Page 1

CONTENTS

CODE: 00ZUP5300USME

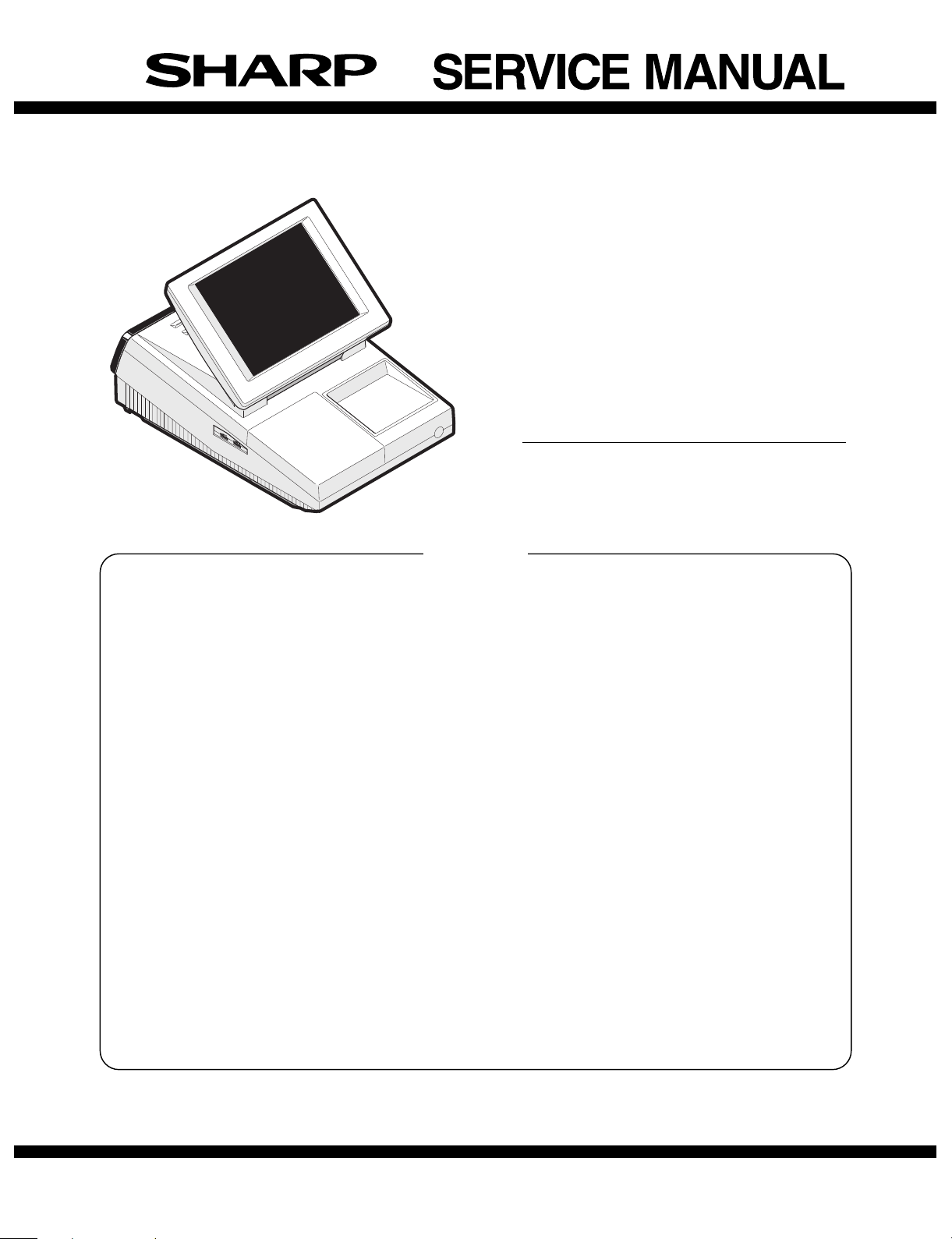

POS TERMINAL

MODEL UP-5300

("U" & "A" version)

CHAPTER 1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

CHAPTER 2. OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

CHAPTER 3. SERVICE PRECAUTION . . . . . . . . . . . . . . . . . . . . . 3-1

CHAPTER 4. UP-5 300 DIAGNOSTICS SPECIFICATIONS . . . . . . 4-1

CHAPTER 5. CIRCUIT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . 5-1

CHAPTER 6. BIOS SETUP UTILITY . . . . . . . . . . . . . . . . . . . . . . . . 6-1

CHAPTER 7. ABOUT UTILITY SOFTWARE AND OTHERS . . . . . 7-1

CHAPTER 8. CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

CHAPTER 9. PWB LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

PARTS GUIDE

Parts marked with "!" is important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

BATTERY DISPOSAL

Contains Nickel Metal Hydride Battery. Must be Disposed of Properly.

Contact Local Environmental Officials for Disposal Instructions.

Page 3

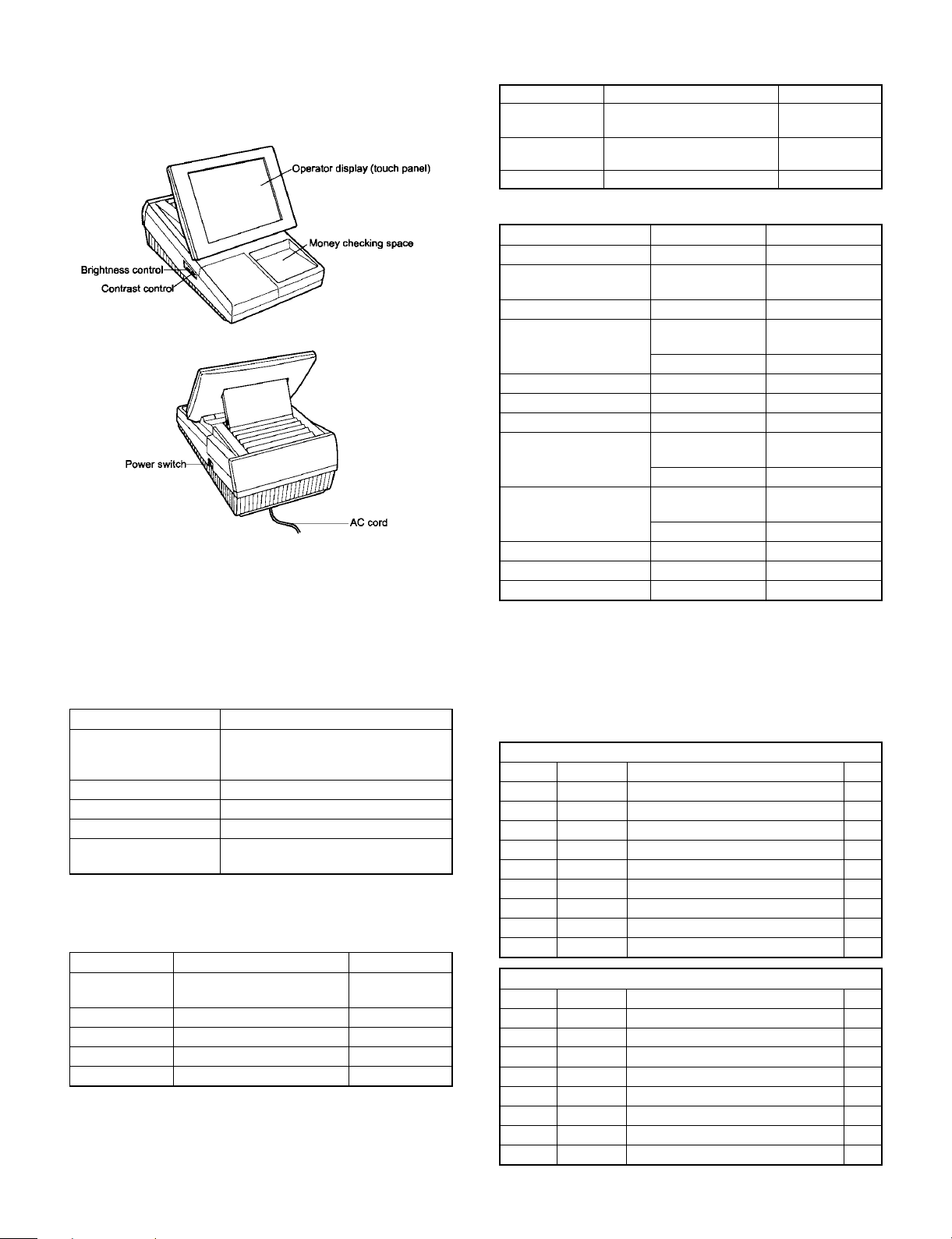

CHAPTER 1. SPECIFICATIONS

1. Appearance

AC cord

Plug your POS terminal into a wall outlet before using.

Power switch

Set the power switch to the ON ( I ) position after plugging your POS

terminal.

2. Ra tin g

ITEM SPECIFICATIONS

External dimensions 11.6 (W) × 16.3 (D) × 12.6 (H) in.

approximately (295 (W) × 414.5 (D) ×

320 (H) mm)

Weight Approximately 13.9 lb. (5.9 kg)

Power source 120V AC ± 10%, 60 Hz

Power consumption Operating : 63W

Working temperature

and humidity

3. Hardware

3-1. Display

ITEM SPECIFICATIONS NOTE

Type DSTN color LCD with back

Screen size 10.4" Full screen

Dot format 640 (W) × 480 (H) dots

Dot size 0.33 × 0.33 mm

Control VGA

32 to 104°F (0 to 40°C)

10 to 90%

With 256 colors

light

3-2. Keyboard

ITEM SPECIFICATIONS NOTE

Type Touch key

(Analog touch panel)

Number of key

positions

Control Mouse emulation

4096 (W) × 4096 (H)

positions

3-3. PC system

ITEM SPECIFICATIONS NOTE

CPU Pentium processor

Chip set FireStar Plus:

82C700U3.2

Graphic controller VGAC : MN89305

Main memory

(for executing MS-DOS,

Application software)

Video RAM 1 Mbytes EDO type

BIOS ROM 512 Kbytes Flash ROM

OS (MS-DOS) ROM 4 Mbytes Mask ROM

ROM disk memory

(for stored Application

software)

RAM disk memory

(for POS data)

Keyboard controller M38802M270

Super I/O M5113 A2

POS system controller PSC2 : LZ9AM22

Standard : 8

Mbytes

Max. : 40 Mbytes adding S.O.DIMM

Standard : 2

Mbytes

Max. : 6 Mbytes adding UP-F04RB

Standard : 1

Mbytes

Max. : 3 Mbytes adding UP-P02MB

EDO type

Flash ROM

PS-RAM

3-4. Serial port

D-SUB 9-pin connector COM1 and COM2 are equipped.

In order to supply +5V power, CI signal and +5V power supply of

COM1 and COM2 can be switched.

2 channels of RJ45 Connector COM port are equipped.

COM3 and COM4 or original I/O address (COM5 and COM6) can be

selected as the 2 channels of RJ45 COM port.

COM1 & COM2: D-sub 9 pin

Pin No. Signal Function I/O

1 CD Data Carrier Detect I

2 RD Receive Data I

3 SD Send Data O

4 ER Data Terminal Ready O

5 SG Signal Ground —

6 DR Data set Ready I

7 RS Request to Send O

8 CS Clear to Send I

9 CI/+5V Ring Indicate / +5V I/–

COM3 or COM5: Modular jack RJ45 8 pin

Pin No. Signal Function I/O

1 RS Request to Send O

2 ER Data terminal Ready I

3 SD Send Data O

4 SG/(+5V) Signal Ground/(+5V) —

5 SG Signal Ground –

6 RD Receive Data I

7 DR Data set Ready I

8 CS Clear to Send I

1 – 1

Page 4

COM4 or COM6: Modular jack RJ45 8 pin

Pin No. Signal Function I/O

1 RS Request to Send O

2 ER Data terminal Ready I

3 SD Send Data O

4 SG Signal Ground —

5 SG Signal Ground –

6 RD Receive Data I

7 DR Data set Ready I

8 CS Clear to Send I

3-5. Expansion slot

ITEM SPECIFICATIONS NOTE

Type ISA bus Half size PC board

Number of slots 2 slots

Power consumption +5V/max. 1.0A

+12V/max. 0.05A

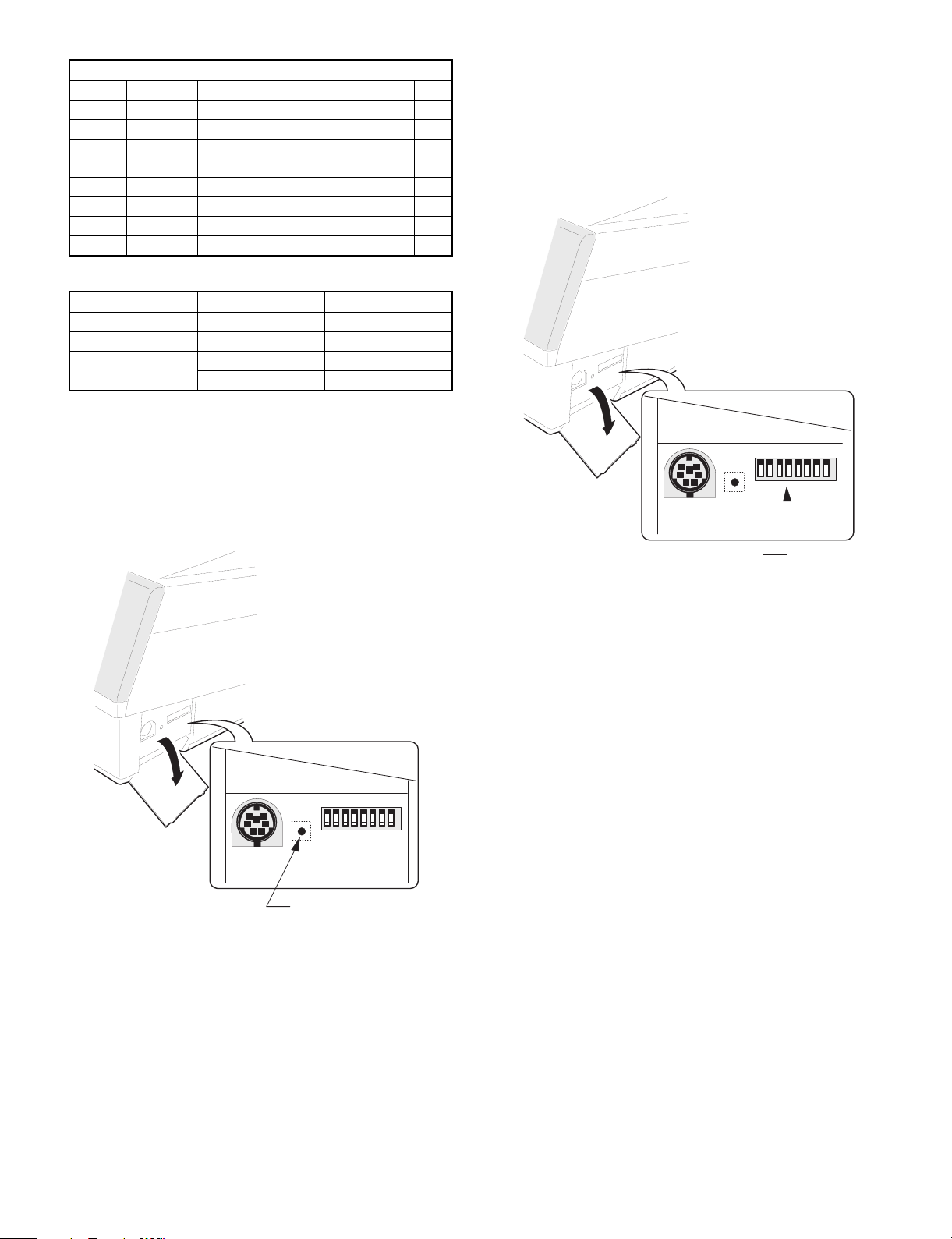

3-6. Shutdown switch

The shutdown switch is used when the OS or application programs

are straying and the system can not return to the normal state.

You must not use this shutdown switch when the UP-5300 is running

normally. Use this switch only when the main power source is not cut

off even if the main unit power switch is set to OFF position. UP-5300

is turned OFF and the hardware is reset by turning the main power

switch OFF and then pressing the shutdown switch.

3-7. System switch

The system switches are used to preset various system configurations.

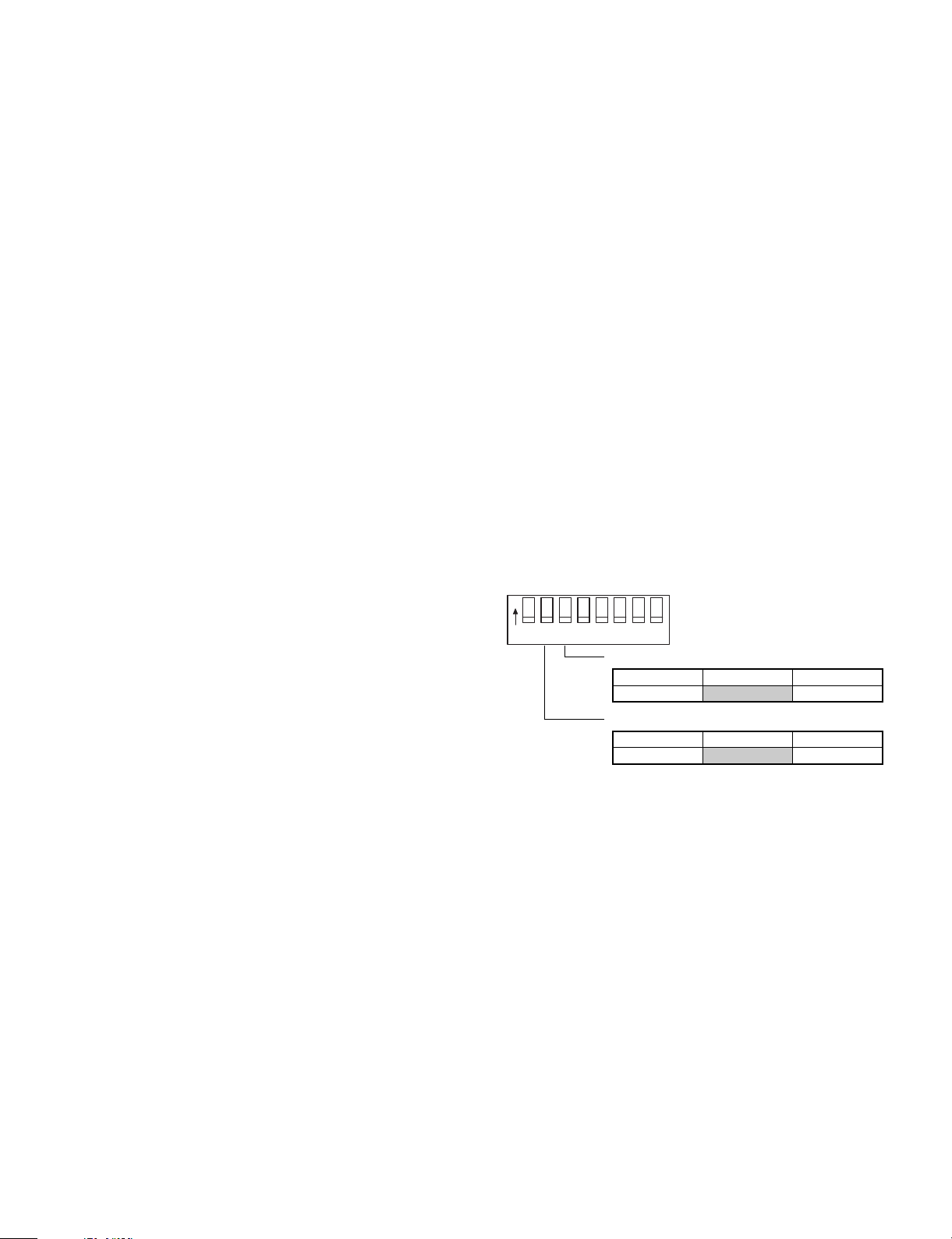

[Out line]

The system switches consists of DIP switches.

[DIP switch]

12345678

12345678

Shut dow n switch

[Out line]

The shutdown switch is single shot type. (Normally OFF position)

Push ON: This position is used to reset stand-by mode for power

supply unit when software hang up.

Release OFF: Usually the shutdown switch needs to be set to this

position when the UP-5300 is operated.

[Operating method]

The shutdown switch is a push switch. If it is pushed to ON, the

UP-5300 stops supplying the power when the power switch is set into

stand-by mode.

NOTE: The shutdown operation will be ignored when te power

switch is set into power-on position.

System sw itch

The PSC2 simply reads the switched signals from the DIP switch as

hardware. The meaning of the switche settings are shown on the next

page.

1 – 2

Page 5

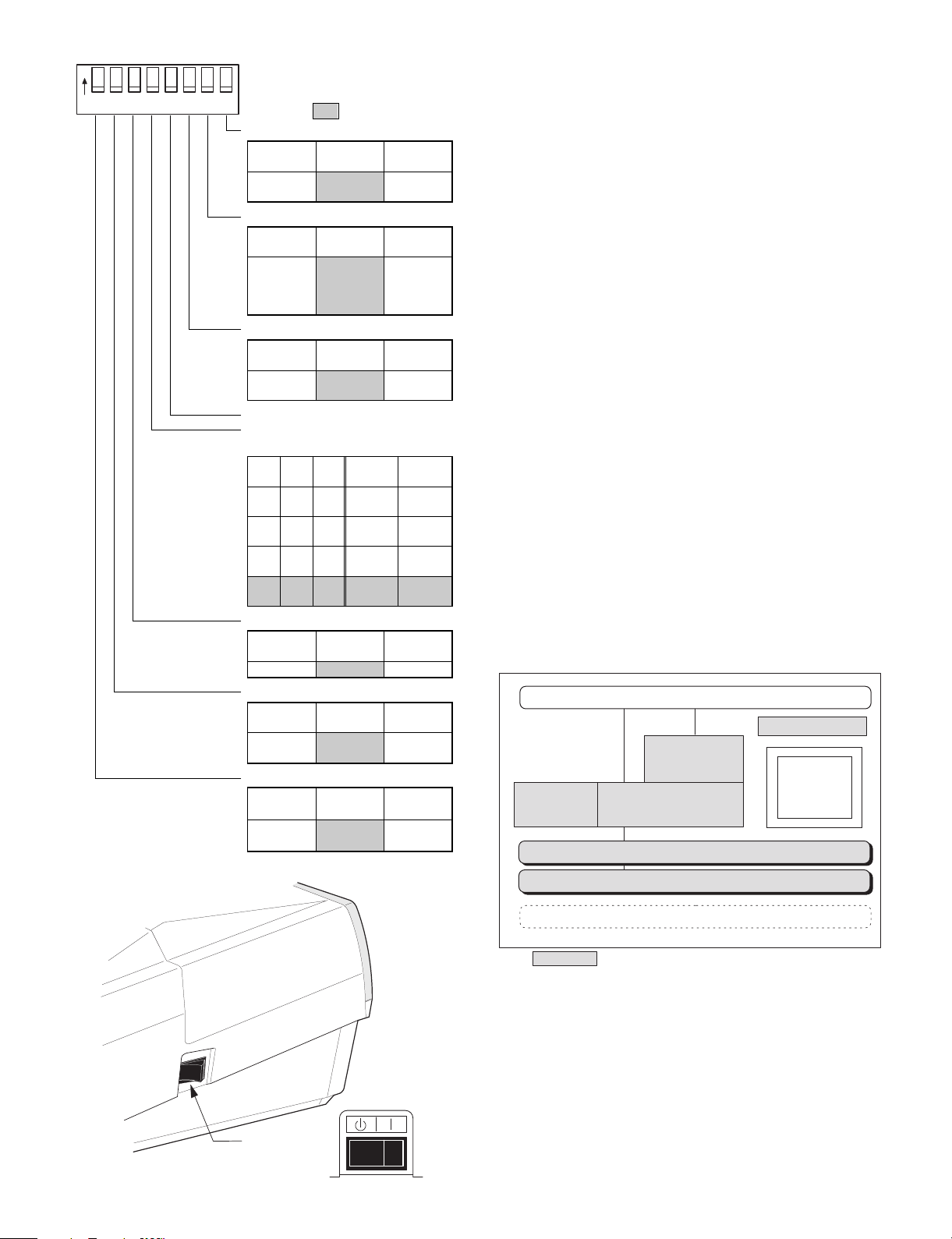

ON

1234567 8

3-8. Power switch

ON

OFF

: De fau lt settin g

DSW-8

Function

Serial 3 & 4

decode mode

OFF

(value=1)

COM3 &

COM4

ON (value=0)

DSW-7

Function

COM3 &

COM4 IRQ

assign

(Serial 3 & 4)

OFF

(value=1)

COM3 =

IRQ11

COM4 =

IRQ10

ON (value=0)

DSW-6

Function

CMOS

Initialize

OFF

(value=1)

Not Initialize Initialize

ON (value=0)

DSW-5

DSW-4

Drive C:, D: & E: Setting

DriveC:DriveD:Drive

HDD — —

PS

HDD

RAM

PS

Flash

RAM

ROM

Flash

ROMPSRAM

DSW-4 DSW-5

E:

ON

(value=0)ON(value=0)

Flash

ROMON(value=0)

OFF

HDD

(value=1)ON(value=0)

OFF

HDD

(value=1)

DSW-3

Function

Boot Drive Drive A: Drive C:

OFF

(value=1)

ON (value=0)

DSW-2

Function

Drive A:

Device

OFF

(value=1)

Mask ROM FDD

ON (value=0)

DSW-1

Function

Floppy Disk

Controller

OFF

(value=1)

Not Exit Exit

ON (value=0)

COM5 &

COM6

COM3 =

IRQ4

COM4 =

IRQ3

OFF

(value=1)

OFF

(value=1)

[Out line]

The power switch has the positions ON and OFF (Stand-by)

ON position: Usually the power switch needs to be set to this posi-

tion when the POS-terminal is operated.

OFF position: This position is used to turn the stand-by mode. When

the power switch is set to this position, the power

supply stops automatically. But if the software program controls the power supply to hold, even if the

power switch is set into this position, power is supplied

until an software program allows power supply no to

hold.

[Operating method]

The power switch is a see-saw switch, and it can be tipped toward

the ON or OFF.

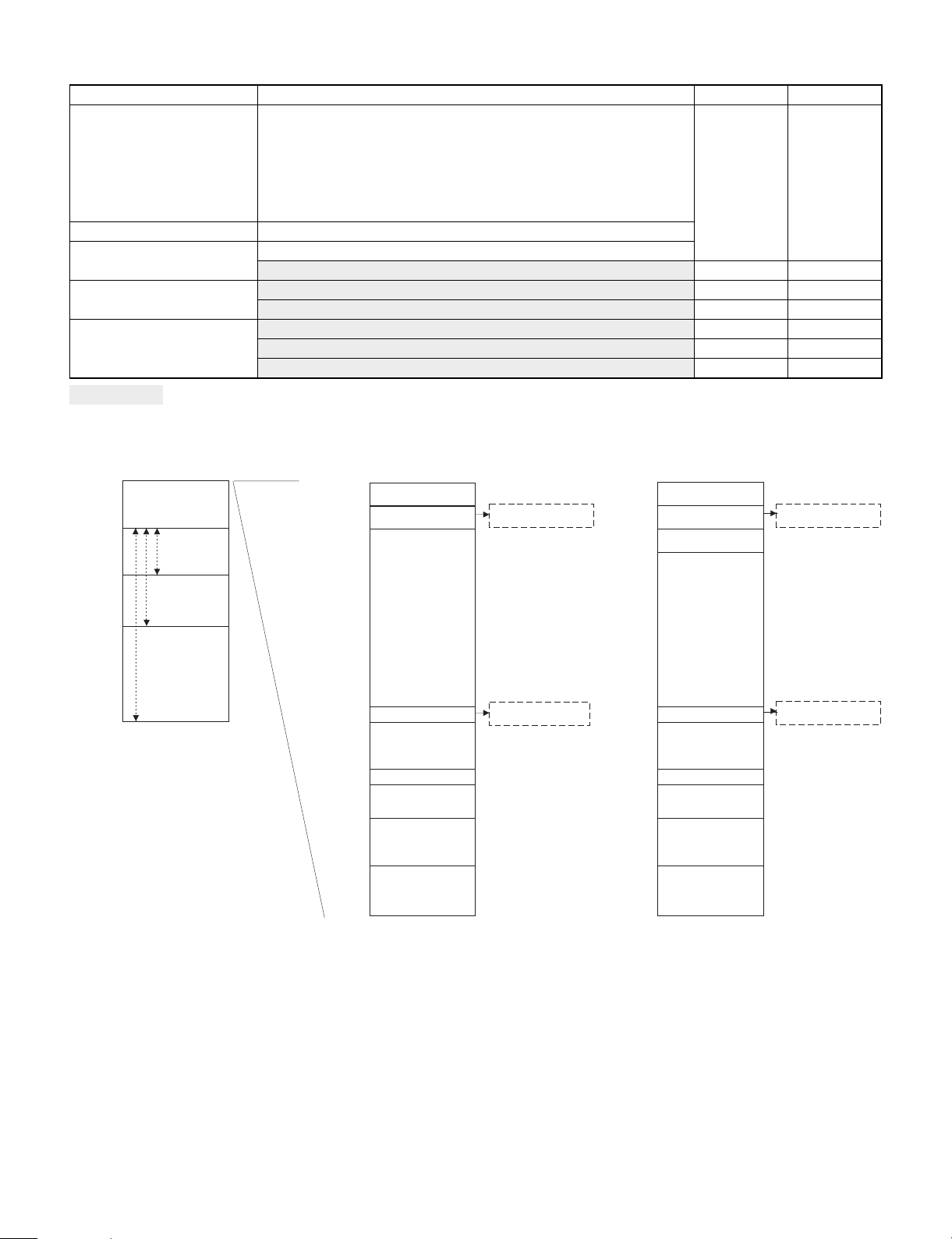

4. Software

4-1. Software Structure

The basic system software mainly consists of the following 3

modules.

(1) MS-DOS Version 6.22

The operating system (MS-DOS Version 6.22) is stored in a MROM

disk.

(2) Drivers

There are following types of drivers

• POS Device Drivers (for Clerk, Buzzer, Drawer, Timer, MCR, Line

Display, Serial Port) POS device drivers adopt the same control

method as previous (ER-A850/A880/UP-5700) softwares.

• Touch Panel Driver

(3) POS Device Middleware

The middleware has been developed to improve the performance of

applications.

(4) Software Structure

Application

POS Utillty

POS Device

Touch

Panel

Driver

Mifddle Wsre

POS Devlce Driver

MS-DOS Version 6.22

BIOS

Standard PC

Device Driver

(Local production)

SCSI

Ethernet

.......etc

Power switch :

Hardware

Provided from SHARP Corporation

1 – 3

Page 6

4-2. Basic system software list

ITEM CONTENTS for UP-5300 for PC

BIOS (FROM) • AT compatible system BIOS

• VGA BIOS for MN89305 VGA LSI

• Standard SETUP program

• Flash Disk/MROM Disk/PSRAM Disk built-in control program

F —

• Memory size/HDD type auto detect function

• No APM/PnP support

OS (MROM disk) MS-DOS Version 6.22 (Subset)

Install program (MROM disk) • System Install program

• APL Install program (for MS-DOS/Windows 95/98/NT) — F

POS device driver • POS device driver F —

• Touch panel driver (mouse emulation I/F only) F —

Middleware software and

application development tools

• POS device MiddleWare F —

• Printer Logo image loading utility program (MS-DOS/Windows 95) FF

• Touch panel calibration utility program (MS-DOS) F —

... These software are provided with FD from SHARP corporation.

Please copy contents of FD provided from department to development PC. Install to UP-5300 by using APL Install Program from PC.

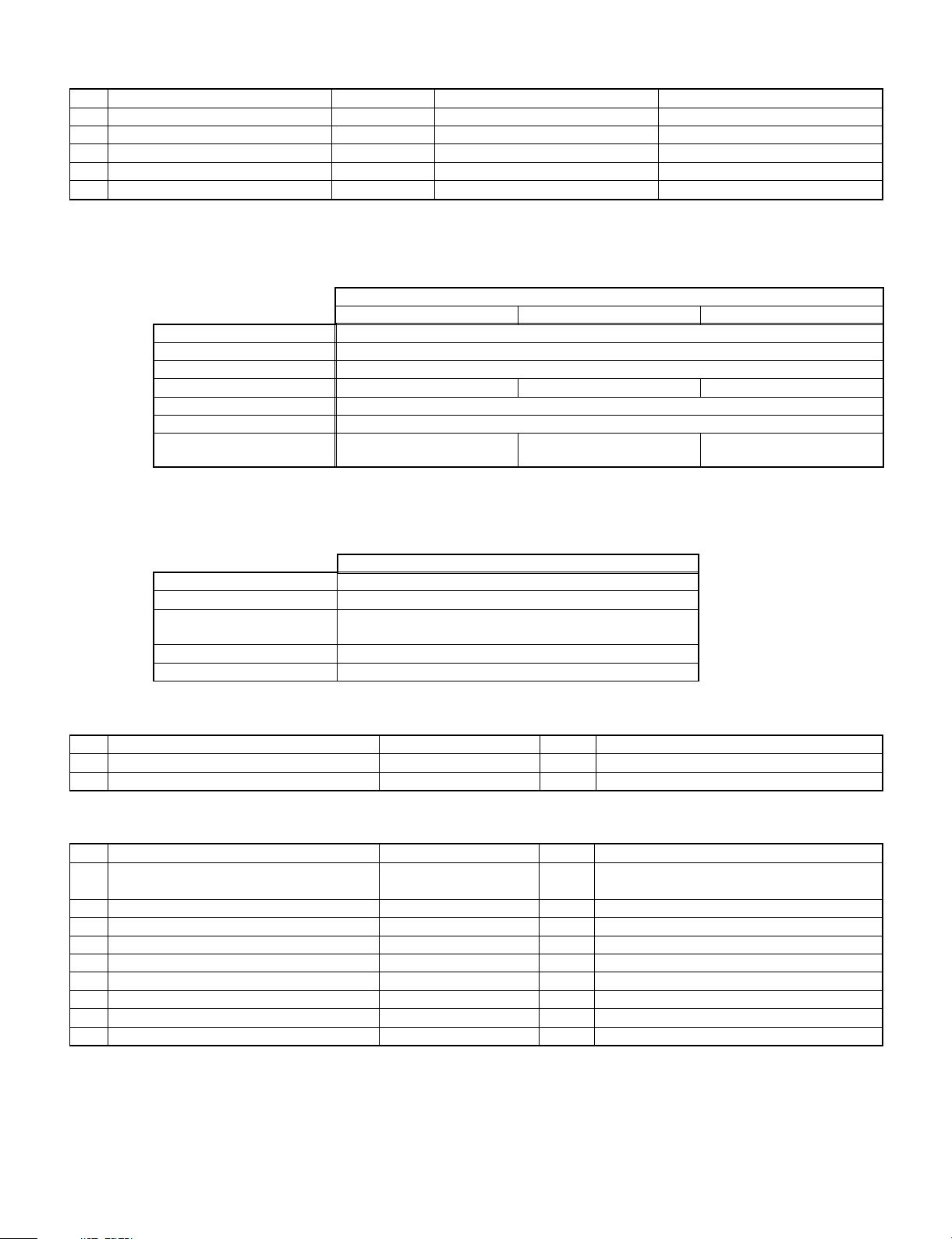

4-3. Memory map

0000000h

STD. 8MB

0800000h

+8MB

1000000h

1800000h

2800000h

(16MB)

+8MB

(24MB)

+32MB

(40MB)

Memory is expandable up to

40MB max. using EMM386 in DOS

00000h

9F4000h

A0000h

C0000h

C8000h

E8000h

100000h

MS-DOS

(25K)

Sharp Driver

(32K)

Free

Conventional

(580K)

EBDA : 3K

VRAM

128K

VGA BIOS(32K)

UMB

(124K)

System BIOS

(96k)

HMA

64K

Middleware Not used

POS Device 20K

Touch Key 12k

(External BIOS

Data Area)

00000h

9F4000h

A0000h

C0000h

C8000h

E8000h

100000h

MS-DOS

(25K)

Sharp Driver

(32K)

Middleware

(15K)

Free

Conventional

(565K)

EBDA:3K

VRAM

128K

VGA BIOS(32K)

UMB

(124K)

System BIOS

(96k)

HMA

64K

Middleware is used

POS Device 20K

Touch Key 12k

(External BIOS

Data Area)

1 – 4

Page 7

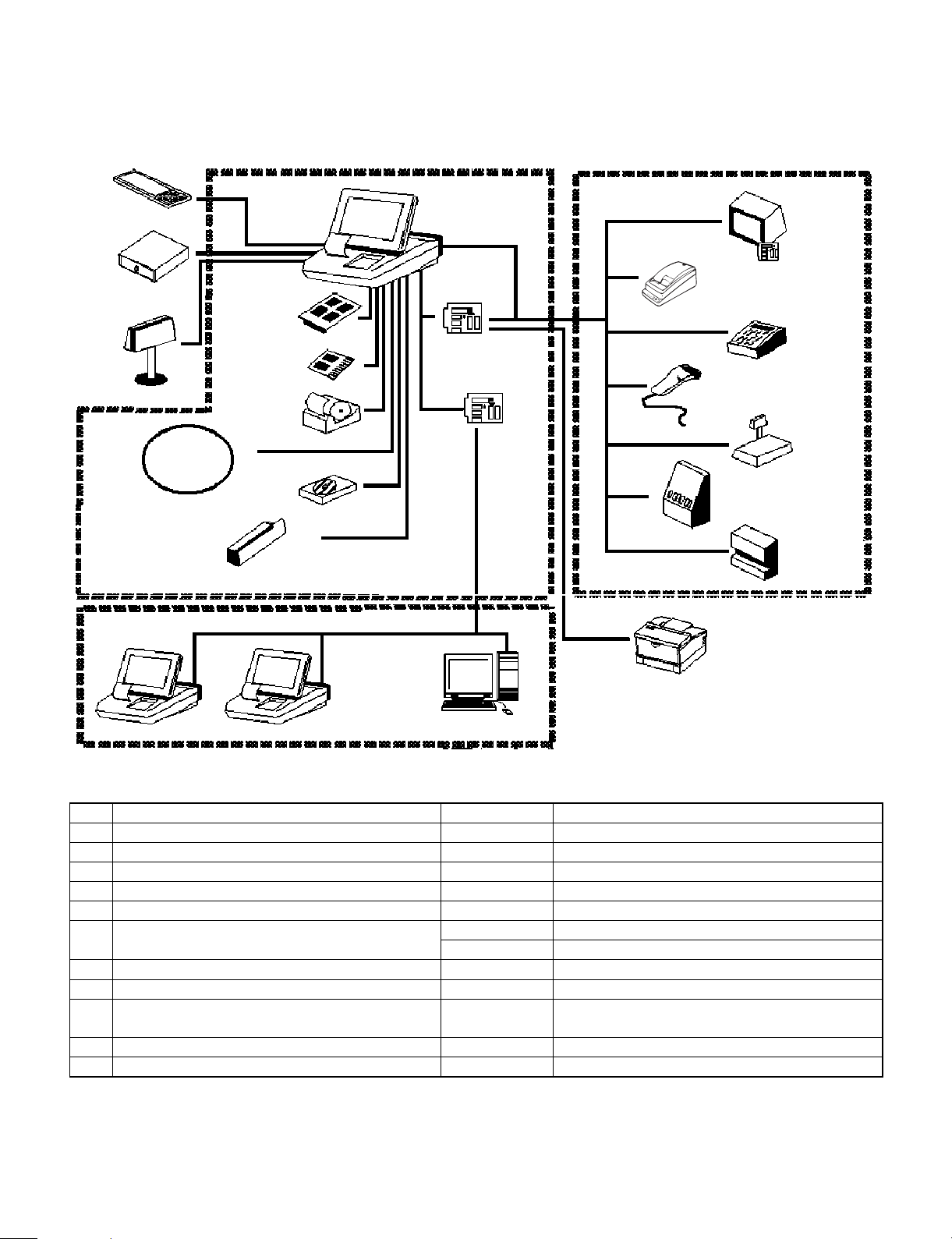

CHAPTER 2. OPTIONS

1. System configuration

Incorporated in Main Unit RS-232 Communication Connection

AT Keyboard

<supplied on site>

max.2

Drawer

<Option>

ER-03DW/

04W/05DW

(In Europe only)

Customer

Poll Display

<Option>

UP-P20DP

Built-in,

customer-side

display

<Option>

UP-I20DP

(NEW)

Additional

RAM Memory

<Option>

UP-P02MB

Additional

ROM Memory

<Option>

UP-F04RB

Additional DRAM

Memory

<supplied on site>

Built-in printer

<Option>

UP-T80BP

HDD Unit

<supplied on site>

UP-5300

(RS-232)

(Standard 4 channels)

(Additional 2 channels)

RS232 Board

<Option>

ER-A8RS

Ethernet Board

<supplied on site>

Kitchen video monitor

<supplied on site>

(For North America only)

Remote Printer

<Option> ER-01PU

<supplied on site>

Hand Scanner

<Option>

ER-A6HS1

Coin dispenser

<supplied on site>

(For North America only)

TM-T80/85/295

ER-FBT40

<supplied on site>

<supplied on site>

CAT/FET

Scale

Magnetic

Card Reader

<Option>

UP-E12MR

In-line Communication

Connection

UP-5300

Host PC

PC

<supplied on site>

Centronics Printer

<supplied on site>

2. Options

No. NAME MODEL NAME DESCRRIPTION

1 Expansion RAM disk board UP-P02MB 2 Mbytes RAM board

2 Expansion ROM disk board UP-F04RB 4 Mbytes ROM board

3 Customer display UP-I20DP 2 line 20 digits dot display

4 Customer pole display UP-P20DP 2 line 20 digits dot display

5 MCR (Magnetic Card Reader) UP-E12MR2 for ISO 1 & 2 stripe card

6 Remote drawer ER-03DW 7B/5C

ER-04DW 5B/5C

7 Receipt/Journal printer ER-01PU 2 station (R/J) thermal printer 45mm width

8 Built-in printer UP-T80BP 1 station thermal printer 80mm width

9 RS232 & CENTRO I/F board ER-A8RS RS232 9 pins connector:2 ports

Centronics 25 pins connector : 1 port

10 Hand scanner ER-A6HS1 for reading bar code

11 FDD unit HZ-H14FD 3.5" Floppy Disk Drive (Newtronics D353M3)

Drink dispenser

<supplied on site>

(For Europe only)

2 – 1

Page 8

3. Locally supplied options

No. NAME MODEL NAME DESCRIPTION

1 S.O.DIMM Small Outline DIMM Max. 32Mbyte *1

2 HDD (by FUJITSU) MHD2021AT 2.5 inch, 2.1Gbyte *2

3 PC keyboard PS/2 type PC keyboard

4 Application software

5 Additional device drivers

*1 EXTENSION RAM MODULE (Provided through SHARP Electronics Corporation)

[Outline] UP-5300 has a socket as Small Outline DIMM.

It is necessary to satisfy with S.O.DIMM memory specification as follows.

[Specification]

144pin S.O.DIMM

8 Mbytes 16 Mbytes 32 Mbytes

TYPE EDO type

ACCESS TIME 60 nsec. (less than)

POWER 3.3 V

REFRESH CYCLE 1024/16 msec. 2048/32 msec. 4096/64 msec.

REFRESH TYPE CBR

POWER CONSUMPTION 700 mA (less than)

OTHER 4 chip × 16 Mbits

*2 HARD DISK DRIVE (Local purchase)

[Outline] UP-5300 may be connected to the Hard Disk Drive.

[Specification]

It is necessary to satisfy the 2.5 inch Hard Disk Drive specification as follows.

MAKER FUJITSU

MODEL MHD2021AT

PARTS No.

REVISION No.

CAPACITY 2.16 Gbytes

INTERFACE ATA-3

1) Part No.: CA 01640-B040

Rev. No.: A4

(1 Mwords × 16 bits)

2.5 inch type Hard Disk Drive

8 chip × 16 Mbits

(2 Mwords × 8 bits)

4 chip × 64 Mbits

(4 Mwords × 16 bits)

4. Service options

No. NAME PARTS CODE PRICE DESCRIPTION

1 Connector cable for Dongle (LPT-1) QCNW-7858BHZZ BL Relay line from Terminal to Dongle

2 HDD mounting kit DKIT-8671RCZZ — Bracked assembly for mounting

5. Service tools

No. NAME PARTS CODE PRICE DESCRIPTION

1 Service tool kit DKIT-8656BHZZ CW ISA checker

ISA relay board

2 Printer connector signal loop back connector UKOG-6717RCZZ BR for ER-A8RS CENTRONICS connector

3 MCR test card UKOG-6718RCZZ BE for UP-E12MR

4 RS232 loop back connector UKOG-6705RCZZ BC for RS232 connector

5 CPU/VGA PWB relay PWB CKOG-6728BHZZ CQ

6 BIOS loading board CKOG-6727BHZZ CS for overwriting BIOS

7 RS232 modular jack loop back connector UKOG-6729BHZZ AZ for RJ45 connector

8 BIOS MASTER ROM VHI27040RBQ1A (P) EP-ROM for overwriting BIOS

9 TOUCH PEN CPENP1004PCN5 AG

2 – 2

Page 9

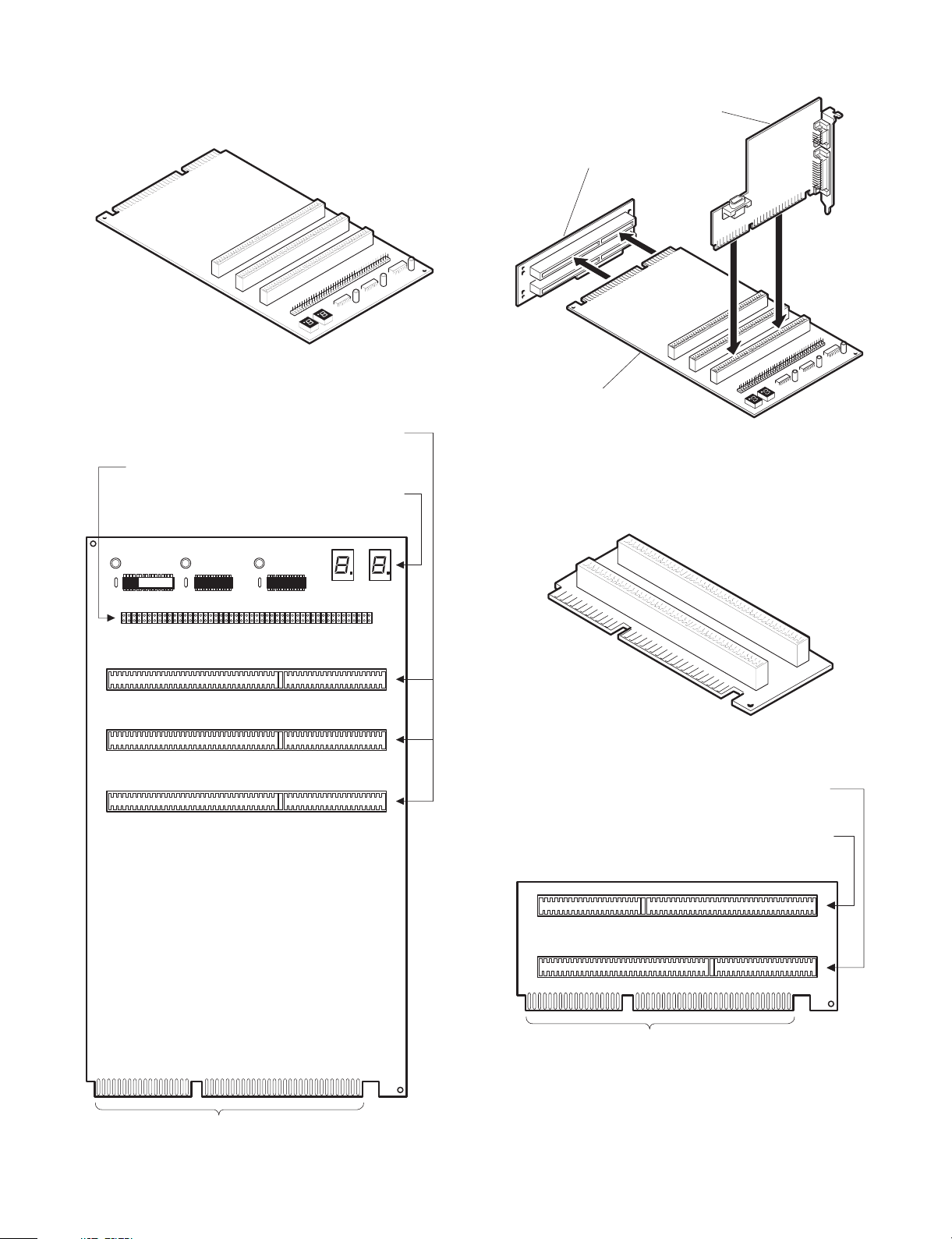

4-1. Service tool kit: DKIT-8656BHZZ

1) ISA checker

Used to repair or check the operation of the optional I/F.

• External view

• Plain view

ISA bus connectors:

Used to connect with the I/F PWB of ER-A8RS etc.

Test pins: Used to check the ISA bus signal.

LED circuit: Not used currently.

• Connection diagram

ER-A8RS

UP-5300

ISA bus connector

ISA checker

2) ISA relay board

Connected to the ISA checker for installation of the optional I/F

horizontally and for repairing and checking the operation .

• External view

RAM1A

• Plain view

ISA bus connector:

Used to check the ER-A8RS parts side.

ISA bus connector:

Used to check the ER-A8RS solder side.

Connected to the UP-5300 ISA bus connectors.

Connected to the ISA bus connector of ISA checker.

2 – 3

Page 10

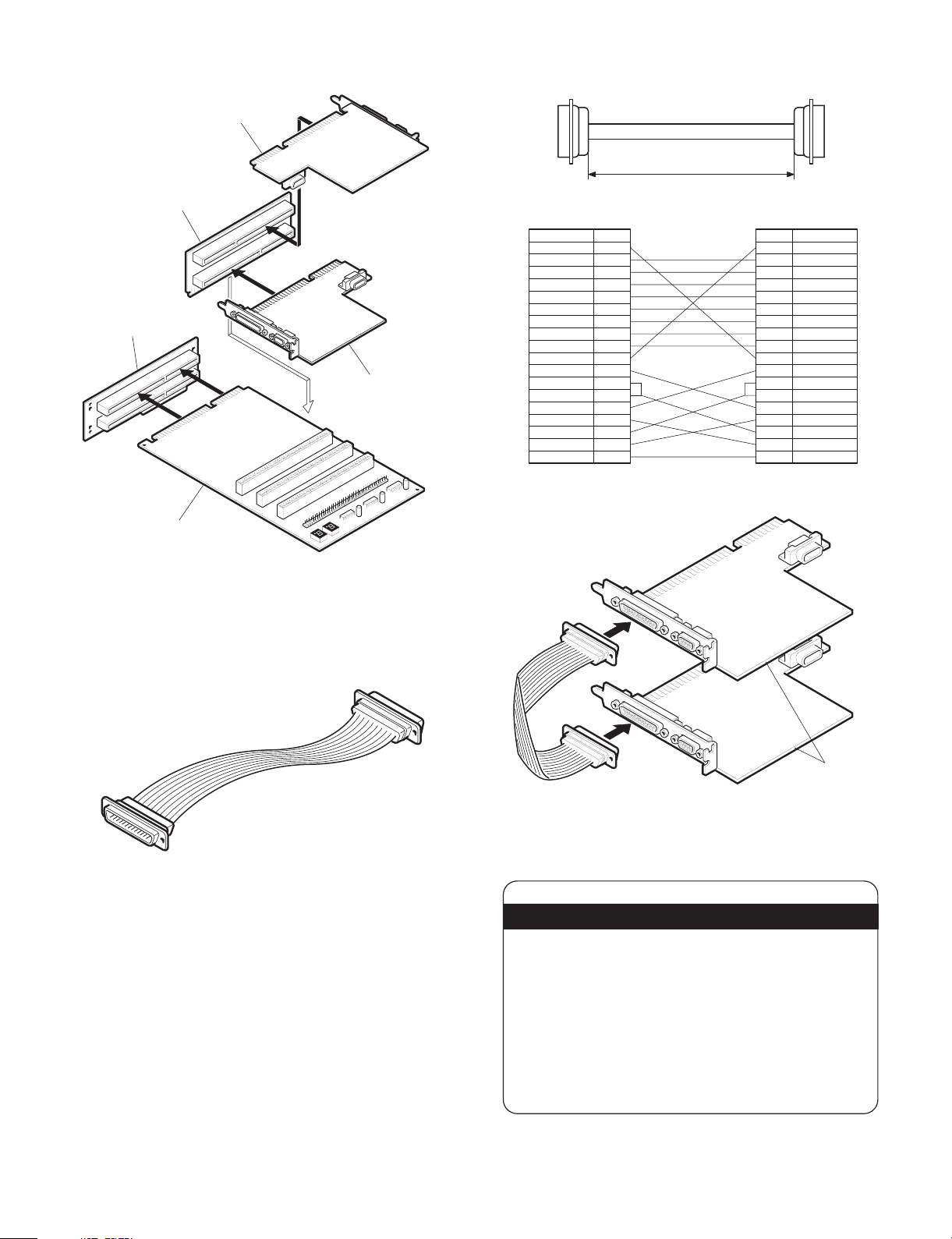

• Connection diagram

ER-A8RS solder side

ISA relay board

• Plan view and connection diagram

150±8

ISA PWB

ER-A8RS parts side

ISA checker

4-2. Printer connector signal loop check cable:

UKOG-6717RCZZ

Connected to the centronics connector (25 pin) of the ER-A8RS, and

is used to check loop signals when executing diagnostics.

• External view

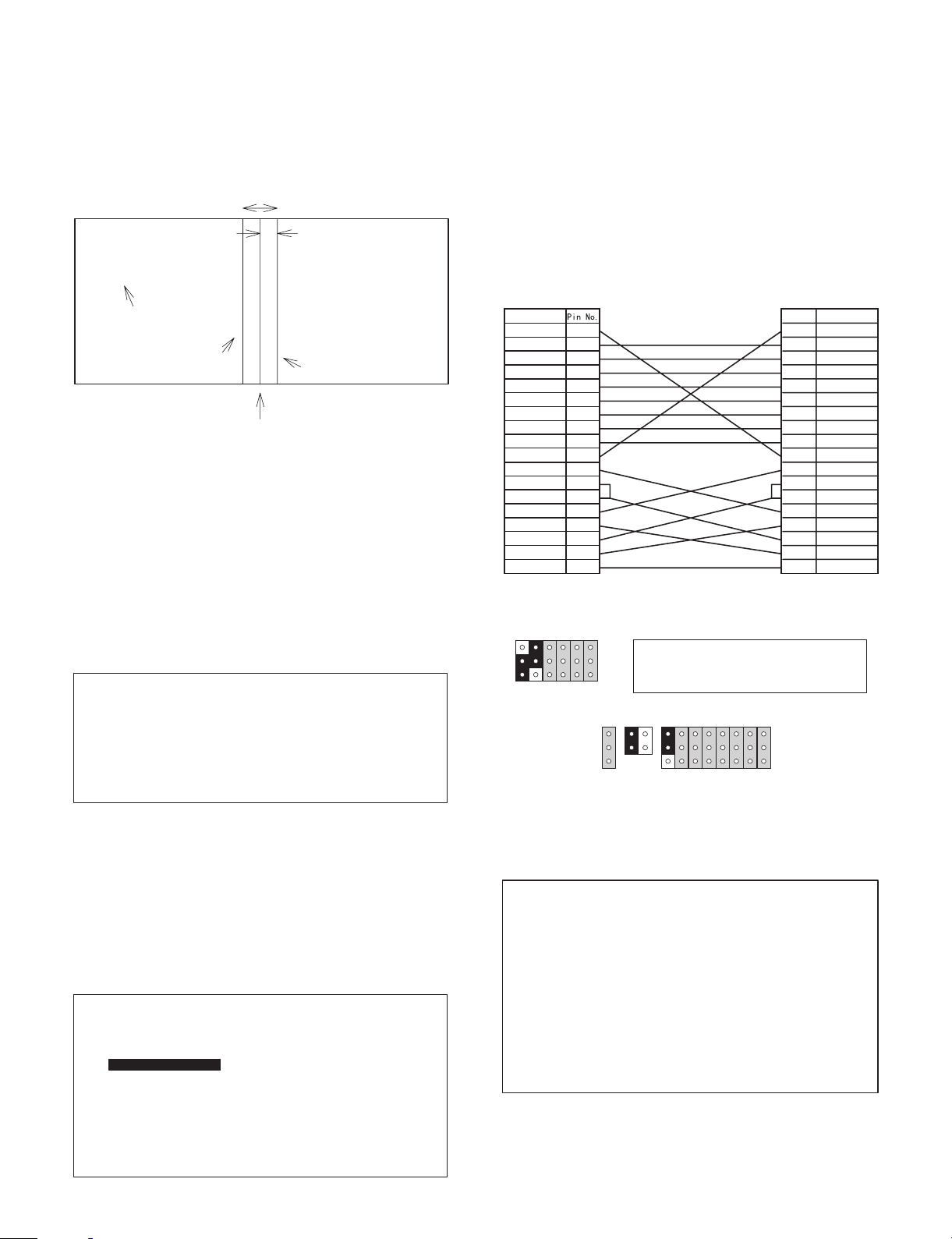

Signal name Pin No.

1STROBE2DB0

3DB1

4DB2

5DB3

6DB4

7DB5

8DB6

9DB7

10ACK11BUSY

12PE

13SLCT

14AUTOFD15ERROR16INIT17SLCTIN-

18~25PE

• Connection diagram

Signal namePin No.

1 STROBE2 DB0

3 DB1

4 DB2

5 DB3

6 DB4

7 DB5

8 DB6

9 DB7

10 ACK11 BUSY

12 PE

13 SLCT

14 AUTOFD15 ERROR16 INIT17 SLCTIN-

18~25 PE

4-3. MCR test card: UKOG-6718RCZZ

• Used when executing the diagnostics of the UP-E12MR2.

• External view

2 – 4

ER-A8RS

Page 11

4-4. RS232 loop back connector: UKOG-6705RCZZ

Connected to the RS232 connector (D-SUB 9 pin: COM1, COM2,

COM3, COM4) of the UP-5300 and ER-A8RS, and used to check

loop signals when executing diagnostics.

• Connection diagram

CD 1pin

RD 2pin

TD 3pin

DTR 4pin

GND 5pin

DSR 6pin

RTS 7pin

CTS 8pin

RI 9pin

4-5. RS232 modular jack loop back connector:

UKOG-6729BHZZ

Connected to the RS232 connector (RJ45: COM3, COM4, COM5,

COM6) of the UP-5300, and used to check loop signals when executing diagnostics.

• Connection diagram

1pin

RTS

2pin

DTR

3pin

TD

4pin

GND

5pin

GND

6pin

RD

7pin

DSR

8pin

CTS

• Plain view

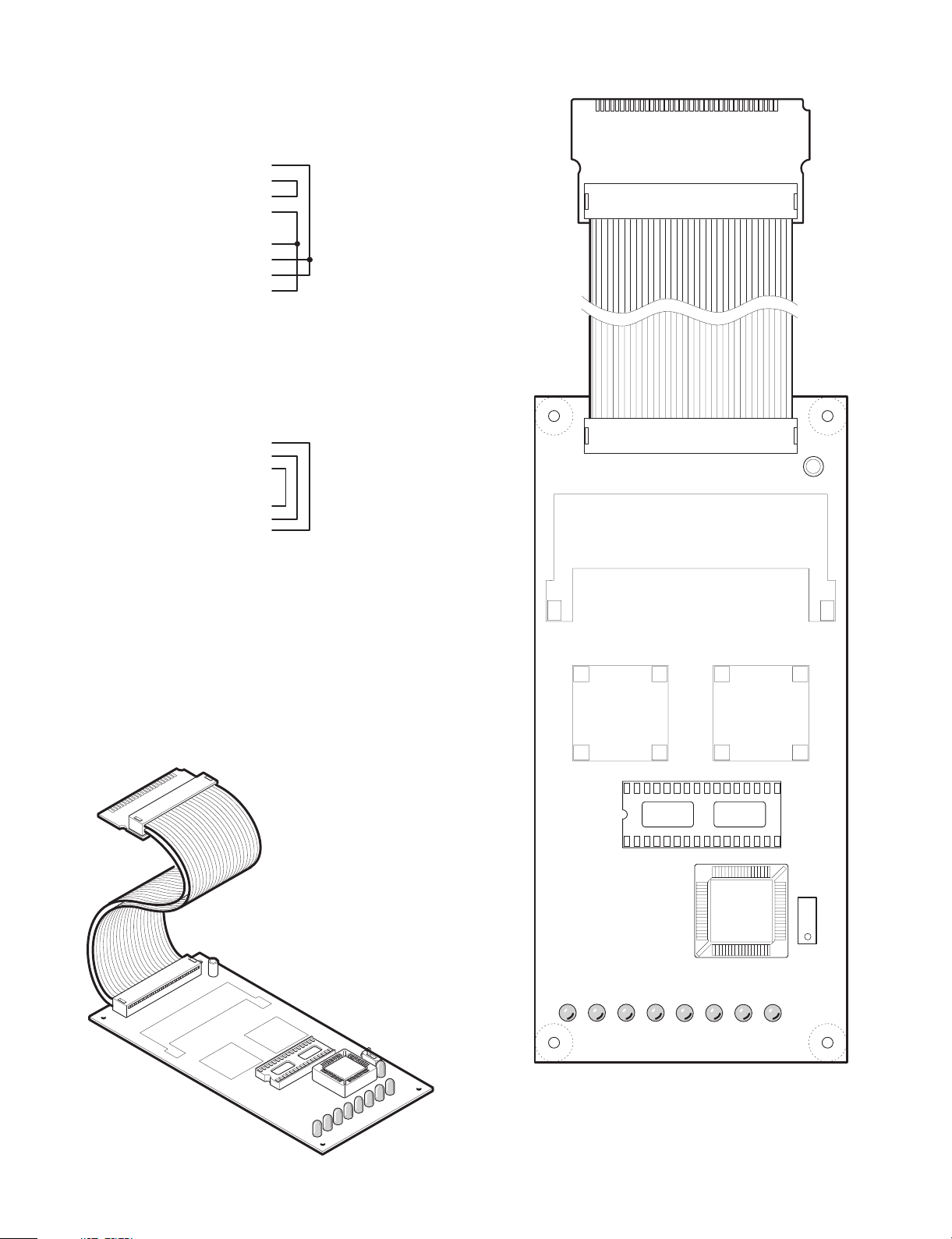

4-6. BIOS loading board: CKOG-6727BHZZ

The BIOS loading board: CKOG-6727BHZZ is a tool to write a BIOS

ROM program in the F-ROM on the UP-5300’s main board. Use this

PWB in the following cases:

• The F-ROM on the UP-5300’s main board be comes unreadible

and a BIOS ROM program must be written in the F-ROM.

• The BIOS ROM program in the F-ROM is overwritten due to the

version up of BIOS ROM program, etc.

The BIOS loading board is connected to the Option ROM/RAM disk

connector (CN5) of the Main PWB.

• External view

SW1

13

• Connection diagram

2 – 5

LED1 LED2 LED3 LED4 LED5 LED6 LED7 LED8

Page 12

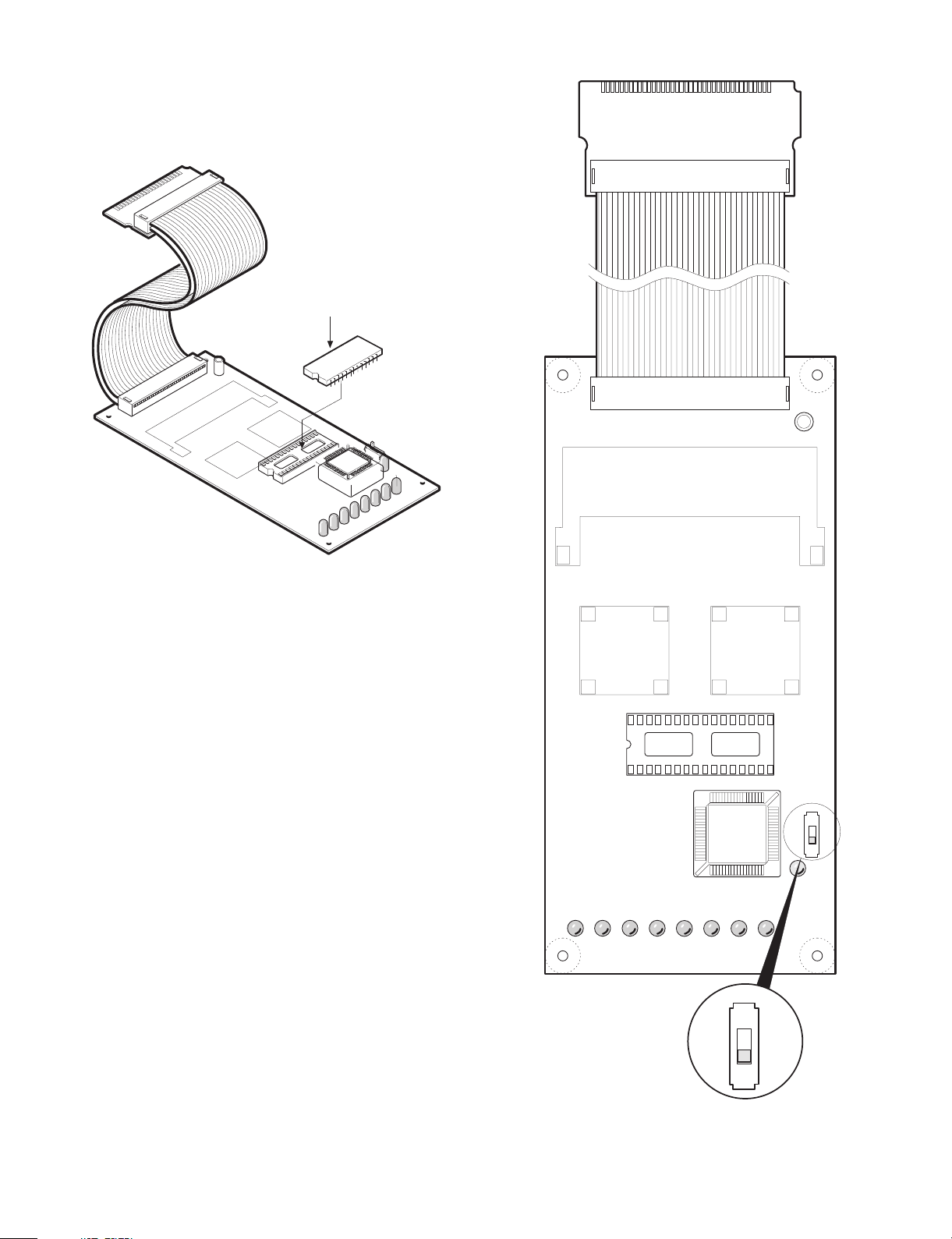

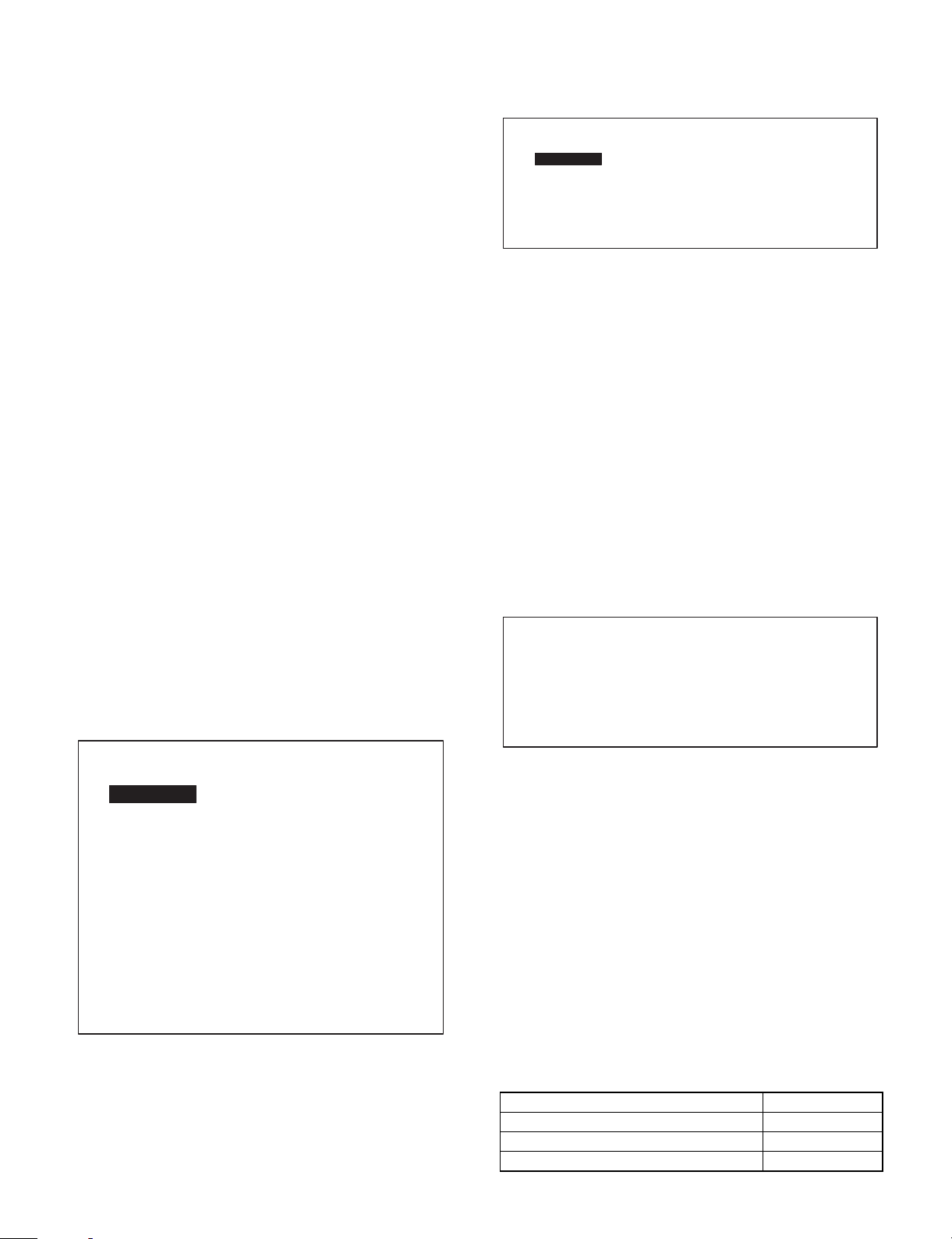

Writing BIOS ROM Program

NOTE: Remove all option boards from the ISA slots before writing

on the BIOS ROM.

1. Install the EP-ROM (master ROM): containing a BIOS program on

the BIOS loading board: CKOG-6727RCZZ.

BIOS MASTER ROM

2. Set SW1 on the BIOS loading board to the side of pin 3.

* Caution: The AC power must be removed prior to installing the

BIOS loading board.

LED1 LED2 LED3 LED4 LED5 LED6 LED7 LED8

SW1

SW1

1

3

LED9

SW1

1

2 – 6

3

Page 13

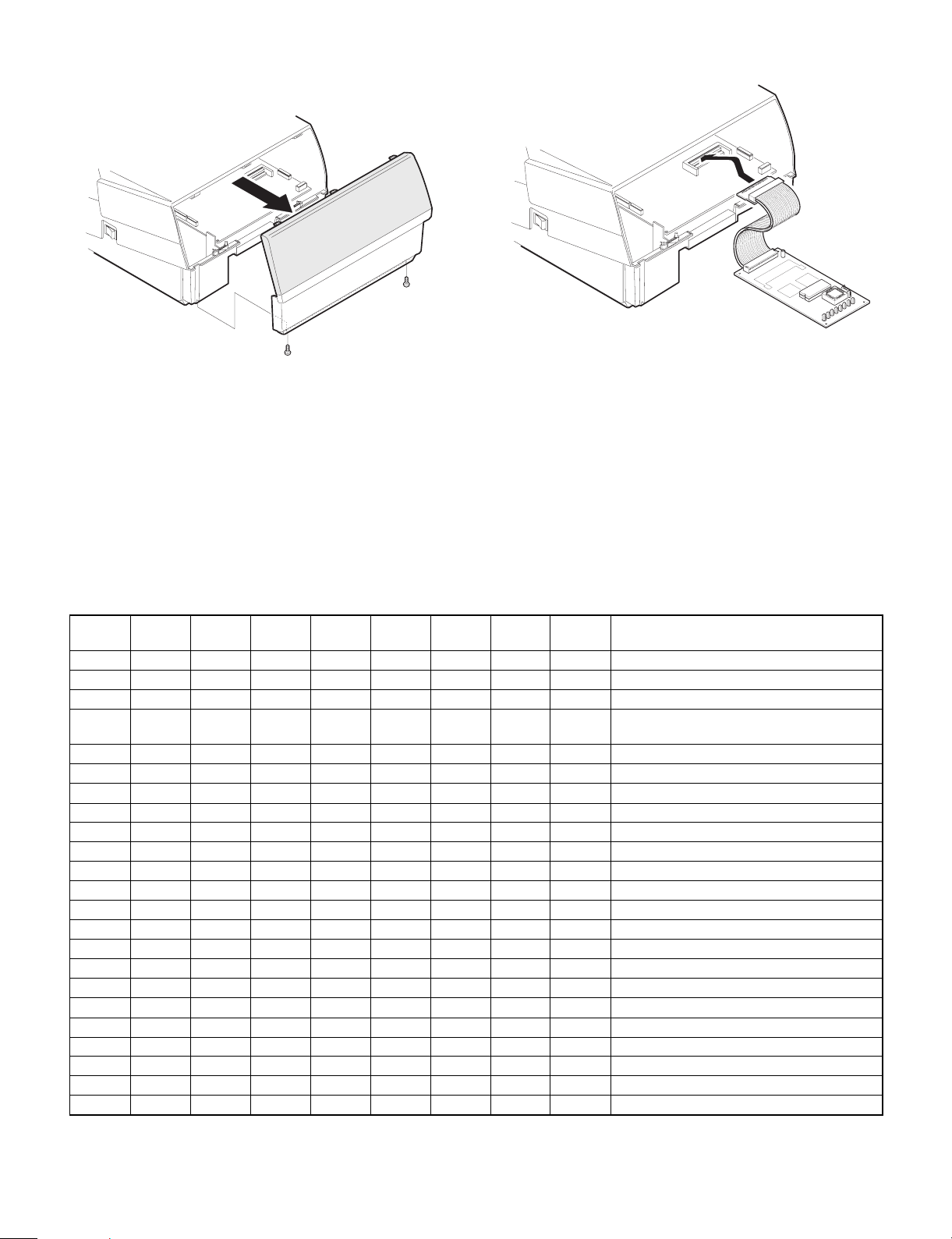

3. Open the upper cabinet.

4. Connect the BIOS loading board to the option ROM/RAM connector CN5 on the main PWB, and then close the cabinet.

5. Writing the BIOS ROM program starts by turning on the power

switch on the right side.

To determine the status of the LED lights on the special service

PWB when a BIOS ROM program is being written, see the table

on the next page.

Writing is complete (automatic completion) when the green LED

(LED9) on the BIOS loading board lights up.

6. After writing is complete, turn off the power switch on the right side

to remove the BIOS loading board, and turn on the power switch

on the left side again to check whether the BIOS program starts

up normally or not.

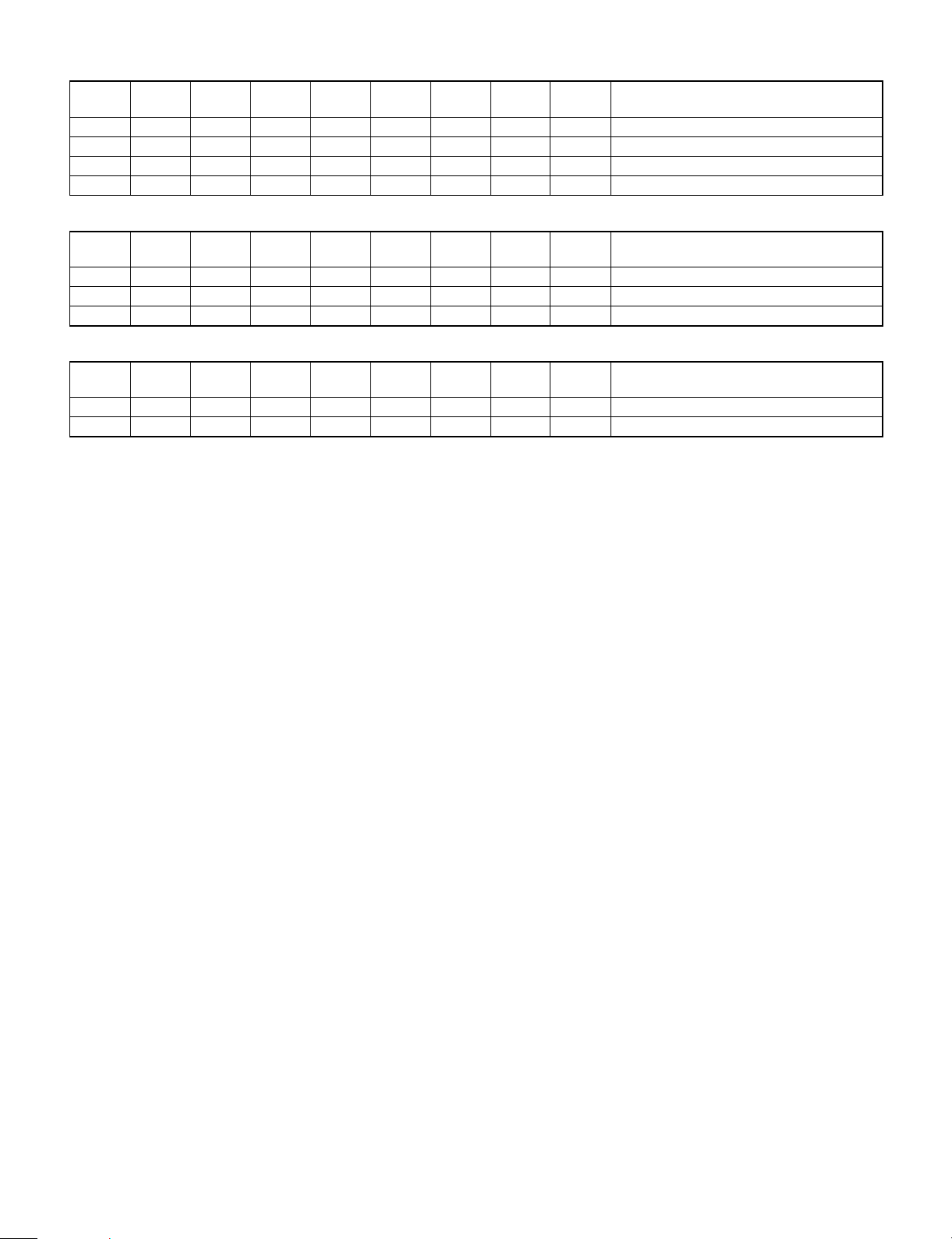

LED DISPLAY STATUS

[E : ON (Lighting) — : OFF]

<In normal operation>

LED1

(RED)

EEEEEEEE— Start of COPY FUNCTION

————E ————Start initializing

—————E — — — Erasing F-ROM (LED6: RED is blinking)

————EE———

————EE— — — Programming: Bank0 C0000 h (64KB)

E ———EE— — — Programming: Bank0 D0000 h (64KB)

— E ——EE— — — Programming: Bank0 E0000 h (64KB)

EE——EE— — — Programming: Bank0 F0000 h (64KB)

———EEE— — — Programming: Bank1 C0000 h (64KB)

E ——EEE— — — Programming: Bank1 D0000 h (64KB)

— E — EE E— — — Programming: Bank1 E0000 h (64KB)

EE— EEE— — — Programming: Bank1 F0000 h (64KB)

——————E — — Start verifying the program in the F-ROM

——————E — — Verifying: Bank0 C0000 h (64KB)

E —————E — — Verifying: Bank0 D0000 h (64KB)

— E ————E — — Verifying: Bank0 E0000 h (64KB)

EE————E — — Verifying: Bank0 F0000 h (64KB)

———E ——E — — Verifying: Bank1 C0000 h (64KB)

E ——E ——E — — Verifying: Bank1 D0000 h (64KB)

— E — E ——E — — Verifying: Bank1 E0000 h (64KB)

EE— E ——E — — Verifying: Bank1 F0000 h (64KB)

————E — E — — Setting protection the F-ROM

EEEEEEEEEEND of complete COPY FUNCTION

LED2

(RED)

LED3

(RED)

LED4

(RED)

LED5

(RED)

LED6

(RED)

LED7

(RED)

LED8

(RED)

LED9

(GREEN)

FUNCTION

Start copy programming to F-ROM from EPROM

2 – 7

Page 14

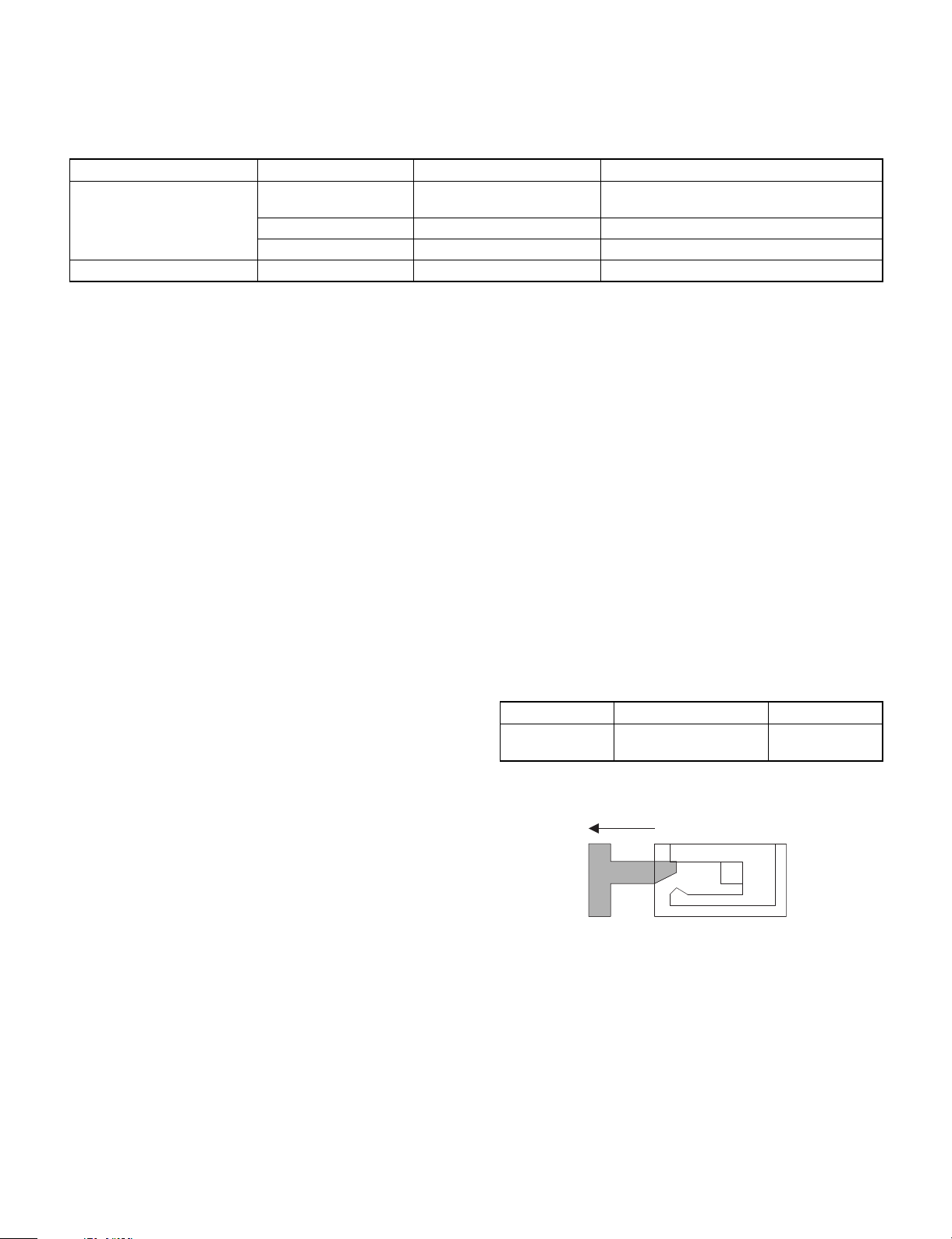

<Erase ERROR in F-ROM>

LED1

(RED)

E ————E — E — Device not ready

— E ——— E — E — VPP error

EE———E — E — Command sequence error

——E —— E — E —

<Programming ERROR in F-ROM>

LED1

(RED)

E ———EE— E — Device not ready

— E ——EE— E — VPP error

EE——EE— E — Command sequence error

<Verifying ERROR in F-ROM>

LED1

(RED)

E ———E — EE— Device not ready while release the protection

— E ——E — EE— Can not release the protection

LED2

(RED)

LED2

(RED)

LED2

(RED)

LED3

(RED)

LED3

(RED)

LED3

(RED)

LED4

(RED)

LED4

(RED)

LED4

(RED)

LED5

(RED)

LED5

(RED)

LED5

(RED)

LED6

(RED)

LED6

(RED)

LED6

(RED)

LED7

(RED)

LED7

(RED)

LED7

(RED)

LED8

(RED)

LED8

(RED)

LED8

(RED)

LED9

(GREEN)

LED9

(GREEN)

LED9

(GREEN)

FUNCTION

FUNCTION

FUNCTION

2 – 8

Page 15

CHAPTER 3. SERVICE PRECAUTION

1. Conditions for soldering circuit parts

To solder the following parts manually, follow the conditions described below.

PARTS NAME PARTS CODE LOCATION CONDITIONS FOR SOLDERING

Ceramic oscillator RCRMZ7002RCZZ TOCH PANEL CONTROL

PWB: X1 (8M)

RCRMZ7003RCZZ MAIN PWB: X2 (24M)

RCRMZ7004RCZZ MAIN PWB: X2 (7.37M)

DIP SWITCH QSW-Z7011XCZZ SWITCH PWB: S2 300°C/3sec.

270°C/3sec.

2. Cautions on handling CPU and POWER

FAN

When removing or performing maintenance activities on the CPU and

POWER FAN, be sure to handle them with care, because it may

cause abnormal sounds or deteriorate their performance if they are

dropped or exposed to a heavy impact.

3. Note for handling of Touch panel

• The transparency of the touch panel should be vitally important.

Use clean gloves and masks.

• For handling, do not hold the transparent area, and do not hold the

heat seal connector section to assure reliability.

• Do not overlay touch panels. The edge may damage the surface.

• Do not place heavy things on the touch panel.

• Do not apply a strong shock, and do not drop it.

• When attaching the protection film again, carefully check for dirt. If

there is any dirt, it is transferred.

• To clean dirt on the surface, use a dry, soft cloth or a cloth im -

mersed in ethyl alcohol.

• Check that the housing does not give stress to the touch panel.

• Be careful not to touch the touch panel with tools.

• The heat seal section is easily disconnected. Be careful not to

place stress to the heat seal section when installing.

• The touch panel is provided with an air groove to make the exter -

nal and the internal air pressure equal to each other. If water or oil

is put around the air groove, it may penetrate inside. Be careful to

keep the air groove away from water and oil.

• Do not use SHARP objects when making input entrres.

4. Note for handling of LCD

• The LCD elements are made of glass. BE careful not to expose

them strong mechanical shock, or they may be broken. Use extreme care not to break them.

• If the LCD element is broken and the liquid leaks, avoid contact

with your mouth or eyes. If the liquid comes in contact with your

skin or clothes, immediately clean with soap.

• Use the unit under the rated conditions to prevent against damage.

• Be careful not to place water or other liquids on the display sur -

face.

• The reflection plate and the polarizing plate are easily scratched.

BE careful not to touch them with a hard object such as glass,

tweezers etc. Never hit, push, or rub the surface with hard objects.

• When installing the unit, be careful not to apply stress to the LCD

module. If excessive stress is applied, abnormal display or uneven

color may result.

5. Cautions on handling connectors

When connecting or disconnecting the following connectors, follow

the procedures below.

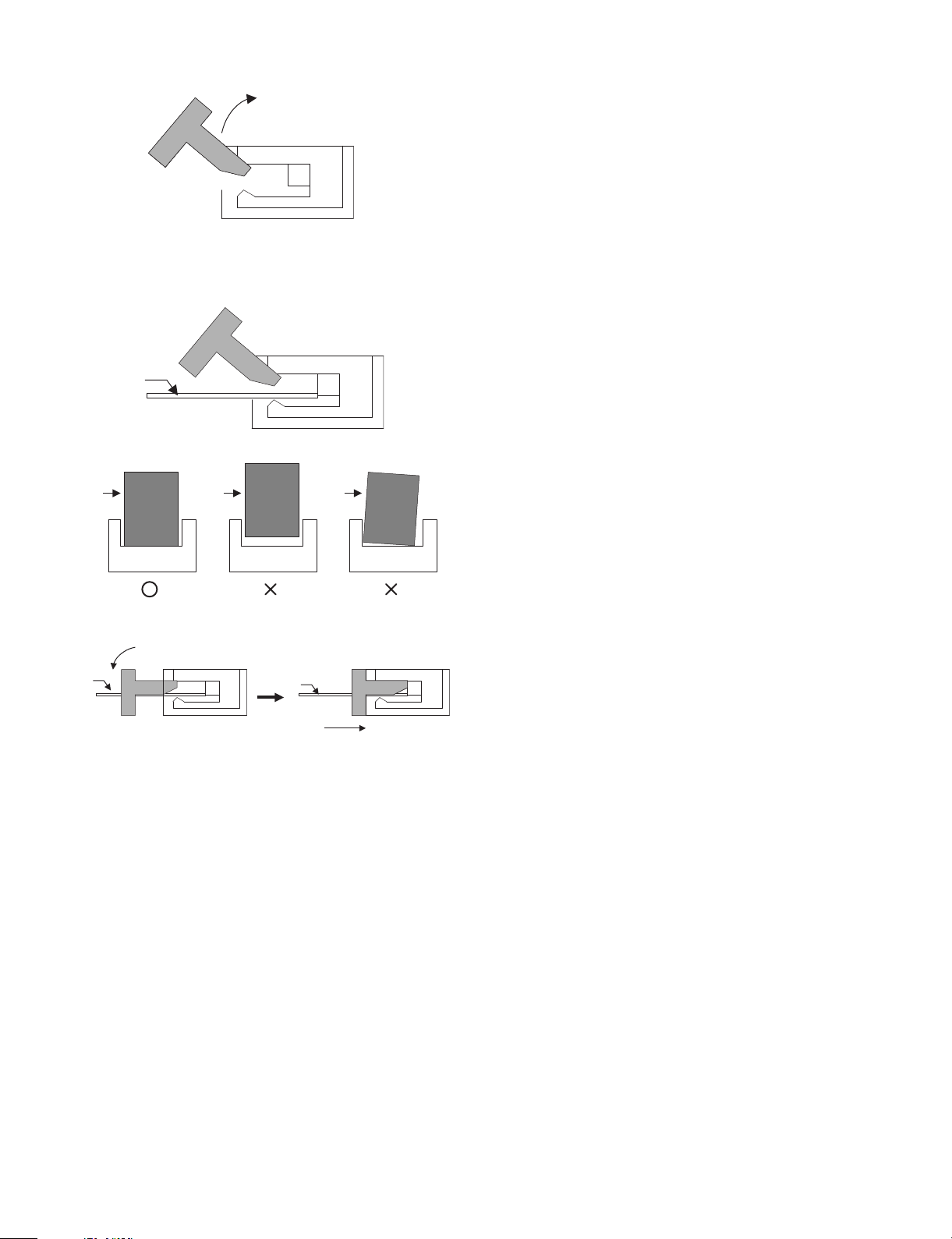

1)

PARTS NAME PARTS CODE LOCATION

FFC

CONNECTOR

• How to insert FFC

(1) Pull the slider to the unlock position.

QCNCW2812BH3J LCD RELAY

PWB: CN8

3 – 1

Page 16

(2) Open the slider upwards.

(3) Inserting the FFC

Insert the FFC firmly until the FFC hits the bottom of the

connector’s insulator.

FFC

FFC FFC FFC

CONNECTOR CONNECTOR CONNECTOR

(4) Close the slider to the lock position

FFC

FFC

6. AT Keyboard usable for UP-5300

The UP-5300 can be externally connected to a keyboard.

The UP-5300’s key BIOS conforms to the PC standard, but this

BIOS’s operation is not compatible for some keyboards.

Some keyboards may cause operation errors due to delicate timing

and conflicts.

It is currently found that the following models of keyboards may malfunction.

When selecting a keyboard to be connected, test the keyboard in

advance to check that it correctly works.

• Japanese keyboard (106 keys)

Manufactured by IBM: TYPE/MODEL5576-B01 FRUPN66G0507

• English keyboard (101 keys)

Manufactured by NMB Technologies Inc.: Model: RT6651T+

3 – 2

Page 17

CHAPTER 4. UP-5300 DIAGNOSTICS

SPECIFICATIONS

CONTENT

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

2. System configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

3. Service diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

3-1. Service diagnostics getting started . . . . . . . . . . . . . . . . 4-2

3-2. Selection menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

3-3. RAM Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

1) D-RAM Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

2) Standard RAM Disk Check . . . . . . . . . . . . . . . . . . . 4-2

3) OPTION RAM Disk Check . . . . . . . . . . . . . . . . . . . 4-3

3-4. ROM Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

1) DOS ROM Check . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

2) BIOS ROM Check . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

3) Standard FLASH ROM Check . . . . . . . . . . . . . . . . 4-4

4) Option FLASH ROM Check . . . . . . . . . . . . . . . . . . 4-4

3-5. Real time clock & CMOS RAM Diagnostics . . . . . . . . . 4-4

1) Real time clock Check . . . . . . . . . . . . . . . . . . . . . . 4-5

2) CMOS RAM Check . . . . . . . . . . . . . . . . . . . . . . . . 4-5

3-6. Touch Panel Diagnostics . . . . . . . . . . . . . . . . . . . . . . . 4-5

1) Controller Diag Test . . . . . . . . . . . . . . . . . . . . . . . . 4-5

2) Touch Key Pad Test . . . . . . . . . . . . . . . . . . . . . . . . 4-5

3) Linearity Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

3-7. Clerk Key Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

1) Clerk Key Check . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

3-8. Printer Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

1) PARALLEL1 Loop Check . . . . . . . . . . . . . . . . . . . . 4-6

2) PARALLEL2 Loop Check . . . . . . . . . . . . . . . . . . . . 4-7

3) PARALLEL3 Loop Check . . . . . . . . . . . . . . . . . . . . 4-7

4) PARALLEL1 Print Check . . . . . . . . . . . . . . . . . . . . 4-7

5) PARALLEL2 Print Check . . . . . . . . . . . . . . . . . . . . 4-8

6) PARALLEL3 Print Check . . . . . . . . . . . . . . . . . . . . 4-8

7) UP-T80BP Test . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

3-9. Serial I/O Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

1) COM1 Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

2) COM2 Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

3) COM3 Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4) COM4 Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

5) COM5 Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

6) COM6 Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

3-10. Liquid Crystal Display Diagnostics . . . . . . . . . . . . . . . 4-10

1) Liquid Crystal Display Check . . . . . . . . . . . . . . . . 4-10

3-13. Magnetic Card Reader Diagnostics . . . . . . . . . . . . . . 4-11

1) Magnetic Card Reader Check . . . . . . . . . . . . . . . 4-11

3-14. System Switch Diagnostics . . . . . . . . . . . . . . . . . . . . . 4-11

1) System Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

3-15. Drawer Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

1) Drawer 1 Check . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

2) Drawer 2 Check . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

3-16. Option Display Diagnostics . . . . . . . . . . . . . . . . . . . . . 4-12

3-17. IDE I/F & HARD DISK Diagnostics . . . . . . . . . . . . . . . 4-12

[READ MODE TEST] . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

1) Drive Status display . . . . . . . . . . . . . . . . . . . . . . . 4-12

2) Sequential Seek Test . . . . . . . . . . . . . . . . . . . . . . 4-12

3) Random Seek Test . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4) Seek&Read Test . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

5) Target Sector Read Test . . . . . . . . . . . . . . . . . . . 4-14

6) HD Dump Test . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

7) Error lnformation Display . . . . . . . . . . . . . . . . . . . .4-14

8) Controller check Test . . . . . . . . . . . . . . . . . . . . . . .4-15

[WRITE MODE TEST] . . . . . . . . . . . . . . . . . . . . . . . . .4-15

9) Seek&Write/Read-Verify Test . . . . . . . . . . . . . . . .4-15

10) Target Sector Write/Read-Verify Test . . . . . . . . . .4-16

11) HDPatch Test (Utility) . . . . . . . . . . . . . . . . . . . . . .4-16

12) Error Logging Area Clear . . . . . . . . . . . . . . . . . . . .4-16

13) Error table display . . . . . . . . . . . . . . . . . . . . . . . . .4-16

14) Other Supplemental Items . . . . . . . . . . . . . . . . . . .4-16

15) Error Content . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

16) Error Information Storing Area Description . . . . . .4-16

3-18. FDD Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

3-19. FAN & LCD ON/OFF Diagnostics . . . . . . . . . . . . . . . . .4-17

1) FAN & LCD ON/OFF Check . . . . . . . . . . . . . . . . .4-17

3-20. Power Hold Diagnostics . . . . . . . . . . . . . . . . . . . . . . . .4-17

1) Power Hold Check . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Subsequently the POS application software is added which may overwrite the F-ROM area.

Please check to insure that the diagnostic program is installed along

with the POS application.

Starting Diagnostics when an Application software is

installed:

(1) Execute the diagnostic program by rebooting the UP-5300 from

the BIOS-ROM (MASK ROM).

1) Remove AC power by placing the power switch to the "off"

position.

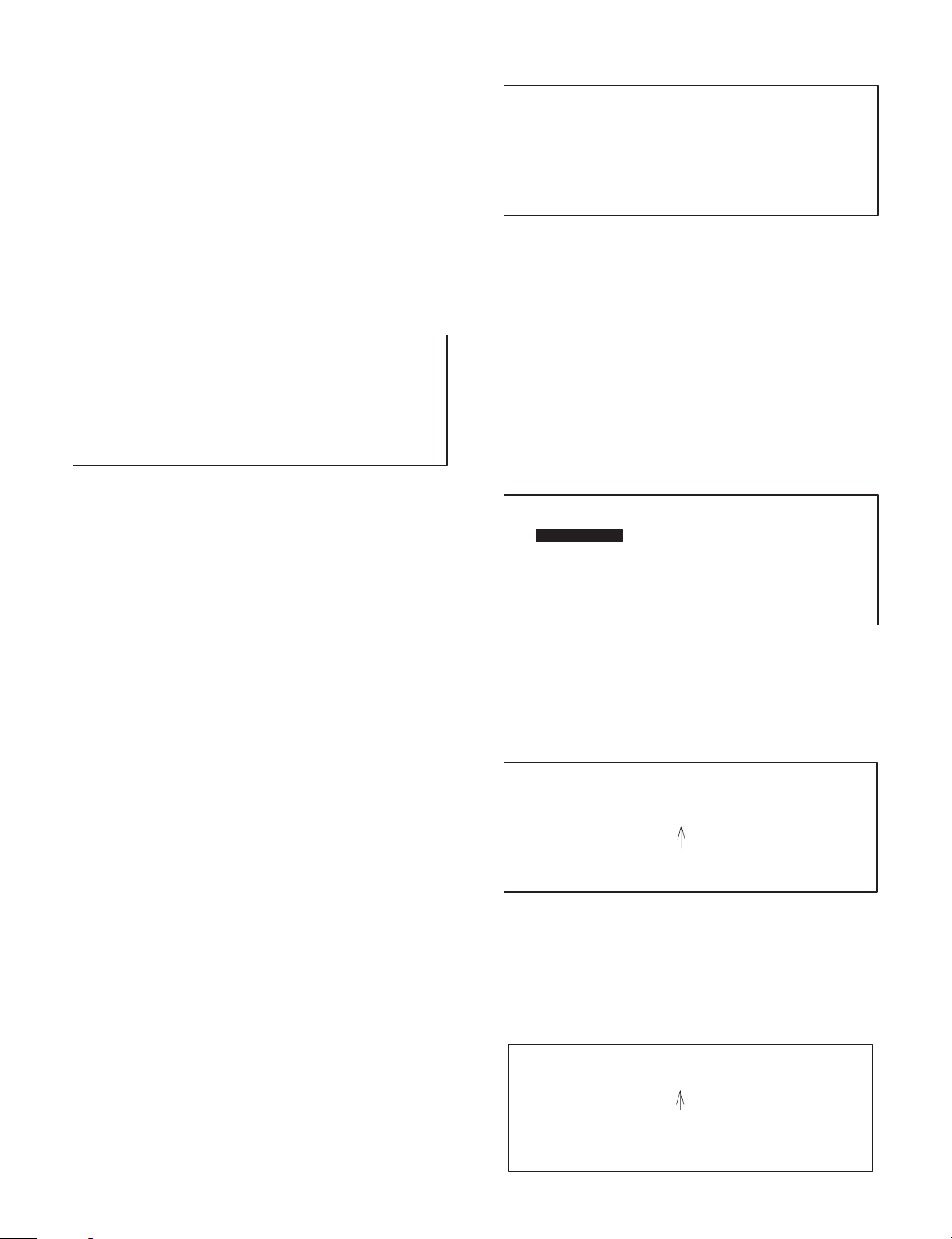

2) Set the system switches (DSW-2 and DSW-3) as follows:

ON

1234567 8

DSW-3

DSW-2

Drive A: Device Mask ROM FDD

3) Connect the AT keyboard.

4) Turn on the AC power on to start upthe BIOS-ROM (MASK

ROM).

Then the incorporated system installer utility will start.

5) Press the ESC key on the AT keyboard, and select "EXIT"

followed by pressing the ENTER key to exit the System

installer.

The UP-5300 will go to the A:\> prompt.

6) To select the drive that of diagnostics program, type "C:\"

followed by the ENTER key.

7) At the "C:\" prompt , type "SRV" followed by the ENTER key

to start the serviceman’s diagnostic program.

ON

OFF

Function OFF (value = 1) ON (value = 0)

Boot Drive Drive A: Drive C:

Function OFF (value = 1) ON (value = 0)

Starting Diagnostics when an Application software is

installed:

(2) To execute the diagnostic program when an application program

is also installed.

1) Remove AC power by placing the power switch to the "off"

position.

2) Set the system switches (DSW-2 and DSW-3) as shown

above:

3) Connect the AT keyboard.

4) Turn on the AC power.

4 – 1

Page 18

5) Depress the F8 function key located on the AT keyboard and

start the UP-5300 without executing the "CONFIG.SYS" and

the "AUTOEXEC.BAT". The UP-5300 will go to the A:\>

prompt.

6) To select the drive that of diagnostics program, type "C:\"

followed by the ENTER key.

7) At the "C:\" prompt , type "SRV" followed by the ENTER key

to start the serviceman’s diagnostic program.

1. General

This diagnostic program is used to check the PWB’s, the process,

and the machine of UP-5300 series in a simplified manner.

This test program is supplied with floppy disks.

2. System configuration

The system requires the UP-5300, and an AT keyboard for diagnostic

operations.

3. Service diagnostics

3-1. Service diagnostics getting started

Getting started:

Execute "SRV.BAT" by entering the command with the AT keyboard

as follows:

C:\> SRV ↵

"C:\>" is the DOS prompt. (Used by the F-ROM disk based on the

settings of the system switches.)

* Do not load any device drivers when using this program.

* To operate other applications after performing this program, reboot

the machine.

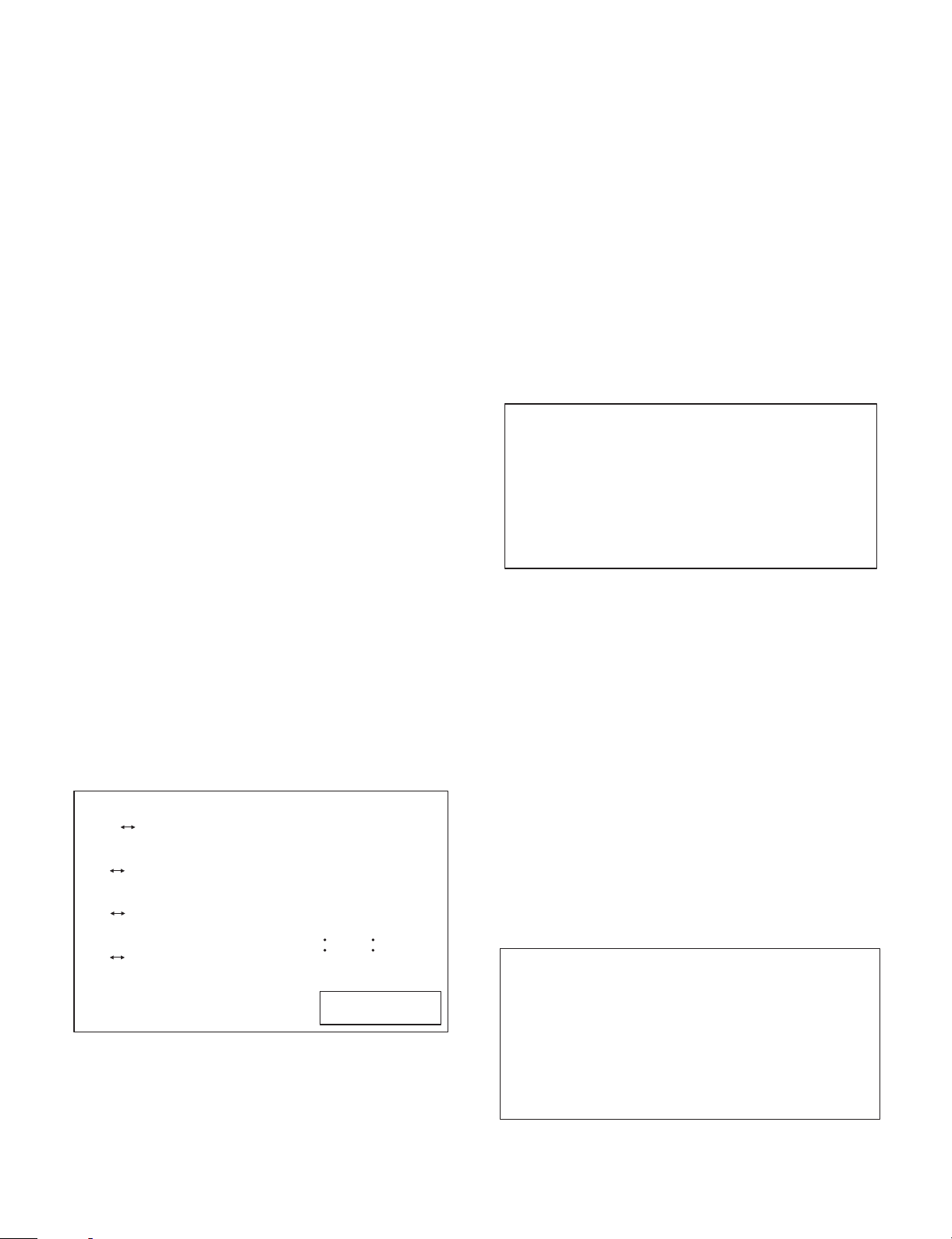

3-2. Selection menu

The diagnostics menu is started and the following menu is displayed.

The highlighted cursor is moved by the cursor keys (UP ↑ and DOWN

↓) of the AT keyboard. Move the cursor to the desired item, and press

the Enter key to execute the selected diagnostics program. When the

selected diagnostics program is completed, the display returns to the

menu screen by pressing the ESC key. Select "Diagnostics End" and

press the Enter key to terminate the diagnostics.

When the selected diagnostics program is completed, Press the ESC

key to return to the RAM menu screen. Pressing the Esc key again

returns to the service diagnostics menu.

RAM Diagnostics

D-RAM Check

Standard RAM Disk Check

Option RAM Disk Check

1) D-RAM Check

1 Checking content

All memory areas are checked in units of 64KB. The checking

procedures are as follows:

i. Test data 5555H is written to all the test areas.

ii. Test data and read data are compared by each word, If it is

O.K., test data AAAAH is written to the test area.

iii. Test data and read data are compared by each word, If it is

O.K., test data 5555H is written to the test area.

iv. Test data 0000H is written to all the test areas.

v. Test data and read data are compared by each word, If it is

O.K., test data FFFFH is written to the test area.

vi. Test data and read data are compared by each word, If it is

O.K., test data 0000H is written to the test area.

When an error occurs during the test, the error address and data

are displayed and the test is stopped.

For the extension memory test, the value set in the setup of read

and test and is made to the area in increments of 64KB.

2 Display

D-RAM Check

Main memory size : 640KB PASS !!(or ERROR !!)

Extended memory size : xxxxKB PASS !!(or ERROR !!)

Error Address xxxxxxH Write Data xxxxH Read Data xxxxH

SHARP PC-POS System Diagnostic Series I

Diagnostics for Service

RAM Diagnostics

ROM Diagnostics

Real time clock & CMOS RAM Diagnostics

Touch Panel Diagnostics

Clerk Key Diagnostics

Printer Diagnostics

Serial I/O Diagnostics

LCD (Liquid Crystal Display) Diagnostics

MCR (Magnetic Card Reader) Diagnostics

System Switch Diagnostics

Drawer Diagnostics

Option Display Diagnostics

IDE I/F & Controller Diagnostics

FDD Diagnostics

FAN&LCD ON/OFF Diagnostics

Power Hold Diagnostic

Diagnostics End

Version 1.00B

3-3. RAM Diagnostics

This program is used to test the standard memory, the extension

memory, and the RAM disk.

When this program is selected, the following menu is displayed.

The highlighted cursor is moved by the cursor keys (UP ↑ and DOWN

↓) of the AT keyboard. Move the cursor to the desired item, and press

the Enter key to execute the selected diagnostics program.

When testing the extension memory size, the value set in the

setup is displayed. The error address and the error data are displayed only when an error occurs. (When no errors occur, they are

not displayed.)

3 Terminating method

After completion of the test, press Esc key to terminate the test to

return to the RAM diagnostics menu.

2) Standard RAM Disk Check

1 Checking content

When testing the standard RAM disk area (BANK 000H ∼ 03FH),

each test area of bank size 16KB is checked. The bank base

address of RAM is set to 0D4000H and after. The checking procedures are as follows:

i. Write different data to the following address by word method.

After the completion of writing, a BANK 03FH 0D4000H data

read verify check is made. (Data in the written area is saved

in the main memory.) If it is OK, the following test is executed.

In case of an error, the error display is made and the test is

terminated.

Write address Write data

BANK BFH (extension) 0D4000H BF40H

BANK 7FH (extension) 0D4000H 7F80H

BANK 3FH (standard) 0D4000H 3FC0H

4 – 2

Page 19

ii. The test area data is saved to the main memory.

iii. Test data 5555H is written to all the test areas.

iv. Test data and read data are compared by each word, If it is

O.K., test data AAAAH is written to the test area.

v. Test data and read data are compared by each word, If it is

O.K., test data 5555H is written to the test area.

vi. Test data 0000H is written to all the test areas.

vii. Test data and read data are compared by each word, If it is

O.K., test data FFFFH is written to the test area.

viii. Test data and read data are compared by each word, If it is

O.K., test data 0000H are written to the test area.

ix. The saved data is written to the test areas.

When an error occurs during the test, the error address and data

are displayed and the test is stopped.

2 Display

Standard RAM Disk Check

Standard RAM Disk size : 1024KB PASS !!(or ERROR !!)

Error Address xxxxxxH Write Data xxxxH Read Data xxxxH

The error address and the error data are displayed only when an

error occurs. (If no errors occur, they are not displayed.)

3 Terminating method

After the test result is displayed, press the Esc key to terminate

the test and return to the RAM diagnostics menu.

3) OPTION RAM Disk Check

1 Checking content

For the standard RAM disk area (BANK 040H ∼ BANK 0BFH),

each test area of bank size 16KB is checked. The bank base

address of RAM is set to 0D4000H and after. The check procedures are as follows:

i. Write different data to each address by a word method similar

to the Standard RAM Disk Check. After completion of writing,

a BANK 0BFH 0D4000H data read verify check is made.

(Data in the written area is saved in the main memory.) If it is

OK, the following test is executed. In case of an error, the

error display is made and the test is terminated.

ii. Test data 55AAH is written to BANK 040H 0D4000H.

iii. BANK 040H 0D4000H is read and compared with 55AAH. If

both data are correct, the following test is executed. If not,

"Exten ded RAM Di sk size: 0KB" is displayed and the test is

terminated.

iv. The test area data is saved to the main memory.

v. Test data 5555H is written to the test area.

vi. Test data and read data are compared. If is OK, test data

AAAAH is written to the test area.

vii. Test data and read data are compared by each word, If it is

O.K., test data 5555H is written to the test area.

viii. Test data and read data are compared by each word, If it is

O.K., test data 0000H is written to all the test areas.

ix. Test data and read data are compared by each word. If it is

OK, test data FFFFH is written to the test area.

x. Test data and read data are compared by each word. If it is

OK, test data 0000H is written to the test area.

xi. The saved data is written to the test areas.

When an error occurs during the test, the error address and data

are displayed and the test is stopped.

2 Display

Option RAM disk Check

Extended RAM Disk size : 1024KB PASS !!(or ERROR !!)

Error Address xxxxxxH Write Data xxxxH Read Data xxxxH

The error address and the error data are displayed only when an

error occurs. (If no error occurs, they are not displayed.)

3 Terminating method

After the test result is displayed, press the Esc key to terminate

the test and return to the RAM diagnostics menu.

3-4. ROM Diagnostics

The DOS ROM, BIOS ROM, standard flash ROM, and option flash

ROM are tested.

The following menu is displayed. The highlighted cursor is moved by

the cursor keys (UP ↑ and DOWN ↓) of the AT keyboard. Move the

cursor to the desired item, and press the Enter key to execute the

selected diagnostics program. When the selected diagnostics program is completed, Press the ESC key to return to the ROM diagnostics menu. Pressing Esc key again returns to the service diagnostics

menu.

ROM Diagnostics

DOS ROM Check

BIOS ROM Check

Standard FLASH ROM Check

Option FLASH ROM Check

1) DOS ROM Check

1 Checking content

A sum check is made for the DOS ROM (BANK 000H ∼ 0FFH). All

data bytes are added. If the check sum is 10H, it is normal.

The ROM version is displayed.

2 Display

DOS ROM Check

Sum Check : PASS !!(or ERROR !!)

ROM Version : VHILH****

The version is displayed.

3 Terminating method

After the test result is displayed, press the Esc key to terminate

and return to the ROM diagnostics menu.

2) BIOS ROM Check

1 Checking content

The BIOS ROM version is displayed.

2 Display

BIOS ROM Check

Version - ROM : SHPUP****

The version is displayed.

4 – 3

Page 20

3 Terminating method

After the test result is displayed, press Esc key to terminate and

return to the ROM diagnostics menu.

3) Standard FLASH ROM Check

Checking content

1

Write and read are performed to the standard FLASH ROM area

(BANK 200H ∼ 27FH) to establish a verify check. The check procedures is as follows:

• The ID code, the manufacture, and the device signature code

are read and displayed.

• The ROM size is specified and the following display is made to

allow the user to select whether to perform the verify check or

not.

• M ove cursor to select "YES", and the messag e in ( ) will be

displayed.

• If the verify check is made, the test area is first erased.

• Increment data for each byte is written to all the test areas.

• (Ex ample: "0001h", " 0202h", "0405h", --- " 0E0Fh", --- "FEFFh"

* The two left digits are the lower address, and the two right

address are the upper address.)

• Read verify check is performed.

When "YES" is selected

• M ove cursor to select "YES", and the messag e in ( ) will be

displayed.

• If the verify check is made, the test area is first erased.

• Increment data for each byte is written to all the test areas.

• (Example: "0001h", "0203h", "0405h", ⋅⋅⋅ "0E0Fh", ⋅⋅⋅ "FEFFh"

* The two left digits are the lower address, and the two right

address are the upper address.)

• Read verify check is performed.

When "NO" is selected

• When "NO" is selected, read check is performed for the above

increment data. Therefore, the option FLASH ROM to be tested

must be passed by write read verify check once.

Option Flash ROM Check

Option Flash ROM S ize : 4096KB

Write Read Verify chek YESNO<- CAUTION!!

Device ID = **** Manu facture ID = ****

All data in Option Flash ROM Disk will be destroyed.

Are you sure?

Changes depending on the capacity.

<-(Read Only)

The cursor is on this side

(Default).

Standard Flash ROM Check

Standard Flash ROM Size : 2048KB

Write Read Verify chek YES

Device ID = **** Manufacture ID = ****

All data in Standard Flash ROM Disk will be destroyed.

Are you sure?

NO

<- CAUTION!!

The cursor is on this side

(Default).

If the proper value is not read, the following display is made.

(Press the ESC key to terminate the test.)

Standard Flash ROM Check

ERROR!

Device is not installed or not work properly.

2 Final display

Standard Flash ROM Check

Standrd Flash ROM Size : 2048KB

Write Read Verify chek : PASS!! (or ERROR!!)

ERROR ADDRESS BANK XXXH,XXXXXXH WRITE DATA XXXXH READ DATA XXXXH

Device ID = **** Manu facture ID = ****

3 Terminating method

After the test result is displayed, press the Esc key to terminate

and return to the ROM diagnostics menu.

4) Option FLASH ROM Check

1 Checking content

Write read verify check or read check is performed for the optional

FLASH ROM area (BANK 280H – 3FFH). The checking procedure

is as follows:

• The ID code, the manufacture, and the device signature code

are read in BANK 280H ∼ 2FFH, BANK 300H ∼ 37FH, and

BANK 380H ∼ 3FFH to check that the proper value is read or

not.

• If the proper value is read, the ROM size is specified and the

following display is made to allow the user to select whether to

perform the verify check or not.

If the proper value is not read, the following display is made.

(Press the ESC key to terminate the test.)

Option Flash ROM Check

ERROR!

Device is not installed or not work properly.

2 Final display

Option Flash ROM Check

Option Flash ROM Size : 2048KB

Write Read Verify chek : PASS!! (or ERROR!!)

ERROR ADDRESS BANK XXXH,XXXXXXH WRITE DATA XXXXH READ DATA XXXXH

Device ID = **** Manu facture ID = ****

3 Terminating method

After the test result is displayed, press the Esc key to terminate

and return to the ROM diagnostics menu.

3-5. Real time clock & CMOS RAM Diagnostics

RTC and CMOS RAM check is performed.

The following menu is displayed. The highlighted cursor is moved by

the cursor keys (UP ↑ and DOWN ↓) of the AT keyboard. Move the

cursor to the desired item, and the press the Enter key to execute the

selected diagnostics program. When the selected diagnostics program is completed. Pressing Esc key again returns to the service

diagnostics menu.

Real time clock & CMOS RAM Diagnostics

Real time clock Check

CMOS RAM Check

4 – 4

Page 21

1) Real time clock Check

1 Checking content

RTC timer function and RTC clock function are tested.

In RTC timer check, the RTC timer is set so that an interrupt is

generated after 2 sec and check that the interrupt is performed

properly. In RTC clock check, the RTC clock is set to 23:59:58,

31/Dec/1989, and checks that the clock shows 0:0:0, 1/Jan/1990

after 2 sec.

2 Display

Real time clock Check

RTC Timer Check : PASS !!(or ERROR !!)

RTC Clock Check : PASS !!(or ERROR !!)

3 Terminating method

After the test result is displayed, press Esc key to terminate and

return to the RTC and CMOS RAM diagnostics menu.

2) CMOS RAM Check

Checking content

1

The read/write check is performed for CMOS-RAM when setting

up. The checking procedure is as follows:

i. Test address data is saved to the main memory.

ii. Test data 55H is written to the test address.

iii. Test data and read data are compared, and test data AAH is

written to the test address.

iv. Test data and read data are compared.

v. The saved test data is written to the test area.

vi. The address is incremented until it becomes 3FH.

If POFF interruption is generated during the test, the test is

stopped and the saved data is written to the test area within 50ms.

2 Display

CMOS-RAM Check

RTC RAM Check : PASS !!(or ERROR !!)

Error Address xxxxxH Write Data xxH Read Data xxH

The error address and the error bit are displayed only when an

error occurs. (When no error occurs, they are not displayed.)

3 Terminating method

After the test result is displayed, press Esc key to terminate and

return to the RTC and CMOS RAM diagnostics menu.

3-6. Touch Panel Diagnostics

The touch panel and its controller are checked. Communication with

the controller is performed by 8250 built in the gate array PSC2.

The controller diag check, the touch keypad test, and the linearity test

are performed.

The initial display is as follows:

1) Controller Diag Test

1 Checking content

After initializing the controller, the diagnostic command is executed. The procedures are as follows:

• One byte of dummy data (FFh) is sent and a wait state of

100ms is made.

• The reset command (80h) is sent and a wait state for the end

code (2 bytes: 90h and 00h) from the controller is made.

• The diagnostic command (2 bytes: 89h, any one-byte data) is

executed, and a wait state for the end code (3 bytes: 90h,

return code, any one-byte data) is made.

• If an error occurs the error display is made with the return code.

* To exit from the controller diagnostic test. press the Esc key

during the wait state for the end code response.

Return code Content

0Ah ROM error

0Bh RAM error

0Ch Panel voltage error

0Dh Reserve

0Eh EPROM write error

0Fh EPROM read error

10h EPROM check sum error

2 Display

Controller Diag Test

Pass!!

ROM Error!!

or

RAM Error!!

PANEL Voltage Error!!

EPROM Write Error!!

EPROM

EPROM SUM Error!!

3 Terminating method

After the test result is displayed, press the Esc key to terminate

and return to the Touch panel diagnostics menu.

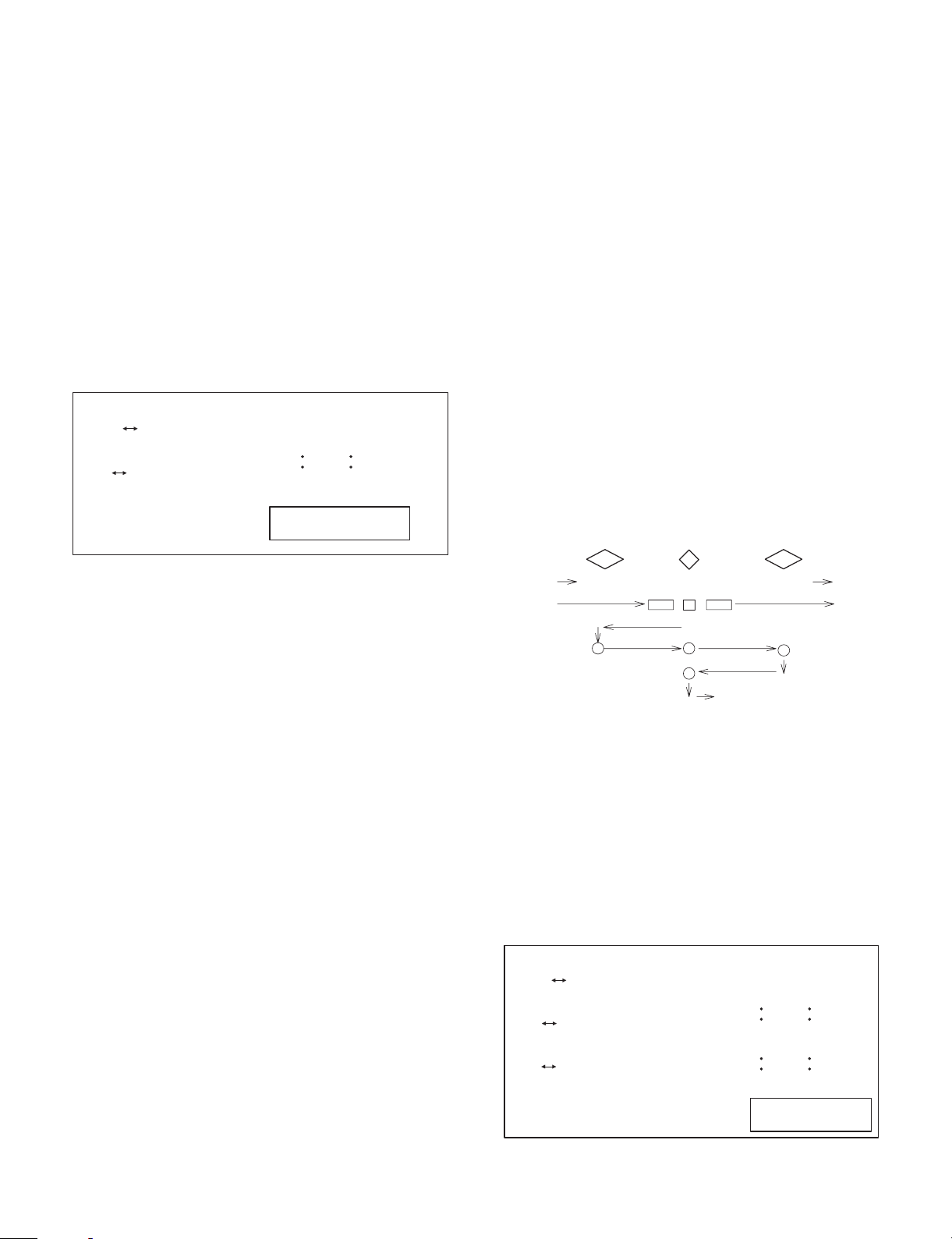

2) Touch Key Pad Test

1 Checking content

The driver function call is used.

is displayed at the four corners of the LCD sequentially.

(In the sequence of upper right, upper left, lower left, lower right.)

When the is touched by the operator, the buzzer sounds

and the screen turns to .

2 Display

Error!!

Error!!

Read Error!!

Touch Key Pad Test

Touch Cursor !!

Touch Panel Diagnostics

Controller Diag Test

Touch Key Pad Test

Line arity

3 Terminating method

Touch all four or press the Esc key to terminate and return

to the Touch panel diagnostics menu.

4 – 5

Page 22

3) Linearity test

1 Checking content

Red lines are displayed at both sides of the blue line at the center.

The operator must touch the blue line without touching the red

lines and drag from top to bottom.

The touched part of the blue line is changed to white.

If the red line is touched, an error message is issued.

2 Display

About 2cm

Linearity

Test

Complete!

(Error!!)

Displayed after termination.

Red line

Blue line

About 1cm

Red line

3 Terminating method

Press Esc key to terminate and return to the Touch panel diagnostics menu.

3-7. Clerk Key Diagnostics (Not used for "U"

version)

The clerk key input test is performed.

Pressing the Esc key returns to the serviceman diagnostics menu.

1) Clerk Key Check

1 Checking content

Key code inserted to the clerk key switch which is then displayed

in a decimal value.

2 Display

Clerk Key Check

Clerk Key Code : xx

The highlighted cursor is moved by the cursor keys (UP ↑ and DOWN

↓) of the AT keyboard. Move the cursor to the desired item, and press

the Enter key to execute the selected diagnostics program.

When the selected diagnostics program is completed, the display

returns to the menu screen. Pressing the Esc key returns to the

serviceman diagnostics menu.

1) PARALLEL1 Loop Check

Checking content

1

A loop check is made for the standard I/O address 378H ∼ 37FH.

(PARALLEL1)

In the loop check, a normally-operating ER-A8RS is inserted and

the loop cable (UKOG-6717RCZZ) is connected between PARALLEL1 and PARALLEL3 (ER-A8RS) for testing. Set the jumpers on

the PWB prior to the test as follows:

Signal name

STROBE-

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

ACKBUSY

PE

SLCT

AUTOFD-

ERROR-

INIT-

SLCTIN-

GND

J3J8J4J5J6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18~2

Loop cable (UKOG-6717RCZZ) wiring diagram

J7

10

UP-5300 : PARALLEL1 OUTPUT MODE

A8RS : PARALLEL3 INPUT MODE

J9

J10

I

L

12

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18~2

Signal namePin No.

STROBE-

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

ACKBUSY

PE

SLCT

AUTOFD-

ERROR-

INIT-

SLCTIN-

GND

The clerk code is displayed at XX.

3 Terminating method.

Press the Esc key to terminate and return to the Serviceman’s

diagnostics menu.

3-8. Printer Diagnostics

The parallel interface (standard) and ER-A8RS parallel interface (option) are tested.

Here, the parallel interface on the main body is mentioned as PARALLEL1, and the parallel interface on ER-A8RS as PARALLEL 2/3.

The following menu is displayed.

Printer Diagnostics

Standard Option(ER-A8RS)

PARALLEL 1 Loop Check

PARALLEL 1 Print Check

PARALLEL2 Loop Check

PARALLEL3 Loop Check

PARALLEL2 Print Check

PARALLEL3 Print Check

4 – 6

H

57

O

J18

J11

J12

J13

J14

J15

J16

J17

Opposite ER-A8RS setting

Jumper pin setting diagram

2 Display

PARALLEL1 Loop Check

ACK- Signal : PASS !!(or ERROR !!)

BUSY Signal : PASS !!(or ERROR !!)

PE Signal : PASS !!(or ERROR !!)

SLCT Signal : PASS !!(or ERROR !!)

ERROR- Signal : PASS !!(or ERROR !!)

STROBE- Signal : PASS !!(or ERROR !!)

AUTOFD- Signal : PASS !!(or ERROR !!)

INIT- Signal : PASS !!(or ERROR !!)

SLCTIN- Signal : PASS !!(or ERROR !!)

INTERRUPT : IRQ X (or ERROR !!)

DATA Bus : PASS !!(or ERROR !!)

The interruption level is displayed at X.

When no access is allowed to PARALLEL1, the following display

is made.

Page 23

PARALLEL1 Loop Check

PARALLEL1 Channel Disabled

3) PARALLEL3 Loop Check

1 Checking content

A loop check is performed for ER-A8RS I/O address 3BCH ∼

3BEH (PARALLEL3), In the loop check, the ER-A8RS to be connected is connected to the extension slot and the loop cable

shown in Fig. 3-4 is connected between PARALLEL3 (ER-A8RS)

and PARALLEL1 for testing. Set the jumpers on the PWB prior to

the test as shown in Fig. 3-6.

3 Terminating method.

Press the Esc key to terminate and return to the Printer diagnostics menu.

2) PARALLEL2 Loop Check

1 Checking content

A loop check is performed for ER-A8RS I/O address 278H ∼ 27FH

(PARALLEL2), In the loop check, the loop cable shown in Fig, 3-4

is connected between PARALLEL2 (ER-A8RS) and PARALLEL1

for testing. Set the jumpers on the PWB prior to the test as shown

in Fig. 3-6.

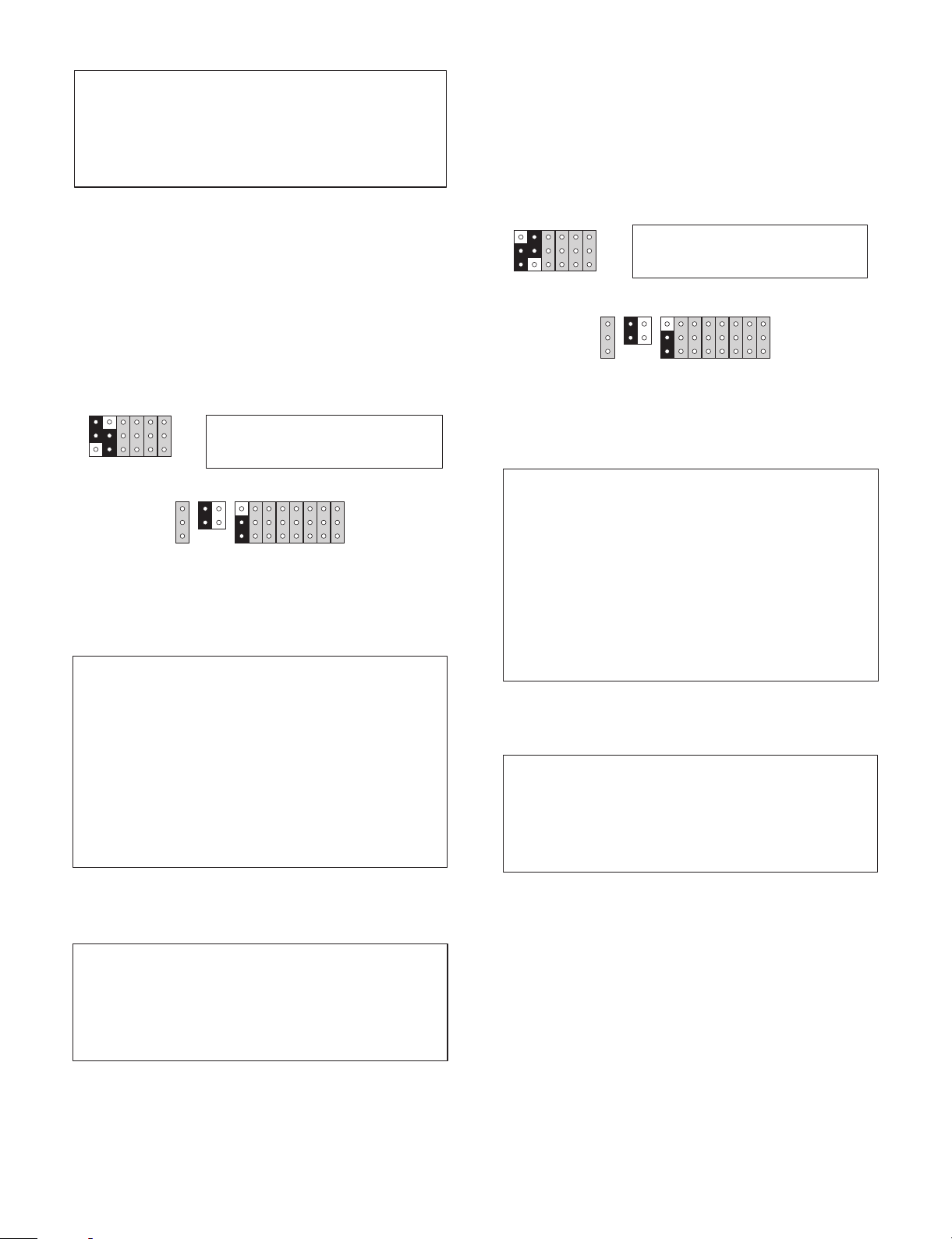

J3J8J4J5J6

J7

10

UP-5300 : PARALLEL1 INPUT MODE

A8RS : PARALLEL2 OUTPUT MODE

J9

L

H

J10

57

I

12

O

J18

J11

J12

J13

J14

J15

J16

J17

Setting of ER-A8RS to be tested

Fig. 3-6 Jumper pin setting

2 Display

PARALLEL2 Loop Check

ACK- Signal : PASS !!(or ERROR !!)

BUSY Signal : PASS !!(or ERROR !!)

PE Signal : PASS !!(or ERROR !!)

SLCT Signal : PASS !!(or ERROR !!)

ERROR- Signal : PASS !!(or ERROR !!)

STROBE- Signal : PASS !!(or ERROR !!)

AUTOFD- Signal : PASS !!(or ERROR !!)

INIT- Signal : PASS !!(or ERROR !!)

SLCTIN- Signal : PASS !!(or ERROR !!)

INTERRUPT : IRQ X (or ERROR !!)

DATA Bus : PASS !!(or ERROR !!)

J3J8J4J5J6

J7

10

UP-5300 : PARALLEL1 OUTPUT MODE

A8RS : PARALLEL3 INPUT MODE

J10

J9

L

H

57

I

12

O

J18

J11

J12

J13

J14

J15

J16

J17

Setting of ER-A8RS to be tested

Fig. 3-6 Jumper pin setting

2 Display

PARALLEL3 Loop Check

ACK- Signal : PASS !!(or ERROR !!)

BUSY Signal : PASS !!(or ERROR !!)

PE Signal : PASS !!(or ERROR !!)

SLCT Signal : PASS !!(or ERROR !!)

ERROR- Signal : PASS !!(or ERROR !!)

STROBE- Signal : PASS !!(or ERROR !!)

AUTOFD- Signal : PASS !!(or ERROR !!)

INIT- Signal : PASS !!(or ERROR !!)

SLCTIN- Signal : PASS !!(or ERROR !!)

INTERRUPT : IRQ X (or ERROR !!)

DATA Bus : PASS !!(or ERROR !!)

The interruption level is displayed at XX.

If no access is allowed to PARALLEL3, the following display is

made.

PARALLEL3 Loop Check

PARALLEL3 Channel Disabled

The interruption level is displayed at XX.

If no access is allowed to PARALLEL2, the following display is

made.

PARALLEL2 Loop Check

PARALLEL2 Channel Disabled

3 Terminating method.

Press the Esc key to terminate and return to the Printer diagnostics menu.

3 Terminating method.

Press the Esc key to terminate and return to the Printer diagnostics menu.

4) PARALLEL1 Print Check

1 Checking content

The print check is performed for the standard port PARALLEL1 at

I/O address 378H ∼ 37FH. In the print check, the D-Sub 25 pin

connector is connected with a printer to allow a print pattern test.

The test procedures are as follows:

i. Data of 55H is written to I/O address 378H, and the same

address is read. If the read data is not 55H, "PARALLEL1

Channel Disabled" is displayed and the following check is not

performed.

ii. Characters of 20H ∼ 7FH (ASCII code) are printed and the

line is changed.

This procedure is repeated for 5 times.

4 – 7

Page 24

2 Display

PARALLEL1 Print Check

PARALLEL1 Channel Disabled

"PARALLEL1 Channel Disabled" is displayed only when no access to PARALLEL1 is allowed.

3 Terminating method.

Press the Esc key to terminate and return to the Printer diagnostics menu.

5) PARALLEL2 Print Check

Checking content

1

The print check is performed for PARALLEL2 at I/O address 278H

∼ 27Fh on the ER-A8RS.

In the print check, set the short pin of the ER-A8RS to be tested

as shown in Fig. 3-9, and connect the D-Sub 25 pin connector to a

printer to allow a print pattern test.

J3J8J4J5J6

J7

10

J3J8J4J5J6

The test procedures are as follows:

i. Data of 55H is written to I/O address 3BCH, and the same

ii. Characters of 20H ∼ 7FH (ASCII code) are printed and the

J7

10

J10

J9

L

H

Fig. 3-10 Jumper pin setting

address is read. If the read data is not 55H, "PARALLEL3

Channel Disabled" is displayed and the following check is not

performed.

line is changed.

This procedure is repeated for 5 times.

57

I

O

J18

J11

J12

J13

J14

J15

J16

12

J17

2 Display

PARALLEL3 Print Check

PARALLEL3 Channel Disabled

J10

J9

L

H

Fig. 3-9 Jumper pin setting

The test procedures are as follows:

i. Data of 55H is written to I/O address 278H, and the same

address is read. If the read data is not 55H, "PARALLEL2

Channel Disabled" is displayed and the following check is not

performed.

ii. Characters of 20H ∼ 7FH (ASCII code) are printed and the

line is changed.

This procedure is repeated for 5 times.

57

I

O

J18

J11

J12

J13

J14

J15

J16

12

J17

2 Display

PARALLLEL2 Print Check

PARALLEL2 Channel Disabled

"PARALLEL2 Channel Disabled" is displayed only when no access to PARALLEL2 is allowed.

3 Terminating method.

Press the Esc key to terminate and return to the Printer diagnostics menu.

6) PARALLEL3 Print Check

1 Checking content

The print check is performed for PARALLEL3 at I/O address

3BCH ∼ 3BEh on the ER-A8RS.

In the print check, set the short pin of the ER-A8RS to be tested

as shown in Fig. 3-10, and connect the D-Sub 25 pin connector to

a printer to allow a print pattern test.

"PARALLEL3 Channel Disabled" is displayed only when no access to PARALLEL3 is allowed.

3 Terminating method.

Press the Esc key to terminate and return to the Printer diagnostics menu.

7) UP-T80BP Test

1 Display

Print Check

Count ? = 01 (00-99)

Pass Count = XX

Hit ESC Key to Stop

On the above screen the setting appears in the box.

The Count can be set from "01" up to "99". If "00" is set, printing

does not stop until the ESC key is pressed.

2 Testing

The following patterns are printed and the paper cut command is

sent by the specified number of times to the Serial 5 of I/O address 980H to 987H..

YOUR RECEIPT

THANK YOU

4 – 8

Page 25

3 Error message

The following error message appears if a communication error

occurs with the UP-T80BP.

Print Check

UP-T80BP I/F ERROR

Hit ESC Key to Stop

********************

4 End of testing

The testing is finished after printing is made by the specified number of times or by pressing the ESC key.

3-9. Serial I/O Diagnostics

The serial interface of UP-5300 and the option PWB ER-A8RS is

performed. To test the 9pin D-Sub port, connect the D-Sub loop back

connector (UKOG-6705RCZZ).

To test the RJ45 port, connect the loop back connector (UKOG6729BHZZ).

1) COM1 Check

1 Content

The loop back check is performed for the UART at I/O address

3F8H ∼ 3FFH. The test procedures are as follows:

i. UART setting is made. If access is denied to UART at that

time, "COM1 Disabled" is displayed and the following check is

not performed.

ii. RTS signal is turned on/off to check that CD, CTS signal is

normally operating. In case of any abnormality, ERROR is

displayed.

iii. DTR signal is turned on/off to check that DSR, RI signal is

normally operating. In case of any error, ERROR is displayed.

When an error occurs in procedure i or ii, the following test is

not performed.

iv. Set the baud rate to 19200bps asynchronous. 256 byte data

of 00H ∼ FFH is transmitted from SD signal. Data received at

RD signal is compared to check that the both are the same. If

the outputted data is not returned for 5 sec or more, ERROR

is displayed and the test is terminated.

v. An interruption signal is issued from UART and the number of

generated interruption request signal is displayed.

2 Display

CD 1pin

RD 2pin

TD 3pin

DTR 4pin

GND 5pin

DSR 6pin

RTS 7pin

CTS 8pin

RI 9pin

Loop back connector (UKOG-6705RCZZ) wiring diagram

RTS

1pin

DTR

2pin

TD

3pin

GND

4pin

GND

5pin

RD

6pin

DSR

7pin

CTS

8pin

Loop back connector (UKOG-6729BHZZ) wiring diagram

The UP-5300’s 9-pin D-sub ports are used as COM1 and 2. In addition, the UP-5300’s RJ45 ports are used as COM3 and 4 or COM5

and 6 according to the setup. On the other hand, ER-A8RS is used

by selecting either COM1 and 2 or COM3 and 4 according to the

setup.

Therefore, when an ER-A8RS is used, you must set COM1, 2, 5, and

6 on the UP-5300 side, and set COM3 and 4 on the ER-A8RS side.

The following menu is displayed.

The highlighted cursor is moved by the cursor keys (UP ↑ and DOWN

↓) of the AT keyboard. Move the cursor to the desired item, and press

the Enter key to execute the selected diagnostics program.

When the selected diagnostics program is completed, the display

returns to the menu screen. Pressing the Esc key returns to the

serviceman diagnostics menu.

Serial I/O Diagnostics

COM1 Check

COM2 Check

COM3 Check

COM4 Check

COM5 Check

COM6 Check

Serial I/O COM1 Check

RTS - CD : PASS !!(or ERROR !!)

RTS - CTS : PASS !!(or ERROR !!)

DTR - DSR : PASS !!(or ERROR !!)

DTR - RI : PASS !!(or ERROR !!)

TD - RD : PASS !!(or ERROR !!)

INTERRUPT : IRQ XX

The number of the interruption request signal is displayed at XX.

If no access is allowed to COM1 UART, the following display is

made.

Serial I/O COM1 Check

COM1 Channel Disabled

3 Terminating method.

Press the Esc key to terminate and return to the Serial I/O diagnostics menu.

2) COM2 Check

1 Checking content

The loop back check is performed for the UART at I/O address

2F8H ∼ 2FFH. The check procedure, the display, and the terminating method are the same as COM1 Check.

3) COM3 Check

1 Checking content

The loop back check is performed for the UART at I/O address

3E8H. When the ER-A8RS is assigned to COM3, the check procedure, display and terminating method are the same as COM1.

When the RJ-45 port of the UP-5300 main unit is assigned to

COM3, the following points are different from COM1 Check :

1 Content

• RTS-CTS is not checked.

• DTR-RI is not checked.

2 Display

• RTS-CTS is not displayed.

• DTR-RI is not displayed.

COM3 is checked as well as COM1 except the above 2 points.

4 – 9

Page 26

4) COM4 Check

1 Checking content

The loop back check is performed for the UART at I/O address

2E8H ∼ 2EFH. The check procedure, the display, and the terminating method are the same as COM3 Check.

5) COM5 Check

Checking content

1

The loop back check is performed for the UART at I/O address

(PSC2 base address) + (410H ∼ 417H). The following points are

different from the COM1 Check:

1 Content

• RTS-CTS is not checked.

• DTR-RI is not checked.

2 Display

• RTS-CTS is not displayed.

• DTR-RI is not displayed.

COM5 is checked as well as COM1 except the above 2 points.

6) COM6 Check

1 Checking content

The loop back check is performed for the UART at I/O address

(PSC2 base address) + (418H ∼ 41FH). The checking procedure,

the display, and the terminating method are the same as COM5

Check.

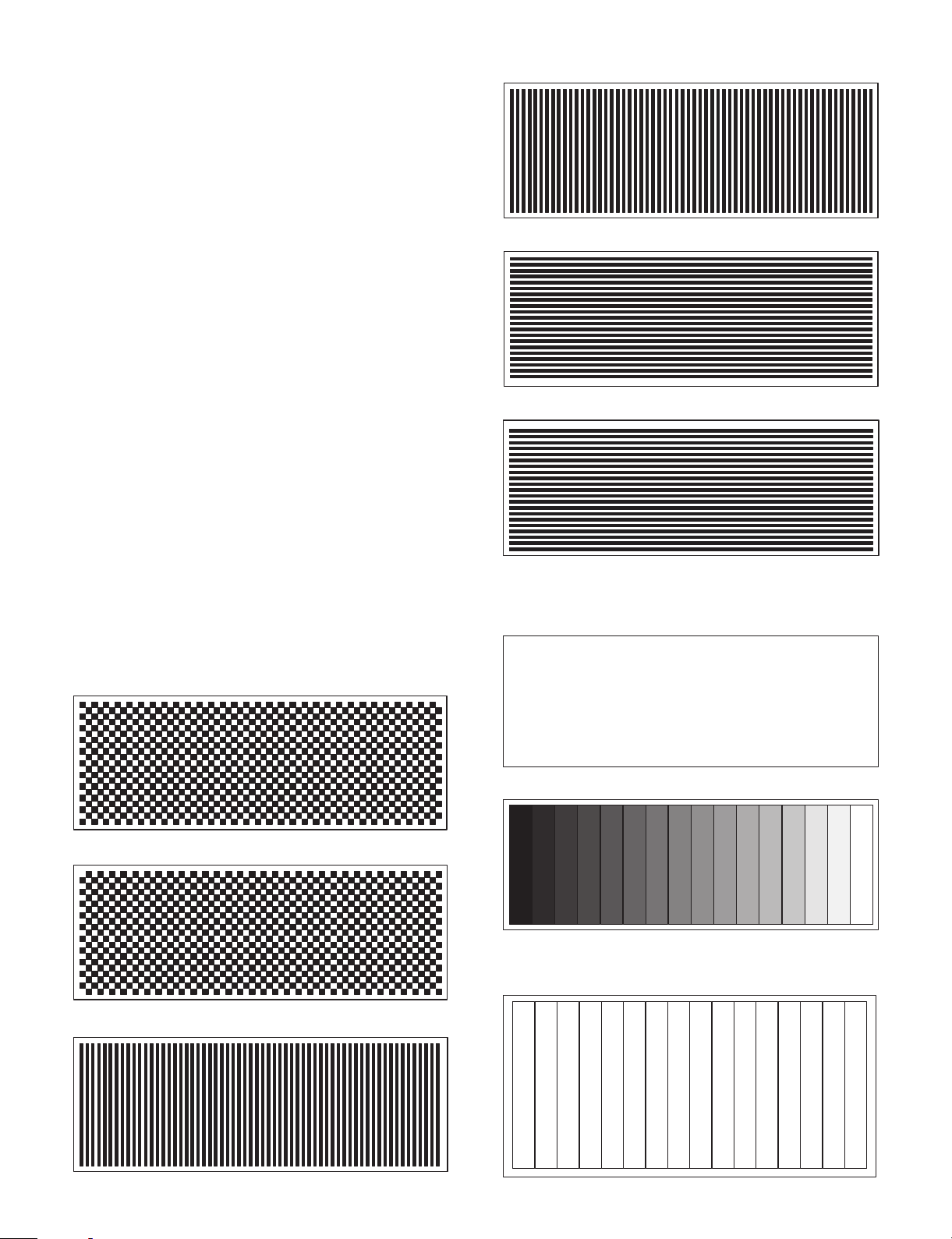

3-10. Liquid Crystal Display Diagnostics

LCD test is performed.

The following patterns are displayed in sequence. Pressing the space

bar proceeds to the next display. Pressing the space bar at the final

pattern or pressing the Esc key during the test, will return the display

to the service diagnostics menu.

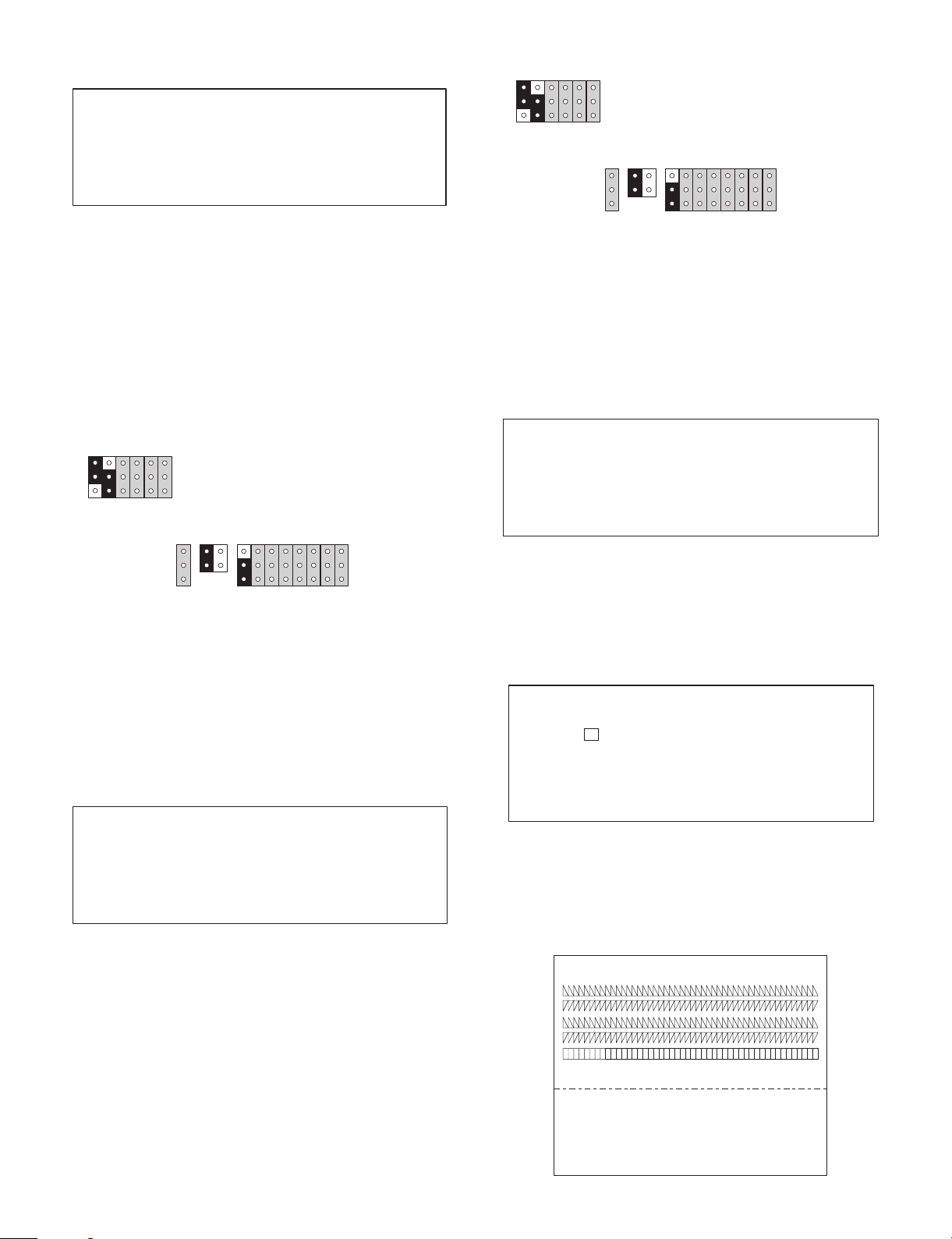

1) Liquid Crystal Display Check

1 Checking content

The test patterns are displayed in the following test procedures.

Pressing the space bar moves to the next pattern.

i. Black-and-white pattern in 1 dot interval

iv. Reversed pattern of pattern iii.

v. Horizontal stripe pattern in 1 dot interval

vi. Reversed pattern of pattern v.

vii. "H" pattern (80 digits × 35 lines) In the 35th line, only 78 digits

of "H" are displayed.

(The actual display range is 25 lines. Scroll for 10 lines to

check.)

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

ii. Reversed pattern of pattern i.

iii. Vertical stripe pattern in 1 dot interval

4 – 10

viii. Gradation pattern from black to white in 16 gradations

ix. All white pattern

x. Color bar (16 colors)

Color bars of 16 colors are displayed.

Black

Blue

Green

Cyan

Red

Brown

White

Magenta

Gray

Light green

Light blue

Light cyan

Light red

Light magenta

Light yellow

Light white

Page 27

xi. Color pattern (256 colors)

Color pattern of 256 colors is displayed. The displayed colors

are the default pallet.

Arrange RAMDAC register No. 0 ∼ 255 from the upper left.

xii. Backlight OFF

The backlight is turned off without turning off the display.

xiii. Backlight ON

2 Terminating method

Press the space bar or Esc key to terminate and return to the

Serviceman’s diagnostics menu.

3-13. Magnetic Card Reader Diagnostics

This test program reads the magnetic card based on the ISO7811/1-5

standard and displays the data.

Pressing the Esc key returns to the service diagnostics menu.

1) Magnetic Card Reader Check

1 Checking content

The test program reads tracks 1 and 2 of the magnetic card (UKOG6718RCZZ) based on the ISO7811/1 ∼ 5 standard, and displays the

data in ASCII code. There ar e tw o kinds of data patterns to be read.

TRACK 1: IATA pattern

76 character 7bit/character (Max. 79 character)

TRACK 2: ABA data pattern

28 character, 5bit/character (Max. 40 character)

To read the card data, the following setting is performed.

• Mode set

46h is set to PSC2 channel 1 mode set register. (IATA, 6bit)

74h is set to PSC2 channel 2 mode set register. (ABA, 4bit)

• Start mark set

45h is set to PSC2 channel 1 start mark register.

0Bh is set to PSC2 channel 2 start mark register.

• Interrupt reset

Dummy data is written to PSC2 channel 2 start mark register.

• Interrupt mask cancel 01h is written to PSC2 MCR mask

register to cancel mask.

In addition, setting for the PSC2 extension interruption is per-

formed.

When the card is scanned, the obtained data is written to the

FIFO buffer from the start mark to LRC in sequence. Then, the

card data is read by interrupt process.

After reading data, the FIFO buffer is reset.

2 Display

The above display is made when the card (UKOG6718RCZZ) is

passed through the MCR. In case of an error, the error code is

displayed as follows:

Magnetic Card Reader Check

TRACK 1 : BUFFER EMPTY

TRACK 1 : MCR ERROR

TRACK 2 : BUFFER EMPTY

TRACK 2 : MCR ERROR

Displayed when TRACK1 EMPTY CODE is returned.

Displayed when TRACK1 ERROR CODE is returned.

Displayed when TRACK2 EMPTY CODE is returned.

Displayed when TRACK2 ERROR CODE is returned.

3 Terminating method

Press the Esc key to terminate the test and return to the

Serviceman’s diagnostics menu.

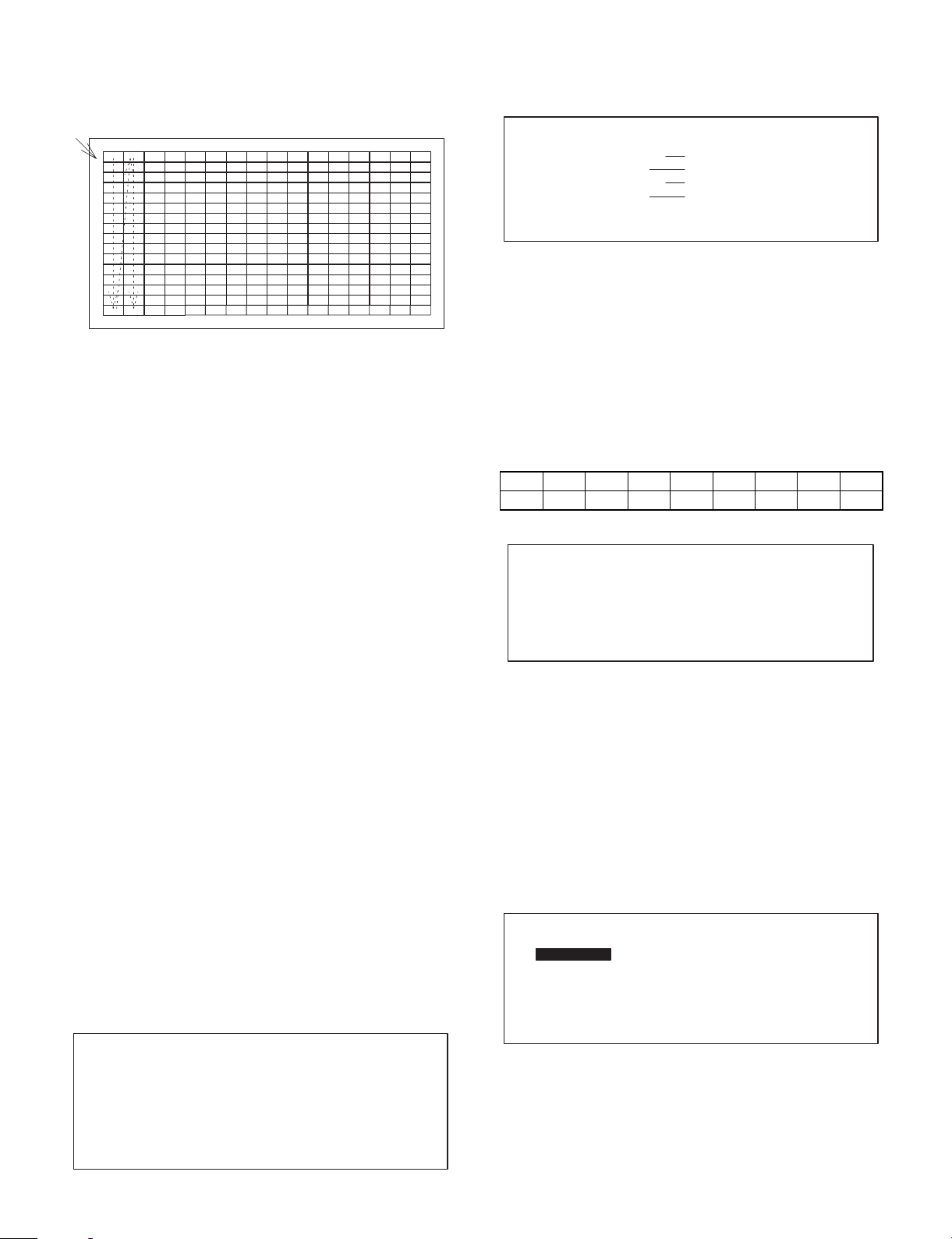

3-14. System Switch Diagnostics

The system switch information of the main PWB is displayed.

Pressing the Esc key returns to the serviceman diagnostics menu.

1) System Switch

Checking content

1

The system switch reads I/O address 7F0H every 10ms to display

the value of bit 0 ∼ 7. The relati onshi p betwee n the bit and SW is

as shown in the table below.

Bit76543210

7F0H SW8 SW7 SW1 SW2 SW3 SW4 SW5 SW6

2 Display

System Switch Diagnostics

SW1 SW2 SW3 SW4 SW5 SW6 SW7 SW8

XXXXXXXX

Each SW data is displayed at X. If bit data is "1," the display is

"OFF". If bit data is "0," the display is "ON".

3 Terminating method

Press the Esc key to terminate the test and return to the

Serviceman’s diagnstics menu.

3-15. Drawer Diagnostics

The drawer open and sensor test are executed.

The following menu is displayed. The highlighted cursor is moved by

the cursor keys (UP ↑ and DOWN ↓) of the AT keyboard. Move the

cursor to the desired item, and press the Enter key to execute the

selected diagnostics program. When the selected diagnostics program is completed, the display returns to the menu screen. Pressing

the Esc key returns to the service diagnostics menu.

Drawer Diagnostics

Drawer 1 Check

Drawer 2 Check

MCR (Magnetic Card Reader) Check

TRACK1: