Page 1

POS TERMINAL

MODEL UP-5350

("U" version)

CONTENTS

1. Removing the Rear Display Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2. Replacing the Rear Display Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3. Removing the Top Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

4. Replacing the Top Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 1

5. Removing the Power Supply Unit and AC cord. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

6. Replacing the Power Supply Unit and AC cord. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

7. Removing the LCD Unit.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

8. Replacing the LCD Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

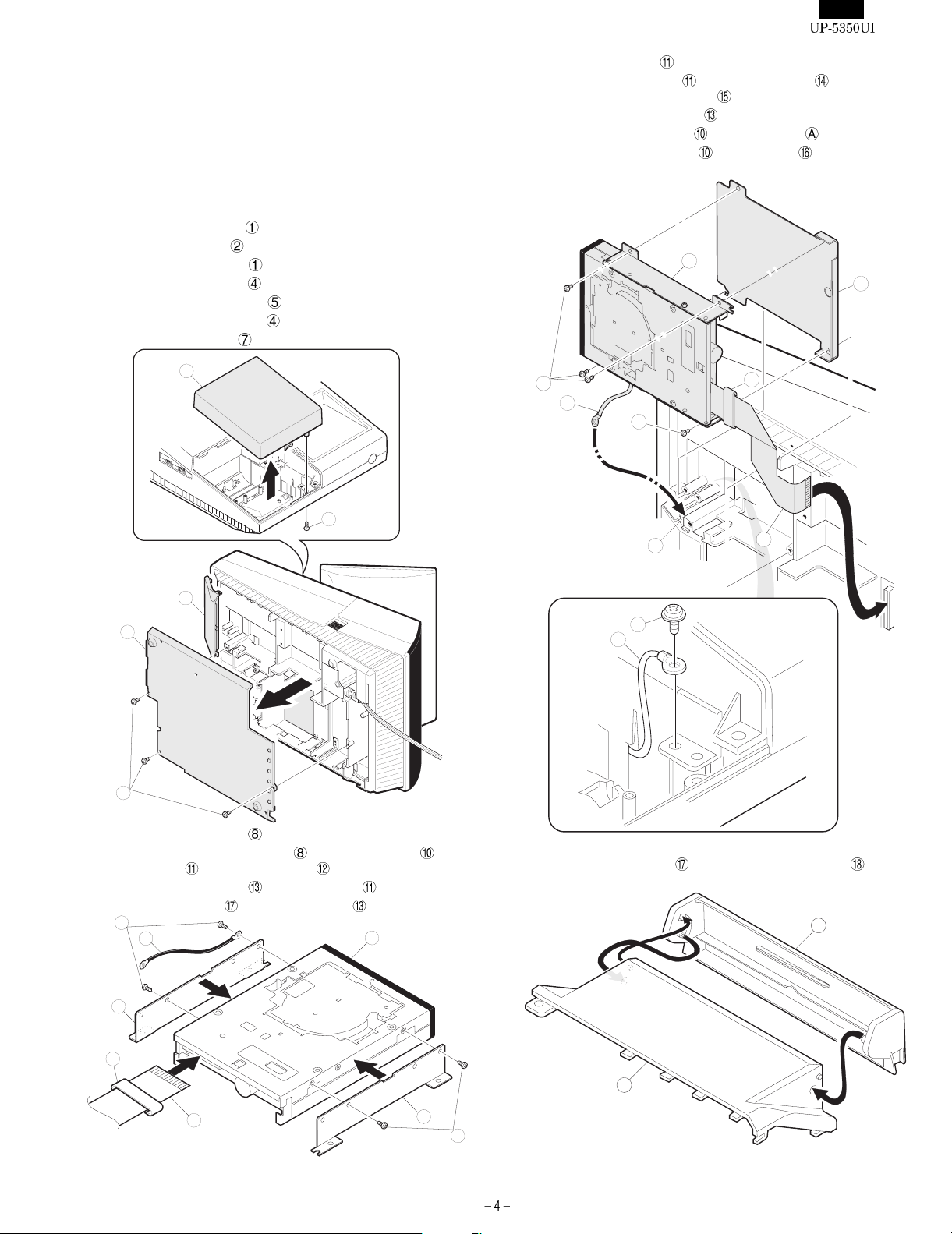

9. Replacing the FDD Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

10. Removing the FDD Unit.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

11. D-RAM disk: S.O. DIMM (Locally supplied .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

12. MCR Unit: UP-E12MR2.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..6

13. Adjusting the IRQ10/11 on the ISA PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6

14. RS232 & CENTRO I/F: ER-A8RS.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

15. Rear Display UP-I20DP.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 7

16. Pole Display: UP-P20DP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 7

17. Drawer Unit: ER-03DW/04DW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 9

18. COM1, COM2, COM3/5, and COM4/6 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

19. Built-in Printer: UP-T80BP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...11

20. Key Pad : UP-C30PK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...15

Parts marked with " " is important for maintaining the safety of the set. Be sure to replace these par ts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

Precautions

•Before installation, be sure to turn off the power.

•Use gloves to protect your hand from being cut by the angle

and the chassis.

•Connect all the cables securely. When connecting or

disconnecting the cables, be careful not to apply stress to the

cables. (It may cause disconnection.)

•Ground the human body to prevent against troubles and dust

adhesion to the LCD by static electricity. When assembling the

LCD, use a discharge blower to prevent against dust intrusion.

•Be careful to the high voltage of the invertor PWB transformer.

•About placing top cabinet with LCD panel side down, Please

use a clean dust free cloth to protect the touch panel and LCD

area.

7

A

1

1

8

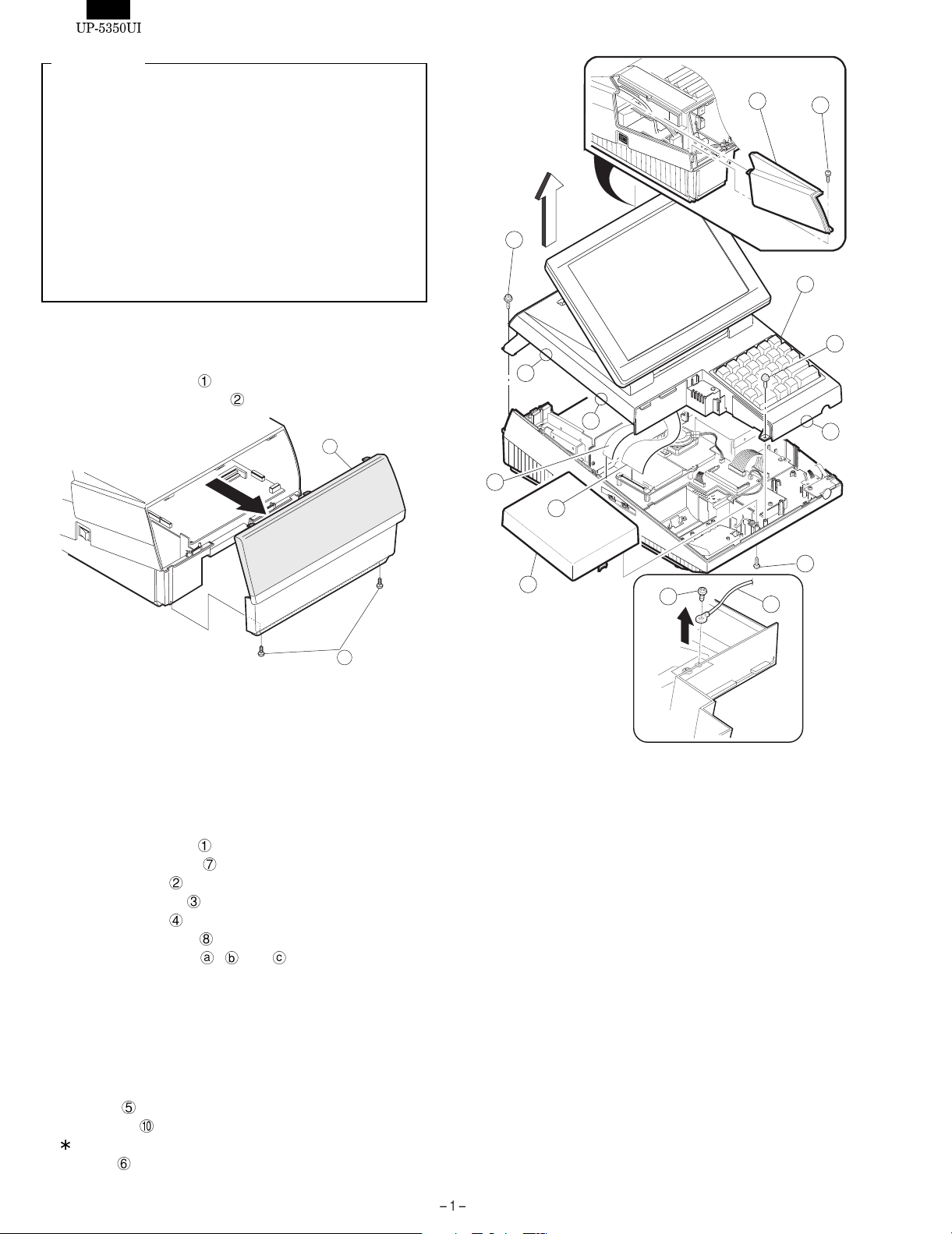

1.Removing the Rear Display Filter

1)Remove the two screws .

2)Remove the Rear Display Filter

.

2

1

2.Replacing the Rear Display Filter

Install the Rear Display Filter in the reverse order of removing.

3.Removing the Top Cabinet

1)Remove the two screws .

2)Remove the Side cabinet

3)Remove the screw

4)Remove the Printer Lid

5)Remove the screw

6)Remove the Top Cabinet

a)Release the latches

Upper Cabinet to the right and release the latch on the right.

b)Lift the Top Cabinet and put it straight in the direction of arrow

A. ( Be careful not to pull the cable between the LCD I/F

PWB-Key Pad PWB of the top cabinet and the MAIN PWB of

the Bottom Cabinet.)

c)Pull and remove the following cables between the LCD I/F

PWB of the Top Cabinet and the MAIN PWB of the Bottom

Cabinet.

•LCD Cable : VGA PWB : CN602

•Key Pad Cable : MAIN PWB :CN10

Key Pad : UP-C30PK is optional.

•Earth Wire .

.

.

.

.

.

, and in that order. Slide the

4

a

10

b

5

3

9

6

c

2

4.Replacing the Top cabinet

Install the Top Cabinet in the reverse order of removing. Before installing, make sure that each connector is connected securely.

Page 3

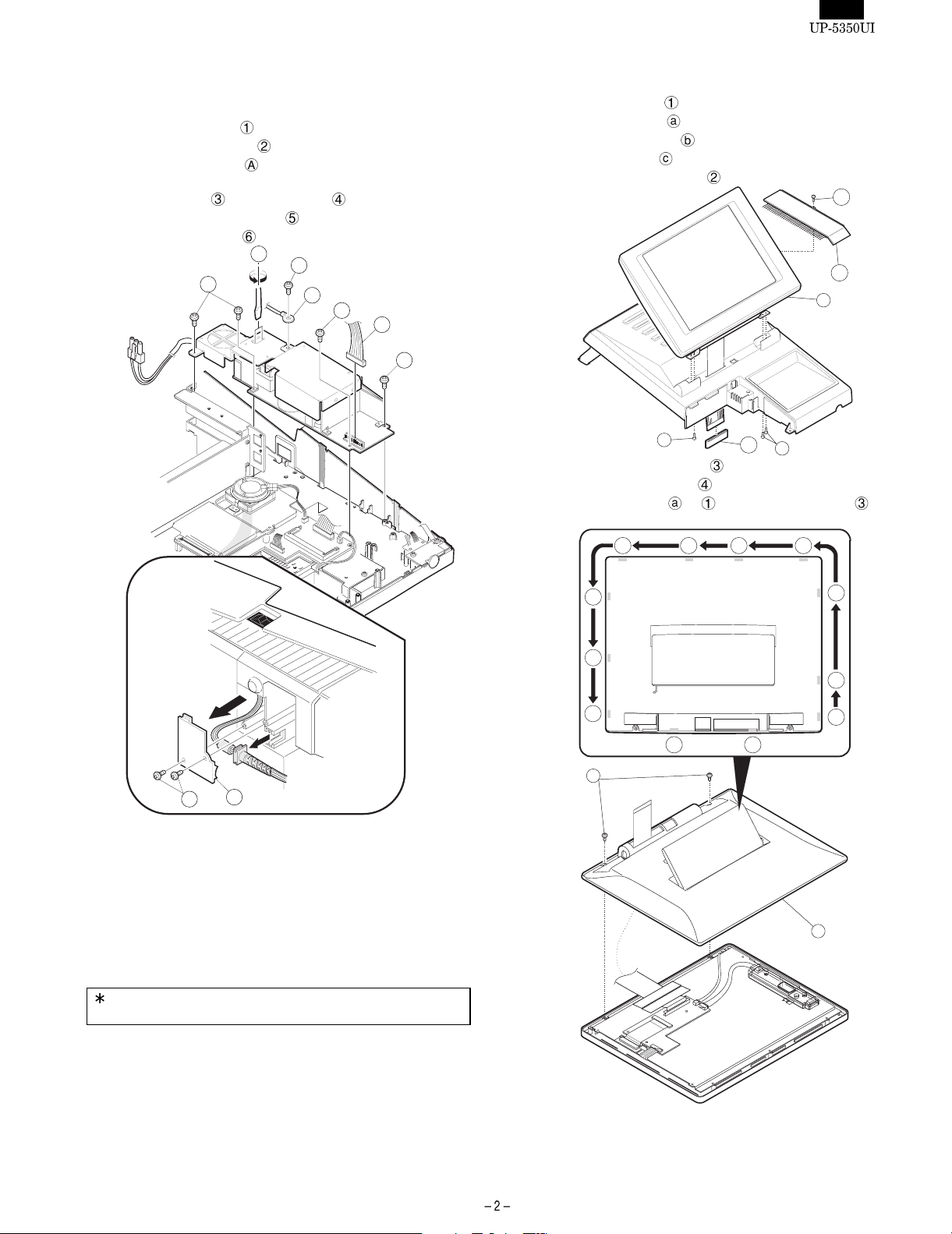

5.Removing the Power Supply Unit

and AC cord

1)Remove the two screws .

2)Remove the AC cord cover

3)Use a minus screwdriver

pcs.) of the Power Supply Unit.

4)Remove the screw

5)Remove the Power Supply Cable

6)Remove the four screws

6

.

to loosen the AC cord fixing screws (2

and the earth wire from the AC cord.

.

.

A

3

4

6

5

6

7.Removing the LCD unit

1)Remove the LCD Unit .

a)Remove the screw

b)Remove the Tilt Cover

c)Remove the Core

d)Remove the three screws

.

.

.

.

a

b

1

2

1

6.Replacing the Power Supply Unit

and AC cord

2

2)Remove the LCD Rear Cabinet

a)Remove the two screws

b)Remove the pawls

order.

g

h

i

j

4

.

to of the LCD Rear Cabinet in that

f

k

c

2

.

de

c

b

a

l

Install the in the Power Supply Unit and AC cord in the reverse order

of removing.

Before installing, make sure that each connector is connected securely.

When connecting the AC cord to the Power Supply Unit in

assembly, tighten with the torque of 3 kg/cm ± 1 kg/cm.

3

Caution:

Please do not place the LCD Unit on hard surfaces, Please take

special care not to place the LCD Unit on any surface that may cause

Page 4

damage to the unit.

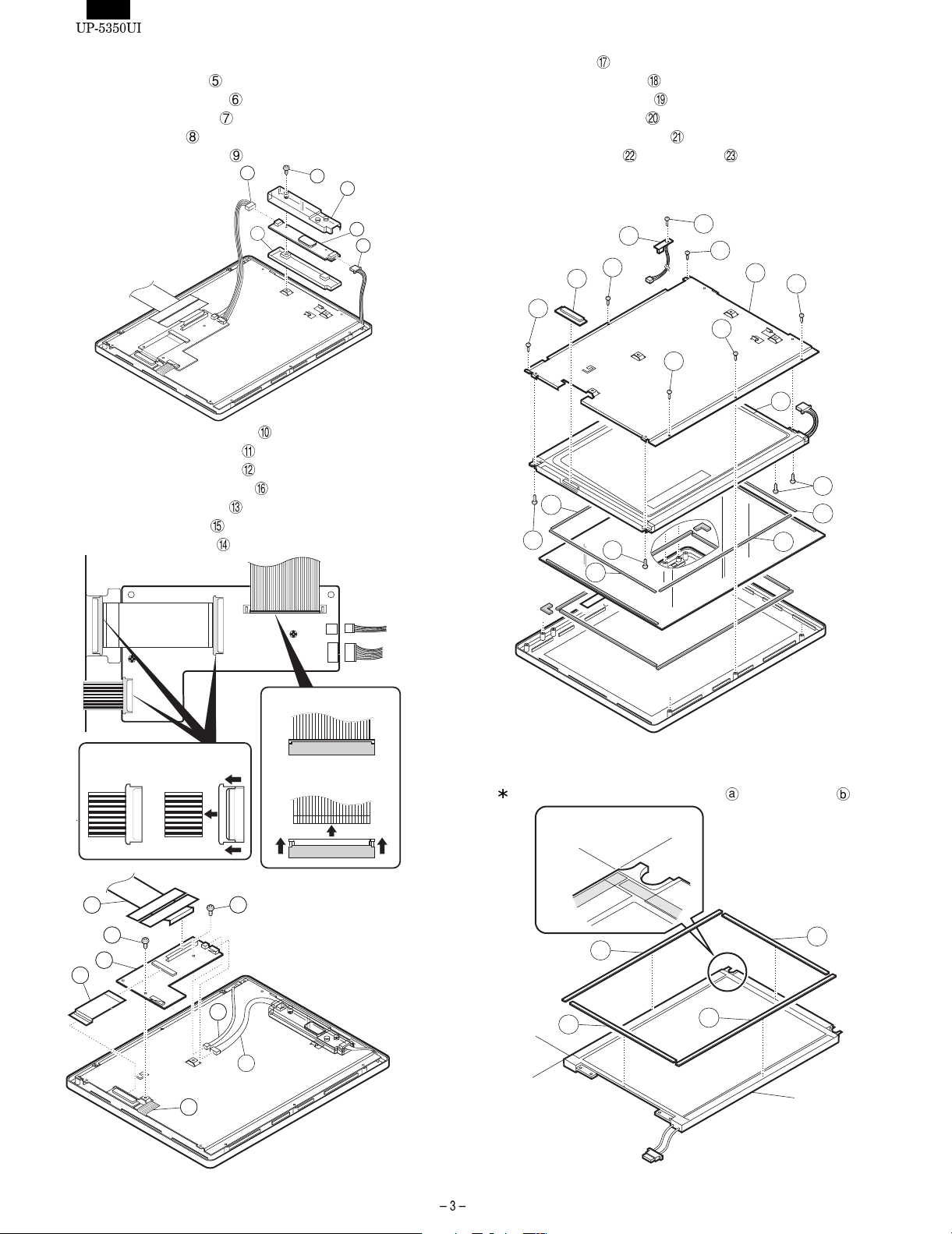

3)Remove the Inverter PWB

a)Remove the Inverter Cable

b)Remove the CCFT Cable

c)Remove the screw

d)Remove the Inverter Cover

5)Remove the LCD

.

.

.

.

.

6

8

9

a)Remove the six screws

b)Remove the four screws

c)Remove the LCD Plate

d)Remove the LCD PWB Unit

e)Remove the screw

.

.

.

.

.

and LED PWB .

4)Remove the Touch Panel PWB Unit

a)Remove the LCD Cable(40P)

b)Remove the LCD Cable(29P)

c)Remove the Touch Panel Cable

d)Remove the Inverter Cable

e)Remove the LED Cable

f)Remove the two screws

.

.

.

9

5

7

21

23

18

22

18

20

18

18

18

18

17

.

.

.

.

a

19

19

19

b

a

b

Lock Unlock

11

14

10

12

16

15

14

13

Lock

Unlock

Reference for attaching LCD GUM A : to LCD GUM B :

R

efer

e

n

ce

e

l

f

i

n

e

e

R

e

n

i

l

ce

en

r

a

Re

f

e

b

r

en

c

e l

i

ne

ne

i

l

e

nc

ere

f

e

R

a

LCD

b

Page 5

8.Replacing the LCD Unit

Install the LCD Unit in the reverse order of removing.

Before installing, make sure that each cables are connected securely.

9.Replacing the FDD Unit

1)Remove to the Printer Lid .

a)Remove the screw

b)Remove the Printer Lid

2)Remove the Bottom Plate

a)Remove the three screws

b)Remove the Bottom Plate

3)Remove the FDD Cover

.

.

.

.

.

.

7)Install the FDD UNIT

a)Install the FDD UNIT

Cabinet with the four screws

b)Connect the FDD CABLE

c)Pass the EARTH WIRE

d)Install the EARTH WIRE

to the UP-5350.

and FDD ANGLE-B to the Bottom

.

to the Main PWB.

through the hole .

with the screw .

11

14

1

2

7

4

5

15

10

15

A

16

10

17

13

4)Install the FDD ANGLE-A

a)Install the two FDD ANGLE-A

FDD UNIT

with the four screws .

5)Connect the FDD CABLE

6)Install the Ferrite Core

12

10

8

17

13

onto the FDD Cable .

.

and EARTH WIRE to the

to the FDD UNIT .

8)Install the FDD COVER

11

17

8

12

to the FDD FRONT COVER .

18

Page 6

9)Install the FDD COVER UNIT , to the Bottom Cabinet.

17 18

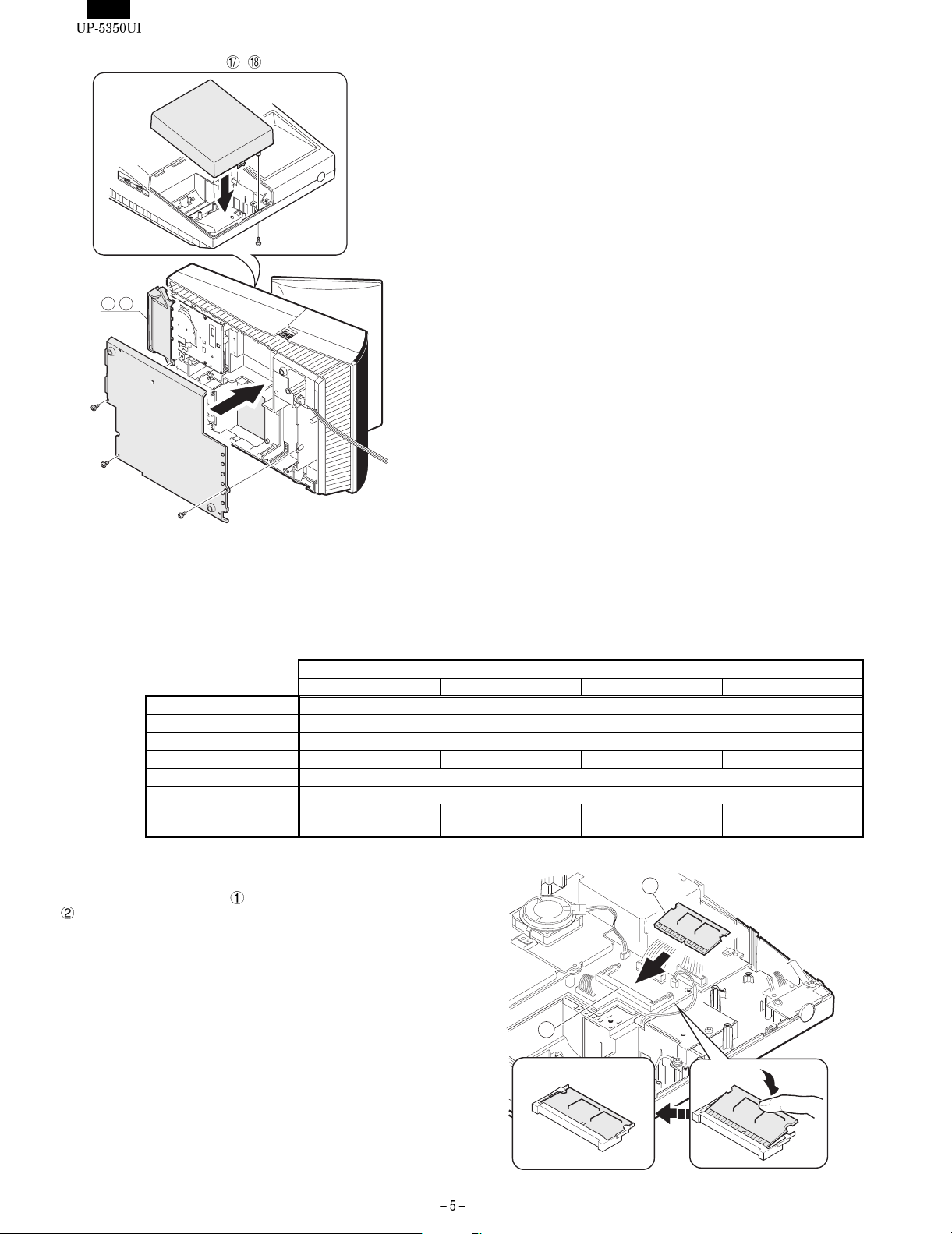

10.Removing the FDD Unit

Install the FDD Unit. In the reverse order of replacing.

11.D-RAM disk: S.O. DIMM (Locally supplied)

[Device]144 pin Small Outline DIMM (8Mbytes/16Mbytes/32Mbytes/64Mbytes)

[Outline]UP-5350 has a socket as Small Outline DIMM.

[Specification]

1)Remove the Top Cabinet.

2)Install the option D-RAM disk

It is necessary to satisfy with S.O.DIMM memory specification as follows.

8Mbytes 16Mbytes 32Mbytes 64Mbytes

Type EDO type

Access time 60 nsec.(less than)

Power 3.3V

Refresh cycle 1024/16 msec. 2048/32 msec. 4096/64 msec. 4096/64 msec.

Refresh type CBR

Power consumption 700 mA (less than)

Other 4 chips x 16Mbits

(1Mwords x 16 bits)

to the D-RAM connector: CN13

on the Main PWB.

a)Insert a D-RAM disk at a slant into the D-RAM connector.

b)Push the D-RAM disk until the D-RAM disk is correctly locked

by the arms of D-RAM connector.

8chips x 16Mbits

(2 Mwords x 8 bits)

144pin S.O.DIMM

4 chips x 64Mbits

(4 Mwords x 16 bits)

8 chips x 64Mbits

(8 Mwords x 8 bits)

1

2

Page 7

3)Remove the option D-RAM disk.

a)Open the arms of D-RAM connector right and left.

b)The D-RAM disk will be lifted automatically.

12.MCR UNIT: UP-E12MR2

14.RS232 & CENTRO I/F: ER-A8RS

ER-A8RS connection

1)Fix the MCR ANGLE to the Lower Cabinet with two screws .

2)Connect the MCR Cable

holder

3)Install the ferrite Core

, and tighter the screw on the back of Lower Cabinet.

to the MCR connector with the cable

to the MCR cable and GND wire .

1

6

4

2

3

5

7

4)Fix the earth wire

from the UP-E12MR2 with the screw.

13.Adjusting the IRQ10/11 on the

ISA PWB.

Adjust the IRQ10 and IRQ11.

(See the "13. Adjusting the IRQ10/11 on the ISA PWB.")

1)Remove the REAR COVER.

2)Remove the screw

3)Insert the I/F PWB

4)Fix the I/F BRACKET to the ISA BUS SHASSIS with screw

Only one ER-A8RS can be installed.

5)Connect the RS232

PWB.

4

If an I/F (locally supplied half-size PC card) other than the ERA8RS is connected to the ISA bus connector, it may be required to

remove reinforcement angle

In this case, remove reinforcement angle

install reinforcement angle

from the ISA BUS SHASSIS.

to the ISA BUS CONNECTOR.

and CENTRONICS cables to the I/F

2

3

when inserting the I/F.

.

1

, insert the I/F, then

.

3

Adjust the IRQ10 and IRQ11 using the switches: S1 and S2 on the

ISA PWB if an option equipment is connected to the ISA slot of the

ISA PWB.

S2

S1 = IRQ10:S = ON (Connect IRQ10 to the ISA Slot.)

M = OFF (Connect IRQ10 to GND, not to the ISA Slot.)

S2 = IRQ11:S = ON (Connect IRQ11 to the ISA Slot.)

M = OFF (Connect IRQ11 to GND, not to the ISA Slot.)

S1

SM SMIRQ11 IRQ10

5

Page 8

Align threaded holes completely before securing the I/F PWB with

screws.

3)Connect the display cable to the connector: CN: 1 on the Ma in

PWB

4)Install the Display unit

a)Align the positioning boss

angle hole

to the cabinet

of the Bottom Cabinet with the

in the Display Unit.

15.Rear Display UP-I20DP

1)Remove the Display Filter

4

A

A

5

A

16.Pole Display: UP-P20DP

1)Install the core to the Display Cable and the display earth

cable

2)Connect the Display Cable

the back of the set.

3)Fix the Display Cable

screw

1

4)Fix the display earth cable

.

to the remote display connector on

with the cable holder , and tighten the

on the back of Bottom Cabinet.

to the Main Chassis with the screw

.

2)Remove the Rear Cover Angle from the Display Filter

a)Remove the two screws

1

2

4

5

1

6

3

Cable holder

3

Use the following type of cable holder supplied with the UPP20DP.

2

•"3N" (large type)

Page 9

How to Extend Display Pole

The pole can be extended by installing the attached pole to the

standard pole.

COMPONENT LIST:

No. NAME USE Q’ty

, Pole cabinet Pole extension 2

Screw (M3 × 4)

Screw (M4 × 16)

Screw (M4 × 20)

Nut

Display cable (S)

Earth wire (S) 1

Pole connection

Securing the UP-P20DP to

the wooden table

Securing the UP-P20DP to

the metal table

Securing the UP-P20DP to

the metal table

This display cable (S)

should be used instead of

the standard cable and

earth wire if the UP-20DP’s

standard pole is removed

to lower the height of the

UP-20DP.

4

4

4

4

1

5)Remove the two screws

6)Remove the Base Cabinet

4

6

.

from the Pole Cabinet .

7

1)Remove the five screws

2)Remove the Base Angle

3)Remove the PWB Unit

4)Remove the display cable

Pattern side(PWB)

Core

2

1

.

.

from the Base Cabinet .

from the PWB Unit .

4

7)Pull the Ratchet

Display Unit

8)Remove the two screws

9)Remove the Pole Cabinet

8

7

attached to the Pole Cabinet out of the

by turning it as shown in Figure A.

10

10

.

from the Ratchet .

9

9

3

1

5

Page 10

10)Install the attached Pole Cabinet to the Pole Cabinet to fix it

with the screw

Display Cable

.

7

7

Lowering the height of the UP-P20DP

Remove the standard Pole and attach the Base cabinet

Ratch

Earth wire with the S type cable

. At this time, replace the standard Display cable and the

and wire .

17.Drawer Unit: ER-03DW/04DW

to the

11

11

11)Install the Pole Cabinet

bly.

12)Fastening on the table:

Secure the Base Cabinet

No. NAME USE Q’ty

Screw (M4 × 16)

Screw (M4 × 20)

Nut

in the opposite order of the disassem-

using the screw.

Securing the UP-P20DP to

the wooden table

Securing the UP-P20DP to

the metal table

Securing the UP-P20DP to

the metal table

1)Connect the drawer cable to the drawer connector .

2)Fix the earth wire

the screw

4

4

4

4

3

to the main chassis from Drawer Box Unit with

.

B

A

1 turn

5

3)Install the Ferrite Core

.

4)Fix the drawer cable

screw

on the back of Lower Cabinet or .

6

7

1

to the drawer cable and the earth wire

with the cable holder , and tighten the

2

Page 11

18.COM1, COM2, COM3/5, and

COM4/6 Connector

1)COM1 & COM2

•D-SUB 9pin Connector

•CI signal of COM1 or COM2 and +5V Power Supply can be

switched in order to supply +5V power.

Main PWB

Connector Specifications*

D-SUB9

Pin No. Signal Function I/O

1 CD Data Carrier Detect I

2 RD Receive Data I

3 SD Send Data O

4 ER Data Terminal Ready O

5 SG Signal Ground —

6 DR Data set Ready I

7 RS Request to Send O

8 CS Clear to Send I

9 CI/+5V Ring Indicate/+5V I/–

S2 = COM1:1 = +5V

3 = CI

S1 = COM2:1 = +5V

3 = CI

S1

13

S1

1

+5V

CI

3

+5V

COM1

COM2

13

S2

+5V CI

S2

31

S1

CI

+5V CI

31

+5V CI

S2

31

Page 12

2)COM3/5, COM4/6

•Two channels of COM port with an RJ45 connector are

equipped.

•For 2 channels of RJ45 COM port, COM3 & COM4 or an I/O

address (COM5 & COM6) can be selected.

•Two CABLE HOLDER and SCREW (M3 × 8) are con-

tained in the package.

2

1

2

1

Connector Specifications*

RJ45

Pin No. Signal Function I/O

1 RS Request to Send O

2 ER Data terminal Ready O

3 SD Send Data O

4 SG Signal Ground —

5 SG Signal Ground —

6 RD Receive Data I

7 DR Data set Ready I

8 CS Clear to Send I

19.Built-in printer: UP-T80BP

1)Remove the BOTTOM PLATE .

a)Remove the three screws .

b)Remove the BOTTOM PLATE

c)Remove the SCREW

PLY CABLE

.

.

, CABLE CLAMP and POWER SUP-

4

3

5

Fig. 1

2)Install the PS+CONTROL PWB .

a)Fix the PS+CONTROL PWB with three screws ,

SCREW : Use the screw which was fixing the CLAMP

3)Connect the POWER SUPPLY CABLE to the

PS+CONTROL PWB

4)Connect the I/F CABLE

PWB

to the UP-5350 MAIN PWB (No.CN109)

8

. (No. CN1)

of the PS+CONTROL

30

3

30

: XEBSD30P08000

5

Fig. 2

6

7

: XHBSD30P06000

7

Page 13

5)Remove the PRINTER LID .

a)Remove the screw .

b)Remove the PRINTER LID

.

6)Install the PAPER ROLLERs (4ea.) .

8)Install the AUTO CUTTER RELAY PWB UNIT .

a)Install the AUTO CUTTER RELAY PWB UNIT with screw

.

b)Pass the AUTO CUTTER RELAY PWB CABLE

hole (C).

through the

11

Fig. 3

7)Install the SWITCH UNIT .

a)Fix the SWITCH UNIT on the cabinet pawl .

b)Pass the SWITCH UNIT CABLE

through the hole (B).

9

10

9)Install the PAPER GUIDE to the PRINTER

UNIT

10)Install the HEAD CABLE

14

UNIT

15

15

: XEBSD30P08000

16

Fig. 5

C

.

to the PRINTER

.

19

17

12

12

13

B

A

Fig. 4

A

18

Fig. 6

Page 14

11)Install the PRINTER UNIT .

a)Connect the AUTO CUTTER CABLE to the AUTO CUTTER

RELAY PWB

b)Pass the HEAD CABLE

c)Pass the MOTOR CABLE

the hole (D).

d)Open the PRINTER UNIT

e)Fix the PRINTER UNIT

Fix the screws in the order of -(a) to -(d).

f)Fix the two EARTH WIREs

.

through the hole (C).

and SENSOR CABLE through

.

with four screws

with a screw .

12)Wiring for each cables as shown below

20

23

23

23

20

a

: XEBSD26P06000

c

: XEBSD26P08000

d

23

18

b

21

23

b

23

23

a

23

c

: XEBSD26P06000

d

: XEBSD26P08000

25

: XHBSD30P06000

25

14

16 19

24

13)Connect the Printer cables to the CONTROL

22

19

C

PWB.

a)SWITCH UNIT CABLE : Connect to the CN7.

b)HEAD CABLE

c)AUTO CUTTER RELAY PWB CABLE

d)MOTOR CABLE

e)SENSOR CABLE

:Connect to the CN5.

Attach the FERRITE CORE (L size)

BLE CLAMP

Fix the CABLE CLAMP

: Connect to the CN2.

: Connect to the CN6

.

with a screw .

: Connect to the CN4.

and CA-

14

Fig. 7

28

: XEBSD30P08000

16

D

26

28

13

4

16

21

19

22

Fig. 8

Page 15

14) Wiring for each cables as shown below

a) Attach the FERRITE CORE (S size) to the I/F CABL E .

b) Fix the I/F CABLE

BAND

c) Set the switch: SW2 to the "MRS" position.

.

and EARTH WIRE with the CABLE

16

21

13

28

22

27

26

19

8

29

31

30

SW2

15) Install the BOTTOM PLATE .

2

1

Fig. 9

16) Install the PRINTER COVER .

29

Fig. 10

Fig. 11

Page 16

1. LIST FOR SCREWS

No. PARTS CODE M [mm] L [mm]

L

M

XEBSD30P08000 3 8

- XEBSD26P06000 2.6 6

-

- XEBSD26P08000 2.6 8

-

20.KEY PAD: UP-C30PK

Opetion for KB.

Standard for TQ, TS, KA

1)Remove the Upper Cabinet.

2)Remove the keyboard lid

from the Upper Cabinet.

XHBSD30P06000 3 8

L

M

2. INSTALLATION OF PAPER NEAR END SENSOR

[PARTS LIST]

No. PARTS NAME PARTS CODE NOTE

PAPER NEAR

1

END SENSOR

NEAR END

2

SENSOR

CONNECTOR

1.Remove the BOTTOM PLATE .

2.Remove the PS+CONTROL PWB .

3.Solder the CONNECTOR

CN1)

4.Install the NEAR END SENSOR UNIT

it with the fixing screw

DUNTK3819BHZZ

QCNCM6865RC0B 2 pin connector

to the PS+CONTROL PWB (No.

.

SENSOR UNIT,

FIXING SCREW

to the CABINET , and fix

1

Keyboard is tightly engaged and hard to be removed.

When removing it, use nippers to cut off four pawls A from the

back of the Upper Cabinet.

Back of the upper cabinet

Pawls A

Pawls A

Pawls B

Pawls B

3)Attach the Keyboard Cover

Cabinet, and fix them with four screws

and Keyboard Unit to the Upper

.

2

2

3

1

Fig. 12

2

4

4

Page 17

When attaching keyboard cover , engage pawls C and D securely

with the Upper Cabinet.

Back of the upper cabinet

Pawls D

Pawls C

How to wire cables :

4)Run the cable along the mark-off line of the cabinet and secure it

at two points with clamps.

5)Connect the cable of the keyboard unit

nector CN10.

6)Attach the earth spring

to the Lower Cabinet with the screw .

to the main PWB con-

Clamp mounting location diagram

Pay attention to the

direction of adherence.

Remove release paper.

6

5

Reference line for attaching CLAMP.

<REFERENCE FOR FOLDING FLAT CABLE>

22mm

90mm

Reinforcement plate

70mm

FLAT CABLE (480mm)

Page 18

COPYRIGHT 2000 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this public ation may be reproduce d,

stored in a retrieval system, or transmitted.

In any form or by any means ,

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

SHARP CORPORATION

Information Systems Group

Quality & Reliability Control Center

Yamatokoriyama, Nara 639-1186, Japan

2000 May Printed in Japan

Loading...

Loading...