Page 1

yp&yT

VL:E665Urr

SHARP

SERVICE MANUAL

SYBASJL-E630U

LIQUID CRYSTAL CAMCORDER

VL-E630U/T

VL=E680U

MODELS

In

the

interests

tions in

original

be used.

some

condition and

of

countries)

VL-E685U/T

user-safety

only parts

(Required by

the

set should be restored to its

identical to those specified

safety regula-

q

NTSC

2. SPECIFICATIONS

4. DISASSEMBLY OF THE SET

5. MECHANISM ADJUSTMENT..

6. ADJUSTMENT OF

8. SCHEMATIC DIAGRAMS..

11

.REPLACEMENT PARTS LIST

12.PACKlNG OF THE SET

SHARP CORPORATlON

..............................................................................................................................

....................................................................................................................

VCR..

....................................................................................................................

CONTENTS

.............................................................................................................

...........................................................................................................

................................................................................................................

..........................................................................................................

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page

2

3

4

5

8

29

35

Page 2

~p3o~fr

VL:E685Un

2. SPECIFICATIONS

Signal System:

Recording System:

Cassette:

Recording/Playback Time:

Tape Speed:

Pickup Device:

Lens:

Lens Filter Diameter:

Monitor:

Microphone:

Color Temperature Compensation

Minimum Illumination:

Video Output Level:

Audio Output Level:

Speaker Output:

Power Requirement:

Power Consumption:

Operating Temperature:

Operating Humidity:

Storage Temperature:

Dimensions (approx.):

Weight (approx.):

NTSC standard

2 rotary heads, helical

8 mm video tape, MP type

120 minutes (P6-

14.345 mm/second

l/4” (6.4mm, effective size: 4.5 mm) CCD image sensor with approx.

270,000 pixels including optical black

16 x power

46 mm

3” (7.5 cm)-full-color LCD screen (TFT active matrix)

Electret monaural microphone

Auto white balance

0.8 lux (5 lux measured by EIA standard) (with gain-up, F1.4)

1 .O Vp-p 75-ohm unbalanced

-8 dBs, impedance less than 2.2 kohms

200 mW

DC 3.6V

E630U:4.8W (during camera recording in full auto mode with zoom

motor off, and backlight in normal mode)

E680U/E685U:4.9W (during camera recording in full auto mode with

zoom motor off, Extend Zoom, DIS and Snapshot functions off, and

backlight in normal mode)

0°C to + 40°C (32°F to 104°F)

30% to 80%

-20°C to +6O”C (-4°F to 140°F)

7 5/32” (W) x 4 g/$ (H) x 3 7/~” (D)

[182 mm (W) x 109 mm (H) x 99 mm (D)]

1.52lbs (690g)

(without battery pack, lithium battery, video cassette, and lens cap)

zoom

scanning system

120)

lens (F1.4, f=4.0-64.0 mm) and full-range auto

focus

AC Adapter/Battery Charger Battery Pack BT-H22

UADP-0274TAZZ(VL-E63OU/680U/685U)

UADP-0275TAZZ(VL-E63OT/685T)

Power Requirement:

DC Output:

Power Consumption:

Dimensions (approx.):

Weight (approx.):

Specifications are subject to change without notice.

AC 11 O-240

4.5 v

16W

2

31/32” (W) x 2” (H) x 5 5/16” (D)

r/5mm(W)x51 mm(H)x

135 mm (D)]

0.65 Ibs (295 g)

V, 50160

Hz

Dimensions (approx.): 2 l/s” (W) x 3/4” (H) x 2 7/32” (D)

Weight (approx.): 0.30 Ibs (136 g)

DC Output: 3.6V

k$,mmm(OJ x 19 mm

SERVICE INFORMATION (For the U.S.)

For the location of the nearest Sharp Authorized Service, or to obtain product literature, accessories,

supplies or customer assistance, please call l -800-BE SHARP (l-800-237-4277) or visit SHARP’s

web site (http://www.sharp-usa.com)

O-4

x

Page 3

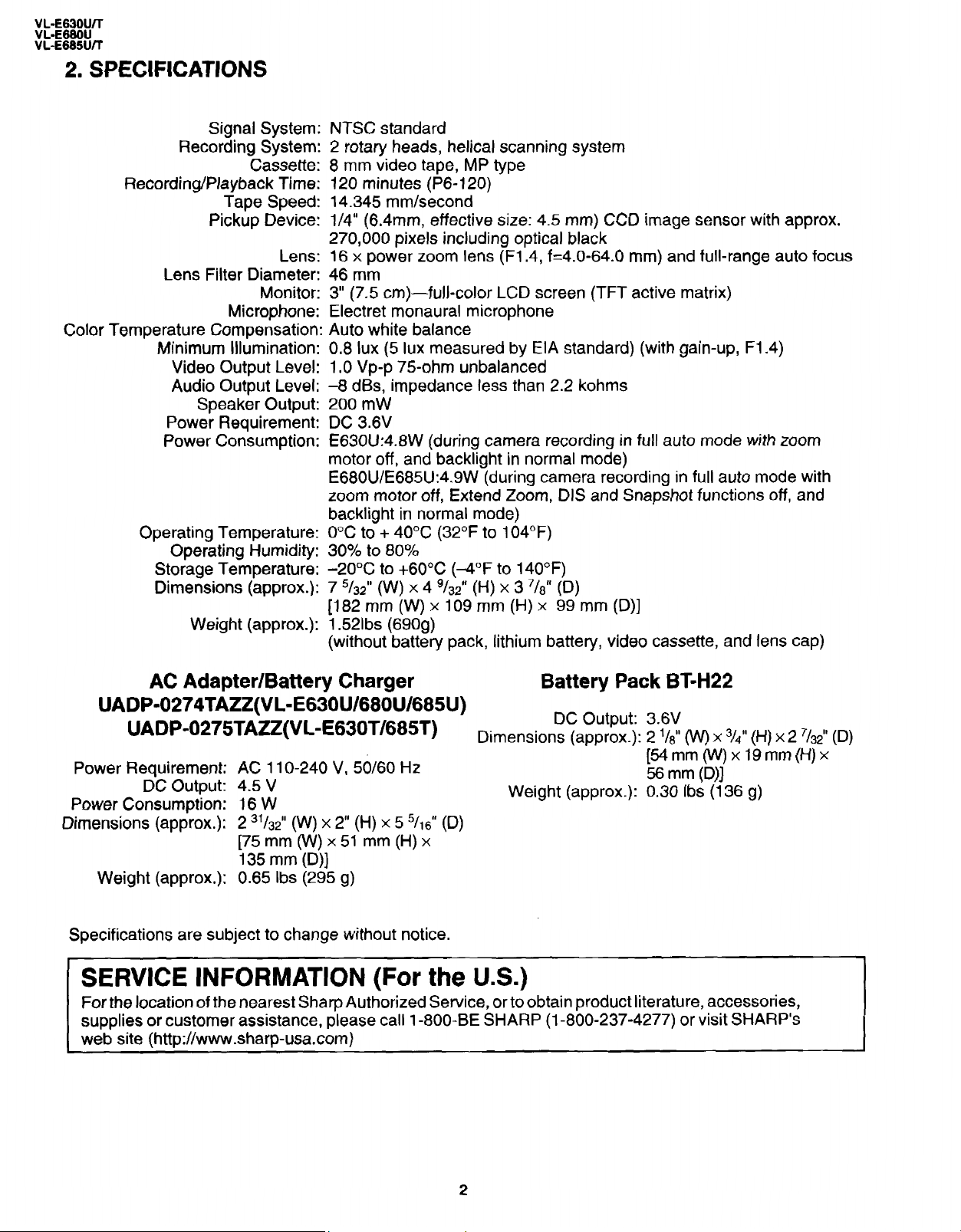

4. DISASSEMBLY OFTHE SET

4-2. Disassembly of the VCR main body

1. Removal of the VCR lid shaft

(l)Remove one screw ((j)LX-HZ0063TAFC).

4-3. REPLACEMENT OF CCD SENSOR

4-3-l. BEFORE REPLACEMENT

1) The CCD image sensor is more sensitive to electrostatic breakage than C-MOS LSI. Therefore sufficient means to

prevent electrostatic damage must be taken when it is replaced.

l Ground the soldering iron.

l Ground also the human body, using the wrist strap(through an 1 Mohm resistor).

l Until the CCDsensor is mounted on the PWB, fit it to the conductive sponge, and short-circuit the foot lead.

2) Take utmost care so that the surface glass of CCD sensor and optical filter are not contaminated and damaged. If any

contamination is found, for example fingerprint, wipe it off with silicon paper or clean chamois skin.

3) When replacing the CCD sensor, use the antistaic grounded soldring iron, and perform quickly soldering.

Index Mark

1 7

SHARP

LZ2413H5

4-4. INITIAL SE-KING OF EzPROM IC

4-4-2. IC702 (E*PROM)

When the IC702 has been replaced, make the following settings and adjustments.

Remove the backup battery (CR2029

1.

Turn power switch to CAMERA

2.

Setting up the V ADJ mode as follows.

3.

l

After press the CONTINUE key, press the VCR ADJ key on service remote control

(RRMCG0033TASA).

4. _ After setting the above data, clear the V ADJ mode and turn off the power by pull out the battery pack or DC cable.

Neglect about 30 seconds after turned of power, because data of address becomes effective after microcomputer is

reset.

Now the setting of data is completion.

Adjustments to follow

Make the system controller servo, VCR, and LCD adjustments according to their respective instructions.

3

Page 4

VL-E63olJ/l

VL-E68ou

VL-E685U/T

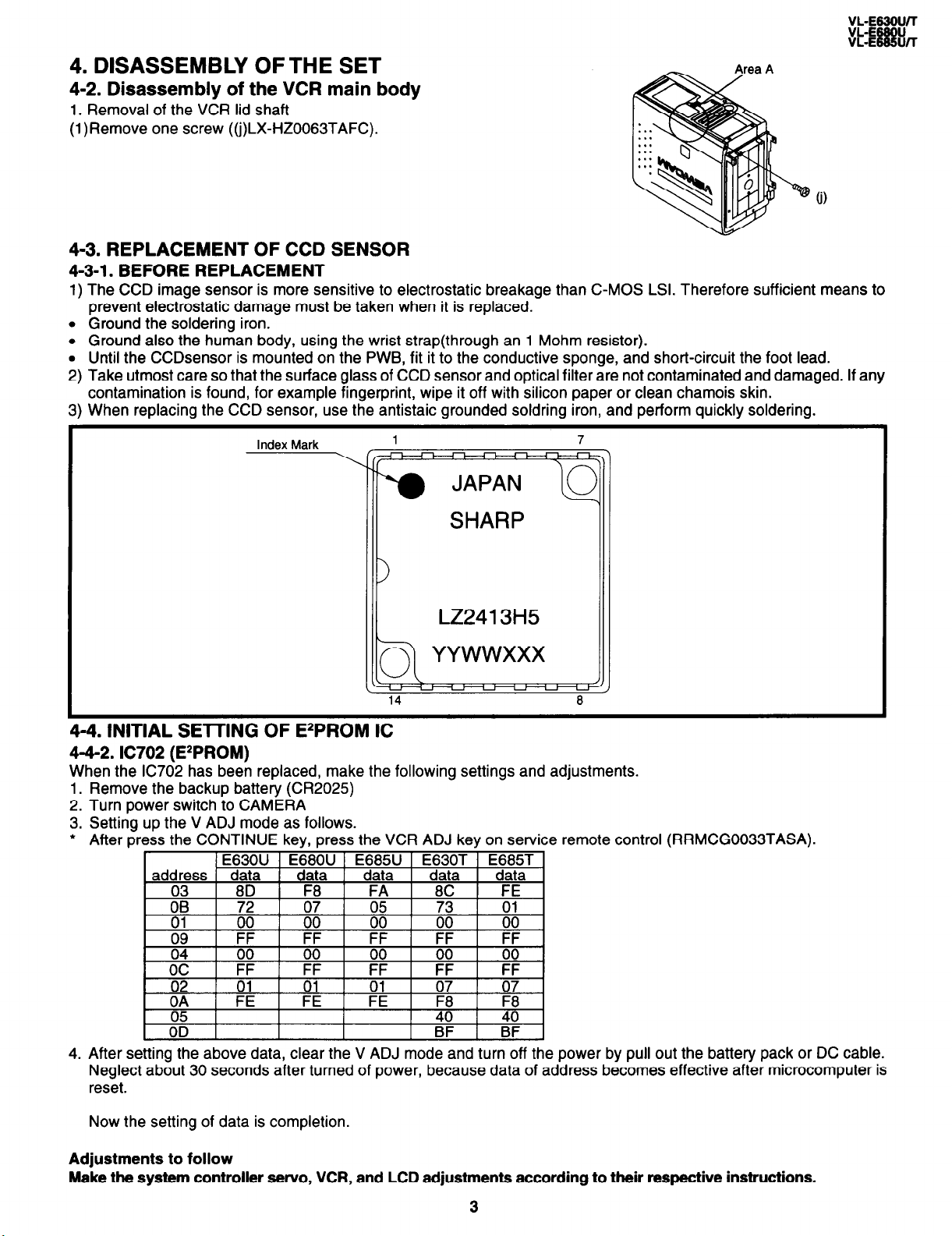

5.

MECHANISM

5-2.

Items and

5-2-l. Inspection

CheckingIvlaintenance point 5oo

Timing belt

Pinch

Capstan D.D. motor

Relay

Pulle gear shaft

Drive gear shaft

timings

and maintenance list

roller

Pulle shaft

ADJUSTMENT

of inspection and maintenance

I

t-

Usag

1,000

cl

-

-

-

!

time

E

,

1,5oc

Cl

0

q

-

q

-

-

-

hrs.)

?,OOO 3,000

cl

cl

no 00

* *

q

0 0

A A

A

l-l

*o 90

cl

cl

o q

A

I

Possible symptom

encountered

l

Lateral

l

Unclean head

l

Screen shaking

l

Improper S/N ratio

l

No color appears.

l Tape does not run.

l

Tape

l

Screen

l Abnormal sound

I

l

Not ejectable

l

The specific mode cannot be set.

noise

slackens.

shakes.

Remarks

Rollers

l

If abnormal rotation or

deflection

cant)

is found,

the roller.

Other

*Clean the tape con-

tacting areas. Besure

to use

cleaning agent.

.

Replace if failure is

found.

l

Apply oil.

(Oil:

Note:

After oil is applied to

the drive

slightly wipe it off with

swab.

l Replace if failure (ab-

normal sound) is de-

tected.

(signifi-

replace

than

rollers

the

specified

gear shaft,

)

Abnormal sound

PBNS-REW take-up torque

PBNS-REW back tension -

torque

Tu brake

HC (Head Cleaner)

Oil:

Grease: MORYCOAT YM-103/X5-6020

Screw locking agent: THERE BOND 1401 B

Cleaning liquid: Industrial-use ethyl alcohol

sr

-

-

*

-

0

0 : Replace.

0

* *

*

: Clean.

I

I

1

I I

I

I

I * I

I I

5-4. ADJUSTMENT OF MECHANISM TAPE TRAVEL SYSTEM

5-4-3. Adjusting the Si roller height

(2) Adjusting the Si roller

1 Playback the tape such to set the V/SR mode.

A :

Apply oil.

+

:

Check.

l

If conformance to the

standard is not ensured, replace part.

4

Page 5

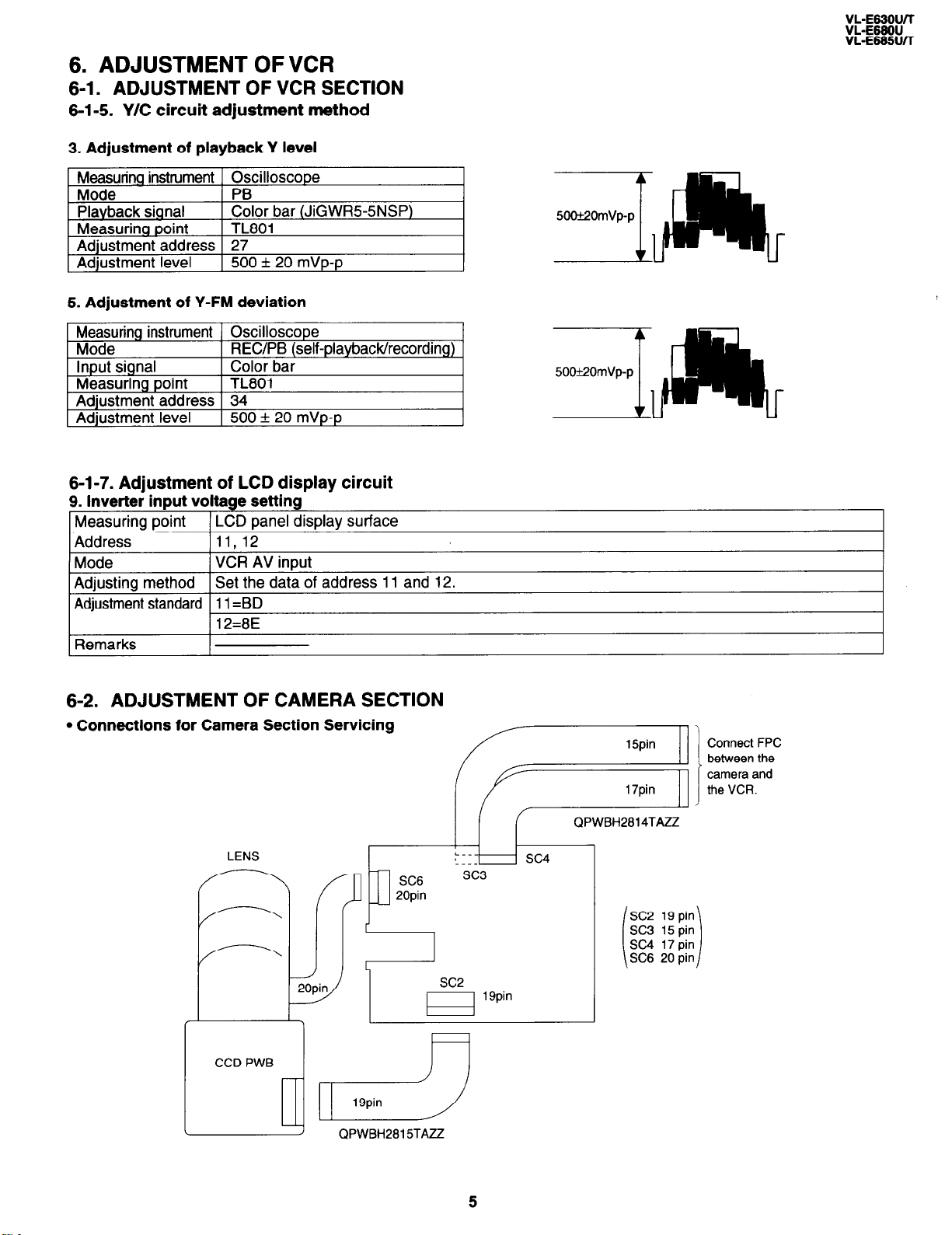

6. ADJUSTMENT OF VCR

6-1. ADJUSTMENT OF VCR SECTION

6-l-5. Y/C circuit adjustment method

3. Adjustment of playback Y level

~,

5. Adjustment of Y-FM deviation

Measuring instrument Oscilloscope

Mode REC/PB (self-playback/recording)

Input signal

Measuring point

Adjustment address 34

Adjustment level 500 f 20 mVp-p

6-l-7. Adjustment of LCD display circuit

9. lnverter input voltage setting

Measuring point

Address 11,12

Mode

Adjusting method

Adjustment standard 11 =BD

Remarks

Color bar

TL801

LCD panel display surface

VCR AV input

Set the data of address 11 and 12.

12=8E

6-2. ADJUSTMENT OF CAMERA SECTION

l Connections for Camera Section Servicing

LENS

-

F

CCD PWB

k-----k

20pin

i

SC3

Page 6

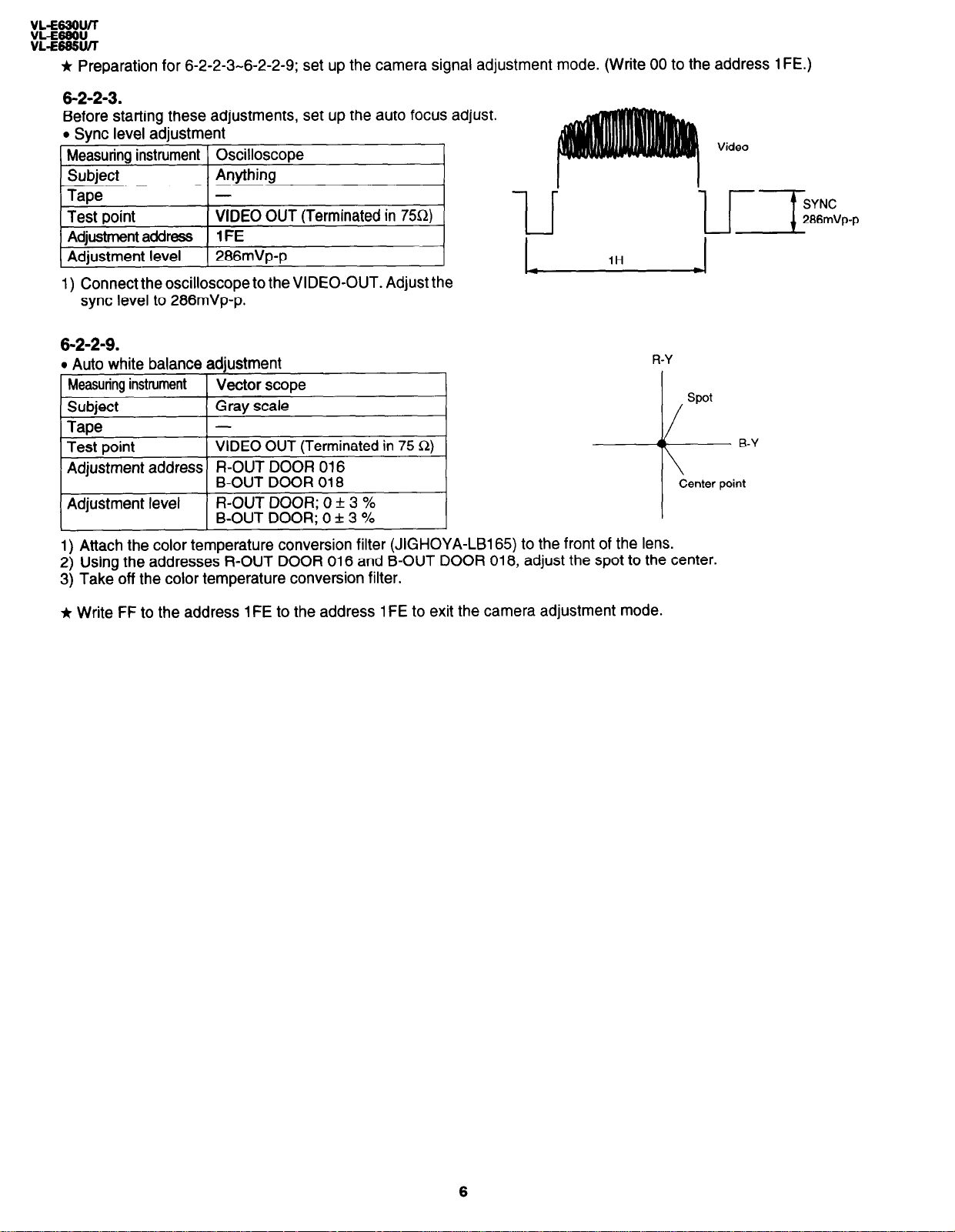

* Preparation for 6-2-2-3-6-2-2-9; set up the camera signal adjustment mode. (Write 00 to the address 1 FE.)

6-2-2-3.

Before starting these adjustments, set up the auto focus adjust.

l Sync level adjustment

Measuring instrument Oscilloscope

Subject

Tape

Test point

Adjustment address

Adjustment level

Anything

VIDEO OUT (Terminated in 75Q)

1FE

286mVp-p

1H

Video

1) Connect the oscilloscope to the VIDEO-OUT. Adjust the

sync level to 286mVp-p.

6-2-2-9.

l Auto white balance adjustment

Measuring instrument

Subject

Tape

Test point

Vector scope

Gray scale

VIDEO OUT (Terminated in 75 Q)

R-Y

spot

/

Adjustment address R-OUT DOOR 016

B-OUT DOOR 018

Adjustment level

R-OUT DOOR; 0 + 3 %

B-OUT DOOR; 0 + 3 %

1) Attach the color temperature conversion filter (JIGHOYA-LB165) to the front of the lens.

2) Using the addresses R-OUT DOOR 016 and B-OUT DOOR 018, adjust the spot to the center.

3) Take off the color temperature conversion filter.

Ir Write FF to the address 1 FE to the address 1 FE to exit the camera adjustment mode.

Page 7

-MEMO-

_-_------___-------________________________-_------________-----______-------_____-------_

_____------_____----------______-------_________---__________-_-__________--_________-----

_-______---_______-----________---________________________________________________________

____------______-------____-_-----_____________________-_____________________--________---

_-----___-------___------------~~~----------~___--------____------~__--------~~__--_---~~~

------___--________----__---------________________________________________________________

_-_-_____--________----_____________________________________~________________--________---

~----___------__----------~~~~----------_____-----_____-----_______---______----_____-----

____------_---------__--------________________________________________________--__________

_-_--______-----____-_--------_______---_______---________--_________-________--_______---

______----______----____________________________________________________________________-_

___---________----______------___________________-________--________--_______---_____----~

Page 8

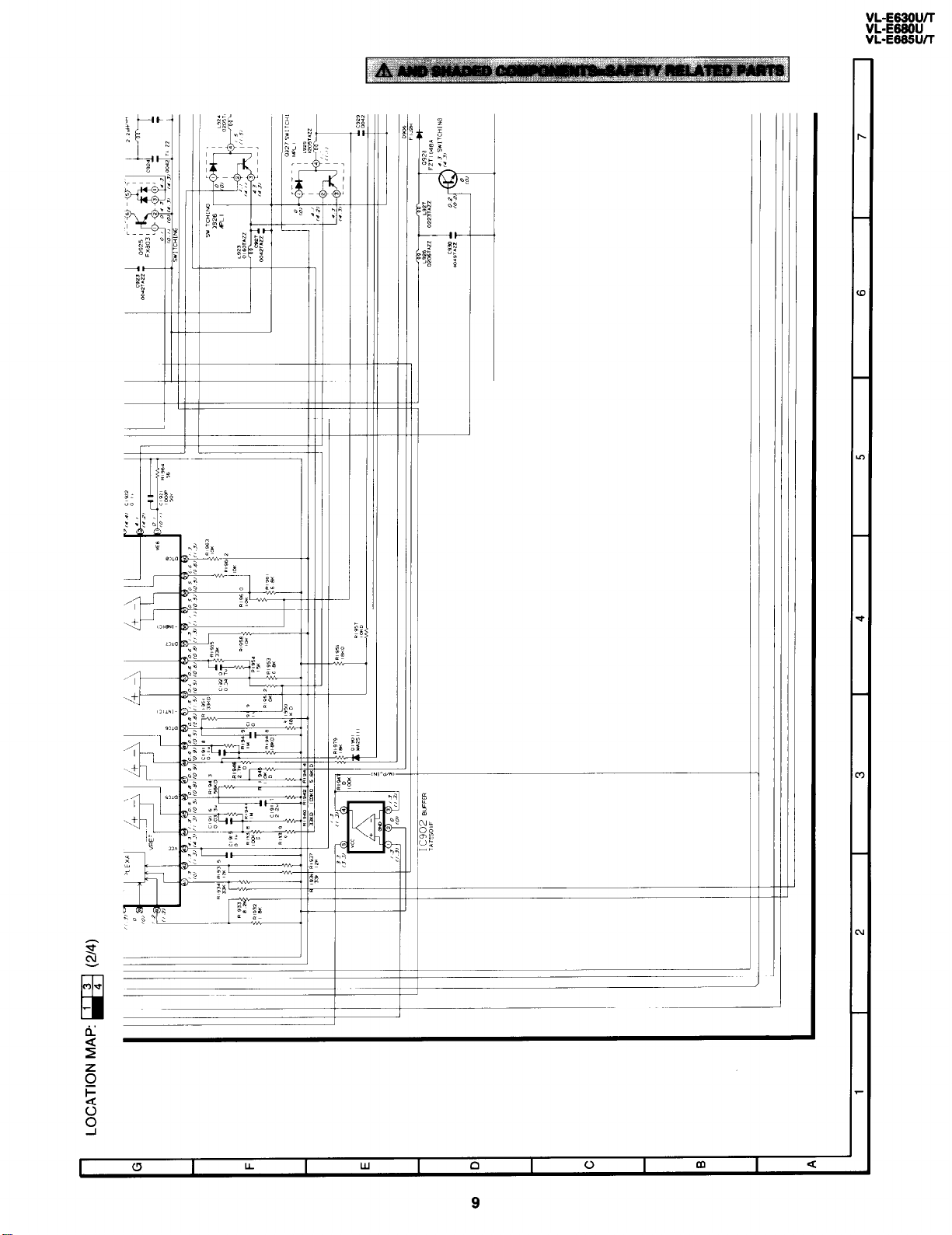

8. SCHEMATIC DIAGRAM

8-2. POWER CIRCUIT SCHEMATIC DIAGRAM

I -

-f

8

Page 9

VL-E63OWT

VL-E66OU

VL-E66!5U/T

‘t

9

Page 10

c-

i

10

/--I

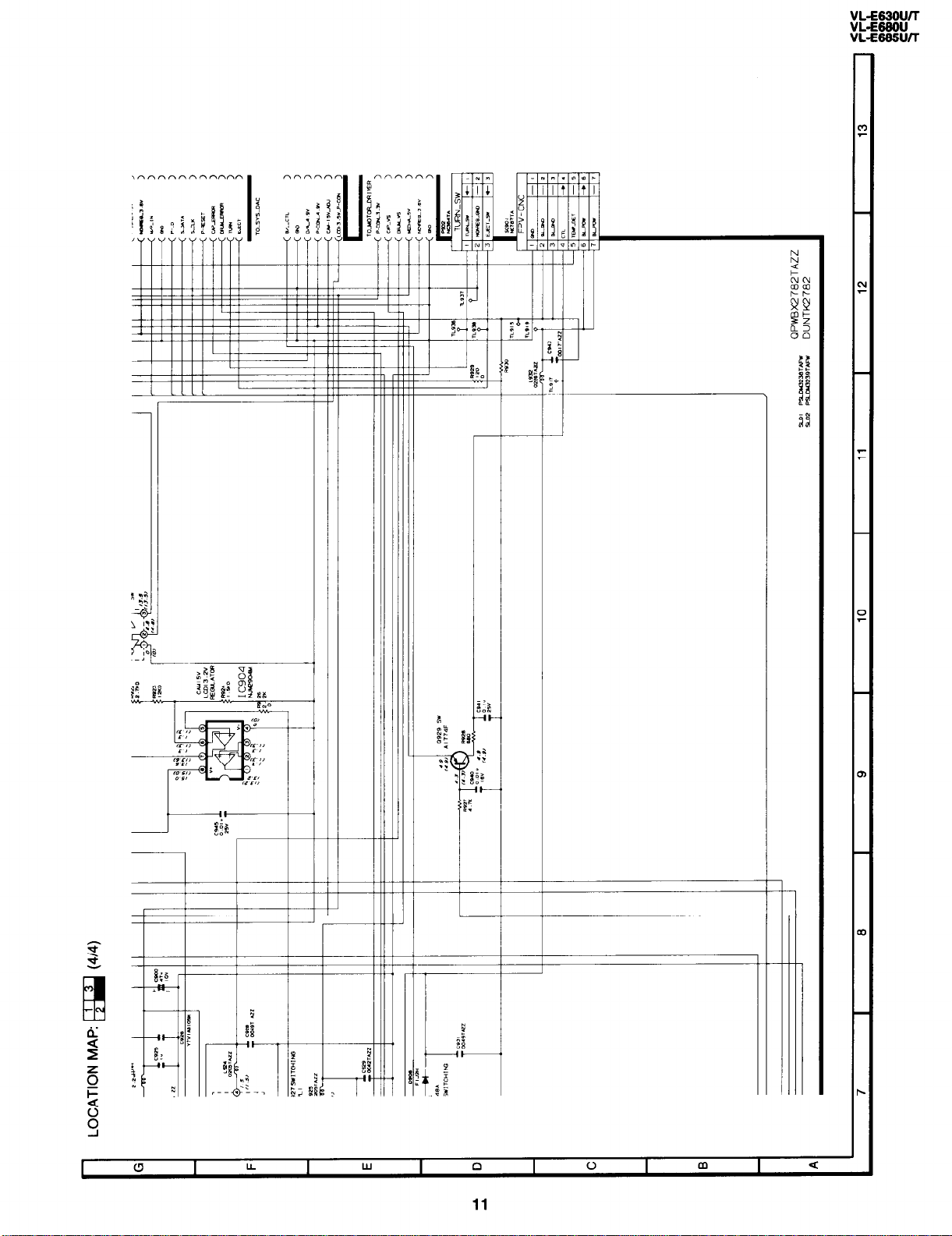

Page 11

_

_

_

_

11

Page 12

8-3. AUDIO CIRCUIT SCHEMATIC DIAGRAM

Page 13

8-4. MOTOR DRIVER SCHEMATIC DIAGRAM

K

I

I I

I

---

1

71

1

I

2 I 3 I

4

I

5

I

6

I

7

1

13

Page 14

kE~uwr

vL-E66!w/-r

8-5. LCD DISPLAY CIRCUIT

SCHEMATIC DIAGRAM

/

I

_

-pfl

“0

9

mt

:; ::%I

&.

L

14

Page 15

-

I

-

166

/ Y--

I

-

_

_

_

_

I i

Page 16

l-l

r

I

I-

-c

16

Page 17

11

t

.

E

t

ta

In

i

VL-E630UK

VL-E66OU

VL-E666UIT

Page 18

8-6. RF CIRCUIT SCHEMATIC DIAGRAM

H

c

G

F

TO_YC

E

1:

D

C

Fc

r

6

QPWX2782TAZZ

DUNTK2782

4

a

A

-

1

I

2

I

3

I

4

I

5

I

I !j

2 v

r

6

I

7

1

18

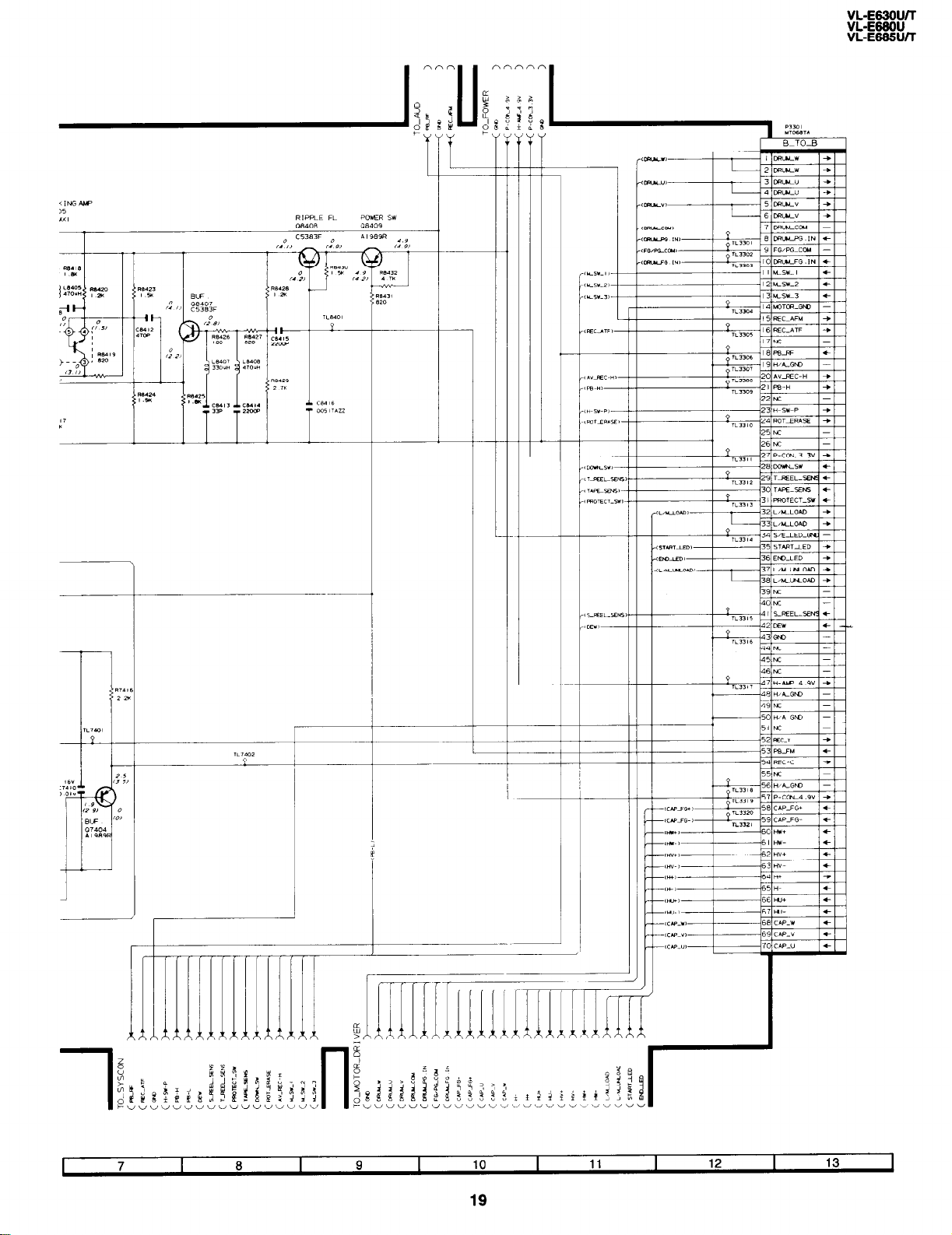

Page 19

I 7

I

8 I 9

I 10 I

11

I 12 I 13 I

19

Page 20

8-7. SYSTEM CONTROL CIRCUIT SCHEMATIC DIAGRAM

_

8

0

c

Page 21

VL-E63OW

VL-E68OU

VL-E6WJK

Page 22

:‘

:I

_

_

_

Page 23

t i

I T

t

t

t

t

i 1

I

------

23

I

Page 24

l See (S38N9VL-E61OU)Page 8-23 When replacing the IC401

ADJ BUF

0406

2PA ,774,-i

LOCATION MAP: m (l/4)

1:

TO-POWER

( P-cmL4 9”

C-NT SAURCE

01403

C5383F

01402

A1989R

RIPPLE FL

VIDEO DR,“ER ;;:;:,,,

Page 25

c

A-

- I

- l-l-l- -1 III1 I

I I

-

-

-

+

25

Page 26

I

QPWBX2782TAZZ

DUNTK2782

I I

I I I I I I

,

t

LOCATION MAP: Eq (3/4)

IC401

8-K SlGNAL PROCESS

AN2492F

I

Page 27

I 1

I I +

JJJJJJJJJJ

6

:

’

c

I I I I

I

C

.

1

C

r

a

a

P

I

a

I

LL

I

w

I

n

I

0

I

m

I

a

27

Page 28

8-10. D/A CIRCUIT

SCHEMATIC DIAGRAM

i%

:I

_

-

t

1

T

-

-

_

-

=

=

II

=

_

_

_

_

_

28

Page 29

11.

REPLACEMENT PARTS

LIST/

EXPLODED VIEWS

ELECTRICAL

Pans

marked

with

“A”

set.

Be sure

the

safety

Les pieces marquess “A”

de

I’appareil. Ne

numero

fonctinnement

in USA:

*MARK

in

CANADA:

To

have

the

following

L’ASSEMBLANGE P.C.I. EST UN ARTICLE NON REMPLACABLE

Ref.

to replace these parts

and

est

specific

((

HOW

Contact

location

Call Toll-free 1-IBEBOO-SHARP

:

SPARE PARTS-DELIVERY SECTION:ALL

Contact

Phone (416) 890-2100.

your order

informations.

1.

MODEL

3. PART NO.

5. PRICE CODE

PWB

No.

are

performance

sont

remplacer

pour maintenir

de

I’appareil.

TO ORDER

your nearest

of SHARP

SHARP Electronics

filled

NUMBER 2.

A

MARK:

A PIECES: RELATIVES A LA SECURITE

ASSEMBLY IS NOT

Part

No.

PRINTED WIRING BOARD ASSEMBLIES

(NOT REPLACEMENT ITEM)

DUNTK2782QA14 J

DUNTK2782QAl2

DUNTK2782QAl3 J

DUNTK2782QAl5 J

DUNTK2782QAl6

DUNTK2785QAOO J

DUNTK2785QAOl

DUNTK2782QA14 VCR UNIT(VL-E830U)

/ DUNTK2782QA12 VCR UNIT(VL-E880U)

DUNTK2782QA13

DUNTK2782QA15 VCR UNIT(VL-E630T)

DUNTK2782QA16 VCR UNIT(VL-E685T)

INTEGRATED CIRCUITS

IC703

IC705

IC904

Q415

Q602

C638

Cl912 VCKYTVlCB474K J 0.47 16V Ceramic

RH-iX0609TAZZ J CXP87460-126R

RH-iX0612TAZZ J IX0612TA

VHiNJM2904M-1 J NJM2904M

TRANSISTORS

VS2PAl774R/-1 J Transistor

VSRTl N441 U/-l J

VCKYCYlCBl04K J 0.1

PARTS

important

with

of

the set.

importantes pour

ces pieces que

REPLACEMENT

Parts Distributor,

promptly and correctly, please furnish

SAFETY RELATED

Ir

J

J

J

LIST

for maintaining

specified ones

la

securite et

maintenir la

par

des pieces

the

safety

for

proteger

PARTS

SHARP

REPLACEMENT

Parts

Distributor. For

of Canada

REF.

4. DESCRfPTlON

PARTS

Limited

NO.

ITEM

Description

VCR Unit(VL-E63OU)

VCR

Unit(VL-E680U) -

VCR

Unit(VL-E685U)

VCR Unit(VL-E63OT) VCR Unit(VL-E685T) CAMERA

CAMERA Unit

(vL-E68ou/685u/T) -

Unit(VL-E630U/T)-

VCR UNIT(VL-E885U)

Transistor

CAPACITORS

16V Ceramic

of

maintaining

securite

dont

le

*

JAPAN

Code

the

bon

-

-

AY

AR

AE

AB

AB

AB

AC

Ref.

No.

R826

R950

R1820

Rl821

Rl901

Rl901

le

R2781

DUNTK2785QAOO

DUNTK2785QAOl

Part No.

VRS-CZl

VRS-CZl JF102J

VRS-CZl

VRS-CZl JF393J

VRS-CZl

VRS-CZl

VRS-CZl JFlO3J

JFl24D

JF393J

JFlO3J

JF332J

CAMERA UNIT(VL-E680U/685U)

*

-

120k

J

lk

J

39k

J

39k

J

10k

J

(VL-ESSOU/68OU)

3.3k 1116W

J

(VL-E630T/685U/T)

1

Ok

J

CAMERA

Description

lll6W Metal Oxide

l/l

6W

Metal

lil6W

1116W

1116W

1/16W

Oxide AA

Metal

Oxide

Metal

Oxide AA

Metal

Oxide AA

Metal

Oxide AA

Metal Oxide

UNIT(VL-E630U)

Code

AA

AA

AA

INTEGRATED CIRCUITS

IC251

lC252

IC501

IC501

RH-iX0490TAZZ

VHiMS548331-1

RH-iXO59OTAZZ

RH-iX0589TAZZ

J

IX0490TA

(VL-E68OU/685U/T)

J

MSM548331TSK

(VL-E68OU/685U/T)

J

UPD784036GK515

(VL-E630U)

J UPD784037GK513

(VL-E68OU/685U/-T)

BB

BD

AW

AX

COIL AND TRANSFORMERS

L251

L252

VPAXMlOOKR42N

VPAXMlOOKR42N J Peaking

J Peaking 10pH 10%

(VL-E680U/685U/T)

1 OpH 10%

(VL-E680U/685U/T)

AC

AC

CAPACITORS

c251

C252

C253

C254

C255

C256

C257

C258

c259

C260

C261

VCSATAOJJl56M J 15

VCKYCZl

VCKYCZlHFlO3Z J

VCKYCZl

VCKYCZl AFl04Z J

VCKYCZI HFIOSZ

VCKYCZl AFlO4Z

VCKYCZl HFlO3Z J

VCKYCZl AFlO4Z J

VCSATAOJJl56M J

VCKYCZlHFlOSZ J

HFl03Z

HFl03Z J

J 0.01

J

J

6.3V Tantalum

(VL-E680U/685U/T)

50V

1

OV

1 OV

1

OV

6.3V

Ceramic

Ceramic

Ceramic

Ceramic

Ceramic

Ceramic

Ceramic

Ceramic

Tantalum

Ceramic

(VL-E680U/685U/T)

0.01 50V

(VL-E680U/685U/-T)

0.01 50V

(VL-E68OU/685U/T)

0.1

(VL-E68OU/685U/T)

0.01 50V

(VL-E680U/685U/-T)

0.1

(VL-E68OU/685U/-T)

0.01 50V

(VL-E680U/685U/-T)

0.1

(VL-E68OU/685U/T)

~VSL-ESSOU/~~~UI-T)

0.01 50V

(VL-E680U/685U/T)

AC

AB

AB

AB

AB

AB

AB

AB

AB

AC

AB

RESISTORS

R252

R254

R256

R536

R576

R582

R597

VRS-CZlJFOOOJ J 0

VRS-CZlJFOOOJ J 0

VRS-CZlJFOOOJ J 0

VRS-CZl JFl53J J 15k 1116W Metal Oxide

VRSCZlJF393J J 39k 1/16W

VRSCZlJF334D J 330k 1/18W Metal Oxide

VRSCZiJF244D J 240k 1/16W Metal Oxide

l/l 6W Metal Oxide

(VL-E68OU/685U/T)

l/l 6W Metal Oxide

(VL-E68OU/685U/T)

l/l 6W Metal Oxide

(VL-E68OU/685U/-T)

Metal Oxide

AA

AA

AA

AA

AA

AA

AA

R447

R454 VRS-CZlJFl02D J 1 k

R455

R719

VRSCZlJFl22J J 1.2k lIl6W Metal Oxide AA

VRSCZlJFl02D J 1 k

VRSCZlJF822J J 8.2k 1/16W Metal Oxide AA

RESISTORS

1116W Metal Oxide AA

1/16W Metal Oxide AA

29

Page 30

k&E=

VL-E665UTT

MECHANISM CHASSIS EXPLODED VIEW

I

i

Page 31

Ref. No. Part No. +

Description Code

Ref. No.

Part No. t

Description Code

MECHANISM PARTS

300

301

302

303

304

305

306

307

308

309

310

311

312

313

314

315

316

317

318 MSPRT0407GEZZ J

319

321

322

323

324

325

326

327

328

329

330

331

332

333

334

335

336

337

338

339

340

341

342

343

344

345

346

348

349

350

351

352

353

354

355

356

357

358

359

360

361

362

363

364

366

367

368

369

370

372

LCHSMOl63GEZZ J

NGERH1280GEZZ J

NGERH1281GEZZ J

MLEVF0470GEFW J

MLEVF0492GEFW J

LHLDZl966GEZZ J

NGERWl064GEZZJ

NGERW1065GEZZJ

NGERH1282GEZZ J

NGERHl283GEZZ J

MARMMOl26GEZZJ

MARMMOl28GEZZJ

LANGAOOBOGEFW J

PGiDMOl46GEZZ J

PGiDM0171 GEZZ J

NGERH1284GEZZ J

NGERH1285GEZZ J

MSPRD0167GEZZ J

MLEVP0310GEZZ J

MSLiF0074GEFW J

PGiDM0148GEZZ J

NGERH3045GEFWJ

MLEVF0472GEZZ J

PGiDP0027GEZZ J

MSPRC0183GEZZ J

MSPRC0184GEZZ J

MSPRCO208GEZZ J

CCHSS0049GEOl J

MLEVF0495GEZZ J

LBNDK3023GEZZ J

NiDR-0016GEZZ J

NGERH1286GEZZ J

NGERH1287GEZZ J

NPLYV0157GEZZ J

MLEVP0284GEZZ J

NGERH1288GEZZ J

MLEVP0285GEZZ J

MLEVP0286GEZZ J

MSPRD0169GEZZ J

LHLDZ2053GEZZ J

LANGG91 MGEFWJ

MSPRT0408GEZZ J

MSPRD0170GEZZ J

CDRMU0032GEOl J

PGiDMOl54GEZZ J

QBRSK0039GEZZ J

PGiDMOl43GEZZ J

DDRML0020HEOi J

RMOTPl137GEZZ J

PSPAQOOlOGEZZ J

NRTR-0096GEZZ J

MSPRC0209GEZZ J

LPOLMOO58GEZZ J

LPOLMOO59GEZZ J

NDAiV1071GEZZ J

NDAiVl072GEZZ J

MLEVFO517GEZZ J

NBLTT0012GEZZ J

NBLTT0013GEZZ J

NROLPO108GEZZ J

NROLPOlOSGEZZ J

QPWBH5428GEZZ J

CPWBN5402GEOl J

QSW-MOO42GEZZ J

RDTCHOO37GEZZ J

RMOTVl 01 SGEZZ J

RMOTM1075GEZZJ

QSW-R0038GEZZ J

RAMP-0017TAN0 J H/A PWB

Main Chassis Ass’y

Main Cam

Sub-Cam

Eject Lever

M Function Lever

L Block Holder

Worm Pulley

Worm

Worm Wheel

Lo Relay Gear

S Lo Arm Ass’y

T Lo Arm Ass’y

S Lo Arm Retainer

Sup Rail

Tu Rail

Sup Lo Gear

Tu Lo Gear

S Lo Arm Double-Acting

Spring

T Lo Arm Double-Acting

Spring

HC Lever Ass’y

Ten Arm Operation Lever

Ten Arm Guide

Segment Gear

Tu Guide Ass’y

Tu Guide

Tu Guide Spring

Si Roller Sprint

Tu Guide Lever Spring

Slide Chassis Ass’y

Ten Arm Ass’y

Ten Band Ass’v

Swing Gear A&y

Drivina Gear

Pulley”Gear

Relay Pulley

S Brake

Tu Brake Gear

Tu Main Brake

Tu Sub-Brake

Tu Brake Spring

Light Guide Hoiber Ass’y

Down Guide

Tension Spring

S Brake Spring

Upper Drum Ass’y

Tape Guide

Earth Spring

Drum Base

Lower Drum Ass’y

Drum Motor

Gap Adjusting Shim

R Tr Rotor Ass’v

Gr Adjusting Spring

S Pole Base

T Pole Base

Sup Reel Support

Tu Reel Support

Pinch Lever Ass’y

Timing Belt S

Timing Belt L

Guide Roller Ass’v

Si Roller Ass’y

Mode FPC

Sensor Ass’y

Recognition SW

Dew Sensor

Cap. Motor /

Load. Motor

Mode SW

AW

AD

AD

AD

AF

AD

AC

AD

AC

AC

AF

AG

AD

AD

AC

AC

AE

AC

AD

AC

AD

AC

AE

AA

AA

AC

AC

AF

AC

AD

AD

AC

AC

AC

AC

AD

AF

AD

AD

BE

AB

AD

AG

AY

AS

AC

AP

AC

AK

AK

AG

AG

AS

AE

AE

AG

AH

AK

AH

AF

AZ

AG

AY

374

375

376

200

201

202

203

204

205

206

207

208

209

211

212

213

214

215 LX-WZl075GE02 J

216 XWHJZ12-02040 J

TLABH0196TAZZ J

PSHEM0014GEZZ J

PSHEP0013GEZZ J

XAPSF17P03200 J

LX-XZ3036GEFP J

LX-BZ3175GEFN J

LX-BZ3163GEFN J

LX-HZ3074GEFN J

LX-BZ3177GEFF J

LX-BZ3132GEFF J

LX-BZ3178GEZZ J

LX-HZ3083GEFF J

LX-HZ3077GEFN J

LX-HZ3084GEFF J

LX-HZ31 16GEFD J

LX-NZ3053GEZZ J

LX-WZ1076GE02 J

Caution Label AB

Counter Balance

Interruption Sheet

Screw Ml .7x3.2

Screw M2.0x6.0

Screw Ml .7x4.0

Screw Ml .7x2.5

Screw Ml .7x5.3 S Tight AA

Screw Ml .4x1.5

Screw Ml .4x1.5xD3.5

Screw Ml .4x1.5xD4.0

Screw Ml .4x2.5 S Tight

Screw Ml .4x3.0 S Tight

Screw Ml .4x4.0 S Tight

Screw Ml .4x3.2 S Tight

Screw Ml .4 Nut

Washer D0.8xD3.0x0.2t

Plastics

Plastics

Washer D1.2xD4.0x0.25t

Plastics

- End of Mechanism Parts -

OTHERPARTS

SUPPLIED ACCESSORIES

TiNSEO31 OTAZZ J

TiNSE031lTAZZ J

TiNSEOBlPTAZZ J

TiNS601lTAZZ J

TiNS-6012TAZZ J

UBATLOOllTAZZ J

UBATMOOl OTAZZ J

UBATMOOl 1 TAZZ J

UBATUOO23GEZZ J

RRMCG0072TASA J

UADP-0274TAZZ J

UADP-0275TAZZ J

PACKING PARTS(NOT REPLACEMENT ITEM)

SPAKC7390TAZZ J Packing Case(VL-E68OU) SPAKC7380TAZZ J Packing Case(VL-E63OU) SPAKC7394TAZZ J Packina CaselVL-E685U) SPAKC7384TAZZ J Packing Case(VL-E63OTj SPAKC7395TAZZ J Packing Case(VL-E685T) -

Operation Manual

(VL-E630U)

Operation Manual

(VL-E680U)

Operation Manual

(VL-E685U)

Operation Manual

(VL-E630T)

bperation Manual

(VL-E685T)

Lithium Battery

Battery

(VL-E630U/680U/685U)

Battery

(VL-E630T/685T)

AA DRYCELL Battery x 2

Remote Control

AC Adapter

(VL-E630U/680U/685U)

AC Adapter

(VL-E630T/685T)

AC

AC

AA

AD

AC

AC

AB

AD

AB

AA

AC

AC

AA

AA Washer D2.1xD5.0x0.25t

AC

31

Page 32

CABINET EXP

n

F

‘LODED VIEW

/

----I

I

9

5

/‘l-b

/\

‘.

34

P

D

C

B

E

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

1

I

A

il

1

I

2

I

3

I

32

4

I

5

I

6

1

Page 33

Ref. No. Part No. *

Description

VL-E639U/T

VL-E68fXf

VL-E685U/T

Code Ref. No. Pert No. Ir Description Code

CABINET PARTS LIST

1

1

1-2 PSPAG0095TAZZ J

l-3

l-4

2 DCABB6183TAK5 J

2 DCABB6183TAK6 J

2-2 QEARP0233TAZZ J

2-3 TLABHO318TAZZ J

2-4 GCOVH 1228TASA J

2-5

2-6

3

3

3-2 GCOVAl539TASB J

4 DCABD6090TAK2 J

4 DCABD6088TAK4 J

4 DCABD6093TAK2 J

4 DCABD6094TAK2 J

4-2 JBTN-0276TASA J

4-2

4-2 JBTN-0277TASA J

4-2 JBTN-0277TASB J

5

5 DFTACl272TAKl J

5

5-2

5-3

5-4

5-5 PSPAZOl93TAZZ J

5-6

6

6

6-2 NSFTZ0049TAFW J

6-3

6-4 TLABH0264TAZZ J

6-5 GFTABl066TAKA J

6-6

6-6

6-7

6-8

6-9 MSPRC0102TAFJ J

6-10

6-11

6-12

6-13

6-14

6-15

6-16

7

DCABA6183TAKl J

DCABA6183TAK2 J

TLABH0326TAZZ J

LHLDBlO27TAZZ J

GCOVAl535TAZZ J

ZTAPEZ800020E J

CCABC6090TAK2 J

CCABC6091 TAK4 J

JBTN-0276TASB J

DFTAC1271TAKl J

DFTACl273TAKl J

HBDGSOO59TASB J

LANGKO428TAFW J

LANGK0400TAFW J

MSPRD0047TAFJ J

CCOVAl536TAK5 J

CCOVAl536TAK8 J

MSPRD0050TAFJ J

HDECPO045TASA J

HDEC P0047TASA J

LHLDZl448TAOO J

MSPRCOl03TAFJ J

MLEVP003OTASA J

LHLDZ1449TAZZ J

MLEVPOO29TASA J

MSPRCOlOlTAFJ J

LHLDZ1445TAZZ J

LANGK0398TAOO J

UBNDTOlPSTAZZ J

DCOVAl538TAKl J Tilt A&y

V Frame Service AL

(VL-E630U/680U/685U)

V Frame Service ’

(VL-E630T/685T)

VCR Lid Cushion

Liiium Exchange Label AB

(Only VL-E630TI685T)

Lithium Holder

L Cabinet Service

(VL-E630U/680U/685U)

L Cabinet Service

(VL-E630TI685T)

LCD Earth Sheet

Facing Recording Caution AB

Label

Jack Cover

Remote Control Receptor AD

Cover

Tape

Camera Front Cabinet AT

Ass’vNL-E63OUIT)

Cam&a Front Cabinet

Ass’y(VL-E680U/685U/)

Lens Hood AK

Camera Back Cabinet A0

Ass’y(VL-E63OU)

Camera Back Cabinet AS

Ass’y(VL-E680U/685U)

Camera Back Cabinet

Ass’y(VL-E630T)

Camera Back Cabinet

Ass’y(VL-E685T)

Camera Button AD

(VL-E63OU)

Camera Button

(VL-E680U/685U)

Camera ButtonlVL-E63OT) AD

Camera Button(VL-E685Tj AF

VCR Lid Service

(VL-ESSOU/T)

VCR Lid Servfce(VL-E680U)

VCR Lid Service

ⅇ;eT)

VCR Lid Reinforcing Angle AG

Eject Fitting - - AD

VCR Lid Sheet AC

VCR Lid Spring

KS Side Cover

(VL-E630U/680U/685U)

KS Side Cover(VL-E63OT/685T)

Battery Lid Axle

Battery Lid Spring

Recvcle Label _. AB

AA

AD

AS

AE

AD

-

AF

AU

AE

AD

AU

AC

AC

Bat&y Lid

Batterv Decoration Plate ;E

(VL-E63OU/680U/685U)

Battery Decoration Plate

(VL-E630T/685T)

Battery Intermediate Lock

Battery Intermediate Lock

Spring

Battery Lock Lever Spring

Battery Lid Open/Close

Lever

Battery Lock Holder

Battery Lock Lever

Battery Push-out Spring

Lens Holder

Battery Lid Angle Fitting

Hand Strap

AC

AC

AD

AA

AC

AC

AC

AD

AD

AH

AU

7-2

7-3

7-4

7-5

8

A

9

10

11

*::

1415

16

16

16

16

16

17

17

17

18

19

20

20

20

20

20 DUNTK2782QA16 J

21 DUNTK2785QAOO J

21 DUNTK2785QAOl J

22

23

24 QSW-Z0286TAZZ J

24 QSW-Z0300TAZZ J

25 QTANZOl29TAZZ J

26 QSW-Z0285TAZZ J

27 LHLDZ1452TAZZ J

28

29

29

30

31 JKNBPOlSPTASA J

32

32 JKNBPOl53TASB J

33

34 JKNBP0154TASA J

35

36

37

38

39

40

41

42

43

44 PCOVP9062TAZZ J

45

46

47 ZTAPEZ800020E J

48

49

50

51

52 QJAKZ0071TAZZ J

53

PSPAZOl SOTAZZ J

GCOVAl537TAKA J

PSPAZOl89TAZZ J

LANGH0071TAFW J

LHLDZ1446TAZZ J

PSHEP0044TAZZ J

PSHEP0045TAZZ J

PSHEP0044TAZZ J

PGiDM0025TAZZ J

PMiR0021TAZZ J

CLMPV0043TA02 J

CPNLC0032RM01 -J

PZETV0343TAZZ J

TLABMl909TAZZ J

TLABM1920TAZZ J

TLABM 1924TAZZ J

TLABM1913TAZZ J

TLABM 1925TAZZ J

TLABNOl71TAZZ J

TLABNO172TAZZ J

TLABNOl73TAZZ J

CLNSAOl27TAOl J

GFTAC1241TASA J

DUNTK2782QA14 J

DUNTK2782QA12 J

DUNTK2782QA13 J

DUNTK2782QA15 J

QPWBH2814TAZZ J

LHLDW1038TAOO J

MSPRC0083TAFJ J

JBTN-0277TASA J

JBTN-0277TASB J

LHLDZ1451TAZZ J

JKNBPOl53TASA J

LHLDZ1453TASA J

PSPAZOl 9lTAZZ J

RMiCC0079TAZZ J

MSPRT0034TAFJ J

LHLDZ1454TAOO J

NSFTZOOWTAFW J

PSPAZO192TAZZ J

LHLDZ145OTAZZ J

VSP0020P-94WN J

PSPAGOlO3TAZZ J

PSPAGOOOSTAZZ J

GCOVA3056TAKA J

QSW-Z0284TAZZ J

MLEVP0031TAZZ J

LANGK0399TAFW J

PSHEPOO74TAZZ J

PSPAG0084TAOO J

GCOVA3057TAKA J

QPWBH2815TAZZ J

Tilt Spacer AE

Tilt Frame V AL

Rotation Spacer

Stopper Fktfng AD

LCD Holder AG

AD

ReflectIon Polarizing Sheet AG

Diffusion Sheet AD

Prism Sheet AG

Light Guide Plate AG

Reflection Sheet AC

Lamp lnverter Unit

LCD Panel BZ

LCD Glass Retaining

Model Label(VL-E630U) AC

Model Label(VL-E680U) AC

Model Label(VL-E685U) AC

Model Label(VL-E63OT) AC

Model LabekVL-E685T) AC

Serial No. Label(VL-E638U) AC

Serial No. Labef(VL-E68OU) AC

Serial No. Label(VL-E685U) AC

Lens Unit

Cassette Compartment AD

Cover

VCR Unit(VL-E63OU) VCR Unit(VL-E68OUj VCR Unit(VL-E685U) VCR Unit(VL-E63OT) VCR Unit(VL-E685T) CAMERA UnitNL-E63OUfl) CAMERA Unit

(VL-E68OU/685U/T) Tilt FPC AQ

FPC Holder AC

VCR Operation Unit AR

(vL-E63ou/68ou/685u)

VCR Ooeration Unit AU

(VL-E6&OT/685T)

Battery TerminalfUnk AG

Power Unit AR

Power Lock Holder AC

Power Lock Spring

Power Button

(VL-E630U/630T)

Power Button

(VL-E680U/685U/685T)

Power Holder

Power Knob

Zoom Knob(VL-E63OU/T) AD

Zoom Knob

(VL-E680U/685U/T)

Zoom Knob Holder

Open Knob

Spacer

Microphone AM

Lid Lock Spring

VCR Lid Lock VCR Lid Shaft

Microphone Lead Spacer

Speaker Holder

Speaker

Speaker Spacer

Speaker Mesh

VCR Lid Cushion

Speaker Cover

Tape

Turn/Eject SW

Eject Lever

Tripod Angle Ass’y

Microphone Lead Sheet AB

Jack Unit

Front Grouo Frame

Rubber ’

Microphone Cover

CCD FPC

AA

BS

AA

AD

AF

AC

AD

AF

AD

AC

AA

AC

AD

AD

AD

AC

AL

AC

AB

AA

AE

-

AH

AC

AK

AD

AG

AE

33

Page 34

Ref. No. Part No. Ir

Description Code

Ref. No. Part No. * Description Code

a

b

:

400

401

402

403

LX-HZ001 8TAFN J

LX-HZ001 8TAFF J

LX-HZ0045TAFN J

XiPSF2OPO4000 J

LX-BZOl 91 TAFD J

XiPSD2OP03000 J

LX-UZOOlGTAFD J

LX-BZ02OOTAFD J

XiPSN20PO4000 J

LX-HZOO63TAFC J

M2x6 Tapping, Silver

M2x6 Tapping, Black

M2x4 Tapping, Silver

M2x4 Small Screw, Black

Zinc Plating

M2 Special Screw

M2x3 Screw

M2x5 Special Screw

M2x7 Special Screw

M2x4 Small Screw, Silver

Ml .7x6 Tapping, Silver

- End of Cabinet Parts -

AA

E

AA

AC

AA

E

AA

AA

CASSElTE HOUSING PARTS

CHLDX3077GEOl J Cassette Compartment AY

MSPRTO414GEZZ J Up Main Spring

MROD-0014GEFJ J DamDer rod

PDMP-0013GEZZ J Cassette Compartment AG

Assy .

AD

AG

Damper

- End of Cassette Housina Parts -

CASSElTE HOUSING CONTROL UNIT

I

r-

/

/

I

I

I

\

\

\

\

\

400

P

\

,

I

I

I

/

/

,

L

\

L_______’

1 I 2 I 3 I 4 I 5 I 6 I

/

Page 35

12. PACKING OFTHE SET

GCOVH1225TASA

QCw.l\]

UBNDSOOlOTASA

(Shoulder Strap)

RRMCG0072TASA

(Remote Control) xQh&

d

VL-E630W

VL-E68OU

VL-E685U/T

>leUADP-0274TAZZ

UBATMOOl OTAZZ

>I<UBATMOOllTAZZ

I

(Battery)

UBATLOOl ITAZZ

(Lithium Battery)

UBATU0023GEZZ

A DRYCELL Battery x 2)

(A/V Cable)

JrSPAKA6176TAZZ

(Packing ADD.)

*SPAKP6049TAZZ

(Wrapping Paper)

*SPAKA6201TAZZ

(Packing ADD.)

1

kSPAKA6237TAZZ

(Packing ADD.)

/

(Packin: Case)

* Not Replacement Item

* For detail, See page 31.

35

Page 36

kEw

vL:EsffluK

SHARP

COPYRIGHT @ 1998 BY SHARP CORPORATION

ALL RIGHTS RESERVED.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted in

any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without

prior written permission of the publisher.

Dec. 1998 Printed in JAPAN

SA. NS

SHARP CORPORATION

AV Systems Group

Quality & Reliability Control Center

Yaita, Tochigi 329-2193, Japan

Loading...

Loading...