Page 1

Date: Aug. 28, 1995

COPIER : SF-2014

No. : STE-003

IMPROVEMENTS TO THE WELDING FOR

THE DEVELOPER TANK.

1.Model Name: SF-2014/21 14/2214

Z-800, SN-1420/1430

2.General: Faults develop in the weld for the developer tank for several reasons. One of these is

that the tank tends to move up and out of place. In response to this problem, the

following improvements are planned.

1. The type of developing problems which are likely to occur when the weld is faulty.

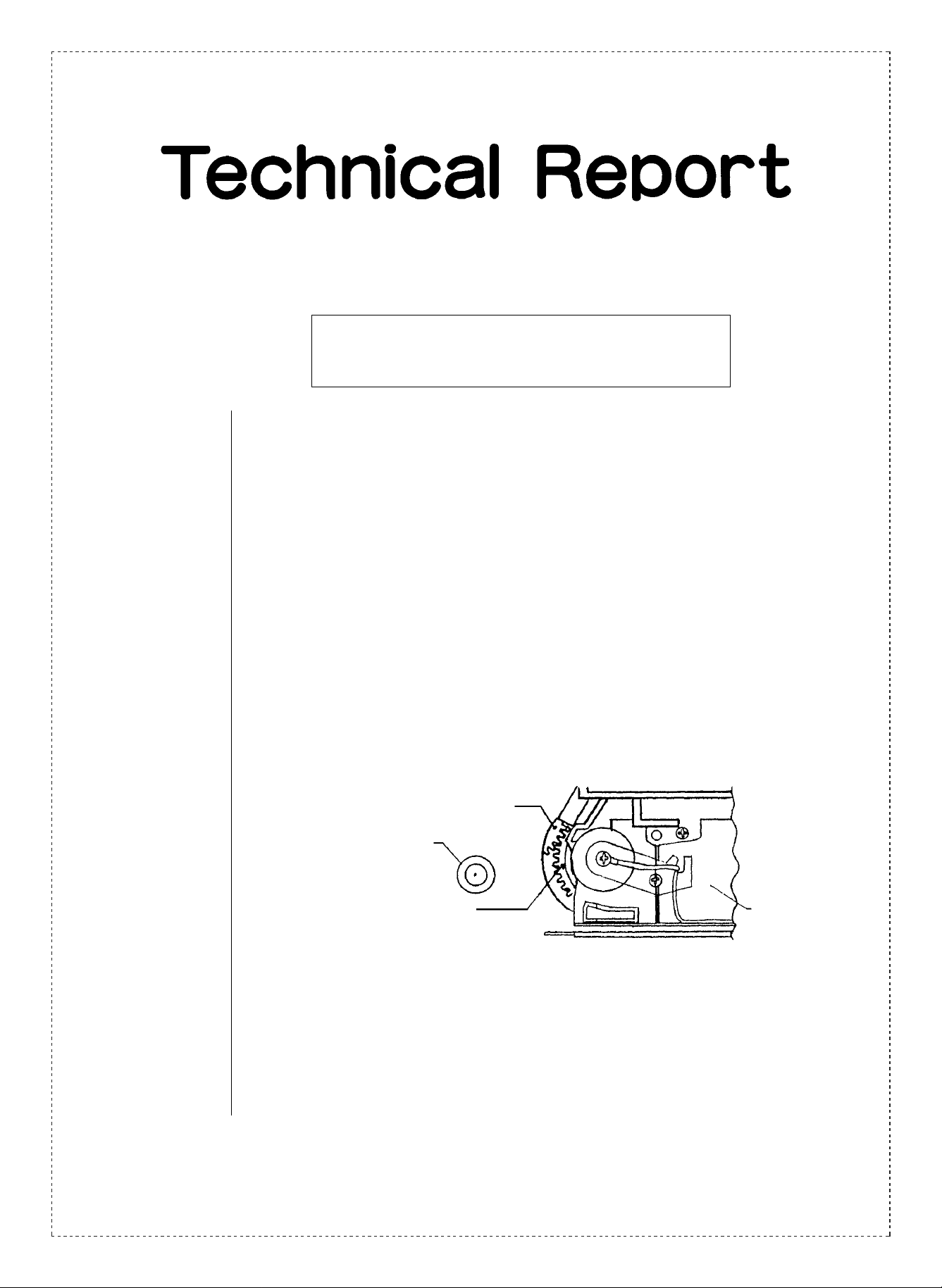

(1) The gear comes loose. (DV drive PWB 23T and 59/24T in the main drive UN)

(2) The image does not appear, or density is too low. (Especially on the rear side).

2. Checking the weld.

(1) Checking the main body of the set.

A. remove the drum unit.

B. move the toner hopper (the joint of the toner cartridge) and check the positioning

of the Developer UN drive gear’s teeth (whether they are properly meshed) as

shown in the figure below.

Main drive UN 59/24T

Drum unit’s fulcrum axis

(The UN above the back of

the frame)

DV drive PWB 23T

.

Because the teeth will mesh in the correct direction during the driving motion of the

unit, as long as there is al ready some meshing, there is no problem.

Developer UN

(front side)

SHARP CORPORATION Printing and Reprographic Supplies Division

1/3

Yellow

C

Page 2

3.Description: (1) We are reducing the base of the developer unit by 0.5 mm.

Rear view of the developer box.

Bottom view of the developer box.

This portion will

be removed.

(Temporary fix)

We will add a step to production in which we will cut the rib at the base of the developer

unit. We will mark the appropriate parts with white paint.

Front of the developer box frame

Location of markings

(Permanent fix)

The mold for the part will be changed.

(2) Widening of the curvature angle of the metal plate in the attachment section of the

DV guide caused by improper pressure welding of the developing unit sometimes

causes the slide surface of the developing unit to bend upward, elevating the

developing unit. All production machines have been checked as of 1995 mid-May

production, but machines already out on the market should be checked as described

in the figures below for the problem arising from the attachment process during

replacements or by detached DV guide plates.

2/3

Page 3

Upward curvature for cases which appear as in the diagrams

below when viewed from the direction marked

by arrow C

B A

NG

Scale

Place the part in contact

with the scale or another

flat object.

Upward curve

B

DV lower guide plate

(LPLTM4543FCZZ)

OK

A

C

Flat to downward

curve

• When attaching the CV guide plate, both the F side and the R side should be

lowered by the amount necessary for attachment play.

• For cases whereby the DV guide plate is curved and the machine shell is closed,

correction can be carried out by pressing down on points A and B .

4.Action: Temporary fix: From the middle of May, 1995.

Permanent fix: Production in Japan: From July, 1995 production on.

SOCC production: From the middle of July, 1995 production.

SMF production: From Aug., 1995 production on.

3/3

Loading...

Loading...