Page 1

TopPage

DESTINATION F

Refer to "HFC-134a COOLING UNIT" Service Manual for handling this refrigerant.

Refrigerant; HFC-134a

SJ-PT55R-HS

SERVICE MANUAL

No.SY746SE55CRYFT

Refrigerator-freezer

MODELS

CONTENTS

CHAPTER 1. SPECIFICATION

CHAPTER 2. DESIGNATION OF VARIOUS PARTS

[1] EXTERNAL DESCRIPTION........................... 2-1

[2] CONSTRUCTIONS ........................................ 2-3

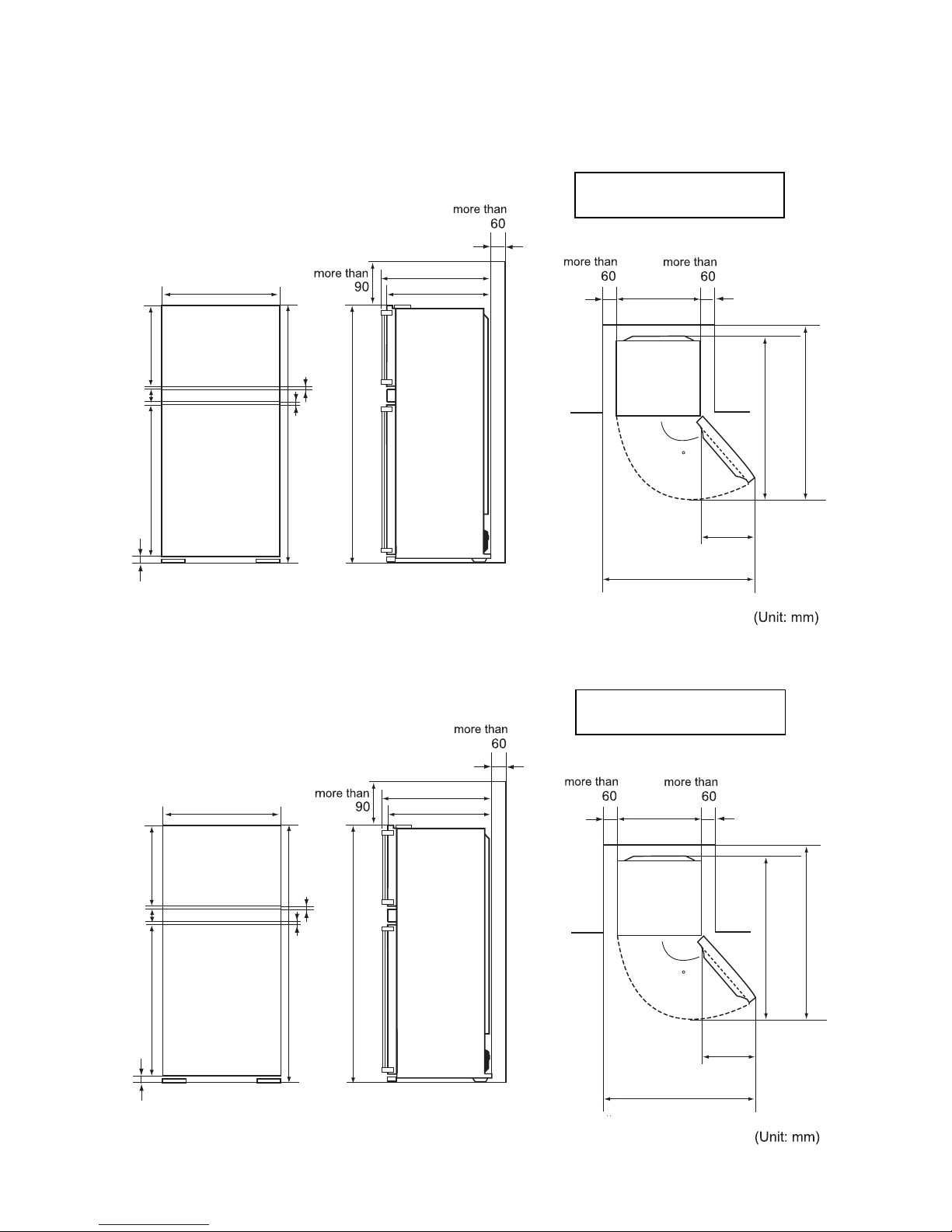

CHAPTER 3. DIMENSIONS

[1] OUTER DIMENSIONS AND

CLEARANCE ................................................. 3-1

[2] INNER DIMENSIONS .................................... 3-3

CHAPTER 4. LIST OF ELECTRICAL PARTS

[1] SJ-PT51R/PT55R .......................................... 4-1

[2] SJ-T51R/T55R ............................................... 4-1

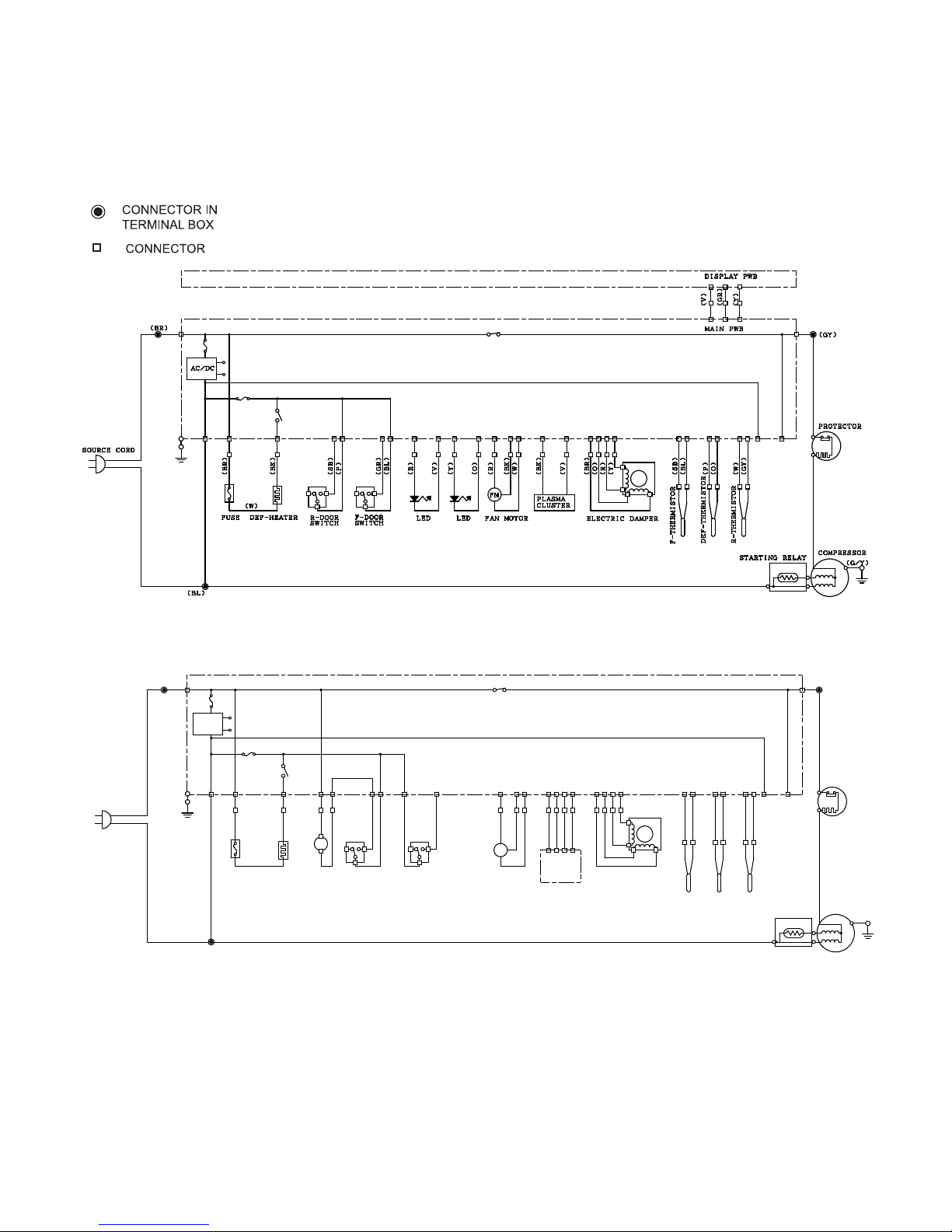

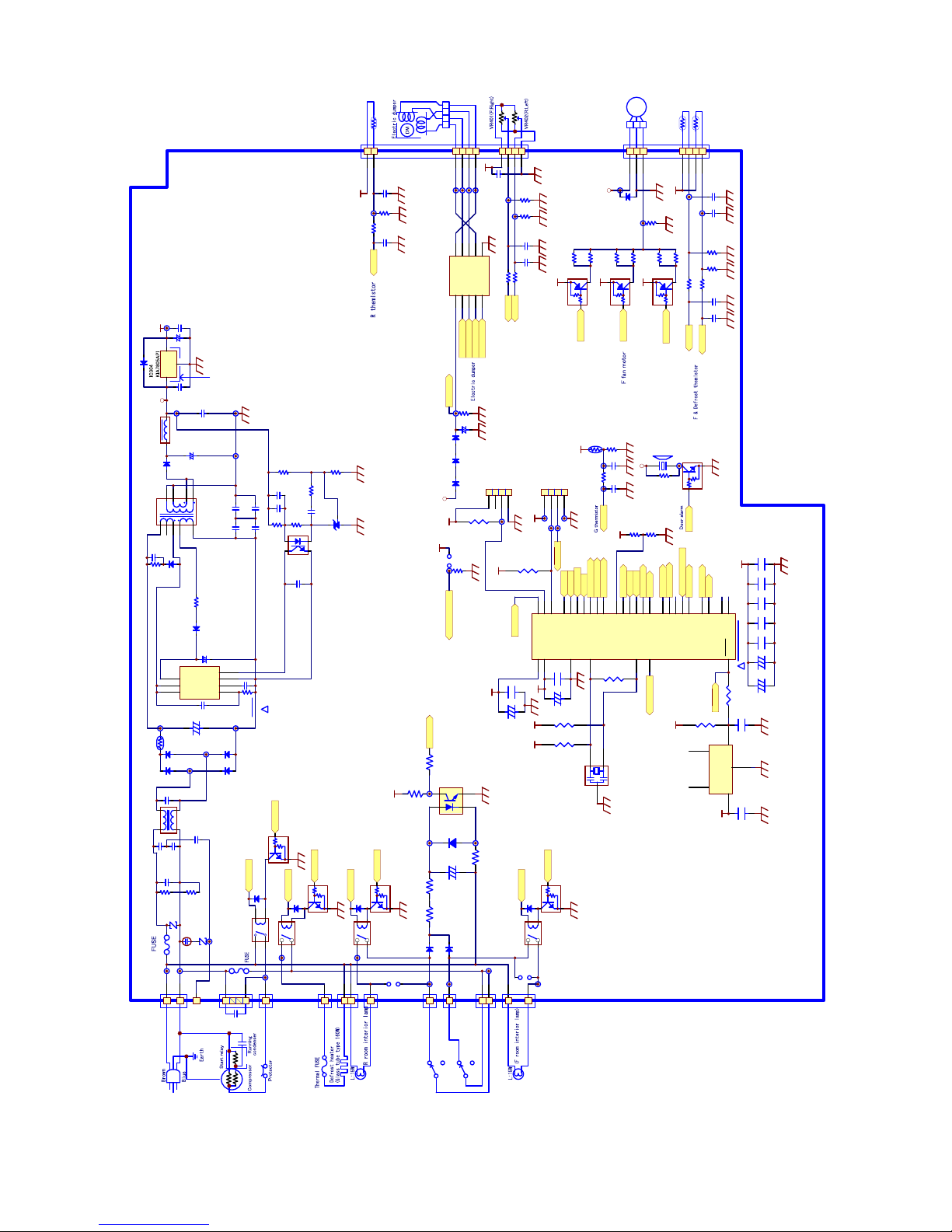

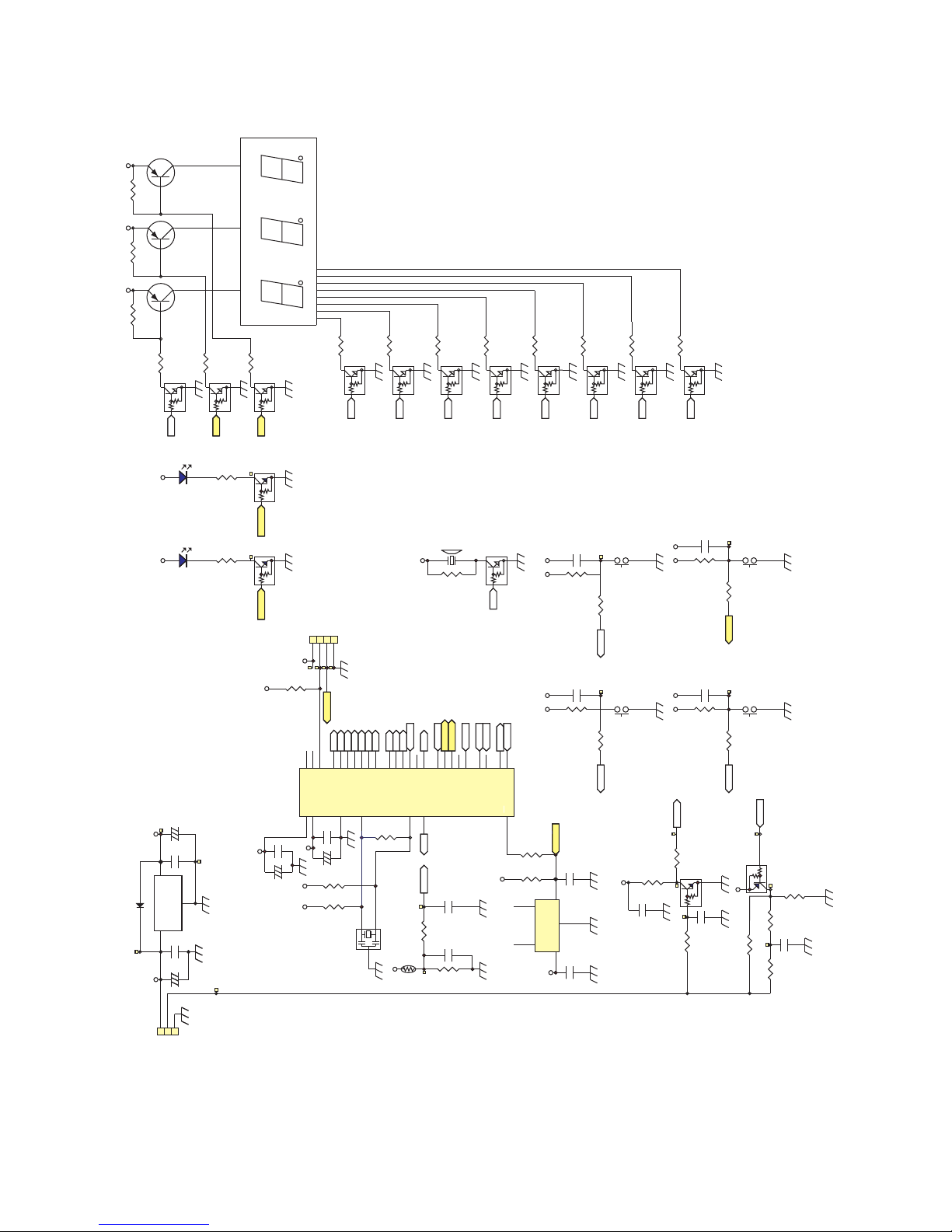

CHAPTER 5. WIRING DIAGRAM

[1] WIRING DIAGRAM ........................................ 5-1

[2] ELECTRIC ACCESSORIES LAYOUT ........... 5-2

[3] CIRCUIT DIAGRAM....................................... 5-4

SJ-PT51R-HS

SJ-PT55R-HS

SJ-T51R-SL

SJ-T55R-SL

[5] CONVERSION TABLE BETWEEN TEM-

PERATURE AND RESISTANCE VALUE........6-3

CHAPTER 7. SELF-DIAGNOSIS MODE (Only for SJPT51R/PT55R)

CHAPTER 8. MODE FOR DISPLAY (Only for SJPT51R/PT55R)

CHAPTER 9. ASSEMBLING PROCEDURES OF

MAIN PARTS AND CAUTIONS

[1] FAN LOUVER AND E.V COVER ASSEM-

BLY ................................................................9-1

[2] R CONTOROL COVER ASSEMBLY (SJ-

PT51R/PT55R) ..............................................9-3

[3] R CONTOROL COVER ASSEMBLY (SJ-

T51R/T55R)...................................................9-5

[4] R SHOWER DUCT ASSEMBLY....................9-7

[5] DEFROST HEATER ASSEMBLY..................9-8

CHAPTER 6. FAILURE DIAGNOSIS

[1] OUTLINE OF CONTROL............................... 6-1

[2] WHEN THE DEFROSTING FAILURE IS

DOUBTFUL(Only for SJ-PT51R/PT55R)........ 6-1

[3] RE-SETTING OF MICROCOMPUTER AT

POWER FAILURE.......................................... 6-1

[4] DIAGNOSIS METHOD OF FAILURE

AROUND PWB .............................................. 6-2

CHAPTER 10. COOLING UNIT

[1] COOLING UNIT...........................................10-1

[2] LOCATION ..................................................10-2

Parts Guide

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

SJPT55RHS

1 – 1

SJPT55RHS

Service Manual

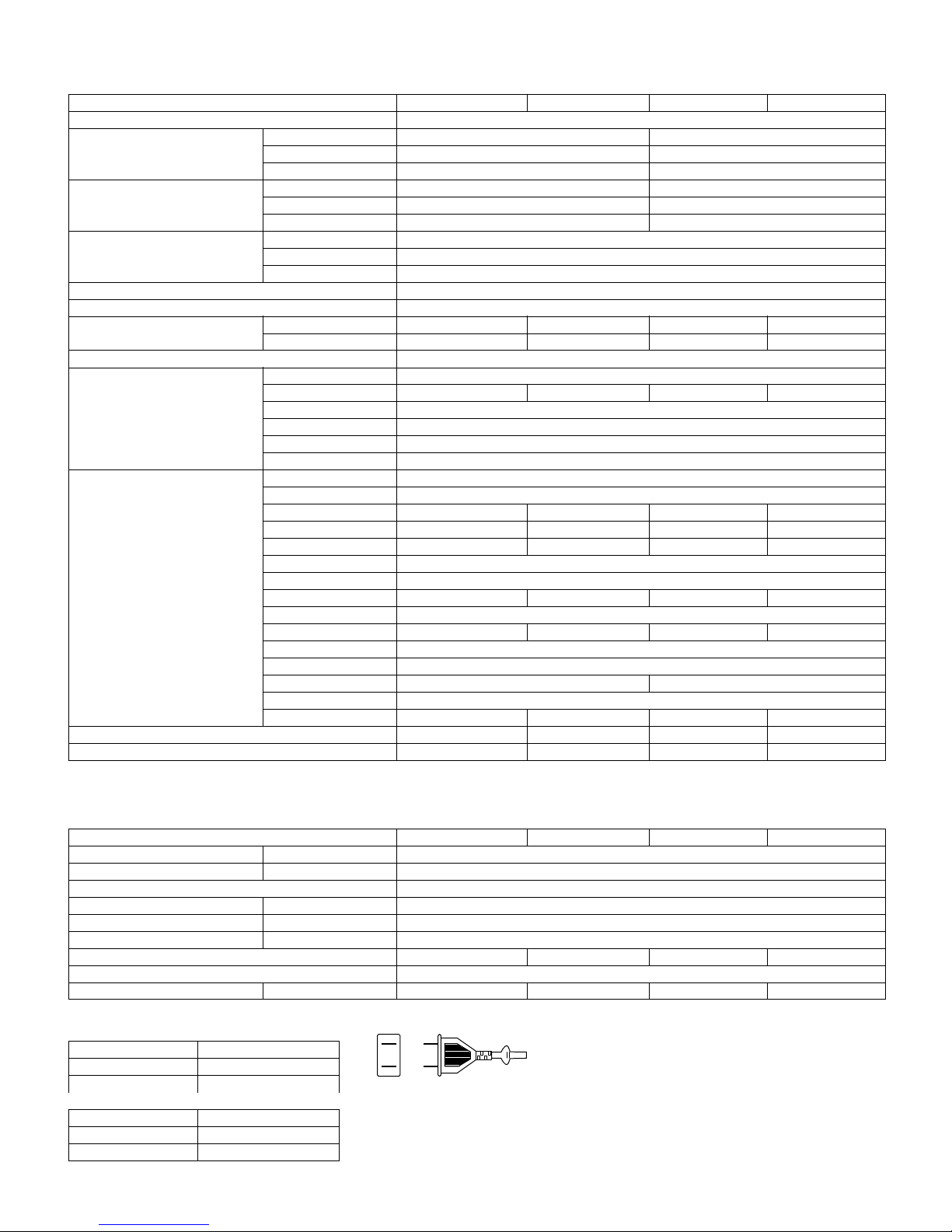

CHAPTER 1. SPECIFICATION

Items SJ-PT51R SJ-T51R SJ-PT55R SJ-T55R

Type 2-Door

Outer dimensions Height 1670mm(65.7") 1770mm(69.7")

Width 800mm(31.5") 800mm(31.5")

Depth 720mm(28.3") 720mm(28.3")

Rated storage volume

(Rated volume)

Total 514liter(18.1cu.ft) 555liter(19.6cu.ft)

Freezer 139liter(4.8cu.ft) 139liter(4.9cu.ft)

Refrigerator 375liter(13.3cu.ft) 416liter(14.7cu.ft)

Defrosting System Heater system

Start Automatic

Finish Automatic

Temperature control Automatic (Adjustable)

No-frost freezer Yes

Interior lamp Freezer 1 (LED) — 1 (LED) —

Refrigerator 1 (LED) 1 1 (LED) 1

Evaporating pan 1 (unremovable)

Freezer Compartment F-shelf 1

F-shelf S 1 — 1 —

Ice cube maker Twin ice cube maker

Ice storage box 1

F door pocket ass'y 1

RF door pocket 1

Refrigerator Compartment Fresh case 1

Fresh door 1

R glass shelf ass'y 1 2 1 2

R glass shelf SF ass'y 1 — 1 —

R glass shelf SB ass'y 1 — 1 —

V glass shelf ass'y 1

Vegetable case 2

Egg tray 2 1 2 1

R door pocket 1

R door cover 1 — 1 —

RF door pocket 1

Utility pocket 2

Utility pocket L — 1

Bottle pocket 1

Tube stand 2 1 2 1

Deodorizing unit (Honeycomb type) 2 1 2 1

Door opening side Changeable*1 — Changeable*1 —

*1 To modify the door, REFRIGERATOR HINGE KITS (SJ-L55CRD) will be required.

All modification work should be carried out by a competent person.

RATING

Items SJ-PT51R SJ-T51R SJ-PT55R SJ-T55R

Rated voltage (V~) 110

Rated frequency (Hz) 60

Climate class ST

Rated input (W) 146

Rated input of heating systems (W) 146

Defrosting input (W) 146

Refrigerant (Charging quantity) [Non-flammable] HFC-134a(110g) HFC-134a(110g) HFC-134a(110g) HFC-134a(110g)

Insulation blowing gas [Flammable] Cyclo pentane (HC)

Net Weight (kg) 80 77 82 79

PLUG TYPE

Plug cord 2 pin

Plug type A-1

Destination mark F

COLOR

Items -HS/SL

Outside color Silver

Inside color White

Page 3

SJPT55RHS

2 – 1

SJPT55RHS

Service Manual

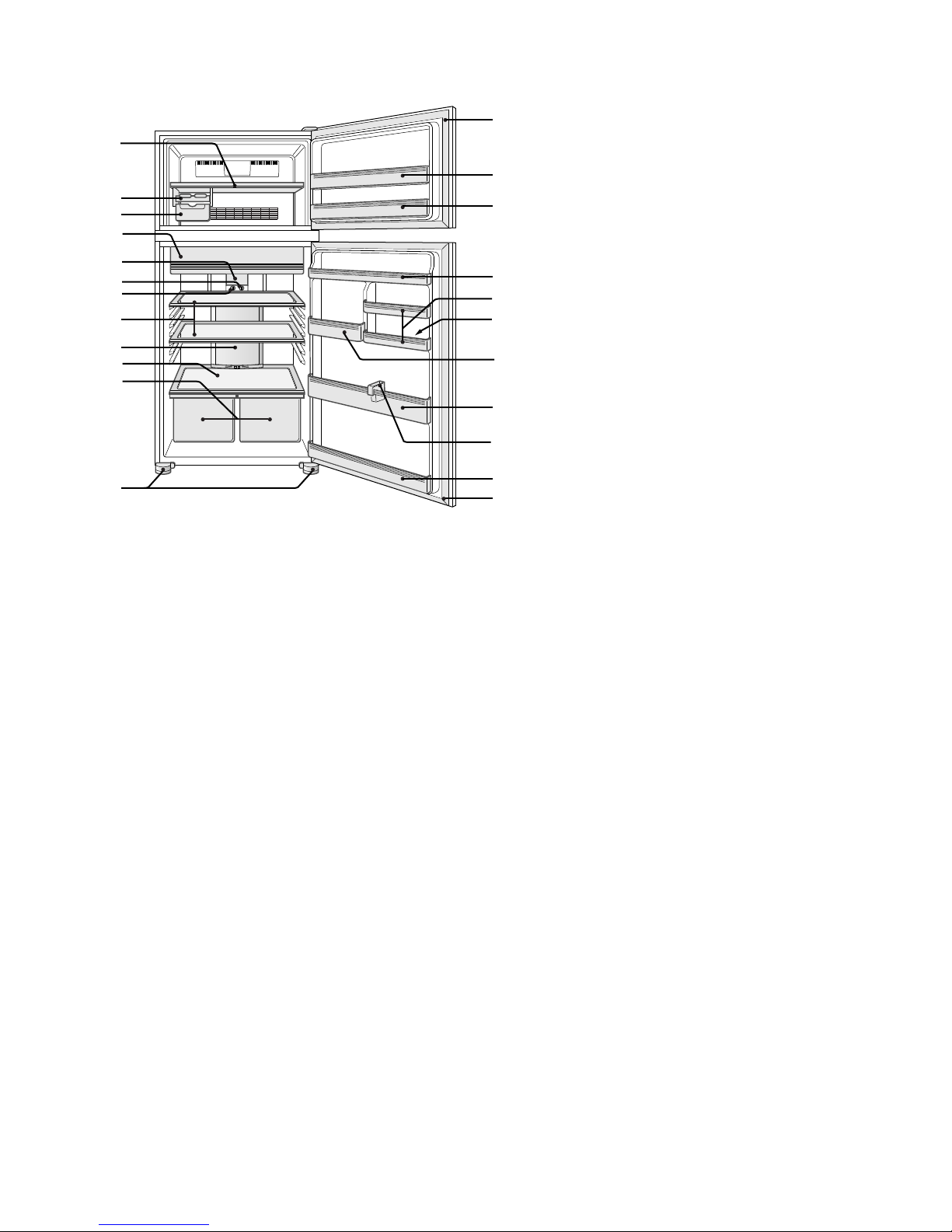

CHAPTER 2. DESIGNATION OF VARIOUS PARTS

[1] EXTERNAL DESCRIPTION

The names in parenthesis “[ ]” are the denominations used in the REPLACEMENT PARTS LIST.

1. SJ-PT51R,PT55R

1. Freezer LED light [LED lamp]

2. Freezer shelf [F-shelf]

3. Movable shelf [F-shelf s]

4. Ice cube maker

5. Ice cube box [Ice storage box]

6. Control panel

7. Fresh case & door

8. Refrigerator LED light [LED Lamp]

9. Refrigerator shelf [R glass shelf ass'y]

10. Hybrid cooling panel (Aluminum panel)

11. Half shelf (1 pair)

[R galss shelf sf ass'y,

R glass shelf sb ass'y]

12. Fruit and vegetable shelf

[V glass shelf ass'y]

13. Fruit and vegetable crisper

[Vegetable case]

14. Adjustable feet & cover [Adjustable leg]

15. Magnetic door seal [Door packing]

16. Flexible pocket [F door pocket ass'y]

17. Door pocket [RF door pocket]

18. Refrigerator pocket & cover

19. Utility pocket

20. Egg holder [Egg tray]

21. Utility pocket (large)

(Only for SJ-PT55R)

22. Bottle pocket

23. Tube stand

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

23

22

17

15

Page 4

SJPT55RHS

2 – 2

2. SJ-T51R,T55R

1. Freezer shelf [F-shelf]

2. Ice cube maker

3. Ice cube box [Ice storage box]

4. Fresh case & door

5. Refrigerator light [Lamp]

6. Freezer temp.conrol knob

7. Refrigerator temp.control knob

8. Refrigerator shelf [R glass shelf ass'y]

9. Hybrid cooling panel (Aluminum panel)

10. Fruit and vegetable shelf

[V glass shelf ass'y]

11. Fruit and vegetable crisper

[Vegetable case]

12. Adjustable feet & cover [Adjustable leg]

13. Magnetic door seal [Door packing]

14. Flexible pocket [F door pocket ass'y]

15. Door pocket [RF door pocket]

16. Refrigerator pocket

17. Utility pocket

18. Egg holder [Egg tray]

19. Utility pocket (large)

(Only for SJ-T55R)

20. Bottle pocket

21. Tube stand

17

18

13

15

16

12

1

2

3

4

5

8

9

10

11

6

7

13

14

15

19

20

21

Page 5

SJPT55RHS

2 – 3

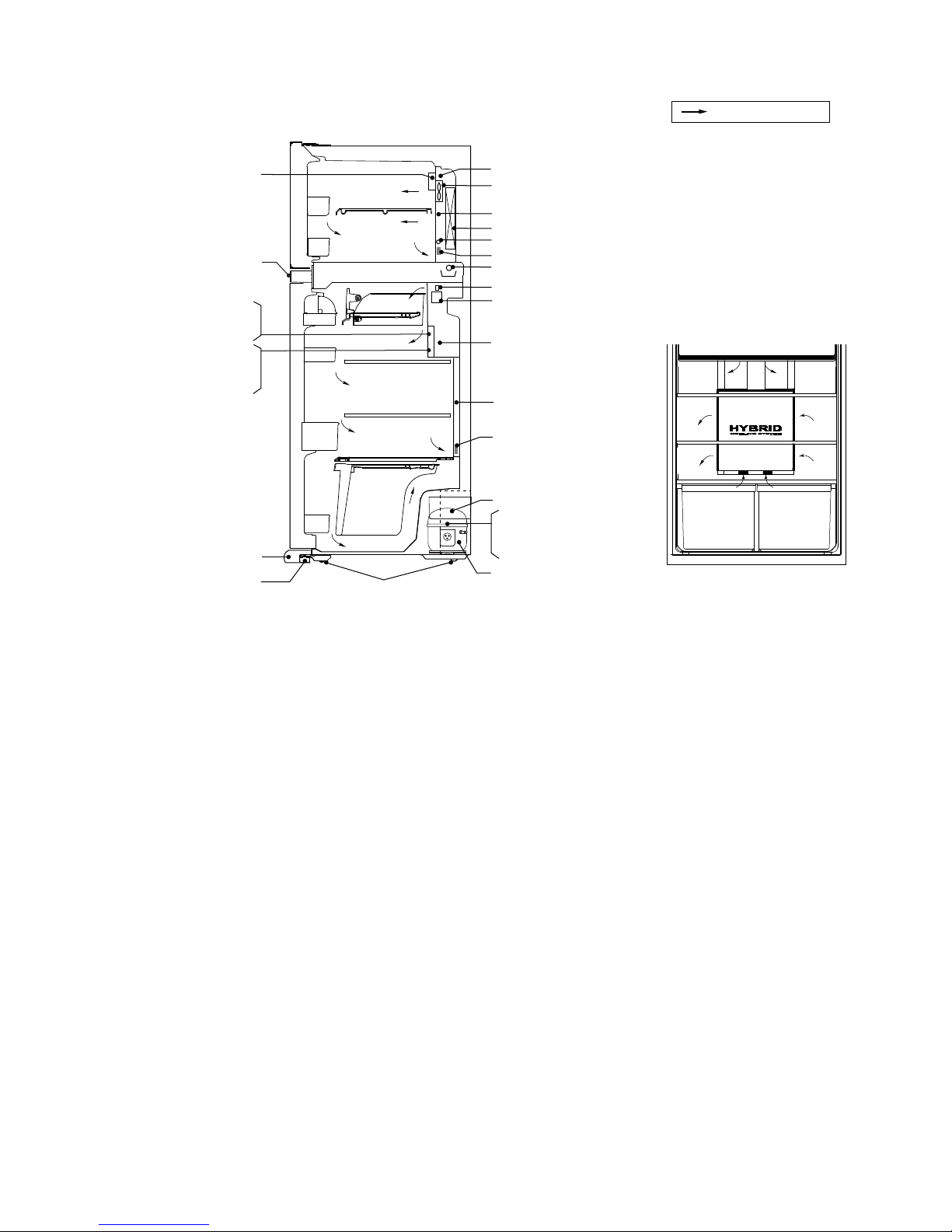

[2] CONSTRUCTIONS

Evaporator

Damper ass'y

Freezer

compartment

Refrigerator

compartment

Defrost heater

R-thermistor

Aluminum panel

F-thermistor

DEF-thermistor

Deodorizer

Deodorizer

F fan motor

Fuse ass'y

Ionizer-K

LED PWB ass'y

(Only for SJ-T51R/T55R)

(for SJ-T51R/T55R)

(Only for SJ-PT51R/PT55R)

(Only for SJ-PT51R/PT55R)

(Only for SJ-PT51R/PT55R)

(for SJ-PT51R/PT55R)

Mark : Cold air flow

Main PWB ass'y

Caster

Foot cover

Evaporating pan

Refrigerator temp. control knob

Lamp

LED lamp PWB L ass'y

R LED lamp PWB L ass'y

Freezer temp. control knob

Adjustable leg ass'y

Compressor

Starting relay

Overload relay(Protector)

Page 6

SJPT55RHS

3 – 1

SJPT55RHS

Service Manual

CHAPTER 3. DIMENSIONS

[1] OUTER DIMENSIONS AND CLEARANCE

1. SJ-PT51R

2. SJ-PT55R

800

800

10

1400

540

135

720

728

1050

49950

60

1670

1500

1440

7

This model is Free standing type.

(Not built-in type.)

800

800

10

1400

540

135

720

728

1150

49950

60

1770

1500

1440

7

This model is Free standing type.

(Not built-in type.)

Page 7

SJPT55RHS

3 – 2

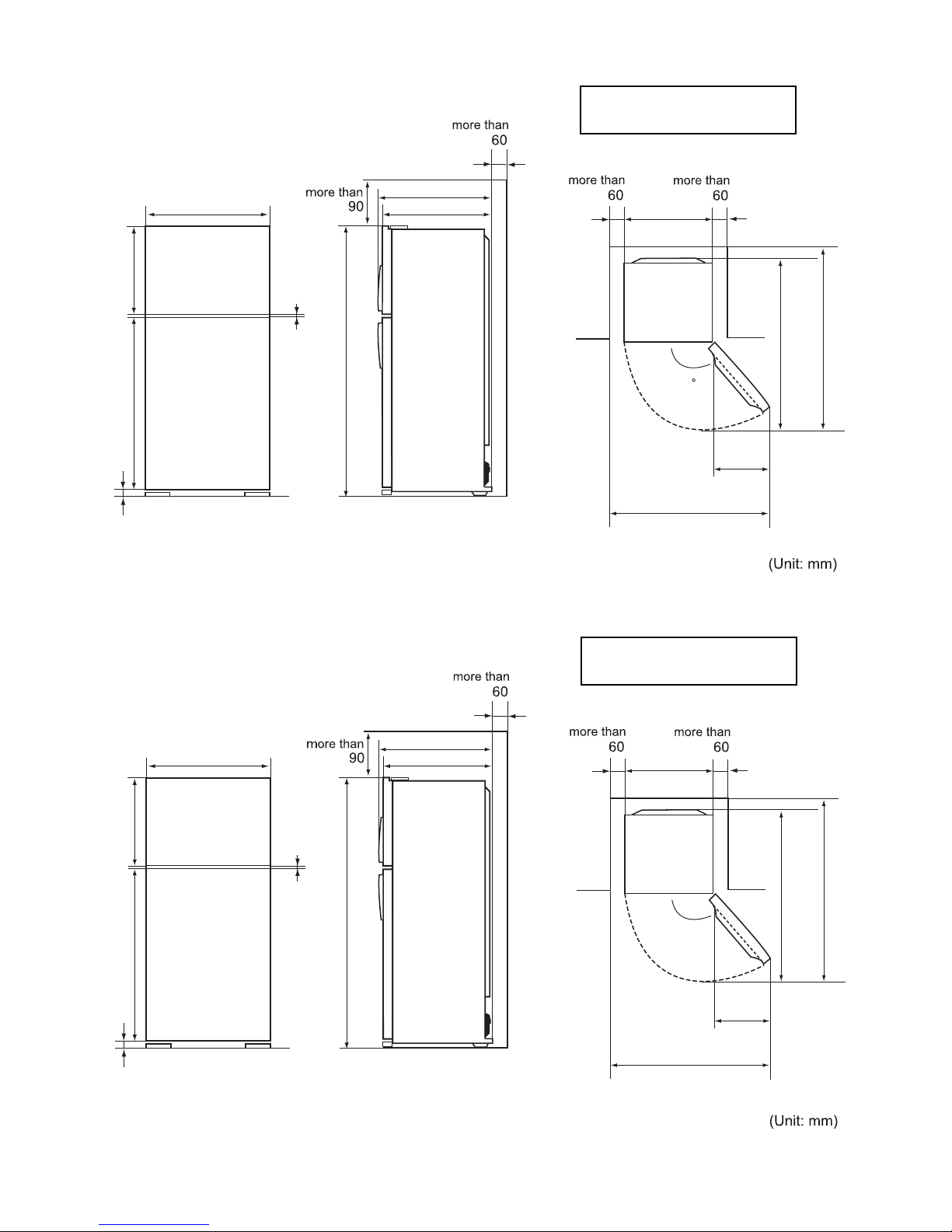

3. SJ-T51R

4. SJ-T55R

800

800

10

1400

540

135

720

725

1076

524

60

1670

1500

1440

This model is Free standing type.

(Not built-in type.)

This model is Free standing type.

(Not built-in type.)

800

800

10

1400

540

135q

720

725

1176

524

60

1770

1500

1440

Page 8

SJPT55RHS

3 – 3

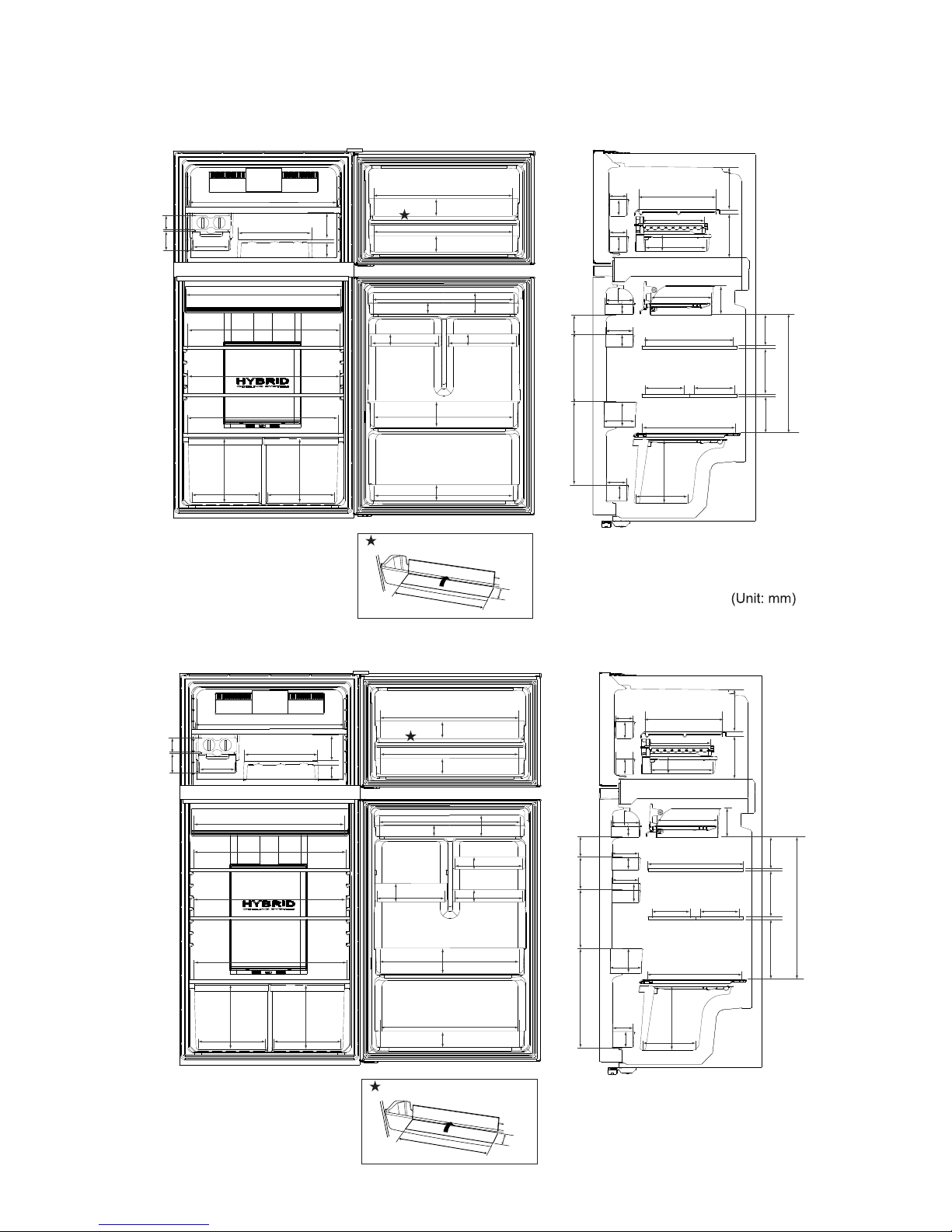

[2] INNER DIMENSIONS

The dimensions between shelves can be changed by setting the shelves on the other rails.

1. SJ-PT51R

2. SJ-PT55R

65

82

135

640

326

660

74

660

74

665

45

10

328

53

328

53

320

250

85

82

268

74

85

74

122

528

653

653

635

648

275 275

265

265

660

74

660

17

265

122

122

120

345

356

165208155

132

17

98

72

235

265

89246244

45

53

63

128

195208

150 150

50

330

65

82

135

640

326

63

128

660

74

660

74

665

45

10

328

53

328

53

330

83

660

17

660

74

635

653

653

275 275

265

265

320

250

85

82

268

74

85

74

195208

265

122

53

122

120

120

45

89

83

142257360

132

17

98

72

150 150

356

345

165203

625

210

235

265

648

50

330

Page 9

SJPT55RHS

3 – 4

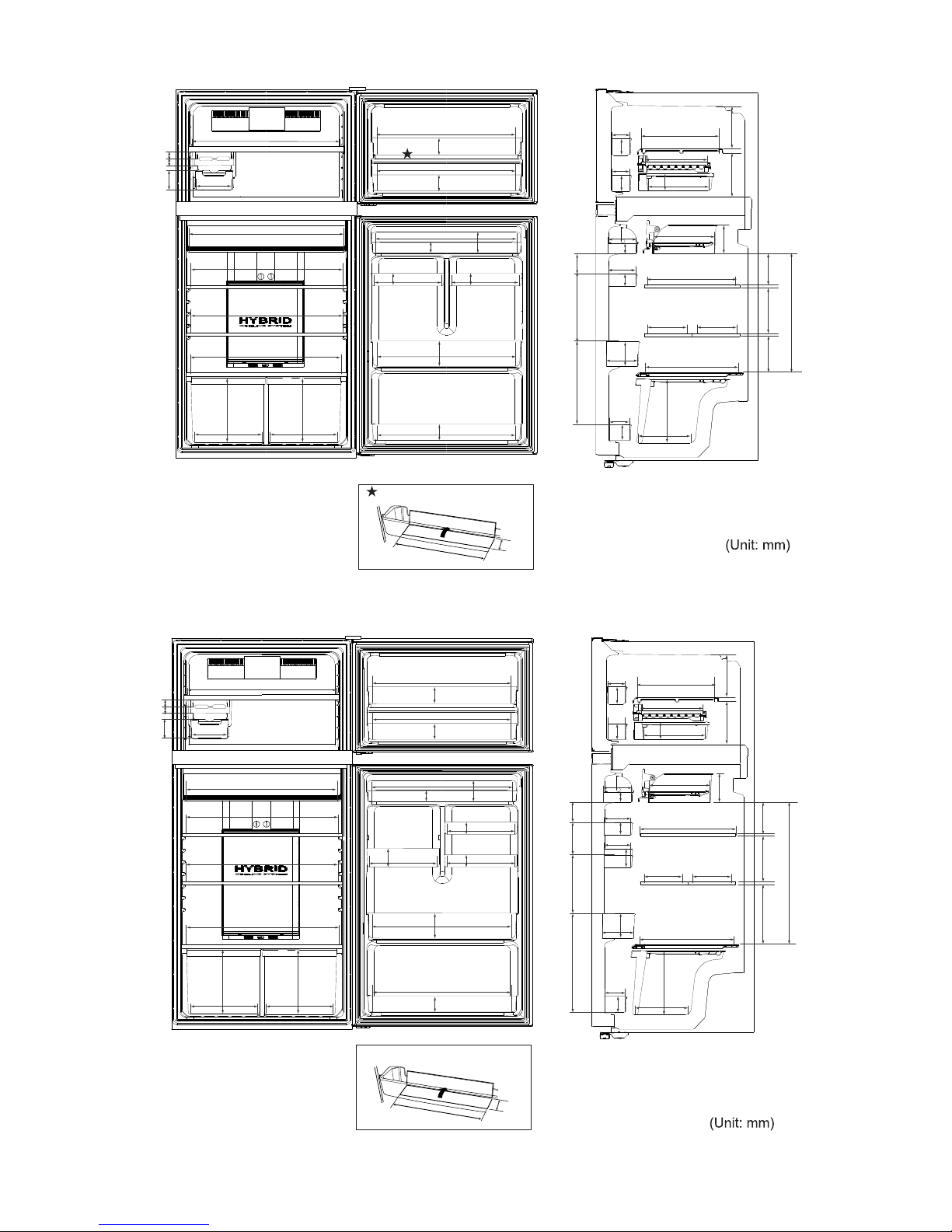

3. SJ-T51R

4. SJ-T55R

82

135

640

660

74

660

74

665

45

10

328

53

328

53

320

250

85

82

268

74

85

74

122

528

653

653

635

648

275 275

265

265

660

74

660

17

265

122

122

120

345

356

165208155

132

17

98

72

235

265

89246244

45

53

195208

50

330

150 150

30 47

82

135

640

660

74

660

74

665

45

110

328

53

328

53

330

83

660

117

660

74

635

653

653

275 275

265

265

320

250

85

82

268

74

85

74

195208

265

122

53

122

120

120

45

89

83

142257360

132

117

98

72

150 150

356

345

165203

625

210

235

265

648

50

330

ڎ

ڎ

30 47

Page 10

SJPT55RHS

4 – 1

SJPT55RHS

Service Manual

CHAPTER 4. LIST OF ELECTRICAL PARTS

[1] SJ-PT51R/PT55R

[2] SJ-T51R/T55R

ITEMS TYPE NAME RATING SPECIFICATIONS

R Thermistor

F Thermistor

Defrost Thermistor

—

—

—

DC 5V

DC 5V

DC 5V

R0 = 6.4 kΩ, B(0) = 3811

R0 = 6.4 kΩ, B(0) = 3811

R0 = 15 kΩ, B(0) = 3811

Thermo. fuse 12Y 250V 2A Working temp. : 76 °C

Defrost heater — 110-120V 77.7Ω 160W at 115V

Fan motor FBA12J15VXD DC 15V —

F Door switch

R Door switch

D3D-211

D3D-211

250V 0.5A/125V 1A

250V 0.5A/125V 1A

3 Terminals lever type

3 Terminals lever type

F Lamp (LED)

R Lamp (LED)

DPWB-A135CBKZ

DPWB-A150CBKZ

DC 14.5V

DC 14.5V

75mA, white LED Lamp

125mA, white LED Lamp

LED Operation FPWB-A499CBKZ DC 14.5V Blue LED

Compressor EG85HLP 110-127V/60Hz Cooling capacity : 248W (50Hz)

Main coil : 1.75 Ω

Aux. coil : 6.65 Ω

(at 25 °C)

Starting Relay PTH7M4R7M 50/60 Hz 4.7 ±0.94Ω (at 25 °C)

Overload Relay(Protector) 4TM771RPBZZ-53 — Open/ Close : 130±5.0 / 61±9.0 °C

Main PWB FPWB-A511CBKZ 100-127V Control by MPU

Ionizer-K(Plasmacluster unit) FTRN-A014CBKZ DC 12V —

ITEMS TYPE NAME RATING SPECIFICATIONS

R Thermistor

F Thermistor

Defrost Thermistor

—

—

—

DC 5V

DC 5V

DC 5V

R0 = 6.4 kΩ, B(0) = 3811

R0 = 6.4 kΩ, B(0) = 3811

R0 = 15 kΩ, B(0) = 3811

Thermo. fuse 12Y 250V 2A Working temp. : 76 °C

Defrost heater — 110-120V 77.7Ω 160W at 115V

Fan motor FBA12J15VXD DC 15V —

F Door switch

R Door switch

D3D-211

D3D-211

250V 0.5A/125V 1A

250V 0.5A/125V 1A

3 Terminals lever type

3 Terminals lever type

R Lamp — 120V 15W #187 Straight Terminal, Pitch 6

Compressor EG85HLP 110-127V/60Hz Cooling capacity : 248W (50Hz)

Main coil : 1.75 Ω

Aux. coil : 6.65 Ω

(at 25 °C)

Starting Relay PTH7M4R7M 50/60 Hz 4.7 ±0.94Ω (at 25 °C)

Overload Relay(Protector) 4TM771RPBZZ-53 — Open/ Close : 130±5.0 / 61±9.0 °C

Main PWB

VR PWB

FPWB-A513CBKZ

FPWB-A506CBKZ

100-127V

DC 5V

Control by MPU

—

Common

Aux. coil

Main coil

Common

Aux. coil

Main coil

Page 11

SJPT55RHS

5 – 1

SJPT55RHS

Service Manual

CHAPTER 5. WIRING DIAGRAM

[1] WIRING DIAGRAM

Be sure to replace the electrical parts with specified ones for maintaining the safety and performance of the set.

1. SJ-PT51R/PT55R

2. SJ-T51R/T55R

STARTING RELAY

COMPRESSOR

(G/Y)

FUSE

DEF-HEATER

LAMP

R-DOOR

SWITCH

F-DOOR

SWITCH

FAN MOT OR

(BL)

(SOURCE CORD)

(BR)

AC/DC

MAIN PWB

(GY)

PROTECTOR

(BR)

(W)

(BK)

(V)

(SB)

L

(SB)

(P)

(BL)

(GR)

(R)

FM

(BK)

(W)

(BR)

(BK)

(GR)

(P)

CONTROL

PWB

(BR)

(O)

(R)

(Y)

ELECTRICAL DAMPER

(SB)

(BL)

(P)

(O)

(W)

(GY)

(F-THERMISTOR)

(DEF-THERMISTOR)

(R-THERMISTOR)

BK : BLACK

BR : BROWN

R : RED

O : ORANGE

Y : YELLOW

GR : GREEN

BL : BLUE

V : VIOLET

GY : GRAY

W : WHITE

P : PINK

SB : SKY-BLUE

G/Y : GREEN/YELLOW STRIPE

Page 12

SJPT55RHS

5 – 2

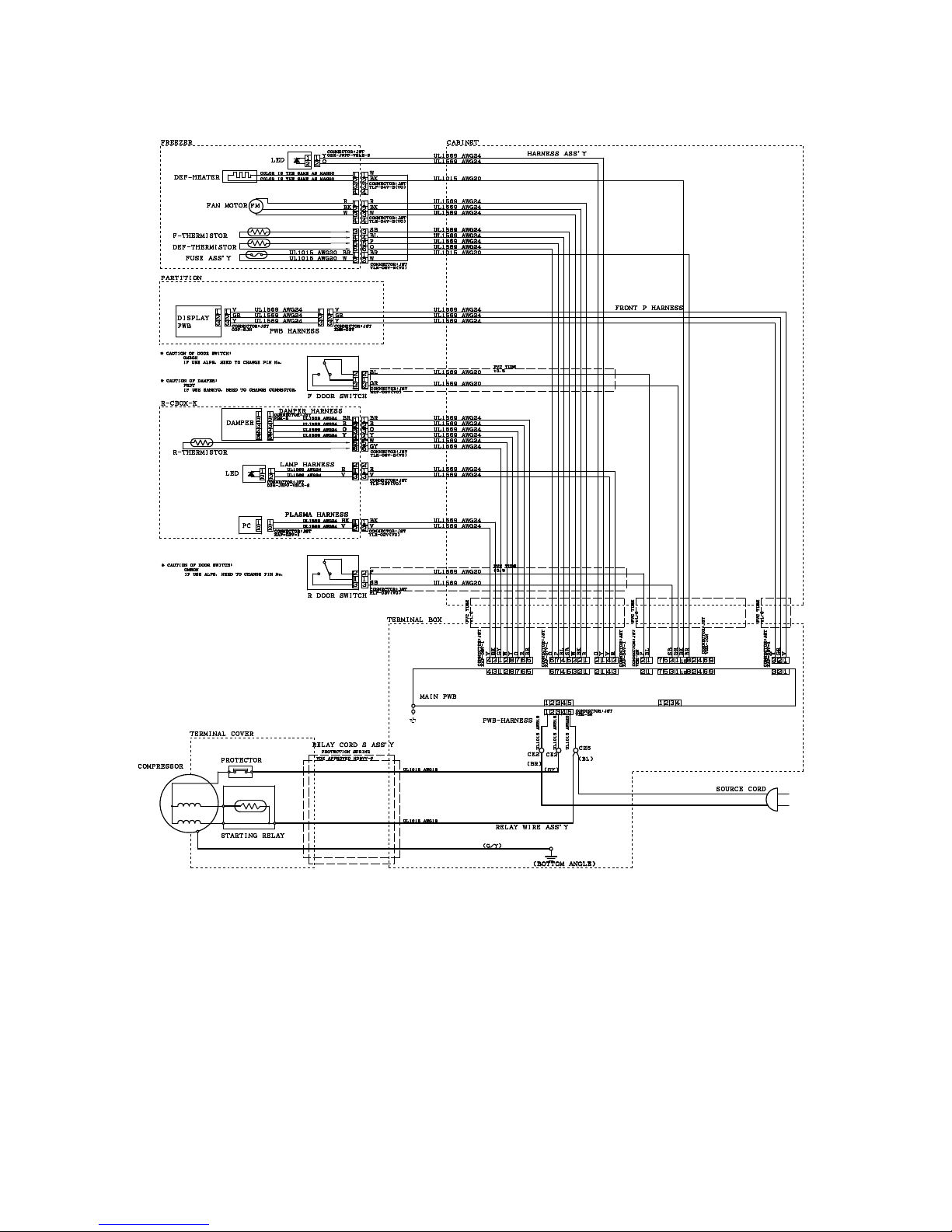

[2] ELECTRIC ACCESSORIES LAYOUT

1. SJ-PT51R/PT55R

BK : BLACK

BR : BROWN

R : RED

O : ORANGE

Y : YELLOW

GR : GREEN

BL : BLUE

V : VIOLET

GY : GRAY

W : WHITE

P : PINK

SB : SKY-BLUE

G/Y : GREEN/YELLOW STRIPE

Page 13

SJPT55RHS

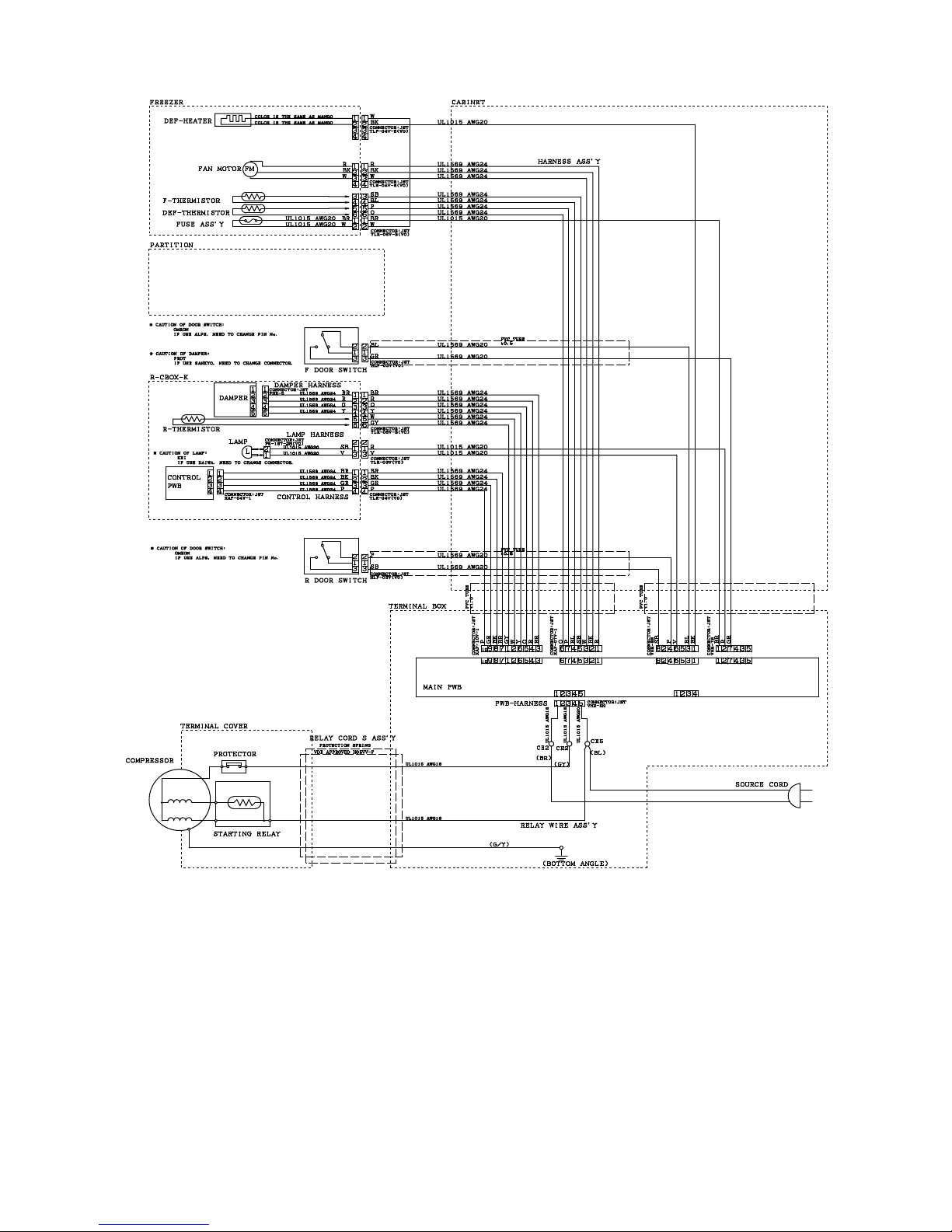

5 – 3

2. SJ-T51R/T55R

BK : BLACK

BR : BROWN

R : RED

O : ORANGE

Y : YELLOW

GR : GREEN

BL : BLUE

V : VIOLET

GY : GRAY

W : WHITE

P : PINK

SB : SKY-BLUE

G/Y : GREEN/YELLOW STRIPE

Page 14

SJPT55RHS

5 – 4

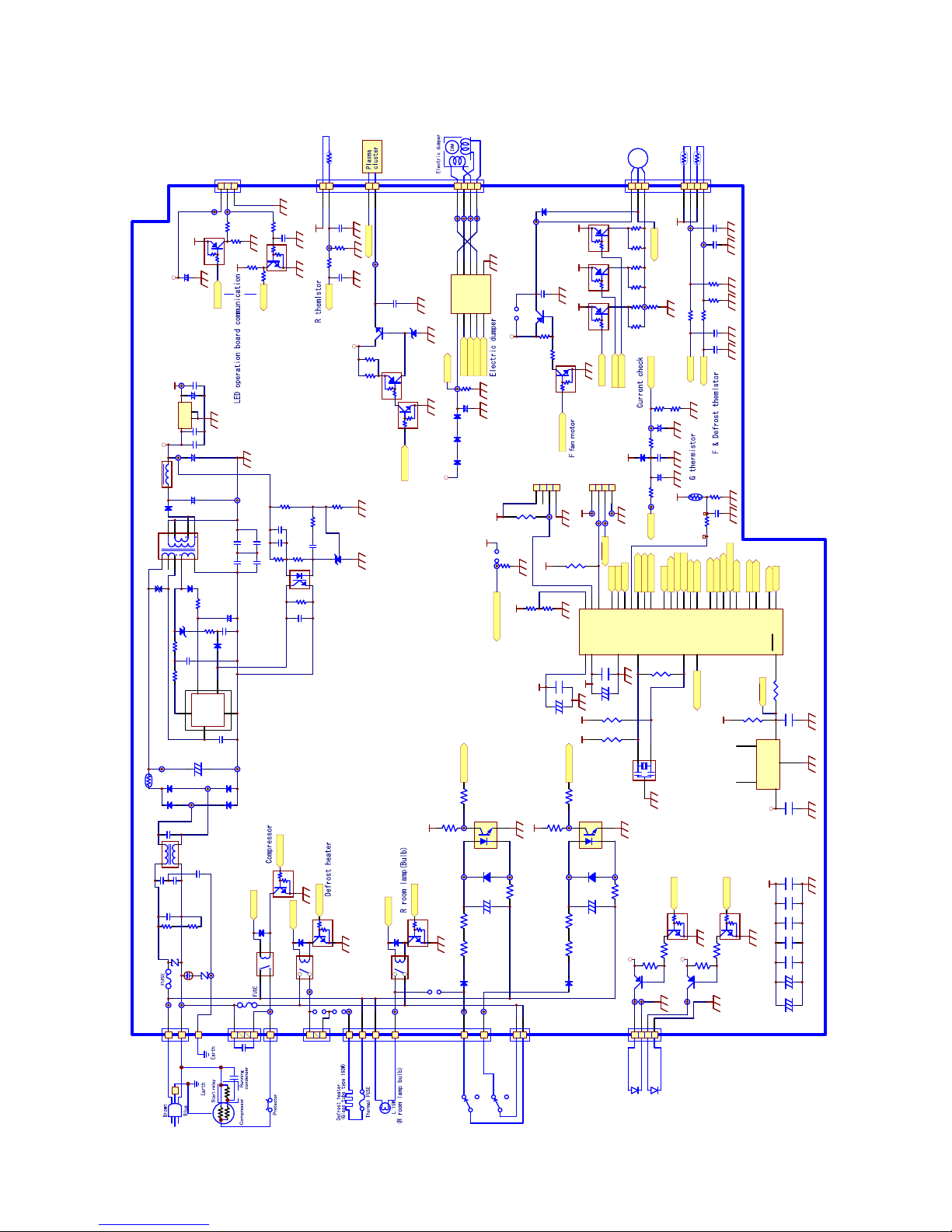

[3] CIRCUIT DIAGRAM

1. Main PWB (SJ-PT51R / PT55R)

DC5V

AC160-288V

VM14.5V

1

2

4

3

RY2

FTR-F3(3 A)

1

3

5

Vin

G

Vou t

4

G

IC4

BP5225

C13

0.1u 25V

C15

0.1u/25V

D8

1N4005SG

(C73)

10000pF

(C75)

10000pF

R11

R14

R9

R7

1000p/50V

C16

1

2

34

PC1

PC123Y52

8.66kF

R8

C18

0.1u/50V

1k

20kF

1.8k

1.8kF

IC3

TA76431S

+

C14

100uF/10V

+

C74

1000uF/25V

D3

D1NL20U

D2

D1NL20U

R6

220pF/50V

Jumper

13kF

C9

C10

ZD1

HZ11C1

D4

D2S6M

R5R34

2200p/50V

C8

16kF

150pF/2kV

+

C11

100uF/25V

910k(1/2W)

(AX)

+

C7

R1

150u/450V

F1

2.5A/250V

VRS1

TNR10V471K

C1

L1

SS21V-050360(36mH)

C2

0.1u/275V

0.1u/275V

C21

0.1u

C20

0.1u

VDD

2

GND

3

VOUT

1

N.C.

4

N.C.

5

IC9

BD4842G

C19

0.01u

+5V

R83

10k

R93

1k

R86

1M

2

1

3

CF1

CST LS8M00G56-A0

RXD

P0032P0131P0230P0329P0428P0527P06

26

AN0

25

P3424P33

23

P1022P11

21

VREF

20

P1219P13

18

TXD0

17

P35

1

TXD1

2

RESET

3

XOUT

4

AVS S5XIN

6

AVC C

7

MODE

8

RXD1

9

P17

10

P3611P31

12

P5413P53

14

P16

15

RXD0

16

IC1

R5F21266SNFP

TXD

C23

0.1u

+C22

100u/25V

+(C24)

100u/25V

(RD)

(RD)

(R87)

10k

(R88)

10k

132

4

CN11

B4B-PH-KL

RESET

RESET

R89

10k

1

3

(CN4)

B2P3-VH

1

4

(CN3)

B2P4-VH-BL (LF)(SN)

123

CN8

B03B-XASK-1-A(LF)(SN)

1

CN10A

B7B-XASK-1-A(LF)(SN)

2

CN10B

B7B-XASK-1-A(LF)(SN)

3

CN10C

B7B-XASK-1-A(LF)(SN)

4

CN10D

B7B-XASK-1-A(LF)(SN)

5

CN10E

B7B-XASK-1-A(LF)(SN)

6

CN10F

B7B-XASK-1-A(LF)(SN)

7

CN10G

B7B-XASK-1-A(LF)(SN)

1

CN9A

B8B-XASK-1-A(LF)(SN)

2

CN9B

B8B-XASK-1-A(LF)(SN)

3

CN9C

B8B-XASK-1-A(LF)(SN)

4

CN9D

B8B-XASK-1-A(LF)(SN)

5

CN9E

B8B-XASK-1-A(LF)(SN)

6

CN9F

B8B-XASK-1-A(LF)(SN)

7

CN9G

B8B-XASK-1-A(LF)(SN)

8

CN9H

B8B-XASK-1-A(LF)(SN)

70m A /12V

F-TH

DEF-TH

R-TH

F-TH

DEF-TH

R58

C56 C5 7

0.1uF/ 25V 0.1uF/ 25V

R56 4.7k

R57 4.7k

16.9kF

R59

16.9kF

(C54)

0.01u

(C55)

0.01u

/50V

/50V

R-TH

R30

C37

0.1uF/ 25V

R29

4.7k

6.34kF

(C36)

0.01u

/50V

(R61)(R60)

R53

F_FA N_H

F-FM

F_FA N_L

VM14.5V

R48

F_FA N_ON

C50

R47

0.1uF/ 25V

4.7k

750(1/2W)

6.19kF

10kF

3.16kF

Q14

KTA1273-Y

Q15

KRC101S

(Q17)

KRA101S

Q16

KRA101S

I_detect

FFanmotor

VM14.5V

+

C42

100uF/25V

OUT110OUT29OUT38OUT4

7

IN12IN23IN34IN4

5

GND

6

VCC

1

IC6

LB1948M

D5

1N4005SG

DUMP_B1

DUMP_B2

DUMP_A1

DUMP_A2

D6

1N4005SG

D7

1N4005SG

PLASMA

Q7

KTC3205

ZD2

HZ12B2

VM14.5V

R32

C38

0.1uF/25V

470

Q8

KRA101S

Q9

KRC101S

I_detect

R31

470

910k(1/2W)

(AX)

R2

D16

1SR139-600

D17

D18

D19

F2

250V4A

1

2

3

D12

1SS133

D10

1SS133

Q2

KRC101S

Q3

DTD123ES

DEF_H

Comp

R16

43k

(1/2W)

(AX)

R15

43k

(1/2W)

(AX)

R26

4.7k

(1/10W)

D13

1SS133

132

4

PC2

PC123Y52

R12

4.7k

(1/10W)

R19

4.7k (1/10W)

+

C25

10uF/ 50V

1

2

3

RDoorSW

(R81)

10k

E8EmulatorConnector

Vcc

Mode

Reset

Vss

F Roomlamp

LED

TP13

(L3)

+

C12

100uF/25V

C31

TXD

RXD

DC5V

DC5V

R18

R17

R21

1k

R22

1k

2.7k

2.7k

Q5

KRA101S

Q6

KRC101S

TP1

Toroidal Core(ESD-R-3810Turns)

RDOORSW

FDOORSW

TP2

TP44

ForIsraelonly

TP11

RY1

FTR-H2AL

TP43

TP14 TP15

TP16

TP17

TP12

TP46

TP47

TP48

TP49

Film

Film

TP45

TP7

TP6

C76

10000pF

C77

10000pF

250V

TP9

TP8

TP18

TP20

VM14.5V

R20

1k

0.01u

TP25

TP28

TP29

TP30

TP31

TP19

TP36

TP37

TP41

TP40

I_me s

R46

DC5V

R44

R45

0.51

1k

R55

1W

1W

4.7k

D11

1SS133T

(AX)

(AX)

+

C78

1uF/50V

+

C49

100uF/10V

0.51

(C48)

0.1u

I_detect

(JMP 2)

OPEN

DC5V

R82

10k

TP26

C67

0.1u

+

C64

100u/25V

C66

0.1u

+C65

100u/25V

C69

0.1u

C68

0.1u

C70

0.1u

DC5V

DEF_H

Comp

I_me s

R-TH

DUMP_B1

DUMP_B2

DUMP_A1

DUMP_A2

F_FA N_H

F_FA N_L

F_FA N_ON

F-TH

DEF-TH

Ma in Control Board Ci rcuit Diagram

1.Ratingof reslstors without appointment are 1/10W, error 5%(J).

2.Ratingof capacitors without appointmentare 0.01u/50V,0.1u/50V.

3.Partswithparenthesesare not in use,but canbe inserted.

ZD3

STO3D-200

1SR139-600

1SR139-600

1SR139-600

TP35

TP34

(C17)

0.1u

TSL11 12RA-100M3R7-PF

Plasmacluster

PLASMA

HALL

GND

COIL

DC5VDC5V

DC5V

DC5V

DC5V

DC5V

DC5V DC5V

DC5V

DC5V

DC5V

DC5V

DC5V

65432

11108

9

TRNS1

EER28/5.95mH

Q10

2SB1237

R27

1k

R28

4.7k

Q1

KRC101S

F_Lam p

VM14.5V

+

(C79)

100uF/25V

(C27)

0.1u

GND

3

F/B

2

Vcc

4

Z/C

1

D

5

IC2

MR1712

1

CN1A

B3P(5-2,4)-VH(LF)(SN)

3

CN1B

B3P(5-2,4)-VH(LF)(SN)

5

CN1C

B3P(5-2,4)-VH(LF)(SN)

C4

SA1

RA-272M-C 6-F

C6

C5

4700pF

4700pF

4700pF

/250VAC

VRS2

TNR10V511K

1

Tab1 TP42098-21

TP3

1

CN5A

B6P(10-2,4,6,9)-VH(LF)(SN)

3

CN5B

B6P(10-2,4,6,9)-VH(LF)(SN)

5

CN5C

B6P(10-2,4,6,9)-VH(LF)(SN)

7

CN5D

B6P(10-2,4,6,9)-VH(LF)(SN)

8

CN5E

B6P(10-2,4,6,9)-VH(LF)(SN)

10

CN5F

B6P(10-2,4,6,9)-VH(LF)(SN)

J3

JumperJ3Jumper

1

2

4

3

(RY3)

FTR-F3(3 A)

(D15)

1SS133

(Q19)

KRC101S

R_Lamp

TP38

D9

1N4005SG

R10

43k

(1/2W)

(AX)

R14

43k

(1/2W)

(AX)

R23

4.7k

(1/10W)

D14

1SS133

1

3

2

4

PC3

PC123Y52

R24

4.7k

(1/10W)

R25

4.7k (1/10W)

+

C26

10uF/ 50V

F DoorSW

TP22

TP23 TP24

DC5V

1

2

CN2B2P2-VH(LF)(SN)

TP4

JMP1

Jumper

TP39

RDoorSWinput

FDoorSWinput

FRoomLamp(LED)

TH1

S8R2K10D315J

AX 1/4W

AX 1/4W

Jumper

R3

AX 1/4W

AX 1/4W

AX 1/4W

Jumper

R4

AX 1/4W

AX 1/4W

TP10

(C28)

1u/50V

R33

10k

TP21

DC12V

AX

(JMP 3)

OPEN

Q18

KRA101S

DC5V

(R62)

10kF

R52

10kF

(R51)

6.19kF

R50

3.16kF

F_FA N_M

AX 1/4W

AX 1/4W AX 1/4W

GTH1

C16X-41-3S

R35

DC5V

(C32)

0.1u/25V

R36

4.7k

10kF

TP33

TP32

DC12V

DC12V

DC12V

F_Lam p

R_Lamp

F_FA N_M

RDoorSW

F DoorSW

ENFORCEDEF

ENFORCEDEF

R91

10kF

(R90)

10kF

DC5V

TP27

132

4

(CN12)

B4B-PH-KL

RAM DataCheck

3216

D1

1N4005SG

TP42

Q11

2SB1237

R38

1k

R37

4.7k

Q4

KRC101S

VM14.5V

RRoomLamp(LED)

132

4

CN7

B04B-XASK-1-A( LF)(SN)

R Roomlamp

LED

R_Lam p

Rating AC220-240V 50/60Hz

50/60Hz

Panasonic

Page 15

SJPT55RHS

5 – 5

2. Main PWB (SJ-T51R / T55R)

DC5V

D309

1N4005SG

AC160-288V

50/60Hz

14.5V

1

2

4

3

RY302

FTR-F3

(C328)

1u/50V

C315

0.1u/25V

D308

1N4005SG

(C373)

10000pF

(C375)

10000pF

R311

R314

R309

4700p/50V

C316

1

2

34

PC301

PC123Y52

8.66kF

R308

C318

0.1u/50V

1k

1.8k

1.8kF

IC303

TA76431S

+

C314

100uF/10V

+

C312

560uF/25V

D303

D1NL20U

D302

EG01C

R305

R306

0.01u/400V

10

C309

C308

D304

RL2Z

R304

220k

47pF/2kV

1/2W1.0

+

C311

22uF /50V

910k(1/2W)

(AX)

+

C307

R301

82u/450V

F301

2.5A/250V

VRS301

TNR10V471K

C301

L301

SS26V-070510(51mH)

C302

0.1u/275V0.1u/275V

C321

0.1u

C320

0.1u

VDD

2

GND

3

VOUT

1

N.C.

4

N.C.

5

IC309

BD4842G

C319

0.01u

R383

10k

R393

1k

(R386)

1M

2

1

3

(CF301)

CST LS8M00G56-A0

P0032P0131P0230P0329P0428P0527P06

26

AN0

25

P3424P33

23

P1022P11

21

VREF

20

P1219P13

18

TXD0

17

P35

1

TXD1

2

RESET

3

XOUT

4

AVS S5XIN

6

AVC C

7

MODE

8

RXD1

9

P17

10

P3611P31

12

P5413P53

14

P16

15

RXD0

16

IC301

R5F21266SNFP

C323

0.1u

+C322

100u/10V

+(C324)

100u/10V

(RD)

(RD)

R387

10k

R388

10k

132

4

CN311

B4B-PH-KS

RESET

RESET

R389

10k

1

4

(CN303)

B2P(4-2,3)VH(LF)(SN)

1

CN310A

B7B-XASK-1-A(LF)(SN)

2

CN310B

B7B-XASK-1-A(LF)(SN)

3

CN310C

B7B-XASK-1-A(LF)(SN)

4

CN310D

B7B-XASK-1-A(LF)(SN)

5

CN310E

B7B-XASK-1-A(LF)(SN)

6

CN310F

B7B-XASK-1-A(LF)(SN)

7

CN310G

B7B-XASK-1-A(LF)(SN)

F-TH

DEF-TH

R-TH

F-TH

DEF-TH

R358

C356 C357

0.1uF/ 25V 0.1uF/ 25V

R356 4.7k

R357 4.7k

16.9kF

R359

16.9kF

(C354)

0.01u

(C355 )

0.01u

/50V

/50V

R-TH

R330

C337

0.1uF/ 25V

R329

4.7k

6.34kF

(C336)

0.01u

/50V

R353

F_FA N_H

F-FM

F_FA N_L

14.5V

(R351)

F_FA N_M

6.19kF

10kF

(Q317)

KRA101S

Q316

KRA101S

FFanmotor

14.5V

+

C342

100uF/25V

OUT110OUT29OUT38OUT4

7

IN12IN23IN34IN4

5

GND

6

VCC

1

IC306

LB1948M

D305

1N4005SG

DUMP_B1

DUMP_B2

DUMP_A1

DUMP_A2

D306

1N4005SG

D307

1N4005SG

910k(1/2W)

(AX)

R302

D316

1N4005SG

D317

D318

D319

F302

250V4A

COM

NO

NC

D312

1SS133

D310

1SS133

Q302

KRC101S

Q303

DTD123ES

DEF_H

Comp

R316

43k

(1/2W)

(AX)

R315

43k

(1/2W)

(AX)

R326

4.7k

AX (1 /4W)

D313

1SS133

1

3

2

4

PC302

PC123Y52

R312

4.7k

(1/10W)

R313

4.7k (1/10W)

+

C325

10uF/50V

COM

NO

NC

DoorSW

132

4

(CN312)

B4B-PH-KS

(R381)

4.7k

E8EmulatorConnector

RAM DataCheck

Vcc

Mode

Reset

Vss

TP313

C310

0.01u/50V

(L303)

TP301

R DOORSW

FDOORSW

TP302

TP344

ForIsraelonly

TP311

RY301

FTR-H2AL012T-SN

TP343

TP314 TP315

TP312

TP346

TP347

TP348

TP349

Film

Film

TP345

TP307

TP306

C376

10000pF

C377

10000pF

250V

TP309

TP8

TP325

TP328

TP329

TP330

TP331

TP336

TP337

TP341

TP340

(JMP 30 3)

OPEN

DC5V

R382

10k

TP326

C367

0.1u

+C364

100u/25V

C366

0.1u

+C365

100u/25V

C369

0.1u

C368

0.1u

C370

0.1u

DC5V

Ma in Control Board Ci rcuit Diagram

1.Ratingof reslstors without appointment are1/10W, error 5%(J).

2.Ratingof capacitors without appointment are 0.01u/50V,0.1u/50V.

3.Partswithparenthesesare not in use,but canbe inserted.

1N4005SG

1N4005SG

1N4005SG

(C317)

0.1u

TSL1112RA-100M3R7-PF

Vcc

GND

Vs

DC5V

DC5V

DC5V

DC5V

DC5V

DC5V

DC5V DC5V

DC5V

DC5V

DC5V

DC5V

DC5V

D301

1N4005SG

Q318

KRA101S

DC5V

(R361)

6.19kF

R352

10kF

(R362)

10kF

R350

3.16kF

(R360)

3.16kF

1

CN309A

B10-XASK-1-A(LF)(SN)

2

CN309B

B10-XASK-1-A(LF)(SN)

3

CN309C

B10-XASK-1-A(LF)(SN)

4

CN309D

B10-XASK-1-A(LF)(SN)

5

CN309E

B10-XASK-1-A(LF)(SN)

6

CN309F

B10-XASK-1-A(LF)(SN)

7

CN309G

B10-XASK-1-A(LF)(SN)

8

CN309H

B10-XASK-1-A(LF)(SN)

9

CN309I

B10-XASK-1-A(LF)(SN)

10

CN309J

B10-XASK-1-A(LF)(SN)

R343

C335 C332

0.1uF/ 25V 0.1uF/25V

R340 4.7k

R342 4.7k

220k

R341

220k

TP338

TP339

DC5V

(C330)

0.1uF/ 25V

F_VR

R_VR

GTH301

C16X-41-3S

R320

DC5V

(C381)

0.1u

R319

4.7k

10kF

(C380)

0.01u

TP332TP333

G_Th

(BZ301)

PKM22E P

(R318)

2.7k

(Q319)

KRC101S

14.5V

Buzzer

R391

10k

C304

SA301

RA-272M-C6-F

C306

C305

4700pF

4700pF

4700pF

/250VAC

VRS302

TNR10V511K

1

Tab3 01

Rating AC 220-240V50/60Hz

DC12V

DC12V

DC12V

1

CN301A

B3P( 5 -2 ,4)-VH(LF)(SN)

3

CN301B

B3P( 5 -2 ,4)-VH(LF)(SN)

5

CN301C

B3P( 5 -2 ,4)-VH(LF)(SN)

TP42098-21

1

CN306A

B5P( 7 -4 ,6)-VH(LF)(SN)

2

CN306B

B5P( 7 -4 ,6)-VH(LF)(SN)

3

CN306C

B5P(7-4,6)-VH(LF)(SN)

5

CN306D

B5P(7-4,6)-VH(LF)(SN)

7

CN306E

B5P(7-4,6)-VH(LF)(SN)

1

CN305A

B5P(8-2,5,7)-VH(LF)(SN)

3

CN305B

B5P( 8 -2 ,5,7)-VH(LF)(SN)

4

CN305C

B5P( 8 -2 ,5,7)-VH(LF)(SN)

6

CN305D

B5P(8-2,5,7)-VH(LF)(SN)

8

CN305E

B5P(8-2,5,7)-VH(LF)(SN)

1

2

4

3

(RY303)

FTR-F3

(D314)

1SS133

(Q321)

KRC101S

R_Lam p

DC12V

TP304

JMP301

Jumper

1

2

4

3

(RY304)

FTR-F3

(D315)

1SS133

(Q322)

KRC101S

DC12V

TP305

(JMP302)

OPEN

F_Lam p

TH301

S8R2K10D315J

D

8

D

7

VCC

5

S/OCP

1

FM/SS

2

GND

3

FB/CC/OLP

4

IC302

STR-A6251M

1W

(C327)

0.1u

AX 1/4W

Jumper

R307

AX 1/4W

1/4W

1/4W

TP9

C313

0.1u25V

3216

1

2

3

I

G

O

TP303

(D320)1N4005SG

1/4W

RK09K1130(10k)

Door SW input

Compressor

F-TH

DEF-TH

R-TH

F_FA N_H

F_FA N_L

F_FA N_M

DUMP_B1

DUMP_B2

DUMP_A1

DUMP_A2

F_VR

R_VR

G_Th

Buzzer

DEF_H

Comp

DoorSW

R_Lamp

ENFORCE_DEF

ENFORCE_DEF

F_Lam p

TP10

DC5V

TP334

R roomlamp(Bulb)

Defrost heater

F roomlamp(Bulb)

D3D-211

D3D-211

(Heat sink)

OSH-1025-SP2

54312

9106

7

TRANS301

123

Panasonic

2345

PH

2

1/2W1.2

2

R5F21265SNFP

(470uF/25V)

TP317

TP318

TP319

TP316

R395

DC5V

(R394)

10k

10k

Page 16

SJPT55RHS

5 – 6

3. LED PWB (Only for SJ-PT51R / PT55R)

1 2

SSWW110011

SS

KK

QQ

NN

AADD

DD

001100

11 2

SS

WW110022

SS

KK

QQ

NN

AADD

DD

001100

11

2

SSWW110033

SSKKQQNNAADDDD001100

V

out

1

GND

2

Vin

3

IC102

KIA7

8

S05P

VL

T

X

D

,R

X

D

GND

+C1

02

47u/

2

5V

C1

01

0.

1

u/50V

C107

0

.1u

TP

101

(D101)

1N4005E

+

C103

47u/10V

+

5

V

VL

TP104

(R

D

)

(2

1

25

)

T

P

10

3

(

1608)

(RD)

T

P

10

2

RR11550

22..77kk

BZ101

PKM 1 3EPY

4kHz

+5

V

RR115522

11kk

RR11

5533

11kk

C1

10

0.

1u

V

DD

2

GND

3

VOUT

1

N.C.

4

N.C.

5

IC1

0

3

BD4842

G

C1

05

0.0

1u

+

5V

d3

d2

C1150.1u

C108

0.1u

(C

140

)

0.

1

u

R130

10kF

R131

4.7k

C1410.01u

GT

H

1

01

C

16X

-4

1-3S

+

5V

T

P

115

TP

116

Q

14

1

KRC101S

R14

2

2.2

k

+5V

RR114477

1k

R1

45

1k

C

132

0.01u

TP1

09

TP

11

0

R143

1

k

R14

4

1k

(R146)

1k

C13

1

0.0

1u

TP114

R1

41

2

..2kk

Q142

KRA101S

+5V

R170

2

.7

k

(C170)

0.01u

+5V +5V

R171

2.7

k

(C171)

0.0

1u

+

5V

+5V

S

W1

R172

2

.7k

(C172)

0.01u

+5V +5V

S

W

2

SW3

R162

820

R1

65

820

R164

820

R163

8

2

0

R160

820

R1

61

820

TT

PP

110055

TTPP110066

TT

PP

110077

TP

112

TP1

11

RXD0

R10110

k

+5V

R1

0

3

1

k

R

10

8

1

M

2

1

3

CF101

CS

T

LS

8M

00G56-A0

RXD0

TXD0

Q1

0

2

2SB1237

Q103

2SB1237

R166

820

VL VL

Q152

KRC1

01

S

Q153KRC1

01

S

SW2

S

W3

d3

d2

a

bcd

e

f

g

BZ

Q150

KRC101S

VL

Q155

KRC105S

R167

820

a

d1

DP

BZ

R156

4

.

7k

R157

4.7k

P00

32

P

0

1

31

P0230P03

29

P04

2288

P

05

2277

P06

2266

AN

0

2

5

P

34

24

P

33

23

P1022P11

21

VREF

20

P

12

19

P

13

18

TXD0

17

P

35

TXD

1

22

RESET

3

X

OU

T

4

AV

S

S

5

XIN

6

AVCC

7

MODE

88

R

X

D

1

99

P17

10

P36

P31

12

P54P53

11

11113

P

16

15

RXD0

16

IC101

R5F

2126

6S

N

F

P

11//

44

WW

11//

22WW

aa

1111

bb

7

cc

4

dd

2

ee

1

ff

10

gg

5

DD..PP11

3

DDiigg..11

1122

DDiigg..22

99

DDiigg..33

88

......

a

fbb

g

ec

d

DD..

PP..

LLEEDD110011

LLTTCC--556611AC BACB

123

CN101

S

03B-

P

A

S

K

-

2

C1110.

1u

+(C109)

100

u/

25V

+

(

C112)

1

00u/25V

(RD)

(RD)

(R195)

10k

(R194)

10

k

+5V

+

5

V

+5V

132

4

((CCNN110022))

B4B-PH-KL

+5V

RESET

RESET

1 2

SSWW110044

SSKK

QQ

NNAADDDD00

11

00

R173

2.7k

(C173)

0

..00

11uu

++55VV ++55VV

SW4

TP108

Q101

2SB1237

VL

R155

4.

7k

Q156

KRC105SbQ

15

7

KRC

1

05S

c

Q158KRC105SdQ159

KRC105SeQ160

KRC105SfQ1

6

1

KRC

10

5S

g

Q16

2

K

RC

105

S

DP

1/2W

1/2W

1/2W

1/2W

1/2W

1/2W

1/2W

R151

1k

d1

Q151

KRC101S

SW1

SW4

A

_

D

A

_D

TTPP112200

T

P

121

T

P

122

TP123

R178

10k

+5V

RR11

7744

44

..77kk

RR11

7755

44..77kk

RR11

7766

44

..77kk

R1774.7k

L

L

ED

ED

10310

2

Q

16

3

K

RC10

5S

LED10

2

VL

R168

820

L

E

D

102

(BL)

1/2W

TP125

Q164

KR

C10

5S

LED103

VL

R169

820

L

E

D

10

3

(BL)

1/

2

W

Flash writing

SW3

SW4

SW2

SW1

Page 17

SJPT55RHS

6 – 1

SJPT55RHS

Service Manual

CHAPTER 6. FAILURE DIAGNOSIS

[1] OUTLINE OF CONTROL

1. ON/OFF Control of Compressor

• ON/OFF of the compressor will be controlled depend on the temperature detected by

the R-thermistor and F-thermistor. (Normal cooling control)

• In case the surrounding temperature is high at the power supply input, the compressor will be ON at once and the normal cooling control will start

after several hours.

• During 5 minutes after the compressor stops, it will not start regardless of the detected temperature by R-thermistor and F-thermistor.

2. Defrosting

Microcomputer calculates the appropriate timing of defrosting and defrosting is made automatically. Therefore no manual operation by user is

required. The cycle of defrosting varies depend on the usage condition of the refrigerator. (Maximum time 50 hours, minimum time 40 minutes)

3. Thermistor

Thermistors are installed in 4 places; in the refrigerator and freezer compartment, and on the Main PWB and close to Evaporator. (R-thermistor, Fthermistor, Outside temp-thermistor, Def-thermistor)

R-thermistor and F-thermistor reads the temperature in the refrigerator and freezer compartment respectively and controls ON/OFF of the compressor and OPEN/CLOSE of the electrical damper.

Def-thermistor detects the temperature around the evaporator and shows the progress of defrosting.

Outside temp-thermistor reads the surrounding temperature of refrigerator. It changes the operation mode when the outside temperature is high.

[2] WHEN THE DEFROSTING FAILURE IS DOUBTFUL(Only for SJ-PT51R/PT55R)

Execute the Self-Diagnosis Mode. (Refer to the Chapter “SELF-DIAGNOSIS MODE”)

• In case the diagnosis result is “ 03” (Def-thermistor system defect), follow up the flowchart of 03. (In case of any abnormity in the Def-thermistor, defrosting will not be made for safety reasons.)

• In case the diagnosis result is “ 07” (Defrost defect), follow up the flowchart of 07.

(This diagnosis result will be displayed when defrosting is made for 120 minutes, the maximum time length. In this case, the defect of PWB itself

and also the breakage of heater and heater circuit (melt down of current fuse and temperature fuse) are considerable.)

[3] RE-SETTING OF MICROCOMPUTER AT POWER FAILURE

• At the power failure for over 0.2 second, the control of the microcomputer will be reset.

(Microcomputer might continue to operate for approximately 10 seconds maximum at power failure depending on the load at the operation. When

you need the difinite power off condition ,approximately 30 seconds is necessary.)

• When the power is re-supplied, the normal cooling will be resumed.

• The temperature set by user is not maintained if a power failure occurred.(Only for SJ-PT51R, PT55R)

(Defrosting also is not maintained.)

• When the self diagnosis is made, each mode and setting are resumed to the initial condition.(Only for SJ-PT51R, PT55R)

Page 18

SJPT55RHS

6 – 2

[4] DIAGNOSIS METHOD OF FAILURE AROUND PWB

In case of any abnormality of refrigerator, check by the following procedure;

1. Disconnect power supply and check the following point.

• Is there any failure portion in inserting connectors?

2. Detach the PWB and check the appearance.

• Is there any burning or abnormal damage?

3. Check the conditions of the fuse and the varistor. (Fuse and varistor are located at the position in the figure.)

• Under the condition of power supply plug connected;

In case of no cooling and no indoor lamp lighting, there might be a possibility of fuse (F1) melt down.

In case of cooling but no indoor lamp lighting, there might be a possibility of fuse (F2) melt down.(Only for SJ-T51R, T55R)

(However, these indications do not conclude the cause of the defect.)

When the fuse F1 is melt down, PWB does not operate at all.

When the fuse F2 is melt down, indoor lamp bulb and defrosting heater are not electrified. (It will be diagnosed as “Defrosting failure” by the

self diagnosis.)

• Melting in the fuse cannot be checked visually (as the safer one than transparent glass tube is used). Be sure to detach the connector “CN1/

CN301” before measuring the resistance between the both ends of the fuse by the tester.

• Next, measure the resistance value between the both leads of the varistor.

1) SJ-PT51R / PT55R

2) SJ-T51R / T55R

Fuse 1

Fuse 2

Varistor 1

Varistor 2

Fuse 1

Fuse 2

Varistor 1

Varistor 2

Page 19

SJPT55RHS

6 – 3

4. Check whether the temperature (resistance value) shown by R-thermistor is correct or not. (Refer to the table below.)

• Detach the connector “CN9/CN309” on the PWB and measure the resistance value between 1 and 2 pins.

5. Check whether the temperature (resistance value) shown by Def-thermistor is correct or not. (Refer to the table below.)

• Detach the connector “CN10/CN310” on the PWB and measure the resistance value between 6 and 7 pins.

6. Check whether the temperature (resistance value) shown by F-thermistor is correct or not. (Refer to the table below.)

• Detach the connector “CN10/CN310” on the PWB and measure the resistance value between 4 and 5 pins.

[5] CONVERSION TABLE BETWEEN TEMPERATURE AND RESISTANCE VALUE

1. R-thermistor, F-thermistor

2. Def-thermistor

Var isto r

Normal (over approx.1.8MΩ) Damage

Fuse

Melting

Flow of excessive current is considerable for some reasons.

Check for any portion to cause short circuits especially on

the primary circuit.

There is a possibility of excessive voltage applied from outside with the factor such as thunder etc. When repeated with a

factor other than thunder, there might be the apparatus near

by generating noises.

Conduction

Fuse and varistor are normal.

Possibility to be caused by excessive current or voltage

near the power supply is low. Proceed to the other check

item.

-

Temperature

(°C)

Resistance Value

(KΩ)

Temperature

(°C)

Resistance Value

(KΩ)

Tem per atu re

(°C)

Resistance Value

(KΩ)

-25 26.1 -9 10.3 7 4.52

-24 24.54 -8 9.75 8 4.3

-23 23.08 -7 9.24 9 4.1

-22 21.72 -6 8.76 10 3.91

-21 20.46 -5 8.3 11 3.73

-20 19.27 -4 7.87 12 3.56

-19 18.16 -3 7.47 13 3.4

-18 17.13 -2 7.09 14 3.24

-17 16.16 -1 6.74 15 3.1

-16 15.25 0 6.4 20 2.47

-15 14.4 1 6.08 25 1.99

-14 13.6 2 5.78 30 1.61

-13 12.85 3 5.5 35 1.31

-12 12.15 4 5.23 40 1.08

-11 11.49 5 4.98

-10 10.88 6 4.74

Temperature

(°C)

Resistance Value

(KΩ)

Temperature

(°C)

Resistance Value

(KΩ)

Tem per atu re

(°C)

Resistance Value

(KΩ)

-25 61.17 -9 24.13 7 10.58

-24 57.51 -8 22.85 8 10.09

-23 54.1 -7 21.65 9 9.61

-22 50.92 -6 20.52 10 9.16

-21 47.94 -5 19.46 11 8.74

-20 45.17 -4 18.46 12 8.34

-19 42.57 -3 17.51 13 7.96

-18 40.14 -2 16.63 14 7.6

-17 37.86 -1 15.79 15 7.26

-16 35.74 0 15 20 5.79

-15 33.74 1 14.26 25 4.66

-14 31.87 2 13.55 30 3.77

-13 30.12 3 12.89 35 3.08

-12 28.48 4 12.26 40 2.52

-11 26.94 5 11.67

-10 25.49 6 11.11

Page 20

SJPT55RHS

7 – 1

SJPT55RHS

Service Manual

CHAPTER 7. SELF-DIAGNOSIS MODE (Only for SJ-PT51R/PT55R)

1. Entering method of the mode

1) Press the [Select] button on the control panel over 5 seconds at the opening condition of

the freezer and refrigerating room doors.

2) With a beep sound of buzzer, the self-diagnosis mode is entered. When the self-diagnosis

mode is not entered by the above operation, defect of Door SW system can be considered.

2. When the self-diagnosis mode is entered, the following movements will be made. Forced release operation is not prepared for the self-diagnosis

mode. It returns to the normal movement after a lapse of 2 minutes.

• When the self-diagnosis mode is entered, beep sound for reminding of closing the door must not be sounded for 20 minutes.

• Defect and various conditions are displayed by [ON/OFF of buzzer].

• Defect and various conditions are displayed on the control panel. In case of plural defects and various conditions, these are displayed one after

another by button operation and all contents are notified.

3. Display of self-diagnosis

• Display example of control panel (at the defect of F-thermistor system)

• Buzzer notice example; (at defrost defect, 2 times of 0.5 second ON)

F

R

R

Select button

F

R

Result of diagnosis

Move to the next display

Move to the previous display

R

ON

OFF

3 seconds stop

Repeating

0.5 second stop

3 seconds stop

0.5 second stop

0.5 second 0.5 second 0.5 second 0.5 second

Buzzer

Page 21

SJPT55RHS

7 – 2

• Buzzer: =0.5 sec ON/0.5 sec OFF, =2 sec ON/0.5 sec OFF

No. Status Buzzer LED

Display

Content

Correspon-

dance

method

- No defects None - - - -

1 F-thermistor system defect

01

Defect of each thermistor, short circuit/wire breakage

of thermistor wiring and defect of main PWB

→[1]

2 R-thermistor system defect

02

→[2]

3 DEF-thermistor system defect

03

→[3]

4

Outside temperature-thermistor system defect

04

→[4]

5 Defrost defect

07

Wire breakage of fuse, defrost heater, defect of main

PWB

(120-minute defrosting has been occurred continuously 2 times within the past 48 hours.)

→[5]

6 Fan motor system defect

08

Defect of wiring / main PWB

(When fan motor is ON, over current or no current is

detected.)

→[6]

7

Ionizer (Plasmacluster) system

defect

11

Defect of wiring / main PWB

(When Plasmacluster is ON, over current or no current

is detected.)

→[7]

8 LED Display communication defect

12

Short circuit/wire breakage of wiring and defect of LED

or main PWB (Communication with LED PWB has

been abnormal over 3 times within the past 48 hours.)

→[8]

9 F-thermistor system defect history

61

Defect of thermistor system has been occurred over 1

minute continuously within the past 48 hours.

→[1]

10 R-thermistor system defect history

62

→[2]

11 DEF-thermistor system defect history

63

→[3]

12

Outside temperature-thermistor

system defect history

64

→[4]

13 F fan motor system defect history

66

Defect of fan motor has been occurred over 3 times

continuously within the past 48 hours.

→[6]

14

Ionizer (Plasmacluster) electrifying

defect history

72

Defect of Ionizer (Plasmacluster) electrifying has been

occurred over 3 times continuously within the past 48

hours.

→[7]

15 F-room high temperature history

76

Temperature of F-thermistor has been reached over

-10°C continuously for 6 hours or more within the past

48 hours. (except right after the installation)

→[1]

16 R-room high temperature history

77

Temperature of R-thermistor has been reached over

+10°

C continuously for 6 hours or more within the past

48 hours. (except right after the installation)

→[2]

Page 22

SJPT55RHS

7 – 3

Correspondence method

Power OFF Power OFF

Replace F-thermistor.

Replace main PWB.

NG?

NG?

(F-thermistor system diagnosis) (R-thermistor system diagnosis)

NO

NO

YES

YES

Remove 6P connector from E.V.

cover Assy and measure the

thermistor resistance between

and .

Replace R-thermistor.

Replace main PWB.

NG?

NG?

NO

NO

YES

YES

Remove 6P connector from R

louver Assy and measure the

thermistor resistance between

and .

01 / 61 / 76

02 / 62 / 77

[1]

[2]

10

3

4

9

56

2.47

Page 23

SJPT55RHS

7 – 4

(DEF-thermistor system diagnosis)

Power OFF

Replace DEF-thermistor.

Replace main PWB.

NG?

NG?

NO

NO

YES

YES

Remove 6P connector from E.V.

cover Assy and measure the

thermistor resistance between

and .

03 / 63

04 / 64

(Outside temperature - thermistor system diagnosis)

Replace Main-PWB.

Outside

temperature thermistor

is installed on

Main-PWB ass'y.

(Defrosting diagnosis)

07

Replace main PWB.

Replace fuse Assy.

Replace

defrost heater.

NO

YES

NO

YES

YES

NO

YES

NO (Open)

Forced defrosting (Measurement is impossible when

DEF-thermistor is set at 10°C or higher because

defrosting ends immediately)

After approx. 15 sec., the voltage

measured across

and of CN5

on the main PWB is equal to supplied

voltage? (e.g. 240 V)

Disconnect CN5 from the main PWB. Measure the

resistance between

and of CN on the wiring.

Check defrost heater wiring for loose

connection or disconnection.

Check cause of defrosting failure

· Check door packing

· Check mounting seal of E.V. cover Assy

[3]

[4]

[5]

5.8

approx. 280

(defrost heater 170~190W)

10

5

6

8

10

Turn power OFF. After approx. 30 sec.,

open door and re-energize.

(Buzzer beeps continuously)

8

10

Between 6P connector2and

4P connector

1(

white line) on

E.V. cover Assy is carrying current?

Resistance of 4P connector between

1

and2on E.V. cover K is normal? (331 )

Page 24

SJPT55RHS

7 – 5

YES

NO

08 / 66

(Fan motor system diagnosis)

Fan motor

rotates?

Check cause of defrosting

failure

· Dislocation of fan

· Check door packing

· Installation of E.V. cover Assy

· Defective seal

[6]

Replace LED-PWB Ass'y.

12

(LED system diagnosis)

Insert connector.

NO

NO

YES

CN8 on the main PWB is positively

engaged?

YES

[8]

Replace Plasmacluster.

(Ionizer system diagnosis)

Insert connector.

NO

NO

YES

and of CN9 on the main PWB

are positively engaged?

YES

and of 2P connector on R

louver Assy are positively engaged?

[7]

Under compressor operating,

close the door switch

Replace Fan motor or

main PWB

.

Fan locked ?

Check position of fan.

11

1

2

3P connector on LED control panel

is positively engaged?

YES

Page 25

SJPT55RHS

8 – 1

SJPT55RHS

Service Manual

CHAPTER 8. MODE FOR DISPLAY (Only for SJ-PT51R/PT55R)

1. Entering method of the mode

Within 2 minutes after main power input, press the [ ] button over 3 seconds at the opening condition of the refrigerating room door.

2. Release of the mode

Press the [ ] button over 3 seconds at the opening condition of the refrigerating room door.

(Even without the above operation, release can be made by main power OFF.)

3. Movement in the mode

1) Compressor, fan motor, heater and Plasmacluster are stopped.

2) Damper is always made [CLOSE] condition.

3) Indoor lamp is lit when door is open.

4) LED display

• Temperature will be displayed in turn automatically.

5) Door alarm is operated only for freezer room door.

F

R

R

button

Page 26

SJPT55RHS

9 – 1

SJPT55RHS

Service Manual

CHAPTER 9. ASSEMBLING PROCEDURES OF MAIN PARTS AND CAUTIONS

CAUTION: DISCONNECT THE UNIT FROM THE POWER SUPPLY BEFORE ANY REPAIRING.

[1] FAN LOUVER AND E.V COVER ASSEMBLY

1. How to remove the Fan louver

1) Take out 2 screws with screw driver.

2) Pull the Fan louver toward yourself to take off.

Figure A-1

2. E.V cover assembly

1) Stick E.V cover sealer d to F fan motor. (Figure A-2)

Figure A-2

2) Insert terminal F-Thermistor and Def-thermistor in the housing.

(Figure A-3)

Figure A-3

3) Stick E.V cover sealer a and c to E.V cover. (Figure A-4)

Figure A-4

Screw

Screw

Fan louver

F fan motor

EV cover sealer d

OVER LAP

YLP-06V-B (VO)

F-THERMISTOR

DEF-THERMISTOR

FUSE ASS’Y

F-THERMISTOR

DEF-THERMISTOR

E.V cover sealer a

E.V cover sealer a

E.V cover sealer c

E.V cover sealer a

E.V cover

ABOUT THE SAME

Page 27

SJPT55RHS

9 – 2

4) Set Fan motor, F-thermistor, Def-thermistor, Fuse ass'y in the EV cover and stick Al tape. (Figure A-5)

Figure A-5

5) Set the Deodorizer to the Fan louver.(Only for SJ-PT51R, PT55R)

Figure A-6

F fan motor

Def-thermistor

F-thermistor

STICK AL TAPE

SEC. AA

AL TAPE (T40 *W30*52L)

Fuse ass’y

Fan louver

Deodorizer

Page 28

SJPT55RHS

9 – 3

[2] R CONTOROL COVER ASSEMBLY (SJ-PT51R/PT55R)

1) Insert R air guider b to R air guider a (Figure A-7)

Figure A-7

2) Fix 1) ass'y with paper tape (Figure A-8)

3) Stick Ra-sealer a to 2) ass'y

4) Stick Ra-sealer b to 2) ass'y

5) Connect Ionizer-k and connector of Plasma harness (Figure A-9)

Figure A-8

Figure A-9

R air guider a

R air guider b

R air guider b

R air guider a

R air guider b

R air guider a

R air guider b

R air guider a

R air sealer b

R air guider a

R air sealer a

R air sealer b

Ionizer-k

Ionizer-k

Ionizer-k

Plasma harness

Plasma harness

Connect IONIZER-K and

connector of PLASMA HARNESS

Connect should be inserted surely.

Page 29

SJPT55RHS

9 – 4

6) Insert 5) ass'y to Plasma holder.

7) Insert 6) ass'y 4) ass'y.

8) Fix 7) ass'y with paper tape.

9) Stick A-sealer rc-d to Damper ass'y.

10) Insert Damper harness to Damper ass'y.

11) Insert 10) ass'y to 8) ass'y

12) Stick A-sealer damper to 11) ass'y

13) Fix 12) ass'y with paper tape.

14)Fix R LED PWB L ass'y to R-c box cover with tapping

screw.

15)Insert the Lamp harness to 14) ass'y, and fix it to R-c

box cover with paper tape.

16)Fix R-thermistor to R-c box cover.

17)Insert 13) ass'y to 16) ass'y.

18)Fix Lamp cover to 17) ass'y.

Figure A-11

A-sealer RC-d

Damper ass’y

Damper Harness

A-sealer RC-d

Stick A-sealer rc-d to Damper ass’y

Insert Damper Harness to Damper ass’y

Ra-sealer a

Ra-sealer b

R air guider b

R air guider b

R air guider a

Damper

ass’y

R air guider a

R air guider b

Damper

ass’y

Plasma holder

Ionizer-k

R air guider b

R air guider a

R air guider b

R air guider a

Rasealer a

Damper

harness

R air guider a

PaperTape

(W20mm)

R air guider b

Ra- sealer b

Ra- sealer a

Plasma

harness

A-sealer

damper

Ionizer-k

Plasma

holder

Plasma

harness

Figure-10

R-thermistor

Insert of pin

Note

Pins should be insert surely,

and check by pulling it.

PL process

R-thermistor

R LED

PWB L ass'y

R LED

PWB L ass'y

R LED PWB L ass'y

Tapping screw

R LED PWB L ass'y

Lamp harness

R-thermistor

R-c box cover

R air guider a

R air guider b

R-c box cover

R-thermistor

sealer

Mask label

Page 30

SJPT55RHS

9 – 5

[3] R CONTOROL COVER ASSEMBLY (SJ-T51R/T55R)

1) Insert R air guider b to R air guider a. (Figure A-12)

Figure A-12

2) Fix 1) ass'y with paper tape. (Figure A-13)

3) Stick Ra-sealer a to 2) ass'y.

4) Stick Ra-sealer b to 2) ass'y.

Figure A-13

5) Stick A-sealer rc-d to Damper ass'y.

6) Insert Damper harness to Damper ass'y. (Figure A-14)

Figure A-14

R air guider a

R air guider b

R air guider b

R air guider a

R air guider b

R air guider a

R air guider b

R air guider a

R air sealer b

R air guider a

R air sealer a

R air sealer b

A-sealer rc-d

Damper harness

A-sealer rc-d

Stick A-sealer rc-d to Damper ass’y

Insert Damper harness to Damper ass’y

Damper ass’y

Page 31

SJPT55RHS

9 – 6

7) Insert 6) ass'y to 4) ass'y.

8) Stick A-sealer damper to 7) ass'y.

9) Fix 8) ass'y with paper tape.

Figure A-15

10) Insert Control harness to VR PWB ass'y.

11) Fix VR PWB ass'y to R-c box cover.

12) Insert Control knob to 11) ass’y.

13) Fix 12) ass'y with Waterproof tape.

14) Fix 13) ass'y with PWB sheet 55DR.

15) Fix Lamp ass'y to R lamp holder.

16) Fix 15) ass'y to 2 Tapping screws.

17) Insert Lamp harness to 16) ass'y.

18) Fix 17) ass'y to R-c box cover.

19) Fix R-thermistor to R-c box cover.

20) Stick Warning label to R-c box cover.

21) Stick Control label to R-c box cover.

22) Fix (21) ass'y with paper tape.

23) Insert (9) ass'y to (22) ass'y.

24) Fix Lamp cover to (23) ass'y.

Figure A-16

Ra-sealer a

R air guider b

Ra-sealer b

R air guider a

R air guider b

Ra-sealer b

Ra-sealer a

Damper

ass’y

A sealer

damper

R air

guider c

R air guider a

R air guider b

Damper ass’y

R air guider b

R air guider a

Damper

harness

Ra-sealer a

R air guider b

R air guider a

Ra-sealer b

Ra-sealer a

R-thermistor

Insert of pin

Note

Control knob

Control knob

PWB sheet 55DR

Pins should be insert surely,

and check by pulling it.

PL process

VR PWB ass’y

R-thermistor

sealer

R-thermistor

R-thermistor

Control knob

PWB sheet 55DR

Lamp harness

R lamp holder

Control label

Control knob

R-c box cover

Rlamp

holder

R air guider b

R air guider a

R lamp holder

R-c box cover

VR PWB ass’y

VR PWB

ass’y

Control

harness

PWB sheet

55DR

Lamp

ass’y

Warning

label

Tapping

screw

Lamp ass’y

Page 32

SJPT55RHS

9 – 7

[4] R SHOWER DUCT ASSEMBLY

1. Insert Deodorizer to R shower duct.

2. Fix R-shower ins.a to “1” ass'y. (Figure A-17)

Figure A-17

3. Stick A-sealer R-shower-d to “2” ass'y. (Figure A-18)

4. Fix Al panel to “3” ass'y. (Figure A-19)

Figure A-18 Figure A-19

R shower duct

Deodorizer

R-shower ins.a

R-shower ins.a

Deodorizer

Al panel

R-shower duct

R-shower ins.a

* One of the A-sealer R-shower-d is divided into 6 pieces

and the other is not divided.

A-sealer

R-shower-d

A-sealer

R-shower-d

Page 33

SJPT55RHS

9 – 8

[5] DEFROST HEATER ASSEMBLY

1. Taking-out Evaporator

1. Take-out Fan louver.

2. Take-out E.V cover ass’y.

Figure A-20

3. As shown in Figure A-20, pull the upper part of Evaporator toward

you, pull it diagonally so that the pipe of Evaporator does not contact the convex part of food liner.

Figure A-21

4. Pull the Evaporator for remove as shown in Figure-21.

NOTE: When pulling Evaporator and bending the pipes,pay attention

so as not to break and deform the pipes. Still, take care not to

hurt yourself by fin of Evaporator.

Figure A-22

2. Replacement of Def. heater ass’y.

1. Take off the Drain support al from the food liner.

Figure A-23

2. Raise the protrusion part of Drain support al.

Then remove Heater cover.

Figure A-24

3. Open Def.heater fixed part of Drain support al to the right and left,

then remove Def.heater ass’y.

Figure A-25

E vaporator

F ood liner c onvex part

Food liner convex part

Evaporator

Pipe

Evaporator

Drain support al

Heater cover

Protrusion part of Drain support al (2 pcs.)

Heater cover

Def. heater ass'y

Drain support al

Protrusion part

Fixed parts

Def. heater ass'y

Drain support al

Page 34

SJPT55RHS

9 – 9

4. Replace Def. heater ass’y with new one.

Figure A-26

5. Bend the end of Drain support 90°.

Figure A-27

6. Aseemble Defrost heater to Drain support al.

7. Assemble Heater cover to Drain support al. Bend top edge to outside.

8. Stick the Vinyl tape on the Lead wire of Defrost heater ass'y.

Figure A-28

3. Installing of Evaporator

1. Install Evaporator as shown in the Figure A-20 in the reverse order of Figure A-21

2. Correct the defromed fin.

NOTE: 1. When installing Evaporator, take care not to deform significantly and break the pipes.

2. Take care not to damage the lead wires and hurt yourself by the fin of Evaporator.

3. You shouldn’t touch Defrost heater with your bare hand. (You should wear pure gloves.)

4. You should wipe that with alcohol. When you touch Defrost heater with your bare hand.

Drain support al

Heater cover

Def. heater ass'y

Drain support al

Drain support al

Page 35

SJPT55RHS

10 – 1

SJPT55RHS

Service Manual

CHAPTER 10. COOLING UNIT

[1] COOLING UNIT

Hot pipe R

(Side condenser)

Hot pipe

(DP-condenser)

Hot pipe L

(Side condenser)

Evaporator

Suction pipe

Compressor

Capillary tube

Dryer

Back condenser

S.P connector

Discharge P connector

Eva pan pipe ass’y

Dryer

Connector

Mark: Brazing portion(copper to copper)

Mark: Brazing portion(steel to copper)

Mark: Refrigerant flow

Charge pipe

Charge pipe

Page 36

SJPT55RHS

10 – 2

[2] LOCATION

1. Location 1

2. Location 2

Capillary tube

Dryer

Charge pipe HC S

Charge pipe

HC S

Suction pipe S.P

connector

Discharge

connector

Evaporator

Compressor

Eva pan pipe ass’y

Hot pipe

Back condenser

(copper to copper)

(steel to copper)

Dryer

connector

Back condenser (outlet)

to Hot pipe (inlet)

S.P. connector

to compressor’s

suction pipe

Charge pipe HC S

to compressor

Compressor’s discharge pipe

to Discharge connector

S.P connector

to Suction pipe

Pinch Point

Dryer connector

to Dryer

Charge pipe HC S

to Dryer

Hot pipe (outlet)

to Dryer connector

Dryer

to Capillary tube

Discharge connector

to Eva pan pipe ass’y

Pinch point

Eva pan pipe ass’y

to Back condenser (inlet)

Page 37

PartsGuide

SJPT55RHS

PARTS GUIDE

Refrigerator-freezer

MODELS

SJ-PT51R-HS

SJ-PT55R-HS

SJ-T51R-SL

SJ-T55R-SL

CONTENTS

[1] SJ-PT51R/PT55R-HS CYCLE

PARTS

[2] SJ-PT51R/PT55R-HS MECHANIAL

PARTS

[3] SJ-PT51R/PT55R-HS DOOR

PARTS

[4] SJ-PT51R/PT55R-HS

ATTACHMENT PARTS

[5] SJ-PT51R/PT55R-HS OTHER

PARTS

[6] SJ-T51R/T55R-SL CYCLE PARTS

[7] SJ-T51R/T55R-SL MECHANIAL

PARTS

[8] SJ-T51R/T55R-SL DOOR PARTS

[9] SJ-T51R/T55R-SL ATTACHMENT

PARTS

[10] SJ-T51R/T55R-SL OTHER PARTS

INDEX

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 38

SJPT55RHS

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PAR T

RANK

DESCRIPTION

6-11

6-14

6-1

2-87

6-3

6-2

4-17

1-12

6-4

1-9

1-35

6-18

6-5

6-18

2-78

1-22

4-15

1-52

2-81

2-83

2-82

2-80

1-11

6-32

6-31

2-70

6-16

6-29

6-19

2-71

4-10

4-11

2-77

1-61

6-9

1-36

4-1 4-2

6-12

[1] SJ-PT51R/PT55R-HS CYCLE PARTS

[1] SJ-PT51R/PT55R-HS CYCLE PARTS

1-9 QACC-A160CBZZ AP Source cord

1-11 RHOG-A190CBZZ BA Protector

1-12 RSTT-A137CBE0 AL Starting relay

1-22 FCNW-B013CBKZ AF Relay cord s ass'y

1-35 QCNW-B295CBZZ AM Emi earth 2pin cr

1-36 QCNW-B283CBZZ AG Pwb earth wire

1-52 FPWB-A511CBKZ AY Main pwb ass'y

1-61 RCILFA011CBZZ AV Emi core esd-r-38

2-70 USRA-A313CBFA AP Drain pan

2-71 LHLD-A797CBFZ AE Ev.pan holder

2-77 LHLD-A359CBFA AE T-box holder

2-78 LPLTMA399CBP0 AD Dryer support

2-80 PBOX-A164CBFA AM Terminal box

2-81 PCOV-A396CBPZ AF Terminal cover

2-82 PCOVMA005CBYZ AF Terminal box cover

2-83 PSHEPA084CBZZ AG Terminal sheet

2-87 LBND-A018CBE0 AP Fastening band a

4-1 LBND-A023CBE0 AC L-band c

4-2 LBND-A019CBE0 AB Nylon band

4-10 QTAN-A013CBE0 AH Solderless term. a

4-11 QTAN-A012CBE0 AH Solderless term. b

4-15 LX-BZA090CBZZ AC Special screw

4-17 LX-WZA035CBZZ AB Washer

6-1 PCMPLA263CBZZ CA Compressor

2

Page 39

SJPT55RHS

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PAR T

RANK

[1] SJ-PT51R/PT55R-HS CYCLE PARTS

6-2 PSPAGA054CBEZ AH Rubber grommet

6-3 PSPAFA047CBEZ AE Sleeve

6-4 FFRM-A152CBKZ AH Base frame ass'y

6-5 FDRY-A006CBK0 AX Dryer ass'y

6-9 PCOVPA271CBEZ AH Terminal cover

6-11 PPIPCA624CBZZ AM S.p connector

6-12 PPIPCA625CBZZ AL Discharge connector

6-14 PGUM-A004CBF0 AH Absorbent rubber a

6-16 PGUM-A003CBF0 AH Absorbent rubber b

6-18 PPIPCA252CBE0 AD Charge pipe

6-19 PPIPCA551CBZZ AF Drier connector

6-29 LHLD-A465CBE0 AG Cord clip

6-31 FPIPCA307CBKZ AN Eva pan pipe s ass'y

6-32 LANG-A058CBPZ AC Absorbent rubber clm

DESCRIPTION

3

Page 40

SJPT55RHS

2-35

1-2

2-66

1-21

6-8

2-67

2-11

2-12

2-61

2-63

1-17

1-3

1-1

2-60

2-13

2-40

2-15

2-16

2-7

2-7-2

2-7-1

2-8

2-8-2

2-7-1

1-10

2-47

2-20

2-23

2-24

2-1

2-2

2-18

1-53

2-46

2-45

2-44

2-41

2-42

2-43

2-14

2-31

2-33

2-34

2-36

2-26

2-27

1-45

1-56

1-4

1-57

1-60

2-51

1-51

2-50

2-52

2-21

2-68

2-37

1-6

2-64

1-55

2-25

2-38

2-39

2-29

2-53

1-50

2-48

2-49

[2] SJ-PT51R/PT55R-HS MECHANIAL PARTS

4

Page 41

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PAR T

RANK

DESCRIPTION

[2] SJ-PT51R/PT55R-HS MECHANIAL PARTS

1-1 RH-HXA104CBZZ AZ F-thermistor

1-2 RH-HXA103CBZZ AZ R-thermistor

1-3 RH-HXA105CBZZ AZ Def-thermistor

1-4 DTHM-A042CBKZ AY Damper ass'y

1-6 RMOTRA096CBZZ BE F fan motor

1-10 QSW-PA097CBZA AG Door switch

1-17 FFS-TA100CBKZ AN Fuse ass'y

1-21 FHETBA224CBZZ AP Def. heater ass'y

1-45 FTRN-A014CBKZ BD Ionaizer-k

1-50 LHLD-A801CBFA AE F-lamp holder

1-51 DPWB-A135CBKZ BR Led lamp pwb l ass'y

1-53 FPWB-A499CBKZ BG Led pwb ass'y

1-55 QCNW-B256CBZZ AP Lamp harness

1-56 QCNW-B257CBZZ AP Plasma harness

1-57 QCNW-B258CBZZ AP Damper harness

1-60 DPWB-A150CBKZ AY Rled lamp pwb l assy

2-1 GCOVPA237CBRA AU Control panel

2-2 GCOVPA236CBFA AE C-hinge slit cover

2-7 FLEGPA077CBKZ AQ Leg holder l ass'y

2-7-1 FAJS-A013CBK0 AE Adjustable leg ass'y

2-7-2 LHLD-A533CBPZ AL Leg holder l

2-8 FLEGPA078CBKZ AQ Leg holder r ass'y

2-8-2 LHLD-A534CBPZ AP Leg holder r

2-11 GCOV-A310CBFA AE Upper hinge cover

2-12 GCOV-A192CBFH AE Top cover

2-13 DHNG-A602CBMZ AG Upper hinge r ass'y

2-14 DHNG-A603CBMZ AG Bottom hinge r ass'y

2-15 DHNG-A604CBMZ AG Center hinge rt assy

2-16 DHNG-A605CBMZ AG Center hinge rb assy

2-18 LHLD-A825CBPZ AE C-box angler

2-20 GCOVPA238CBFA AK R-c box cover

2-21 LHLD-A714CBFZ AR Plasma holder

2-23 PGID-A172CBFZ AK R air guider a

2-24 PGID-A173CBFZ AK

2-25 PSEL-C669CBZZ AD A-sealer rc-d

2-26 PSEL-C955CBZZ AE Ra sealer a

2-27 PSEL-C956CBZZ AE Ra sealer b

2-29 PSEL-C958CBZZ AH A-sealer damper

2-31 LPLTMA818CBPZ AG Al panel [PT55R]

2-31 LPLTMA822CBPZ AK Al panel [PT51R]

2-33 MLOV-A064CBFA AR R shower duct [PT55R]

2-33 MLOV-A065CBFA AR R shower duct [PT51R]

2-34 PGID-A174CBFZ AH R-shower ins.a [PT55R]

2-34 PGID-A176CBFZ AG R-shower ins.a [PT51R]

2-35 PSEL-C966CBZZ AE A-sealer r-shower-d [PT55R]

2-35 PSEL-C968CBZZ AE A-sealer r-shower-d [PT51R]

2-36 PFIL-A047CBEZ AC Deodorizer

2-37 PFIL-A050CBEZ AM Deodorizer

2-38 GCOVPA234CBFA AE Leg cover l

2-39 GCOVPA235CBFA AE Leg cover r

2-40 LSTPPA161CBFA AE Case stopper

2-41 JBTN-A045CBRA A F Button fr

2-42 JBTN-A046CBRA A F Button dw

2-43 JBTN-A047CBRA A F Button up

2-44 JBTN-A048CBRA A F Button dc

2-45 JBTN-A049CBRA A F Button pl

2-46 LHLD-A802CBFA AE Led pwb holder

2-47 GDAI-A084CBFA AR Control box base

2-48 TLAB-B605CBRA AE Mask label

2-49 PSEL-D085CBZZ BK R thermistor sealer

2-50 HGRL-A269CBFA AU Fan louver

2-51 PCOV-A391CBRA AH F lamp cover

2-52 PCOV-A392CBRA AG R lamp cover