Sharp S101S05V, S101S06V, S201S06V, S201S05V Datasheet

S101S05V/S101S06V/S201S05V/S201S06V

S101S05V/S101S06V

S201S05V/S201S06V

■ Features

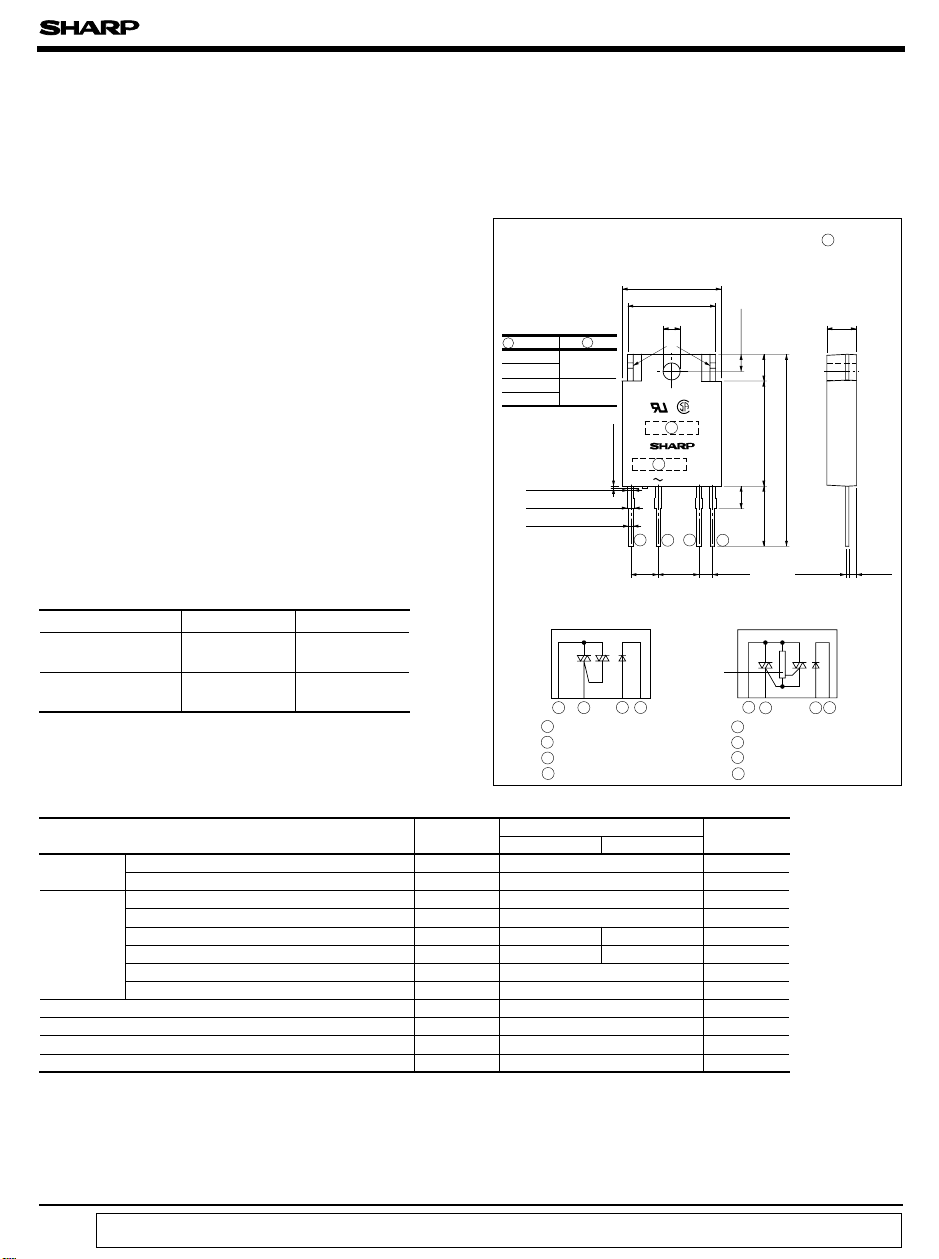

■ Outline Dimensions

SIP Type SSR with

Mounting Capability for

External Heat Sink

1. High radiation resin mold package.

2. RMS ON-state current

: MAX. 3Arms at TC<=100˚C

I

T

(With heat sink

3. Isolation voltage between input and output

(V

: 3 000 V

iso

4. Built-in zero-cross circuit

(

S101S06V/S201S06V

5. Recognized by UL, file No. E94758

Approved by CSA, No. LR63705

■ Applications

1. OA equipment such as copiers

)

A(Model No.)B

)

rms

)

S101S05V

S101S06V

S201S05V

S201S06V

4-1.1

4-1.25

4-0.8

3A125VAC

3A265VAC

±

0.2

±

0.3

±

0.2

MAX.

❈0.2

2. FA equipment

(+)

(-)

(

■ Model Line-ups

No built-in

zero-cross circuit

Built-in

zero-cross circuit

For 100V lines For 200V lines

S101S05V S201S05V

S101S06V S201S06V

Internal connection diagram

S101S05V /S201S05V S101S06V /S201S06V

1 Output (Triac T2

2 Output (Triac T1

3 Input

4 Input

■ Absolute Maximum Ratings

Rating

50 mA

6V

*4

3

30 A

400 600 V

400 600 V

3 000

- 25 to + 100 ˚C

- 30 to + 125 ˚C

260 ˚C

)

Input

Output

Parameter Symbol

Forward current I

Reverse voltage V

RMS ON-state current I

*1

Peak one cycle surge current

I

Repetitive peak OFF-state voltage V

Non-repetitive peak OFF-state voltage

Critical rate of rise of ON-state current

Operating freguency f 45 to 65 Hz

*2

Isolation voltage

V

dIT/dt 40 A/ µ s

Operating temperature T

Storage temperature T

*3

Soldering temperature

S101S05V / S101S06V S201S05V / S201S06V

F

R

T

surge

DRM

DSM

V

iso

opr

stg

T

sol

*1 60Hz sine wave, start at Tj= 25˚C

*2 60Hz AC for 1 minute, 40 to 60% RH. Apply voltages between input and output, by the dielectric withstand

voltage tester with zero-cross circuit. (Input and output shall be shorted respectively

(Note) When the isolation voltage is necessary at using external heat sink, please use the insulation sheet.

*3 For 10 seconds

*4 Tc<=100˚C

* The metal parts marked *

are common to terminal 1 .

❈ Do not allow external connection.

( )

: Typical dimensions

±

0.2

18.5

±

0.3

16.4

±

0.2

φ

3.2

*

A

B

123 4

5.08)(7.62

)(

Zero-cross

circuit

)

)

(

0.2

±

-

+

MAX.

)

2.54

12 3412 34

1 Output (Triac T2

2 Output (Triac T1

3 Input

4 Input

Ta= 25˚C

3.2

4.2

0.3

±

0.2

±

MIN.

5.0

19.6

11.2

)

Unit

A

rms

V

rms

(

Unit : mm

5.5

)

36.0

(

±

0.1

0.6

(+)

(-)

)

±

0.2

(

)

1.4

)

)

“ In the absence of confirmation by device specification sheets, SHARP takes no responsibility for any defects that occur in equipment using any of SHARP's devices, shown in catalogs,

data books, etc. Contact SHARP in order to obtain the latest version of the device specification sheets before using any SHARP's device.”

S101S05V/S101S06V/S201S05V/S201S06V

■ Electrical Characteristics

Parameter

Input

Output

Transfer

characteristics

Foward voltage

Reverse current

Repetitive peak OFF-state current

RMS ON-state current

Holding current

Critical rate of rise of OFF-state voltage

Critical rate of rise of com-

mutating OFF-state voltage

Minimum trigger

current

S101S05V/ S201S05V

S101S06V/ S201S06V

Isolation resistance

Zero-cross voltage

Turn-on time

Turn-off time

S101S05V/ S201S05V

S101S06V/ S201S06V

S101S05V/ S201S05V

S101S06V/ S201S06V

Thermal resistance

(

Between junction and case

)

Thermal resistance

(

Between junction and ambience

S101S06V

S201S06V

)

Symbol

V

F

I

R

I

DRM

V

T

I

H

dV/dt

(

dV/dt

I

FT

R

ISO

V

OX

t

on

t

off

R

th(j-c

R

th(j-a

Conditions

= 20mA

I

F

=3V

V

R

V

D=VDRM

Resistance load, IF= 20mA

= 1.5A

I

T

rms

-

VD= 2/3V

Tj= 125˚C, VD= 400V

)

C

dI

V

V

DRM

= -1.5A/ms

t/dt

= 12V, RL=30Ω

D

= 6V, RL=30Ω

D

DC500V, 40 to 60 % RH

I

= 15mA

F

AC50Hz

AC50Hz

)

)

-

-

(

Ta= 25˚C

)

MIN. TYP. MAX. Unit

- 1.2 1.4 V

-4

--10

-- A

10

- - 1.5 V

A

-4

rms

- - 50 mA

30 - - V/µ s

4--V/µs

-15

-15

10

--

--

--1

--10

--10

--10

-

-

10

--Ω

35

35

mA

V

ms

ms

- 6 - ˚C/W

- 45 - ˚C/W

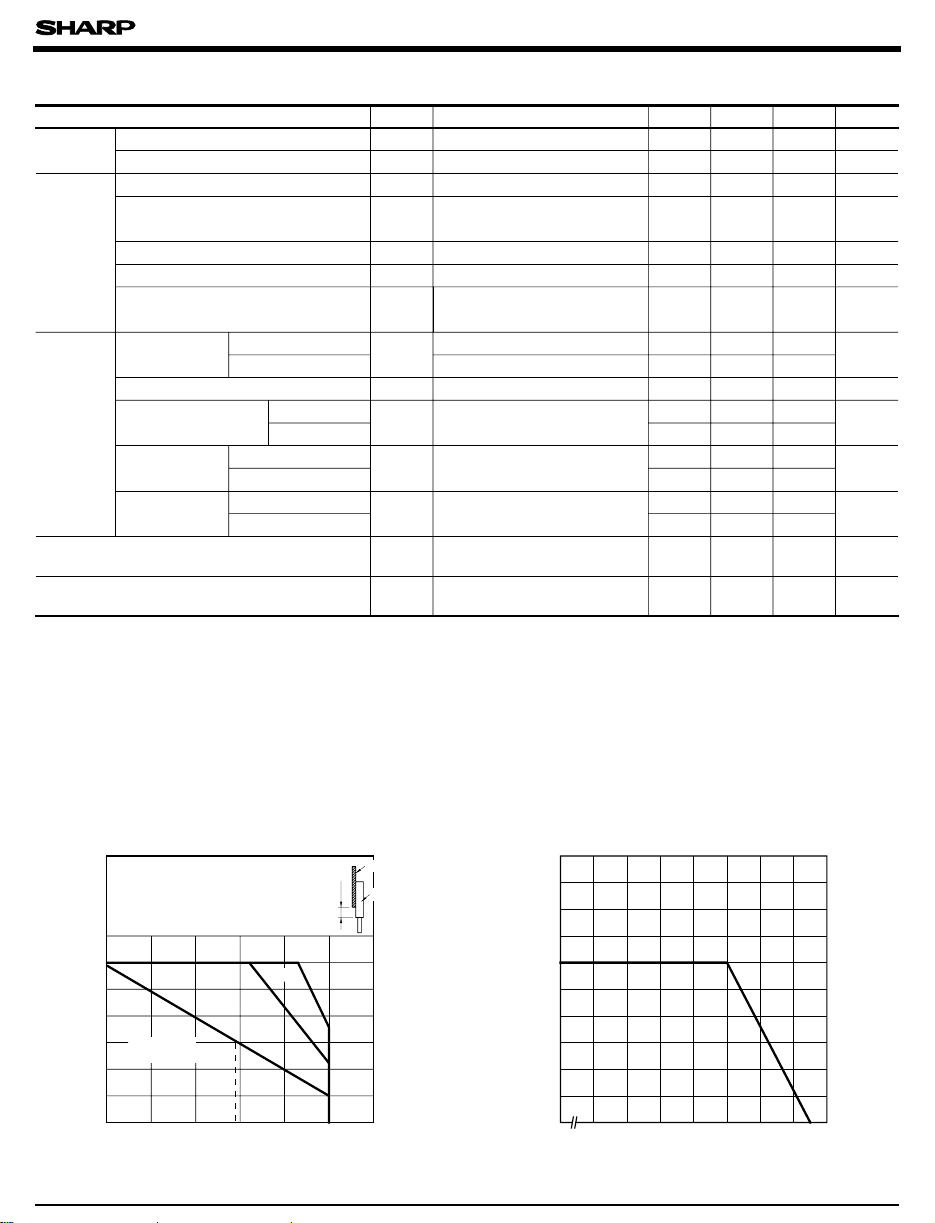

Fig. 1 RMS ON-state Current vs.

Ambient Temperature

(1)

With heat sink(Al 100x100

(2)

With heat sink(Al 50x 50

5

Note) With the Al heat sink set up vertically,

install it as shown in the figure

Torque : 0.4N • m

)

Apply thermal conductive silicone grease

4

on the heat sink mounting plate. Forcible

cooling shall not be carried out.

Arms

(

T

3

2

Without

heat sink

1

RMS ON-state current I

0

- 25 0 25 504575 100 125

Ambient temperature Ta (˚C

(2)

t

)

x

2mm

t

)

x

2mm

Al plate

SSR

5mm

(1)

)

Fig. 2 RMS ON-state Current vs.

Case Temperature

5

)

4

Arms

(

T

3

2

1

RMS ON-state current I

0

- 25 60 70 80 90 100 110 120 130

Case temperature Tc (˚C

125

)

Loading...

Loading...