl

TZ

T3

&T601

REPLACEMENT PARTS LIST

“HOW TO ORDER

*MARK:

NOTE:

Parts marked with “01” are important for maintaining the safety of the set. Be sure to replace these parts wtth specified ones

for maintaming the safety and performance of the set.

REF.NO.

PART NO.

VHiTA7378P/-1

VHrTAEllOAP-1

VHiTA7343P/-1

92LiC-TA8189N J

92L iC-TA8207K

VH1BA3706//-1

VH I TA7283AP-

VSZSC1740SR-1

VSZSC174OSR-1

VSZSCZOOI-K-l

VSZSCl740SRVSZSCl740SRVSZSC2236Y/VSZSCl740SR- 1

VSZSCl740SR-1

VSZSC1740SRVSZSC174DSR-1

VSZSCZOO I-K-

VHDlSS133//-1

VHPSLR34VR3-1

VHDlSSl33//-1

VHDlSS133//-1

VHERDBRZJBL-1

VHPSLR34VR3-1

VHDlSS133//-1

VHDlSSl33//-1

VHDIOE-4FD/-1

VHDlSS133//-1

92LLED-SLR34MG

VHPSLR34VR3-1

RCi LA062OAFZZ

92LFiLTFml342A

RF i

LA0057AFZZ

RCiLi0405AFZZ

RC I L I 0406AFZZ

RClLi0407AFZZ

92LPT-1240A

SPARE PARTS-DELIVERY SECTION

*

DESCRlPTlON

INTEGRATED CIRCUITS

J FM Front End,TA7378P

J FM/AM

J PLL FM

J Power Amp.,TA8207K

J APSS,BA3706

1

TRANSISTORS

J Sllicon,NPN,ZSC1740 SR

J

J S~lican.NPN.2SC2001 K

1

1

1

J Sllicon,NPN,ZSC1740 SR

J SIIICO~,NPN,ZSCI~~O SR

1

J Silicon,NPN,ZSC1740 SR

1

DIODES

J

J LED,Red,SLR34VR3

J

J

J Zener.8.2V,RD8.2JBZ

J LED.Red.SLR34VR3

J

J

J Silicon,lOE~4FD

J

J LED,Green,SLR34MG

J LED,Red,SLR34VR3

FILTERS

J FM IF,10.7

TRANSFORMERS

J FM IF

J AM IF

IF,TABllOAP

Pre. Amp..TA8189N

J Silicon.NPN.ZSC1740 SR

MPX.,TA7343AP

J Power Amp.,TA7283AP

Silicon,NPN,ZSCl740

J

Sihcon,NPN,ZSCl740

J Sllicon.NPN.ZSC1740 SR

J Sillcon,NPN,ZSC2236 Y

J Silicon,NPN,ZSCZOOl K

Silicon.lSS133

SiliccqlSS13.3

Silicon.lSSl33

Silicon.lSSl33

Silicon,lSSl33

Silicon,lSSl33

J FM Band Pass Filter

J AM IF,455

J FM Detector

J

Power

ktiz

MHz

REPLACEMENT PARTS”

CODE REF.NO.

AE

AC

AC

AL

AL

At

Ak

AE

SR

AE

AC

SR

AE

AE

AC

A@

AE

A@

AP

AC

AA

A!3

AA

AA

AB

AB

AA

AA

AB

AA

AC

AB

AC

AD

AD

AC

AC

AC

AV

PART NO. *

COILS

Ll

L2

L3

L5

L201.202

L251

L471

VRl

VR302-304

VR401

VR501

VCl-4

There are

other by reading

ceranw

A symbol “c” or “K” is

K)

Semiconductor type capacitor:

A symbol “T” 1s

The capackance error of each capacitor IS Indicated by the symbol

13th dlgit of the Part Number as

“N”

(Tubular type

Part NO.

(Tubular type

NO. VCOOMFWWYK”X,0:

Unless otheiwse specified,

Cl

c2

c3

c4

c5

C6

c7

Cl1

Cl2

RCiLR0364AFZZ

92LCoiL6-523A

YZLCoiLA-1556A

92LCGiLs-666A

RCiLZ0155AFZZ

VPmCK331KOOOO

RCiLF0014AGZZ

VARIABLE RESISTORS

RVR-MO216AFZZ

RVR-QOZZZAFZZ

RVR-QOLLlAFZZ

RVR-M0391AFZZ

VARIABLE

RVC-R0085AFZZ

two

types of

capacitors

thew

type capacitor:

J.,’

(230%). ‘72”

Part Numbers.

given

@“en

at the 3rd digit of its Part Number

(i0.25

pF),

ceramic

VCOOTV(TQ/CY)OOOOO~O. this

capacitor is

ceramic

capacitor 1s

thts

VCCSMNIHLIOOJ

VCKYMNlHBlOZK

VCCSMNlHL4R7K

VCCCPAIHHZZOJ

VCCCMNlHHlSOJ

VCCRPAlHHZZOJ J

VCCCMNlHH3R3K

VCTYMNlCX472K

RC-GZA474AFlH

J’FM RF

J FM Oscillation

J AM Bar Antenna

J AM Oscillation

J 6.8 mH

J 330

J

47fiH

J

10

J

100

J 20 kohms

J 10 kohm

CAPACITOR

J Variable Capacitor with

CAPACITORS

available and they can be idenwed from each

at the 3rd diglt of

follows:“J” (i5%), “K”(+lO%),

“D” (+O 5

pF), “L” (+80-20%)

identified

TV(TQ/CY) does

identified

MF(MN) does not mean the lead

electrolytic capacitors are f20%

by the symbol MF(MN) of the part

J 10

J

0.001

J 4.7

J 22 pF (CH),SOV AA

J 15 pF (CH),SOV AA

22 pF (RH),SOV AA

J 3.3 pF (CH),SOV AA

J 0.0047

J 0.47 pF,SOV,Electrolytlc

DESCRlPTlON

sH,Choke

kohm

(B),Semi-VR

NC01

kohm

(B)XZ

EQ.1

(BIX

2

[vdumej

(B).Semi-VR

,.

[Tape 2 Normal

Speed1

Trimmer

its

Part Number

by the symbol TV(TQ/CY) of the

not

mean the lead wire.)

type.

pF,SOV

vF,50V

pF,6OV

$F,16V

CODE

AA

AA

AH

AA

AC

AB

AC

AB

[Graphic A E

AE

AB

A L

lake “VCC (or

Ike

“VCT... ..J.”

given

at the

“M”

(?20%),

we.)

AA

AA

AA

AA

A A

REF.NO.

Cl4

Cl5

Cl6

Cl7

C18,19

c20

c21

c23

C24

C25

C26

C27

C28

c29,30

C31.32

c33,34

c39

c45

c101,102

c103,104

ClO5,106

C107.108

c109.110

c111,112

c113,114

Cl15

Cl16

c119,120

ClZl-124

Cl25

Cl51

Cl52

Cl53

Cl54

Cl57

c201.202

C205,206

c209,210

c211,212

C213,214

C216

C217,218

c219,220

c221,222

C251,252

C253

C254

C255

C256

C257

C258

C301.302

c303,304

C305,306

c307

c309,310

C311.312

C341,342

c343,344

C351,352

c353.354

C355,356

C357.358

C363.364

C365,366

C367

C371.372

c373,374

C383,384

PART NO.

VCTYMNlEF223Z

VCKYMNlHElOEK

VCTYPAlEX333K

RC-GZA226AFlA

VCTYMNlEF223Z

VCKZPAlHF473Z

VCTYMNlEF223Z

RC-GZAlOfiAFlC

RC-GZAIOSAFIH

RC-GZA335AFlH

VCQSMVlHLlOPJ

RC-GZAlOSAFlH

RCmGZA477AFlA

VCTYPAlEX223K

RCmGZAlOSAFlH

VCTYMNlEF223Z

VCKYMNlHBZLlK

VCCRPAlHHBRLD

VCKYMNlHB561K

VCKYMNlHB681K

VCKYMNlHB33lK

RC-GZA476AFlA

VCTYPAlEX333K

VCKYMNlHE33lK

RC-GZA335AFIH

RC-GZVlOBAFlA

RC-GZA225AFlH

VCKYMNlHB471K

VCKYMNlHBl5lK

RC-GZA106AFlC

RC-GZAlOSAFlH

VCKYMNlHEPZlK

RC-GZAlOSAFlH

RCmGZAl07AFIA

VCTYMNOJY223N

VCTYMNlCX472M

RC-GZA335AFlH

RC-GZAl06AFlC

VCTYMNOJY153M

VCTYPAlEX104K

RC-GZA476AFlA

VCKYMNlHB331K

VCKYMNlHBlOZK

VCTYPAlEXl83K

VCKYMNlHBlSlK

VCKYPAIHB68lK

VCKYPAlHBlBlK

RCmQZAl03AFYK

VCQPKAZAA472J

RCmQZA563AFYJ

RC-GZA107AFlC

RC-GZA475AFlC

VCKYMNIHBZLIK

RC-GZA226AFlA

RC-GZA107AFlA

VCKYMNlHB561K

VCTYMNlCX472K

VCTYMNOJY223N

VCTYMNlCY103K

VCTYMNOJY153M

VCTYMNlCX682K

VCTYMNlCX392K

VCTYMNlCX272K

RC-EZD225AFlH

VCKYMNlHB33lK

RCmGZA476AFlA

VCTYPAlCX823J

VCKYMNlHBlOLK

VCTYMNOJY153M

DESCRIPTION

*

J

0.022 pF,25V

J

0.001

/1F,5OV

J

0.033 /1F,25V

J

22

~F,lOV,Electrolytic

J

0 022 IrF,25V

J

0.047 /rF,SOV

J

0.022 pF.25V

J10

gF,16V,Electroiytic

J

1 aF,SOV,Electrolytic

J

3.3 pF,5OV,Electrolyt!c

J

0.001

/IF,SOV,Styrol

J1 ~F,SOV.Electrolytic

J

470

pF,lOV,Electrolytic

J

0.022 pF.25V

J1 ~F,SOV,Electrolytic

J

0.022 pF.25V

J

220

pF,SOV

J 8.2 pF (RH),SOV

J

560

pF,SOV

J

680

pF,SOV

J

330

pF,SOV

J

47

~F,lOV,Eiectrolytic

J

0.033 fiF,25V

J

330

pF.SOV

J

3.3 yF,SOV,Electrolytic

J

1000

~F,lOV,Electrolytic

J

2.2 ~F,50V,Electrolytlc

J

470

pF,SOV

J

150

pF.SOV

J

10

pF,lBV,Electrolytic

J1 pF.SOV,Electrolytic

J

220

pF,SOV

J1 rF,50V,Electrolytic

J

100

pF,lOV,Electrolytic

J

0.022 pF.6.3V

J

0.0047 pF,16V

J

3.3 pF.SOV,Electrolytic

J

10

/1F,16V,Ekctrolytlc

J

0.015

pF,6.3V

J

0.1

fiF,25V

J

47

rF,lOV.Electrolytic

J

330

pF,SOV

J

O.OOi JIF,SOV

J

0.018 /1F,25V

J

150

pF,SOV

J

680

pF.SOV

J

180

pF,SOV

J

0.01

pF,SOV,Mylar

J

0.0047

rF,lOOV,

Polypropylene

J

0.056 fiF,SOV,Mylar

J

100

pF,16V,Electrolytlc

J

4.7 gF,16V,Electrolytic

J

220

pF,SOV

J

22

~F,lOV,Electrolytic

J

100 ,uF.lOV.Electrolytic

J

560

pF,SOV

J

0.0047

,‘F,16V

J

0.022

rF,6.3V

J

0.01

/rF,16V

J

0.015 fiF.6.3V

J

0.0068

#F,16V

J

0.0039

pF,l6V

J

0.0027 pF,16V

J

2.2 ~F,SOV,Electrolytic

J

330

pF,SOV

J

47 gF,1OV,Electrolyt~c

J

0.082

rF,16V

J

0.001

fiF,16\c

J

0.015

rF.6.3V

CODE

REF.NO.

AP

C401.402

AP

c403,404

AP

C405,406

AE

C407,408

c409,410

AA

AP

C411,412

c413

AP

c451

A!?

C452

A@

c453

AE

AE

c454

A@

c455

C456

AC

c471

AP

AE

c473

AA

c501

AA

C502

AA

C601-604

AA

c701

AA

C702,703

AA

c704

AB

C705.706

AA

c707

AA

C708

AB

C766

AD

c771

AB

C772

AA

c773

AA

c774

C776

AB

AB

c777

AA

C780

AB

C781

AB

C782

AA

C783

AA

c784

AB

C785

AB

C786

AA

C788

AB

C789.790

AB

c79 1,792

AA

c793.794

AA

AA

AA

(Unless otherwise ~pwf~ed, resistors are ?5%,carbon type) (Tubular type

AA

carbon

AA

AB

AB

AB

AB

AB

AA

AB

AB

AA

AA

AA

AA

AA

AA

AA

AA

AB

AA

AP

A/

A/

A/

film

MF(MN)OOOOOOO; this

RI

R2

R3

R4

R5

R6

R7

RE

R9

RIO

Rll

Rl2

R13

R14

R15

16

R17,18

R20

R23.24

R33

PART NO.

RC-GZA476AFlA

VCKYMNlHBlOLK

RC-GZA336AFlA J

RC-GZA107AFlA

RC-QZAl84AFYK

RC-GZVlOBAFIA

RC-GZA337AFIA

RC-EL 125

VCTYMNlEF223Z

VCTYPAlEX223M

VCTYMNlEF2232

RCmGZAlOlAFlA

VCTYPAlEX222M

RC-GZA107AFlC

RC-GZA336AFlC

VCKZPUlHF2232 J 0.022

VCCSPUlHLlOlJ

VCKZPAlHF1032 J 0.01 #F,SOV

VCTYMNlCXlSLK

RC-GZA474AFlH

RCmGZA107AFlA

RC-GZA474AFlH

RGGZA475AF

VCTYMNlEF223Z

RC-GZA335AF 1H J 3.3 rF,SOV,Electrolytic

VCTYMNlEF223Z

RC-GZA107AFlA J

RC-GZAl05AF IH

VCKYMNlHBZZlK

VCTYPVlEX104K

VCTYPAlEX683K

RC-GZALOSAFLH

RC-GZA226AFlA

RC-GZAlOSAFlH

VCTYPAlEXlOLJ J

RC-GZAl04AF 1H

RC-GZA107AFlA

RC-GZA477AFlC

VCTYPAlEXl04K

RCmGZA107AFlA

RC-QZA184AFYK

RCmGZVlOBAFlA

resistor

+5%

is

MF(MN) does “at mean lead

VRD-MNZBDOOOC

VRD-STZCDlOOJ

VRD-MN2BD47OJ

VRD-MNLBD104J

VRD-STZCD104J

VRD-MNZBD562J J

VRD-STZCDlO

VRD-STZCD33

VRD-MNZBD472J

VRD-STZCD470J

VRD-MNLEDlOLJ

VRD-MNZBD682J

VRD-STZCD561J

VRD-MNzBD224J J

VRD-STZEE270J

VRD-STZCD332J

VRD-STZCDl23J J

VRD-MNZBD152J

VRD-MN2BD182J

VRD-ST2CD330J

*

DESCRKWON

J 47

aF,lOV,Electrolytic

J

0.001

pF,50V

33

sF.lOV,Electrolytic

J

100

@F,lOV,Electrolytic

J

0.18

pF,50V,Mylar

J

1000

~F,lOV,Electrolytlc

J 330

~F,lOV,Electrolytic

J 3300

ZAFZZ

1H J 4.7

RESISTORS

identlfled

1 J

1 J

pF.lhV,Electrolyt\c

J

0.02ZpF,25V

J 0.022

@F,25V

J 0.022

#F,25V

J 100

~F.lOV,E,ectro,yt,c

J 0.0022 wF,25V

J 100

fiF.l6V,Electrolytlc

J 33

flF,l6V,Electrolytic

gF,SOV

J

100

pF.SOV

J 0.0018

j.zF.16V

J 0.47 /IF.50V,Electrolyttc

J 100

pF,lOV,Electrolytic

J 0.47 pF,SOV,Electrolytic

rF,50V,Elsctrolytic

J 0.022 pF,25V

J OOZZaF.ZSV

100

~F,lOV,Electrolytlc

J 1 ~F,SOV.Electrolytic

J 220

pF,SOV

J

0.1

/1F.25V

J 0.068

sF.25V

J 1 pF,SOV,Electrolytic

J 22

pF,lOV,Electrolytic

J 1 #F,SOV.Electrolytic

0.001

pF,25”

J 0.1 rF,SOV.Electrolytic

J

100

rF,lOV.Electroiytlc

J 470 pF,16V,Electrolytic

J

0.1

irF,25V

J

100

,uF.lOV.Electrolytic

J 0.18 pF,SOV.Mylar

J

1000

aF,lOV,Electrolytlc

the symbol MF(MN) of the part NO.

J 0 ohm.Jumper.~1.4X3.5nm, A A

J 10

J 47

J

J 100

5.6

J 4.7

J 47 ohms,1/6W

J 1

J 68

J 560 ohms,1/6W

220

J 27

J 3.3

12

J 1.5

J 1.8

J 33

100

J 100

J 330

IWY

ohm,l/6W

ohms.l/8W

kohm.l/8W

kohm,l/6W

kohms,l/BW

ohm,l/6W

ohms,l/6W

kohms.l/8W

kohm,l/8W

kahms.ll8W

kohms,li8W

ohms.l/4W

kohms.l/6W

kohms.l/6W

kohms,l/8W

kahms.l/8W

ohms,l/6W

we.)

CODE

AB

AA

AB

AB

AC

AD

AB

AF

AA

AA

AA

AB

AA

AB

A0

AA

AA

AA

,AA

AA

AB

AA ;

AB

AA

AB

AA

AB

AB

AA

AB

AB

AB

AB

AB

AB

AB

AB

AC

AB

AB

AC

AD

VRO-

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

Ak

A$

AA,

APf

P

(!

Page 17

REF.NO.

R101,102

R103,104

R105,106

R107,108

R109,llO

Rlll

R112

R113

R114

R115,116

R117,118

R119

R120

R121

R123,124

R125-128

R130

R131-133

R134

R151

R152

R153

R154

R155

R156

R157,158

R201,202

R203,204

R205,206

R207,208

R209,210

R211,212

R213,214

R215,216

R217

R250

R251

R252

R253

R254

R255

R256

R257

R301,302

R303,304

R305,306

R307,308

R309,310

R3l+1,312

R313,314

R315,316

R317

R341,342

R343,344

R345,346

R347,348

R349,350

R351-354

R355,356

R357-360

R361,362

R363,364

R365,366

R367,368

R371,372

R373,374

R375,376

R377,378

R401,402,

>,R403.404

PART

NO.

VRD-MN2BD560J

VRD-MN2BD683J

VRD-MN2BD472J

VRD-MN2BD184J

VRD-MNZBD562J

VRD-STPCD103J

VRD-MN2BD103J

VRDST2CD562J

VRD-MN2BD562J

VRD-MN2BD223J

VRD-MN2BD683J

VRD-MN2BD562J

VRD-ST2CD562J

VRD-MN2BD562J

VRD-ST2CD123.l

VRD-MN2BD103J

VRD-ST2EE470J

VRD-STPCD102J

VRD-MN2BDlOPJ

VRD-ST2CD561J

VRD-MN2BD334J

VRD-MN2BD472J

VRD-ST2CD56

1 J

VRD-MN2BD390J

VRD-ST2CD103J

VRD-MN2BD103J

VRD-ST2CD153J

VRD-MN2BD103J

VRD-MN2BD274J

VRD-MN2BD122J

VRD-MN2BD561J

VRD-MN2BD563J

VRD-MN2BD682J

VRD-MN2BD394J

VRD-MNPBD105J

VRD-ST2EE330J

VRD-ST2EE181J

VRD-MNZBD223J

VRD-MN2BD393J

VRD-ST2CDlOOJ

VRD-MNPBDlOlJ

VRD-ST2CD270J

VRD-ST2EE151J’

VRD-MN2BD473J

VRD-ST2CDlOPJ

VRD-MN2BDlOPJ

VRD-MN2BD103J

VRD-MN2BD224J

VRD-MN2BD151J

VRD-MN2BD272J

VRD-MNPBDlOPJ

VRD-ST2CD561J

VRD-MN2BD333J

VRD-MN2BD153J

VRD-MN2BD562J

VRD-MN2BD223J

VRD-MNPBD104J

VRD-MN2BD822J

VRD-MN2BD682J

VRD-MN2BD472J

VRD-MN2BD152J

VRD-MN2BD332J

VRD-MN2BD472J

VRD-MN2BD27

1 J

VRD-MN2BD684J

VRD-MN2BD392J

VRD-MN2BDlOPJ

VRD-MN2BD562J

VRD-MN2BD102J

VRD-MN2BD15lJ

*

J

56

J

68

J

4.7

J

180

J

5.6

J

10

J

10

J

5.6

J

5.6

J

22

J

68

J

5.6

J

5.6

J

5.6

J

12

J

10

J

47

DESCRIPTION

ohms,l/aW

kohms,l/8W

kohms,l/8W

kohms,l/8W

kohms,l/8W

kohm,l/6W

kohm,l/aW

kohms,l/6W

kohms,l/8W

kohms,l/8W

kohms,l/dW

kohms,l/8W

kohms,1/6W

kohms,l/8W

kohms,l/6W

kohm,l/aw

ohms,l/4W

J1 kohm,l/6W

J1 kohm,l/dW

J

560

ohms,l/6W

J

330

kohms,l/dW

J

4.7

kohms,l/8W

J

560

ohms,l/6W

J

39

ohms,l/8W

J

10

kohm,l/6W

J

10

kohm,l/8W

J

15

kohms,l/6W

J

10

kohm,l/8W

J

270

kohms,l/8W

J

1.2

kohms,l/8W

J

560

ohms,l/aW

J

56

kohms,l/8W

J

6.8

kohms,l/8W

J

390

kohms,l/8W

J1 Mohm,l/8W

J

33

ohms,l/4W

J

180

ohms,l/4W

J

22

kohms,l/8W

J

39

kohms,l/aW

J

10

ohm,l/GW

J

100

ohm,l/aW

J

27

ohms,l/6W

J

150

ohms,l/4W

J

47

kohms,l/8W

J1 kohm,l/6W

J1 kohm,l/bW

J

10

kohm,l/8W

J

220

kohms,l/8W

J

150

ohms,l/8W

J

2.7

kohms,ll8W

J1 kohm,l/aW

J

560

ohms,l/6W

J

33

kohms,l/dW

J

15

kohms,l/bW

J

5.6

kohms,l/8W

J

22

kohms,1/8W

J

100

kohm,l/dW

J

8.2

kohms,l/8W

J

6.8

kohms,l/dW

J

4.7

kohms,l/8W

J

1.5

kohms,1/8W

J

3.3

kohms,l/8W

J

4.7

kohms,l/bW

J

270

ohms,l/8W

J

680

kohms,l/8W

J

3.9

kohms,l/aW

J1 kohm,l/8W

J

5.6

kohms,l/8W

J1

kohm,l/8W

J

150

ohms,l/8W

CODE

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

R451

9R452

i

R453

R454

R455

R457

R458

R472,473

8R475

L

R501,502

R503

R504,505

R701

R702

R707

R708,709

R710

R712

R713

R714

R751

R752

R761

R762

R765

R766

R772

R773

R775

R776,777

R778

R779

R781-783

R784

R785,786

R787,788

R789

B1742

CNPlOl

CNP251

CNP501

CNP601

CNP741

CNP742

CNP751

CNSlOl

CNS251

CNS501

CNS601

CNS741

CNS742

CNS751

IF601

J151

J301

J302

J771

J772,773

M501

SO601

B

SOL501

SP1,2

SP3,4

SP5

REF.NO.

PART

NO.

VRD-MN2BD56

VRG-ST2EF150J

VRD-MN2BD33

VRD-MN2BD18

VRD-STPCD102J

VRD-ST2EE270J

VRD-MN2BD33

VRD-MNZBD103J

VRG-ST2EG2R2J

VRD-MN2BD103J

VRD-MN2BD122J

VRD-MN2BD472J

VRD-ST2CD103J

VRD-MN2BD333

VRD-MN2BD472J

VRD-MN2BD224J

VRD-ST2EE22

VRD-MN2BD563J

VRD-MN2BD473J

VRD-ST2CD103J

VRD-ST2CD473J

VRD-MN2BD473J J

VRD-ST2CD47

VRD-ST2CD82

VRD-ST2CDl5

VRD-ST2CD103J

VRD-ST2CD22

VRD-MN2BD684J

VRD-MN2BD820 J

VRD-MN2BD153J

VRD-MN2BD472J

VRD-MN2BD392J

VRD-STPCD103J

VRD-STPCDlOPJ

VRD-ST2CD470J

VRD-STPCDlOlJ

VRD-ST2CD682J

*

1 J

J 560

J 15

1 J

J 330

1 J

J 180

J 1

J 27

1J J 330

J

10

J 2.2

J 10

J 1.2

J 4.7

J 10

J

J 33

J 4.7

J 220

1 J

J 220

J 56

J 47

J

10

J 47

47

1 J

J 470

1 J

J 820

1 J

J 150

J

10

1 J

J 220

J 680

J a2

J 15

J 4.7

J 3.9

J 10

J 1

J 47

J 100

J 6.8

DESCRIPTION

ohms,l/aW

ohms,l/4W,Fusible

ohms,l/8W

ohms,l/8W

kohm,l/6W

ohms,l/4W

ohms,l/8W

kohm,l/8W

ohms,l/4W,Fusible

kohm,l/8W

kohms,l/aW

kohms,l/8W

kohm,l/6W

kohms,l/8W

kohms,1/8W

kohms,l/8W

ohms,l/4W

kohms,l/8W

kohms,l/8W (

kohm,l/6W

kohms,l/6W

kohms,l/aW

ohms,l/6W

ohms,l/6W

ohms,l/6W

kohm,l/6W

ohms,l/6W

kohms,l/8W

ohms,l/8W

kohms,l/8W

kohms,l/8W

kohms,l/dW

kohm,l/6W

kohm,l/6W

ohms,l/6W

ohm,l/GW

kohms,l/6W

OTHER CIRCUITRY PARTS

9 2

LCaNE -

QCNCM5 8 4CAFZZ J Plug,3Pin

15 5 3 E

QCNCM586EAFZZ

QCNCM592LAFZZ

QCNCM583BAFZZ

QCNCM584CAFZZ

QCNCMS 8 9 i AFZZ J Plug,8Pin

QCNCM583BAFZZ

92LM-CoNE666A

92LM-CoNE666B

92LMCoNE1553C

9 2

LCENE -

15

92LCoNE-1553F

92LCoNE-

1553A J Connector Ass’y,PPin

QFS-CPOPGAFN

QJAKEO

157AFZZ

QJAKE0145AFZZ

Q

JAKEO

146AFZZ J Jack,CD/Line Input [R

92LJACK-

Q

JAKEO

1553A J Jack,Headphones

157AFZZ J

92LMoT666AASSY

QSoCA0293AFZZ

RPLU-0175AFZZ J APSS Solenoid

92LSP-1553A

RALMBO 10

1AFZZ

VSP0080WBD34A

J Connector

Ass’y,9-8Pin

J Plug,5Pin

J

Plug,llPin

J Plug,2Pin

J Plug,3Pin

J Plug,2Pin

J Connector

Ass’y,3Pin

J Connector Ass’y,SPin

J Connector

5 3B

J Connector

J Connector

Ass’y,llPin

Ass’y,2Pin

Ass’y,3Pin

Part of Ref.

i J Fuse,TZA

J Jack,Mixing Mic.

J

Jack,CD/Line

Input

-ch]

-chl

JackSurround

J Motor with Pulley

J Socket,AC Power Supply

J Woofer

J Tweeter

J Speaker,X-Bass

No.Bl742

[L

Speaker

COD

AA

AB

AA

AA

AA

AA

AA

AA

AB

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AH

AA

AB

AC

AA

AA

AB

AA

AF

AH

AK

AC

AD

-

AD

AD

A0

AB

AB

AG

AB

AW

AG

AG

AS

AB

AR

-23.

Page 18

REF.NO.

SW1

SW101

SW201

SW251

SW301

SW501

SW502

SW503

SW504

SW751A,B

1

2

3

4

5

6

7

8

9

12

13

14

15

16

17

18

19

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

41

42

43

44

45

46

41

48

50

51

52

53

54

55

PART

NO.

*

9 2 LSW i CH- 13 7 OA J

QSW-SO72OAFZZ

92LSWfCH-1553B

J

J

QSW-S0267AFZZ J

92LSW

i CH-1370A J

QSW- FO 2 1

SAFZZ

QSW- F 0 13 6AFZZ

QSW- FO 13 6AFZZ

QSW-F0216AFZZ J

92LSW

iCH-1553A

J

MECHANICAL PARTS

92LMBUTsN1295B

9 2

LMBUTsN12

92LMBUToN1295F

92LMBUTsN1295A

92LMBUTSN1295D

92LMBUToN1295E

LANGF 13 83AFZZ

LANGF

1107AFZZ

32LM-RANG1553A

LBSHZ0086AFZZ

LCHSMO82 1AFZZ

92LM-SCA666A

LDAiH0067AFZZ

92LNBAND087

LRTNP0058AFZZ

LRTNP0059AFOO

LRTNP0073AFZZ

MCAMPO 0 7 8AFZZ

MLEVF1967AFFW

MLEVF 18 24AFZZ J

MLEVF 18 2 5AFZZ

MLEVF 182 6AFZZ J

MLEVF1827AFZZ

92LM-TLA666A

MLEVF1829AFZZ

MLEVFI830AFZZ

MLEVF 183

MLEVF1832AFZZ

92LM-PBLA666A

92LM-SLA666B

92LM-SLA666A

92LM-MPLA666A

MLEVF

18 7

MLEVPO502AFZZ

MLEVP0654AFZZ

MLEVP0655AFZZ

MLEVP0656AFZZ

MLEVP0657AFZZ

MLEVP0658AFZZ

MLEVP0660AFZZ

MLEVP0684AFZZ

MLEVP0685AFZZ

92LMCSPR666A

92LMCSPR666B

92LMCSPR666C

92LMCSPR666D

J

3 5C J Knob,Fast Forward

J

J

J Knob,Rewind

J Knob,Record

J Bracket,Motor

J Plate

J

J Main Chassis

J Head Base

J Stopper

J Retaining Ring

J Stoper

J

J

J Lever,Record

J Lever,Rewind

1AFZZ

J

J

J Lever,Main Lock

6AFZZ

J

J Lever,Fast Forward/

J

J

J Lever,Lock Release

J Lever,Brake

J

J Lever,Mechanism Mode

J Lever,Erase Prevention

DESCRIPTION

Switch,Slide

Type [Band

CODE

AE

Selector]

SwitchSlide

Type

AE

[Record/Playback]

SwitchSlide

Type

AG

[Function]

Switch,Slide

Type [Beat

AD

Cancel1

SwitchSlide

Type

AE

[Dubbing Speed]

J Switch,Leaf Type

AE

[Mechanism Model

J Switch,Leaf Type

J Switch,Leaf Type

Switch,Leaf

Switch,Push

Type

Type

[Stop]

[Main]

[APSSI

AD

AD

AC

AK

[Surround/X-Bass]

Knob,Pause

AA

AA

Knob,Play

Knob,Stop/Eject

AA

AA

AA

AA

J

Bracket,Flywheel

AF

AD

Spring,Record

Cushion,Motor

AE

AA

AP

J Sub Chassis

AK

AB

J Nylon

Band,6Omm

AA

AA

AA

AA

J

Cam,Auto

Stop

Lever,Stop,Tape

Lever,Stop,Tape

J

LeverStop

Lever,Play

Interlocking

Release

Lever,Play

J Lever,Trigger

1

2

AA

AB

AA

AA

AB

AD

AD

AC

AC

J Lever,Fast Forward

LeverStop

Lever,Pause

J

LeverSelect

J Lever,Prevention

AC

AC

AE

AB

AE

AF

J Lever,Active Prevention

Lever,Pause

Lock

AA

AB

AC

Rewind

GuideSensor

TipSensor

AA

AA

AC

AC

Lever,Eject

AB

AC

Selector

AA

J

Spring,Azimuth

J Sprlng,Luch

Adjust.

AA

AA

J Spring,Back Tension,Tape A A

1

J

Spring,Back

Tension,Tape A A

2

REF.NO.

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

73

75

76

77

79

80

81

82

83

84

85

86

87

88

89

90

91

32

94

95

96

97

98

39

102

103

106

107

111

112

113

114

501

502

503

504

505

506

507

508

509

510

512

513

514

515

516

517

518

PART

NO.

92LMCSPR666E

92LMTSPR666R

92LMTSPR666B

92LMTSPR666C

92LMTSPR666D

92LMTSPR666E

92LMTSPR666F

92LMTSPR666G

92LMTSPR666H

92LMTSPR666i

92LMTSPR666J

92LMTSPR666K

92LMTSPR666S

92LMTSPR666M

92LMTSPR666N

MSPRP043

PAFF

92LMESPR666A

92LMESPR666B

92LMESPR666C

92LMBELT666B

92LM-BRNG666B

NDAi R0328AFZZ%

NDA i RO 2 0 7AFZZ

NDA i RO 198AFZZ

NDAi R0199AFZZ

NDAiR0200AFZZ

92LM-FWHEL666D

NGERHO

192AFZZ

92LM-PGLA666A

92LM-PGLA666B

NRoLW0034AFZZ

NRoLY0077AFZZ

NRoLY0078AFZZ

92LMERHD677A

92LMPHD666A

92LMRPHD666A

LANGF1021AFZZ

MSPRD0763AFFJ

MSPRD0764AFFJ

NDAiR0327AFZZ

92LMCSPR666F

MLEVP0661AFZZ

MLEVF1873AFZZ

92LMTSPR666Q

92LMESPR740R

PCaVS3102AFZZ

92LM-SLE666A

LX-BZ0451AFFD

LX-BZ0559AFFD

LX-BZ0566AFFD

92L2RlW4R13L

92LlR7SZPZ

XBPSDPOPO5JSO

92LZS3PZ

XBPSDZOWIOXSO

92L2R6S4PZ

XHPSD20WlZXSO

92L2R6TTS14PZ

92L2BTSlOBZ

92LElR5

92L2R6W4R13P

92LZR9W5R5P

92L3RlW5R25P

92LSZR6S666C

J

Spring,Detent

J

Spnng,Pinch

DESCRIPTION

Roller

*

J Spring,Over Stroke

J Spring,Brake Leve

J

Spring,Play

Lever Return A A

J Spring,Trigger Lever AA

J

Spring,Play

Tape

J

Spring,Play

Gear Lever, A A

1

Gear Lever, A A

Tape 2

J Spring,Record Lever AA

J

Spring,Fast

Forward/ AA

Rewind Lever

J

SpringStop

J

Spring,Pause

J

SpringSelect

J

Spring,Lock

Lever AA

Lever AA

Lever AA

Release Lever A A

J Spring,Prevention Lever A A

J J

Spring,Cassette Retainen

J

Spring,Eject

J

Spring,Fast

Lever

Forward/

Rewind Roller

J

SpringSensor

J

Belt,Drive

J Capstan Metal

J Slip Roller

J

Take-up,Reel

J Cap,Take-up Reel

J

CapSupply

Reel

J Supply Reel

J Flywheel

J Gear,Fast Forward/Rewind A A

J

Lever,Play

Gear,Tape

1

J Lever,Play Gear,Tape 2

J

Roller,Fast

Forward/

Rewind

J Pinch

J Pinch

Roller,Tape

Roller,Tape

1

2

J Head,Erase

J Head,Playback

J Head,Record/Playback

J

BracketSwitch

J

Spring,Brake

J

Spring,Bra

J

CapTape

ke

2 Take-up

J Spring,Take-up

J

Lever,APSS

J

Lever,APSS

J

Spring,APSS

J

Spring,APSS

Lock

Lever

Lock

J Cover,Head Shield

J

Sleeve,Pause

J

Screw,d2X6mm

J

Screw&2.6X9mm

J

Screw,d2X4mm

J

Washer,~2.lXQ4XO.l3mm

J

Screw,d1.7X2mm

J

Screw,dZX5mm

J

Screw,C2X3mm

J

Screw,$2X 1Omm

Lever

J Screw,+2.6X4mm

J

Screw,dZXlZmm

J

Screw,d2,6X14mm

J

Screw,CPX 1Omm

J Stop

Ring,E-Type,$l5XO.

4mm

J

Washer,d2,6X ~4X0.13mm.

J

Washer,d2,9X

J

Washer,&3.1X~5X0.25mm:- .‘A,A

J

Screw,$26X 1Omm

~5X0.5mrrx, -.A A

.

A A

,‘;>.&&A

CODE

AA

AA

AA

AA

A C

AA

AA

AA

AD

AB

AE

AE

AA

AA

At3

AM

AE

AE

AE

AD

AD

AL

AP

AP

AC

AB

AA

AA

AA

AC

AF

AA

AA

AB

AA

AA

AB

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

A A

‘.

-24-

Page 19

REF.NO.

520

521

522

524

526

527

528

529

530

531

M501

SOL501

SW501

SW502

SW503

SW504

201

201-l

201-2

201-3

201-4

202

202-1

!---

202-2

203

205

206

207

208

209

210

211

212

213

214

216

217

218

220

223

*

228

229

230

231

232

234

237

238

239

240

242

243

244

245

246

247

248

249

250

PART

NO.

92L2R6BTS6BZ

92LlR5WC3R8R5P

LX-WZl IOSAFZZ

LSTWC2403AFZZ

92L2RlW5R2L

92L3RlW6R13P

XHPSD20W17XSO

92LZS8PZ

LX-WZ9066AFZZ J

XHBSD20P06000

92LMoT666AASSY J

RPLU-0175AFZZ J APSS Solenoid

QSW-F02 15AFZZ J Switch,Leaf Type AE

QSW-F0136AFZZ J Switch,Leaf Type

QSW-F0136AFZZ

QSW-FOP 1

GAFZZ

*

J

J Stop Ring,d2.4mm AA

J Screw,,$2X17mm AA

J

J Switch,Leaf Type [Main] AD

DESCRIPTION

J

Screw,$2,6X6mm

Washer,dl.SX+3.8X0.5mm

J

Washer,dP.lX4.3X4.3X0.5

mm

J

Washer,d2.1Xd5X0.2mm

J

Washer,43.1Xd6XO.l3mm

J Screw,d2XBmm AA

Washer,~l.ZX,$3.2X0.5mm

Screw,42.6X6mm

Motor with Pulley AW

[Mechanism Mode]

J Switch,Leaf Type

CODE REF.NO.

A A

A A

A A

A A

[Stop]

A D

[APSS]

A C

AA

A A

AA

AG

CABINET PARTS

PWBI

BA

-

AF

A C

A M

AH

A F

AA

AC

AC

AB

AZ

AA

AA

AD

AV

AB

A B

A A

AA

AC

A B

A B

AG

A F

AC

A B

AE

AD

AA

92LCAB1556ASl

92LPANEL1553A

9

PLPANEL

92LWiND1217A

92LMEC1553CTSl

92LCT-CoV1553A

92LCT-CoV1553B

9 2 LCT

92LADAPT666A

92LARM1228A-R

92LARM1228B-L

92LSUPT976A

92LCSPR666A

92LCAB1556B-GY

92LGRiP1553A

92LHNDLFR1553L

92LHNDLFR1553R

92LSHAFT1228A

92LBTML1295A

92LBSPR666B

92LBSPR666A

92LR-ANT158A

92LSCAB1553ASl

92LS-CHS1554A

92LHoLD1553A

92LSPAC1553A

92LKNoB666D

92LKNoB1449A

92LKNoB976B

92LPiNT717A

92LRooL009

92LDSTR1553AS2

92LWHEL976A

92LKNoB666C

92LCSPR666B

92LRDAT-1553A J

92LRDAT-1553B

92LSHLD1553A

92LKNoB1553A

92LLiD1491A

92LSPEC1556A

92LN-BAND13

15 53B

-HsLD9

7 6A J Cassette Holder AF

18A J Nylon Band

J Front Cabinet Ass’y

Front Cabinet(Not

Replacement Item)

J Decoration Panel,

Surround/X-Bass

J Decoration

J Dial Window AB

J Cassette Holder Cover

Ass’y

J Cassette Holder Cover

J Window,Cassette Holder

Cover

J Tape Adaptor

J

Arm,Fulcrum,Right

J

Arm,Fulcrum,Left

J

Bracket,Fulcrum

J

SpringCassette

J Rear Cabinet

J Handle Grip AG

J Handle Fram,Left AF

J Handle Fram,Right AF

J

Shaft,Handle

J Battery Terminal(+)

J Battery Spring(-) AC

J Battery

J Rod Antenna AP

J Air Duct Ass’y

J Frame AK

J

Holder,Tuning

J Spacer,LED AA

J

Knob,Tuning

J Knob,Graphic

J

Knob,Dubbibg

Function/Band Selector

J Dial Pointer AB

J Dial Pulley

J Dial Cord Ass’y AD

J Drum

J

Knob,Mechanism

J Spring,Mechanism Mode

Knob

Heat Sink [Main PWB]

J Heat Sink [Socket

J Shield,Graphic EQ.

J Knob,Surround/X-Bass

J Battery Lid

J

LabelSpecifications

PanelJnsulator

Arm

Holder Up A A

Spring(+,-)

Knob AA

EQ./Volume

Speed/

Mode

252

256

257

258

259

601

602

605

606

608

609

610

611

612

613

614

615

616

617

618

b

PWB-Al-7

PART

NO.

92LLUG-1553A

QFSHD~O~~AFZZ

QLUGPO~I~CEFW

92LFELT666B

92LFELT1228G

92L4PTSflOBZ

92L3TSA+14RCB

92L3PTS+lOBZ

92L3SPW

92LS2R6S258B

92L3R2W15-R8S

92L3TTS+6BZ

92L3PTSflOPZ

92L4PTS+12BZ

92L3PTS+12BB

92L3PTS+12BZ

92L3R2W13-1S

92L3PTSS65BZM

92L3PTS+BBZ

92L3PTS+12PZ

*

J

J Holder,Fuse

J

Lug

J Felt,FM Mode Switch AA

J

J

J

J

J Washer,d3mm AA

J Screw,d2.6XSmm AA

J

J

J

J

J

J

J

J

J

J

DESCRIPTION

Tip,Antenna

FelLBattery

Screw,44X 1Omm

Screw,d3X14mm

Screw,d3X 1Omm

Washer,43.2Xr$15X0.8mm

Screw,d3X6mm

Screw,d3X 1Omm

Screw,d4X

Screw,Q3X

Screw,d3X

Washer,~3,2X+13Xlmm

Screw,d3X65mm

Screw,43Xdmm *

Screw,d3

Lid AA

12mm

12mm

12mm

X 12mm

ACCESSORIES/PACKING PARTS

QACCL0059AFOO

92LBAG002B

92LBAG002C

92LBAG1510A

92LG-CARD1266A

92LiNST1556A

92LLABL1554A

92LP-AD1553A

92LP-CASE1556A

92LSHEET1555A

J AC Power Supply Cord A L

’ 1.

J Polyethylene Bag,

Accessories

J Polyethylene Bag,AC AA

Power Supply Cord

J Polyethylene

J Warranty Card

J Operation Manual

J

LabeLFeature

J Packing

J Packing Case

J

Sheet,Mechanism

Add.,Left/Right

Protection

BagUnit

P.W.B. ASSEMBLY (Not Replacement Item)

9 2 LPWB 15 5 GMANS J Main/Power/Socket/

Graphic

Plug/LED

(Combined Ass’y)

EQ./Switch/

COD

AC

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

A A

AB

AA

AA

AA

A B

AC

AC

AC

A K

AQ

AA

-

-25-

Page 20

Writer and Editor: Quality & Reliability Control Center of Audio Systems Group, Sharp Corp.

[

A901

Z-865NS

Printed in ~~~~~

SA

. OD . M

j

Loading...

Loading...