Page 1

VL-E990E

SERVICE MANUAL

SERVICE MANUAL

S50A2VL-FD1U/

LIQUID CRYSTAL DIGITAL CAMCORDER NTSC

VL-FD1U

VL-FD1U

LIQUID CRYSTAL DIGITAL CAMCORDER

1. IMPORTANT SERVICE NOTES.........................................................................................................2

2. SPECIFICATIONS .............................................................................................................................. 5

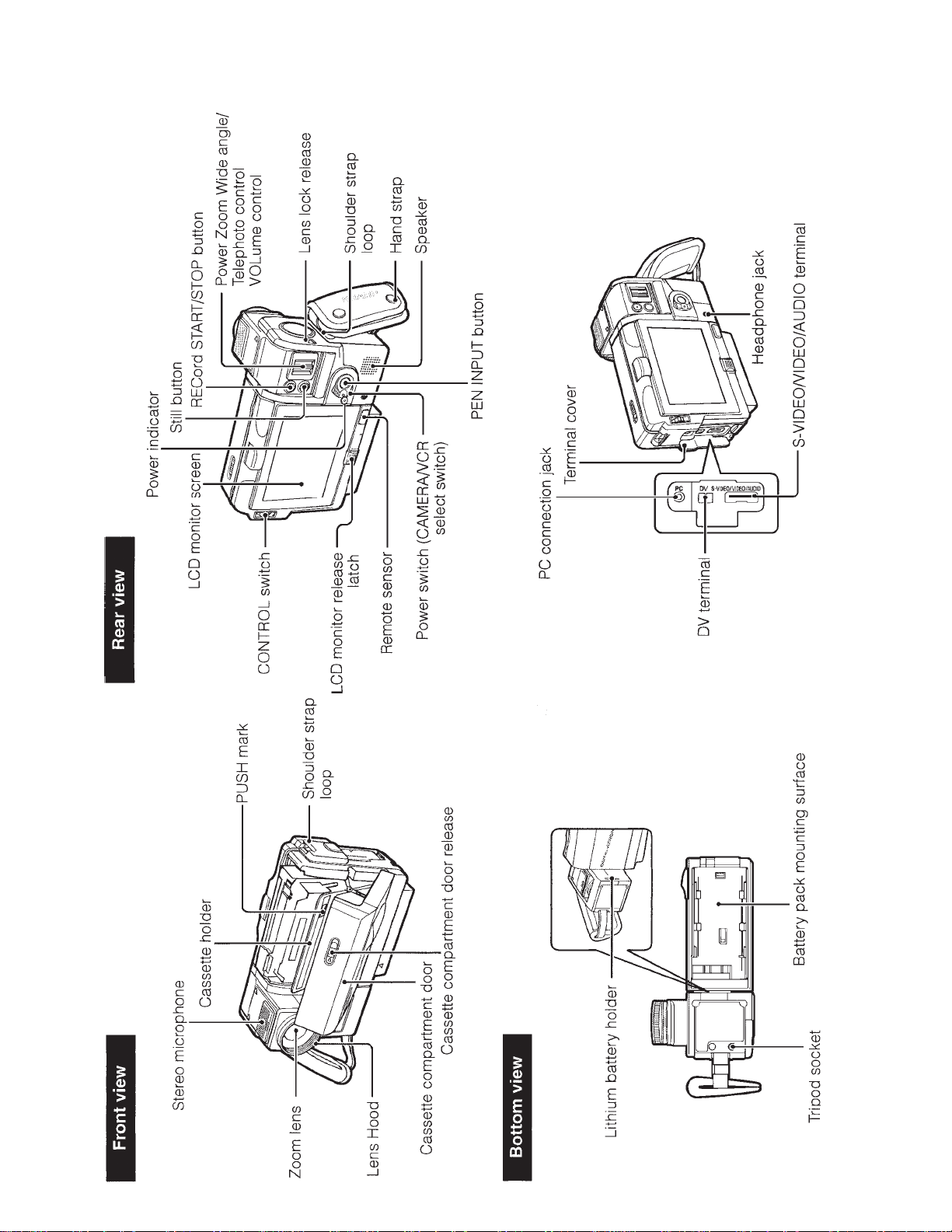

3. PART NAMES AND FUNCTION......................................................................................................... 6

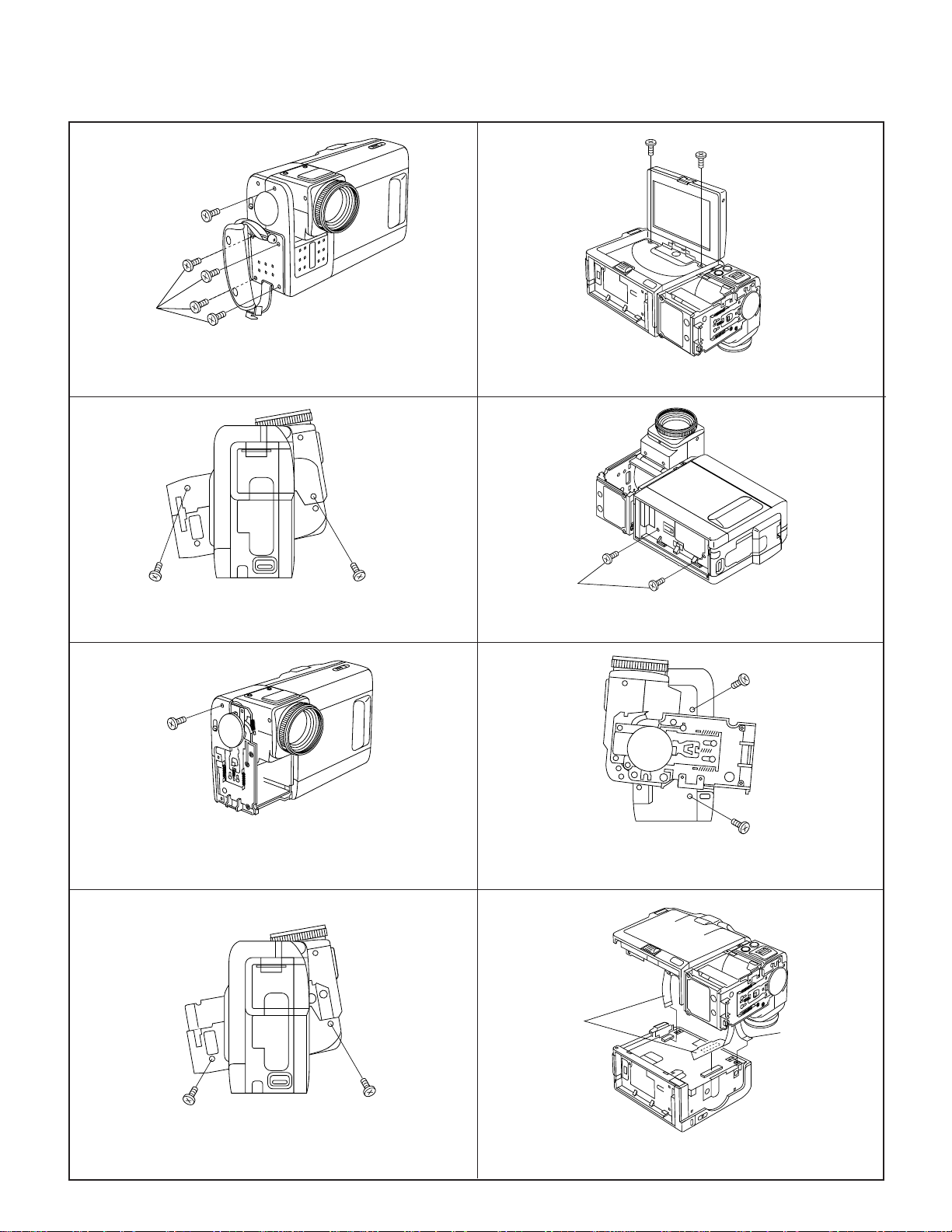

4. DISASSEMBLY OF THE SET ............................................................................................................7

5. MECHANISM ADJUSTMENT JIGS AND PARTS ............................................................................10

6. INSPECTION AND MAINTENANCE

NTSC

MODEL VL-FD1U

ITEMS AND INTERVALS .................................................................................................................11

7. MECHANICAL ADJUSTMENTS AND CHECKS .............................................................................. 12

8. TAPE RUNNING ADJUSTMENT......................................................................................................15

9. MECHANICAL SECTION ASSEMBLY AND PARTS REPLACEMENT

(DISASSEMBLY AND REASSEMBLE) ........................................................................................... 17

10.ADJUSTING THE ELECTRICAL CIRCUITS .................................................................................... 24

11.USEFUL TIPS ................................................................................................................................... 40

12.SIGNAL FLOW DIAGRAMS ............................................................................................................. 41

13.BLOCK DIAGRAMS..........................................................................................................................44

14.SCHEMATIC DIAGRAMS.................................................................................................................50

15.SEMICONDUCTOR LEAD IDENTIFICATION ................................................................................ 106

16.PRINTED WIRING BOARD ASSEMBLIES .................................................................................... 108

17.REPLACEMENT PARTS LIST........................................................................................................ 119

18.PACKING OF THE SET..................................................................................................................139

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its

original condition and only parts identical to those specified

be used.

CONTENTS

VL-FD1U

Page

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

1

Page 2

VL-FD1U

VTVM

AC SCALE

1.5k ohms

10W

CONNECT TO

KNOWN EARTH

GROUND

TO EXPOSED

METAL PARTS

0.15 µF

TEST PROBE

0.15 µF

SONDE D'ESSAI

VERS PIECES

METALLIQUES

EXPOSEES

VTVM

ECHELLE CA

1.5KOHMS

10W

CONNECTER A

UNE MASSE DE

TERRE CONNUE

1. IMPORTANT SERVICE NOTES

BEFORE RETURNING THE VIDEO CAMERA

RECORDER

Before returning the video camera recorder to the user,

perform the following safety checks.

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the video camera

recorder.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields, isolation resistor/capacitor networks, mechanical insulators etc.

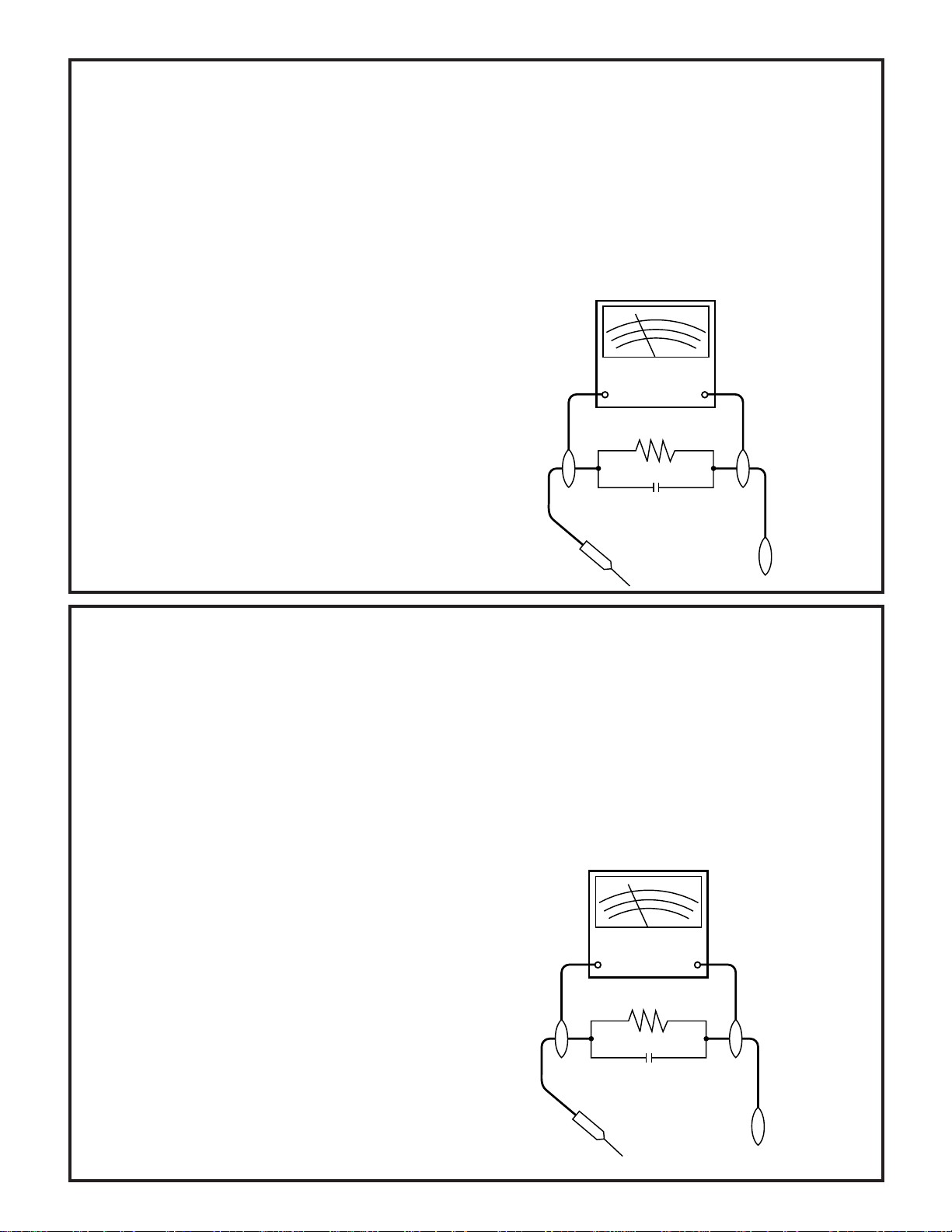

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

· Plug the AC line cord directly into a 120 volt AC outlet

(Do not use an isolation transformer for this test).

· Using two clip leads, connect a l.5k ohm, 10 watt resistor

paralleled by a 0.15µF capacitor in series with all

exposed metal cabinet parts and a known ground,

such as a water pipe or conduit.

· Use a VTVM or VOM with 1000 ohm per volt, or higher

sensitivity or measure the AC voltage drop across the

resistor (See Diagram).

· Move the resistor connection to all exposed metal

parts having a return path to the chassis (antenna

VL-E990E

connections, metal cabinet, screw heads, knobs and

control shafts, etc.) and measure the AC voltage drop

across the resistor. Reverse the AC plug (a non

polarized adaptor plug must be used but only for the

purpose of completing these checks) on the set and

repeat the AC voltage measurements for each exposed metallic part. Any reading of 0.45V rms (this

corresponds to 0.3mA rms AC.) or more is excessive

and indicates a potential shock hazard which must be

corrected before returning the video camera recorder

to the user.

AVANT DE RENDRE LE MAGNETOSCOPE

Avant de rendre le magnétoscope à l’utilisateur, effectuer

les vérifications de sécurité suivantes.

1. Vérifier toutes les gaines de fil pour être sûr que les fils

2. Vérifier tous les dispositifs de protection tels que les

3. Pour être sûr qu’il n’y a aucun risque de choc électrique,

· Brancher le cordon d’alimentation secteur directement

· Utiliser deux fils à pinces et connecter une résistance

· Utiliser un VTVM ou VOM avec une sensibilité de

· Déposer la connexion de la résistance à toutes les

1. NOTES DE SERVICE IMPORTANTES

ne sont pas pincés ou que le matériel n’est pas coincé

entre le châssis et les autres pièces métalliques dans le

magnétoscope.

boutons de commande non métalliques, les matériaux

d’isolement, le dos du coffret, les couvercles de

compartiment et ajustement ou les boucliers, les

réseaux de résistance / condensateur d’isolement,

Ies isolateurs mécaniques, etc.

vérifier le courant de fuite de la maniére suivante.

dans une prise de courant de 120 volts. (Ne pas

utiliser de transformateur d’isolement pour cet essai).

de 10 watts 1,5 kohm en parallèle avec un

condensateur de 0,15 µF en série avec des pièces du

coffret métallique exposées et une masse de terre

connue telle qu’un tuyau ou un conduit d’eau.

1000 ohms par volt ou plus ou mesurer la chute de

tension CA entre la résistance (voir diagramme).

pièces métalliques exposées ayant un parcours de

retour au châssis (connexions d’antenne, coffret

métallique, tétes de vis, boutons et arbres de commande,

etc.) et mesurer la chute de tension CA entre la résistance.

Inverser la fiche CA (une fiche intermédiaire non polarisée

doit être utilisée à seule fin de faire ces vérifications.) sur

l’appareil et répéter les mesures de tension CA pour

chaque piéce métallique exposée. Toute lecture de

0,45 V rms (ceci correspond à 0,3 mA rms CA) ou plus

est excessive et signale un danger de choc qui doit être

corrigé avant de rendre le magnétoscope à son

utilisateur.

2

Page 3

VL-E990E

WARNING :TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NO T EXPOSE

THIS APPLIANCE T O WET LOCA TIONS.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC

SHOCK. DO NOT REMOVE COVER. NO

USER·SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

This symbol warns the user of uninsulated

voltage within the unit that can cause dangerous electric shocks.

This symbol alerts the user that there are

important operating and maintenance instructions in the literature accompanying this unit.

CAUTION

This symbol mark means following.

For continued protection against fire hazard, replace only with same type fuse.

(CP901; 1.25A 24V, CP902; 1.25A 24V,

CP903; 1.25A 24V)

VL-FD1U

Camcorder

only

ATTENTION:POUR REDUIRE LES RESQUES D'INCENDIE OU DE CHOC ELECTRIQUE,

NE PAS EXPOSER CET APP AREIL A LA PLUIE OU A L'HUMIDITE.

ATTENTION

RISQUE DE CHOC ELECTRIQUE

NE PAS OUVRIR

ATTENTION: AFIN DE REDUIRE LES RISQUES DE

CHOC ELECTRIQUE, NE PAS RETIRER LE

COUVERCLE, AUCUN ORGANE INTERNE

NE PEUT ETRE REPARE PAR

L'UTIUSATEUR, CONFIER L'APPAREIL A

UN DEPANNEUR QUALIFIE.

Ce symbole signale à l'utilisateur la présence

d'une tension non isolée à l'intérieur de l'appareil

qui peut être la cause de secousses électriques

dangereuses.

Ce symbole avertit l'utilisateur que des instructions importantes relatives à l'utilisation

et àl'entretien se trouvent dans le manuel

accompagnant l'appareil.

ATTENTION

Ce symbole signifie que l'on devra utiliser un fusible de même type (CP901;

1,25A 24V, CP902; 1,25A 24V, CP903;

1,25A 24V) pour assurer la sécurité.

Camcorder

seulement

3

Page 4

VL-FD1U

VL-E990E

CAUTION

BEFORE BATTERY DESTROY

NICKEL-CADMIUM BATTERY

The following program is available in the United States. Please consult local environmental

authorities concerning the availability of this or other programs in your area.

The RBRCTM Seal

SHARP participates in the RBRCTM* Nickel-Cadmium Battery Recycling Program in the United

States. The RBRCTM Seal on our battery pack contained in our product indicates that SHARP is

voluntarily participating in an industry program to collect and recycle these batteries. The RBRCTM

program provides you with a convenient alternative to placing spent Nickel-Cadmium battery packs into

the trash or municipal waste stream, which is illegal in some areas. At the end of their useful life, the

Nickel-Cadmium battery can be dropped off at the nearest collection center for recycling. For information

on the nearest collection center, call 1-800-8-BATTERY or your local recycling center. If you are located

outside the United States, contact your local authorities for information concerning proper disposal and/

or recycling of this battery. SHARP’s involvement in this program is part of our commitment to protecting

our environment and conserving natural resources.

[Footnote] *RBRCTM is trademark of the Rechargeable Battery Recycling Corporation.

NICKEL-METAL HYDRIDE BATTERY

LITHIUM or LITHIUM-ION BATTERY

SEALED LEAD BATTERY

Battery disposal

Contains the above (Rechargeable) Battery. must be recycled or disposed of properly.

Remove the Battery from the products and contact Federal or State Environmental Agencies for

information on recycling and disposal options.

4

Page 5

VL-E990E

2. SPECIFICATIONS

Signal System: NTSC standard

Recording System: 2 rotary heads, helical scanning system

Cassette: Digital VCR Mini DV video cassette

Recording/Playback Time: 90 minutes (DVM60, LP mode)

Tape Speed: SP mode; 18.812 mm/second

LP mode; 12.555 mm/second

Pickup Device: 1/4" (6.4mm, effective size: 4.5 mm) CCD image sensor (with approx.

380,000 pixels including optical black)

Lens: 10 × optical/200 × digital power zoom lens (F1.4-3.0, f=4.7-47 mm),

full-range auto focus

Lens Filter Diameter: 30 mm

Monitor: 3.5" (8.9 cm) full-color LCD screen (TFT active matrix)

Microphone: Electret stereo microphone

Color Temperature Compensation: Auto white balance with white balance lock

Minimum Illumination: 7 lux (20 lux measured by EIA standard ) (with gain-up, F1.4)

Video Output Level: 1.0 Vp-p 75-ohm unbalanced

Audio Output Level: –8 dBs, impedance less than 2.2 kohms

Speaker Output: 300 mW

Power Requirement: DC 7.4V

Power Consumption:

Operating Temperature: 32°F to 104°F (0°C to +40°C)

Operating Humidity: 30% to 80%

Storage Temperature: –4°F to 140°F (–20°C to +60°C)

Dimensions (approx.): 6" (W) × 2

Weight (approx.): 1.23 lbs (560 g)

4.8 W (during camera recording in Full Auto mode with zoom motor off

and backlight in normal mode)

7

/32" (H) × 3 19/32" (D)

[152 mm (W) × 56 mm (H) × 91 mm (D)]

(without battery pack, lithium battery and video cassette)

VL-FD1U

AC Adapter/Battery Charger

UADP-0294TAZZ(FD1U)

UADP-0295TAZZ(FD1UT)

UADP-0296TA01(FD1UK)

UADP-0296TAZZ(FD1UW)

Power Requirement: AC 110-240 V, 50/60 Hz

DC Output: 7.3 V

Power Consumption: 10 W

Dimensions (approx.): 3

Weight (approx.): 0.54 lbs (245 g)

Specifications are subject to change without notice.

5

/32" (W) × 125/32" (H) × 37/8" (D)

[80 mm (W) × 45 mm (H) × 98 mm (D)]

SERVICE INFORMATION (For the U.S.)

For the location of the nearest Sharp Authorized Service, or to obtain product literature, accessories,

supplies or customer assistance, please call 1-800-BE SHARP (1-800-237-4277) or visit SHARP's

website (http://www.sharp-usa.com)

5

Page 6

VL-FD1U

3. PART NAMES AND FUNCTION

For details on the use of each control.

VL-E990E

6

Page 7

VL-E990E

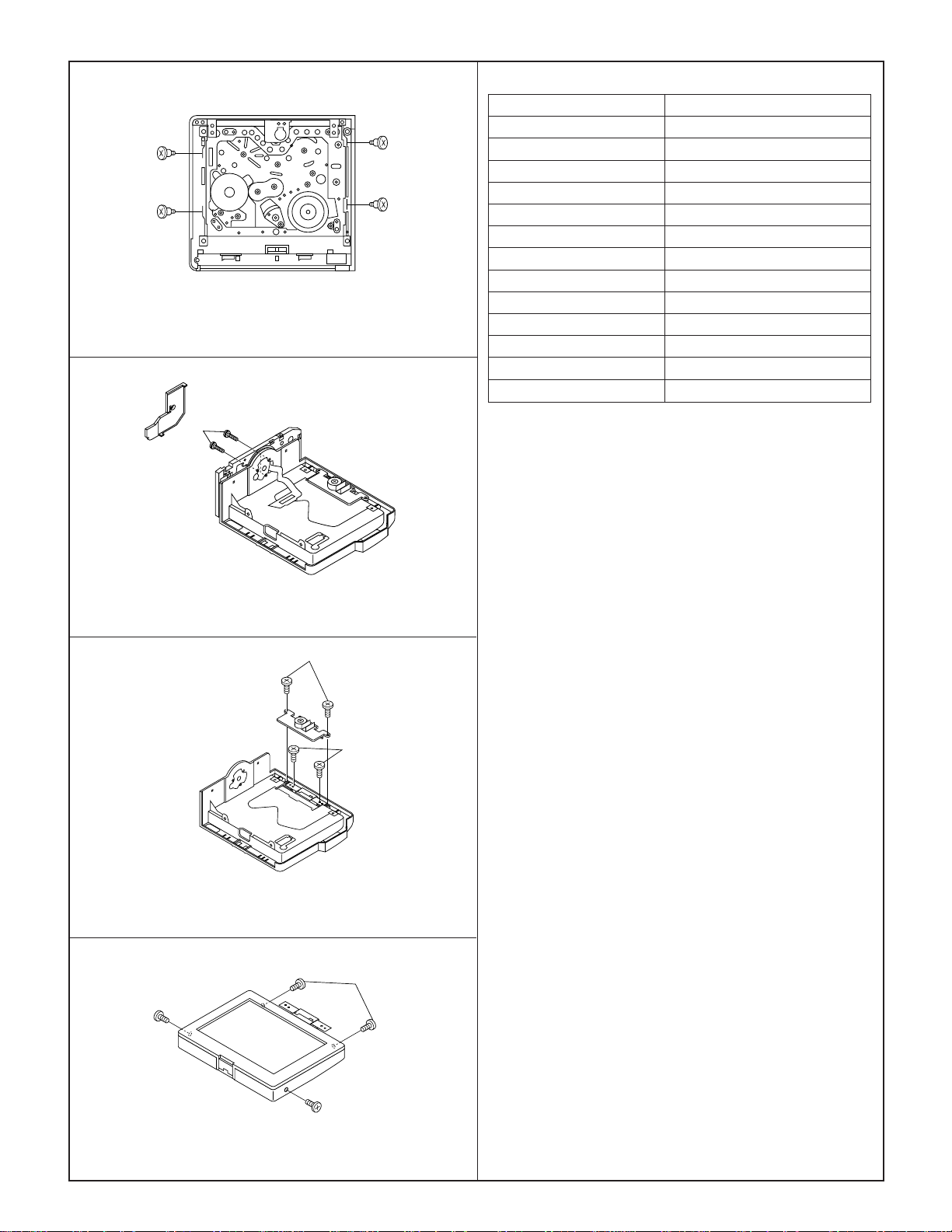

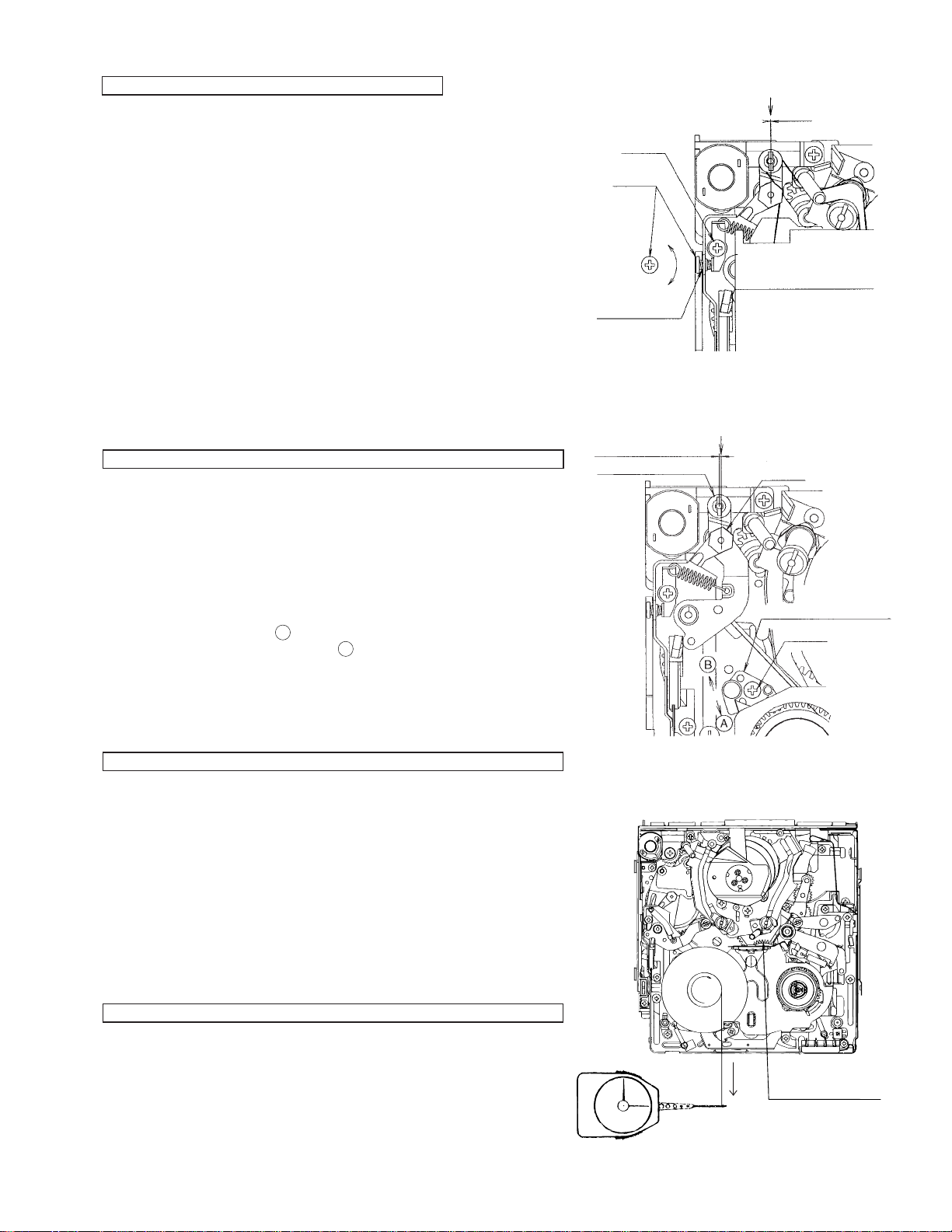

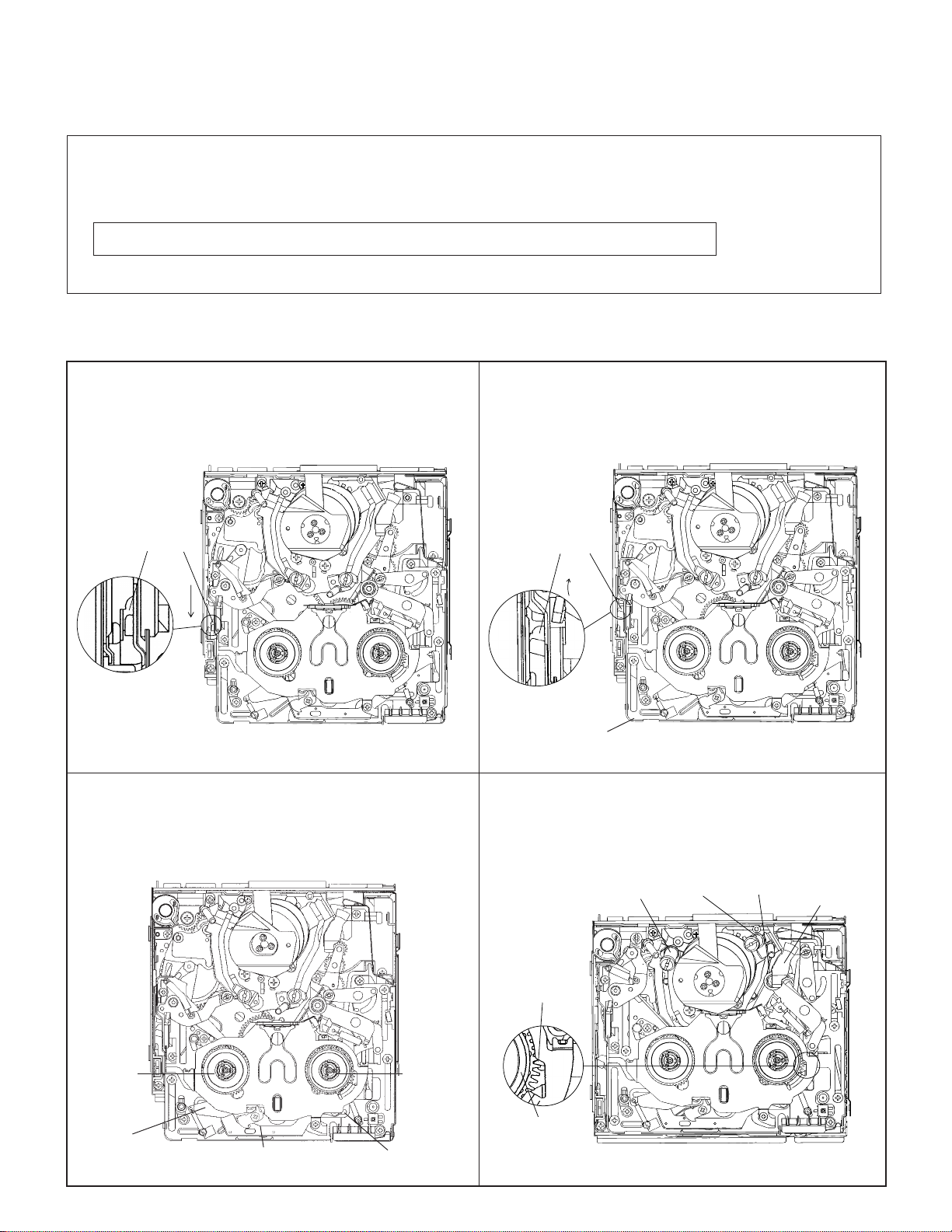

4. DISASSEMBLY OF THE SET

Note:

Before removing the cabinet, turn off the power supply, and ascertain that the battery has been removed.

1. 5.

(f)

(c)

• Remove the screws ((f)LX-BZ0224TAFC)(1 pc.) and

((c)XiPSC17P04000)(4 pcs.) fixing the camera front cabinet

and camera side cover.

2. 6.

• Open the LCD section and remove the screws ((f)LXBZ0224TAFC)(2 pcs.).

VL-FD1U

(f)

(f)

(f)

(f)

• Remove the screws ((f)LX-BZ0224TAFC)(2 pcs.) fixing the

camera front cabinet.

3. 7.

(f)

• Remove the screw ((f)LX-BZ0224TAFC)(1 pc.) fixing the camera rear cabinet.

4. 8.

(g)

• Remove the screws ((g)LX-BZ0222TAFF) fixing the battery

holder.

(d)

(d)

• Turn the camera and remove the screws ((d) XiPSC17P05000)

(2 pcs.).

FPC

Shielded wire

(f)

(f)

• Remove the screws ((f)LX-BZ0224TAFC)(2 pcs.) fixing the

camera rear cabinet.

• Remove the FPCs (2 pcs.) and shielded wire (1 pc.).

7

Page 8

VL-FD1U

VL-E990E

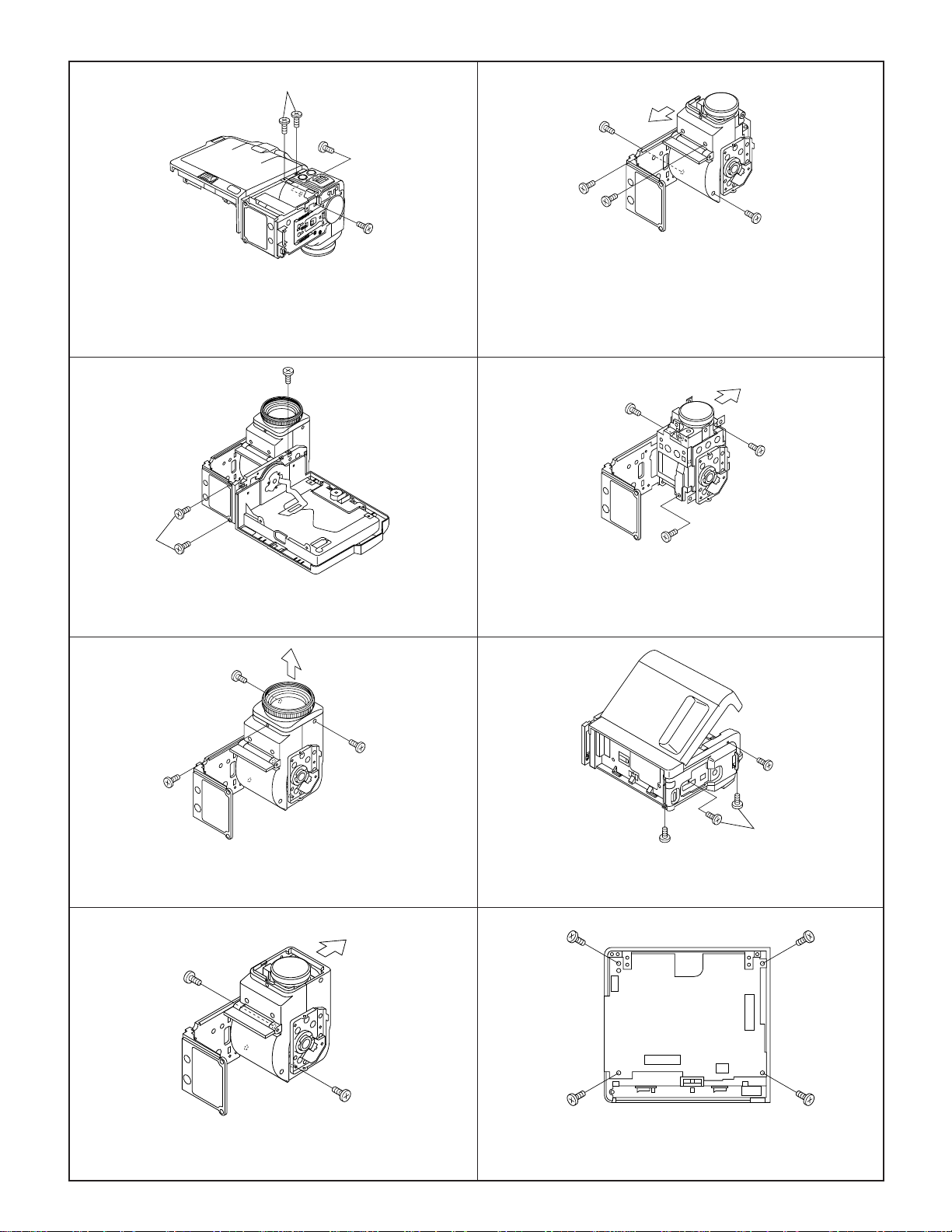

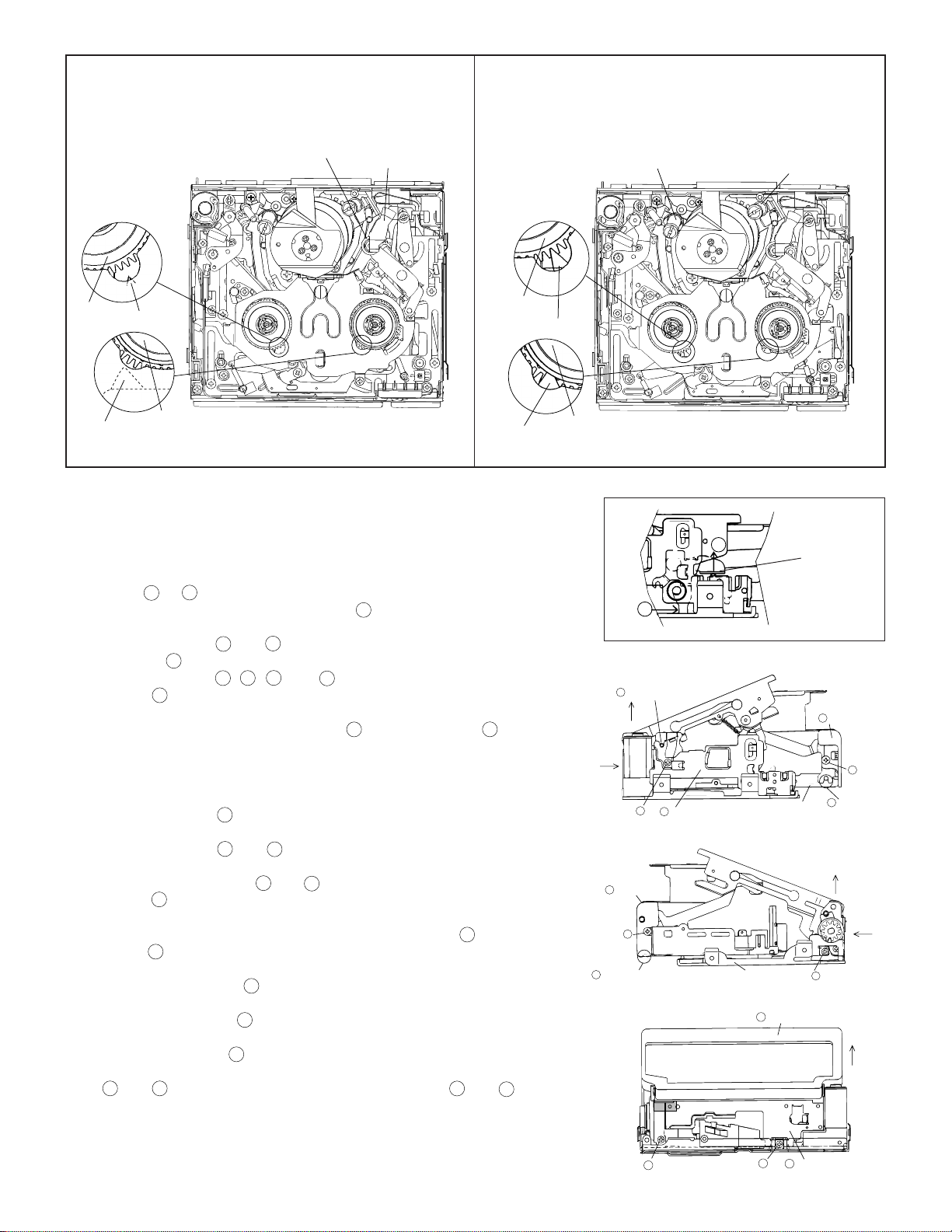

9. 13.

• Remove the screws ((e)XiPSF17P02000)(2 pcs.) fixing the

(e)

(e)

(e)

• Remove the screws ((c)XiPSC17P04000)(4 pcs.) fixing the

camera frame coupling metal and the screws

((e)XiPSF17P02000)(2 pcs.) fixing the camera frame C to

detach the camera section.

10. 14.

(e)

(c)

(c)

(c)

camera lower cabinet.

(p)

(c)

(p)

(f)

• Remove the screws ((f)LX-BZ0224TAFC)(2 pcs.) fixing the

• Remove the screws ((p)LX-HZ0050TAFF)(2 pcs.) and the

camera frame and the screw ((e)XiPSF17P02000)(1 pc.) fixing

the camera frame C.

11. 15.

(c)

(c)

(26)

• Remove the screws ((c)XiPSC17P04000)(2 pcs.) and

• Remove the screws ((e)XiPSF17P02000)(1 pc.), ((p)LX-

((26)XASSN17P04000)(1 pc.) fixing the lens front cover.

12. 16.

(c)

(f)

screw ((f)LX-BZ0224TAFC)(1 pc.) fixing the lens to detach the

lens.

(e)

(p)

(f)

HZ0050TAFF)(1 pc.) and ((f)LX-BZ0224TAFC)(2 pcs.) fixing

the VCR side cover.

(b)

(p)

(c)

• Remove the screws ((c)XiPSC17P04000)(2 pcs.) fixing the

camera upper cabinet.

(b)

(b)

• Remove the screws ((p)LX-HZ0050TAFF)(1 pc.) and

((b)XiPSC17P03000)(3 pcs.) fixing the PWB.

8

Page 9

VL-E990E

VL-FD1U

17.

(r)

(k)

(r)

(r)

• Remove the floating screw ((k)LX-BZ0231TAFE)(1 pc.) and

the screws ((r)LX-BZ0232TAFD)(3 pcs.) fixing the mechanism.

18.

(A11)

<Screws>

(b)XiPSC17P03000 M1.7×3 Silver Small Screw

(c)XiPSC17P04000 M1.7×4 Silver Small Screw

(d)XiPSC17P05000 M1.7×5 Silver Small Screw

(e)XiPSF17P02000 M1.7×2 Black Small Screw

(f)LX-BZ0224TAFC M1.7×2.5 Chrome

(g)LX-BZ0222TAFF M1.7×3 Black

(h)LX-BZ0221TAFC M1.7×3 Chrome

(k)LX-BZ0231TAFE Floating Screw

(n)XiPSF20P04000 M2×4 Black Small Screw

(p)LX-HZ0050TAFF M1.7×4 Black P Tight

(r)LX-BZ0232TAFD Floating Screw

(s)XAPSH17P02000 M1.7×2 Chrome

(A11)LX-BZ0238TAFD M1.7×5 Small Screw

(26)XASSN17P04000 M1.7×4 Flat Head Nickel Screw

• Detach the FPC holder and remove the screws ((A11)LXBZ0238TAFD)(3 pcs.) fixing the tilt.

19.

(c)

(n)

• Remove the screws ((c)XiPSC17P04000)(2 pcs.) fixing the

pop-up cover and the screws ((n)XiPSF20P04000)(2 pcs.)

fixing the LCD hinge.

20.

(s)

(h)

(h)

• Remove the screws ((h)LX-BZ0221TAFC)(2 pcs.) and

((s)XAPSH17P02000)(2 pcs.) fixing the LCD cover.

9

Page 10

VL-FD1U

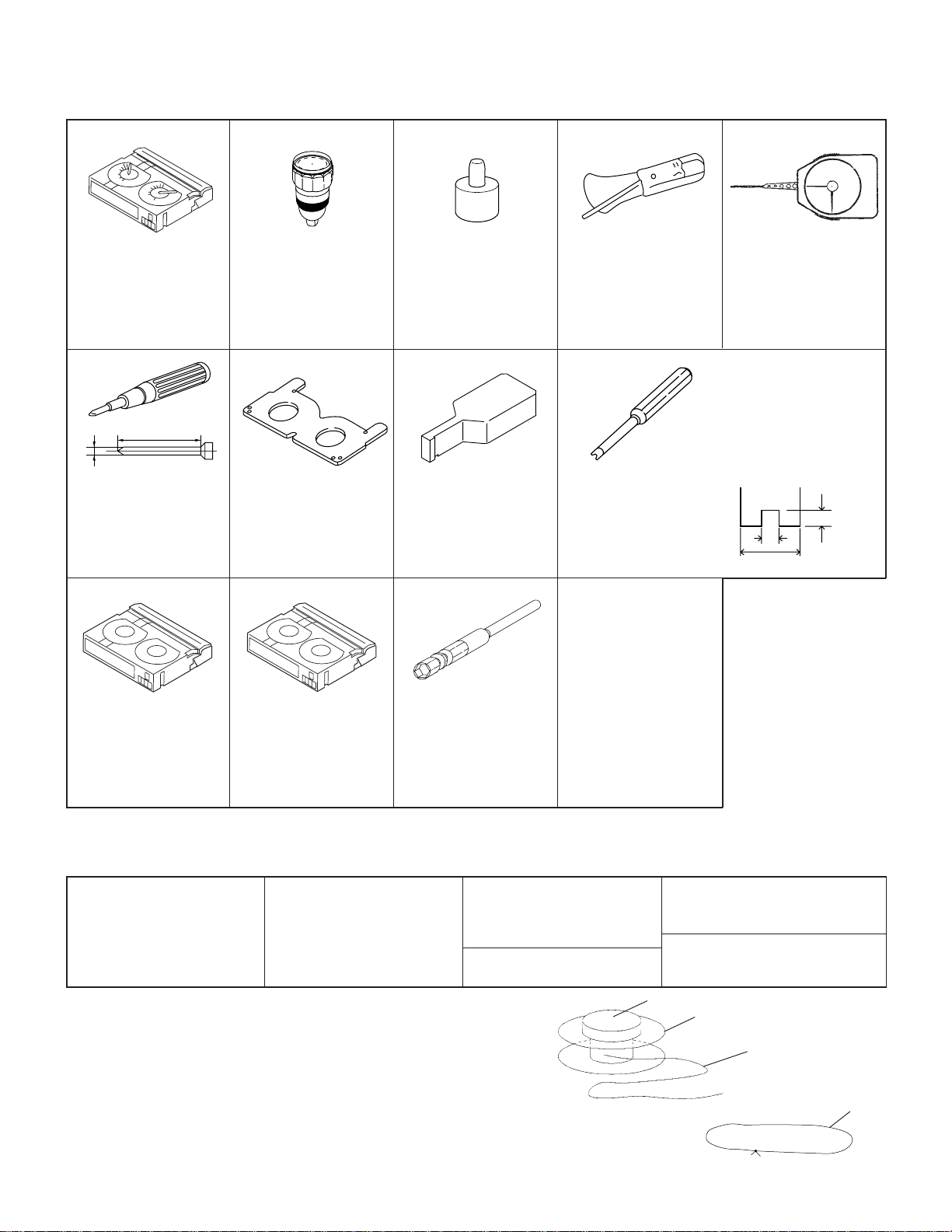

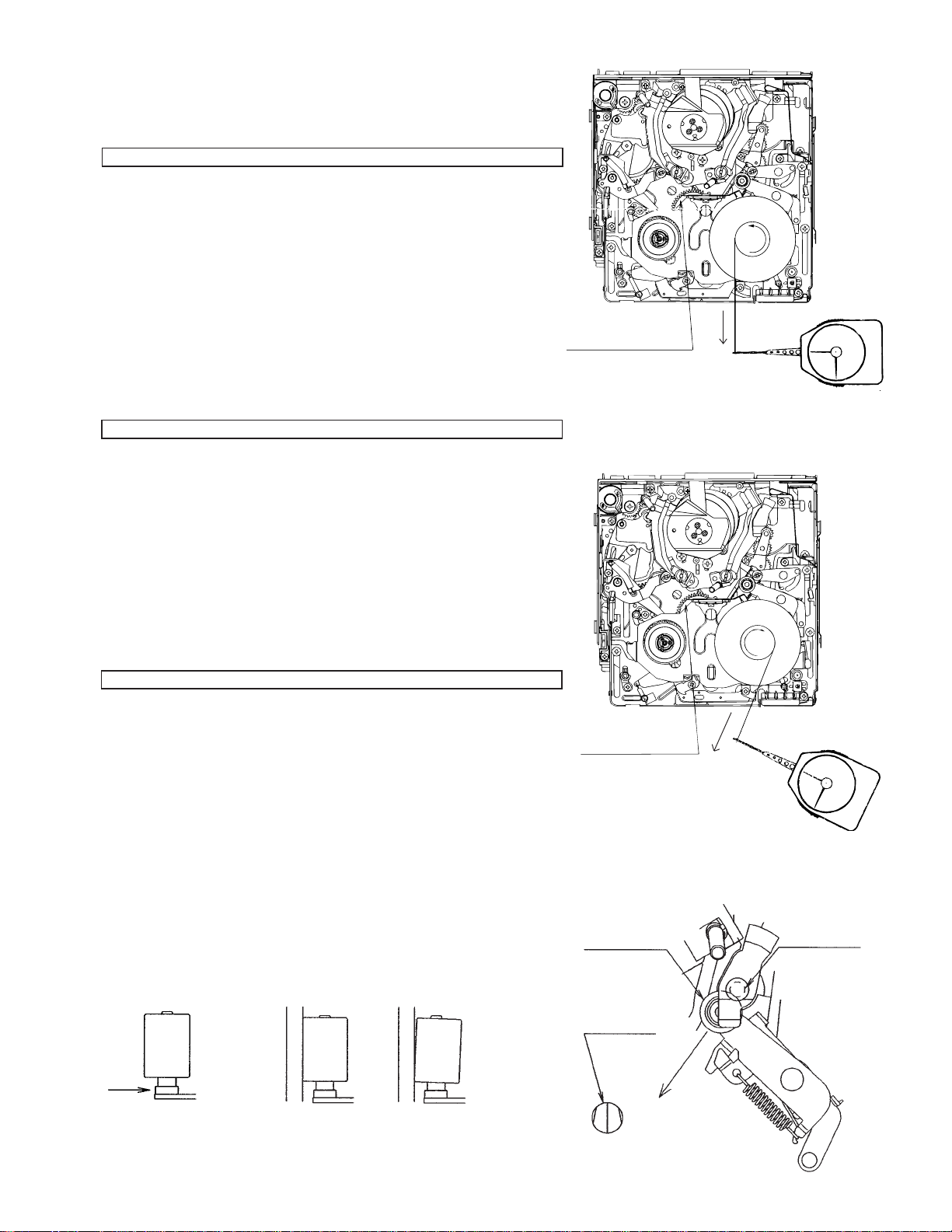

5. MECHANISM ADJUSTMENT JIGS AND PARTS

5-1. Mechanism check adjustment jigs

1. PB-use cassette

Torque meter

2. 9DASD-1015

3. DB

* SD-1015

50 or more

ø2

No. 0 cross-bit

1. Torque screwdriver

150mN·m

2. JiGTD1500RTDH

3. CB

1. Torque gauge

2. JiGTG0045

3. CN

For use in VS-REW wind-

*

ing torque measurement.

1. Master plane

2. 9EQMP-VLPD1

3. CL

* For checking reel base

height.

1. Torque gauge head

2. 9EQTGH-DH5000

3. BW

* For use with the above

torque gauge.

1. Height adjustment jig

2. 9DAHG-PD1

3. BZ

* For height adjusting.

<Note: The entries of list>

1. Tension gauge 4N

2. JiGSG0400

3. BK

* For measurement of

pinch roller pressure.

1. Height adjustment

screwdriver

2. 9EQDRiVER-DH5

3. BC

*

For guide roller adjustment.

Configuration

1. Name

2. Part No.

3. Code

* Model, Uses Remarks

1. Dial tension gauge

2. 9DAPTG-10-10W

3. CA

* PTG-10

*

For Tu guide adjustment.

*

For T roller adjustment.

*

Bit shape (see figure below).

Tolerance ± 0.1

2

1.4

Tip thickness 0.5

3

<Miscellaneous>

(1) Slide caliper

(2) Precision screwdrivers

1. Alignment tape – ( I )

2. VR3-GAZXS

3. CF

*

For tape running adjust-

ment.

1. Alignment tape – ( II )

2. VR3-GTZQS

3. CG

*

For SW point adjustment.

* 90ADVC-TAPE can use,

too. (Code CU)

1. For hexagon nut opposite side 3mm bit.

2. 95CM22001

3. BL

* For S guide hexagon

nut installation.

(Phillips head and slotted)

(3) Radio needle-nose pliers

(4) Tweezers

5-2. Parts for regular periodic inspection and maintenance

1. Oil

Cosmo Hydro HV22

2. HV22 : 9EQ-Oil-HV22

3. HV22 : AE

* Cosmo Petroleum K.K.

1. Cleaning paper

2. JiGDUSPER

3. AP

* DUSPER ∑ (SIGMA)

(ozu Co., LTD.)

<How to make jigs for mechanism checking and adjustment>

(1)Reel hub for back tension measurement (Fig. 1)

1) Obtain a commercially available cassette tape reel hub.

(Disassemble the cassette tape and remove the tape from

the reel hub.)

2) Paste one end of a string (about 20cm long) to the reel hub

with (for example) cellophane tape.

3) Paste the weight of about 0.21N on the upper side reel hub.

(2)String for use in pinch roller snap-fit force measurement (Fig. 2)

1) Obtain an approximately 20cm length of commercially available string.

2) Tie the 2 ends together to form a loop.

1. Grease: Moly Coat

YM-103

2. 99FGREASE-YM103

* Dow coaning

1. Screw lock (1401B)

* Three Bond

<Note:

The entries of list>

1. Cleaning liquid:

industrial-use ethyl alcohol

* Commercially avaitable item

1. Extremely thin cotton swab

* Commercially available item

Weight

Reel hub

Fig. 1

Configuration

1. Name

2. Part No.

3. Code

* Model, Uses Remarks

String

String

Fig. 2

10

Page 11

VL-FD1U

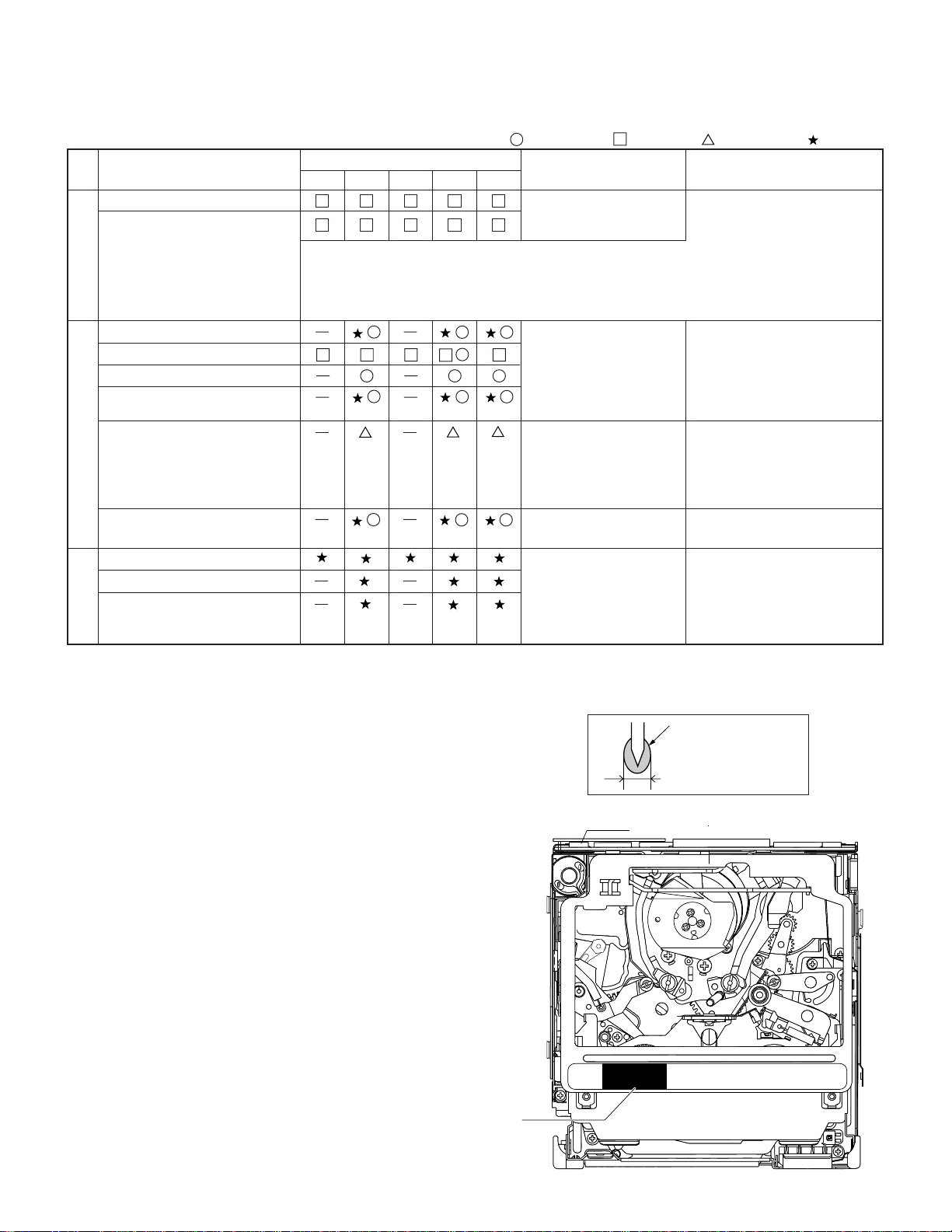

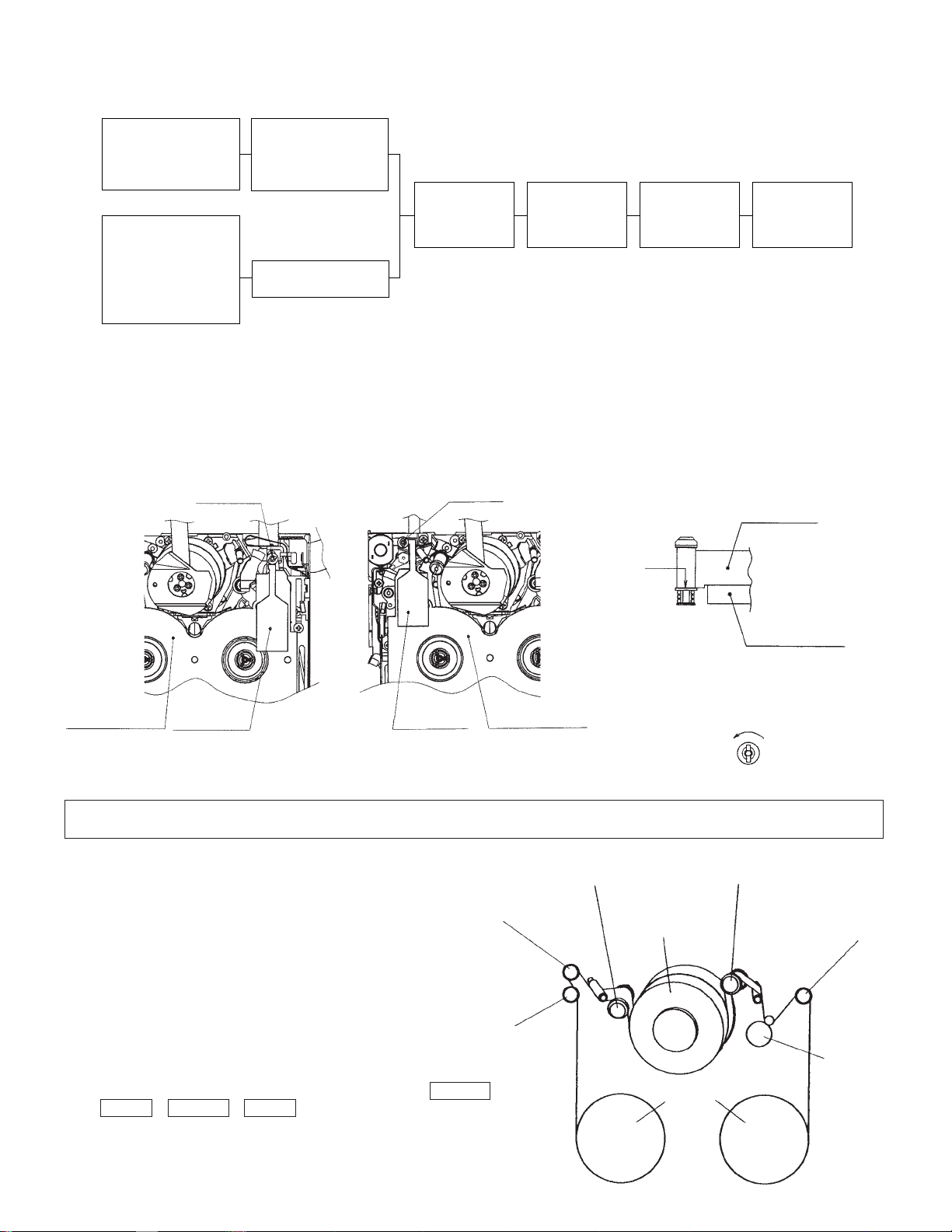

6. INSPECTION AND MAINTENANCE ITEMS AND INTERVALS

In order to keep the mechanical section always in good condition, perform the following inspection and maintenance at regular intervals.

In addition, after repair, perform the following maintenance items regardless of how long the user has been using the unit.

6-1. List of inspection and maintenance items

Inspection and

maintenance location

Tape running section (see section 8-3)

Drum section, Video head

(see section 8-3)

Tape running system

Timing belt

Pinch roller

Capstan motor

Swing arm

S reel base, Tu reel base

Center pulley shaft

Intermediate pulley shaft

Swing arm boss

Drive system

Intermediate gear A shaft,

Intermediate gear B shaft

Loading motor

Mode switch

Abnormal noise

PB · VS/REW winding torque

PB · VS/R · loading back tension

Tu reel base ratchet torque

S reel base no-load torque

Performance checks

500 1,000 1,500 2,000 3,000

<Rollers>

• Replace if there is anything abnormal in the rotation, or if there is run-out

(that becomes large).

<Other than the above>

• Clean the section that contacts the tape (especially the lower drum helical

section). Use the specified cleaning liquid.

Time of use (h)

[Oil] Cosmo Hydro HV22

[Grease] Moly Coat YM-103

• • • Replace. • • • Clean. • • • Lubricate. • • • Check.

Symptoms that indicate

need for maintenance

• Block-type noise

• Head hole clogging

• Tape damage

• The tape fails to run.

• The tape becomes slack.

• Block-type noise

• Abnormal noise

• Abnormal noise

• Cannot eject.

• Fails to enter a mode.

• The tape fails to run.

• The tape becomes slack.

• Tape damage

• The play-back image is

abnormal.

[Screw lock] Three Bond 1401B

[Cleaning liquid] Industrial-use ethyl alcohol

Note:

Replace the drum ass'y if the

video head is cleaned but the

envelope still does not appear.

(When the envelope is normal,

refer to "11. USEFUL TIPS".)

• Replace if there is anything

abnormal.

• Lubricate with oil.

[Oil]

Cosmo Hydro HV22

Note:

• Replace if anything is abnormal

(including the noise).

• Replace any part that fails to

perform within the standard.

Remarks

Apply oil to the shaft, then

wipe lightly with a cloth.

6-2. Precautions

(1) When replacing any part, always replace the cut washer that was

removed with a new one.

(2) This mechanism does not have control adjustment. If the control

cannot be set as required, clean and or replace parts.

(3)On the oil

a) Always use the specified oil. (Using another kind of oil can cause

various kinds of trouble.)

b) Always use clean oil, without any mixed-in dirt, to lubricate bearings.

(Using oil with dirt mixed in can cause the bearings to wear or to

stick.)

c)

One drop of oil is the amount shown in the Fig. 1, on the point of a pin.

(4)Perform circuit repair, tape running adjustment, etc. with the cassette

controller assembly attached to the mechanism.

(5)When operating the mechanism separately, apply voltage to the

loading motor. However, the terminal voltage must be DC3V or less.

(When the mechanism is connected to the main PWB, do not apply

external voltage to the loading motor. It may cause a trouble.)

(Forcing the gears to turn by hand entails danger of breakage.)

If the mechanism is separated from the unit, the capstan motor may rub

and be damaged if spacing under the mechanism is inadequate.

(6)To install the cassette controller, push section A in the Fig. 2. Do not

push anything else.

(7)Do not deform any of the mechanical parts.

Oil

1.5mm diameter or less

Fig. 1

B

•

PUSH

A

11

Fig. 2

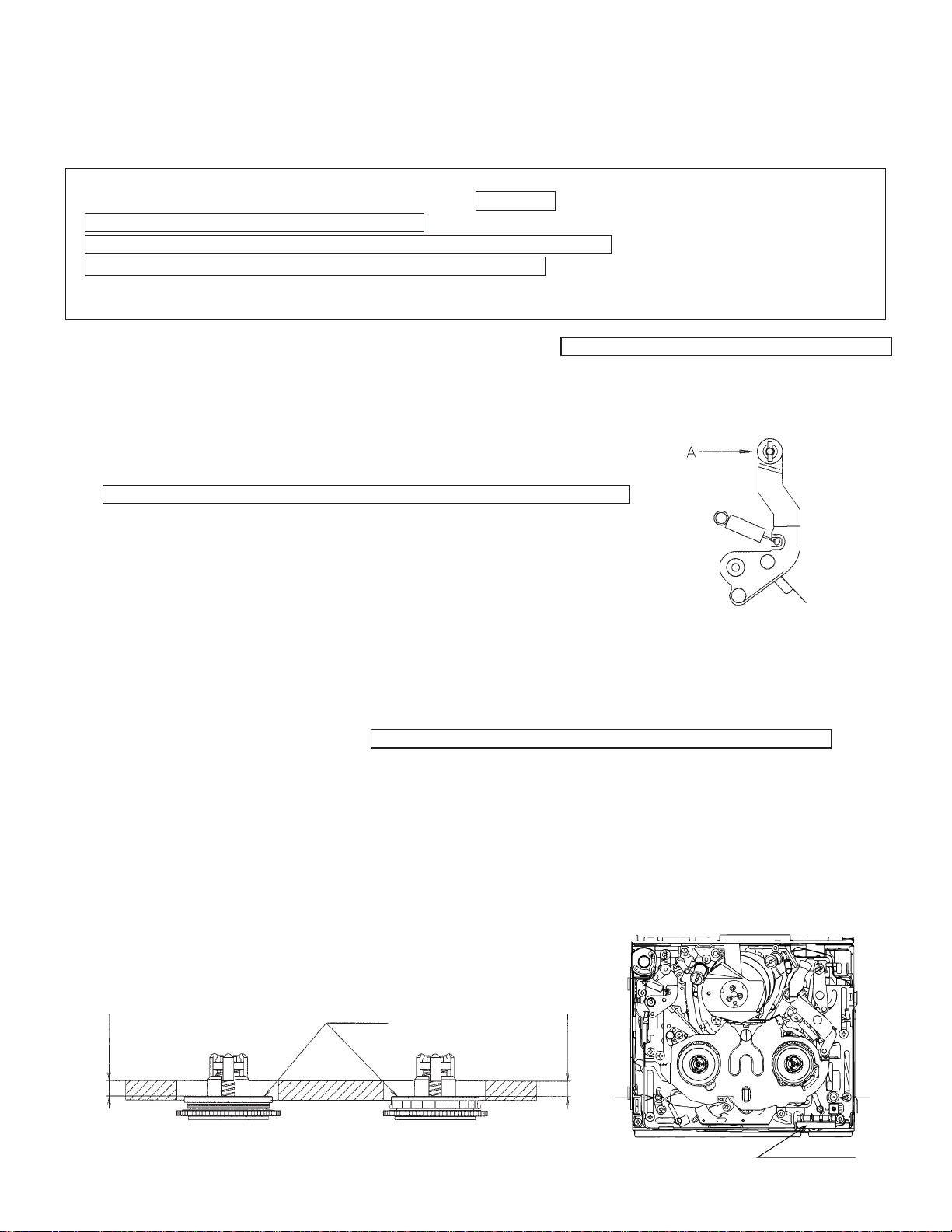

Page 12

VL-FD1U

AB

MIC contacts

7. MECHANICAL ADJUSTMENTS AND CHECKS

The items discussed here relate to general on-site servicing (field servicing). Adjustments and replacements that require

sophisticated facilities, jigs and technology are omitted.

In addition, in order to maintain the characteristics that the unit has when it is new, not only are inspection and maintenance necessary,

but it is absolutely necessary that, for example, the tape not be damaged, and always use jigs for adjustments that require them.

<Precautions>

(1)Always set the power supply and state of the unit as follows Notes for mechanism adjustments and checks.

AC adapter used, with cassette controller assembly

AC adapter used, without cassette controller assembly (Independent Mechanism)

DC3V, without cassette controller assembly (Independent Mechanism)

(2) When the mechanism is connected to the main PWB, do not apply external voltage to the loading motor. It may cause a trouble.

(3) Always run the tape with the cassette controller assembly attached.

7-1. Checking the playback (recording) winding torque AC adapter used, with cassette controller assembly

(1)Set the torque cassette with the cassette controller assembly attached, then, in SP recording mode (playback mode if a signal has

already been recorded in SP mode on the tape), confirm that the torque on the winding side is within the standard.

<Winding torque standard in record (playback) mode>

(If there is torque ripple, read the center value.)

0.70 +0.4/-0.3mN·m, ripple 0.4mN·m or less

7-2. Checking the rewinding playback (VS-REW) winding torque

AC adapter used, without cassette controller assembly (Independent Mechanism)

(1)Remove the cassette controller assembly, press the DOWN switch, using the

adhesive tape and referring to 9-3, operate in the TEST mode (T01) to rewind,

and set the rewinding playback (VS-REW) mode.

(2)Set the torque gauge on the S reel base, press the front end of tension post with

your finger in the arrow A direction so as to ascertain that the winding torque is

as specified. (Check without rotating the torque gauge.)

<Rewinding playback (VS-REW) winding torque standard>

(If torque ripple exists, read its center value.)

1.6 ± 0.6mN·m, ripple 0.5mN·m or less

(3)After checking the winding torque remove the torque gauge, and remove the

adhesive tape used in item (1) above (refer to 9-3). The STANDBY mode is set

automatically.

Fig. 1. Removal of tension band when

measuring the rewinding playback (VS-REW) winding torque

7-3. Checking of reel base height DC3V, without cassette controller assembly (Independent Mechanism)

(1)Remove the cassette controller assembly (refer to 9-2).

(2)Referring to 9-1, apply DC3V to the loading motor and put the system into playback mode.

(3)Taking adequate care so that the master plane does not contact drum, running parts (guide roller, etc.), or the MIC contacts. Fit

the master plane holes to the 2 guides (A and B) in Fig. 2.

(4)Confirm that the heights of the S reel base reel receiving surface and the Tu reel base reel receiving surface below the master plane

top surface are within the set values, using, for example, a slide calliper (Fig. 3).

When checking the S reel base height, press the front end of tension post in the arrow A direction with your finger to release the

tension band, and then check the height in this state (Fig. 1).

(5)If the height is not within set values, replace the washer under the reel base, and adjust as specified.

Note: After the adjustment, make sure that the reel bases rotate smoothly.

Reel receiving

surfaces

2.4 ± 0.1

Reel base height

setting values

Fig. 3

2.4 ± 0.1

Reel base height

setting values

Fig. 2

12

Page 13

7-4. Back tension torque check and adjustment in record (playback) mode

AC adapter used, with cassette controller assembly

(1)Checking

Set the torque cassette (SD-1015), and make sure in the SP record mode that

the supply side torque is within the standard shown below (or in the playback

mode for the tape on which the signal has been SP-recorded).

<Standard>

(If torque ripple exists, read its center value.)

0.7 ± 0.1mN·m

(2)Adjustment (Fig. 4)

If the value is out of standard range, adjust, using the screw 1 shown in Fig. 4.

1. Loosen the screw 2 slightly.

2. Adjust to turning the screw 1. When back tension is too high, turn the screw

1 counterclockwise (CCW).

When back tension is too low, turn the screw 1 clockwise (CW).

3. After adjustment fix the angle with the screw 2. (At this time take care so as

to prevent excessive tightening.) Apply Screw Lock to the screw 1.

<Caution>

Screw tightening torque: 0.04N·m

Screw2

Screw1

Apply screwlock

Tension roller position (S guide standard)

CCW

CW

Fig. 4. Check (tape exists)

VL-FD1U

0 ± 0.3

7-5. Checking and adjustment of tension roller position in

record (playback) mode

DC3V, without cassette controller assembly (Independent Mechanism)

(1)Checking

Before winding the 60-min tape make sure that the tension roller is in the same

position as S guide as shown in Fig. 4.

If not, take out the tape and adjust in the following procedure.

(2)Adjustment (Fig. 5)

1. Set the playback mode without loading the tape.

2. Loosen the screw 3 slightly (to such an extent that the tension band holder

4 can be moved).

3. If the tension roller is inside from the specified position, shift the tension

band holder 4 in the arrow

the tension band holder in the arrow

direction. If the tension roller is outside, shift

A

direction, and fix with the screw 3.

B

(Proper shift must be 0.2 to 0.6mm outside from the specified position.)

4. Check the position by the procedure described in item (1) Checking above.

5. If the position is not specified position, adjust again.

7-6. Checking of supply S reel base no-load torque

DC3V, without cassette controller assembly (Independent Mechanism)

(1)Remove the cassette controller assembly, then apply DC3V to the loading

motor and put the system into L. start mode (refer to 9-1).

(2)Move the swing arm toward the Tu reel base side.

Be careful not to cause damage to the gears and other parts in the process.

(Fig. 6)

(3)Set a back tension measurement reel hub on the S reel base.

(4)Using a dial tension gauge, pull the string in the A direction, then confirm that the

tension is within the standard.

<FF back tension standard>

(If the tension fluctuates, read its center value.)

30mN or less

Tension roller position (S guide standard)

0.2~0.6mm (Standard)

Tension roller

S guide

Tension band holder 4

Screw 3

Fig. 5. Position adjustment

(tape does not exist)

7-7. Checking of loading back tension

DC3V, without cassette controller assembly (Independent Mechanism)

(1)Remove the cassette controller assembly, then apply DC3V to the loading

motor and put the system into L. start mode.

(refer to 9-1)

(2)Move the swing arm toward the S reel base side. Be careful not to cause

damage to the gears and other parts in the process. (Fig. 7)

(3)Set a back tension measurement reel hub on the Tu reel base.

(4)Using a dial tension gauge, pull the string in the A direction, then confirm that

the tension is within the standard.

13

Move the swing arm

A

toward the Tu reel

base side.

Fig. 6. S reel base no-load torque

measurement method

Page 14

VL-FD1U

<REW back tension standard>

(If the tension fluctuates, read its center value.)

15 ± 12mN

7-8. Checking of winding Tu reel base ratchet torque

DC3V, without cassette controller assembly (Independent Mechanism)

(1)Remove the cassette controller assembly, then apply DC3V to the loading

motor and put the system into standby mode. (refer to 9-1)

(2)Move the swing arm toward the S reel base side.

Be careful not to cause damage to the gears and other parts in the process.

(Fig. 8)

(3)Set a back tension measurement reel hub on the Tu reel base.

(4)Using a dial tension gauge, pull the string in the A direction, then confirm that

the tension is within the standard.

<Winding Tu reel base ratchet torque standard >

(If the tension fluctuates, read its center value.)

100mN or less

7-9. Checking of rewinding playback (VS-REW) back

tension

DC3V, without cassette controller assembly (Independent Mechanism)

(1)Remove the cassette controller assembly, then apply DC3V to the loading

motor and put the system into rewinding playback (VS-REW) mode. (refer to

9-1)

(2)Move the swing arm toward the S reel base side.

Be careful not to cause damage to the gears and other parts in the process.

(3)Set a torque gauge on the Tu reel base.

(4)Turning the torque gauge to counterclockwise (1 turn for 3 seconds), then

confirm that the torque is within the standard.

<Rewinding playback (VS-REW) back tension standard value>

(If the tension fluctuates, read its center value.)

0.70 +0.6/-0.3mN·m

Move the swing arm

toward the S reel base

side.

A

Fig. 7. Loading back tension measurement

method

7-10.Checking of pinch pressing force

DC3V, without cassette controller assembly (Independent Mechanism)

(1) Set the pinch roller pressing force measuring thread on the pinch lever

(position A , Fig. 9).

(2)Set the mechanism to the playback mode, press the pinch roller against the

capstan axis.

(3)Fit the tension gauge to the pinch roller pressing force measuring thread, pull

in the arrow B direction shown in Fig. 11 to separate a little the pinch roller from

the capstan axis.

(4)Gradually return the pinch roller, and when the pinch roller contacts parallel

the capstan axis, read the value (see Fig. 10) to make sure that the value

conforms to the standard shown below.

<Standard>

1.8 +0.3/-0.5N

<Caution>

After making this measurement, quickly release the system from playback

mode and remove the pinch roller from the capstan shaft. (If the pinch roller

is left fitted onto the capstan shaft for a long time, the pinch roller will be

deformed.)

A

Move the swing arm

toward the S reel base

side.

A

Fig. 8. Winding Tu reel base ratchet torque

measurement method

Pinch roller

Right guide

Capstan shaft

B

Fig. 9

OK

Fig. 10

NG

Fig. 11

14

Page 15

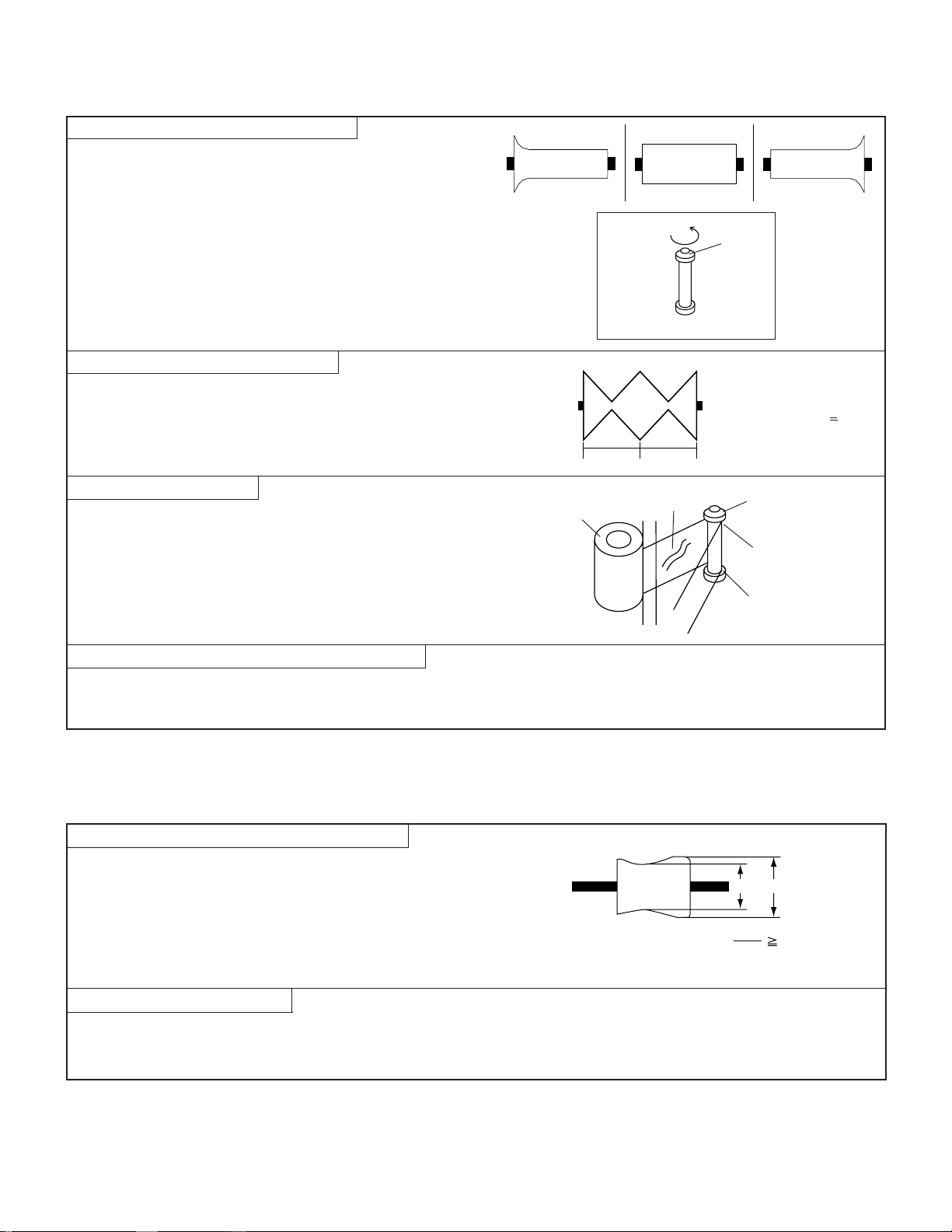

8. TAPE RUNNING ADJUSTMENT

8-1. Adjustment locations

VL-FD1U

<Replacement parts>

· T roller, arm

· Tu guide, arm

· Slide chassis

<Replacement parts other

than those shown above>

· S guide

· Pole base

· Guide roller

· Drum assembly

· Capstan motor, etc.

Adjust the height of only

replaced parts with the

adjusting jig.

Adjustment procedure 8-2

Height presetting is not

necessary.

Running adjustment preparation

Adjustment

procedure 8-3

Running rough

adjustment

Adjustment

procedure 8-4

Cassette controller

installation

Running final

adjustment

Adjustment

procedure 8-5

8-2. Running height adjustment

· After replacement of T roller or Tu guide adjust the height . (Adjust only the replaced parts.)

· After height adjustment do not turn the T roller. If crease is found on the tape of Tu guide, remove the crease by rotating.

(As for details refer to the “running rough adjustment”.)

· After height adjustment of T roller or Tu guide, apply Screw lock to an end of shaft.

(After replacement of S guide apply Screw lock to same point, too.)

Tu guide

T roller

Height setting

jig

Lower edge

fitting

Master plane

Fit height the par on low edge fitting.

Master plane

Height setting

jig

Height setting

jig

8-3. Preparation for tape running adjustment

Master plane

After setting adjustment jigs, turn T roller

and S guide counterclockwise to 225°.

T roller

Meters, jig… Oscilloscope, Adjustment remote control, Height adjustment screw driver, Alignment tape (for tape running

adjustment, for switch point adjustment), Master plane, Height adjustment jig.

<Method and description>

(1)Remove the cassette controller assembly.

Sup guide roller

Tu guide roller

(2)Clean the tape running surface (especially, adequately clean

the drum surface and the lower drum helicam surface).

(3)Connect an oscilloscope to each TP on the relay circuit board.

Tension roller

Drum

Tu guide

(4)Turn the AC adapter power ON.

(5)Using the adjustment remote control unit, put the system TEST

mode T-05.

(6)Replay the alignment tape for running adjustment, and make

sure that the tape is running in the SP mode.

(7)Check the oscilloscope playback envelope, then, at +1/4 shift

and -1/4 shift, check whether all of it is flat. If it is not, perform

the following adjustment so that it becomes flat.

(Each time you push the PLAY key, the shift will change; +1/4 shift

→ Normal → -1/4 shift → Normal , in order.)

S guide

Pinch roller

Reels

15

Page 16

VL-FD1U

8-4. Running rough adjustment

(Since this adjustment is performed without cassette controller, put a proper weight so that the cassette does not rise , and make an

adjustment.)

1) Su, Tu guide roller height adjustment

<Method and description>

(1)Loosen the guide roller lock screw, then tighten loosely so that

the roller turns easily.

(2)Replay an alignment tape, and adjust the Sup, Tu guide roller

so that the envelope sides of entrance and exit are flat.

(3)Perform ± 1/4 shift, then, as in the above case, adjust until the

envelope becomes flat.

* If running is difficult for the entrance changed, turn the T roller

to counter clockwise 180°. (refer to Fig. 1)

2) Check of V/SR envelope wave form

<Method and description>

(1)Confirm that the envelope waveform peaks in V/SR mode are

uniform.

(2) If they are not uniform, fine-adjust the guide roller and the Tu

guide.

3) Check of tape wrinkles

<Method and description>

(1)Check that the tape is not distorted between the Tu guide and

pinch in the PB mode and the V/SR mode.

-If crease is found, make an adjustment in the range of ±180°.

-After adjustment apply Screw Lock.

NG

±1/4 shift ±1/4 shift

Entrance side

Turn to 180°

Exit side

Normal

T roller

Fig. 1

Adjust so that A B.

A

Pinch roller

B

Wrinkles

Tu guide

Deformation

Deformation

NG

•

•

4) Check the rising time of the envelope wave form

<Method and description>

(1)Check the rising time of the envelope when switching from V/SR mode to PB mode. (Within 5 sec)

(2)Check the rising time of the envelope when switching from STOP mode to PB mode. (Within 5 sec)

8-5. Final running adjustment

(Perform adjustment without removing the cassette controller.)

1) Adjustment of Sup and Tu guide roller height

<Method and description>

(1)Perform ± 1/4 shift, then if the envelope wave's ratio of MAX.

to MIN. are 60% or less, adjust again the height of guide roller.

(Refer to Fig. 2)

(2)Finally adjust the lock screw of Sup and Tu guide roller.

(3)Once perform unloading and then loading to set the PB mode,

and make sure that the envelope waveform does not change.

Fig. 2

2) Adjustment of playback SWP

<Method and description>

(1)Playback the alignment tape for switch point adjustment.

(2)Perform SWP automatic adjustment with adjustment remote control.

* When replacing the mechanism and drum, adjust the phase and equalizer using the adjustment remote control.

(Refer to "10. ADJUSTMENT THE ELECTRICAL CIRCUIT".)

E

MIN

E

MIN

E

MAX

E

MAX

60 (%)

16

Page 17

VL-FD1U

9. MECHANICAL SECTION ASSEMBLY AND PARTS REPLACEMENT

(DISASSEMBLY AND REASSEMBLY)

Mechanical section disassembly and reassembly are explained in this section.

For removal of the cabinet, etc., refer to 4. DISASSEMBLY OF THE SET.

<Precautions>

1. Always replace cut washers that have been removed, for example in parts replacement, with new ones.

When reassembling, be careful not to allow screws, washers or foreign matter to enter. They can cause mechanical misoperation.

2.

3. Use the cleaning liquid, oil, grease and screw lock that are specified below. Use of any other kind can cause mechanical

misoperation.

Oil: Cosmo Petroleum : Cosmo Hydro HV22 Screw lock: Three Bond :1401B

Grease: Dow Corning : Moly Coat YM-103 Cleaning liquid: Industrial-use ethyl alcohol

4. Turn the mechanical section over, do not place it on, for example, a desk. Deformation and scratching of mechanical parts can

cause trouble.

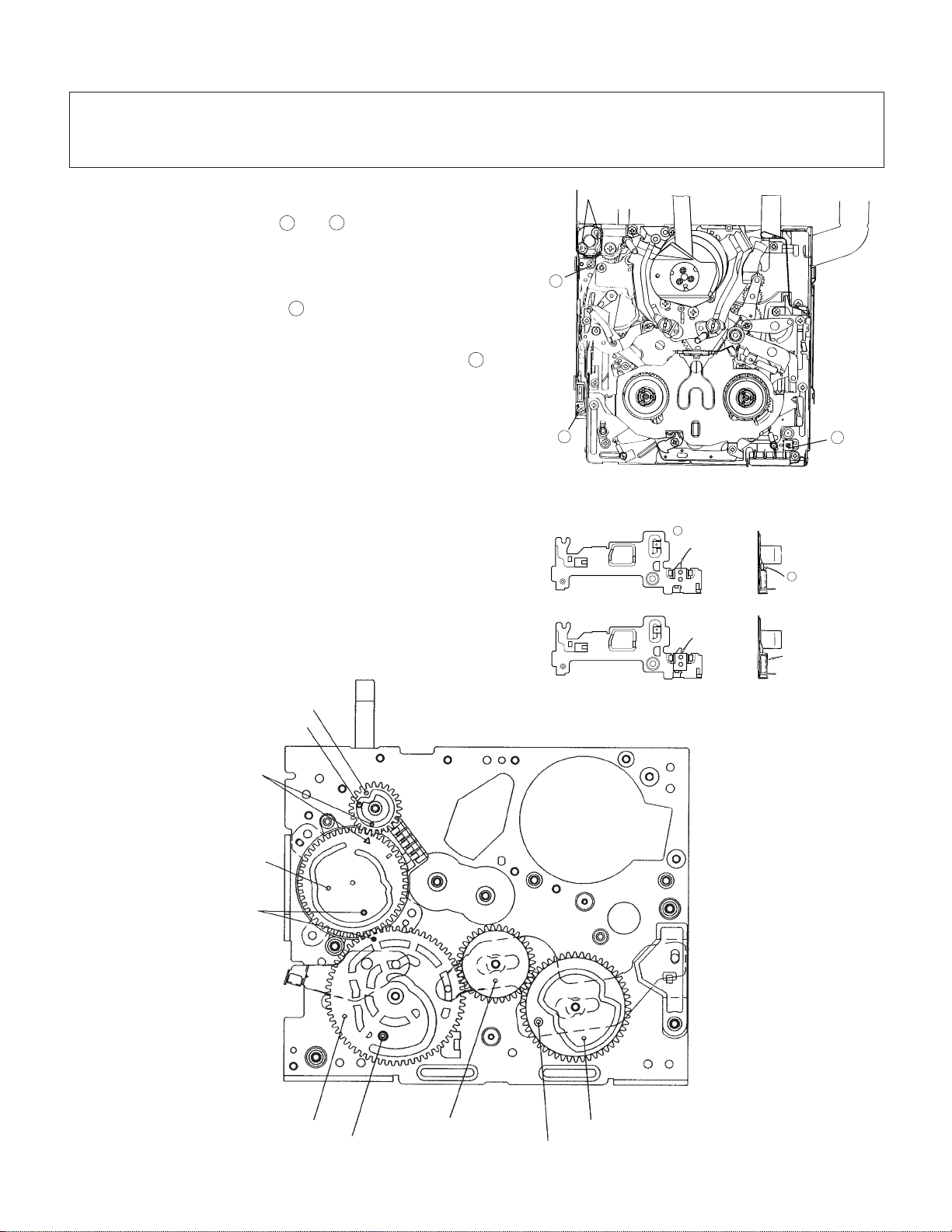

9-1. On the mechanical modes

When operating the mechanism separately, apply DC3~4V to the loading motor.

(When the mechanism is connected to the main PWB, do not apply external voltage to the loading motor. It may cause operational problems.)

(1) EJECT mode

The mechanism position to take out the cassette where the

EJECT lever is extremely shifted in the A direction. (It is impossible to lock the cassette controller assembly in this mode.)

EJECT lever

A

EJECT mode diagram

(3)LOADING START mode

This is the mode where the tape is wound around the winding

reel when a cassette with visible wind start leader tape is

loaded. (The brake shifter moves to the left, the S main brake

is separated from the S reel base and the Tu main brake is

separated from the Tu reel base.)

(2)STANDBY mode

The mechanism position to set the cassette where the slide

chassis is at the farthest position from the drum and the

EJECT lever is in clockwise rotated position (position where

the cassette controller assembly can be locked).

EJECT lever

Rotation

Slide chassis

STANDBY mode diagram

(4)REWINDING (VSR) mode

The mechanism position to rewind the tape (fast rewinding

playback). The S and T pole base is pressed, the pinch roller

is pressed to the capstan axis, the brake shifter VSR brake

section engages with the Tu reel base gear.

S pole base

T pole base

Pinch roller

Capstan shaft

S reel base

S main brake

Brake shifter

LOADING START mode diagram

VSR brake section

Tu reel base

Tu reel base

Tu main brake

REWINDING (VSR) mode diagram

17

Page 18

VL-FD1U

A

B

F

O

E

A

Fig. 4

Down guide positioning

I

Down guide

Slide chassis

K

R

Top cover

J

G

Side plate

H

K

K

L

A

Fig. 4

Down guide

positioning

I

N

C

M

Down guide

Slide chassis

Side plate positioning

Down switch angle

D

(5)PLAYBACK (RECORD, FF, VSF) mode

The mechanism position for playback, record, FF and fast

feed playback.

The pinch roller is pressed to the capstan axis, and the S/Tu

main brake is separated from the S/Tu reel base.

S reel base

Tu main brake

(Not visible)

Pinch roller

S main brake

Tu reel base

PLAYBACK mode diagram

Capstan shaft

(6)STOP mode

The system is in the STOP (Rec Lock in CAMERA mode)

position; the S and the T pole bases are snap-fitted to the drum

base, the S brake is in contact with the S reel base, and the Tu

brake is in contact with the Tu reel base.

S reel base

S main brake

Tu main brake

Tu reel base

(RECORD, FF, VSF)

9-2. Cassette controller assembly

<Removing>

(1)Remove the CAP FPC cover. (Remove the Head amplifier PWB unit and

tighten screw together.)

(2)Apply DC3V to the loading motor to set the standby mode. Press the lock

lever in the arrow direction to move up the cassette controller. (See Fig. 1,

direction

(When the lever is pressed in the direction

controller to release.)

(3)Remove the screws C and E shown in Fig. 2 and Fig. 3, and remove the

Down guide

(4)Remove the screws

side plate

Note) When removing the cassette controller, take care so that the drum motor

FPC provided between the side plate J and the top cover R is not

damaged and so that the drum is not damaged.

or B)

A

.

I

, F, G, and H shown in Fig. 2, 3 and 4, raise the

D

in the direction K to remove it.

J

, gently raise the cassette

A

S pole base

STOP mode diagram

Fig. 1. Lock lever

T pole base

Lock lever

<Installing>

(1)Apply DC3V to the loading motor to set the standby mode.

J

(2)Install the side plate

.

1) Lower the cassette controller assembly in the direction contrary to K in Fig. 4,

and fit the screws G and H as shown in Fig. 4.

Tightening torque 40 ± 4mN·m

Before fitting the screws G and H make sure that the side plate positioning

L

section

engages with the down switch angle in Fig. 2.

Note) When lowering the cassette controller assembly in the direction contrary

to K, place the drum motor FPC between the side plate J and the top

cover

. At this time be careful so that FPC is not damaged. Take care

R

so that the drum is not damaged.

2) In Fig. 2 fit the screws D.

Tightening torque 40 ± 4mN·m

3) In Fig. 3 fit the screw

.

F

Tightening torque 40 ± 4mN·m

(3)Install the down guide I.

1) In Fig. 2 and Fig. 3 engage the slide chassis down guide positioning sections

(4)Attach the CAP FPC cover.

1) Attach the Head amplifier PWB unit and tighten screw together.

and O with the down guide, install with the screws C and E.

N

Tightening torque 40 ± 4mN·m

Tightening torque 40 ± 4mN·m

18

Fig. 2

Fig. 3

Fig. 4. (Fig. from direction A)

Page 19

VL-FD1U

R

Down switch angle

Adhesive tape

Adhesive tape

Down switch

moving piece

R

Down switch moving

piece

9-3. How to operate with the circuit board without the cassette controller assembly.

In this method, if the procedure is followed incorrectly there is danger of damaging the mechanism and the tape, so except in special

cases, such as when measuring the VSR torque, do not perform this procedure. Normally operate this unit with the cassette controller

assembly attached.

Be sure to follow each caution mentioned.

(1)Apply DC3V to the loading motor to set the EJECT mode.

(2)Remove the down switch angle.

1) In Fig. 5 remove the screws P and Q.

Note) The loading motor solder joint (part T, Fig. 5) of DEW sensor

FPC applied to the down switch angle is not removed. After the

down switch angle is removed, take care so that the DEW

sensor FPC is not broken.

R

(3)Surely secure the moving piece

of down switch as shown in Fig.

6 with the aid of adhesive tape so that the switch is turned on.

(4)Install the down switch angle.

S

Note) To set the REC mode, press the pin of recognition switch

(not

required in other modes).

(5)Set the test mode (T-01) with the adjustment remote controller

without loading the tape. Thereby the mechanism operation is

enabled with the mode key.

(6)To eject, remove the tape (3).

9-4. Phase matching

For the parts listed below, match the phases as shown in Fig. 7.

(1) AHC cam (2) MODE switch (3) Main cam (4) Sub cam

Note) Before disassembling, check the marker positions carefully.

Note)

When installing the engagement gear, make sure that the main cam

and sub cam phase matching hole aligns with the chassis hole.

Note) After phase matching, turn the MODE switch by hand and confirm

that it turns almost one complete turn. (After checking, return it to

its original position.)

T

P

Q

Fig. 5. STANDBY mode

S

Phase matching hole

(for chassis)

Phase matching

mark

MODE switch

Phase matching

mark

AHC cam

Main cam

Phase matching hole

(for chassis)

Coupling gear

Fig. 7

19

Fig. 6

Sub cam

Phase matching hole

(for chassis)

Page 20

VL-FD1U

305

311

314

462

306

386

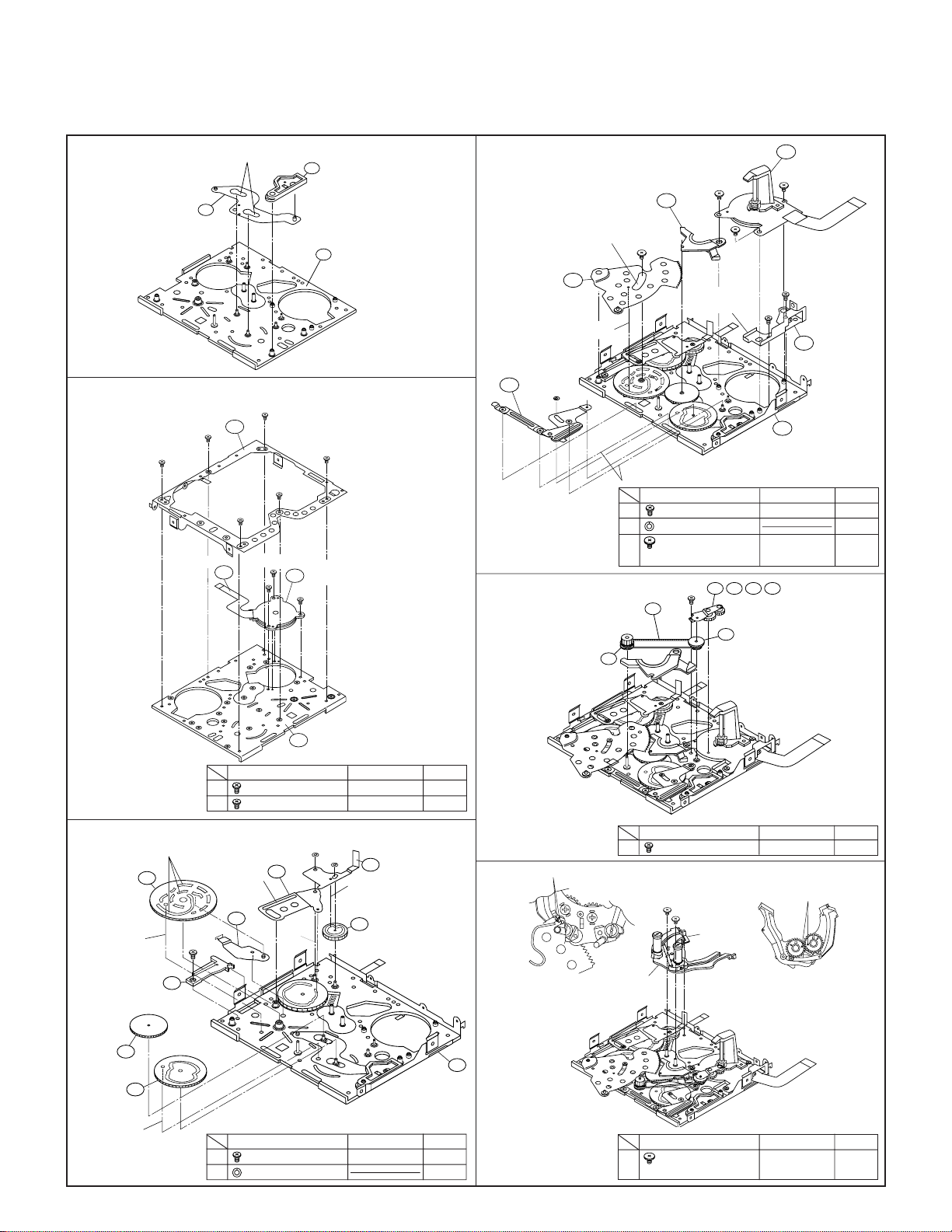

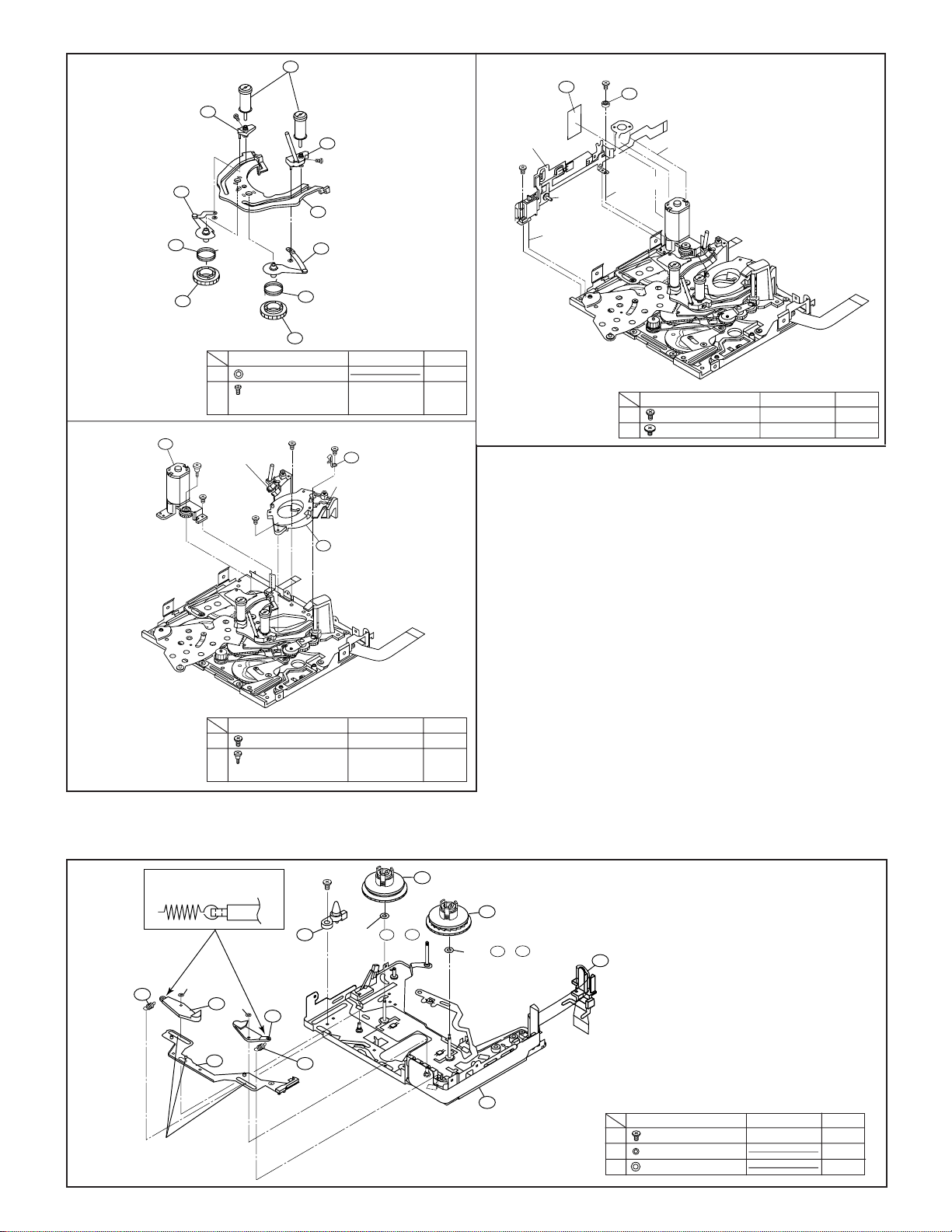

9-5. Reassembly

9-5-1. Reassembly in side of the main chassis.

Note) Numbers before part names are given as a guide to the order of assembly.

As for greasing/oiling/cleaning places refer to the attached drawings (Grease/Oil application Fig. 1, 2).

1.

(1) Pinch control lever

2.

(2) Mechanism fixing angle

assembly (Rear surface)

B-4

Mode FPC

Groove grease

303

B-3

314

B-5

B-1

441

A-1

B-6

A-2

463

(2) Pinch drive lever

361

301

Main chassis assembly

(Front surface)

B-2

(1) Mode switch

A-3

Note) The numbers following

A and B indicate the

screw tightening order.

4.

(1)Slide chassis guide

Groove grease

(3) Loading lever

To cam groove

(2) Shifter drive

lever assembly

C

5.

(2) Center pulley assembly

(3) Timing belt

(5) Capstan motor

D

D

D

Drawing part

grease

D

B

B

(4) Tu guide cam

Mechanism fixing angle

To cam groove

Item

Tightening torque

B S Tight · M1.4 x L2 70mN·m 2

C CWø1.2-ø3.0-t0.25 1

D Special screw · 40mN·m 4

M1.4 x L1.6

312

364

365

B

459

367

421

(4) Intermediate gear angle

sub assembly

366

(1) Intermediate pulley

assembly

Quantity

3.

Cam groove grease

(3) Main cam

Positioning

hole

(2) Lock lever guide

(5) Coupling

gear

(4) Sub cam

Positioning hole

304

370

371

379

Main chassis assembly

301

(Rear surface)

Item

A S Tight · M1.4 x L3 70mN·m 3

B S Tight · M1.4 x L2 70mN·m 6

B

(1) EJECT

lever

(7) T arm

control lever

Groove

grease

302

309

To cam

groove

C

C

Item

B S Tight · M1.4 x L2 70mN·m 1

C CWø1.2-ø3.0-t0.25 2

Tightening torque

(8) AHC control lever

310

To cam groove

(6) AHC cam

369

Tightening torque

Quantity

314

Quantity

Phase match check

6.

Item

Tightening torque

B S Tight · M1.4 x L2 70mN·m 1

E

E

Enter part of

convexity

rear surface

(1) Guide rail sub

assembly

Item

Guide rail sub assembly

(Rear surface)

Tightening torque

E Special screw · 40mN·m 2

M1.4 x L1.5

Quantity

Phase match check

Quantity

20

Page 21

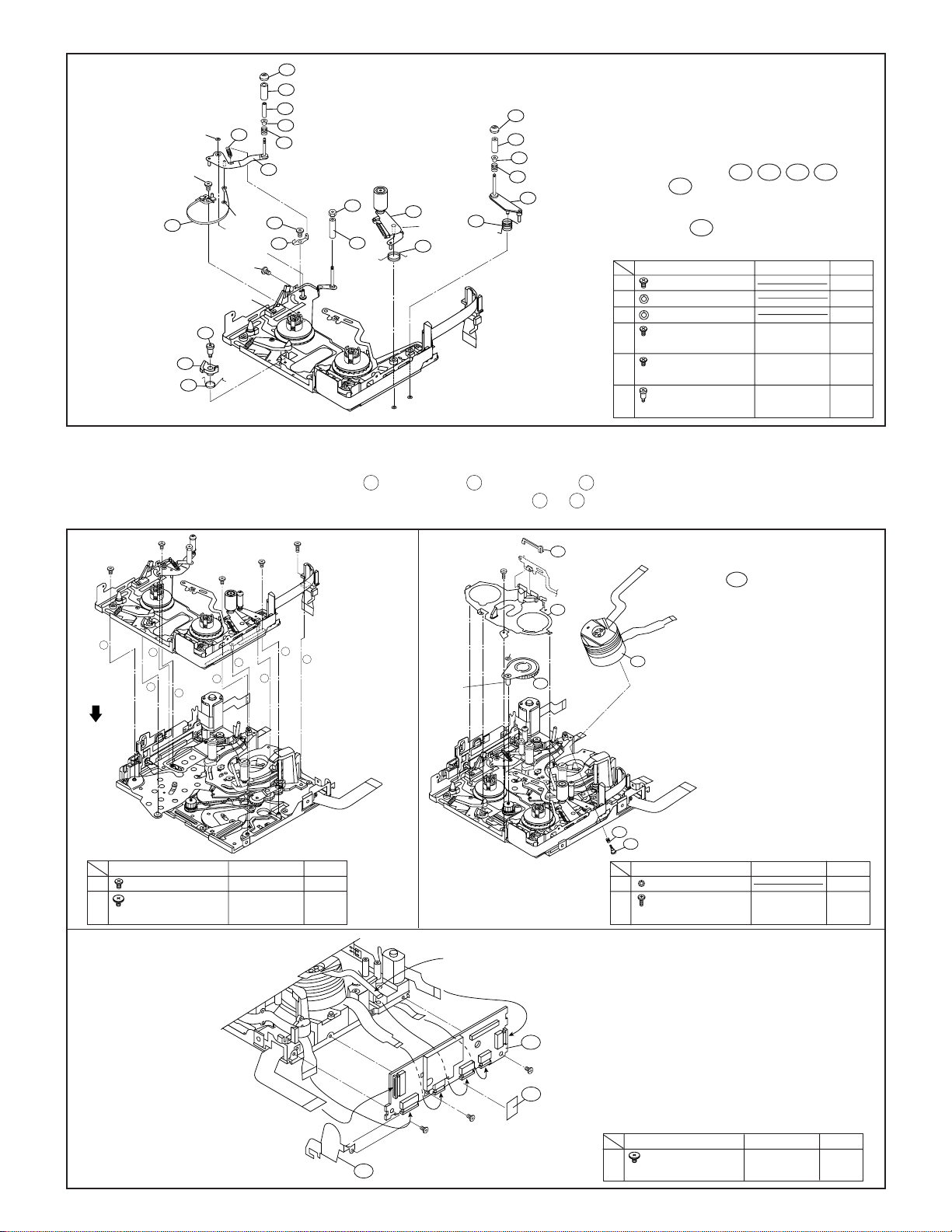

7.

S pole base assembly

S loading arm assembly

S pressure spring

8.

(3) Loading motor

assembly

395

S loading gear

461

Guide roller assembly

454

G

451

452

Tu pole base assembly

G

307

362

F

F

372

Item

Guide rail

308

Tu loading arm assembly

396

Tu pressure spring

Tu loading gear

373

Tightening torque

F CWø0.7-ø2.2-t0.25 2

G Special screw · 5mN·m 2

(Tentative tightening)

A

399

Grease

(Front surface, rear surface,

groove side surface)

Grease

(Rear surface,

groove side

H

surface)

A

M1.2 x L1.8

A

A

Quantity

(2) PB guide spring

9.

(3) Dew FPC cover

(2) Down switch

attachment

angle sub

assembly

A

Positioning

325

Grease

P

SL chassis holder S

378

Solder-joint

Positioning

Item

Tightening torque

A S Tight · M1.4 x L3 70mN·m 1

P S Tight · M1.4 x L4 70mN·m 1

VL-FD1U

Quantity

453

(1) Drum base sub assembly

Item

Tightening torque

Quantity

A S Tight · M1.4 x L3 70mN·m 4

Special screw with step

H

· 70mN·m 1

M1.4 x L6.25

9-5-2. Reassembly in side of the Slide chassis.

Note) Numbers before part names are given as a guide to the order of assembly.

As for greasing/oiling/cleaning places refer to the attached drawings (Grease/Oil application Fig. 3, 4).

Fit the main brake SPR from

above, and close with the hook.

(4) Main brake

SPR.

391

(3) I

Grease

(3) S main

brake

374

(5) I

(2) Brake shifter

Ass'y

353

(7) S cassette

stay

(5) Tu main

brake

375

(7) B

376

391

(6) Main brake

SPR.

(8) J ( 411 ~ 415 )

(8) S reel base Ass'y

456

(9) J ( 411 ~ 415 )

(9) Tu reel base Ass'y

457

(1) Slide chassis assembly

330

with sensor FPC

Sensor FPC guide

337

B S Tight · M1.4 x L2 40mN·m 1

I CWø0.7-ø1.8-t0.1 2

J Wø1.2-ø2.5-t0.3 2

Item

Tightening torque

Quantity

21

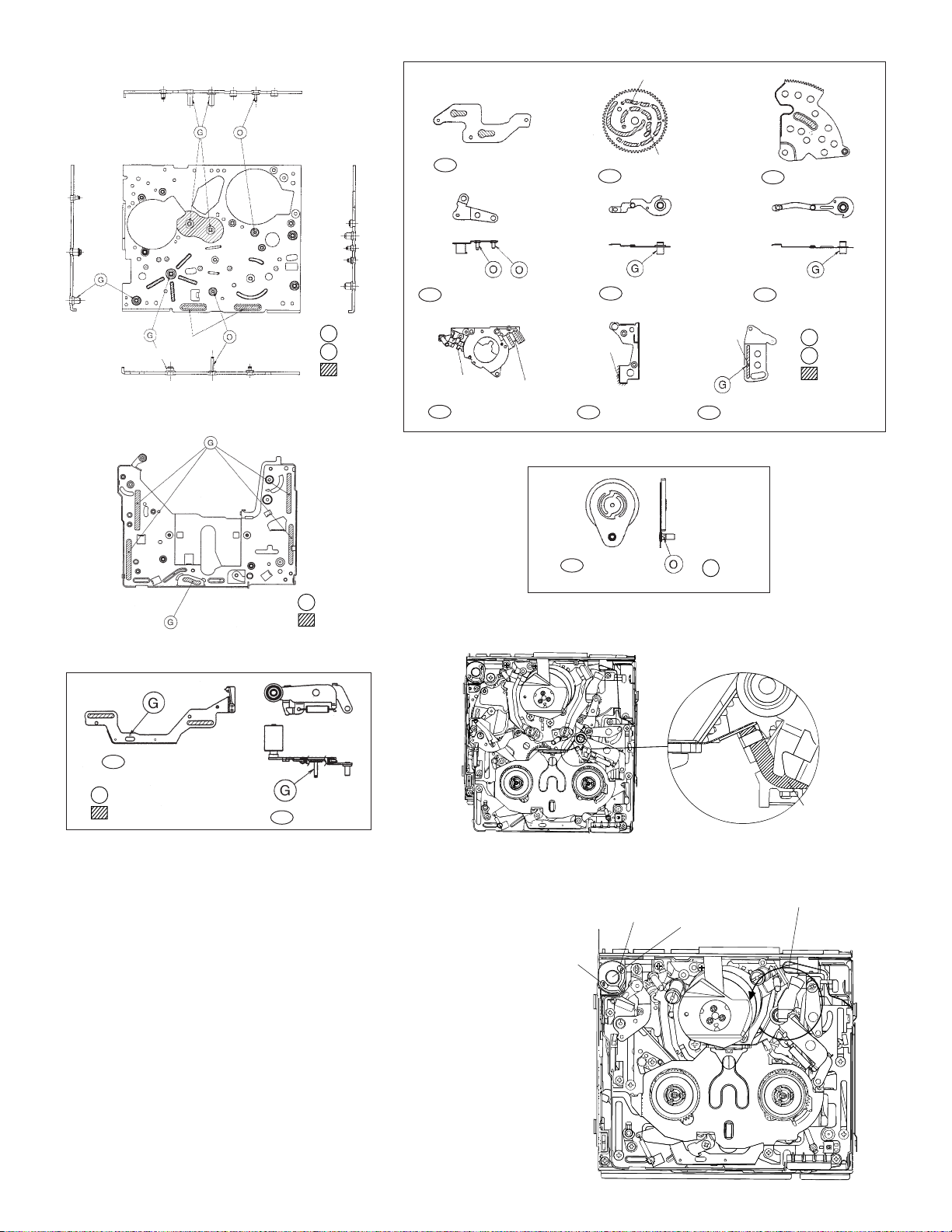

Page 22

VL-FD1U

382

(6) T roller upper flange

455

(6) T roller Ass'y

384

(6) F

(7) K

354

(7) Tension band

Ass'y

T arm SPR.

392

(7) C

(5) T spring

hanging

ANG

(5) B

(6) T roller inner

383

(6) T roller bottom flange

397

(6) Guide adjustment SPR.

351

(6) Tension arm Ass'y

(9) S guide hexagon

nut

(5) L

431

356

428

385

(9) S guide

sleeve

(4) Pinch lever Ass'y

458

Grease

(1) Tu guide

arm SPR.

394

(3) Pinch lever

return SPR.

393

(2) T roller upper

382

flange

(2) Tu pole

381

(2) T roller bottom

383

flange

(2) Guide adjustment

397

SPR.

(2) Tu guide

352

arm Ass'y

B S Tight · M1.4 x L2 1

(10) Swing arm release

lever fixing screw M

(10) Swing arm

release lever

(10) Swing arm

release SPR.

420

357

390

(8) K

F

F

F

F

C CWø1.2-ø3-t0.25 1

F CWø0.7-ø2.2-t0.25 3

L Type 2 minuteness

K

M

9-5-3. Main chassis assembly and slide chassis assembly assembling method

(1)Set the L/S mode (see the figure below).

(2)Insert the slide chassis side operation pins (

main chassis side, move the slide chassis in the arrow direction, using

into the groove of slide chassis, and install with the 4 screws.

D

D

D

B

D

tension arm, 2 Tu guide arm, 3 pinch lever) in the position shown below at the

1

to E as guides, insert the loading lever operation pin

A

(3) FPC cover

(2) N

377

(2) Reel cover

Ass'y

355

Note1) Be careful not to scratch or dent in

the parts ( 381, 382, 383, 384, and

455 ), be careful not to deform the

tension band in handling it.

Note2) Be careful not to deform to tightening

the 428 coat the Screw lock to the

point of shaft.

Item

M1.4 x L1

Special head screw ·

M1.4 x L2

Special screw with step

M1.4 x L1

Tightening torque

·

40mN·m 1

40mN·m 2

· 40mN·m 1

* 438 Tightening torque

70 ± 7mN·m

Quantity

B

1

4

D

A

C

3

E

2

Assembly Mode

Item

B S Tight · M1.4 x L2 40mN·m 1

D Special screw · 40mN·m 4

M1.4 x L1.6

Tightening torque

Quantity

(2) Cap FPC cover

326

(1) I

Oil

Through the groove in the cassette control.

(1) D

(1) D

313

500

(1) D

325

(3) Dew FPC Stopper

(1) Swing arm Ass'y

398

438

I CWø0.7-ø1.8-t0.1 1

N

(1) Head amplifier PWB unit

D Special screw · 40mN·m 3

(4) Drum Ass'y

470

(4) Drum fixing SPR

(4) Drum installation screw

Item

Type 1 minuteness ·

M1.4 x L1

Item

M1.4 x L1.6

• Numbers before part names

are given as a guide to the

order of assembly.

• When treating the sensor

FPC wire, pay attention to

the part A shown in Fig. 6.

• Oil application place is

shown in Fig. 5.

Tightening torque

40mN·m 1

Tightening torque

Quantity

Quantity

22

Page 23

VL-FD1U

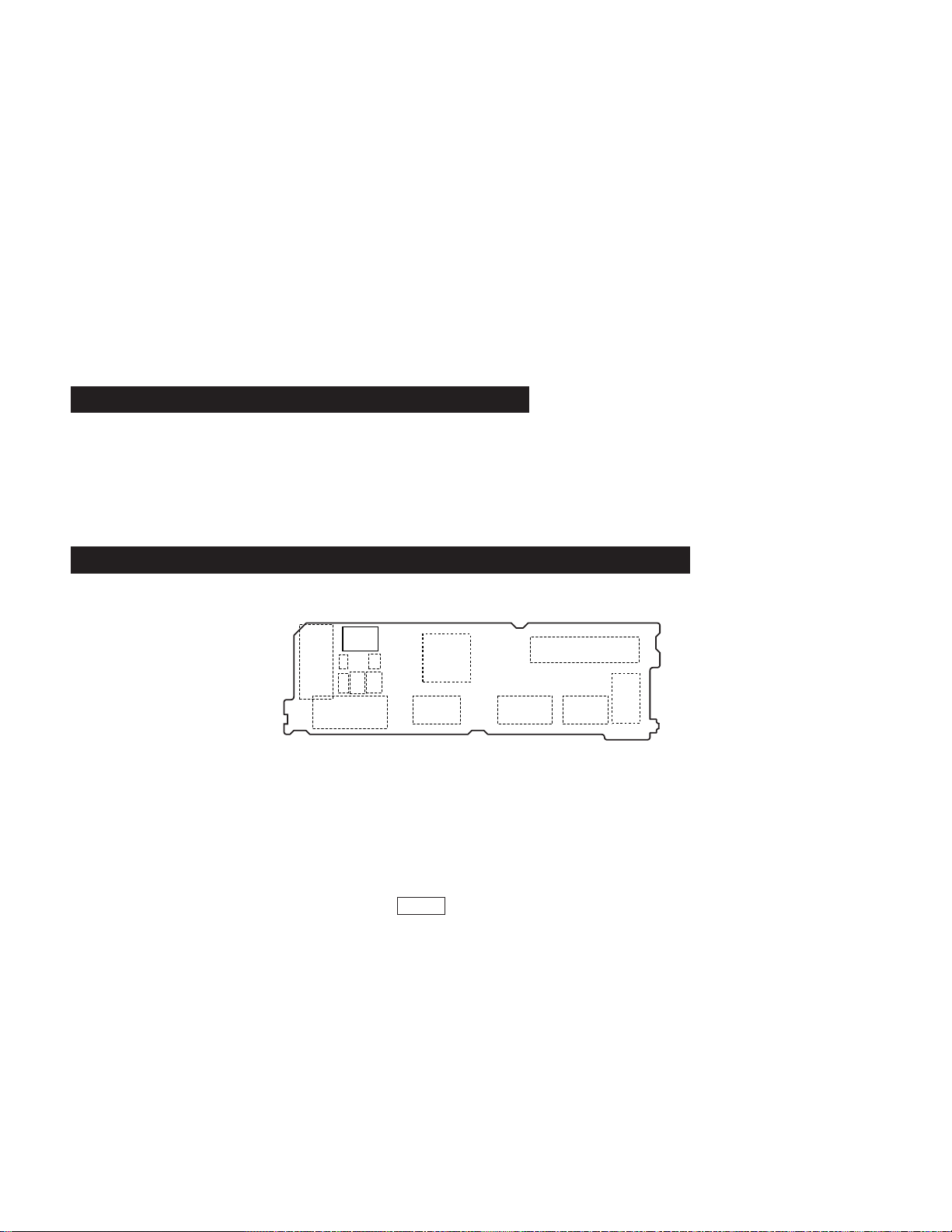

GREASE/OIL APPLICATION

: Oiling

Including groove

side surface

Fig. 1. Side of the main chassis

O

: Greasing

G

: Greasing

303 Pinch control lever

312 Intermediate gear angle

(Front surface · rear

(Rear surface · groove

side surface)

453 Drum base assembly 311 Tu guide cam

surface · groove

side surface)

304 Main cam

307 S loading arm

Enabled after

assembling

Fig. 2. Side of the main chassis

From rear

surface side

From rear

surface side

Enabled after

assembling

306 Loading lever

308 Tu loading arm

309 T arm control lever

: Oiling

O

: Greasing

G

: Greasing

: Greasing

G

: Greasing

Fig. 5. After joining the main chassis and slide chassis

Fig. 3. Side of the slide chassis

353 Brake shifter

: Greasing

G

: Greasing

458 Pinch lever

Fig. 4. Side of the slide chassis

9-6. Removing the cassette

(1)Apply DC3V to the loading motor unload slightly.

(2)After the tape is slackened, turn the rotor (lower side of mechanism)

of capstan motor to tighten the tape. (Arrow direction, Fig. 1)

(3) Repeat the operations (1) and (2). After the pole base has been

completely unloaded, ascertain that the tape is not loose.

(4)Finally apply again DC3V to the loading motor, so that the cassette

controller ejects.

(5)Take out the cassette.

Note) DC3V is applied to the loading motor as shown Fig. 1. Then,

the mechanism moves in the unloading direction.

313 Swing arm

Fig. 6. Sensor FPC wiring

Minus pole

Plus pole

Loading motor

:

Oiling

O

Sensor FPC

Part A

Capstan motor rotor rotation direction

(from rear side of mechanism)

23

Fig. 1

Page 24

VL-FD1U

10. ADJUSTING THE ELECTRICAL CIRCUITS

Before starting the electric circuit adjustment

• The adjustment methods described herein are used, in most cases, when the expendable mechanical parts, including

the video head, have been replaced, at which time the electrical circuits need to be readjusted. Before adjusting the

electrical circuits, make sure that the mechanism works properly (i.e., the mechanism is properly adjusted). Incase of

the occurrence of any problem to the electrical circuits, be sure to use the specified measuring instruments to locate

the area to which the problem is occurring, and then take the necessary action, including repair, replacement or

adjustment, exactly as instructed in the electrical adjustment methods that will follow.

Do not attempt to make adjustments without using the proper measuring instruments.

• This machine is configured so that the electrical circuits inside its PWB unit are composed, for the most part, of highdensity, small surface-mounted component parts for downsized machine body.

To perform repair service or parts replacement, do so using a soldering iron, but in as short a time as possible; this is

because surface-mounted component parts are generally so small in size and susceptible to heat, as compared with

the large discrete parts used in TV sets, desk-top video decks, etc., that attempting to heat their electrodes for a longer

time than is necessary with a soldering iron may result in their becoming defective.

This applies particularly when replacing the laminated chip capacitors.

For this purpose, ceramic soldering irons with a temperature regulator are recommended (iron tip temperature 250°C

and soldering time 5 seconds or shorter).

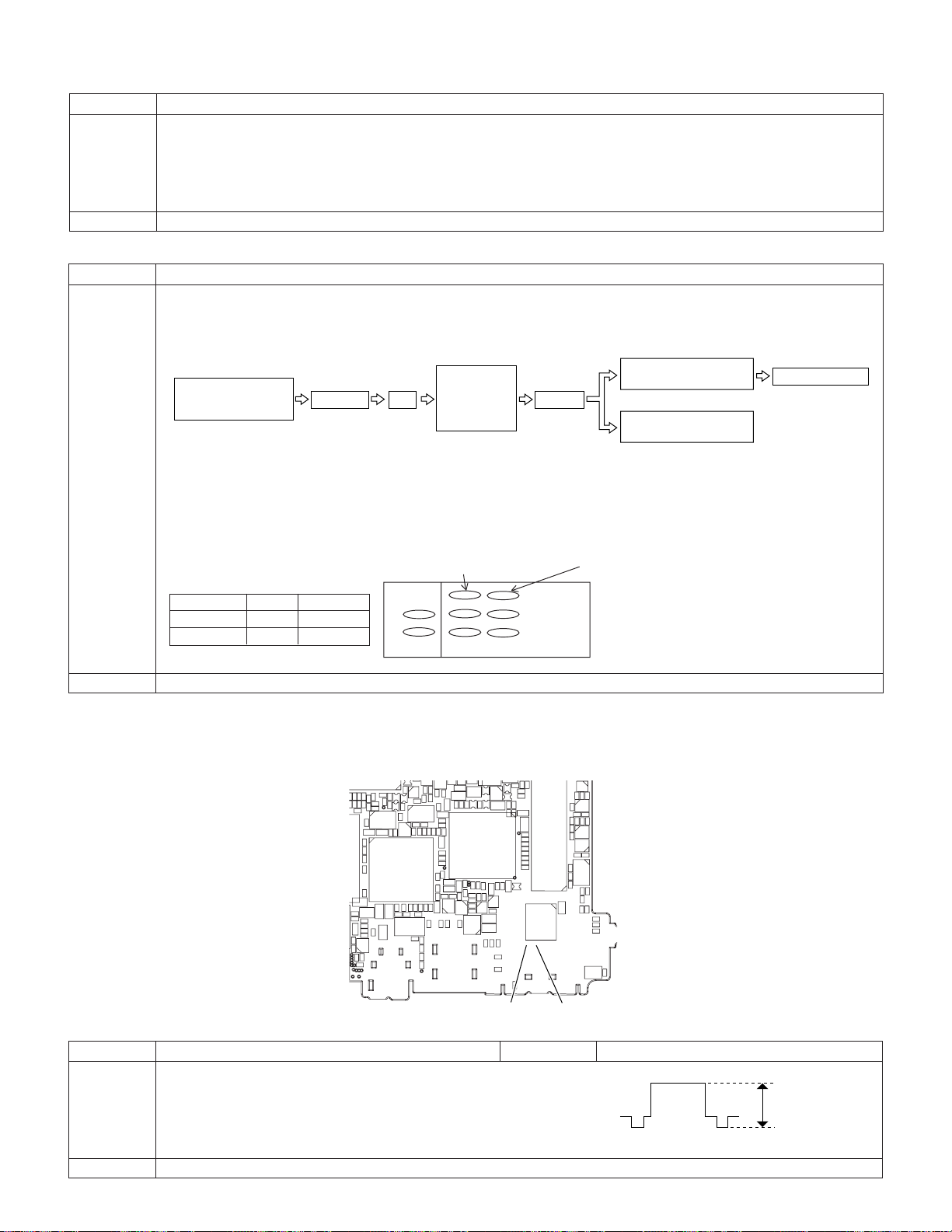

Chip ID as per Digital Interface IEEE1394 Standard

The VL-FD1U and other models that follow are newly equipped with the digital interface function. The Digital Interface

IEEE1394 Standard stipulates that each set with the digital interface function be given its specific ID number. The ID

number is written on the E2PROM of the set while it is manufactured. If the E2PROM alone or the PWB having this E2PROM

on it has been replaced for repair purpose, it is necessary to write a new ID number again. (Note that any replacement

part does not have an ID number yet.)

Accordingly, the repair engineer must obtain the new ID number.

VL-SD20U

Writing a Chip ID number as per Digital Interface IEEE1394 Standard

Head amplifier PWB

IC302

IC301

If the IC302 (E2PROM) or the head amplifier PWB has been replaced, it is necessary to write a new ID number. (Note that

any replacement part does not have an ID number yet.)

Obtain a new ID number from the service department of sales company. Take the following steps to write the ID number

on the E2PROM.

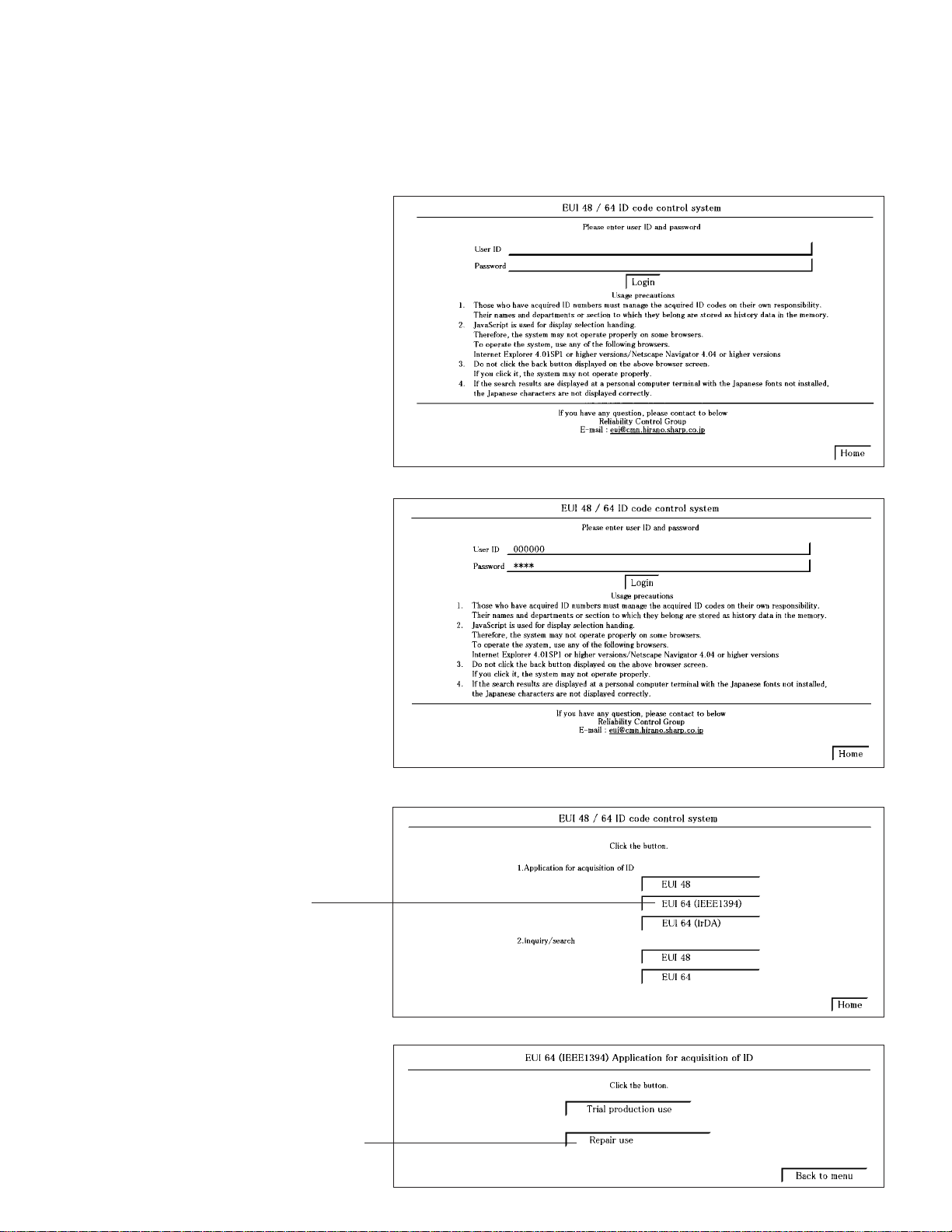

■ Manual for obtaining and handlig IEEE1394 ID number

1. Access the intranet URL for the number below.

URL: http://www.rog.kami.sharp.co.jp/quics/e_index.html

2. Now enter User ID and Password, then click Login .

*ID and Password should be same as for "PARTS PEICE LIST".

24

Page 25

VL-SD20U

■ ID code is acquired

1. Connect with the EUI48/64 ID code control system.

(1) Start the Internet Explorer or Netscape Navigator.

(2) Access the following address.

(URL:http://www.rcg.kami.sharp.co.jp/quics/e_index.html)

Select the "EUI48/64 ID code control system" from the "Service" item.

Note: If you want to establish a connection by directly inputting the URL, please input the following.

URL:http://www1.rcg.kami.sharp.co.jp:7000/adrs_agt/adrs_dba/ide00010.main

The login screen will appear.

VL-FD1U

(3) For the [User ID], input the [Password].

Click on [Login].

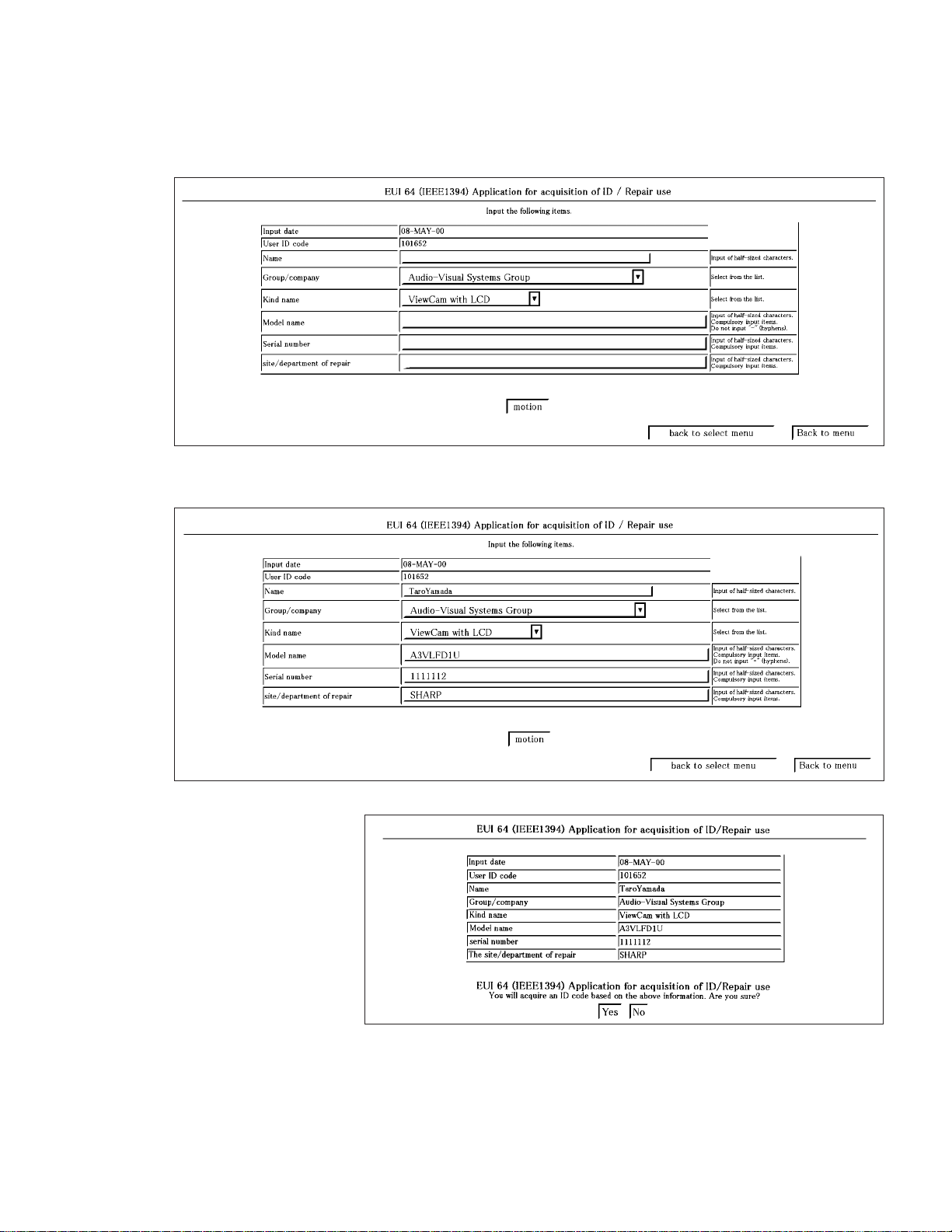

(4) Click on [EUI 64 (IEEE 1394)] from the [1. Application for acquisition of ID].

Click

(5) Click on [Repair use].

Click

25

Page 26

VL-FD1U

(6) Input the necessary information for the application.

VL-SD20U

For the indispensable input items, be sure to input them.

Select the [Group/company] and [Kind name] from the list.

Input the [Model name].

Input the [Serial number].

Input the [Site/department of repair].

For the input items when making each application, refer to the "Input item list for the ID acquisition application".

(7) Click on [motion].

The confirmation screen will appear.

(8) Click on [Yes].

5. Print the application result.

(1) Print out the application result screen.

Control the application result as evidence.

To print it, select "Print (P)" from the "File (F)" in the menu bar or click on the print button in the tool bar.

(2) Click on [Menu] to complete the application.

If you create applications in succession, repeat steps (1)~(8).

To complete it, click on [End] in the menu screen.

26

Page 27

VL-SD20U

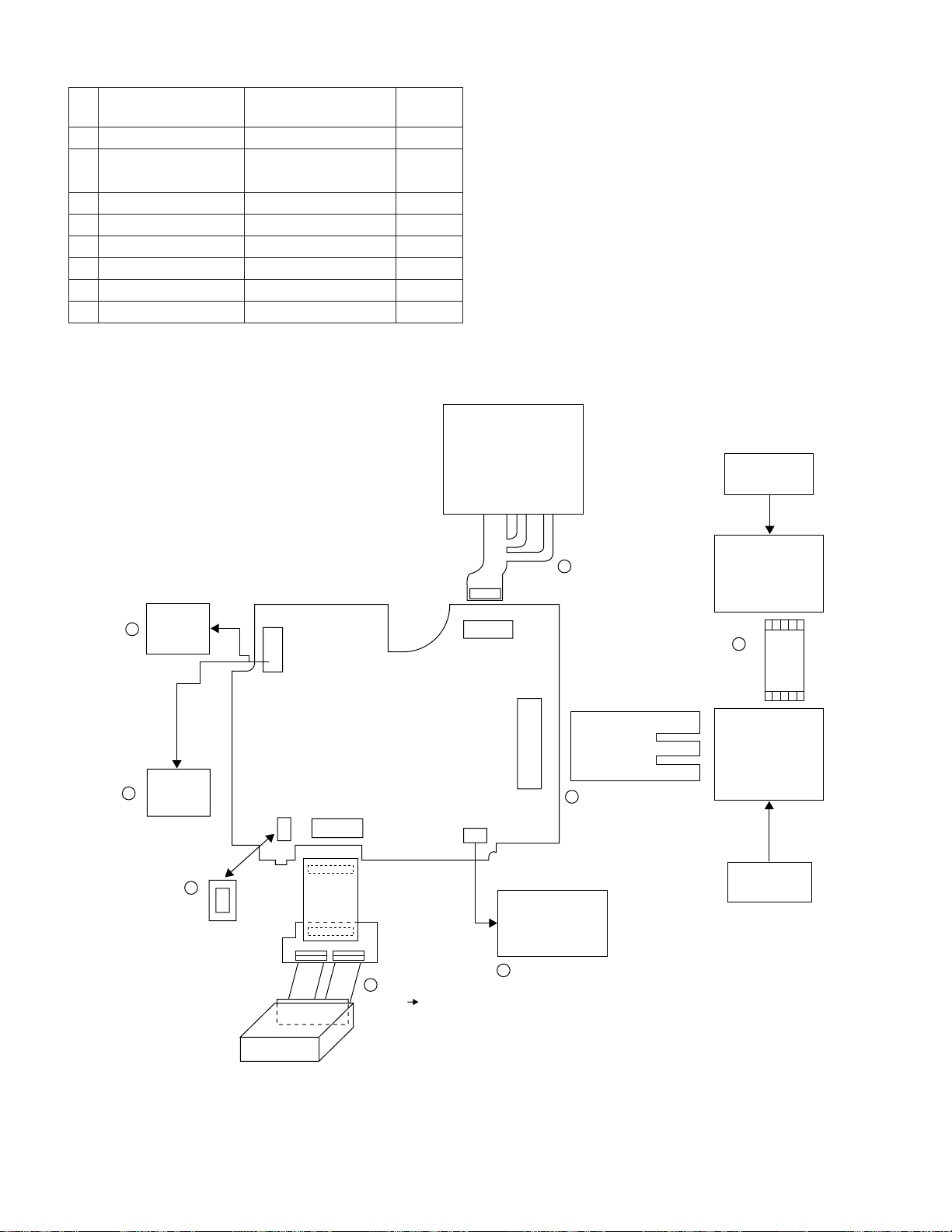

VL-FD1U Specifications of service jigs

VL-FD1U

No. Connection section Part cord

1 Main–LCD Panel CPWBH2923TA01 AS

2 Camera Head– QPWBH2924TAZZ AL

Audio I/O PWB

3 Main–Audio I/O PWB CPWBH2922TA01 AX

4 Main–Battery Terminal QTANZ0143TAZZ AU

5 Main–Envelope Check RUNTK0348TAZZ BE

6 Main–Eject SW Unit QSW-Z0333TAZZ AK

7 Main–Jog SW Unit QSW-Z0332TAZZ AM

8 Main–Mechanism QCNW-1832TAZZ BV

VL-FD1U Service jig configuration

Price

code

LCD Panel

Zoom SW

QSW-Z0332TAZZ

Jog SW

7

Unit

Eject SW

6

Unit

QSW-Z0333TAZZ

for the Envelope

check jig.

RUNTK0348TAZZ

1

CPWBH2923TA01

LCD Tilt FPC

SC800

SC900

SC1001

QPWBH2924TAZZ

Lens Tilt FPC

CPWBH2922TA01

3

Camera Tilt Unit

SC2401

SC6704

MAIN

SC3301

5

Battery Terminal

Unit

QTANZ0143TAZZ

4

CAMERA HEAD

PWB

2

AUDIO I/O

PWB

Lens

Turn detection

8

Mecha VCR

Mechanism

27

Page 28

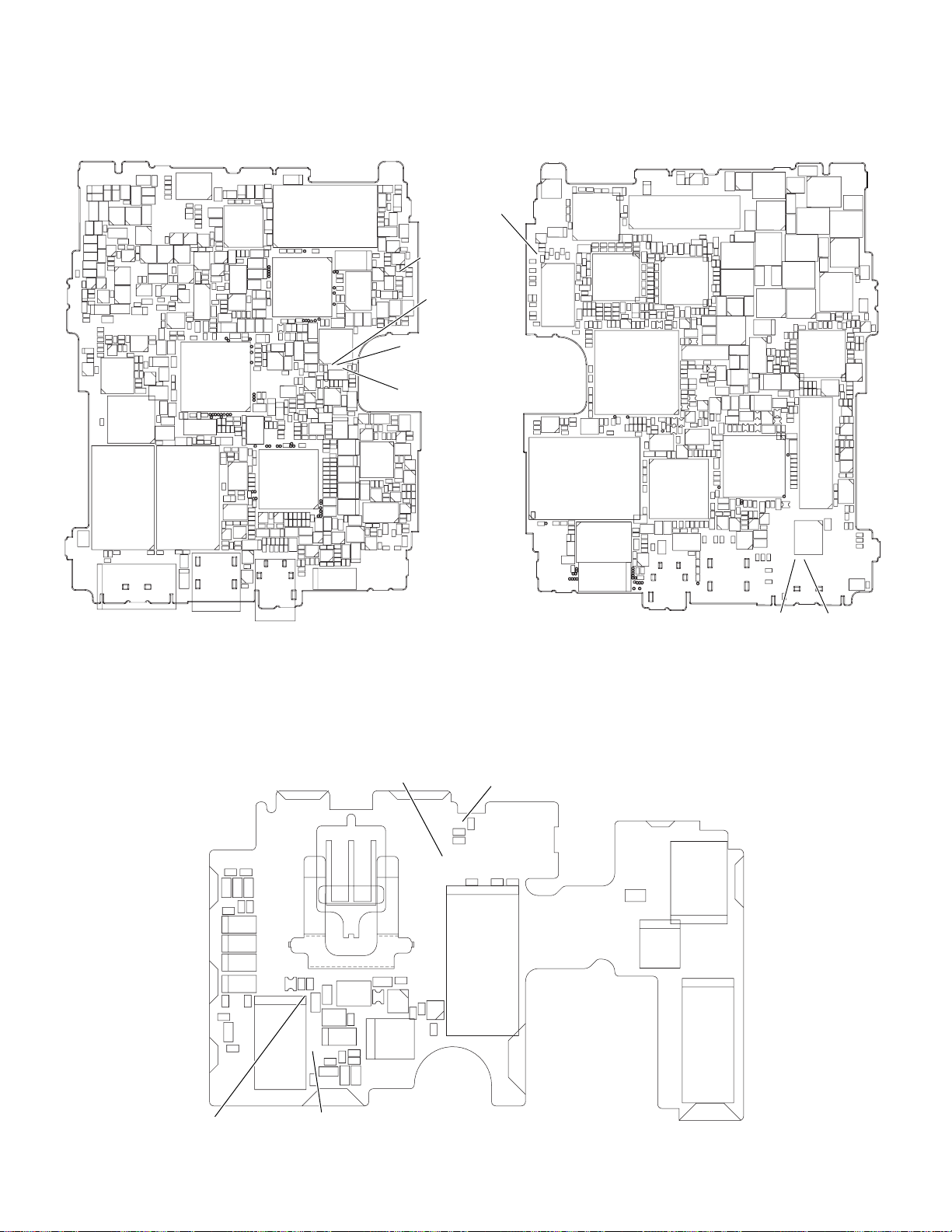

VL-FD1U

[TEST POINT]

VL-SD20U

(Wiring board diagram: Main Side B)(Wiring board diagram: Main Side A)

TL1907

TL1916

R1960

L1905

R1963

FB1902

R1964

D961

D963

D962

L1901

D960

R1932

TL1906

C971

C9924

Q930

Q990

C970

C969

R999

C991

L960

TL1902

TL1903

C1901

R1911

R1914

L961

Q1904

TL908

TL909

TL910

Q1903

L962

R1909

R1910

C974 C973

R1913

L963

R1912

C975

C972

R9913

Q9901

Q951

Q950

R906

R904

R905

Q910

R1900

D950

Q1900

R903

R1937

C960

C3454

C901

C900

R902

D3401

R3405

R3484

D1901

Z2

R3456

TL3406

C3460

R3454

C3470

R3455

C769

C3458

C3467

R3479

IC707

C3455

R3450

R3478

R3470

Q3404

TL3408

C3457

R3453

Q3408

R3485

R3451

IC3404

R3468

R3499

IC4701

C4701

IC408

L2402

C2402

R2403

FB2402

J2401

IC1903

C1912

R1966

C1919

C968

C1902

TL823TL912

C990

Q940

Q1921

C1928

Q980

Q9902

R1916R1917

C9925

C1914

C983

R1919

R1939

R1938

R1941

R1918

IC1904

IC1901

C1909

R1923

C1913

TL1909

C1910

R1924

C1907

TL1908

TL1905

C1915

Q1913

R1927R1928

R471

TL1915

R463

R3462

R462

R413

FB1901

R3463

TL416

L1904

C1911

C3456

R405

R3471

R3457C3459

L3405

R3469

C3475R3452C3453

IC3403

C3452

C433C444

L912

R403

C962

C401

C1920

C4702

L1907

C468

TL1912

C462C463C465

C1608

C1607

L1601

R1602

C1605C1606

TL1904

R1979

R1961

R1962

L1902

R1958

R1965

R1959

C1908

R1955

TL1911

TL1910

C1903

Q1920

R1957

R1954

IC204

R1956

C1610

C229

R214

C230

Q970

IC4452

R1604

C1611

C1609

IC203

IC4451

C4455

R213

R751

Q1907

R4450

D702

C754

X4452

C4456

R4459 R4458

C4458

C452

Q1908

R443

IC405

R446

IC702

R444

R445

R758

C751

R453

R442

C451

R759

R771

R757

C453

C763

TL417

R464

TL4439

C407

C750

C758

C757

C417

R404

TL410

R419

C424

C422

TL403

TL411

IC452

TL404TL406

TL419

TL421

TL418

TL449TL448

TL447

R435

R472

TL405

TL450

C420

R469

R438

C429

C436

D404

R451R452

FB456

C456

FL403

C447

R437

C445

IC407

R423

R429

R421

C427

R428

R470R402

C470C428

R426

D403

R436

C435

C4454

C4453

R4454

R4453

R4455

D4452

X4451

C467

R4451

C4451

TL4451

C4452

D4451

IC4461

R4469

R4465

R4464

C460

Q4461

Q4462

C4463

R4457

C4462

R4461

R4462

J7401

R4432

C1604

C1602

IC1602

C1617

C1612

C1615

C1616

C1613

L202

C227

C448

L203

C228

R440

R441

C450

TL4411

R409

TL4414

R410

TL4412

C412

C413

TL412

R430

R401

TL420

TL422

TL423

C411

C403

X401

C419 R418 R417 C418

TL4421

L4451

R4452 R4456

C4437

C4424

C4422

C4423

TL4417

TL4416

C4420

TL4413

TL4410

R4460

C4411 C4433C4443

C4466

C4467

C4465

C4464

R4437

R4467

R4468

R4463

C4461

Q4431

R4431

Q4432

C155

C210

C1603

C1601

R1662

C1614

R1603

TL4433

TL210

TL209

TL208

TL4434

TL906

TL207

C449

C404

R407

R411R412

R480

R483

C7825

C7828

TL4428

TL4426

Q4434

R4435

L4461

R4421R4422

C208

FB202 FB201

C222

C211 C223

TL206

L402

C405

R416

IC401

D472

C7808

C7810

C7830

C7829

C7811

C7836

TL4418

TL4425

R4404

R4436

C4448

R4405

C4405

R4420

J701

C209 C215 C217

R202

R206

R204

R205

R210

R212

L401

C402

R414

L471

C474

R476

C472

D471

R477 R478

C473

R7841

R7842

R7843

C7837

TL4422

C4444

TL4424

TL4423

IC4401

R4406

Q4433

R4415C4406

C4449

L4401

R4407

C4412

C4404

R4423R4408

R4425

R4424

TL205

IC201

C216

TL212TL215TL213

R203

R207

C2800

R406

R768

R473

R474

R420

R427

R425

R422

R7854

R7855

R7851

D7800

C7815

TL4437

C7813

R4416R4411

R4413R4410

R4412R4409

L4402

C4410

R4477

R4470

R4476

R4489

R4478

TL6721

R4473

TL6720

R4471

TL6719

TL6723

TL211

L2801

L2800

C408

Q401

C416

C7842

R7827

Q4471

IC202

C214

TL204

TL214

C2801

C409

IC402

R7846

R7845

Q402

R424

L7801

TL4436

TL4438

TL4409

TL4405

TL4404

TL4403

TL4402

R1982

C4419C4417

C4473

R4474

TL201TL202

C202

C201

TL4441

C207

TL203

R408

R201

TL4435

C226

L201

C204

R211

IC2800

TL2800

TL2801

TL2802

R2803

C7841

R7850

R7849R2804

R7848

R7844

C7840

R7847

R7853

FB7800

C7839

IC7800

R4403

C4403

C7844

C7838

R7852

L1402

TL1410

C7831

C7821

C1402

R7813

C7816

R7814

C7822

C7807

C7806

C1415

R7812

TL4440

R4414

R7805

C7805

C1407

R7810

C7801

R7809

R7804

R7811

R7802

C1406

C7804

R7800

R7803

C4430

R7801

C4421

C7802

R7807

C1411

R7808

R7806

TL4407

C7800

TL4401

C1431

L7800

R4402

C4402

C4401

R4401

Q4482

Q4472

C4481

R4487

R4484

R4488

C4485

R4485

Q4481

C4482

R4483

R4482

R4486

R4475

C4484

P6701

R1809

D1801

R1814

C1809

D1802

R1815

R1816 C1806

C1803

R1817

C1805

R1805

R1810

C1808

L151

R156

Q1801

C1801

R1807

R1812

C213

Q1802

R1808

TL1801

C2804

R1452

C1412

C1432

C1437

R1440

R1441

R1453

R1800

TL1800

R769

Q1800

Q704

C767

D1800

C765

C766

R770

L2802

C2805

C2808

C1800

C1405

R1408

R1415

C1409

R1409

IC1401

R1451

R1421

C1418

C1417

R1462

D1401

R1461

IC1431

R1439

TL1431

Q1434

R1438

R1442 C1436

R1811

R1819

R1804

R1802

TL1801

C1810

R1803

R1801

L1801

R1818

R2802

L2803

L2804 C1804

C2806

C2807

C2809

C2810

R2801

R2800

TL2801

DAC full-scale

TL2802

DAC full-scale

C1403

R1410

L1403

C1408

R1407

R1418

R1411

C1404

Q1404

L1401

C1401

R1417

R1405

Q1402

R1406

C1413

Q1432

C1410

R1416

C1414

C1416

D1402

R1431C1433

R1434R1433

R1435

TL1412

Q1433

R1436

R1403

R1404

TL1411

R1413

R1414

C1438

C1439

R1402

C1441

R1419

COM-amplitude

TL2800

DAC full-scale

C1435R1437C1434R1432

FL703

IC706

C2803

C2802

R215

R7857

R7856

TL4408

R748

R746

R745

C7843

Q1401

R1401

Q1405

L1404

L1431

C1440

Q1431

L4481

C4483

TL6722

C4472

TL807

VCO free-run

P151

C159

C158

C156C157

TL151

C160

C162 C161

IC151

R154

C163

C167

Q151

TL152

R9960

R9954

R157

C168

R5820

TL807