Page 1

Date: May. 22, 1995

COPIER : SF-2014

No. : STE-001

PREVENTING THE “TONER LOW ” LAMP

FROM TURNING ON.

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (U.S. Version)

2.Genaral: Occasionally, the “Toner Low” lamp may go on although there is still toner in the

cartridge. This may be due to the “scrape off sheet”, which is affixed to the

supplementary toner feed in the toner hopper, rising too far up (reducing the angle of an

input lever) and causing the toner level in the hopper to drop.

3.Description: Because of strict quality control and thorough visual checks, this problem should not

occur in machines produced after November 1994. Some improvements have been

carried out in the shape and quality of the sheet and replacement should be carried out

on any machines produced previous to that date.

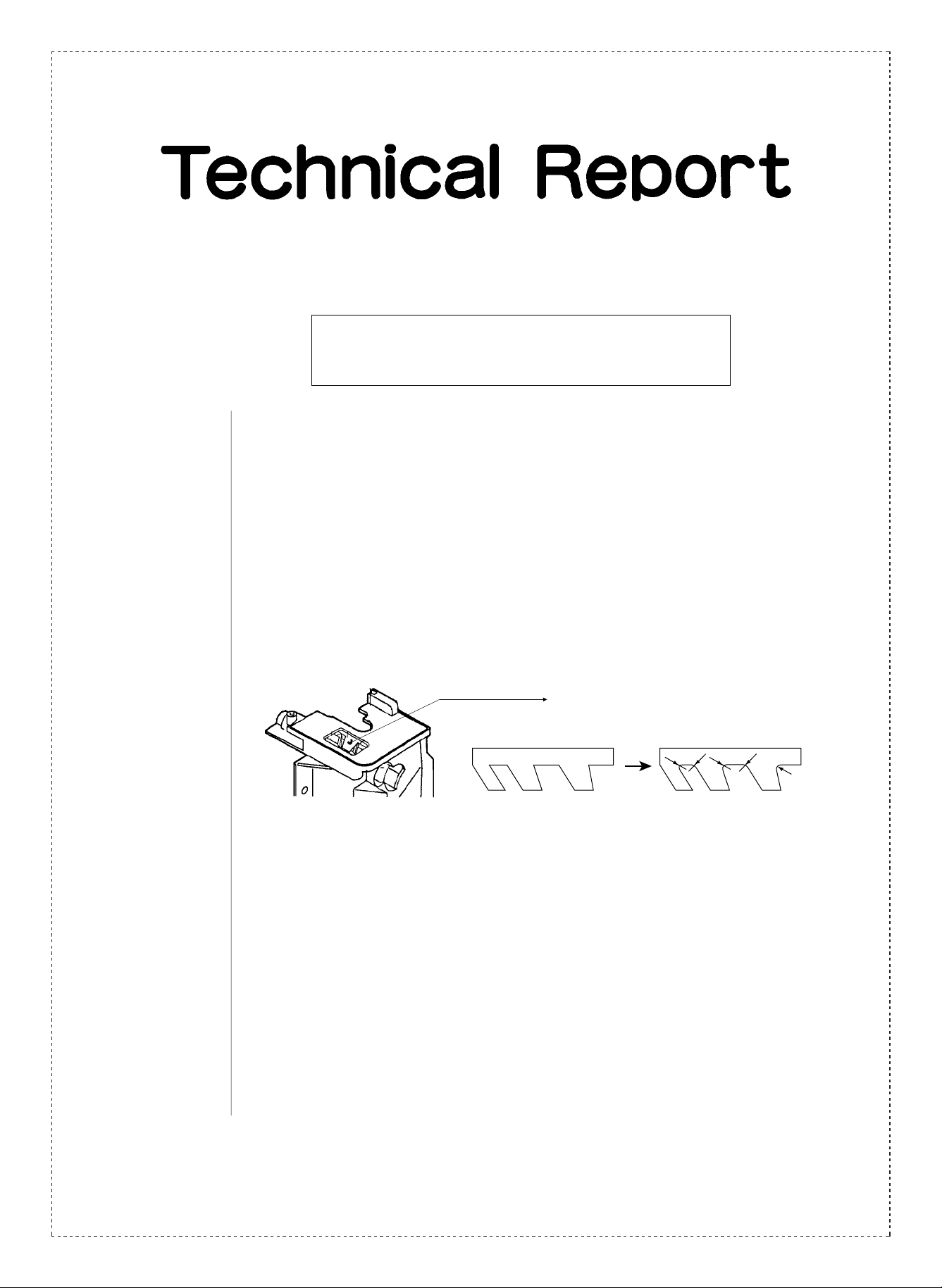

Scrape off sheet

(New)

R R

RR

Material PC

Toner hopper

(Old)

Material PET

<Items needed for the exchange of parts>

• Scrape-off sheet : PSHEP3756FCZ1

• Shutter : PSHT-0064FCZZ

Please prepare these in advance

<Procedure for changing the parts>

(1) Remove the toner cartridge from the toner holder in the developing unit.

(2) Remove the connector for the toner motor.

R

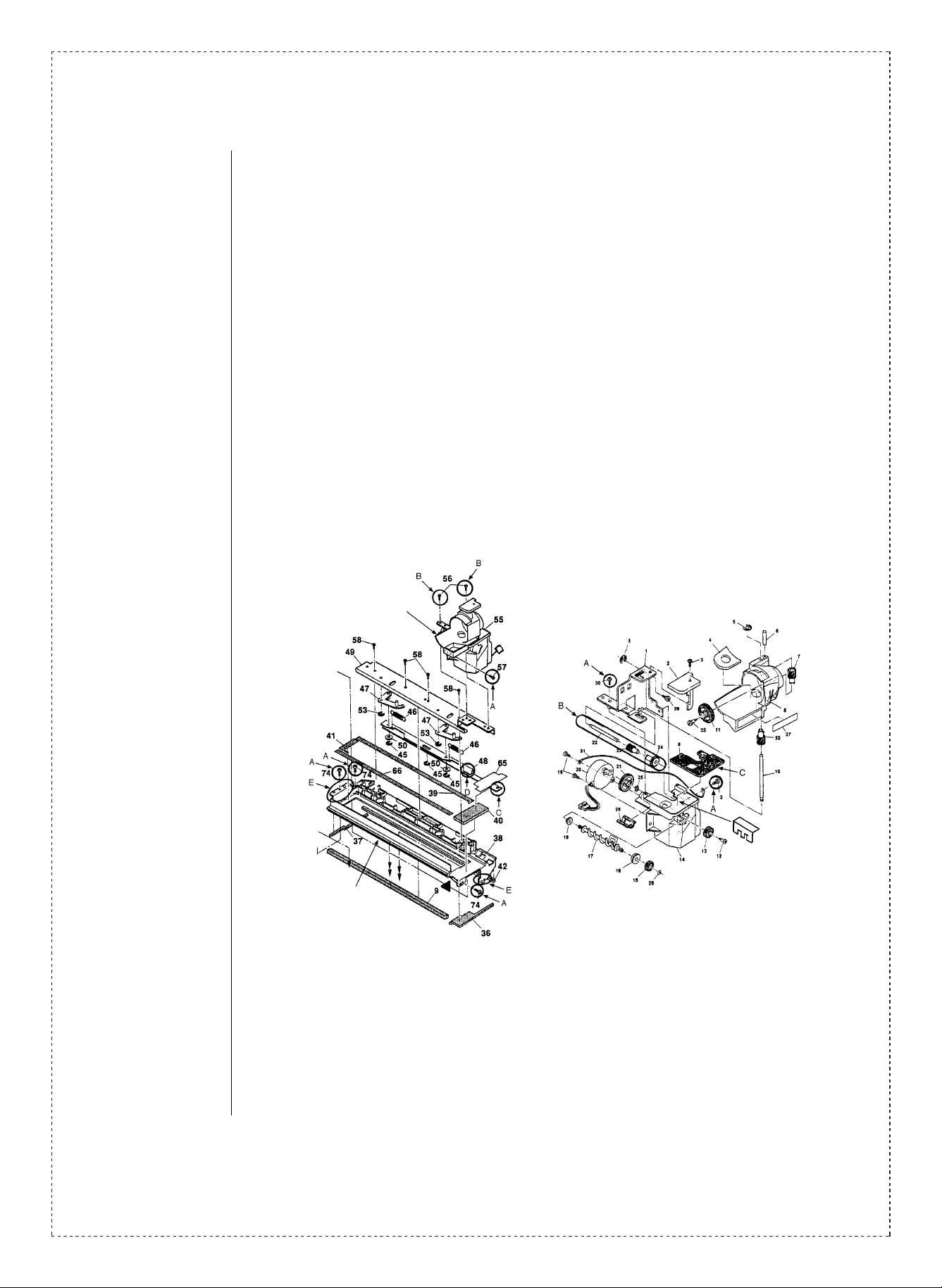

(3) Remove the four blue screws and take the cover off the DV Box as shown in Fig. 1, A.

lift the back portion of the frame slightly, and remove while turning the cover

clockwise around the point indicated by the triangle

SHARP CORPORATION Printing and Reprographic Supplies Division

1/4

Yellow

C

Page 2

(4) Remove the 2 screws and remove the toner hopper unit from itUs cover as shown in

Fig. 1, B.

(5) Clean up any toner remaining in the unit.

(6) Remove the 2 screws and separate the toner hopper (No.14) from the toner holder

(No.8) as shown in Fig. 2, A.

(7) Draw the shafts and gears apart as shown in Fig. 2, B.

(Work can proceed without this being done, but there is a possibility that the shafts

and gears will come apart spontaneously later on)

(8) Peel off the “scrape-off sheet”, which is affixed to the supplementary toner feed, and

remove the shutter, as shown in Fig. 2, C.

(9) Peel the double sided tape off of the top of the toner hopper.

(Be careful not to allow any foreign particles to enter the toner hopper)

(10) Clean the affixing portions of the Rscrape-off sheetS and the shutter with alcohol.

Fig. 1

Toner hopper unit

Cover

Fig. 2

Connector

Scrape-off sheet

2/4

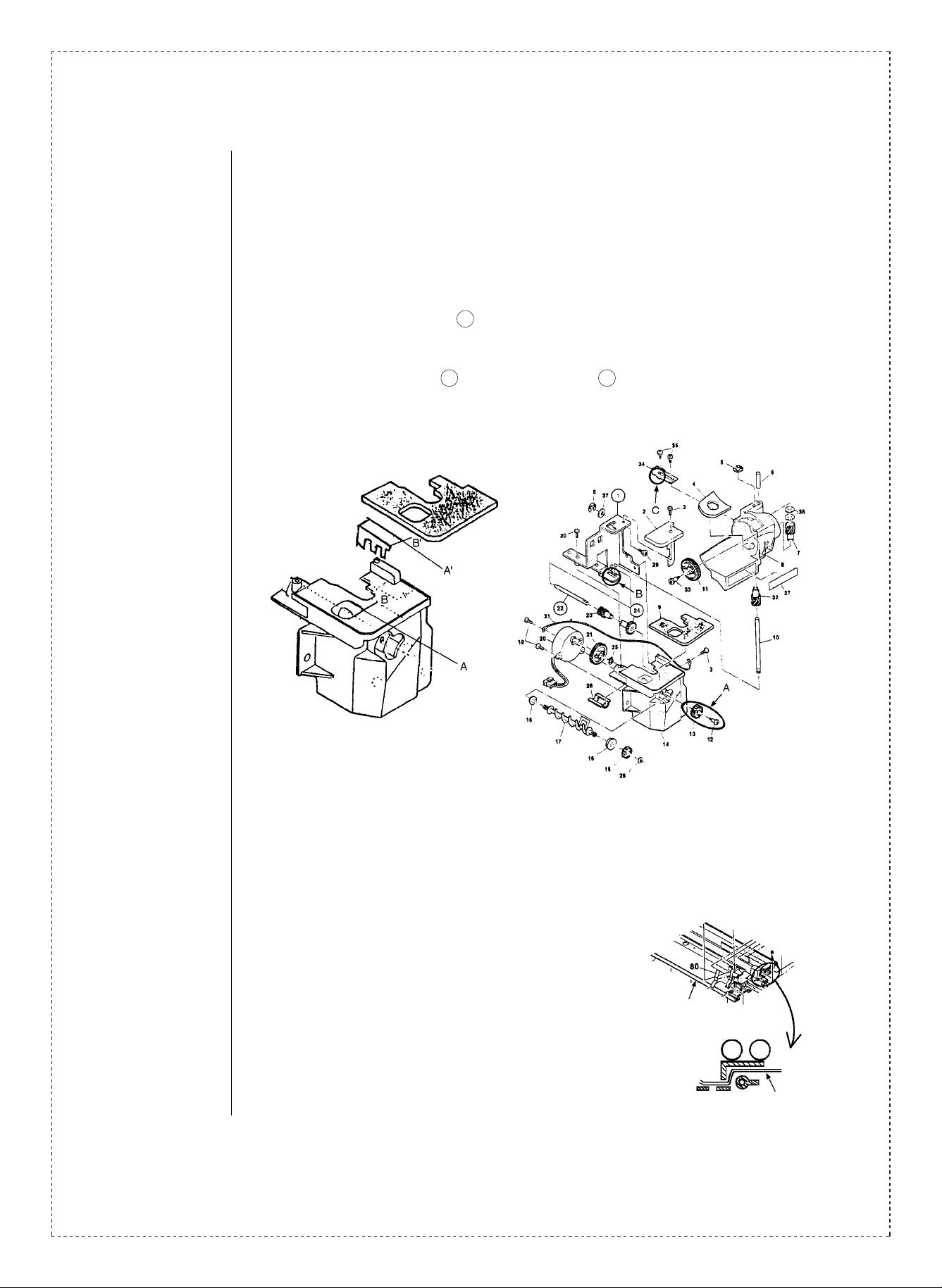

(11) Af fix the new sheet, being careful to match up A’, B’ on the sheet to the standard

A,B on the toner hopper.

(Press down firmly when affixing the sheet)

• As it is difficult to fix the front of the sheet to the convex portion of the screw unit

(No.17), it is preferable to affix the front of the sheet to the concave portion of the unit.

Page 3

(In cases where the front of the sheet comes to the convex portion of the unit,

it is possible to remove the screws and gears and rotate the unit until the sheet

matches up with the concave portion)

(12) Affix the new shutter to the top of the toner hopper.

(Allow no foreign substances to fall in)

(13) Reinstall the gears and shafts removed in (11) and (7).

(Match up the toner gear 24 and the DV gear in the toner motor)

(14) Reconnect the toner hopper and toner holder which were disconnected in (6)

(Insert the toner shaft 22 into the toner bracket 1 , and then reinsert the screws)

Fig. 3 Fig. 4

(15) Reinsert the toner hopper into the developing unit cover, using the reverse of the

steps outlined in (4).

• Do this only after attaching the parts shown in diagram 1,C to the boss (No.10)

shown at the back of Fig. 4,B

• B e careful not to put the compression stopper shown in diagram 4,C onto the parts

shown in Fig. 1,D

(16) Reversing the steps described in (3), fix the cover

to the DV box.

• Insert the lead into the inside portion of the rib,

as shown in the Fig. to the right.

• Make sure that the parts shown in 1,E are

DV box

inserted into the ribs of the DV box.

(17) Connect the toner motor connector and insert the

connector into the inside of the toner hopper.

Lead cable

3/4

Page 4

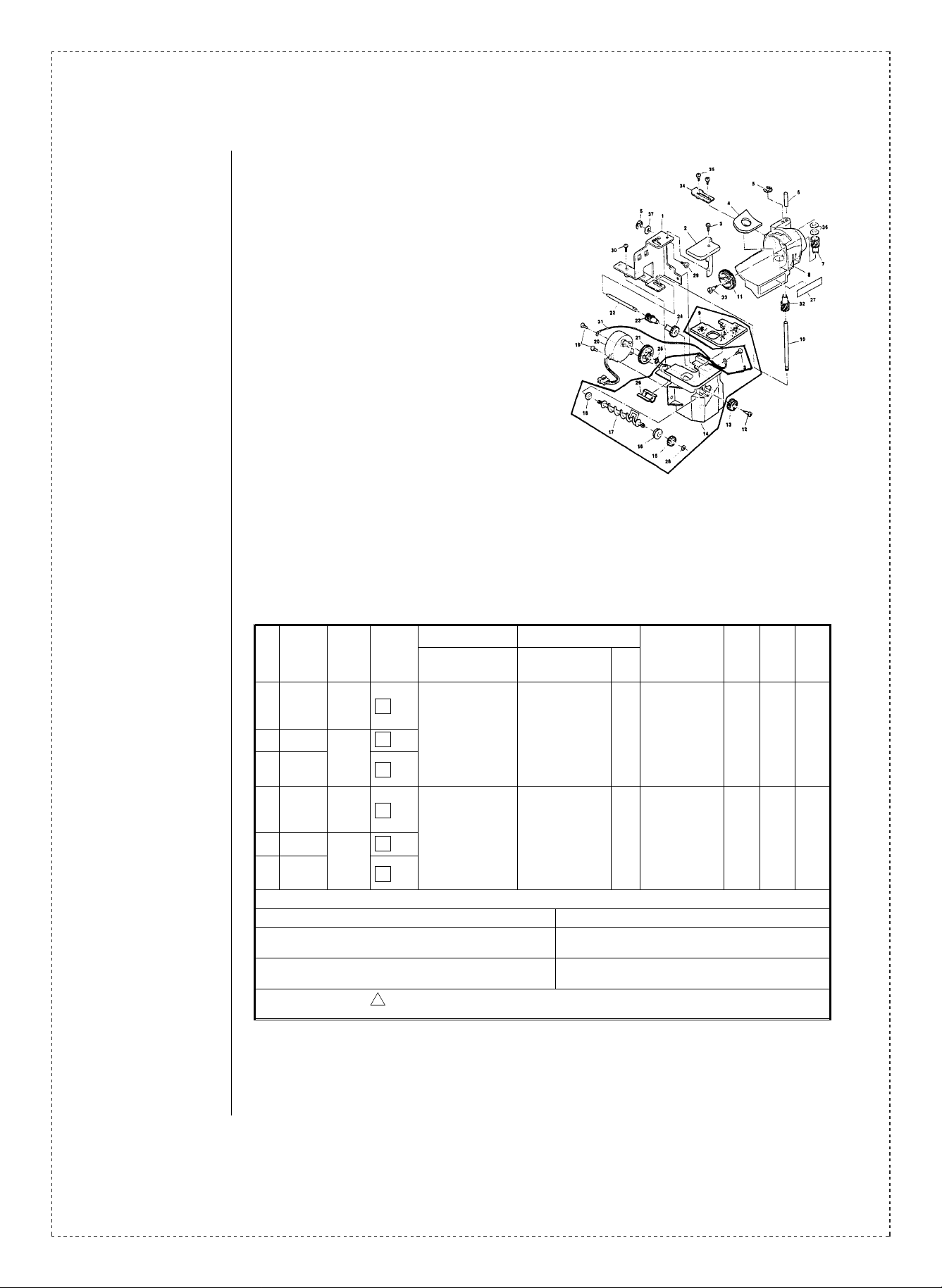

The parts shown to the right and the

scrape-off sheet, known as the Assen L

THS Unit, are provided free of charge.

Please recycle or reuse any other parts

necessary. The unit is only to be used

when replacing the scrape off sheet, and

may not be used for any other purposes.

4.Action: Production started in mid-March, 1995

Production of these parts started in March, 1995, but the changes described should

be made to machines produced between August and November, 1994.

Ref.

Model

No.

SF-2014

SF-2114

SF-2214

Z-800

SN-1420

SN-1430

SF-2014

SF-2114

SF-2214

Z-800

SN-1420

SN-1430

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

s p ec ifi e d on es fo r m aintaini ng t he s a fe ty an d pe r fo rma nc e o f th e s et .

name

Version P/G No.

10

All

only

All

only

9

10

10

9

10

!

U.S.A

U.S.A

Current parts New parts

Parts code Parts code

PSHEP3756FCZZ PSHEP3756FCZ1 AE Scrape off sheet

— CBOX-0097FC71 AV THS unitt — 6

Price

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

Parts name

rank

Effec-

tive

time

1st lot

’95/3

Inter-

change-

ability

3

Note

Service

parts

only

4/4

Loading...

Loading...