Page 1

Date: Mar. 31, 1993

COPIER : SF-2022

No. : SP-1546

[Parts changes]

1. CHANGE IN THE OPERATION PWB, TO AVOID TWISTING

2. CHANGE IN THE TAKEUP DRIVE SHAFT BUSHING, FOR PRODUCTIVITY

ENHANCEMENT

3. PREVENTING CONTACT WITH THE COPY LAMP UNIT

4. MS2 ACTUATOR STRUCTURAL CHANGE

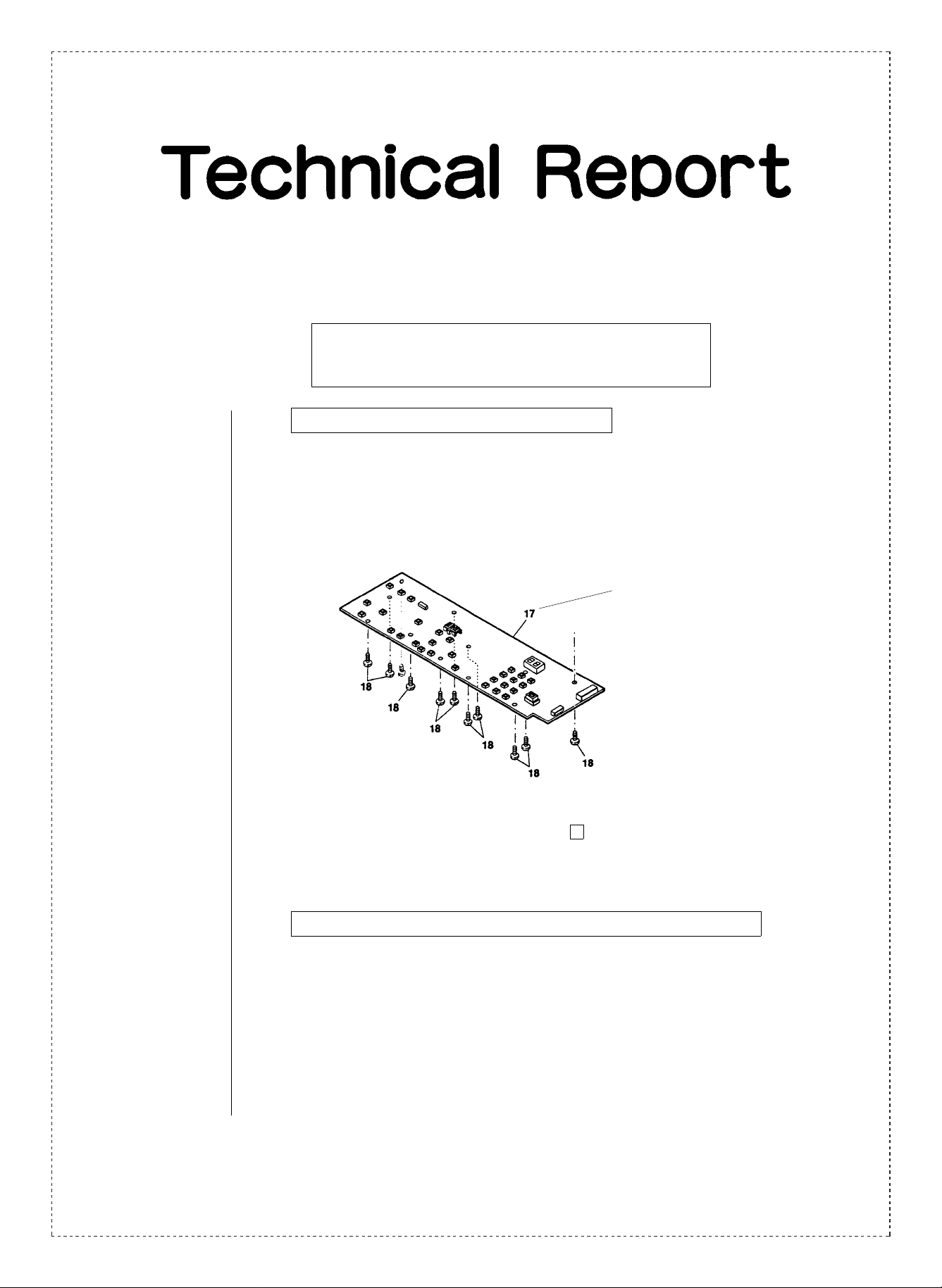

1. Change in the operation PWB, to avoid twisting

1.General: To prevent twisting of the operation PWB, a screw is newly used.

2.Description: A screw hole is bor ed in t he operation P WB to use a screw to prevent t he

operation PWB from twis ting.

Operation PWB

Change is also met for the parts code of t he operation P WB. In addit ion to it,

correction is also needed for three s crews ( 2 -18) that used to f asten the

operation PWB as they wer e given with wrong part s code.

2. Change in the takeup drive shaft bushing, for productivity enhancement

1.General: Owing to the following reason, change is met for the bushing of the takeup

drive shaft.

2.Reason: For productivity enhancement at the work line.

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

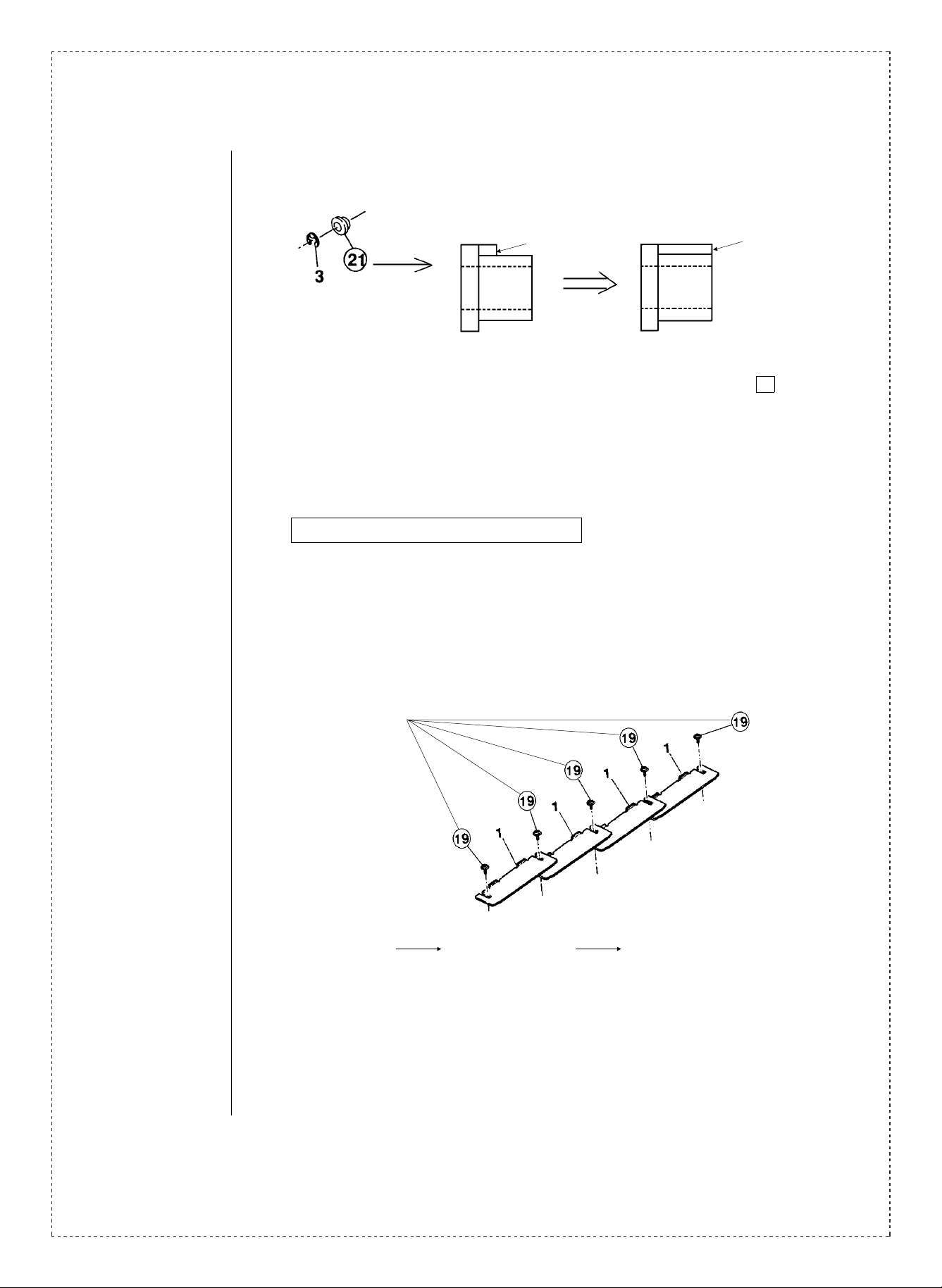

3.Description: The bushing a deeper stop collar is now used.

Current New

Stop collar

NBRGC0254FCZZ

NBRGC0133FCZZ

Stop collar

Stop collar The old type bushing is also used in another location (P/G 18 -15).

4.Action: (Factory action)

Since November 1992.

3. Preventing contact with the copy lamp unit

1.General: During a full scan operation, the screw in the exposure control plates may hit

the optical baseplate. To avoid thi s, change is made to t he screws.

2.Description: The screw which is 2mm top high is changed with the one 1.5mm high, to

prevent the contact. In addition to i t, correct ion is r equired for the parts code of

the screw.

New screws

XHBSD30P08000 XHPSD30P06XS0 LX-BZ0688FCZZ

Parts code

correction

New screw

and quantity

(For exposure

control plate)

NOTE: The XHBSD30P08000 is used within the copy lamp unit.

3.Action: (Factory action)

Since November 1992.

2/4

Page 3

4. MS2 actuator structural change

1.General: The weight balance attached to the MS2 actuator since the first production unit

is now quit to us e after changing the shape of the act uator.

2.Description: The shape of the MS2 actuator is changed as shown below.

Enlarged view

Current New

3.Action: (Factory action)

Since October 1992.

Weight balance

(cemented)

3/4

Page 4

Ref.

No.

1

Model

name

SF-2022

SF-2027

Version P/G No.

2 -17 CPWBF0929FC52 CPWBF0929FC55 BR Operation PWB

2 -17 CPWBF0929FC53 CPWBF0929FC56 BR Operation PWB 1

2 -18

Current parts New parts

Parts code Parts code

Price

rank

Parts name

XJPSD30P06000 XJPSD30P08000 AA Screw, M3x8 – –

Effective

time

Running

change

since

Sep.

1992.

All

2 -16 XEPSD20P05000 XEBSD20P06000 BB Screw, M2x6 – –

SF-2022

2027

12 -21 NBRGC0254FCZZ NBRGC0133FCZZ AC Bushing ’92/11 1

2 10 -19 XHBSD30P08000 Quantity change AA Screw, M3x8 –

3 10 — LX-BZ0688FCZZ AB

4

18 -54 MLEVP0583FCZZ MLEVP0583FCZ1 AE MS2 actuator ’92/10 3

Screw, M3x6, for

exposure control

plate

’92/11 3 Q’ty: 5

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe ca n be us ed i n pl a c e of n ew t y pe .

New ty pe cann ot be us ed in place of curr ent type .

3. C urr e nt t y pe c a nn ot b e us e d in p l ac e o f ne w ty p e.

New t y pe c a n be u s ed i n pl a ce of cur ren t type.

5. In te r changeabl e i f r epl ac e d wi th sa m e ty p es of

relate d pa r ts in us e.

6. Others.

Parts marked with “ ! ”i s import an t fo r m ain ta in i ng t he sa fe ty of t he s e t. B e sur e t o rep l ace these pa rts wi th

specified ones for maintaining the safety and performance of the set.

Interchangability

1

Note

Parts

code

correctionQ’ty:

10 to 11

Parts

code

correction

Q’ty:

12 t o 7

4/4

Loading...

Loading...