Page 1

SERVICE MANUAL

SERVICE MANUAL

SY8A8VL-E780U

LIQUID CRYSTAL CAMCORDER 8 NTSC

VL-E780U

VL-E785U

VL-E780U

VL-E780U

VL-E785U

VL-E785U

VL-E785T

VL-E785T

In this Service Manual, only the differences from VL-E760U/765U are described.

Therefore, for the parts which are not described in this Service Manual, refer

to the Service Manual for VL-E760U/765U (S38N2VL-E760U).

NTSC

8

8

2. SPECIFICATIONS .............................................................................................................................. 2

MODELS VL-E780U/E785U/E785TLIQUID CRYSTAL CAMCORDER

4. DISASSEMBLY OF THE SET............................................................................................................. 3

5. MECHANISM ADJUSTMENT ............................................................................................................. 4

6. ADJUSTMENT OF VCR...................................................................................................................... 4

8. SCHEMATIC DIAGRAMS .................................................................................................................. 8

11.REPLACEMENT PARTS LIST ......................................................................................................... 29

12.PACKING OF THE SET ................................................................................................................... 35

MODELS

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its

original condition and only parts identical to those specified

be used.

CONTENTS

VL-E785T

Page

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

1

Page 2

VL-E780U

VL-E785U

VL-E785T

2. SPECIFICATIONS

Signal System: NTSC standard

Recording System: 2 rotary heads, helical scanning system

Cassette: 8 mm video tape, MP type

Recording/Playback Time: 120 minutes (P6-120)

Tape Speed: 14.345 mm/second

Pickup Device: 1/4" (6.4mm, effective size: 4.5 mm) CCD image sensor (with approx.

270,000 pixels including optical black)

Lens: 16 × power zoom lens (F1.4, f=4.0-64.0 mm) and full-range auto focus

Lens Filter Diameter: 46 mm

Monitor: 4" (10.1 cm) full-color LCD screen (TFT active matrix)

Microphone: Electret monaural microphone

Color Temperature Compensation: Auto white balance

Minimum Illumination: 0.8 lux (5 lux measured by EIA standard) (with gain-up, F1.4)

Video Output Level: 1.0 Vp-p 75-ohm unbalanced

Audio Output Level: –8 dBs, impedance less than 2.2 kohms

Speaker Output: 200 mW

Power Requirement: DC 3.6V

Power Consumption:

Operating Temperature: 0°C to + 40°C (32°F to 104°F)

Operating Humidity: 30% to 80%

Storage Temperature: –20°C to +60°C (–4°F to 140°F)

Dimensions (approx.): 7

Weight (approx.): 1.57 lbs (710g)

5.3W (during camera recording in full auto mode with zoom motor off,

Extend Zoom, DIS and Snapshot functions off, and backlight in normal

mode)

5

/32" (W) × 4 9/32" (H) × 3 7/8" (D)

[182 mm (W) × 109 mm (H) × 99 mm (D)]

(without battery pack, lithium battery, video cassette, and lens cap)

AC Adapter/Battery Charger

Battery Pack BT -H22

UADP-0274T AZZ(VL-E780U/E785U)

UADP-0275T AZZ(VL-E785T)

Dimensions (approx.): 2

Power Requirement: AC 110-240 V, 50/60 Hz

DC Output: 4.5 V

Power Consumption: 16 W

Dimensions (approx.): 2

31

/32" (W) × 2" (H) × 5 5/16" (D)

[75 mm (W) × 51 mm (H) ×

135 mm (D)]

Weight (approx.): 0.65 lbs (295 g)

Specifications are subject to change without notice.

*Minimum illumination: Since there is no widely accepted testing procedure for determining minimum illumina-

SERVICE INFORMATION (For the U.S.)

For the location of the nearest Sharp Authorized Service, or to obtain product literature, accessories,

supplies or customer assistance, please call 1-800-BE SHARP (1-800-237-4277) or visit SHARP's

tion capability, lux ratings are comparable only between models from the same

manufacturer.

web site (http://www.sharp-usa.com)

DC Output: 3.6V

1

/8" (W) × 3/4" (H) × 2 7/32" (D)

[54 mm (W) × 19 mm (H) ×

56 mm (D)]

Weight (approx.): 0.30 lbs (136 g)

2

Page 3

VL-E780U

VL-E785U

VL-E785T

4. DISASSEMBLY OF THE SET

Area A

4-2. Disassembly of the VCR main body

1. Removal of the VCR lid shaft

(1)Remove one screw ((j)LX-HZ0063TAFC).

(j)

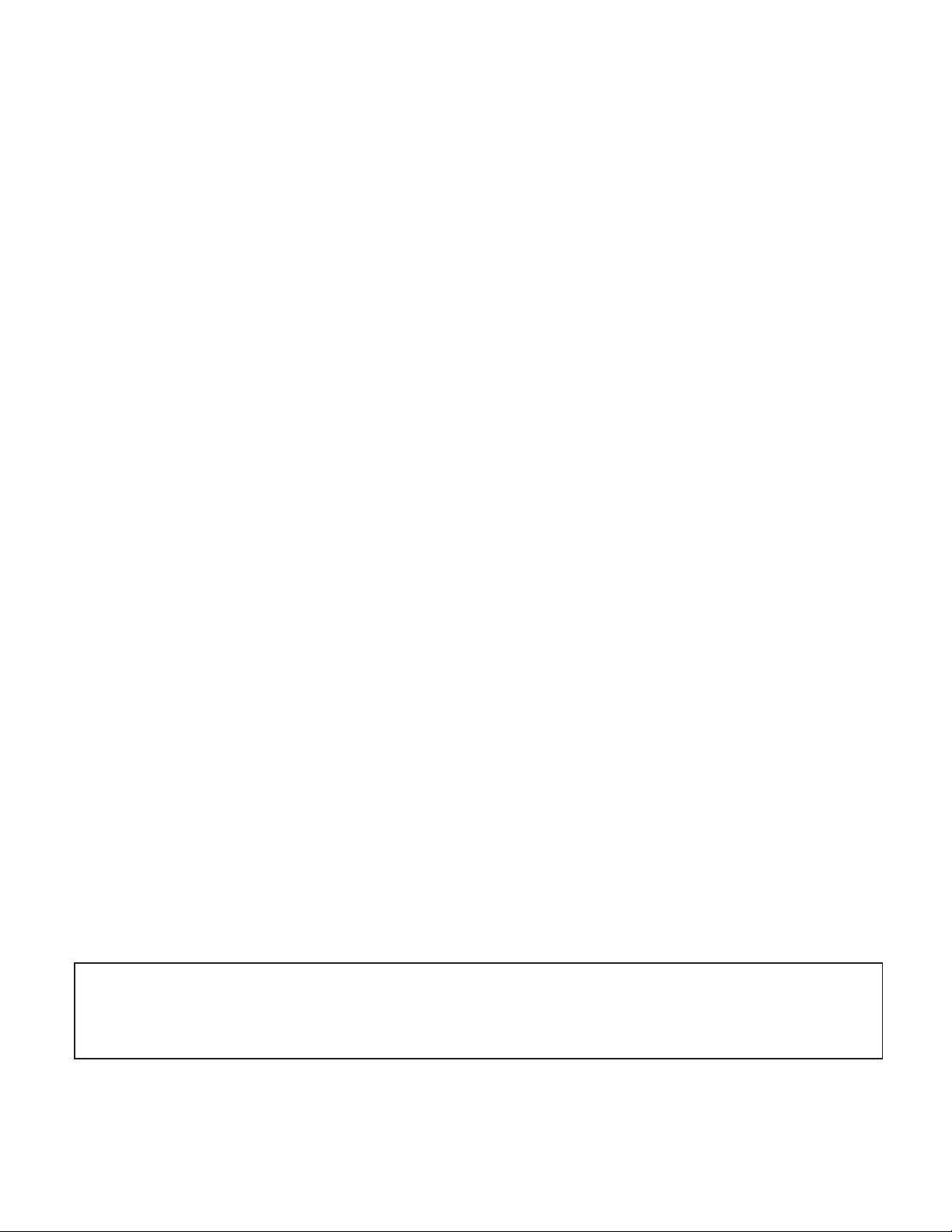

4-3. REPLACEMENT OF CCD SENSOR

4-3-1. BEFORE REPLACEMENT

1) The CCD image sensor is more sensitive to electrostatic breakage than C-MOS LSI. Therefore sufficient means to

prevent electrostatic damage must be taken when it is replaced.

• Ground the soldering iron.

• Ground also the human body, using the wrist strap(through an 1 Mohm resistor).

• Until the CCDsensor is mounted on the PWB, fit it to the conductive sponge, and short-circuit the foot lead.

2) Take utmost care so that the surface glass of CCD sensor and optical filter are not contaminated and damaged. If any

contamination is found, for example fingerprint, wipe it off with silicon paper or clean chamois skin.

3) When replacing the CCD sensor, use the antistaic grounded soldring iron, and perform quickly soldering.

Index Mark

17

JAPAN

SHARP

LZ2413H5

YYWWXXX

14 8

4-4. INITIAL SETTING OF E2PROM IC

4-4-2. IC702 (E2PROM)

When the IC702 has been replaced, make the following settings and adjustments.

1. Remove the backup battery (CR2025)

2. Turn power switch to CAMERA

3. Setting up the V ADJ mode as follows.

* After press the CONTINUE key, press the VCR ADJ key on service remote control (RRMCG0033TASA).

address data data data

03 F8 FA FE

0B 07 05 01

01 00 00 00

09 FF FF FF

04 00 00 00

0C FF FF FF

02 01 01 07

0A FE FE F8

E780U E785U E785T

3

Page 4

VL-E780U

500±20mVp-p

VL-E785U

VL-E785T

5. MECHANISM ADJUSTMENT

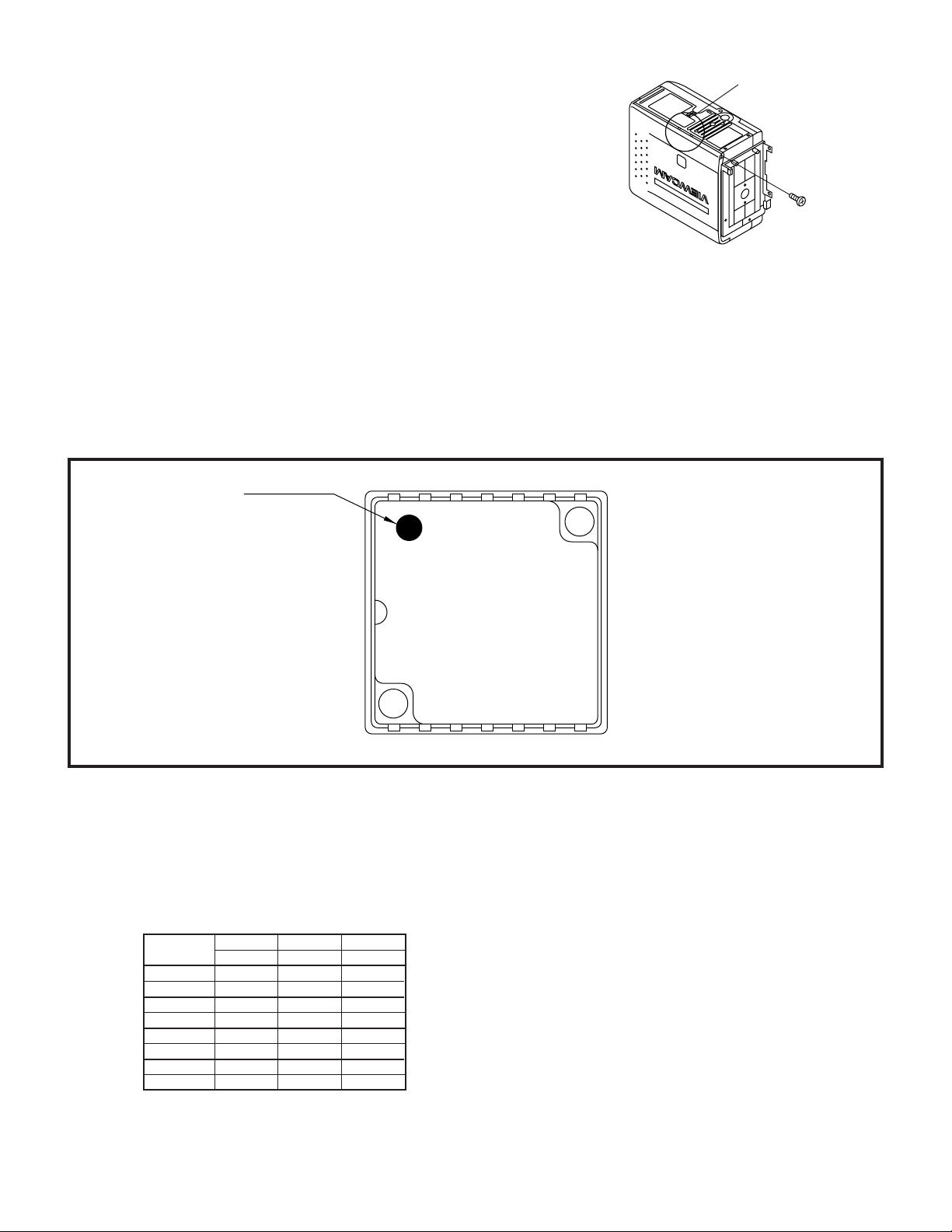

5-2. Items and timings of inspection and maintenance

5-2-1. Inspection and maintenance list

Checking/Maintenance point

Tape travel system

Tape travelling route

(Refer to Section)

Drum (Refer to Section)

Video head

Timing belt

Pinch roller

Capstan D.D. motor

Driving system

Relay Pulle shaft

Pulle gear shaft

Drive gear shaft

Loading motor

Performance check

Abnormal sound

PB/VS-REW take-up torque

PB/VS-REW back tension

torque

Tu brake

HC (Head Cleaner)

Oil:

Grease: MORYCOAT YM-103/X5-6020

Screw locking agent: THERE BOND 1401B

Cleaning liquid: Industrial-use ethyl alcohol

Usage time (hrs.)

500 1,000 1,500 2,000 3,000

★★★

∆∆∆

∆∆∆

★★★

★★★★★

★★★

★★★

★★★

: Replace.

: Clean.

Possible symptom

encountered

• Lateral noise

• Unclean head

• Screen shaking

• Improper S/N ratio

• No color appears.

• Tape does not run.

• Tape slackens.

• Screen shakes.

• Abnormal sound

• Not ejectable

• The specific mode cannot be set.

∆ : Apply oil.

★ : Check.

Remarks

Rollers

• If abnormal rotation or

deflection (significant) is

found, replace the roller.

Other than rollers

• Clean the tape contacting areas. Be sure to

use the specified cleaning agent.

• Replace if failure is

found.

• Apply oil.

(Oil: )

Note:

After oil is applied to the

drive gear shaft, slightly

wipe it off with swab.

• Replace if failure (abnormal sound) is detected.

• If conformance to the

standard is not ensured,

replace part.

5-4. ADJUSTMENT OF MECHANISM TAPE TRAVEL SYSTEM

5-4-3. Adjusting the Si roller height

(2)Adjusting the Si roller

6. ADJUSTMENT OF VCR

6-1. ADJUSTMENT OF VCR SECTION

6-1-5. Y/C circuit adjustment method

2. Adjustment of input Y level

1 Playback the tape such as to set the V/SR mode.

Measuring instrument Oscilloscope

Mode VCR STOP

Input signal Color bar

Measuring point TL801

Adjustment address 32

Adjustment level 500 Vp-p ± 20 mVp-p

4

Page 5

3. Adjustment of playback Y level

500±20mVp-p

Measuring instrument Oscilloscope

Mode PB

Playback signal Color bar (JiGWR5-5NSP)

Measuring point TL801

Adjustment address 27

Adjustment level 500 Vp-p ± 20 mVp-p

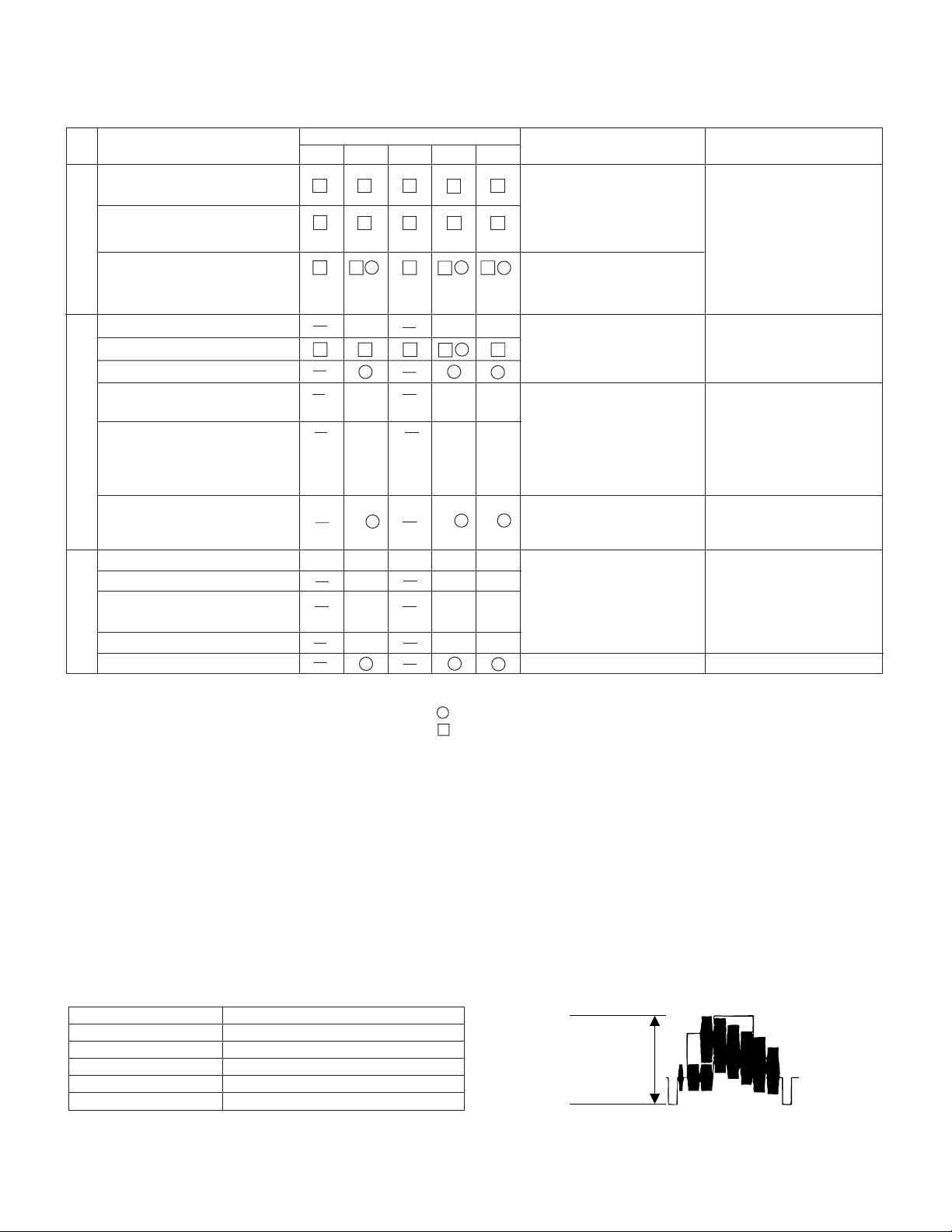

5. Adjustment of Y-FM deviation

VL-E780U

VL-E785U

VL-E785T

Measuring instrument

Oscilloscope

Mode REC/PB (self-playback/recording)

Input signal Color bar

Measuring point TL801

Adjustment address 34

Adjustment level 500 Vp-p ± 20 mVp-p

6-1-7. Adjustment of LCD display circuit

9. Inverter input voltage setting

Measuring point LCD panel display surface

Address 11, 12

Mode VCR AV input

Adjusting method Set the data of address 11 and 12.

Adjustment standard

11=C5

12=A4

Remarks ———————

6-2. ADJUSTMENT OF CAMERA SECTION

6-2-1. Servicing of camera section

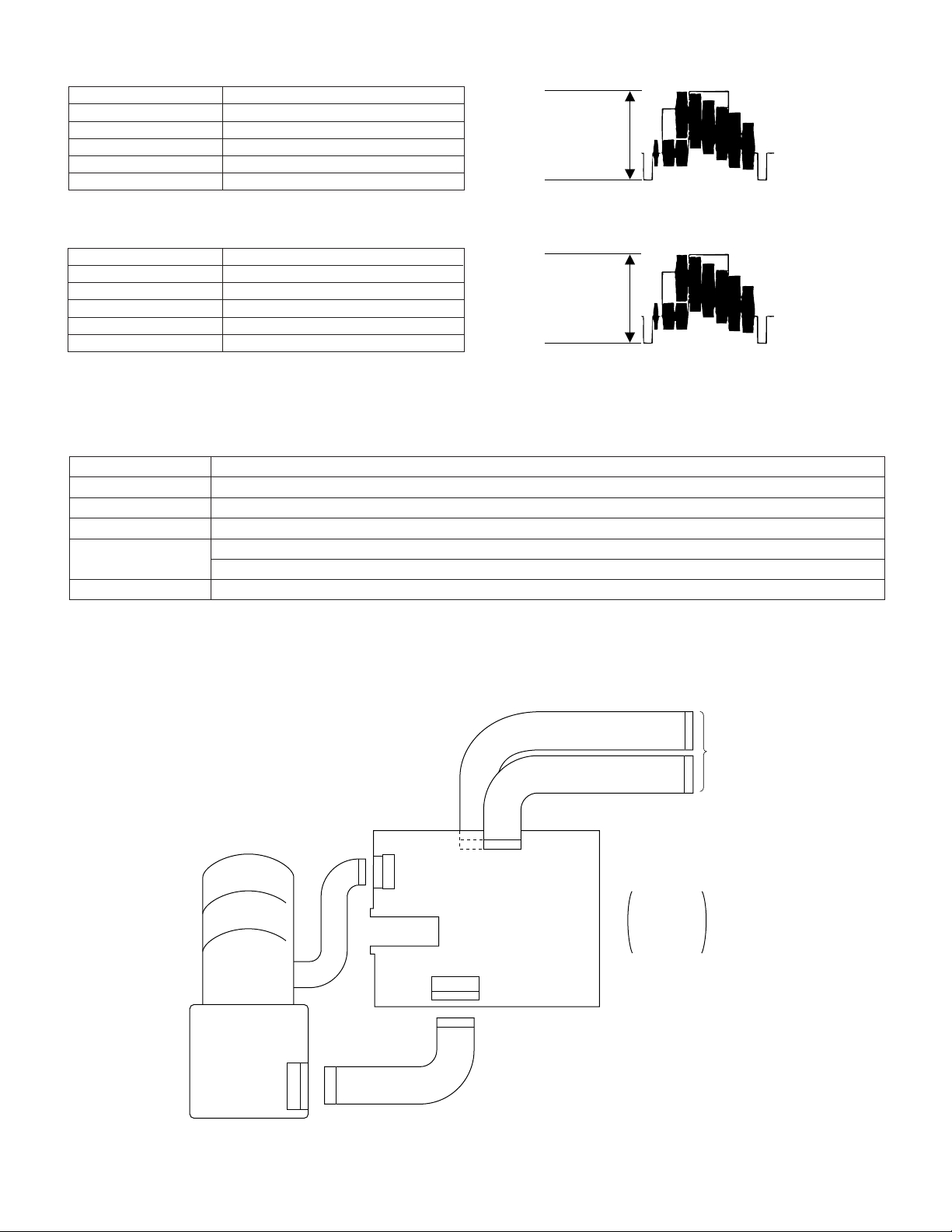

• Connections for Camera Section Servicing

500±20mVp-p

LENS

CCD PWB

20pin

19pin

QPWBH2815TAZZ

SC6

20pin

SC2

SC3

19pin

QPWBH2814TAZZ

SC4

15pin

17pin

SC2 19 pin

SC3 15 pin

SC4 17 pin

SC6 20 pin

Connect FPC

between the

camera and

the VCR.

5

Page 6

VL-E780U

VL-E785U

VL-E785T

6-2-2. Adjustment procedures

6-2-2-2. Auto focus adjustment

Measuring instrument

None

Subject —

Tape —

Test point None

Adjustment address 1FF

Adjustment level 09, 0A, 0B

` Preparation for 6-2-2-3~6-2-2-9, setup the camera signal adjustment mode. (Write 00 to the address 1FE.)

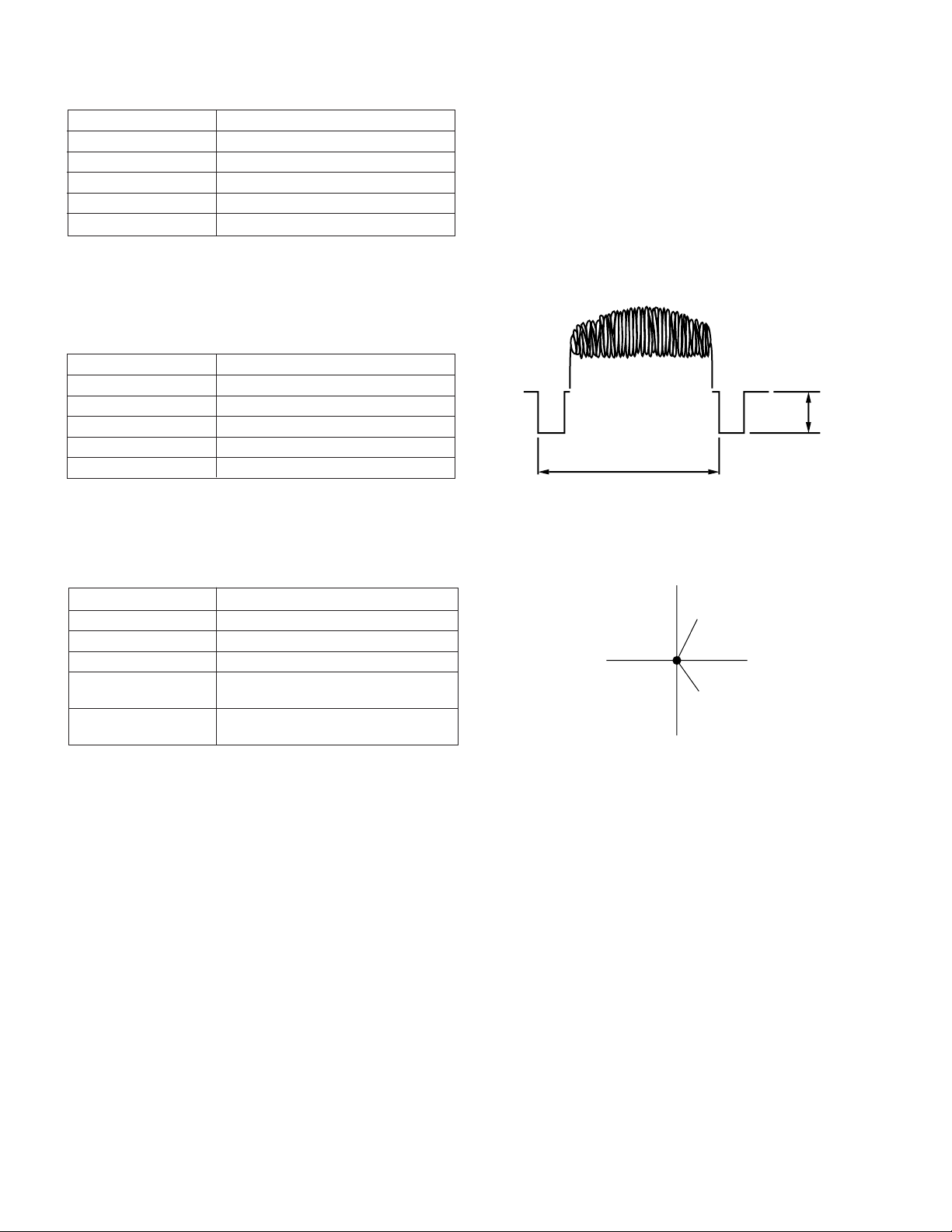

6-2-2-3.

Before starting these adjustments, set up the auto focus adjust.

• Sync level adjustment

Measuring instrument

Oscilloscope

Video

Subject Anything

Tape —

Test point

VIDEO OUT (Terminated in 75Ω)

Adjustment address 1F8

Adjustment level 286mVp-p

1H

1) Connect the oscilloscope to the VIDEO-OUT. Adjust the sync level to 286mVp-p.

6-2-2-9.

• Auto white balance adjustment

Measuring instrument

Vector scope

Subject Gray scale

Tape —

Test point

VIDEO OUT (Terminated in 75 Ω)

Adjustment address R-OUT DOOR 016

B-OUT DOOR 018

Adjustment level R-OUT DOOR; 0 ± 3 %

B-OUT DOOR; 0 ± 3 %

1) Attach the color temperature conversion filter (JIGHOYA-LB165) to the front of the lens.

2) Using the addresses R-OUT DOOR 016 and B-OUT DOOR 018, adjust the spot to the center.

3) Take off the color temperature conversion filter.

` Write FF to the address 1FE to exit from the camera signal adjustment mode.

R-Y

Spot

B-Y

Center point

SYNC

286mVp-p

6

Page 7

- M E M O -

VL-E780U

VL-E785U

VL-E785T

7

Page 8

VL-E780U

G

H

I

J

K

L

M

1

234 5 6

7

å

å

VL-E785U

VL-E785T

H

G

F

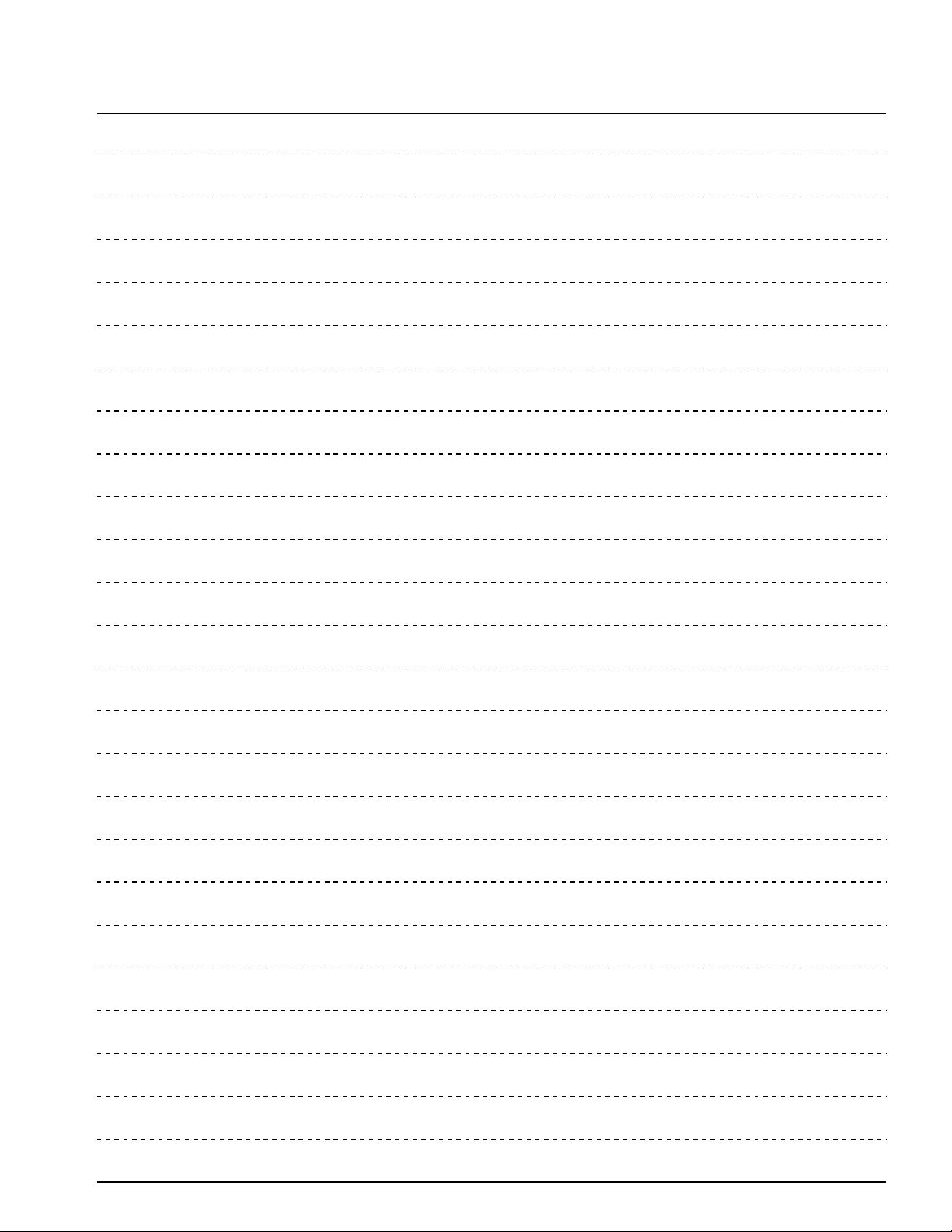

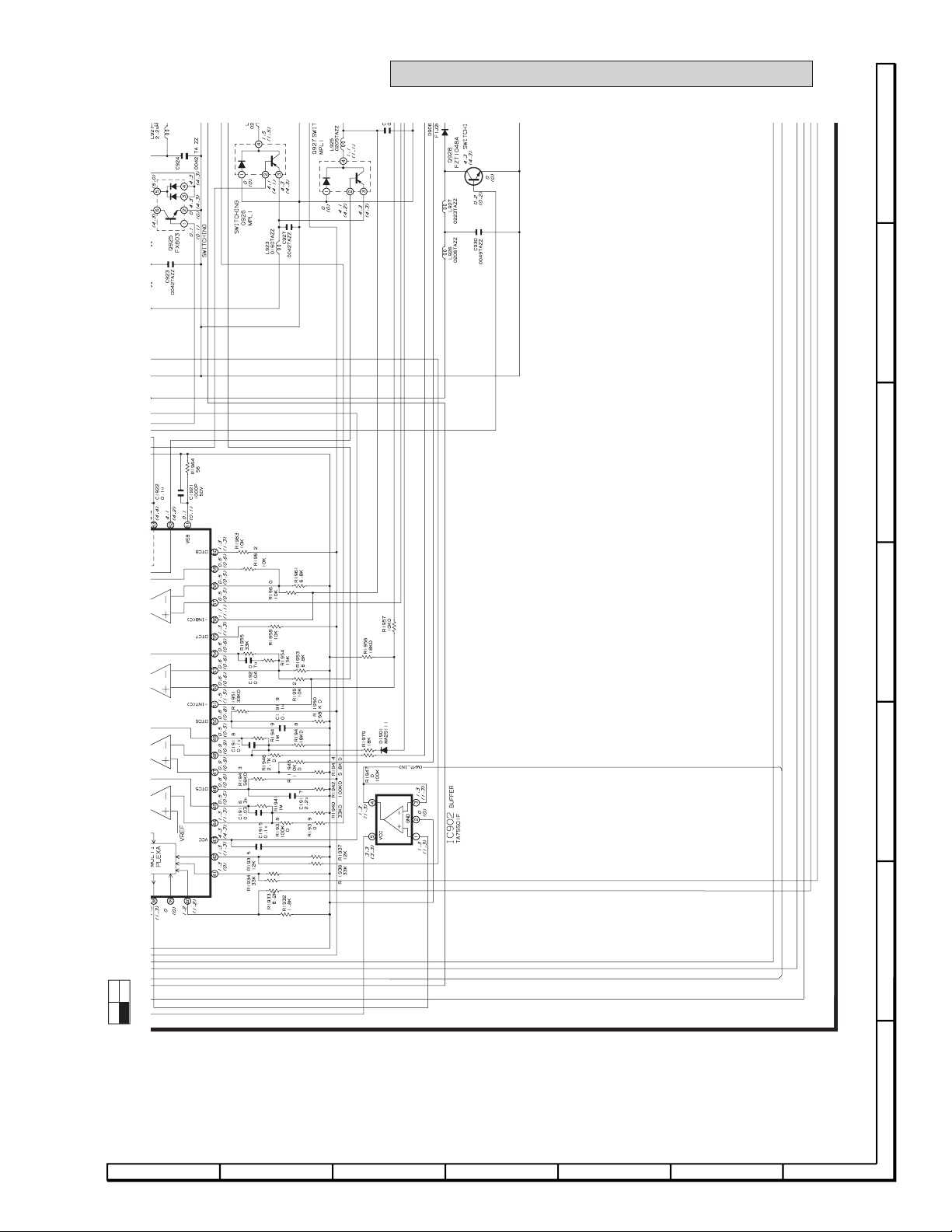

8. SCHEMA TIC DIAGRAMS

8-2. POWER CIRCUIT SCHEMATIC DIAGRAM

E

D

C

B

13

24

A

LOCATION MAP: (1/4)

1234567

8

Page 9

A

B

C

D

E

F

G

1

234 5 6

7

å

AND SHADED COMPONENTS=SAFETY RELATED PARTS

VL-E780U

VL-E785U

VL-E785T

13

24

LOCATION MAP: (2/4)

78910111213

9

Page 10

VL-E780U

G

H

I

J

K

L

M

7

8 9 10 11 12

13

VL-E785U

VL-E785T

H

G

F

E

D

C

B

13

24

A

LOCATION MAP: (3/4)

1234567

10

Page 11

A

B

C

D

E

F

G

7

8 9 10 11 12

13

VL-E780U

VL-E785U

VL-E785T

13

24

LOCATION MAP: (4/4)

78910111213

11

Page 12

VL-E780U

VL-E785U

VL-E785T

H

G

F

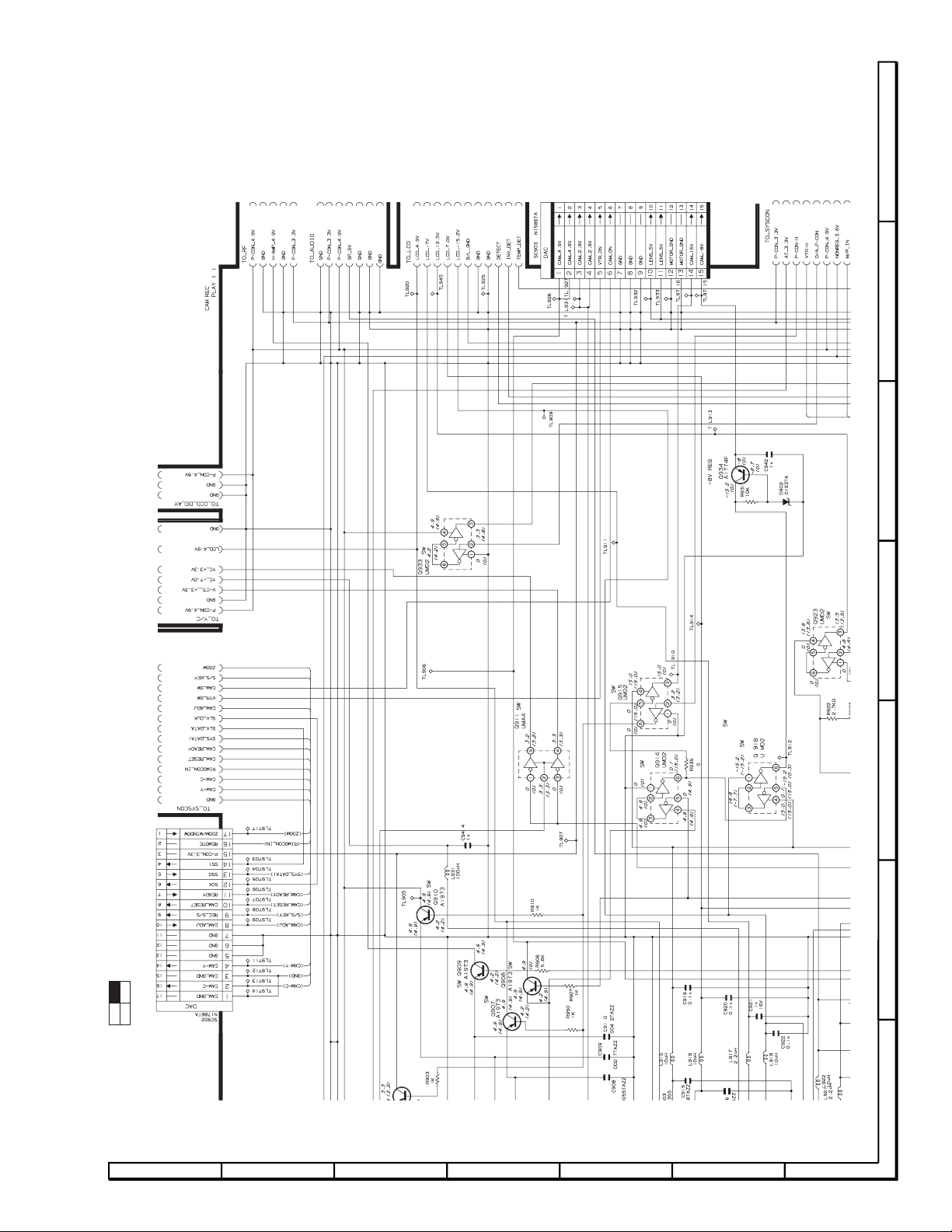

8-3. AUDIO CIRCUIT SCHEMATIC DIAGRAM

E

D

C

B

A

1234567

12

Page 13

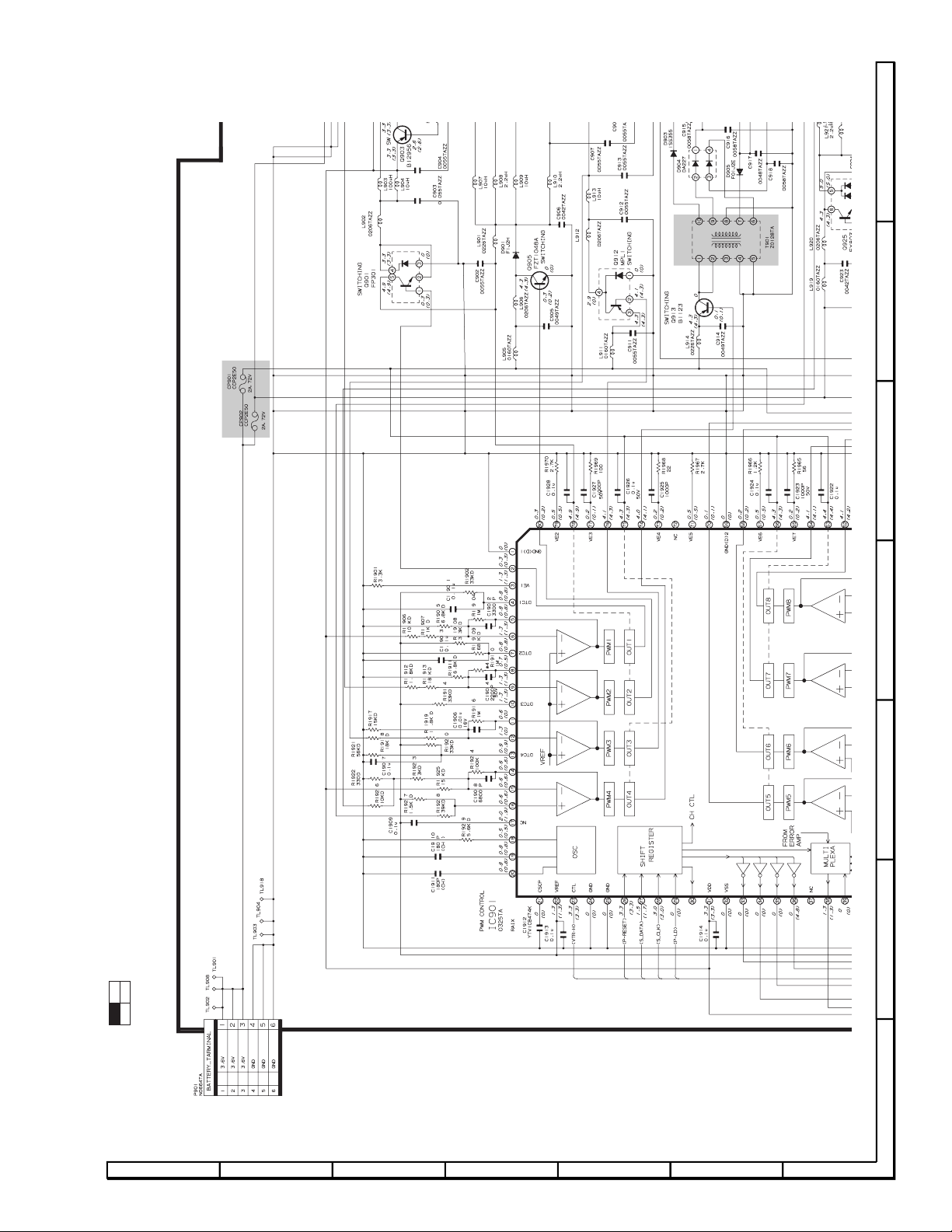

8-4. MOTOR DRIVER SCHEMATIC DIAGRAM

H

G

F

VL-E780U

VL-E785U

VL-E785T

E

D

C

B

A

1234567

78910111213

13

Page 14

VL-E780U

G

H

I

J

K

L

M

1

234 5 6

7

VL-E785U

VL-E785T

H

G

F

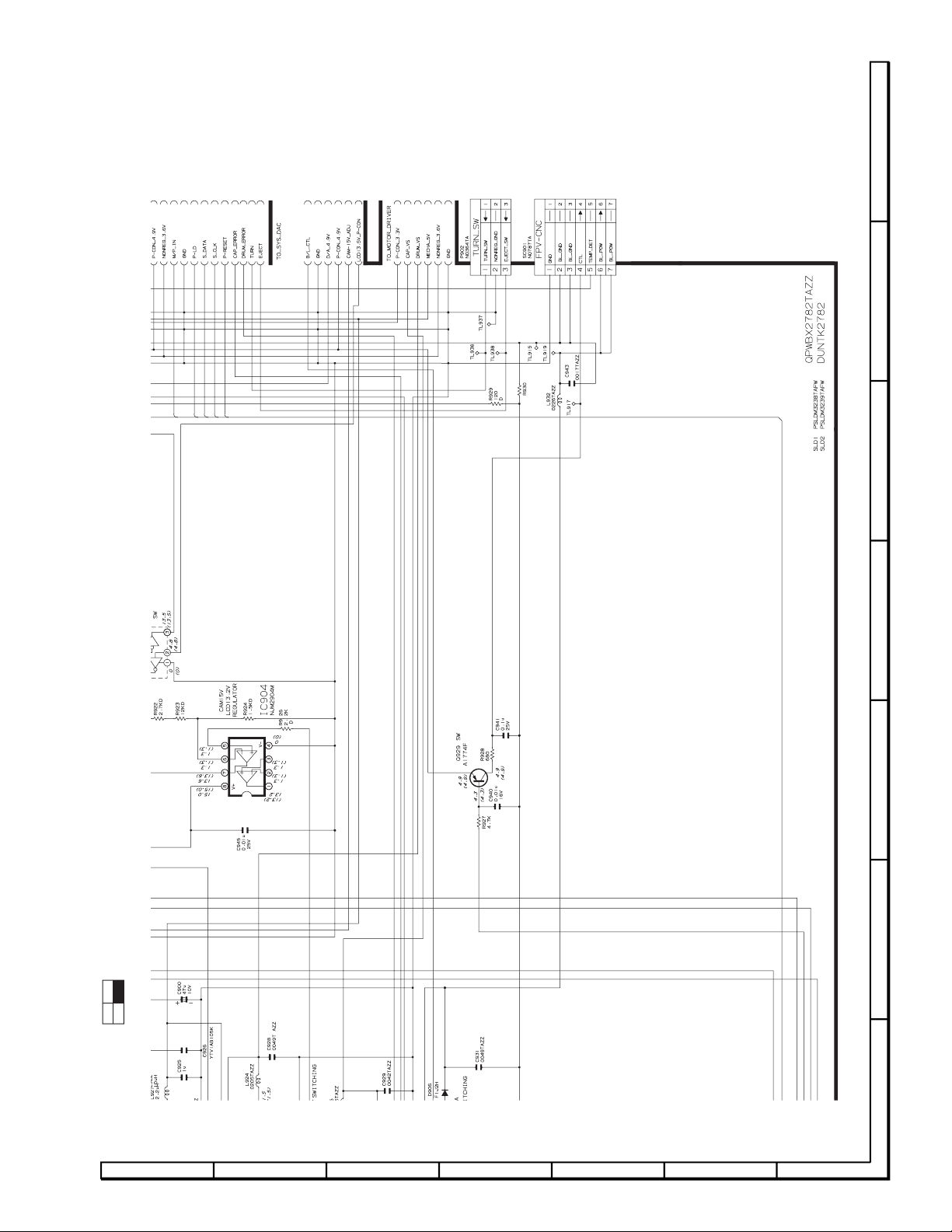

8-5. LCD DISPLAY CIRCUIT SCHEMATIC DIAGRAM

E

* See (S38N2VL-E710U) Page 8-21 When replacing the IC800

D

C

B

13

24

A

LOCATION MAP: (1/4)

1234567

14

Page 15

VL-E780U

A

B

C

D

E

F

G

1

234 5 6

7

VL-E785U

VL-E785T

13

24

LOCATION MAP: (2/4)

78910111213

15

Page 16

VL-E780U

G

H

I

J

K

L

M

7

8 9 10 11 12

13

VL-E785U

VL-E785T

H

G

F

E

D

C

B

13

24

A

LOCATION MAP: (3/4)

1234567

16

Page 17

A

B

C

D

E

F

G

7

8 9 10 11 12

13

VL-E780U

VL-E785U

VL-E785T

13

24

LOCATION MAP: (4/4)

78910111213

17

Page 18

VL-E780U

VL-E785U

VL-E785T

H

G

F

8-6. RF CIRCUIT SCHEMATIC DIAGRAM

E

D

C

B

A

1234567

18

Page 19

VL-E780U

VL-E785U

VL-E785T

78910111213

19

Page 20

VL-E780U

G

H

I

J

K

L

M

1

234 5 6

7

VL-E785U

VL-E785T

H

G

F

8-7. SYSTEM CONTROL CIRCUIT SCHEMATIC DIAGRAM

E

* See (S38N2VL-E710U) Page 8-22 When replacing the IC703,705

D

C

B

13

24

A

LOCATION MAP: (1/4)

1234567

20

Page 21

VL-E780U

A

B

C

D

E

F

G

1

234 5 6

7

VL-E785U

VL-E785T

13

24

LOCATION MAP: (2/4)

78910111213

21

Page 22

VL-E780U

G

H

I

J

K

L

M

7

8 9 10 11 12

13

VL-E785U

VL-E785T

H

G

F

E

D

C

B

13

24

A

LOCATION MAP: (3/4)

1234567

22

Page 23

A

B

C

D

E

F

G

7

8 9 10 11 12

13

VL-E780U

VL-E785U

VL-E785T

13

24

LOCATION MAP: (4/4)

78910111213

23

Page 24

VL-E780U

G

H

I

J

K

L

M

1

234 5 6

7

VL-E785U

VL-E785T

H

G

F

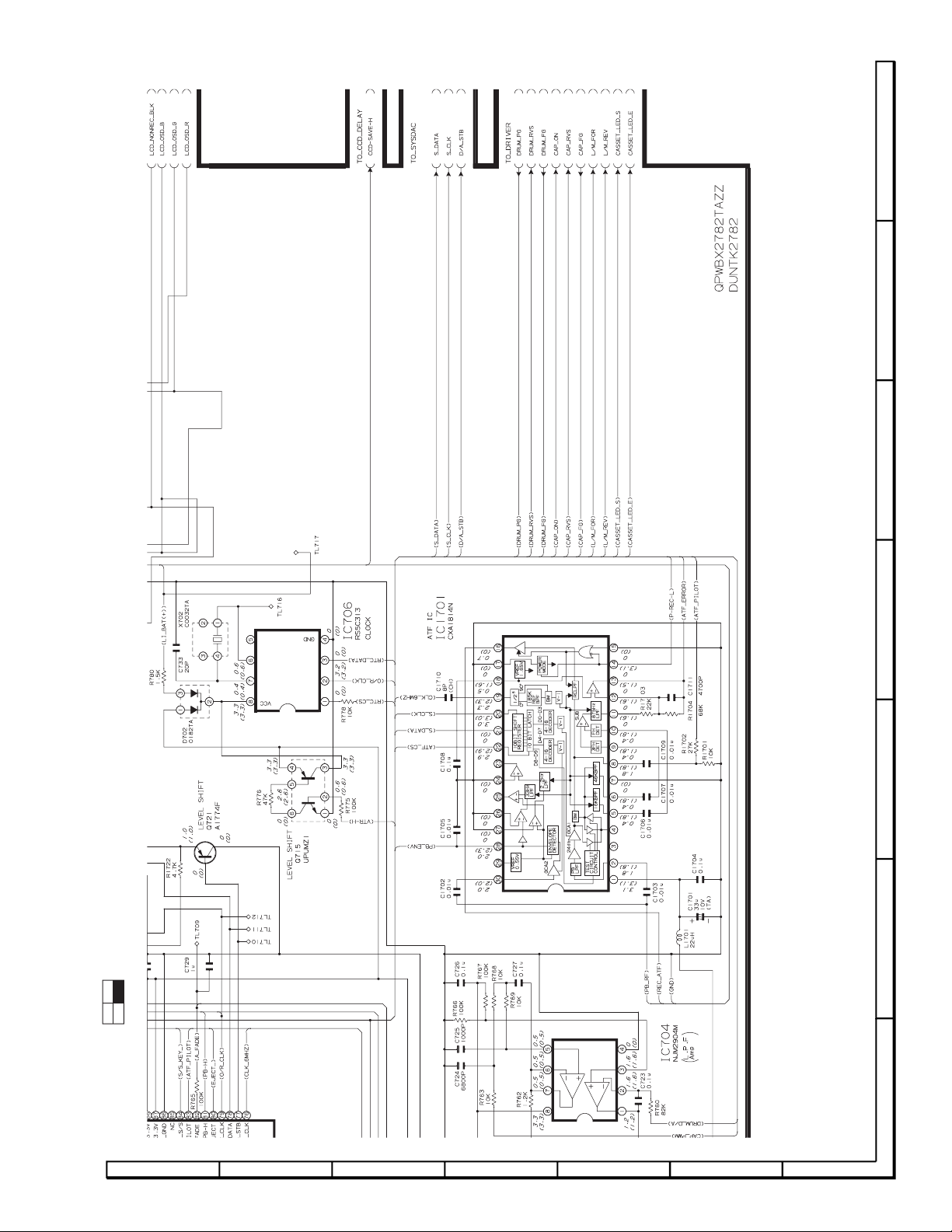

8-9. Y/C CIRCUIT SCHEMATIC DIAGRAM

E

* See (S38N2VL-E710U) Page 8-21 When replacing the IC401

D

C

B

13

24

A

LOCATION MAP: (1/4)

1234567

24

Page 25

VL-E780U

A

B

C

D

E

F

G

1

234 5 6

7

VL-E785U

VL-E785T

13

24

LOCATION MAP: (2/4)

78910111213

25

Page 26

VL-E780U

G

H

I

J

K

L

M

7

8 9 10 11 12

13

VL-E785U

VL-E785T

H

G

F

E

D

C

B

13

24

A

LOCATION MAP: (3/4)

1234567

26

Page 27

A

B

C

D

E

F

G

7

8 9 10 11 12

13

VL-E780U

VL-E785U

VL-E785T

13

24

LOCATION MAP: (4/4)

78910111213

27

Page 28

VL-E780U

VL-E785U

VL-E785T

H

G

F

8-10. D/A CIRCUIT SCHEMATIC DIAGRAM

E

D

C

B

A

1234567

28

Page 29

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

11.REPLACEMENT PARTS LIST/

EXPLODED VIEWS

ELECTRICAL PARTS LIST

Parts marked with

set. Be sure to replace these parts with specified ones for maintaining

the safety and performance of the set.

Les pièces marquéss

de l'appareil. Ne remplacer ces pieces que par des pièces dont le

numéro est spécifié pour maintenir la sécurité et protéger le bon

fonctinnement de l'appareil.

"

HOW TO ORDER REPLACEMENT PARTS

in USA: Contact your nearest SHARP Parts Distributor. For

★MARK : SPARE PARTS-DELIVERY SECTION:ALL JAPAN

in CANADA: Contact SHARP Electronics of Canada Limited

To have your order filled promptly and correctly, please furnish

the following informations.

"å"

are important for maintaining the safety of the

"å"

sont importantes pour maintenir la sècurité

location of SHARP Parts Distributor,

Call Toll-free 1-IBE800-SHARP

Phone (416) 890-2100.

1. MODEL NUMBER 2. REF. NO.

3. PART NO. 4. DESCRIPTION

5. PRICE CODE

"

VL-E780U

VL-E785U

VL-E785T

å MARK: SAFETY RELATED PARTS

å PIECES: RELATIVES A LA SECURITE

PWB ASSEMBLY IS NOT REPLACEMENT ITEM

L'ASSEMBLANGE P.C.I. EST UN ARTICLE NON REMPLACABLE

Ref. No. Part No. ★ Description Code

PRINTED WIRING BOARD ASSEMBLIES

(NOT REPLACEMENT ITEM)

DUNTK2782QA10 J VCR Unit(VL-E780U) —

DUNTK2782QA11 J VCR Unit(VL-E785U) —

DUNTK2782QA17 J VCR Unit(VL-E785T) —

DUNTK2785QA01 J CAMERA Unit —

DUNTK2782QA10 VCR UNIT(VL-E780U)

DUNTK2782QA11 VCR UNIT(VL-E785U)

DUNTK2782QA17 VCR UNIT(VL-E785T)

IC703 RH-iX0609TAZZ J CXP87460-126R(VL-E785T)AY

IC705 RH-iX0612TAZZ J IX0612TA(VL-E785T) AR

Q415 VS2PA1774R/-1 J Transistor AB

Q602 VSRT1N441U/-1 J Transistor AB

R447 VRS-CZ1JF122J J 1.2k 1/16W Metal Oxide AA

R454 VRS-CZ1JF102D J 1k 1/16W Metal Oxide AA

R455 VRS-CZ1JF102D J 1k 1/16W Metal Oxide AA

R826 VRS-CZ1JF124D J 120k 1/16W Metal Oxide AA

R950 VRS-CZ1JF102J J 1k 1/16W Metal Oxide AA

R1820 VRS-CZ1JF393J J 39k 1/16W Metal Oxide AA

R1821 VRS-CZ1JF393J J 39k 1/16W Metal Oxide AA

INTEGRATED CIRCUITS

TRANSISTORS

RESISTORS

DUNTK2785QA01 CAMERA UNIT

RESISTORS

R536 VRS-CZ1JF153J J 15k 1/16W Metal Oxide AA

R576 VRS-CZ1JF393J J 39k 1/16W Metal Oxide AA

R582 VRS-CZ1JF334D J 330k 1/16W Metal Oxide AA

Note

:

In this chapter, only the differences from VL-E760U/765U

are described. Therefore, for the parts which are not

described in this page, refer to the Service Manual for VLE760U/765U (S38N2VL-E760U) chapter 11.

29

Page 30

VL-E780U

VL-E785U

VL-E785T

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

MECHANISM CHASSIS EXPLODED VIEW

315

214

312

354

345

375

352

202

200

204

209

214

317

303

301

362

356

319

209

211

209

314

368

209

332

214

333

213

318

325

215

316

302

359

326

324

328

311

304

209

370

364

349

200

204

202

310

209

322

323

214

203

351

H

351

G

208

367

F

E

208

365

376

341

366

208

D

212

330

343

214

339

209

209

354

355

305

214

362

306

209

307

337

346

201

369

348

208

205

202

208

353

350

204

208

313

363

327

308

309

321

C

331

357

216

207

344

206

336

B

329

A

209

342

209

340

338

206

358

216

209

209

374

372

209

334

209

214

335

214

361

360

214

300

123456

30

Page 31

VL-E780U

VL-E785U

VL-E785T

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

MECHANISM PARTS

300 LCHSM0163GEZZ J Main Chassis Ass'y AW

301 NGERH1280GEZZ J Main Cam AD

302 NGERH1281GEZZ J Sub-Cam AD

303 MLEVF0470GEFW J Eject Lever AD

304 MLEVF0492GEFW J M Function Lever AF

305 LHLDZ1966GEZZ J L Block Holder AD

306 NGERW1064GEZZJ Worm Pulley AC

307 NGERW1065GEZZJ Worm AD

308 NGERH1282GEZZ J Worm Wheel AC

309 NGERH1283GEZZ J Lo Relay Gear AC

310 MARMM0126GEZZJ S Lo Arm Ass'y AE

311 MARMM0128GEZZJ T Lo Arm Ass'y AF

312 LANGA0069GEFW J S Lo Arm Retainer AD

313 PGiDM0146GEZZ J Sup Rail AD

314 PGiDM0171GEZZ J Tu Rail AD

315 NGERH1284GEZZ J Sup Lo Gear AC

316 NGERH1285GEZZ J Tu Lo Gear AC

317 MSPRD0167GEZZ J S Lo Arm Double-Acting AE

Spring

318 MSPRT0407GEZZ J T Lo Arm Double-Acting AC

Spring

319 MLEVP0310GEZZ J HC Lever Ass'y AF

321 MSLiF0074GEFW J Ten Arm Operation Lever AD

322 PGiDM0148GEZZ J Ten Arm Guide AC

323 NGERH3045GEFWJ Segment Gear AD

324 MLEVF0472GEZZ J Tu Guide Ass'y AC

325 PGiDP0027GEZZ J Tu Guide AE

326 MSPRC0183GEZZ J Tu Guide Spring AA

327 MSPRC0184GEZZ J Si Roller Spring AA

328 MSPRC0208GEZZ J Tu Guide Lever Spring AC

329 LCHSS0049GEZZ J Slide Chassis Ass'y AP

330 MLEVF0495GEZZ J Ten Arm Ass'y AC

331 LBNDK3023GEZZ J Ten Band Ass'y AF

332 NiDR-0016GEZZ J Swing Gear Ass'y AF

333 NGERH1286GEZZ J Driving Gear AC

334 NGERH1287GEZZ J Pulley Gear AD

335 NPLYV0157GEZZ J Relay Pulley AD

336 MLEVP0284GEZZ J S Brake AC

337 NGERH1288GEZZ J Tu Brake Gear AC

338 MLEVP0285GEZZ J Tu Main Brake AC

339 MLEVP0286GEZZ J Tu Sub-Brake AC

340 MSPRD0169GEZZ J Tu Brake Spring AD

341 LHLDZ2053GEZZ J Light Guide Holder Ass'y AF

342 LANGG9102GEFWJ Down Guide AF

343 MSPRT0408GEZZ J Tension Spring AD

344 MSPRD0170GEZZ J S Brake Spring AD

345 CDRMU0032GE01 J Upper Drum Ass'y BF

346 PGiDM0154GEZZ J Tape Guide AB

348 QBRSK0039GEZZ J Earth Spring AD

349 PGiDM0143GEZZ J Drum Base AG

350 DDRML0020HE01 J Lower Drum Ass'y AY

351 RMOTP1137GEZZ J Drum Motor AS

352 PSPAQ0010GEZZ J Gap Adjusting Shim AC

353 NRTR-0096GEZZ J R Tr Rotor Ass'y AP

354 MSPRC0209GEZZ J Gr Adjusting Spring AC

355 LPOLM0058GEZZ J S Pole Base AK

356 LPOLM0059GEZZ J T Pole Base AK

357 NDAiV1071GEZZ J Sup Reel Support AG

358 NDAiV1072GEZZ J Tu Reel Support AG

359 MLEVF0517GEZZ J Pinch Lever Ass'y AS

360 NBLTT0012GEZZ J Timing Belt S AE

361 NBLTT0013GEZZ J Timing Belt L AE

362 NROLP0108GEZZ J Guide Roller Ass'y AG

363 NROLP0109GEZZ J Si Roller Ass'y AH

364 QPWBH5428GEZZJ Mode FPC AG

365 CPWBN5402GE01 J Sensor Ass'y BC

366 QSW-M0042GEZZ J Recognition SW AH

367 RDTCH0037GEZZ J Dew Sensor AF

368 RMOTV1019GEZZ J Cap. Motor AZ

369 RMOTM1075GEZZJ Load. Motor AL

370 QSW-R0038GEZZ J Mode SW AG

372 RAMP-0017TAN0 J H/A PWB AY

374 TLABH0196TAZZ J Caution Label AB

375 PSHEM0014GEZZ J Counter Balance AC

376 PSHEP0013GEZZ J Interruption Sheet AC

200 XAPSF17P03200 J Screw M1.7x3.2 AA

201 LX-XZ3036GEFP J Screw M2.0x6.0 AD

202 LX-BZ3175GEFN J Screw M1.7x4.0 AC

203 LX-BZ3163GEFN J Screw M1.7x2.5 AC

204 LX-HZ3074GEFN J Screw M1.7x5.3 S Tight AA

205 LX-BZ3177GEFF J Screw M1.4x1.5 AB

206 LX-BZ3132GEFF J Screw M1.4x1.5xD3.5 AA

207 LX-BZ3178GEZZ J Screw M1.4x1.5xD4.0 AD

208 LX-HZ3083GEFF J Screw M1.4x2.5 S Tight AB

209 LX-HZ3077GEFN J Screw M1.4x3.0 S Tight AA

211 LX-HZ3084GEFF J Screw M1.4x4.0 S Tight AC

212 LX-HZ3116GEFD J Screw M1.4x3.2 S Tight AB

213 LX-NZ3053GEZZ J Screw M1.4 Nut AC

214 LX-WZ1076GE02 J Washer D0.8xD3.0x0.2t AA

215 LX-WZ1075GE02 J Washer D2.1xD5.0x0.25t AA

216 XWHJZ12-02040 J Washer D1.2xD4.0x0.25t AC

Plastics

Plastics

Plastics

—— End of Mechanism Parts ——

OTHER PARTS

SUPPLIED ACCESSORIES

RRMCG0072TASA J Infrared Remote Control AP

RRMCG0073TASA J Infrared Remote Control

TiNSE0313TAZZ J Operation Manual AG

TiNSE0314TAZZ J Operation Manual AH

TiNS-6013TAZZ J Operation Manual

UBATM0010TAZZ J Battery (VL-E780U/785U) BC

UBATM0011TAZZ J Battery (VL-E785T) BC

UADP-0274TAZZ J AC Adapter —

UADP-0275TAZZ J AC Adapter (VL-E785T) —

ACCESSORIES

UBATL0011TAZZ J Lithium Battery —

UBATU0023GEZZ J AA Drycell Battery —

(NOT REPLACEMENT ITEM)

PACKING PARTS

SPAKC7399TAZZ – Packing Case(VL-E780U) —

SPAKC7403TAZZ – Packing Case(VL-E785U) —

SPAKC7404TAZZ – Packing Case(VL-E785T) —

SPAKP6049TAZZ – Wrapping Paper —

SSAKA0087TAZZ – Polyethylene Bag —

(VL-E780U/785U)

(VL-E785T)

(VL-E780U)

(VL-E785U)

(VL-E785T)

(VL-E780U/785U)

(NOT REPLACEMENT ITEM)

31

Page 32

VL-E780U

VL-E785U

VL-E785T

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

CABINET EXPLODED VIEW

54

34

37

38

43

b

1

b

45

46

12

11

9

10

9

10

8

b

15

2-2

2-3

5-4

5

5-2

c

5-5

5-3

5-6

48

e

1-2

e

50

18

21

51

13

49

a

3-2

j

H

3

a

a

G

26

27

30

c

b

28

29

F

31

b

33

4-2

a

4

a

39

47

c

49

32

d

d

16

17

E

6

6-16

b

d

D

C

6-3

6-2

6-10

6-5

6-6

d

6-7

7

7-2

6-15

6-4

h

h

b

25

c

g

6-14

6-12

6-9

6-9

6-8

b

b

53

b

6-13

b

6-11

20

35

36

c

c

41

40

b

42

44

1-3

e

1-4

52

b

56

14

a

B

b

b

b

b

7-4

7-3

d

7-5

A

f

d

22

23

f

f

24

2-4

2-5

2

123456

32

Page 33

VL-E780U

VL-E785U

VL-E785T

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

CABINET PARTS LIST

1 DCABA6183TAK3 J V Frame Service AL

(VL-E780U)

1 DCABA6183TAK1 J V Frame Service AL

(VL-E785U)

1 DCABA6183TAK2 J V Frame Service AL

(VL-E785T)

1-2 PSPAG0095TAZZ J VCR Lid Cushion AA

1-3 TLABH0355TAZZ J Lithium Exchange Label AB

(VL-E780U/785U)

1-3 TLABH0259TAZZ J Lithium Exchange Label AD

(VL-E785T)

1-4 LHLDB1027TAZZ J Lithium Holder AD

2 DCABB6184TAK3 J L Cabinet Service AS

(VL-E780U/785U)

2 DCABB6184TAK4 J L Cabinet Service

(VL-E785T)

2-2 QEARP0234TAFJ J LCD Earth Sheet AE

2-3 TLABH0318TAZZ J Facing Recording Caution AB

Label (VL-E780U/785U)

2-3 TLABH0326TAZZ J Facing Recording Caution AB

Label (VL-E785T)

2-4 GCOVH1226TASA J Jack Cover AD

2-5 GCOVA1535TAZZ J Remote Control Receptor AD

Cover

3 CCABC6091TAK4 J Camera Front Cabinet AT

Ass’y

3-2 GCOVA1539TASB J Lens Hood AK

4 DCABD6088TAK4 J Camera Rear Cabinet AS

Ass’y (VL-E780U/785U)

4 DCABD6094TAK2 J Camera Rear Cabinet

Ass’y (VL-E785T)

4-2 JBTN-0276TASB J Camera Button AF

5 DFTAC1277TAK1 J VCR Lid Service AU

(VL-E780U)

5 DFTAC1278TAK1 J VCR Lid Service AU

(VL-E785U/T)

5-2 HBDGS0059TASB J LCD Badge AE

5-3 LANGK0428TAFW J VCR Lid Reinforcing Angle AG

5-4 LANGK0400TAFW J Eject Fitting AD

5-5 PSPAZ0193TAZZ J VCR Lid Sheet AC

5-6 MSPRD0047TAFJ J VCR Lid Spring AD

6 CCOVA1536TAK5 J KS Side Cover AU

(VL-E780U/785U)

6 CCOVA1536TAK8 J KS Side Cover AT

(VL-E785T)

6-2 NSFTZ0049TAFW J Battery Lid Axle AC

6-3 MSPRD0050TAFJ J Battery Lid Spring AC

6-4 TLABH0264TAZZ J Recycle Label AB

6-5 GFTAB1066TAKA J Battery Lid AE

6-6 HDECP0045TASA J Battery Decoration Plate AC

6-7 LHLDZ1448TA00 J Battery Intermediate Lock AC

6-8 MSPRC0103TAFJ J Battery Intermediate Lock AD

Spring

6-9 MSPRC0102TAFJ J Battery Lock Lever Spring AA

6-10 MLEVP0030TASA J Battery Lid Open/Close AC

Lever

6-11 LHLDZ1449TAZZ J Battery Lock Holder AC

6-12 MLEVP0029TASA J Battery Lock Lever AC

6-13 MSPRC0101TAFJ J Battery Push-out Spring AD

6-14 LHLDZ1445TAZZ J Lens Holder AD

6-15 LANGK0398TA00 J Battery Lid Angle Fitting AH

6-16 UBNDT0122TAZZ J Hand Strap

7 DCOVA1538TAK1 J Tilt Ass’y AU

7-2 PSPAZ0190TAZZ J Tilt Spacer AE

7-3 GCOVA1537TAKA J Tilt Frame V AL

7-4 PSPAZ0189TAZZ J Rotation Spacer AD

7-5 LANGH0071TAFW J Stopper Fitting AD

8 LHLDZ1447TAZZ J LCD Holder AG

9 PSHEP0048TAZZ J Diffusion Sheet AE

10 PSHEP0047TAZZ J Prism Sheet AH

11 PGiDM0026TAZZ J Light Guide Plate AH

12 PMiR-0022TAZZ J Reflection Sheet AD

å 13 CLMPV0045TA01 J Lamp Inverter Unit

14 CPNLC0030RM02 J LCD Panel CE

15 PZETV0370TAZZ J LCD Glass Retaining AB

16 TLABM1930TAZZ J Model Label(VL-E780U) AC

16 TLABM1934TAZZ J Model Label(VL-E785U) AC

16 TLABM1935TAZZ J Model Label AD

(VL-E785T)

16 TLABG0118TAZZ J Tax Paying Label AC

(VL-E785T)

17 TLABN0174TAZZ J Serial No. Label(VL-E780U)AC

17 TLABN0175TAZZ J Serial No. Label AC

(VL-E785U)

18 CLNSA0127TA01 J Lens Unit BS

19 GFTAC1241TASA J Cassette Compartment AD

Cover

20 DUNTK2782QA10 J VCR Unit(VL-E780U) —

20 DUNTK2782QA11 J VCR Unit(VL-E785U) —

20 DUNTK2782QA17 J VCR Unit(VL-E785T) —

21 DUNTK2785QA01 J Camera Unit —

22 QPWBH2814TAZZ J Tilt FPC AQ

23 LHLDW1038TA00 J FPC Holder AC

24 QSW-Z0287TAZZ J VCR Operation Unit AW

(VL-E780U/785U)

24 QSW-Z0301TAZZ J VCR Operation Unit AV

(VL-E785T)

25 QTANZ0129TAZZ J Battery Terminal Unit AG

26 QSW-Z0285TAZZ J Power Unit AR

27 LHLDZ1452TAZZ J Power Lock Holder AC

28 MSPRC0083TAFJ J Power Lock Spring AA

29 JBTN-0277TASB J Power Button AF

30 LHLDZ1451TAZZ J Power Holder AC

31 JKNBP0152TASA J Power Knob AD

32 JKNBP0153TASB J Zoom Knob AF

33 LHLDZ1453TASA J Zoom Knob Holder AD

34 JKNBP0154TASA J Open Knob AC

35 PSPAZ0191TAZZ J Spacer AA

36 RMiCC0079TAZZ J Microphone AM

37 MSPRT0034TAFJ J Lid Lock Spring AC

38 LHLDZ1454TA00 J VCR Lid Lock AD

39 NSFTZ0084TAFW J VCR Lid Shaft AD

40 PSPAZ0192TAZZ J Microphone Lead Spacer AD

41 LHLDZ1450TAZZ J Speaker Holder AC

42 VSP0020P-94WN J Speaker AL

43 PSPAG0103TAZZ J Speaker Spacer AC

44 PCOVP9062TAZZ J Speaker Mesh AB

45 PSPAG0095TAZZ J VCR Lid Cushion AA

46 GCOVA3056TAKA J Speaker Cover AE

47 ZTAPEZ800020E J Tape —

48 QSW-Z0284TAZZ J Turn/Eject SW AH

49 MLEVP0031TAZZ J Eject Lever AC

50 LANGK0399TAFW J Tripod Angle Ass’y AK

51 PSHEP0074TAZZ J Microphone Lead Sheet AB

52 QJAKZ0071TAZZ J Jack Unit AS

53 PSPAG0084TA00 J Front Group Frame AD

Rubber

54 GCOVA3057TAKA J Microphone Cover AG

55 QPWBH2815TAZZ J CCD FPC AS

56 PSPAZ0209TAZZ J LCD Spacer AF

a LX-HZ0018TAFN J M2x6 Tapping, Silver AA

b LX-HZ0018TAFF J M2x6 Tapping, Black AA

c LX-HZ0045TAFN J M2x4 Tapping, Silver AA

d XiPSF20P04000 J M2x4 Small Screw, Black AA

Zinc Plating

e LX-BZ0191TAFD J M2 Special Screw AC

f XiPSD20P03000 J M2x3 Screw AA

g LX-UZ0016TAFD J M2x5 Special Screw AA

h LX-BZ0200TAFD J M2x7 Special Screw AB

i XiPSN20P04000 J M2x4 Small Screw, Silver AA

j LX-HZ0063TAFC J M1.7x6 Tapping, Silver AA

—— End of Cabinet Parts ——

33

Page 34

VL-E780U

VL-E785U

VL-E785T

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

CASSETTE HOUSING PARTS

400 CHLDX3077GE01 J Cassette Compartment AY

Assy

401 MSPRT0414GEZZ J Up Main Spring AD

402 MROD-0014GEFJ J Damper rod AG

403 PDMP-0013GEZZ J Cassette Compartment AG

Damper

—— End of Cassette Housing Parts ——

CASSETTE HOUSING CONTROL UNIT

D

403

402

400

401

C

401

B

A

123456

34

Page 35

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

12. PACKING OF THE SET

GCOVH1225TASA

(Lens Cap)

UADP-0274TAZZ

(VL-E780U/E785U)

UADP-0275TAZZ(VL-E785T)

(AC Adapter)

QCNW-1338TA00

(DC Cable)

★UBATU0023GEZZ

(Battery (AA x 2))

VL-E780U

VL-E785U

VL-E785T

UBNDS0010TASA

(Shoulder Strap)

RRMCG0072TASA

(Remote Control)

QCNW-1448 or 1295TAZZ

(A/V Cable)

★SPAKA6176TAZZ

(Packing ADD.)

Fold

down

★SPAKA6202TAZZ

(Packing ADD.)

UBATM0010TAZZ

(VL-E780U/E785U)

UBATM0011TAZZ(VL-E785T)

(Battery)

★UBATL0011TAZZ

(Lithium Battery x 2)

Fold down

★SPAKP6049TAZZ

(Wrapping Paper)

TiNSE0313TAZZ(VL-E780U)

TiNSE0314TAZZ(VL-E785U)

TiNS-6013TAZZ(VL-E785T)

(Operation Manual)

★SPAKA6237TAZZ

(Packing ADD.)

★SPAKC7399TAZZ(VL-E780U)

★SPAKC7403TAZZ(VL-E785U)

★SPAKC7404TAZZ(VL-E785T)

(Packing Case)

★ Not Replacement Item

35

Page 36

VL-E780U

VL-E780U

VL-E785U

VL-E785U

VL-E785T

VL-E785T

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

COPYRIGHT C 1998 BY SHARP CORPORATION

ALL RIGHTS RESERVED.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted in

any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without

prior written permission of the publisher.

Dec. 1998 Printed in JAPAN

SA. NS

SHARP CORPORATION

AV Systems Group

Quality & Reliability Control Center

Yaita, Tochigi 329-2193, Japan

36

Loading...

Loading...