Page 1

WF-1000W

SERVICE MANUAL

No. S0957WF1000WK

WF-1000W(BK)

WF-1000W(S)

• In the interests of user-safety the set should be restored to its original

condition and only parts identical to those specified should be used.

CONTENTS

Page

SPECIFICATIONS ...............................................................................................................................................................2

VOLTAGE SELECTION.......................................................................................................................................................2

AC POWER SUPPLY CORD AND AC PLUG ADAPTOR ................................................................................................... 2

NAMES OF PARTS ............................................................................................................................................................. 3

FITTING OF DIAL POINTER ...............................................................................................................................................4

DISASSEMBLY....................................................................................................................................................................5

ADJUSTMENT .....................................................................................................................................................................6

NOTES ON SCHEMATIC DIAGRAM .................................................................................................................................. 7

TYPES OF TRANSISTOR AND LED...................................................................................................................................7

SCHEMATIC DIAGRAM / WIRING SIDE OF P.W.BOARD.................................................................................................8

PARTS GUIDE / EXPLODED VIEW

SHARP CORPORATION

– 1 –

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

WF-1000W

g

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER

TO THE OPERATION MANUAL.

SPECIFICATIONS

● General

Power source: AC 110-127 V/220-240 V,

50/60 Hz

DC 15 V ["D" size

(UM/SUM-1, R20 or HP-2)

battery × 10]

Power

consumption: 28 W

Output power: PMPO; 200 W (total)

(AC operation)

MPO; 50 W (25 W + 25 W)

(AC operation, 10 % T.H.D.)

RMS; 25 W (12.5 W + 12.5

W)

(DC operation, 10 % T.H.D.)

Input terminal: Mixing microphone;

600 ohms

CD/LINE; 350 mV/47 kohms

Output terminal: Headphones; 16-50 ohms

(recommended; 32 ohms)

Dimensions: Width; 300 mm (11-13/16")

Height; 240 mm (9-1/2")

Depth; 220 mm (8-11/16")

Weight: 3.8 kg (8.4 lbs.) without bat-

teries

● Radio section

Frequency range: FM; 88 - 108 MHz

SW1; 2.3 - 7.3 MHz

SW2; 7.3 - 22 MHz

MW; 526.5 - 1,606.5 kHz

● Tape recorder section

Frequency response: 60 - 12,000 Hz (Normal tape)

Signal/noise ratio: 40 dB (TAPE 1, recording/playback)

55 dB (TAPE 2, playback)

Wow and flutter: 0.15 % (WRMS)

Motor: DC 9 V electric governor

Bias system: AC bias

Erase system: Magnet erase

● Speaker section

Type: 2-way type

Speakers: 12 cm (4-3/4") free-edge speaker × 2

Tweeter × 2

Impedance: 8 ohms

Dimensions: Width; 235 mm (9-1/4")

Height; 262 mm (10-5/16")

Depth; 220 mm (8-11/16")

Wei

ht: 1.8 kg (4.0 lbs.)/each

Specifications for this model are subject to change without

prior notice.

VOLTAGE SELECTION

Before operating the unit on mains, check the preset voltage. If the voltage is different from your local voltage, adjust the voltage

as follows: Slide the AC power supply socket to the visible indication of the side of your local voltage.

AC POWER SUPPLY CORD AND AC PLUG ADAPTOR

QACCE0007AW00

QACCA0001SJ00

QPLGA0253AFZZ

– 2 –

Page 3

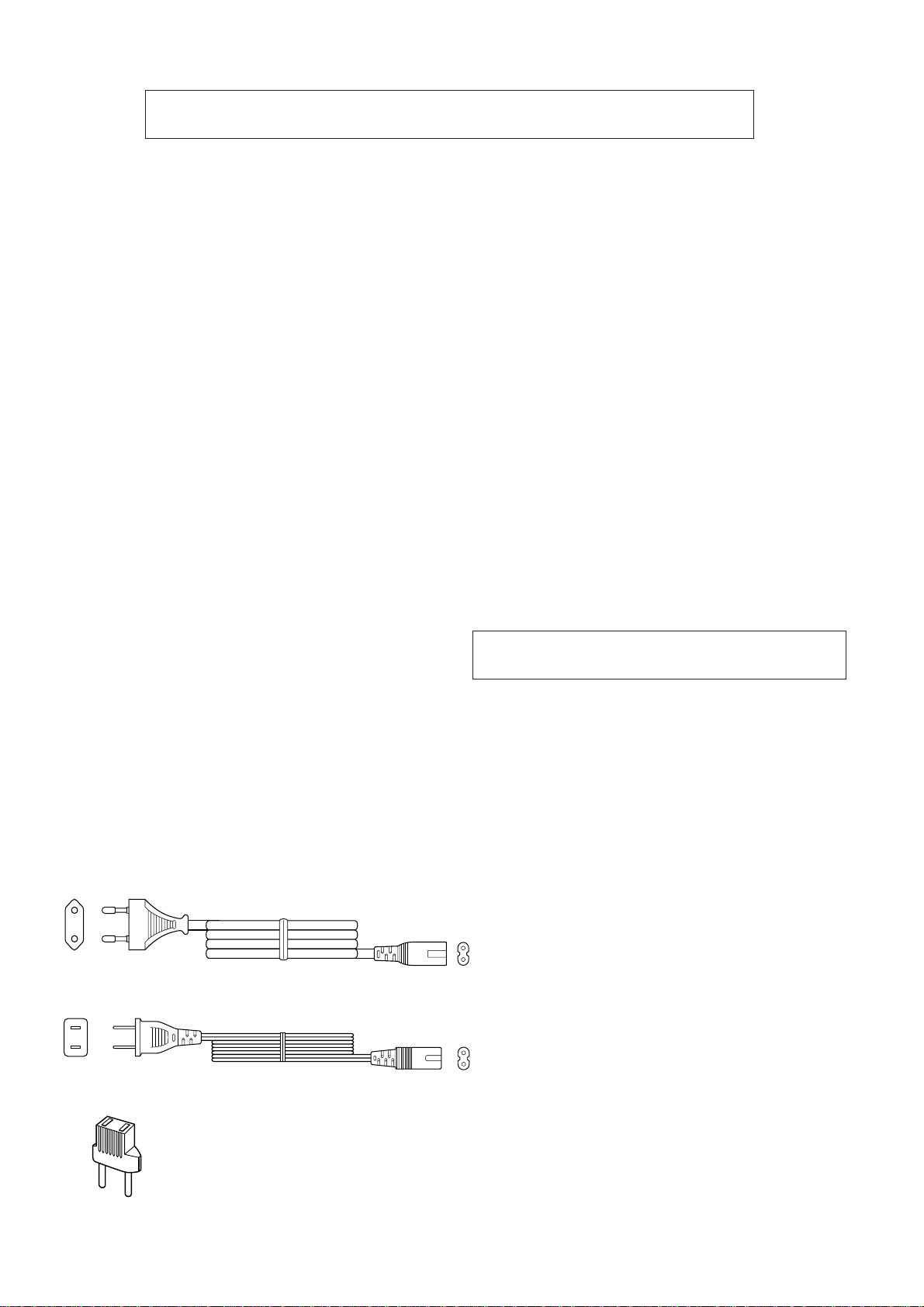

NAMES OF PARTS

11.

Graphic Equalizer Controls

12.

Power Indicator

13.

Volume Control

14.

FM Stereo Indicator

15.

Fine Tuning Control

16.

Built-in Microphone

17.

Mixing Microphone Socket

18.

Headphone Socket

19.

Function Selector Switch

10.

(TAPE 1) Cassette Compartment

11.

Tuning Control

12.

Extra Bass Switch

13.

Band Selector Switch

14.

Dubbing Speed/Built-in Microphone/FM Mode Switch

15.

(TAPE 2) Cassette Compartment

16.

(TAPE 1) Record Button

17.

(TAPE 1) Play Button

18.

(TAPE 1) Rewind Button

19.

(TAPE 1) Fast Forward Button

20.

(TAPE 1) Stop/Eject Button

21.

(TAPE 1) Pause Button

22.

(TAPE 2) Play Button

23.

(TAPE 2) Rewind Button

24.

(TAPE 2) Fast Forward Button

25.

(TAPE 2) Stop/Eject Button

6

7

8

9

10

16

17

12 4 5

18

3

21

2019

22

2423

WF-1000W

11

12

13

14

15

25

26.

FM/SW Telescopic Rod Aerial

27.

CD/Line Input Sockets

28.

Beat Cancel Switch

29.

Speaker Terminals

30.

AC Voltage Selector

31.

AC Power Input Socket

32.

Battery Compartment

33.

Tweeter

34.

Bass Reflex Duct

35.

Woofer

36.

Speaker Release Lever

37.

Speaker Wire

26

27 28

33

34

35

29

30

31

32

36

37

– 3 –

Page 4

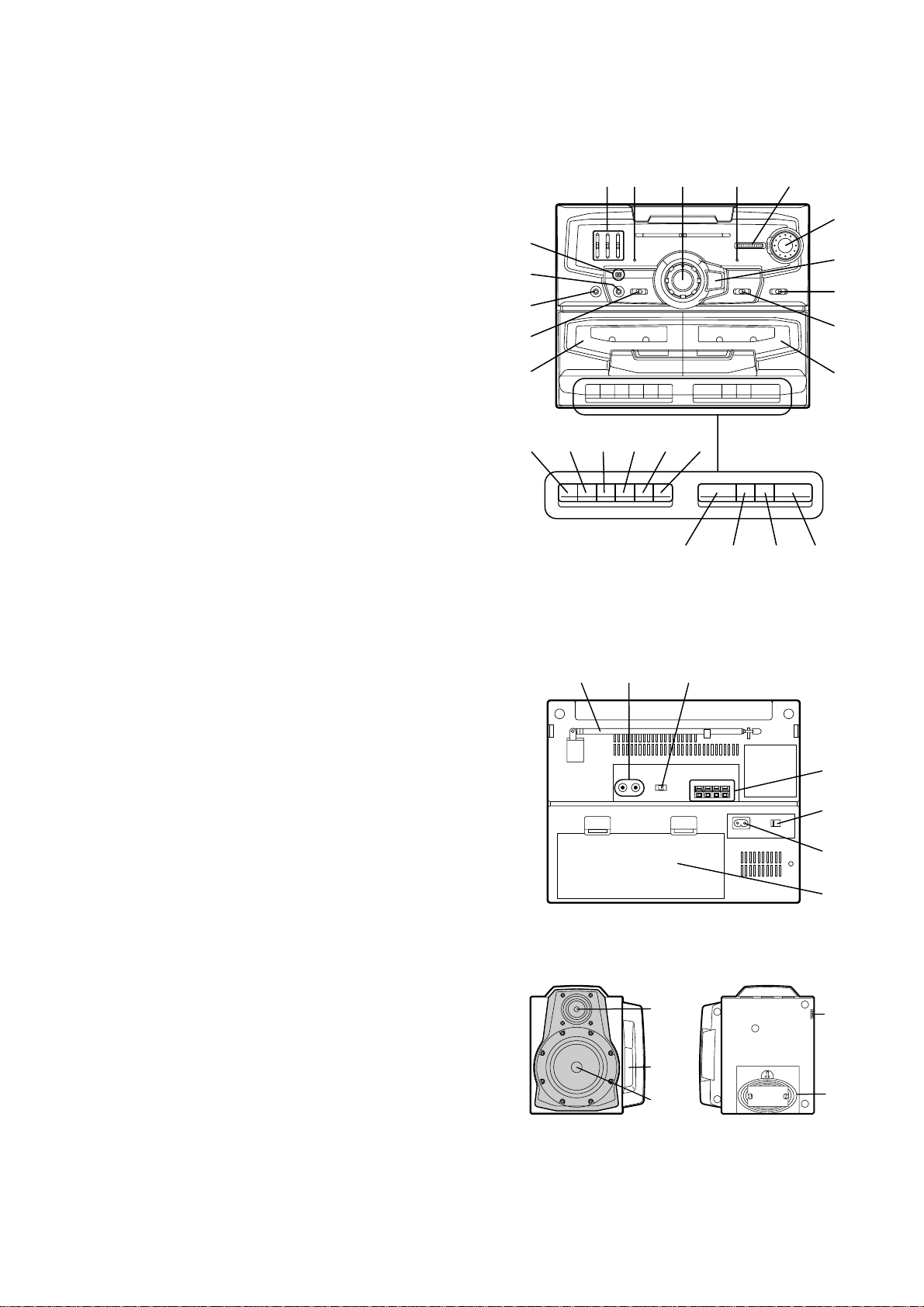

WF-1000W

Tuner Gear

Stopper

Main PWB

Variable Capacitor

Dial Pointer

PWB

Make the minimum space.

Front Cabinet

Pointer Gear

FITTING OF DIAL POINTER

1. Remove the Main PWB, the Graphic Equalizer PWB, the

Volume PWB and the Fine Tuning PWB. (See Figure 5-2

in the "Disassembly" on page 5.)

2. Remove the dial pointer guide and PWB.

3. Insert the dial pointer from , lead it under , hang it on

the tuner gear and then pass it through .

A

B

C

4. Replace the Main PWB, the Graphic Equalizer PWB, the

Volume PWB and the Fine Tuning PWB.

5. Rotate the tuning knob in the arrow direction until it stops.

(Set the tuner variable capacitor to "0" point (F-LOW

state).)

6. Adjust the dial pointer so that its stopper becomes the

Figure 4-2 position. (Adjust the engagement of the pointer

gear and the tuner gear to get the minimum space between

the PWB and the stopper.) This position is the "0" point.

7. Screw up the PWB and the dial pointer guide.

Front Cabinet

Tuning Knob

C

Dial Pointer Guide

(218)

Dial Pointer(211)

B

PWB

Tuner

Gear

"0" Point

Fine Tuning

PWB

Screw(601)

ø3x10mm

Main PWB

Figure 4-1

A

Dial Pointer(211)

Graphic Equalizer

PWB

Volume PWB

Figure 4-2

– 4 –

Page 5

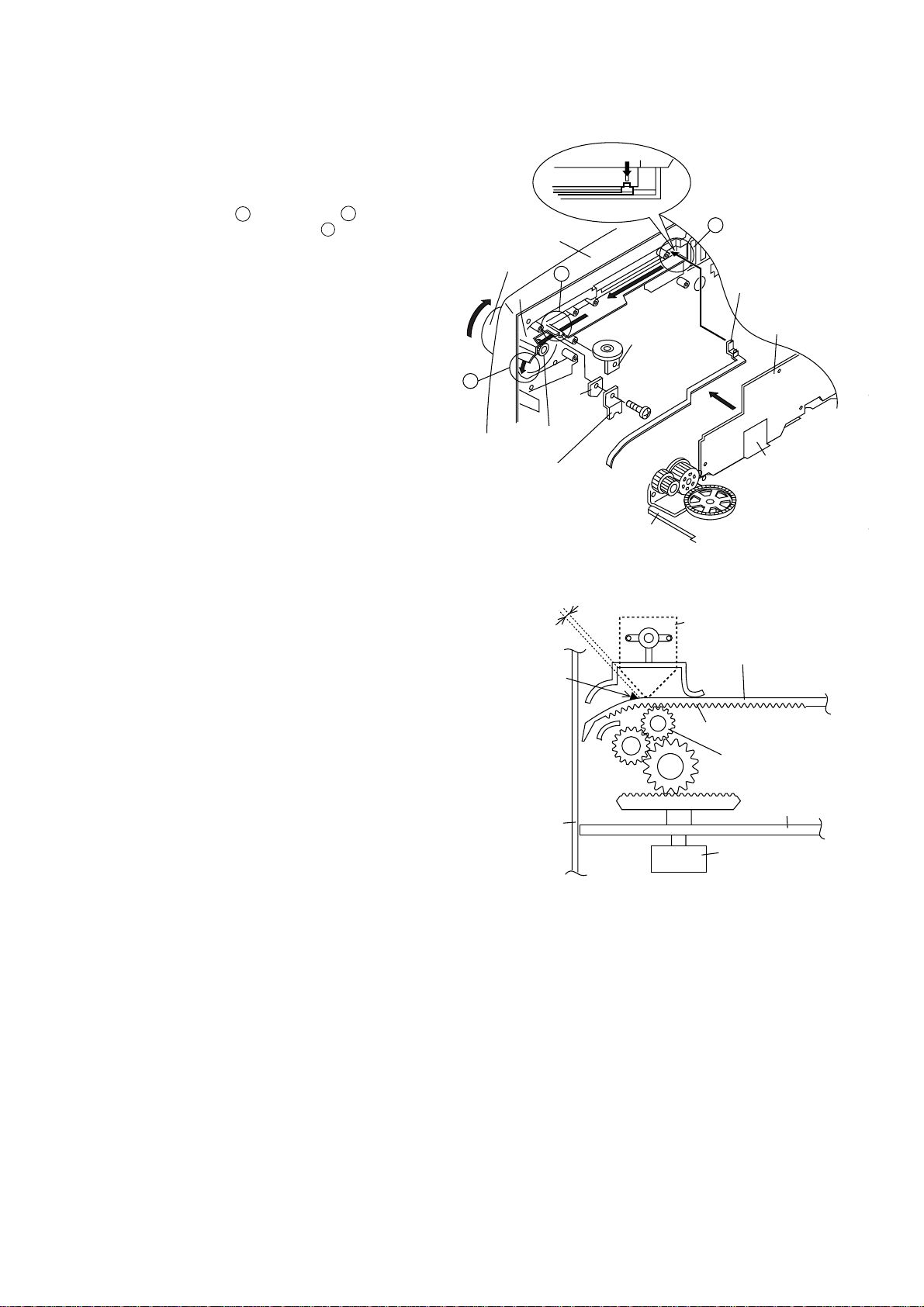

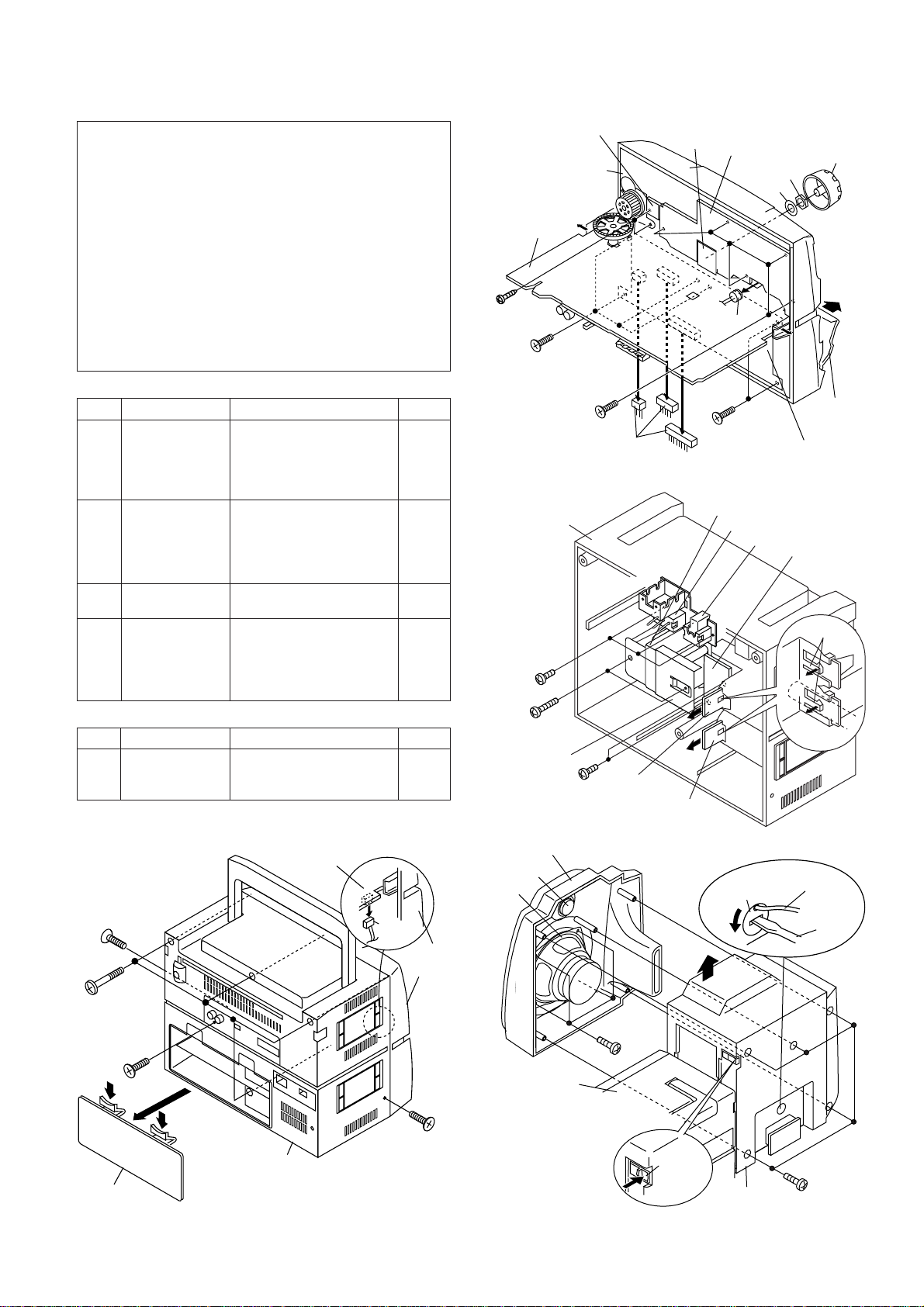

DISASSEMBLY

Rear Cabinet

(D1)x3

ø3x10mm

(D2)x2

ø4x16mm

(D4)x2

ø3x10mm

Power

Transformer

Voltage Selector

AC Socket

(D3)x1

Power

PWB

Terminal B

PWB

Terminal A

PWB

(D5)x2

(E3)x4

ø3x10mm

(E1)x5

ø4x16mm

Speaker Box

Main Unit

Speaker

Release

Lever

Speaker Cord

Holder

Speaker

Cord

Driver

Woofer

Tweeter

Front Panel

(E2)x1

Caution on Disassembly

Follow the below-mentioned notes when disassembling

the unit and reassembling it, to keep it safe and ensure

excellent performance:

1. Take cassette tape out of the unit.

2. Be sure to remove the power supply plug from the wall

outlet before starting to disassemble the unit and remove

the batteries from the unit.

3. Take off nylon bands or wire holders where they need

to be removed when disassembling the unit. After

servicing the unit, be sure to rearrange the leads where

they were before disassembling.

4. Take sufficient care on static electricity of integrated

circuits and other circuits when servicing.

MAIN UNIT

STEP REMOVAL PROCEDURE FIGURE

1 Front Cabinet/ 1. Battery Compartment Lid. 5-1

Rear Cabinet ................................. (A1)x1

2. Screw ................... (A2)x3

3. Screw ................... (A3)x4

4. Socket .................. (A4)x1

2 Main PWB/ 1. Knob.....................(B1)x1 5-2

Graphic Equalizer 2. Socket .................. (B2)x3

PWB/ 3. Screw................... (B3)x5

Volume PWB/ 4. Screw ................... (B4)x2

Fine Tuning PWB 5. Mic ....................... (B5)x1

3 Tape mechanism 1. Open the cassette holder. 5-2

2. Screw ................... (C1)x6

4 Power PWB/ 1. Screw ................... (D1)x3 5-3

Terminal A PWB/ 2. Screw ................... (D2)x2

Terminal B PWB 3. Bracket.................(D3)x1

4. Screw ................... (D4)x2

5. Hook.....................(D5)x2

Front Cabinet

Main PWB

(B4)x2

ø3x10mm

(C1)x4

ø3x10mm

Fine Tuning PWB

(B3)x5

ø3x10mm

(B2)x3

Volume

PWB

Figure 5-2

Graphic

Equalizer PWB

Washer

(B5)x1

(C1)x2

ø3x10mm

WF-1000W

(B1)x1

Nat

Open

Cassette

Holder

(Left/Right)

Tape

Mechanism

SPEAKER UNIT

STEP REMOVAL PROCEDURE FIGURE

1 Speaker 1. Screw ................... (E1)x5 5-4

2. Front Panel .......... (E2)x1

3. Screw ................... (E3)x4

Main PWB

(A2)x1

ø3x6mm

(A3)x4

ø3x20mm

(A2)x1

ø3x10mm

(A1)x1

Cabinet

Rear

(A4)x1

(A2)x1

ø3x6mm

Figure 5-1

Figure 5-3

Front

Cabinet

Figure 5-4

– 5 –

Page 6

WF-1000W

ADJUSTMENT

MECHANISM SECTION

• Driving Force Check

Torque Meter

Play: TW-2412 Tape 1: Over 60 g

Specified Value

Tape 2: Over 60 g

• Torque Check

Torque Meter

Play: TW-2111 30 to 70 g.cm 30 to 70 g.cm

Fast Forward: TW-2231 Over 55 g.cm Over 55 g.cm

Rewind: TW-2231 Over 55 g.cm Over 55 g.cm

Specified Value

Tape 1 Tape 2

• Head Azimuth

Test Tape

MTT-114 Headphones Socket

Instrument Connection

(Load resistance: 32 ohms)

• Tape Speed (Normal only)

Test Tape

MTT-111 Tape 1,2:VR102 3,000 ± 60 Hz Headphones

Adjustment

Point

Specified

Value

Instrument

Connection

Socket

(Loadresistance:

32 ohms)

DECK SECTION

• Bias Oscillation

• Beat Cancel Switch: C

Adjustment Point Specified value Instrument

L301 100 kHz + 4 kHz Pin 1 of CNS102

Specified Value

Beat Cancel A: 104 ± 4 kHz

B: 94 ± 4 kHz

C: 100 ± 4 kHz

• Playback Amplifier Sensitivity Check

Test tape

MTT-118 2.5 V ± 3 dB Speaker terminal

Specified value Instrument Connection

(Load resistance: 8 ohms)

Connection

TUNER SECTION

fL: Low-range frequency

fH: High-renge frequency

• FM IF/RF

Test Stage

FM IF L9 Input: FM Antenna

FM Detection L10 Output:Pin 9 of IC2

FM Band fL: L1 Input: Antenna

Coverage fH: TC1 Output: Headphone Socket

FM Tracking fL(88.0 MHz): L2 (Load resistance:

Specified Value/

Adjusting

Point

fH(108 MHz): TC2 32 ohms)

• AM IF/RF

Test Stage

AM IF L11

MW Band fL: L6

Coverage fH: TC3

MW Tracking fL(600 kHz): L3

SW1 Band fL(2.3 MHz): L7

Coverage fH(7.3 MHz): TC5

SW1 fL(2.6 MHz): L4

Tracking fH(6 MHz): TC6

SW2 Band fL(7.3 MHz): L8

Coverage fH(22 MHz): TC7

SW2 fL(8.5 MHz): L5

Tracking fH(19 MHz): TC8

Specified Value/

Adjusting

Point

fH(1,400 kHz):TC4

• VCO Frequency

Adjustment

Point

VR1 76 kHz ± 200 Hz Pin 13, Pin 21 and ground

Specified value Instrument Connection

Note:

After preparing the test circuit shown in Fig. 6, connect the Pin

13, Pin 21 and ground of the IC2 with the test circuit, and

measure the value.

Pin 13 of IC2

10 pF

1M ohm

Pin 21 of IC2

G

D

FET: 2SK212

(or Other 2SK Type FET.)

S

0.1 µF

10K ohm

Instrument

Connection

Instrument

Connection

Input: Antenna

Output: Pin 9 of IC2

Input: Antenna

Output: Headphone Socket

(Load resistance

32 ohms)

of IC2

TO FREQUENCY

COUNTER

– 6 –

Figure 6 VCO FREQUENCY TEST CIRCUIT

Page 7

WF-1000W

SW401

CF2

IC2

TC6

SW1

TC5

SW103

L7

TC7

L1

L2

L8

L6

L5

TC8

L9

L11

CF3

IC1

CF1

IC501

CNP103

IC502

VR102

VR1

L10

CNP501

SPEAKER TERMINALS

1

24

12

SW1

TRACKING fH

TC1

TC2

TC3

TC4

MW

TRACKING fH

MW BAND

COVERAGE fH

FM TRACKING

fH

FM BAND

COVERAGE

fH

fL

SW2

TRACKING

fH

fL

L4

L3

SW1

TRACKING fL

MW

TRACKING fL

FM

TRACKING fL

AM IF

FM IF

FM DETECTION

VCO

SW1 BAND

COVERAGE

fH

fL

SW2 BAND

COVERAGE

fH

fL

MW BAND

COVERAGE fL

TAPE SPEED

MAIN PWB

9

21

13

L301

SW102

BIAS OSCILLATION

Figure 7-1 ADJUSTMENT POINTS

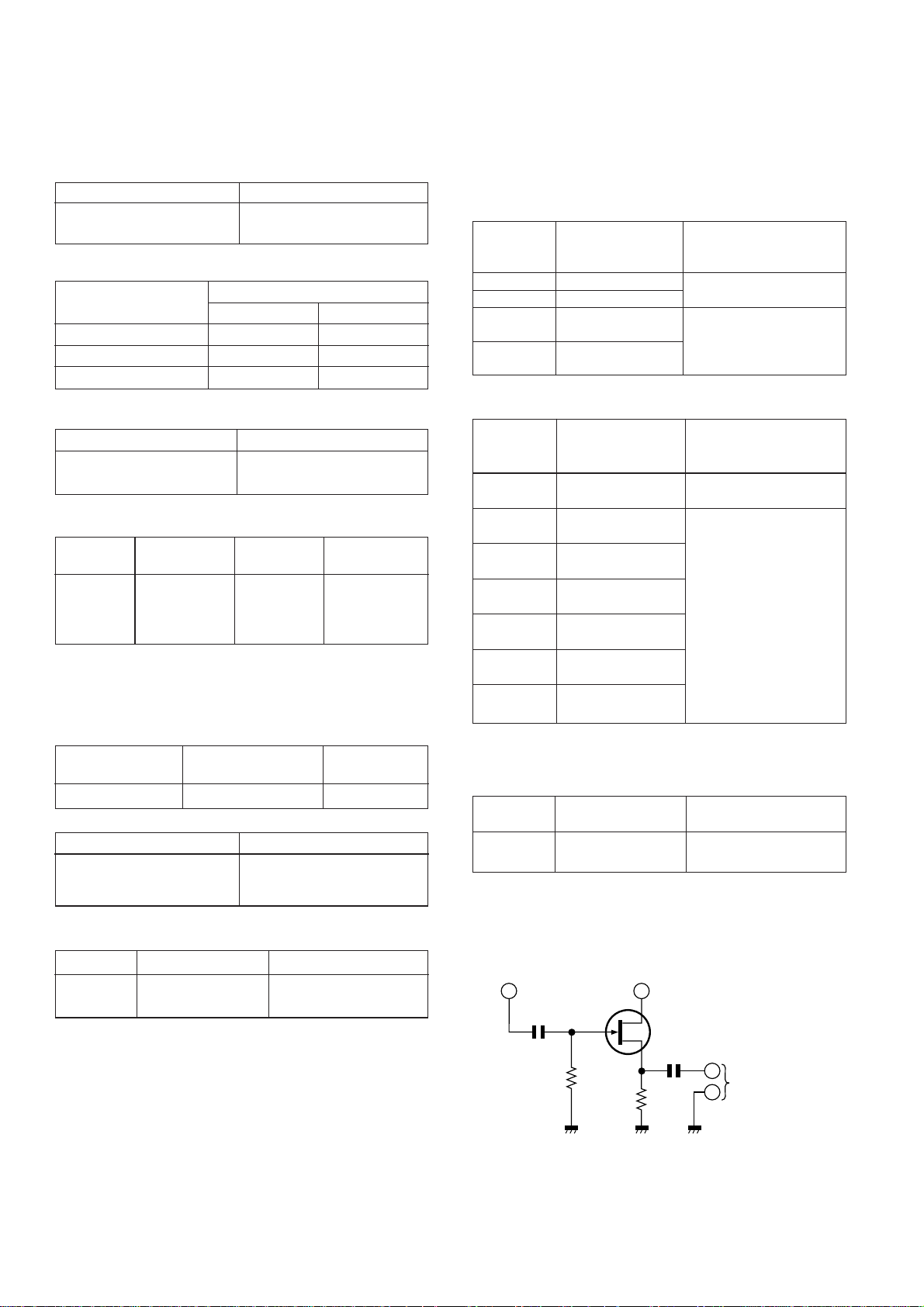

NOTES ON SCHEMATIC DIAGRAM

• Resistor:

To differentiate the units of resistors, The symbol as K and

M are used: the symbol K means 1000 ohm and the symbol

M means 1000 kohm and the resistor without any symbol

is an ohm resistor. The resistor designated “Fusible” is a

fuse type resistor.

• Capacitor:

To indicate the unit of capacitor, a symbol P is used: this

symbol P means pico-farad and the unit of the capacitor

without such a symbol is microfarad. As to electrolytic

capacitor, the expression “capacitance/withstand voltage”

is used.

(CH),(RH),(UJ): Temperature compensation

(ML): Mylar type

(S): Styrol type

• The indicated voltage in each section is the one measured

by Digital Multimeter between such a section and the

chassis with no signal given.

• Schematic diagram and Wiring Side of P.W. Board for this

model are subject to change for improvement without prior

notice.

• Parts marked with “ ” ( ) are important for

maintaining the safety of the set. Be sure to replace these

parts with specified ones for maintaining the safety and

performance of the set.

– 7 –

REF. NO.

DESCRIPTION POSITION

SW1 BAND SELECTOR FM

SW101 RECORD/PLAYBACK PLAYBACK

SW102 BEAT CANCEL A

SW103 DUBBING SPEED/MIC/ MIC/FM MONO

SW401 X-BASS ON

SW501 FUNCTION SELECTOR CD/LINE

SW501A TAPE 2 MAIN OFF

FM MODE

SW502 TAPE 1 MAIN OFF

SW503 TAPE 2 PLAY OFF

SW601 VOLTAGE SELECTOR AC220-240V

FRONT

VIEW

E B C

KTA1271 Y

KTC3199 GR

333ID

KTC3203 Y

Figure 7-2 TYPES OF TRANSISTOR AND LED

FRONT

VIEW

Page 8

WF-1000W

A

B

C

D

E

MIC151

BUILT-IN

MICROPHONE

CONDENSER

MIC

F

L-CH

R-CH

RECORD/

PLAYBACK HEAD

L-CH

R-CH

G

ERASE HEAD

H

FM/SW

ROD

ANTENNA

L-CH

SO351

CD/LINE

R-CH

J151

MIC

IN

TAPE2

PLAYBACK HEAD

TAPE1

FM SIGNAL

FM BAND PASS

FILTER

1

SW1-A

BAND

SELECTOR

D1

DS1SS133

SW1-B

BAND

SELECTOR

SW2

VC4

SW1-C

BAND

SELECTOR

SW1

SW2

C153

0.01

(ML)

C151

0.33/50

CNP101

CNS101

1

1

2

2

3

3

1

1

2

2

3

3

4

4

CNS102

CNP102

SW102

BEAT

CANCEL

C307

150P

CF1

2

FM

MW

SW1

SW2

FM

MW

SW1

FM

MW

R351

47K

R352

47K

R151

2.2K

C131

120P

C133

C

B

C306

390P

MW/SW1/SW2 SIGNAL

RF AMP

3

0.7V

1

1.5V 5.8V

C5

0.001

FM

TRACKING

C4

24P

L2

(CH)

R1

10

C6

0.0047

C7

0.0047

TC4

TC6

L3,L4: MW/SW1

BAR ANTENNA

TC8

SW2 ANTENNA

R353

2.2K

R354

2.2K

R162

47K

Q151

KTC3199 GR

C155

MIC AMP.

1/50

0.6V

R153

0V

220K

R152

560

C154

10/16

C152

10/16

R135

15K

L103

22mH

P

R R P

R

SW101-D

SW101-C

SW101-B

L104

22mH

SW101-A

R

P

L301

BIAS OSC.

C304

0.022

R136

15K

150P

C134

150P

C132

120P

C305

0.0015

(ML)

A

IC1 TA7358AP

FM FRONT END

IC1 TA7358AP

MIX

1.4V0V5.8V

432

C2

5P(CH)

TC2

VC2

C8

0.022

L3

MW

L4

SW1

L5

R160

4.7K

3.2V

1.3V

0.7V

1.3V

Q152

KTC3199 GR

MIC AMP.

R161

330

R154

560

SW101

RECORD/

PLAYBACK

P

R306

47

C303

0.0056

(ML)

9

5.8V

D2

SW1

SW2

C15

0.022

R156

1K

+B

C101

470P

C102

470P

R305

27K

C302

0.0022

(ML)

6

FM OSC.

DS1SS133

C9

0.022

FM

MW

FINE

TUNING

C157

1/50

R155

39K

CH1/A

Q301

KTC3203 Y

(0.7V)

( ): RECORD

R2

33

L1

( ): RECORD

C105

330P

C106

330P

C104

820P

MAIN PWB-A1/VOLUME PWB-A3/FINE TUNING PWB-A4

PLAYBACK SIGNAL

TC3

C20

1500P

(P.P)

C27

0.0047

(P.P)

R167

10K

0V(0V)

R169

10K

LINE AMP.

Q156

KTC3199 GR

20

PRE

OUT

PRE

OUT

5

C114

4.7/50

+B

R

P

C13

0.022

R5

100

1

2

CF2

10.7MHz

FM IF

D151

DS1SS133

R168

10K

R121

19

A/B

MIX

OUT

6

R7

820K

C22

0.022

C18

10/16

24

AM

OSC

FM IF

IN

3

C25

0.022

C21

5P

(UJ)

TC5

TC7

SW103

DUBBING SPEED/

MIC

HIGH

NORMAL

MIC

10K

18

VCC

GND1

7

C129

22/16

R122

10K

R123

10K

R124

10K

R301

100

IC101 : VOLTAGE

PIN

PLAY

REC

PIN

PLAY

REC

R4

7

330K

C12

5.0V

OSC

8

5.7V

C11

22P

(CH)

SW1-D

BAND SELECTOR

SW1-E

BAND

SELECTOR

C14

5P(CH)

TC9

C156

47/16

C103

820P

CH1/B

BIAS OSC.

(0.1V)

R304

3P(CH)

5

C10

15P(CH)

TC1

VC1

R3

47

L9

FM IF

C19

300P

(P.P)

FM

MW

SW1

SW2

VC3

R166

560

MIC AMP.

0V(3.4V)

R157

47K

R173

10K

2324

C110

10/16

10

0V(0V)

Q153

KTC3199 GR

OTHER:NORMAL

( ): HIGH

(0V)

(0.6V)

0V

R103

C113

56K

4.7/50

R101

56

R109

C111

4.7K

0.033

(ML)

R107

5.6K

C109

10/16

R105

180K

C107

330P

22

21

NFCH2/B CH2/A

MATAL

OUT

IC101

RECORD/PLAYBACK AMP. TA8189N

MATAL

NF

OUT

4 3 2 1

C108

330P

R106

180K

R108

5.6K

C112

0.033

R110

(ML)

4.7K

R104

56K

R102

56

R302

100

(5.5V)

SW101-E

RECORD/

C301

100/16

PLAYBACK

R303

100

RECORD SIGNAL

+B

C121

330P

C122

330P

R10

47

C158

4.7/50

R117

330K

REC IN

R120

390

R118

330K

1.3V

1.3V

1.3V

20

FM DET

AGC

4

C29

22/16

FM

MW

SW1

SW2

SW1-F

BAND

SELECTOR

R11

47

D153

DS1SS133

R119

390

14

REC IN

11

1.3V

1.3V

2.1V

2.1V

R8

3.9K

AM OUT

AM IF

1

2

FM

MW

SW1

SW2

C43

220P

D154

D158

DS1SS133

C119

0.015

(ML)

C123

0.0015

13

ALC

GND

12

C124

0.0015

C120

0.015

(ML)

C31

0.0047

(ML)

R9

12K

C32

0.0082

(ML)

19

IF AD

GND

5

3

CF3

455kHz

AM IF

SW1-G

BAND

SELECTOR

D156

DS1SS133

+B

C160

22/16

R125

1M

1.4V

1.4V

1.4V

1.5V

18

AM IN

6

7

C30

0.022

+B

C159

4.7/50

DS1SS133

L101

2.7mH

C125

4.7/50

C130

22/16

C126

4.7/50

L102

2.7mH

1.4V

1.4V0V0V0V0V

5.2V

5.2V

C23

220/10

FM

DETECTION

C17

0.022

L10

21

23

22

+B

AM RF

STB

IC2

FM/AM IF MPX. LA1805

AM MIX

3 2 1

L11

C24

0.022

AM IF

L6

MW OSC.

L7

SW1 OSC.

L8

SW2 OSC.

C26

0.022

SW101-F

RECORD/PLAYBACK

R

P

R172

10K

SW103-A

D152

DS1SS133

R100

D101

150

DS1SS133

R115

2.2K

C115

C128

4.7/50

2.2/50

C127

1000/10

C117

10/16

R113

180K

16

15

17

REC

REC NF

OUT

REC

REC

M/N

NF

OUT

10

8

9

R114

180K

C118

C116

10/16

4.7/50

R116

2.2K

123456789101112

0V0V0V0V1.3V

13 14 15 16 17 18 19 20 21 22 23 24

0.9V

0.9V0V0V

17 16

IF AD

DET OUT

8

C37

0.012

(ML)

R12

1K

R13

100

FM

MW

SW1

SW2

R177

1K

C135

0.0027

(ML)

R127

47K

R128

47K

2.1V0V1.4V

MPX

IN

D155

DS1SS133

R131

4.7K

R132

4.7K

1.4V

FM STEREO

C34

470P

C33

3.3/50

15 14 13 12

L-CH

9

R15

10K

SW1-H

BAND

SELECTOR

D162

DS1SS133

D159

DS1SS133

R111

22K

R129

22K

R130

22K

C136

0.0027

(ML)

R112

22K

2.1V

2.1V

1.3V

1.3V

SW103-B

FM MODE

R14

100K

C35

3.3/50

MO/ST

C38

0.012

(ML)

C39

1/50

R17

2.7K

C42

0.022

R133

82K

R134

82K

+B

1.3V

1.3V0V0V0V0V

1.3V

1.3V0V0V0V0V

R-CH

R174

22K

10

FM MONO

C36

1500P

(P.P)

VCO

AM/FM

11

C40

1/50

R16

10K

VR1

10K(B)

VCO

NC

C41

1/50

R20

10

R18

2.7K

CD/LINE

TUNER

TAPE

SW501-A

FUNCTION

SELECTOR

CD/LINE

TUNER

TAPE

CD/LINE

TUNER

R19

15K

TP1

VCO

76kHz

+B

+B

SW501-B

FUNCTION

SELECTOR

TAPE

L-CH

R-CH

SW501-C

FUNCTION

SELECTOR

R181

1K

+B

R182

1K

C181

1/50

R511

10K

C182

1/50

R183

330K

R184

330K

+B

• NOTES ON SCHEMATIC DIAGRAM can be found on page 7.

1

2

34 5

Figure 8 SCHEMATIC DIAGRAM (1/2)

– 8 –

6

Page 9

WF-1000W

IC2 : VOLTAGE

fH

fH

Q181

2V

KTC3199 GR

0.2V

R185

220

R186

220

0.2V

2V

fL

fH

fL

GRAPHIC

EQUALIZER

R188

3.9K

C186

1/50

R180

560

+B

TC6

L4

TC8

L5

SW1 BAND

COVERAGE

SW2 BAND

COVERAGE

C185

1/50

R187

3.9K

C180

100/16

MW

fH

TC5

TRACKING

fL

L7

fH

TC7

MW BAND

COVERAGE

fL

L8

GRAPHIC EQUALIZER PWB-A2

L-CH

R-CH

GND

+B

R-CH

L-CH

SW1

TRACKING

SW2

TRACKING

R183

330K

C181

0.8V

1/50

C183

220P

C184

220P

C182

1/50

0.8V

R184

182

330K

Q182

KTC3199 GR

GRAPHIC

EQUALIZER

+B

fH

TC4

FM

TRACKING

fL

L3

fH

TC3

FM BAND

COVERAGE

fL

L6

R203

2.2K

R205

10K

R201

1K

+B

R200

330

C200

220/16

R202

C202

1K

4.7/50

R204

R206

2.2K

10K

TC2

L2

TC1

L1

R211

1K

19

2V

3.5V

2V

18

20

R212

1K

PIN

FM

MW/SW1/SW2

PIN

FM

MW/SW1/SW2

R209

100K

C217

0.47/50

C221

4.7/50

C219

0.039(ML)

15

17

13

5.1V

4.5V

3.5V

4.5V

5.1V

16

14

C208

470P

C212

C206

0.01

(ML)

VR205-B

VR204-B

100K(B)

100K(B)

(10kHz)

(2kHz)

GRAPHIC EQUALIZER

VR203-A

100K(B)

(500Hz)

C215

5.1V

12

0.0015(ML)

fL

fH

fL

C203

1/50

C201

4.7/50

23

21

2.7V

5.5V

IC201 GRAPHIC EQUALIZER BA3822LS

2.7V

0V

24

22

C222

4.7/50

C204

1/50

123456789101112

1.6V

1.6V

5.8V

0.2V

1.6V

10.7V

1.7V

1.7V

6.5V

1.4V

13 14 15 16 17 18 19 20 21 22 23 24

1.1V0V2.1V

1.9V1V1.8V

GRAPHIC EQUALIZER

VR205-A

VR204-A

100K(B)

100K(B)

(10kHz)

(2kHz)

C209

C213

0.082

0.33/50

(ML)

C207

C211

0.0015(ML)

9

5.1V

5.1V

8

C216

0.0056(ML)

7

4.5V

6

C214

0.33/50

BI1

5

4.5V

C220

1

470P

5.1V

5.1V

4 3 2

0.039(ML)

R210

100K

1

0.0056(ML)

11

5.1V

4.5V

4.5V

10

C210

0.082

(ML)

VR203-B

100K(B)

(500Hz)

1.7V0V0V

1.8V

1.6V

1.8V

1.7V

C205

0.01

(ML)

1

4.5V

4.5V

C218

0.47/50

STEREO

33

1

3

2

3

1

2

LED1

333ID

1.6V

1.6V

BI2

10.7V0V0V

0.4V

1.1V

+B

GND

5.8V

6.3V

2.4V

2.4V

5.8V

6.3V

R518

1K

LED502

333ID

POWER

2.4V

2.4V

0.5V

1.7V

5.1V

6.4V

1.6V

1.7V

0.9V

0.9V

1.4V

1.6V

R511

10K

+B

+B

Q501

KTC3203 Y

7.4V

C502

8V

0.022

VOLTAGE

REGULATOR

C503

0.022

Q502~Q504:

TAPE SPEED CONTROL

OTHER:NORMAL

( ): HIGH

Q502

KTC3199 GR

0V(0.7V)

R512

0V(0V)

10K

12V

R503

100

C504

100/16

DZ501

DZ8.2BSB

0.7V(0V)

C505

100/16

R504

680

C507

0.022

R513

10K

Q503

KTC3199 GR

0V(7.8V)

0.7V(0V)

0V(0V)

C511

0.022

IC501

VOLTAGE REGULATOR

KIA7812P

12V

IC501

OUT IN

1

GND

C506

2

0.022

L501

47µH

C508

100/16

Q504

KTA1271 Y

7.8V

(7.9V)

R514

100K

VR102

C512

470

100/16

TAPE

SPEED

SW401

X-BASS

ON

OFF

R415

VOLUME

1K

C413

0.001

(ML)

C415

R417

0.15

22K

(ML)

R419

3.3K

R420

3.3K

C416

R418

0.15

22K

(ML)

C414

0.001

(ML)

R416

1K

15V

3

C513

0V

1/50

SW501-D

FUNCTION

SELECTOR

CD/LINE

TUNER

R516

3.9K

OUT

TAPE

15V

IC502

3

IN

GND

C514

2

0V

1/50

R517

56K

1

2

3

4

5

6

7

8

CNP103

IC502

9V

C509

0.022

8.4V(8.4V)

8.4V(6.2V)

VOLTAGE

REGULATOR

KIA7809P

1

R515

47

CNS103

1

2

3

4

5

6

7

8

VR401-A

50K(B)

VR401-B

50K(B)

VOLUME

R425

1K

C418

22/16

R429

100K

R427

4.7K

R428

4.7K

R426

1K

0.7V

0.7V

C510

3300/25

+

-

B

A

C419

4.7/50

0V

0V

0V

0V

C420

4.7/50

M

SW502

TAPE1 MAIN

SW501A

TAPE2 MAIN

SW503

TAPE2 PLAY

Q403

KTC3199 GR

POWER MUTE

Q404

KTC3199 GR

POWER MUTE

M501

TAPE

MOTOR

R441

15K

L-CH

R442

1

2

2

6

C423

10/16

3

C424

47/25

1

15K

R-CH

4

6.5V

R431

27K

D401

DS1SS133

1

2

CNP601

CNS601

C652

0.022

C653

0.022

TERMINAL B

PWB-A6

IC402

LA4663

POWER AMP.

+OUT1

0V

0V

0V

14.2V

0V

14

6.9V

13

0V

-OUT1

12

6.9V

IC402

+OUT2

6.9V

0V

10

-OUT2

11

6.9V

8

5

7

15V

15V

C433

0.022

+B

POWER PWB-A7

D651

TS4B03GM

BATTERYES DC15V

["D" SIZE(UM/SUM-1,

R20 or HP2)

BATTERY x 10]

9

R433

C425

2.2

0.1(ML)

R435

C427

2.2

0.1

(ML)

C426

0.1(ML)

C428

0.1

(ML)

F601

T4A L

250V

C651

0.022

C654

0.022

TERMINAL A

PWB-A5

R434

2.2

R436

2.2

C430

10/16

CNP501

SPEAKER

+

L-CH

R-CH

+

C429

J401

10/16

HEADPHONES

R437

120

R438

120

SW601

VOLTAGE SELECTOR

AC110V-127V

AC220V-240V

T601

POWER

TRANSFORMER

TERMINALS

SP403

TWEETER

SP404

TWEETER

SO601

AC POWER

INLET

SOCKET

AC110-127V/

AC220-240V,

50/60Hz

SO601

L-CH

SP401

WOOFER

8 Ohm

SP402

WOOFER

8 Ohm

R-CH

78 9101112

Figure 9 SCHEMATIC DIAGRAM (2/2)

– 9 –

Page 10

WF-1000W

M501

TAPE

MOTOR

SW503

TAPE2

PLAY

SW501A

TAPE2

MAIN

SW502

TAPE1

MAIN

AB

+-

BR

GY

GY

RD

OR

YL

GR

BL

VL

GR

1

CNS103

2

3

4

5

6

7

8

WH

CNS102

CNS101

RD

RD

WH

BK

BK

2

3

4

1

2

3

1

ERASE

HERAD

RD

WH

BK

GY

GY

RECORD/PLAYBACK

HEAD

TAPE 2

TAPE 1

BR

COLOR TABLE

RD(R)

OR

YL

GR

BL

VL

GY

WH(W)

BK

PK

BROWN

RED

ORANGE

YELLOW

GREEN

BLUE

VIOLET

GRAY

WHITE

BLACK

PINK

FM/SW ROD ANTENNA (253)

C217

VR203

VR204

VR205

C206

C208

C210

C218

C214

C220

C216

C212

IC201

C200

C213

C209

C211

C219

R200

C201

C202

R202

C221

C205

C207

C203

C204

R204

R205

R203

C222

LED502

R206

R201

C215

R518

C414

C416

R420

R419

C413

C415

LED1

FW1

VR401

VOLUME

R212

TC9

FINE TUNING

PWB-A4

VOLUME

PWB-A3

GRAPHIC

EQUALIZER

PWB-A2

BK

BK

FW2

2

1

5

10

15

20

24

23

A

B

A

B

A

B

5

1

A

B

(249)

TC9

FINE TUNING

VR203

500Hz

GRAPHIC

EQUALIZER

VR204

2kHz

VR205

10kHz

RD

WH

BK

PLAYBACK HEAD

R209

R210

R211

BR

RD

YL

OR

GR

BL

BR

RD

A

B

C

D

E

F

G

H

1

2

34 5

6

Figure 10 WIRING SIDE OF P.W.BOARD (1/3)

– 10 –

Page 11

MIC151

BUILT-IN

MICROPHONE

WH

BK

J151

MIC

IN

TAPE

RADIO

SW501

CD/LINE

FUNCTION

SELECTOR

GR

SW401

X-BASS

OFF ON

OR

SW103

DUBBING SPEED/

MIC/FM MODE

FM

MONO

NORMAL

FM

STEREO

BAND

SELECTOR

J401

HEADPHONE

C151

MIC

HIGH

SW1

FM

MW

SW1

SW2

R151

R152

SW501

C

BL

YL

SW103

A

C153

R10

WH

C152

BK

BD

A

B

H

G

B

SW1

A

R437

R438

C155

R415

C429

R153

R418

R416

C30

E

F

C

D

C430

C154

R154

C159

SW401

1

BI2

C19

C42

C156

R161

R417

C27

E

C

B

R177

C20

R156

Q151

C14

R155

1

L7

TC6

C157

E

C

B

Q152

R162

3

3

Q153

R157

E

C

B

R160

R166

C158

D151

R168

SW101

RECORD/

PLAYBACK

BI1

TC5

C44

R11

TC4

TC3

BL

R169

D401

R301

BK

C26

VC4

VC3

D153

R167

C134

WH

CNP102

R13

TC7

L8

C4

VC2

VC1

C428

R436

C426

D154

R186

R180

R187

R181

PLAYBACK

RECORD

SW101

A

B

C

C133

4

3

D

2

1

E

F

L2

C11

R434

D162

R431

R182

R188

C180

C21

C6

TC2

TC1

CNP601

2 1

C425

R185

C132

CNP101

C131

L103

R303

L6

L1

R183

3

2

1

R1

C12

C7

1

C110

C102

C5

C10

C427

C184

C183

E C B

L104

C104

C101

IC1

R2

TC8

14

C182

E C B

C181

C103

C109

1

2

3

1

2

3

4

5

6

7

8

9

R433

R435

12

13

FW1

R104

C106

R102

R101

C105

R4

11

R184

R130

C107

R103

CF1

10

Q182

Q181

R511

C112

C111

R20

C2

C8

C9

L5

9

C423

5

R129

C108

R109

R172

C13

C433

IC402

8

7

C186

C185

R133

R124

R110

R136

R108

R106

5201

IC101

R105

R107

D152

R14

D2

6

R442

C114

C41

C25

L9

4

5

R426

R112

R114

C37

D1

3

R425

R134

C116

R122

10

1524

R113

C115

R135

B

Q156

L11

C15

2

C420

C129

C118

12

13

CE

R12

C38

1

D156

R123

C160

R121

R15

R3

C424

Q404

E C B

R441

E C B

Q403

C419

D155

C418

D158

1

2

3

4

C512

5

6

CNP103

7

8

C514

C506

C513

C120

L102

R120

C136

R128

R116

R118

C122

C128

C127

R125

C130

C121

R117

R115

R119

C117

R18

R17

R16

C22

C23

C39

C40

12

10

CF3

1

IC2

2

520

3

CF2

1

3

2

1

C24

C43

R5

C510

R429

IC502

IC501

C126

C124

C113

C125

R131

R173

C36

24

C17

C29

R427

1

2

3

1

2

3

R132

R127

D101

C123

13

15

C18

R428

R19

R8

R512

R174

R111

C135

C119

R516

L501

D159

C33

C32

L10

C508

E

C

Q502

B

C505

L101

VR1

C35

C31

C509

R9

R515

R517

E C B

R513

B C E

R504

R100

C303

C34

C511

E C B

Q301

R302

BK

VCO

R7

R503

Q501

C302

R351

VR102

Q504

R514

Q503

C507

DZ501

B C E

FROM POWER PWB

TAPE

SPEED

C504

C503

C502

R304

C307

R305

R306

C304

L301

WH

C305

R354

R353

R352

C301

C306

SW102

CNS601

P12 5-F

C

B

A

WF-1000W

L-CH

CNP501

SPEAKER

TERMINALS

R-CH

C

SW102

B

BEAT

CANCEL

A

L-CH

SO351

CD/LINE

INPUT

R-CH

MAIN PWB-A1

L4

SW1

MW/SW1 BAR ANTENNA

78 9101112

MW

L3

Figure 11 WIRING SIDE OF P.W.BOARD (2/3)

– 11 –

Page 12

WF-1000W

A

SW601

VOLTAGE SELECTOR

AC220V-240V AC110V-127V

B

OR

SO601

AC POWER INLET

SOCKET

AC110V-127V/

AC220V-240V,

50/60Hz

(250)

TERMINAL A

PWB-A5

(251)

BATTERYS

DC15V

["D" SIZE (UM / SUM-1,

R20 or HP2) battery x 10]

C

BK

RD

(251)

T601

POWER

TRANSFORMER

D

BL

WH

(237)

RD

TERMINAL B

PWB-A6

E

F

COLOR TABLE

WH

OR

BK

RD

BK

CNS601

1

2

TO MAIN PWB

CNP601

P11 12-A

BR

BROWN

RD(R)

OR

G

YL

GR

BL

VL

GY

WH(W)

H

BK

PK

1

RED

ORANGE

YELLOW

GREEN

BLUE

VIOLET

GRAY

WHITE

BLACK

PINK

F601

T4A L 250V

2

C653

C654

D651

POWER

PWB-A7

C652

C651

34 5

6

Figure 12 WIRING SIDE OF P.W.BOARD (3/3)

– 12 –

Page 13

PARTS GUIDE

WF-1000W

“HOW TO ORDER REPLACEMENT PARTS”

To have your order filled promptly and correctly, please furnish the

following information.

1. MODEL NUMBER 2. REF. No.

3. PART NO. 4. DESCRIPTION

MARK: SPARE PARTS-DELIVERY SECTION

Explanation of capacitors/resistors parts codes

Capacitors

VCC ....................... Ceramic type

VCK........................ Ceramic type

VCT........................ Semiconductor type

VC • • MF ............... Cylindrical type (without lead wire)

VC • • MN............... Cylindrical type (without lead wire)

VC • • TV................ Square type (without lead wire)

VC • • TQ ............... Square type (without lead wire)

VC • • CY ............... Square type (without lead wire)

VC • • CZ ............... Square type (without lead wire)

VC • • • • • • • • • J .. The 13th character represents capacity difference.

("J" ±5%, "K" ±10%, "M" ±20%, "N" ±30%,

"C" ±0.25 pF, "D" ±0.5 pF, "Z" +80-20%.)

If there are no indications for the electrolytic capacitors, error is ±20%.

MODEL

WF-1000W(BK)

WF-1000W(S)

For U.S.A. only

Contact your nearest SHARP Parts Distributor to order.

For location of SHARP Parts Distributor,

Please call Toll-Free;

1-800-BE-SHARP

Resistors

VRD ....................... Carbon-film type

VRS........................ Carbon-film type

VRN ....................... Metal-film type

VR • • MF ............... Cylindrical type (without lead wire)

VR • • MN............... Cylindrical type (without lead wire)

VR • • TV................ Square type (without lead wire)

VR • • TQ ............... Square type (without lead wire)

VR • • CY ............... Square type (without lead wire)

VR • • CZ ............... Square type (without lead wire)

VR • • • • • • • • • J .. The 13th character represents error.

("J" ±5%, "F" ±1%, "D" ±0.5%.)

If there are no indications for other parts, the resistors are ±5%

carbon-film type.

NOTE:

Parts marked with “ ” are important for maintaining the safety of the set.

Be sure to replace parts with specified ones for maintaining the safety and performance of the set.

Page 14

WF-1000W

PARTS CODE NO. PARTS CODE

PRICE

RANK

DESCRIPTIONNO.

INTEGRATED CIRCUITS

IC1 VHITA7358AP-1 J AG FM Front End,TA7358AP

IC2 VHILA1805//-1 J AM FM/AM IF MPX.,LA1805

IC101 VHITA8189N/-1 J AM Record/Playback Amp.,TA8189N

IC201 VHIBA3822LS-1 J Graphic Equalizer,BA3822LS

IC402 VHILA4663//-1 J Power Amp.,LA4663

IC501 VHIKIA7812P-1 J AE Voltage Regulator,KIA7812P

IC502 VHIKIA7809P-1 J Voltage Regulator,KIA7809P

TRANSISTORS

Q151~153 VSKTC3199GR-1 J AB Silicon,NPN,KTC3199 GR

Q156 VSKTC3199GR-1 J AB Silicon,NPN,KTC3199 GR

Q181,182 VSKTC3199GR-1 J AB Silicon,NPN,KTC3199 GR

Q301 VSKTC3203Y/-1 J AC Silicon,NPN,KTC3203 Y

Q403,404 VSKTC3199GR-1 J AB Silicon,NPN,KTC3199 GR

Q501 VSKTC3203Y/-1 J AC Silicon,NPN,KTC3203 Y

Q502,503 VSKTC3199GR-1 J AB Silicon,NPN,KTC3199 GR

Q504 VSKTA1271Y/-1 J AC Silicon,PNP,KTA1271 Y

DIODES

D1,2 VHDDS1SS133-1 J AB Silicon,DS1SS133

D101 VHDDS1SS133-1 J AB Silicon,DS1SS133

D151~156 VHDDS1SS133-1 J AB Silicon,DS1SS133

D158,159 VHDDS1SS133-1 J AB Silicon,DS1SS133

D162 VHDDS1SS133-1 J AB Silicon,DS1SS133

D401 VHDDS1SS133-1 J AB Silicon,DS1SS133

! D651 VHDTS4B03GM-1 J AK Silicon,TS4B03GM

DZ501 VHEDZ8R2BSB-1 J AB Zener,8.2V,DZ8.2BSB

LED1 VHP333ID///-1 J LED,Red,333ID

LED502 VHP333ID///-1 J LED,Red,333ID

FILTERS

CF1 RFILR0008AWZZ J AE FM Band Pass Filter

CF2 RFILF0106AFZZ J AC FM IF,10.7 MHz

CF3 RFILA0057AFZZ J AD AM IF,455 kHz

TRANSFORMER

! T601 RTRNP0001BGZZ J Power

COILS

L1 RCILB0001BGZZ J FM Oscillation

L2 RCILR0001BGZZ J FM Tracking

L3,4 RCILA0001BGZZ J MW/SW1 Bar Antenna

L5 RCILA0003BGZZ J SW2 Antenna

L6 RCILB0002BGZZ J MW Oscillation

L7 RCILB0003BGZZ J SW1 Oscillation

L8 RCILB0004BGZZ J SW2 Oscillation

L9 RCILI0002BGZZ J FM IF

L10 RCILI0003BGZZ J FM Detection

L11 RCILI0001BGZZ J AM IF

L101,102 VP-MK272K0000 J 2.7 mH,Choke

L103,104 VP-MK223K0000 J 22 mH,Choke

L301 RCILB0005BGZZ J Bias Oscillation

L501 VP-MK470K0000 J AB 47 µH,Choke

VARIABLE RESISTORS

VR1 RVR-M0026AWZZ J AC 10 kohm (B),Semi-VR [VCO]

VR102 RVR-M0018AWZZ J 470 ohms (B),Semi-VR

VR203~205 RVR-Q0001BGZZ J 100 kohm (B)×2

VR401 RVR-B0001BGZZ J 50 kohms (B)×2 [Volume]

[Tape Speed]

[Graphic Equalizer]

VARIABLE CAPACITORS

TC5,6 RTO-H1003SJZZ J AG Trimmer,5 pF

TC7,8 RTO-H1001BGZZ J Trimmer,10 pF

TC9 RVC-Z0001BGZZ J Fine Tuning

VC1~4 RVC-R0001BGZZ J Variable Capacitance with

Trimmer (TC1~4)

PRICE

RANK

DESCRIPTION

CAPACITORS

C2 VCCCPU1HH5R0J J AA 5 pF (CH),50V

C4 VCCCPU1HH240J J AA 24 pF (CH),50V

C5 VCKYPA1HB102K J AA 0.001 µF,50V

C6,7 VCKYPA1HB472K J AB 0.0047 µF,50V

C8,9 VCKZPA1HF223Z J AA 0.022 µF,50V

C10 VCCCPU1HH150J J AA 15 pF (CH),50V

C11 VCCCPU1HH220J J AA 22 pF (CH),50V

C12 VCCCPU1HH3R0J J AA 3 pF (CH),50V

C13 VCKZPA1HF223Z J AA 0.022 µF,50V

C14 VCCCPU1HH5R0J J AA 5 pF (CH),50V

C15 VCKZPA1HF223Z J AA 0.022 µF,50V

C17 VCKZPA1HF223Z J AA 0.022 µF,50V

C18 RC-GZA106AF1C J AB 10 µF,16V,Electrolytic

C19 VCQPKV2AA301J J 300 pF,100V,Polypropylene

C20 VCQPKV2AA152J J 1500 pF,100V,Polypropylene

C21 VCCUPA1HH5R0C J 5 pF (UJ),50V

C22 VCKZPA1HF223Z J AA 0.022 µF,50V

C23 RC-GZA227AF1A J AB 220 µF,10V,Electrolytic

C24~26 VCKZPA1HF223Z J AA 0.022 µF,50V

C27 VCQPKV2AA472J J AB 0.0047 µF,100V,Polypropylene

C29 RC-GZA226AF1C J AB 22 µF,16V,Electrolytic

C30 VCKZPA1HF223Z J AA 0.022 µF,50V

C31 VCQYKA1HM472K J AB 0.0047 µF,50V,Mylar

C32 VCQYKA1HM822K J AA 0.0082 µF,50V,Mylar

C33 RC-GZA335AF1H J AB 3.3 µF,50V,Electrolytic

C34 VCKYPA1HB471K J AA 470 pF,50V

C35 RC-GZA335AF1H J AB 3.3 µF,50V,Electrolytic

C36 VCQPKV2AA152J J 1500 pF,100V,Polypropylene

C37,38 VCQYKA1HM123K J AA 0.012 µF,50V,Mylar

C39~41 RC-GZA105AF1H J AB 1 µF,50V,Electrolytic

C42 VCKZPA1HF223Z J AA 0.022 µF,50V

C43 VCKYPA1HB221K J AA 220 pF,50V

C101,102 VCKYPA1HB471K J AA 470 pF,50V

C103,104 VCKYPA1HB821K J AA 820 pF,50V

C105~108 VCKYPA1HB331K J AA 330 pF,50V

C109,110 RC-GZA106AF1C J AB 10 µF,16V,Electrolytic

C111,112 VCQYKA1HM333K J AB 0.033 µF,50V,Mylar

C113~116 RC-GZA475AF1H J AB 4.7 µF,50V,Electrolytic

C117,118 RC-GZA106AF1C J AB 10 µF,16V,Electrolytic

C119,120 VCQYKA1HM153K J AB 0.015 µF,50V,Mylar

C121,122 VCKYPA1HB331K J AA 330 pF,50V

C123,124 VCKYPA1HB152K J AA 0.0015 µF,50V

C125,126 RC-GZA475AF1H J AB 4.7 µF,50V,Electrolytic

C127 RC-GZA108AF1A J AD 1000 µF,10V,Electrolytic

C128 RC-GZA225AF1H J AB 2.2 µF,50V,Electrolytic

C129,130 RC-GZA226AF1C J AB 22 µF,16V,Electrolytic

C131,132 VCKYPA1HB121K J AA 120 pF,50V

C133,134 VCKYPA1HB151K J AA 150 pF,50V

C135,136 VCQYKA1HM272K J AA 0.0027 µF,50V,Mylar

C151 RC-GZA334AF1H J AA 0.33 µF,50V,Electrolytic

C152 RC-GZA106AF1C J AB 10 µF,16V,Electrolytic

C153 VCQYKA1HM103K J AA 0.01 µF,50V,Mylar

C154 RC-GZA106AF1C J AB 10 µF,16V,Electrolytic

C155 RC-GZA105AF1H J AB 1 µF,50V,Electrolytic

C156 RC-GZA476AF1C J AB 47 µF,16V,Electrolytic

C157 RC-GZA105AF1H J AB 1 µF,50V,Electrolytic

C158,159 RC-GZA475AF1H J AB 4.7 µF,50V,Electrolytic

C160 RC-GZA226AF1C J AB 22 µF,16V,Electrolytic

C180 RC-GZA107AF1C J AB 100 µF,16V,Electrolytic

C181,182 RC-GZA105AF1H J AB 1 µF,50V,Electrolytic

C183,184 VCKYPA1HB221K J AA 220 pF,50V

C185,186 RC-GZA105AF1H J AB 1 µF,50V,Electrolytic

C200 RC-GZA227AF1C J AB 220 µF,16V,Electrolytic

C201,202 RC-GZA475AF1H J AB 4.7 µF,50V,Electrolytic

C203,204 RC-GZA105AF1H J AB 1 µF,50V,Electrolytic

C205,206 VCQYKA1HM103K J AA 0.01 µF,50V,Mylar

C207,208 VCKYPA1HB471K J AA 470 pF,50V

C209,210 VCQYKA1HM823K J AC 0.082 µF,50V,Mylar

C211,212 VCQYKA1HM152K J AB 0.0015 µF,50V,Mylar

C213,214 RC-GZA334AF1H J AA 0.33 µF,50V,Electrolytic

C215,216 VCQYKA1HM562K J AA 0.0056 µF,50V,Mylar

C217,218 RC-GZA474AF1H J AA 0.47 µF,50V,Electrolytic

C219,220 VCQYKA1HM393K J AB 0.039 µF,50V,Mylar

C221,222 RC-GZA475AF1H J AB 4.7 µF,50V,Electrolytic

C301 RC-GZA107AF1C J AB 100 µF,16V,Electrolytic

C302 VCQYKA1HM222K J AA 0.0022 µF,50V,Mylar

C303 VCQYKA1HM562K J AA 0.0056 µF,50V,Mylar

C304 VCKZPA1HF223Z J AA 0.022 µF,50V

C305 VCQYKA1HM152K J AB 0.0015 µF,50V,Mylar

– 1 –

Page 15

WF-1000W

NO. PARTS CODE

C306 VCKYPA1HB391K J AA 390 pF,50V

C307 VCKYPA1HB151K J AA 150 pF,50V

C413,414 VCQYKA1HM102K J AA 0.001 µF,50V,Mylar

C415,416 VCQYKA1HM154K J AB 0.15 µF,50V,Mylar

C418 RC-GZA226AF1C J AB 22 µF,16V,Electrolytic

C419,420 RC-GZA475AF1H J AB 4.7 µF,50V,Electrolytic

C423 RC-GZA106AF1C J AB 10 µF,16V,Electrolytic

C424 RC-GZA476AF1E J AB 47 µF,25V,Electrolytic

C425~428 VCQYKA1HM104K J AB 0.1 µF,50V,Mylar

C429,430 RC-GZA106AF1C J AB 10 µF,16V,Electrolytic

C433 VCKZPA1HF223Z J AA 0.022 µF,50V

C502,503 VCKZPA1HF223Z J AA 0.022 µF,50V

C504,505 RC-GZA107AF1C J AB 100 µF,16V,Electrolytic

C506,507 VCKZPA1HF223Z J AA 0.022 µF,50V

C508 RC-GZA107AF1C J AB 100 µF,16V,Electrolytic

C509 VCKZPA1HF223Z J AA 0.022 µF,50V

C510 RC-GZW338AF1E J AG 3300 µF,25V,Electrolytic

C511 VCKZPA1HF223Z J AA 0.022 µF,50V

C512 RC-GZA107AF1C J AB 100 µF,16V,Electrolytic

C513,514 RC-GZA105AF1H J AB 1 µF,50V,Electrolytic

C651~654 VCKZPA1HF223Z J AA 0.022 µF,50V

PRICE

RANK

DESCRIPTION

RESISTORS

R1 VRD-ST2EE100J J AA 10 ohm,1/4W

R2 VRD-ST2CD330J J AA 33 ohms,1/6W

R3 VRD-ST2CD470J J AA 47 ohms,1/6W

R4 VRD-ST2CD334J J AA 330 kohms,1/6W

R5 VRD-ST2CD101J J AA 100 ohm,1/6W

R7 VRD-ST2CD824J J AA 820 kohms,1/6W

R8 VRD-ST2CD392J J AA 3.9 kohms,1/6W

R9 VRD-ST2CD123J J AA 12 kohms,1/6W

R10,11 VRD-ST2EE470J J AA 47 ohms,1/4W

R12 VRD-ST2CD102J J AA 1 kohm,1/6W

R13 VRD-ST2EE101J J AA 100 ohm,1/4W

R14 VRD-ST2CD104J J AA 100 kohm,1/6W

R15,16 VRD-ST2CD103J J AA 10 kohm,1/6W

R17,18 VRD-ST2CD272J J AA 2.7 kohms,1/6W

R19 VRD-ST2CD153J J AA 15 kohms,1/6W

R20 VRD-ST2EE100J J AA 10 ohm,1/4W

R100 VRD-ST2EE151J J AA 150 ohms,1/4W

R101,102 VRD-ST2CD560J J AA 56 ohms,1/6W

R103,104 VRD-ST2CD563J J AA 56 kohms,1/6W

R105,106 VRD-ST2CD184J J AA 180 kohms,1/6W

R107,108 VRD-ST2CD562J J AA 5.6 kohms,1/6W

R109,110 VRD-ST2CD472J J AA 4.7 kohms,1/6W

R111,112 VRD-ST2CD223J J AA 22 kohms,1/6W

R113,114 VRD-ST2CD184J J AA 180 kohms,1/6W

R115,116 VRD-ST2CD222J J AA 2.2 kohms,1/6W

R117,118 VRD-ST2CD334J J AA 330 kohms,1/6W

R119,120 VRD-ST2CD391J J AA 390 ohms,1/6W

R121~124 VRD-ST2CD103J J AA 10 kohm,1/6W

R125 VRD-ST2CD105J J AA 1 Mohm,1/6W

R127,128 VRD-ST2CD473J J AA 47 kohms,1/6W

R129,130 VRD-ST2CD223J J AA 22 kohms,1/6W

R131,132 VRD-ST2CD472J J AA 4.7 kohms,1/6W

R133,134 VRD-ST2CD823J J AA 82 kohms,1/6W

R135,136 VRD-ST2CD153J J AA 15 kohms,1/6W

R151 VRD-ST2CD222J J AA 2.2 kohms,1/6W

R152 VRD-ST2CD561J J AA 560 ohms,1/6W

R153 VRD-ST2CD224J J AA 220 kohms,1/6W

R154 VRD-ST2CD561J J AA 560 ohms,1/6W

R155 VRD-ST2CD393J J AA 39 kohms,1/6W

R156 VRD-ST2CD102J J AA 1 kohm,1/6W

R157 VRD-ST2CD473J J AA 47 kohms,1/6W

R160 VRD-ST2CD472J J AA 4.7 kohms,1/6W

R161 VRD-ST2CD331J J AA 330 ohms,1/6W

R162 VRD-ST2CD473J J AA 47 kohms,1/6W

R166 VRD-ST2EE561J J AA 560 ohms,1/4W

R167~169 VRD-ST2CD103J J AA 10 kohm,1/6W

R172,173 VRD-ST2CD103J J AA 10 kohm,1/6W

R174 VRD-ST2CD223J J AA 22 kohms,1/6W

R176 VRD-ST2CD224J J AA 220 kohms,1/6W

R177 VRD-ST2CD102J J AA 1 kohm,1/6W

R180 VRD-ST2EE561J J AA 560 ohms,1/4W

R181,182 VRD-ST2CD102J J AA 1 kohm,1/6W

R183,184 VRD-ST2CD334J J AA 330 kohms,1/6W

R185,186 VRD-ST2CD221J J AA 220 ohms,1/6W

R187,188 VRD-ST2CD392J J AA 3.9 kohms,1/6W

R200 VRD-ST2EE331J J AA 330 ohms,1/4W

R201,202 VRD-ST2CD102J J AA 1 kohm,1/6W

NO.

R203,204 VRD-ST2CD222J J AA 2.2 kohms,1/6W

R205,206 VRD-ST2CD103J J AA 10 kohm,1/6W

R209,210 VRD-ST2CD104J J AA 100 kohm,1/6W

R211,212 VRD-ST2CD102J J AA 1 kohm,1/6W

R301~303 VRD-ST2EE101J J AA 100 ohm,1/4W

R304 VRD-ST2EE100J J AA 10 ohm,1/4W

R305 VRD-ST2EE273J J AA 27 kohms,1/4W

R306 VRD-ST2EE470J J AA 47 ohms,1/4W

R351,352 VRD-ST2CD473J J AA 47 kohms,1/6W

R353,354 VRD-ST2CD222J J AA 2.2 kohms,1/6W

R415,416 VRD-ST2CD102J J AA 1 kohm,1/6W

R417,418 VRD-ST2CD223J J AA 22 kohms,1/6W

R419,420 VRD-ST2CD332J J AA 3.3 kohms,1/6W

R425,426 VRD-ST2CD102J J AA 1 kohm,1/6W

R427,428 VRD-ST2CD472J J AA 4.7 kohms,1/6W

R429 VRD-ST2CD104J J AA 100 kohm,1/6W

R431 VRD-ST2CD273J J AA 27 kohms,1/6W

R433~436 VRD-ST2CD2R2J J AA 2.2 ohms,1/6W

R437,438 VRD-ST2EE121J J AA 120 ohms,1/4W

R441,442 VRD-ST2CD153J J AA 15 kohms,1/6W

R503 VRD-ST2EE101J J AA 100 ohm,1/4W

R504 VRD-ST2EE681J J AA 680 ohms,1/4W

R511~513 VRD-ST2CD103J J AA 10 kohm,1/6W

R514 VRD-ST2CD104J J AA 100 kohm,1/6W

R515 VRD-ST2CD470J J AA 47 ohms,1/6W

R516 VRD-ST2CD392J J AA 3.9 kohms,1/6W

R517 VRD-ST2CD563J J AA 56 kohms,1/6W

R518 VRD-ST2CD102J J AA 1 kohm,1/6W

PRICE

RANK

DESCRIPTIONPARTS CODE

OTHER CIRCUITRY PARTS

BI1 QCNWN0024BGZZ J Board in Lead wire,3Pin

BI2 QCNWN0025BGZZ J Board in Lead wire,3Pin

CNP101 QCNCM705CAFZZ J AA Plug,3Pin

CNP102 QCNCM705DAFZZ J AB Plug,4Pin

CNP103 QCNCM698HAFZZ J AC Plug,8Pin

CNP501 QTANA0404AWZZ J AF Terminal,Speaker

CNP601 QCNCM698BAFZZ J AA Plug,2Pin

CNS101 QCNWN0023BGZZ J Connector Ass’y,3Pin

CNS102 QCNWN0002BGZZ J Connector Ass’y,4Pin

CNS103 QCNWN0020BGZZ J Connector Ass’y,8Pin

CNS601 QCNWN0006BGZZ J Connector Ass’y,2Pin

! F601 QFS-C402ABGNI J Fuse,T4A L 250V

FW1 QCNWN0011BGZZ J Flat Wire,5Pin

FW2 QCNWN0014BGZZ J Flat Wire,2Pin

J151 QJAKA0001BGZZ J Jack,Mic

J401 QJAKM0001BGZZ J Jack,Headphones

M501(300-9) 9GK1921123187 J Motor with Pulley [Tape]

MIC151 RMICC0001BGZZ J Built-in Microphone

SO351 QSOCJ0001BGZZ J Jack,CD/LINE Input

! SO601 QSOCA0002SJZZ J AK AC Inlet Socket

SP401,402 VSP0012PBF88A J Speaker,Woofer

SP403,404 RALMB0001BGZZ J Speaker,Tweeter

SW1 QSW-S9001BGZZ J Switch,Slide Type

SW101 QSW-S9002BGZZ J Switch,Slide Type

SW102 QSW-S9003BGZZ J Switch,Slide Type [Beat Cancel]

SW103 QSW-S9004BGZZ J Switch,Slide Type

SW401 QSW-P9001BGZZ J Switch,Push Type [X-BASS]

SW501 QSW-S9005BGZZ J Switch,Slide Type

(300-10)

SW501A

SW502(300-11) 9GK640101149 J AE Switch,Leaf Type [Tape 1 Main]

SW503(300-12) 9GK640101161 J Switch,Leaf Type [Tape 2 Play]

! SW601 QSW-S0004SJZZ J AK Switch,Slide Type

9GK640101149 J AE Switch,Leaf Type [Tape 2 Main]

[Band Selector]

[Record/Playback]

[Dubbing Speed/Mic/FM Mode]

[Function Selector]

[Voltage Selector]

– 2 –

Page 16

WF-1000W

PARTS CODE NO. PARTS CODE

PRICE

RANK

DESCRIPTIONNO.

CABINET PARTS

201 GCABA1002BGSA J Front Cabinet [S]

201 GCABA1002BGSB J Front Cabinet [BK]

202 GFTAC0003BGSA J Cassette Holder [Tape 1] [S]

202 GFTAC0003BGSB J Cassette Holder [Tape 1] [BK]

203 GFTAC0004BGSA J Cassette Holder [Tape 2] [S]

203 GFTAC0004BGSB J Cassette Holder [Tape 2] [BK]

204 HBDGA1001BGSA J Badge,SHARP

205 HBDGS1002BGSA J Sheet,Extra-Bass System

206 HDECQ0009BGSA J Panel,Display

207 HDECQ0004BGSA J Ring,Volume Knob

208 HDECQ0010BGSA J Panel,Cassette Holder [Tape 1]

209 HDECQ0011BGSA J Panel,Cassette Holder [Tape 2]

210 HDECZ0001BGSA J Panel,Dial Pointer

211 HSSND0001BGSA J Dial Pointer

212 JKNBQ0001BGSA J Knob,Tuning

213 LANGT0001BGFW J Bracket,Front Cabinet

214 MLIFP0001BGZZ J Gear,Cassette Holder

215 MSPRD0001BGFW J Spring,Cassette Holder Up

216 NGERH0002BGZZ J Gear,Tuning Knob

217 PCOVS7001BGZZ J Shield Paper,Graphic Equalizer

218 LANGG0001BGFW J Guide,Dial Pointer

219 HDECQ0005BGSA J Cap,Volume Knob

220 JKNBK0001BGSA J Knob,Volume

221 9GKNBAND1318A J Nylon Band

222 JBTN-0001BGSA J Button,Record [Tape 1] [S]

222 JBTN-0001BGSB J Button,Record [Tape 1] [BK]

223 JBTN-0002BGSA J Button,Play [Tape 1] [S]

223 JBTN-0002BGSB J Button,Play [Tape 1] [BK]

224 JBTN-0003BGSA J Button,Rewind [Tape 1] [S]

224 JBTN-0003BGSB J Button,Rewind [Tape 1] [BK]

225 JBTN-0004BGSA J Button,Fast Forward [Tape 1] [S]

225 JBTN-0004BGSB J Button,Fast Forward[Tape 1][BK]

226 JBTN-0005BGSA J Button,Stop/Eject [Tape 1] [S]

226 JBTN-0005BGSB J Button,Stop/Eject [Tape 1] [BK]

227 JBTN-0006BGSA J Button,Pause [Tape 1] [S]

227 JBTN-0006BGSB J Button,Pause [Tape 1] [BK]

229 JBTN-0013BGSA J Button,Play [Tape 2] [S]

229 JBTN-0013BGSB J Button,Play [Tape 2] [BK]

230 JBTN-0014BGSA J Button,Rewind [Tape 2] [S]

230 JBTN-0014BGSB J Button,Rewind [Tape 2] [BK]

231 JBTN-0015BGSA J Button,Fast Forward [Tape 2] [S]

231 JBTN-0015BGSB J Button,Fast Forward[Tape 2][BK]

232 JBTN-0016BGSA J Button,Stop/Eject [Tape 2] [S]

232 JBTN-0016BGSB J Button,Stop/Eject [Tape 2] [BK]

234 LANGF0001BGZZ J Support,Mechanism Button Shaft

235 LHLDZ8001BG00 J Holder,Mic

236 LHLDZ1002BGZZ J Holder,LED

237 MSPRC0001BGFJ J Spring,Battery,238 PRDAR0001BGFW J Heat Sink,Main

239 NGERK0001BGZZ J Dial Drum

240 PSHEP0003BGSA J Sheet,LED,Left

241 PSHEP0004BGSA J Sheet,LED,Right

242 JKNBZ0001BGSA J Knob,Fine Tuning

243 PCOVZ9001BGZZ J Cover,Dial Pointer

244 MSPRP0001BGFW J Plate,Record

245 GCABB1001BGSA J Rear Cabinet [S]

245 GCABB1001BGSB J Rear Cabinet [BK]

246 GLEGG0001BG00 J Cushion,Leg

247 JHNDP1001BGSA J Handle [S]

247 JHNDP1001BGSB J Handle [BK]

248 LHLDQ1001BGZZ J Holder,AC Socket/

249 MSPRB0002BGFW J Spring,Rod Antenna

250 MSPRC0002BGFJ J Spring,Battery,+/251 MSPRC0003BGFJ J Spring,Battery,+/252 PSLDM3001BGFW J Plate,Power Transformer Shield

253 QANTR0001BGZZ J FM/SW Rod Antenna

254 LHLDR1001BGZZ J Holder,Tuning

255 NGERK0002BGZZ J Gear,Tuning A

256 NGERK0003BGZZ J Gear,Tuning B

257 JKNBM0001BGSB J Button,X-BASS

258 JKNBP0001BGSA J Knob,Function Selector

259 JKNBP0001BGSA J Knob,Dubbing Speed

260 JKNBP0002BGSA J Knob,Band Selector

261 LHLDS1002BGZZ J Holder,Record Lever

262 MLEVP0002BGZZ J Lever,Record

263 GFTAB1001BGSA J Battery Compartment Lid [S]

263 GFTAB1001BGSB J Battery Compartment Lid [BK]

Voltage Selector

PRICE

RANK

264 TSPC-0008BGZZ J Label,Specifications [S]

264 TSPC-0009BGZZ J Label,Specifications [BK]

264 TSPC-0014BGZZ J Label,Specifications [S] [For

264 TSPC-0015BGZZ J Label,Specifications [BK] [For

! 265 QFSHD0001AWZZ J AB Holder,Fuse

266 PRDAR0002BGZZ J Heat Sink,Sub

300 CMECB0002BG01 J Tape Mechanism Ass’y

300- 1 9GK192104309 J AE Pinch Roller Arm Ass’y

300- 2 9GK192104309 J AE Pinch Roller Arm Ass’y,Fast

300- 3 9GK6201-01-111 J Head,Record/Playback,Tape 1

300- 4 9GK6209-10-10 J Head,Erase,Tape 1

300- 5 9GK6201-01-111 J Head,Playback,Tape 2

300- 6 9GK19210703 J AB FF/REW Belt

300- 7 9GK19210940 J AC Main Belt,Tape 1

300- 8 9GK19210940 J AC Main Belt,Tape 2

300- 9(M501) 9GK1921123187 J Motor with Pulley [Tape]

(SW501A)

300-10

300-11(SW502) 9GK640101149 J AE Switch,Leaf Type [Tape 1 Main]

300-12(SW503) 9GK640101161 J Switch,Leaf Type [Tape 2 Play]

601 XEBSD30P10000 J AA Screw,ø3×10mm

602 XJBSD30P08000 J AA Screw,ø3×8mm

603 XBPSD26P04JS0 J Screw,ø2.6×4mm

604 XHBSD20P04000 J AA Screw,ø2×4mm

605 XJSSD30P10000 J AA Screw,ø3×10mm

606 XBBSF30P10000 J AA Screw,ø3×10mm

607 XJBSD40P16000 J Screw,ø4×16mm

608 XEBSD30P20000 J AA Screw,ø3×20mm

609 XHSSF30P06000 J AA Screw,ø3×6mm

610 XJSSF30P10000 J AA Screw,ø3×10mm

611 LX-JZ0002AWFD J AA Screw,ø3×10mm

9GK640101149 J AE Switch,Leaf Type [Tape 2 Main]

DESCRIPTION

[For Malaysia/Asia Middle East/

Africa/Syria]

[For Malaysia/Asia Middle East/

Africa/Syria]

Jordan/Egypt/Saudi Arabia]

Jordan/Egypt/Saudi Arabia]

Forward

SPEAKER BOX PARTS

301 CCAB-100LBG01K J Front Panel,Ass’y,Left [BK]

301 CCAB-100LBG01S J Front Panel,Ass’y,Left [S]

302 CCAB-100RBG01K J Front Panel,Ass’y,Right [BK]

302 CCAB-100RBG01S J Front Panel,Ass’y,Right [S]

303 GCABD1001BGSA J Speaker Box,Left [S]

303 GCABD1001BGSB J Speaker Box,Left [BK]

304 GCABF1001BGSA J Speaker Box,Right [S]

304 GCABF1001BGSB J Speaker Box,Right [BK]

305 GLEGG0001BG00 J Cushion,Leg,Speaker

306 LHLDW1001BGSA J Holder,Speaker Cord [S]

306 LHLDW1001BGSB J Holder,Speaker Cord [BK]

307 QCNWG0001BGZZ J Cord,Speaker

308 LPLTW0001BGZZ J Support H,Speaker Box

309 LPLTW0002BGZZ J Support V,Speaker Box

701 XEBSD30P10000 J AA Screw,ø3×10mm

702 XJBSD40P16000 J Screw,ø4×16mm

SP401,402 VSP0012PBF88A J Speaker,Woofer

SP403,404 RALMB0001BGZZ J Speaker,Tweeter

ACCESSORIES/PACKING PARTS

! QACCA0001SJ00 J AS AC Power Supply Cord

! QACCE0007AW00 J AH AC Power Supply Cord

! QPLGA0253AFZZ J AE Adaptor,AC Plug

SPAKA0001BGZZ J Packing Add.,Unit

SPAKC0007BGZZ J Packing Case [S] [For Malaysia]

SPAKC0011BGZZ J Packing Case [BK]

SPAKC0015BGZZ J Packing Case [S]

SPAKC0017BGZZ J Packing Case [BK]

SSAKA0002BGZZ J Polyethylene Bag,AC Plug

SSAKH0002BGZZ J Polyethylene Bag,Accessories

SSAKH0004BGZZ J Polyethylene Bag,Unit

SSAKH0005BGZZ J Polyethylene Bag,Speaker

TINSZ0002BGZZ J Operation Manual

[For Saudi Arabia]

[Except for Saudi Arabia]

[Saudi Arabia Only]

[For Malaysia]

[Except for Malaysia]

[Except for Malaysia]

Adaptor [Saudi Arabia Only]

– 3 –

Page 17

WF-1000W

NO. PARTS CODE

TLABB0001BGZZ J Label,Japan [Syria Only]

TLABB0002BGZZ J Label,Japan [Syria Only]

TLABJ0001BGZZ J Label,Orisin

TLABJ0002BGZZ J Label,Orijin

TLABN0005BGZZ J Label,Serial No. Bar Code [S]

TLABN0006BGZZ J Label,Serial No. Bar Code [BK]

TLABS0001BGZZ J Label,Manufucture

TLABZVR09BGZZ J Label,VY

TLABZ0003BGZZ J Label,Feature,Left [For Malaysia]

TLABZ0004BGZZ J Label,Feature,Right

TLABZ0005BGZZ J Label,Feature,Left

TLABZ0006BGZZ J Label,Feature,Right

PRICE

RANK

DESCRIPTION

[Asia Middle East/Africa Only]

[Asia Middle East/Africa Only]

[For Malaysia]

[Except for Malaysia]

[Except for Malaysia]

P.W.B. ASSEMBLY (Not Replacement Item)

! PWB-A1~9 DUNTK0002BG01 J — Main/Graphic Equalizer/Volume/

Fine Tuning/Terminal A/

Terminal B/Power/Holder A/

Holder B (Combined Ass’y)

NO.

PRICE

RANK

DESCRIPTIONPARTS CODE

– 4 –

Page 18

WF-1000W

264

608x4

A

B

C

D

E

F

G

H

607x2

205

213

201

204

212

With VR401

219

601x3

252

601x2

216

220

206

248

601

207

SW601

217

T601

PWB-A7

PWB-A9

265

x2

MIC151

235

221

SO601

240

211

210

208

609

246x2

PWB-A6

PWB-A5

241

PWB-A8

236

242

245

601

213

601

237

PWB-A2

218

258

243

214x2

601

601

PWB-A4

202

PWB-A3

257

260

262

222

223

215

249

605x5

224

246

601x2

VR401

259

225

226

209

203

227

229

601x2

261

230

603

605x6

231

215

Note: Only the unit and consumale parts are supplied as aprts supply for the Tape mechanism.

1

2

34 5

Figure 5 CABINET EXPLODED VIEW

– 5 –

232

253

609

239

254

601x2

IC502

247

606

610

250

246

601

PWB-A1

602x2

244

300(300-1, 300-2, 300-3,

300-4, 300-5, 300-6, 300-7,

300-8, 300-9(M501),

300-10(SW501A),

300-11(SW502),

300-12(SW503))

611

255

IC501

604

263

251

251

601

256

IC402

602x2

Silicon

Grease

238

266

TAPE

MECHANISM

602

234x2

6

Page 19

WF-1000W

A

301(LEFT)

SP403(L-CH)

SP404(R-CH)

303(LEFT)

304(RIGHT)

702x5

302(RIGHT)

B

307

701x4

306

C

D

305

SP401(L-CH)

SP402(R-CH)

305

E

308

309

305

TWEETER

SP403(L-CH)

SP404(R-CH)

305

WHITE

BLACK

F

TWEETER

RED

BLACK

SP403(L-CH)

SP404(R-CH)

G

WOOFER

SP401(L-CH)

SP402(R-CH)

WOOFER

SP401(L-CH)

SP402(R-CH)

H

1

2

Figure 6 SPEAKER EXPLODED VIEW

34 5

– 6 –

6

Page 20

WF-1000W

COPYRIGHT 1999 BY SHARP CORPORATION

©

ALL RIGHTS RESERVED.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted in

any from or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without

prior written permission of the publisher.

SHARP CORPORATION

Communication Systems Group

Quality & Reliability Control Center

Higashihiroshima, Hiroshima 739-0192, Japan

Printed in Japan

A9910-1413NS•HA•I

EX

Loading...

Loading...