SHARP VLE780U, VLE785U, VLE785T Service Manual

SERVICE MANUAL

SERVICE MANUAL

SY8A8VL-E780U

LIQUID CRYSTAL CAMCORDER 8 NTSC

VL-E780U

VL-E785U

VL-E780U

VL-E780U

VL-E785U

VL-E785U

VL-E785T

VL-E785T

In this Service Manual, only the differences from VL-E760U/765U are described.

Therefore, for the parts which are not described in this Service Manual, refer

to the Service Manual for VL-E760U/765U (S38N2VL-E760U).

NTSC

8

8

2. SPECIFICATIONS .............................................................................................................................. 2

MODELS VL-E780U/E785U/E785TLIQUID CRYSTAL CAMCORDER

4. DISASSEMBLY OF THE SET............................................................................................................. 3

5. MECHANISM ADJUSTMENT ............................................................................................................. 4

6. ADJUSTMENT OF VCR...................................................................................................................... 4

8. SCHEMATIC DIAGRAMS .................................................................................................................. 8

11.REPLACEMENT PARTS LIST ......................................................................................................... 29

12.PACKING OF THE SET ................................................................................................................... 35

MODELS

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its

original condition and only parts identical to those specified

be used.

CONTENTS

VL-E785T

Page

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

1

VL-E780U

VL-E785U

VL-E785T

2. SPECIFICATIONS

Signal System: NTSC standard

Recording System: 2 rotary heads, helical scanning system

Cassette: 8 mm video tape, MP type

Recording/Playback Time: 120 minutes (P6-120)

Tape Speed: 14.345 mm/second

Pickup Device: 1/4" (6.4mm, effective size: 4.5 mm) CCD image sensor (with approx.

270,000 pixels including optical black)

Lens: 16 × power zoom lens (F1.4, f=4.0-64.0 mm) and full-range auto focus

Lens Filter Diameter: 46 mm

Monitor: 4" (10.1 cm) full-color LCD screen (TFT active matrix)

Microphone: Electret monaural microphone

Color Temperature Compensation: Auto white balance

Minimum Illumination: 0.8 lux (5 lux measured by EIA standard) (with gain-up, F1.4)

Video Output Level: 1.0 Vp-p 75-ohm unbalanced

Audio Output Level: –8 dBs, impedance less than 2.2 kohms

Speaker Output: 200 mW

Power Requirement: DC 3.6V

Power Consumption:

Operating Temperature: 0°C to + 40°C (32°F to 104°F)

Operating Humidity: 30% to 80%

Storage Temperature: –20°C to +60°C (–4°F to 140°F)

Dimensions (approx.): 7

Weight (approx.): 1.57 lbs (710g)

5.3W (during camera recording in full auto mode with zoom motor off,

Extend Zoom, DIS and Snapshot functions off, and backlight in normal

mode)

5

/32" (W) × 4 9/32" (H) × 3 7/8" (D)

[182 mm (W) × 109 mm (H) × 99 mm (D)]

(without battery pack, lithium battery, video cassette, and lens cap)

AC Adapter/Battery Charger

Battery Pack BT -H22

UADP-0274T AZZ(VL-E780U/E785U)

UADP-0275T AZZ(VL-E785T)

Dimensions (approx.): 2

Power Requirement: AC 110-240 V, 50/60 Hz

DC Output: 4.5 V

Power Consumption: 16 W

Dimensions (approx.): 2

31

/32" (W) × 2" (H) × 5 5/16" (D)

[75 mm (W) × 51 mm (H) ×

135 mm (D)]

Weight (approx.): 0.65 lbs (295 g)

Specifications are subject to change without notice.

*Minimum illumination: Since there is no widely accepted testing procedure for determining minimum illumina-

SERVICE INFORMATION (For the U.S.)

For the location of the nearest Sharp Authorized Service, or to obtain product literature, accessories,

supplies or customer assistance, please call 1-800-BE SHARP (1-800-237-4277) or visit SHARP's

tion capability, lux ratings are comparable only between models from the same

manufacturer.

web site (http://www.sharp-usa.com)

DC Output: 3.6V

1

/8" (W) × 3/4" (H) × 2 7/32" (D)

[54 mm (W) × 19 mm (H) ×

56 mm (D)]

Weight (approx.): 0.30 lbs (136 g)

2

VL-E780U

VL-E785U

VL-E785T

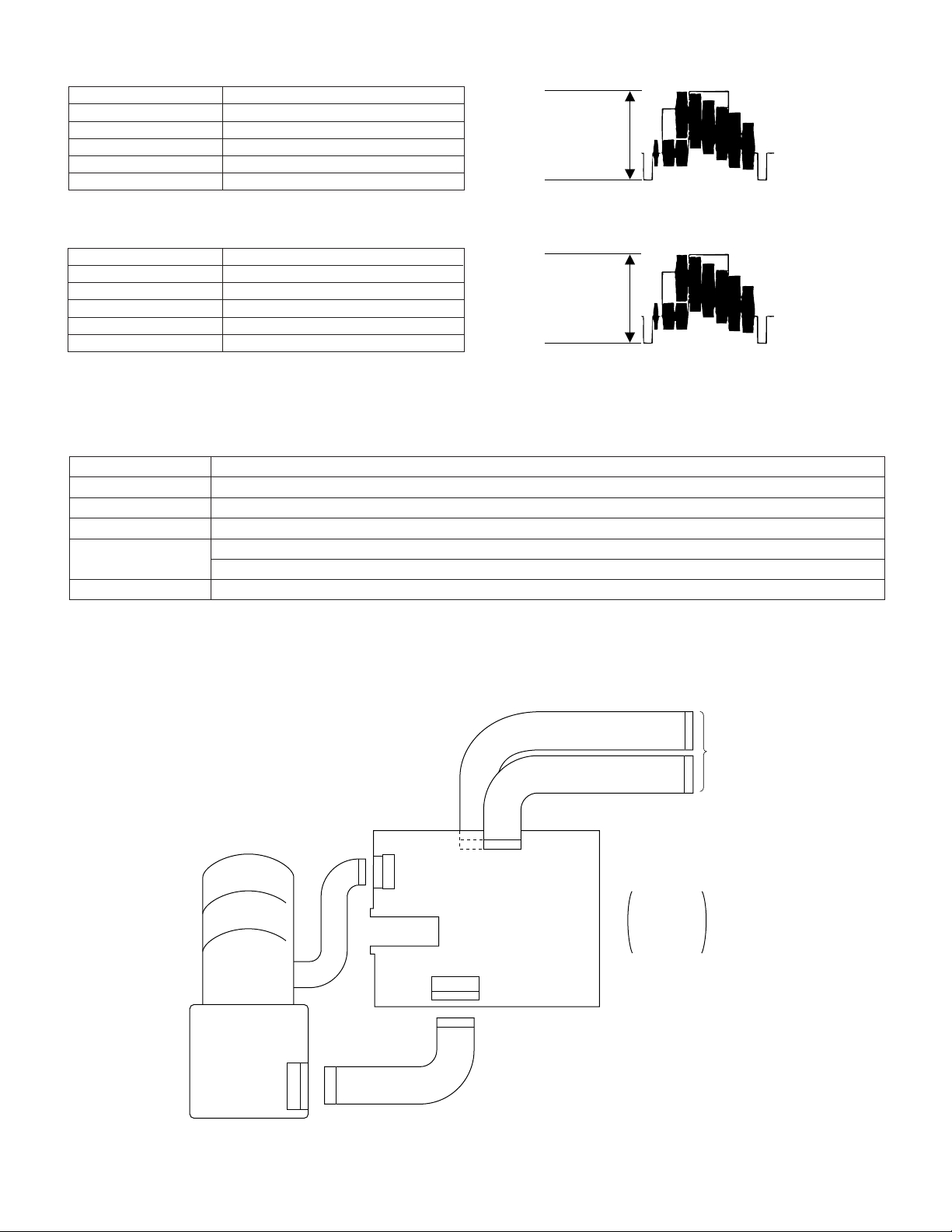

4. DISASSEMBLY OF THE SET

Area A

4-2. Disassembly of the VCR main body

1. Removal of the VCR lid shaft

(1)Remove one screw ((j)LX-HZ0063TAFC).

(j)

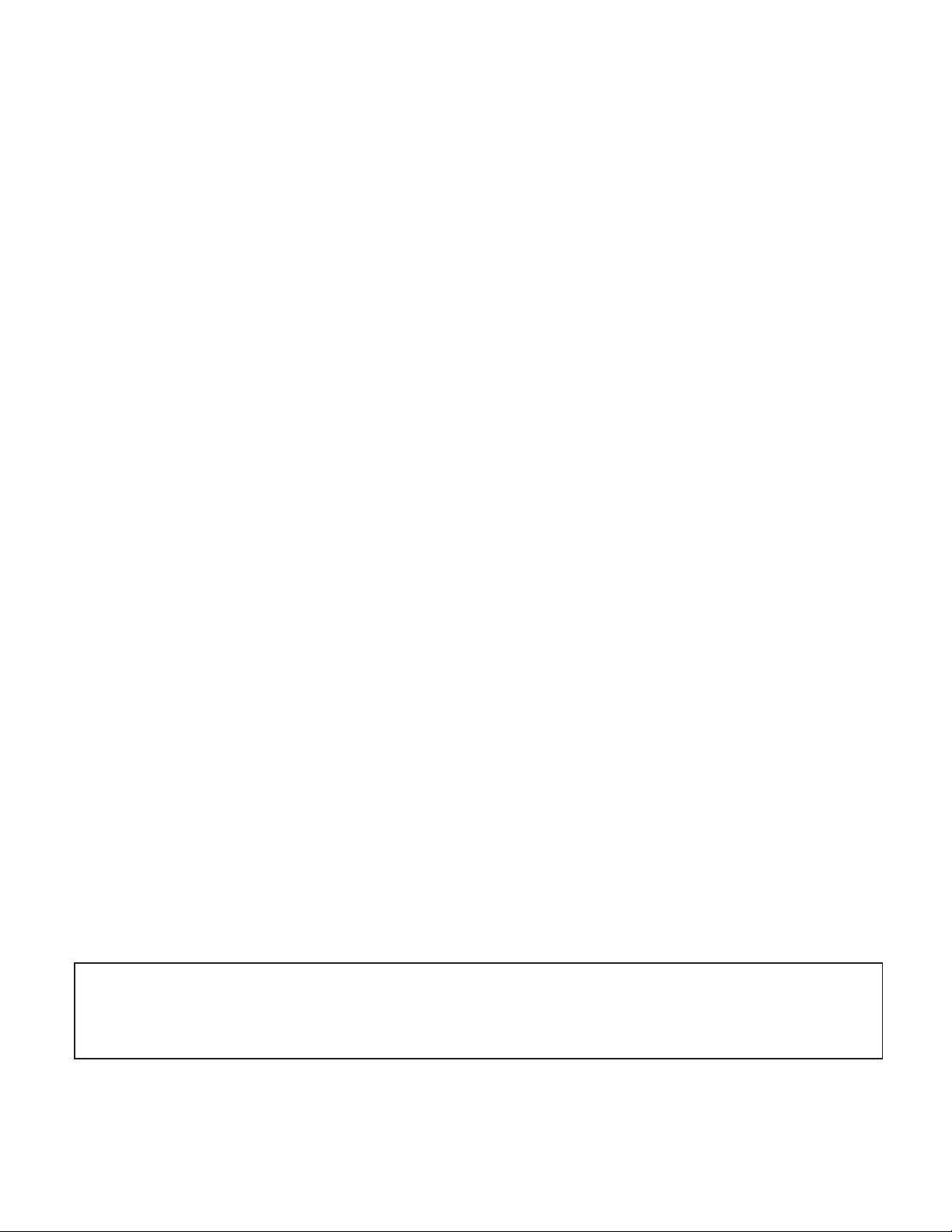

4-3. REPLACEMENT OF CCD SENSOR

4-3-1. BEFORE REPLACEMENT

1) The CCD image sensor is more sensitive to electrostatic breakage than C-MOS LSI. Therefore sufficient means to

prevent electrostatic damage must be taken when it is replaced.

• Ground the soldering iron.

• Ground also the human body, using the wrist strap(through an 1 Mohm resistor).

• Until the CCDsensor is mounted on the PWB, fit it to the conductive sponge, and short-circuit the foot lead.

2) Take utmost care so that the surface glass of CCD sensor and optical filter are not contaminated and damaged. If any

contamination is found, for example fingerprint, wipe it off with silicon paper or clean chamois skin.

3) When replacing the CCD sensor, use the antistaic grounded soldring iron, and perform quickly soldering.

Index Mark

17

JAPAN

SHARP

LZ2413H5

YYWWXXX

14 8

4-4. INITIAL SETTING OF E2PROM IC

4-4-2. IC702 (E2PROM)

When the IC702 has been replaced, make the following settings and adjustments.

1. Remove the backup battery (CR2025)

2. Turn power switch to CAMERA

3. Setting up the V ADJ mode as follows.

* After press the CONTINUE key, press the VCR ADJ key on service remote control (RRMCG0033TASA).

address data data data

03 F8 FA FE

0B 07 05 01

01 00 00 00

09 FF FF FF

04 00 00 00

0C FF FF FF

02 01 01 07

0A FE FE F8

E780U E785U E785T

3

VL-E780U

500±20mVp-p

VL-E785U

VL-E785T

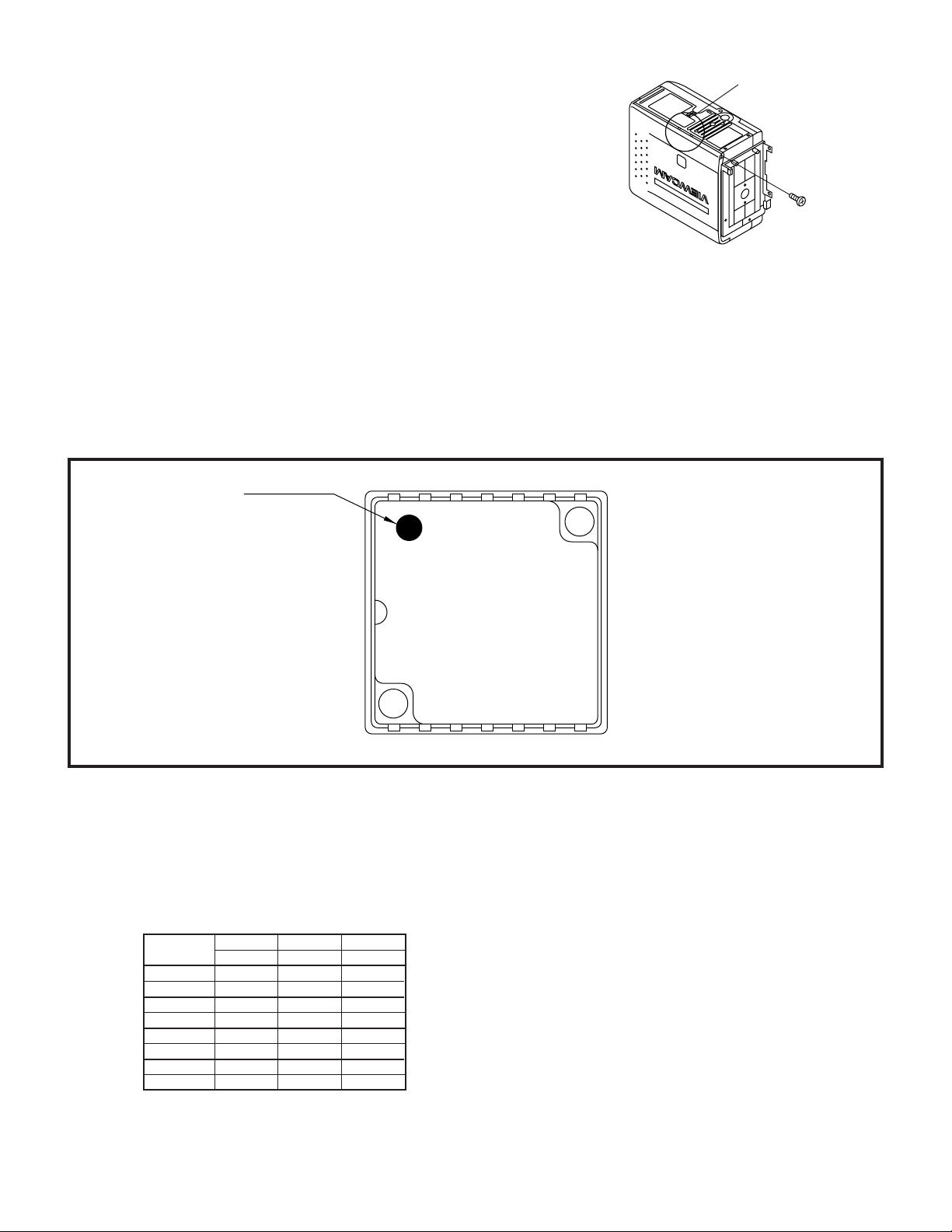

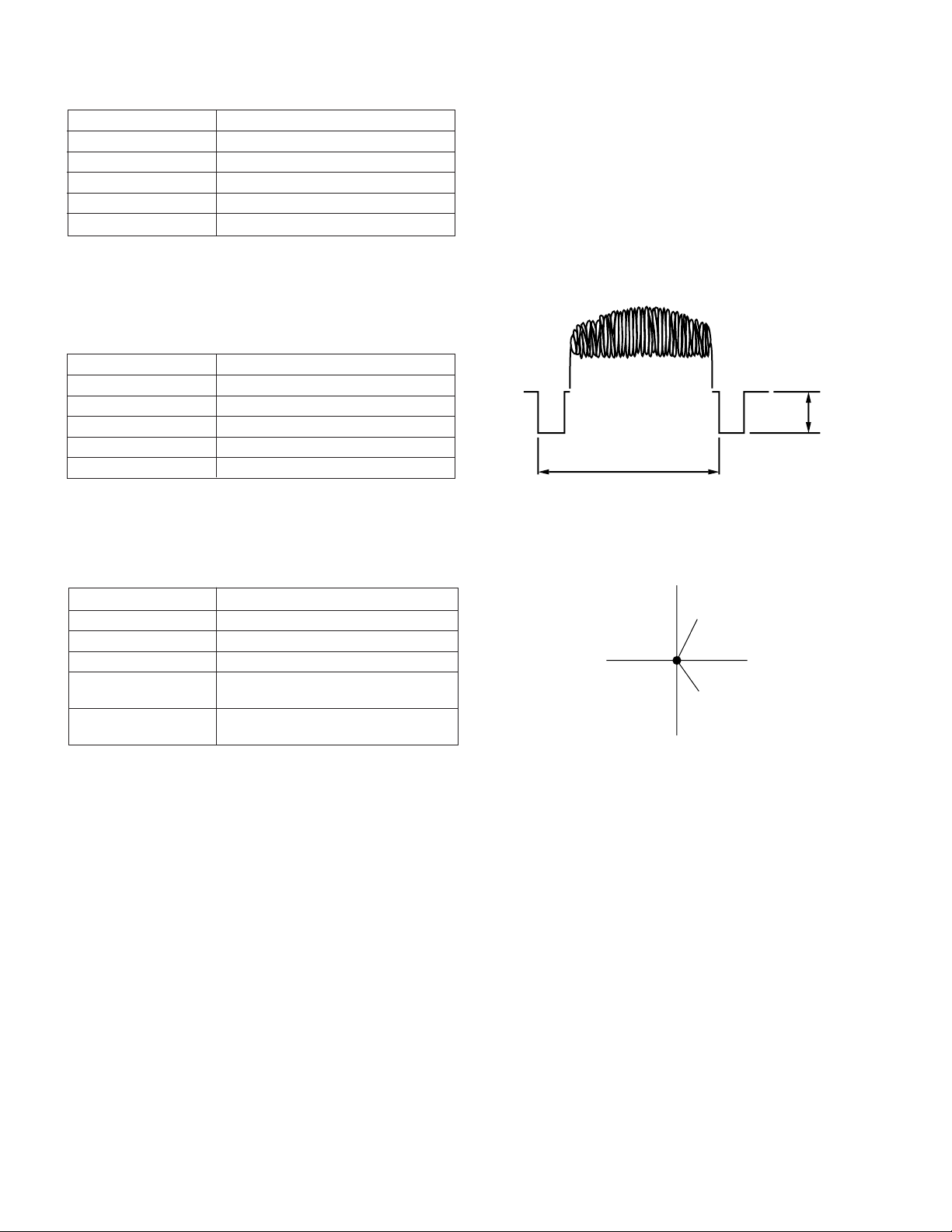

5. MECHANISM ADJUSTMENT

5-2. Items and timings of inspection and maintenance

5-2-1. Inspection and maintenance list

Checking/Maintenance point

Tape travel system

Tape travelling route

(Refer to Section)

Drum (Refer to Section)

Video head

Timing belt

Pinch roller

Capstan D.D. motor

Driving system

Relay Pulle shaft

Pulle gear shaft

Drive gear shaft

Loading motor

Performance check

Abnormal sound

PB/VS-REW take-up torque

PB/VS-REW back tension

torque

Tu brake

HC (Head Cleaner)

Oil:

Grease: MORYCOAT YM-103/X5-6020

Screw locking agent: THERE BOND 1401B

Cleaning liquid: Industrial-use ethyl alcohol

Usage time (hrs.)

500 1,000 1,500 2,000 3,000

★★★

∆∆∆

∆∆∆

★★★

★★★★★

★★★

★★★

★★★

: Replace.

: Clean.

Possible symptom

encountered

• Lateral noise

• Unclean head

• Screen shaking

• Improper S/N ratio

• No color appears.

• Tape does not run.

• Tape slackens.

• Screen shakes.

• Abnormal sound

• Not ejectable

• The specific mode cannot be set.

∆ : Apply oil.

★ : Check.

Remarks

Rollers

• If abnormal rotation or

deflection (significant) is

found, replace the roller.

Other than rollers

• Clean the tape contacting areas. Be sure to

use the specified cleaning agent.

• Replace if failure is

found.

• Apply oil.

(Oil: )

Note:

After oil is applied to the

drive gear shaft, slightly

wipe it off with swab.

• Replace if failure (abnormal sound) is detected.

• If conformance to the

standard is not ensured,

replace part.

5-4. ADJUSTMENT OF MECHANISM TAPE TRAVEL SYSTEM

5-4-3. Adjusting the Si roller height

(2)Adjusting the Si roller

6. ADJUSTMENT OF VCR

6-1. ADJUSTMENT OF VCR SECTION

6-1-5. Y/C circuit adjustment method

2. Adjustment of input Y level

1 Playback the tape such as to set the V/SR mode.

Measuring instrument Oscilloscope

Mode VCR STOP

Input signal Color bar

Measuring point TL801

Adjustment address 32

Adjustment level 500 Vp-p ± 20 mVp-p

4

3. Adjustment of playback Y level

500±20mVp-p

Measuring instrument Oscilloscope

Mode PB

Playback signal Color bar (JiGWR5-5NSP)

Measuring point TL801

Adjustment address 27

Adjustment level 500 Vp-p ± 20 mVp-p

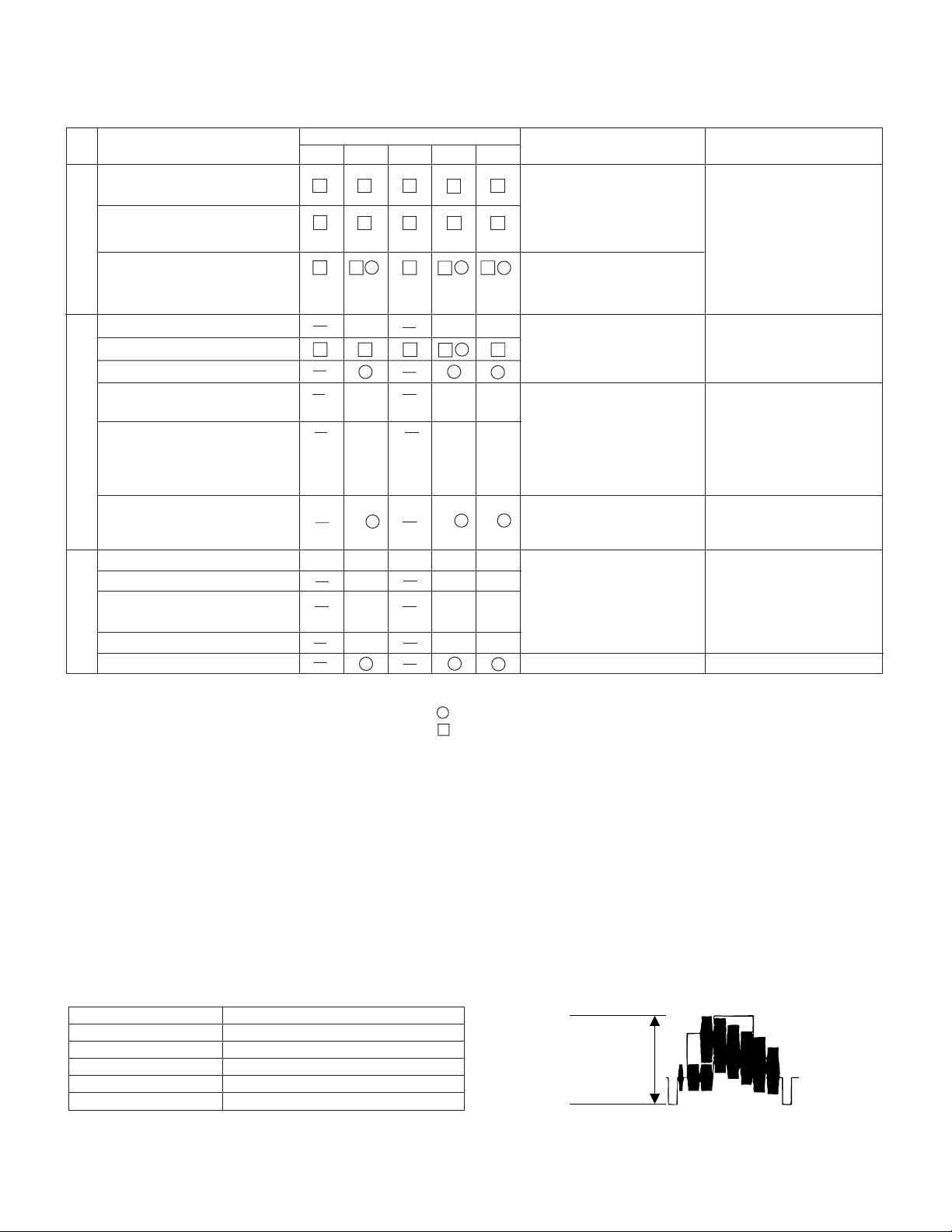

5. Adjustment of Y-FM deviation

VL-E780U

VL-E785U

VL-E785T

Measuring instrument

Oscilloscope

Mode REC/PB (self-playback/recording)

Input signal Color bar

Measuring point TL801

Adjustment address 34

Adjustment level 500 Vp-p ± 20 mVp-p

6-1-7. Adjustment of LCD display circuit

9. Inverter input voltage setting

Measuring point LCD panel display surface

Address 11, 12

Mode VCR AV input

Adjusting method Set the data of address 11 and 12.

Adjustment standard

11=C5

12=A4

Remarks ———————

6-2. ADJUSTMENT OF CAMERA SECTION

6-2-1. Servicing of camera section

• Connections for Camera Section Servicing

500±20mVp-p

LENS

CCD PWB

20pin

19pin

QPWBH2815TAZZ

SC6

20pin

SC2

SC3

19pin

QPWBH2814TAZZ

SC4

15pin

17pin

SC2 19 pin

SC3 15 pin

SC4 17 pin

SC6 20 pin

Connect FPC

between the

camera and

the VCR.

5

VL-E780U

VL-E785U

VL-E785T

6-2-2. Adjustment procedures

6-2-2-2. Auto focus adjustment

Measuring instrument

None

Subject —

Tape —

Test point None

Adjustment address 1FF

Adjustment level 09, 0A, 0B

` Preparation for 6-2-2-3~6-2-2-9, setup the camera signal adjustment mode. (Write 00 to the address 1FE.)

6-2-2-3.

Before starting these adjustments, set up the auto focus adjust.

• Sync level adjustment

Measuring instrument

Oscilloscope

Video

Subject Anything

Tape —

Test point

VIDEO OUT (Terminated in 75Ω)

Adjustment address 1F8

Adjustment level 286mVp-p

1H

1) Connect the oscilloscope to the VIDEO-OUT. Adjust the sync level to 286mVp-p.

6-2-2-9.

• Auto white balance adjustment

Measuring instrument

Vector scope

Subject Gray scale

Tape —

Test point

VIDEO OUT (Terminated in 75 Ω)

Adjustment address R-OUT DOOR 016

B-OUT DOOR 018

Adjustment level R-OUT DOOR; 0 ± 3 %

B-OUT DOOR; 0 ± 3 %

1) Attach the color temperature conversion filter (JIGHOYA-LB165) to the front of the lens.

2) Using the addresses R-OUT DOOR 016 and B-OUT DOOR 018, adjust the spot to the center.

3) Take off the color temperature conversion filter.

` Write FF to the address 1FE to exit from the camera signal adjustment mode.

R-Y

Spot

B-Y

Center point

SYNC

286mVp-p

6

- M E M O -

VL-E780U

VL-E785U

VL-E785T

7

VL-E780U

G

H

I

J

K

L

M

1

234 5 6

7

å

å

VL-E785U

VL-E785T

H

G

F

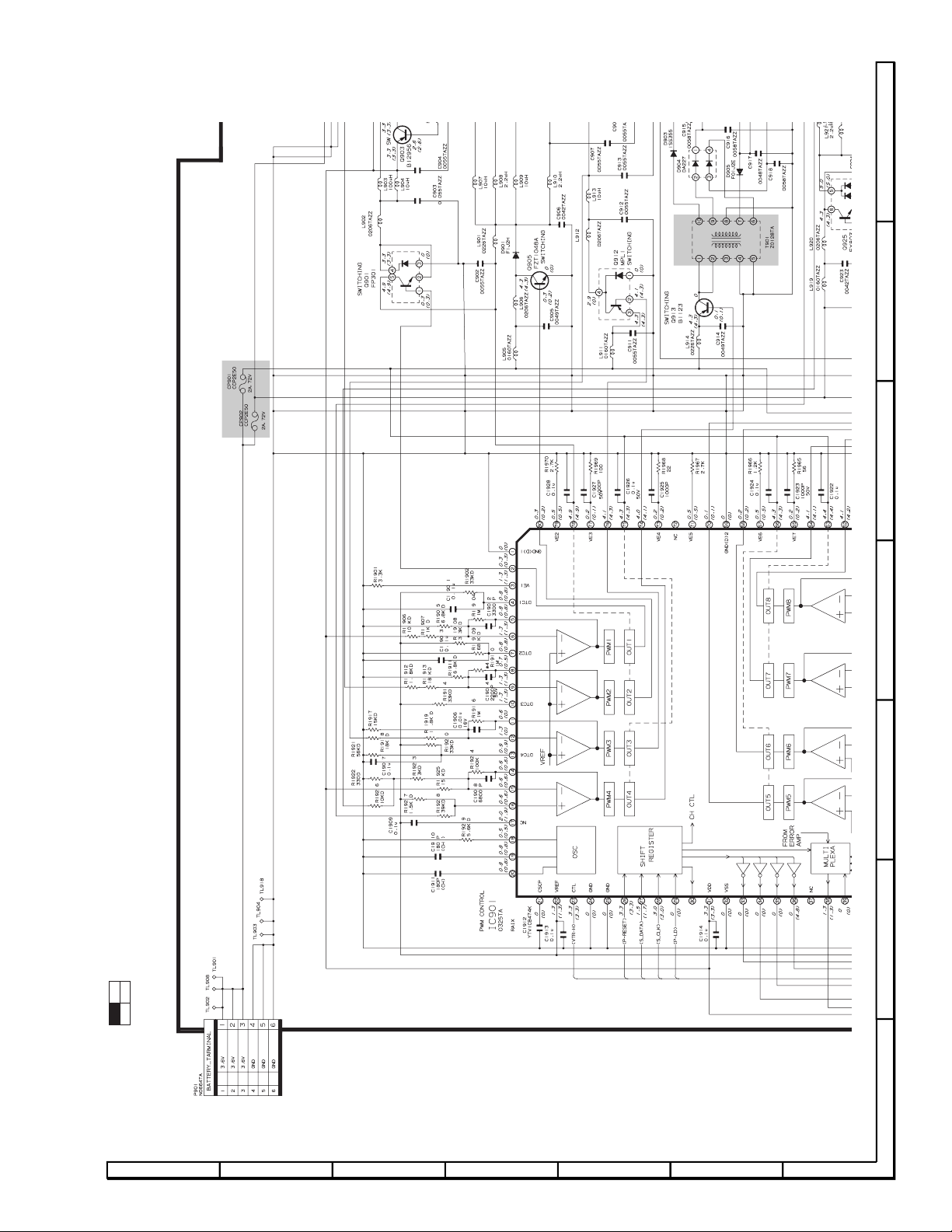

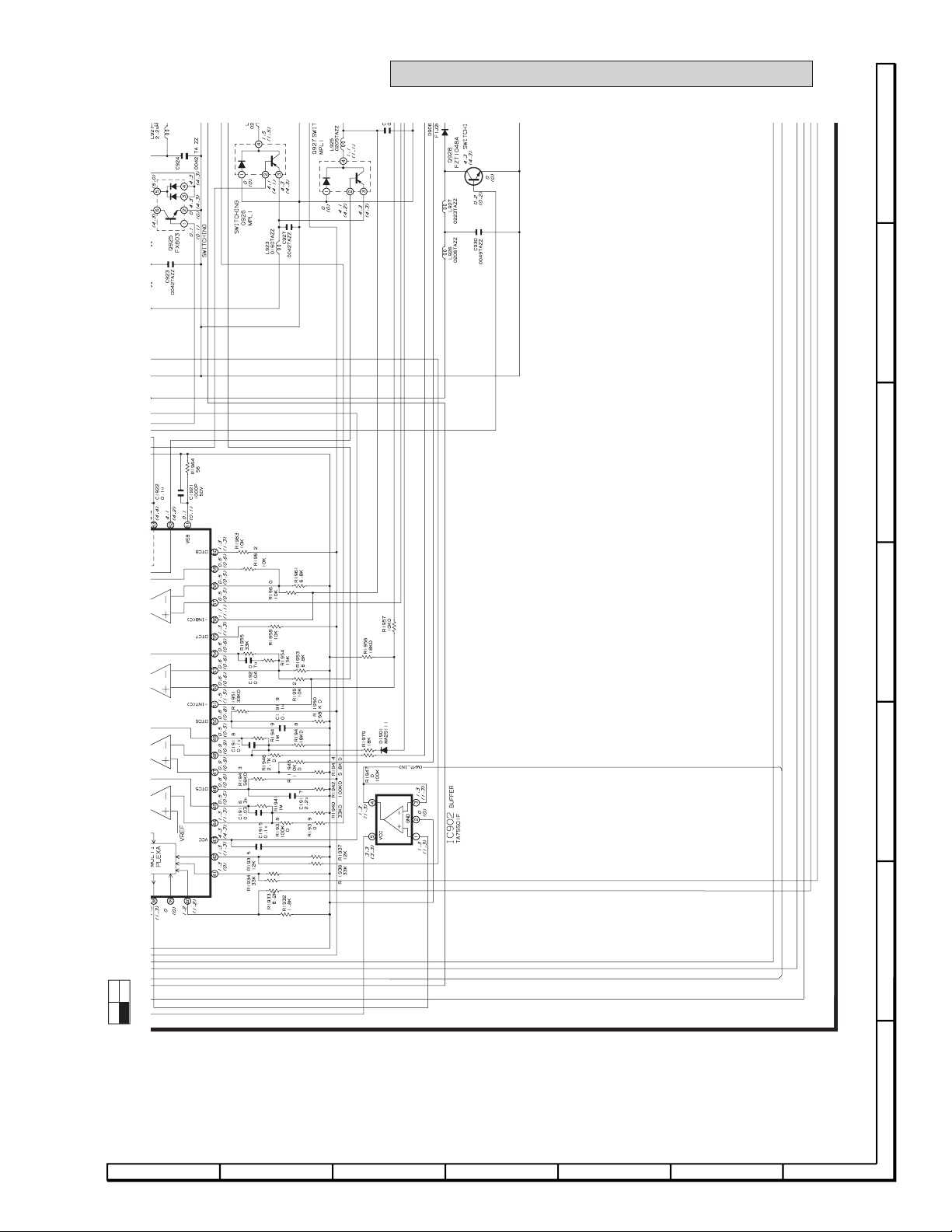

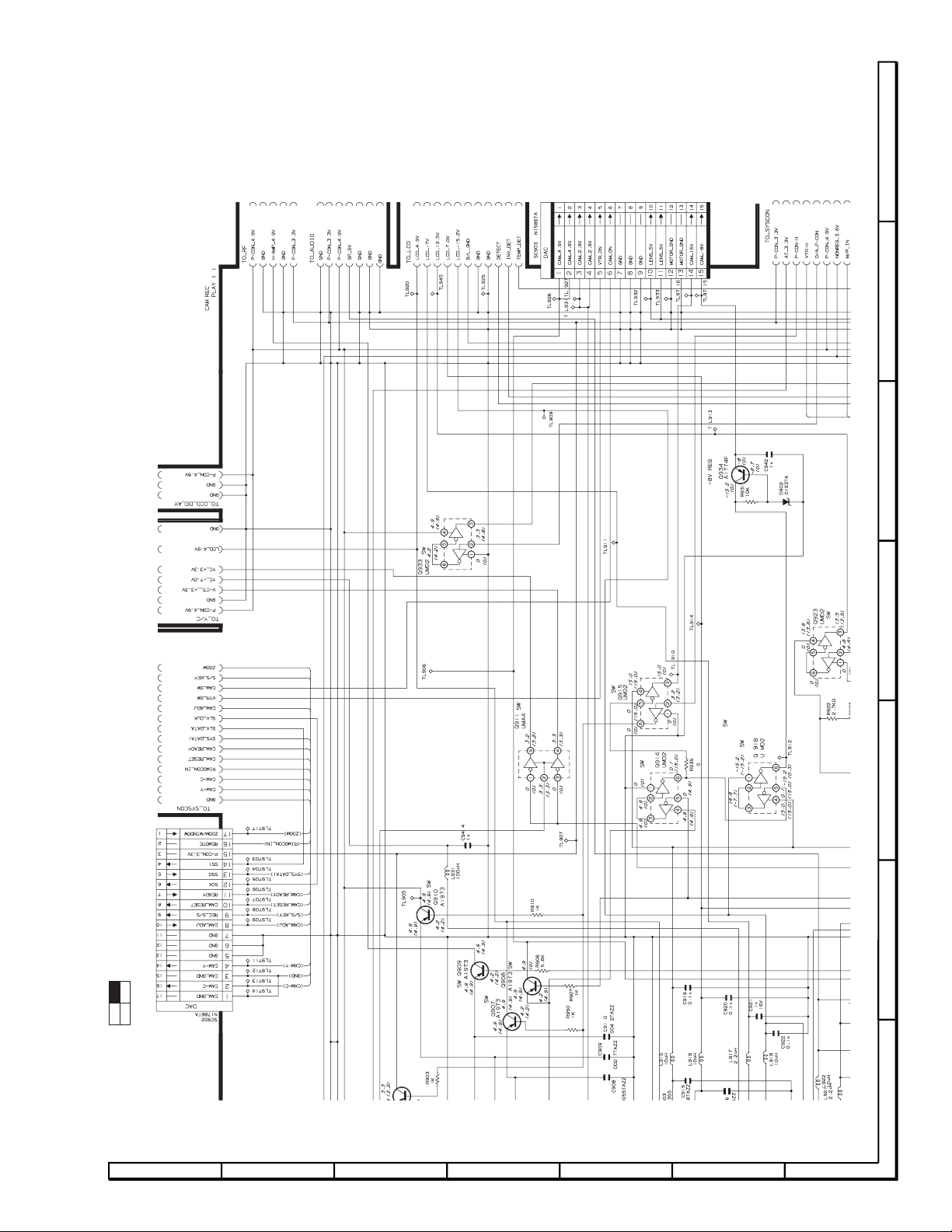

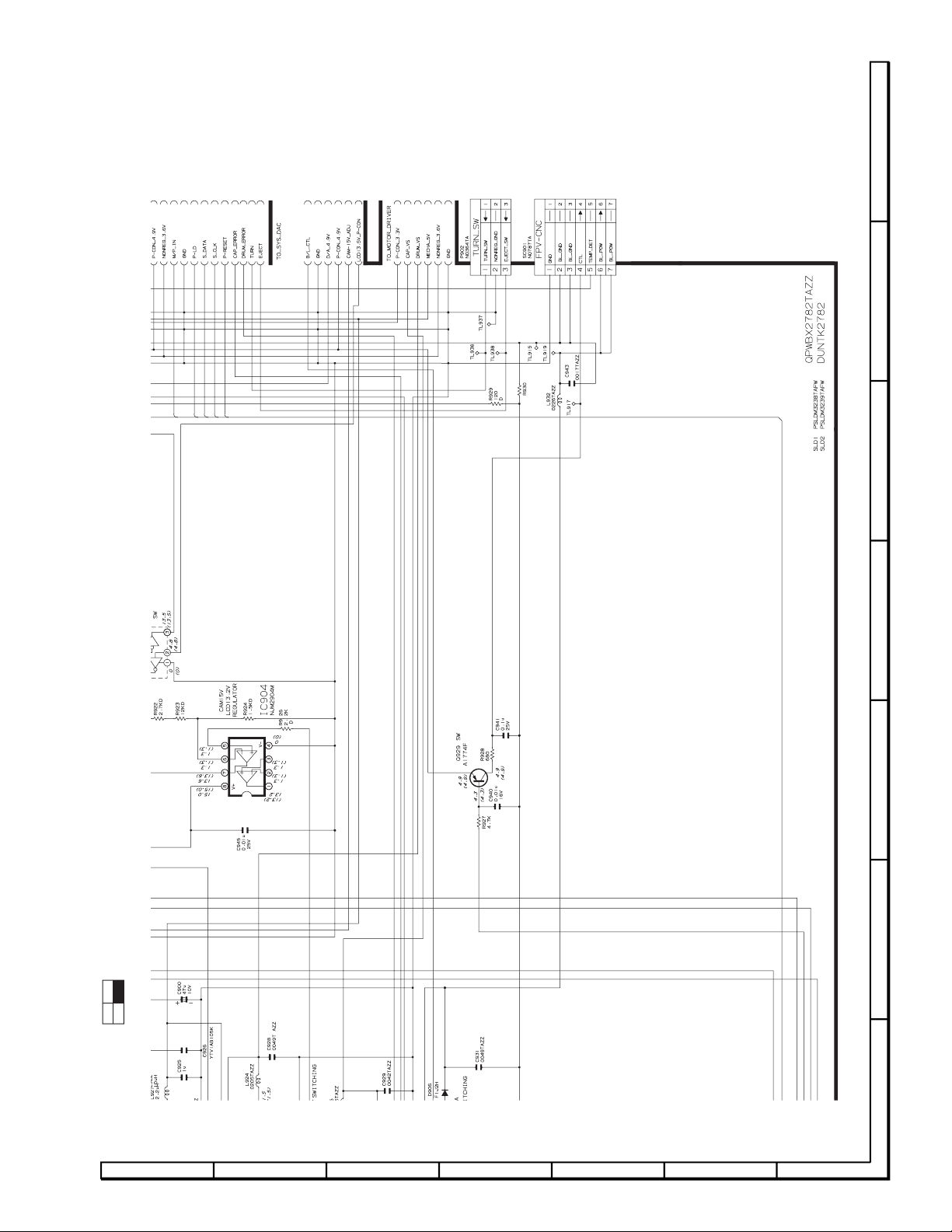

8. SCHEMA TIC DIAGRAMS

8-2. POWER CIRCUIT SCHEMATIC DIAGRAM

E

D

C

B

13

24

A

LOCATION MAP: (1/4)

1234567

8

A

B

C

D

E

F

G

1

234 5 6

7

å

AND SHADED COMPONENTS=SAFETY RELATED PARTS

VL-E780U

VL-E785U

VL-E785T

13

24

LOCATION MAP: (2/4)

78910111213

9

VL-E780U

G

H

I

J

K

L

M

7

8 9 10 11 12

13

VL-E785U

VL-E785T

H

G

F

E

D

C

B

13

24

A

LOCATION MAP: (3/4)

1234567

10

A

B

C

D

E

F

G

7

8 9 10 11 12

13

VL-E780U

VL-E785U

VL-E785T

13

24

LOCATION MAP: (4/4)

78910111213

11

Loading...

Loading...