Page 1

Date: Feb. 9, 1993

COPIER : SF-2022

1.Applicable

models:

No. : SP-1538

1. CHANGE IN THE PAPER EXIT INVERSION AREA (TO PREVENT THE TRAY FROM DROPPING

AND TO IMPROVE THE LOCK)

2. CHANGE IN THE UPPER SUCTION DUCT (FOR PRODUCTIVITY ENHANCEMENT)

3. IMPROVING THE MAIN PWB PAPER ENTRY SENSOR SIGNAL (PID) SIGNAL TOLERANCE

1. Change in the paper exit inversion area (to prevent the tray from dropping and to

improve the lock)

SF-2022/2027

2.General: The following changes are made to the paper exit inversion area.

3.Reason: 1. The paper exit tray might drop due to a shock when opened to remove a jammed

paper.

2. If accessing is repeated, the lock pawl might become loose.

4.Description: 1. Ribs are provided in the tray insertion zone of the paper exit to prevent it from

dropping.

Paper exit

Rib added (at four locations)

2. To improve the locking performance of the paper exit inversion area, the compression

spring is replaced by a tension spring. With this change, holes are newly provided on

the paper exit cabinet and the lock pawl to hold the springs.

Compressing spring

MSPRP1950FCZZ

Changed

Tension spring

MSPRT2033FCZ

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

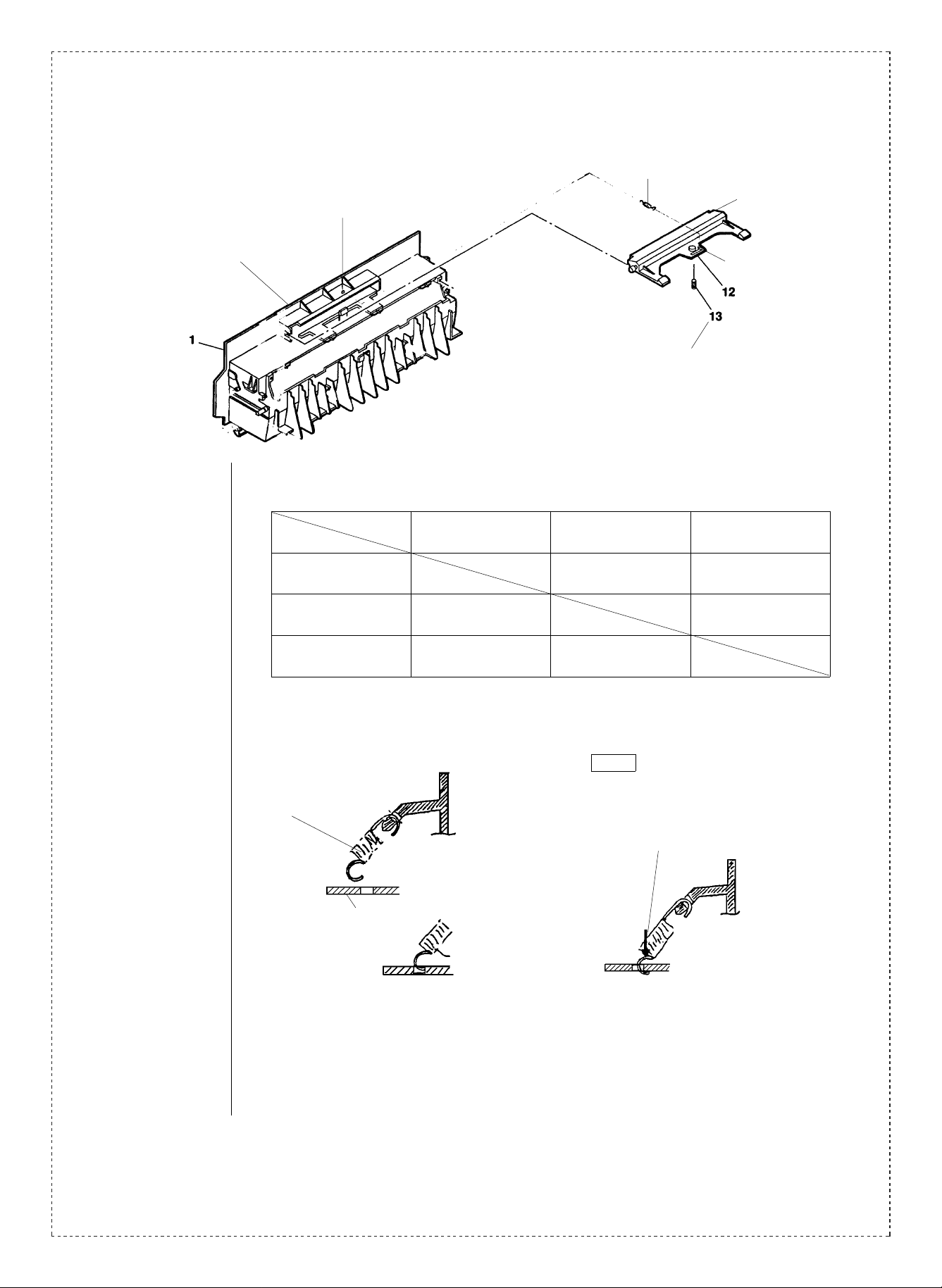

Newly provided spring

Spring holding hole (newly added)

Paper exit cabinet

Note that, after these changes in springs, new springs cannot be used in the paper exit

cabinet and the lock pawl of the old type.

New paper exit cabinet

GCAB-0752FCZ1

Current paper exit cabinet

GCAB-0752FCZZ

Spring discontinued to use

(MSPRP1950FCZZ)

Current lock pawl

PTME-0221FCZZ

O Yes O Yes

Lock pawl

Spring holding hole

(newly added)

Current spring

MSPRP1950CZZ

New lock pawl

PTME-0221FCZ1

New spring

MSPRT2033FCZZ

O Yes O Yes

X No X No

* When a spring is replaced with a new type, there is a need of replacing the paper exit

cabinet and the lock pawl with the new type.

[ 1 ]

Paper exit cabinet

Lock spring

(1) Lock spring

Hold the hook on the

paper exit cabinet.

Lock pawl

[ 2 ]

Lock spring

The round hook area

must be held in the hole.

NOTE The lock sprin g and t he hook

must be free from deformation.

The hook area must be pushed

in using a long nose pliers.

[ 3 ]

5.Action: (Factory action)

Since August 1992 for the domestic version.

Since the first production unit for the export version.

2/4

Page 3

2. Change in the upper suction duct (for productivity enhancement)

1.General: Change is made to the upper suction duct due to the following reason.

2.Reason: To enhance the productivity when installing and removing the high voltage transformer.

3.Description: After the change, a change is also met for the upper suction duct.

(Current) (New)

PDUC-0056FCZZ PDUC-0056CZ1

4.Action: (Factory action)

Since mid-October 1992.

3.Improving the main PWB paper entry sensor signal (PID) tolerance

1.General: A resistor is inserted in the main PWB to increase the tolerance in detecting the PID

(paper entry detect).

2.Description: The 1.2KΩ resistor is inserted to the PID line, as shown beiw.

+10V +10V

IC109

5

IIN

IR2C23

BR124

3.Action: (Factory action)

Since mid-August 1992.

Inserted

R316

1.2KΩ

H-8 (pid)

3/4

Page 4

Ref.

No.

Model

name

Version P/G No.

Current parts New parts

Parts code Parts code

Price

rank

Parts name

Effective

time

Inter-

change-

ability

Note

1

2

3

SF-2002

2027

6-1

6 -12

6 -13

All

9 -24

9-4

32 -901

32 -78

GCAB-0752FCZZ GCAB-0752FCZ1 AZ

PTME-0221FCZZ PTME-0221FCZ1 AH

MSPRP1950FCZZ MSPRT2033FCZZ AA

PDUC-0056FCZZ PDUC-0056FCZ1 AK

CPWBN0928FC51 CPWBN0928FC52 CD

VRS-TS2AD122J Q’ty change AA

Paper exitc a binet

Lock pawl

Lock spring

Upper suction

duct

Main PWB

Resistor,1.2Ω

(R316)

Since

the first

production unit

Since midOct. 1992

Since

midAug.

1992

5 *

1

1

–

<Inter chang e>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n place of n ew type.

New ty pe cann ot be us ed in place of curr ent type .

3. C urr e nt type c a nn ot b e us e d in p l ac e o f ne w ty p e.

New t y pe c a n be u s ed i n pl a ce of cur ren t ty p e.

Parts m ar ke d wi th “ ” is im p ort an t fo r m ain ta in i ng the sa fe ty of the s e t. B e sur e t o rep l ac e t he se pa r ts wi th

!

5. Interchang ea bl e i f rep l ac e d wi th sa m e ty p es of

relate d pa r ts in us e.

6. Others.

specified ones for maintaining the safety and performance of the set.

* The old type spring can be used for the new type lock pawl of the paper exit cabinet.

Q’ty:

6 to 7

4/4

Loading...

Loading...